Aviation buffer rubber gasket and production method thereof

A rubber gasket and cushioning rubber technology, which is applied to springs made of plastic materials, mechanical equipment, low internal friction springs, etc., can solve the problems of complex structure of the cushioning device, cumbersome replacement process, high maintenance cost, etc., and achieve excellent cushioning effect, The effect of high product qualification rate and extended maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the present invention.

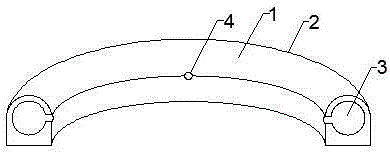

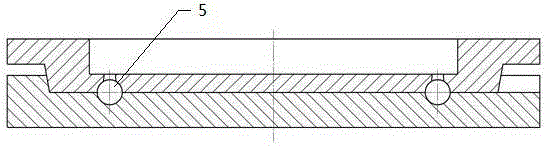

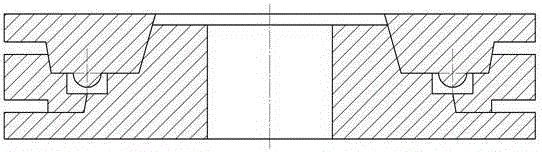

[0030] Such as figure 1 , an aviation cushioning rubber gasket, comprising a gasket main body 1 and a hollow cavity 3, the surface of the main body 1 is provided with a warp-knitted reinforcement layer 2, and the main body 1 is also provided with an installation hole 4 communicating with the hollow cavity 3 . The washer main body 1 and the warp-knitted fabric reinforcement layer 2 are flatly bonded together with an adhesive. The hollow cavity 3 is an annular cavity with an "O" cross-section. The upper part of the section of the washer main body 1 is semicircular, and the lower part is rectangular. The four mounting holes 4 are evenly distributed on the inner side of the washer main body 1 .

[0031] The above-mentioned rubber gasket is made of silicone rubber that is resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com