Patents

Literature

51results about How to "Automatic grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

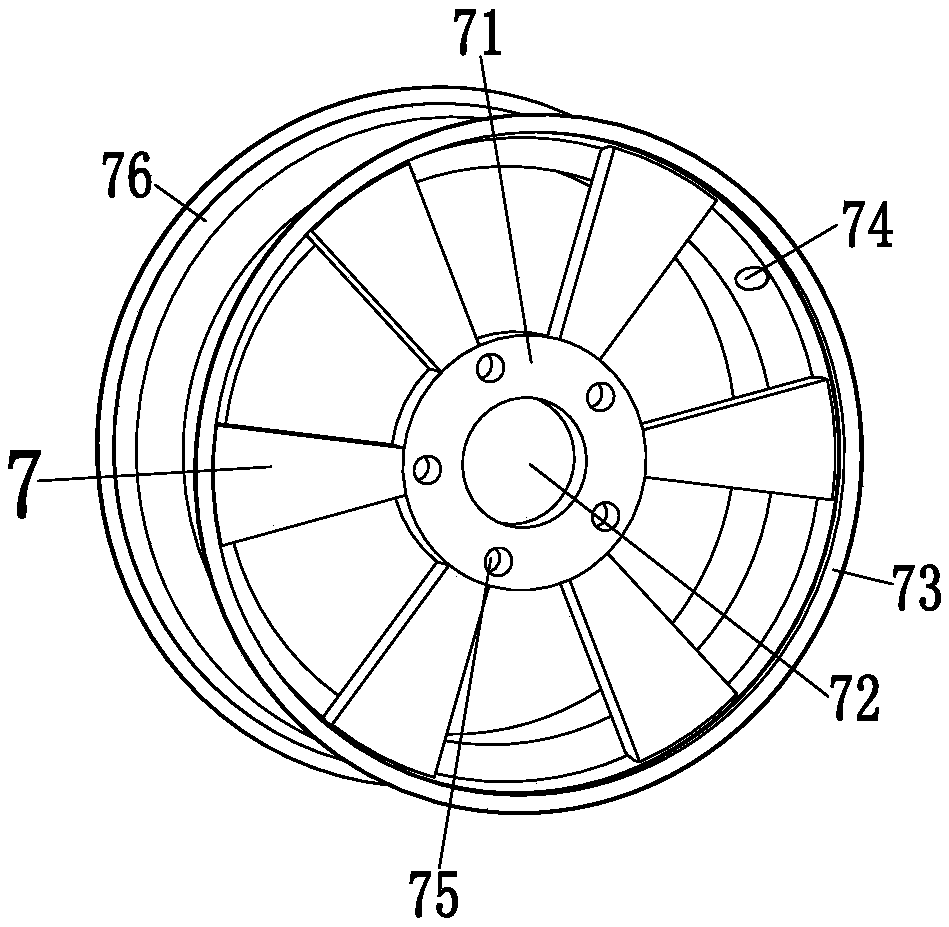

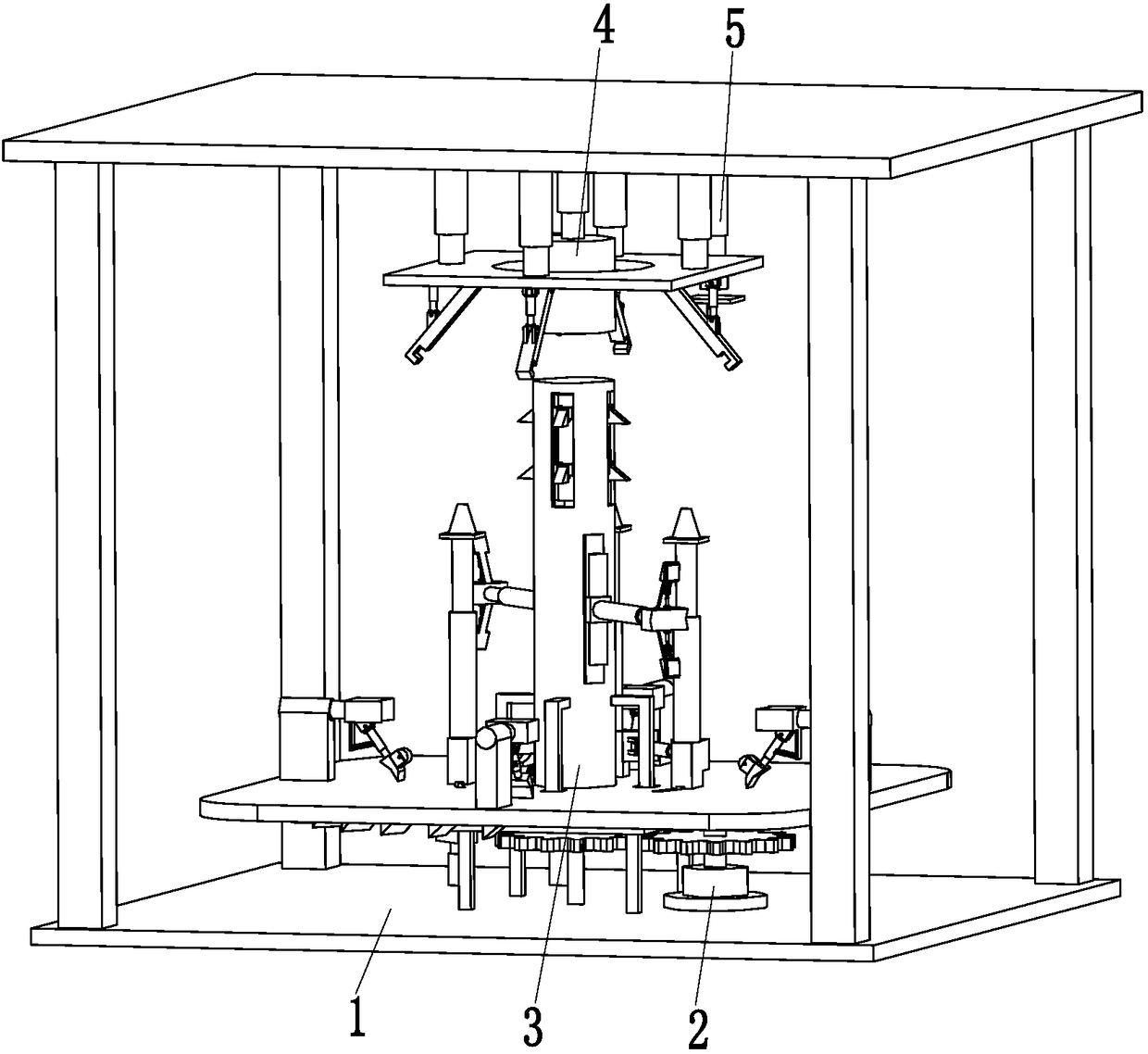

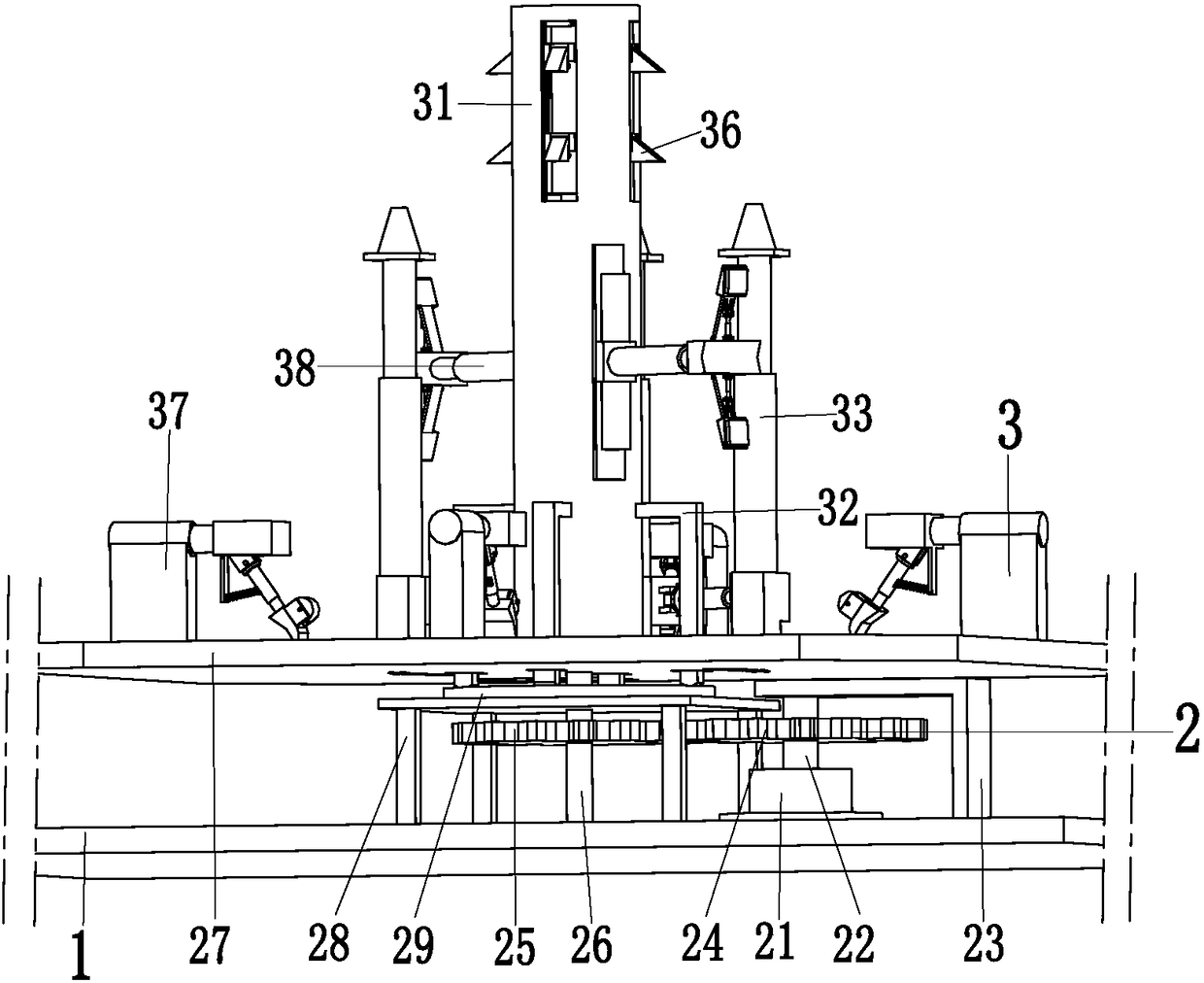

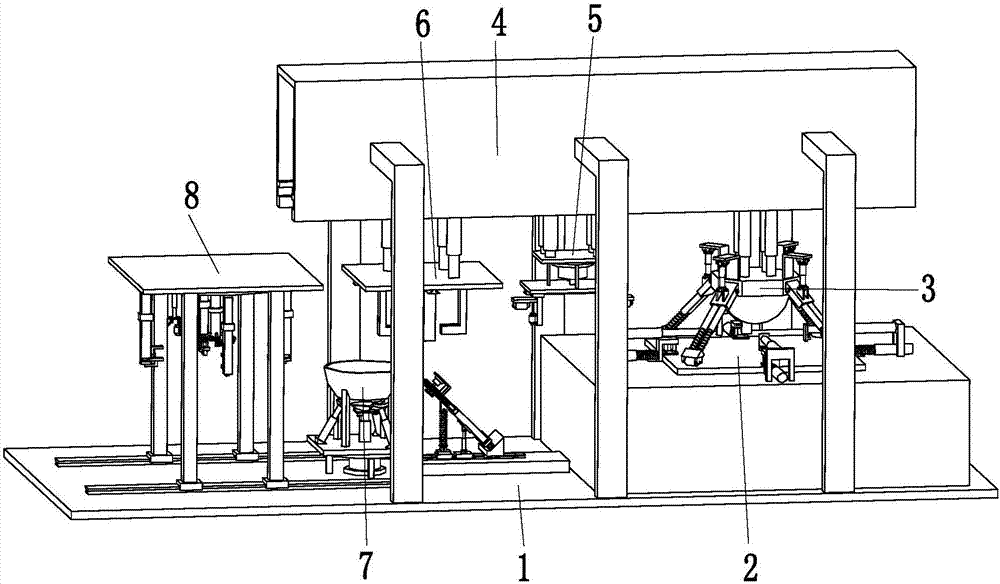

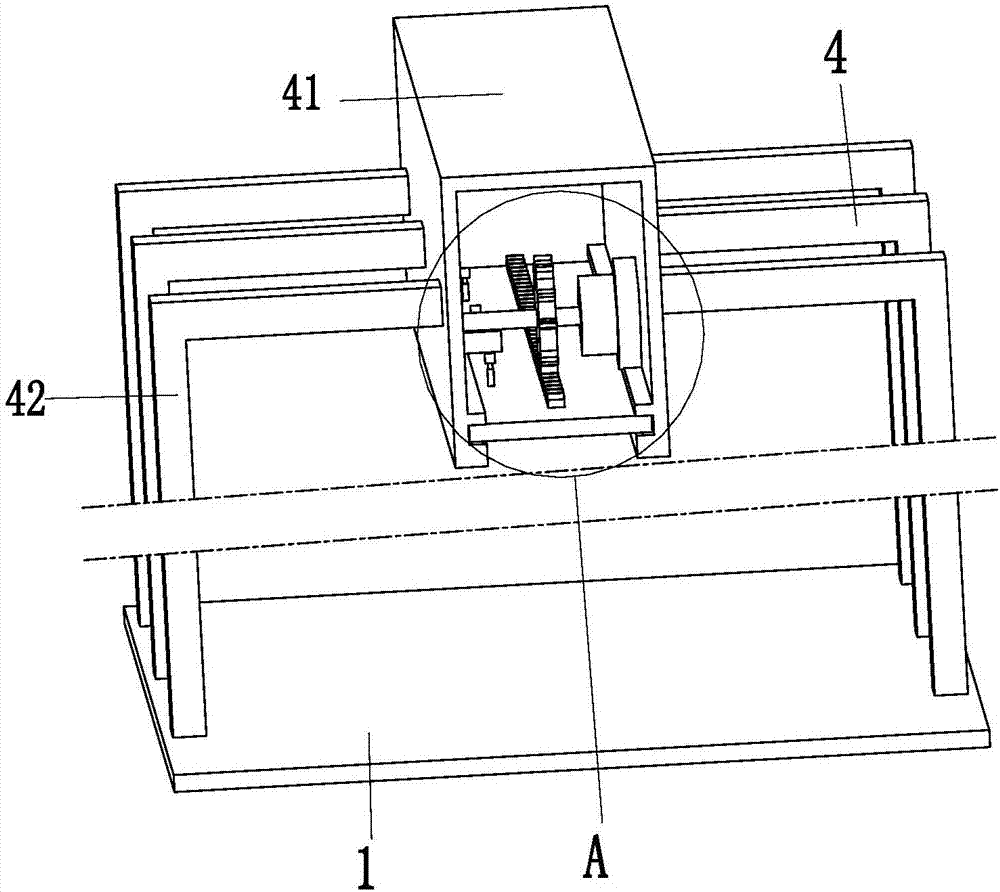

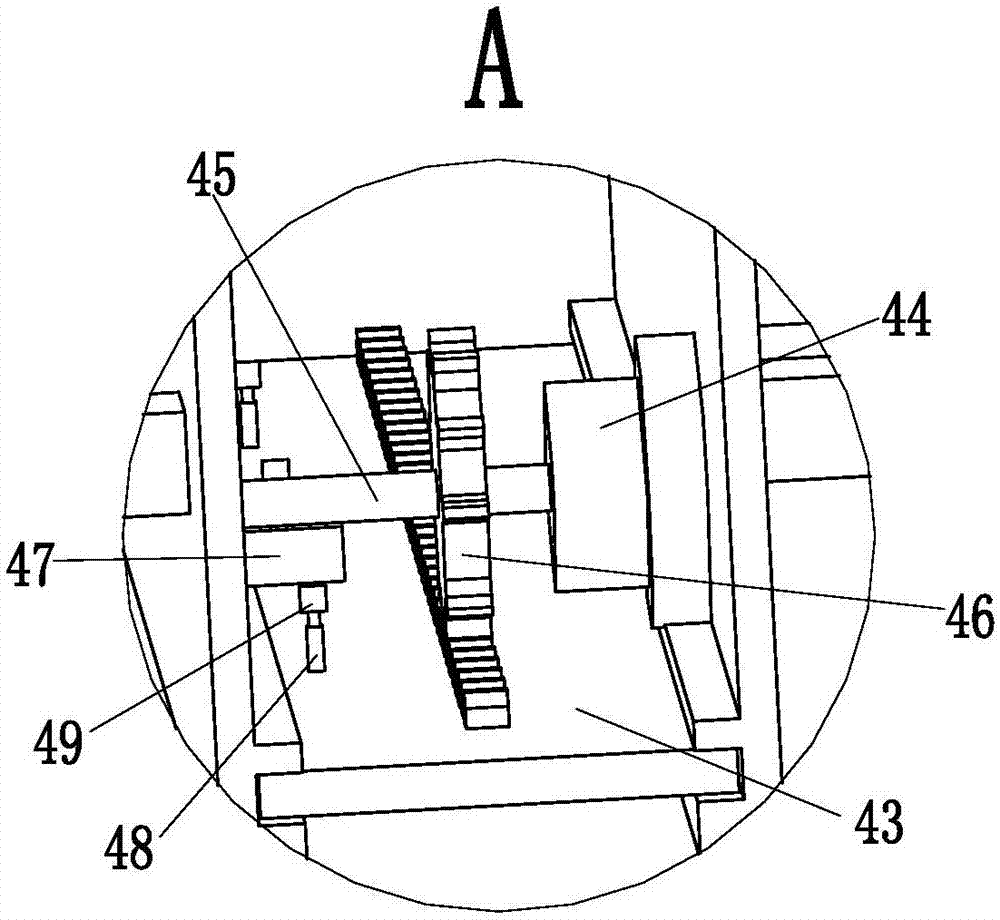

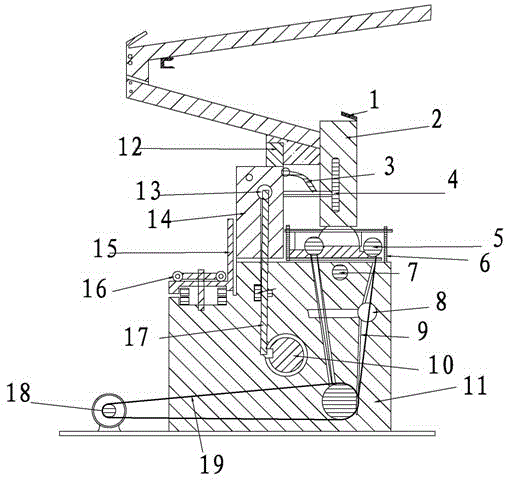

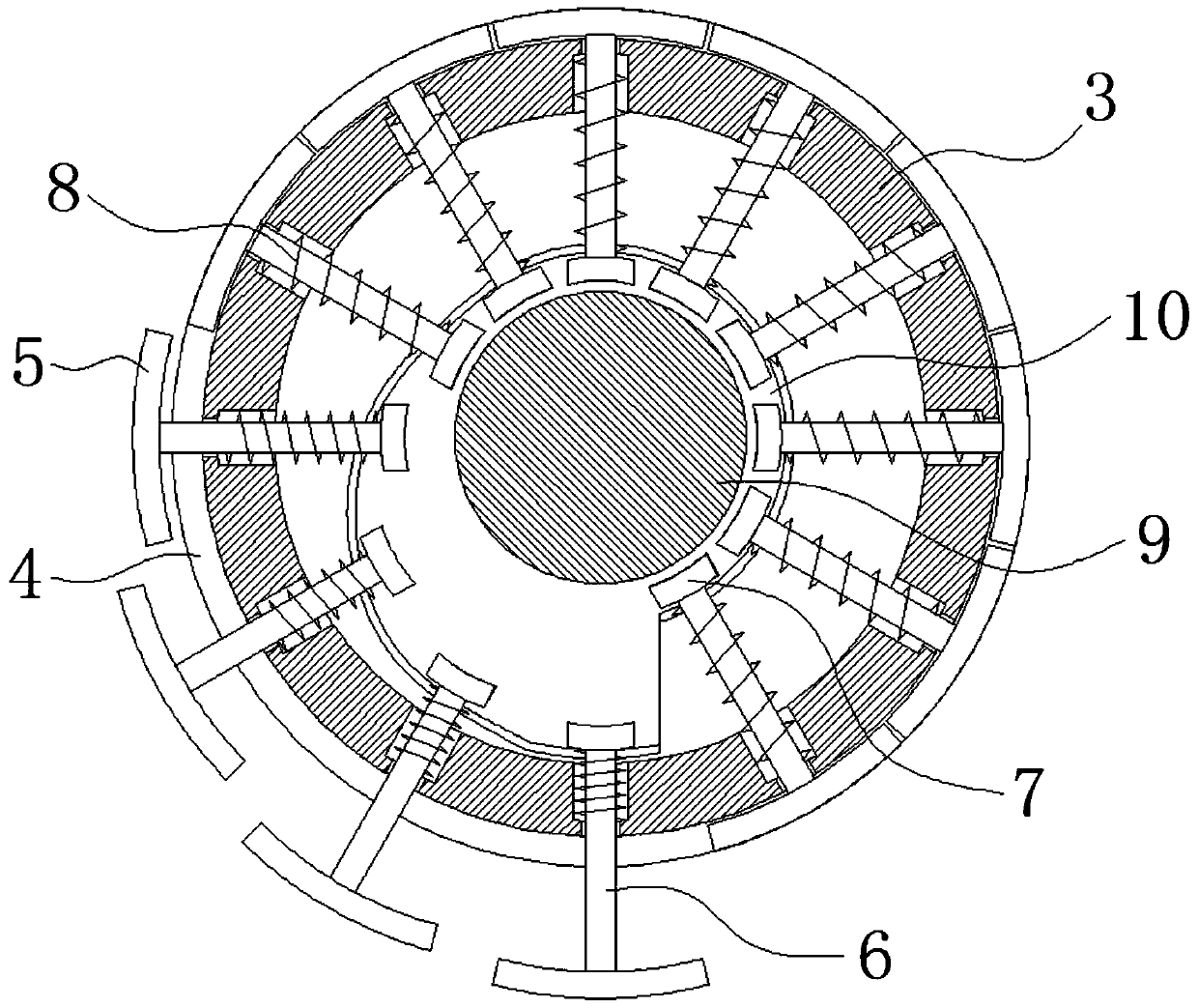

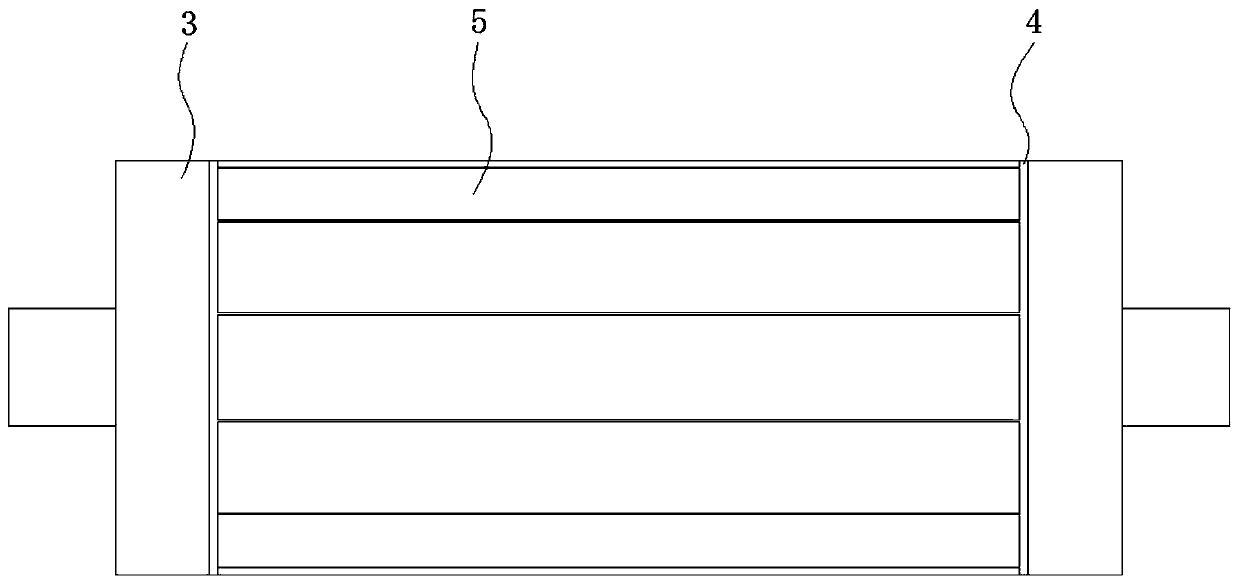

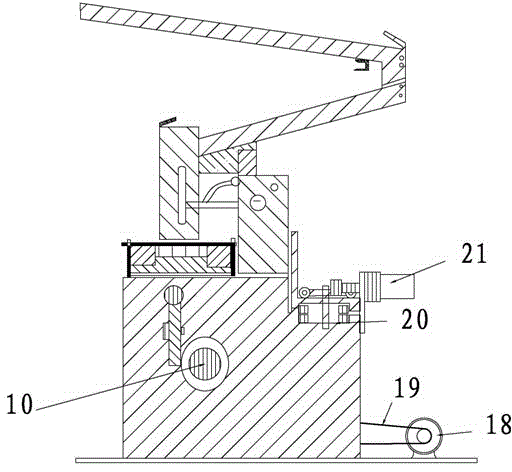

New energy automobile wheel hub valve hole perforation fixture with automatic positioning function

InactiveCN108080961AEasy to fixAutomatic grindingOther manufacturing equipments/toolsPositioning apparatusEngineeringStable fixation

The invention relates to a new energy automobile wheel hub valve hole perforation fixture with an automatic positioning function. The new energy automobile wheel hub valve hole perforation fixture comprises a support bottom plate, a rotary device, a fixing device, a clamping device and a hole drilling device. The rotary device is mounted on the top of the support bottom plate, the fixing device ismounted on the top of the rotary device, the clamping device is connected with the support bottom plate, and the hole drilling device is mounted on the clamping device. The new energy automobile wheel hub valve hole perforation fixture has the advantages that the difficult problems of incapability of fixing existing wheel hubs for existing wheel hub structures when existing valve holes are drilled in the existing new energy automobile wheel hubs in certain factories, incapability of firmly fixing the existing wheel hubs, deviation when the existing wheel hubs rotate under the control, requirements on manually polishing the existing valve holes and the like at present can be solved by the aid of the new energy automobile wheel hub valve hole perforation fixture; the new energy automobile wheel hub valve hole perforation fixture can have functions of stably fixing new energy automobile wheel hubs and drilling and polishing valve holes in the wheel hubs, the wheel hubs can be fixed for wheel hub structures by the aid of the new energy automobile wheel hub valve hole perforation fixture and can be firmly fixed by the aid of the new energy automobile wheel hub valve hole perforation fixture, the wheel hubs can stably rotate without deviation under the control, the valve holes can be automatically polished, and the like.

Owner:盛亚明

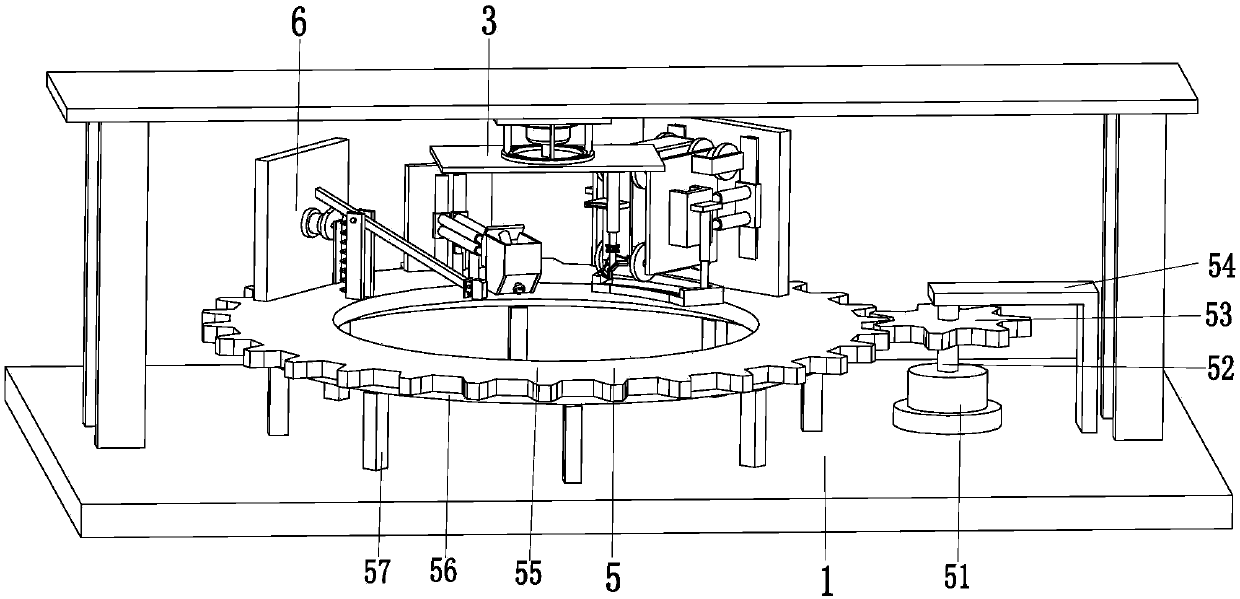

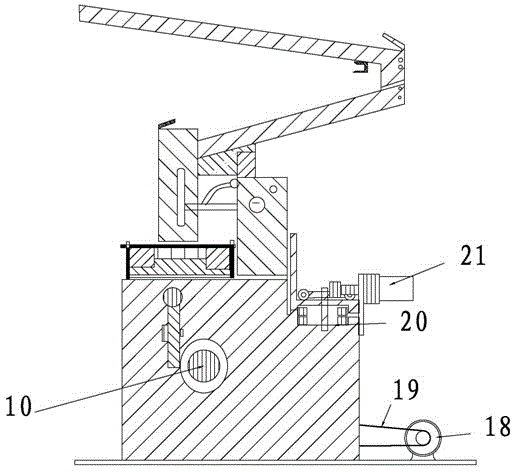

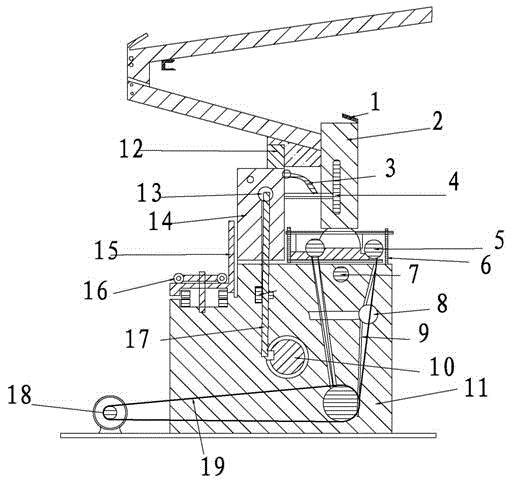

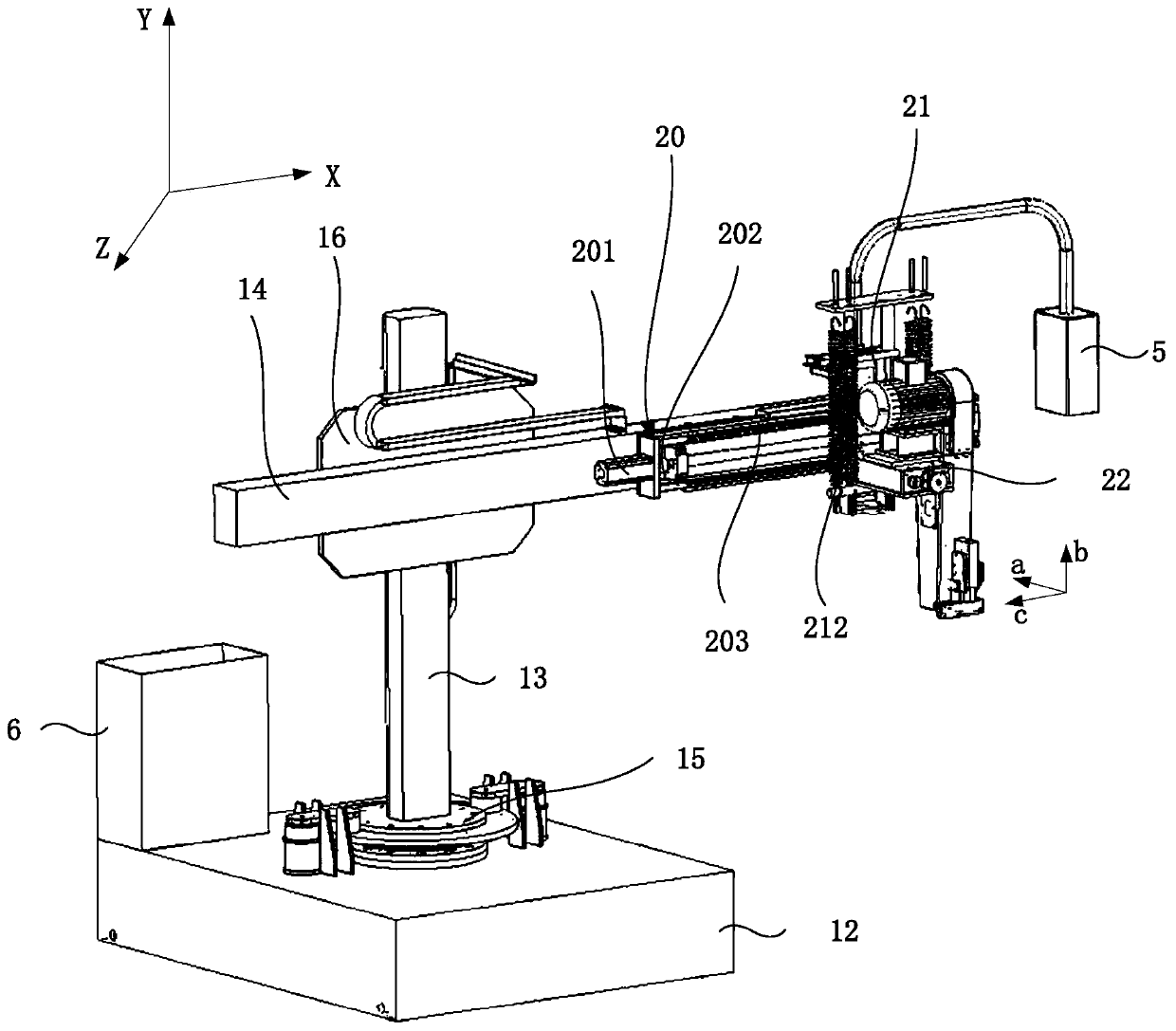

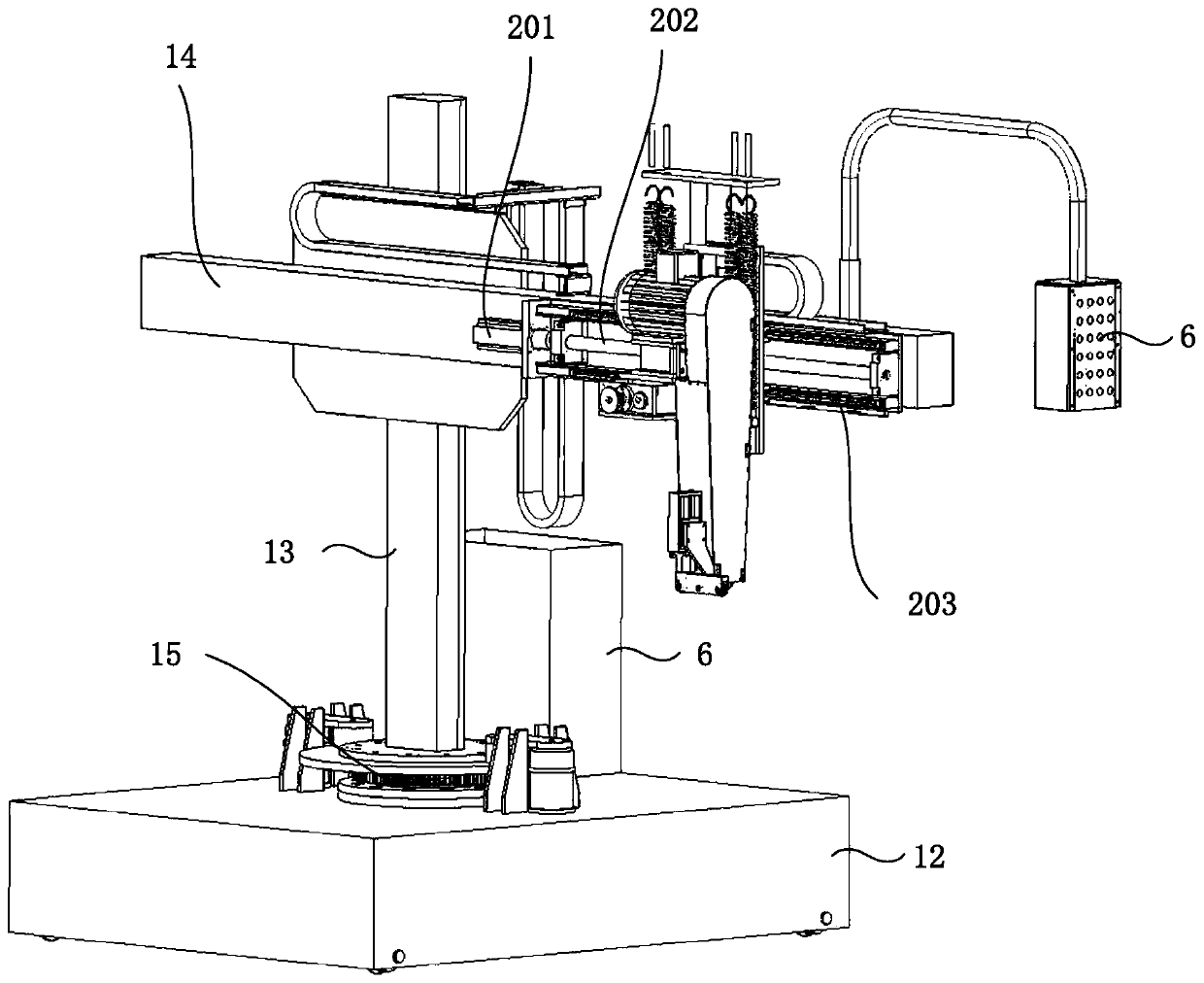

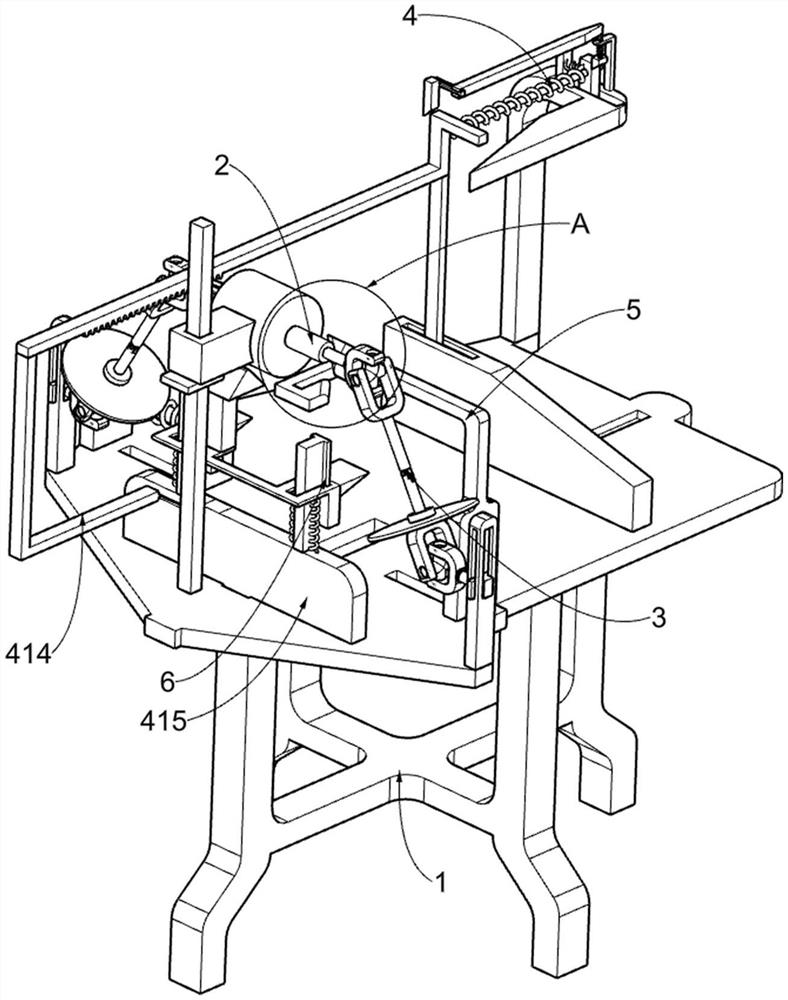

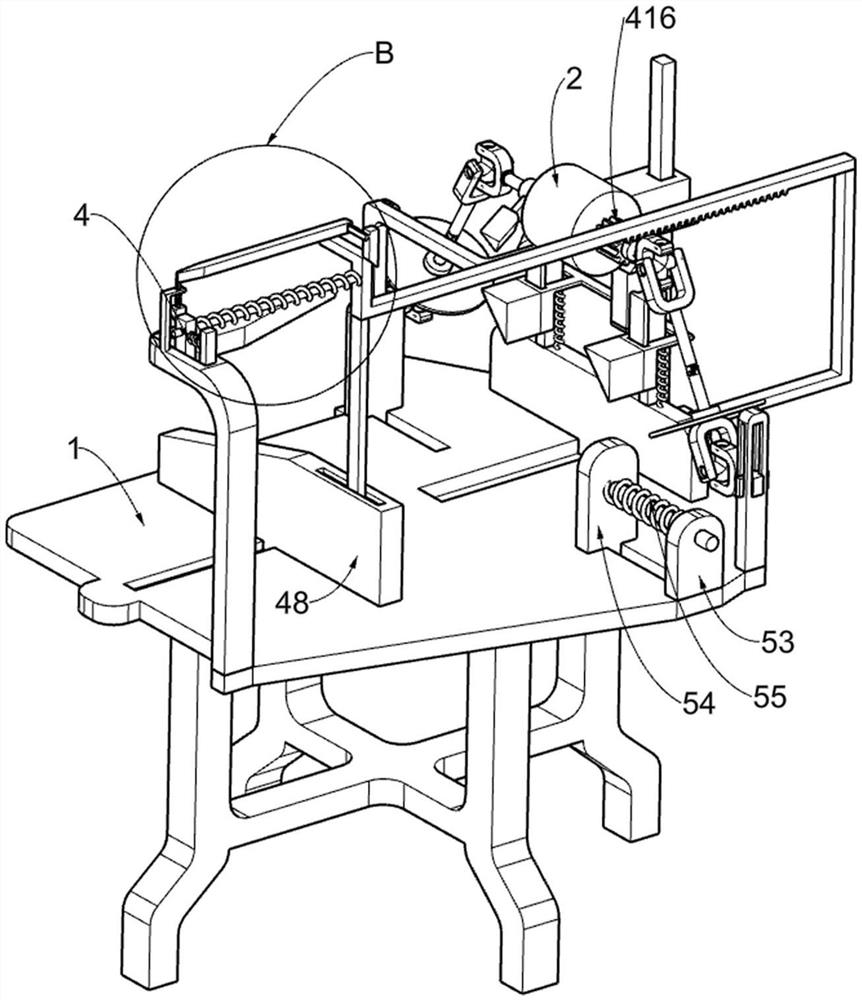

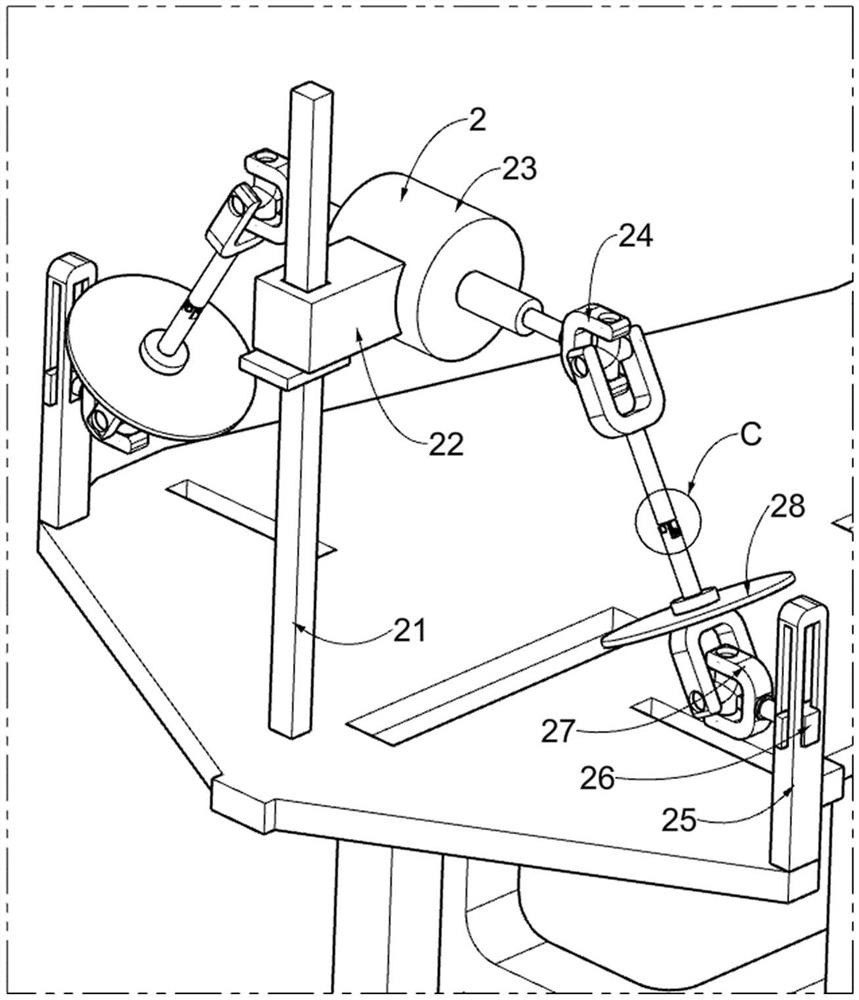

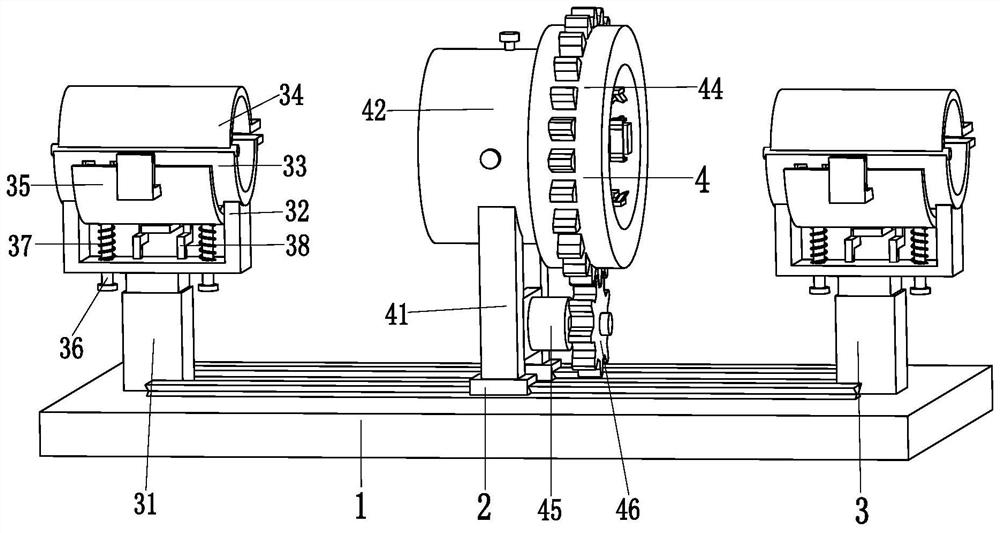

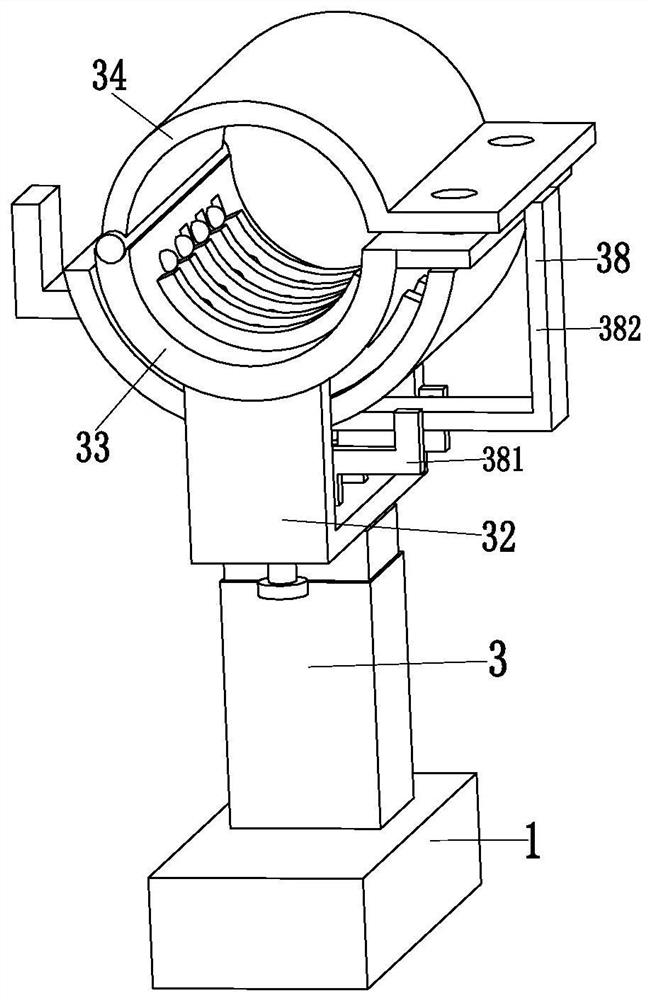

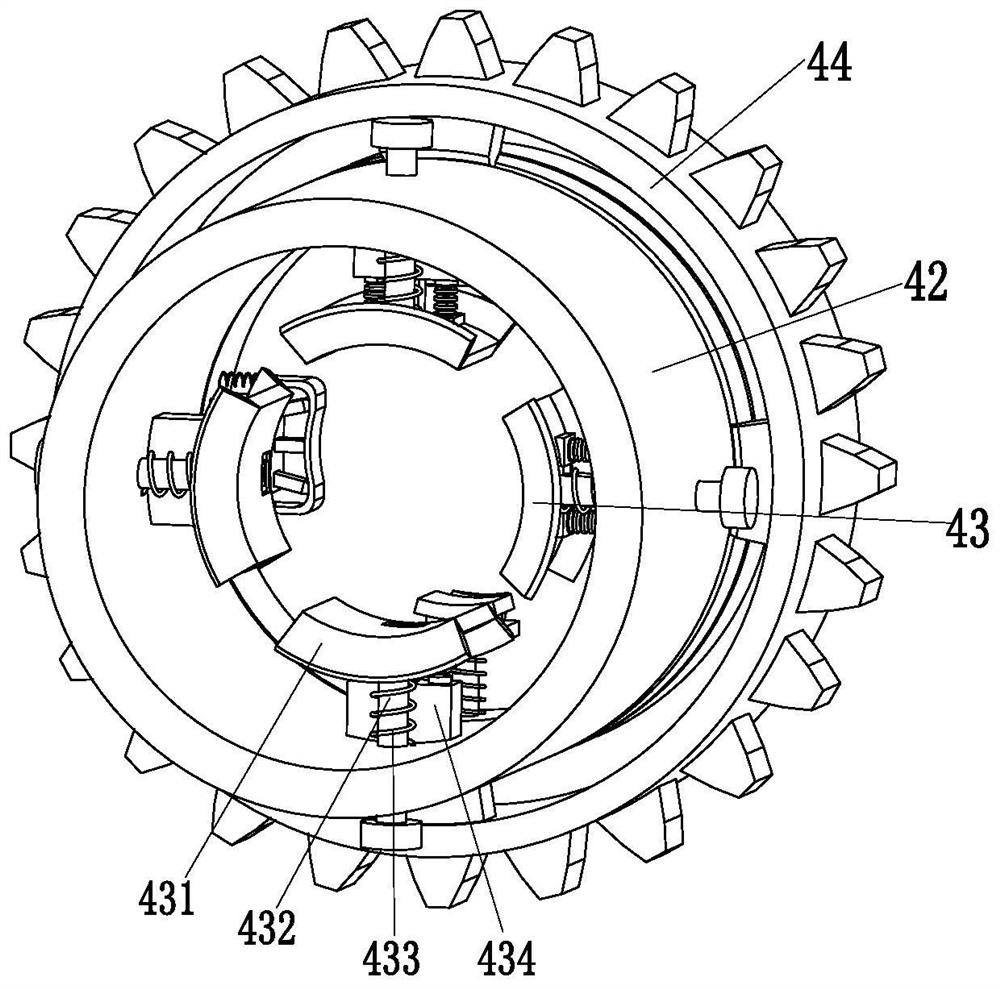

Pre-welding and post-welding intelligent treatment equipment for pipeline engineering stainless steel flange

InactiveCN107914195AAutomatic grindingImprove work efficiencyEdge grinding machinesGrinding carriagesEngineeringSteel tube

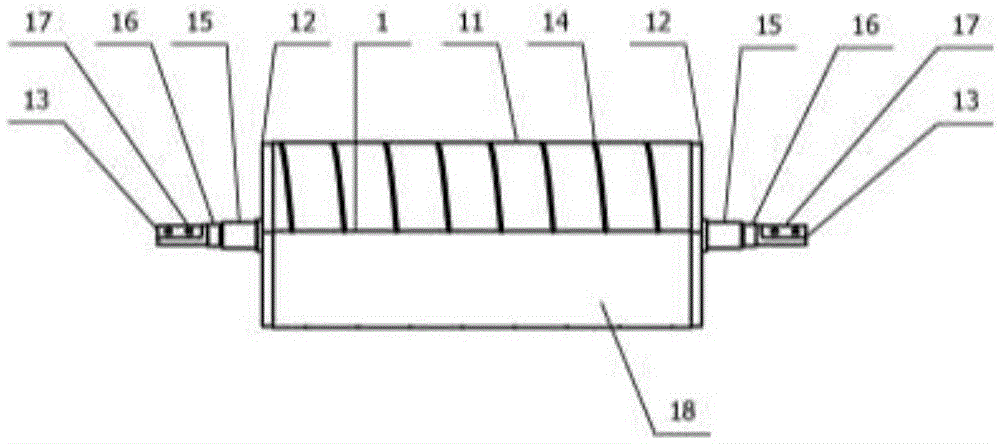

The invention relates to pre-welding and post-welding intelligent treatment equipment for a pipeline engineering stainless steel flange. The pre-welding and post-welding intelligent treatment equipment for the pipeline engineering stainless steel flange comprises a supporting bottom plate, a grinding device, a rotary device and a post-welding treatment device. The grinding device is installed on the supporting bottom plate. The rotary device is located below the grinding device and connected with the supporting bottom plate. The post-welding treatment device is installed on the rotary device.The problems that in the existing process of welding the flange and a steel pipe, the flange needs to be ground manually before welding, the pre-welding grinding effect of the flange is not good, post-welding treatment needs to be conducted on the flange and the steel pipe manually, and manual post-welding treatment is not thorough are solved. The functions of conducting pre-welding grinding on flanges with different specifications and chamfering angles and conducting post-welding thorough cleaning on the flange and the steel pipe can be achieved, and the pre-welding and post-welding intelligent treatment equipment for the pipeline engineering stainless steel flange has the advantages of automatically carrying out pre-welding grinding on the flange, being good in flange pre-welding grinding effect, automatically carrying out post-welding treatment on the flange and the steel pipe, automatically carrying out thorough post-welding treatment and the like.

Owner:吴丹

Processing device for antibacterial metal material for titanium intramedullary nail

InactiveCN110026893ALock firmlyAutomatic grindingSpraying apparatusGrinding machinesLocking mechanismEngineering

The invention relates to a processing device for an antibacterial metal material for a titanium intramedullary nail. The processing device comprises a supporting bottom plate, an electric guide rail,locking devices and a detection device, wherein the electric guide rail is arranged on the upper end surface of the middle of the supporting bottom plate, the detection device is arranged on the top of the electric guide rail, and two locking devices are installed on the left side and the right side of the top of the supporting bottom plate respectively; each locking device comprises a locking base, a locking connecting frame, a locking bottom sleeve, a clamping pressing sleeve, a locking sleeve, locking sliding columns, sliding column springs and a buckling branch chain; and the detection device comprises a detection support, a detection sleeve, marking mechanisms, a rotating sleeve, a rotating motor, a rotating gear, grinding mechanisms and cleaning mechanisms. The processing device forthe antibacterial metal material for the titanium intramedullary nail can solve the problems that an existing titanium bar is not firm in locking, a locking mechanism cannot be used for conveying thetitanium bar, the bending degree of the titanium bar cannot be visually marked, and the titanium bar needs to be polished manually, when the existing titanium bar is subjected to bending detection andpolishing.

Owner:THE PEOPLES HOSPITAL SHAANXI PROV

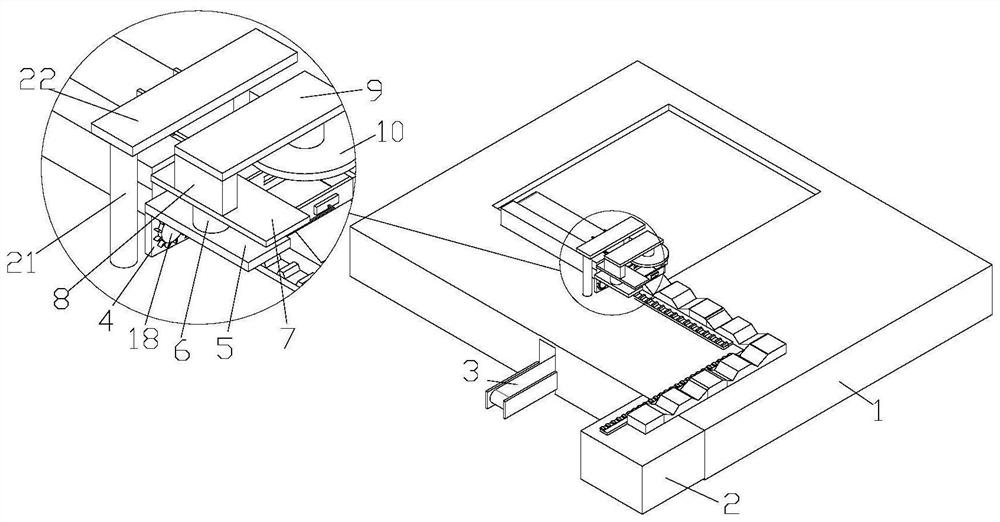

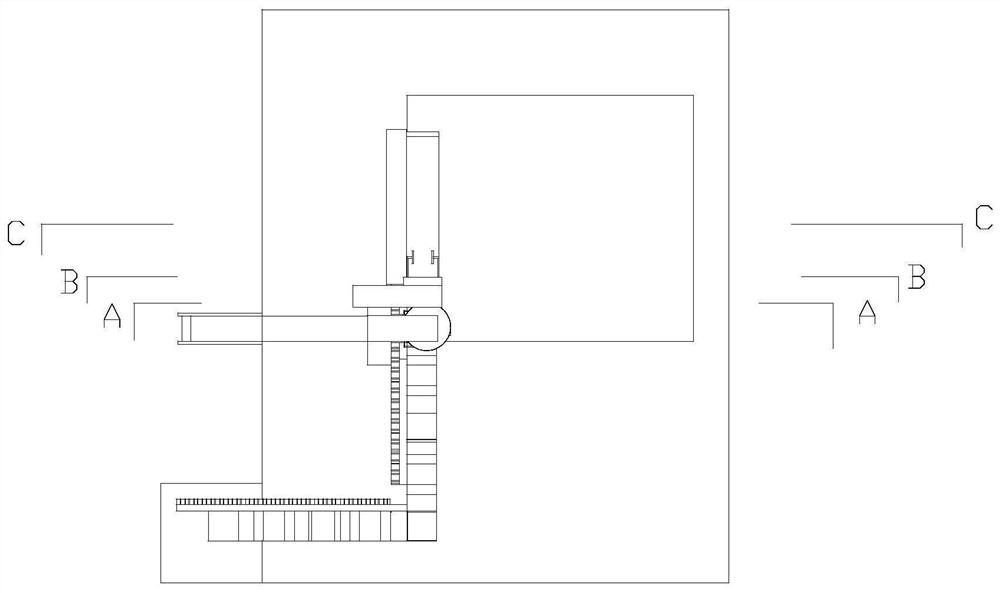

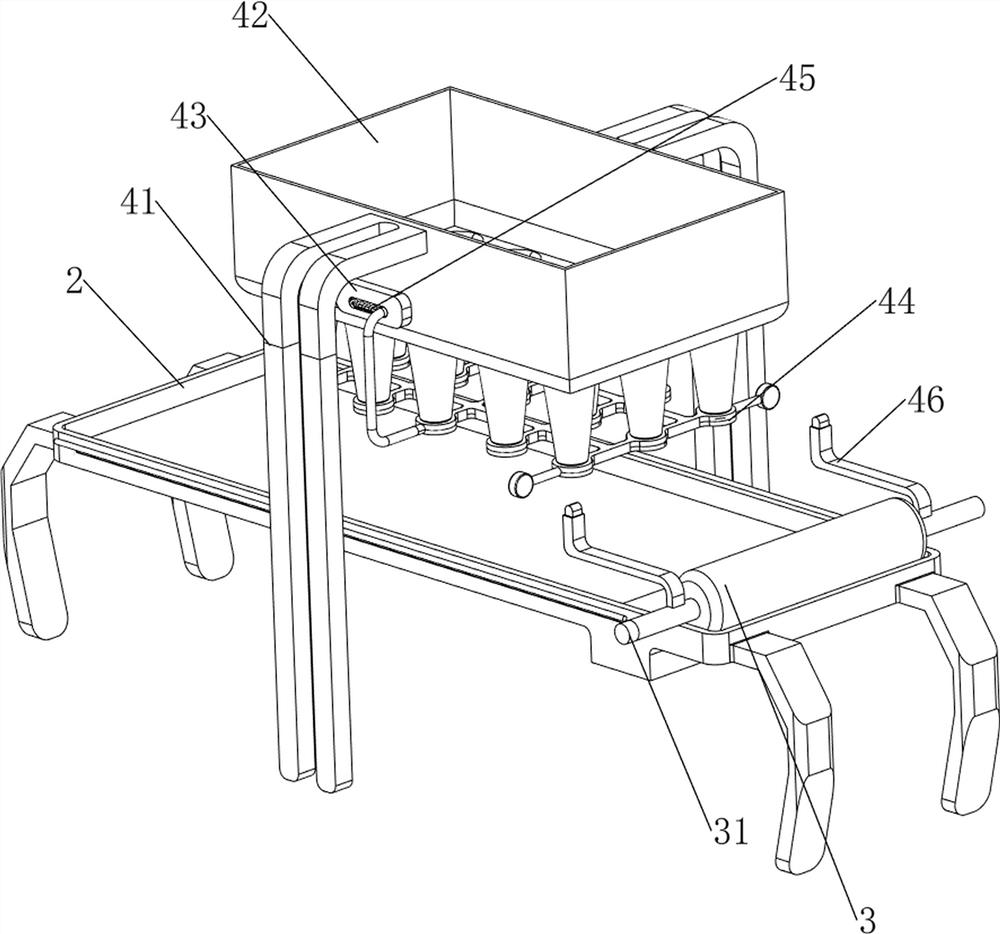

Steel structure assembly type building material producing and processing processor

InactiveCN108000161ASupport fixed and stableAutomatic grindingOther manufacturing equipments/toolsSteel platesBuilding material

The invention relates to a steel structure assembly type building material producing and processing processor. The steel structure assembly type building material producing and processing processor comprises a supporting bottom plate, a fixed device, an extruding device, a conversion device, a correcting device, a carrying device, a cutting device and a supporting grinding device, wherein the fixed device is mounted at the right end of the supporting bottom plate; the extruding device is connected with the right end of the conversion device; the conversion device is mounted on the supporting bottom plate; both the correcting device and the carrying device are mounted on the conversion device; the correcting device is positioned at the right side of the carrying device; the cutting device is mounted on the middle part of the supporting bottom plate; and the supporting grinding device is connected with the upper end surface of the left side of the supporting bottom plate. The steel structure assembly type building material producing and processing processor can solve the problems that all-around leveling cannot be performed when a steel plate is extruded, the extruded steel plate cannot be corrected, a cutting angle of the cut and extruded steel plate cannot be regulated, the cutting effect is poor, a cut ball body needs to manually grind, and the like during welding ball processing in the prior art.

Owner:黄远明

Circuit board welding device for intelligent manufacturing

InactiveCN113478043APrevent movementAutomatic grindingGrinding drivesWelding/soldering/cutting articlesPolishingAir pump

The invention relates to a welding device, in particular to a circuit board welding device for intelligent manufacturing. According to the circuit board welding device for intelligent manufacturing, alcohol can be automatically wiped, and accurate welding can be achieved. The circuit board welding device for intelligent manufacturing comprises a first supporting plate, first fixing frames, a fixing plate and a second supporting plate, the first fixing frames are symmetrically installed at the upper parts of the two sides of the first supporting plate, the fixing plate is mounted between the upper parts of the inner sides of the first fixing frames, and the second supporting plate is installed in the middle of the upper part of one side of the first supporting plate. According to the circuit board welding device, air in an ejecting block can be pumped away through an air pump, the ejecting block can suck a circuit board, the circuit board is prevented from moving, then a third motor and a second motor serve as driving force, a polishing plate can be driven to reciprocate leftwards and rightwards once, and therefore the circuit board is automatically polished, manual polishing is not needed, and time and labor are saved.

Owner:江西环境工程职业学院

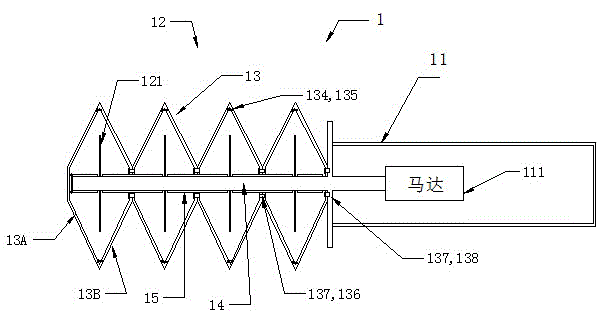

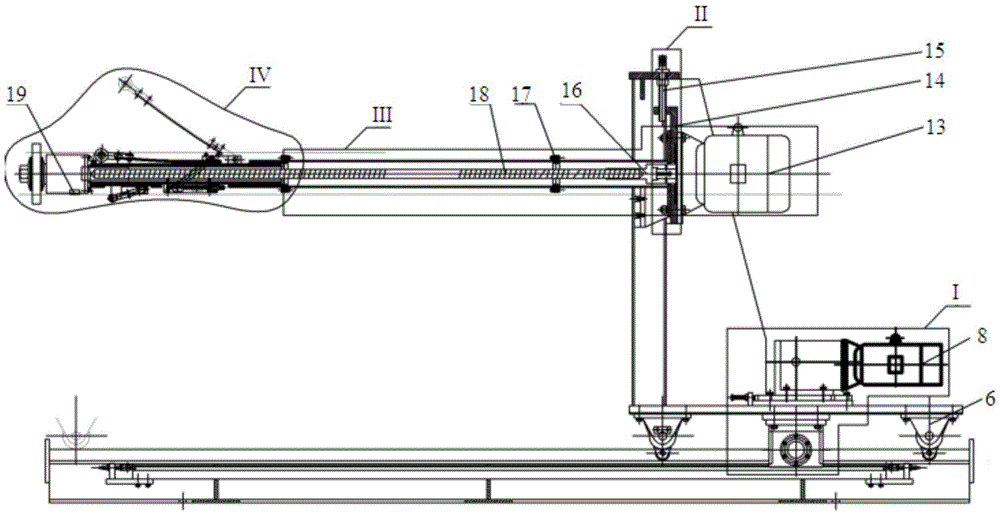

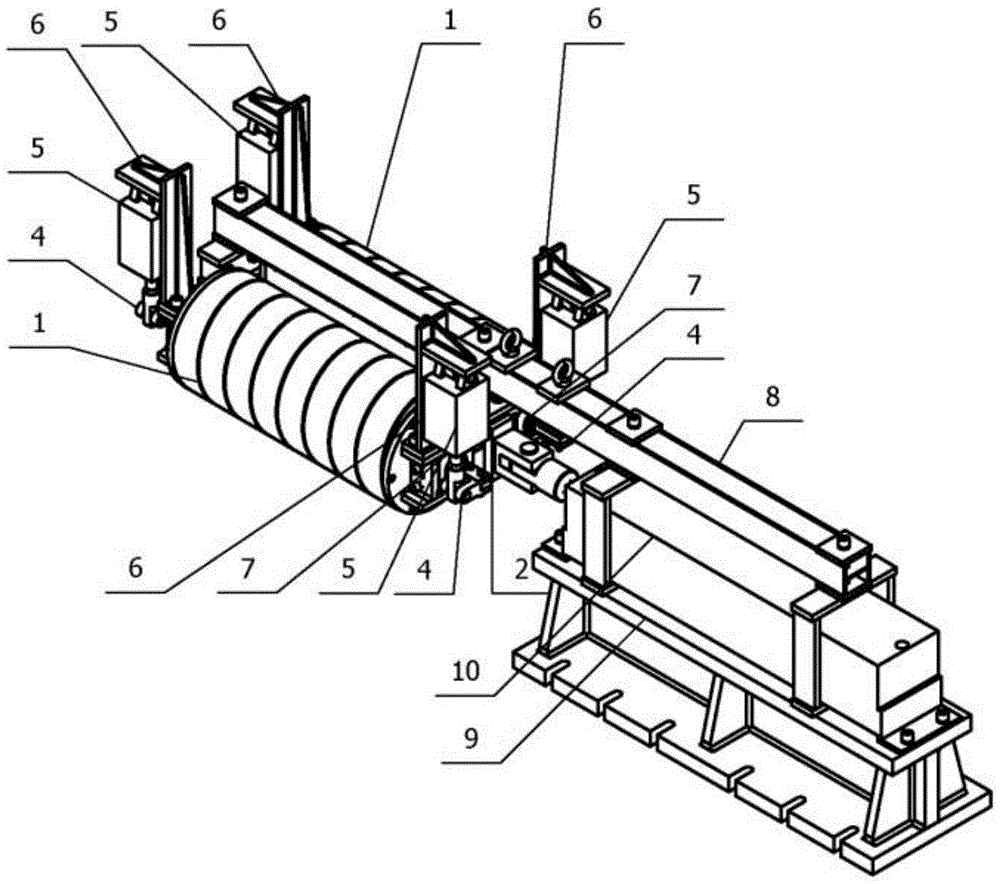

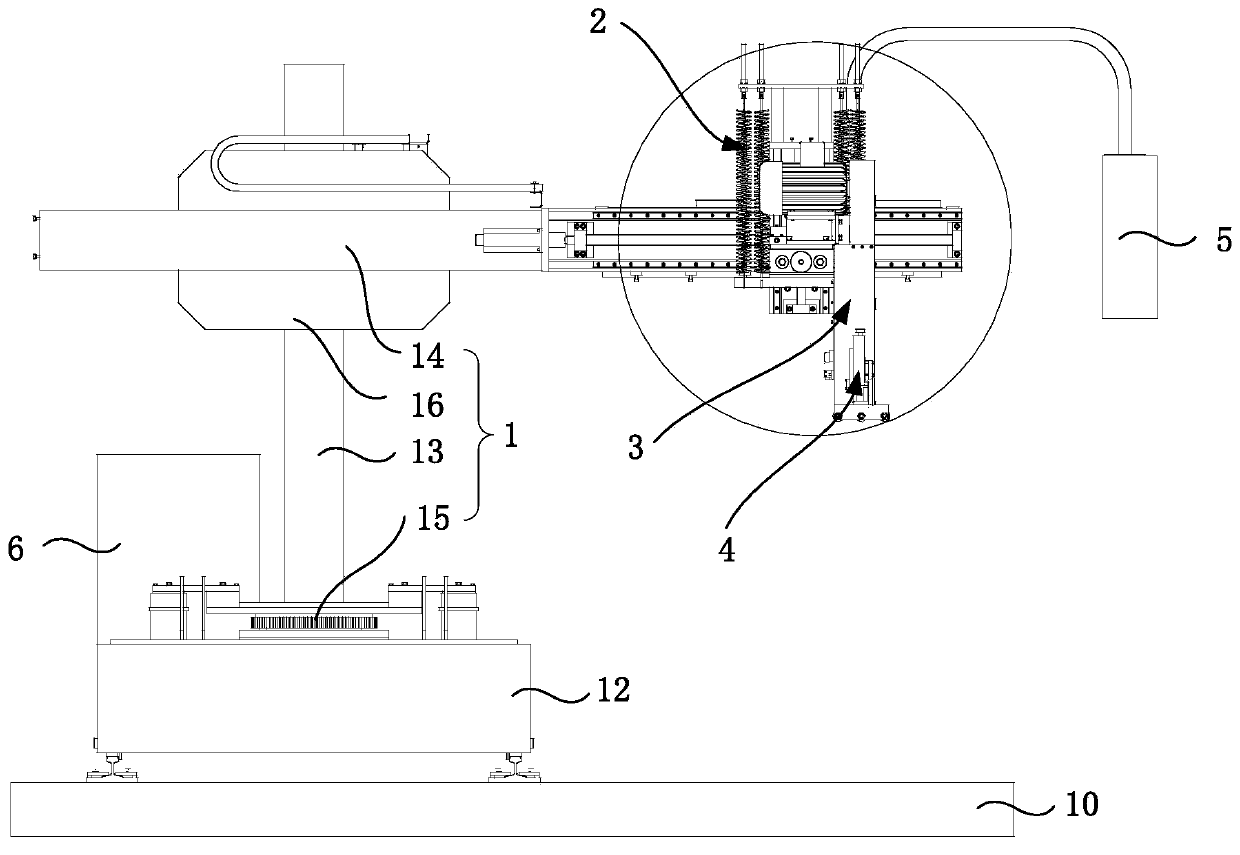

Inner wall-grinding and heat-chamfering device and method for overlength large diameter aluminum alloy tube

ActiveCN108000158AAutomatic grindingImprove efficiencyOther manufacturing equipments/toolsFriction stir weldingFlange

The invention discloses an inner wall-grinding and heat-chamfering device and method for an overlength large diameter aluminum alloy tube. The device comprises a rotary base, an aluminum alloy tube, amain bracket, a guide bar, a guide bar supporting wheel, a substrate A, a guiding powder device, a heat chamfering device, a substrate B, an auxiliary bracket, a grinding head, a gentle mechanism anda grinding head bracket, wherein the substrates are connected to the ground through expansion screws; the rotary base and the main bracket drive the aluminum alloy tube to rotate; the grinding head is used for grinding a weld joint in the aluminum alloy tube; the guiding power device and the guide bar drive the grinding head to penetrate into the aluminum alloy tube to grind the weld joint in thealuminum alloy tube. The device can overcome deficiencies that the manual grinding efficiency is low, the environment is severe, the grinding quality is poor and the like as flanges of the large diameter aluminum alloy tube which is automatically machined by means of friction stir welding effectively, and high efficiency, high quality and automatic grinding of the weld joint in the large diameteraluminum alloy tube by means of friction stir welding is achieved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

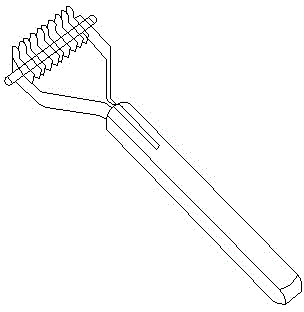

Electric hair knot opener

InactiveCN104057474AQuick cutEfficient cuttingOther manufacturing equipments/toolsMetal working apparatusEngineeringMicromotor

The invention provides an electric hair knot opener which can be used for rapidly and efficiently cutting hair knots, replacing blades and being reused by automatically polishing the blades. The electric hair knot opener provided by the invention comprises a handle, a cutting head and blade covers, wherein a micromotor is arranged in the handle; the micromotor drives a spindle when being electrified; the spindle extends to the cutting head in the length direction of the handle; a plurality of blades are arranged in parallel at certain intervals on the spindle; the blade covers cover the corresponding blades; one sides of the blade covers are provided with a plurality of notches formed in the direction perpendicular to the axial direction of the spindle; the blades are exposed out of the plurality of notches.

Owner:杨广恩

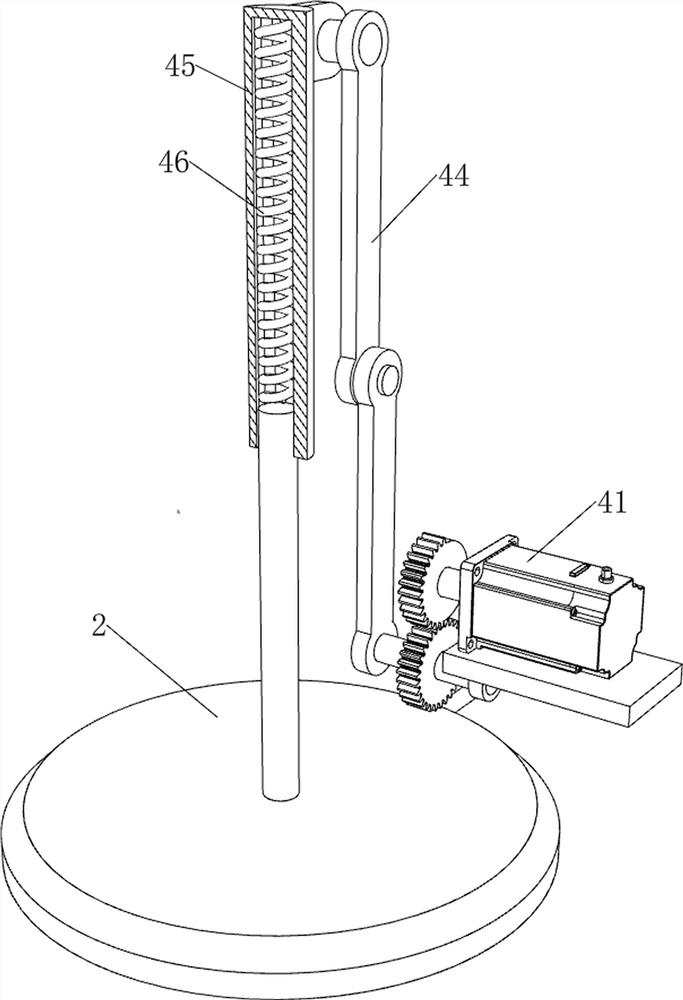

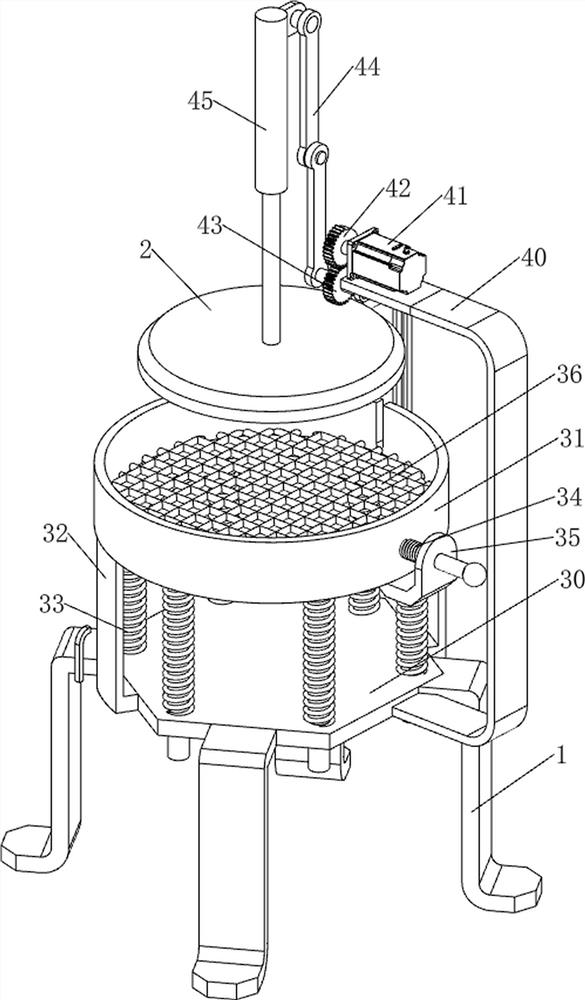

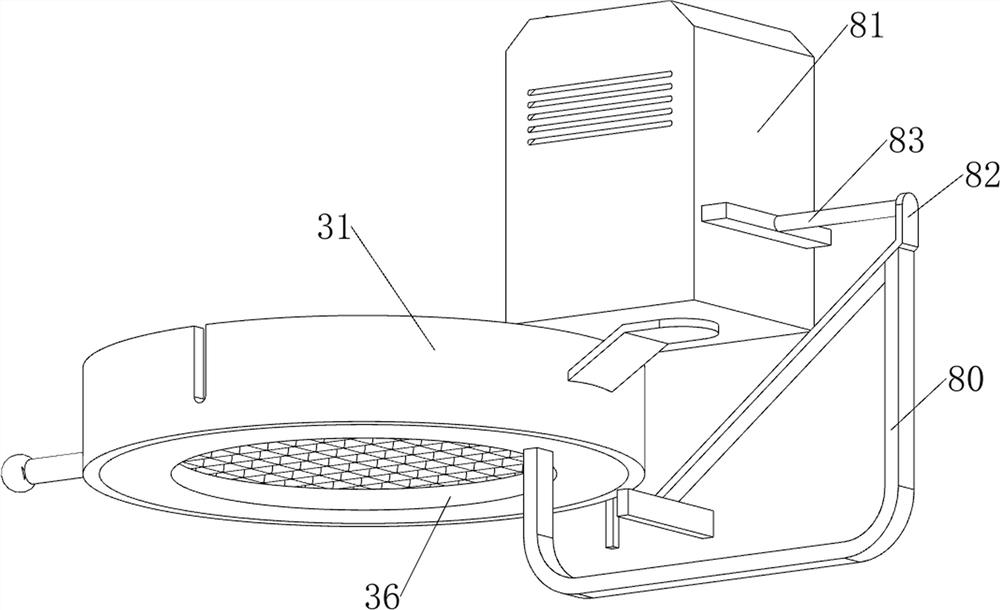

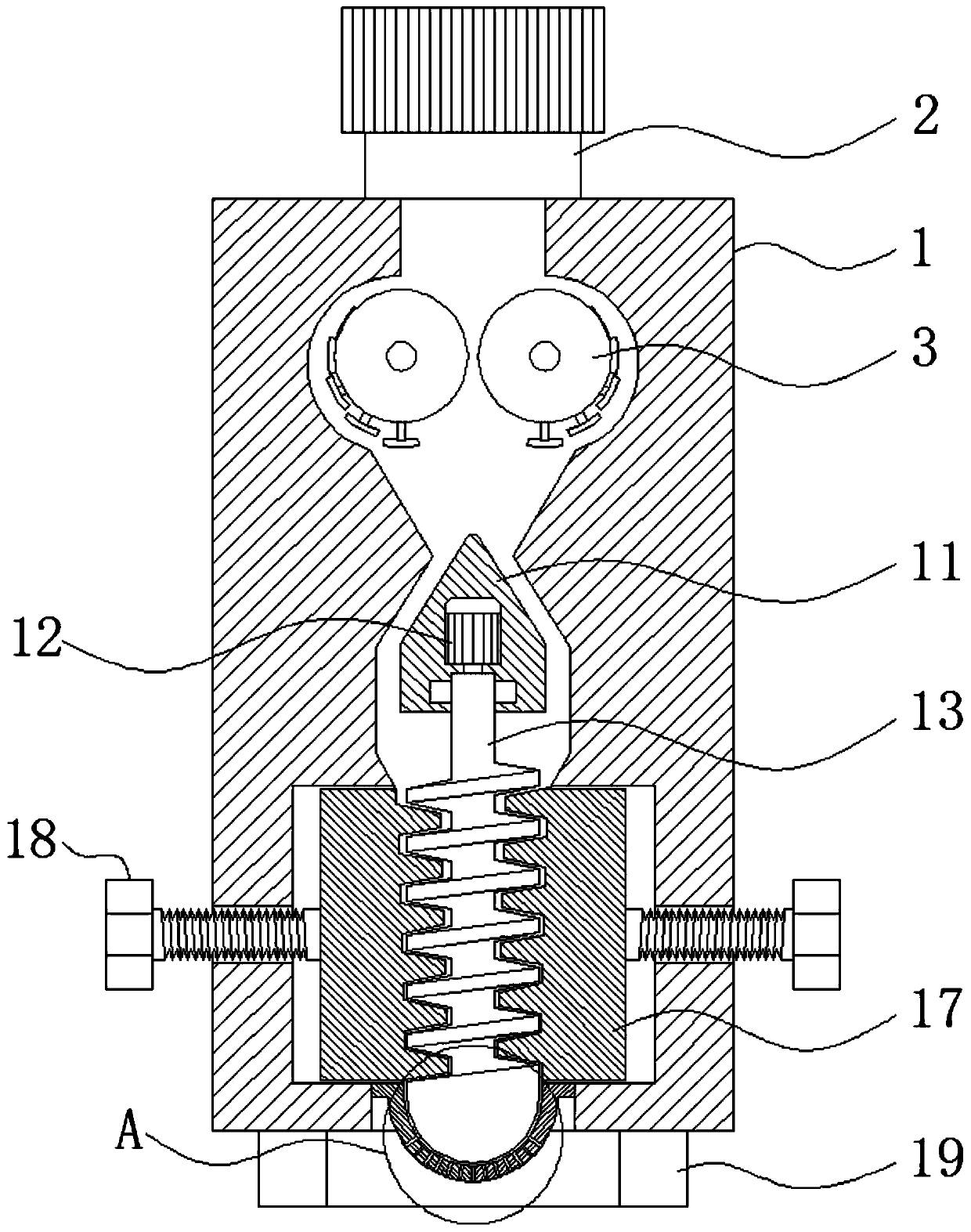

Medical traditional Chinese medicinal material grinding and mashing equipment

ActiveCN113856818AAutomatic grindingImprove work efficiencyPlastic recyclingPharmaceutical product form changeProcess engineeringMechanical engineering

The invention relates to mashing equipment, in particular to medical traditional Chinese medicinal material grinding and mashing equipment. The technical problem to be solved is to provide the medical traditional Chinese medicinal material grinding and mashing equipment which can automatically feed traditional Chinese medicinal materials and is time-saving and labor-saving. The medical traditional Chinese medicinal material grinding and mashing equipment comprises supporting plates and a material containing mechanism, and the four supporting plates are arranged on the material containing mechanism. A grinding mechanism is included and is arranged on one side of the material containing mechanism. And a grinding disc is further included and is arranged on the grinding mechanism. Through cooperation of the grinding disc, the grinding mechanism and the material containing mechanism, the traditional Chinese medicinal materials can be automatically ground in a reciprocating mode, manual operation by people is not needed, and time and labor are saved. Through cooperation of a rotating mechanism and a reset mechanism, the grinding disc can be automatically driven to rotate so that the traditional Chinese medicinal materials can be automatically ground, and the working efficiency is improved.

Owner:广东省药材公司中药饮片厂

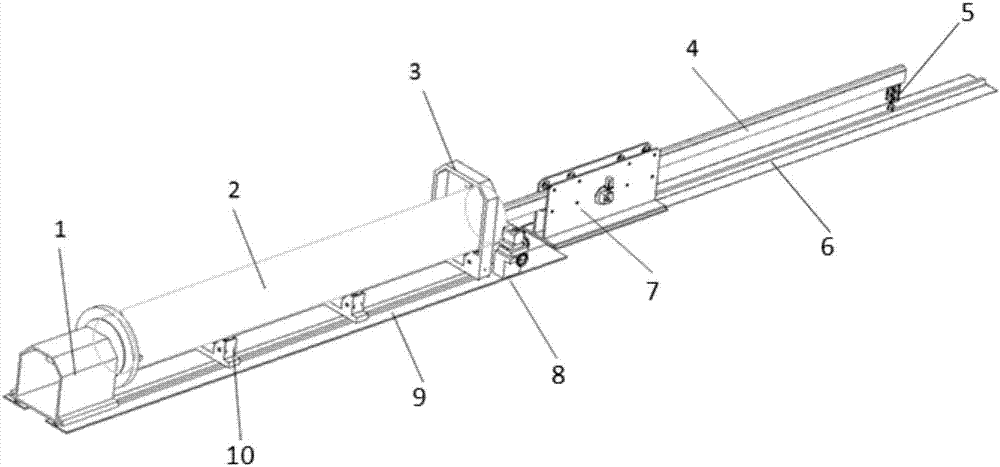

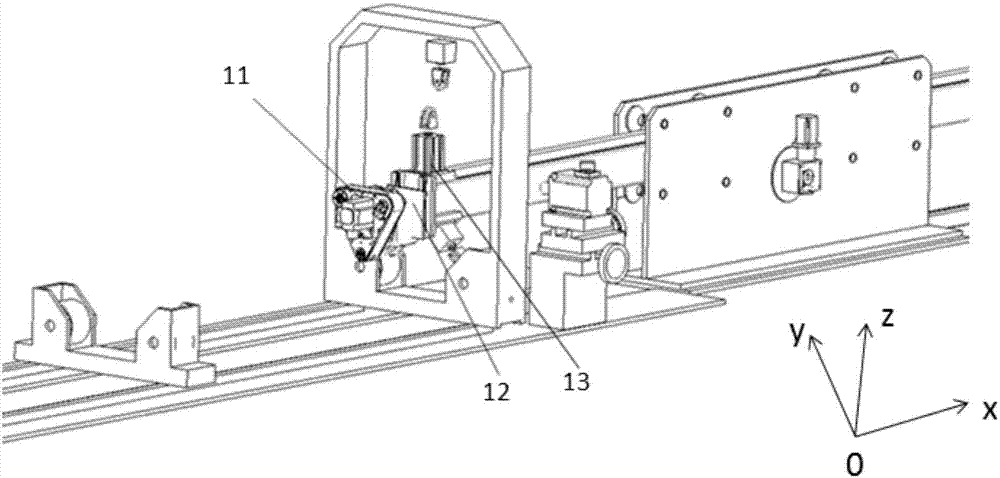

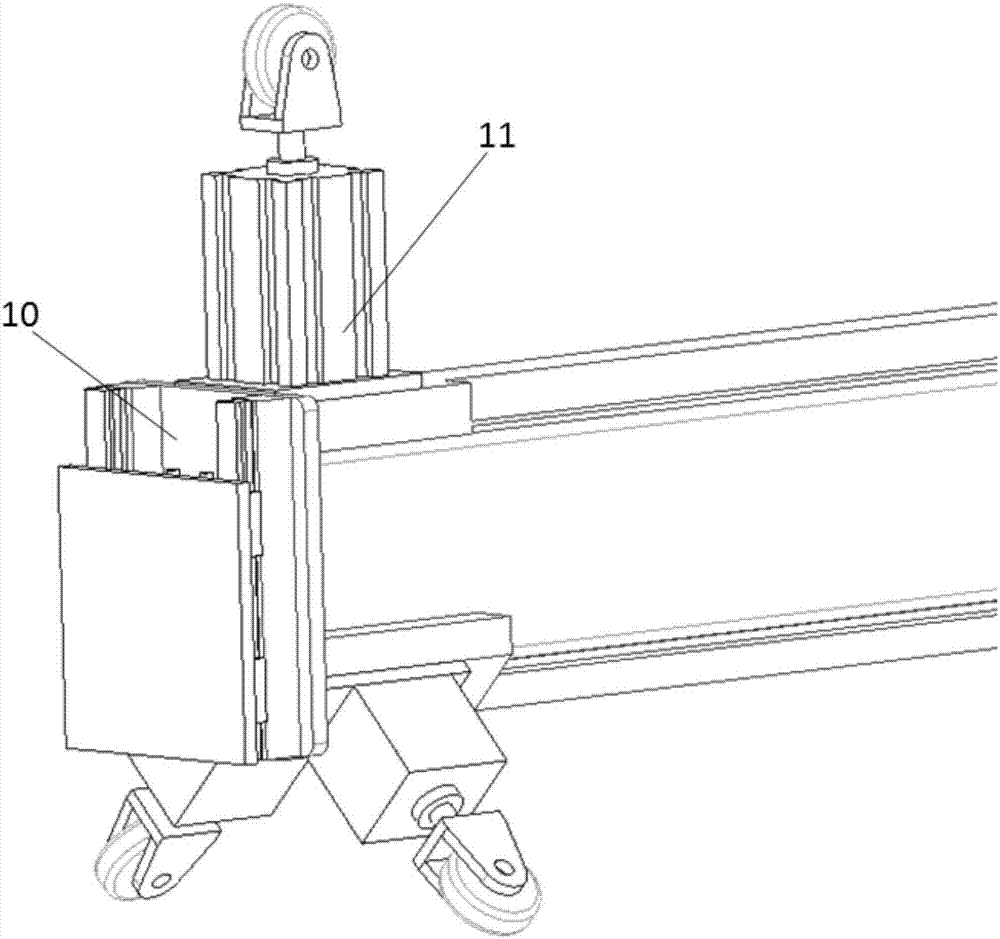

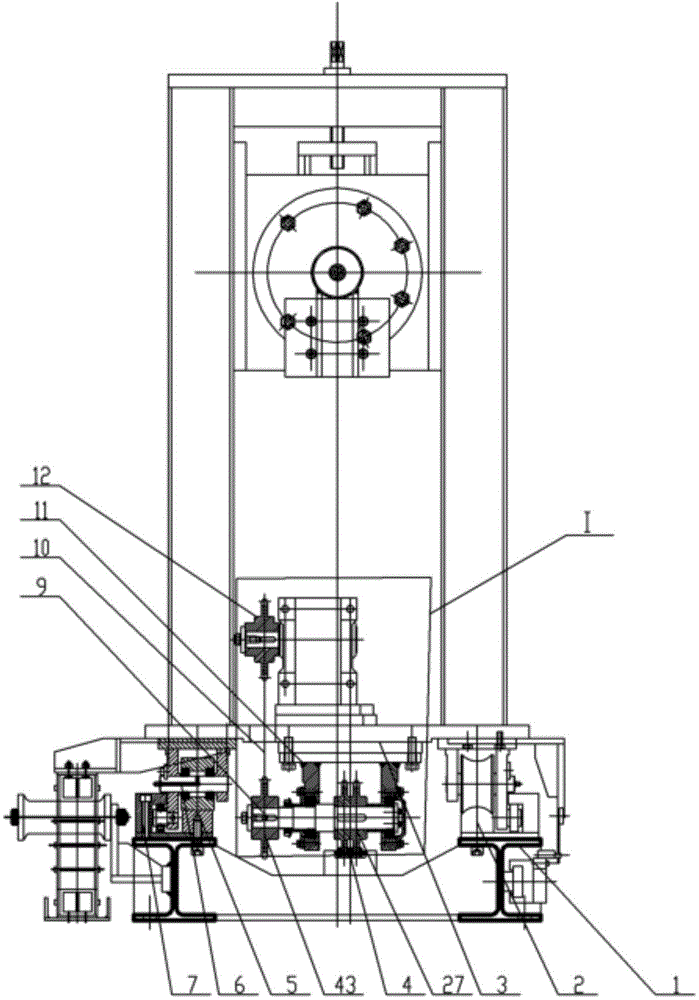

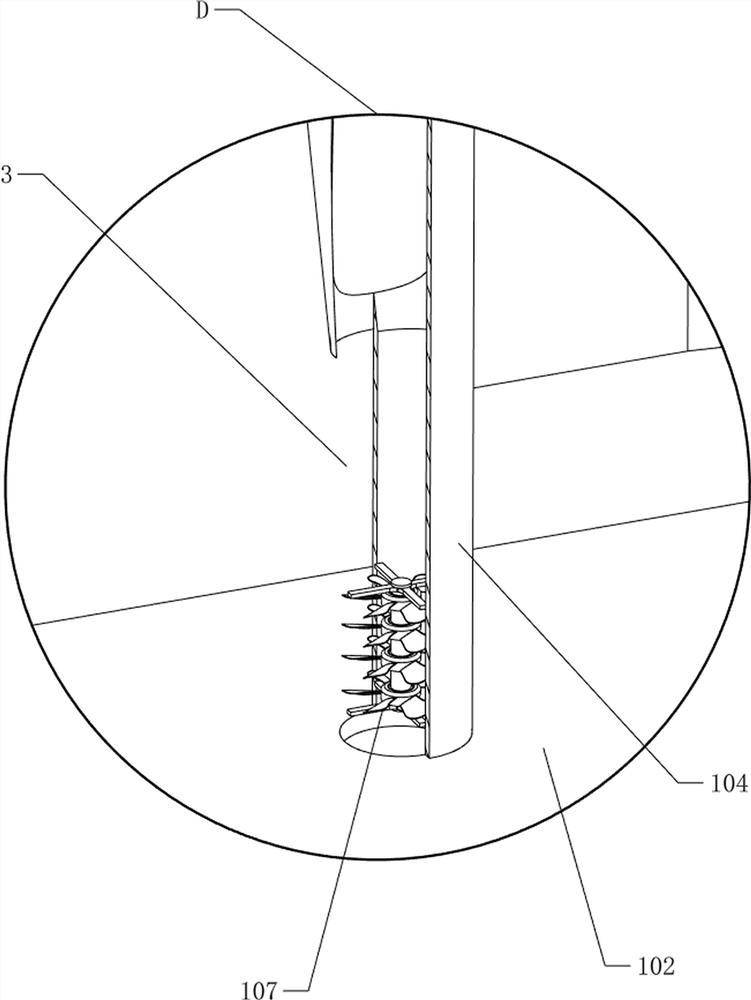

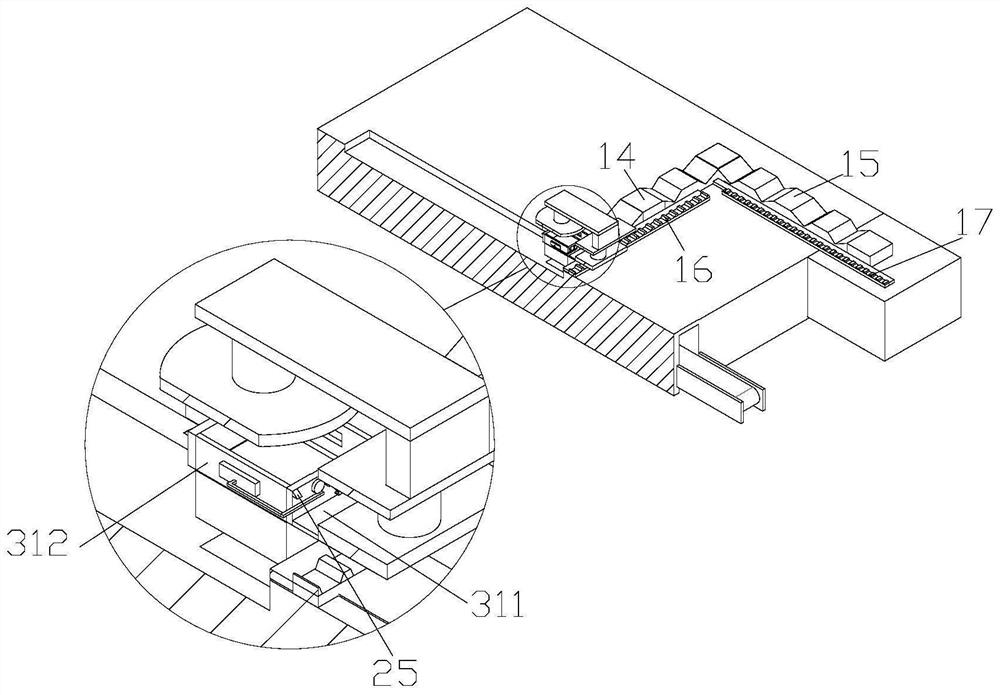

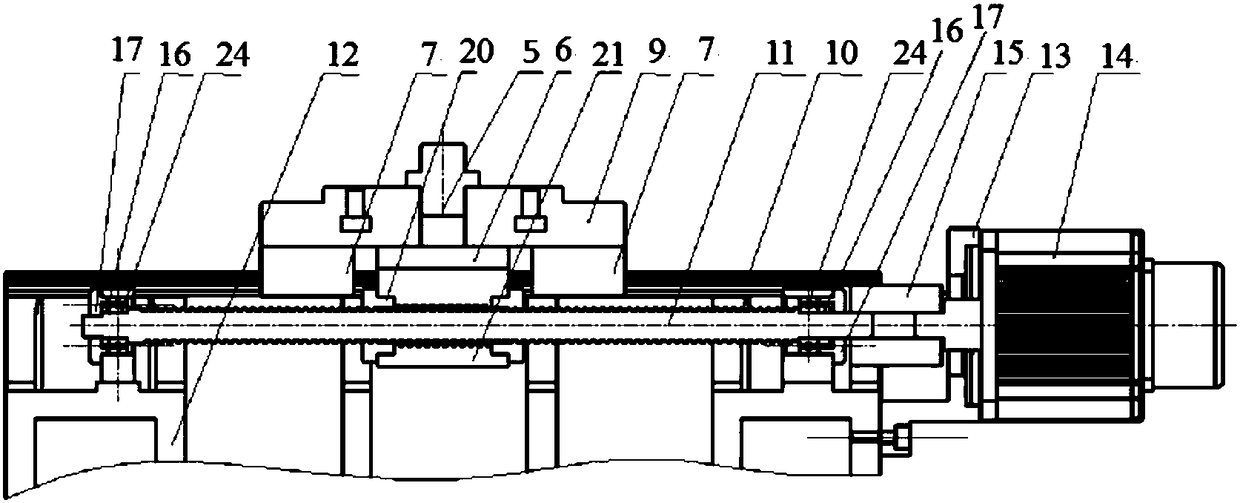

Sharpening machine for weld reinforcement in longitudinal welded pipe

ActiveCN105290907AAvoid cracking damageSafe welding seam grinding processEdge grinding machinesWork performanceEngineering

The invention discloses a sharpening machine for the weld reinforcement in a longitudinal welded pipe. The sharpening machine comprises a sharpening trolley comprising a trolley body, a sharpening grinding machine arranged on the trolley body, and a driving device connected with the sharpening trolley; a driving element drives the sharpening trolley to go into the longitudinal welded pipe to sharpen the weld reinforcement. The sharpening machine for the weld reinforcement in the longitudinal welded pipe is capable of performing total-length or local sharpening on a weld joint in a steel pipe stably, reliable and automatically, and therefore, the labor intensity of the working personnel is reduced and the working performance is improved. Besides, the overall structure of the sharpening machine is simple, and an adjustment method of the sharpening machine is simple, convenient and easy to operate; the involved sharpening parts are not easy to damage and low in maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

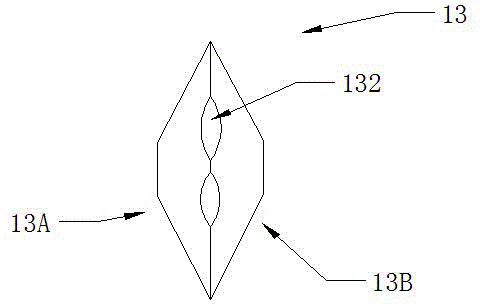

PPC pipe excess material processing device

PendingCN114523387AThe effect of automatic transportAutomatic grindingGrinding carriagesGrinding drivesMaterials processingIndustrial engineering

The invention relates to a processing device, in particular to a PPC pipe excess material processing device. The technical problem to be solved is to provide the PPC pipe excess material processing device which can support irregular PPC pipe excess materials and can automatically transport the PPC pipe excess materials at the same time. According to the technical scheme, the PPC pipe excess material processing device comprises a bottom plate, a lower half body frame, a main body frame, an upper half body frame and a lifting mechanism, the lower half body frame is arranged on the front side of the upper portion of the bottom plate, the main body frame is arranged in the lower half body frame, the upper half body frame is arranged on the outer side of the upper portion of the main body frame, and the lifting mechanism is arranged between the lower half body frame and the bottom plate. According to the PPC pipe excess material conveying device, the telescopic rod of the air cylinder extends to drive the oval corner to move upwards, PPC pipe excess materials can be lifted upwards in the upward moving process of the oval corner, and therefore the effect of automatically conveying the PPC pipe excess materials can be achieved.

Owner:邹昌全

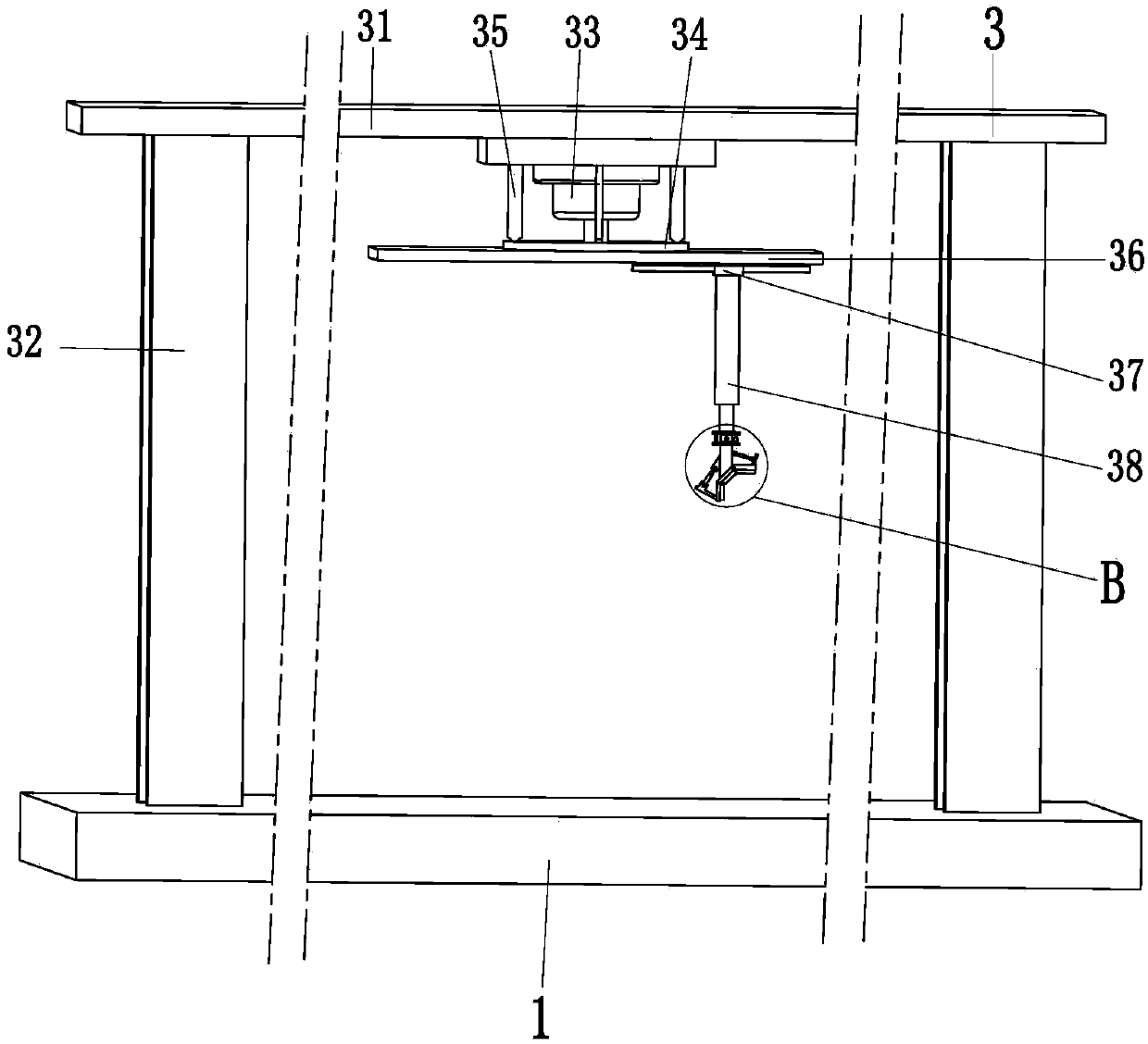

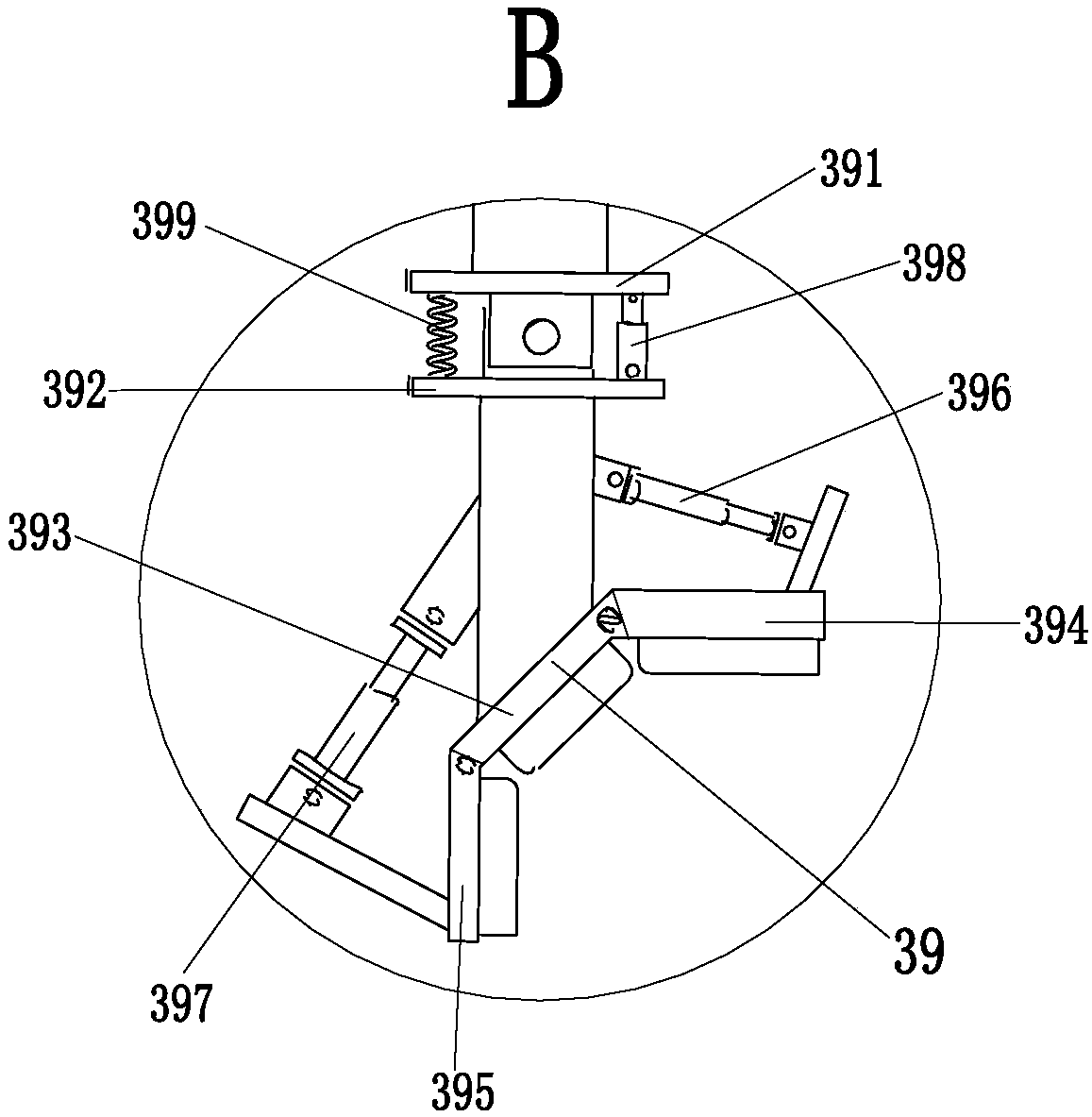

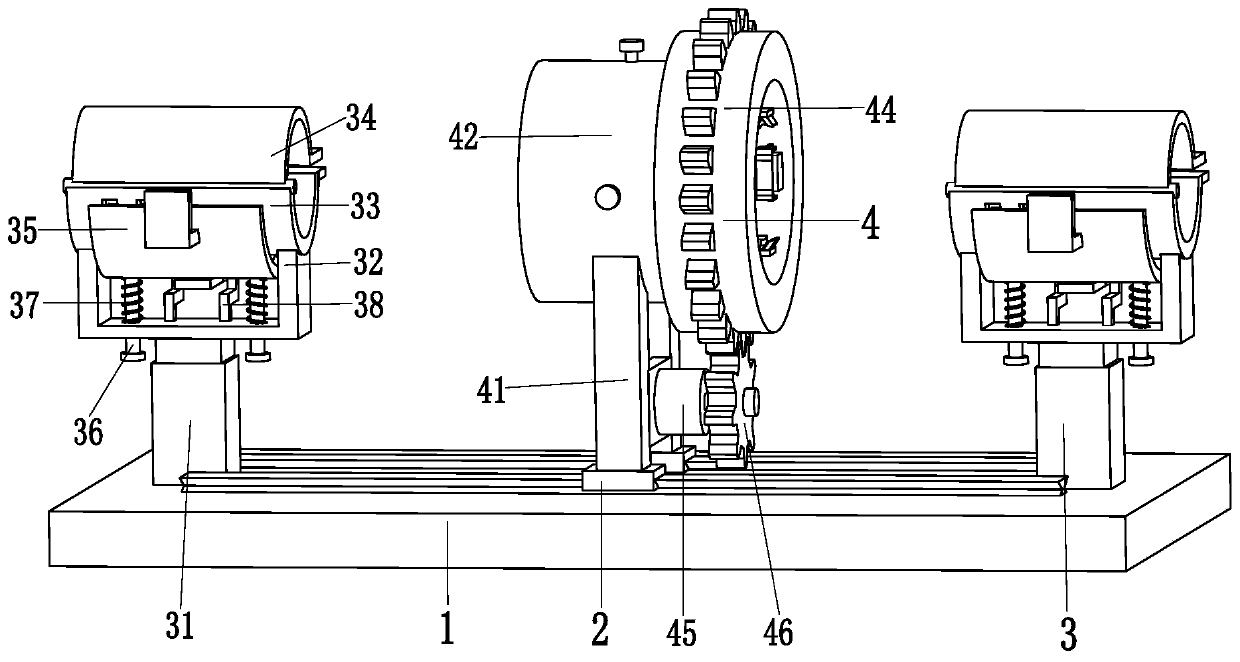

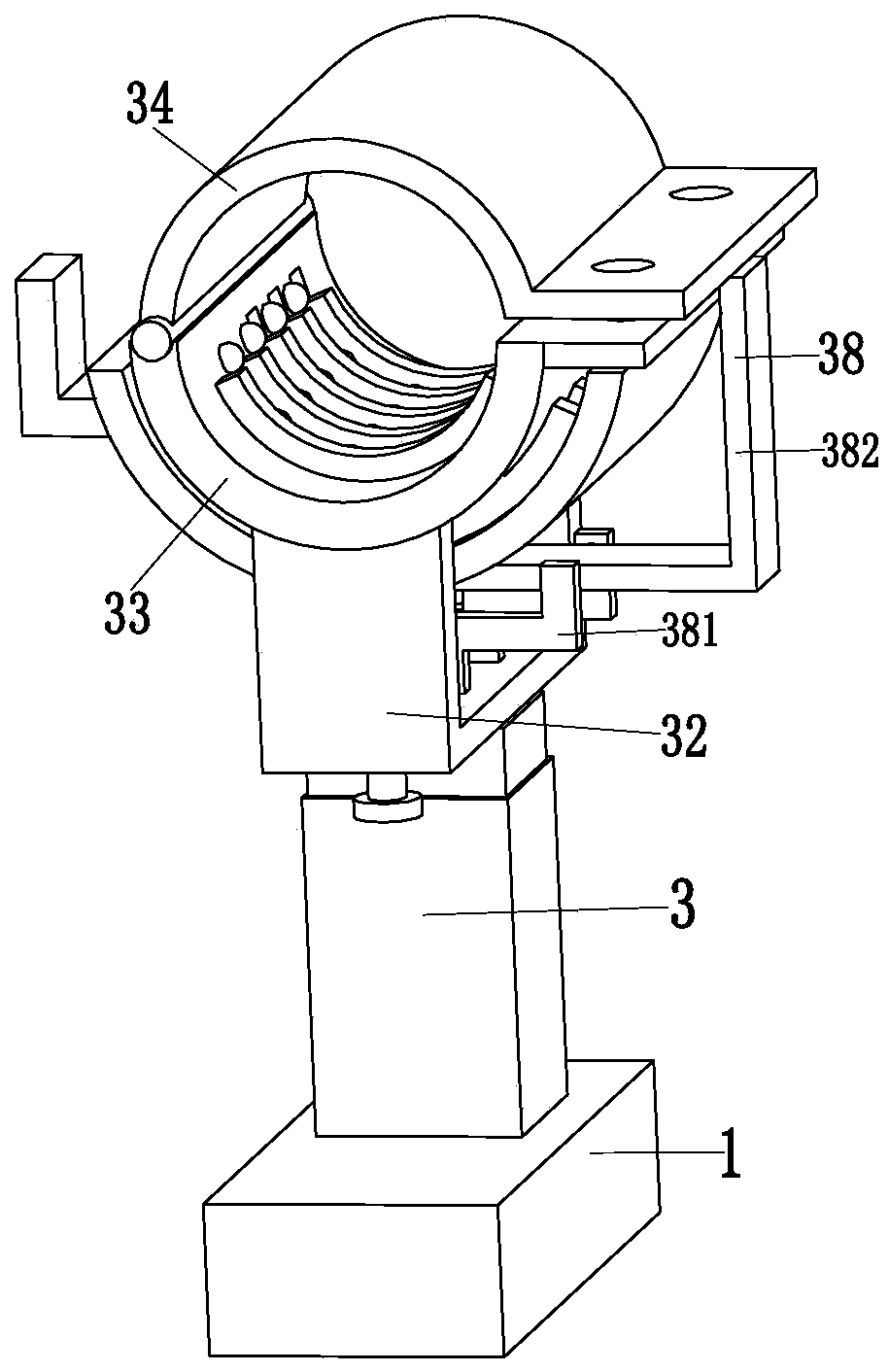

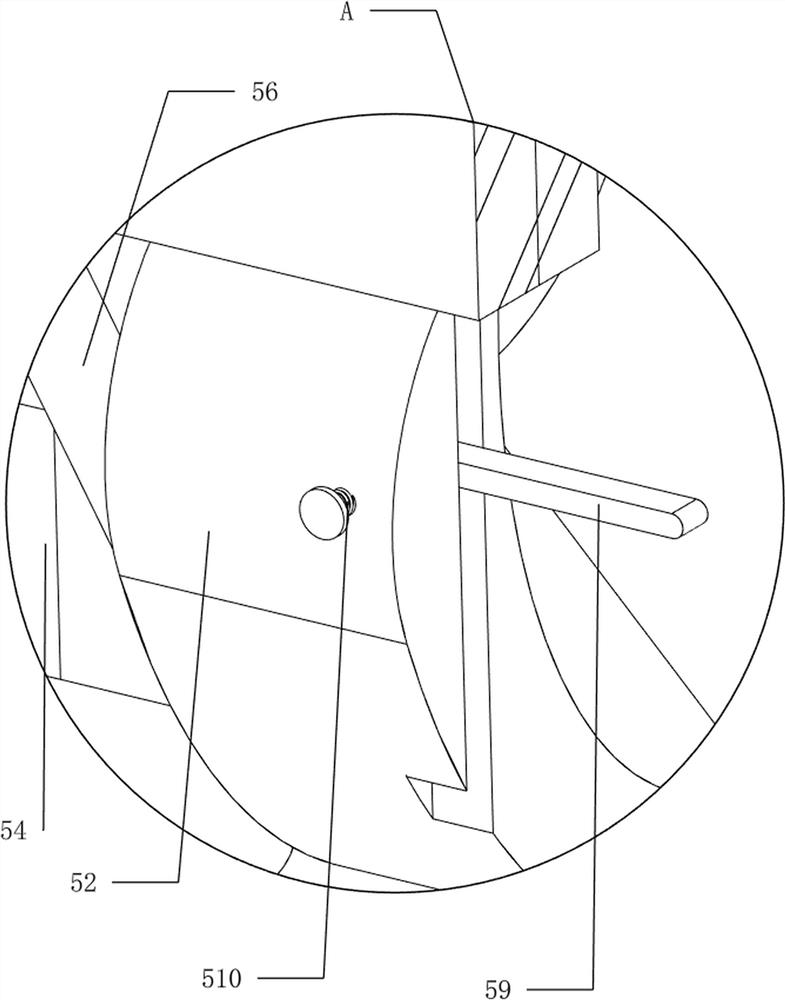

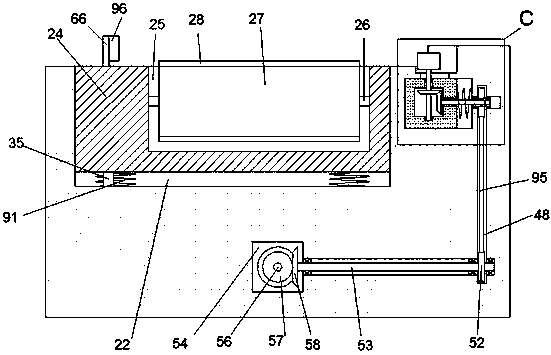

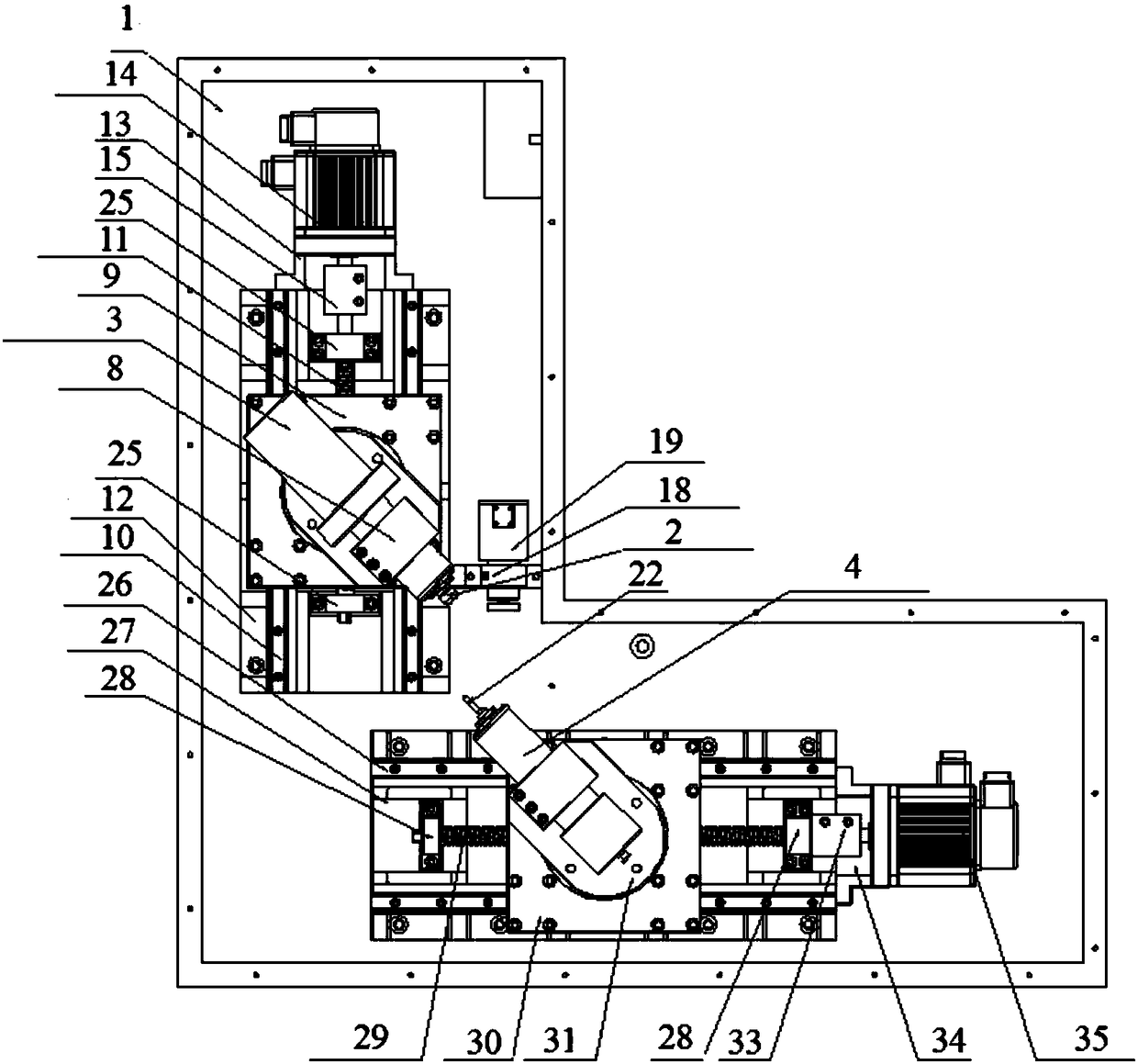

Automatic grinding device

ActiveCN105643377AAutomatic grindingMeet the requirements of parallelismRevolution surface grinding machinesGrinding drivesEngineeringMechanical engineering

The invention relates to an automatic grinding device. The automatic grinding device comprises two mutually-parallel grinding tool bodies, a rotary grinding cylinder, a linear grinding cylinder and a frame, wherein the rotary grinding cylinder is used for controlli8ng the grinding tool bodies to rotate; the linear grinding cylinder is used for controlling the grinding tool bodies to perform rectilinear motion; the frame is connected with the grinding tool bodies, the rotary grinding cylinder and the linear grinding cylinder; the automatic grinding device also comprises a bearing seat and a hoisting device, wherein the bearing seat is used for supporting the grinding tool bodies, and the hoisting device is used for hoisting; two frames are respectively mounted at the two ends of the two parallel grinding tool bodies; the other side of one frame is connected with the linear grinding cylinder. The grinding tool is capable of realizing automatic grinding on 20 frame holes of a rolling machine by rotation motion and rectilinear motion of the grinding tool bodies and is also capable of guaranteeing the requirements on toughness and parallelism degree of the frame holes.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

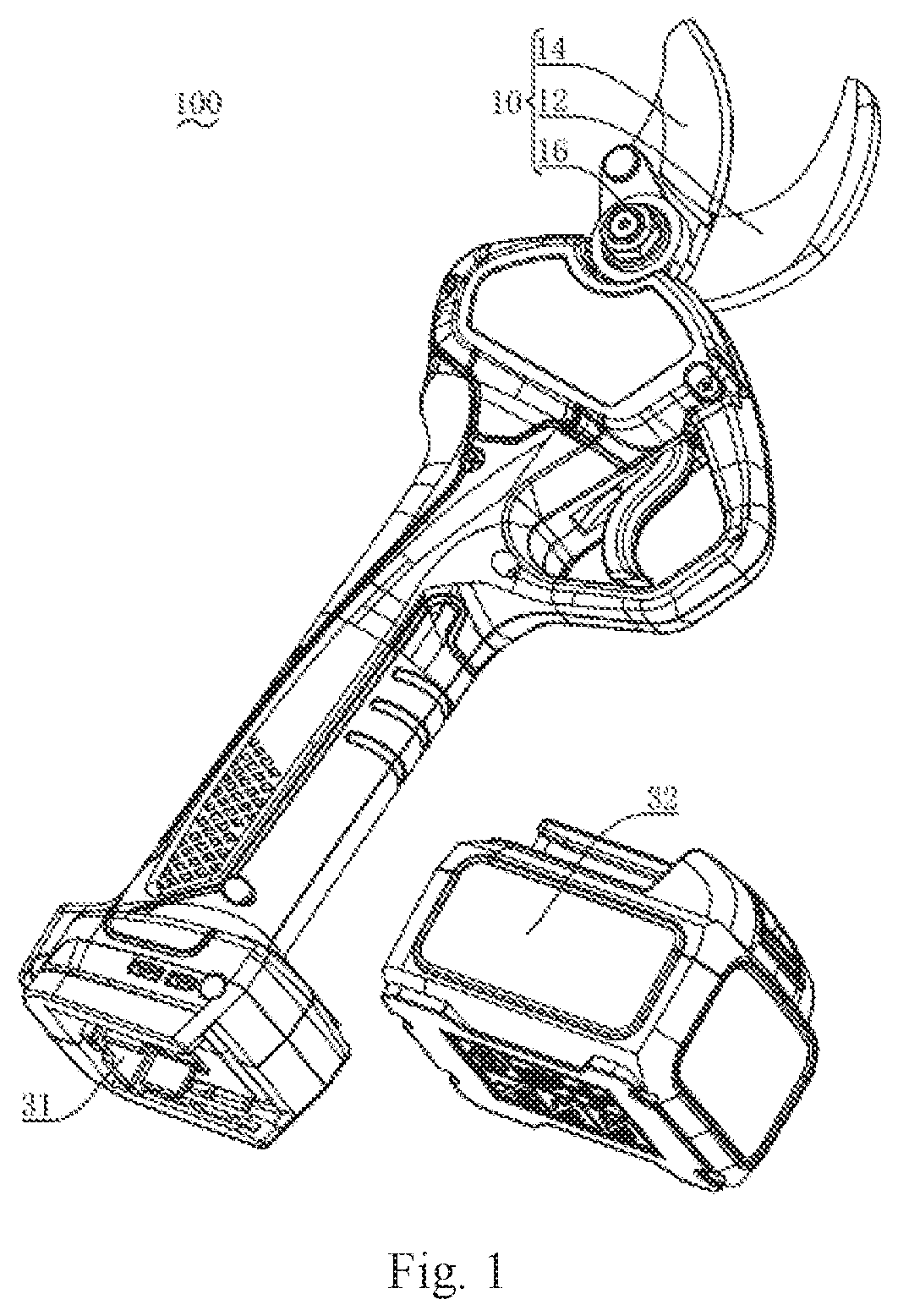

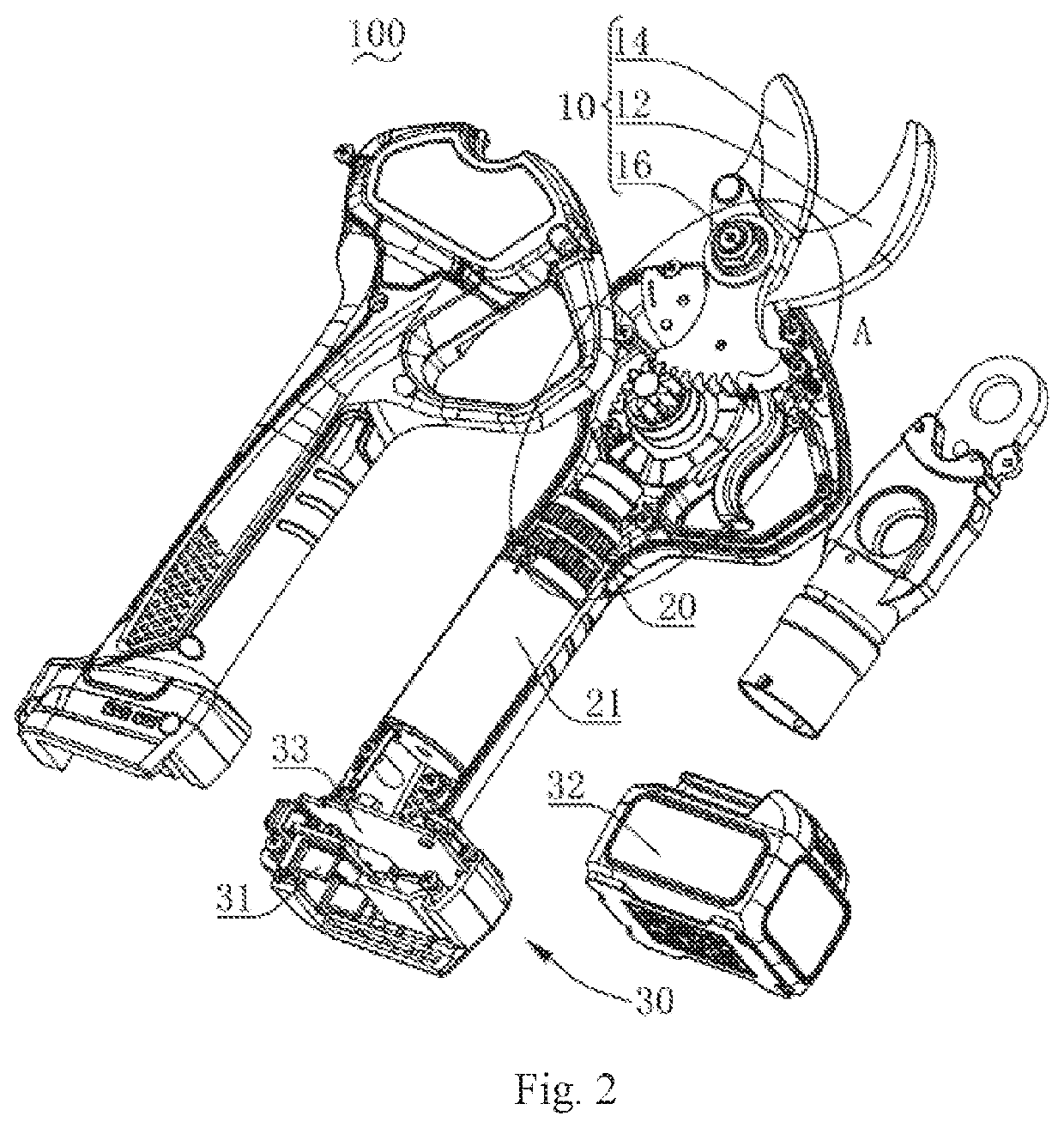

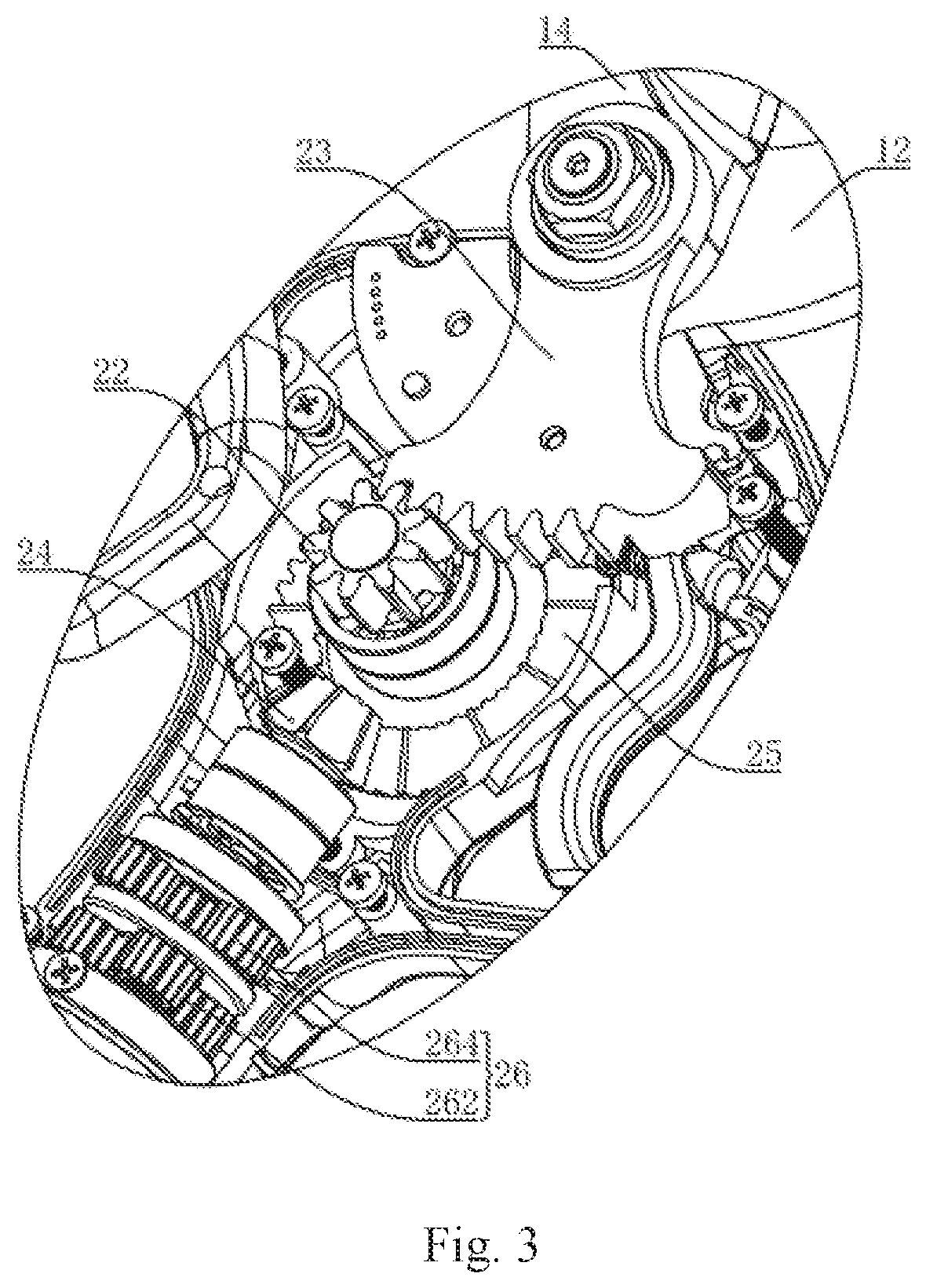

Blade mechanism and electric scissors having blade mechanism

ActiveUS20210299894A1Increased durabilityAutomatic grindingCuttersCutting implementsStructural engineeringKnife blades

The present application discloses a blade mechanism and an electric scissors having the blade mechanism. The blade mechanism includes a setting blade, a moving blade, and a rotating shaft assembly. The rotating shaft assembly respectively passes through the setting blade and the moving blade to allow the setting blade and the moving blade being rotatablely connected. The cutting edge of the moving blade is automatically ground when the moving blade frictionally rotates relative to the setting blade. According to the present application, the moving blade and the setting blade of the blade mechanism open or close to generate friction, allowing the cutting edge of the moving blade to be automatically ground by the setting blade, thus the durability of the moving blade is improved.

Owner:YONGKANG WEIDE IND & TRADE CO LTD

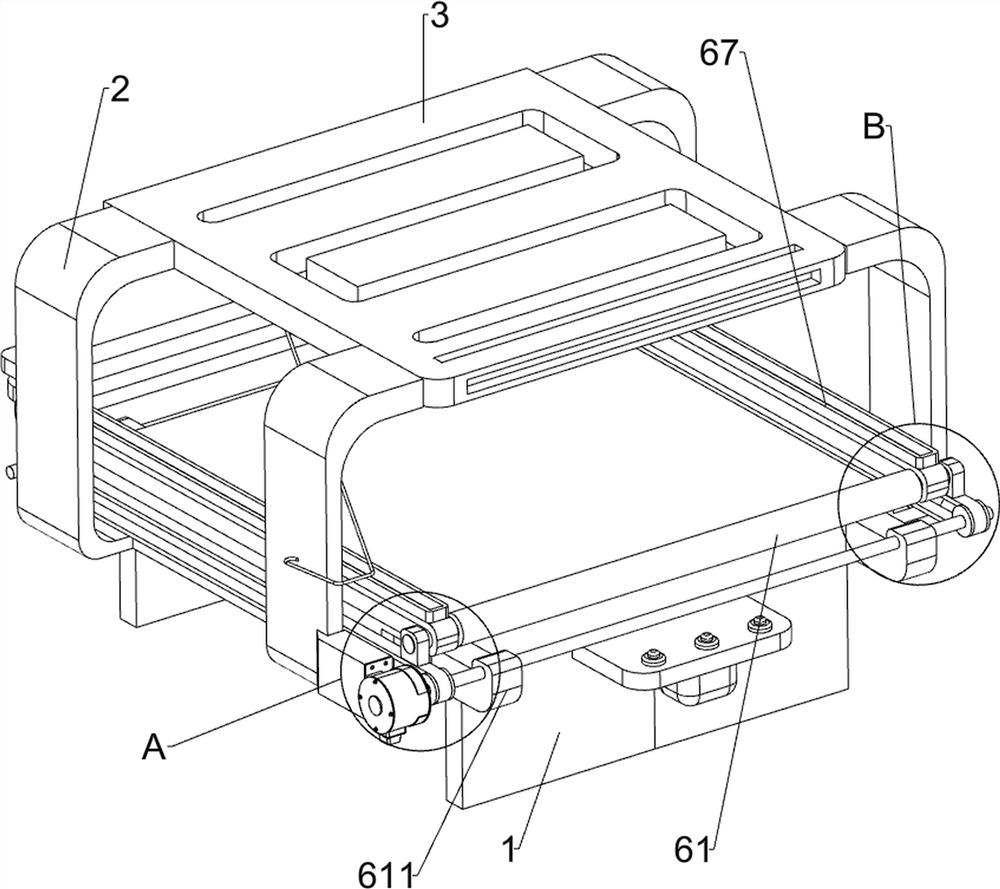

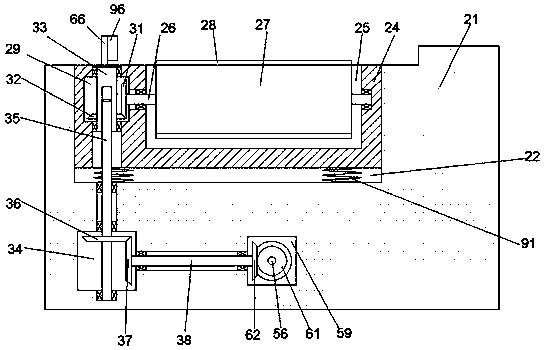

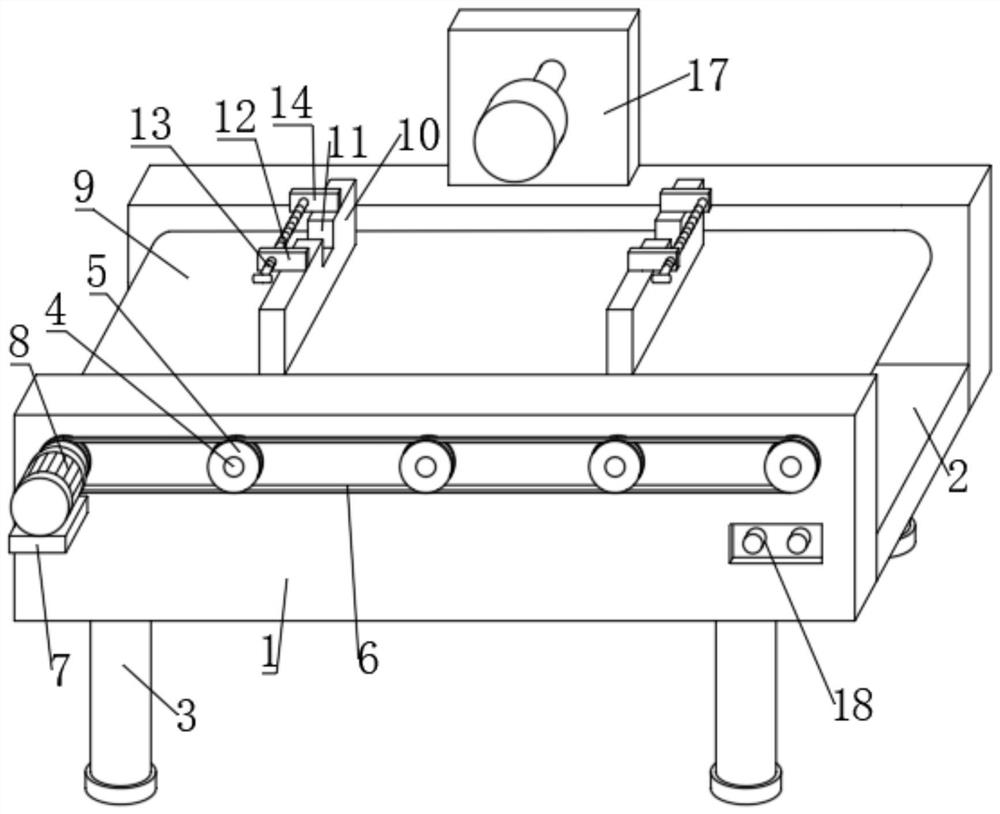

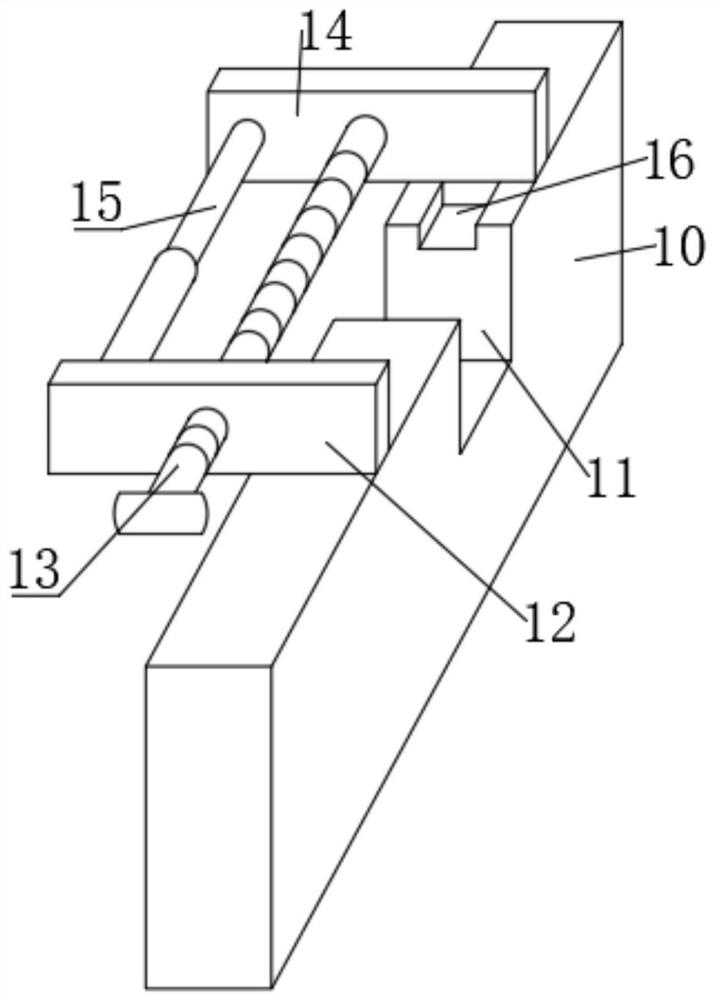

Automatic plate edge-grinding machine

InactiveCN110421433AReduce loss rateClose contactEdge grinding machinesGrinding drivesEngineeringGrinding wheel

The invention discloses an automatic plate edge-grinding machine. The automatic plate edge-grinding machine comprises a workbench, wherein a running slide cavity is formed in the upper end surface ofthe workbench; a lifting slide block is slidably arranged in the running slide cavity; four running compression springs are uniformly distributed and fixedly arranged at the lower side of the liftingslide block; a running device is arranged in the lifting slide block; and the running device is used for driving a plate needing to be subjected to edge-grinding to move to left and right on the upperend surface of the workbench. According to the automatic plate edge-grinding machine, the plate is driven to move and the edge of the plate is grinded through a grinding wheel at a fixed position andthe running device; through the action of grinding springs, closer contact between the plate and the grinding wheel, and a better grinding effect are achieved, the loss speed of the grinding wheel can be effectively reduced, and inconvenience brought due to frequent replacement for the grinding wheel is avoided; the position of the plate is limited through a fastening device, so that the grindingaccuracy is guaranteed, and the grinding quality is ensured; and the grinding working is automatically carried out, and manual intervention is not needed during the grinding working, so that higher working efficiency is achieved while the labor is saved.

Owner:宁波暮春自动化科技有限公司

Bearing grinding device

InactiveCN104440430AAutomatic grindingControl timeGrinding carriagesRevolution surface grinding machinesTransducerEngineering

The invention discloses a bearing grinding device. The bearing grinding device comprises a feeding unit, a grinding unit and a discharging unit. The feeding unit comprises a material frame, a material pouring device and a lever, wherein the outlet of the material frame is connected with the material pouring device, the lever is connected with the material pouring device, and the material pouring device is used for feeding a bearing to be machined to the grinding unit. The grinding unit comprises a machining tank and two cooling bars arranged in the machining tank, wherein the machining tank is used for collecting the bearing to be machined, and the cooling bars are used for grinding an inner ring and an outer ring of the bearing. The discharging unit comprises a track connected with the machining tank, and the discharging unit is used for discharging the bearing which is machined. The two cooling bars are used for driving the bearing grinding device to carry out grinding, centering positioning and transducer speed adjusting are utilized, three working stations are used for machining at the same time, the bearing can be automatically ground, a worker can operate a plurality of devices at the same time, the yield is improved, and the operation processes are reduced.

Owner:WUXI BAISHUN MACHINERY PLANT

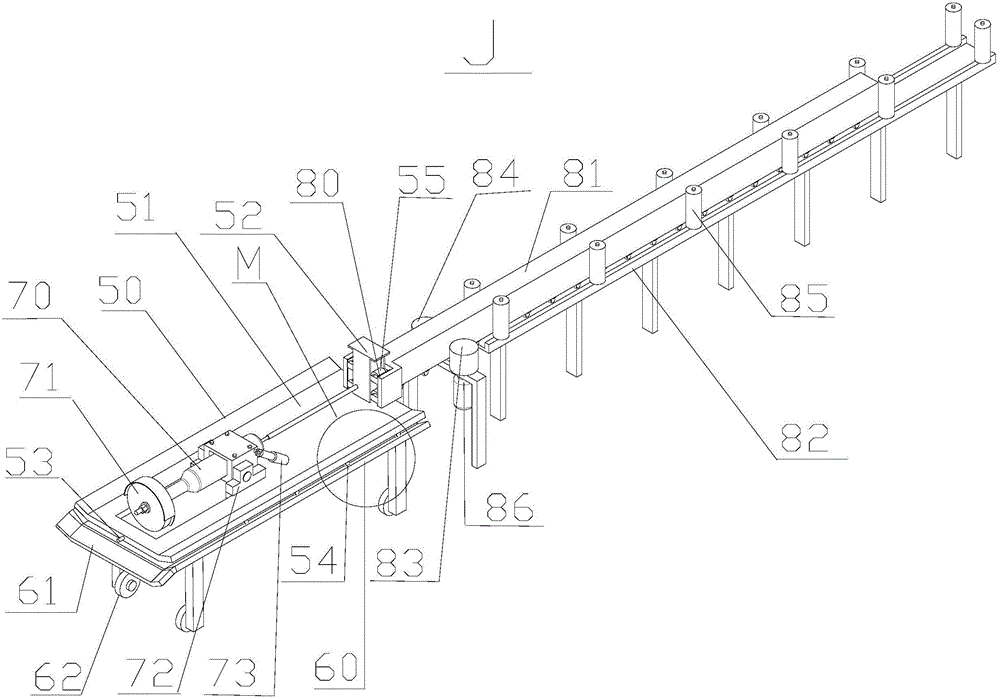

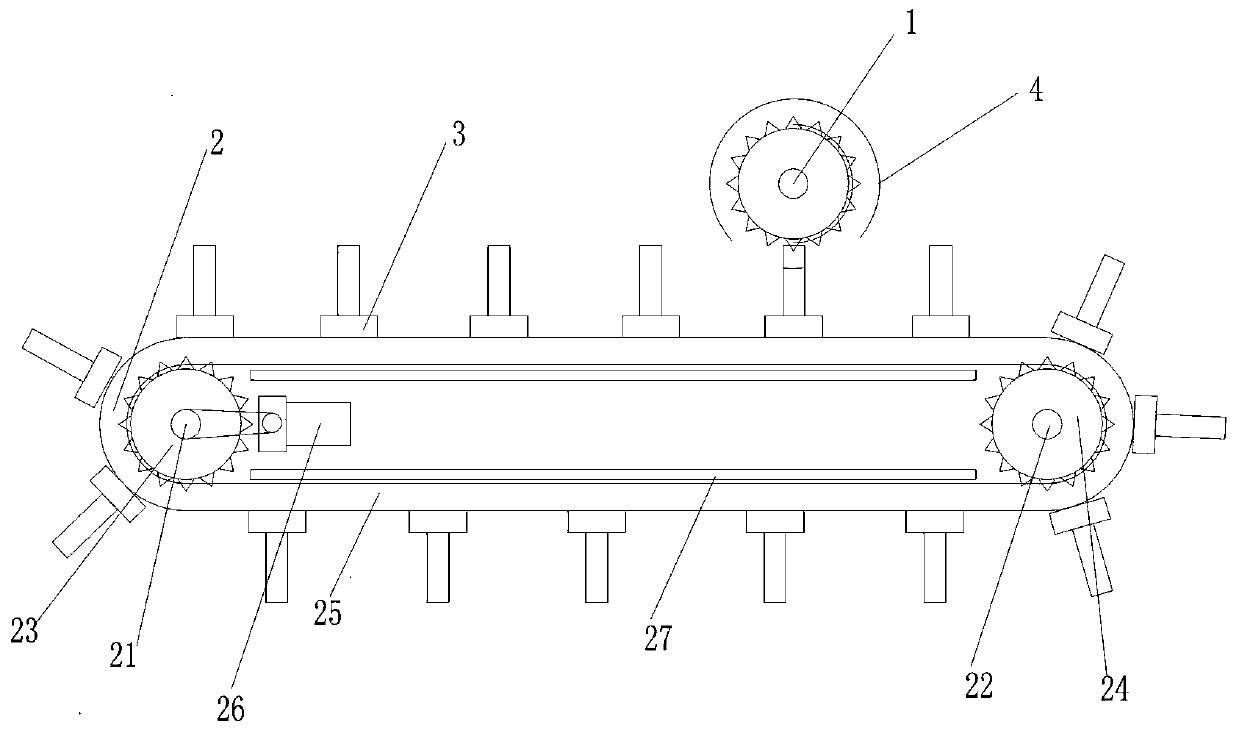

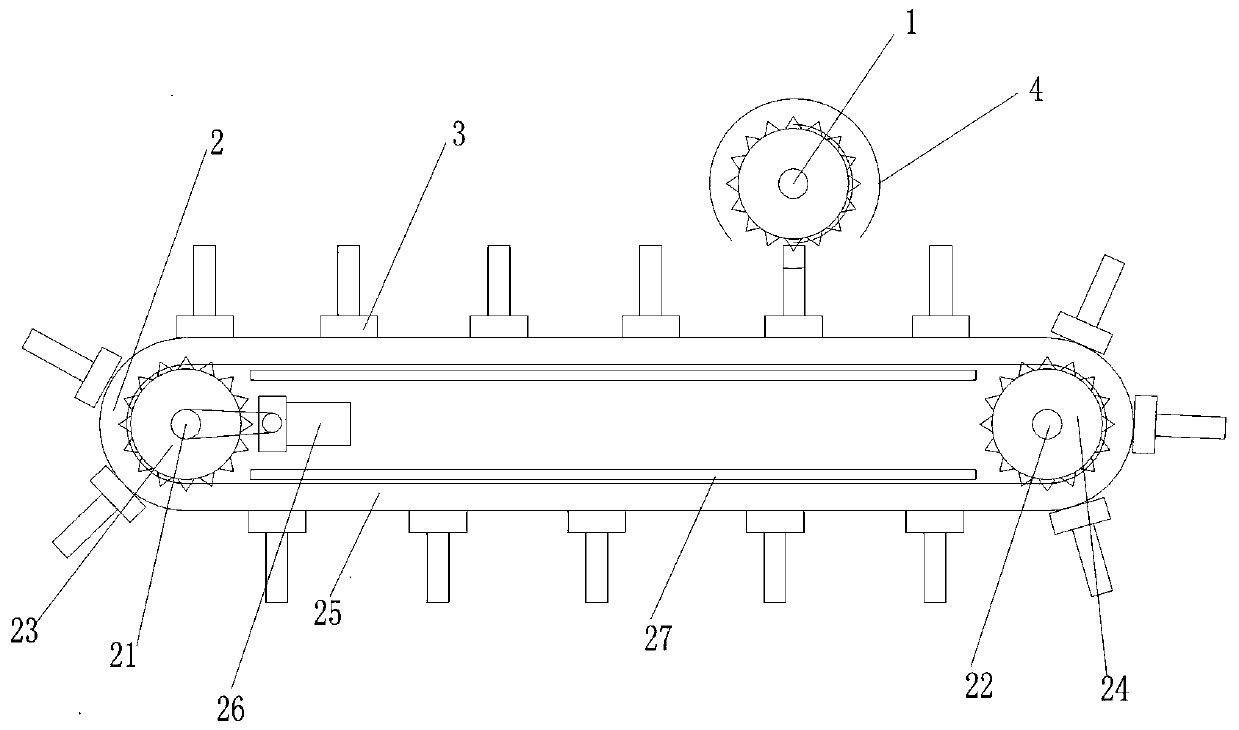

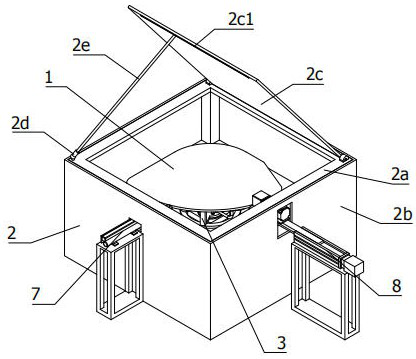

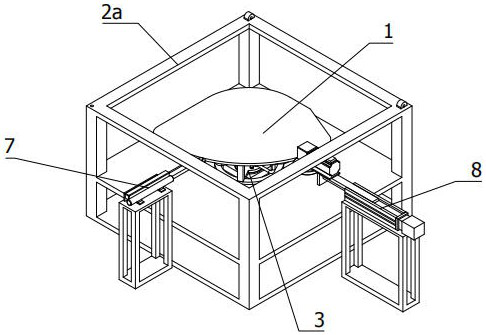

Circulated automatic grinding equipment

InactiveCN109834591AImprove processing efficiencyKeep healthyGrinding machinesGrinding work supportsEngineeringFixed position

The invention relates to circularly operated automatic grinding equipment, in particular to the circularly operated automatic grinding equipment. The circularly operated automatic grinding equipment has the technical effects of being simple and mature in structure, and convenient and safe to use. The circularly operated automatic grinding equipment comprises an automatic grinding head, wherein thegrinding head is covered by a grinding cover so that grinding waste can be prevented from being splashed, meanwhile, the waste can be collected, the grinding equipment can complete fixed-position grinding of workpieces, the circularly operated automatic grinding equipment further comprises a circulation conveying line, a plurality of positioning mechanisms are arranged along the circulation conveying line, the face portion of the circulation conveying line is a horizontal working face, so that the positioning mechanisms are opposite to the grinding head.

Owner:沈阳益泰科信息技术有限公司

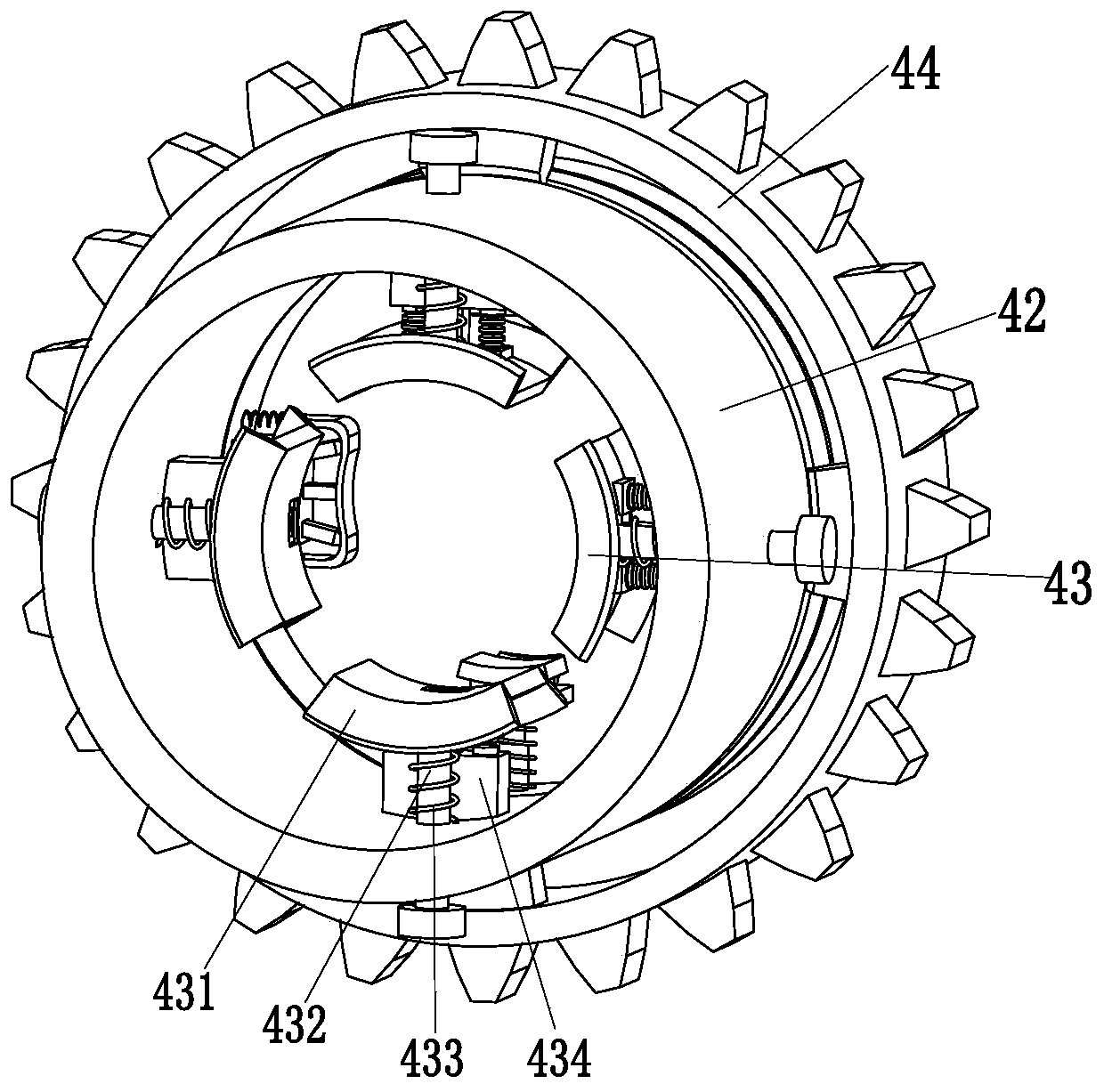

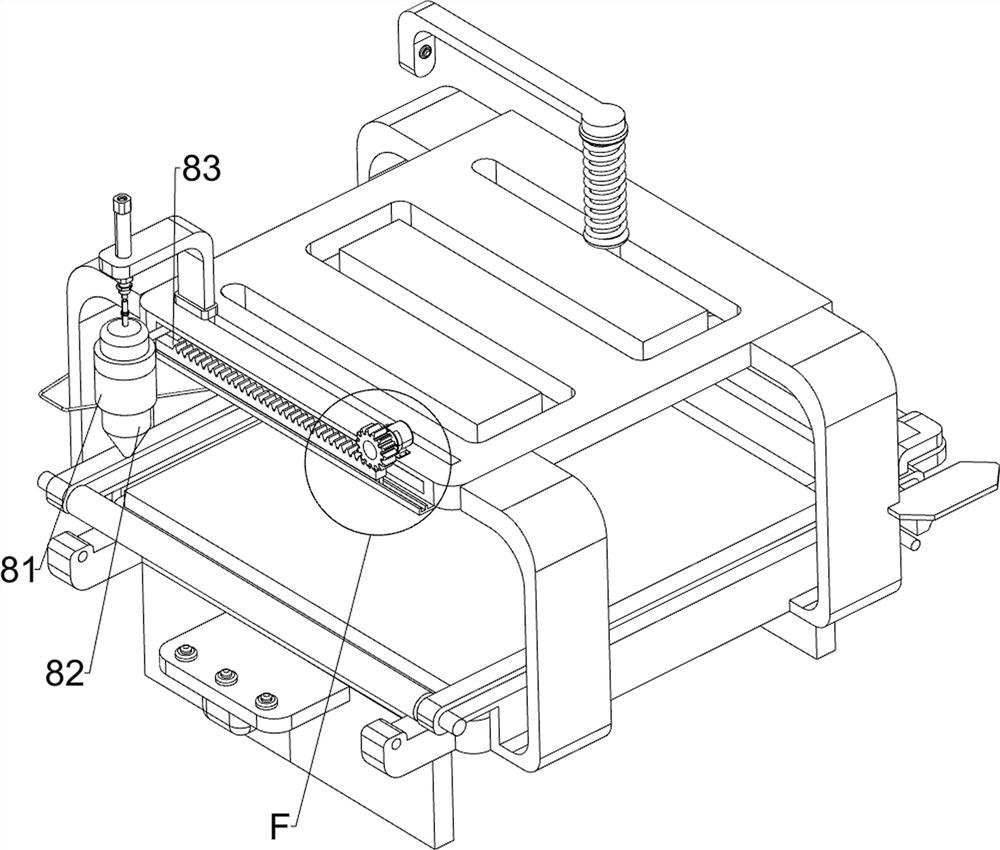

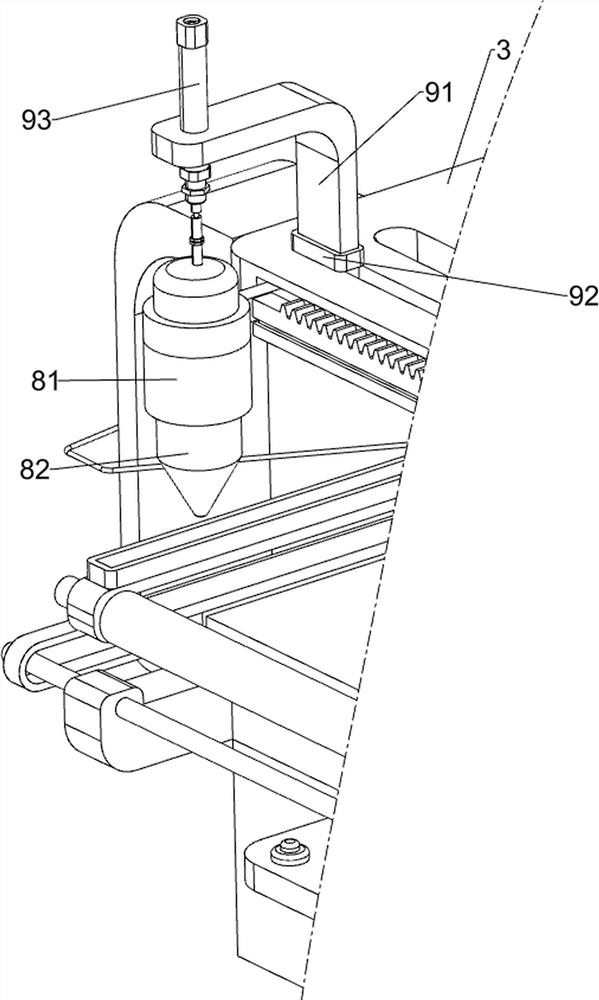

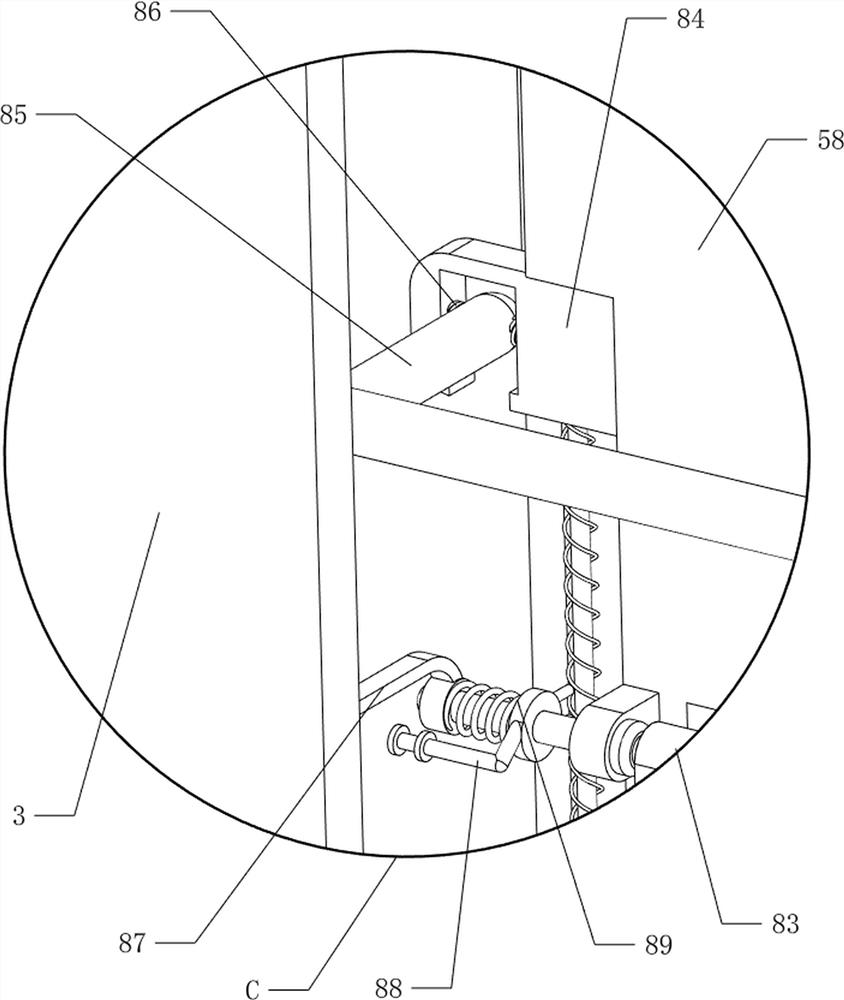

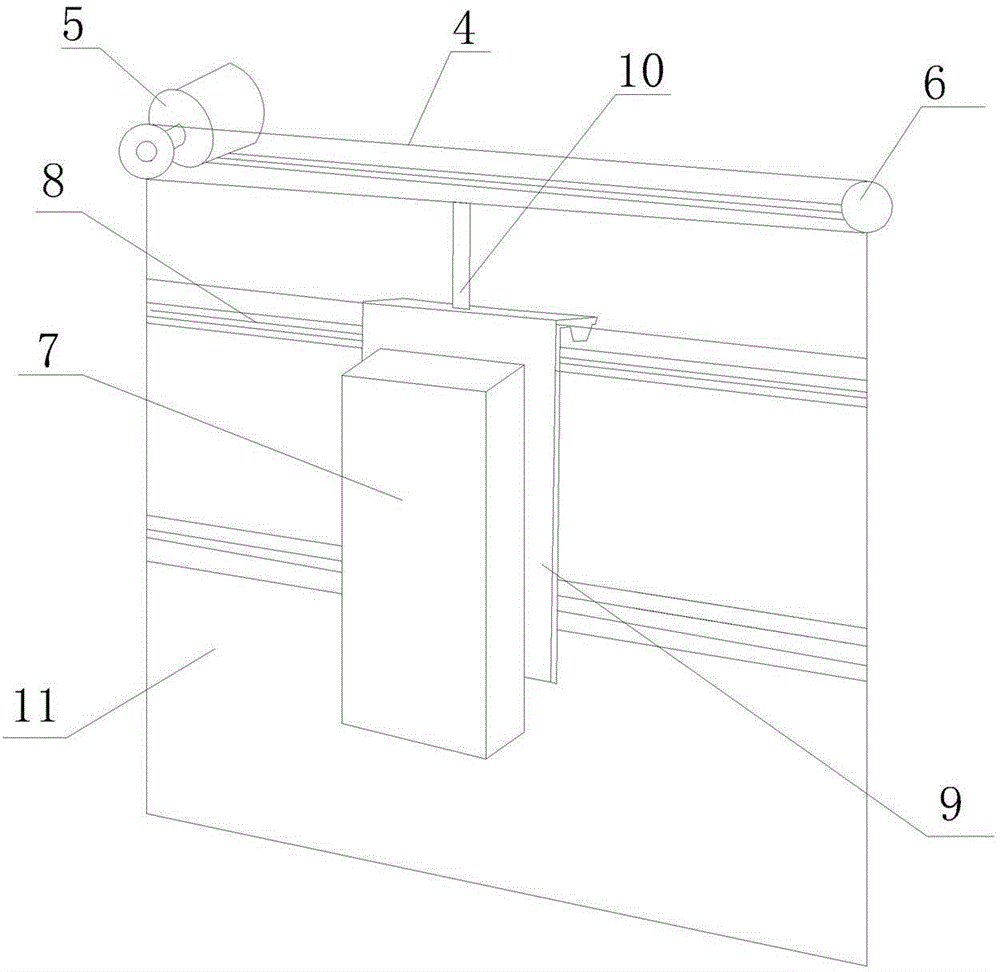

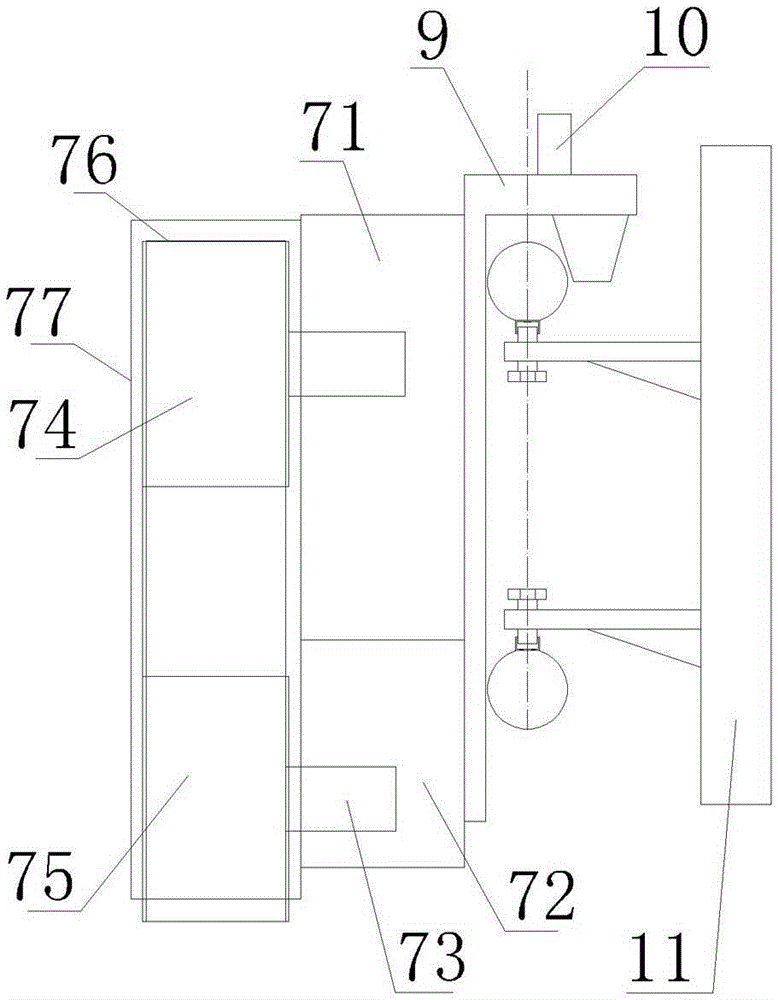

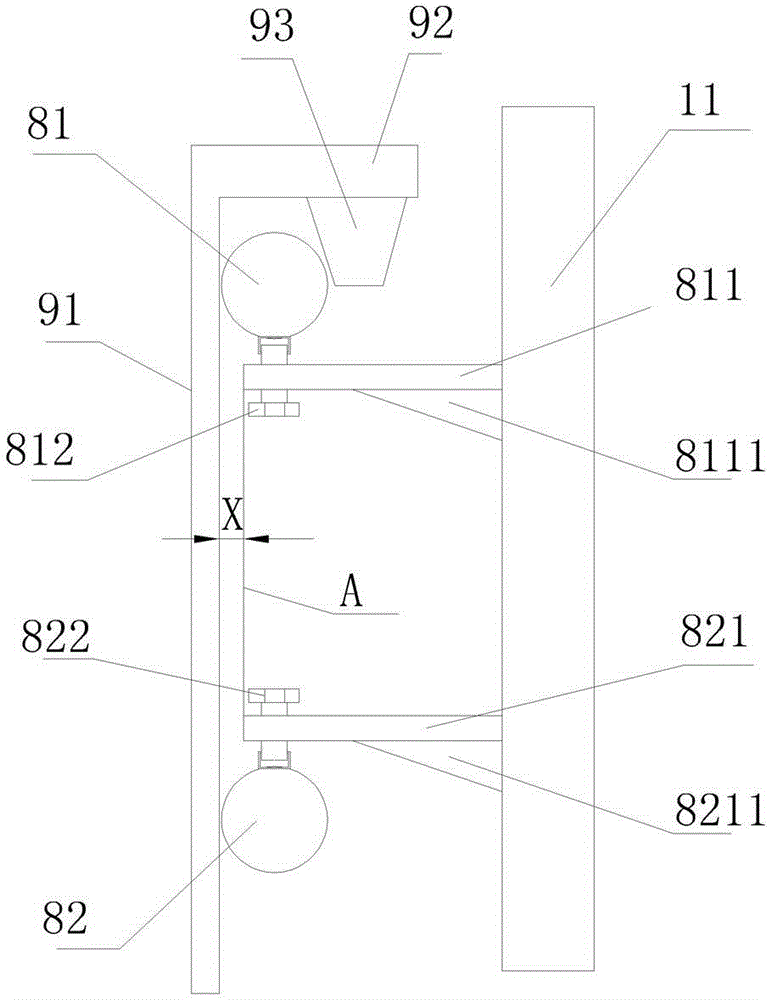

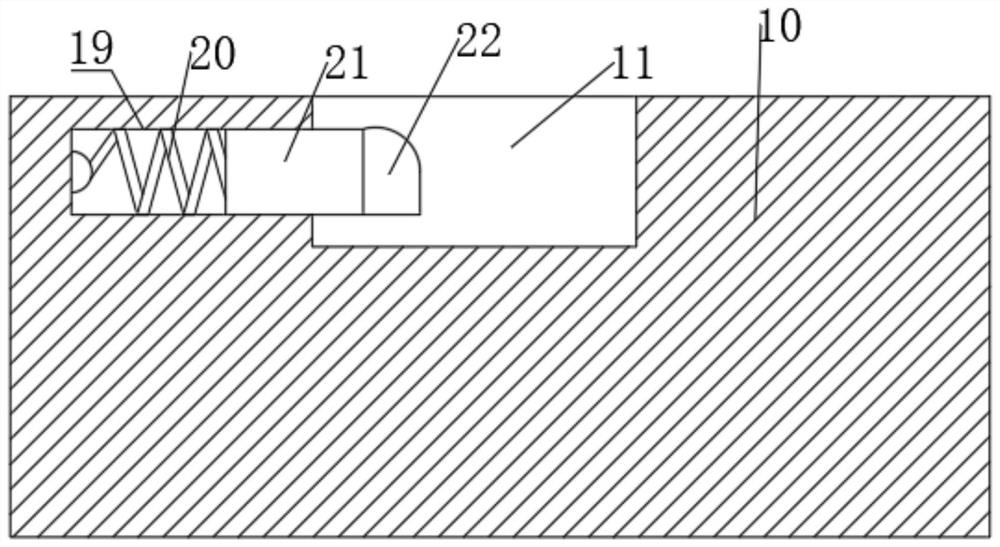

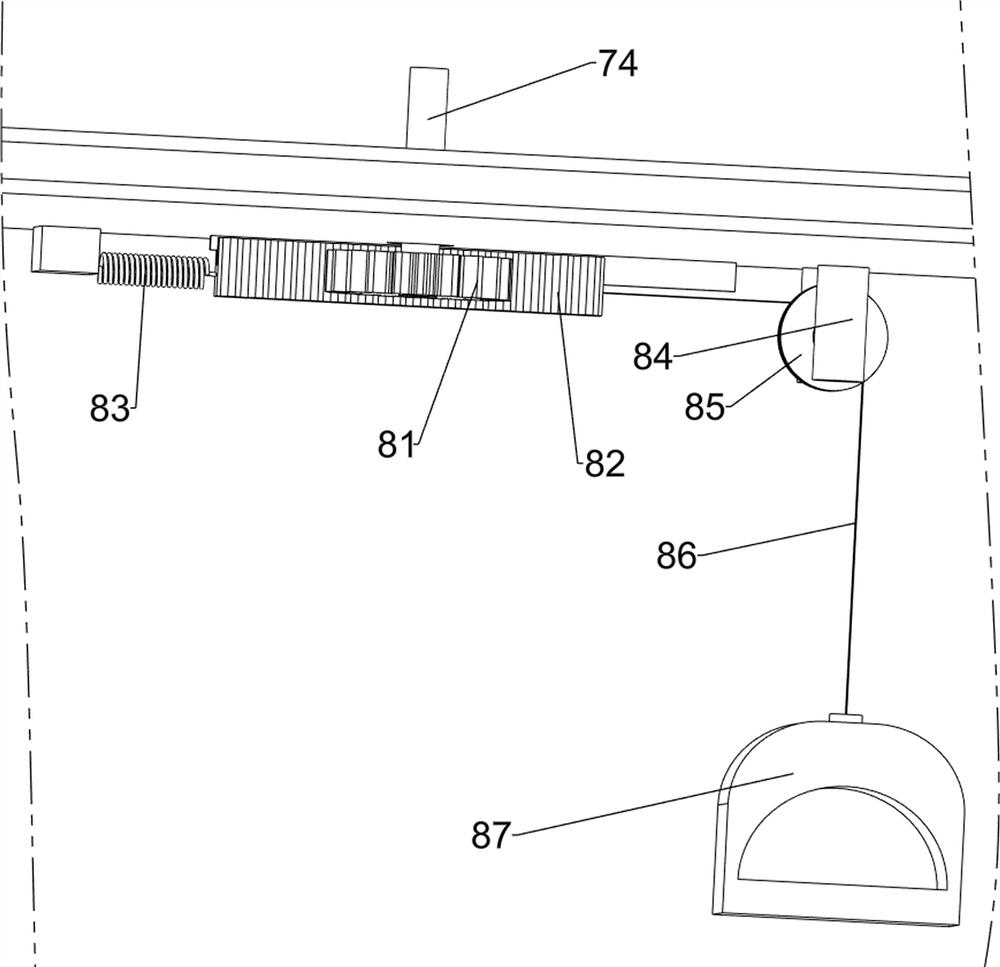

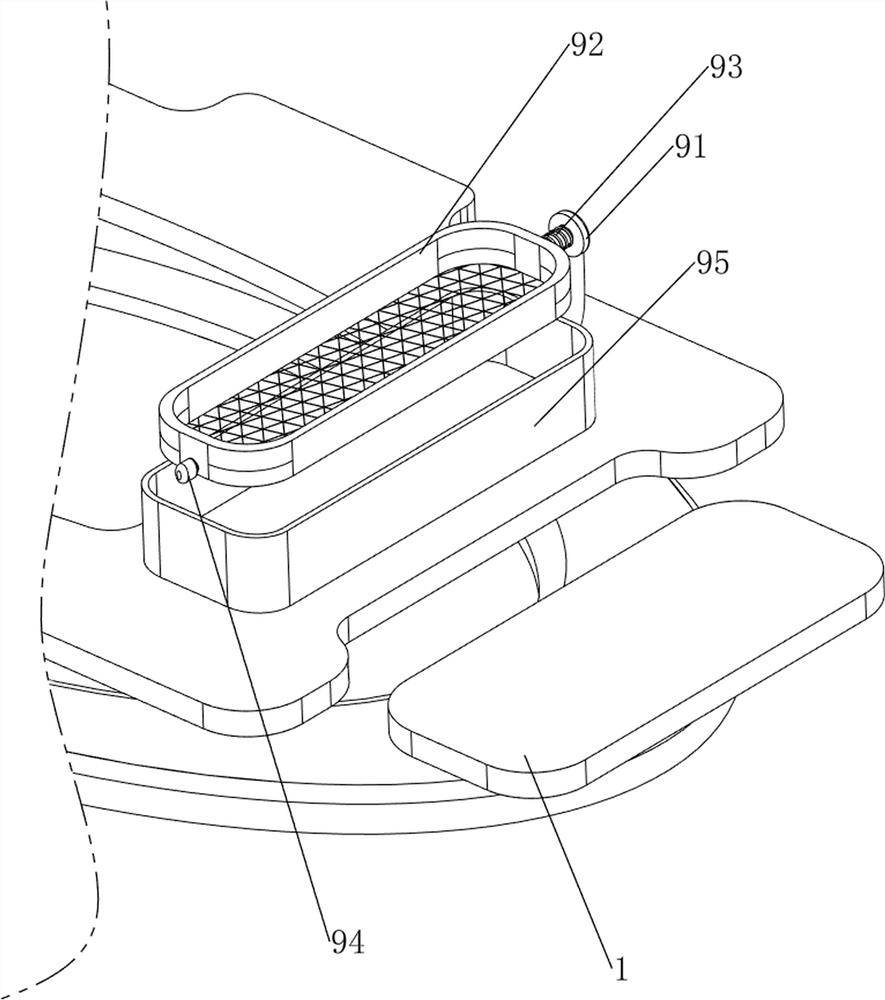

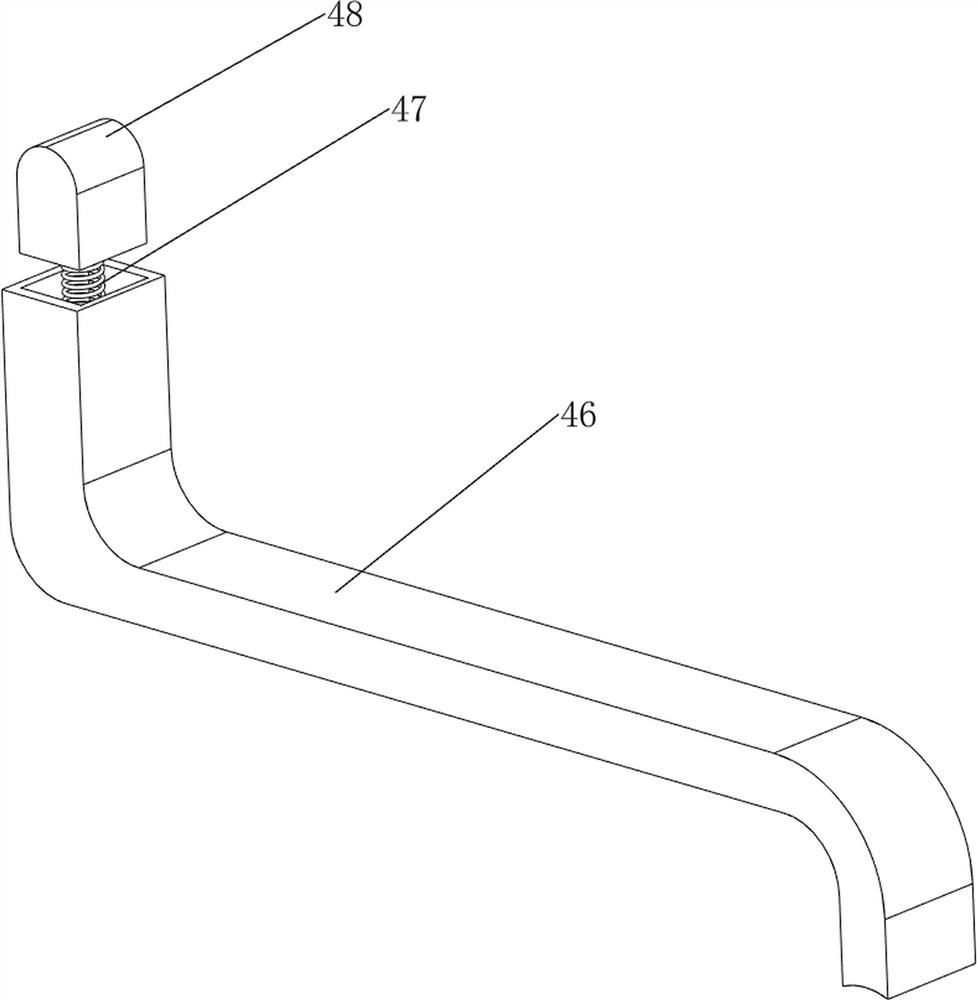

Sliding rail mechanism conducting automatic sliding and grinding

InactiveCN105290961ASimple structureReasonable designGrinding carriagesGrinding bedsEngineeringSprocket

The invention discloses a sliding rail mechanism conducting automatic sliding and grinding. The sliding rail mechanism comprises a rear supporting plate 11. A sliding rail is fixedly installed on the side wall of the rear supporting plate 11. The sliding rail 8 comprises an upper sliding rail body 81 and a lower sliding rail body 82. A sliding frame 9 is clamped to the upper sliding rail body 81. The sliding frame 9 comprises a vertical frame 91 and a transverse frame 92 fixed to the upper end of the vertical frame 91. A clamping block 93 is downwards fixed to the transverse frame 92. The clamping block 93 is clamped to the upper sliding rail body 81. The side edge of the vertical frame 91 abuts against the side edge of the lower sliding rail body 82. A grinder 7 is fixedly installed on the sliding frame 9. A push handle 10 is fixedly installed on the transverse frame 92 of the top end of the sliding frame 9. An annular chain 4 is fixedly connected to the upper end of the push handle 10. The left end of the chain 4 is connected with a chain motor 5 in a sleeved manner, and the right end of the chain 4 is connected with a chain wheel 6 in a sleeved manner. At least suspension type automatic moving grinding is achieved, positioning is accurate, and an upper position and a lower position are accurately positioned for parallel automatic grinding.

Owner:倪煌斌

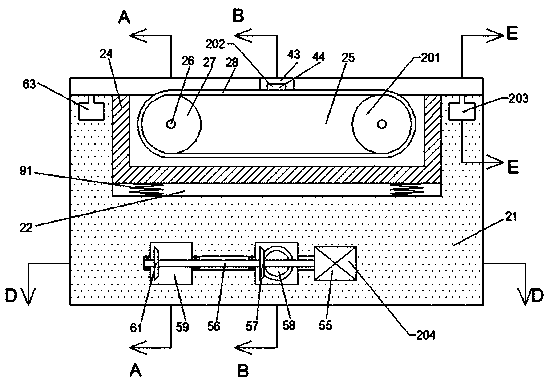

Automatic passing-through type grinding machine

InactiveCN111660187AAutomatic grindingAvoid turningGrinding machinesGrinding feedersElectric machineryEngineering

The invention discloses an automatic passing-through type grinding machine, which comprises a bottom plate, wherein two ends of the bottom plate are symmetrically fixed with two side plates; the frontend of one side plate is rotatably connected with a plurality of straight shafts; the front end of each straight shat is fixedly provided with a belt wheel; a plurality of belt wheels are sheathed with a belt; the rear end of each straight shaft is welded with a conveying roller; a plurality of conveying rollers are sheathed with a conveying belt; the top of the conveying belt is provided with afixing mechanism; the front end of one side plate is fixedly provided with a supporting plate and a control switch; the top of the supporting plate is fixedly provided with a motor; a motor output shaft is connected with a speed reducer; and the output shaft of the speed reducer is connected with one belt wheel. Since the control switch is arranged, a workpiece is fixed on a fixing mechanism in advance, a control motor can be controlled through the control switch to carry out positive and negative rotation, the motor drives the belt wheels and the straight shafts to rotate, the plurality of belt wheels rotate together through belt transmission so as to drive the conveying rollers and the conveying belt to rotate, the fixing mechanism moves in a horizontal direction, and the workpiece on the fixing mechanism is automatically polished and processed.

Owner:惠州市通达磁材科技有限公司

Anti-adhesion tablet processing device used for medicine detection

InactiveCN110333116AImprove accuracyAutomatic grindingPreparing sample for investigationEngineeringUltimate tensile strength

The invention provides an anti-adhesion tablet processing device used for medicine detection and relates to the medicine detection technology field. The anti-adhesion tablet processing device used formedicine detection comprises a barrel. A top end of the barrel is fixedly provided with a feeding port, and an internal portion of the barrel is rotatably connected with a rotating stick. A peripheryof the rotating stick is provided with a ring groove, and the periphery of the rotating stick is slidably connected with a rolling plate. A slide block is fixedly arranged on one side, which is closeto a center of the rotating stick, of the rolling plate through a connecting rod, and a spring is fixedly connected between the slide block and an inner wall of the rotating stick. By using the anti-adhesion tablet processing device used for medicine detection, medicine can be automatically grinded, grinding is uniform, and a thickness degree of the grinding is adjustable so that working intensity of an inspector is reduced and accuracy of medicine detection is improved. During a grinding process, the medicine adhered on the rolling plate can be automatically fallen off, adhesion of the medicine is avoided, and a grinding effect is improved.

Owner:陈立夫

Bearing grinding device with controller

InactiveCN104526479AAutomatic grindingControl timeRevolution surface grinding machinesAutomatic grinding controlEngineeringMachining

The invention discloses a bearing grinding device with a controller. The bearing grinding device comprises a feeding unit, a grinding unit and a discharging unit. The feeding unit comprises a material rack, a material pouring device and a lever, and an outlet of the material rack is connected with the material pouring device; the lever is connected with the material pouring device, and the material pouring device is used for feeding a bearing to be machined to the grinding unit; the grinding unit comprises a machining groove and two cold bars arranged in the machining groove; the machining groove is used for receiving a bearing to be machined; the cold bars are used for grinding the inner ring and the outer ring of the bearing; and the discharging unit comprises a track, and the track is connected with the machining groove and used for moving out the completed bearing. The bearing grinding device is driven by the two cold sticks to carry out grinding, the bearing can be automatically ground, a worker can operate multiple devices at the same time, the yield is improved, and the number of operation steps is reduced.

Owner:WUXI BAISHUN MACHINERY PLANT

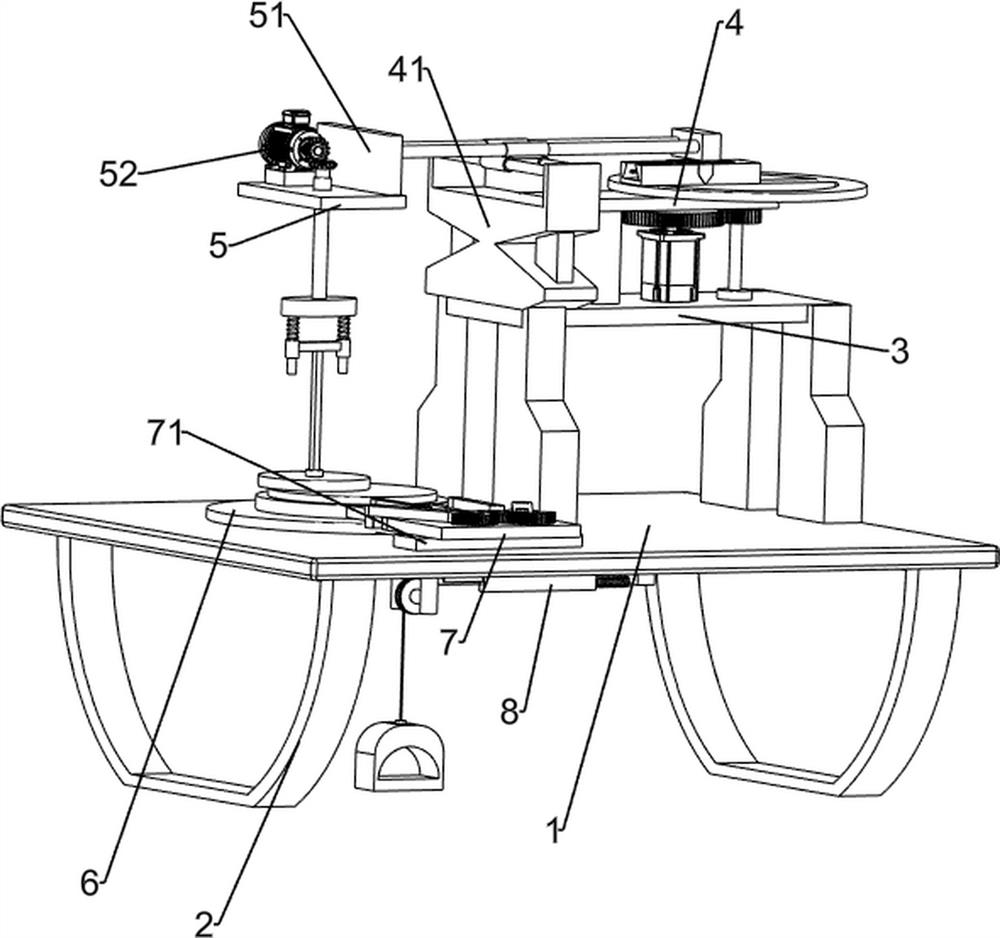

Surface grinding device for circular cutting board machining

PendingCN112757092AAutomatic grindingGrinding speed is fastEdge grinding machinesGrinding carriagesSurface grindingManufacturing engineering

The invention relates to a grinding device, in particular to a surface grinding device for circular cutting board machining. According to the surface grinding device for circular cutting board machining, the surface of a circular wood block can be automatically ground, time and labor can be saved, and the grinding speed can be increased. The surface grinding device for round cutting board machining is characterized by comprising a bottom plate, a supporting frame and a base plate, and two foot stools are connected to the bottom of the bottom plate; the supporting frame is connected to one side of the top of the bottom plate, a rotating mechanism is installed on the supporting frame, and a grinding mechanism is connected to the rotating mechanism; and the other side of the top of the bottom plate is connected with the base plate. According to the surface grinding device for circular cutting board machining, the grinding mechanism can move along the circular wood block through the rotating mechanism, the grinding mechanism moves along the circular wood block and can polish and remove burrs on the surface of the circular wood block in all directions, and therefore the effects that the surface of the circular wood block can be automatically polished, time and labor are saved, and the polishing speed can be increased are achieved.

Owner:万小华

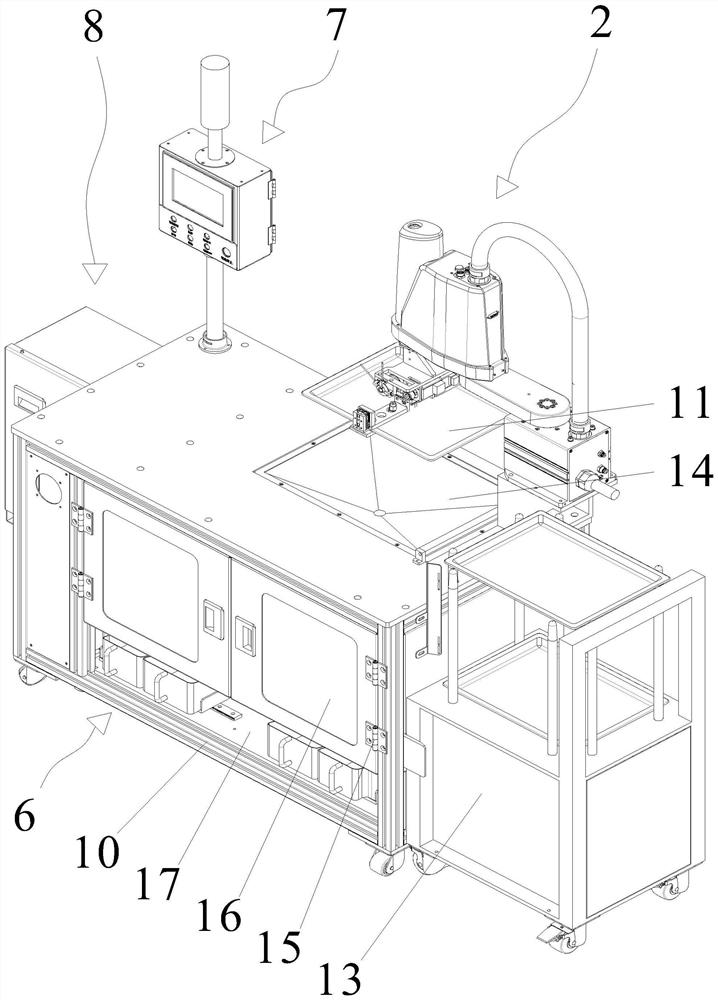

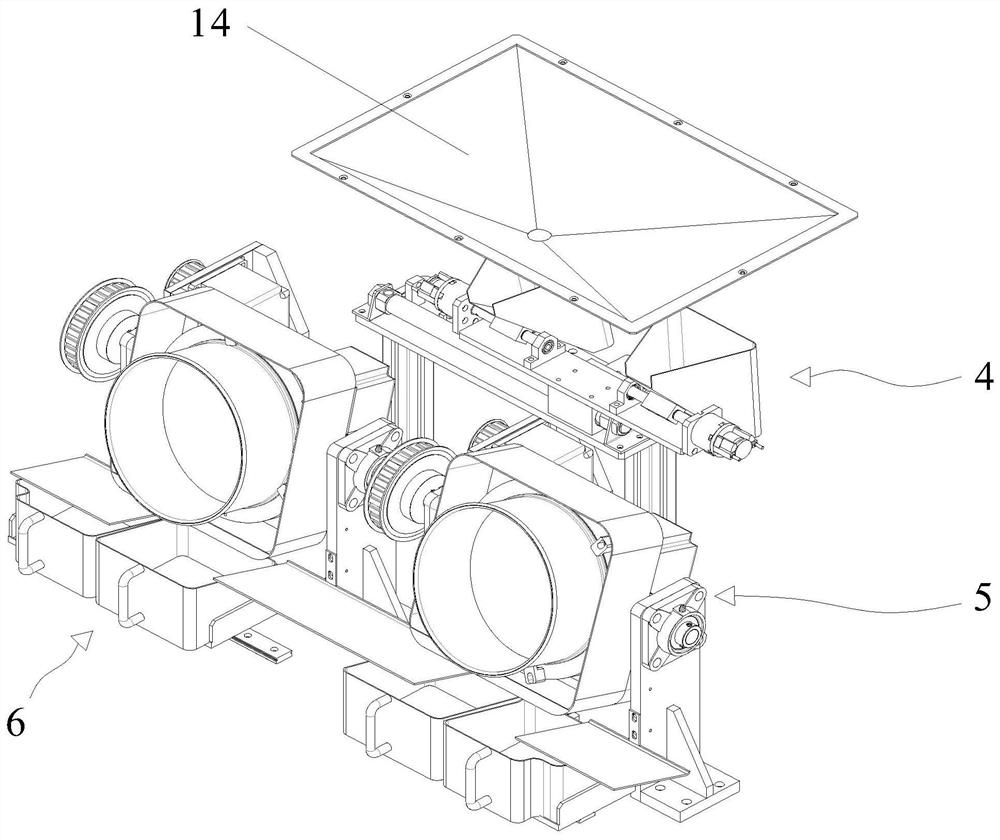

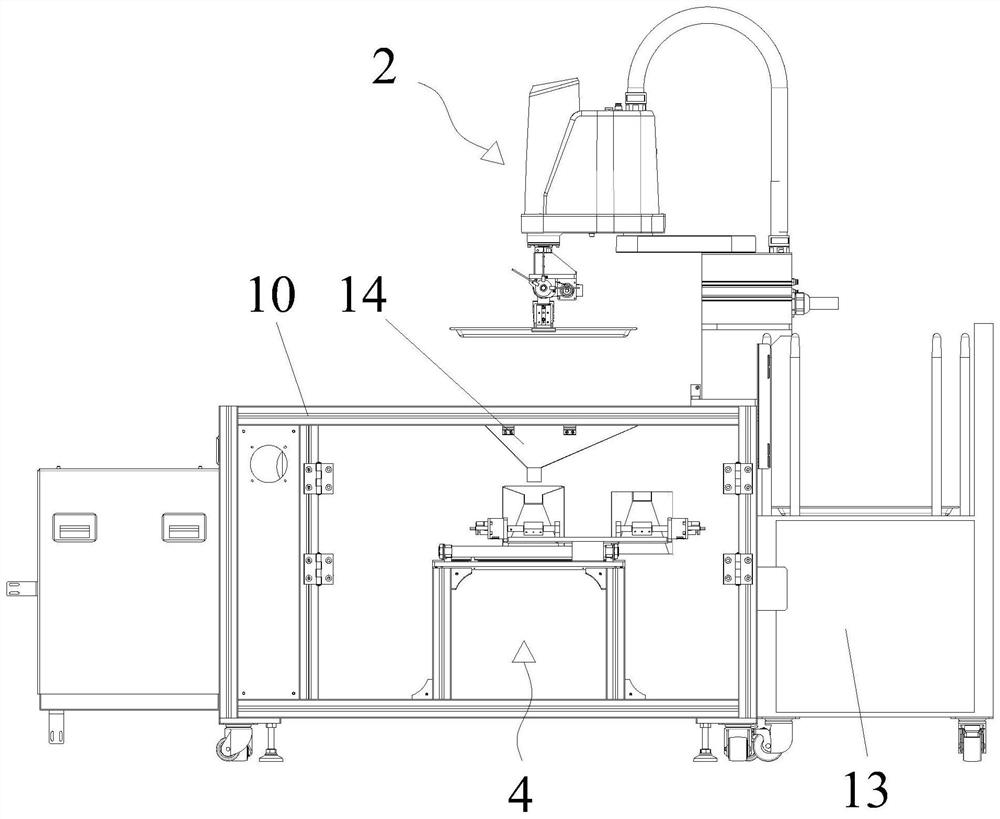

An induction grinding machine

ActiveCN110496687BSimple structureLow costFouling preventionGrain treatmentsProcess engineeringIndustrial engineering

The invention discloses an induction feeding grinder, which comprises a frame and a feeding mechanism arranged on it for collecting and discharging dispersed materials, capable of receiving the materials dropped by the feeding mechanism and performing grinding in batches Batch mechanism, touch mechanism for checking working status and setting working parameters and electrical mechanism for providing electrical support. It can automatically collect, grind, and batch inductors. It has a high degree of automation, saves production time, improves production efficiency, and prevents personnel from being exposed to harmful environments, which is beneficial to personnel health.

Owner:苏州鸣动智能设备有限公司

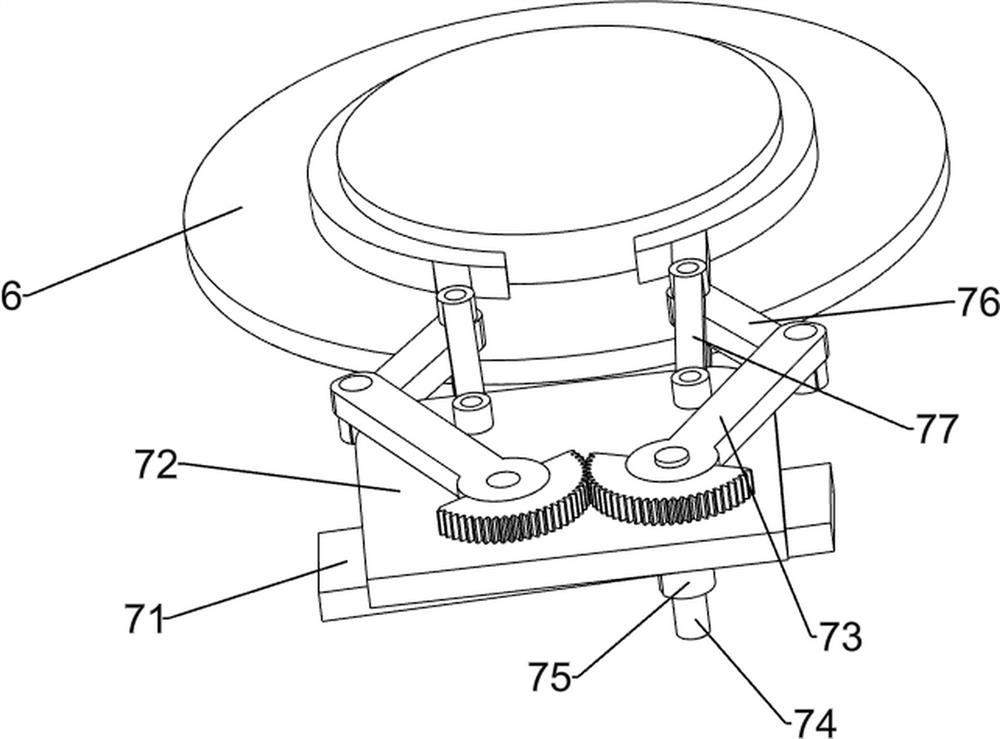

A fully automatic faceted crystal glass grinding machine

ActiveCN110774119BSimple structureAutomatic grindingEdge grinding machinesGrinding carriagesEngineeringMachine

The invention discloses a full-automatic facet crystal glass surface polishing machine. The machine comprises a base, base space arranged on the upper end surface of the base, a main machine fixedly arranged in the base space, two clamping devices arranged on the front and back sides of the upper end surface of the base, and a support device arranged on the base; and the clamping device on the front side comprises two travel grooves arranged on the left and right sides of the upper surface of the base, movable plates arranged on the upper sides of the two travel grooves, and two limiting plates fixedly arranged on the lower end surfaces of the movable plates and positioned in the two travel grooves.

Owner:浦江县凯帝服装饰品有限公司

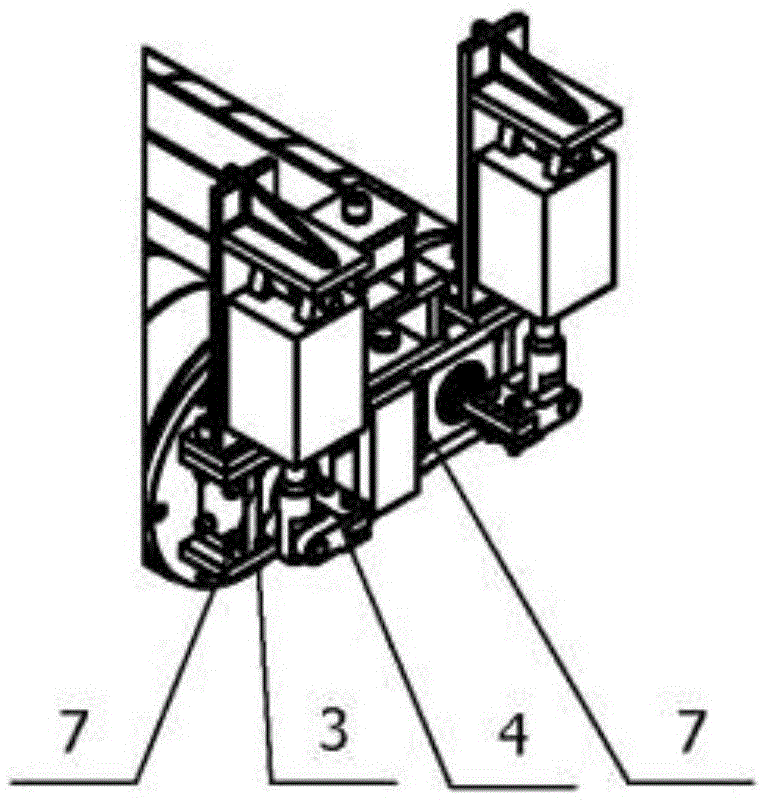

Weld joint grinding equipment

PendingCN111451875AThe action process is not complicatedPrecision grindingEdge grinding machinesGrinding carriagesEngineeringMechanical field

The invention discloses weld joint grinding equipment, relates to the field of engineering machinery, and is used for simply, conveniently and efficiently grinding weld joints. The welding joint grinding equipment comprises a mounting base, a posture adjusting device and a grinding mechanism, wherein the mounting base is configured to provide support, the posture adjusting device is installed on the mounting base, the grinding mechanism is installed on the posture adjusting device, and the posture adjusting device is constructed to adjust the position of the grinding mechanism in the space. According to the technical scheme, automatic weld joint grinding is achieved, the structure is compact, and the grinding performance is reliable.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

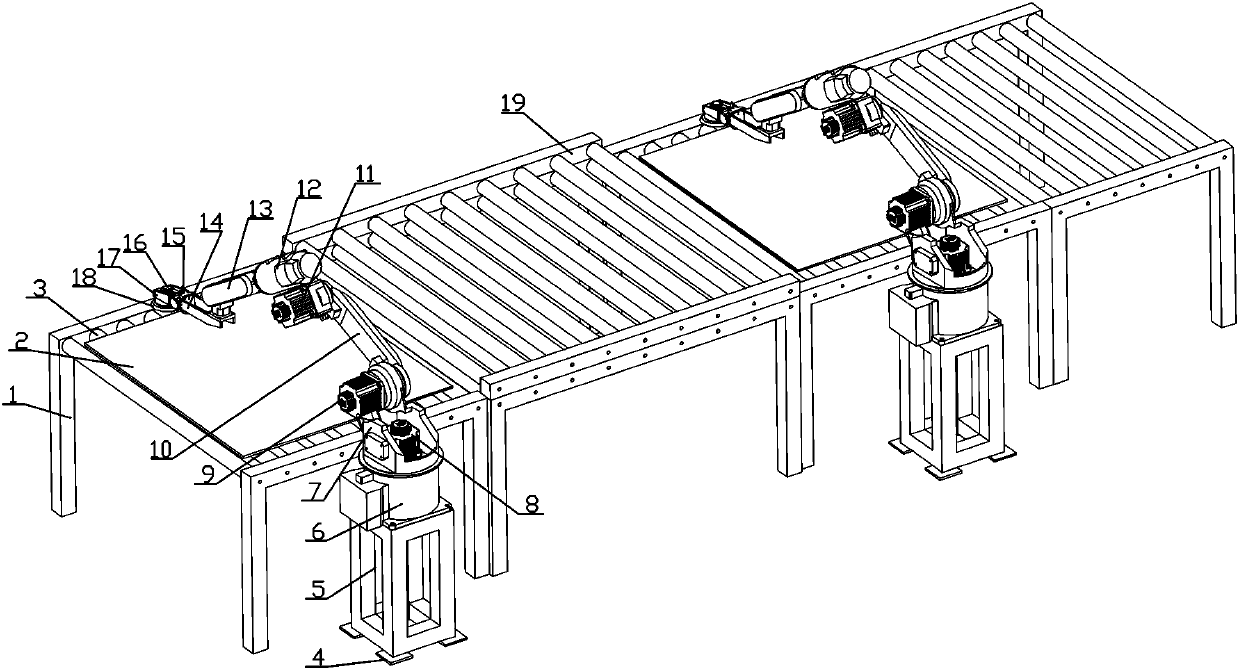

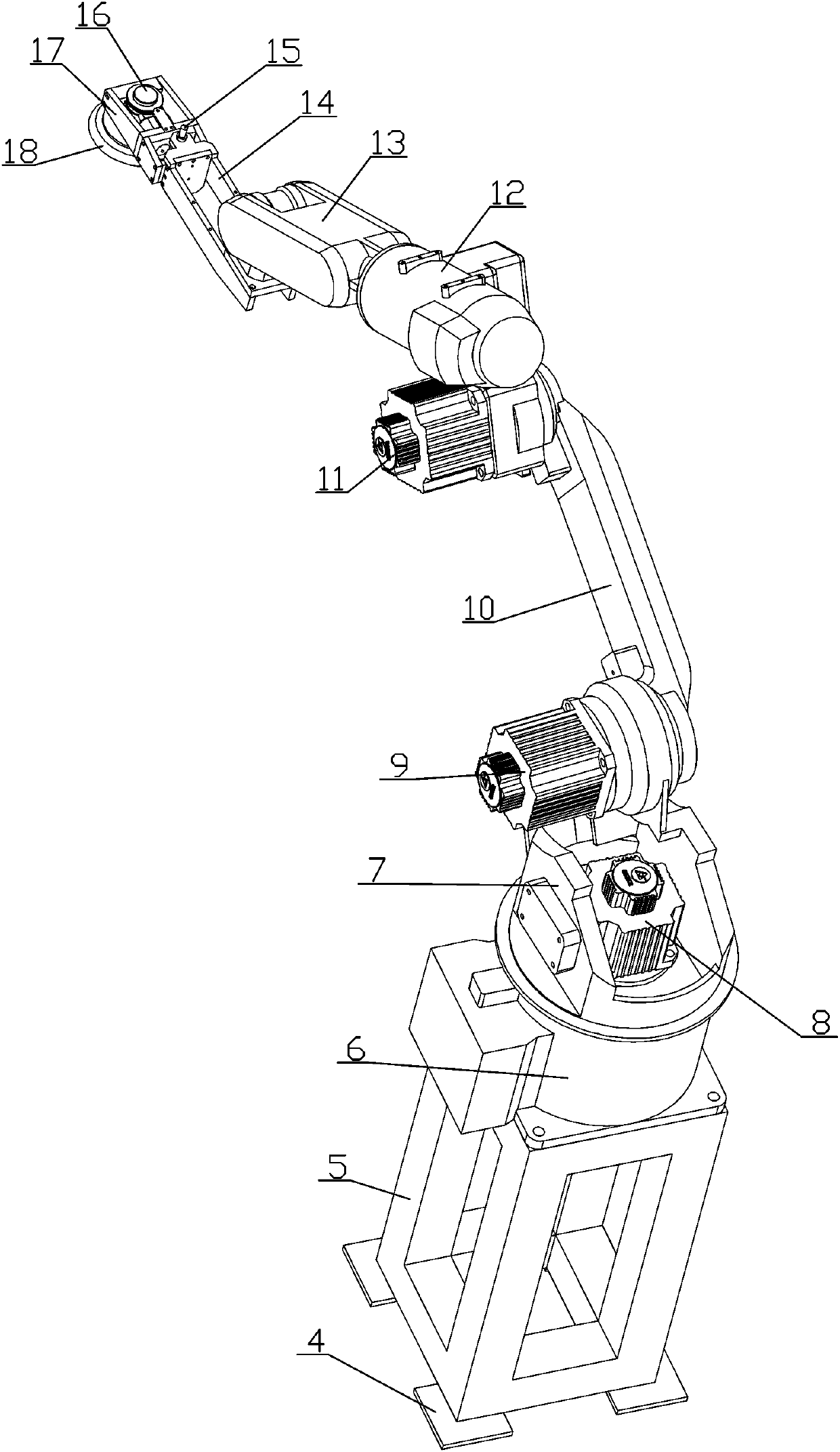

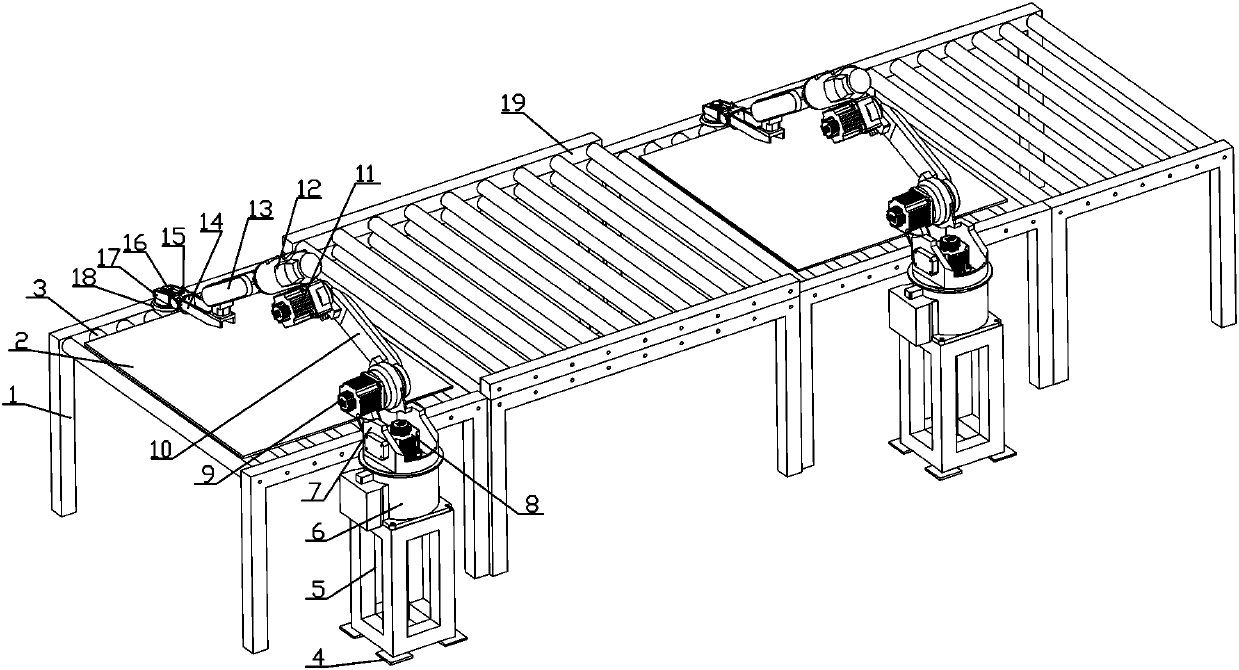

Automatic grinding production line of touch screen glass

InactiveCN109702559AAutomatic grindingImprove grinding efficiencyOptical surface grinding machinesProduction lineEngineering

The invention provides an automatic grinding production line of touch screen glass. The automatic grinding production line of the touch screen glass comprises conveying line racks. The tops of the conveying line racks are provided with roller assemblies which are used for conveying the touch screen glass. The side faces of the conveying line racks are provided with automatic grinding manipulatorswhich are used for grinding and polishing the glass. Transition roller assemblies are arranged between the two adjacent conveying line racks. Tail ends of the grinding manipulators are provided with grinding devices. By means of the automatic grinding production line, the grinding and polishing efficiency of the touch screen glass can be improved.

Owner:梅鹏程

Grinding machine for sheet metal part machining and suitable for different thicknesses

ActiveCN113103122AEasy to polishAutomatic grindingEdge grinding machinesGrinding carriagesMachineMaterials science

The invention relates to the field of sheet metal part grinding, in particular to a grinding machine for sheet metal part machining and suitable for different thicknesses. The grinding machine comprises a first fixing frame, a grinding mechanism, a clutch mechanism, a pushing mechanism, a moving mechanism and the like. The grinding mechanism is arranged on the first fixing frame, the clutch mechanism is arranged on the grinding mechanism, the pushing mechanism is arranged on the first fixing frame, and the moving mechanism is arranged on the first fixing frame. Through cooperation of a second sliding frame and devices on the second sliding frame, when a sheet metal part on the first fixing frame is thick, the sheet metal part on the first fixing frame can push the second sliding frame and the devices on the second sliding frame to move upwards, a wedge-shaped frame pushes a sliding block and devices on the sliding block to move upwards, and therefore a grinding disc can grind the thick sheet metal part; and when the sheet metal part on the first fixing frame is thin, the sliding block and the devices on the sliding block can reset under the action of gravity, and the effect that sheet metal parts with different thicknesses can be ground is achieved.

Owner:佛山市顺德区奇睿电气有限公司

Antibacterial metal material processing device for titanium intramedullary nail

InactiveCN110026893BLock firmlyAutomatic grindingSpraying apparatusGrinding machinesElectric machineryMetallic materials

The invention relates to a processing device for an antibacterial metal material for a titanium intramedullary nail. The processing device comprises a supporting bottom plate, an electric guide rail,locking devices and a detection device, wherein the electric guide rail is arranged on the upper end surface of the middle of the supporting bottom plate, the detection device is arranged on the top of the electric guide rail, and two locking devices are installed on the left side and the right side of the top of the supporting bottom plate respectively; each locking device comprises a locking base, a locking connecting frame, a locking bottom sleeve, a clamping pressing sleeve, a locking sleeve, locking sliding columns, sliding column springs and a buckling branch chain; and the detection device comprises a detection support, a detection sleeve, marking mechanisms, a rotating sleeve, a rotating motor, a rotating gear, grinding mechanisms and cleaning mechanisms. The processing device forthe antibacterial metal material for the titanium intramedullary nail can solve the problems that an existing titanium bar is not firm in locking, a locking mechanism cannot be used for conveying thetitanium bar, the bending degree of the titanium bar cannot be visually marked, and the titanium bar needs to be polished manually, when the existing titanium bar is subjected to bending detection andpolishing.

Owner:THE PEOPLES HOSPITAL SHAANXI PROV

Medical device for grinding particulate medicinal materials into powder

ActiveCN114433295AAutomatic grindingAutomatic collection effectSievingScreeningMedicinal herbsMedicine

The invention relates to a grinding and powdering device, in particular to a medical particulate medicinal material grinding and powdering device. The technical problem of the invention is to provide the device for grinding the medical particulate medicinal materials into powder, which can be used for automatically grinding the medicinal materials and automatically collecting the ground medicinal materials. A device for grinding medical particulate medicinal materials into powder comprises a supporting plate, a grinding plate, a roller, a connecting rod, a discharging mechanism and a protection mechanism, the grinding plate is arranged at the top of the supporting plate, the roller is movably arranged on the grinding plate, the connecting rod is arranged in the middle of the roller, the discharging mechanism is arranged in the middle of the top of the supporting plate, and the protection mechanism is arranged on the discharging mechanism. The device achieves the effects that the medicinal materials can be automatically ground, and the ground medicinal materials are automatically collected; medicinal materials are placed on the grinding plate, the rodless air cylinder drives the first movable rod, the connecting rod and the rolling wheels to move, and therefore the effect of automatically grinding the medicinal materials can be achieved.

Owner:湖南守诚堂品牌管理有限公司

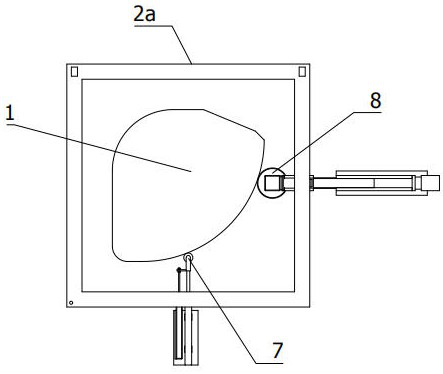

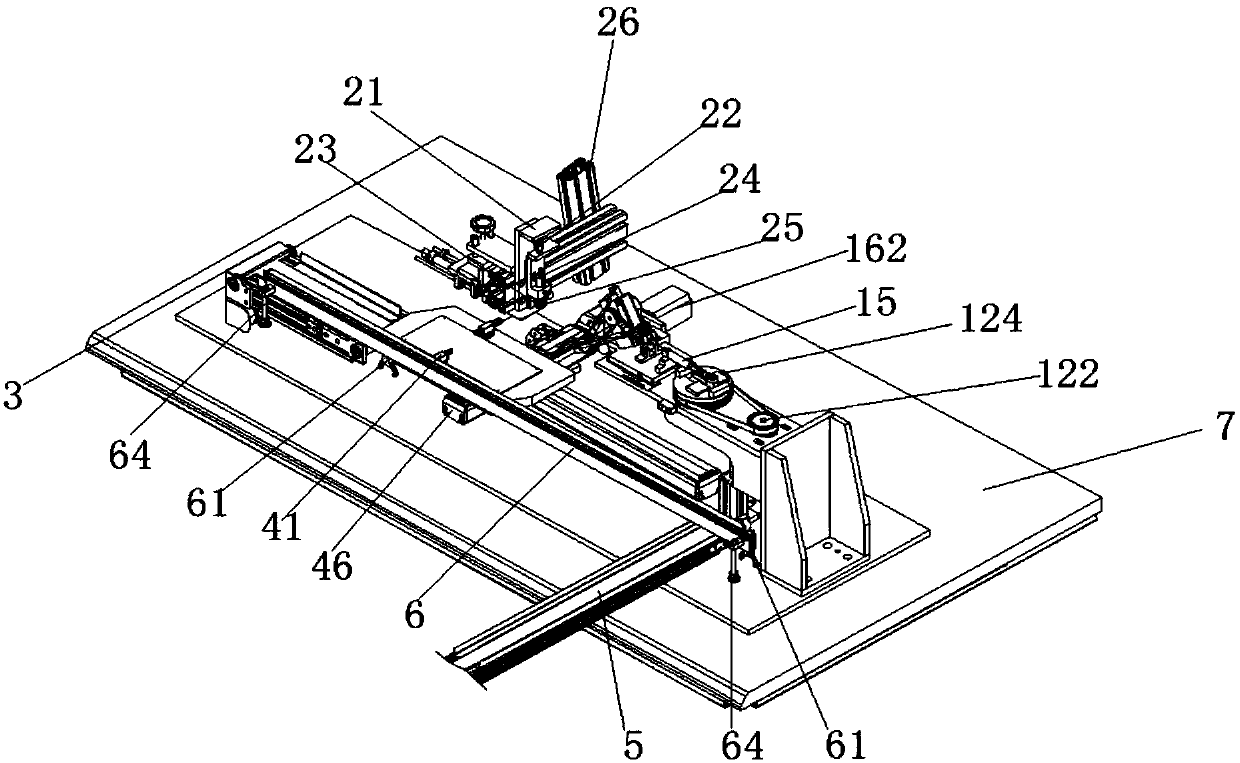

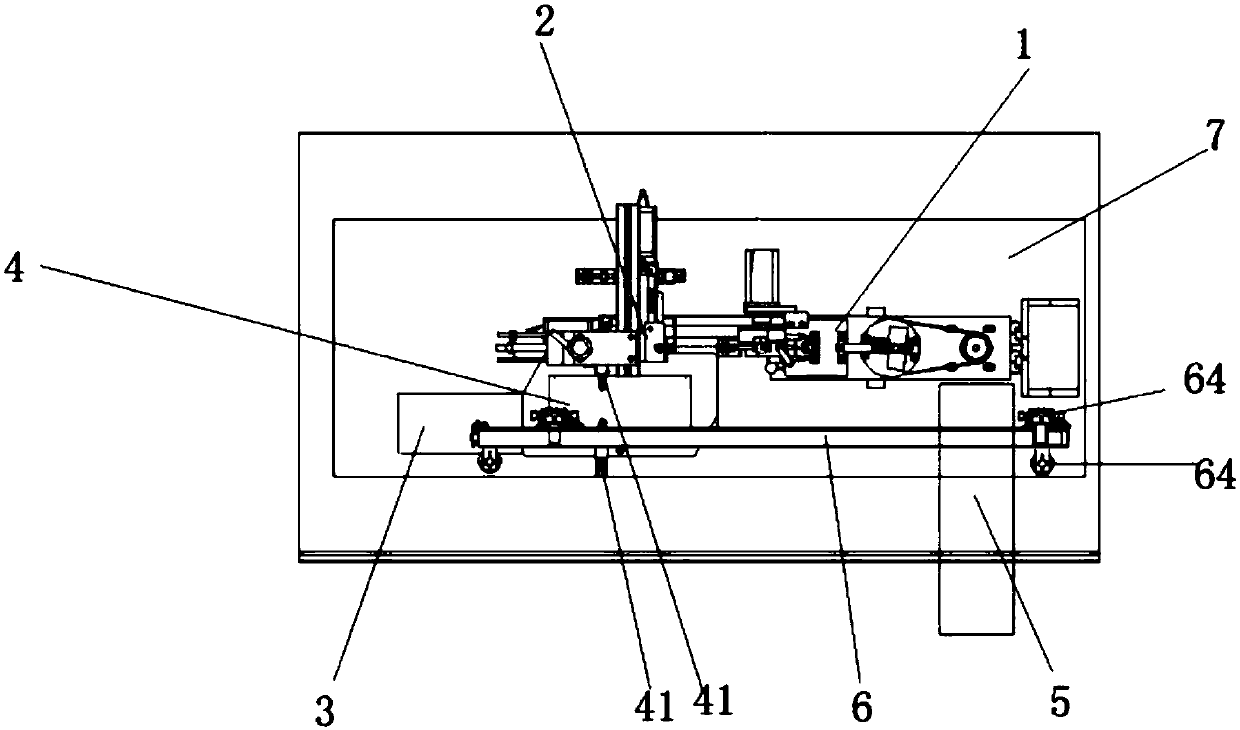

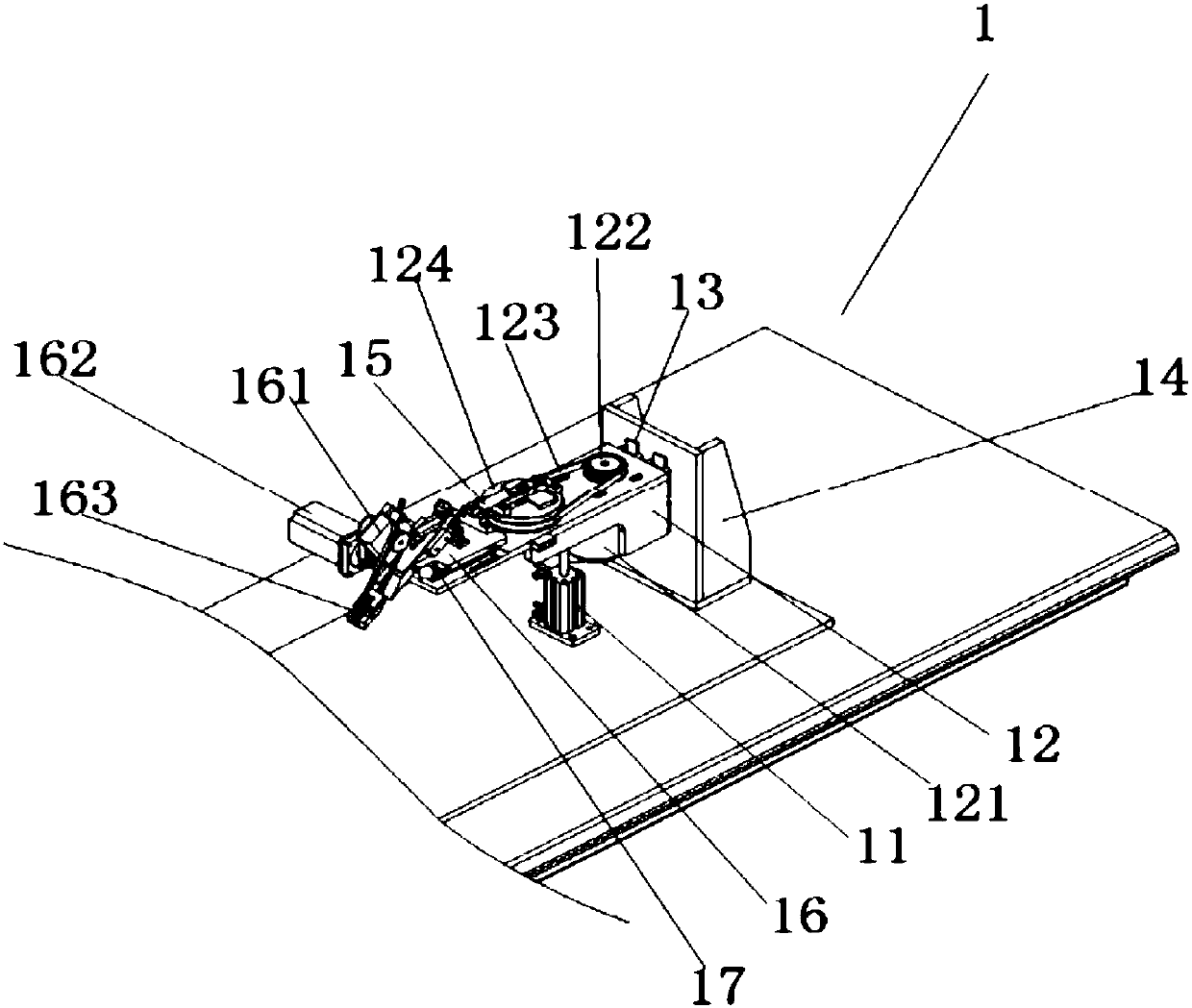

A special-shaped glass edge grinding device

ActiveCN111098200BPrevent escapeAutomatic grindingEdge grinding machinesGrinding drivesEngineeringSelf adaptive

The invention relates to the field of automatic glass machining equipment, in particular to a special-shaped glass edge grinding device. The special-shaped glass edge grinding device comprises a closed workbench, a vacuum generator, an electric rotary disc and a controller are arranged in the closed workbench, the working end of the electric rotary disc is vertically arranged upwards, a suction cup fixing frame is fixedly installed at the working end of the electric rotary disc, a plurality of vacuum suction cups are movably installed on the suction cup fixing frame, the working ends of the vacuum suction cups are vertically arranged upwards, the working ends of all the vacuum suction cups are located at the same height, the input ends of the vacuum suction cups communicate with the outputend of the vacuum generator, the special-shaped glass is fixed to the vacuum suction cups, and a measuring mechanism and a self-adaptive grinding mechanism of which the working ends penetrate throughthe closed workbench and extend to the edge of the special-shaped glass are arranged beside the closed workbench. According to the special-shaped glass edge grinding device, the problems that the special-shaped glass is troublesome to machine and the cost is high in the traditional technology are solved.

Owner:丹阳市金星光学仪器有限公司

Automobile rotating shaft tube automatic grinding device

ActiveCN106141857BAutomatic grindingEasy to operateGrinding drivesCleaning using toolsEngineeringMechanical engineering

The invention discloses an automatic grinding device for an automobile rotating shaft tube, which includes a workbench. A grinding device, a dust removal device and a fixing device are installed on the workbench. A feeding device and a discharging device are respectively installed at both ends of the fixing device. The workbench is also equipped with a grabbing device. The invention has reasonable design, solid structure, reliable operation, high work efficiency, convenient operation, reduces safety hazards and is safe to use.

Owner:江苏宏宝优特管业制造有限公司

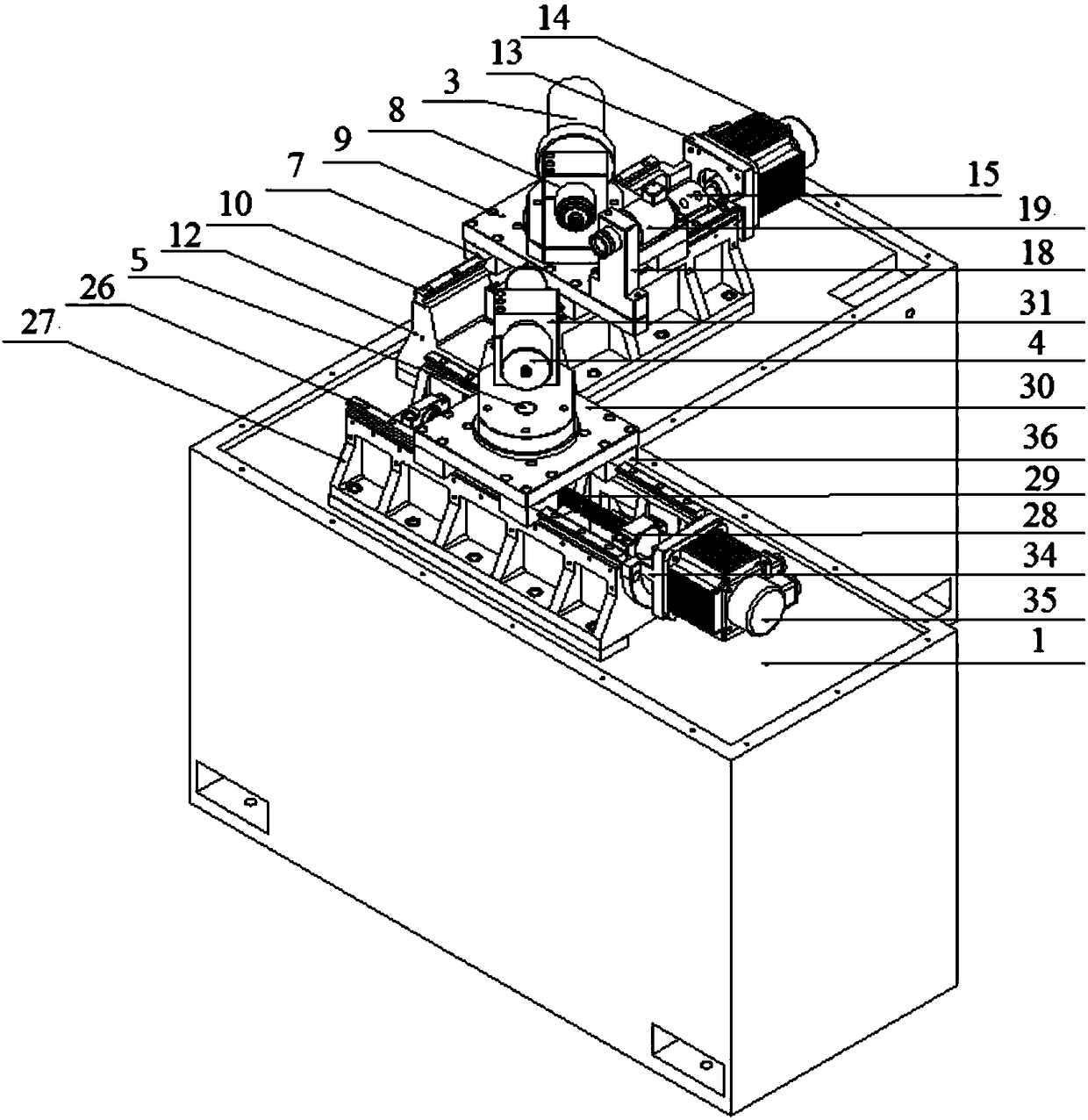

A kind of precision numerical control grinding machine for inner cone surface of small hole

InactiveCN105751019BIncrease productivityHigh degree of automationGrinding carriagesRevolution surface grinding machinesCnc grindingEngineering

The invention discloses a precision numerical control small-hole interior conical surface grinder, which comprises a grinder body, a transverse feeding unit and a longitudinal feeding unit, wherein the transverse feeding unit and the longitudinal feeding unit are arranged on the grinder body; the longitudinal feeding unit is provided with a first variable frequency high-speed motorized spindle; a precise valve seat positioning and clamping device is fixedly arranged in the axle center of the first variable frequency high-speed motorized spindle; a second variable frequency high-speed motorized spindle is arranged on the transverse feeding unit; a grinding wheel is arranged on the second variable frequency high-speed motorized spindle. According to the precision numerical control small-hole interior conical surface grinder, the first and second variable frequency high-speed motorized spindles can be matched to implement grinding machining of the grinding wheel over a workpiece; the precision numerical control small-hole interior conical surface grinder has the advantages of short process flow, once clamping, high production efficiency, high automation degree, high machining accuracy, stable machining quality and the like.

Owner:WUHAN PRECISE PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com