Medical device for grinding particulate medicinal materials into powder

A technology of granular matter and medicinal materials, applied in grain processing, solid separation, chemical instruments and methods, etc., can solve the problems of insufficient grinding of medicinal materials, slow grinding speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

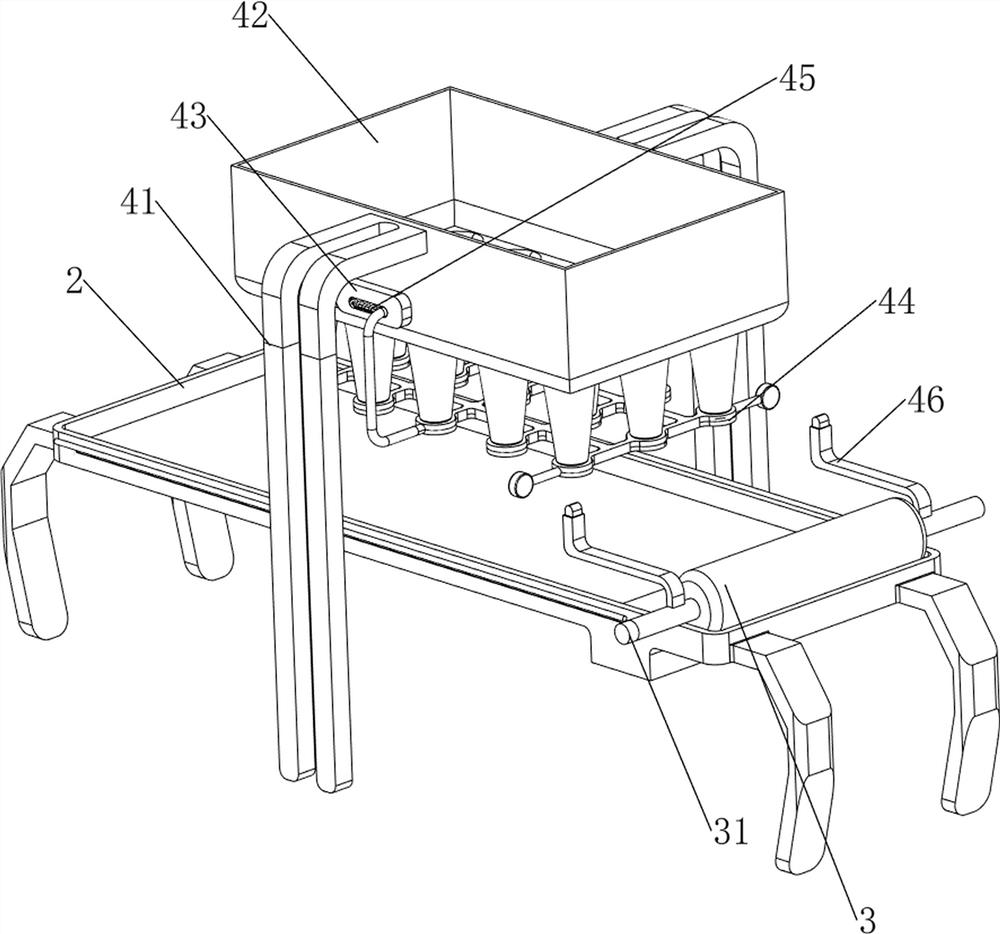

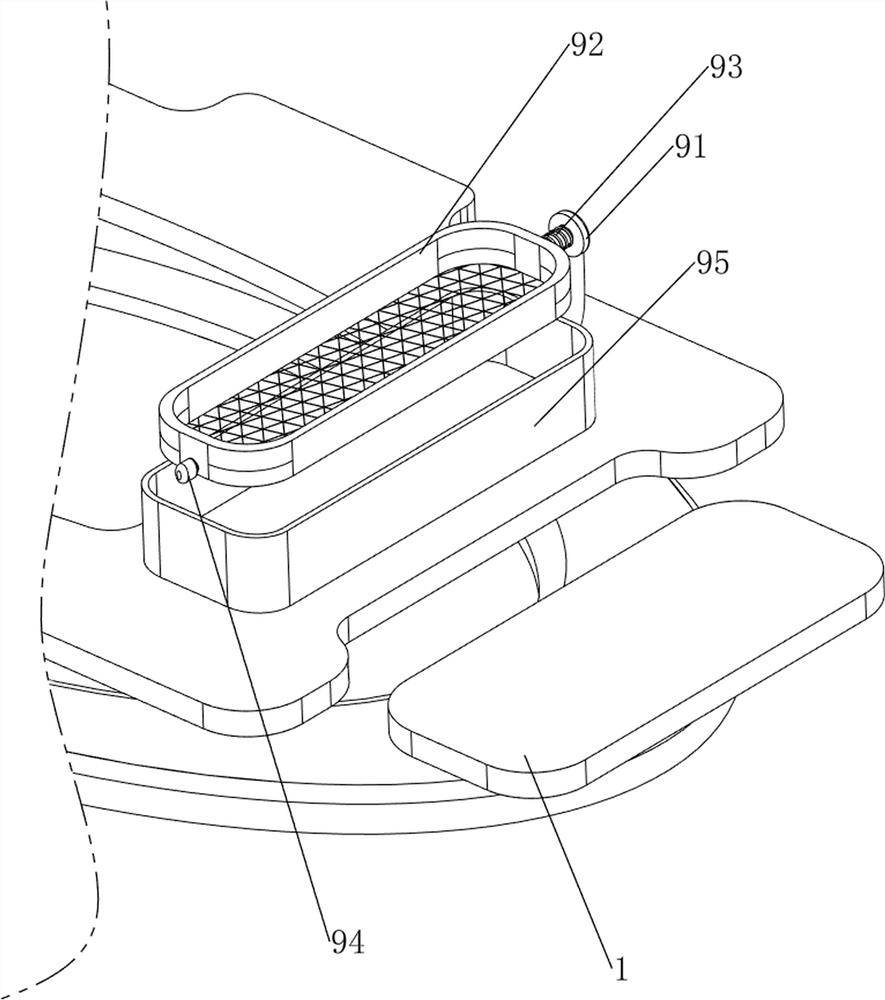

[0030] A device for grinding medical granular medicinal materials into powder, such as figure 1 As shown, it includes a support plate 1, a grinding plate 2, a roller 3, a connecting rod 31, a blanking mechanism 4 and a protection mechanism 5. The top of the support plate 1 is provided with a grinding plate 2, and the grinding plate 2 is movable with a roller 3. A connecting rod 31 is arranged in the middle of the roller 3, a blanking mechanism 4 is arranged in the middle of the top of the support plate 1, and a protective mechanism 5 is arranged on the blanking mechanism 4.

[0031] When users need to grind medicinal materials, they can use this device. First, place the medicinal materials to be ground in the feeding mechanism 4. The protection mechanism 5 can close the feeding mechanism 4 to prevent the medicinal materials in the feeding mechanism 4 from being exposed to the outside world. The contamination is then discharged onto the grinding plate 2 through the unloading me...

Embodiment 2

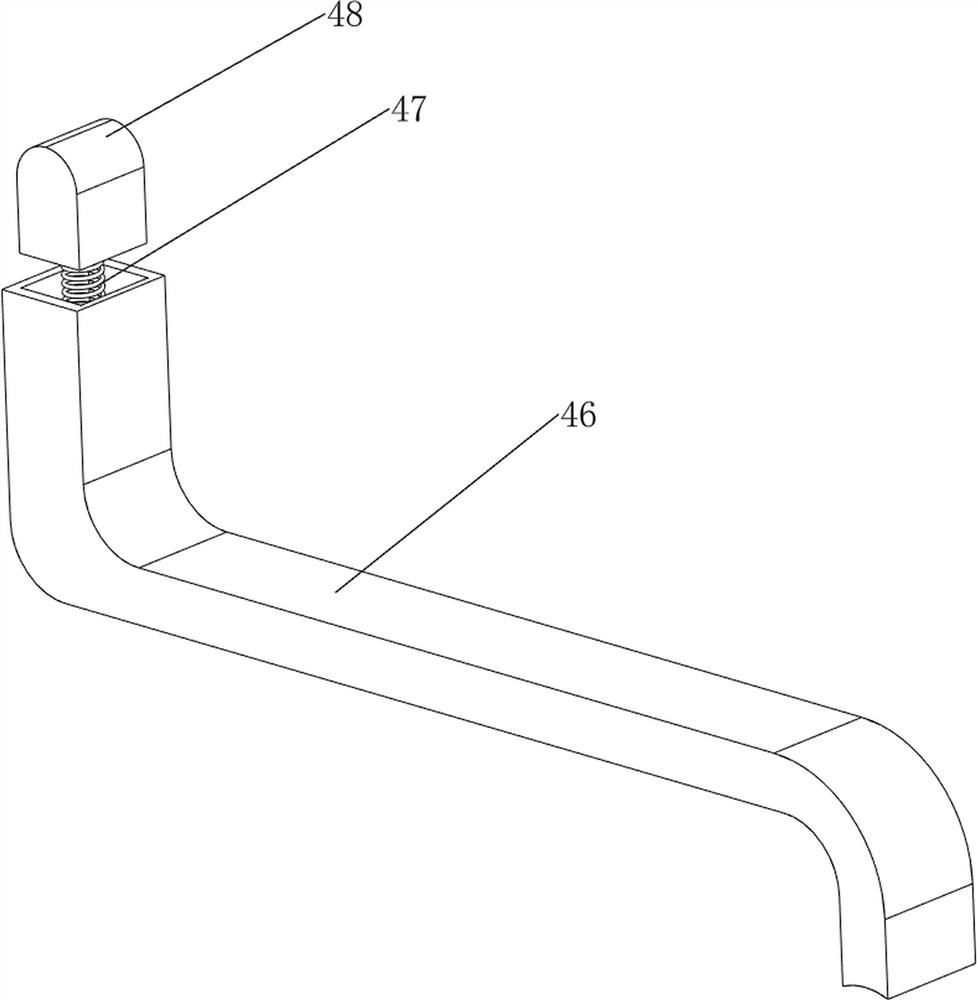

[0033] On the basis of Example 1, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the blanking mechanism 4 includes a first support frame 41, a blanking frame 42, a first slide rail 43, a first movable plate 44, a first spring 45, a first fixed rod 46, a second spring 47 and a movable block 48. A first support frame 41 is arranged symmetrically front and back in the middle of the top of the support plate 1. A blanking frame 42 is arranged between the first support frames 41. A first slide rail 43 is provided in the middle of the front and rear sides of the blanking frame 42. A first movable plate 44 is slidably arranged between the slide rails 43, and a first spring 45 is connected between the first movable plate 44 and the first slide rail 43, and a first fixed rod is arranged on the connecting rod 31 in front and rear symmetry. 46 , the top of the first fixed rod 46 is slidably provided with a movable block 48 , and a second spring 47 is connected between ...

Embodiment 3

[0038] On the basis of Example 2, such as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, an automatic grinding mechanism 6 is also included. The automatic grinding mechanism 6 includes a second slide rail 61, a first movable rod 62, a second support frame 63 and a rodless cylinder 64. The top of the support plate 1 is symmetrically provided with a first Two slide rails 61, all sliding type is provided with the first movable rod 62 in the second slide rail 61, and the top of the first movable rod 62 is connected with the connecting rod 31, and the left and right sides of the support plate 1 top are symmetrically provided with the second movable rod. A rodless cylinder 64 is connected between the support frame 63 and the second support frame 63 on the left and right sides, and the rodless cylinder 64 is connected with the first movable rod 62 .

[0039] Start the rodless cylinder 64, and the rodless cylinder 64 drives the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com