Patents

Literature

224results about How to "Prevent sideways movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of bamboo wood reinforcement bidirectional enhanced part-cut and part-fill weak roadbed

The invention discloses a construction method of a bamboo wood reinforcement bidirectional enhanced part-cut and part-fill weak roadbed, comprising the following steps of: (1) machining a bamboo wood; processing a bamboo sheet; and manufacturing a bamboo rib cage, a bamboo rib grid and a bamboo rib U-shaped anchor nail; (2) flattening a field and setting out a pile position; (3) utilizing a vibration shock method of a vibration immersed tube method to construct to form a bamboo rib cage crushed stone pile and paving a crushed stone cushion layer on a pile top; and (4) digging a step; paving, connecting and anchoring the bamboo rib grid; and backfilling a soil material and rolling and leveling. The construction method is characterized in that the bamboo rib cage can effectively improve the bearing capability and the stability of the crushed stone pile; the bamboo rib grid can reinforce the connection between a filling region and a digging region, the differential deposition is reduced, and sliding and instability of sliding along a filling and digging connecting face is prevented; and the construction method has the beneficial effects that a bamboo rib is used as a reinforcement material so that a construction industry is developed towards a low-carbon, energy-saving, environment-friendly and sustainable development direction, and saves the investment under the condition of meeting the requirements of roadbed bearing capability and deformation stability.

Owner:HUNAN UNIV

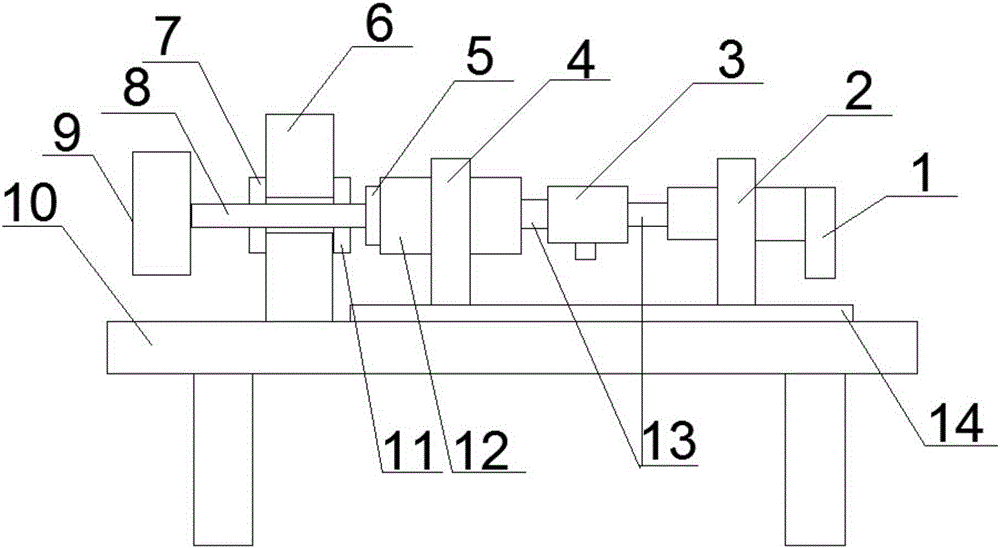

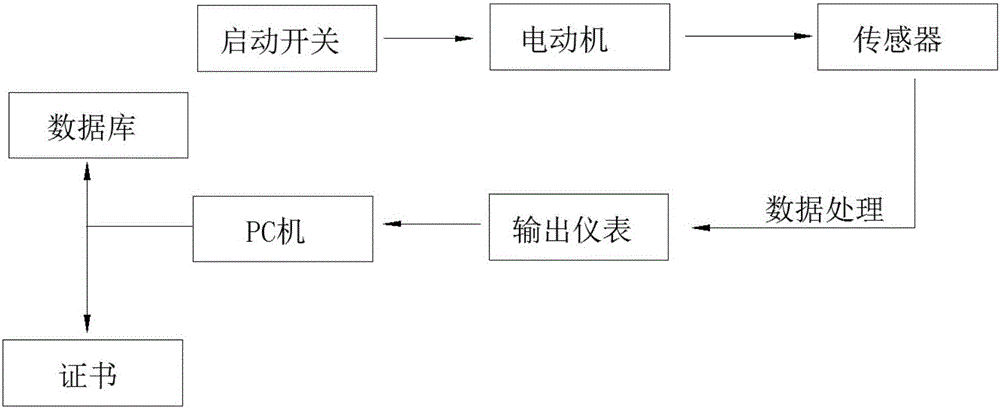

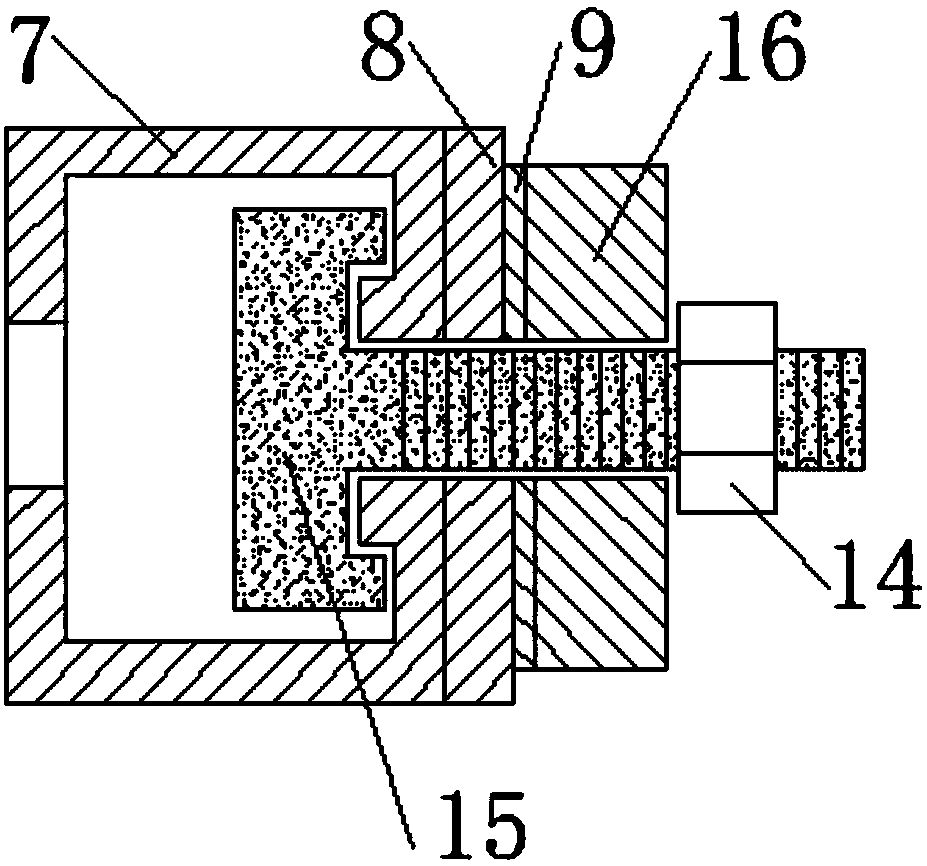

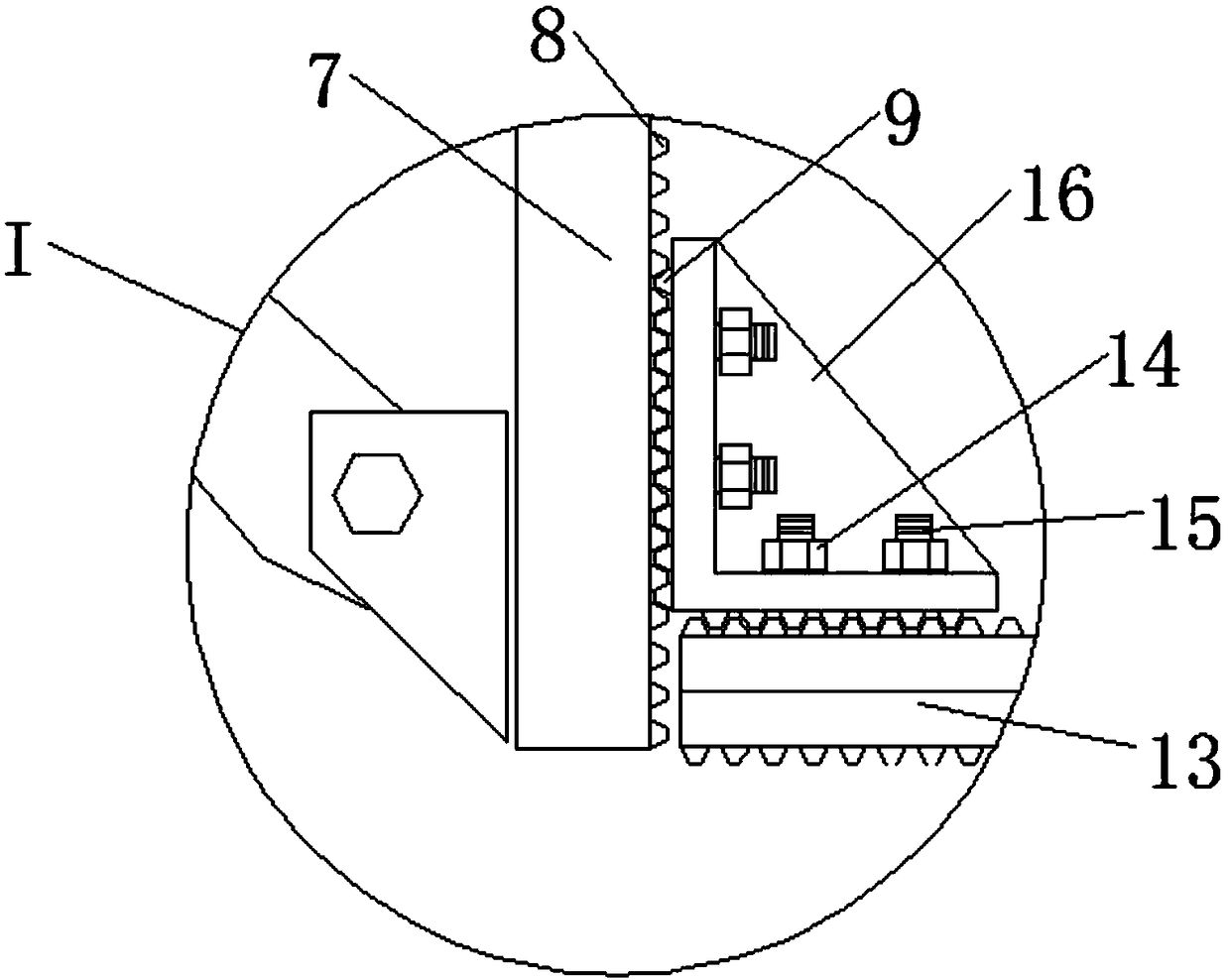

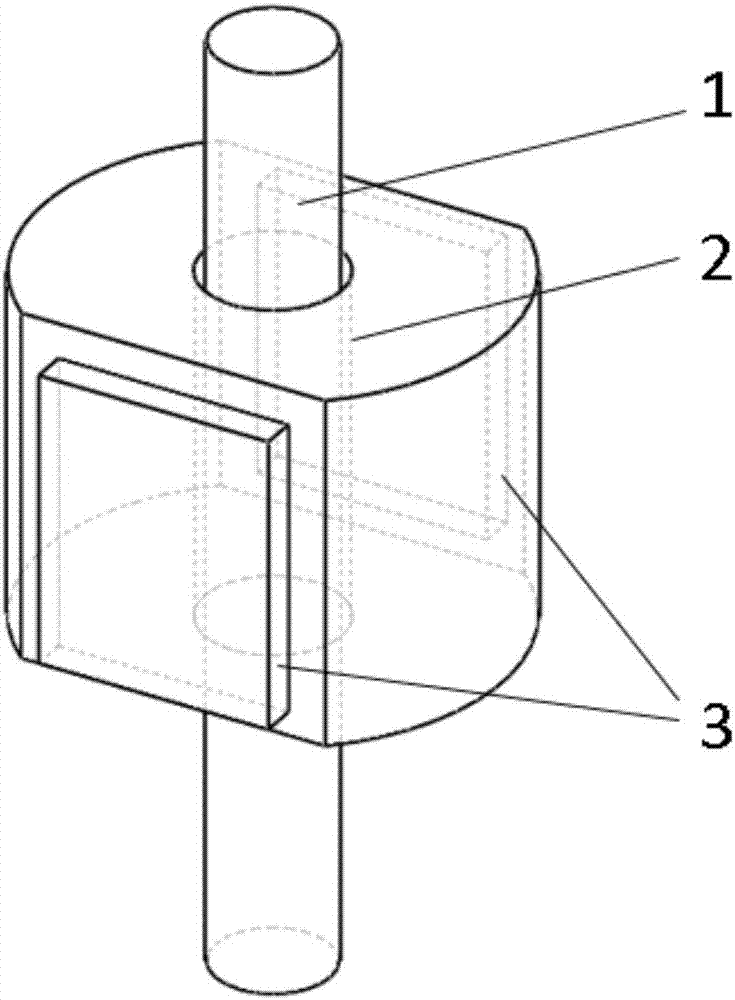

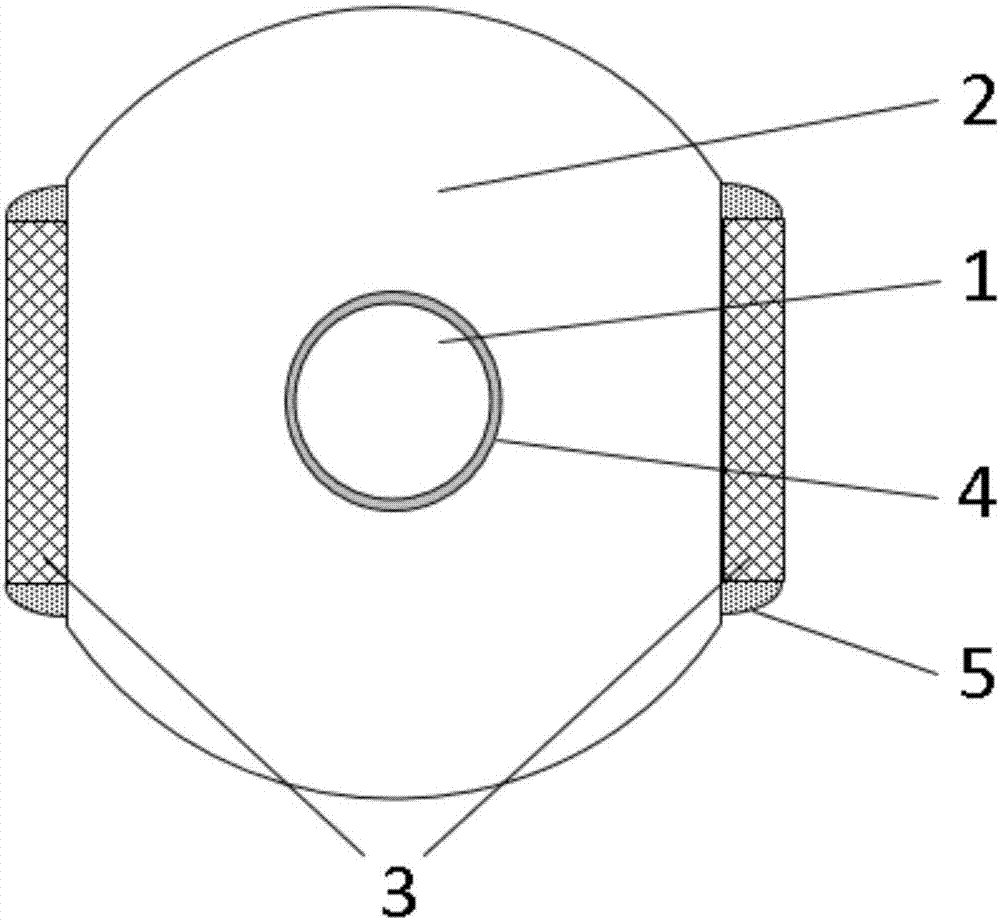

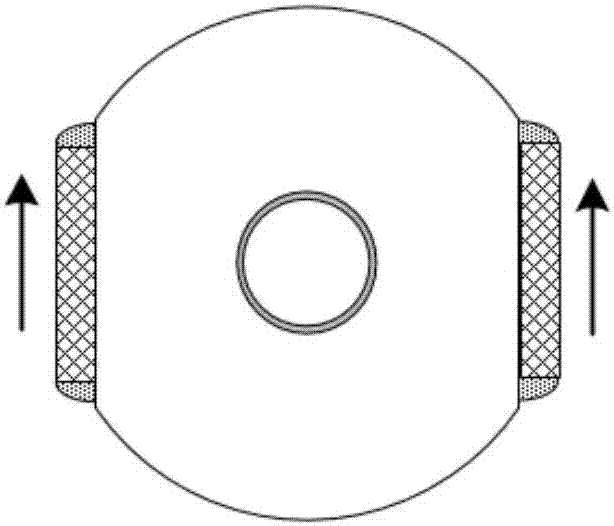

Dynamic torque detection system

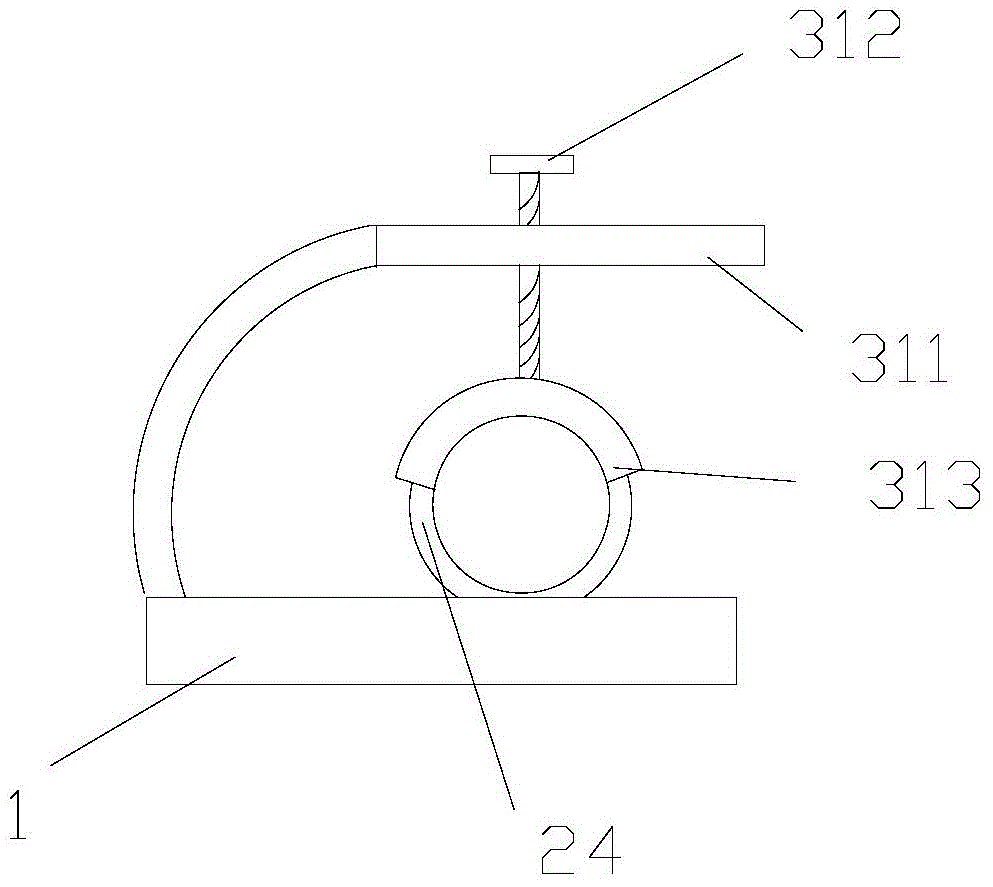

PendingCN106768621AHigh measurement accuracyPrevent sideways movementForce/torque/work measurement apparatus calibration/testingAerodynamic torqueElectricity

The invention discloses a dynamic torque detection system, comprising a bench and a torque sensor; an electrical-pneumatic torque wrench is fixedly mounted on the bench; one end of the torque sensor is connected with an output shaft of the electrical-pneumatic torque wrench; the other end of the torque sensor is connected with a sleeve through a coupling; the sleeve is rotationally fixed on the bench and is connected with a torque brake device that may provide continuous braking for torque. By providing the torque brake device that may provide continuous braking for torque to detect a torque peak, measurement precision is improved; the torque brake device is arranged as a bolt, continuous braking is achieved by tightening the bolt; compared with simulated bolts, the dynamic torque detection system as a calibrator allows an actually used bolt to be sued in the detection process, and the actual condition can be simulated to maximum extent.

Owner:SICHUAN DONG TAI MACHINERY MFG CO LTD

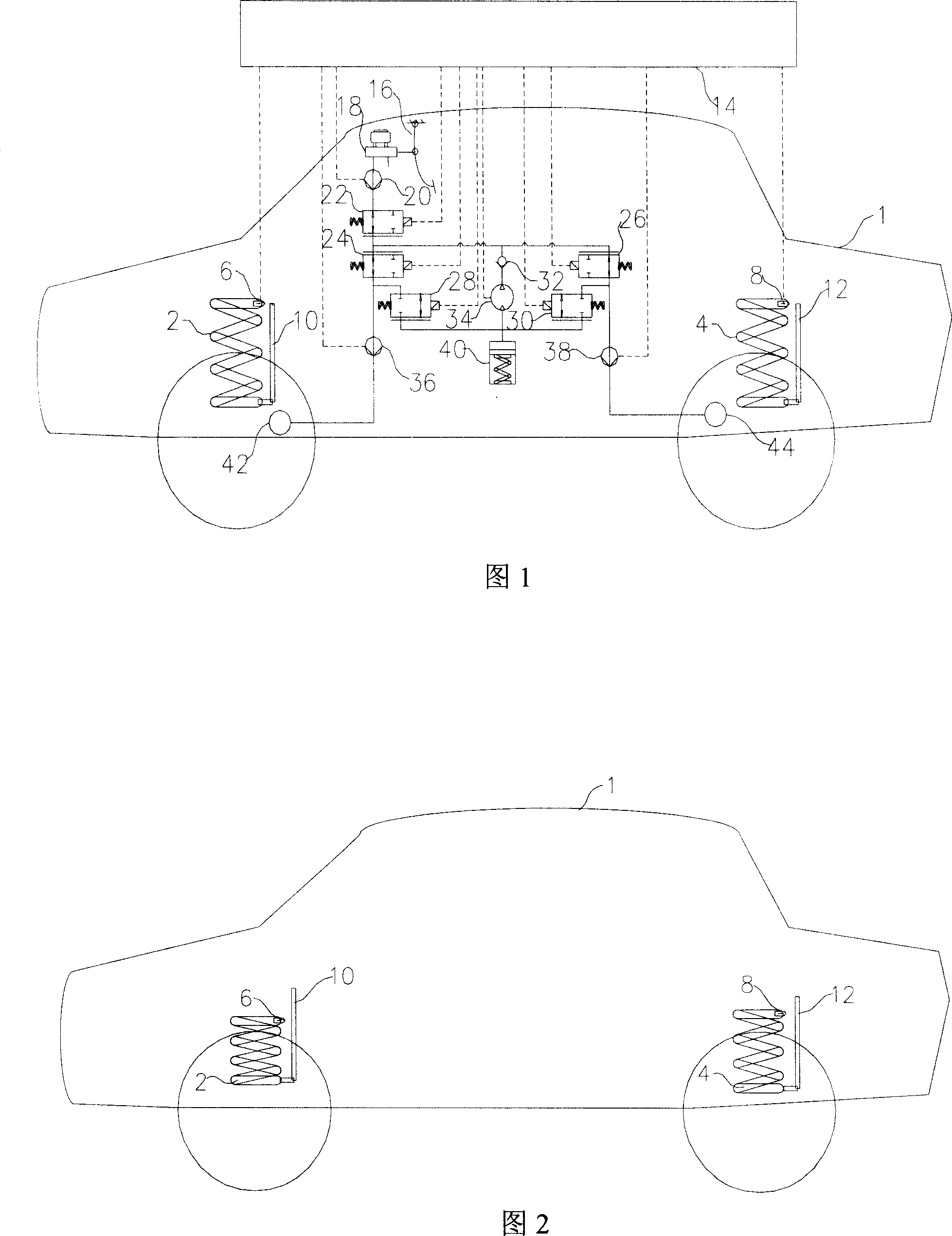

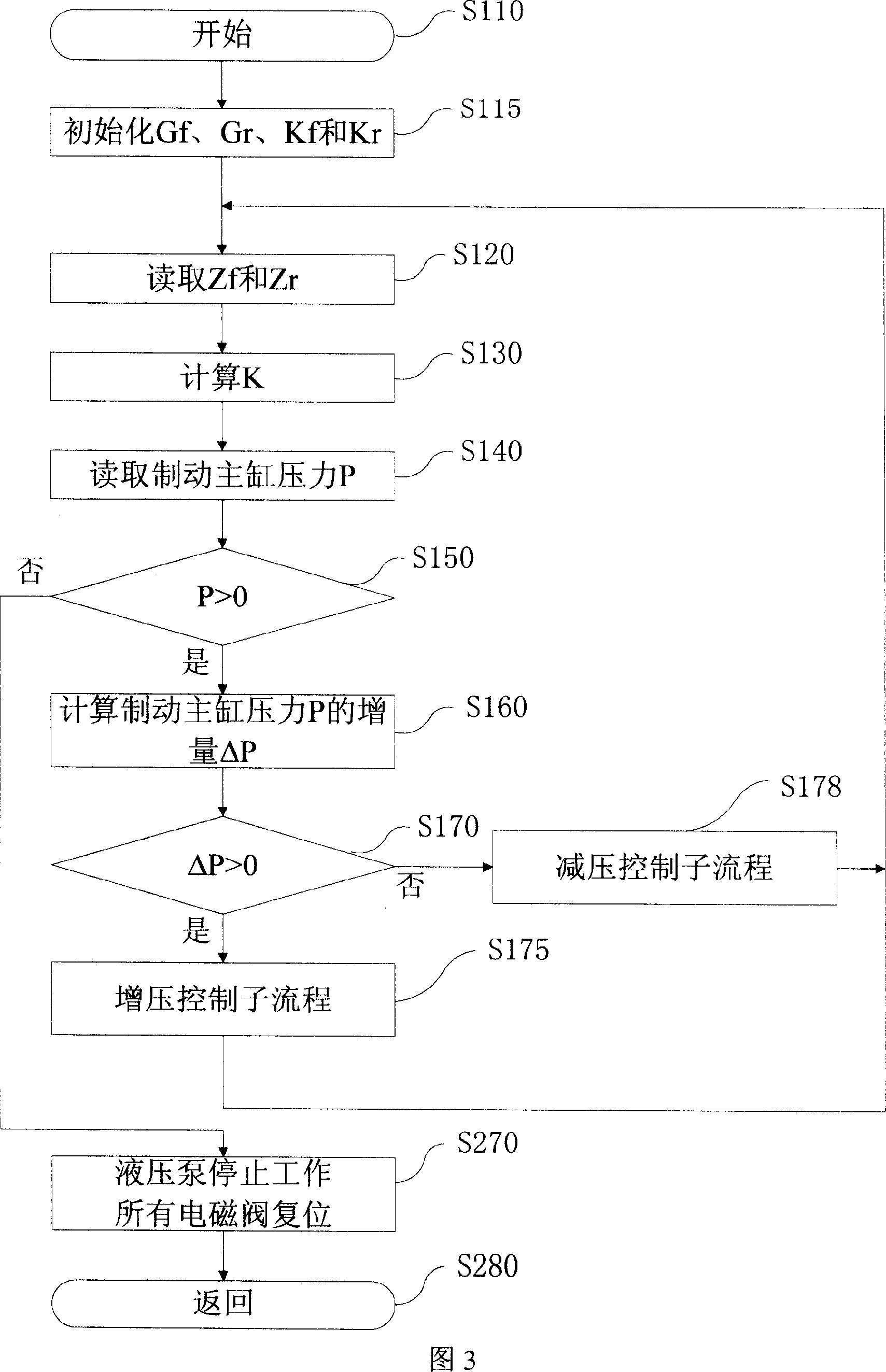

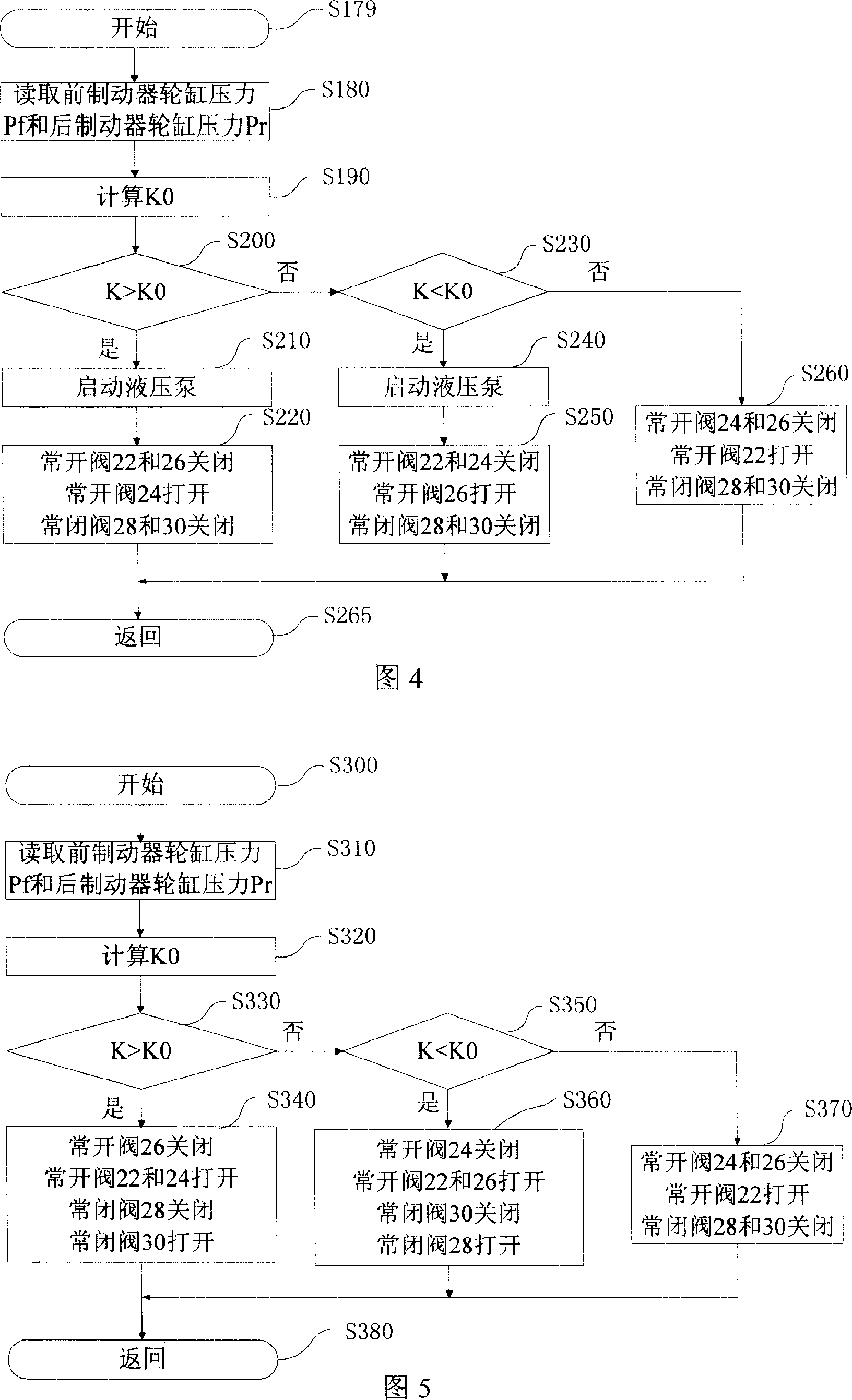

Real-time braking distributing device and method for motor vehicle

ActiveCN101088816AShorter braking distanceStable and safe drivingBraking systemsLoad ratioBrake force

The present invention discloses real-time braking force distributing device and method for motor vehicle. The real-time braking force distributing device includes one front suspension displacement sensor and one rear suspension displacement sensor for detecting the compression deformations of the front and the back suspension springs separately, and one electronic control unit to accept the detected compression deformations. The real-time braking force distributing method includes the following steps: 1. entering to the main control process to calculate the load ratio between front and rear wheels; 2. recognizing whether the vehicle to be in brake state and selecting whether to enter the braking force distribution; and 3. recognizing whether the vehicle to be in emergency brake state, selecting the boost control sub-process or decompression control sub-process and controlling the front-to-rear braking pressure ratio to equal to the load ratio. The present invention can ensure smooth and safe running.

Owner:BYD CO LTD

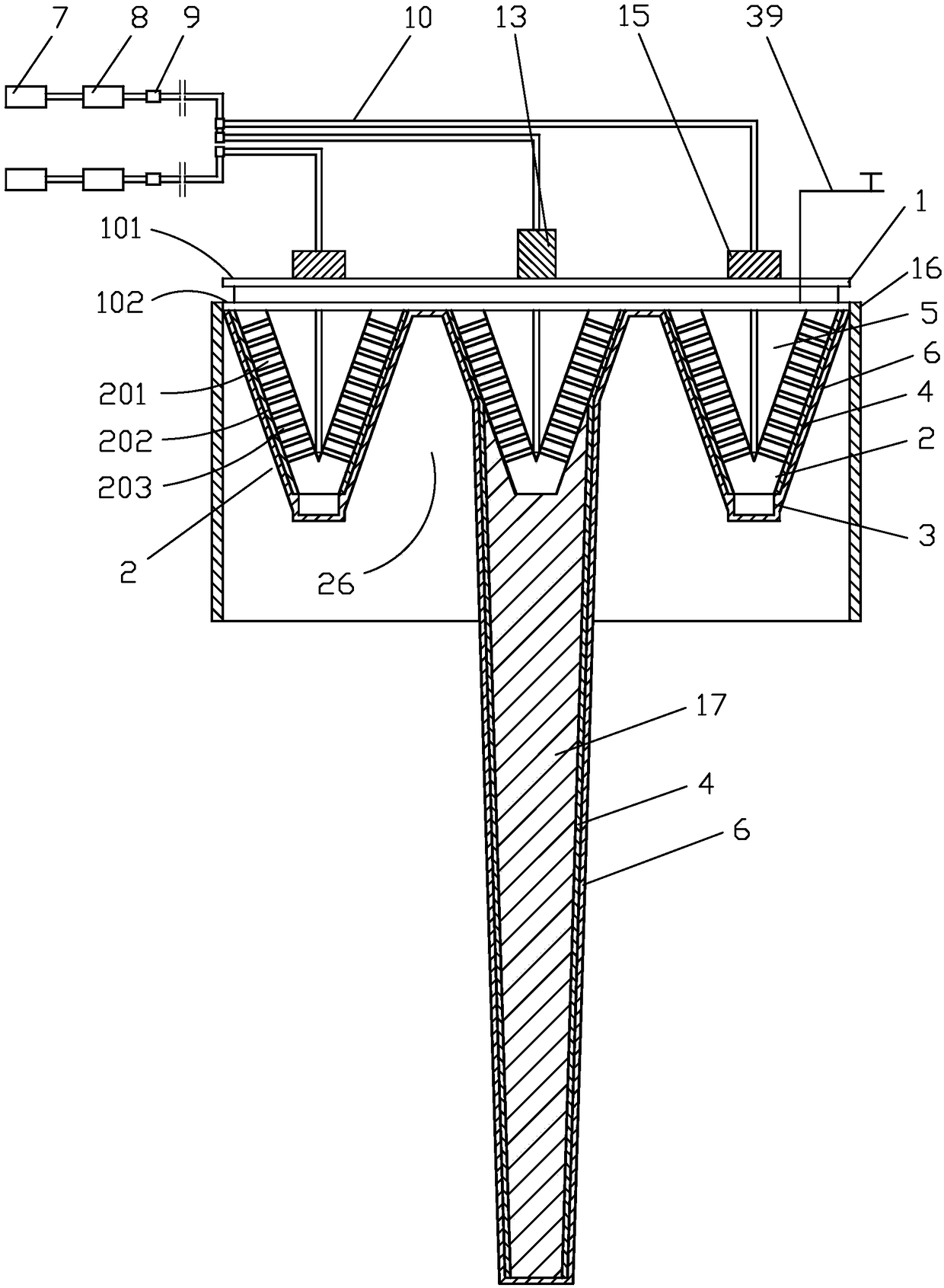

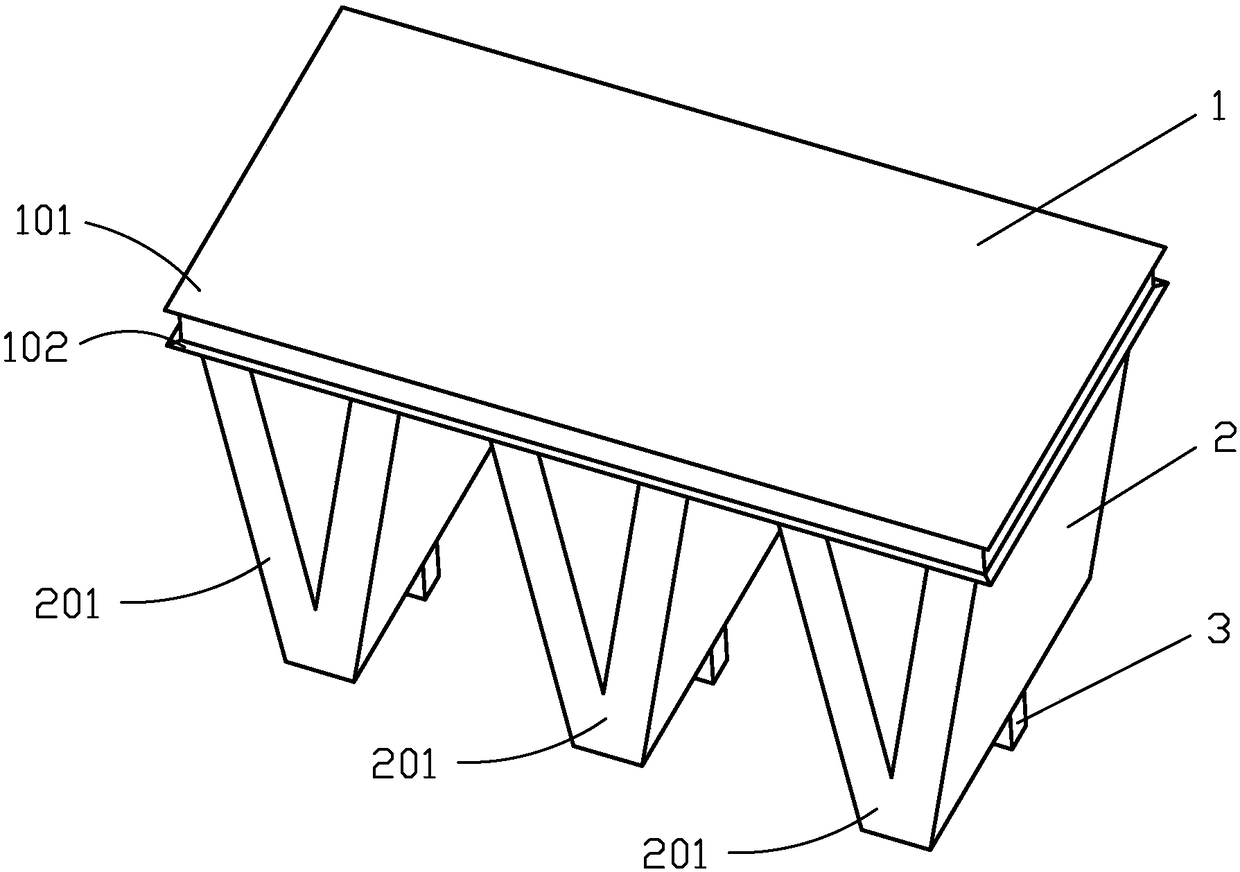

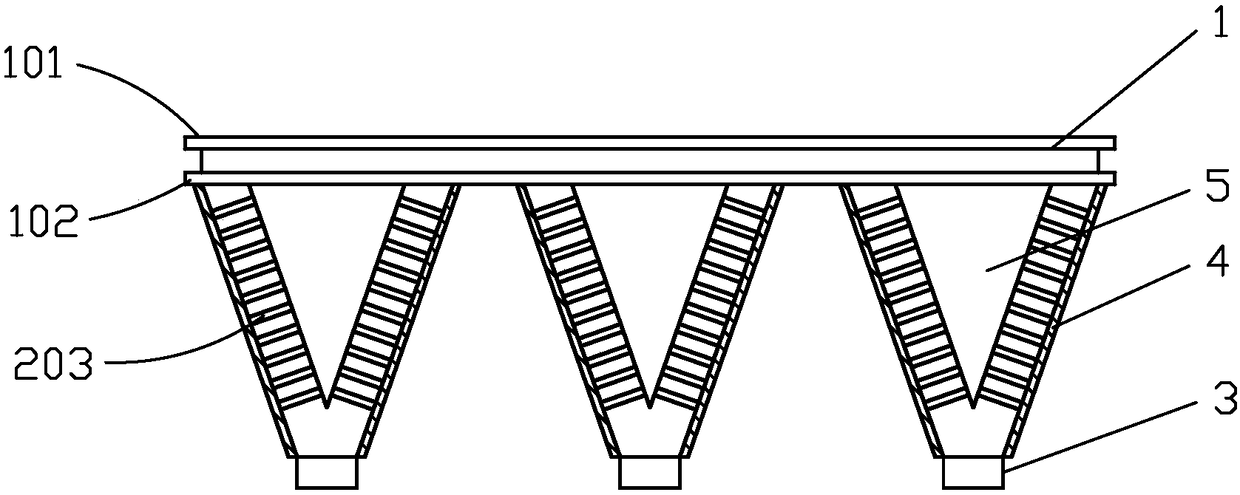

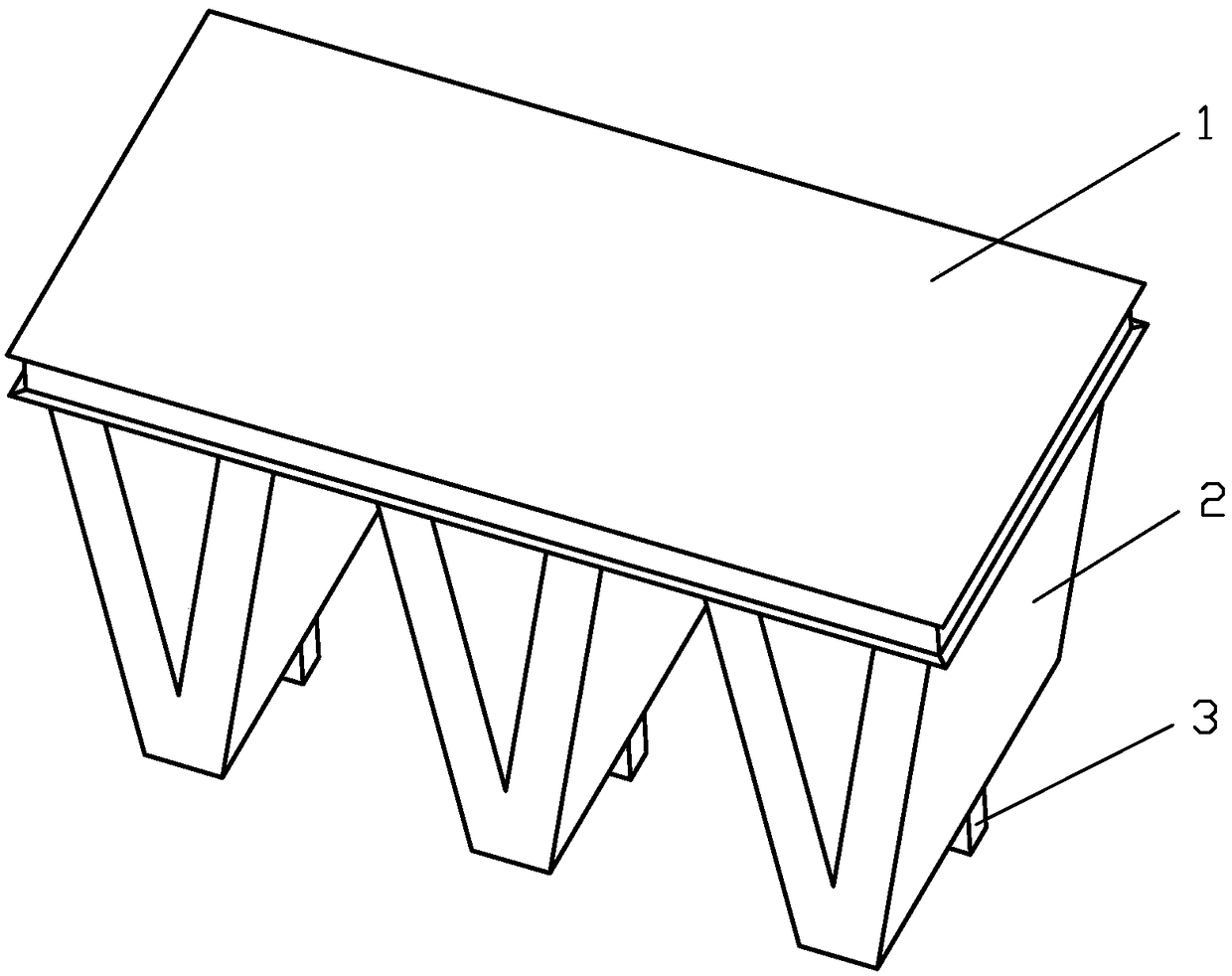

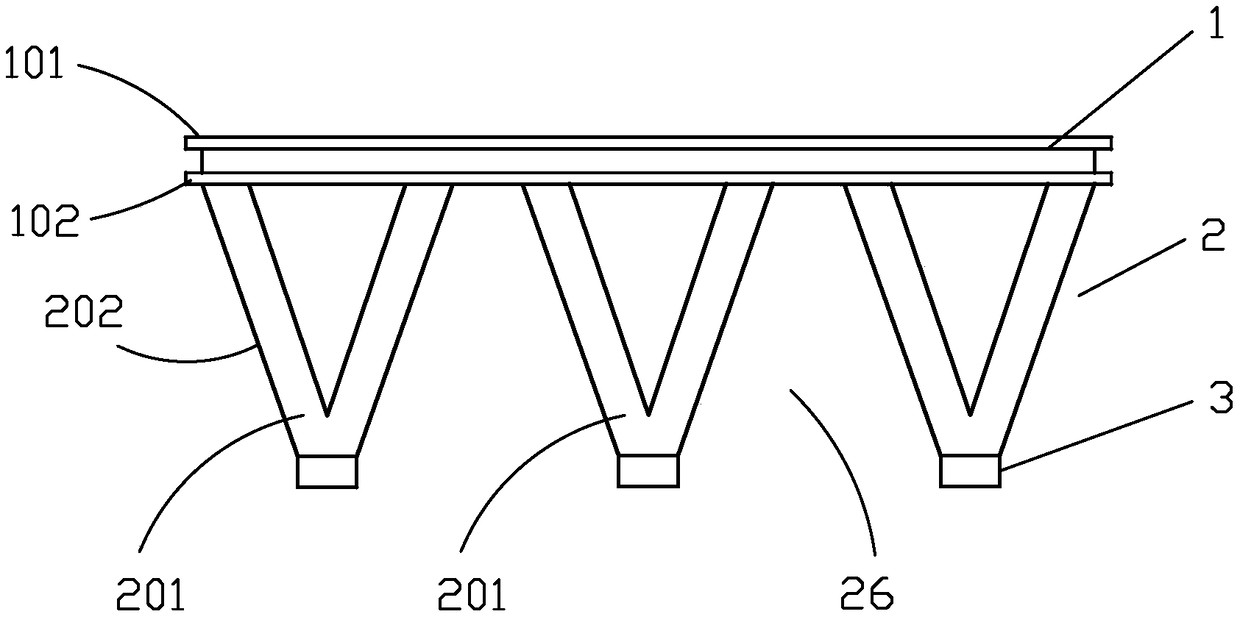

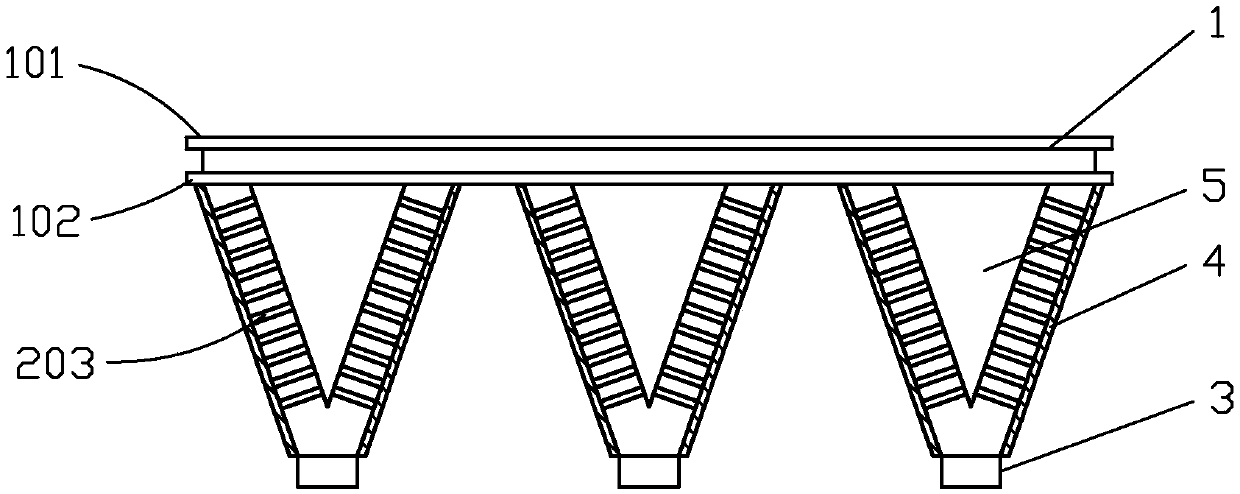

Multifunctional module type soil pressure applying and forming device

InactiveCN108360496APlay a blocking rolePrevent sideways movementSoil preservationEngineeringMultiple function

The invention discloses a multifunctional module type soil pressure applying and forming device. The forming device comprises a top frame, a pressure applying forming module and soil body strength detection devices, is characterized in that baffles are arranged on the periphery of the top frame, and the pressure applying forming module comprises a plurality of convex bodies; filter devices are further arranged on the part, in contact with the soil body, of the module, and reinforcement bodies sleeve the filter devices; the upper part of the module and a top plate form a vacuum water collectingchamber, and the module is provided with water guide channels; and the top frame and / or the pressure applying forming module are further provided with auxiliary pressure applying devices, the bottomsof the convex bodies are further provided with vertical pile bodies. According to the device, the soil body can be subjected to rapid drainage, consolidation and forming, the device is suitable for shallow layers, middle layers and deep layers treatment, and therefore the device is wide in applicability, high in construction efficiency, short in construction period and low in construction cost.

Owner:ZHEJIANG JIA YUAN CIVIL ENG CO LTD

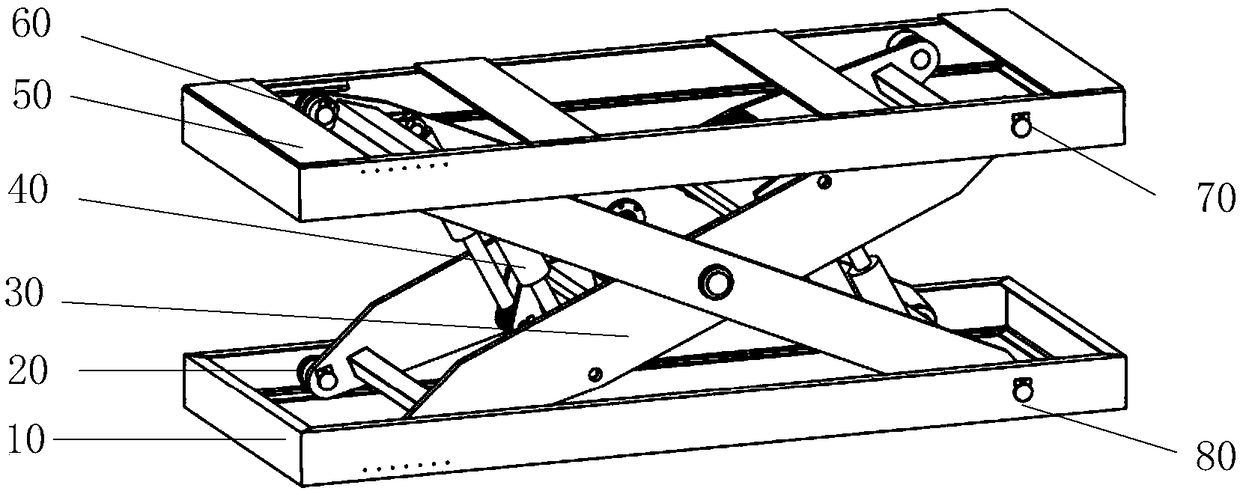

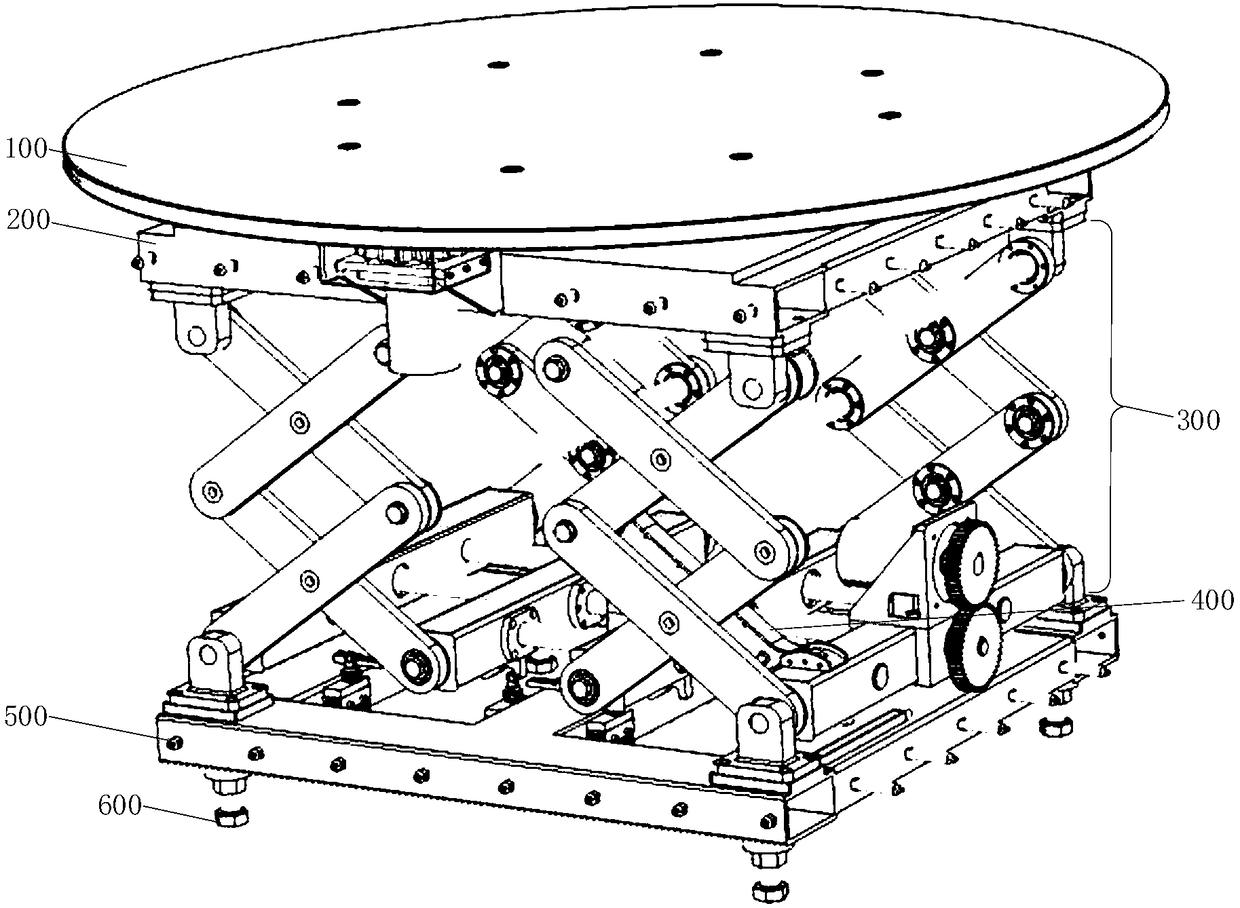

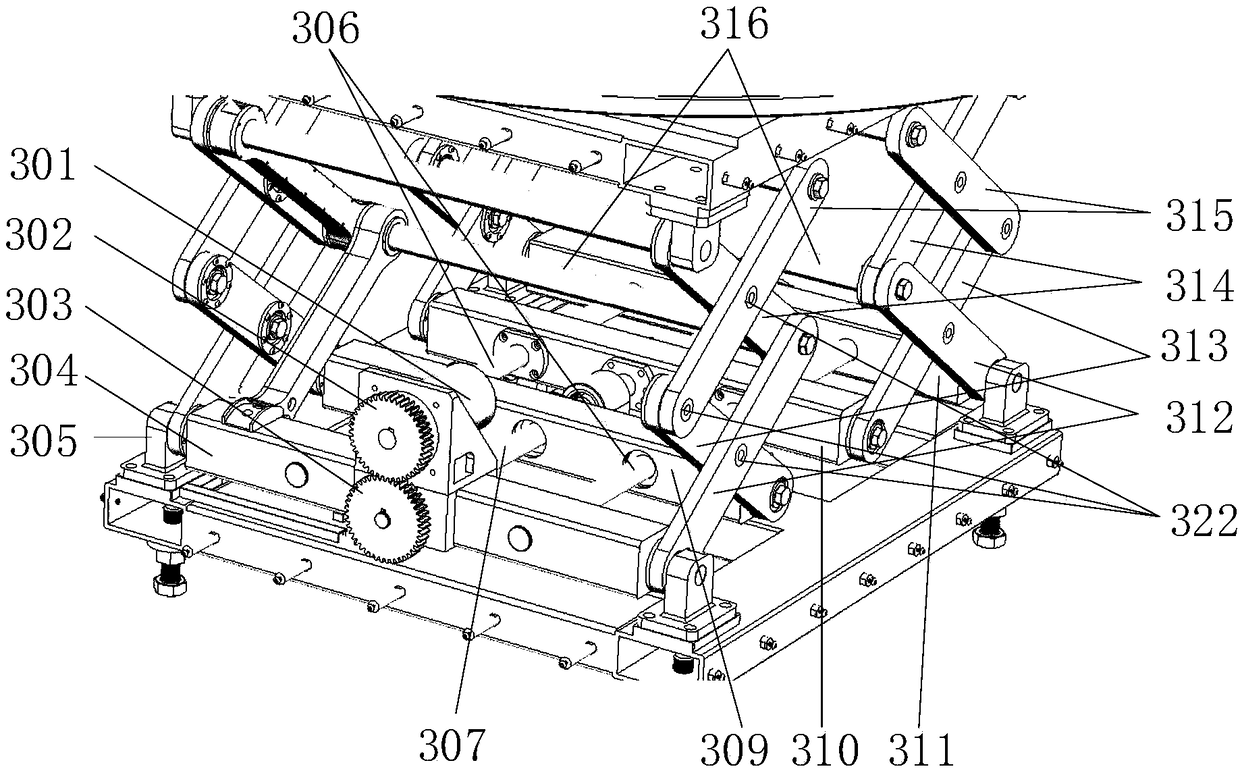

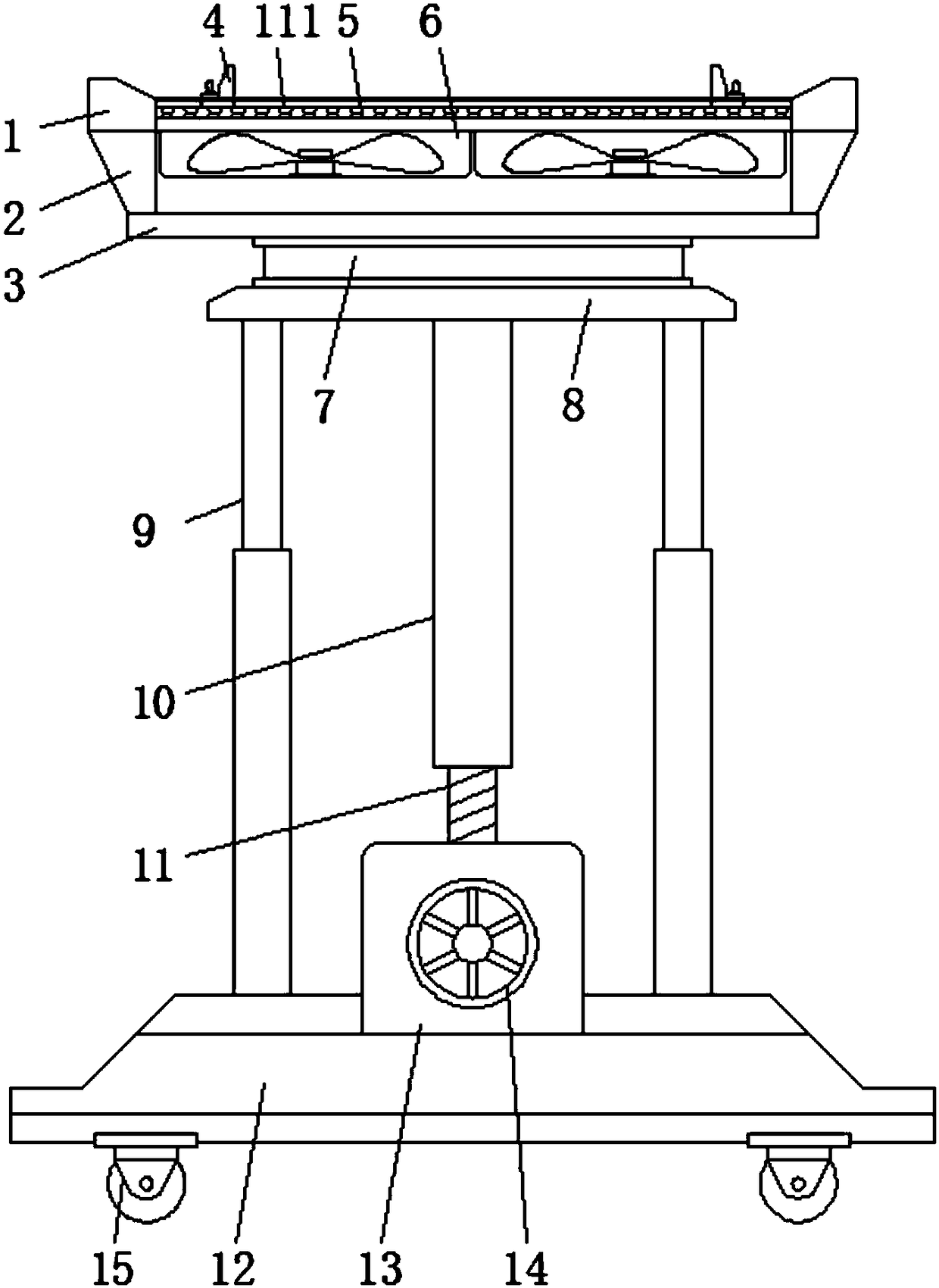

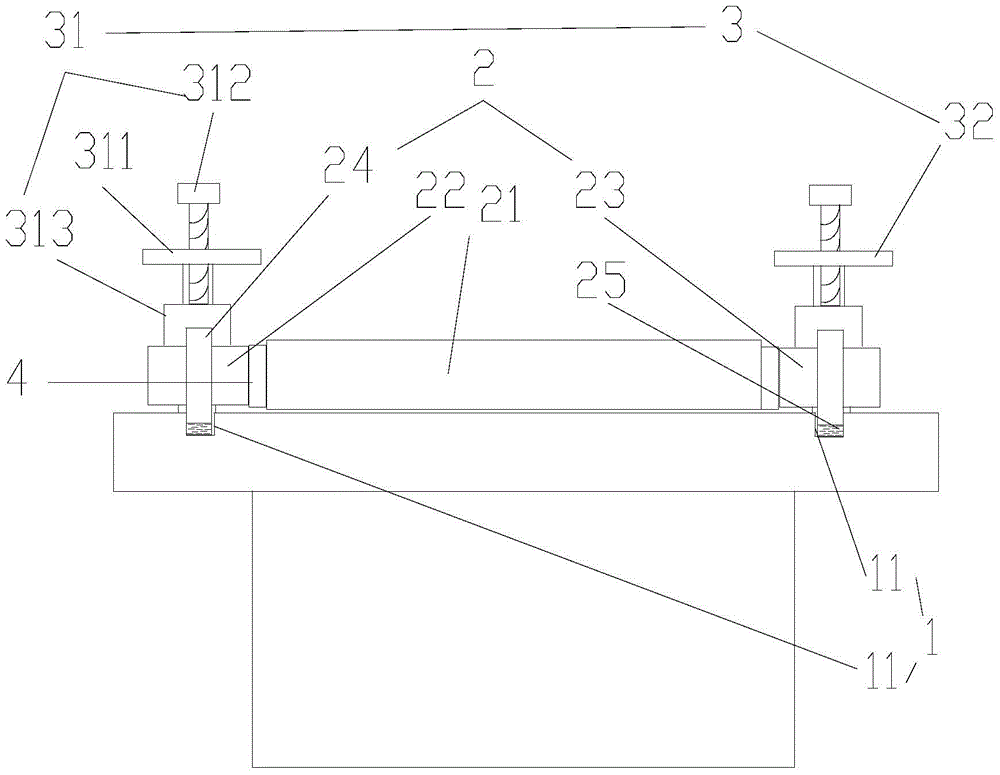

Double-scissors type rotary lifting table

InactiveCN108545656APrevent sideways movementPrevent sideways slidingLifting framesBall screwEngineering

The invention discloses a double-scissors type rotary lifting table. According to the double-scissors type rotary lifting table, a rotary table body is installed above an upper base, capable of rotating relative to the upper base and used for bearing to-be-borne objects, the upper base is installed at the top end of a double-scissors lifting mechanism and used for bearing the rotary table body; the double-scissors lifting mechanism is installed above a lower base and used for driving the upper base and the rotary table body to vertically ascend and descend; the double-scissors lifting mechanism controls two ball screws to rotate at the same time so as to make two ball nut bases in threaded connection with the two ball screws move away from or get close to a middle bearing base at the sametime; the two ball nut bases drive scissor mechanisms connected with the two ball nut bases to achieve ascending / descending movement of a platform; and the lower base is used for bearing the rotary table body, the upper base and the double-scissors lifting mechanism. The double-scissors lifting structure is adopted, lateral movement in the platform lifting process is avoided, and stability of thelifting process is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

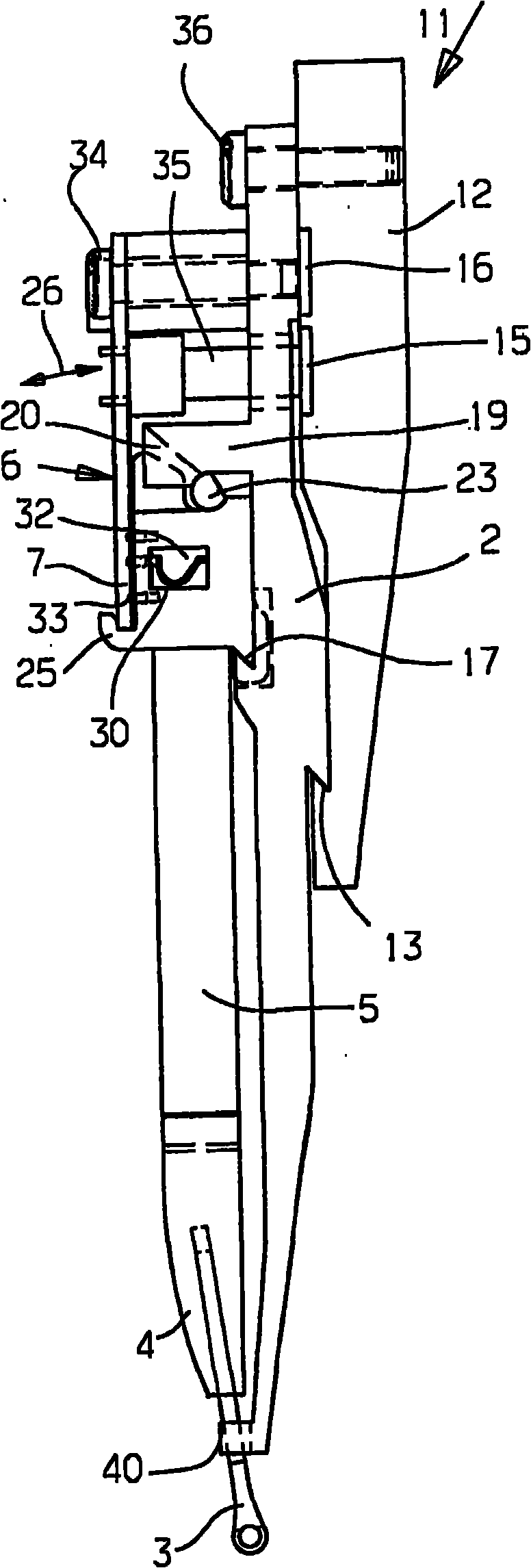

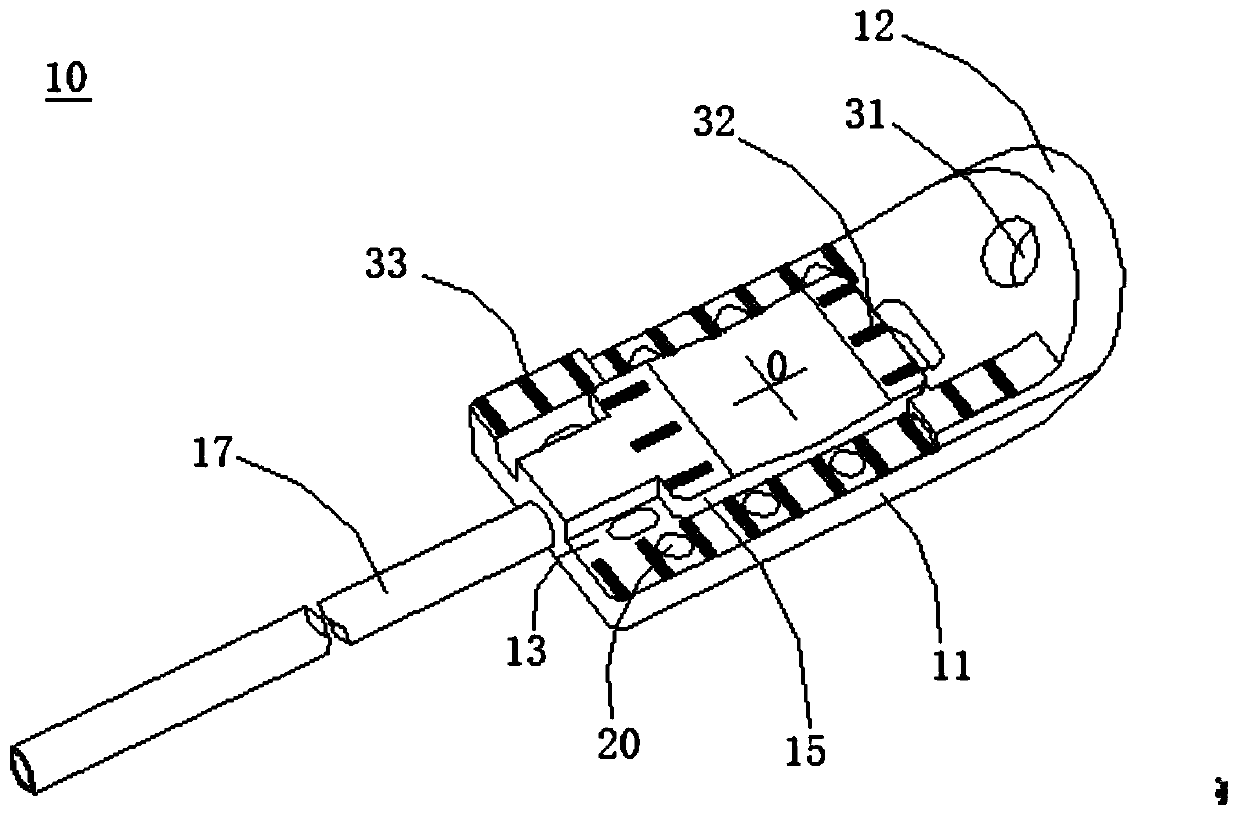

Glass hole drilling tool

InactiveCN104369272APrevent sideways movementAvoid burning drillWorking accessoriesStone-like material working toolsThin walledEngineering

The invention discloses a glass hole drilling tool which comprises a handheld electric drill, a hollow thin-walled drill and a positioning cover. A slide cavity is formed in a drill body of the handheld electric drill. The positioning cover is embedded in the slide cavity through a spring. Suction cups are arranged on the lower portion of the positioning cover. The hollow thin-walled drill is installed on a rotating central shaft of the handheld electric drill. The working part of the hollow thin-walled drill is an interval multi-tooth drilling face, a strip-shaped drill bit is fixedly arranged at the rotating center of a drill bit, and the diameter of the positioning cover is two times larger than the diameter of the hollow thin-walled drill. The glass hole drilling tool has the advantage that the hollow thin-walled drill can be prevented from deflecting sidewards in the hole drilling process.

Owner:CHONGQING UNION MACHINE MFG

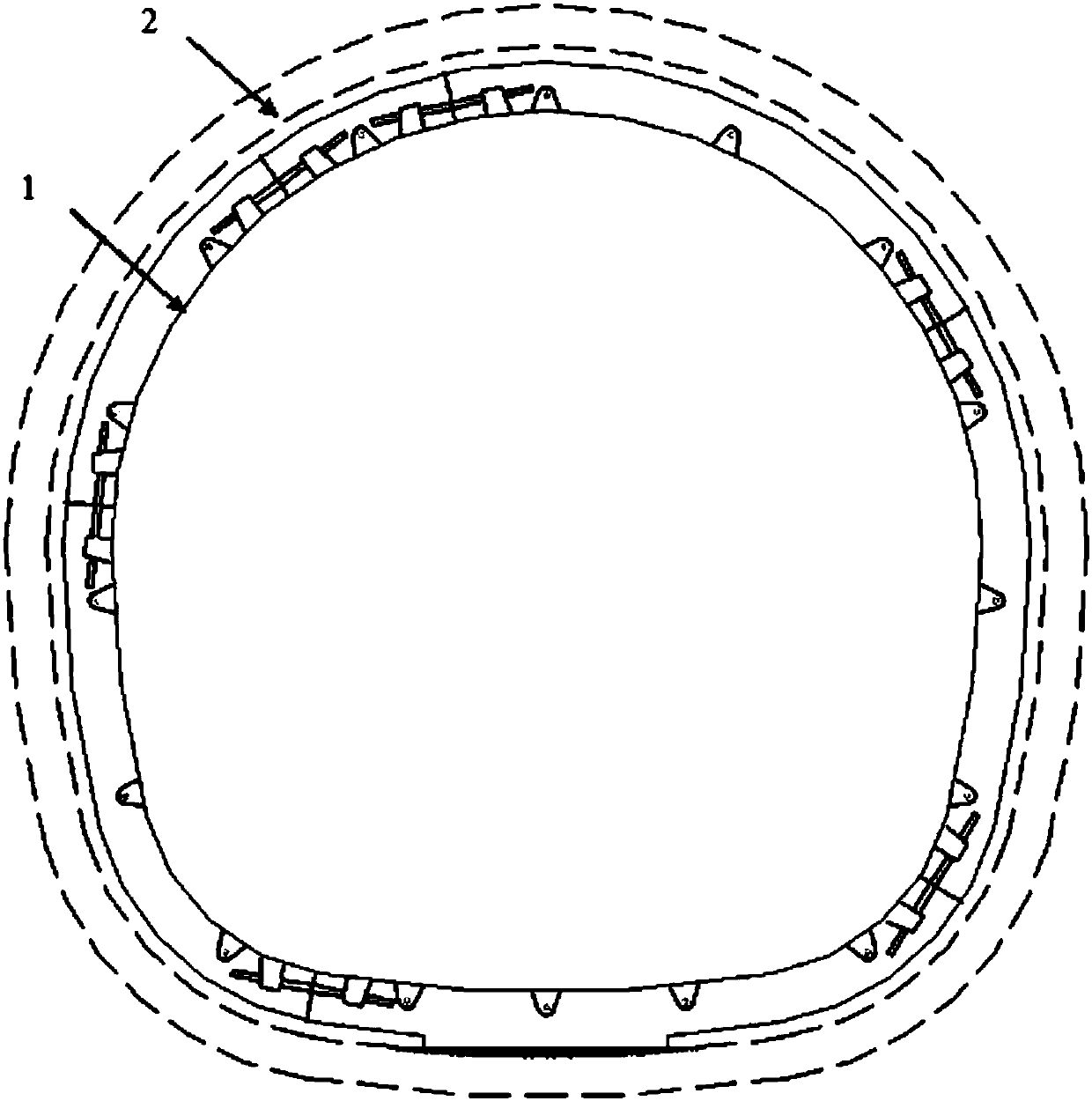

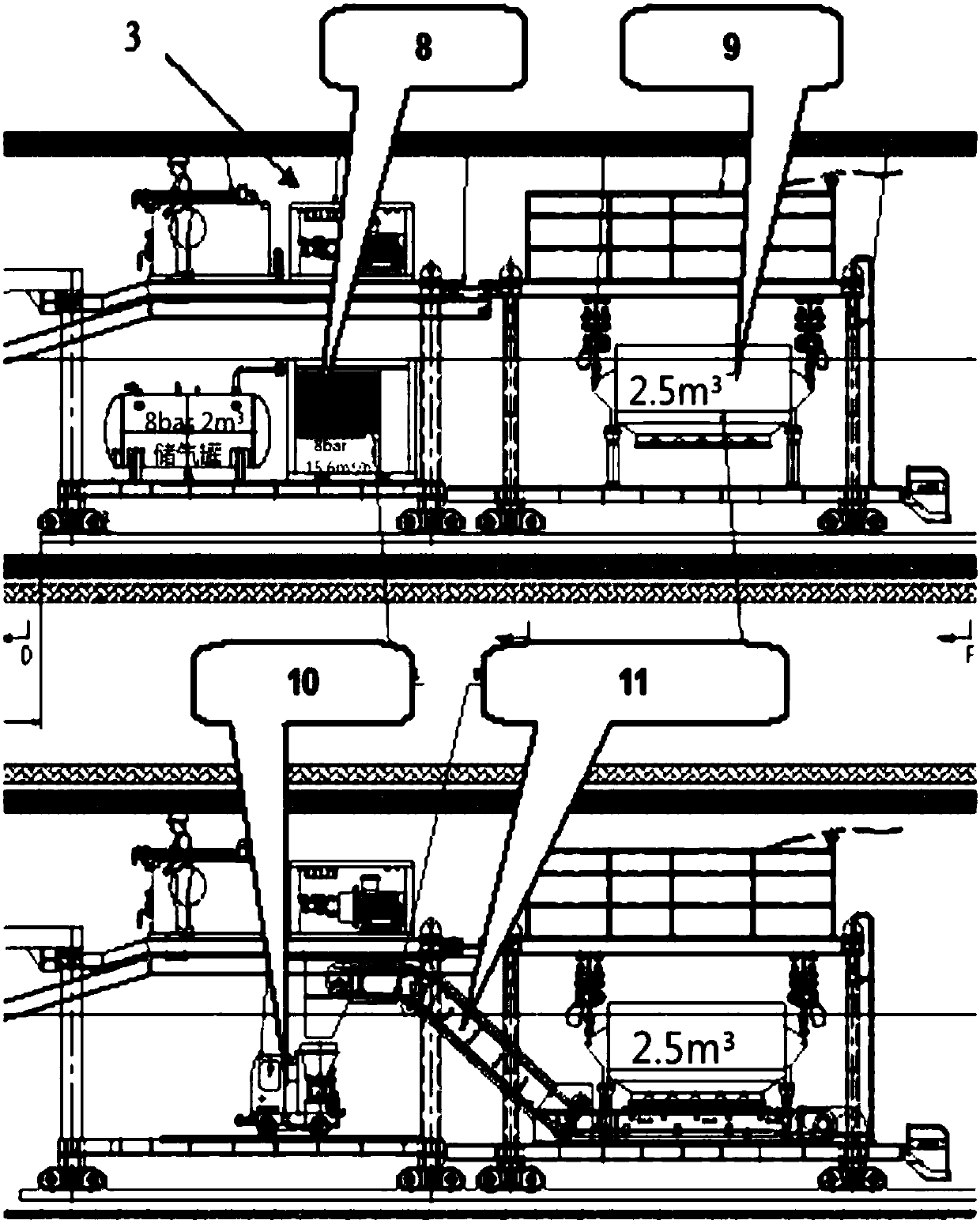

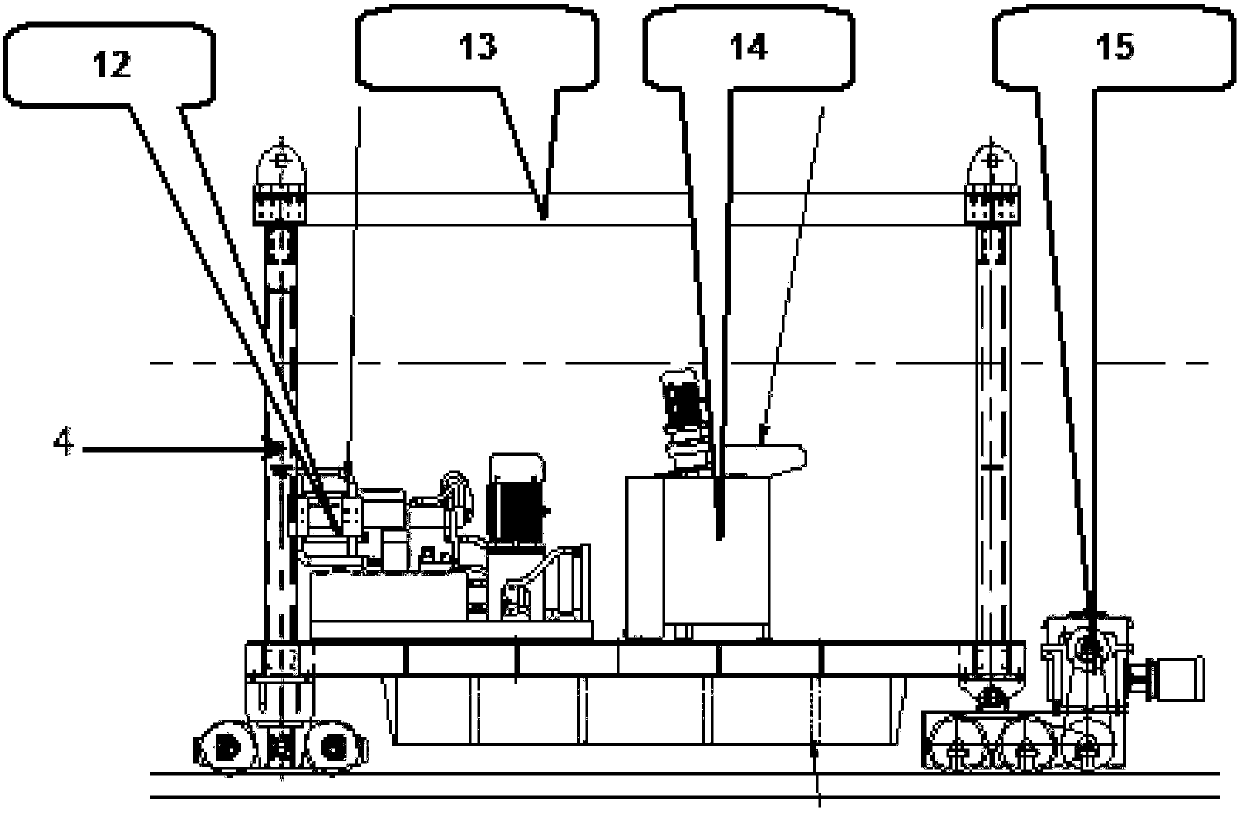

Construction method for filling of back of fabricated secondary lining of concealed excavated tunnel

InactiveCN107939420AControl land subsidenceImprove water resistanceUnderground chambersTunnel liningShort durationRail transportation

The invention relates to a construction method for backfilling of an assembled secondary lining of a submerged tunnel, which belongs to the technical field of rail transit engineering construction. It is characterized in that: after the assembly of each ring segment is completed, the bean-gravel construction is carried out in the gap between the back of the prefabricated segment and the primary support structure of the main line; the order of the bean-gravel filling is from bottom to top, left and right symmetrical; Install an airbag seal at the end of the pipe ring. The airbag seal is inflated and pushed against the wall of the cave. When the equipment moves forward, the airbag deflates, and the mounting seat drives the airbag forward; after assembling 20 rings, the ring is prefabricated with cement slurry The bean gravel gaps filled behind the segments are fully filled to form a closed ring. When grouting, grout is injected vertically through the holes, and one hole is injected every five rings; the ring is sealed once every 20 rings, and the ring is sealed by chemical grouting. The invention can control the subsidence of the ground surface, enhance the waterproof ability of the assembled tunnel, prevent the segments from floating up and sideways, and is convenient for construction, high in safety, short in construction period and low in cost.

Owner:CHINA RAILWAY SIXTH GROUP +1

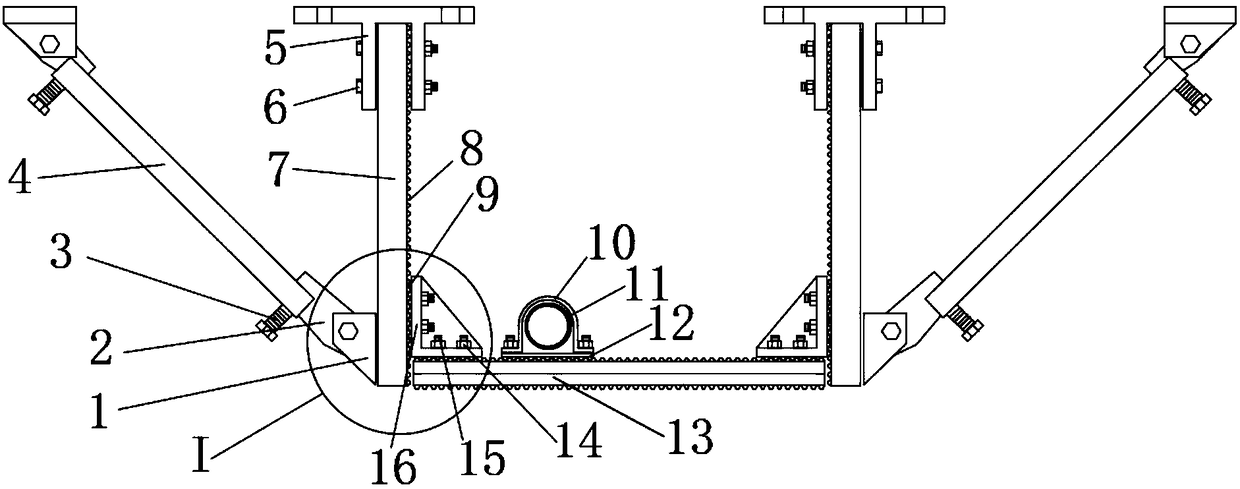

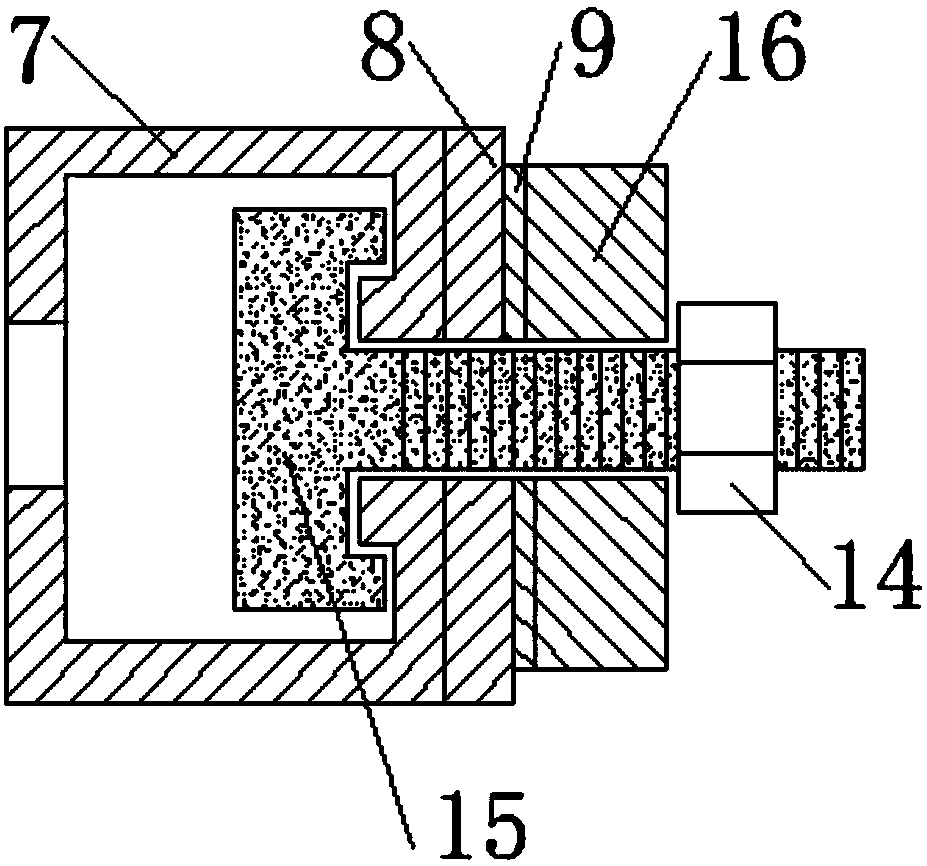

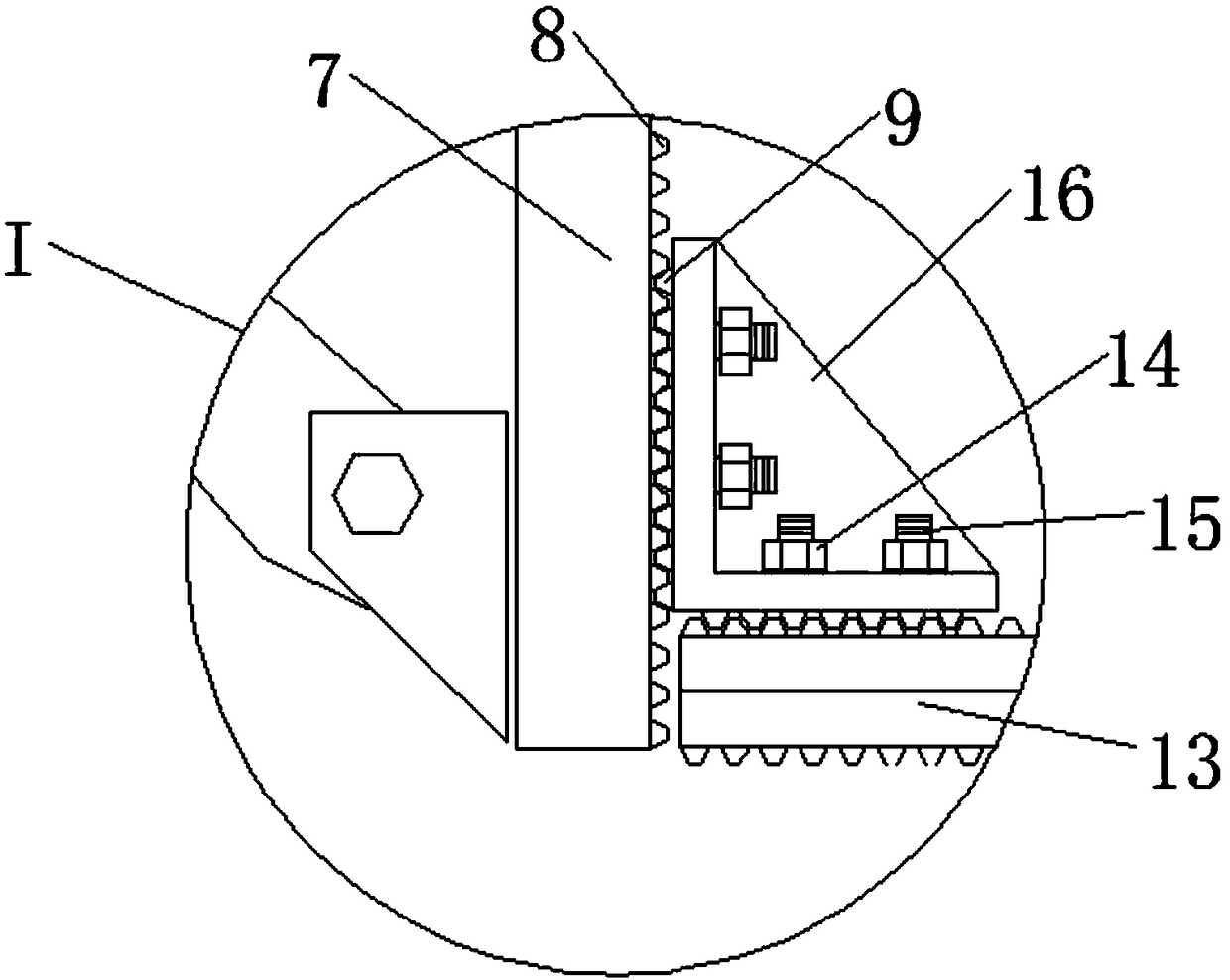

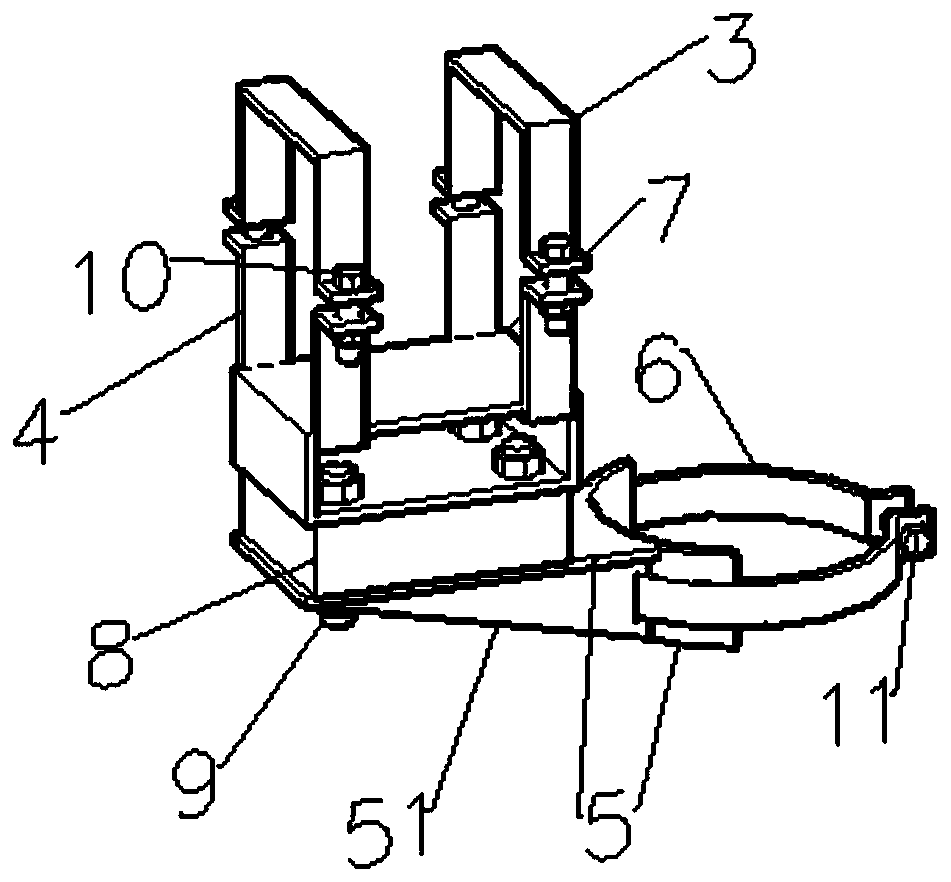

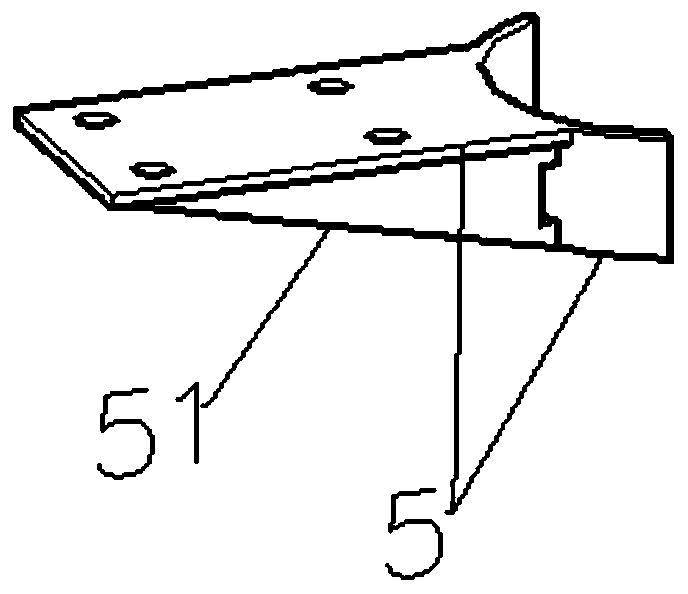

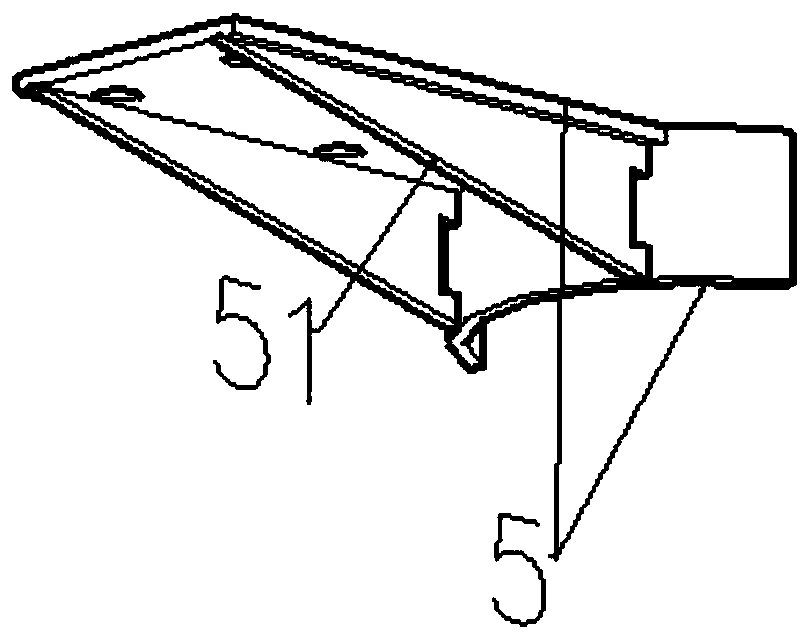

Anti-loose anti-seismic supporting hanging bracket for installing pipeline

InactiveCN108150720APrevent sideways movementGuaranteed locking forcePipe supportsNutsShock resistanceStructural engineering

The invention discloses an anti-loose anti-seismic supporting hanging bracket for installing a pipeline. The anti-loose anti-seismic supporting hanging bracket comprises first channel steel bases, hinges, first screws, channel steel connecting rods, second channel steel bases, anti-loose bolts, single-side channel steel, first racks, second racks, a U-shaped fixing part, a pipeline, a bottom plate, double-spliced channel steel, nuts, second screws and fixing and connecting pieces. The supporting hanging bracket has the advantages of being simple in structure, the first racks and the second racks are arranged so that after the fixing and connecting pieces are installed on the single-face channel steel, locking force between the single-face channel steel and the fixing and connecting piecescan be effectively guaranteed, the fixing and connecting pieces are prevented from laterally moving when being stressed, and therefore shock resistance of the anti-seismic supporting hanging bracket is effectively improved; the first racks are arranged on the side surfaces of the single-face channel steel so that the mutual position between the single-sided steel channel and the fixing and connecting pieces can be continuously adjusted, the double-spliced channel steel on the adjacent anti-seismic supporting hanging bracket can be adjusted to the same horizontal height during installation, andtherefore bending stress is prevented when the pipeline is fixed, and the stability of supporting of the anti-seismic supporting hanging bracket is facilitated; and the anti-loose bolts are arrangedso that the anti-loose performance of the anti-seismic supporting hanging bracket can be greatly improved.

Owner:JIANGSU YIDINGGU ELECTROMECHANICAL TECH CO LTD

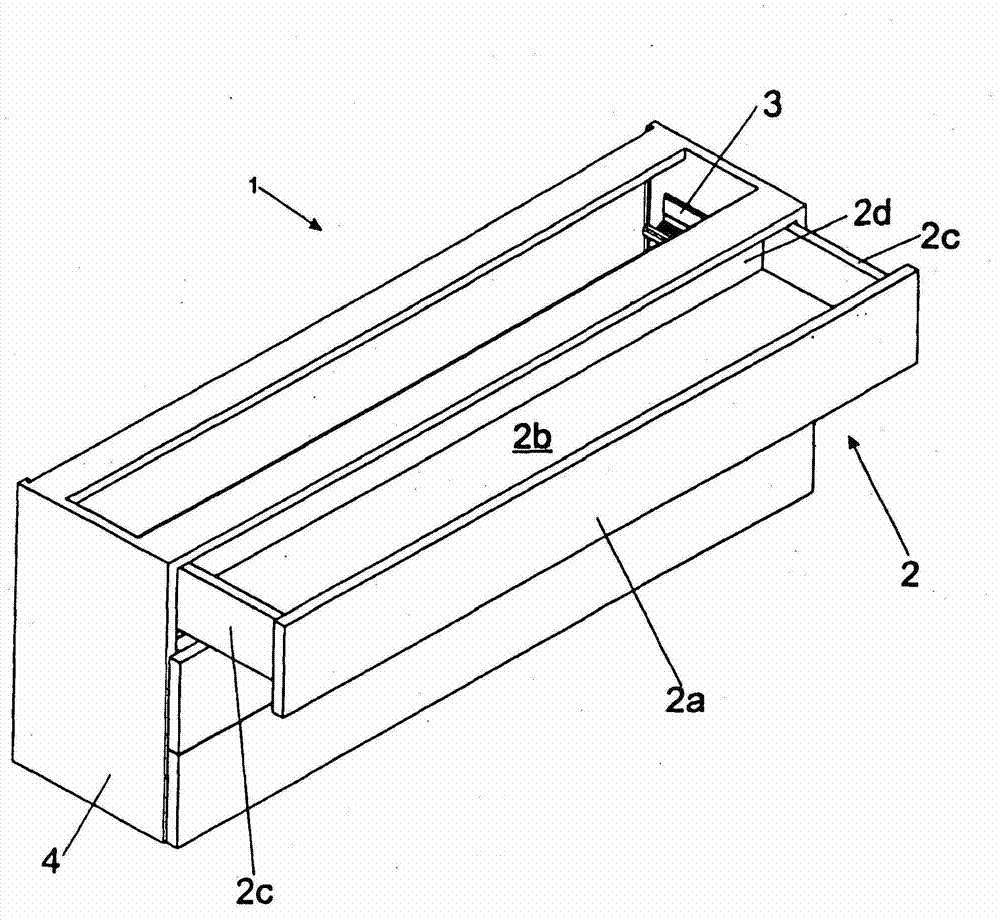

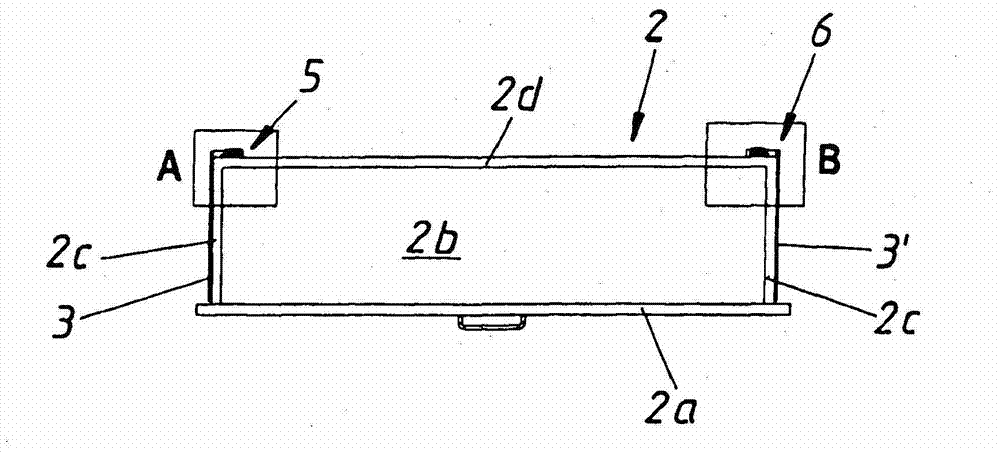

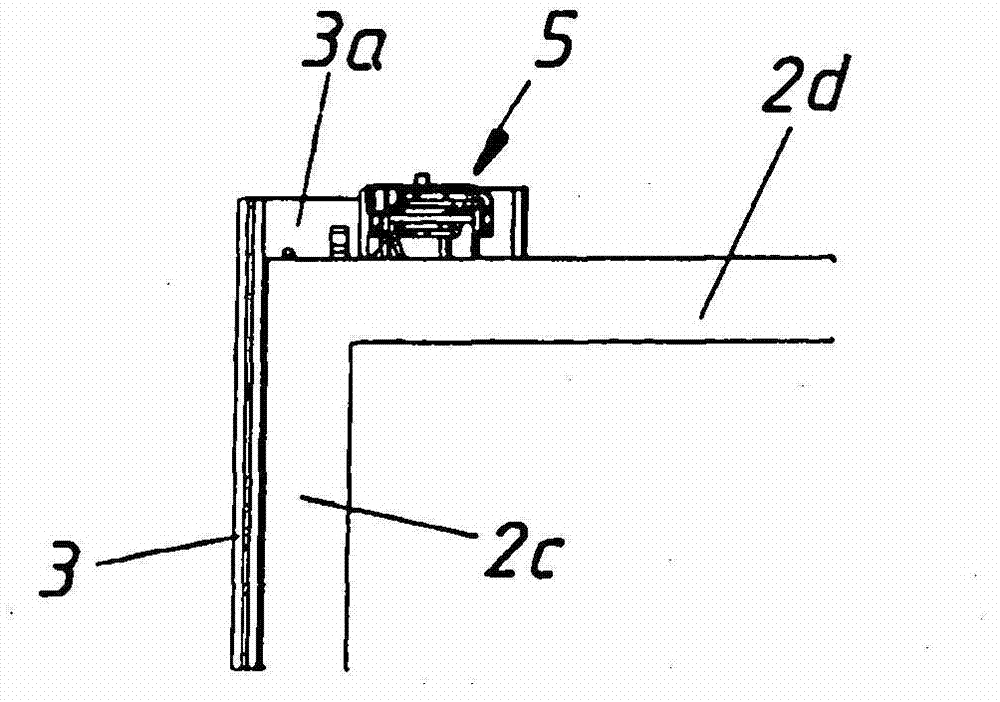

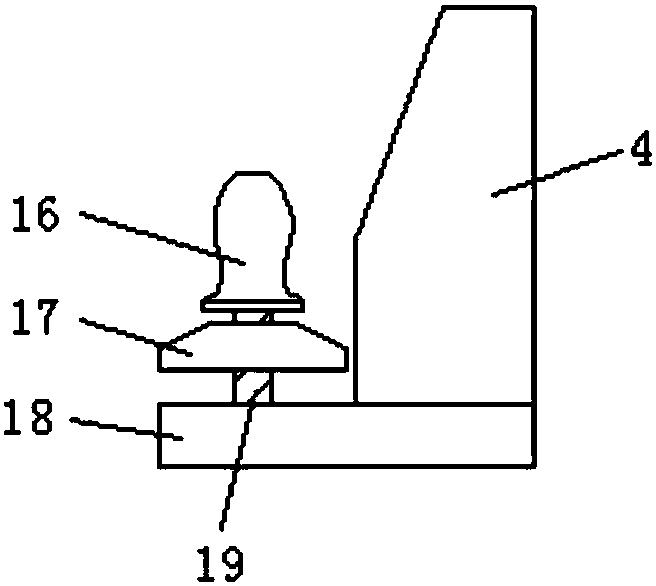

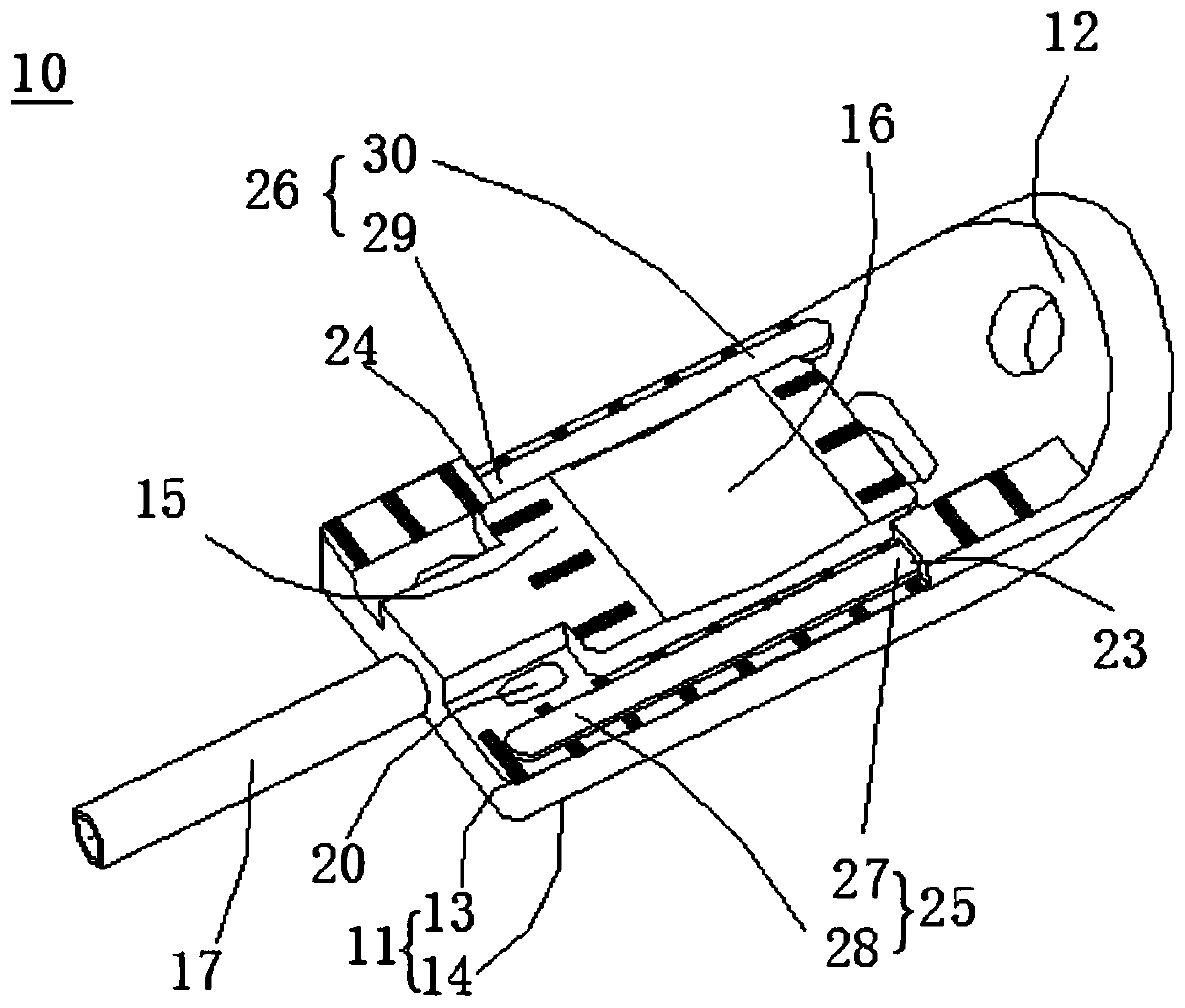

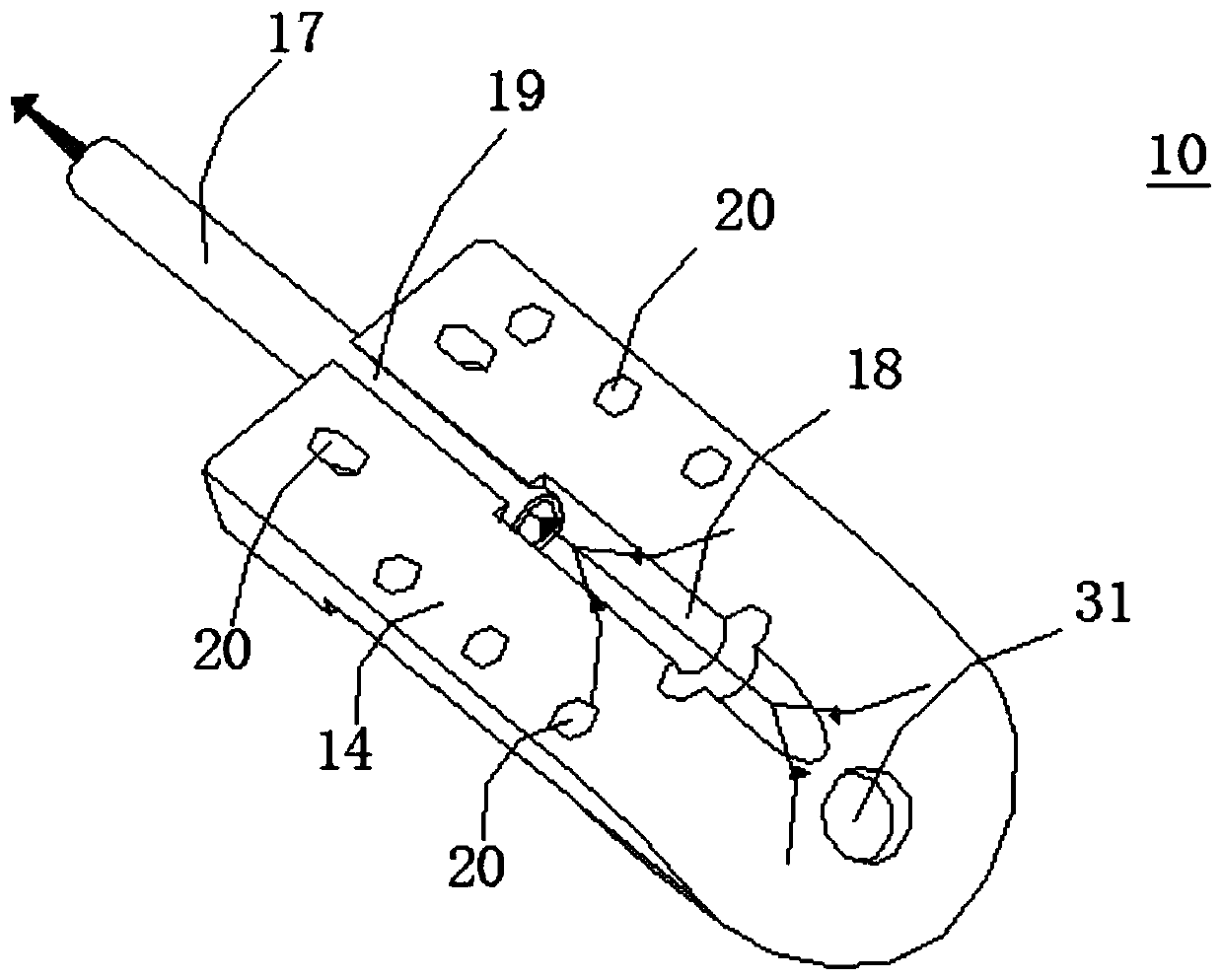

Pull-out guide for a drawer

The invention relates to a pull-out guide (3) for a drawer (2), wherein the pull-out guide has a body rail (3c) to be fastened to the furniture body (4) and at least one pull-out rail (3a) that can be moved relative to the body rail (3c), the pull-out guide comprising a retaining element (5) having a connecting element (7), by means of which the drawer (2) can be adjustably connected to the pull-out rail (3a), wherein the retaining element (5) is or can be connected to the pull-out rail (3a) and wherein the connecting element (7) is movably mounted relative to the retaining element (5), wherein an adjusting device for horizontally moving the connecting element (7) is arranged on the retaining element (5), wherein the adjusting device comprises a converting device (9, 18, 32), which can be rotationally moved about an axis arranged substantially parallel to the longitudinal axis of the pull-out rail (3a) and by means of which a rotational motion component can be converted into a translational motion of the connecting element (7).

Owner:JULIUS BLUM GMBH

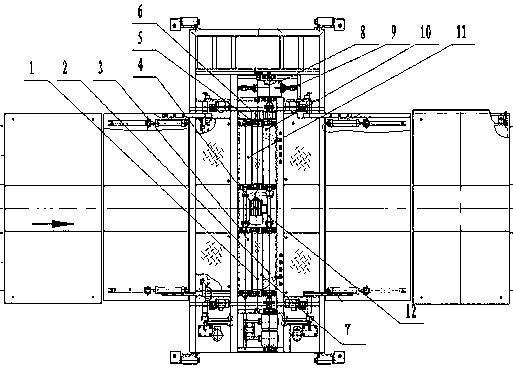

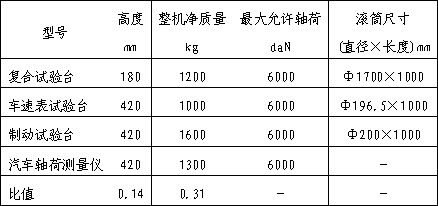

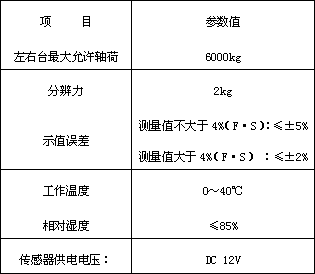

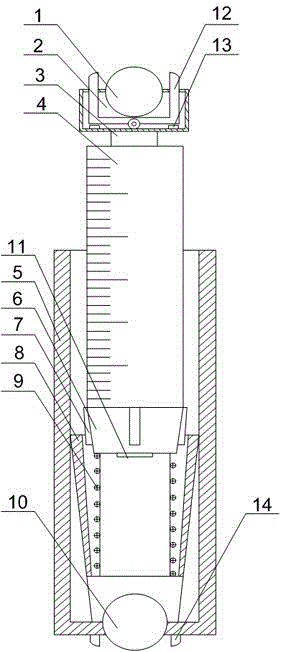

Axle weight and brake and vehicle speed combined test bench

InactiveCN103105299AGuaranteed Spacing RequirementsSimple structureVehicle testingTesting/calibration of speed/acceleration/shock measurement devicesCombined testMiniaturization

The invention discloses a small-sized integrated axle weight and brake and vehicle speed combined test bench. The axle weight and brake and vehicle speed combined test bench is composed of a test platform foundation frame, a left test bench framework, a right test bench framework and two testing systems, wherein the left test bench framework and the right test bench framework are connected with the test platform foundation frame through pressure sensors respectively mounted at four corners of the left test bench framework and four corners of the right test bench framework, the testing systems are mounted on the test bench frameworks, and each testing system is composed by a rotary drum, a lifting mechanism, a force measuring device, a rotation speed measuring device and a third rotary drum in a combination mode. According to the axle weight and brake and vehicle speed combined test bench, a brake test bench, a speedometer test bench and two sets of rotary drums of an axle load meter are combined to one group, a driving motor and a speed reducer are arranged in the rotary drums, due to the integrated design, the structure is simplified, the occupied space is reduced, cost is lowered, the space requirement for installation of other devices can be met, and a test vehicle is enabled to finish all testing tasks according to national standard requirements.

Owner:MILITARY TRANSPORTATION UNIV PLA

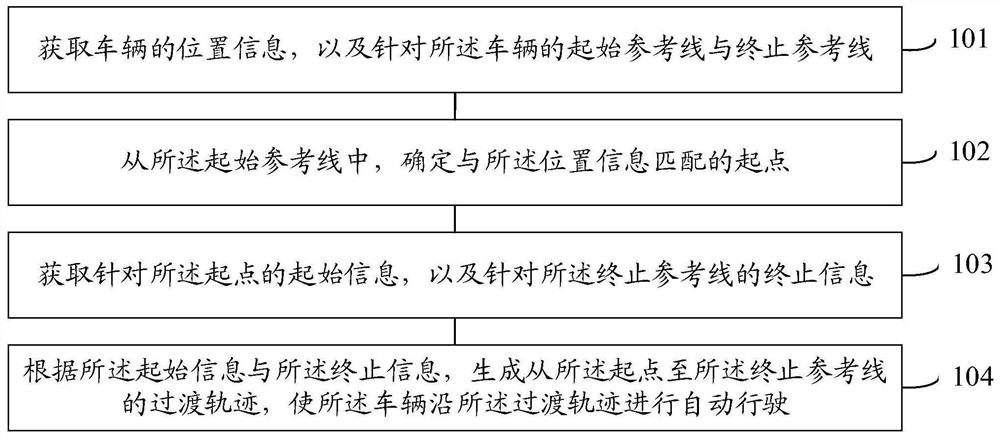

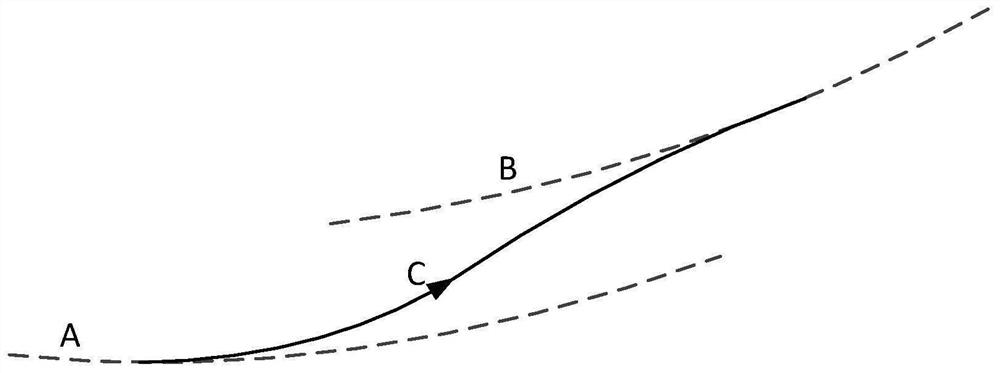

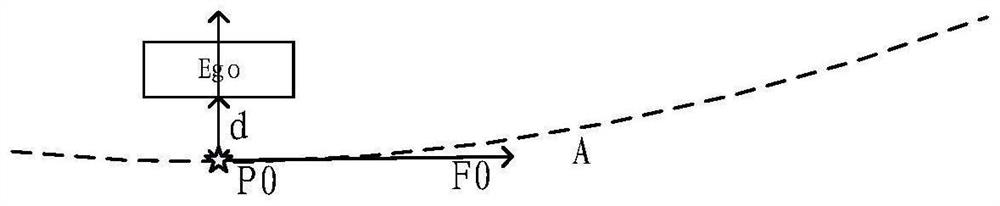

Vehicle transition track generation method and device

ActiveCN112146667APrevent sideways movementGuaranteed reasonablenessInstruments for road network navigationVehicle drivingCar following

The embodiment of the invention provides a vehicle transition track generation method and device. The method comprises the steps that the position information of a vehicle is obtained, and a startingreference line and an ending reference line aiming at the vehicle are obtained; a starting point matched with the position information is determined from the starting reference line; the starting information aiming at the starting point and the ending information aiming at the ending reference line are obtained; and then according to the starting information and the ending information, a transition track from the starting point to the ending reference line is generated, and the vehicle automatically travels along transition track. By presetting the starting information aiming at the starting point and the ending information aiming at the ending point reference line, the vehicle can obtain the transition track according to the starting information and the ending information after obtainingthe current position and the ending point reference line, and the vehicle can travel along the transition track; and automatic driving modes such as lane changing, lane changing car following and lanekeeping can be achieved, the calculation efficiency is improved, the reasonability of a vehicle driving path can be guaranteed, and lateral movement of the vehicle is avoided.

Owner:GUANGZHOU XIAOPENG CONNECTIVITY TECH CO LTD

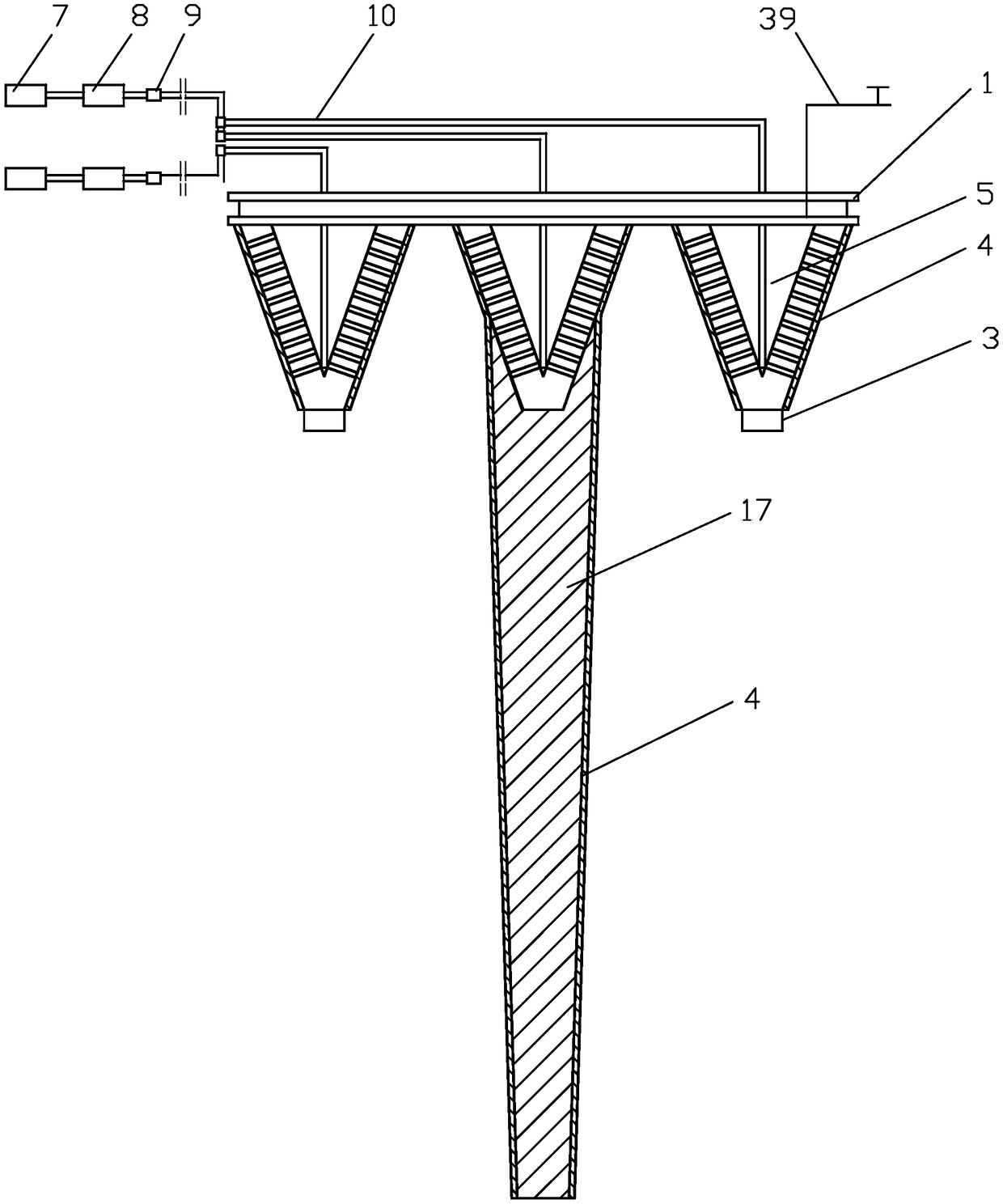

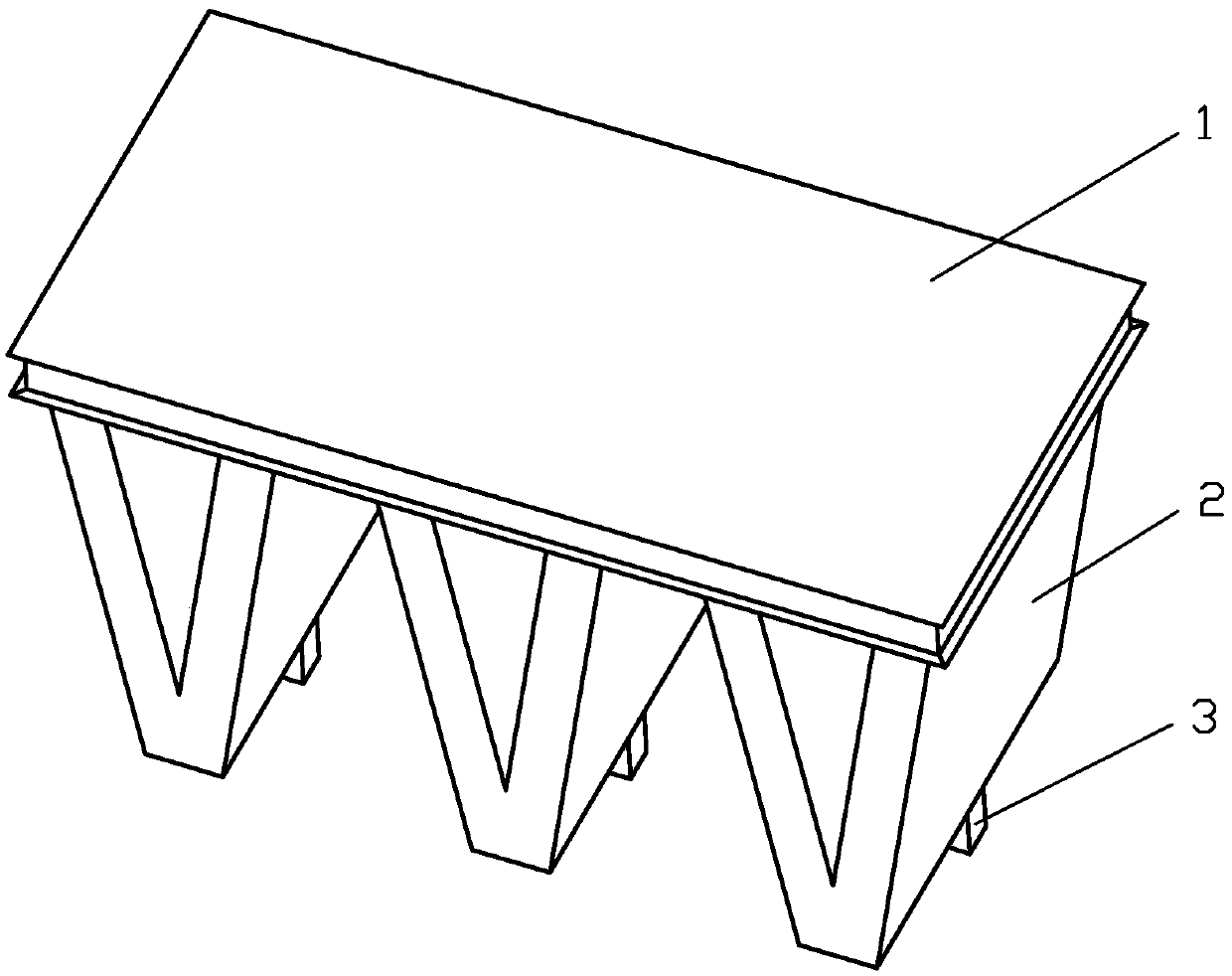

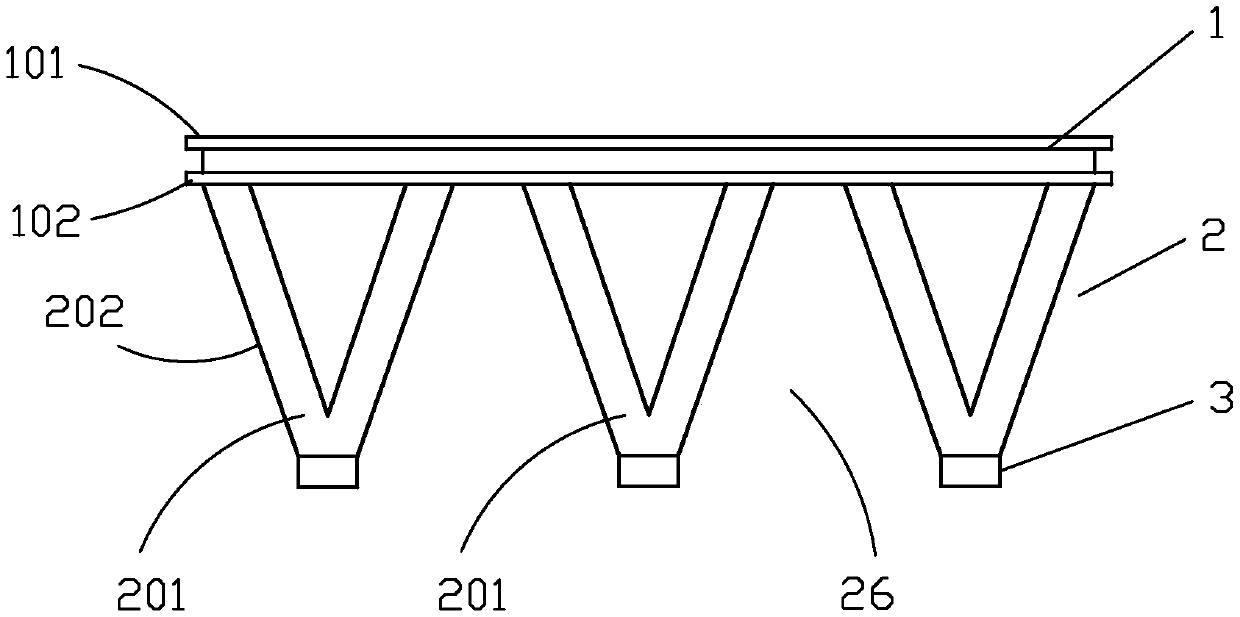

Modular soil compaction molding device applicable for treatment of deep and shallow soft soil foundations

InactiveCN108330948APlay a blocking rolePrevent sideways movementSoil preservationEngineeringUltimate tensile strength

The invention discloses a modular soil compaction molding device applicable for treatment of deep and shallow soft soil foundations. The modular soil compaction molding device comprise an upper frame,a compaction molding module and a soil strength detection device, and is characterized in that the compaction molding module comprises a plurality of convex bodies; the top of the module is connectedto the upper frame, and the part, coming into contact with soil, of the compaction molding module is further provided with a filter device; and the bottom of the compaction molding module is furtherprovided with a vertical pile body. The soil is blocked by the convex bodies at the bottom of the compaction molding module, and prevented from offsetting so that the soil is centralized in spaces among the convex bodies and extruded fully, and the effects of quick drainage and compaction are achieved. Moisture extruded from the soil is discharged through the filter device, and the construction efficiency is improved greatly; and the construction period is shortened, and the construction cost is reduced.

Owner:ZHEJIANG JIA YUAN CIVIL ENG CO LTD

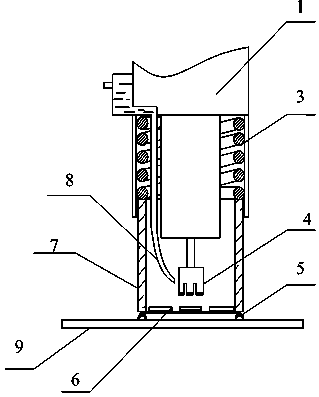

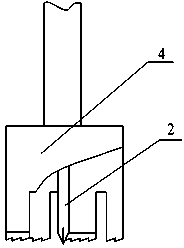

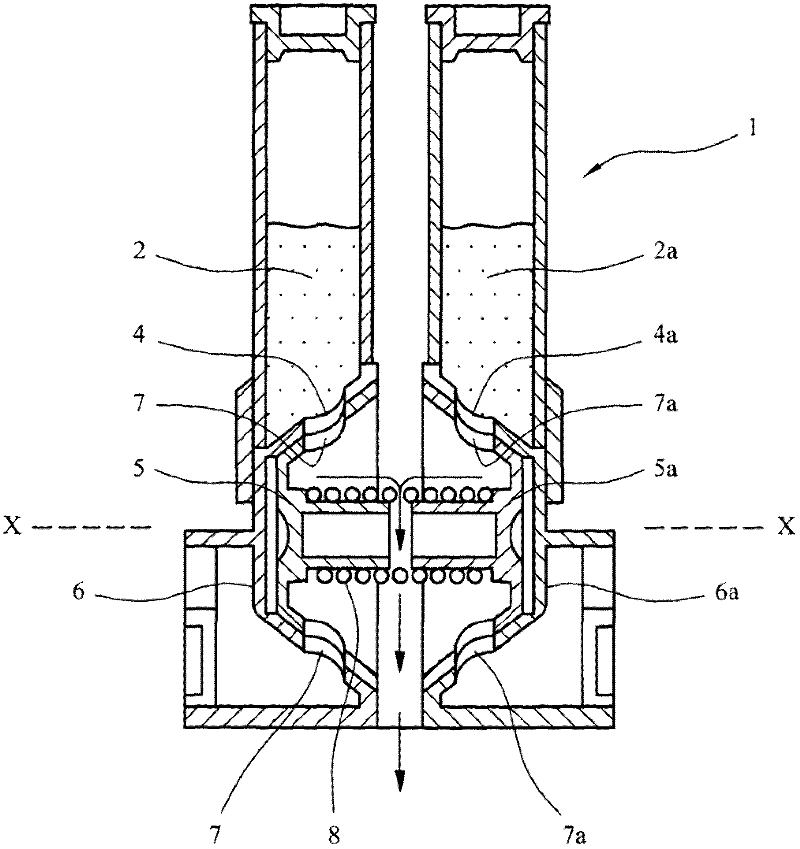

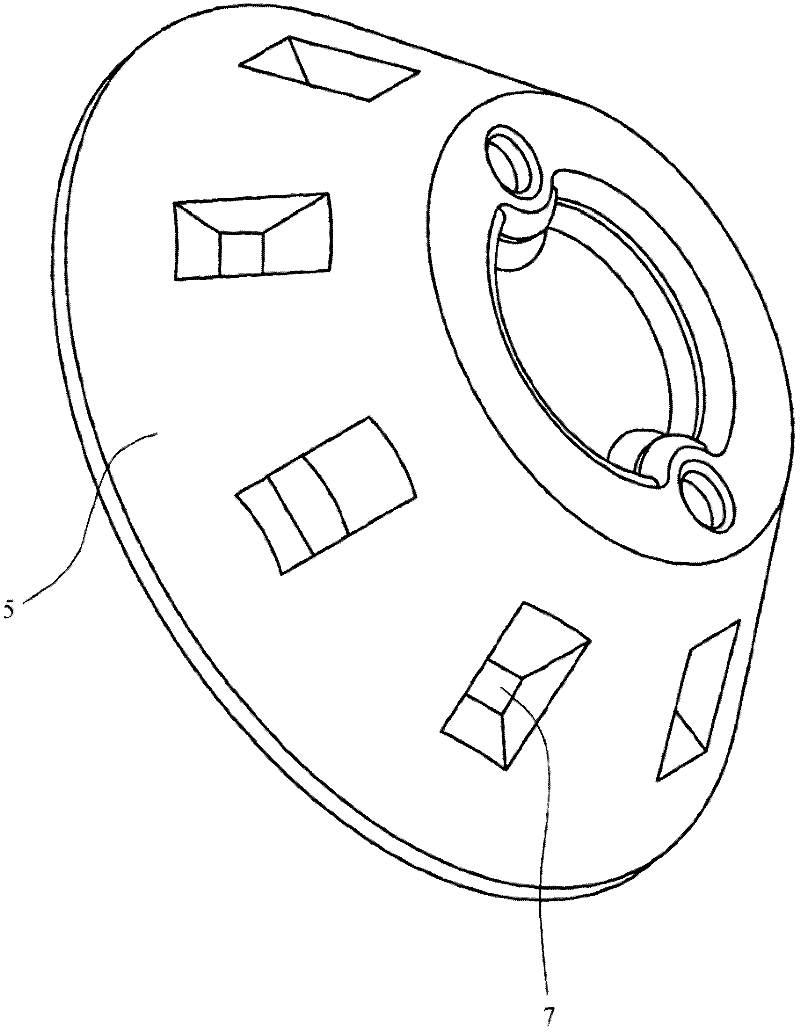

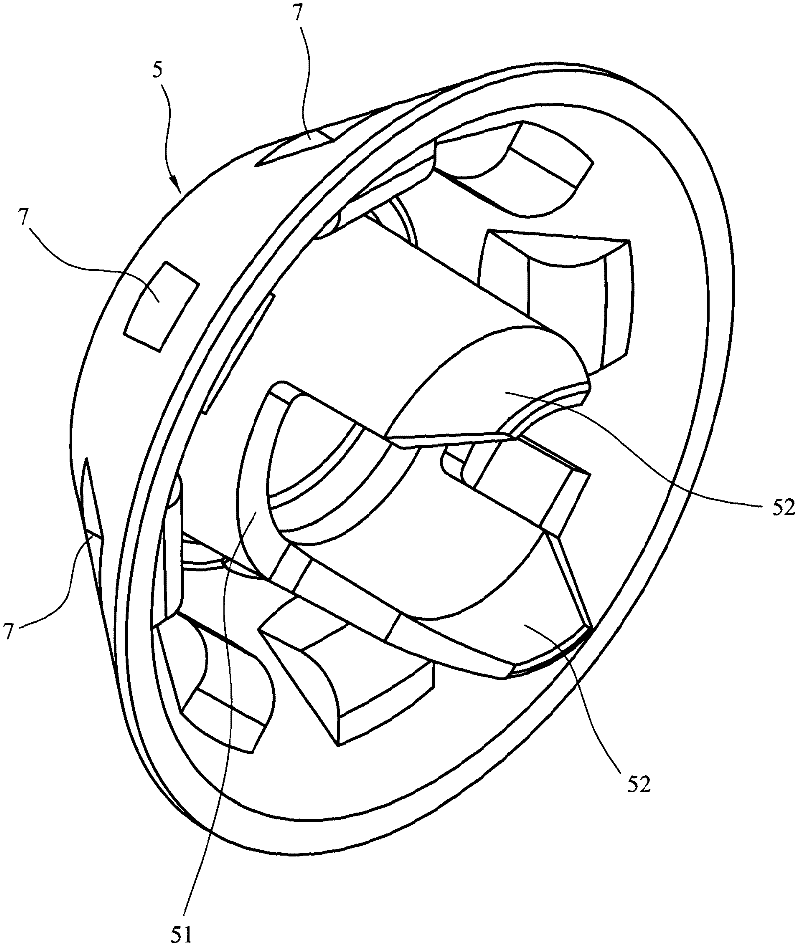

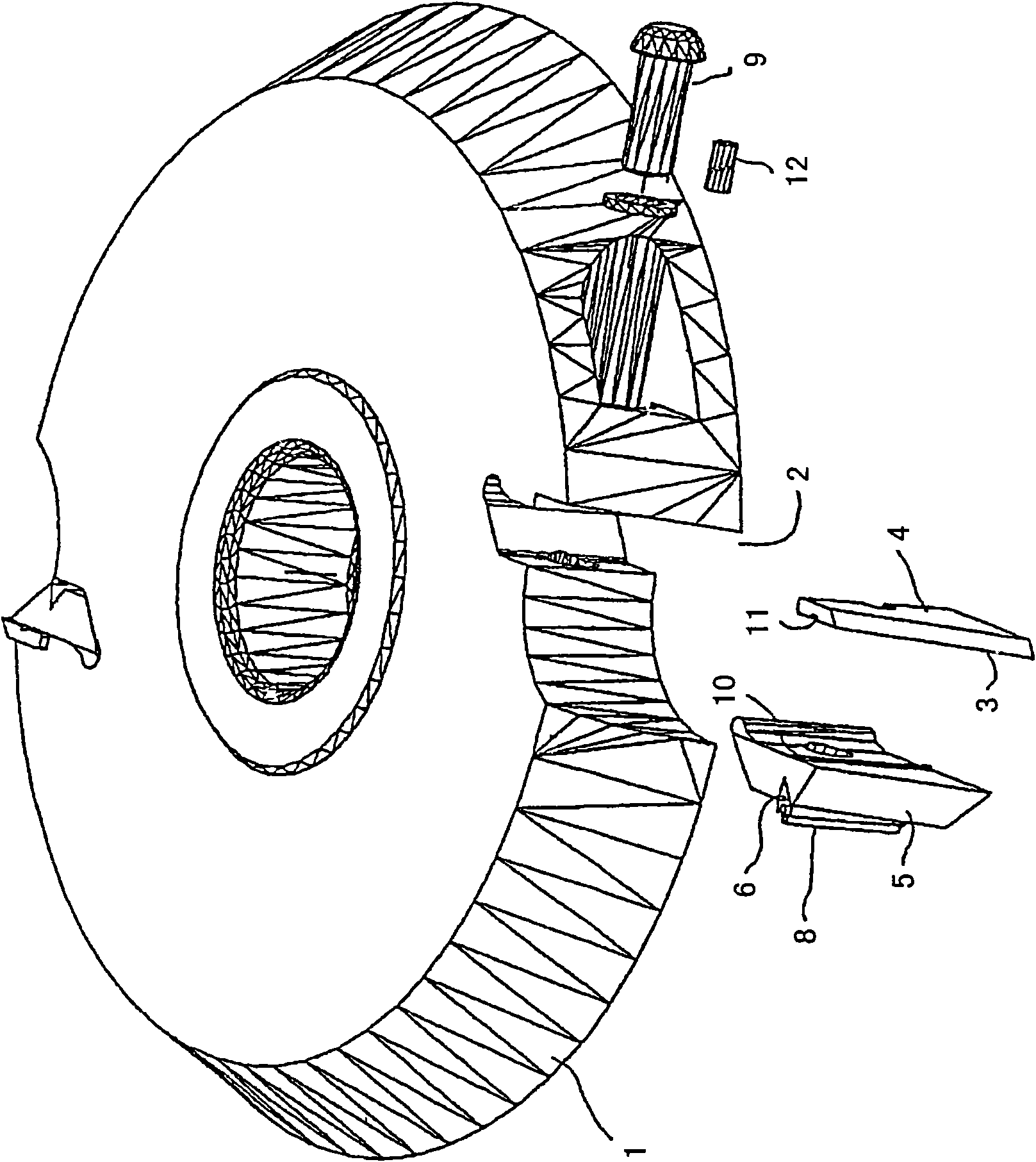

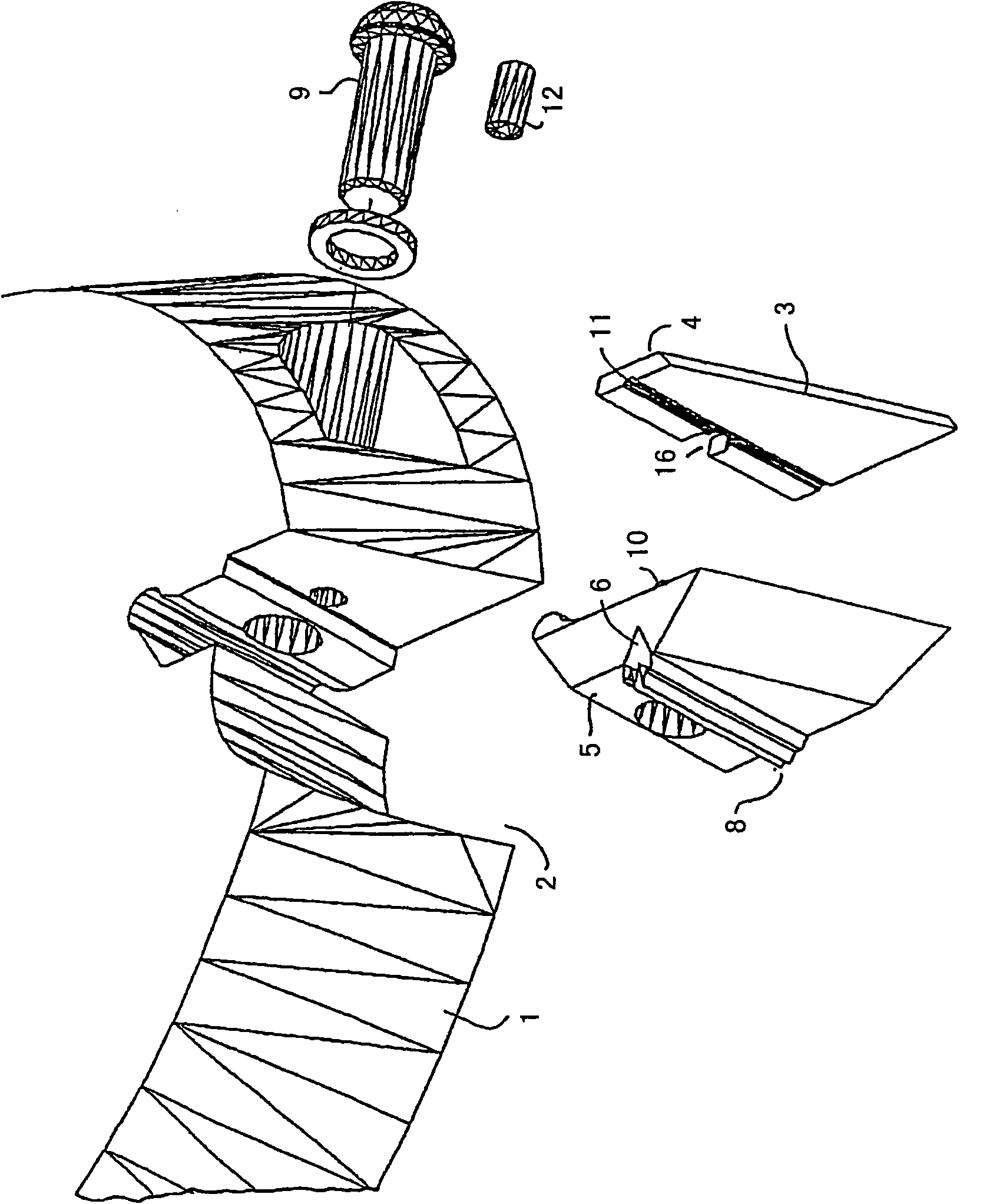

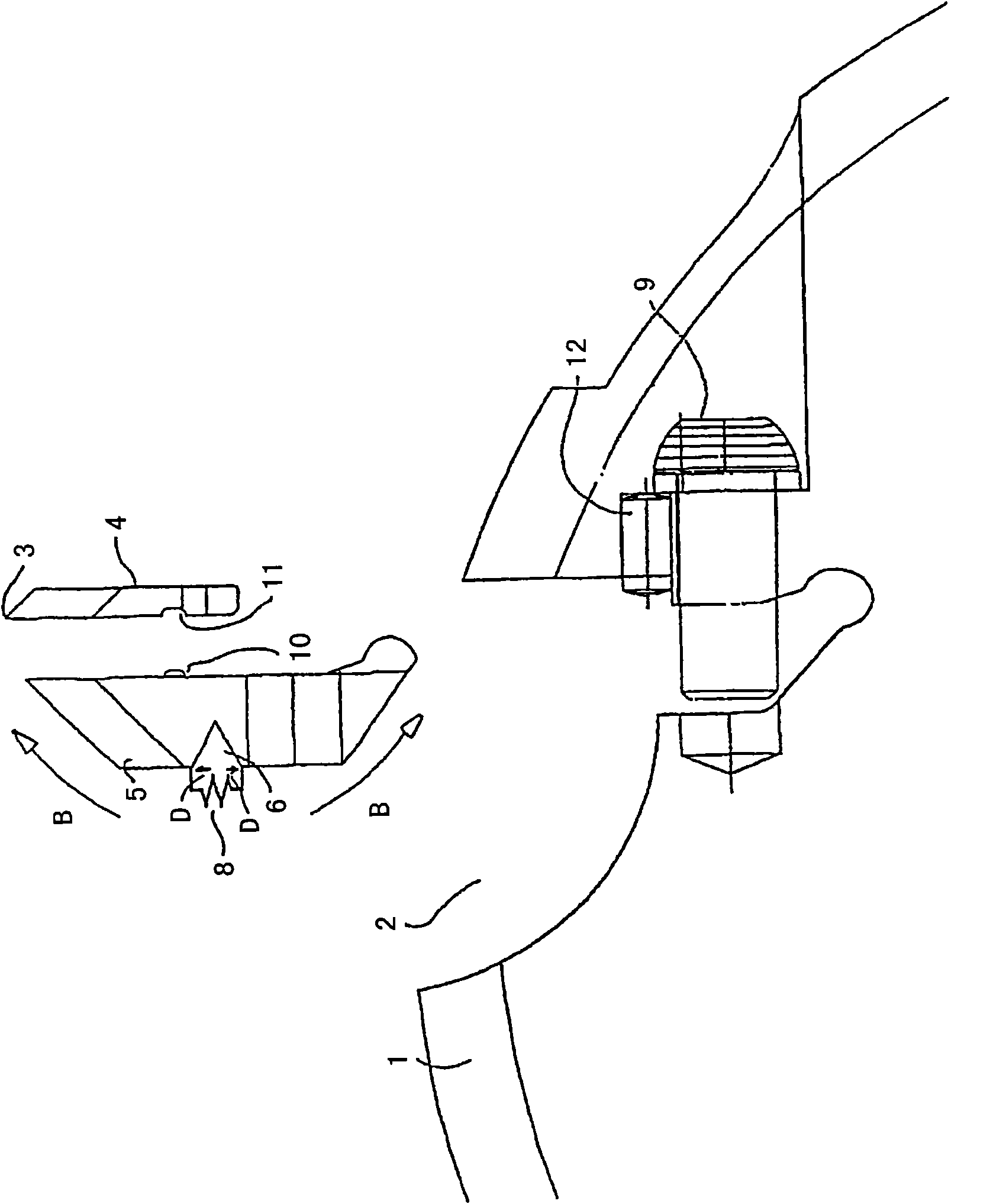

Improvements in or relating to dry powder inhalers

A dry powder inhaler (1) is disclosed comprising first and second medicament reservoirs (2, 2a) and respective rotatable first and second metering members (5, 5a), which are urged into sealing engagement with the respective medicament reservoir (2, 2a) by a compression spring (8) located between the metering members(5, 5a). The inhaler (1) includes an actuator by which the first and second metering members (5, 5a) are rotated in unison from a metering position to a dispensing position. The actuator acts upon the first and second metering members (5, 5a) via a wheel (9) mounted between the first and second metering members(5, 5a). The first and second metering members (5, 5a) are provided with sockets (51) that receive the respective ends of the compression spring (8). The sockets (51) have extensions (52) that project into an axial bushing (92) of the wheel (9), the bushing (92) being provided on its internal surface with formations (94a, 94b, 94c, 94d) that engage the extensions (52) to cause the metering members (5,5a) to rotate when the wheel (9) is rotated.

Owner:TIANJIN KINNOVATA PHARMA CO LTD

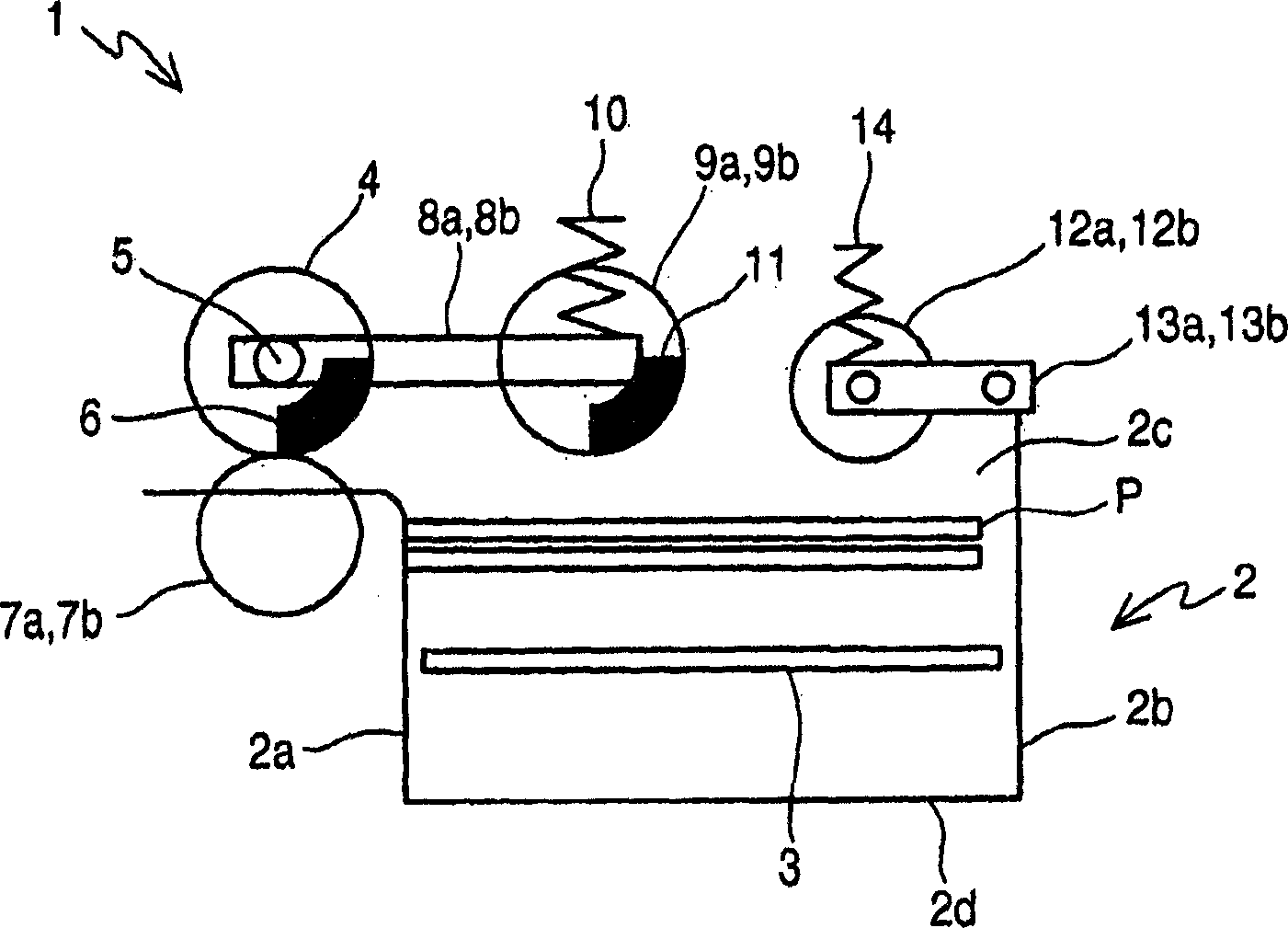

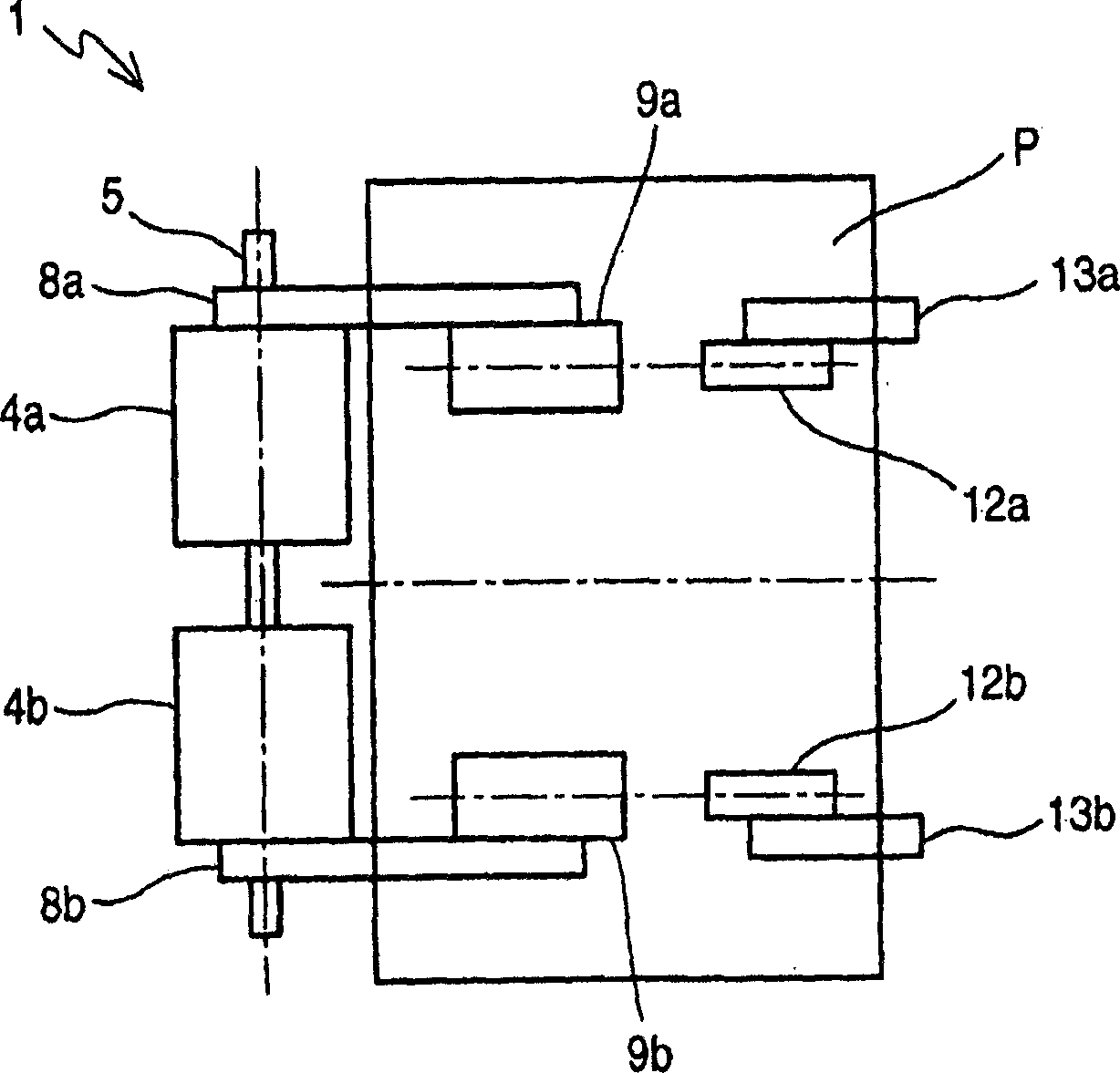

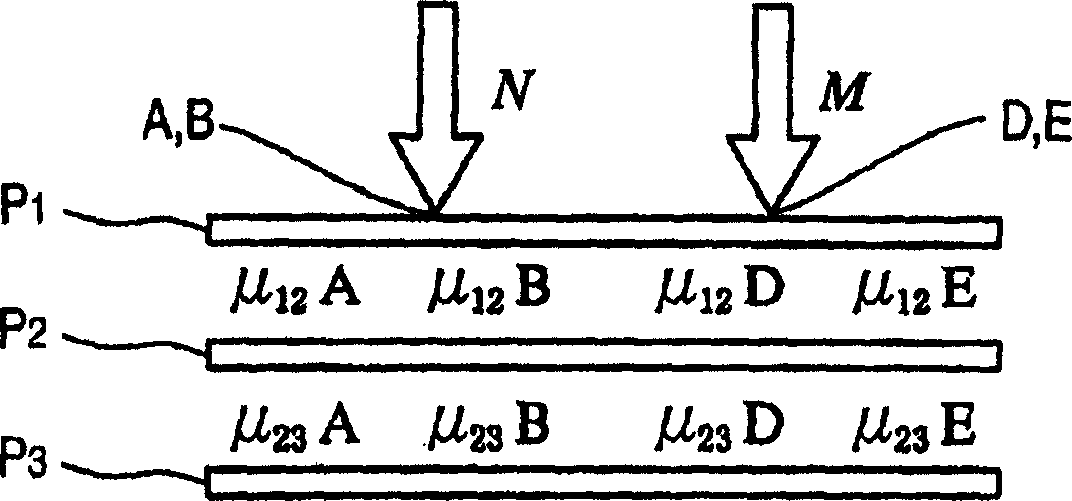

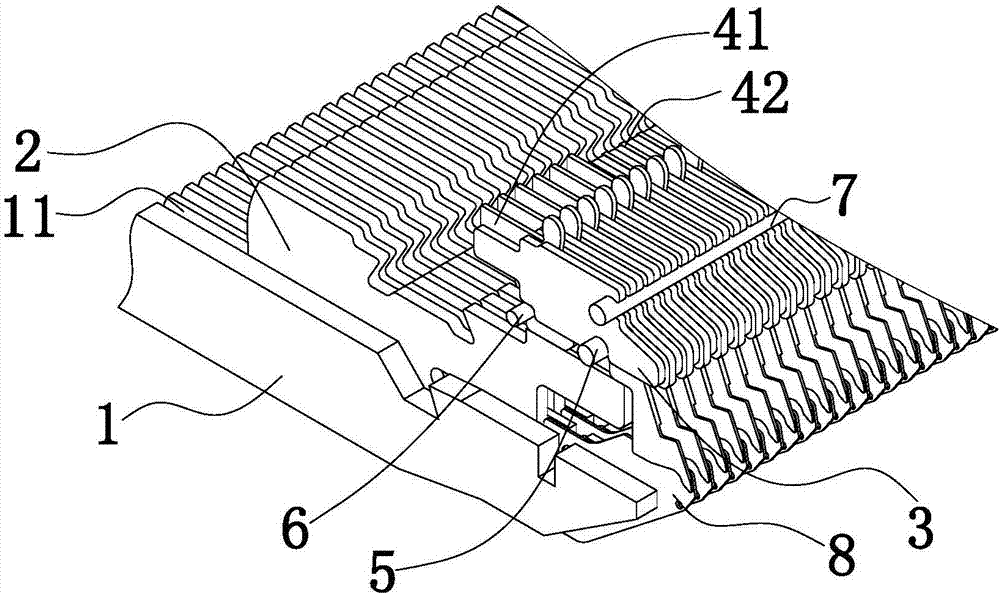

Paper separating mechanism and paper separation and focusing mechanism using same

InactiveCN1895975APrevent sideways movementPreventing troubles such as paper jamsArticle separationPulp and paper industryPaper sheet

To provide a means for preventing generation of trouble such as a paper jam due to collapse of attitude of paper sheet as a moment is added to the paper sheet fed second. This paper sheet separating mechanism is provided with a stage composed to be capable of reciprocating, on which paper sheets are loaded, and picker rollers disposed on both sides of a center line along the paper sheet feeding direction to feed the paper sheets. It is provided with a pushing means to push the paper sheets loaded on the stage in the feeding upstream side more than the picker roller.

Owner:OKI ELECTRIC IND CO LTD

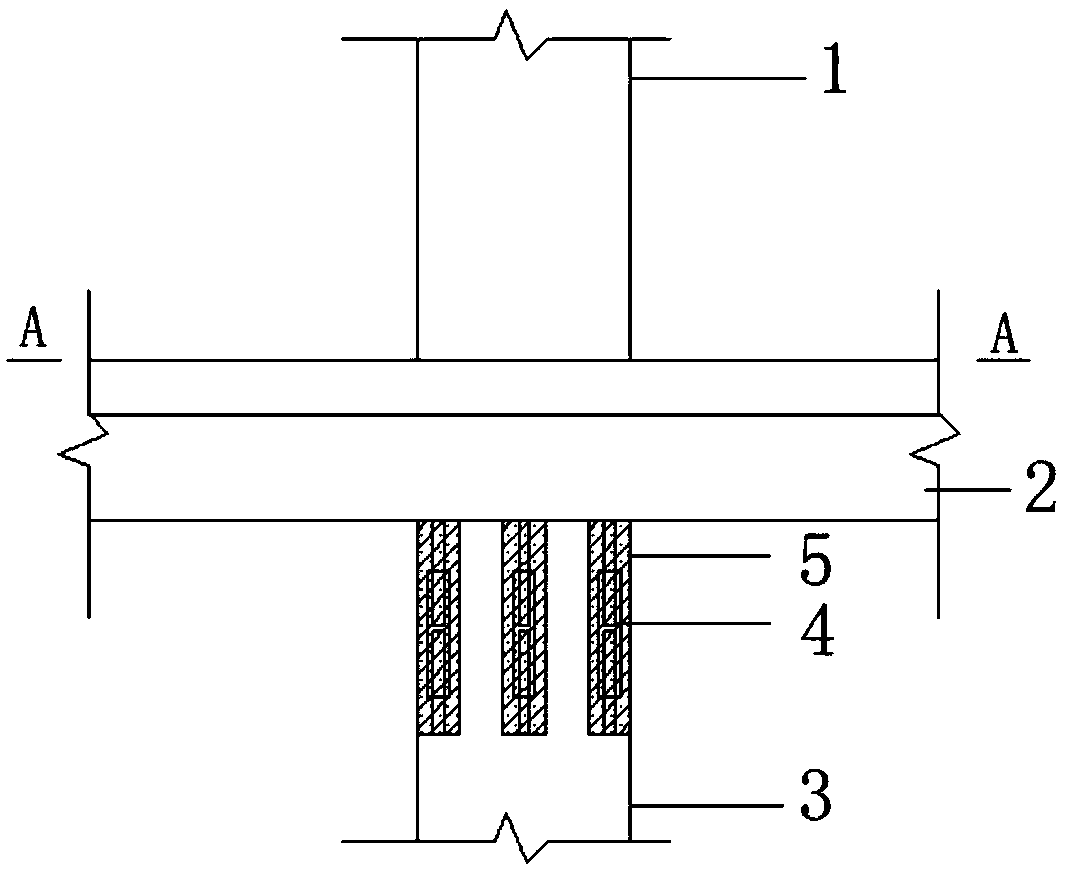

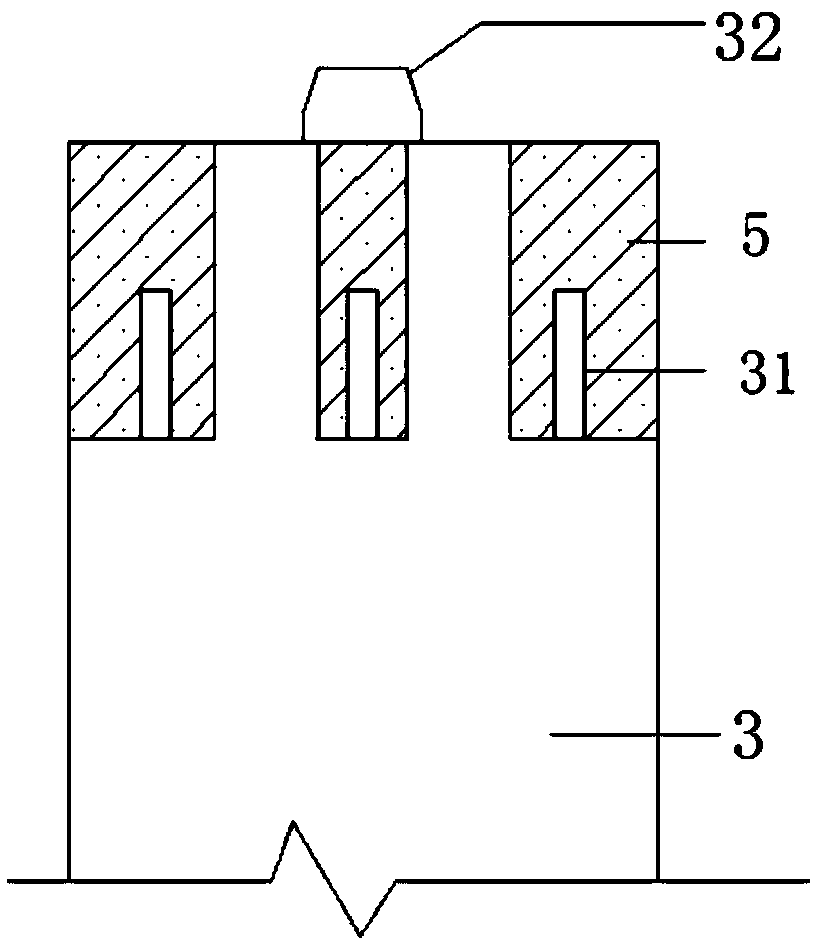

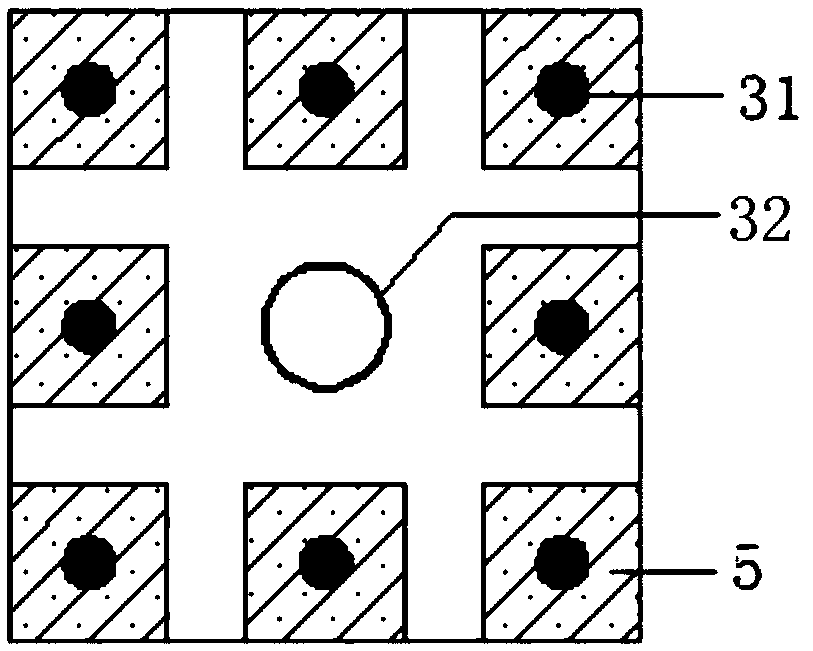

Assembly joint of prefabricated column and integrated prefabricated beam plate and construction method of assembly joint

The invention discloses an assembly joint of a prefabricated column and an integrated prefabricated beam plate and a construction method of the assembly joint. The assembly joint comprises the horizontal integrated prefabricated beam plate and the vertical prefabricated column; the prefabricated column includes a lower prefabricated column body and an upper prefabricated column body; concave post-cast connection areas are formed in the upper surface of the lower prefabricated column body, multiple upper reserved longitudinal bars are reserved on the upper surface of the lower prefabricated column body and extend from the bottoms of the post-cast connection areas, the extension length is smaller than the depth of the post-cast connection areas, and a vertical upper steel pipe is embedded inthe upper surface of the lower prefabricated column body in advance; the integrated prefabricated beam plate is arranged on the lower precast column body, and a steel pipe connection hole and multiple rib penetrating holes vertically run through the integrated prefabricated beam plate. The upper prefabricated column body is placed on the integrated prefabricated beam plate, a vertical lower steelpipe is embedded in the lower surface of the upper prefabricated column body, and multiple lower reserved longitudinal bars are reserved on the lower surface of the upper prefabricated column body, are coaxial with the rib penetrating holes and the upper reserved longitudinal bars one to one and penetrate through the rib penetrating holes to extend to the post-cast connection areas; the upper steel pipe and the lower steel pipe both extend into the steel pipe connection hole and are internally provided with connection steel bars.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Errhysis-preventing hemodialysis device

InactiveCN108721721APrevent sideways movementAvoid loose situationsRestraining devicesDialysis systemsHemodialysisHaemodialysis machine

The invention belongs to the field of medical instruments and particularly provides an errhysis-preventing hemodialysis device. For solving the problem that existing errhysis-preventing viscose clothinfirmly fixes a blood inlet tube and a blood outlet tube, accidental loosening likely causes offset and accordingly errhysis is caused to harm the life of a patient, the following solution is proposed at present: the errhysis-preventing hemodialysis device comprises a placement plate, wherein a U-shaped fixed plate is integrally arranged at the top of the placement plate, and a U-shaped movable plate located above the top of the placement plate is arranged on one side of the U-shaped fixed plate. By arranging the U-shaped movable plate, the U-shaped fixed plate, a second connecting block, a threaded column, a first connecting block, a rectangular column, an arc-shaped compression strip, an arc-shaped clamping groove, a second connecting block, a plug pin, a color sensor, a controller anda voice alarm, a blood transfusion tube and the arm of the patient can be limited, thus prevention can be achieved before errhysis, meanwhile timely reminding can be also given after errhysis, and accordingly a very good errhysis preventing effect is achieved.

Owner:夏金雪

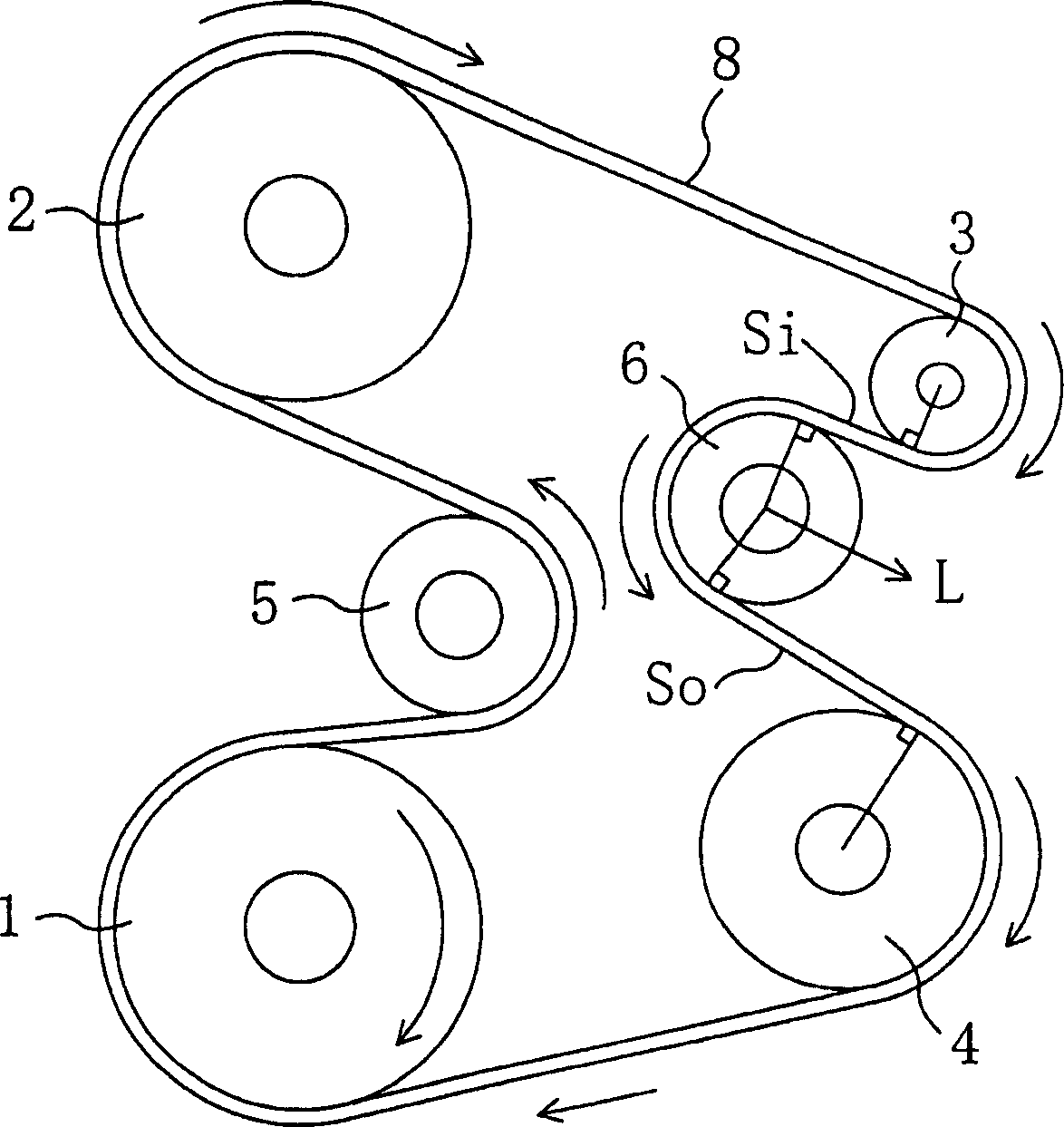

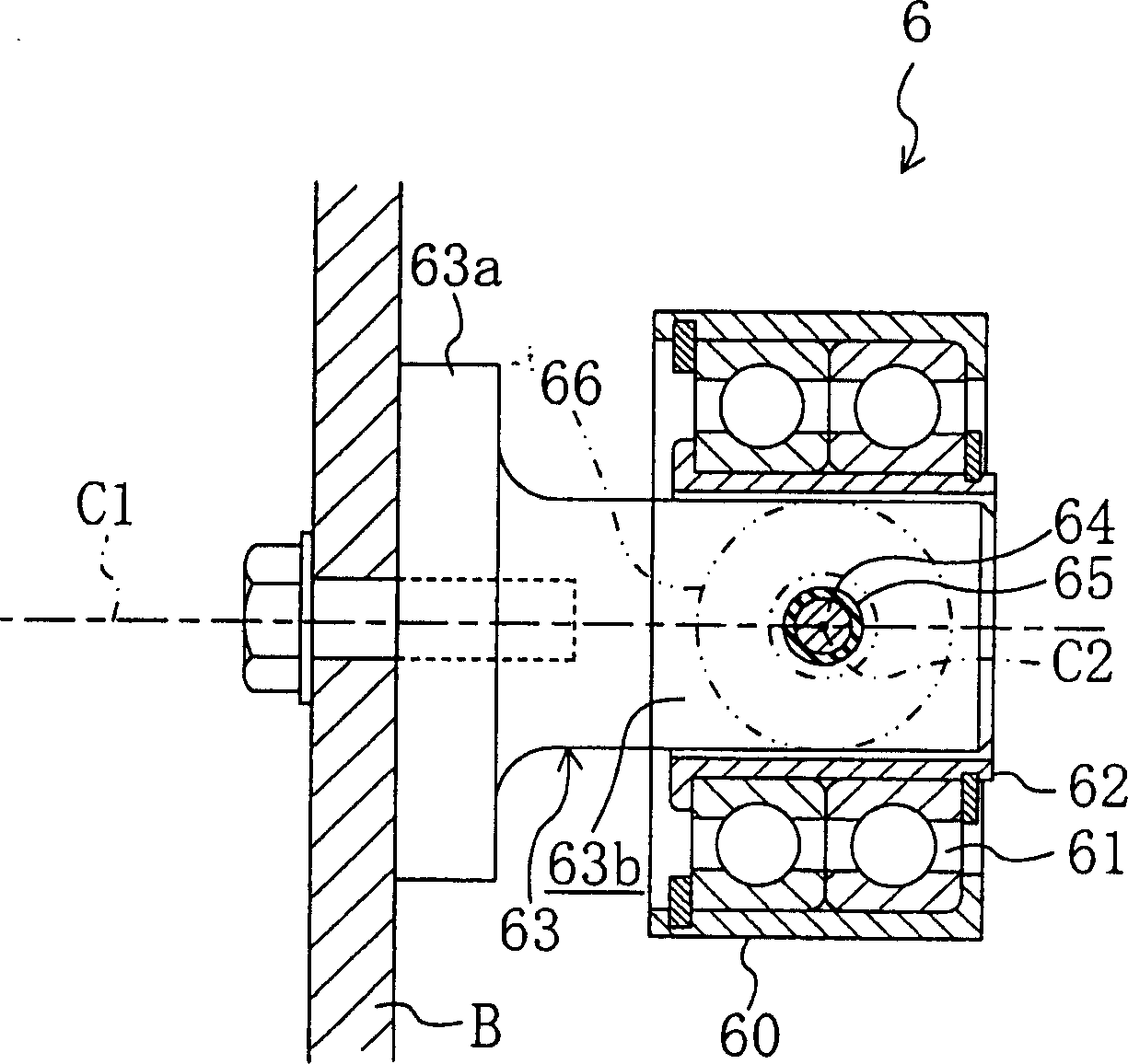

Belt drive system

Owner:BANDO CHEM IND LTD

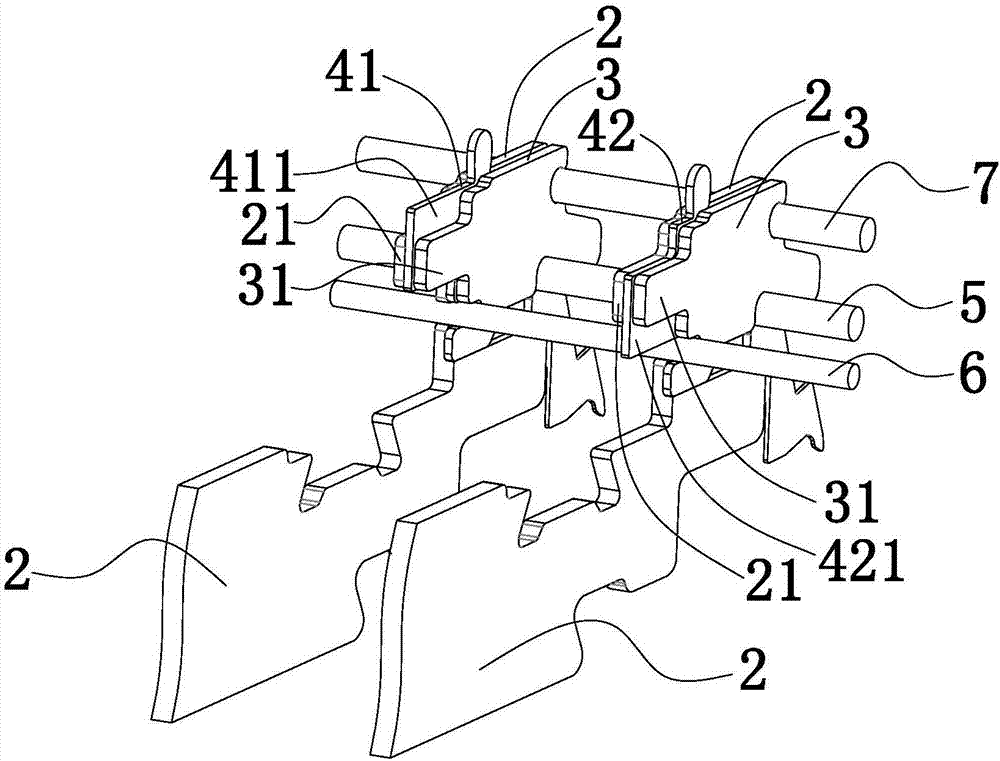

Flat knitting machine

ActiveCN107385659APlay a protective effectWork smoothly and smoothlyWeft knittingEngineeringStructural engineering

The invention discloses a flat knitting machine. The flat knitting machine comprises a traction mechanism and a needle bed, wherein a plurality of inserting plates, spacer plates and sinkers are arranged on the needle bed; each sinker is arranged between the corresponding inserting plate and the corresponding spacer plate; butts are arranged at the rear ends of the sinkers; the traction mechanism drives the butts; each inserting plate is provided with an inserting plate protecting plate; each spacer plate is provided with a spacer plate protecting plate; and each inserting plate protecting plate and the corresponding spacer plate protecting plate are positioned on two sides of the corresponding butt to limit the corresponding butt from laterally moving and deviating from a movement plane of the butt. Deformation or damage of the butts due to pushing, traction and the like can be avoided.

Owner:ZHEJIANG FENGFAN NC MACHINERY

Acoustic-optic coupling fiber-optic liquid-level sensor system

ActiveCN107167217AOvercome the shortcoming that the measurement range is too small and limited to the length of the fiber gratingAvoiding the Drawbacks of Continuously Writing GratingsMachines/enginesLevel indicatorsFiberContinuous measurement

The invention discloses a fiber-optic liquid-level sensor. The sensor is characterized in that an optical fiber stretching into the interior of a to-be-tested liquid is used as a measurement body; a structure used for simultaneously coupling light waves and sound waves into optical fiber is designed at one end of the optical fiber; the other end of the optical fiber is a free end and suspended in the to-be-tested liquid; and the surface of the optical fiber is covered with a coating layer which is not attached to the to-be-tested liquid. The acoustic-optic coupling fiber-optic liquid-level sensor has the following beneficial effects: the sensor is ultra-small in size; continuous measurement in a wide range is achieved; the sensor is non-metal and does not have conduction characteristics; the sensor is resistant to corrosion resistance and high and low temperature and is low in cost; and compared with a conventional liquid level sensor, the sensor has strong advantages in detection of liquid level under the extreme environment such as liquid hydrogen, liquid oxygen, liquid helium, water level in a nuclear reactor and conductive liquid.

Owner:田志鹏

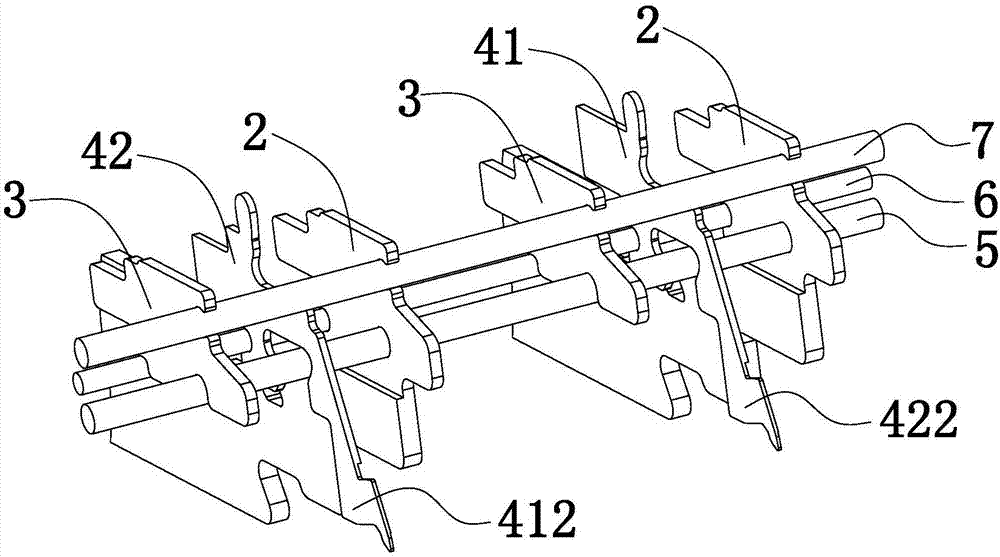

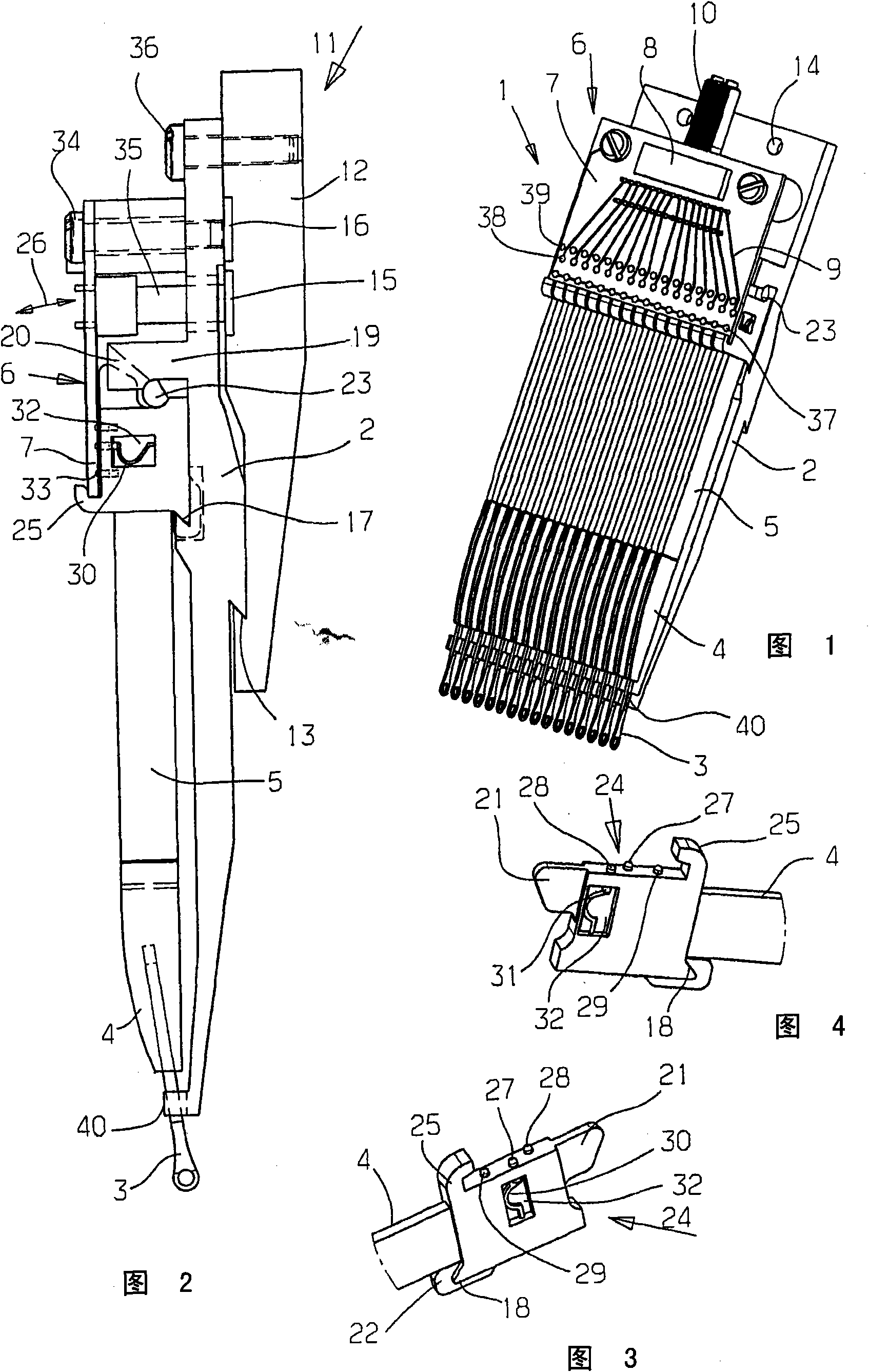

Guide Needle Assembly For A Jacquard Guide Bar And Jacquard Guide Bar

ActiveCN102400281AFree touchReliable electrical connectionWarp knittingBiomedical engineeringStructural engineering

The insert needle assembly includes a support (2), and several guide needles (3) arranged on the support. Each needle is provided with an offset drive (5), and a drive unit (6) is electrically connected with the offset drive. The drive unit is detachably connected to the support and to the offset drive by the spring contacts including a contact surface (33) on which the drive unit is formed. The guide needle is pivotably connected to the drive unit by the mechanical abutment (25). An independent claim is included for jacquard guide bar.

Owner:KARL MAYER TEXTILMASCHFAB GMBH +1

Projector bracket for handling official business

InactiveCN108506695APrevent sideways movementPlay a protective effectProjectorsStands/trestlesEngineeringBevel gear

The invention discloses a projector bracket for handling official business. A frame plate and a base are included; a hollow-out plate is arranged on the inner side of the frame plate, and is providedwith a slide groove; two sliding pieces are connected in the slide groove in a sliding manner; a limiting block is welded to one side of the top of each of the two sliding pieces; and one side of eachlimiting block is located on the corresponding sliding piece and is in threaded connection with a screw. In the projector bracket for handling the official business, firstly, the limiting blocks aremoved and made to be attached to the side edges of a projector; then by twisting a rotary knob, a gasket is made to be closely fixed to the upper surface of the hollow-out plate, at the moment, the positions of the limiting blocks are limited, the structure is simple, lateral migration of the projector can be avoided, and therefore a certain protective effect is achieved for the projector; secondly, by rotating a rotating disk, a second bevel gear drives a first bevel gear to rotate, and therefore a lead screw is made to rotate, due to the rotating effect of the lead screw, a spiral sleeve slowly moves upwards, and therefore the purpose of adjusting the height of the projector bracket is achieved; and the structure is simple, operation saves labor and is convenient, and the lifting processis stable and reliable.

Owner:郑州匹客科技有限公司

Anti-shock supporting and hanging frame used for installing pipeline

InactiveCN108167537APrevent sideways movementGuaranteed locking forcePipe supportsPipe elementsEngineeringMechanical engineering

The invention discloses an anti-shock supporting and hanging frame used for installing a pipeline. The anti-shock supporting and hanging frame comprises a first channel steel base, a hinge, a first screw, a channel steel connecting rod, a second channel steel base, a bolt, single-face channel steel, a first rack, a second rack, a U-shaped fixing part, the pipeline, a bottom plate, double-splicingchannel steel, a nut, a second screw and a fixing connecting part. The anti-shock supporting and hanging frame is simple in structure, by arranging the first rack and the second rack, after the fixingconnecting part is installed on the single-face channel steel, the locking force degree between the single-face channel steel and the fixing connecting part can be effectively ensured, the fixing connecting part is prevented from moving laterally when stressed, and the anti-shock performance of anti-shock supports is effectively improved. The first rack is arranged on the side face of the single-face channel steel, the mutual position between the single-face channel steel and the fixing connecting part can be adjusted continuously, in the installing process, the double-splicing channel steelon the adjacent anti-shock support can be adjusted to the same horizontal height beneficially, bending stress is prevented from being generated when the pipeline is fixed, and supporting stability ofthe anti-shock supporting and hanging frame is benefitted.

Owner:JIANGSU YIDINGGU ELECTROMECHANICAL TECH CO LTD

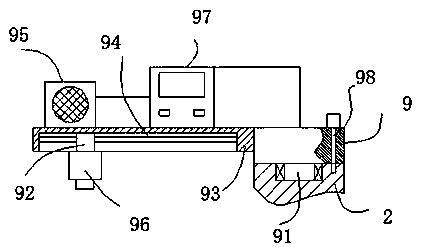

PCCP pipe diameter measuring device

InactiveCN104677241APrevent sideways movementImprove viewing angleMechanical diameter measurementsEngineeringSteel ball

The invention discloses a PCCP pipe diameter measuring device. The PCCP pipe diameter measuring device comprises a fixed cylinder, a limiting cylinder which is mounted in the fixed cylinder, a truncated cone-shaped moving block and a fixed seat; a steel ball is rotatably arranged at the bottom of the limiting cylinder; the steel ball is partially protruded from the bottom end of the fixed cylinder; a spring is mounted in the fixed cylinder; the moving block is connected with the free end of the spring and is connected with the fixed seat through a graduated scale; a plurality of bulges are formed on the outer wall of the moving block; a plurality of grooves which are matched with the bulges are formed in the inner wall of the fixed cylinder; a rolling ball is rotatably arranged on the upper surface of the fixed seat. When the axis of the fixed cylinder is overlapped with the straight line in which the diameter of a pipeline is positioned, the data on the graduated scale is read, and is the displacement generated by the linear movement of the moving block; the inside diameter of the pipeline can be obtained by calculating, namely subtracting the linear displacement of the moving block from the linear distance between the bottom end of the steel ball and the top end of the rolling ball.

Owner:重庆巨龙管业有限公司

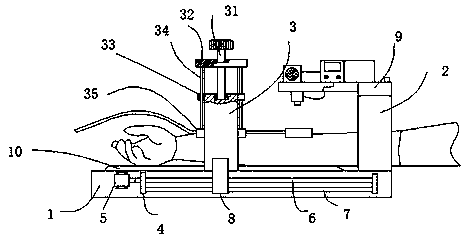

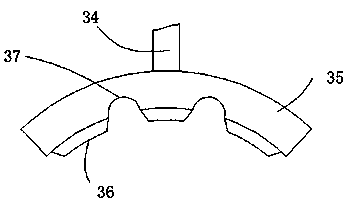

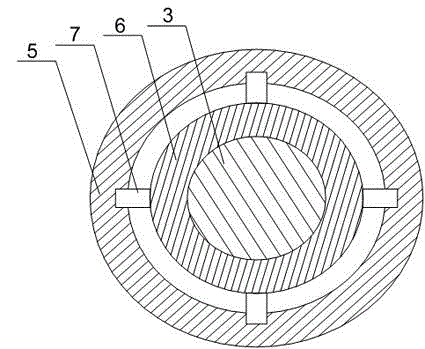

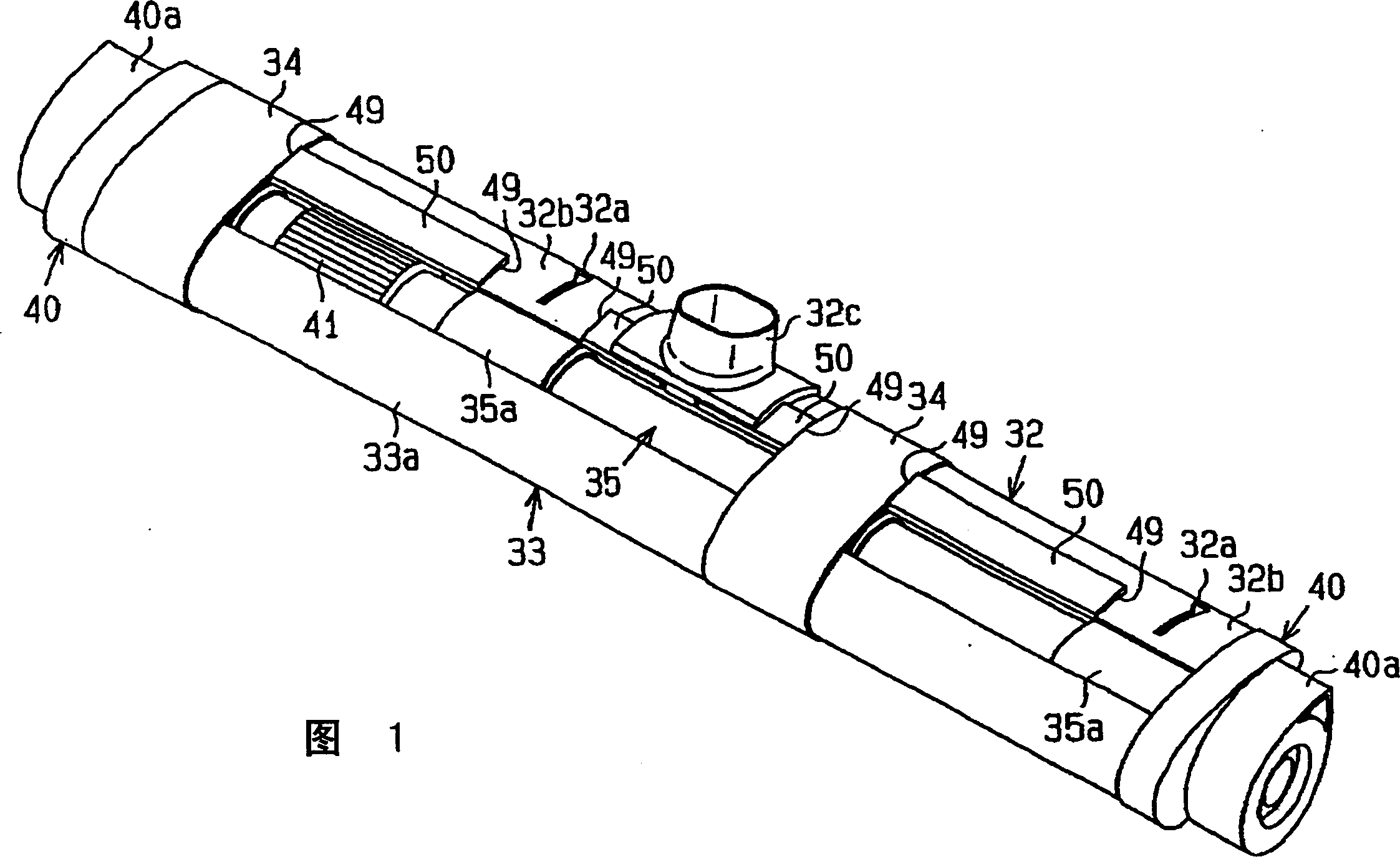

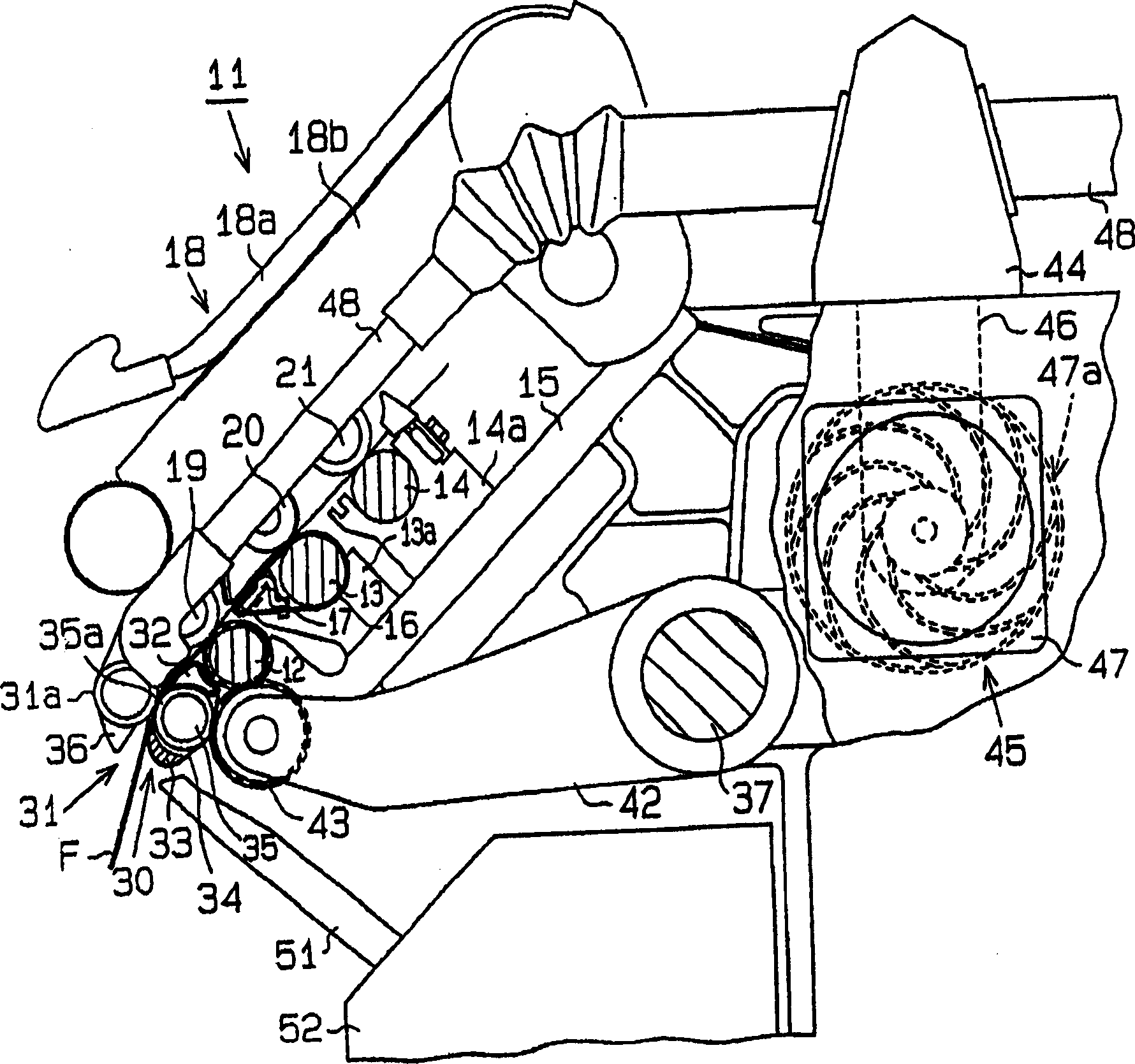

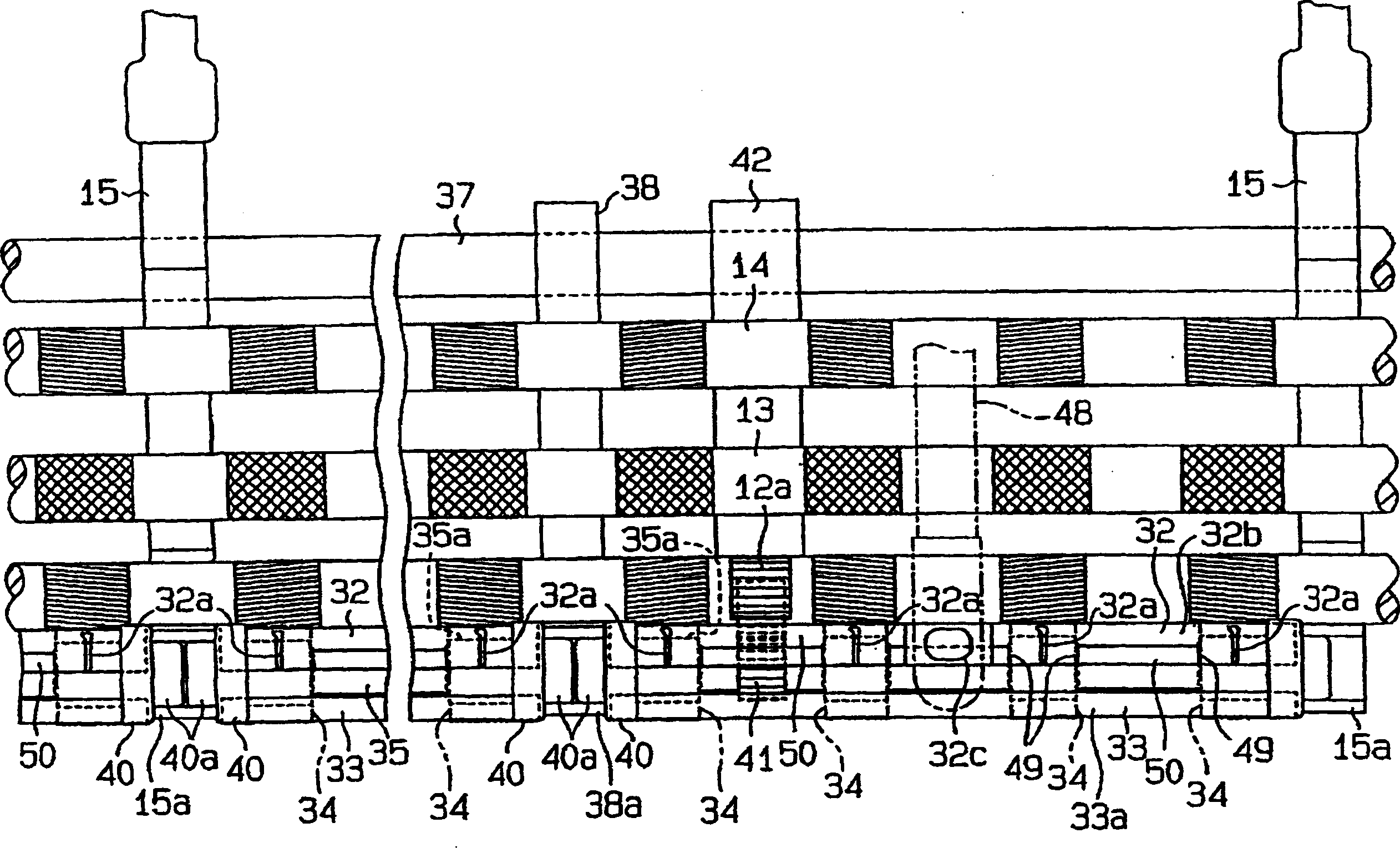

Fibre bundle buncher for spinning machine

InactiveCN1495303AImprove the limit effectPrevent sideways movementDrafting machinesContinuous wound-up machinesFiber bundleEngineering

A fiber bundle collecting device is provided on the downstream side of a final delivery roller pair of a drafting device and includes a delivery portion and a suction pipe 32 having a sliding surface 32b that is equipped with a suction hole 32a provided on the upstream side of the nip point of the delivery portion with respect to a direction in which a fiber bundle moves. A wrapping member 33 is provided on the side opposite to the suction pipe 32 across a bottom nip roller 35a constituting the delivery portion. An air-permeable apron 34 is wrapped around the suction pipe 32, the wrapping member 33, and the bottom nip roller 35a. A regulating guide 49 for preventing lateral displacement of the air-permeable apron 34 is formed integrally with the suction pipe 32. The regulating guide 49 is formed by removing a part of an elevated step portion 50 in conformity with the width of the air-permeable apron 34, the step portion 50 being formed on the front side of the top surface of the suction pipe 32 so as to extend in a longitudinal direction.

Owner:TOYOTA IND CORP

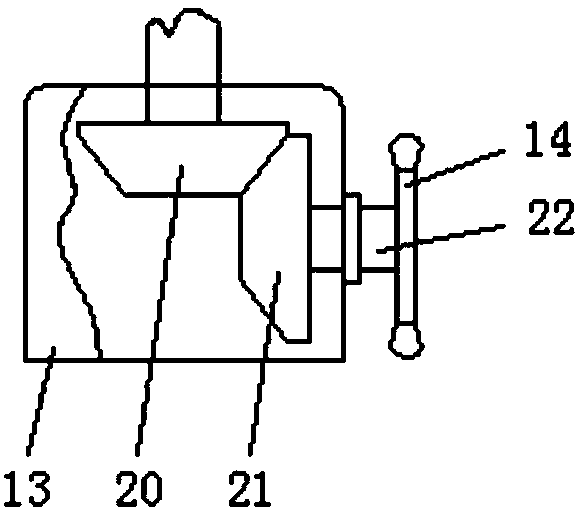

Cutting tool with a supporting body

InactiveCN101687337ANeat cuttingReduce tool costsRotary cutting toolsShaping cuttersEngineeringMechanical engineering

The invention relates to a cutting tool with a supporting body and at least one receptacle (2), which is arranged in the supporting body (1), is openly formed to allow a cutting edge (3) of a cuttingelement (4) to pass through and in which the cutting element (4) is clamped in its seat by means of at least one clamping jaw (5). The object of the invention is to improve the cutting tool with respect to the cutting behaviour and cost-effectiveness. This object is achieved by the cutting jaw (5) being formed resiliently in the direction of the cutting element (4).

Owner:LEITZ GMBH & CO KG

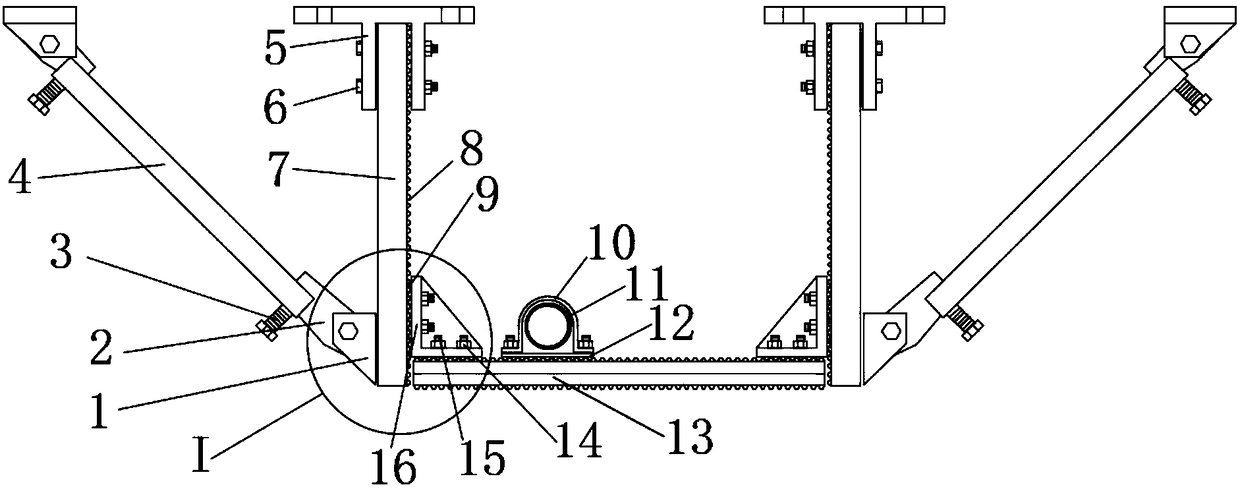

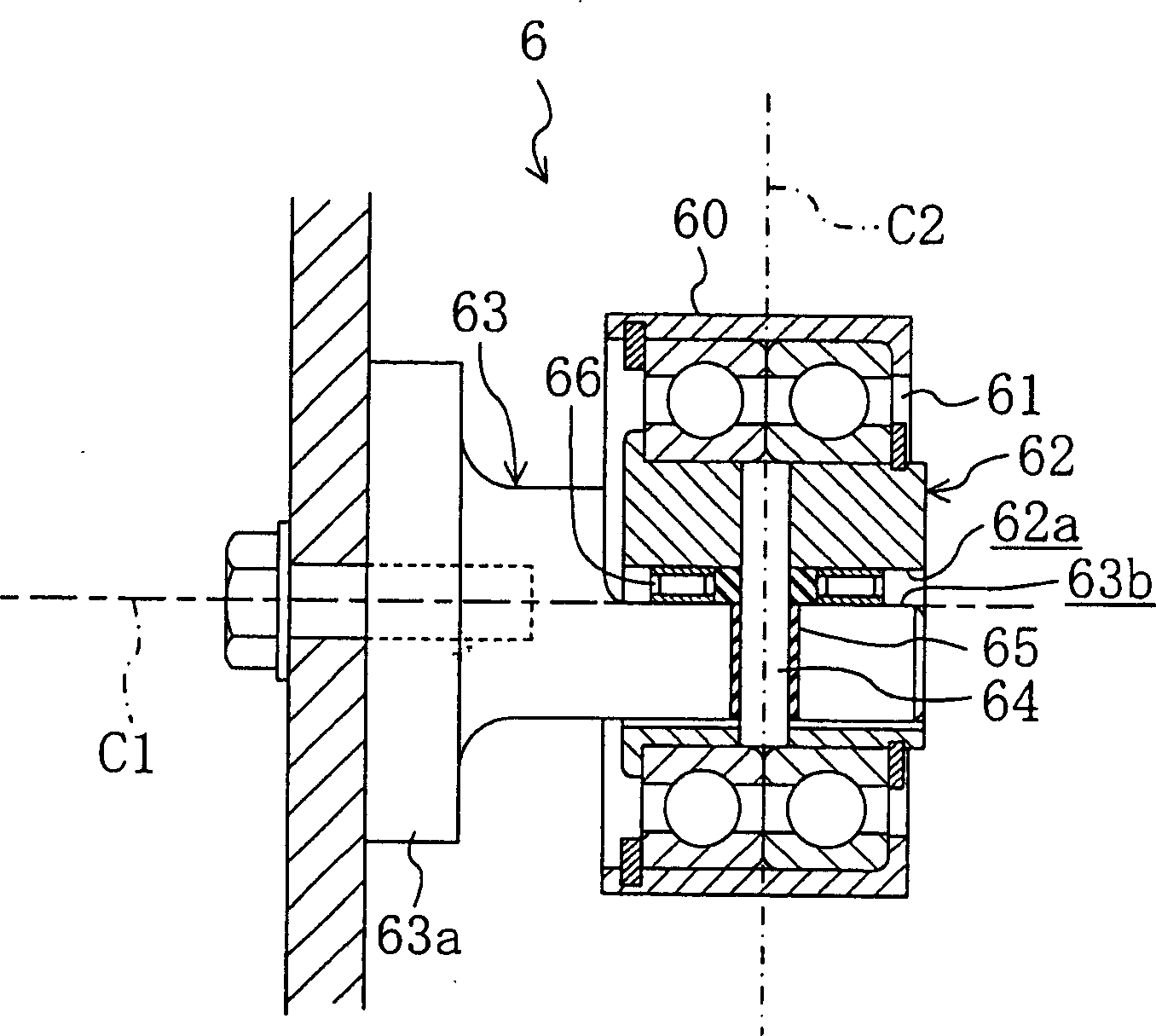

Roller position adjusting device

InactiveCN105173846APrevent rollers from moving sidewaysIncrease contact areaWebs handlingPulp and paper industry

The invention discloses a roller position adjusting device. The roller position adjusting device comprises a roller rack, a roller and a clamping assembly, wherein the roller comprises a roller body, a left roller shaft and a right roller shaft; the left end and the right end of the roller body are respectively rotationally connected with mounting ends of the left roller shaft and the right roller shaft through bearings; connection ends of the left roller shaft and the right roller shaft are respectively connected with the left end and the right end of the roller rack in a sliding manner; the clamping component is used for limiting the positions of the left roller shaft and the right roller shaft on the roller rack. The roller position adjusting device is capable of effectively preventing the roller from moving laterally and adjusting the tension by regulating the front position and the rear position.

Owner:ANQING XINGFENG IND & TRADE

Module type soil pressure applying and forming device and processing method of soft soil foundation

InactiveCN108677911APlay a blocking rolePrevent sideways movementSoil preservationEngineeringUnit structure

The invention discloses a module type soil pressure applying and forming device. The module type soil pressure applying and forming device comprises a top frame, a pressure applying forming module anda soil body strength detecting device, wherein the pressure applying forming module comprises a plurality of convex bodies, and the top of the pressure applying forming module is connected with the top frame. The invention further discloses a processing method of a soft soil foundation, and is used for extruding, draining and forming a soil body by adopting the module type soil pressure applyingand forming device. The device can be integrally manufactured and can also be manufactured in a unit splicing mode. Different functional components can be added on each unit according to needs. The manufacturing mode of unit splicing is adopted, and the size of each unit is small, so that the manufacturing is simpler, and the manufacturing difficulty and the manufacturing cost can be reduced. Moreover, the units can be used as standard sizes or as a series of products, and each series of unit structures are the same in size, so that splicing is carried out according to design or construction requirements, and the design and the use are more flexible.

Owner:HANGZHOU YONGCHUANG INFRASTRUCTURAL ENG SCI & TECHCAL CO LTD

Energy-dissipating damping device suitable for mortise-tenon joints of timber structures of ancient buildings

PendingCN110173129APrevent sideways movementRealize mixed energy consumptionBuilding repairsProtective buildings/sheltersMortise and tenonViscous friction

An energy-dissipating damping device suitable for the mortise-tenon joints of the timber structures of ancient buildings comprises connecting parts II and a connecting part III, wherein the upper endsof the connecting parts II are connected with connecting parts I through bolts I to form closed structures fixed around a wooden beam; two ends of the connecting part III are connected through a boltII to form a closed structure fixed around a wooden pillar; the connecting part III is mounted on a steel support frame with a horizontal steel plate; the lower ends of the connecting parts II are connected to the upper surface of a rectangular steel tube; a viscous friction damper is arranged between the upper surface of the steel support frame and the lower surface of the rectangular steel tube; and metal energy-dissipating rods run from the lower surface of the rectangular steel tube to the horizontal steel plate of the steel support frame through the viscous friction damper. Under the action of earthquake, relative sliding occurs between all layers of the viscous friction damper to drive the metal energy-dissipating rods to bend to dissipate energy together. The energy-dissipating damping device has the advantages of strong energy-dissipating capacity and resistant-lateral rigidity, simple structure, convenient mounting, easy replacement and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

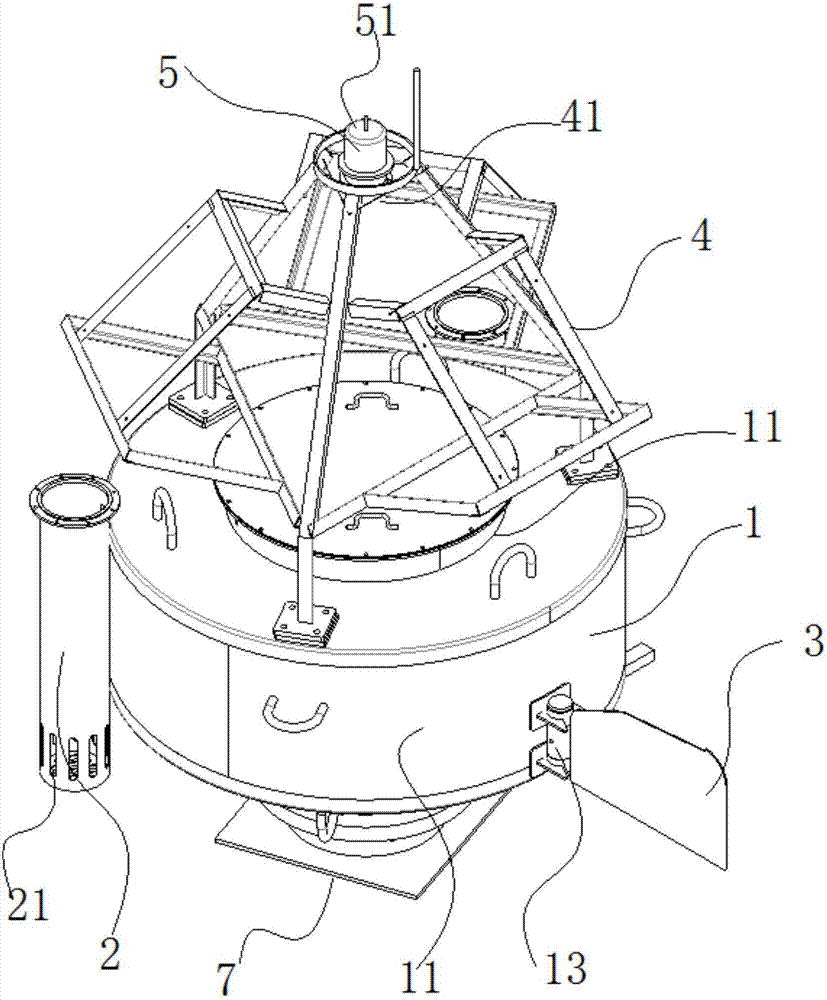

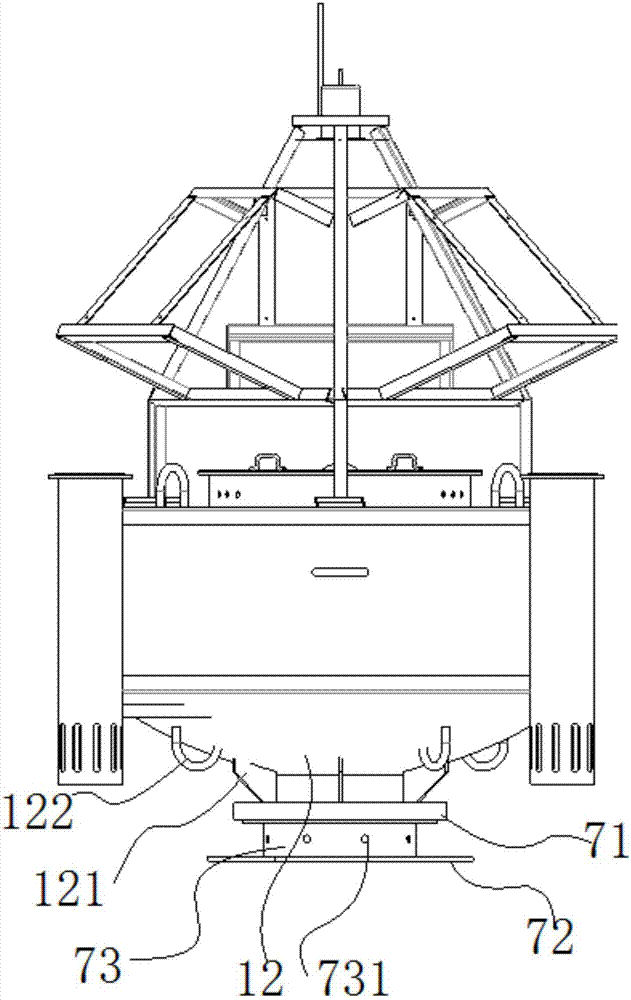

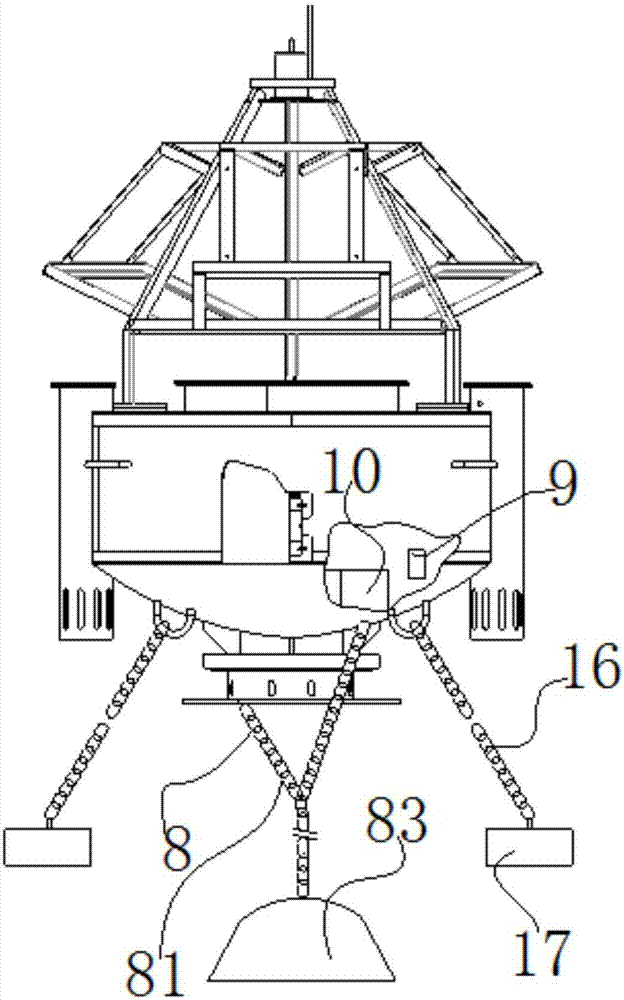

Water quality online detection buoy station of high-drop limit water level river

The invention discloses a water quality online detection buoy station of a high-drop limit water level river, which belongs to the technical field of water quality detection. The buoy station comprises a buoy body, a probe well and a wing pendulum, wherein the major structure of the buoy body is a fully sealed hollow cylinder body; a water quality detection probe is arranged in the probe well; the probe well and the wing pendulum are the same in weight and are detachably fixed on the outer side of the cylinder body uniformly and symmetrically. In the buoy station, the wing pendulum is mounted below a water line on the side surface of the buoy body and is matched with the probe with the same weight, so that the buoy is kept to be balanced; by setting the amplitude of swing of the wing pendulum, the wing pendulum faces to the direction of water flow; when the wing pendulum is impacted by flood, the water flow and wind direction are dramatically changed, and the wing pendulum forms resistance under the influence of acting force and counter-acting force, so that the buoy body is prevented from being moved and rotated, therefore, the stability is enhanced, the balance and direction can be kept, and the problems that water quality detection equipment of a high-drop water body is high in technical requirements and is overturned easily in the prior art can be solved.

Owner:马鞍山市桓泰环保设备有限公司

Vascular anastomosis fixing support apparatus and operation method thereof

PendingCN109793580AAvoid liftingPrevent sideways movementInstruments for stereotaxic surgeryVascular anastomosisCerebrospinal fluid

The invention discloses a vascular anastomosis fixing support apparatus and an operation method thereof. The vascular anastomosis fixing support apparatus comprises a main support part and a bending part extending upwards along one end of the main support; the main support part includes an upper surface and a lower surface, the middle of the upper surface of the main support part extends upwards to form a raised support part, and the middle of the top face of the raised support part sinks inwards to form a support camber surface to fit the vessel; positioning strips used for positioning the vessels are respectively arranged on the upper surface of the main support part and two sides of the raised support part; a plurality of overflow holes are further formed in the main support part and isarranged in the manner of penetrating the upper surface and the lower surface of the main support part; the main support part uses bright colors such as green to distinguish easily, and horizontal and vertical scales are arranged on the upper surface of the main support part. By the arrangement, the anastomosed vessels can be placed smoothly without infiltrating in the nearby cerebrospinal fluidor blood and other fluids and can be completely exposed to the surgeon's line of sight, and convenience in operation is achieved.

Owner:SPARKLE MEDICAL EQUIP (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com