Graphene / montmorillonite nano composite material, and preparation method and application thereof

A technology of nanocomposite materials and montmorillonite, which is applied in the field of graphene/montmorillonite nanocomposite materials and its preparation, can solve the problem of loss of specific surface area and achieve the effect of low equipment requirements, abundant reserves and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

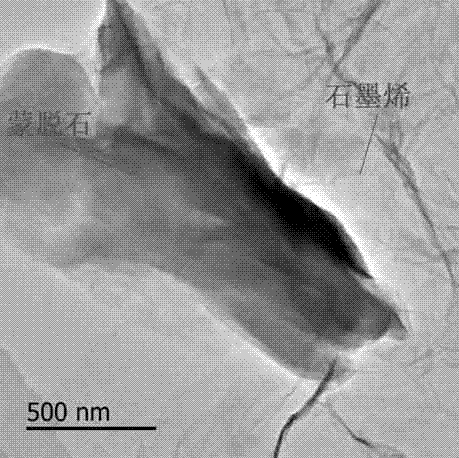

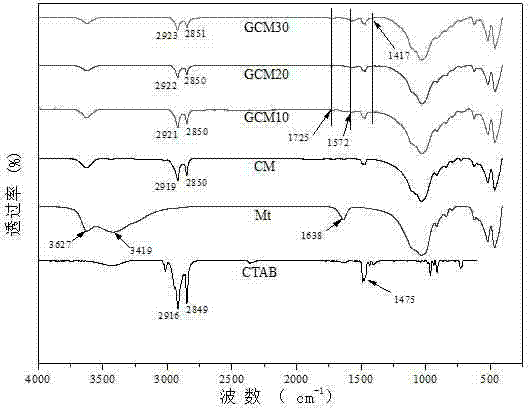

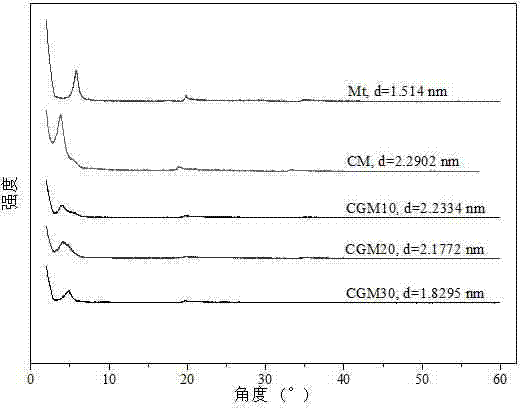

Image

Examples

Embodiment 1

[0038] (1) 0.25g graphite oxide solid was added into water, and after ultrasonic treatment for 2 h, the graphene oxide suspension with a concentration of 0.25 g / L was obtained;

[0039] Graphite oxide in this example is prepared by the improved Hummers method, and the specific steps are: add 120 ml of concentrated sulfuric acid to a 1 L beaker and place it in an ice-water bath, stir it slowly with an electric stirrer, and when the temperature drops to 4 At about ℃, add 5 g of graphite and 2.5 g of sodium nitrate, continue to stir for 30 minutes, then slowly add 15 g of potassium permanganate, keep the temperature of the reaction system not higher than 20 ℃, and continue to react for 90 minutes; move the beaker to In a constant temperature water bath at 35°C, when the temperature of the system rises to 35°C, continue to stir for 30 minutes; add 230 ml of deionized water to the beaker continuously and slowly, control the temperature of the system below 98°C, and keep the temperat...

Embodiment 2

[0046] (1) Add 0.5g of graphite oxide solid into water, and obtain a graphene oxide suspension whose concentration is 0.25 g / L after ultrasonic treatment for 2h;

[0047] (2) Dispersing the organically modified montmorillonite in water, the amount added meets: the mass ratio of graphene oxide to montmorillonite is 2:10;

[0048] (3) Place the graphene oxide suspension obtained in step (1) in an ultrasonic cleaner, ultrasonically and stir it with an electric stirrer (350 rpm) while slowly adding the organic modification obtained in step (2). For the montmorillonite suspension, stir well to mix the two evenly; continue ultrasonic stirring for 1 h, stop the ultrasonic, then stir (300 rpm) and let the system react for 2 h, and finally obtain a uniform and stable brown suspension; use the suspension Disperse in 1 L deionized water after washing with deionized water for several times;

[0049] (4) Put the brown suspension obtained in step (3) in a constant temperature water bath at...

Embodiment 3

[0054] (1) 0.75g of graphite oxide solid was added into water, and obtained after ultrasonic treatment for 2h, was a graphene oxide suspension of 0.25 g / L;

[0055] (2) Dispersing an appropriate amount of organically modified montmorillonite in water, the amount of organically modified montmorillonite meets: the mass ratio of graphene oxide to montmorillonite is 3:10;

[0056] (3) Place the graphene oxide suspension obtained in step (1) in an ultrasonic cleaner, ultrasonically and stir it with an electric stirrer (350 rpm) while slowly adding the organic modification obtained in step (2). For the montmorillonite suspension, stir well to mix the two evenly; continue ultrasonic stirring for 1 h, stop the ultrasonic, then stir (300 rpm) and let the system react for 2 h, and finally obtain a uniform and stable brown suspension; use the suspension Disperse in 1 L deionized water after washing with deionized water for several times;

[0057] (4) Put the brown suspension obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com