Grinding machine for sheet metal part machining and suitable for different thicknesses

A grinding machine and sheet metal parts technology, applied in the field of sheet metal parts grinding, can solve the problems of lack of automation and inconvenient replacement of grinding discs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

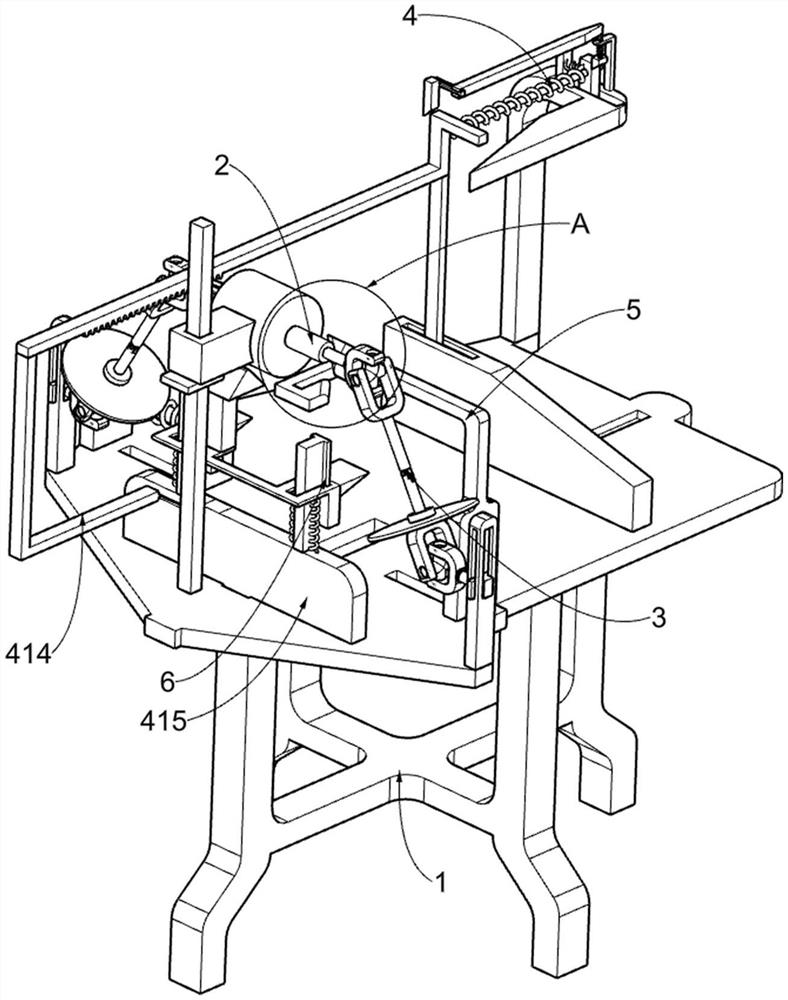

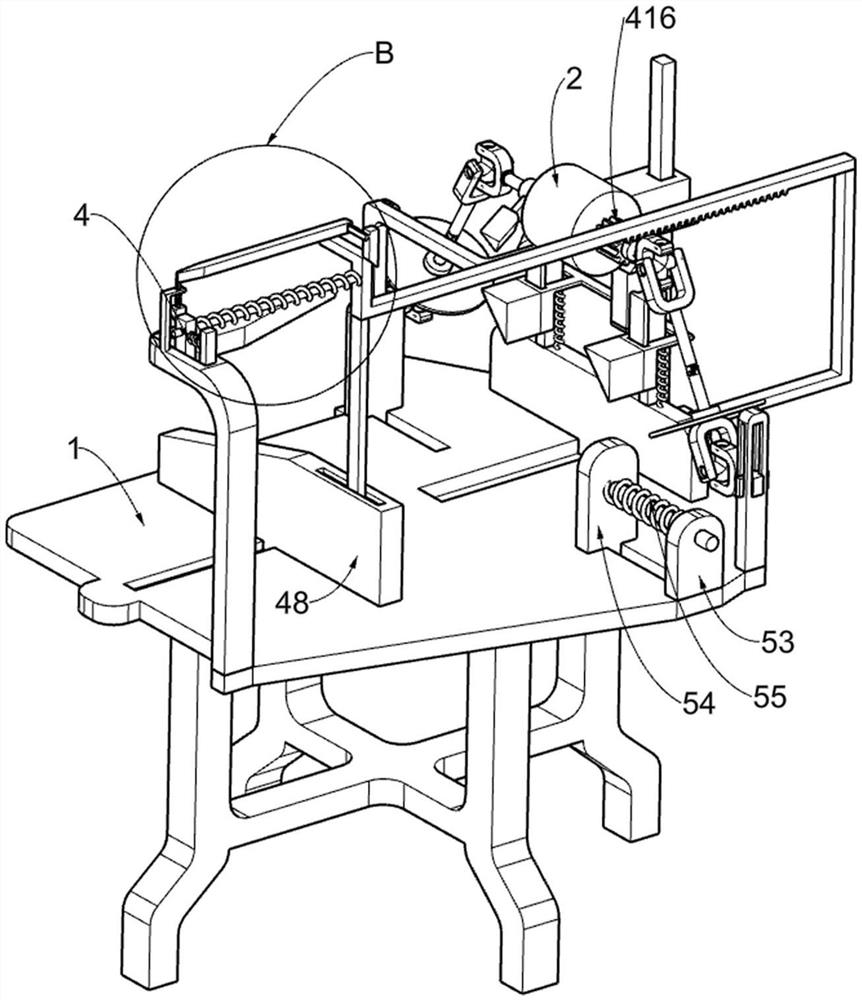

[0026] A grinding machine suitable for different thicknesses for processing sheet metal parts, such as Figure 1-8 As shown, the first fixed mount 1, the grinding mechanism 2, the clutch mechanism 3, the pushing mechanism 4 and the moving mechanism 5 are included, the grinding mechanism 2 is arranged on the first fixed mount 1, and the grinding mechanism 2 is used to set the first fixed mount 1 The sheet metal parts above are fully polished, the clutch mechanism 3 is set on the grinding mechanism 2, the clutch mechanism 3 is used to replace the new grinding disc 28, the push mechanism 4 is set on the first fixed frame 1, and the push mechanism 4 is used to push the first The sheet metal parts with two corners polished on the fixed frame 1 move, and the moving mechanism 5 is arranged on the first fixed frame 1 .

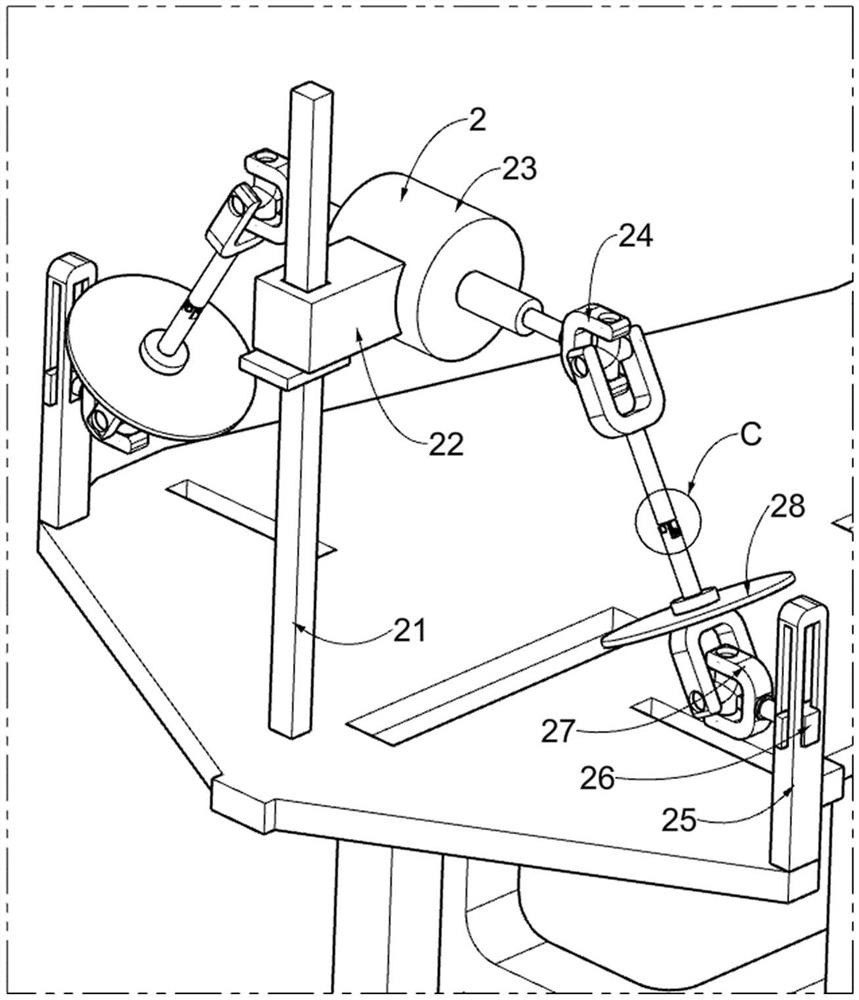

[0027] The grinding mechanism 2 includes a fixed rod 21, a slide block 22, a bidirectional motor 23, a first universal joint 24, a second fixed frame 25, a first slid...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 8 As shown, a height adjustment mechanism 6 is also included, and the height adjustment mechanism 6 is located on the second slide plate 415. The height adjustment mechanism 6 is used to enable the grinding disc 28 to grind sheet metal parts of different thicknesses. The height adjustment mechanism 6 includes The sixth fixed frame 61, the second sliding frame 62, the fifth return spring 63 and the wedge frame 64, a pair of the sixth fixed frame 61 is positioned on the second sliding plate 415, and the sixth fixed frame 61 is jointly slidably connected with the first Two sliding frames 62, two pairs of fifth return springs 63 are connected to the bottom of the second sliding frame 62, the other end of the fifth return spring 63 is connected with the second slide plate 415, and the fifth return spring 63 is used to drive the second sliding frame 62 and The upper device resets, and the wedge frame 64 is welded to the top of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com