Low-frequency two-degree-of-freedom horizontal vibration isolation mechanism

A degree of freedom and horizontal technology, applied in the direction of shock absorbers, mechanical equipment, springs/shock absorbers, etc., can solve the problems of reduced load placement area, unstable load placement, poor system stability, etc., to achieve stable support surface, The effect of reducing the horizontal natural frequency and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, specific embodiment of the present invention and structural principle are described further:

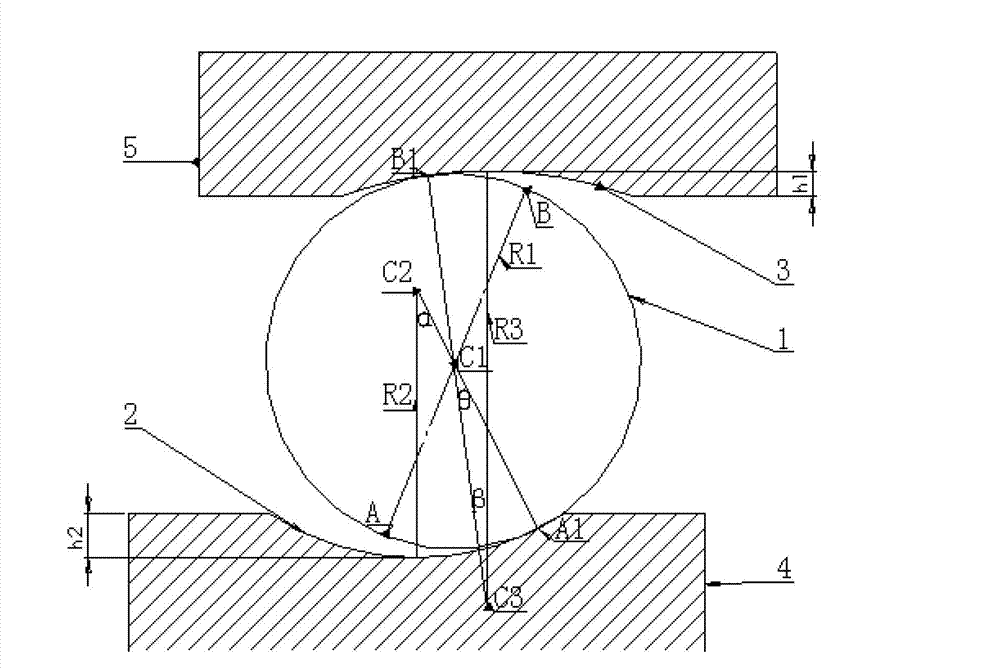

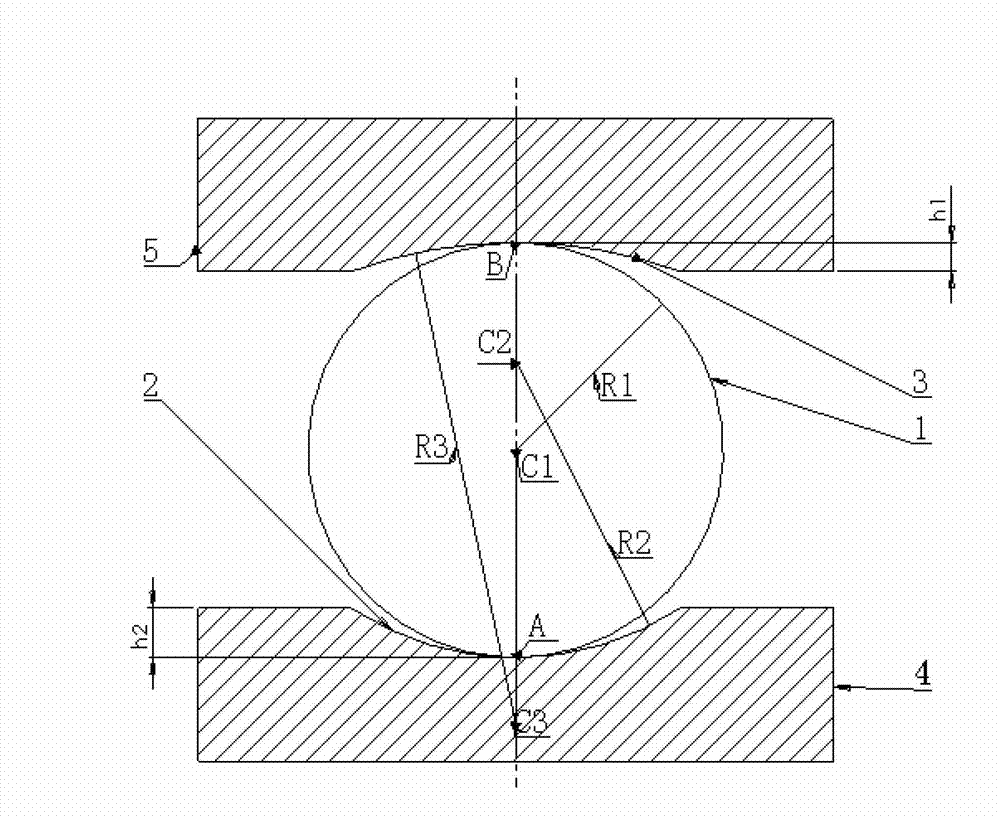

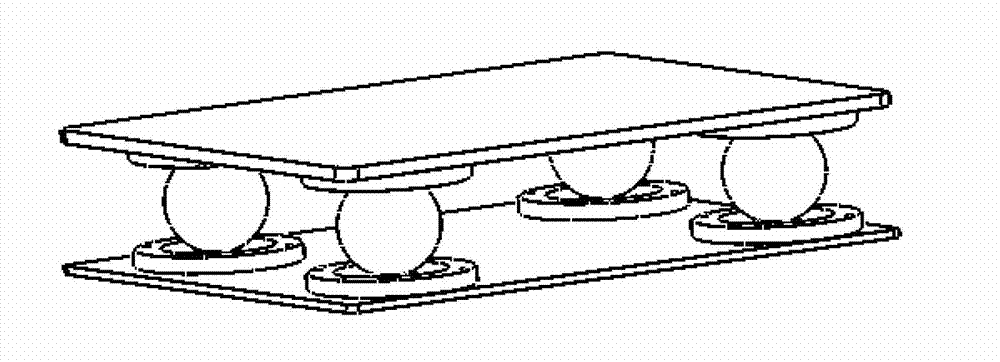

[0016] The low-frequency two-degree-of-freedom horizontal vibration isolation mechanism provided by the present invention includes three parts: an upper support plate 5, a rigid ball 1 and a lower support plate 4, the upper support plate 5 is provided with an upper support plate arc 3, and the lower support plate 4 is provided with The arc 2 of the lower support plate, the rigid ball 1 is placed between the arc 3 of the upper support plate and the arc 2 of the lower support plate, the center C3 of the arc of the upper support plate, the center C1 of the rigid ball and the arc of the lower support plate The three points of the center C2 are located on the same vertical line, and the radii of the upper support plate arc 3 and the lower support plate arc 2 should be greater than the radius of the rigid ball 1; the radii of the two ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com