Fibre bundle buncher for spinning machine

A bundling device and a fiber bundle technology are applied in the field of fiber bundle bundling devices, which can solve the problems of increased cost, troublesome replacement of breathable aprons, and a large amount of time to replace, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

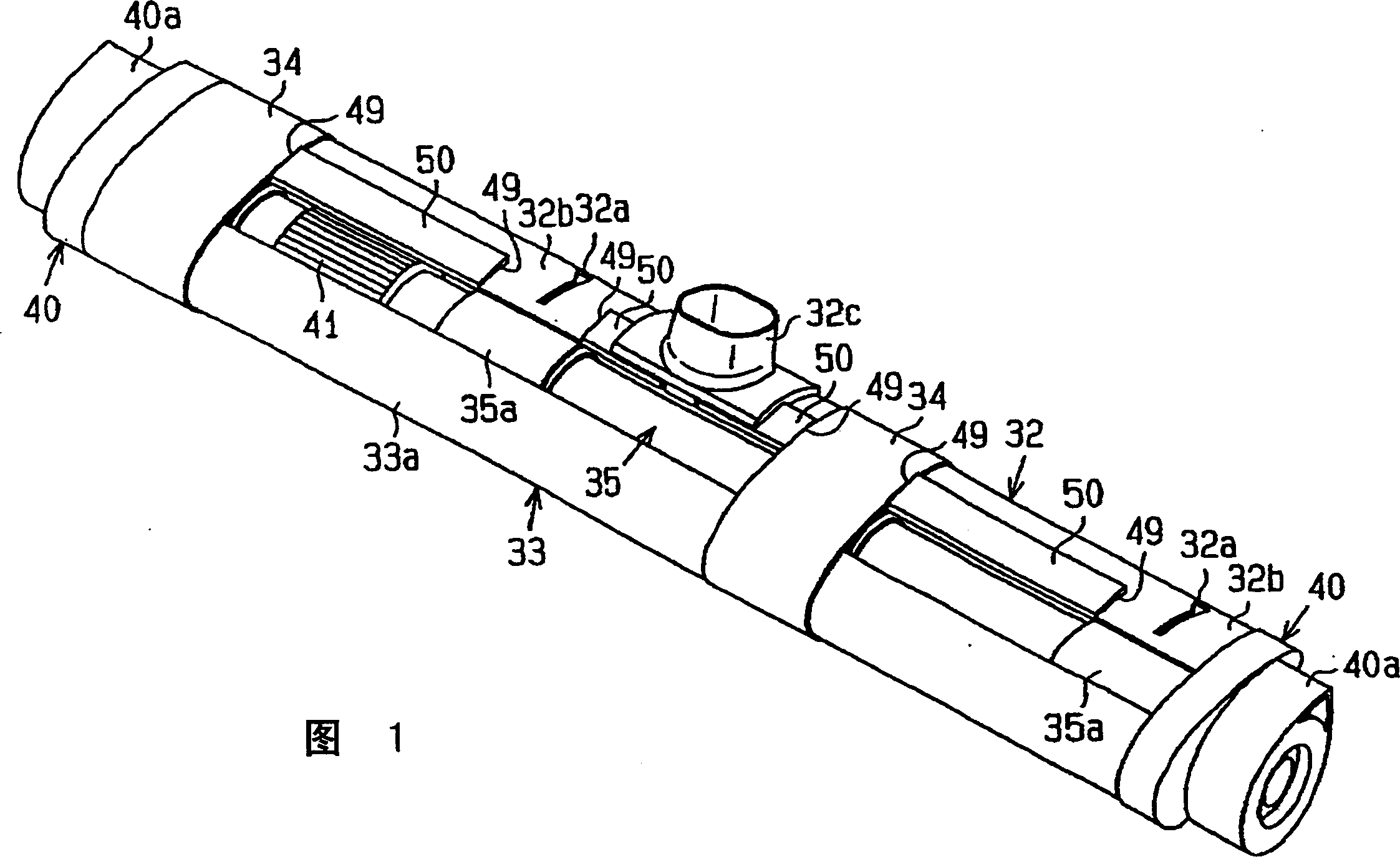

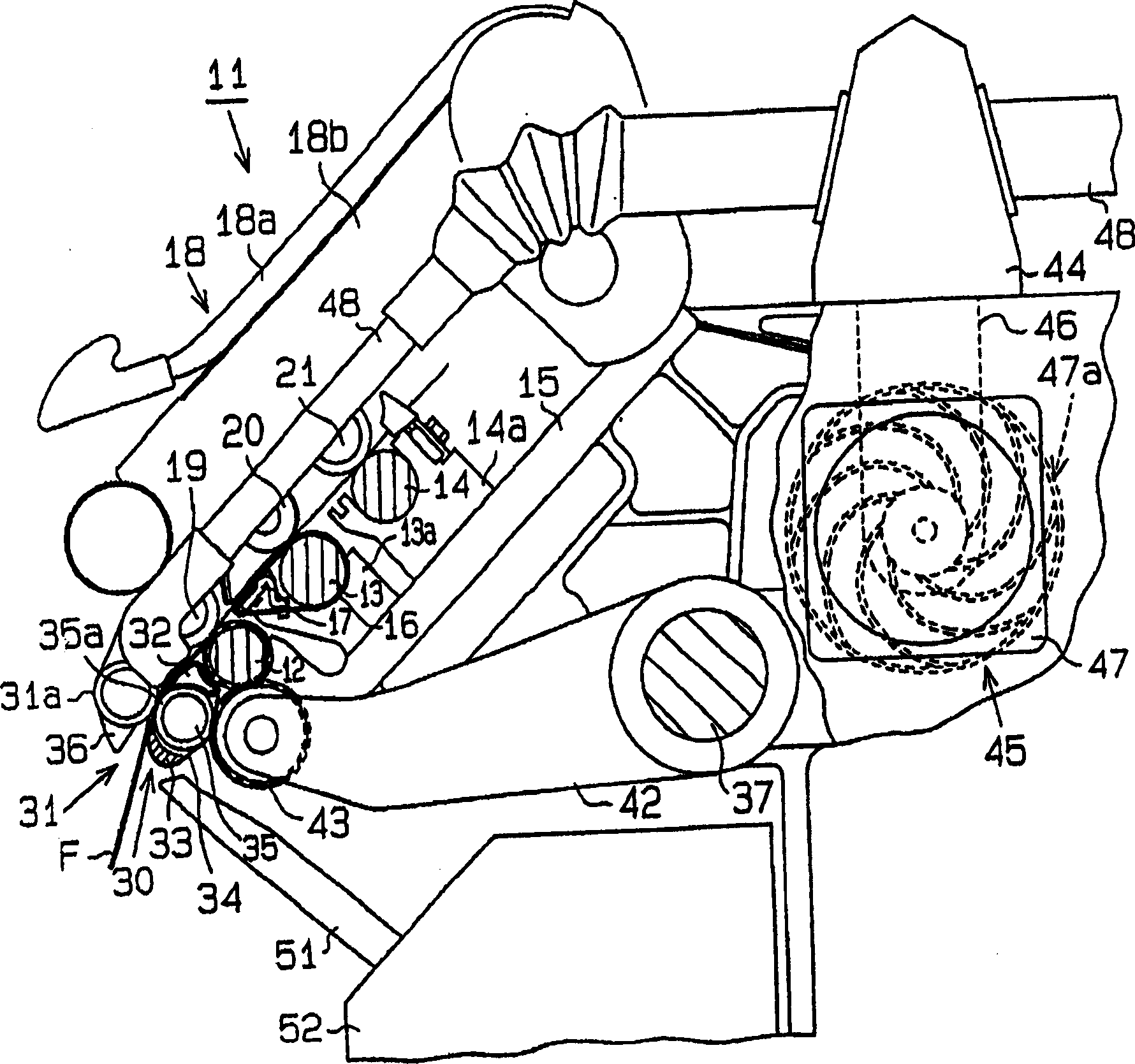

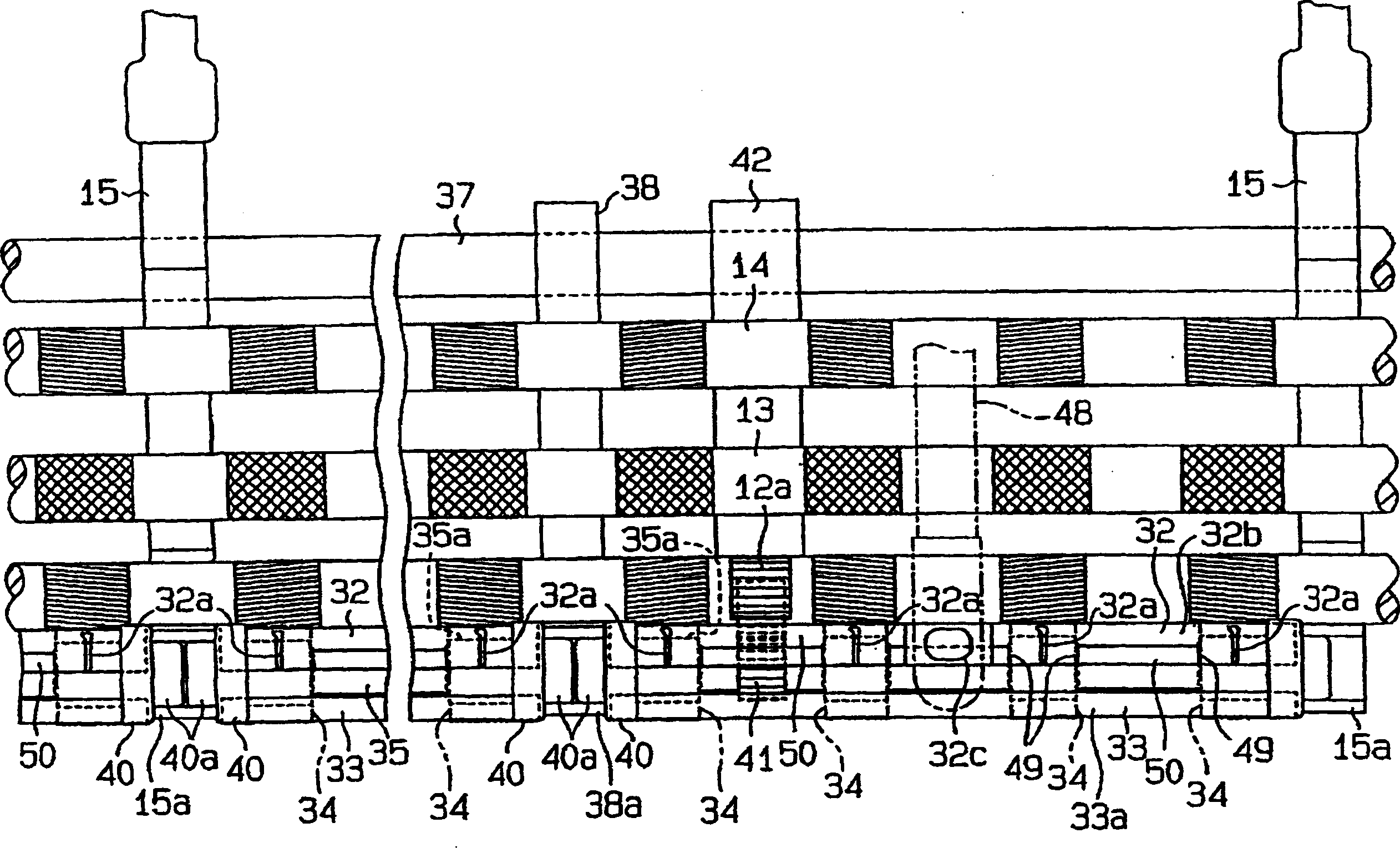

[0022] An embodiment of the present invention will now be described with reference to FIGS. 1-6. Fig. 1 is a schematic perspective view of a unit equipped with a suction tube, a winding element, breathable aprons and the like. figure 2 is a partial side view in section showing one side of a drafting unit and a fiber bundle bundling unit. image 3 It is a partial schematic view omitting the top roller side, showing the relationship between the bottom roller of the drafting device and the suction portion of the fiber bundle concentrating device, and the bottom nip roller. Figure 4A is a schematic view of the fiber bundle bundling device at a nip point as seen in the fiber bundle drawing direction (viewed from the front side with respect to the fiber bundle moving direction in the drafting device).

[0023] Such as figure 2 As shown, a drafting unit 11 as a drafting section is a 3-row structure equipped with front bottom rollers 12 , middle bottom rollers 13 and rear bottom ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com