Patents

Literature

937 results about "Stable fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

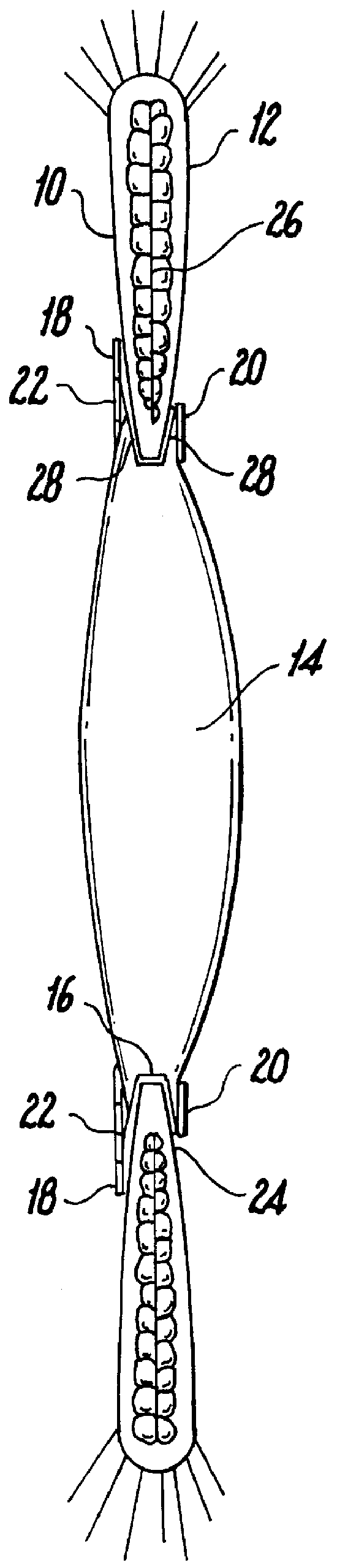

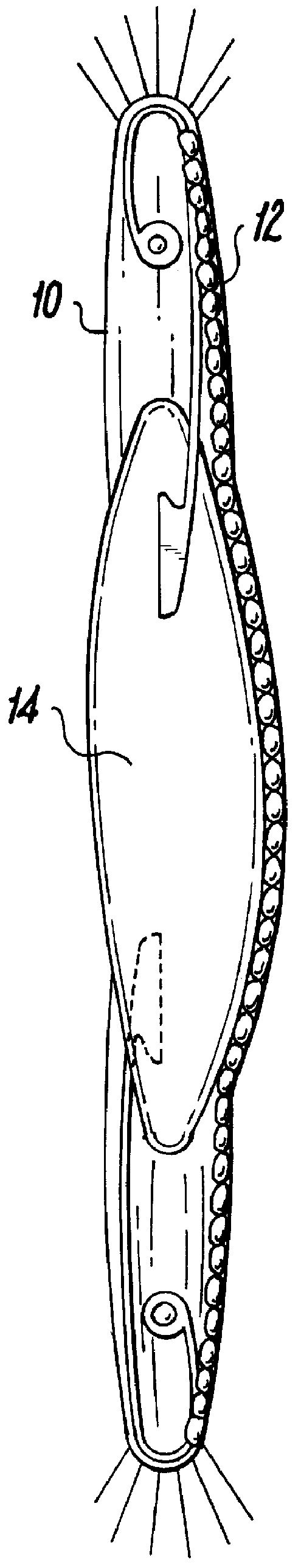

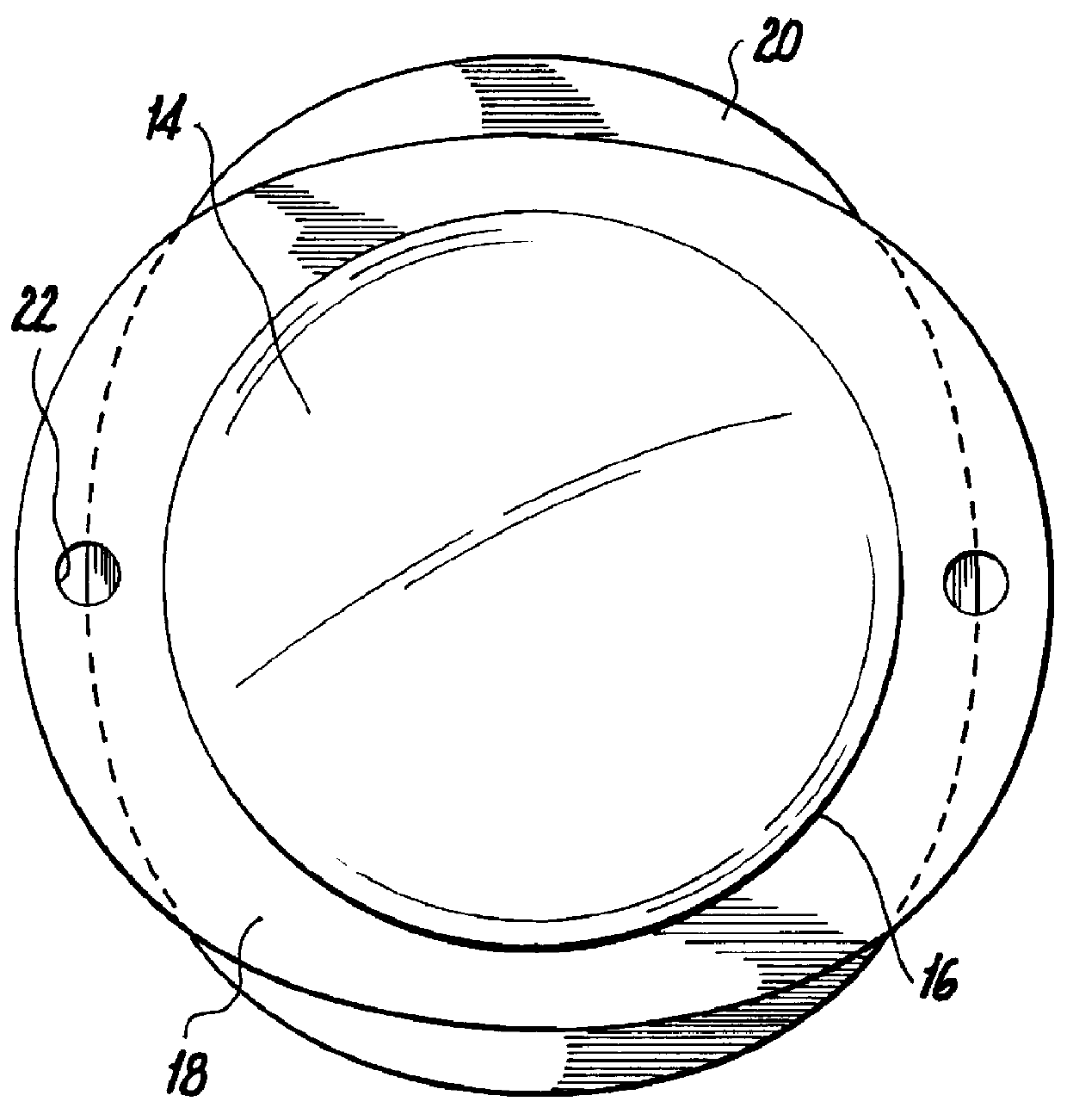

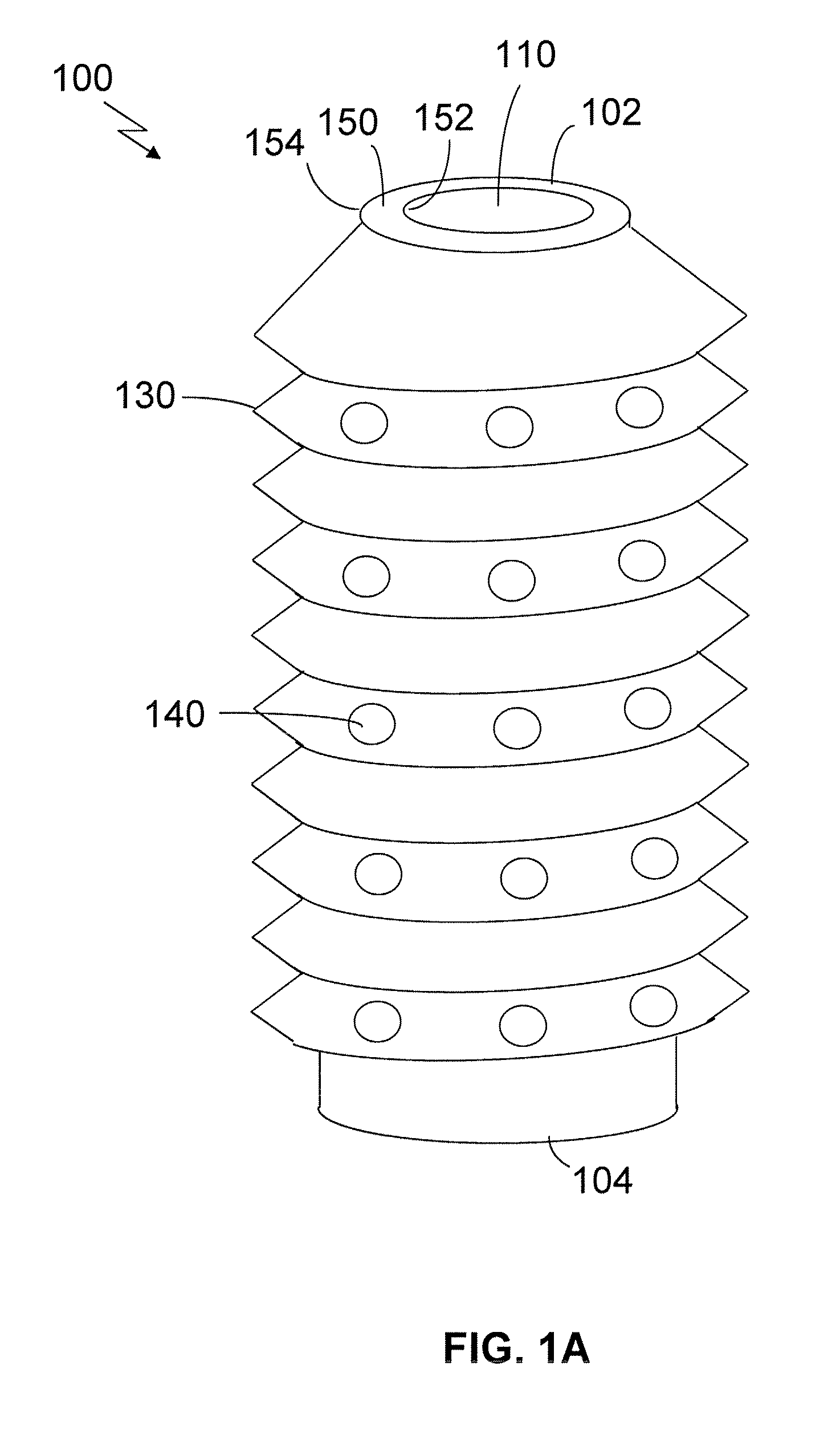

Intraocular lens and method for preventing secondary opacification

InactiveUS6027531APrevent proliferationImprove stabilityDiagnosticsSurgeryCataract extractionPosterior capsulorhexis

An intraocular lens for use in extracapsular cataract extraction has a haptic pat that surrounds the optical pat of the lens and further contains a groove of such shape to accommodate the anterior and posterior capsules of the lens bag after anterior capsulorhexis, extracapsular cataract extraction and posterior capsulorhexis. The lens is preferably inserted in a calibrated, circular and continuous combined anterior and posterior capsulorhexis, slightly smaller than the inner circumference of the groove as to induce a stretching of the rims of the capsular openings. This new approach is believed to prevent the appearance of secondary opacification of the capsules, allows a very stable fixation of the intraocular lens and ensures a tight separation between the anterior and posterior segment of the eye. This new principle of insertion is called the bag-in-the-lens technique, in contrast with the classical lens in-the-bag technique.

Owner:TASSIGNON MARIE JOSE B R

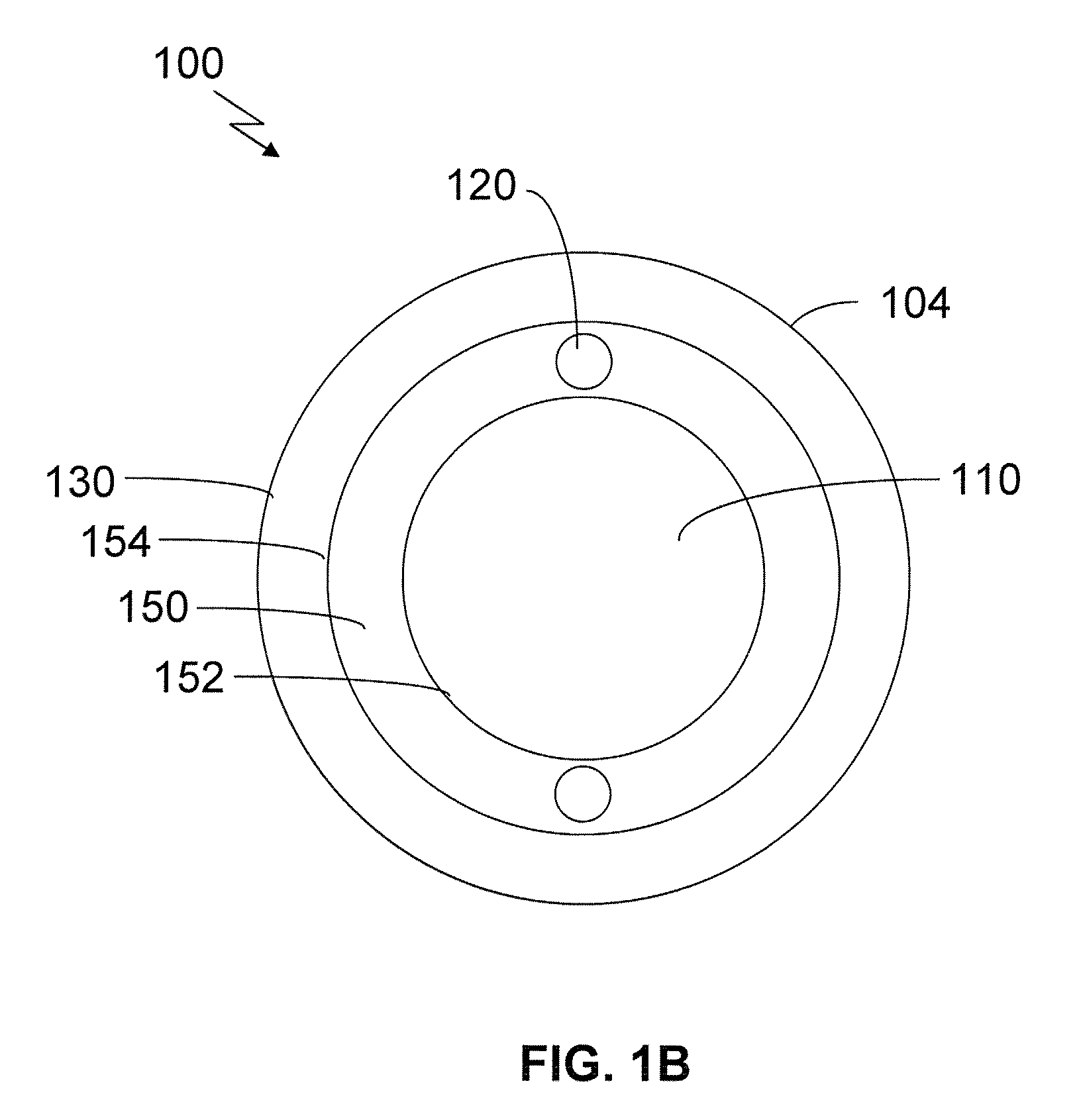

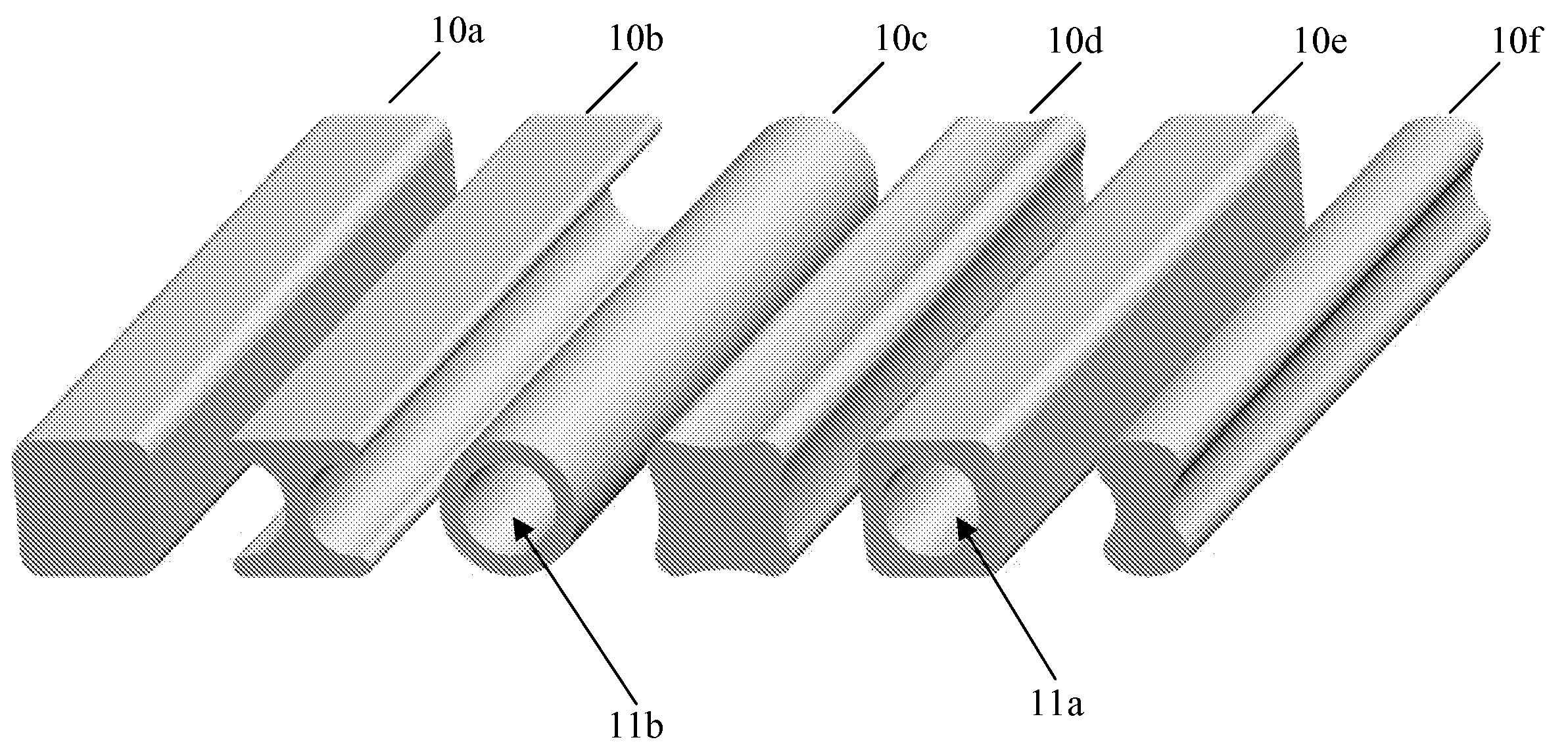

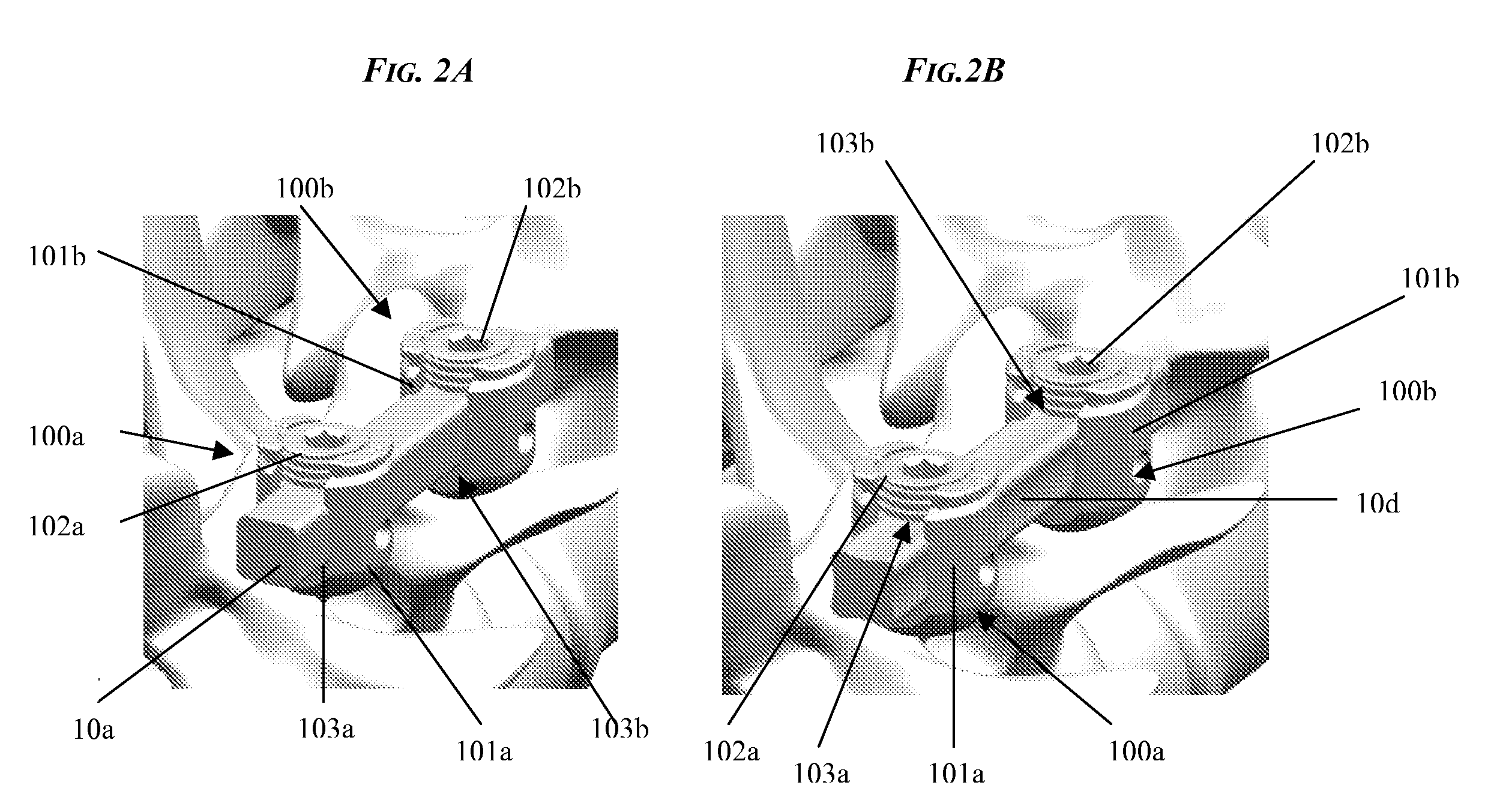

Method and system for graft ligament attachment

Various embodiments described herein provide methods and apparatus for achieving the secure and stable fixation of a graft ligament within a bone tunnel using a screw that includes a cylindrical wall having a leading end and a trailing end, threads arranged on an outside surface of the cylindrical wall, and a plurality of portals arranged in the cylindrical wall and adapted to receive a plurality of prongs of a screwdriver.

Owner:MANDERSON EASTON L

Torsionally stable fixation

InactiveUS20080086130A1Increased torsional stiffnessPrevent rotationInternal osteosythesisJoint implantsStable fixationBiomedical engineering

Methods and devices are provided for spinal fixation. In one exemplary embodiment, the methods and devices provide a spinal fixation system that can include a spinal connector which can be disposed within a recess in a head of a bone anchor. The spinal connector can have a variety of configurations. The methods and devices are particularly useful for unilateral fixation, in which one or more levels of the spine are stabilized along a single lateral side of the spine.

Owner:DEPUY SPINE INC (US)

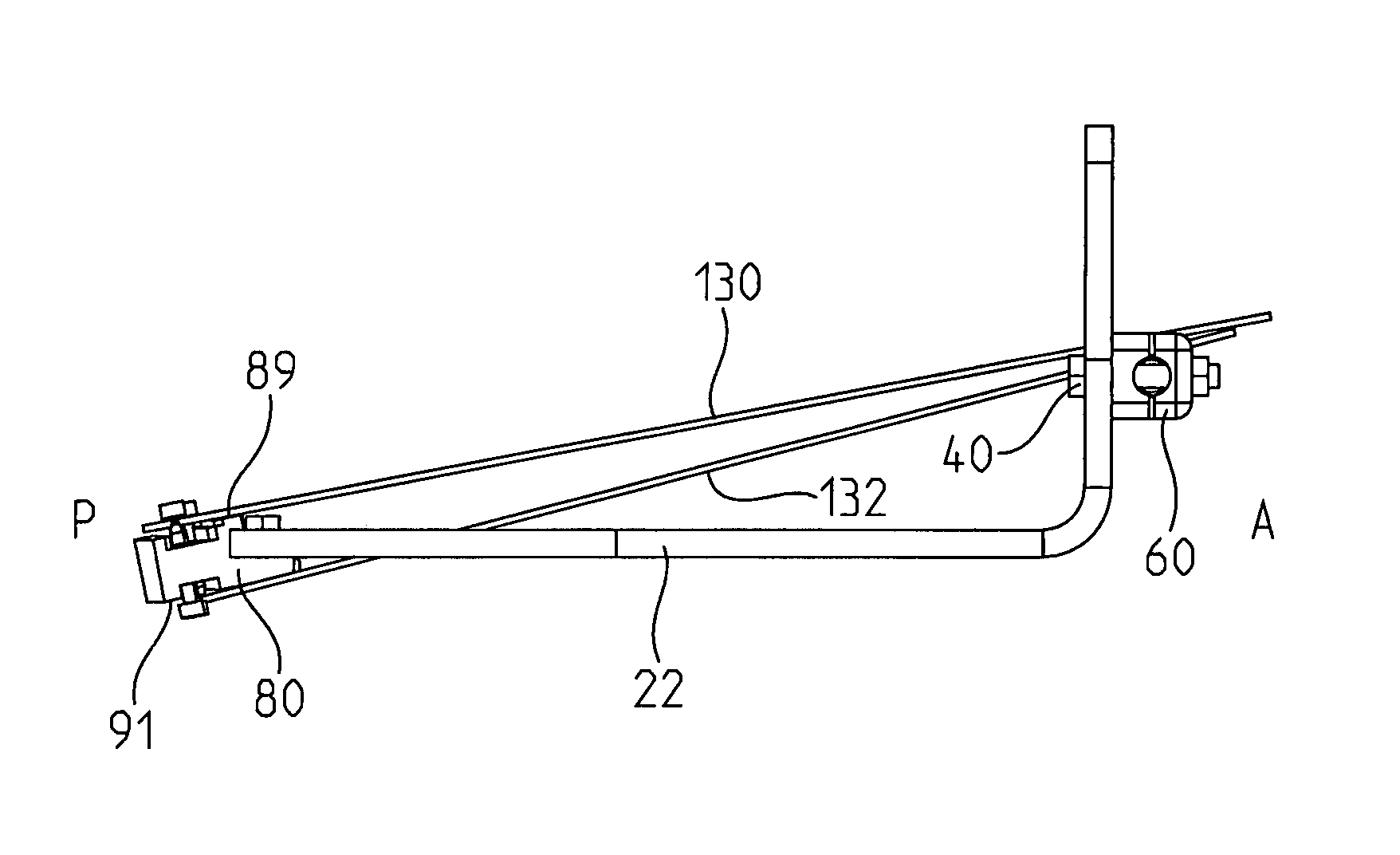

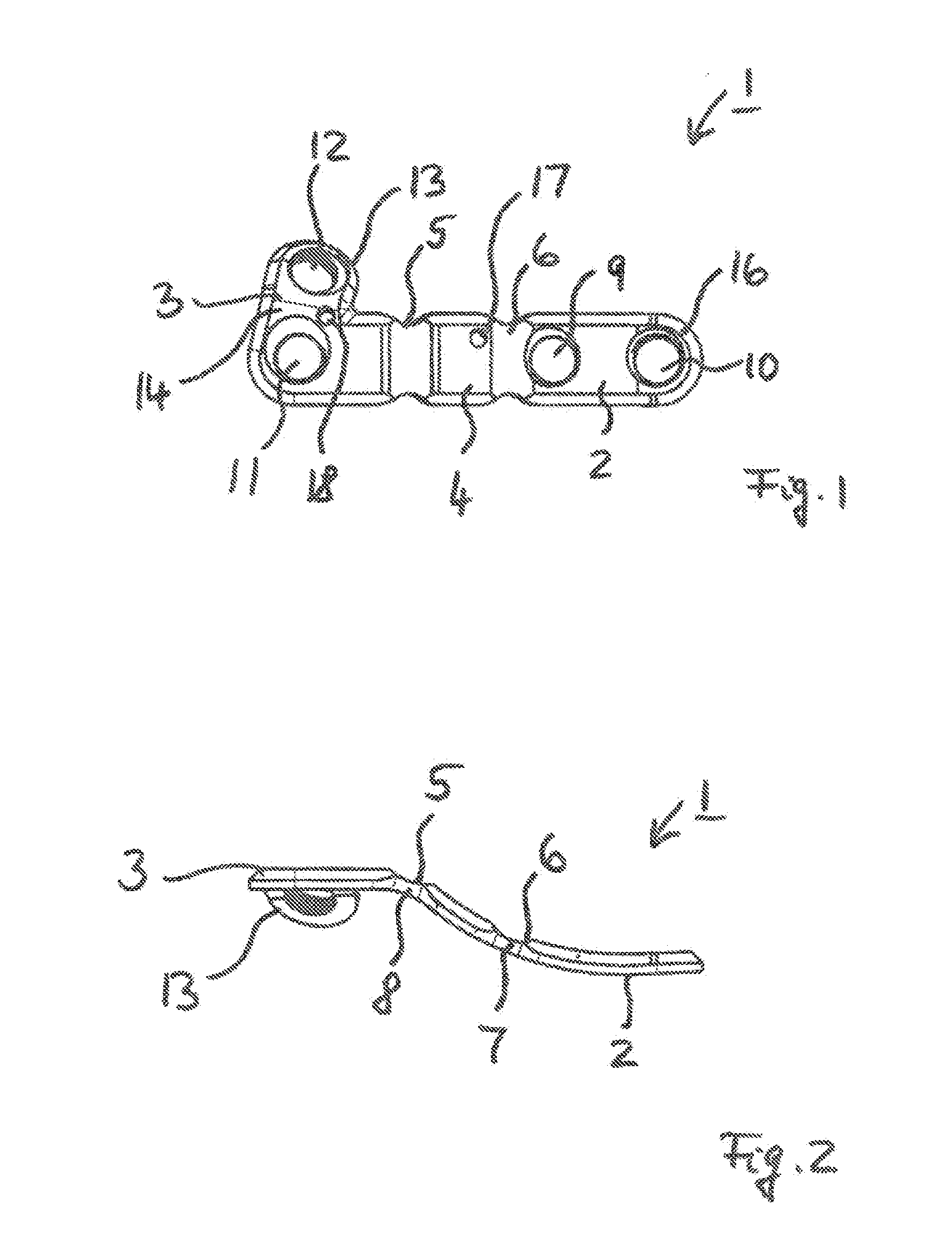

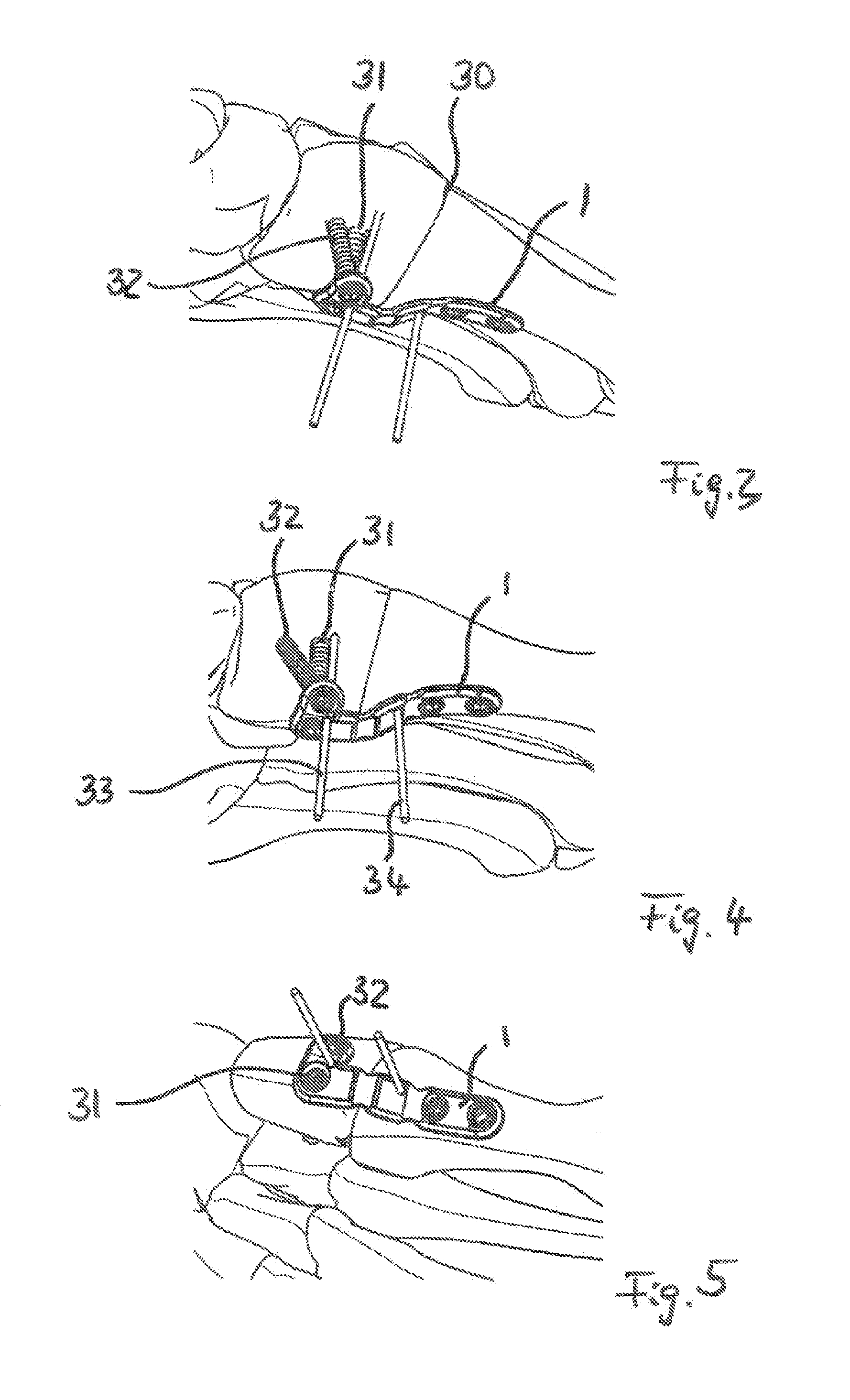

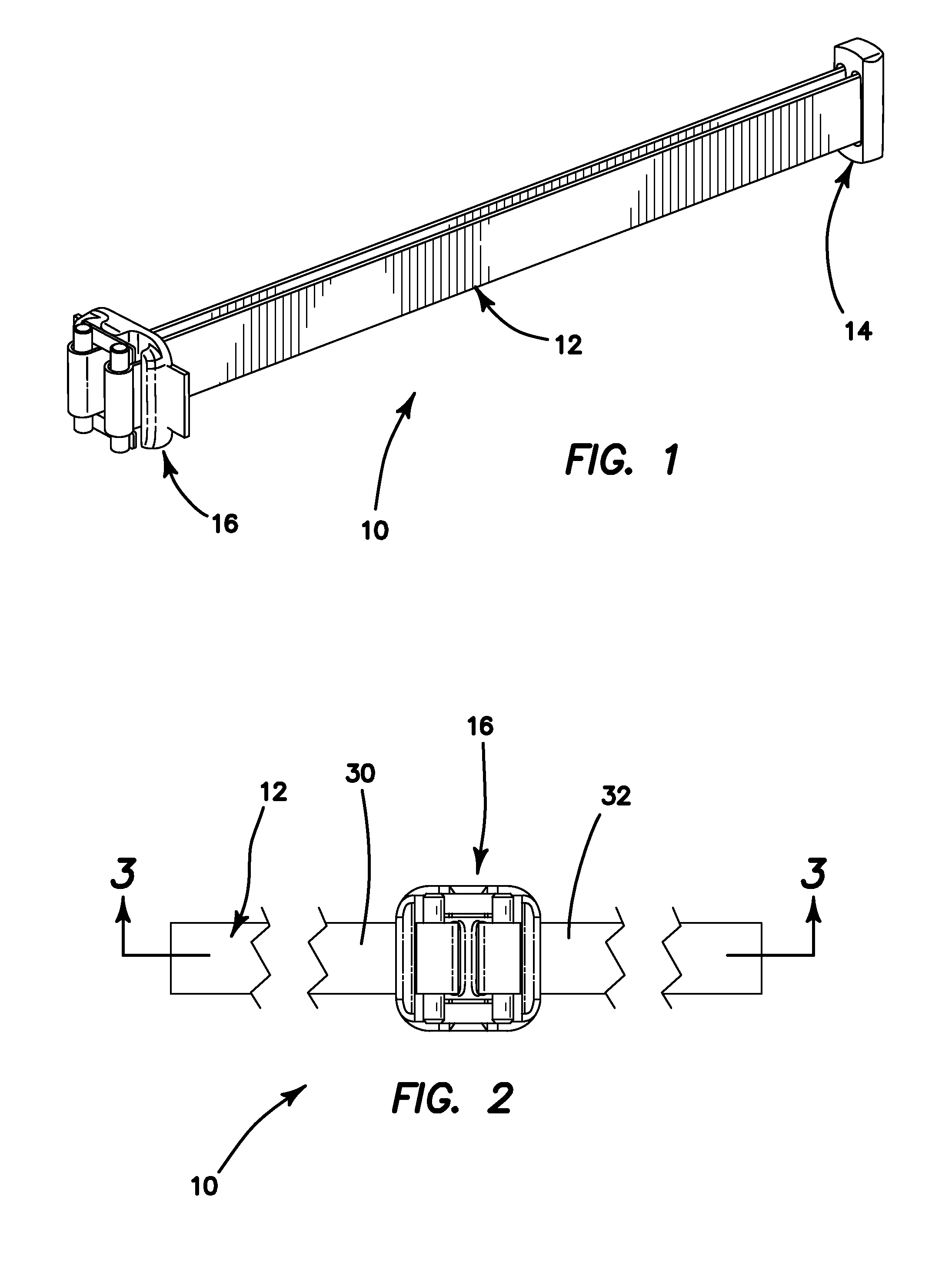

External bone/joint fixation device

ActiveUS20050149018A1Improve variationProtect the bottomFractureInvalid friendly devicesIn planeStable fixation

An external foot / ankle fixation device has a one-piece frame component and a positionable cross bar that allows the attachment of generally anterior / posterior directed fixation wires or rods emanating from the foot / ankle of a patient. The external fixation device provides a stable fixation platform both in-plane and out-of-plane of the object of fixation (e.g. foot or ankle). The fixation device through the cross bar also provides various degrees of angulation of anterior / posterior directed wires in two planes. Posterior angulation components may be provided to the posterior portion of the frame component that provide additional fixation wire / rod angulation variations. Compression rails may also be provided. An optional elevator component may be attached to the bottom of the frame component that does not obstruct access to the soft tissues on the bottom of the foot. The elevator component protects the bottom of the foot from contaminated surfaces.

Owner:BIOMET CV

External bone/joint fixation device

ActiveUS7361176B2Protect the bottomFix instabilityFractureInvalid friendly devicesPhysical medicine and rehabilitationFoot soles

An external foot / ankle fixation device has a one-piece frame component and a positionable cross bar that allows the attachment of generally anterior / posterior directed fixation wires or rods emanating from the foot / ankle of a patient. The external fixation device provides a stable fixation platform both in-plane and out-of-plane of the object of fixation (e.g. foot or ankle). The fixation device through the cross bar also provides various degrees of angulation of anterior / posterior directed wires in two planes. Posterior angulation components may be provided to the posterior portion of the frame component that provide additional fixation wire / rod angulation variations. Compression rails may also be provided. An optional elevator component may be attached to the bottom of the frame component that does not obstruct access to the soft tissues on the bottom of the foot. The elevator component protects the bottom of the foot from contaminated surfaces.

Owner:BIOMET CV

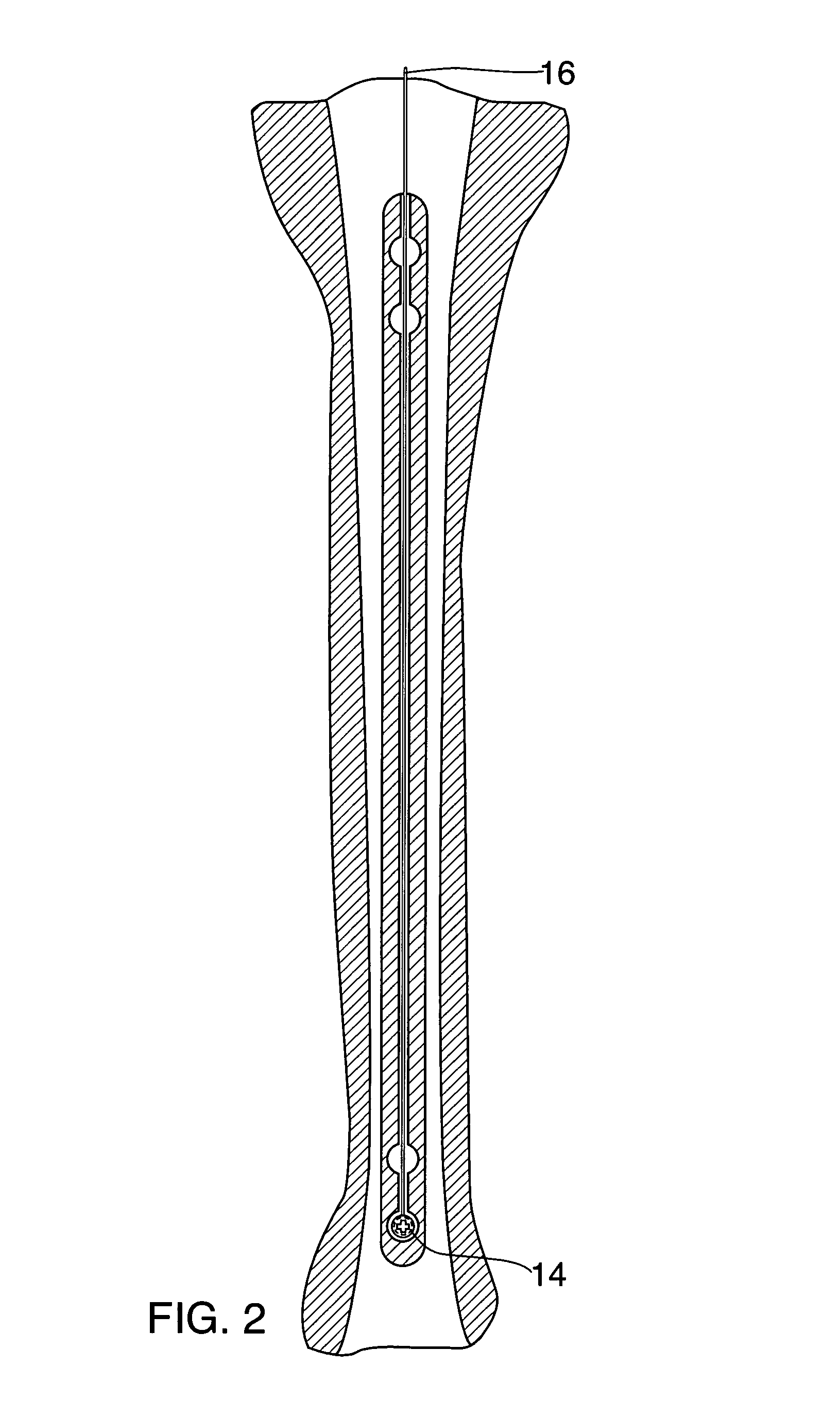

Anatomically Customized Plantar Bone Plate and Bone Plate System

ActiveUS20140180343A1Mechanical stabilityInhibition effectToe jointsBone platesJoint arthrodesisDistal portion

An anatomically customized plantar hone plate and system for an angularly stable fixation for the arthrodesis of the tarsometatarsal I joint. The bone plate has a distal plate portion which extends in the longitudinal direction and in which a distal bore is formed for receiving a bone screw at a stable angle, a proximal plate portion which extends transverse to the longitudinal direction, and a central plate portion which extends between the distal and the proximal plate portions and which is made with a curved plate portion with at least one bending zone for the purpose of anatomical customization. A plantar bore for receiving a bone screw to be fixed to the sole of the foot at a stable angle and a bore that is medially inclined for receiving a bone screw to be fixed in a medially inclined manner at a stable angle are arranged in the proximal plate portion adjacently to each other transverse to the longitudinal direction.

Owner:MERETE MEDICAL

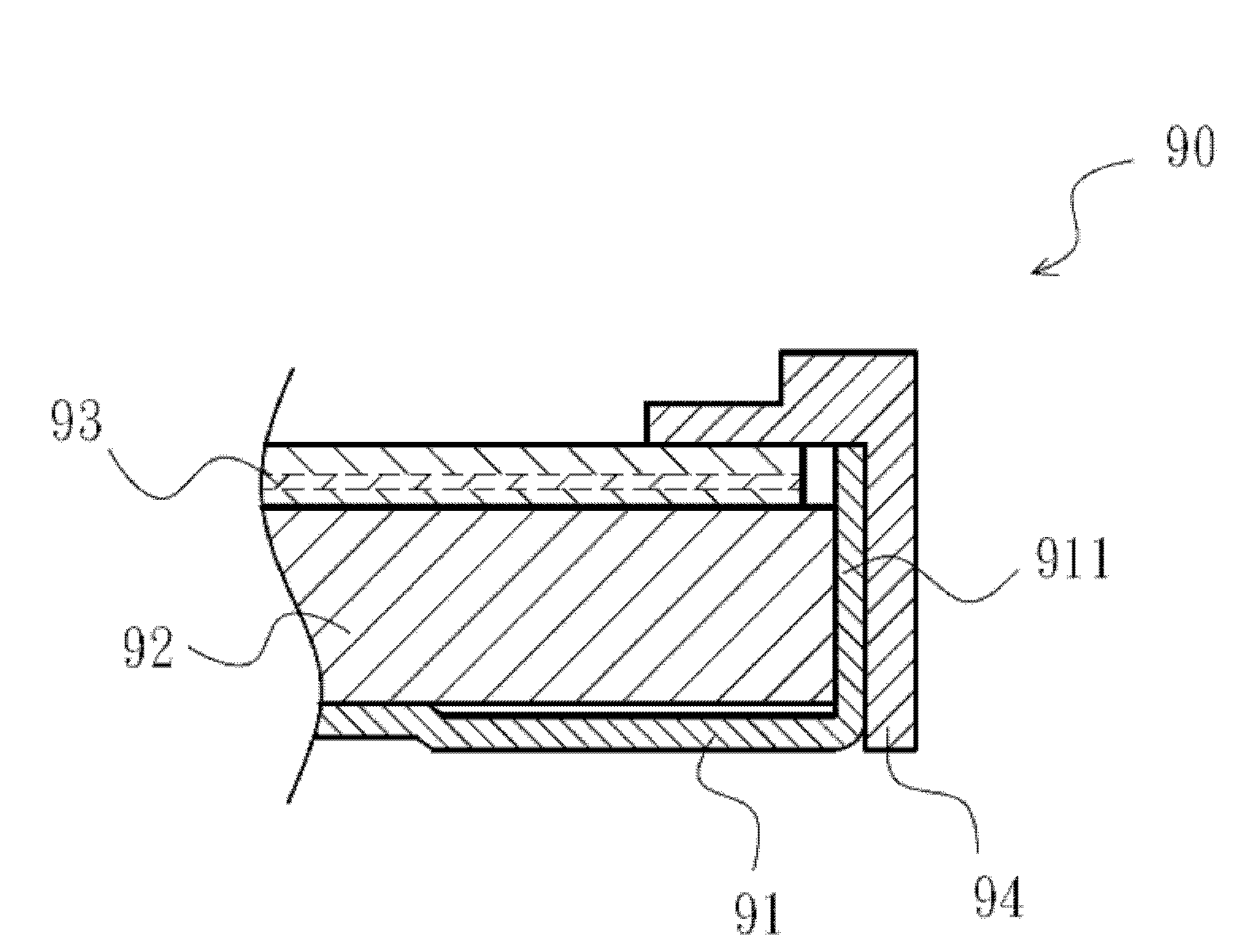

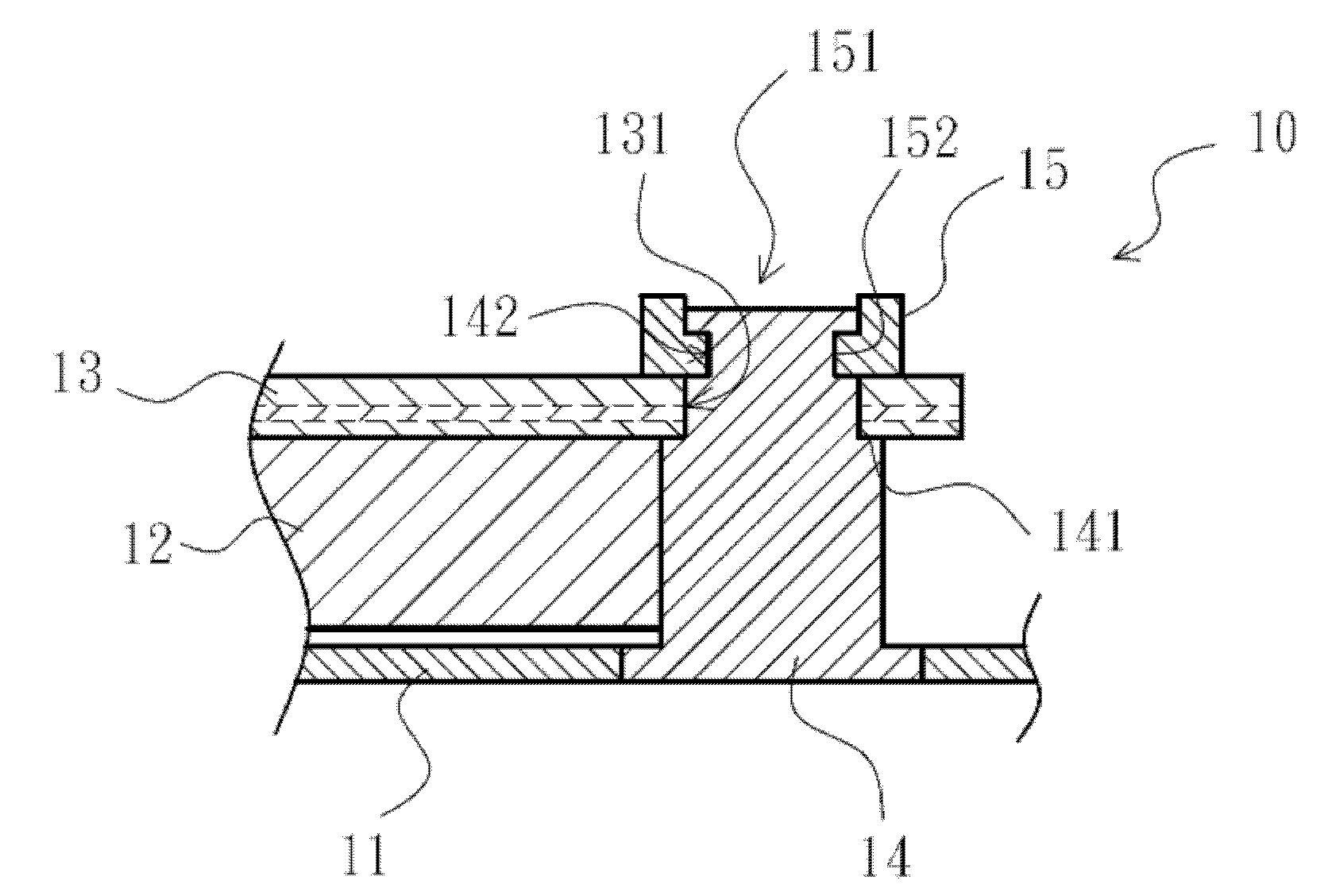

Backlight module and fixing mechanism for same

InactiveCN102182989AEasy to installLight materialPlanar/plate-like light guidesLight fasteningsBiochemical engineeringStable fixation

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Electrical connector with stable retaining terminals

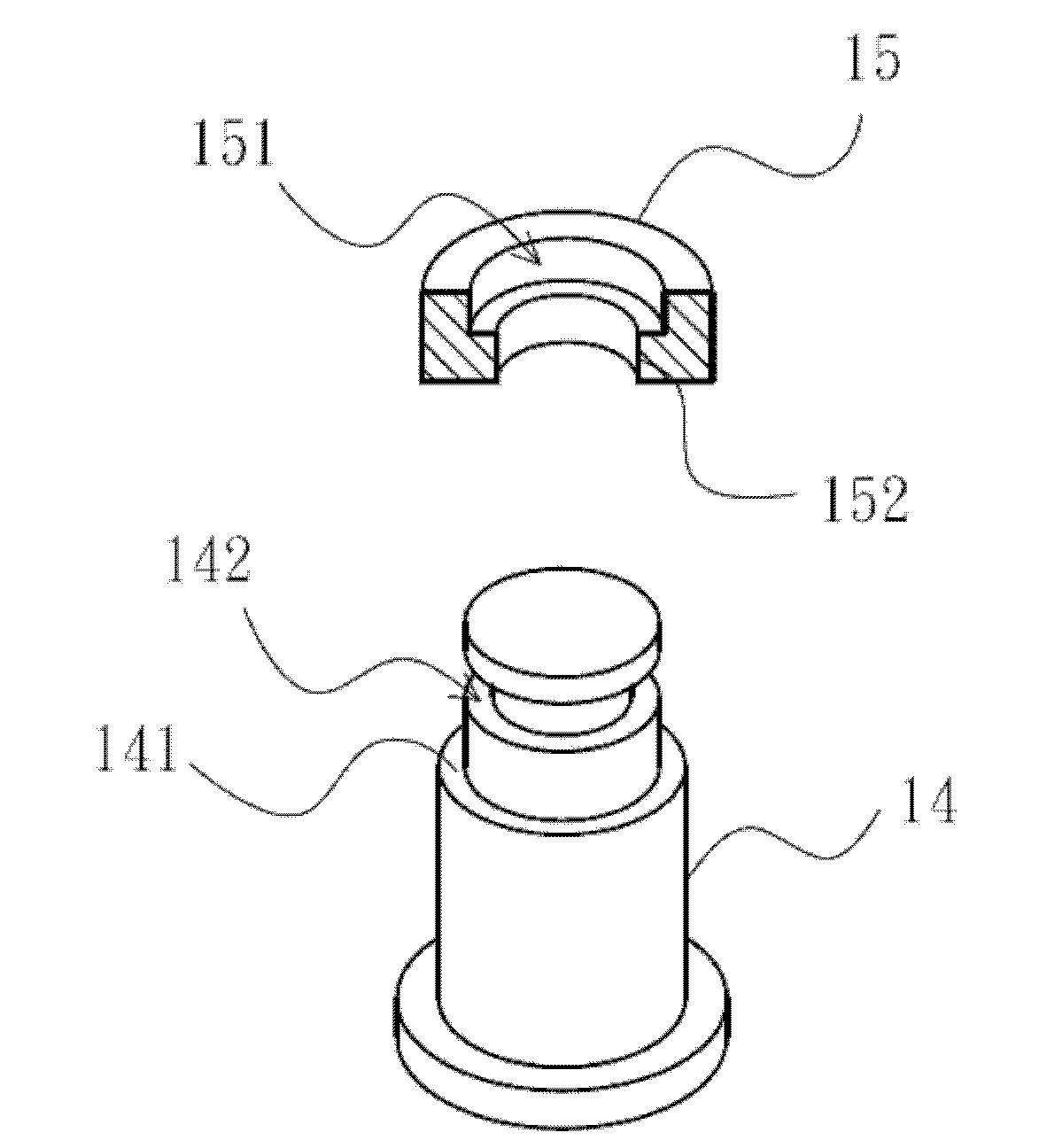

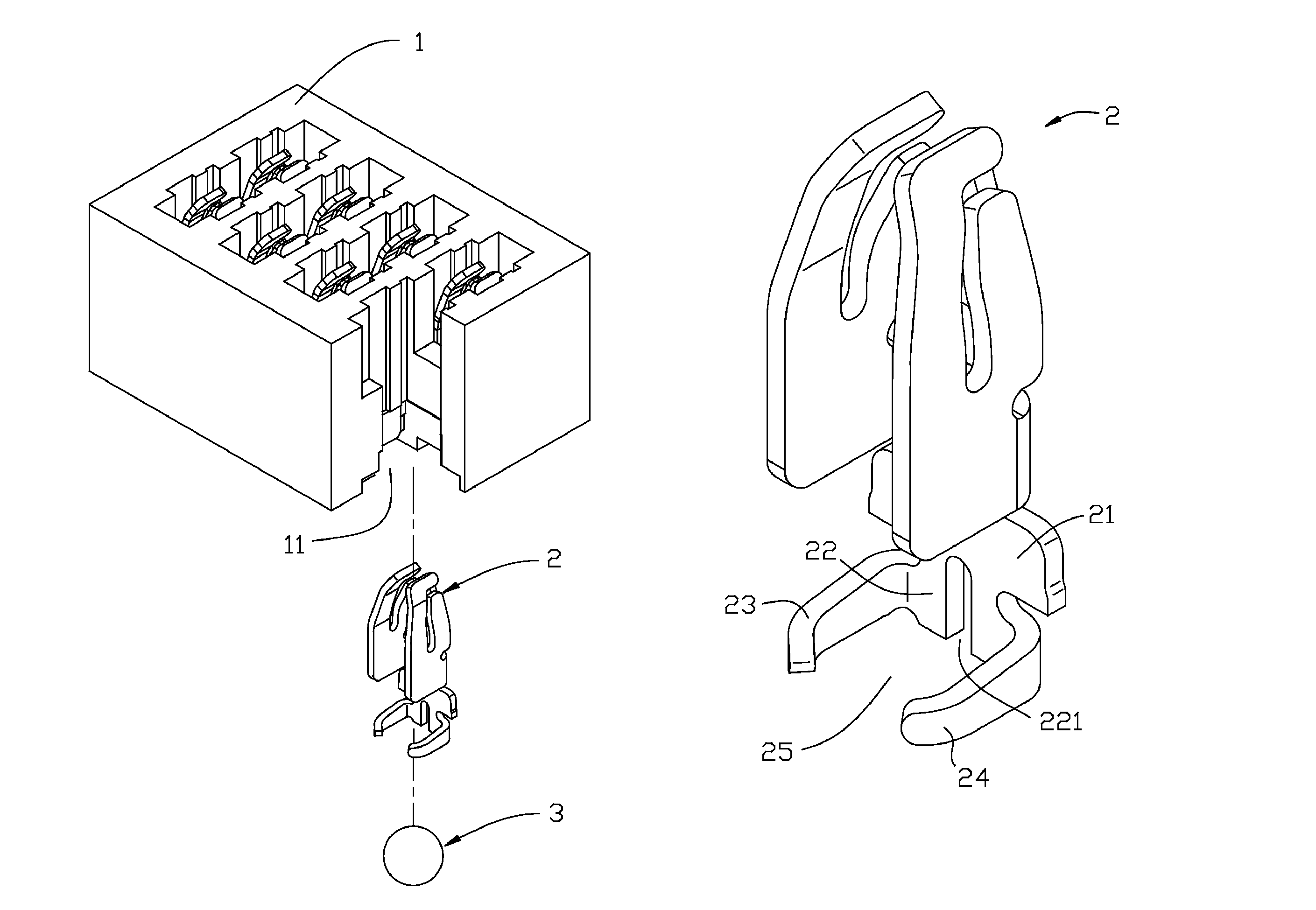

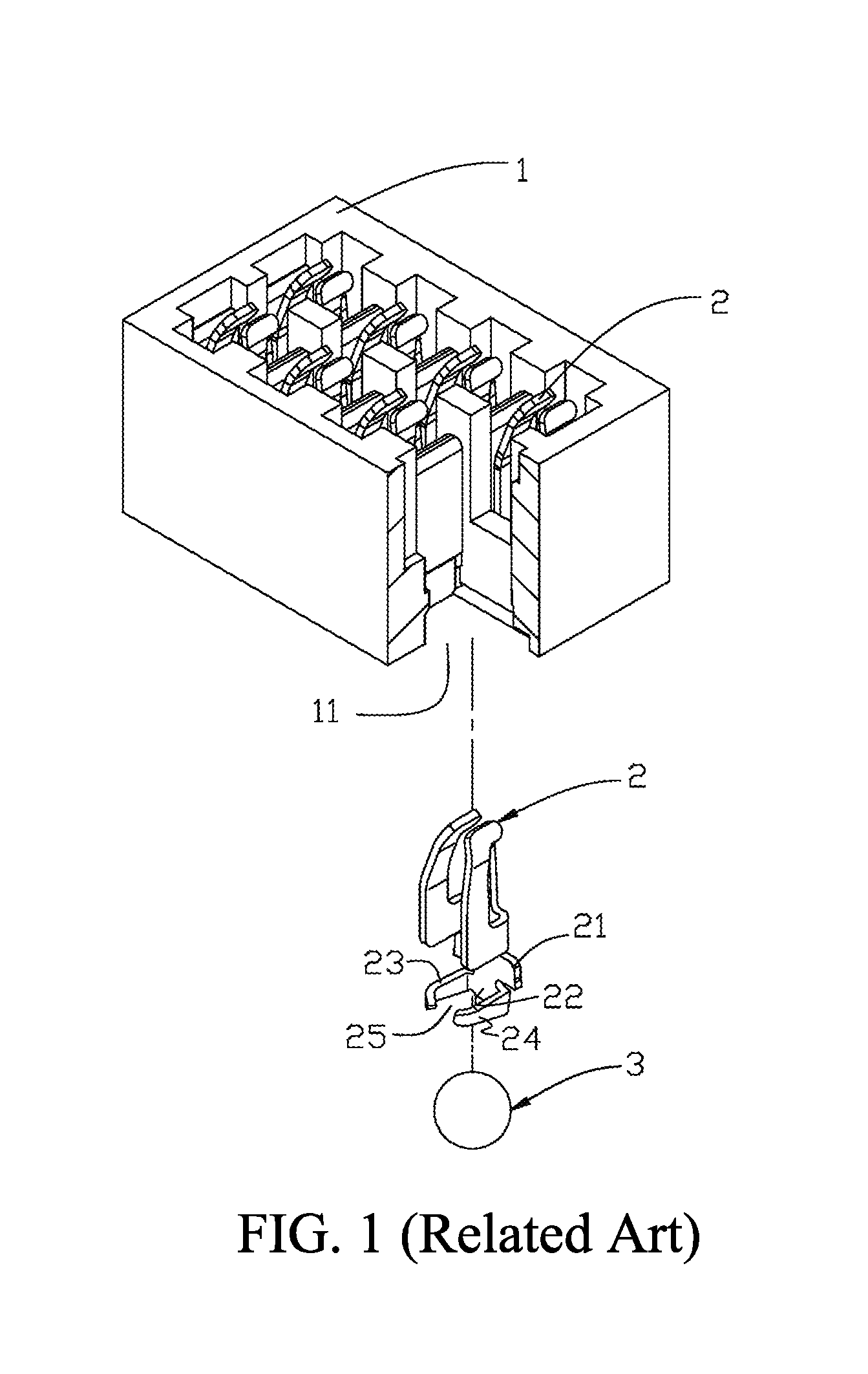

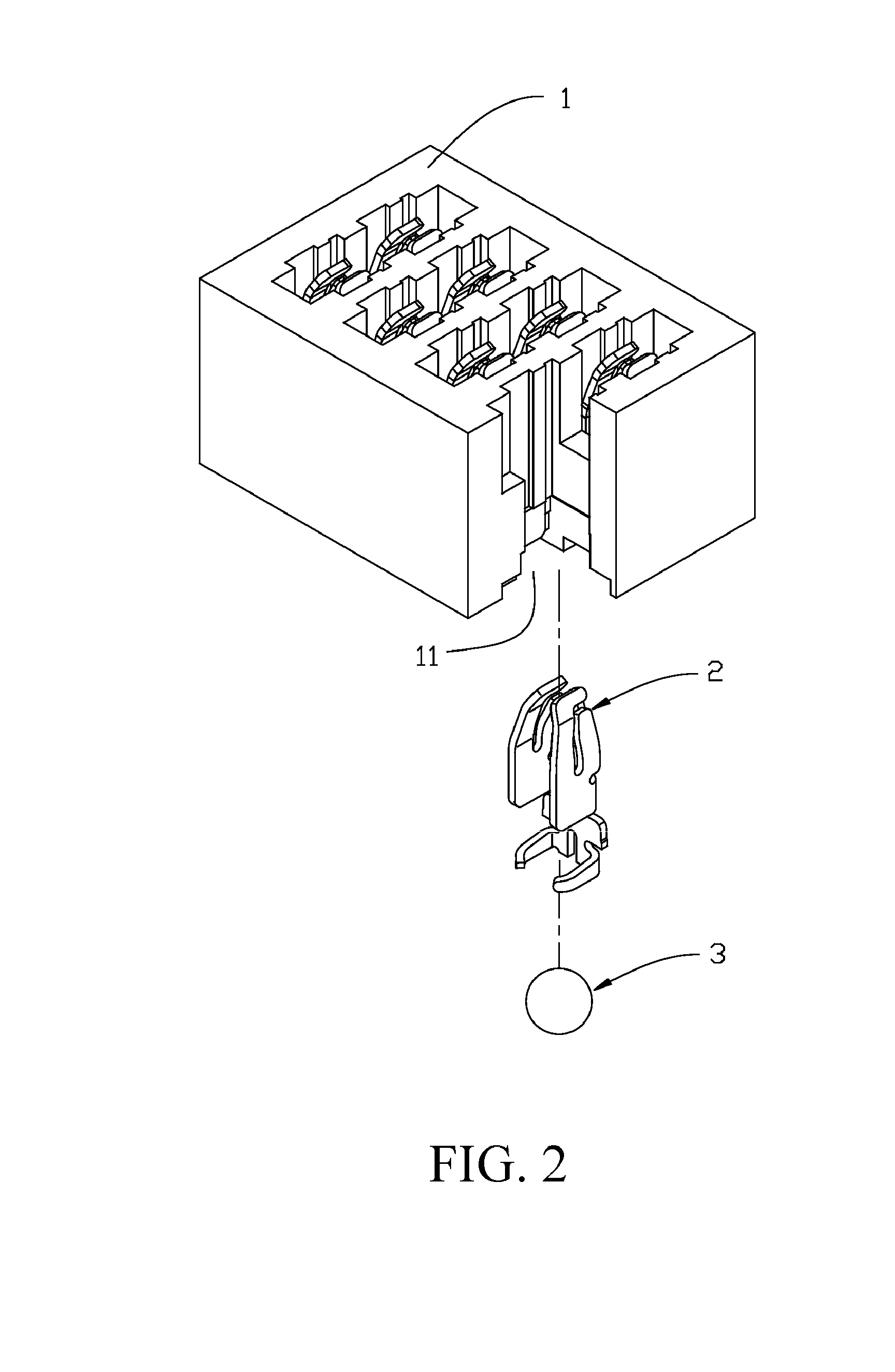

InactiveUS8052436B1Increase elasticityEasy to insertCoupling device detailsFixed connectionsElectricitySolder ball

An electrical connector includes an insulating body, having a plurality of receiving slots running through the insulating body; a plurality of terminals respectively received in the receiving slots; and a plurality of solder balls, in which each of the solder balls is disposed corresponding to each terminal and each receiving slot. Each terminal includes a base, a first retaining portion formed by extending downwards the base, a second retaining portion and a third retaining portion formed by bending and extending two side surfaces of the first retaining portion, and a groove formed at one end of the first retaining portion away from the base.

Owner:LOTES

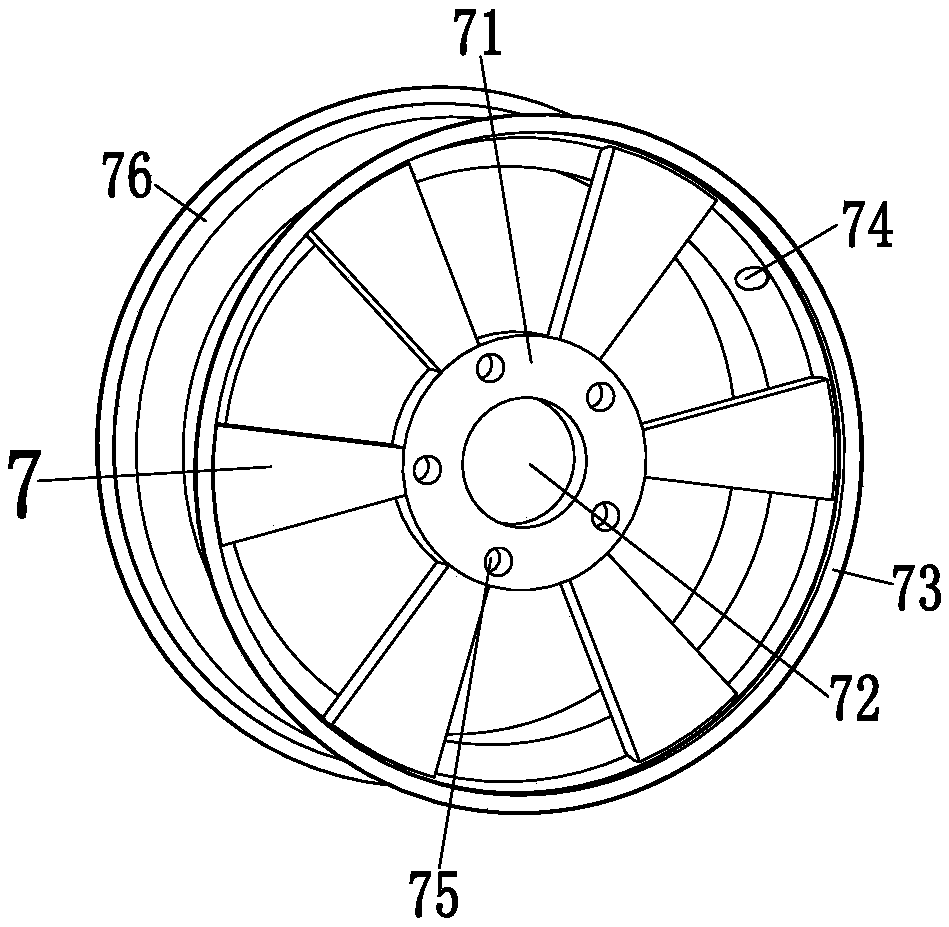

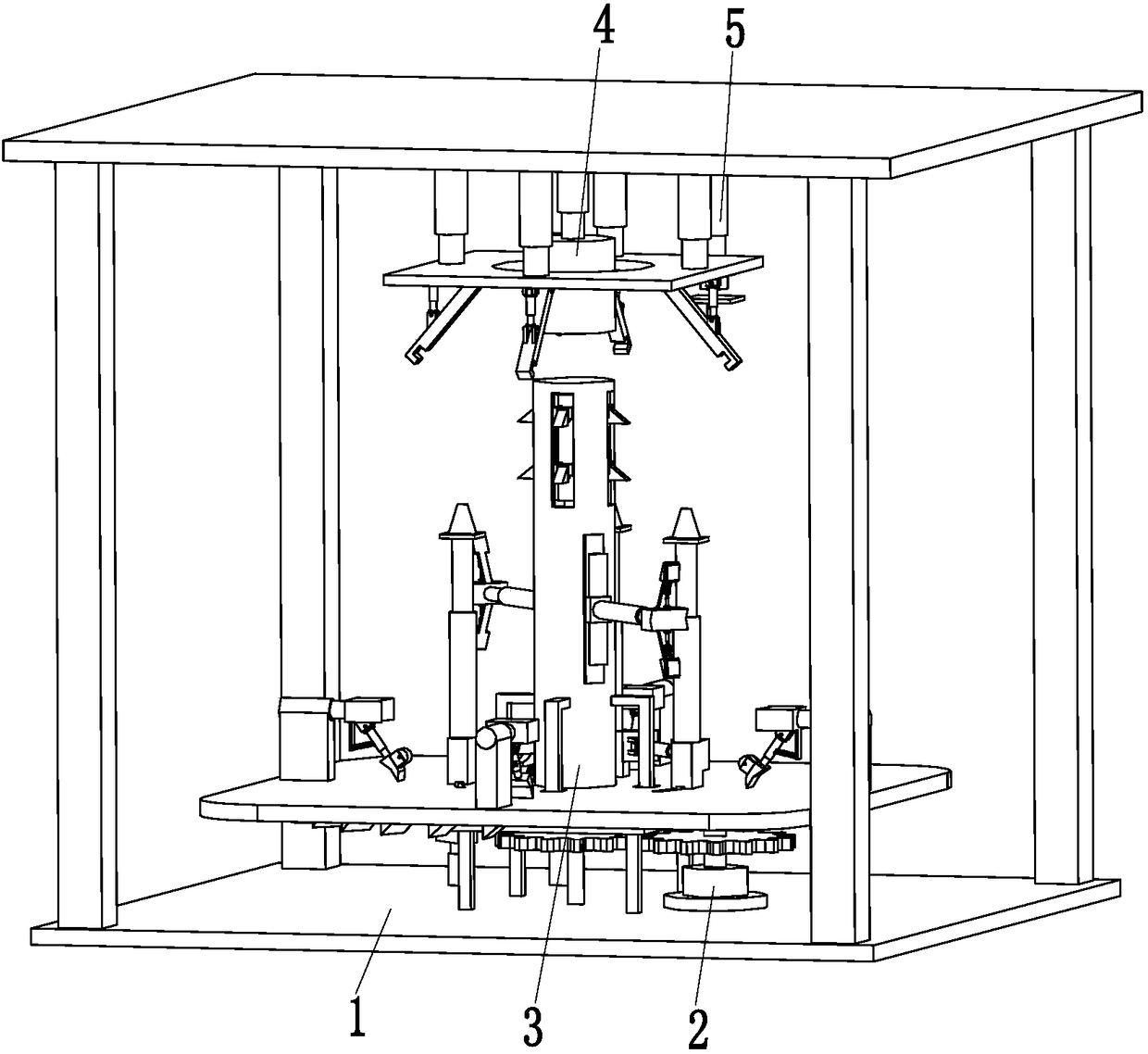

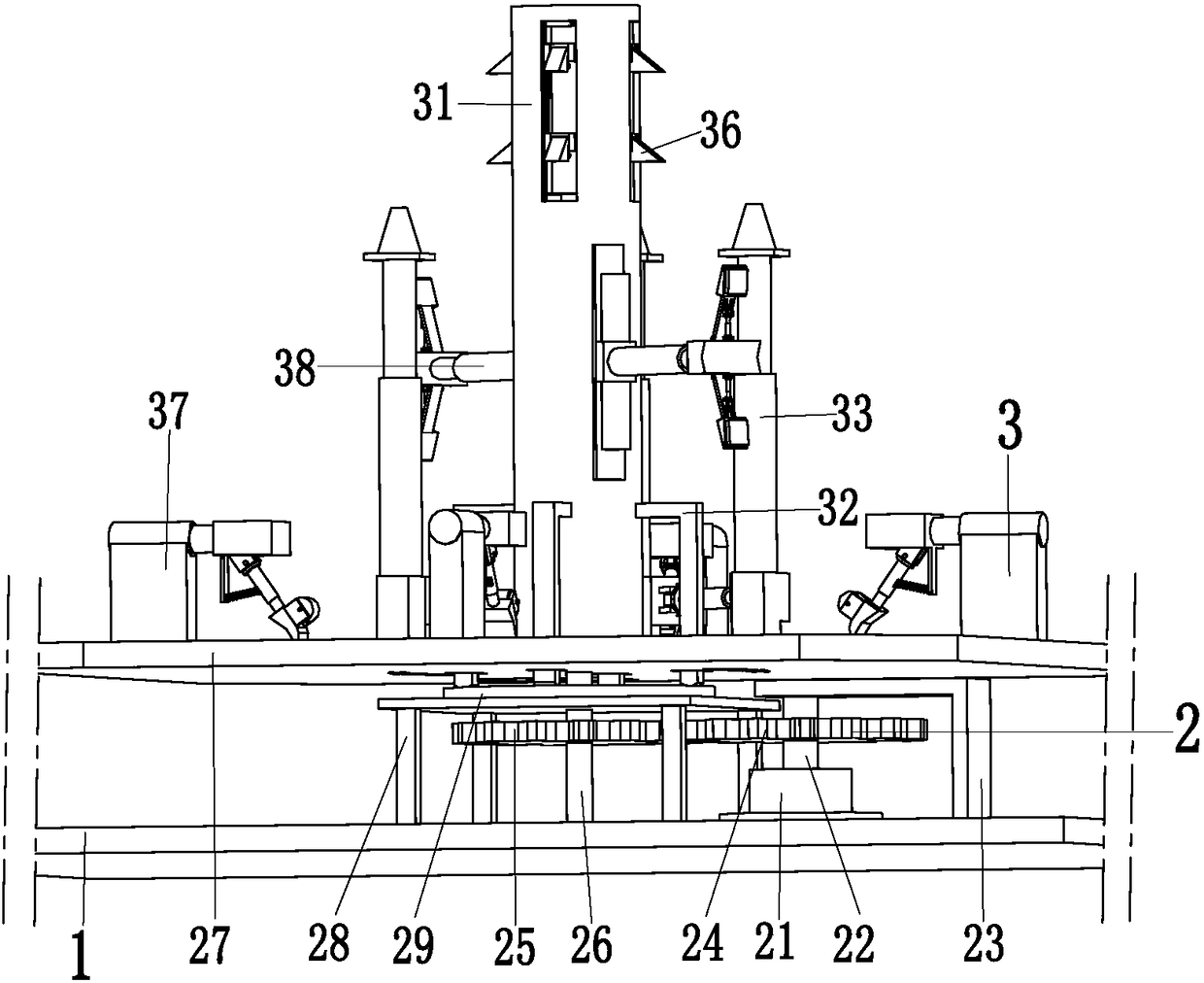

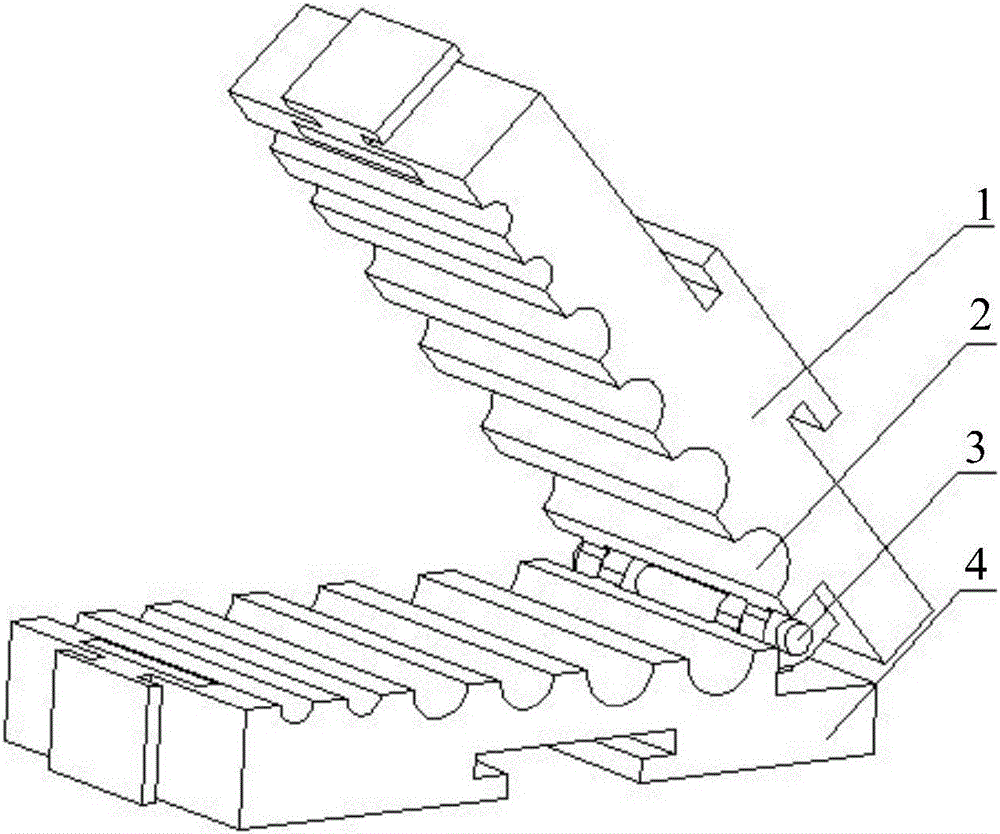

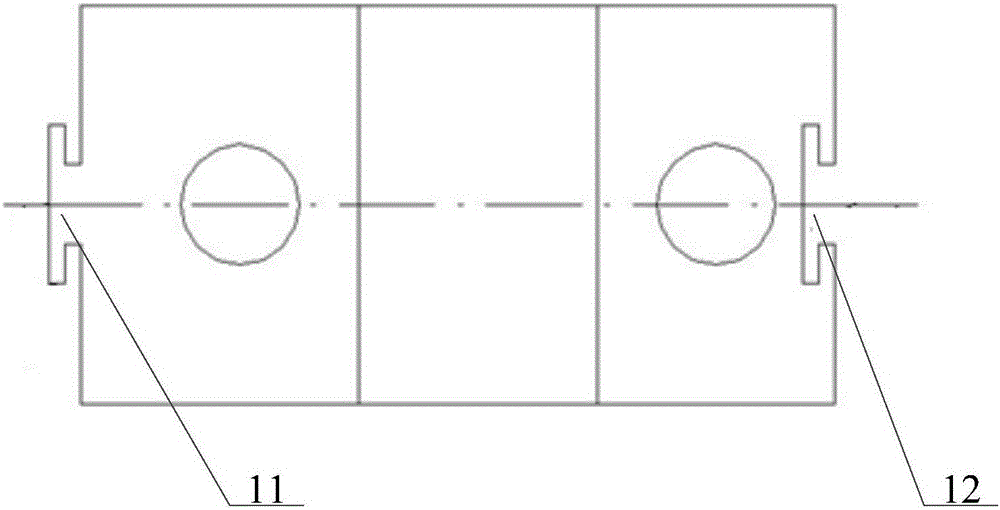

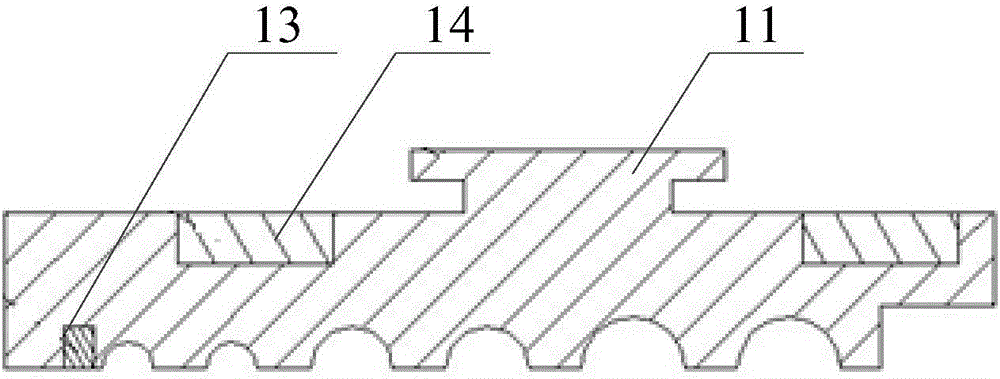

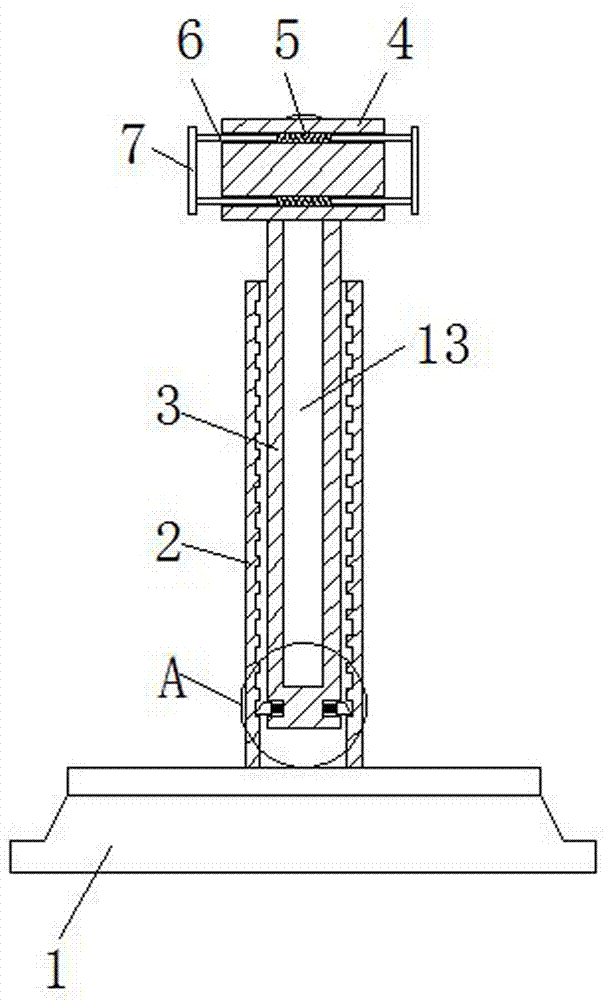

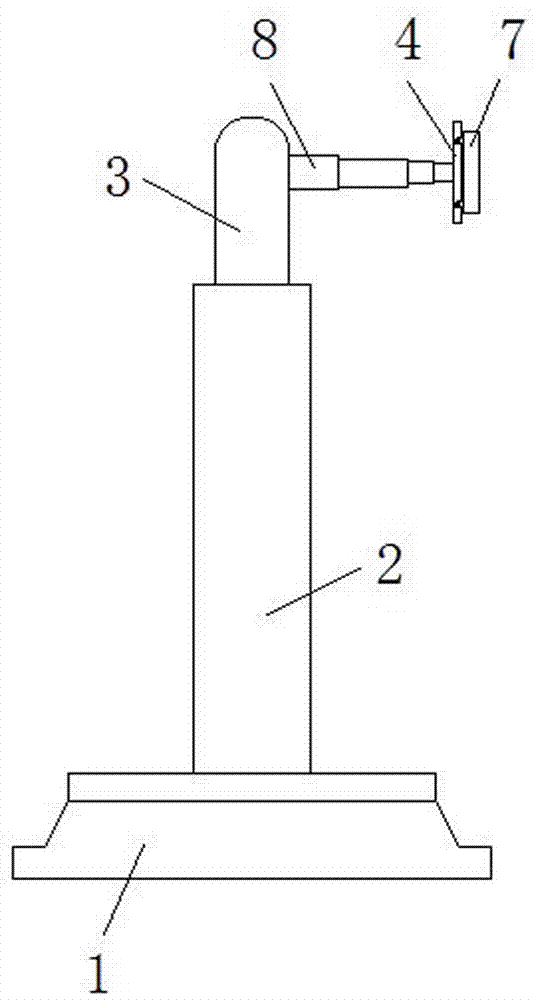

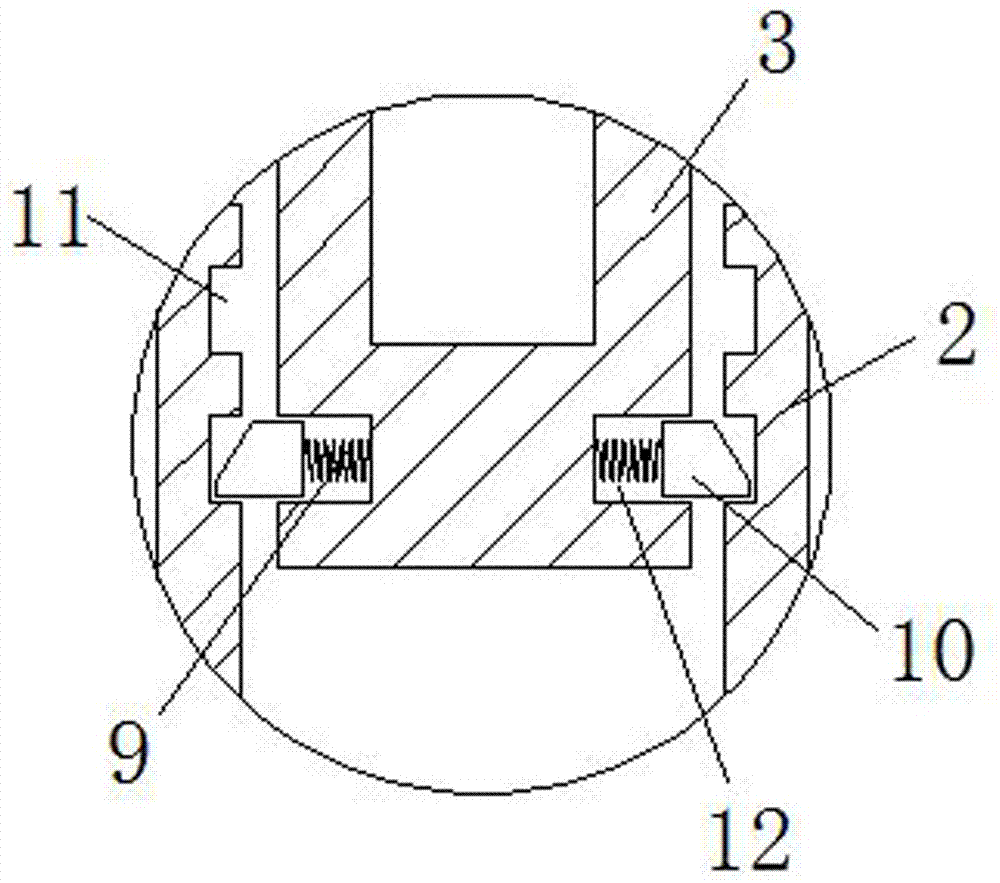

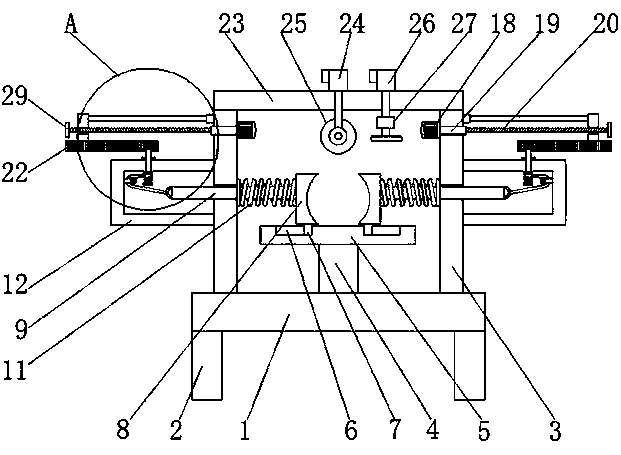

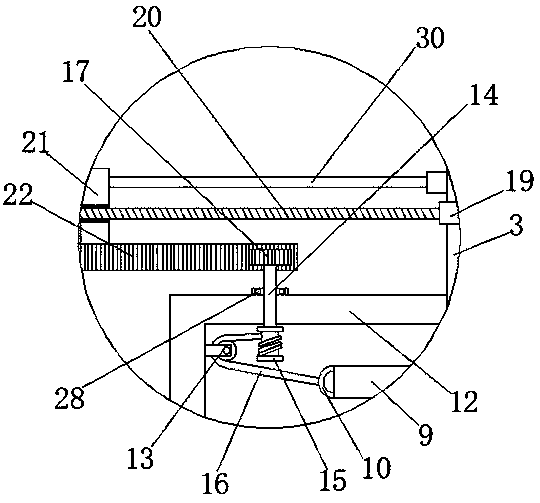

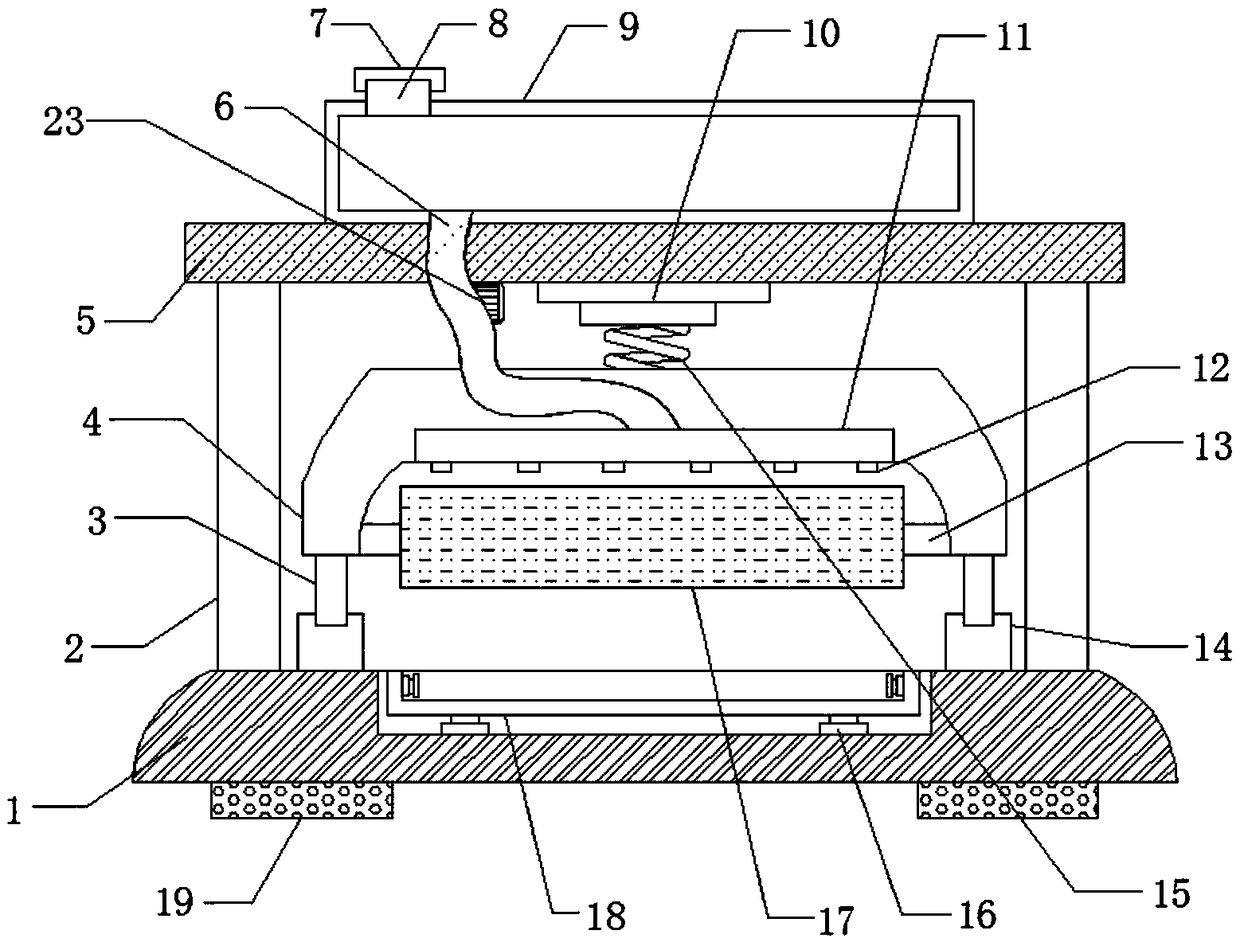

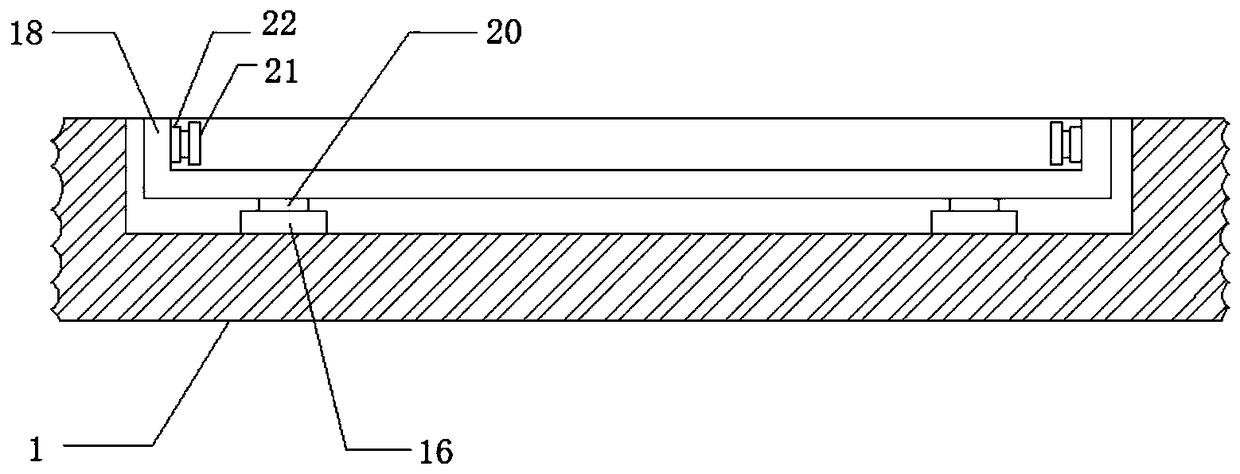

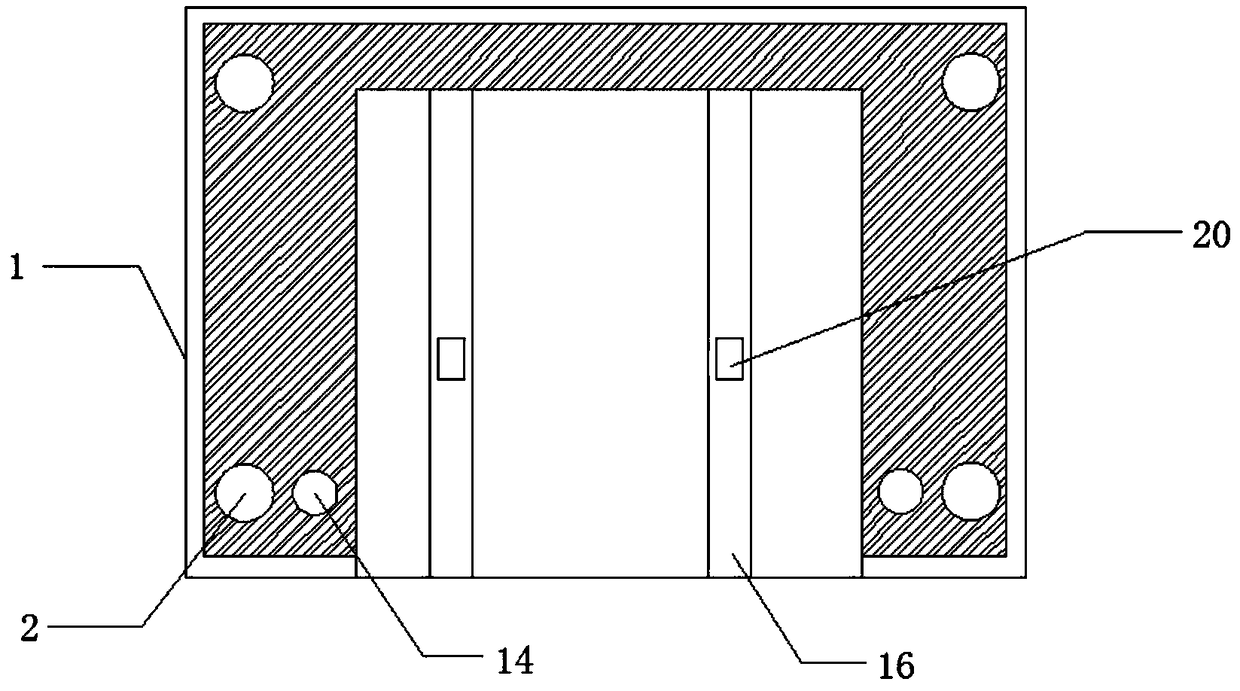

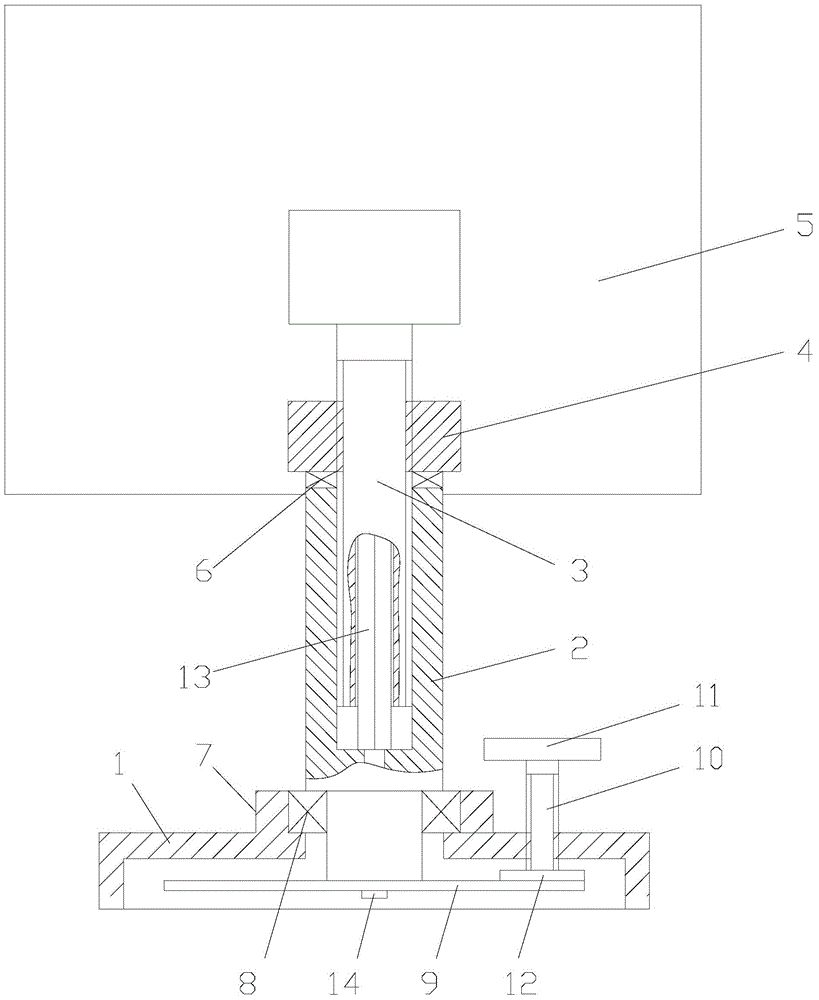

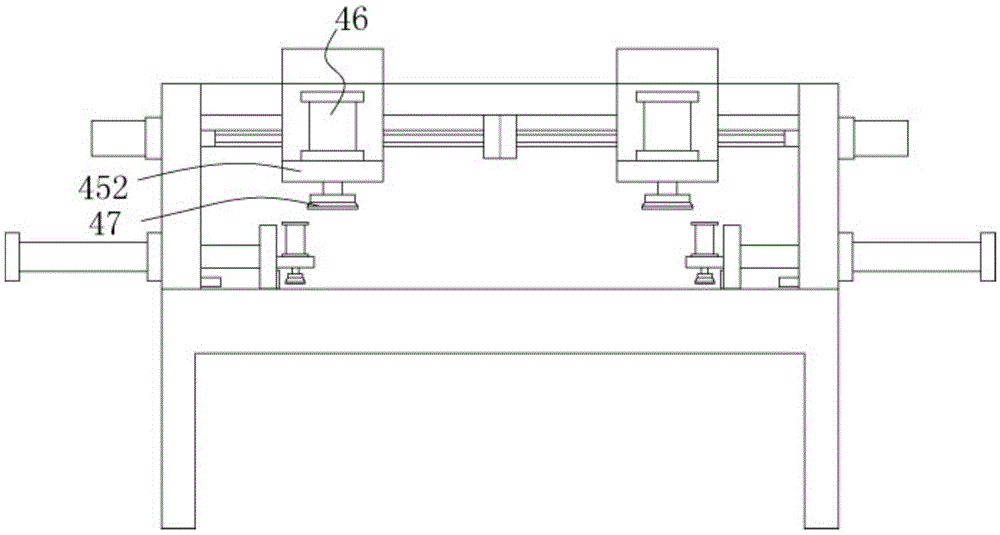

New energy automobile wheel hub valve hole perforation fixture with automatic positioning function

InactiveCN108080961AEasy to fixAutomatic grindingOther manufacturing equipments/toolsPositioning apparatusEngineeringStable fixation

The invention relates to a new energy automobile wheel hub valve hole perforation fixture with an automatic positioning function. The new energy automobile wheel hub valve hole perforation fixture comprises a support bottom plate, a rotary device, a fixing device, a clamping device and a hole drilling device. The rotary device is mounted on the top of the support bottom plate, the fixing device ismounted on the top of the rotary device, the clamping device is connected with the support bottom plate, and the hole drilling device is mounted on the clamping device. The new energy automobile wheel hub valve hole perforation fixture has the advantages that the difficult problems of incapability of fixing existing wheel hubs for existing wheel hub structures when existing valve holes are drilled in the existing new energy automobile wheel hubs in certain factories, incapability of firmly fixing the existing wheel hubs, deviation when the existing wheel hubs rotate under the control, requirements on manually polishing the existing valve holes and the like at present can be solved by the aid of the new energy automobile wheel hub valve hole perforation fixture; the new energy automobile wheel hub valve hole perforation fixture can have functions of stably fixing new energy automobile wheel hubs and drilling and polishing valve holes in the wheel hubs, the wheel hubs can be fixed for wheel hub structures by the aid of the new energy automobile wheel hub valve hole perforation fixture and can be firmly fixed by the aid of the new energy automobile wheel hub valve hole perforation fixture, the wheel hubs can stably rotate without deviation under the control, the valve holes can be automatically polished, and the like.

Owner:盛亚明

Method for performing zero moment point (ZMP) calibration autonomously by robot

ActiveCN101950176AHigh degree of automationHigh precisionAttitude controlPosition/direction controlStable fixationEngineering

The invention provides a method for performing zero moment point (ZMP) calibration autonomously by a robot. The robot has at least two legs and feet, wherein the at least two legs can drive the robot to walk; the feet are connected with the legs through ankle joints respectively; and the feet are provided with force sensors. The method comprises the following steps of: calculating the projection of a barycenter of the robot on the ground according to each part and the position thereof of the robot, wherein the robot is supported by a single foot to maintain a certain stable fixed posture and the part above the ankle joint of the supporting foot of the robot is seen as a mass point; adjusting the ankle joint of the supporting foot of the robot so as to make the projection of the barycenter spread over the surface of the supporting foot; and obtaining a table by sampling, wherein in the table, a true ZMP corresponds to the ZMP measured by the force sensors. The robot can perform the ZMP calibration according to the projection of the barycenter of the robot and the movement of the ankle joints, so the method has the advantages of no need of human intervention, high efficiency, a large number of sampling points, high precision and low requirement on a mounting environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

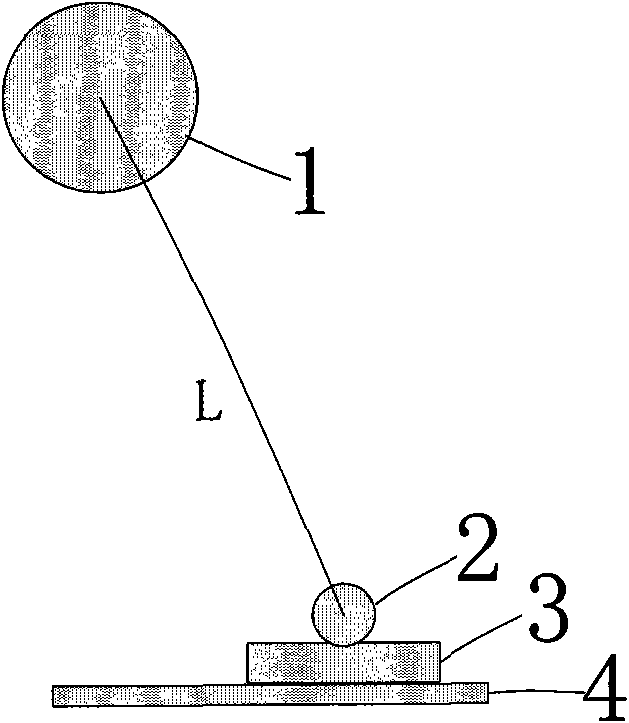

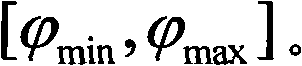

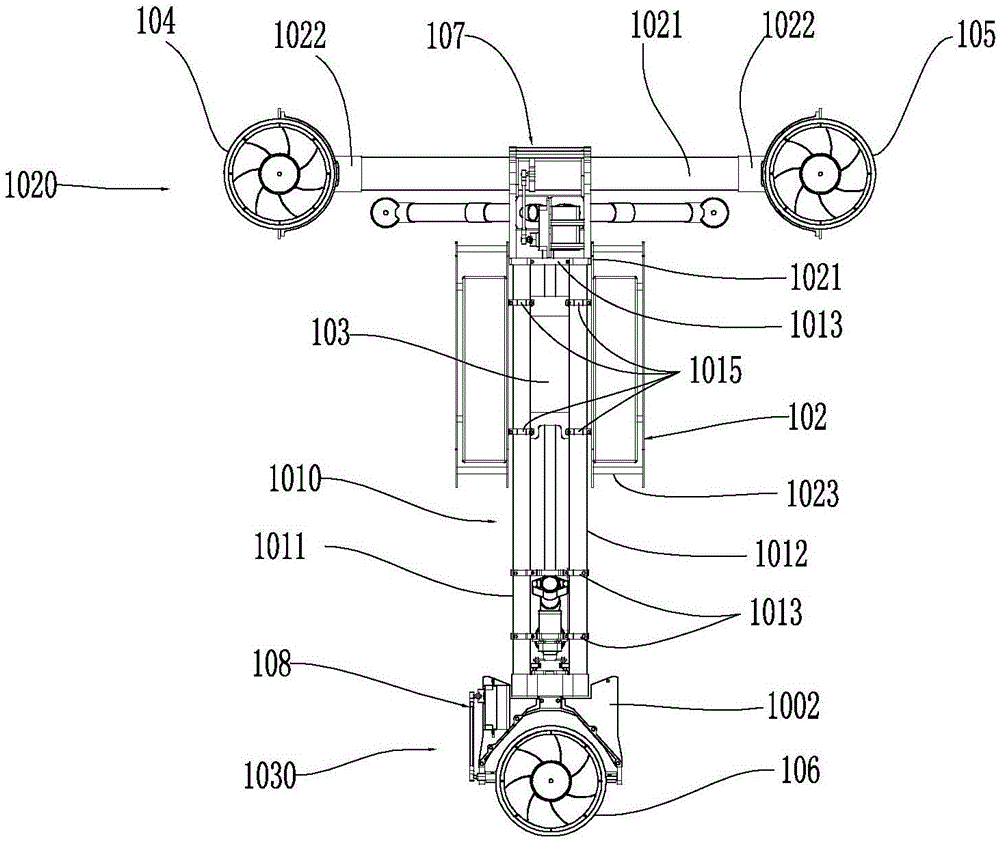

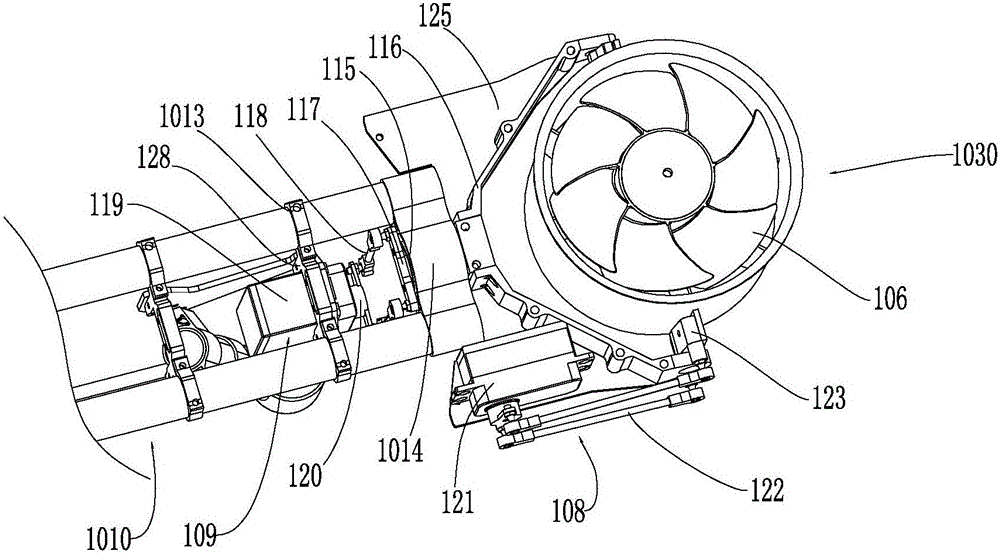

Take-off and landing platform for aircraft

InactiveCN106379550AExtended Vibration Conduction PathReduce vibration transmissionHelicopter landing platformTemporary pavingsStable fixationMulti axis

The invention provides a take-off and landing platform for assisting an aircraft to take off and land in a bumpy environment. The take-off and landing platform comprises a fixing plate and an attitude adjustment seat, wherein the fixing plate is used as a platform where the aircraft takes off and lands, and is used for fixing the aircraft before the aircraft takes off; the attitude adjustment seat is mounted on the lower side of the fixing plate and is used for stabilizing a space attitude of the fixing plate; and the attitude adjustment seat is at least provided with two degrees of freedom capable of rotating around the X axis and the Y axis. The multi-axis aircraft is fixed on the fixing plate before taking off, and the attitude adjustment seat dynamically stabilizes the attitude of the aircraft, so that the aircraft can be prevented from swinging back and forth, and good take-off conditions are supplied to taking off; and the stable fixing plate can supply a good landing environment to the multi-axis aircraft.

Owner:ZHUHAI PANSHI ELECTRONICS TECH CO LTD

Cable wire wrapper and centrally installed switchgear with same

The invention discloses a cable wire wrapper. The cable wire wrapper comprises a clamping part used for clamping a cable wire, and the clamping part is provided with a fixing part used for fixing the position of the cable wire wrapper and a connecting part used for being fixed with the other cable wire wrapper. The cable wire wrapper can be used for arrangement and storage of cable wires in electrical equipment, multiple cable wire wrappers can be fixed through the connecting parts arranged on the clamping parts, and the positions of the cable wire wrappers are fixed through the fixing parts finally. According to the cable wire wrapper, the connecting part is arranged on the clamping part, multiple cable wire wrappers can be connected for use, fixation to the cable wires is more stable, the efficiency for fixing the cable wires is high, the disassembling and assembling processes are easy and convenient, damage to outer skin of the cable wires is avoided, and the service life of the cable wires is prolonged. The invention further discloses a centrally installed switchgear comprising the cable wire wrapper.

Owner:ZHEJIANG TRULY ELECTRIC +1

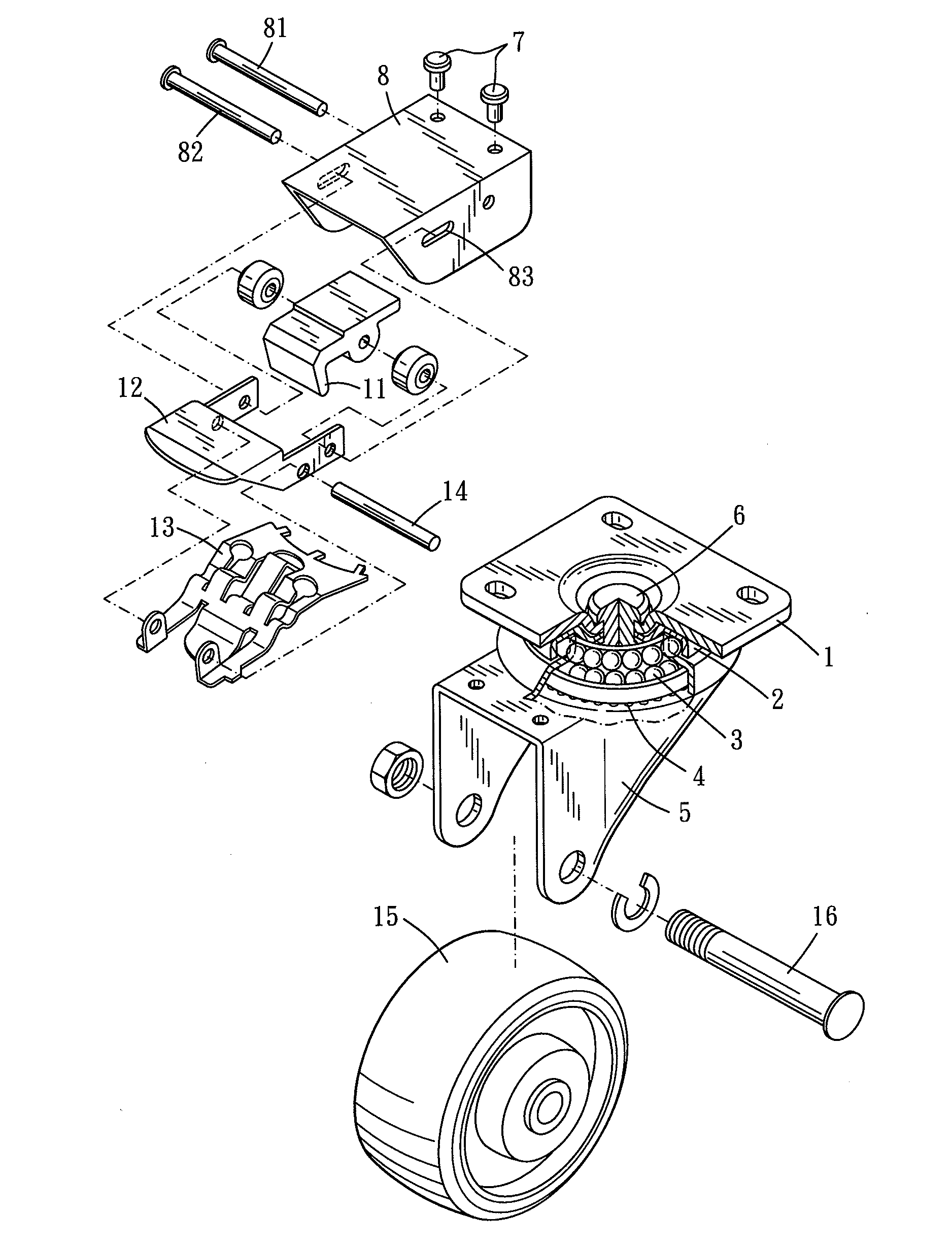

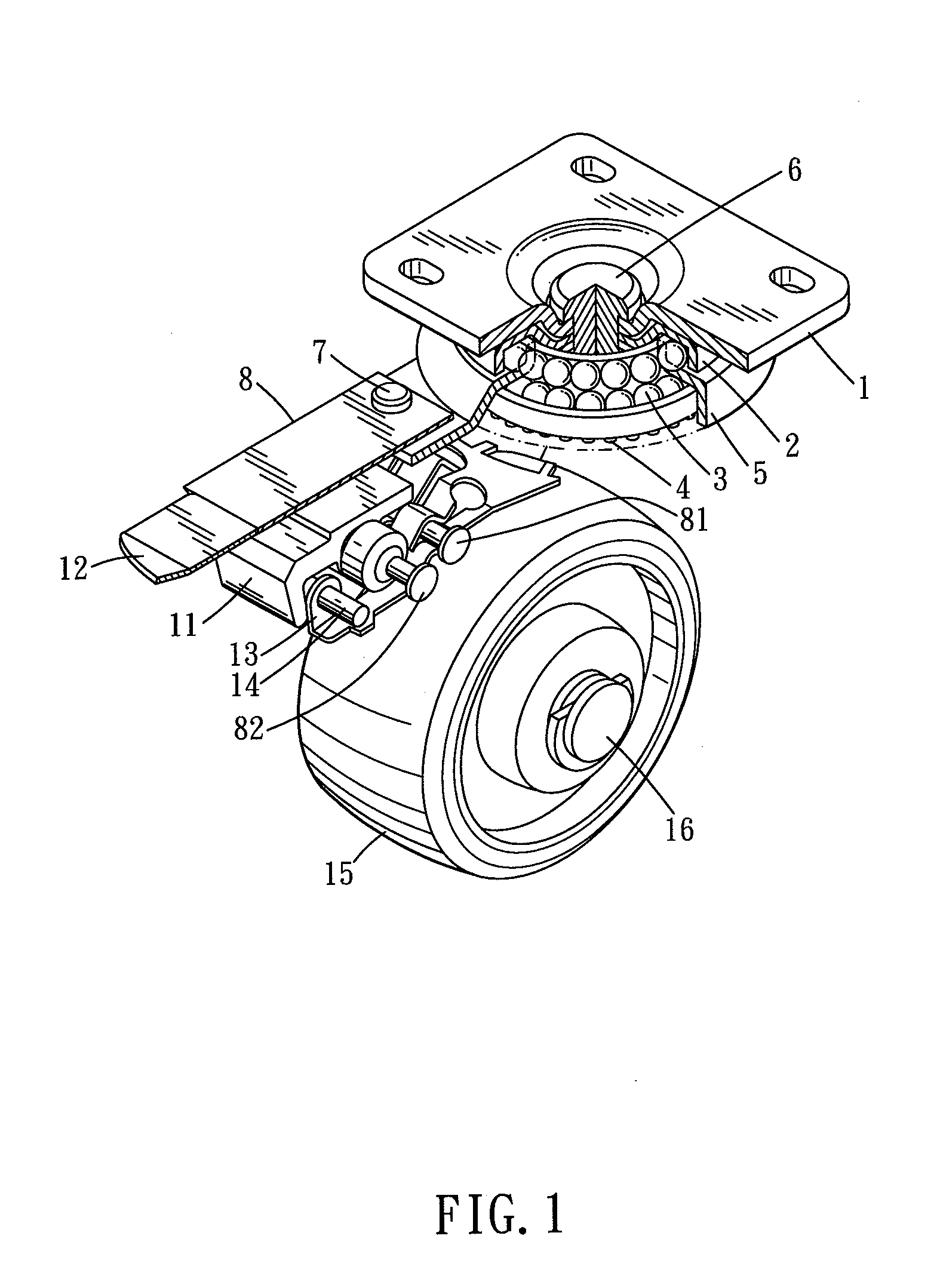

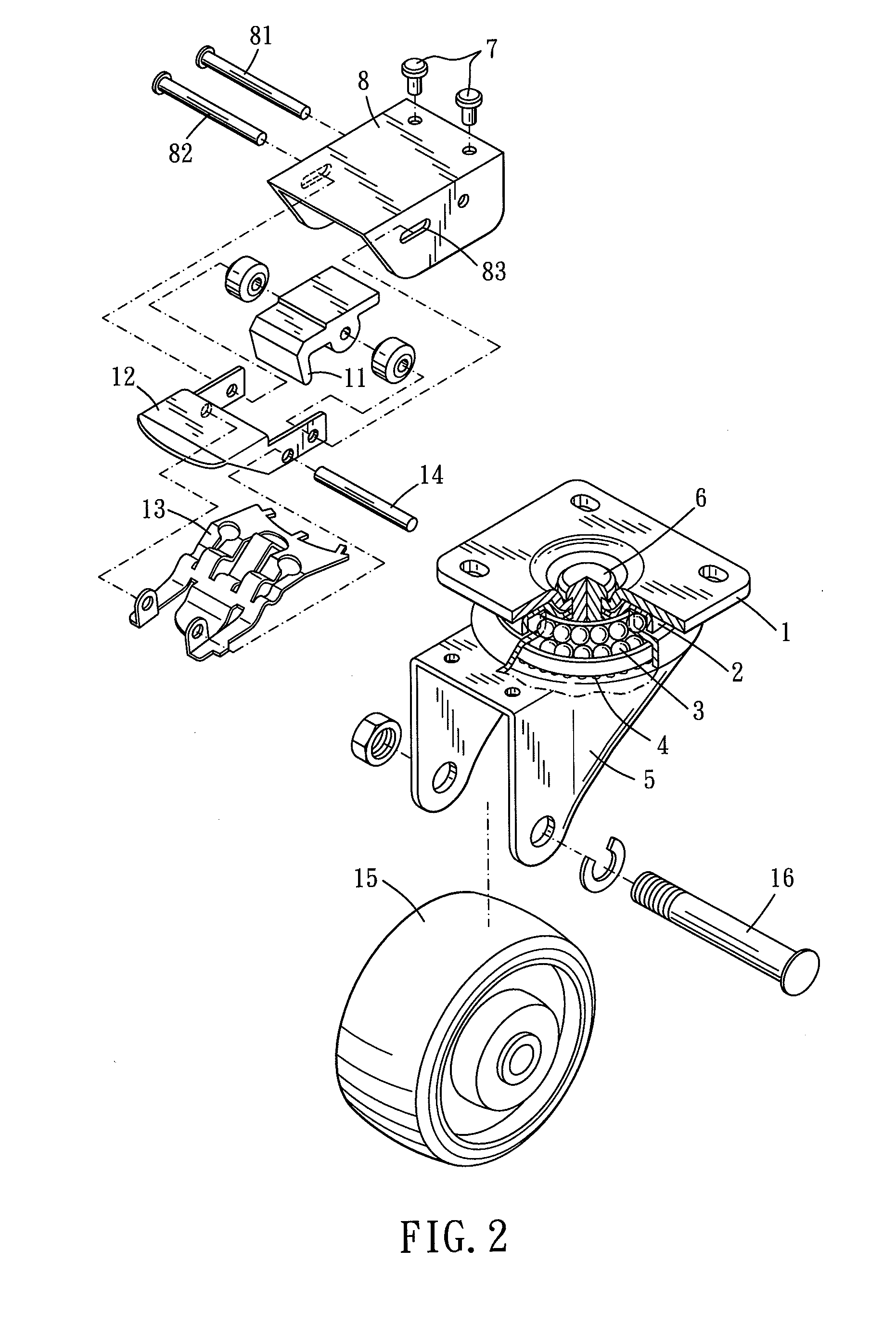

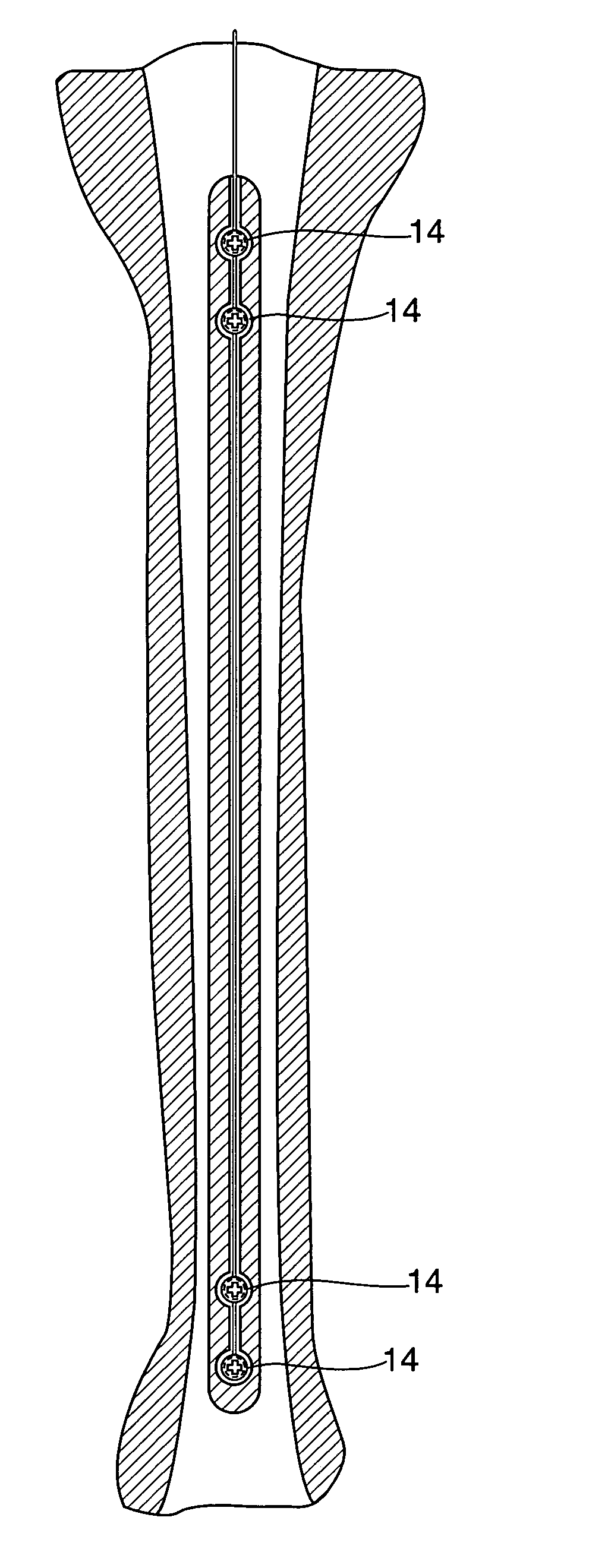

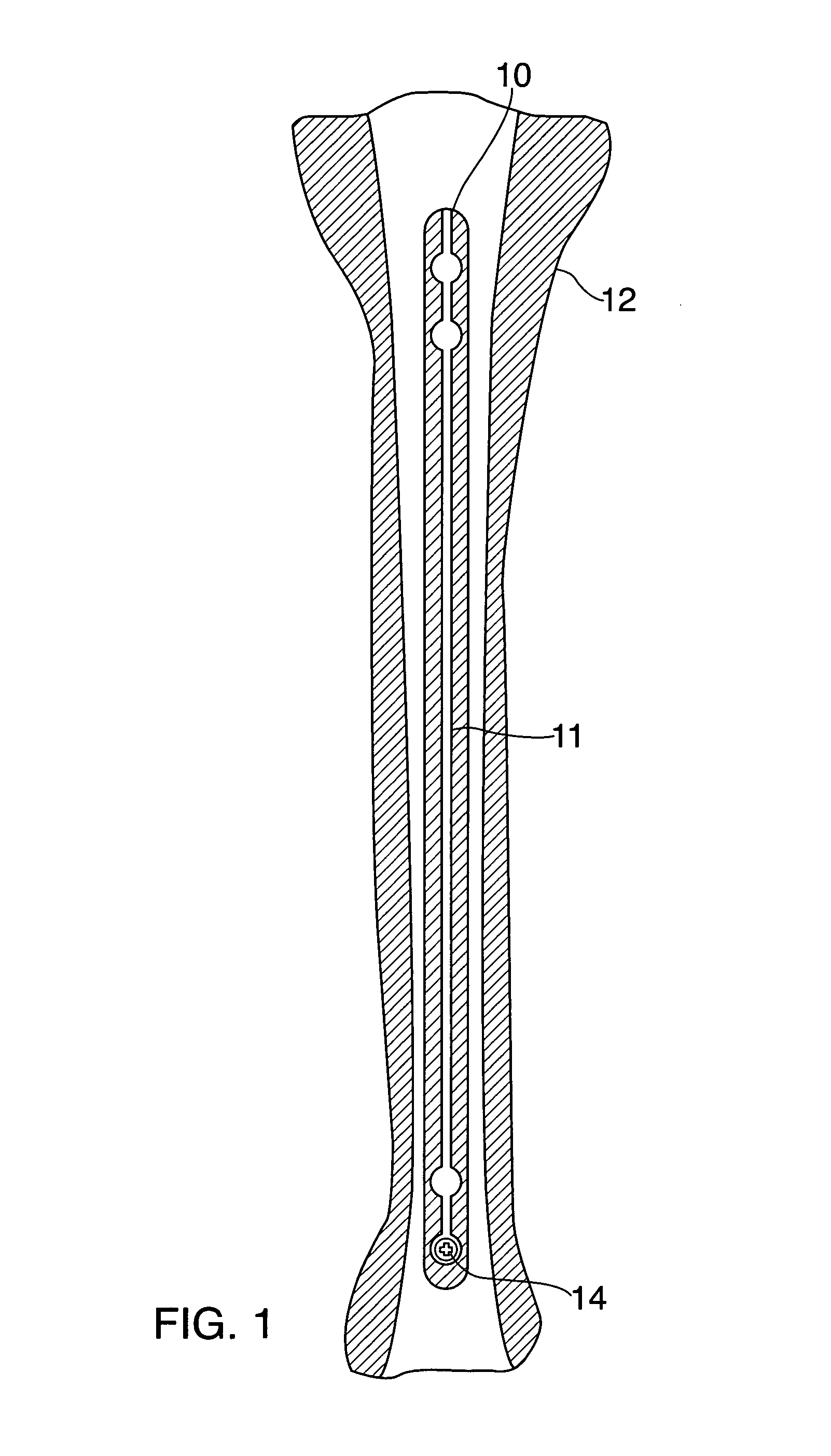

Caster assembly

InactiveUS20130212834A1Prevent both rolling and spinningCastorsMulti-purpose toolsStable fixationEngineering

A caster assembly of the present invention includes a fixation base, a rotary base which is rotatably disposed on the fixation base, a wheel which is rotatably disposed on the rotary base, and a brake mechanism. The brake mechanism is disposed on the rotary base. The brake mechanism can be activated to abut against the wheel and the fixation base, so that rotations of the rotary base and the wheel are obstructed. Thus, stably fixation function is provided.

Owner:DERSHENG

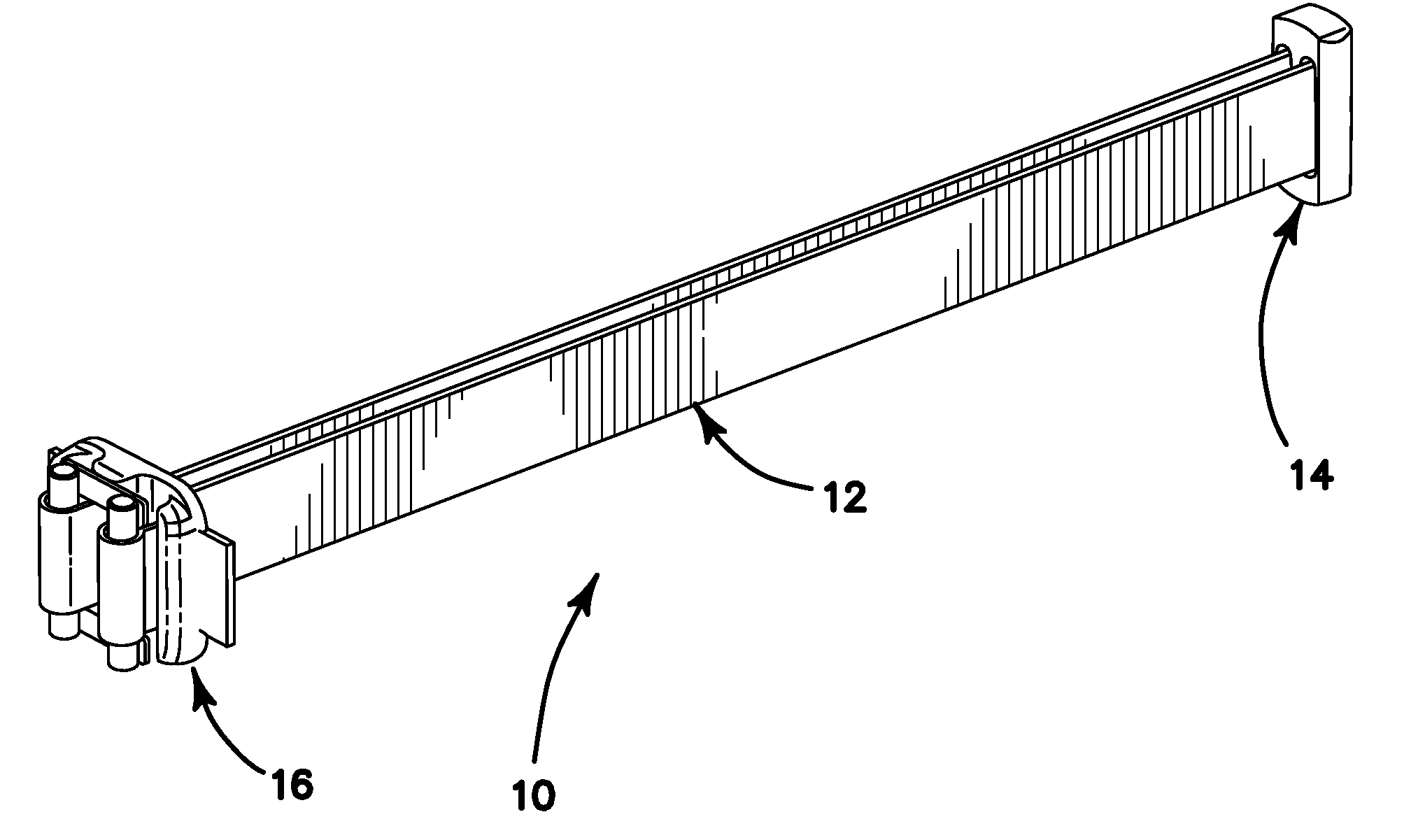

Interlocking IM Nails with threaded guidewire

InactiveUS7101376B2Loss of reductionStable formInternal osteosythesisJoint implantsStable fixationEngineering

Owner:SEMET ELLIOT CHARLES

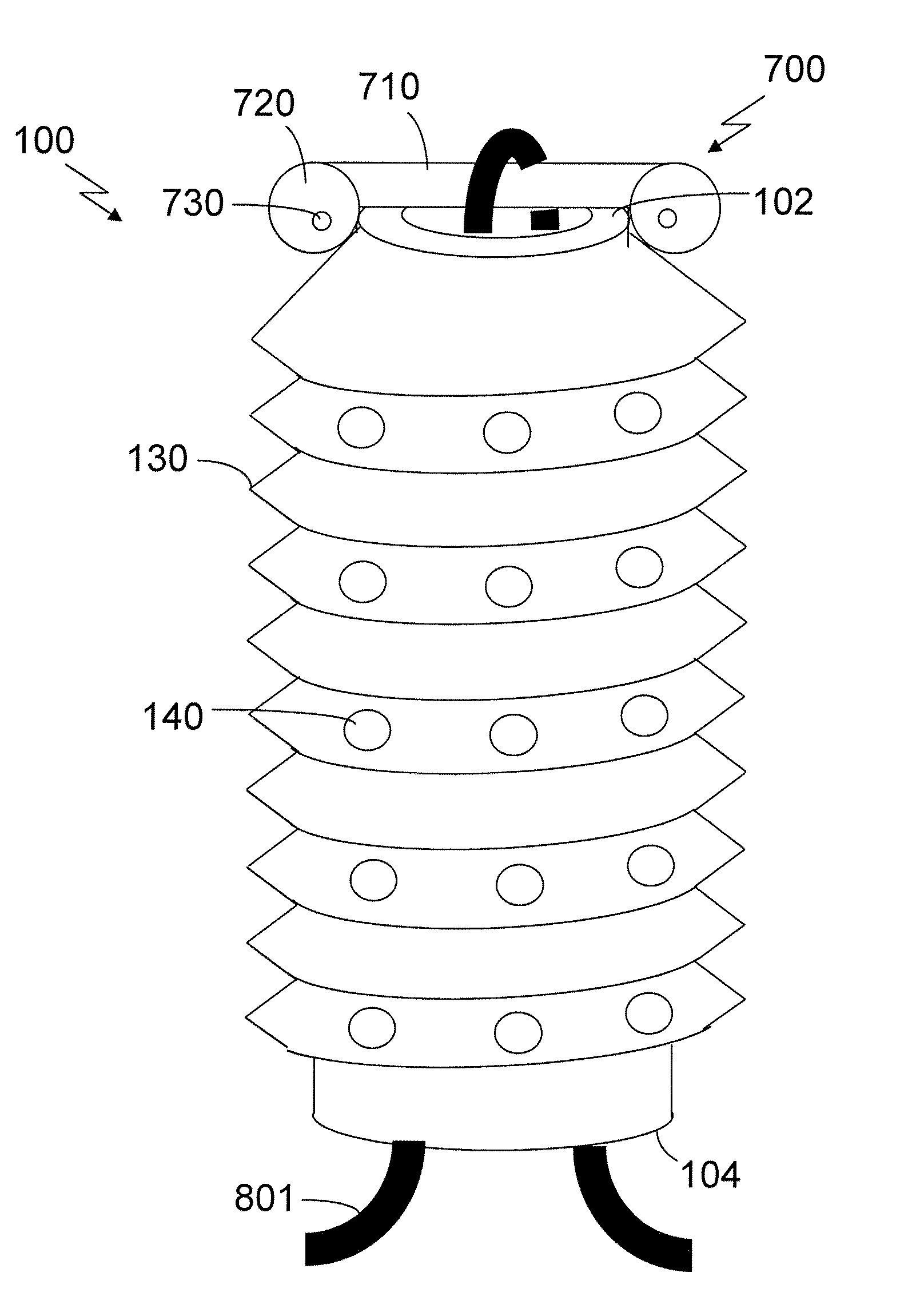

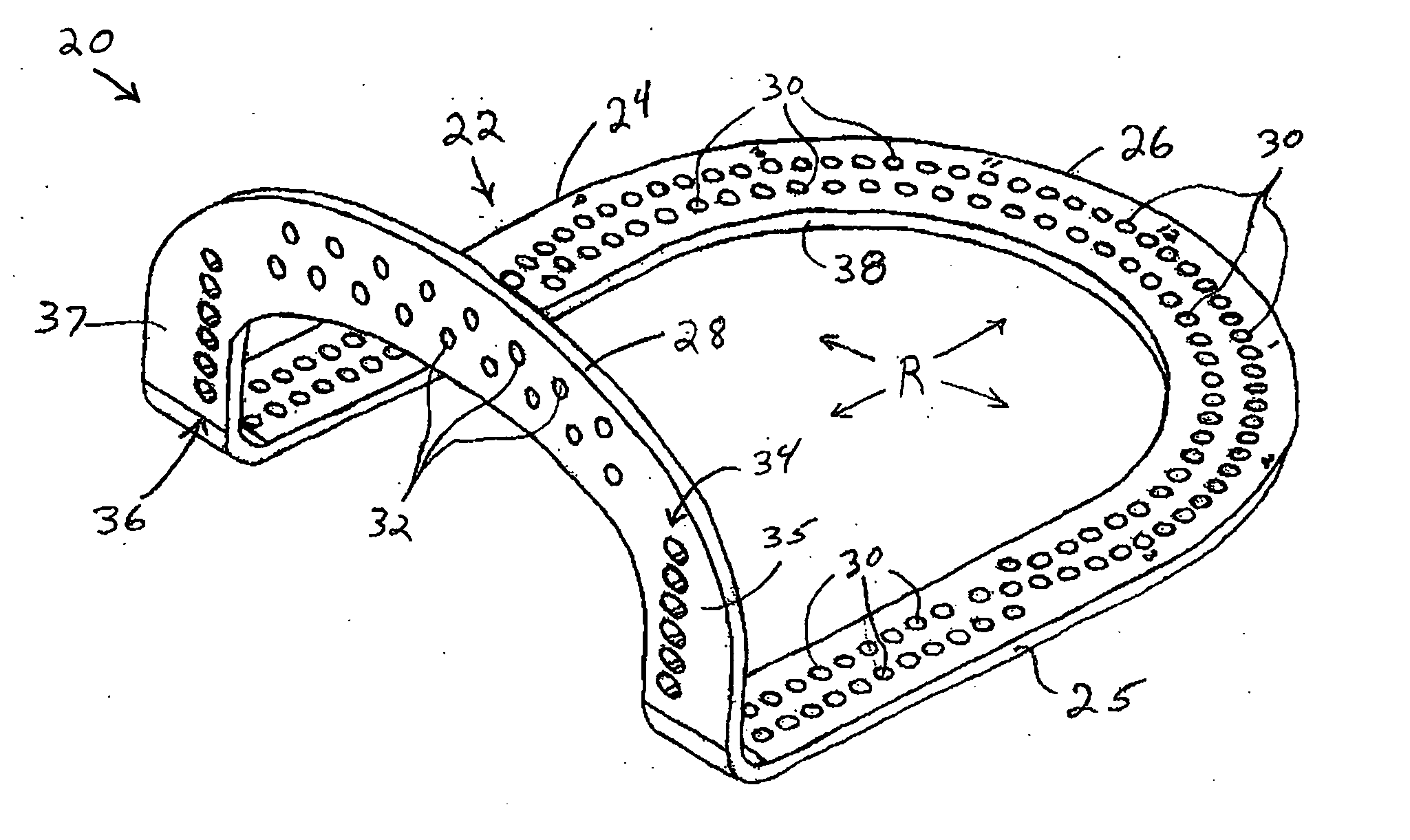

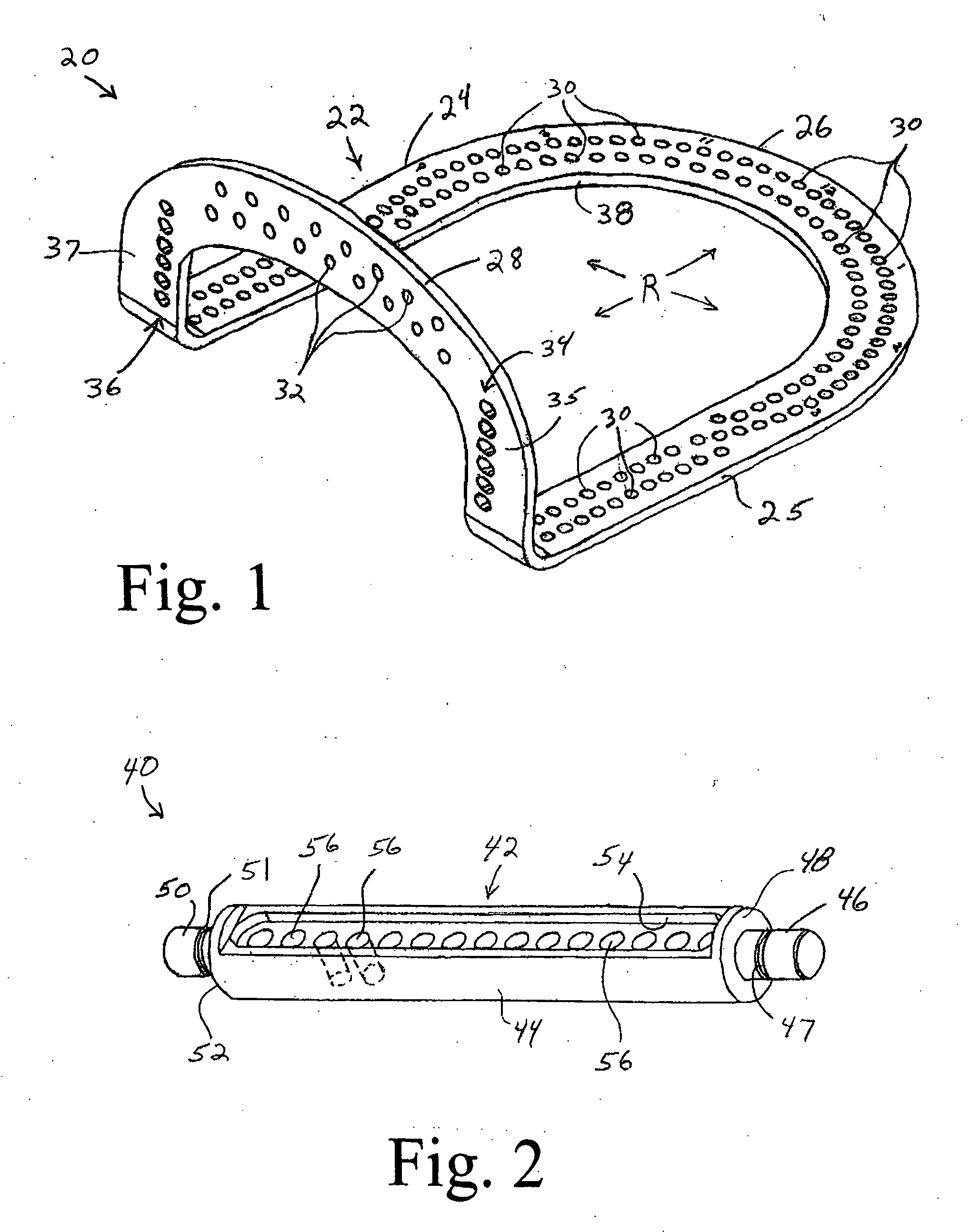

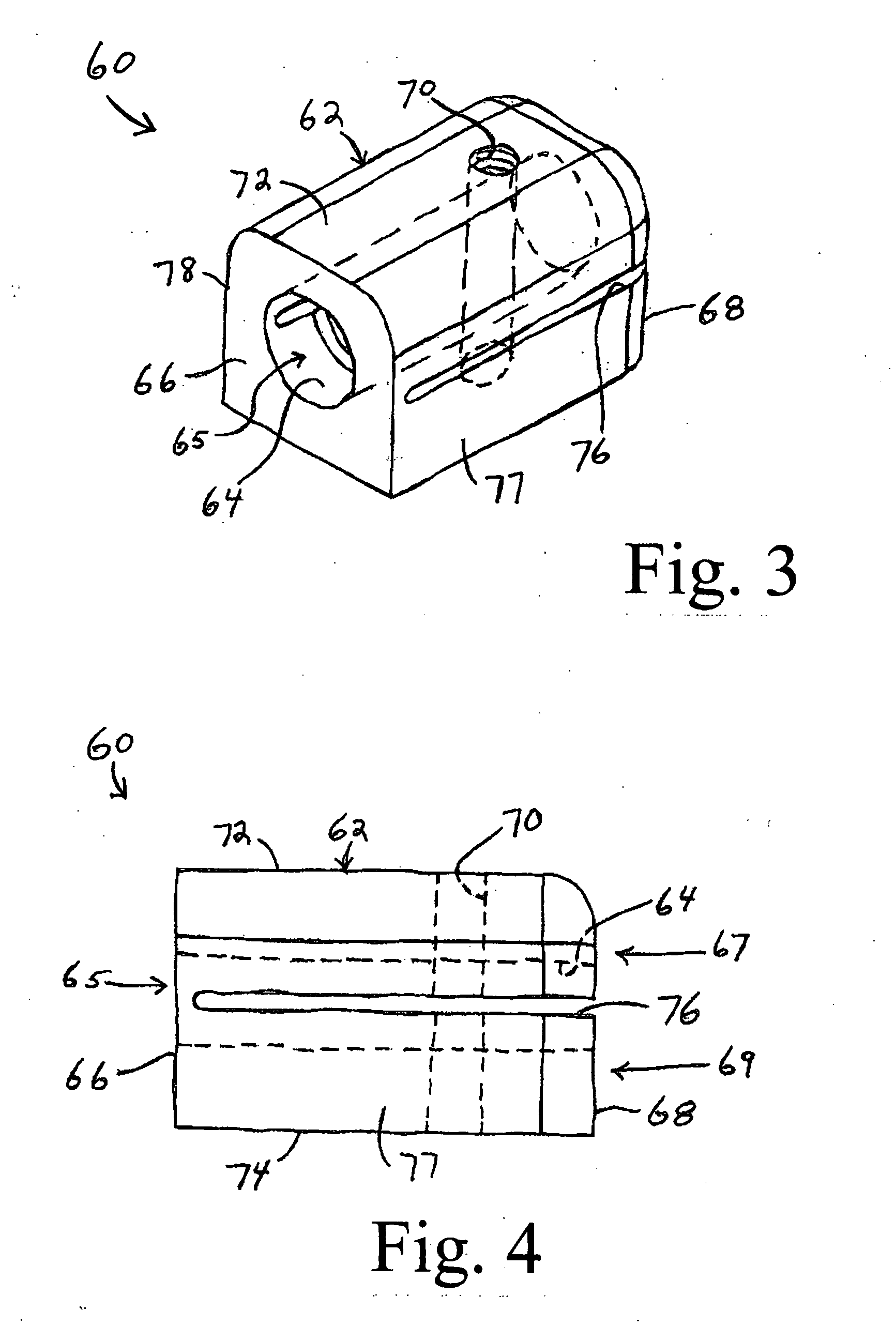

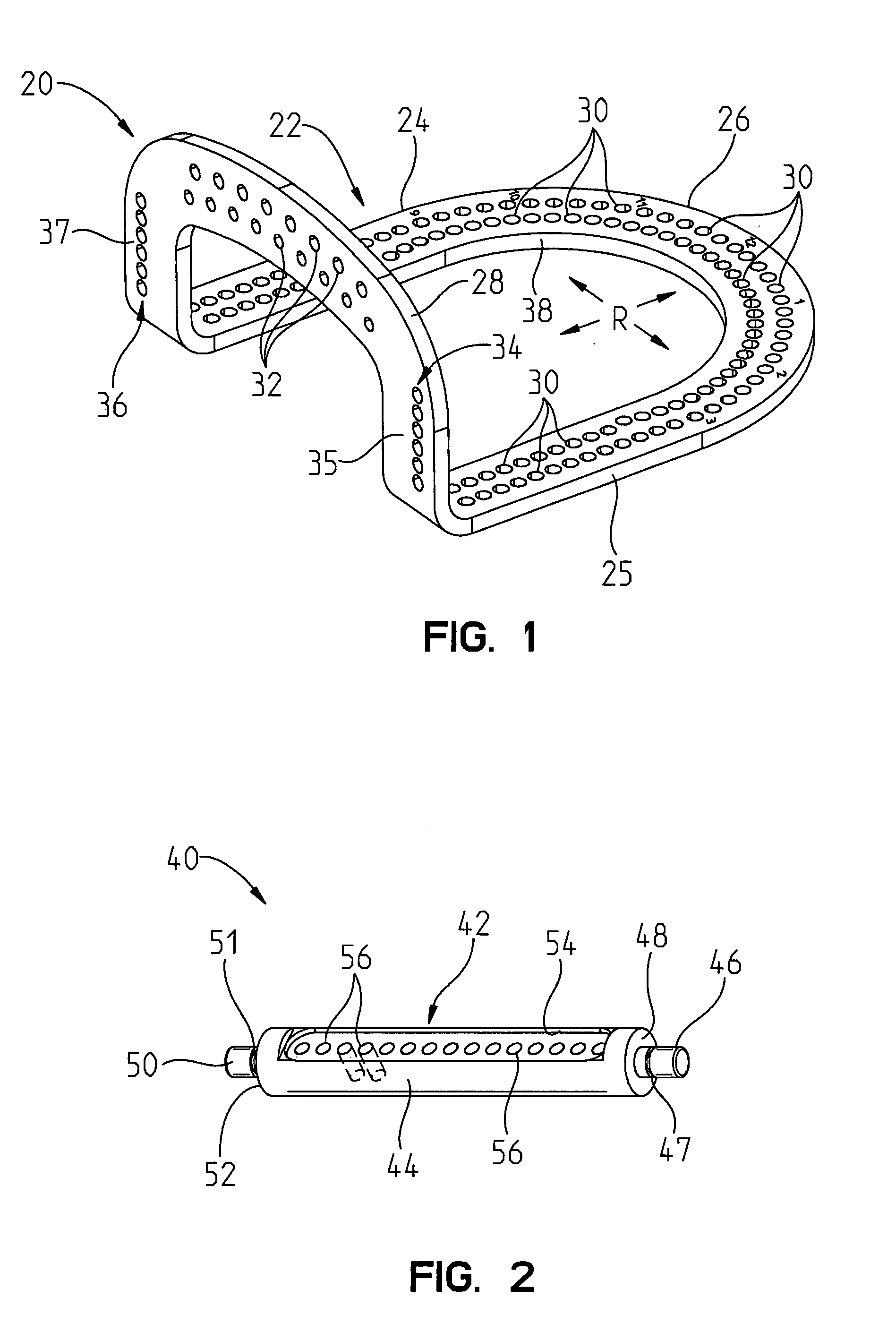

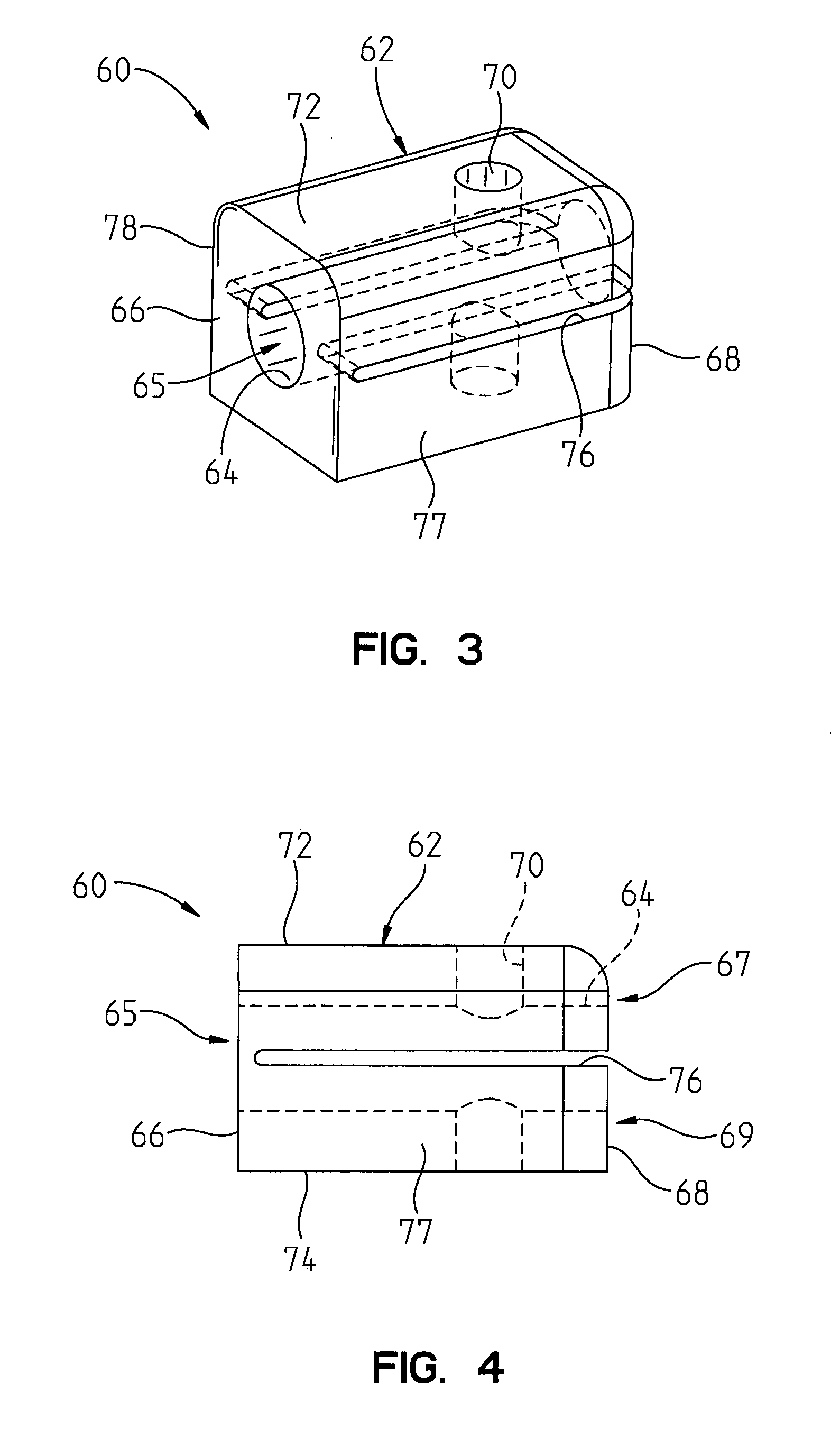

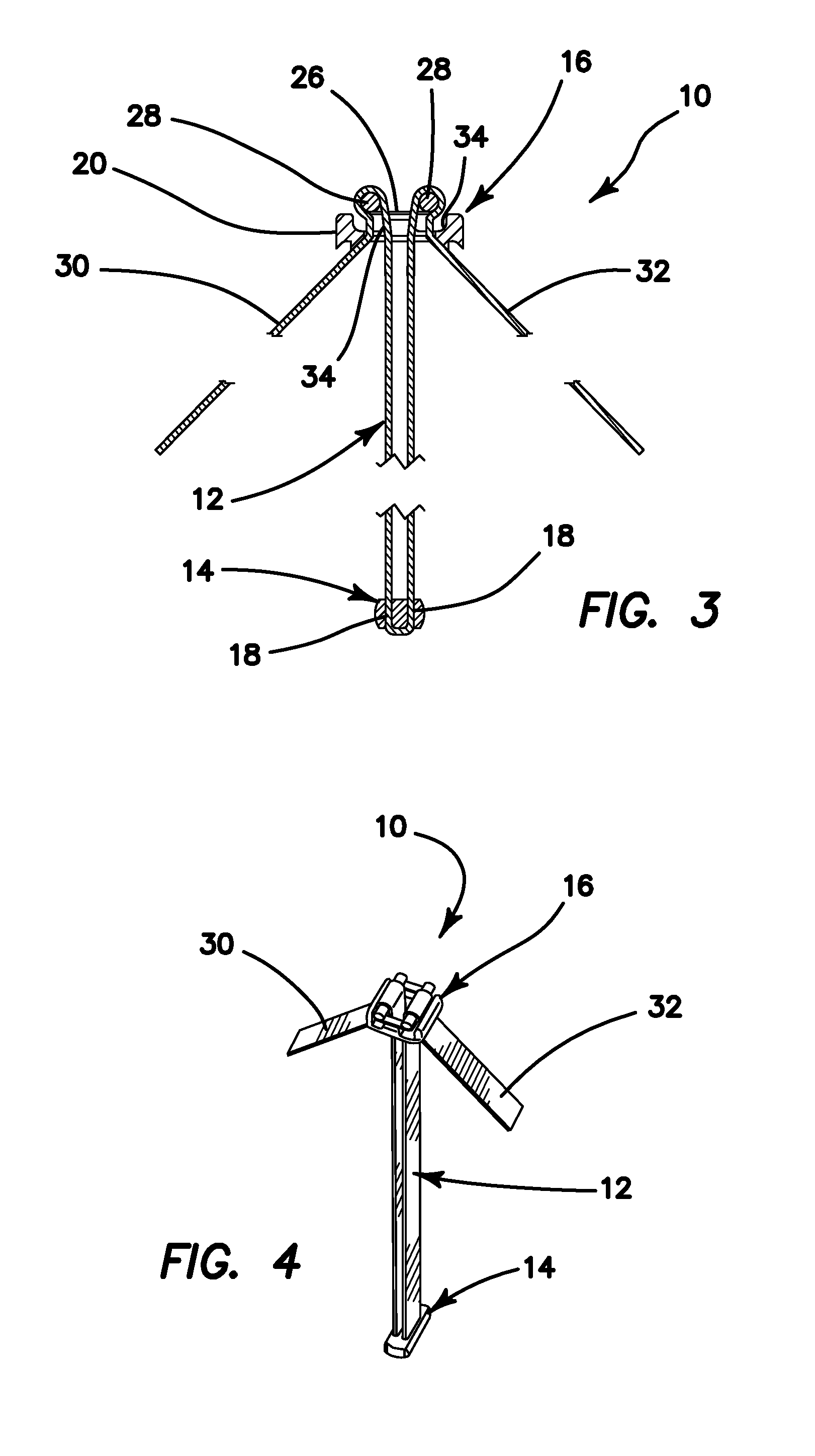

Implant device and system for stabilized fixation of bone and soft tissue

A system for syndesmosis repair includes a flat band secured to bone by pulling a metal button through both the tibial and fibula bones, which button is then toggled into position to create tension, along the band, across the two bone segments to be fixated. Once the button is secure against the bone, flat suture tails against the lock at the initial insertion site serves to tension the band and bone segments in place. The system band offers syndesmosis repair with a knotless closure. The system is designed to provide this stabilized fixation for bone fractures, osteotomies, and arthrodesis, plus soft tissue to bone attachment, if desired. It is designed to apply a restorative fixation force across the tissue segments to stabilize them. The band's rigidity and compliant nature provides consistent and rigid fixation during the healing phase.

Owner:DALLEN MEDICAL

Portable type electronic product fixing device

InactiveCN107166151AEasy to useEasy to carryStands/trestlesTelephone set constructionsStable fixationMechanical engineering

Owner:安徽赛度智能科技有限公司

Energy-saving type plastic pipe cutting and polishing device

ActiveCN108943103AEasy to fixAvoid damageRevolution surface grinding machinesMetal working apparatusStable fixationThreaded rod

The invention discloses an energy-saving type plastic pipe cutting and polishing device comprising a base plate. The left side and the right side of the bottom of the base plate are both fixedly connected with supporting seats. The left side and the right side of the top of the base plate are both fixedly connected with side plates. A supporting block is fixedly connected with the center point ofthe top of the base plate. A fixing plate is fixedly connected with the top of the supporting block. The top of the fixing plate is symmetrically provided with two sliding grooves. According to the energy-saving type plastic pipe cutting and polishing device, through mutual operation of the sliding grooves, arc clamping plates, fixing rods, reset springs, protective covers, pulleys, rotating shafts, coiling drums, steel wire ropes, gears, forward and reverse motors, forward and reverse rotating shafts, threaded rods, threaded sleeves and racks, the plastic pipe cutting and polishing device achieves a good fixing effect and can stably fix the plastic pipes of different diameters, the situation that in the cutting process, since the plastic pipe deflects, the plastic pipe is damaged is avoided, unnecessary economic loss is avoided, and the production cost is reduced for a factory.

Owner:宿迁市名扬建设工程有限公司

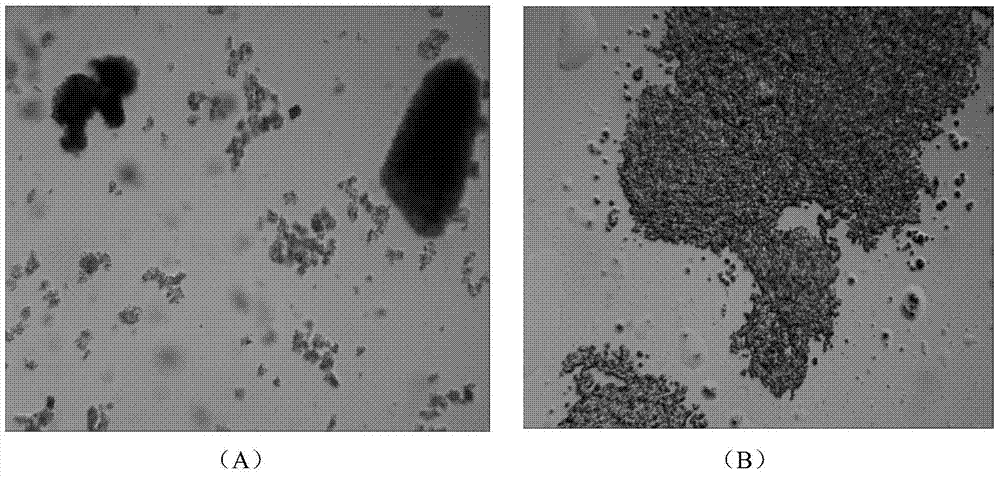

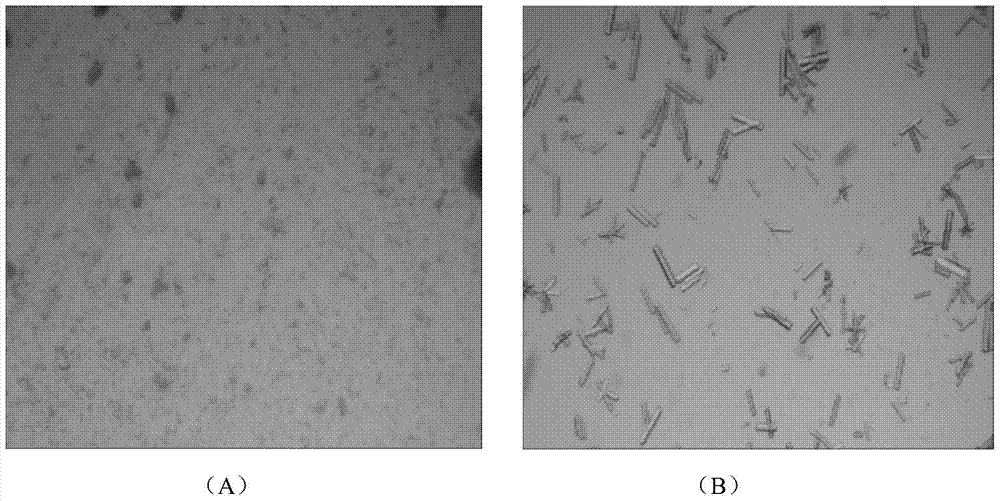

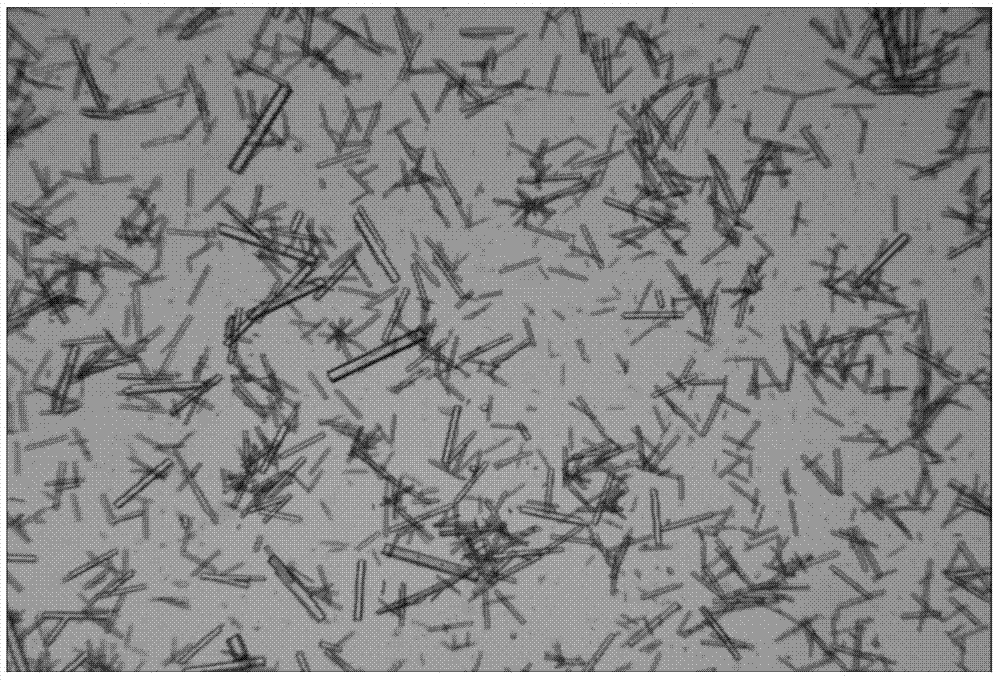

Preparation method and application of insulin detemir crystal

InactiveCN104761632AOvercoming crystallization difficultiesUniform and stable crystalInsulinsOrganic solventFreeze-drying

The invention discloses a preparation method and application of an insulin detemir crystal. The preparation method comprises the following step: under the conditions of a 0.1-0.2M trisodium citrate system and a 5-10 vol% organic solvent, crystallizing insulin detemir from a crystalline liquid containing insulin detemir, zinc ions, phenols and certain salts under the pH value of 8.0-8.5. The insulin detemir obtained by the preparation method has uniform and stable definite form, has the advantages of low sedimentation volume, high tendency to separation from the supernatant, short freeze-drying time and high production efficiency, and is suitable for industrial production.

Owner:ZHUHAI UNITED LAB

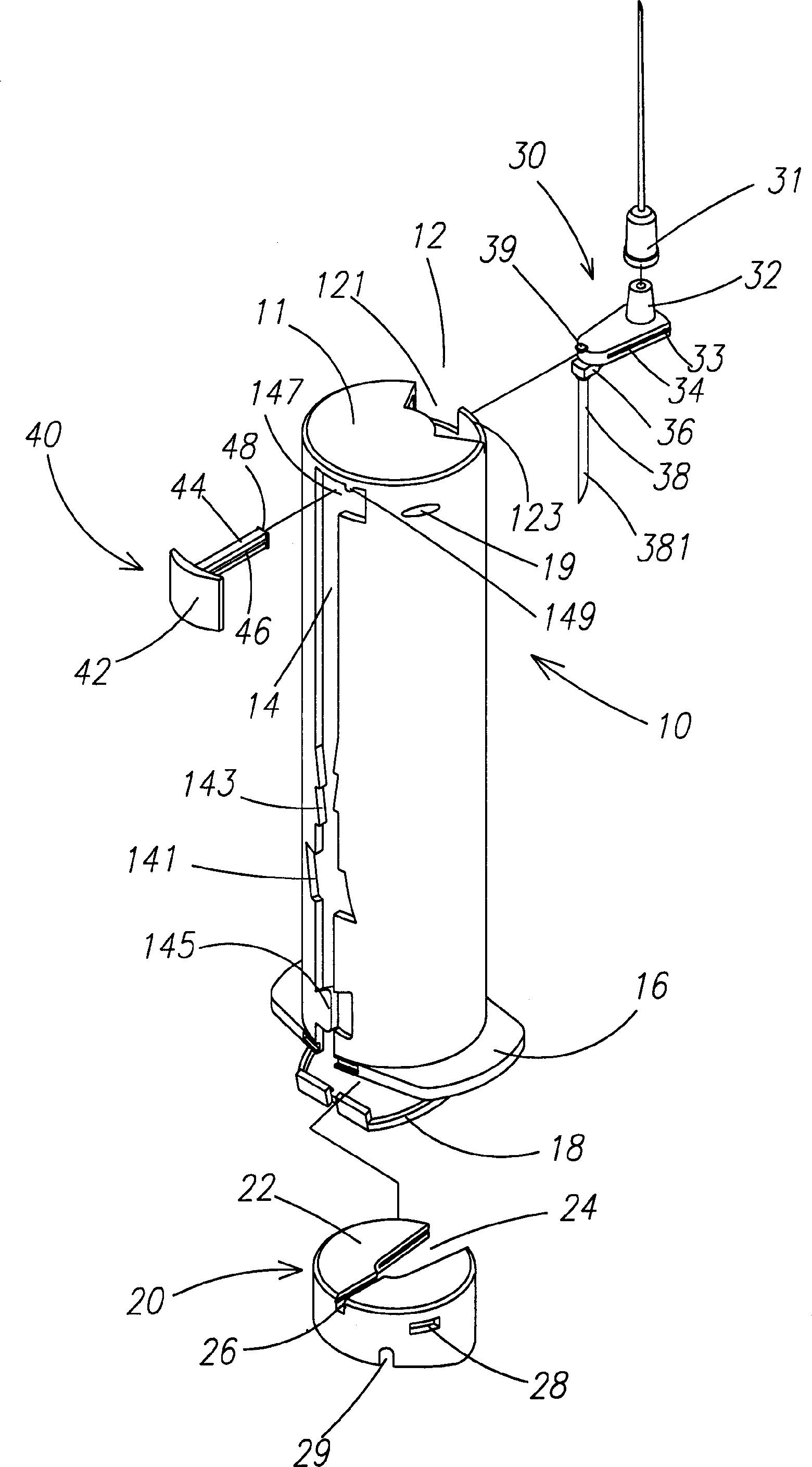

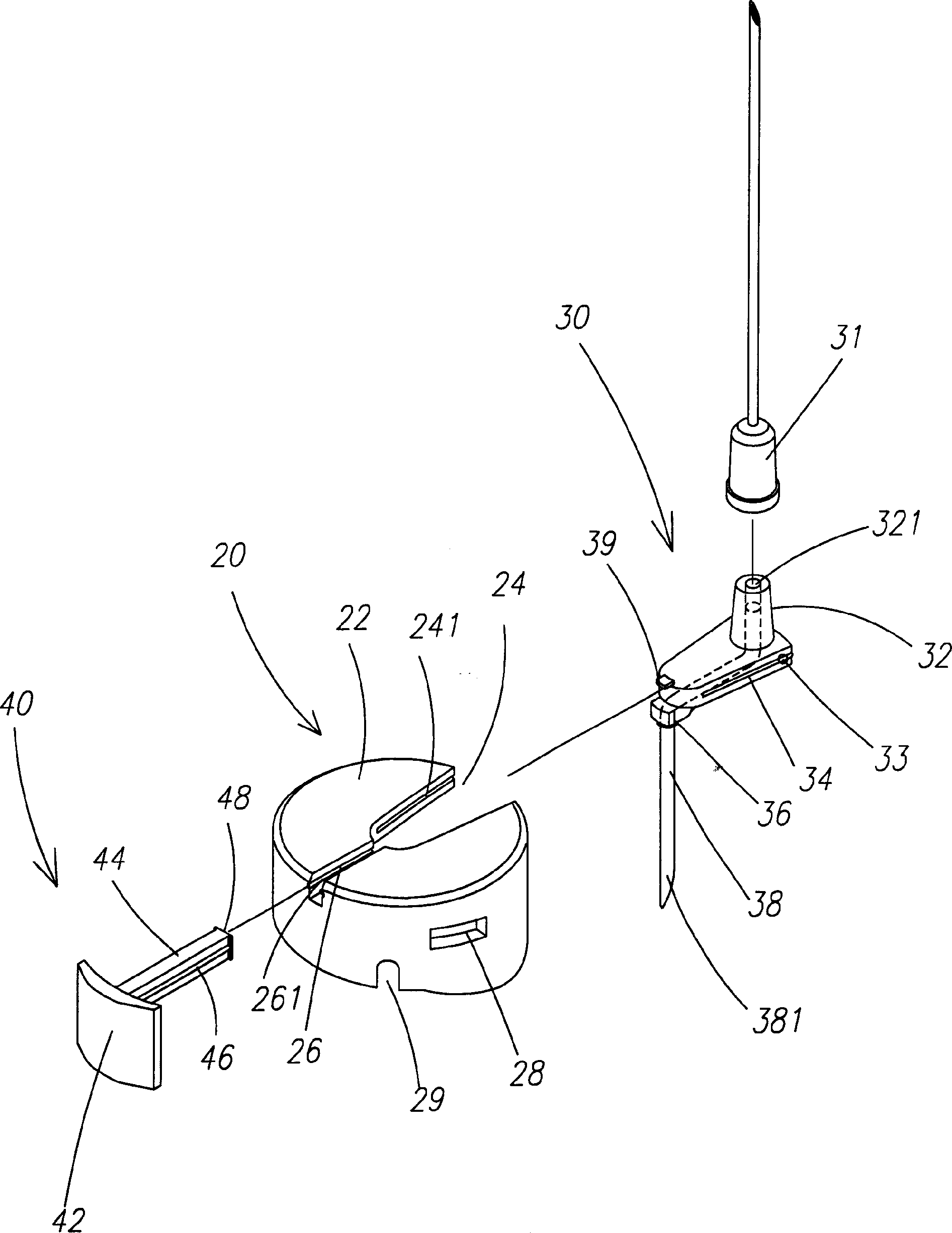

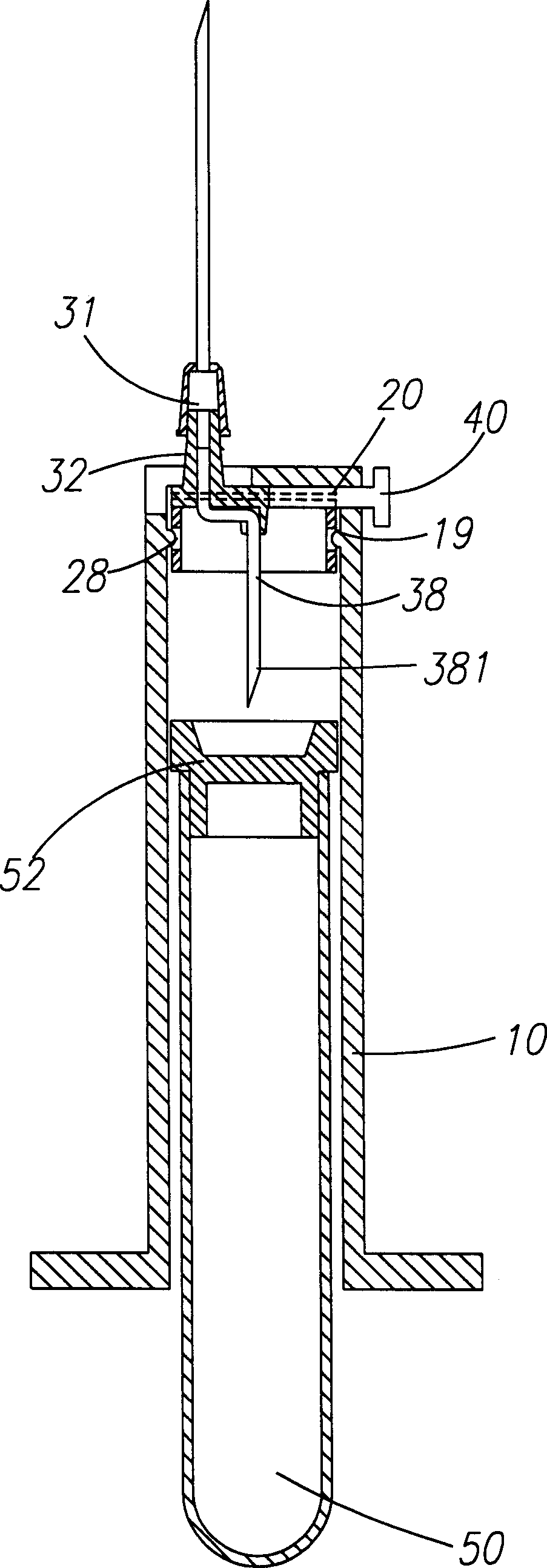

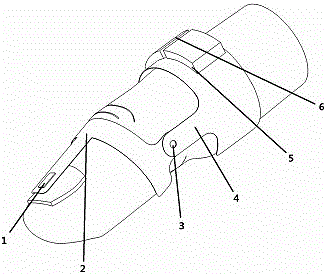

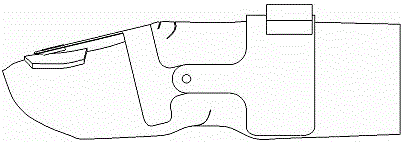

Multifunctional safety vacuum blood drawing ergonomic syringe

The multifunctional safe phlebotomizing syringe includes one hollow needle tube with one eccentric opening in the top and one guide slot in the side, one inner sleeve inside the needle tube with one pressing board and one needle seat, and one double-L shaped needle fixed to the inner sleeve with lower tip in the axis of the needle tube. The present invention may be combined with one vacuum bloodsampling cup, and by means of the said structure the needle may be fixed inside the needle tube or detached conveniently to protect medical staff and protect environment.

Owner:陈晖纮

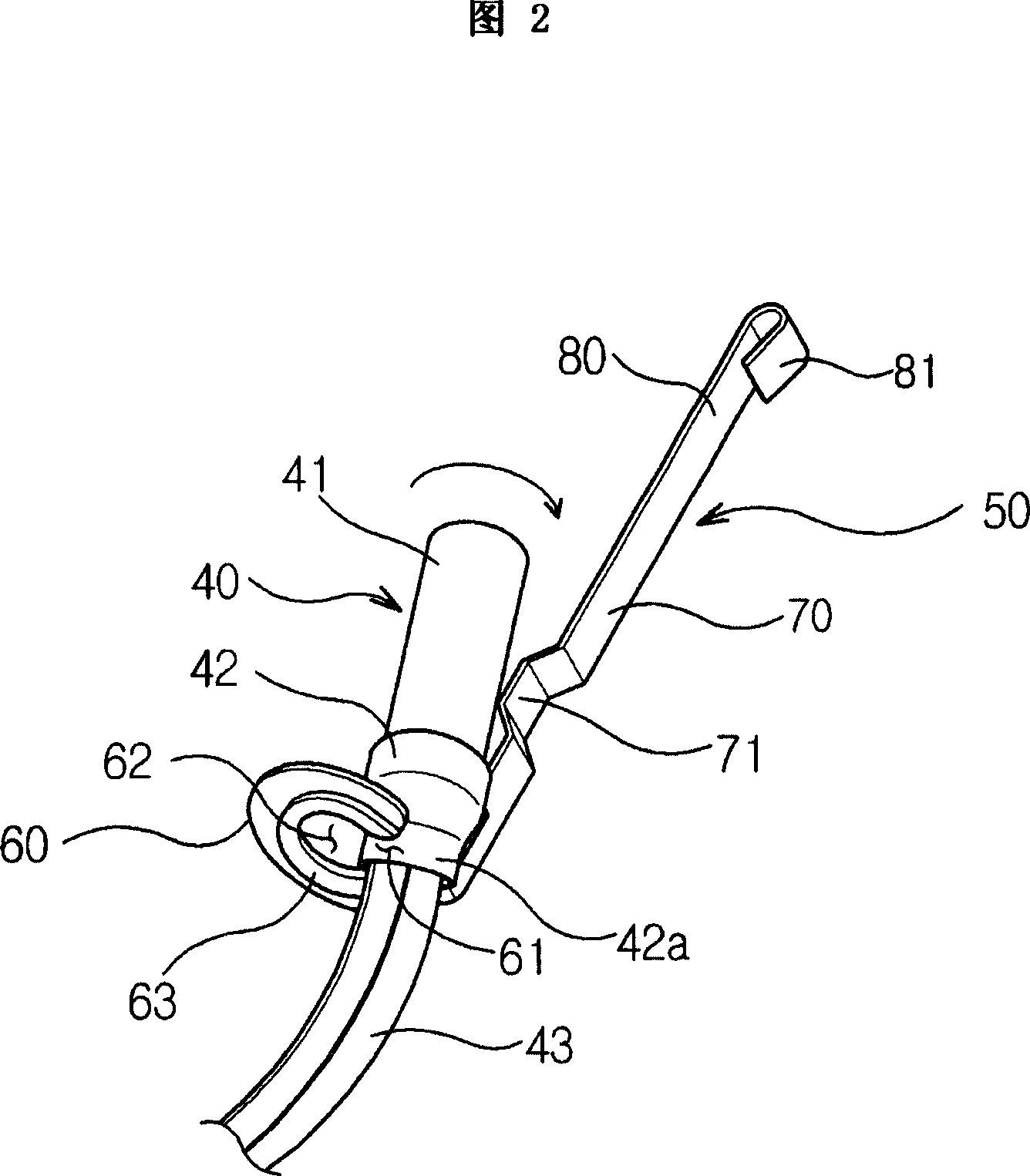

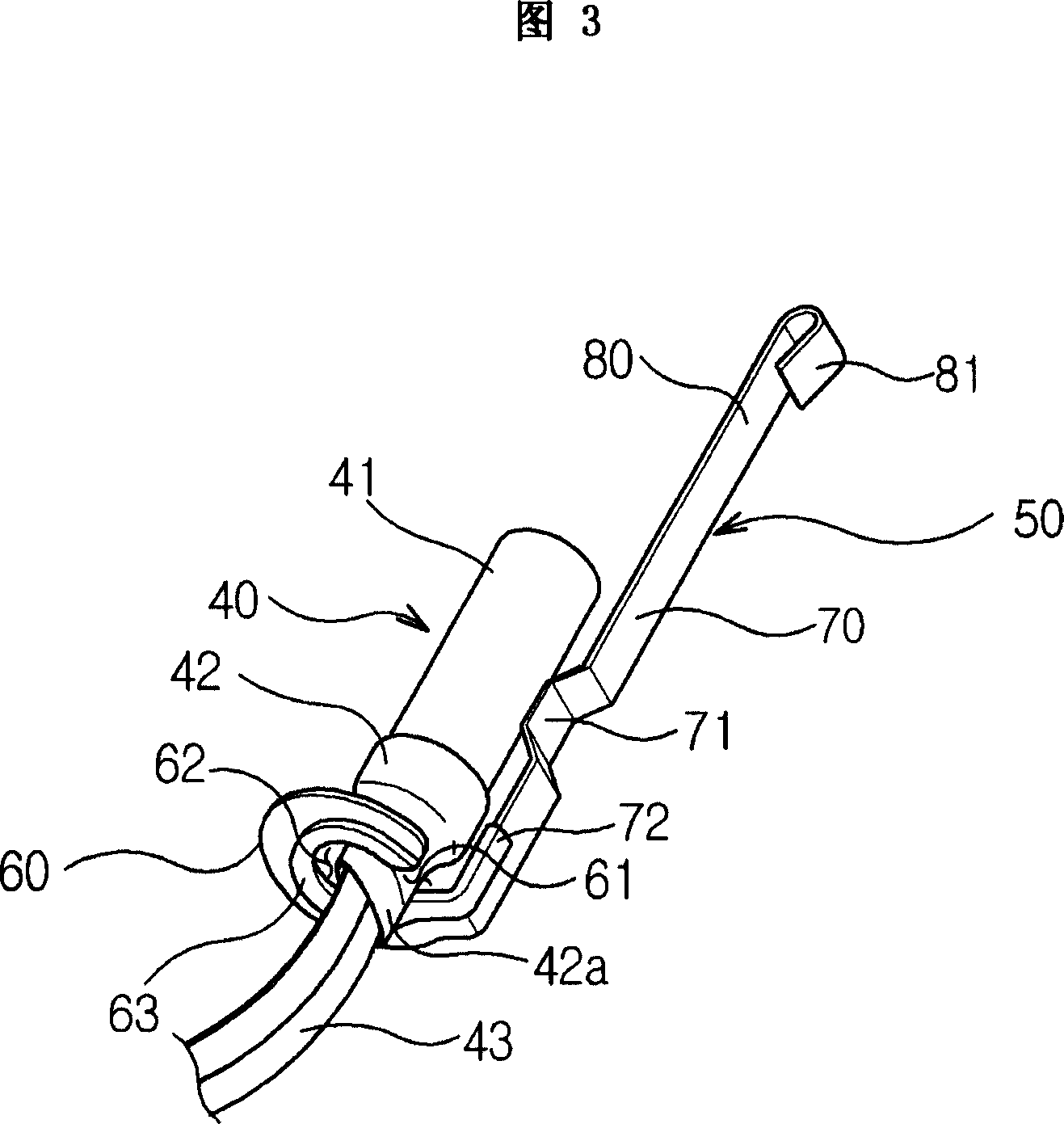

Temperature sensor fixing apparatus and air conditioner having the same

InactiveCN1979104APrevent disengagementFixed state stableThermometer detailsMechanical apparatusStable fixationRefrigerant

The invention discloses a temperature sensor fixing apparatus and an air conditioner having the same, which is used for preventing the temperature sensor from being detached from a mounted position and used for holing the temperature sensor in a stable fixing state even if being subjected by impact or durative vibration. The temperature sensor fixing apparatus provided in the invention includes a sensor fixing clamp and a fixed portion embeded in the sensor fixing clamp, the fixed portion has a retaining ring region for accepting an end portion of the temperature sensor, an adhering region for adhering the temperature sensor to the sensor fixing clamp, and a fixing region for fixing the fixed portion to the sensor fixing clamp. An adhering portion which is bended in a side direction is formed in the adhering region to enable a detection unit to be adhered and be fixed at an inner surface of the sensor. The temperature sensor fixing apparatus is combined with a cooling tube in the air conditioner by the sensor fixing clamp, so that the temperature sensor can detect the temperature of a coolant on the air conditioner.

Owner:SAMSUNG ELECTRONICS CO LTD

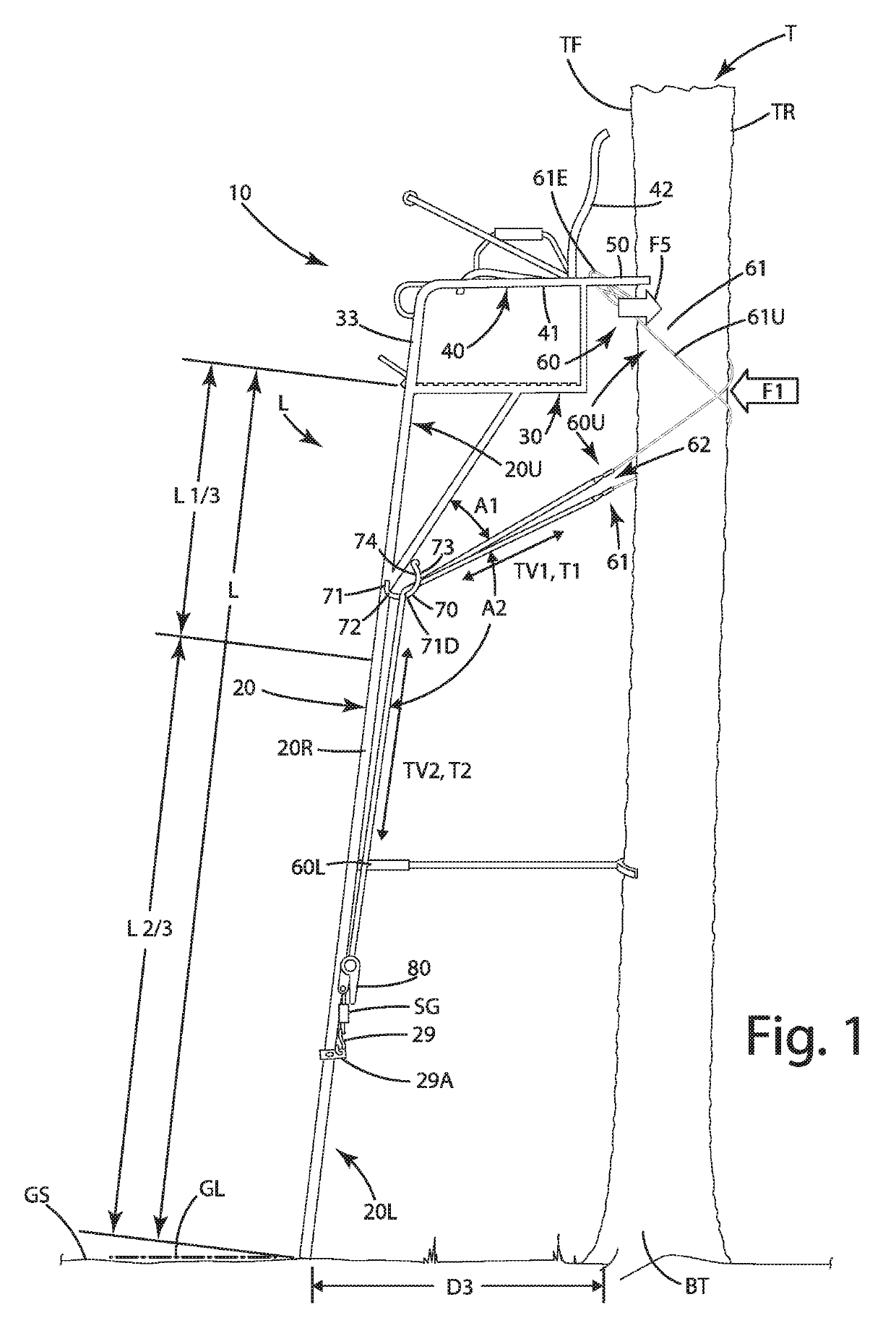

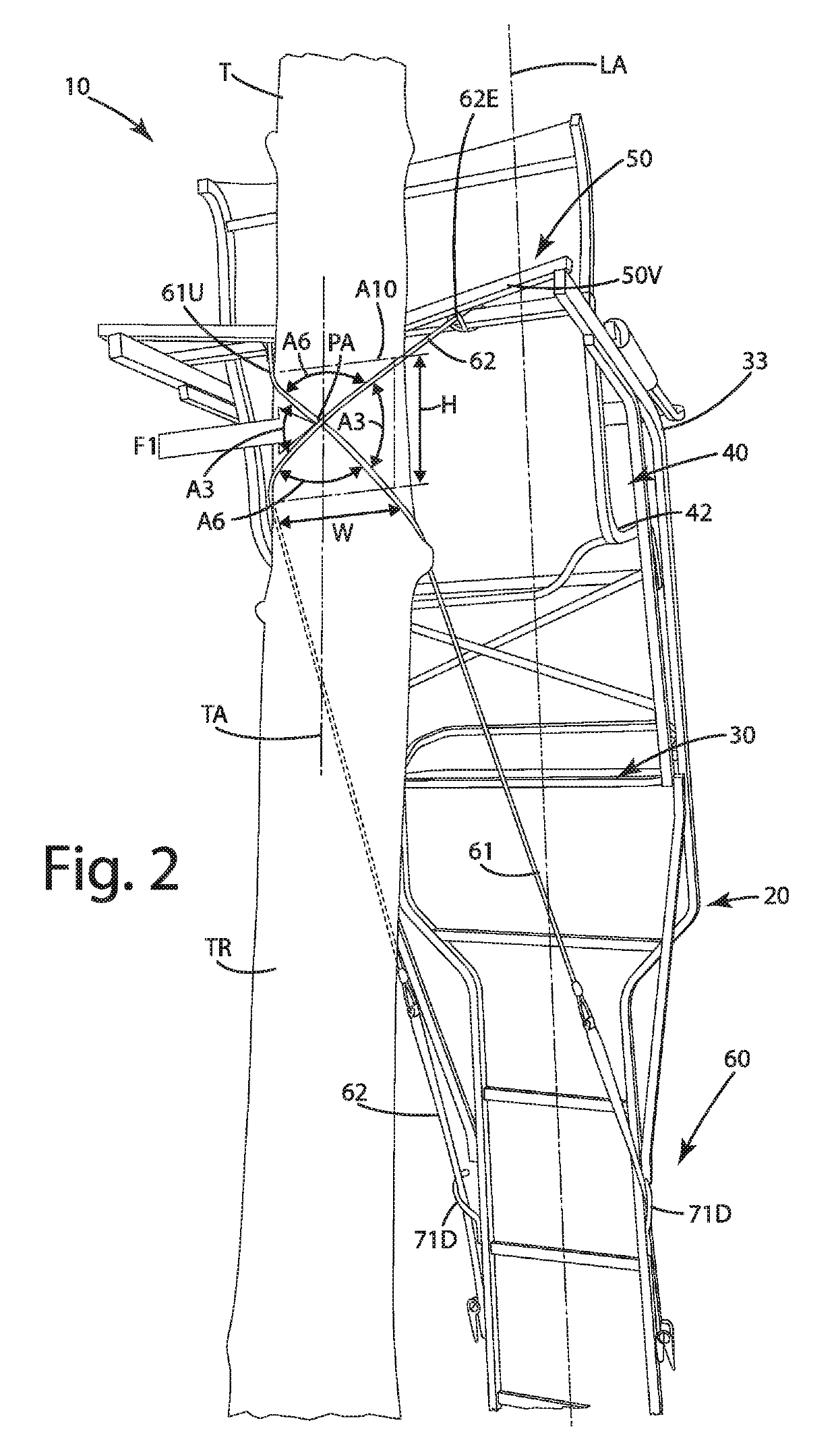

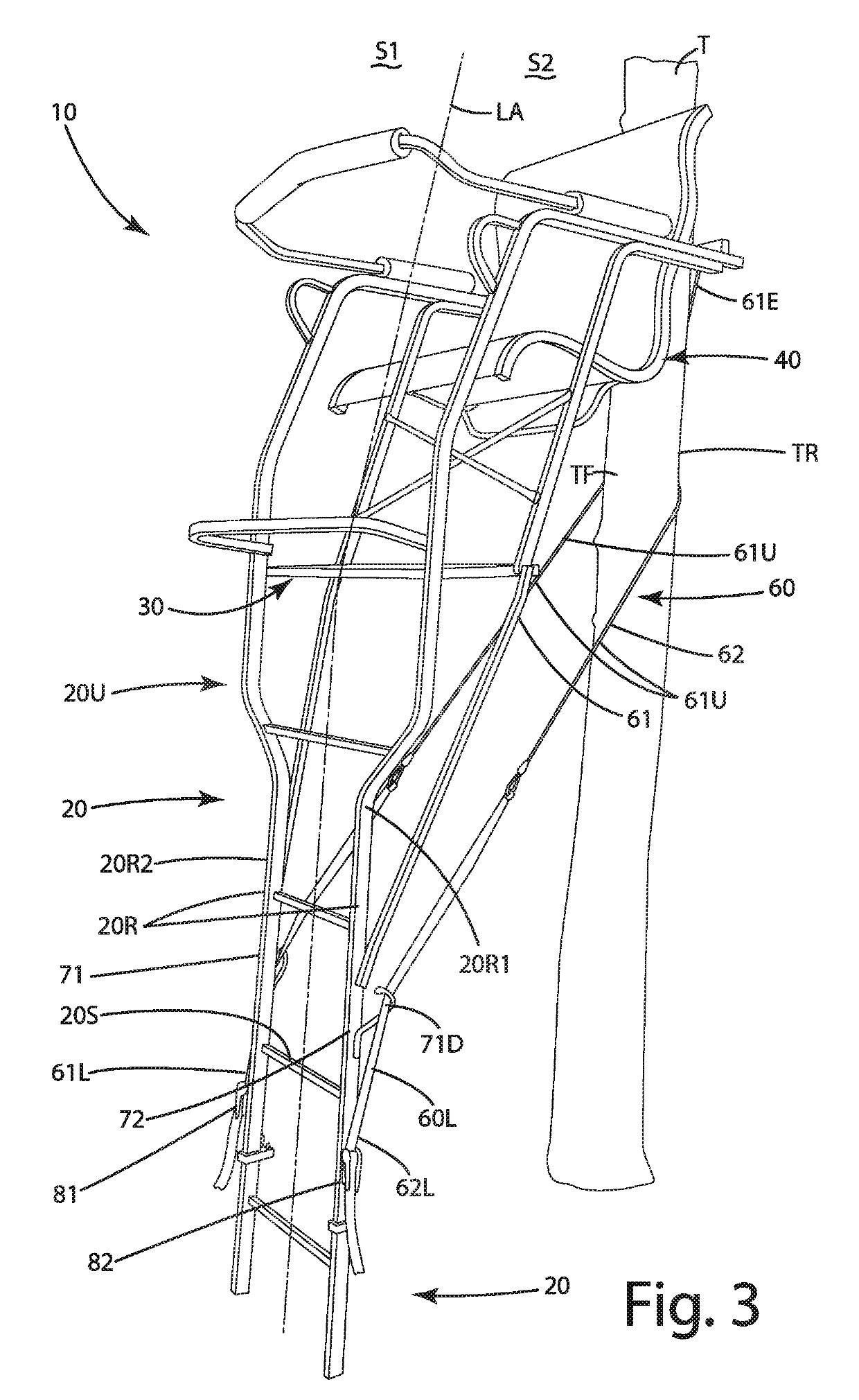

Ladder stand and related method of use

A ladder stand includes a ladder, a platform, an optional seat, a tree engagement bracket, straps and strap diverter guides. The straps can be crisscrossed around the rear of the tree and extend forwardly to respective strap diverter guides. These guides can redirect the straps from a generally acute angle relative to the ladder to an orientation substantially parallel to the ladder, with the lower portions of the straps extending downwardly along the ladder. One or more tensioners can provide tension in the straps, thereby pulling the bracket into the tree under significant force to provide safe and stable securement of the ladder stand to the tree. The strap tensioning can be accomplished by a user on the ground, without ever having to climb the ladder or secure any additional straps to the tree. A related method of use is provided.

Owner:GOOD SPORTSMAN MARKETING LLC

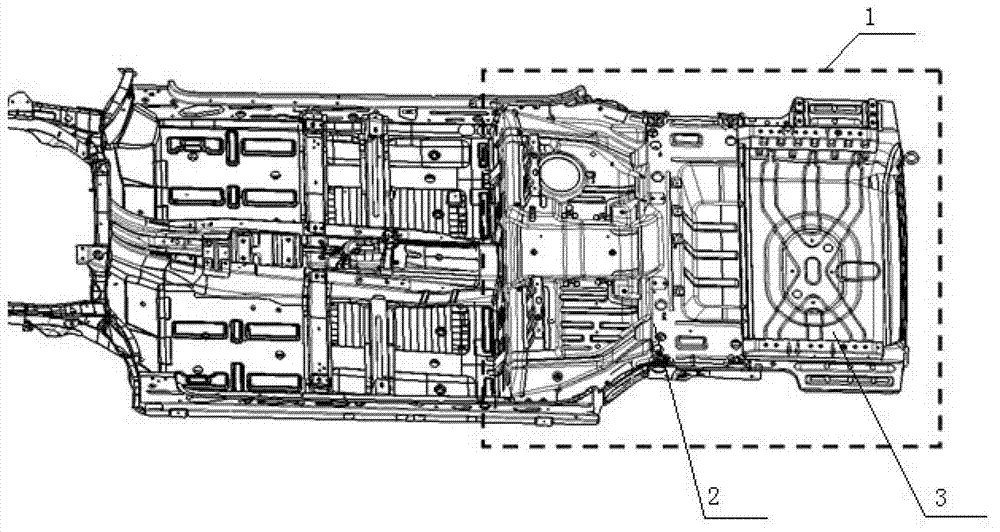

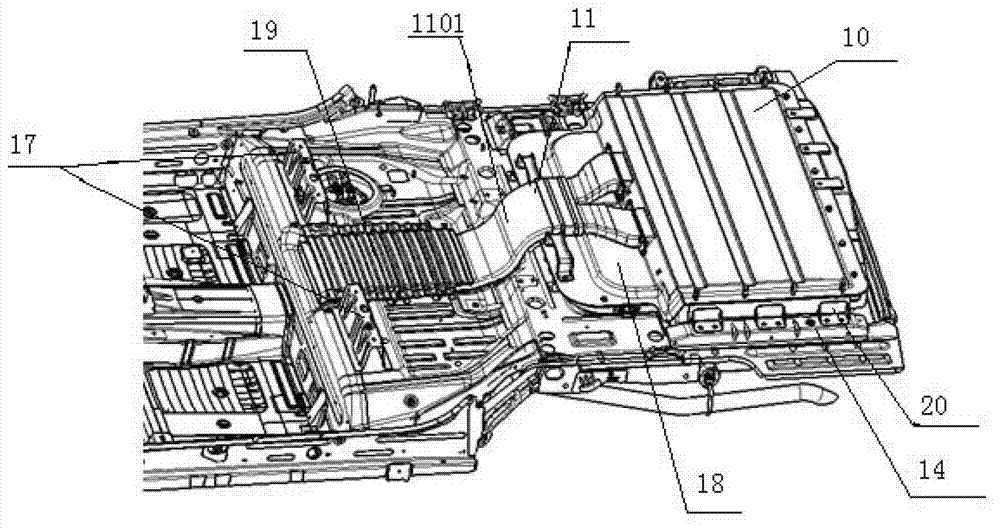

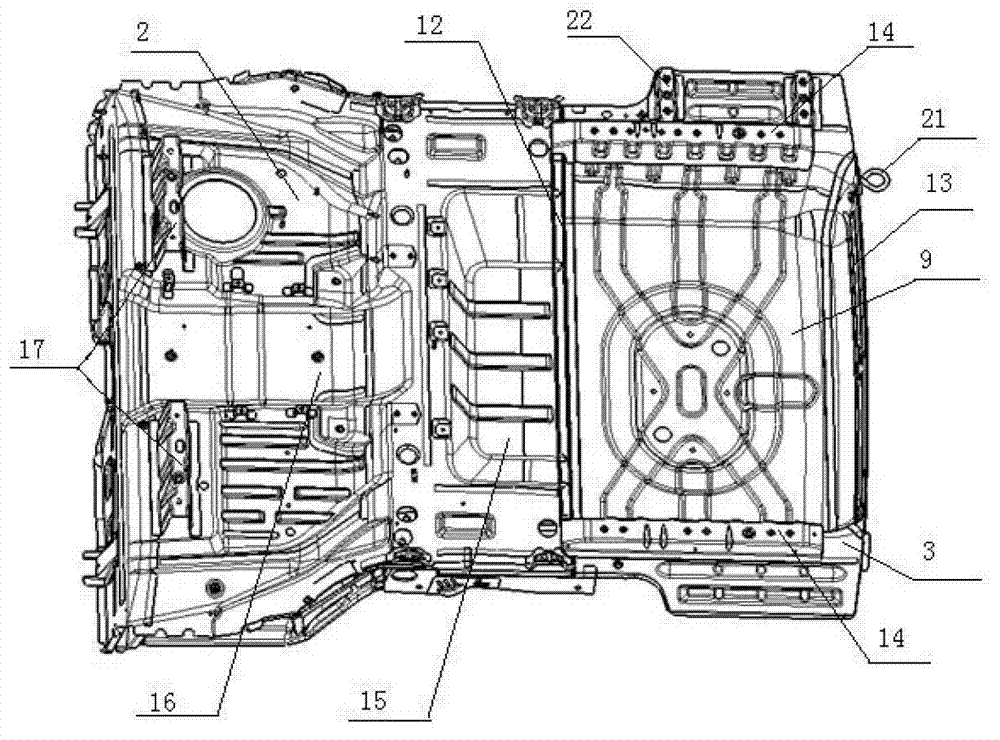

Rear floor assembly structure for plug-in hybrid electric vehicle

ActiveCN102897228AGuaranteed StrengthEnsure safetyElectric propulsion mountingSuperstructure subunitsStable fixationFuel tank

The invention discloses a rear floor assembly structure for a plug-in hybrid electric vehicle, which comprises a rear-floor front part and a rear-floor rear part, wherein a left side longitudinal beam and a right side longitudinal beam extending to the downside of the rear-floor rear part are respectively arranged on the two sides of the downside of the rear-floor front part, a cross beam is connected between the left side longitudinal beam and the right side longitudinal beam below the rear-floor front part and is connected with a fuel tank and an exhaust pipe muffler, a battery compartment is arranged on the rear-floor rear part between the left side longitudinal beam and the right side longitudinal beam, a battery pack is hung above the battery compartment, the front end of the battery pack is connected with a battery cooling system, and the battery cooling system is fixed above the rear-floor front part. According to the rear floor assembly structure, a mode of directly loading floors in the conventional thinking is abandoned, but the battery pack is hung above a rear floor at the bottom of a suitcase and loaded on the side longitudinal beams, so that the strength is ensured, and meanwhile a stable fixation state is formed; and through reasonable partitioning, spaces above and below the rear floor are fully used, so that the function components such as the battery pack and the cooling system thereof, the fuel tank and the exhaust pipe muffler are reasonably arranged on a vehicle body.

Owner:DONGFENG MOTOR CORP HUBEI

Glue pressing device for wood furniture processing

InactiveCN108943204AAvoid affecting the glue effectEasy to fixWood veneer joiningAdhesive application devicesHydraulic cylinderStable fixation

The invention discloses a glue pressing device for wood furniture processing. The glue pressing device comprises a supporting base, the outer walls of top four corners of the supporting base are all connected with vertically-arranged supporting columns through bolts, the top outer walls of the four supporting columns are all connected with one same horizontally-arranged supporting top plate through the bolts, the top central outer wall of the supporting top plate is connected with a glue storage box through the bolts, the outer wall of one side of the bottom of the glue storage box is connected with a glue guide flexible pipe through the bolts, and the bottom central outer wall of the supporting top plate is connected with a vertically-arranged hydraulic cylinder through the bolts. According to the glue pressing device for the wood furniture processing provided by the invention, by means of the manners that electric stretching and contracting rods and fixing clamping plates are provided and the fixing clamping plates are driven to move by the electric stretching and contracting rods, wood furniture plate materials of different sizes can be fixed, the quite stable fixing effect is achieved, and the situation that the plate materials are loosened to affect the glue pressing effect in later glue pressing is avoided.

Owner:湖北乔木森家具有限公司

Display support having multi-azimuth adjusting function

The invention discloses a display support having a multi-azimuth adjusting function. The display support comprises a base plate, a sleeve, a screw and a nut, wherein a plane thrust bearing is arranged between the nut and sleeve, a bearing seat is arranged on the base plate, the sleeve is fixed to the base plate through a bearing arranged on the bearing seat, and a first friction plate is arranged at the lower end of the sleeve. The display support further comprises a brake device. The height of a display main body can vertically adjusted conveniently by rotating the nut, the using demands of users different in height can be met, the problem that the users need to stoop down and lower their heads to view a display is solved, and health protection of the computer users is facilitated. The display main body can be conveniently turned in a horizontal plane to be at a required angle by turning a handle to loosen a second friction plate, the first friction plate and the second friction plate are combined during handle turning, the display main body can be stably fixed, accordingly the problem that an existing display is difficultly turned in the horizontal plane is solved, and computers are more convenient to use.

Owner:重庆宝丽佰格电子科技有限公司

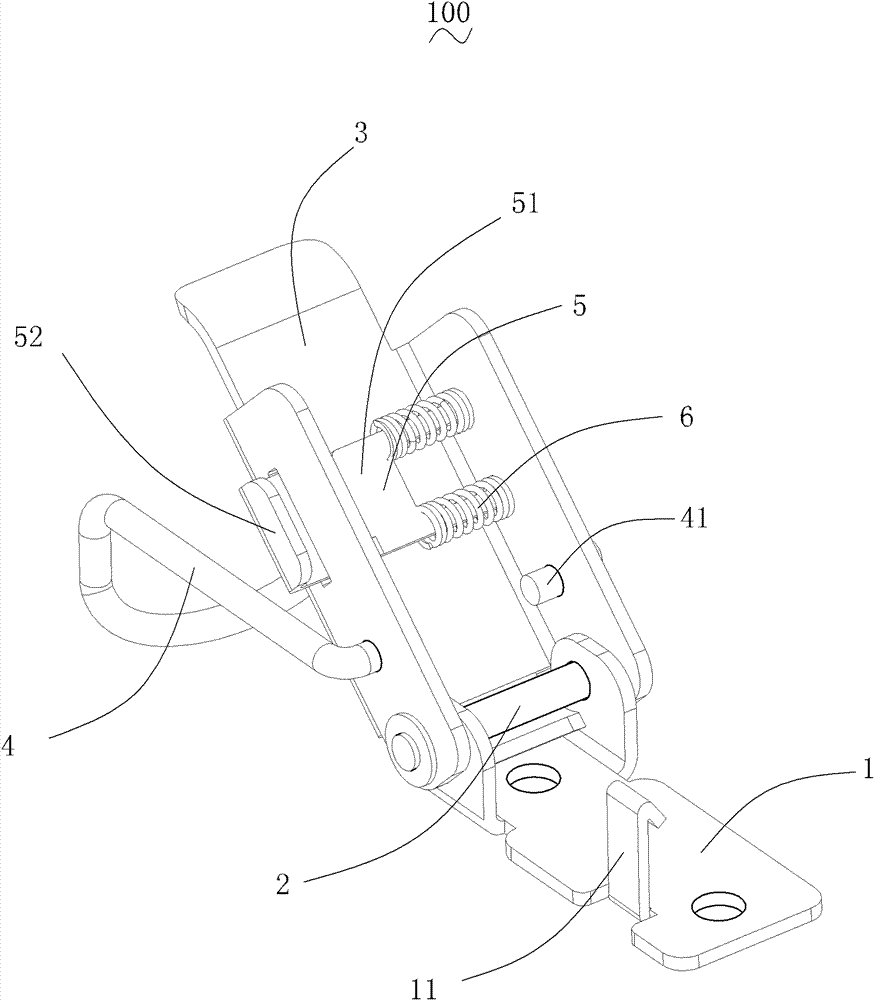

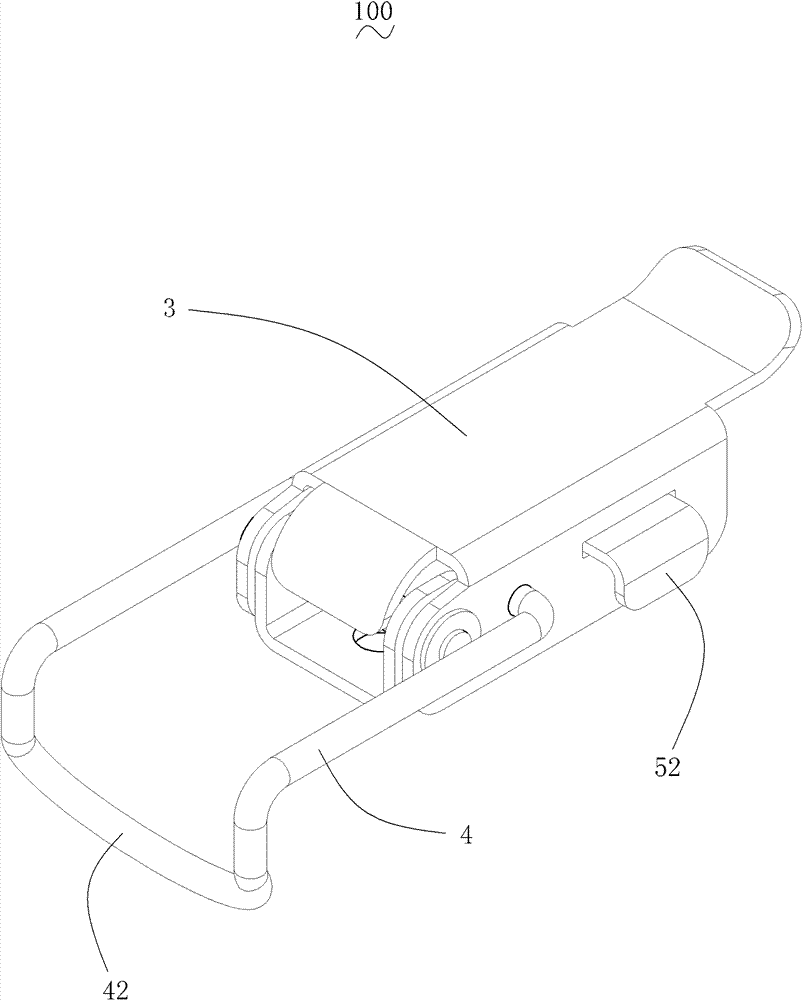

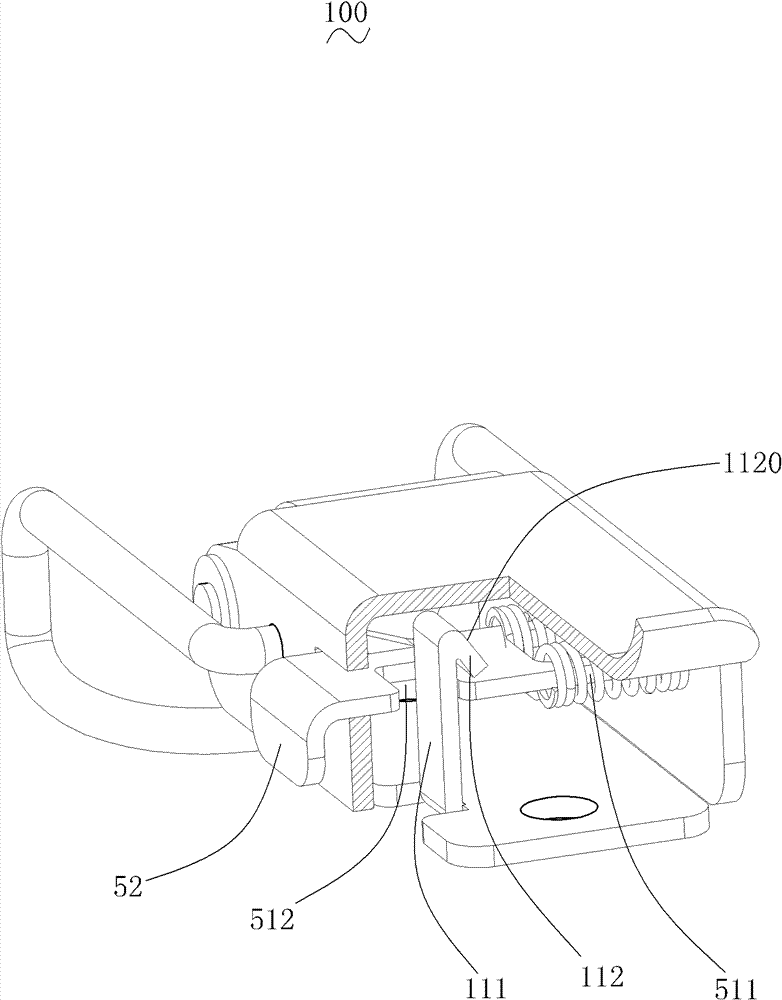

Hasp structure

The invention discloses a hasp structure, which is used for locking a lamp shell and comprises a basal body, a pin roll assembly which is arranged in the basal body in a penetrating way, a movable piece which is connected with the basal body through the pin roll assembly, and a hasp which is assembled on the movable piece. The hasp structure additionally comprises a locking piece, an elastic element which is connected with the locking piece and the movable piece, and a fastening part which extends from the basal body. The movable piece covers the basal body. The locking piece moves relative to the movable piece due to the elastic deformation of the elastic element. The fastening part automatically clamps the locking piece. Since the hasp structure comprises the fastening part which is arranged on the basal body and the locking piece which is elastically connected with the movable piece, when the movable piece covers the basal body, the fastening part automatically clamps the fastening piece to realize the stable fixation between the movable piece and the basal body, so as to enable the hasp structure to be in a stable closed state.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

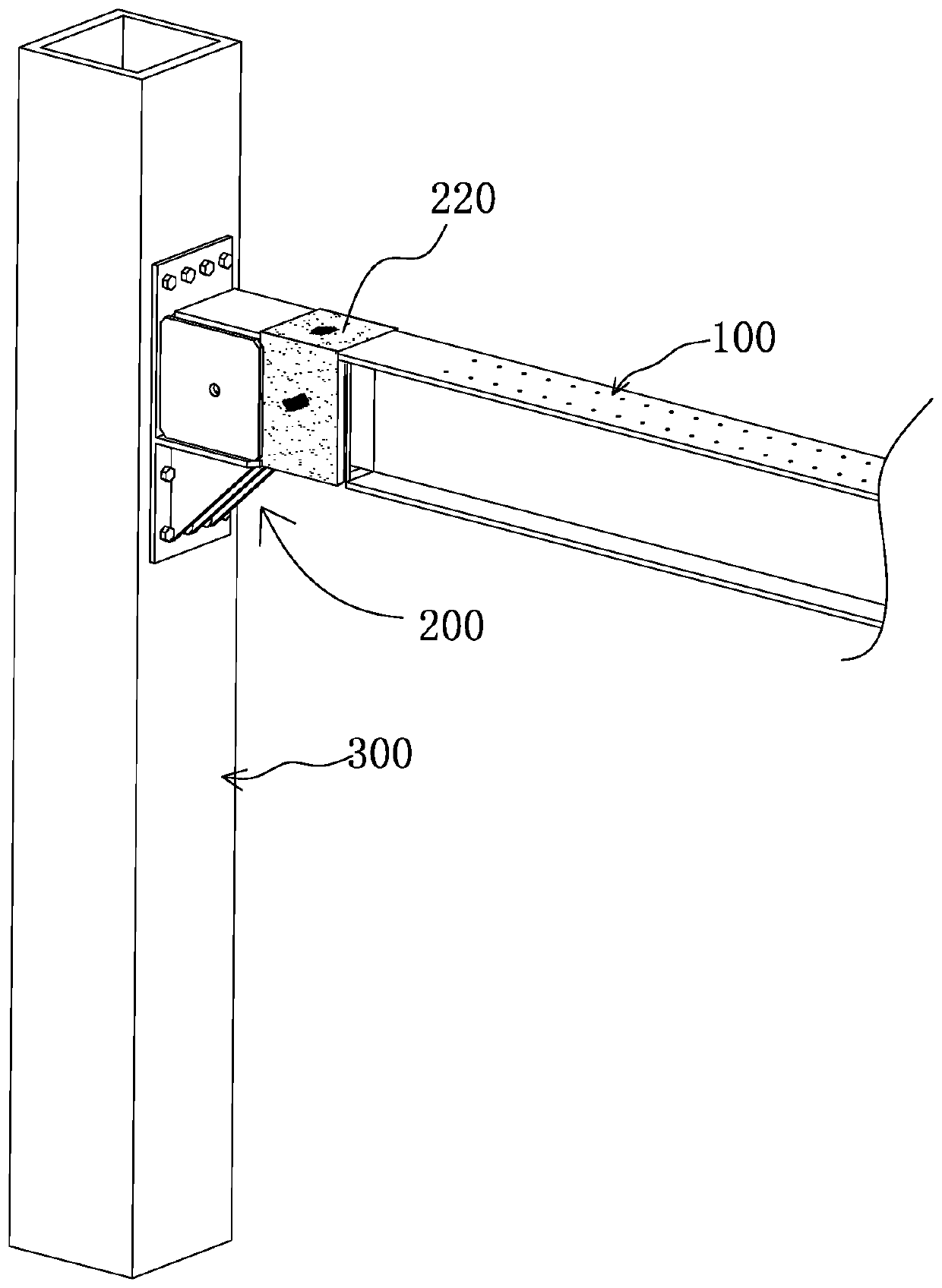

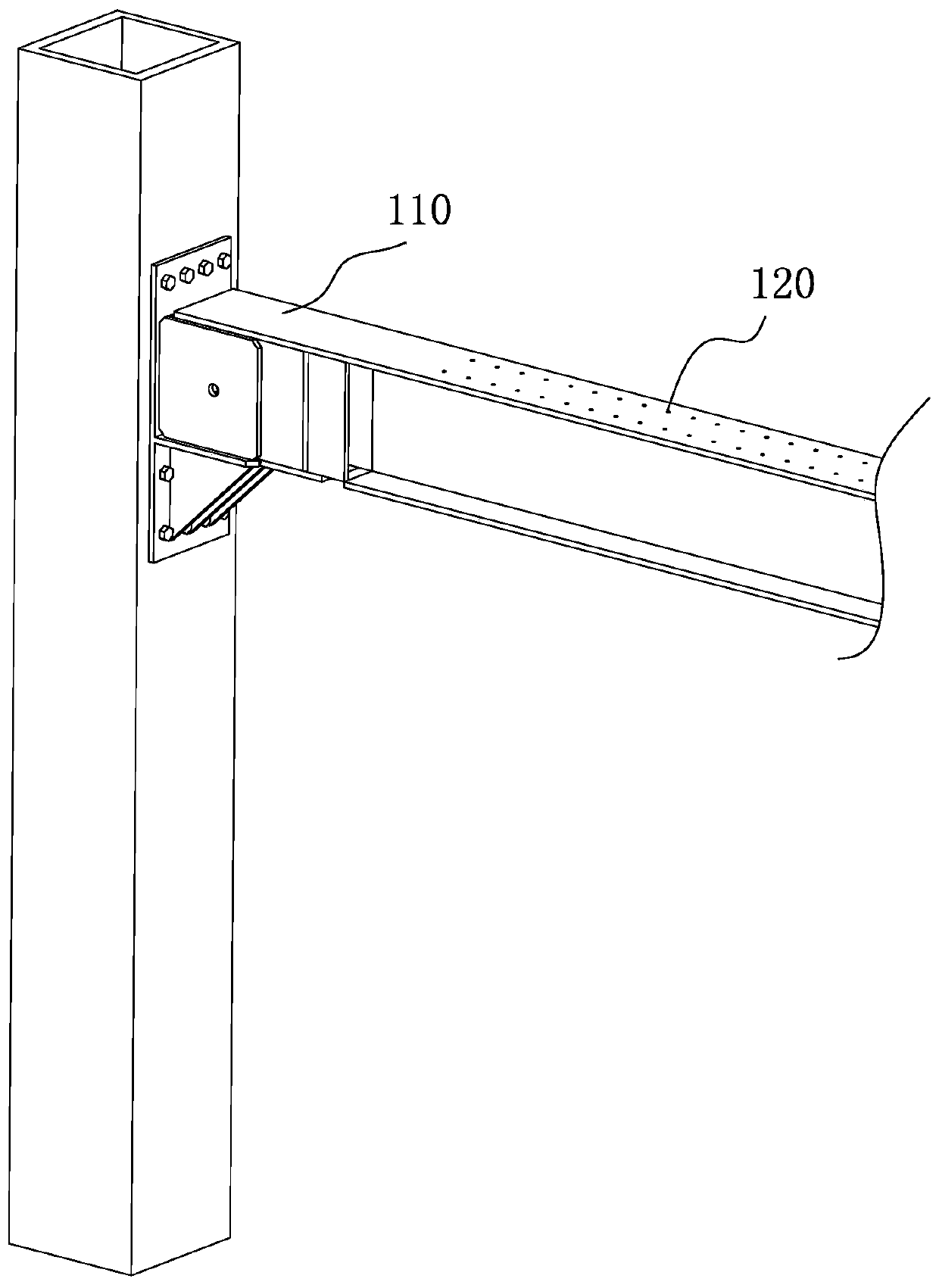

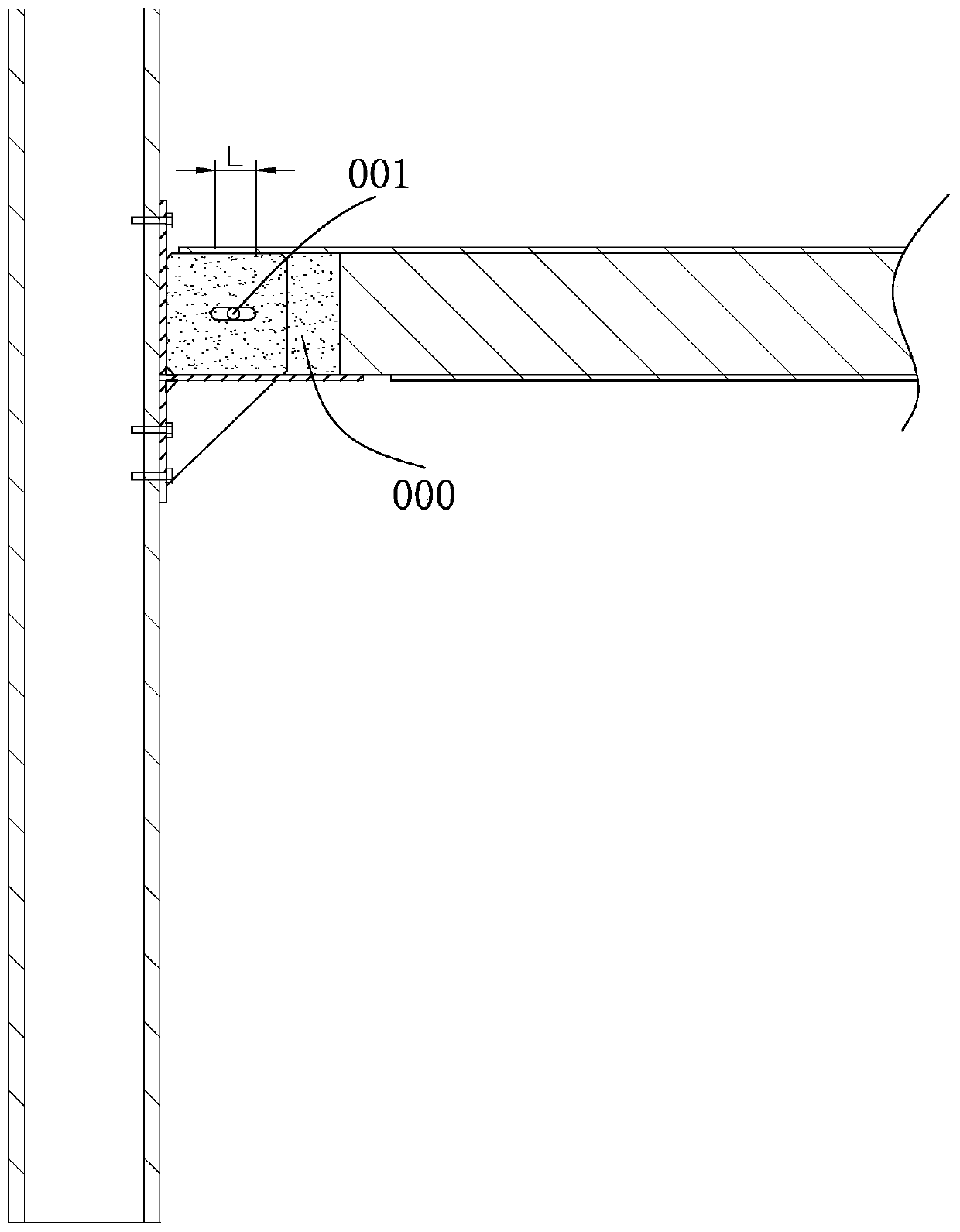

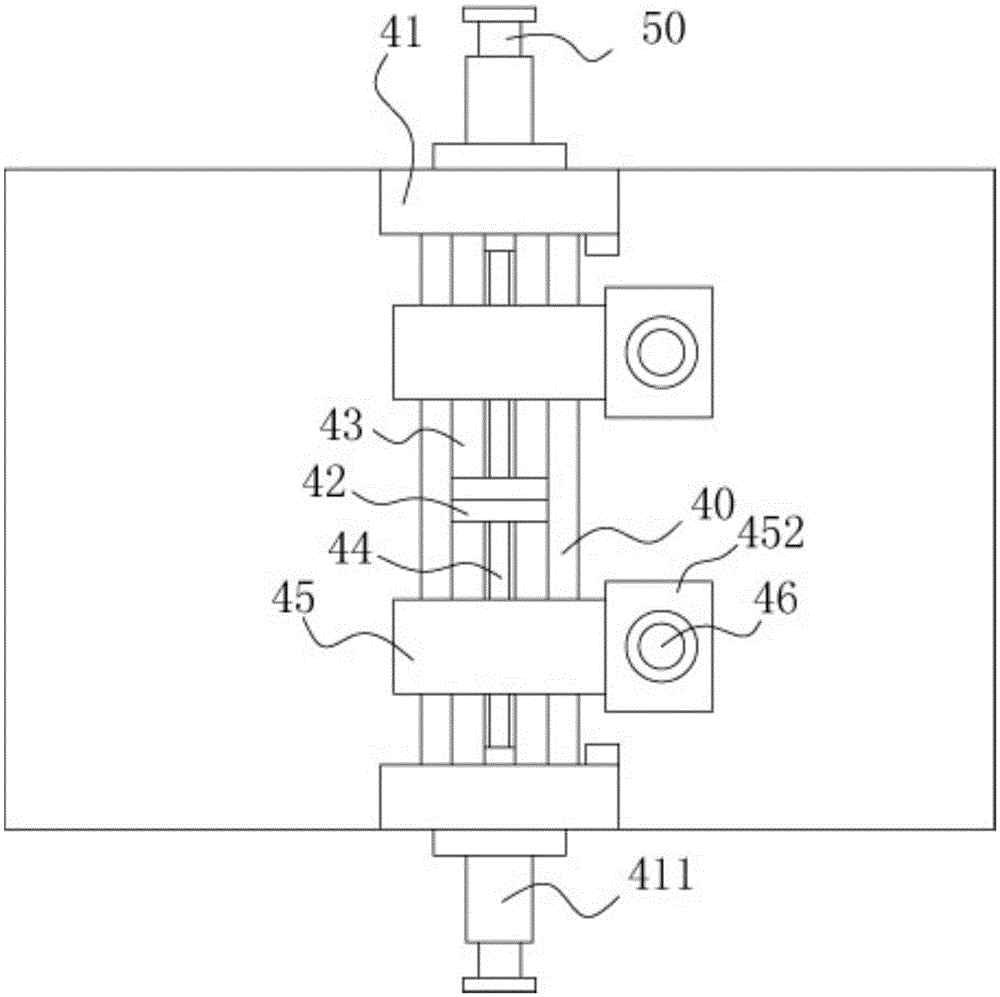

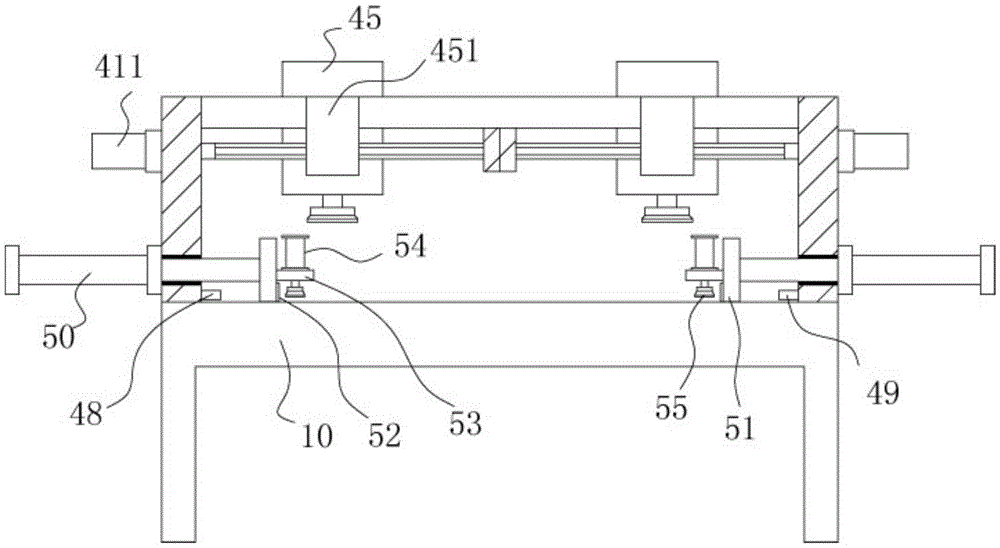

Fabricated steel structure beam and column connection joint and construction method

InactiveCN110306657AStrong rigidityRapid Assembly ConstructionProtective buildings/sheltersBuilding material handlingFiberStable fixation

The invention discloses a fabricated steel structure beam and column connection joint and a construction method thereof and provides a novel joint structure. The fabricated steel structure beam and column connection joint comprises a steel beam, a steel column and a bracket. The bracket is composed of a supporting part and an installation part, wherein the steel beam and the installation part of the bracket are in insertion connection through a comb structure, and an extensible and retractable space exits for the insertion connection in the length direction of the steel beam; and a gap of theinsertion connection is filled with emulsified asphalt, and the periphery of the insertion connection is wrapped with carbon fiber gridding cloth. According to the fabricated steel structure beam andcolumn connection joint and the construction method, the comb-shaped insertion structure is in a fixed connection state under a non-earthquake state, and a relatively stable fixed state is formed. When a strong earthquake happens, the insertion connection part relatively moves, slides and shifts, an energy consumption effect is achieved at the insertion connection part, that is, the connection joint of the insertion structure has a certain effect of counteracting and consuming earthquake energy, and the steel structure building per se is more resistant to earthquakes.

Owner:孔瑞清

Pressing mechanism for artificial processing of ceramics

InactiveCN105619632AEasy to fixWith automatic induction clamping and fixingWorking accessoriesStable fixationEngineering

The invention discloses a pressing mechanism for artificial processing of ceramics. The pressing mechanism comprises a rack; vertical support plates are fixed on front and rear sides of a top surface of the rack; an upper connecting beam is fixed on the two vertical support plates; a partition is fixed at the middle part of the upper connecting beam; two sliding grooves are formed between the partition, and front and rear ends of the upper connecting beam; an adjusting screw is located directly below each sliding groove, and one end of the adjusting screw is hinged to the partition, while the other end of the adjusting screw is hinged to the corresponding vertical support plate; hold-down blocks are located above the upper connecting beam; a bottom surface of each hold-down block is provided with an extension portion extending downwards, and the extension portion is inserted in a sleeving manner in the corresponding sliding groove, and connected by means of screw threads in the corresponding adjusting screw; a cylinder connecting plate is fixed on each hold-down block; a hold-down cylinder is fixed on each cylinder connecting plate; a push rod of each hold-down cylinder penetrates through the corresponding cylinder connecting plate vertically and downwards, and a hold-down chuck is fixed on the push rod; and each hold-down chuck is located right above the top surface of the rack. The pressing mechanism for artificial processing of ceramics has the advantages of stable fixation, and automatic sensing clamping and fixation, and is good in fixation effect.

Owner:HUBEI XIONGTAO CERAMICS CO LTD

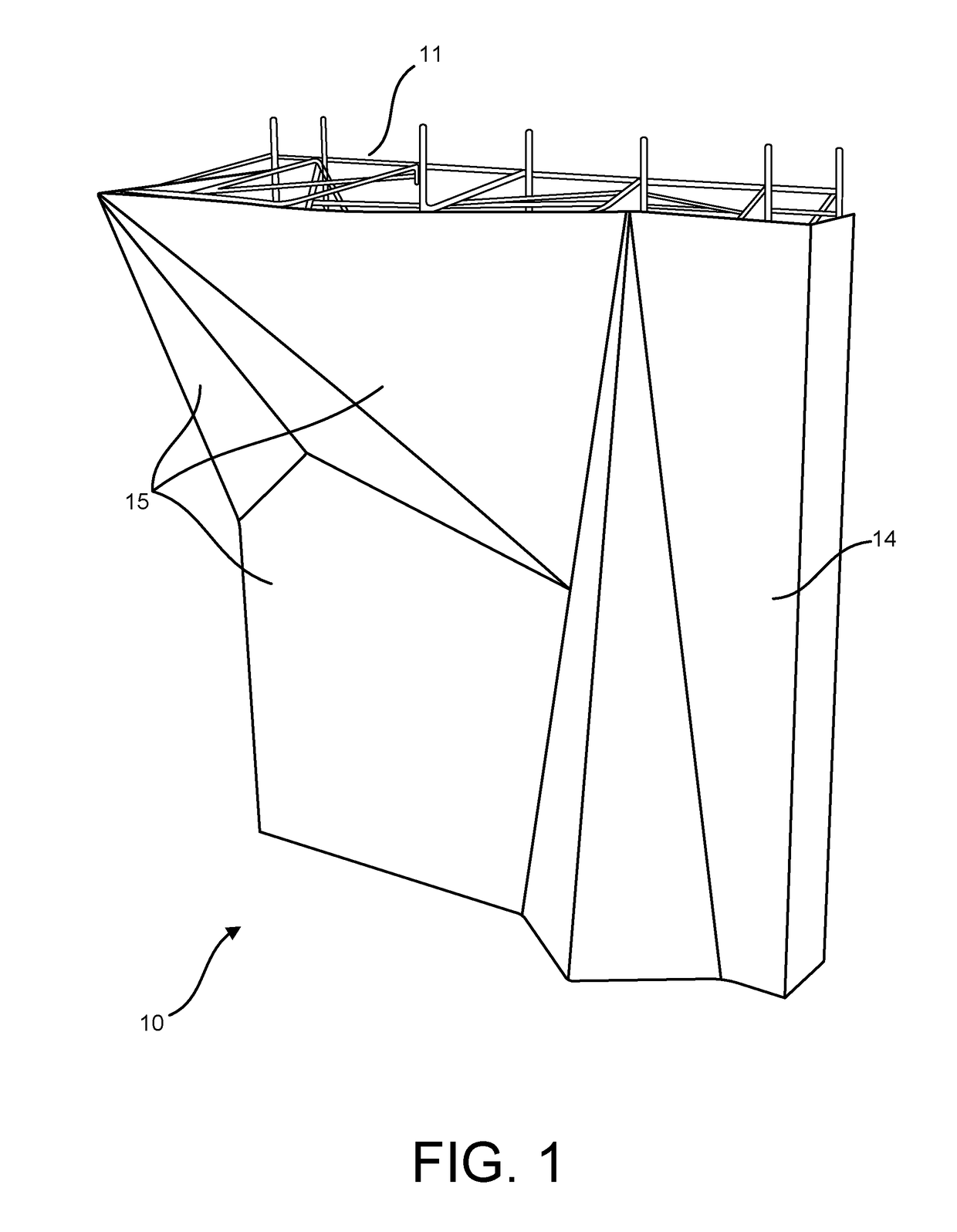

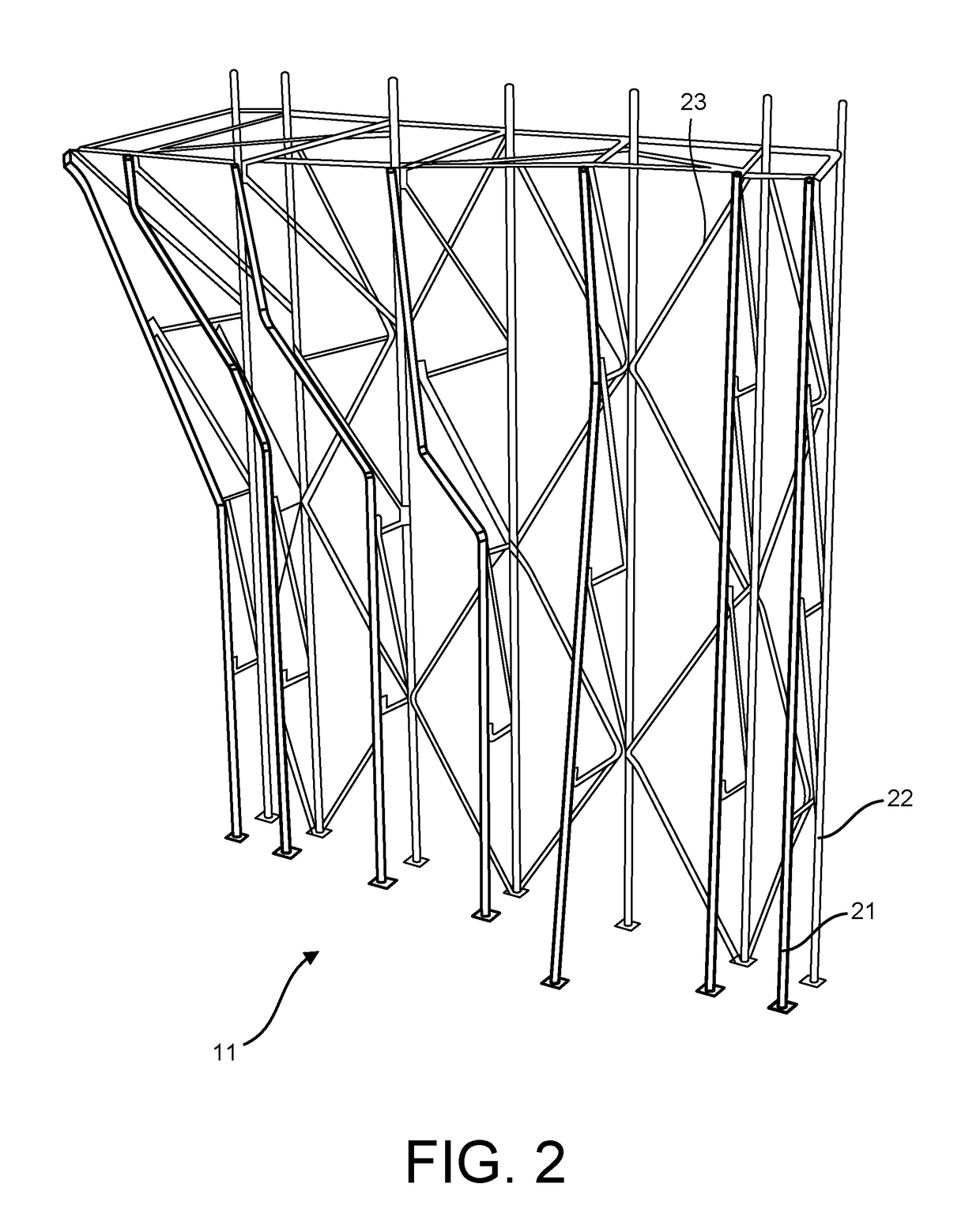

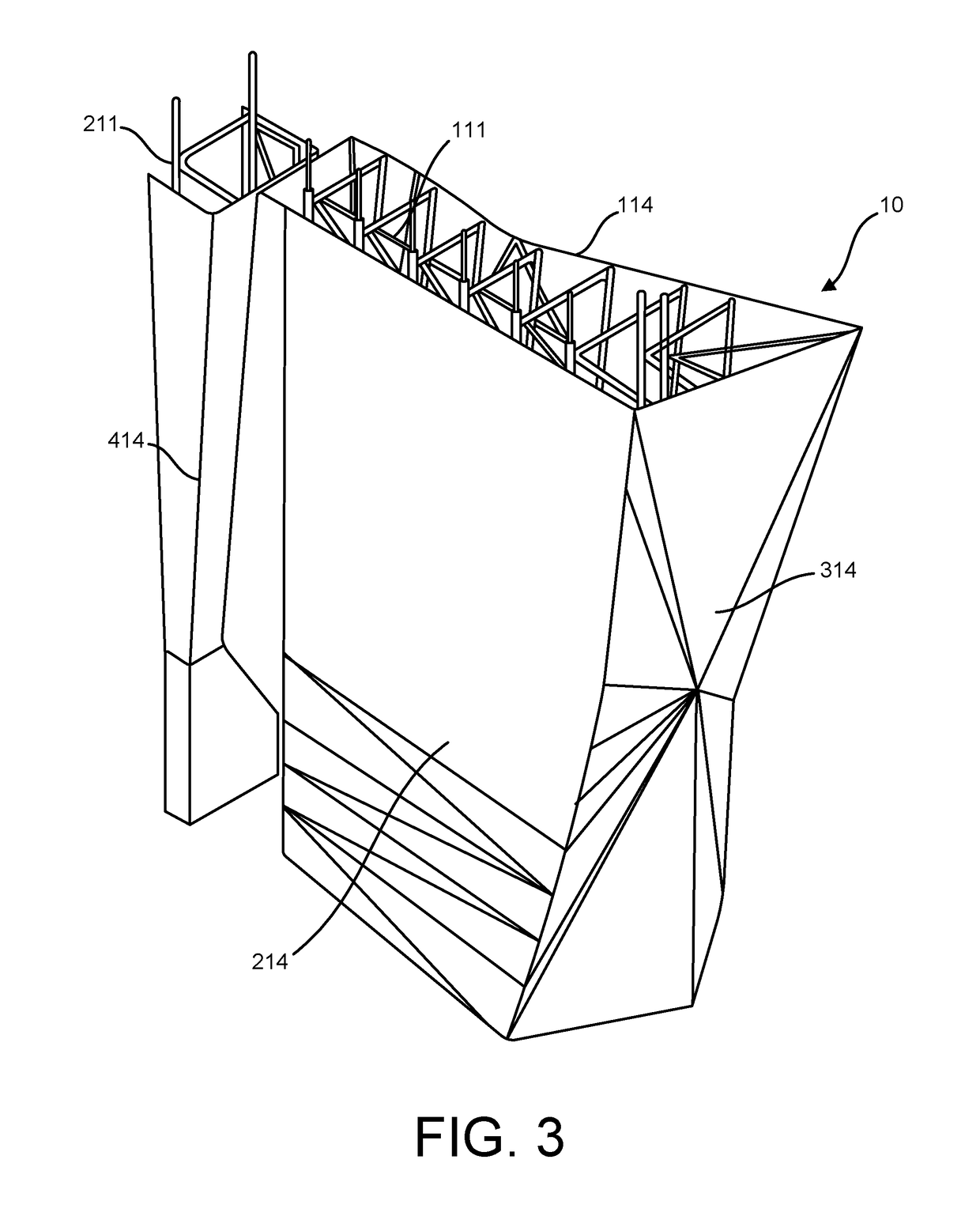

Climbing wall assemblies

ActiveUS20190032335A1Adjustable distanceAdjustable lengthWallsLoad-supporting elementsStable fixationVariable angle

Owner:EVERLAST CLIMBING INDS

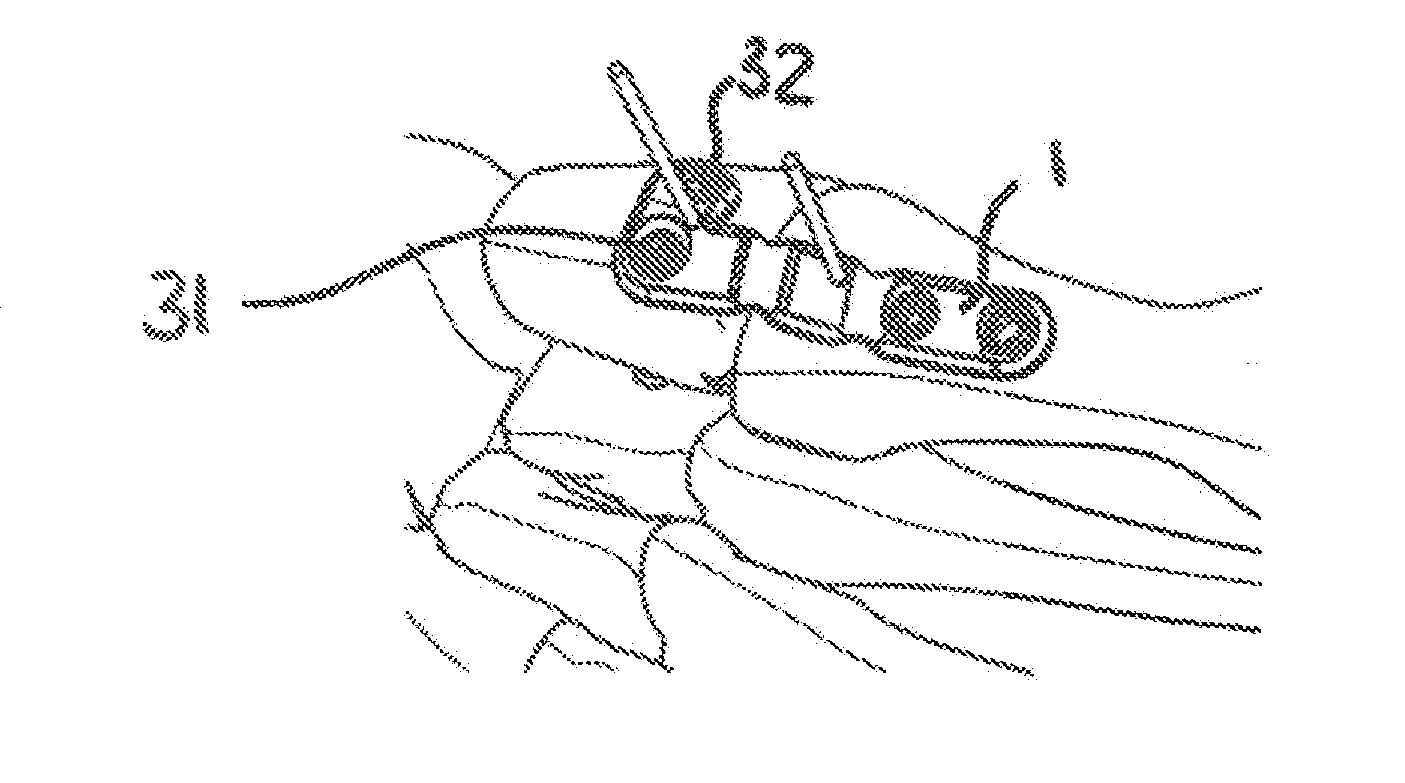

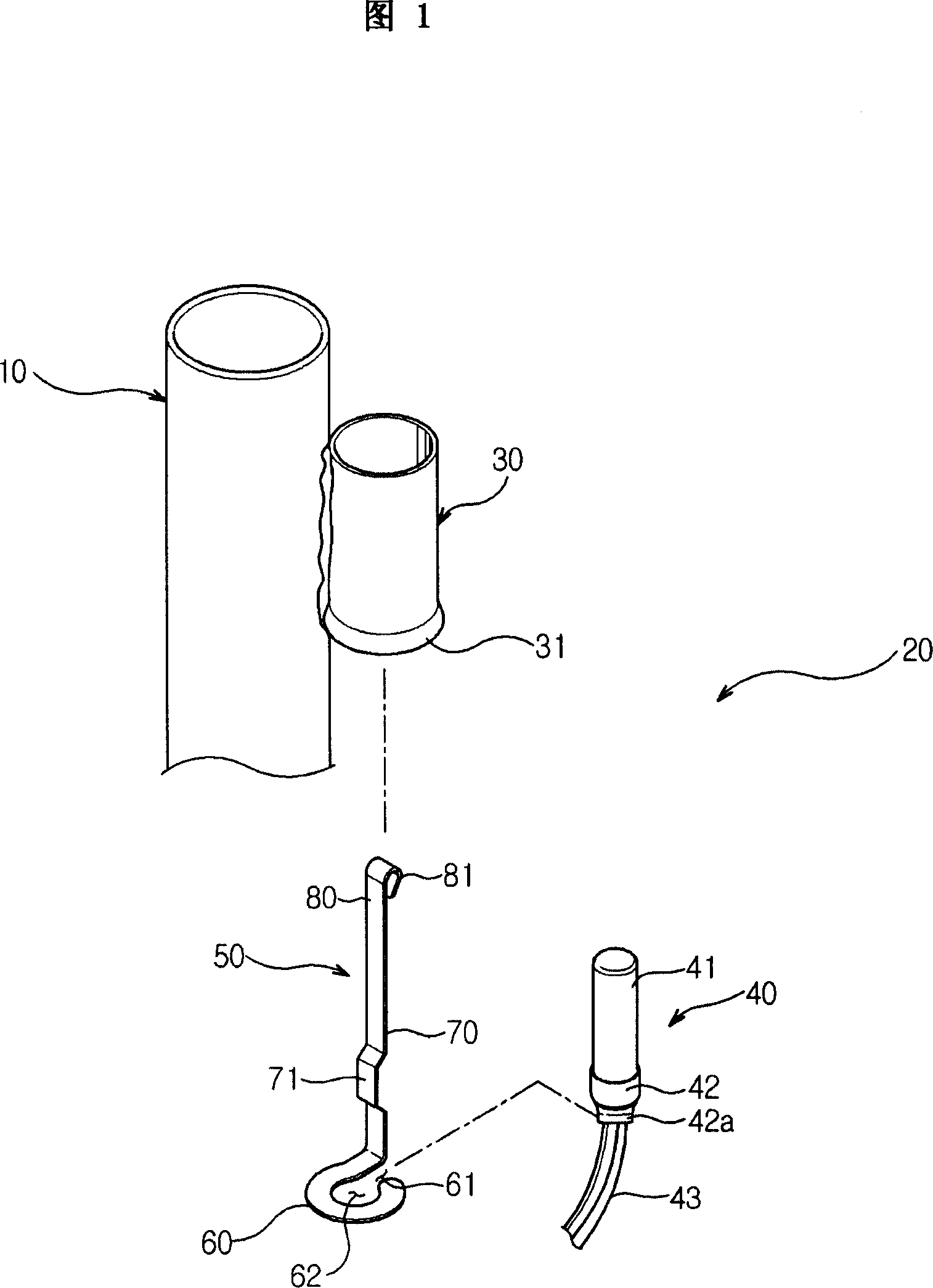

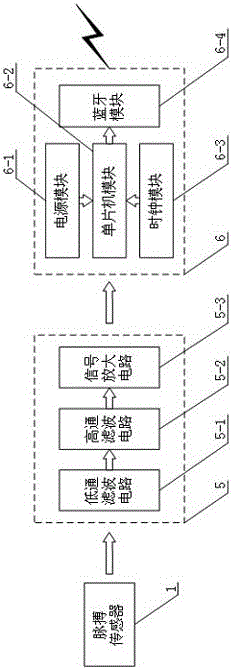

Pulse signal acquisition and data wireless transmission device located on fingernail

InactiveCN105769139AReduce detection impactImprove the lack of inaccurate detectionCatheterSensorsMicrocontrollerMicrocomputer

The invention discloses a pulse signal acquisition and data wireless transmission device located on a fingernail. The device comprises a pulse transducer (1), a non-closed clamping elastic piece (2), a hinge (3), a non-closed finger part fixing sleeve (4), a signal conditioning circuit module (5) and a single chip microcomputer acquiring and sending module (6), wherein the pulse transducer (1) is arranged at the front end of the clamping elastic piece (2) which can fix the pulse transducer (1) stably on the fingernail; the clamping elastic piece (2) is connected with the finger part fixing sleeve (4) through the hinge (3) and can rotate along with the movement of a finger part; the pulse signals are processed by the signal conditioning circuit module (5), and processed data are acquired by the single chip microcomputer acquiring and sending module (6) and are transmitted wirelessly to another equipment through Bluetooth of the single chip microcomputer acquiring and sending module (6).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

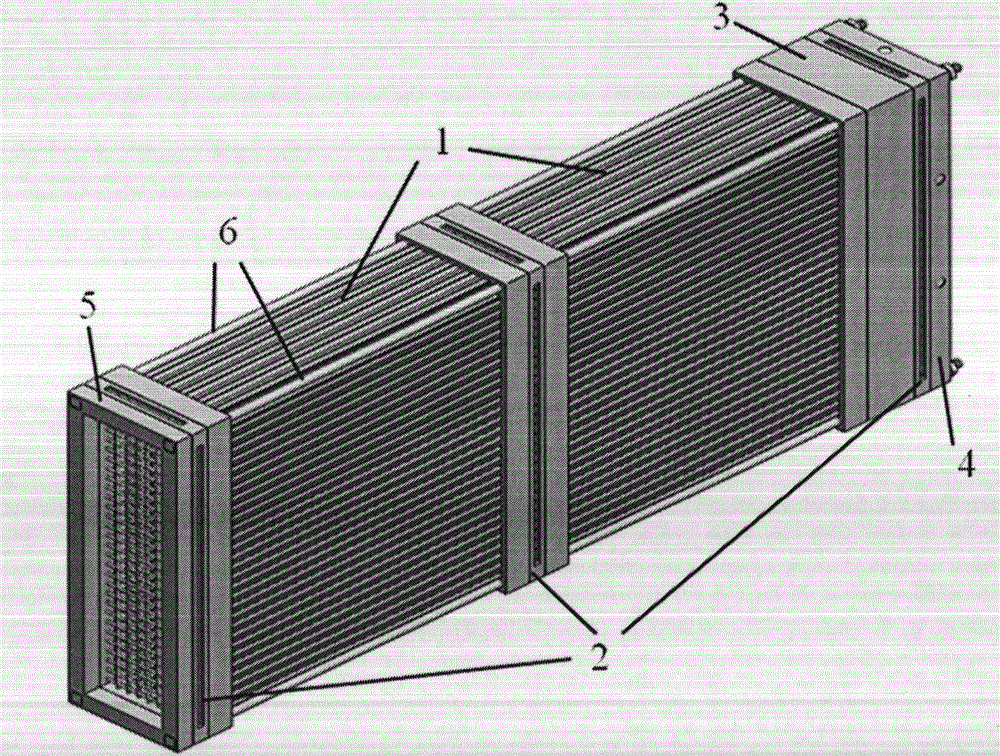

Wind tunnel rectification device

The invention provides a wind tunnel rectification device which comprises a honeycomb device, a damping net, a front end head, a back end head and supporting rods. The honeycomb device comprises a honeycomb and a honeycomb and honeycomb clamp covers, wherein the honeycomb is clamped by the honeycomb clamp covers. The internal flow passage edge of the honeycomb device is flush with the internal flow passage edge of a stable section. The damping net comprises a steel wire net and damping net clamp covers, wherein the steel wire net is fixedly connected with the damping net clamp covers. The internal flow passage edge of the damping net is flush with the internal flow passage edge of the stable section. The internal flow passage of the back end head is rectangle in shape, and the inner edge is flush with the internal flow passage edge of the stable section. The internal flow passage of the front end head is rectangle in shape, and the edge is flush with the internal flow passage edge of the stable section. The front end head is fixedly arranged in the stable section of a wind tunnel. The honeycomb device, the damping net and a connecting section are arranged between the front end head and the back end head. The relative position of the honeycomb device, the damping net and the connecting section can be changed. The honeycomb device, the damping net, the front end head and the back end head are connected and locked tightly through the supporting rods. The wind tunnel rectification device is stably and fixedly arranged in the stable section of the wind tunnel, thereby not introducing new turbulent flow; the positions of the honeycomb device and the damping net can be changed flexibly; and the whole structure is simple, and convenient installation is achieved.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com