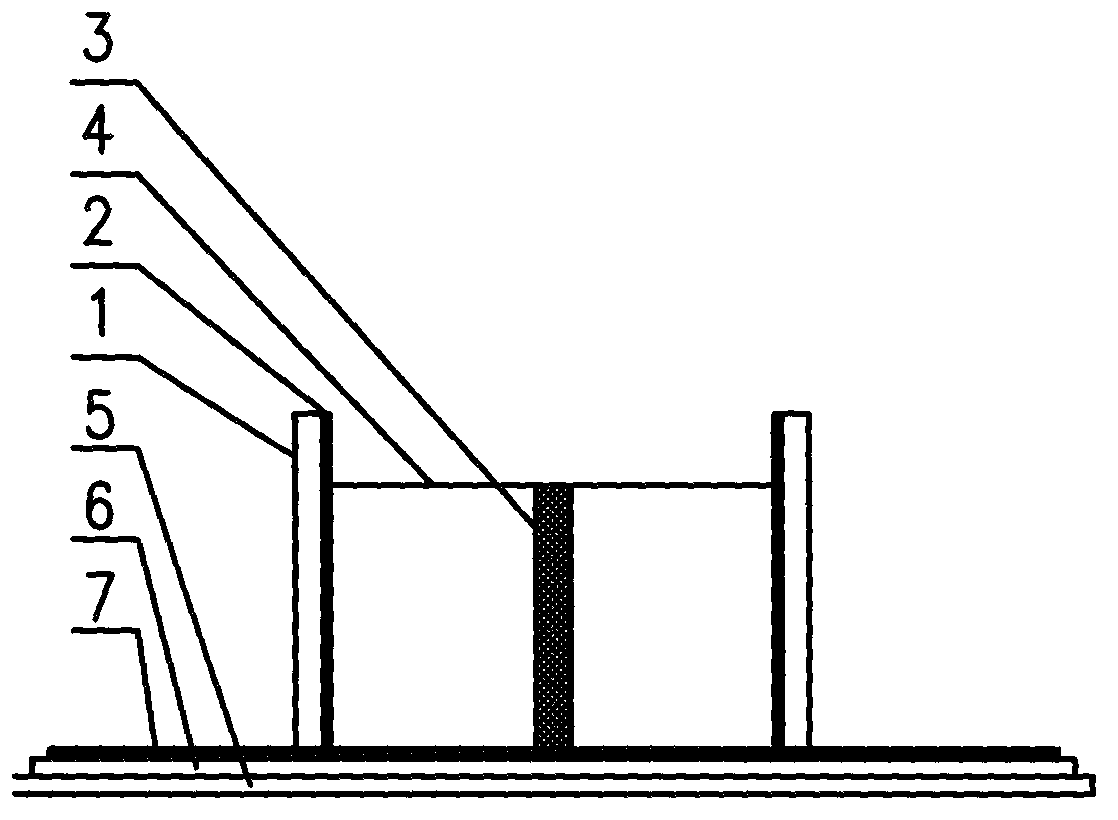

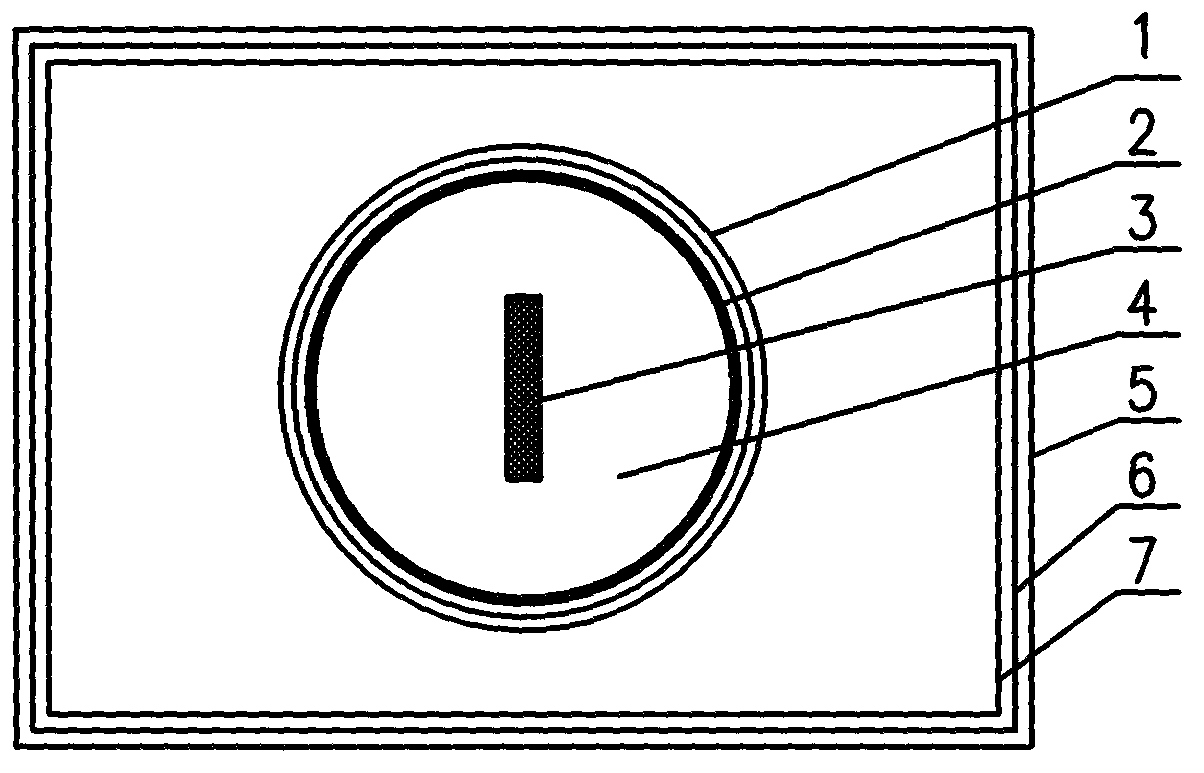

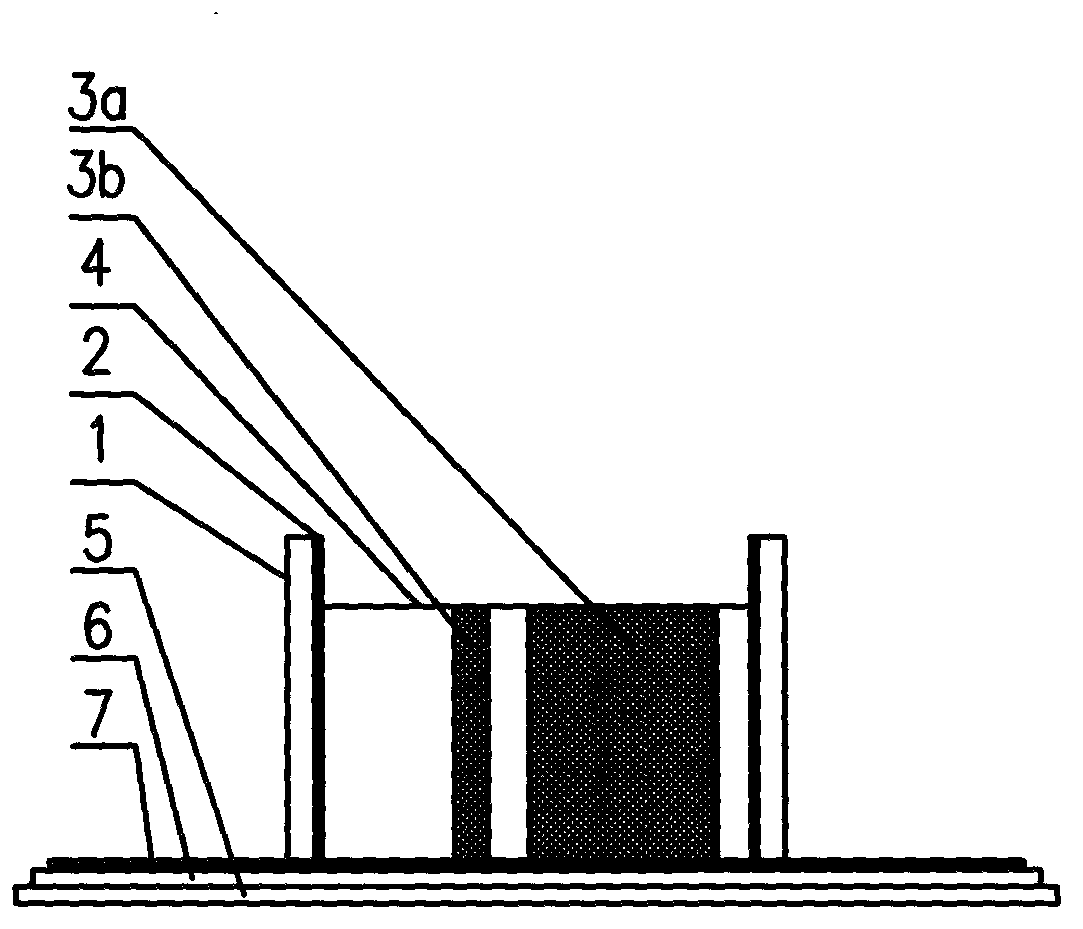

Corrosion sample inlaying method

A corrosion sample and mounting technique, which is applied in the field of inlaying of the corrosion sample to be tested, can solve the problems such as the inability to truly reproduce the structure of the corroded material, the damage of the internal organization and structure of the metal sample, the compression and deformation of the corrosion product layer, etc. To achieve the effect of easy observation and analysis, significant antistatic effect, and intact preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation of the epoxy resin mounting material is shown in Examples 1-3.

[0054] See Examples 4-7 for the preparation and application of mosaic samples.

Embodiment 1

[0056] Use an electronic balance to weigh 50g of epoxy resin E-44 (6101) in a beaker, heat at 60°C for 10min, then add 2.5g of dispersant n-butyl glycidyl ether, heat again at 60°C for 2min, then add conductive graphite Powder 7.5g, stir well, continue to heat for 15min after being dispersed evenly, then add curing agent diethylenetriamine 5g, after mixing evenly, this mounting material can be used as pouring liquid for standby, and the effective pouring time is 30min. The composition of the pouring solution is: matrix resin (A): 76.92% by weight, conductive powder (B): 11.54% by weight, dispersant (C): 3.85% by weight, curing agent (D): 7.69% by weight.

Embodiment 2

[0058] Use an electronic balance to weigh 50g of epoxy resin E-51 (618) in a beaker, heat at 70°C for 10min, then add 2.5g of dispersant glycerol glycidyl ether, heat again at 70°C for 2min, then add conductive carbon 7.5g of black powder, stir well, continue to heat for 10min after being dispersed evenly, then add 5.5g of curing agent triethylenetetramine, after mixing evenly, the mounting material can be used as pouring liquid for standby, and the effective pouring time is 20min. The pouring solution is composed of: matrix resin (A): 76.34% by weight, conductive powder (B): 11.45% by weight, dispersant (C): 3.82% by weight, and curing agent (D): 8.40% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com