Improvement method and device based on conventional ship vibration isolation system

A vibration isolation system and ship technology, applied in non-rotational vibration suppression and other directions, can solve the problems of poor fit, bulky, unclear response characteristics and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

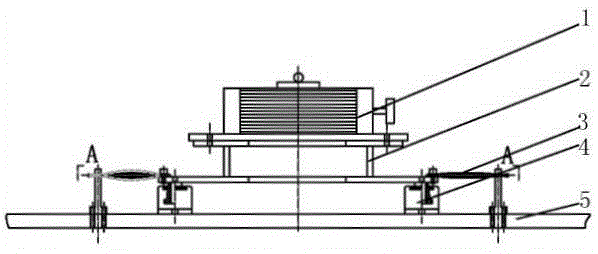

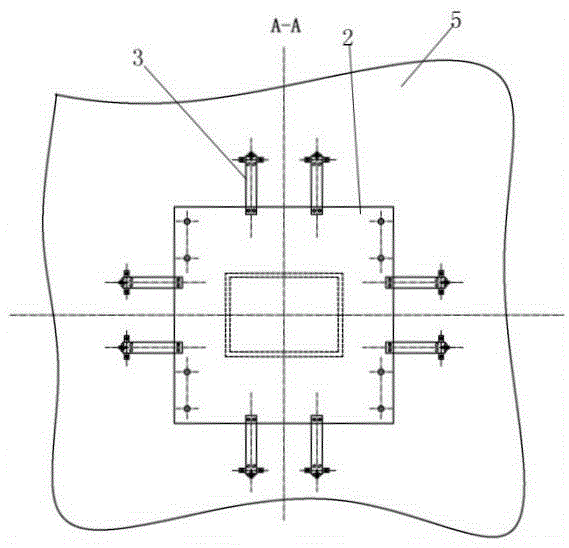

[0039] refer to Figure 1-3 , the present invention provides an improved device based on the existing ship vibration isolation system, which is improved on the basis of the original ship vibration isolation system to reduce the natural frequency of the vibration isolation system, improve the vibration isolation effect, reduce Vibration transmission, improve the role of acoustic invisibility. The vibration isolation system system includes a vibration-isolated equipment rack 2 and a base, wherein the base adopts an elastic base 5, and the vibration-isolated equipment rack 2 is equipped with the vibration-isolated equipment 1, the vibration-isolated equipment rack 2 and the vibration-isolated equipment rack 2. Several shock absorbers 4 are also arranged between the elastic bases 5 . Wherein, the specific structural form of the shock absorber 4 can be selected according to specific conditions, and is not limited here; the distribution form of the shock absorber 4 can be according...

Embodiment 2

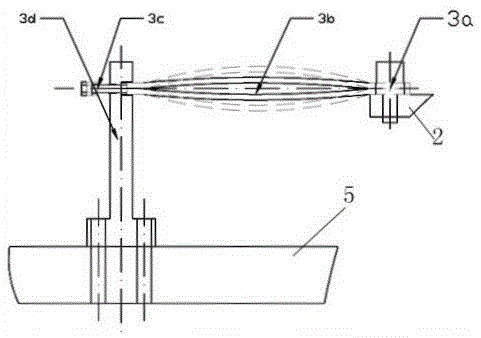

[0059] refer to Figure 4-5 , this embodiment is a transformation embodiment based on the first embodiment. In this embodiment, the negative stiffness adjustment mechanism adopts a vertically arranged Euler buckling beam, and the structure of the remaining parts can refer to the relevant description of the first embodiment. There are no restrictions.

[0060] In this embodiment, one end of the Euler buckling beam 3 is installed to the bottom surface of the vibration-isolated equipment frame 2 through the frame connection structure 3a, and the specific frame installation mechanism 3a is fixedly installed on the bottom surface of the vibration-isolated equipment frame 2 Above, the Euler buckling beam 3 is connected to the frame mounting structure 3a; the other end of the Euler buckling beam is installed on the upper surface of the elastic base 5 through the base connecting structure 3d, and the specific base connecting structure 3d is fixedly installed on the elastic base On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com