PPC pipe excess material processing device

A technology for processing devices and surplus materials, which is applied in the direction of grinding drive devices, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

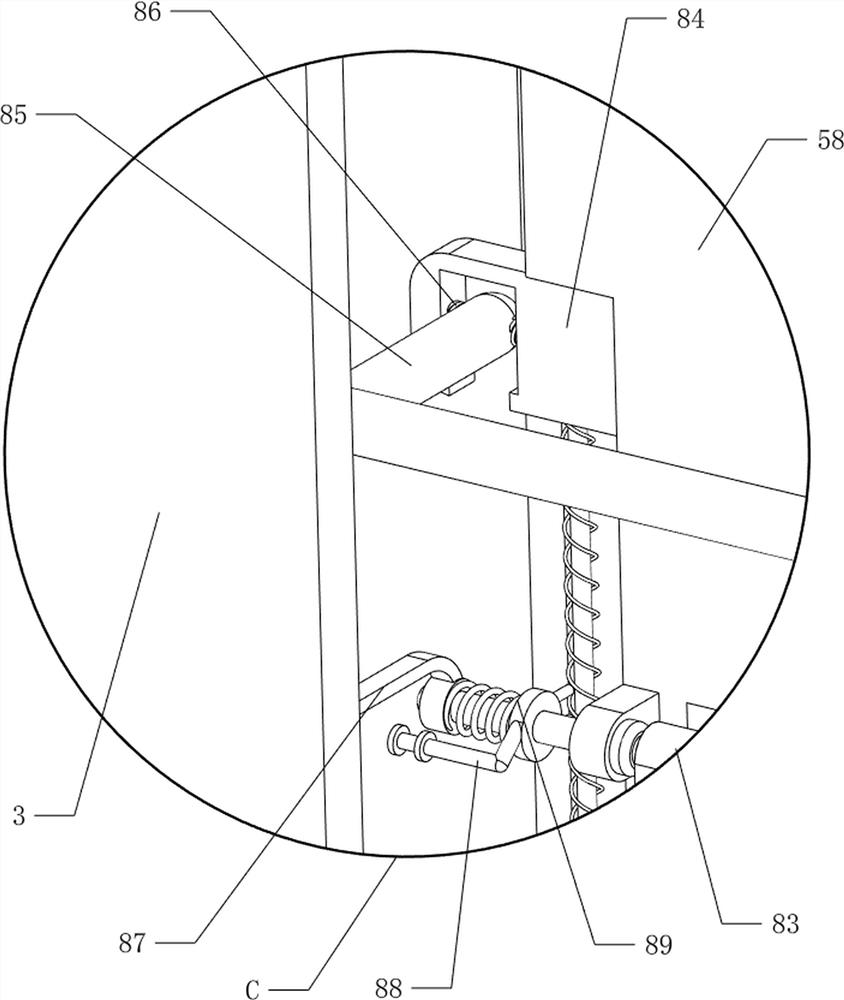

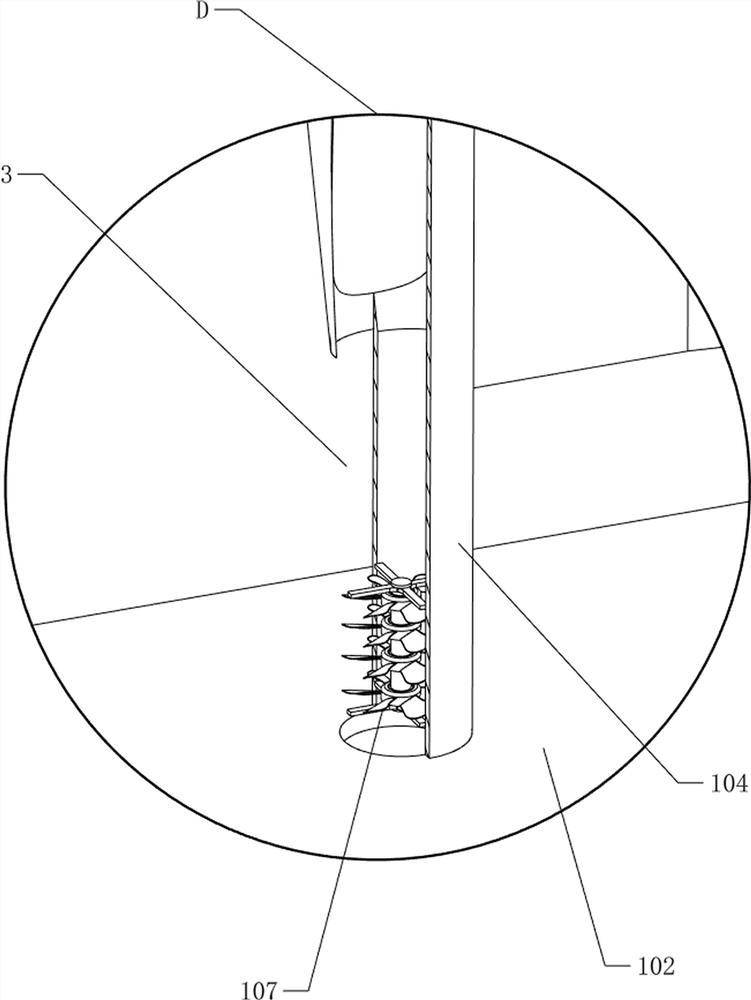

[0034] A PPC pipe residual material processing device, such as Figure 1-5 As shown, it includes a bottom plate 1, a lower half frame 2, a main body frame 3, an upper half body frame 4, a lifting mechanism 5 and a grinding mechanism 6. The front side of the upper part of the bottom plate 1 is provided with a lower half body frame 2 through bolts. Rubber is provided at the bottom, a main frame 3 is arranged in the lower half frame 2, an upper half frame 4 is arranged on the outer side of the upper part of the main frame 3, and a lifting mechanism 5 is arranged between the lower half frame 2 and the bottom plate 1, which can drive the PPC pipe The residual material rises, and a grinding mechanism 6 is provided in the upper part of the main frame 3, which can grind the residual material of the PPC pipe.

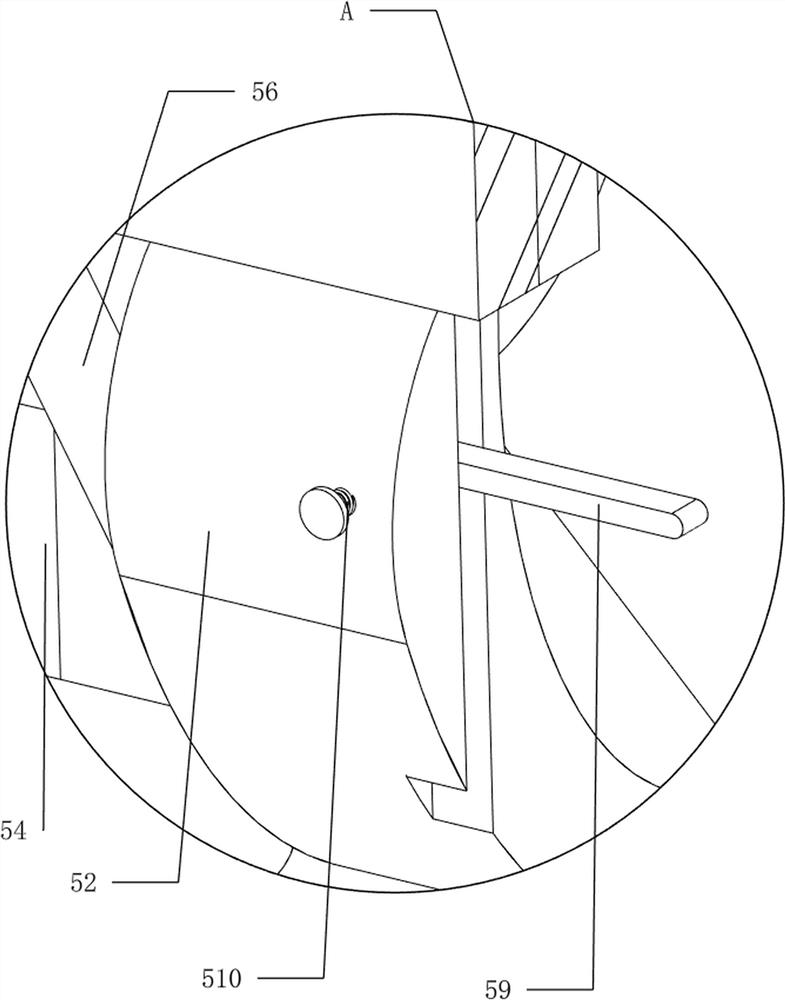

[0035] like figure 2 and image 3 As shown, the lifting mechanism 5 includes a cylinder 51, an oval angle 52, a contact floor 53, an extension rod 54, a straight rack 55, an ...

Embodiment 2

[0039] On the basis of Example 1, as figure 1 , Image 6 , Figure 7 and Figure 13 As shown, it also includes a feeding mechanism 7, which can facilitate feeding. The feeding mechanism 7 includes a first fixing frame 71, an arc-shaped hollow channel 72, a limit plate 73, a large sliding plate 74, a first return spring 75, The distance limiting plate 76, the hollow sliding plate 77, the rotating ramp 78, the sliding track 79, the second limiting rod 710 and the second return spring 711, the upper part of the front side of the bottom plate 1 is provided with a first fixing frame 71 through bolts, the first fixing The top of the frame 71 is welded with an arc-shaped hollow channel 72. The arc-shaped hollow channel 72 communicates with the main frame 3. The remaining PPC pipe material slides down to the contact floor 53 through the arc-shaped hollow channel 72. The lower part of the main frame 3 is provided with a limit plate 73 through bolts. , a large sliding plate 74 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com