Vacuum-coating machine with motor-driven rotary cathode

A technology of rotating cathode and coating machine, applied in coating, vacuum evaporation coating, metal material coating process, etc., can solve the problems of compensating the limitation of swing freedom, inconvenient refurbishment, high design and financial cost, etc. Achieve the effect of reducing noise and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

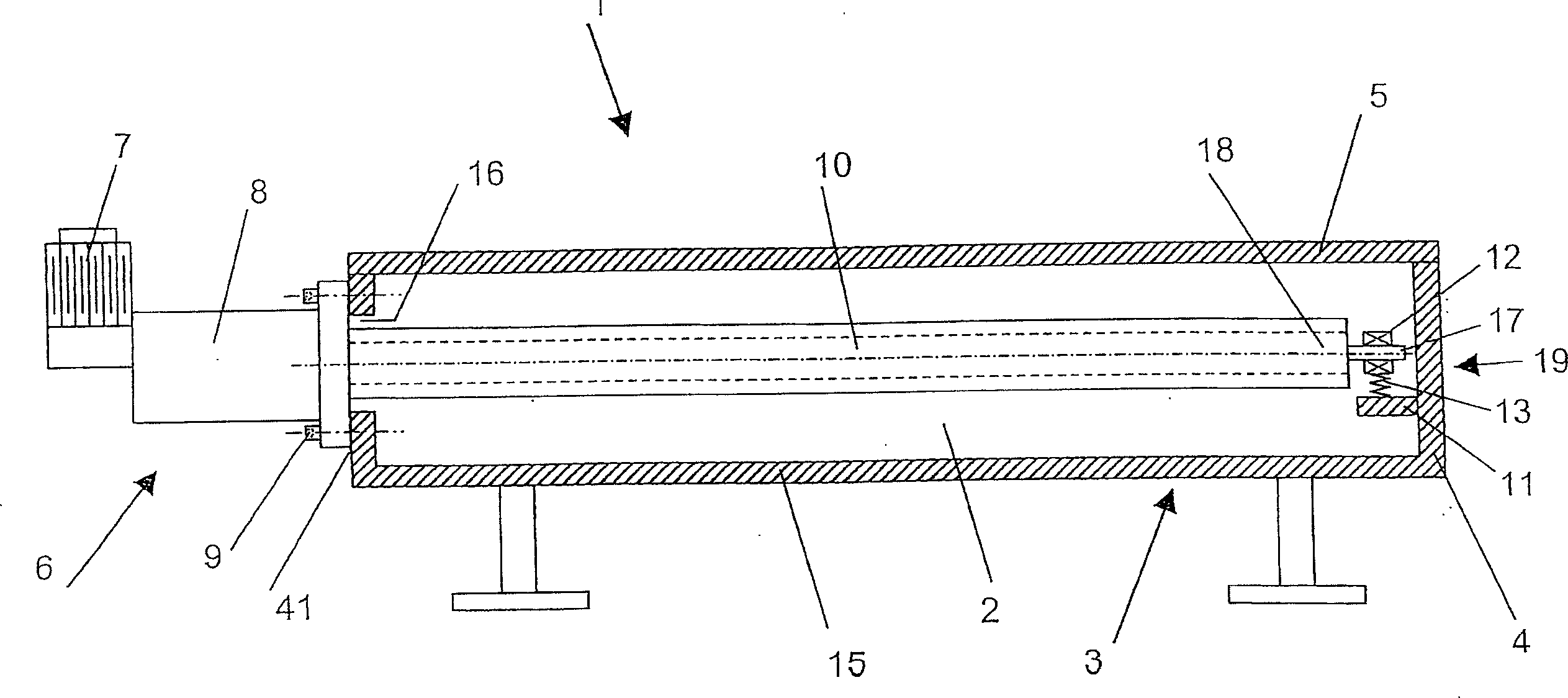

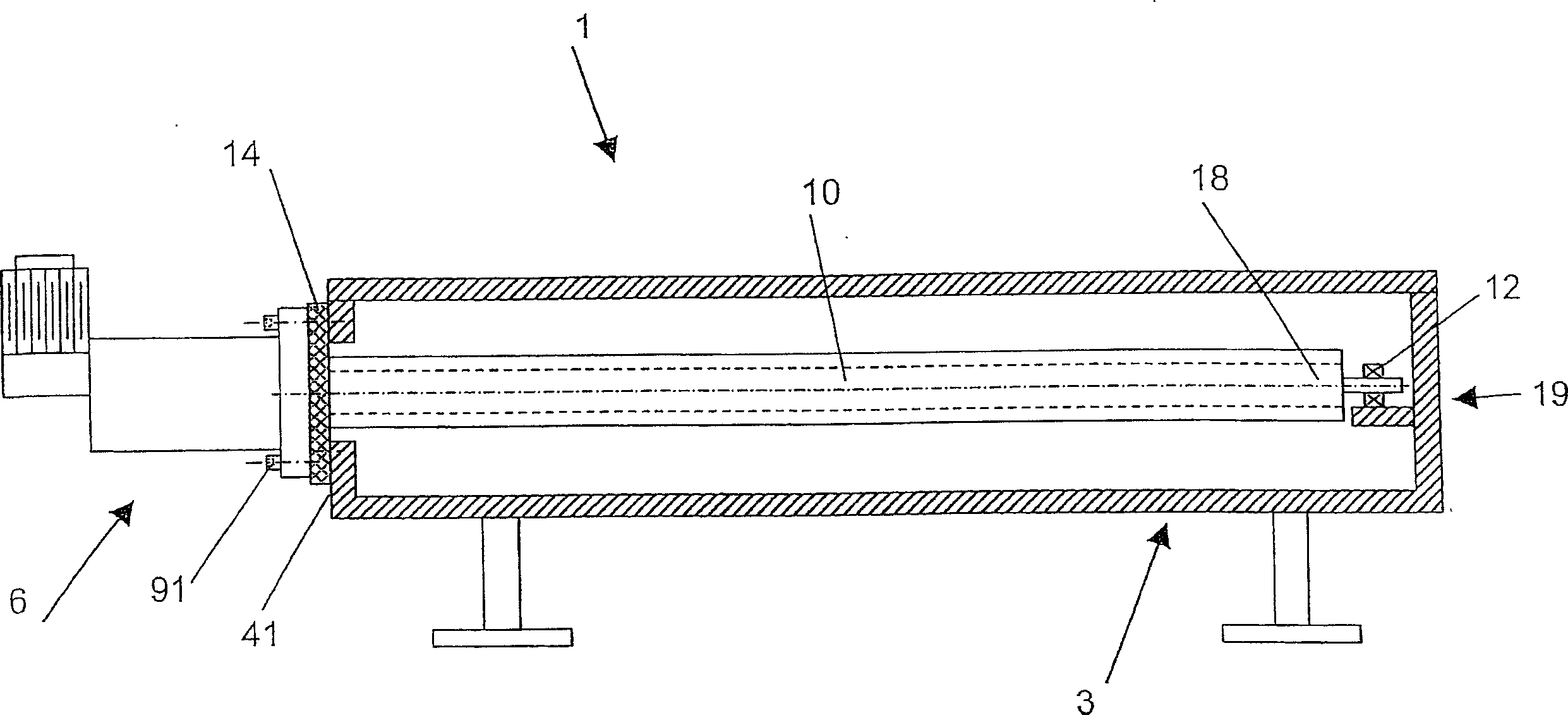

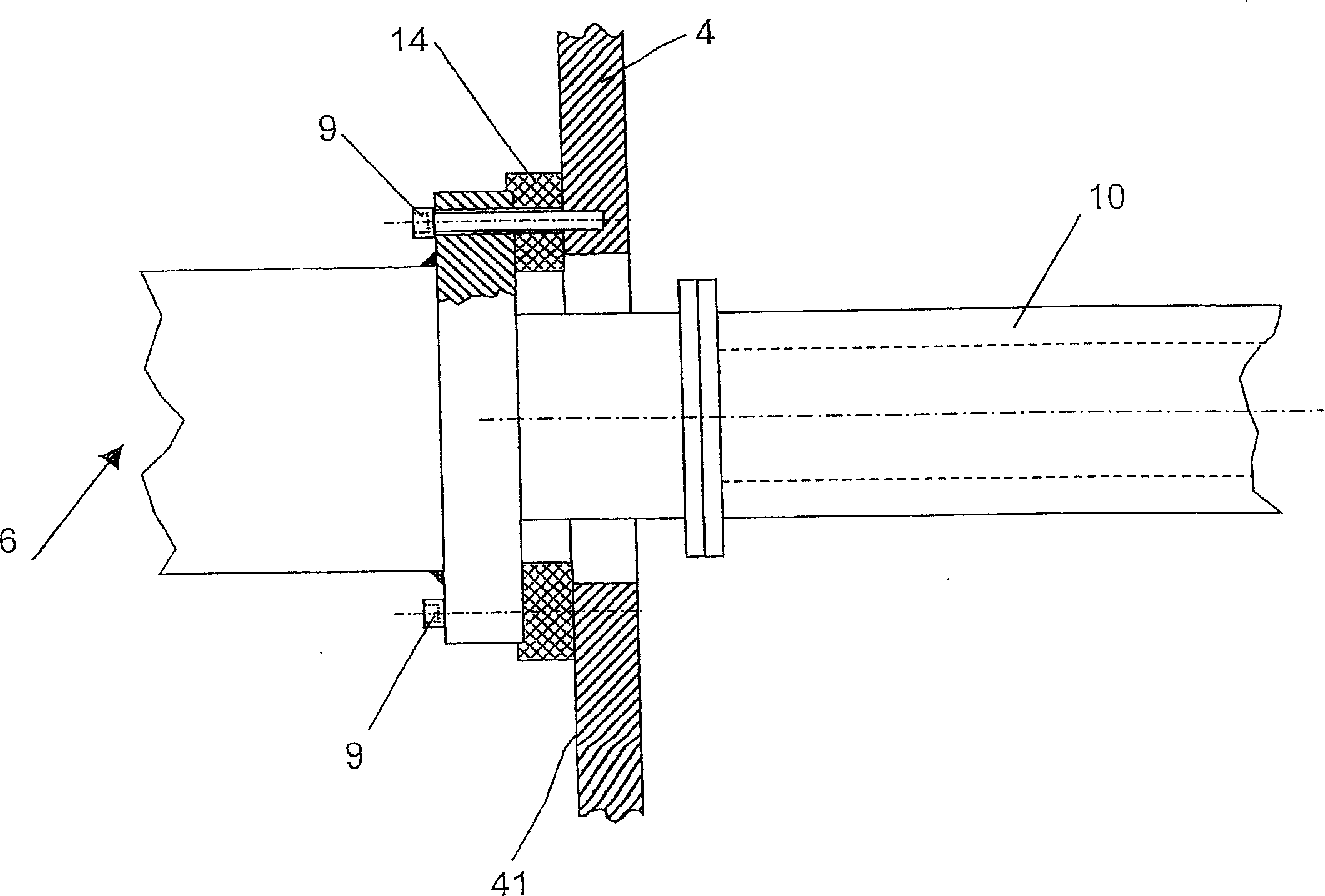

[0045]figure 1 A horizontal vacuum coating machine 1 according to the prior art is illustrated. The processing chamber 2 is limited by the lateral chamber walls 4, the chamber bottom 15 and the chamber cover 5, wherein the chamber cover 5 facilitates access to the processing chamber for maintenance and repair work. At least one rotating cathode 10 is arranged in the processing chamber 2, in this embodiment with a tubular target. However, the rotating cathode can likewise be of a solid design. The figure does not show the usual prior art fixtures such as magnets and / or cooling systems installed in the cathodes of the tubes. For the sake of clarity, the support and transport means for the workpiece to be processed in the processing chamber 2 are also not shown. These tools are well known to those of ordinary skill in the art, so those descriptions are superfluous. One end of the rotating cathode 10 is connected to a drive 6 via a wall opening 16 in the lateral chamber wall 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com