Combined vibration isolation device installed in transformer oil tank and design method

A technology for transformer oil tank and transformer, applied in the field of transformers, can solve the problems of ineffectiveness of vibration isolation measures, increasing magnetostriction of Guangxi steel sheets, and destroying material properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

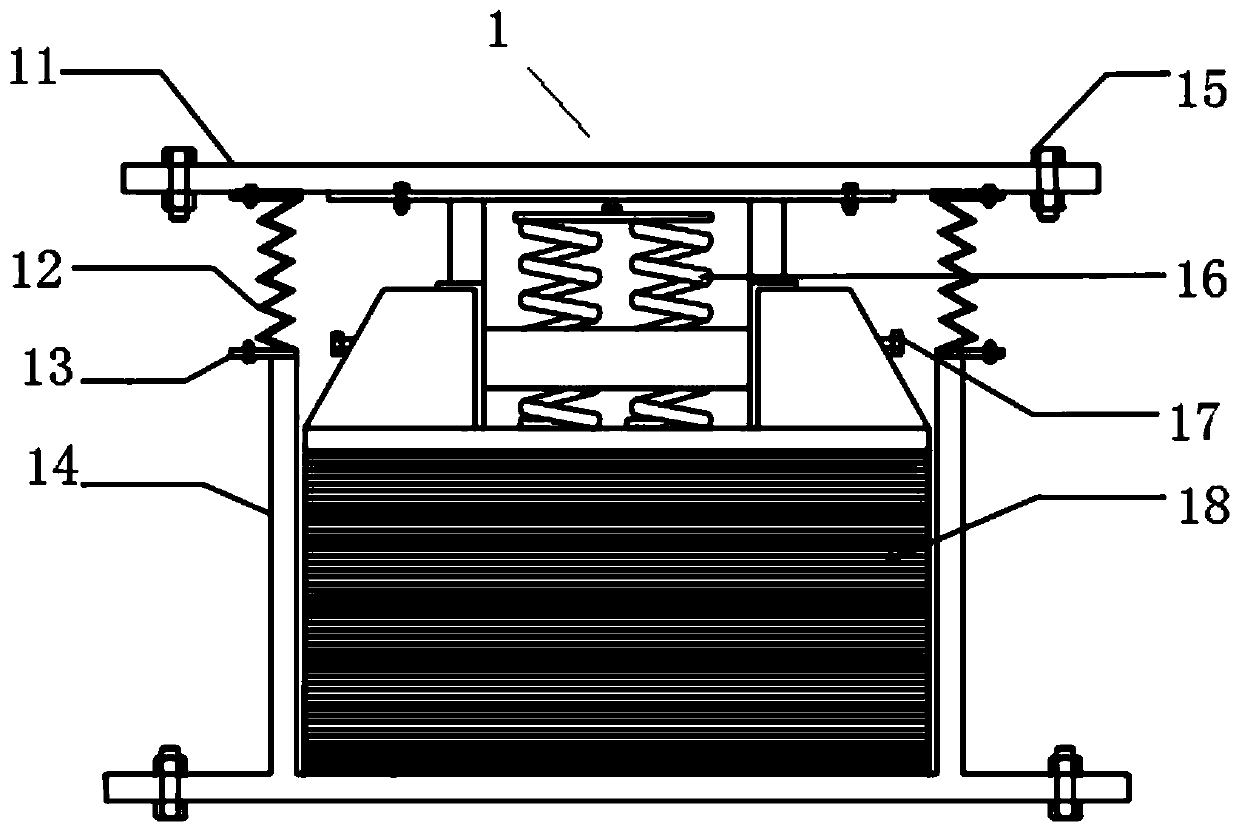

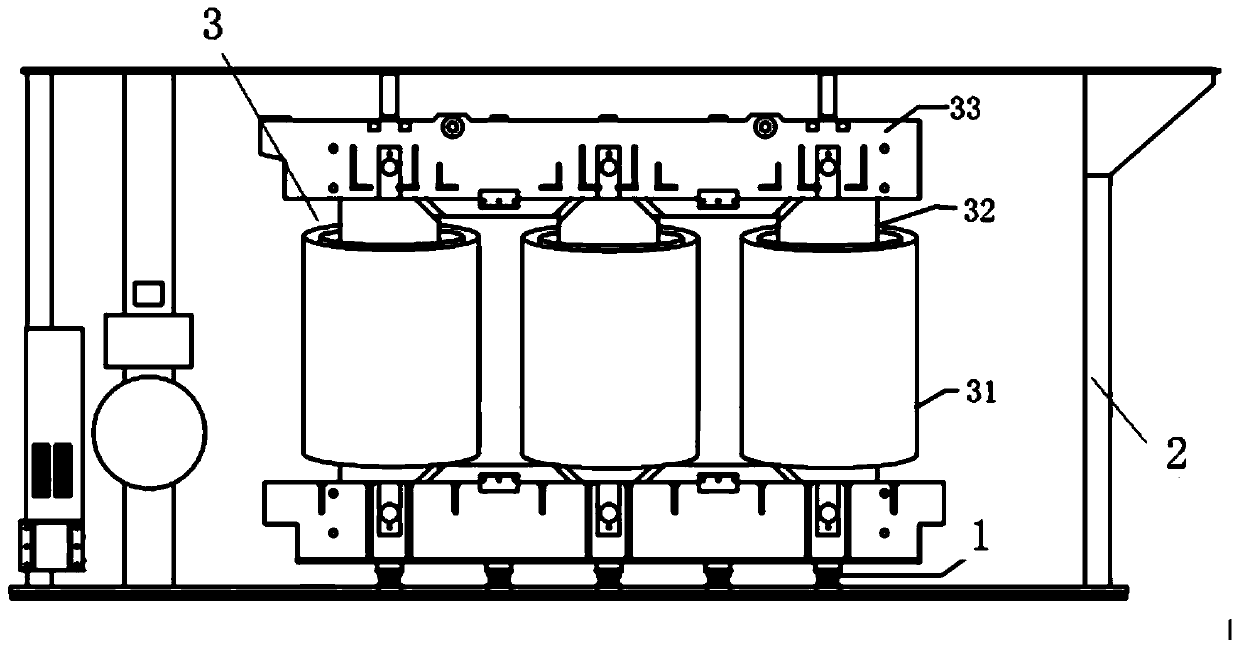

[0046] refer to figure 1 and figure 2 As shown, a vibration isolation and noise reduction device 1 for a transformer body is installed at the connection between the body 3 and the box inside the transformer oil tank 2 . The body 3 includes a base, a winding 31 , an iron core 32 , a clip 33 , etc. For specific structures, reference may be made to the prior art. This vibration isolation and noise reduction device 1 comprises a container 14 positioned at the bottom, a metal rubber vibration damping pad 18 installed in the container, a top cover 11 positioned above the container, and a flange 13 is connected to the periphery of the upper port of the container, so that A bellows 12 is connected between the flange 13 and the top cover 11, the upper edge of the bellows 12 is connected with a flange, and a damping spring vibration isolator is provided between the metal rubber damping pad 18 and the top cover 11. .

[0047]When the vibration isolation and noise reduction device is ...

Embodiment 2

[0053] A design method for a transformer body vibration isolation and noise reduction device installed inside a transformer oil tank.

[0054] Technical principle

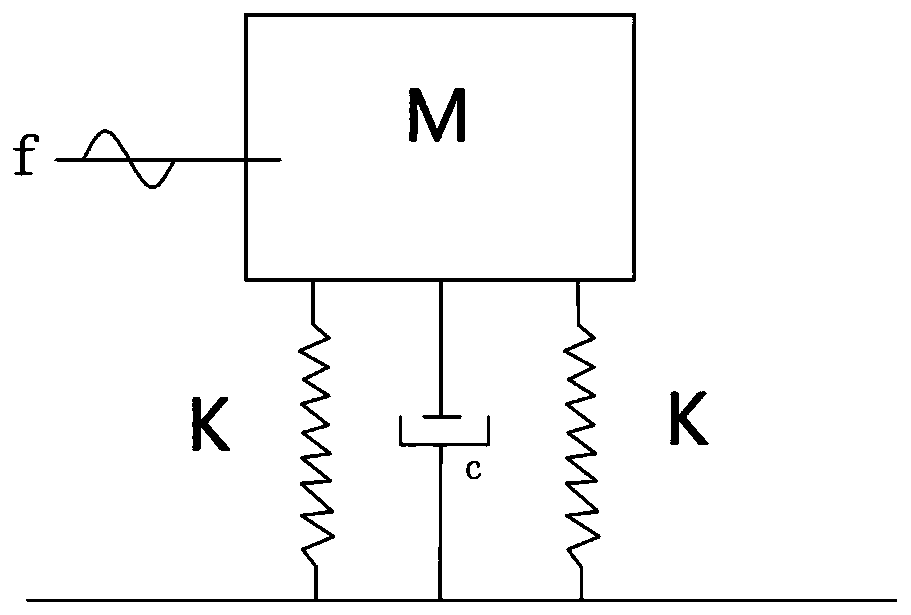

[0055] The general active vibration isolation model can be regarded as a single-degree-of-freedom vibration system with mass M, stiffness K, and viscoelastic damping coefficient c. Such as image 3 shown. Its vibration transmissibility is:

[0056]

[0057] In the formula: f is the vibration source frequency, f 0 is the natural frequency of the support system, and the damping ratio of the ξ vibration isolator.

[0058] The natural frequency of the support system is:

[0059]

[0060] In the formula: K is the stiffness of the vibration isolator, and m is the mass of the object.

[0061] Figure 4 is the vibration transmissibility curve, given by Figure 4 It can be seen that:

[0062] when f / f 0 = 1, the vibration transmission rate is the largest, and the system is in a dangerous resonance state at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com