FRP reinforced rubber vibration isolator and method of producing the same

A technology for reinforcing rubber and manufacturing methods, applied in the direction of non-rotational vibration suppression, etc., to achieve the effect of reducing natural frequency, excellent damping performance, and excellent damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

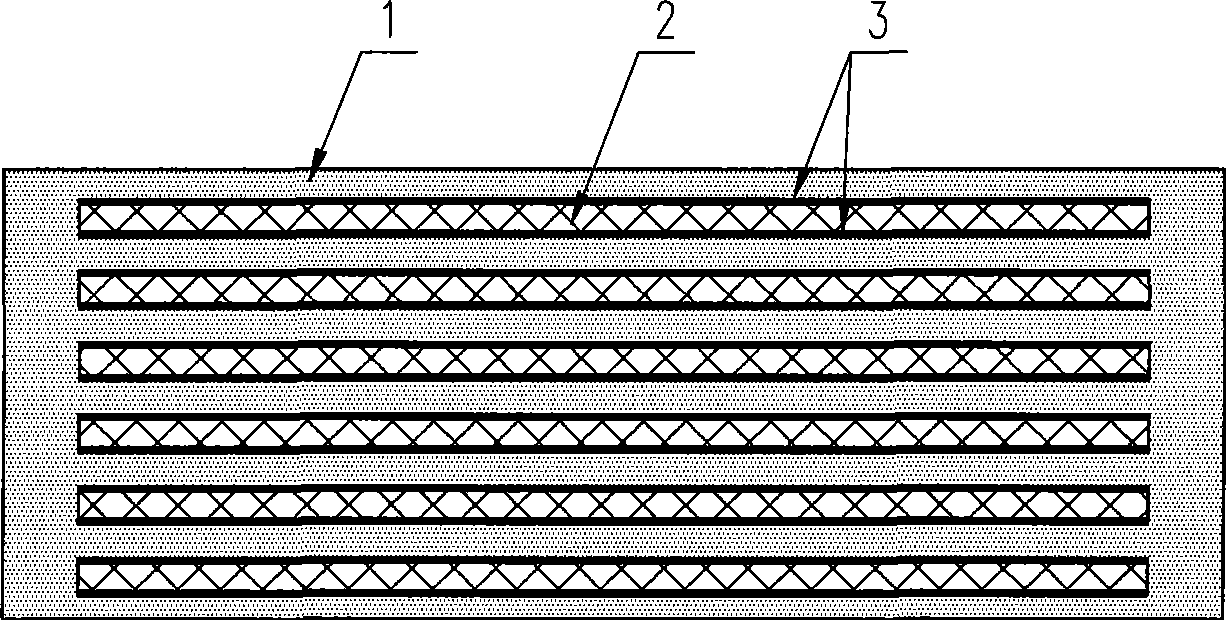

[0038] A cuboid FRP reinforced rubber vibration isolator, the vibration isolator is made of rubber layer 1, FRP plate 2 with adhesive layer 3 interlaced and laminated and bonded by vulcanization (see figure 1 ), the rubber of the rubber layer 1 is natural rubber, the FRP plate 2 is made of glass fiber reinforced material and epoxy resin matrix, and the upper and lower surfaces of the FRP plate 2 are coated with a layer of epoxy adhesive formed Structural Adhesive Layer 3.

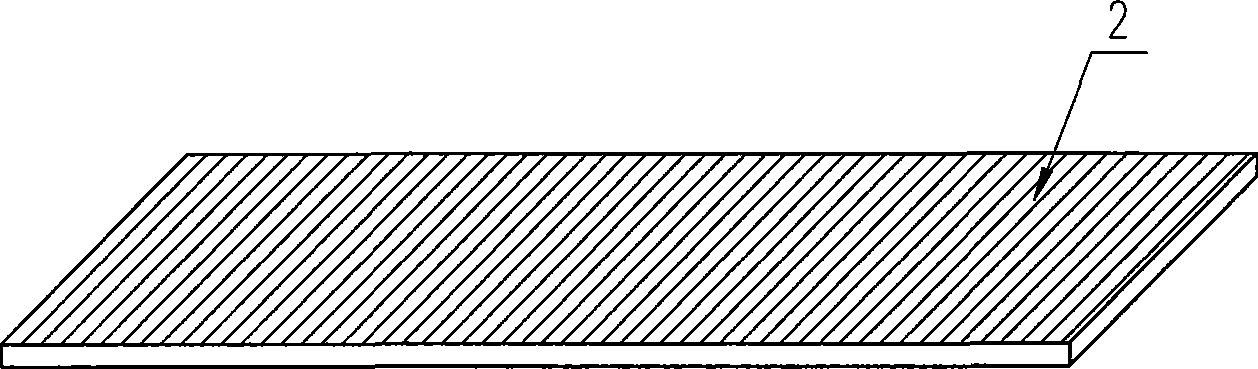

[0039] The FRP board 2 is a laminated board structure formed by stacking six FRP single-layer boards 21 with different main directions, and each single-layer board is formed by a plane arrangement of unidirectional glass fiber reinforced materials in an epoxy resin matrix (see figure 2 , image 3 ).

[0040] As a modification of the embodiment of the present invention, the structural adhesive layer 3 on the upper and lower surfaces of the FRP board 2 may also be an epoxy adhesive layer formed by coatin...

Embodiment 2

[0047] A kind of manufacturing method of FRP reinforced rubber vibration isolator, this method is to be coated with the FRP plate and rubber layer of adhesive interlaced lamination, become a whole after being vulcanized and bonded, it comprises the following main steps:

[0048]A. Preparation of FRP board:

[0049] ① Preparation of fiber prepregs: impregnate the resin matrix with surface-treated fibers to prepare unidirectional or multidirectional fiber prepregs;

[0050] ② Lamination: According to the designed lay-up method, the lay-up of FRP laminates is completed by laying fiber prepreg impregnated with resin matrix layer by layer;

[0051] ③ Compression molding: According to the different curing temperatures of different resin substrates, select appropriate temperature and pressure to mold the FRP laminate, and cut the molded FRP laminate into the required size;

[0052] B. Setting the adhesive layer: coating the upper and lower surfaces of the FRP board with adhesive or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com