Energy-saving type plastic pipe cutting and polishing device

A technology for cutting and grinding plastic pipes, which is applied in the direction of grinding machines, grinding workpiece supports, grinding/polishing equipment, etc., can solve problems such as unsatisfactory fixing effects, achieve good fixing effects, avoid economic losses, and reduce the size of the working space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

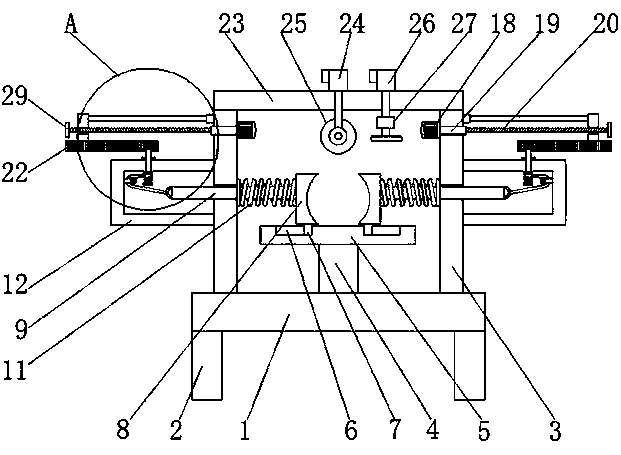

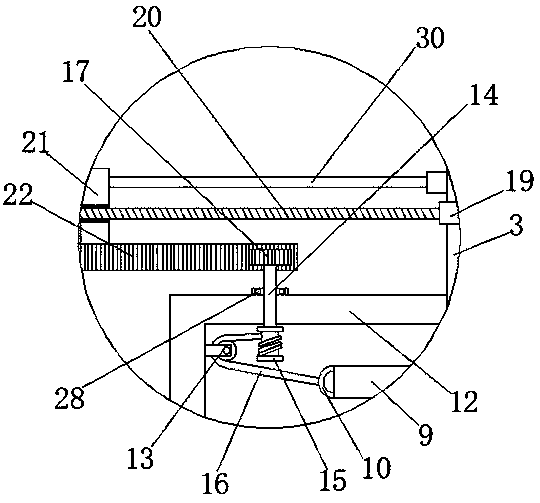

[0017] First implementation: see Figure 1-2 , an energy-saving plastic pipe cutting and polishing device, comprising a bottom plate 1, the left and right sides of the bottom of the bottom plate 1 are fixedly connected with support seats 2, the left and right sides of the top of the bottom plate 1 are fixedly connected with side plates 3, and the middle of the top of the bottom plate 1 The point is fixedly connected with a support block 4, and the top of the support block 4 is fixedly connected with a fixed plate 5, and the top of the fixed plate 5 is symmetrically provided with two chute 6, and the inside of the chute 6 is movably connected with a slider 7, and the slider 7 The top of the top passes through the chute 6 and extends to the outside to be fixedly connected with an arc splint 8, and the opposite sides of the two arc splints 8 are fixedly connected with a fixing rod 9, and the end of the fixing rod 9 away from the arc splint 8 runs through the side plate 3 and exte...

no. 2 approach

[0020]The second embodiment: an energy-saving plastic pipe cutting and polishing device, including a bottom plate 1, the left and right sides of the bottom of the bottom plate 1 are fixedly connected with support seats 2, and the left and right sides of the top of the bottom plate 1 are fixedly connected with side plate 3, a support block 4 is fixedly connected to the midpoint of the top of the base plate 1, and a fixed plate 5 is fixedly connected to the top of the support block 4, and two slide grooves 6 are symmetrically opened on the top of the fixed plate 5, so that The inside of the chute 6 is movably connected with a slider 7, and the top of the slider 7 runs through the chute 6 and extends to the outside thereof to be fixedly connected with an arc-shaped splint 8, and the opposite sides of the two arc-shaped splints 8 are fixedly connected. There is a fixed rod 9, and the end of the fixed rod 9 away from the arc-shaped splint 8 runs through the side plate 3 and extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com