Method for performing zero moment point (ZMP) calibration autonomously by robot

A robot and sensor technology, applied in the field of autonomous foot ZMP calibration of humanoid robots, can solve problems such as time-consuming, error, limited number of calibration points, etc. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

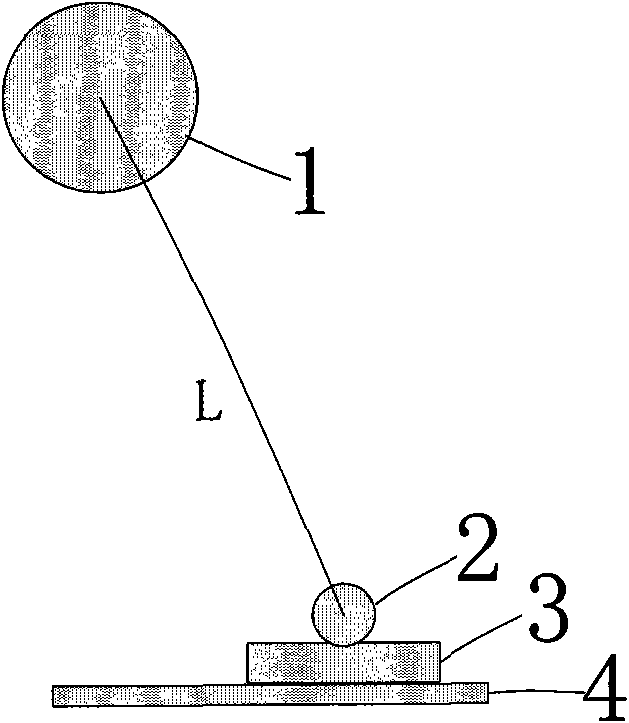

[0024] figure 1 A simplified diagram of a humanoid robot model when calibrating ZMP according to the present invention is shown. The robot includes a simplified particle 1 supporting the part above the ankle joint, an ankle joint 2, a force sensor 3, and a foot surface 4. The ankle joint can rotate side to side and front to back. ZMP is measured by a six-dimensional force sensor 3 .

[0025] figure 2 Taking the right foot of a humanoid robot as an example shows the direction of the center of gravity movement, some parameters and the establishment of the coordinate system of the present invention. The vertical distance from the upper surface of the sensor to the sole of the foot is d, p R Indicates the coordinates of the ZMP.

[0026] Before the assembly of each part of the humanoid robot, the position of its center of mass can be measured. After the assembly is completed, the center of mass of the robot with any posture can be obtained through calculation. Suppose the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com