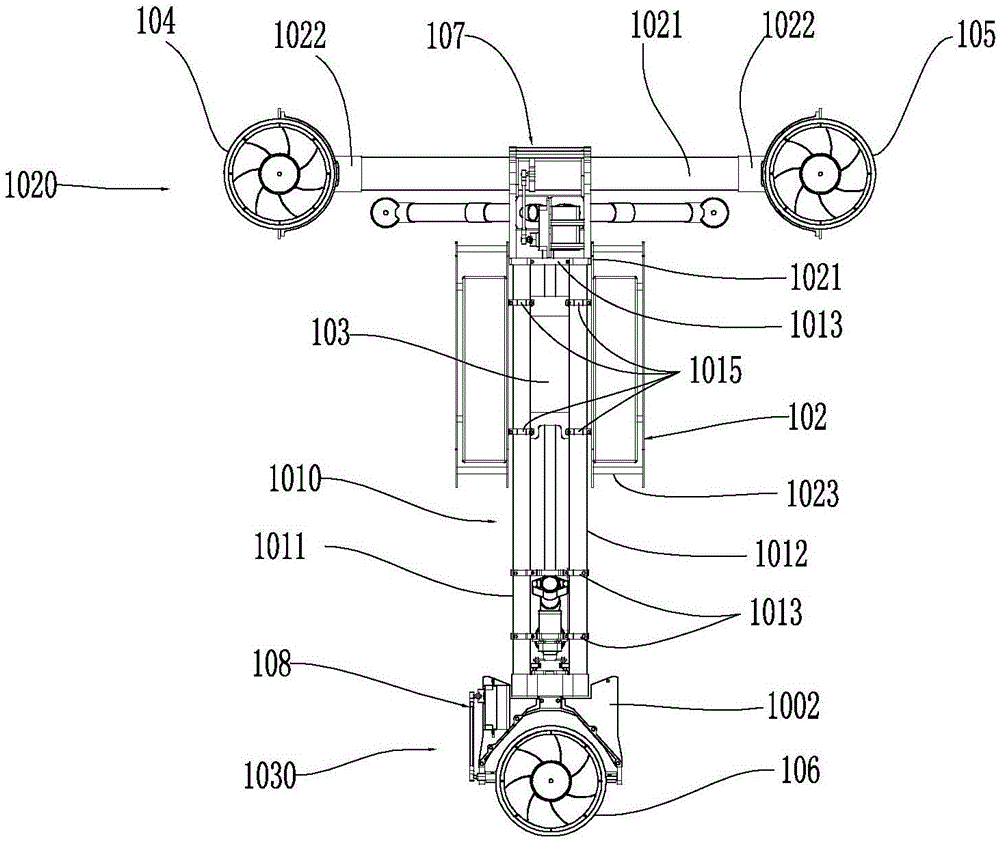

Take-off and landing platform for aircraft

A landing platform and aircraft technology, applied in the field of multi-axis aircraft landing platform, can solve the problems of increased flight resistance, unfavorable multi-axis aircraft take-off and landing, UAV take-off dependence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

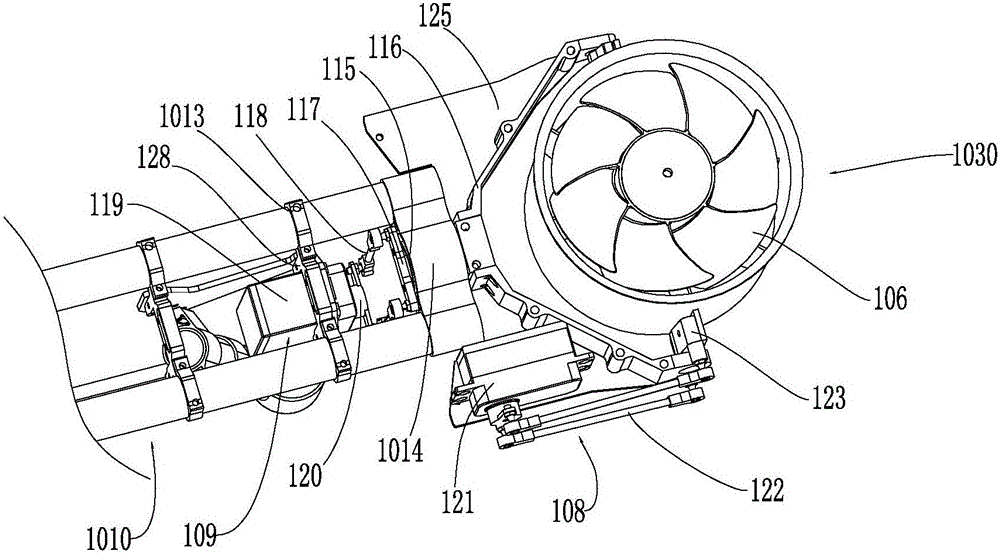

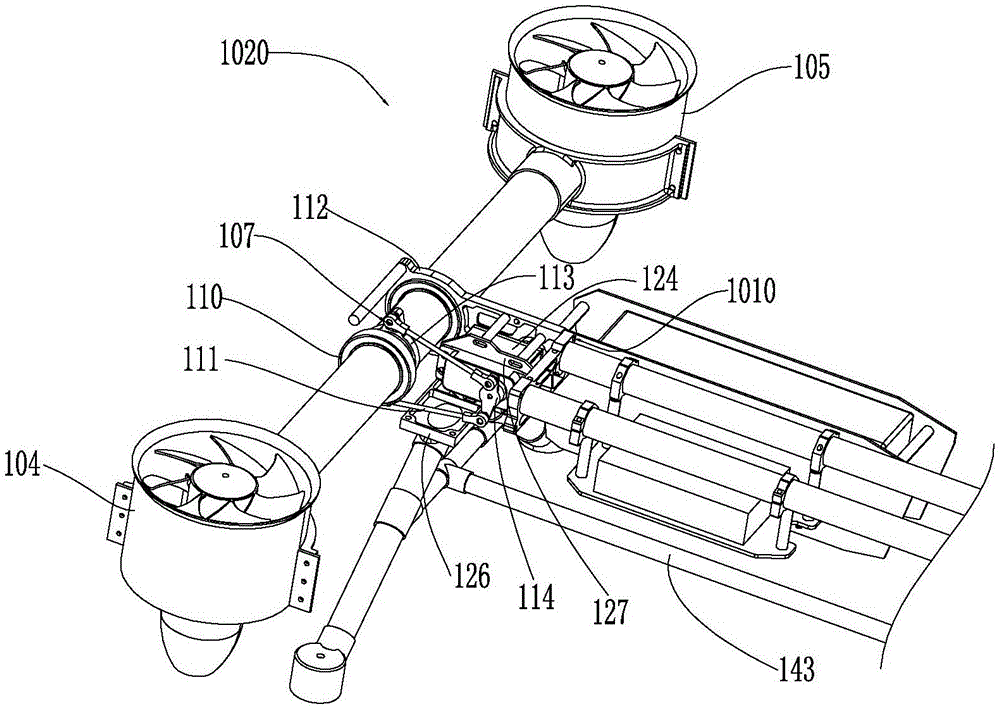

[0049] The difference between this embodiment and the first embodiment lies in the first tilting driving device and the second tilting driving device.

[0050] like Figure 5 As shown, the first tilting drive device 200 includes: a fixed frame 201, a steering gear 202, a steering gear output synchronous pulley 203, a synchronous belt 204, and a synchronous pulley 205, and the first end of the fixed frame 201 is rotatably supported by a bearing 206. The first machine arm 2020, the second end opposite to the first end of the fixed frame 201 is connected with the frame 2010 by screws, the third end of the fixed frame 201 located on the lower side is connected with the tripod by screws, and the steering gear 202 is positioned by The column is connected with the fixed frame 201, and the steering gear output synchronous pulley 203 is connected with the synchronous pulley 205 fixed on the first machine arm 2020 through the synchronous belt 204, so that the first machine arm 2020 tilt...

Embodiment 1

[0053] like Figure 7 As shown, the landing platform 1000 includes a fixed plate 810 and an attitude adjustment seat 900 . The attitude adjustment seat 900 has a Stewart-style base 910 with six degrees of freedom. An annular buffer rubber pad 920 as a buffer portion is disposed between the fixed plate 810 and the attitude adjustment seat 900 . The base 910 includes a lower ring frame 911 as a lower frame, six telescopic rods 912 and an upper ring frame 913 as an upper frame. The upper ring frame 913 and the fixing plate 810 are connected by bolts 914 , and the bolts pass through holes in the buffer rubber pad 920 , and the buffer rubber pad 920 is placed between the upper ring frame 913 and the fixing plate 810 . Preferably, the six telescopic rods 912 are electric cylinders or hydraulic cylinders. Apparently, the cushioning part is not limited to the cushioning rubber pad 920, and may also be composed of a plurality of silicone shock-absorbing balls with holes in the middl...

Embodiment 3

[0061] like Figure 13 As shown, the difference between this embodiment and the second embodiment of the landing platform is that the base of the attitude adjustment seat is a base 3910 with three degrees of freedom. The base 3910 includes an upper ring frame 3920 as an upper frame, a lower frame 3930 and a telescopic rod 3940 connecting the upper ring frame 3920 and the lower frame 3930 . The upper ring frame 3920 can tilt around the X and Y axes, and move up and down along the Z axis. The upper end of the telescopic rod 3940 is connected to the upper ring frame 3920 through a universal joint or a ball hinge; the lower end of the telescopic rod 3940 is hinged to the lower frame 3930, and its hinge shaft 3931 is arranged horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com