Patents

Literature

88 results about "Corrosion morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

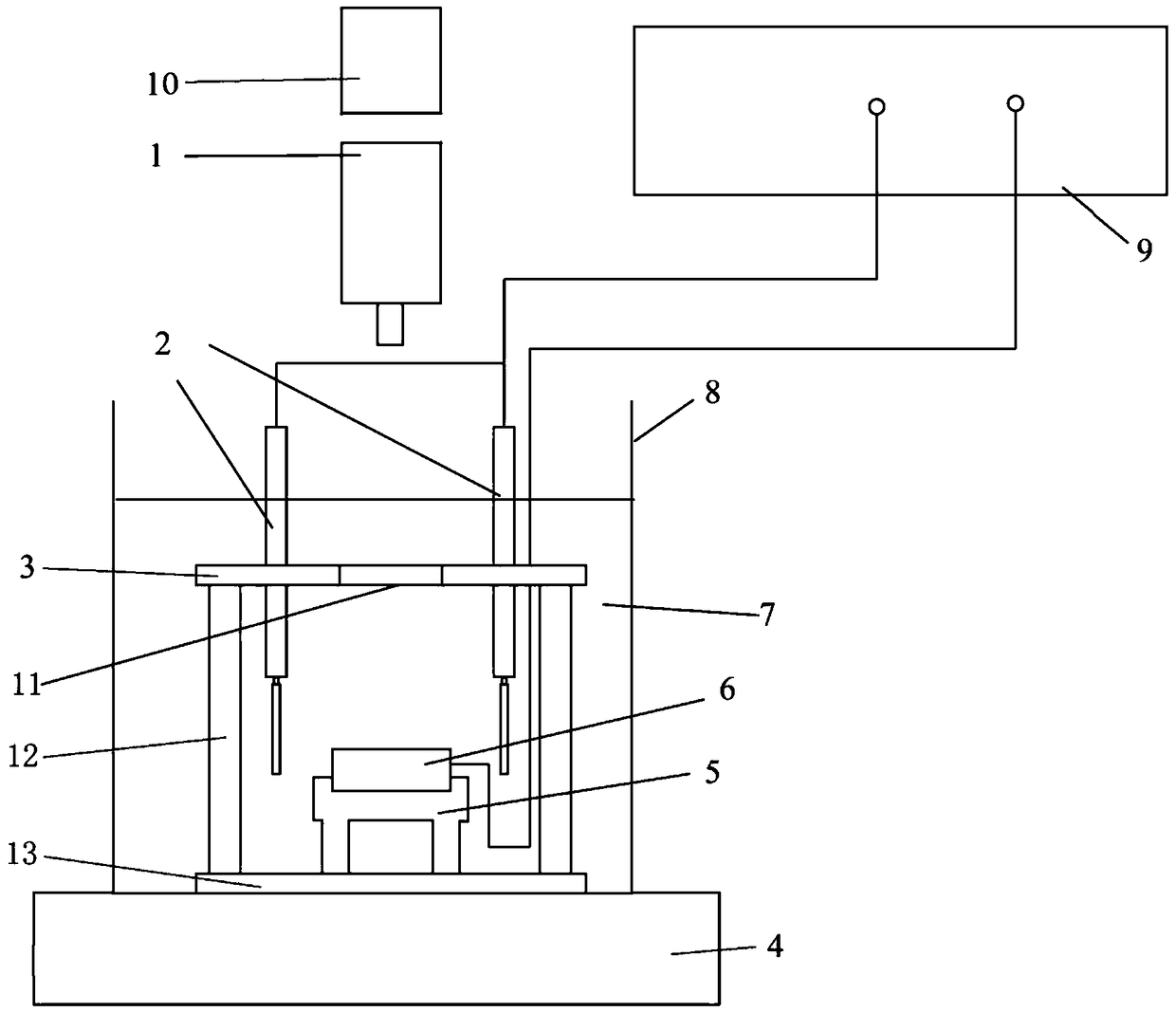

An electrochemical corrosion test device that realizes multiple in-situ monitoring

InactiveCN102288536ACorrosivity researchResearch FeaturesWeather/light/corrosion resistanceSpectroscopyOptical observation

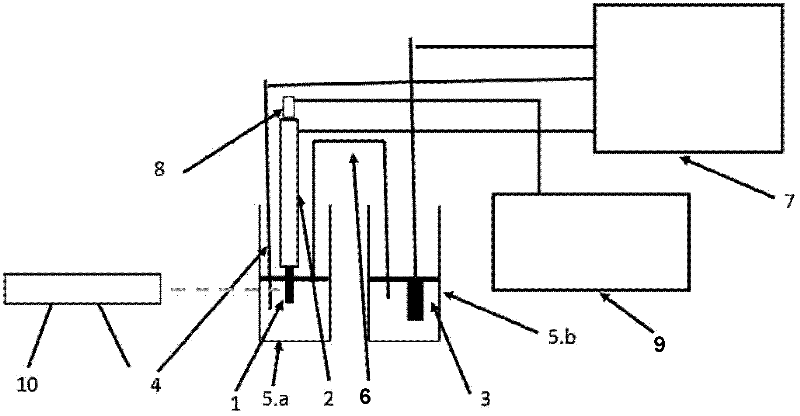

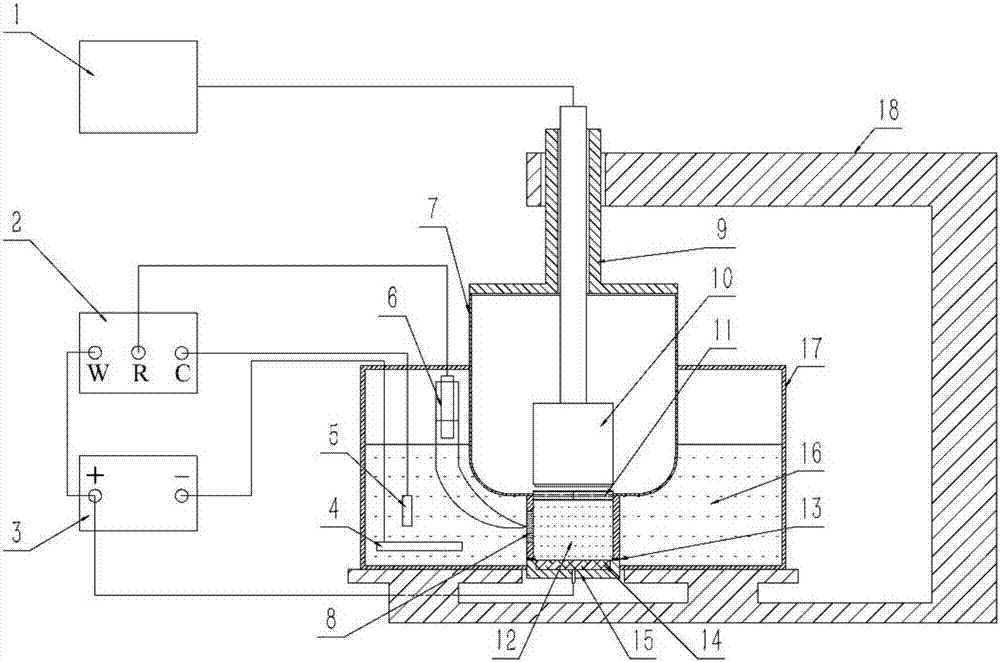

The invention belongs to the field of material electrochemical corrosion test monitoring, more precisely, relates to a kind of electrochemical corrosion test device for realizing multiple in-situ monitoring, and solves the in-situ in-situ monitoring of material surface corrosion morphology existing in the prior art. information, and is not suitable for issues such as long-term online monitoring. The device is mainly composed of three parts: electrochemical test device, acoustic emission test device, and optical observation system. The working electrode is connected to the waveguide rod, and forms a three-electrode system with the counter electrode and reference electrode. Electrochemical (polarization curve, impedance spectrum, etc.) tests can be performed through the electrochemical workstation; the acoustic emission probe is fixed on the waveguide rod and can be collected synchronously. The acoustic emission signal during the corrosion process of the working electrode; the long focal length microscope can observe the corrosion morphology of the surface of the working electrode in situ. The device can realize various in-situ monitoring such as electrochemistry, acoustic emission, and long-focus microscope at the same time, and realize electrochemical corrosion monitoring of materials at room temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

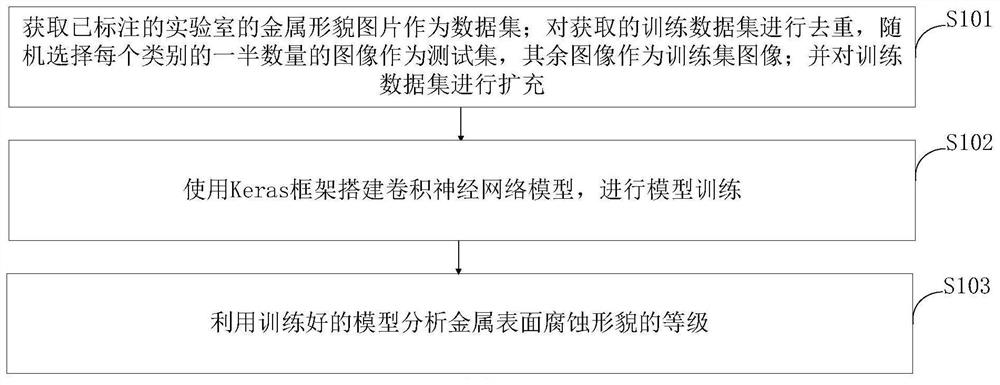

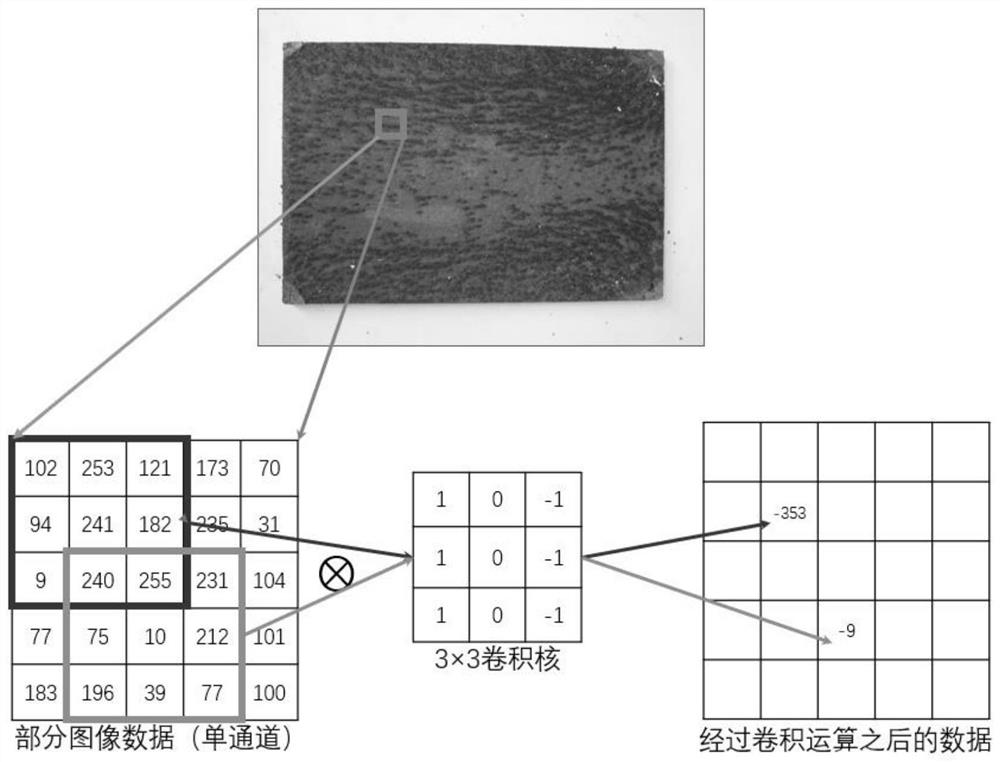

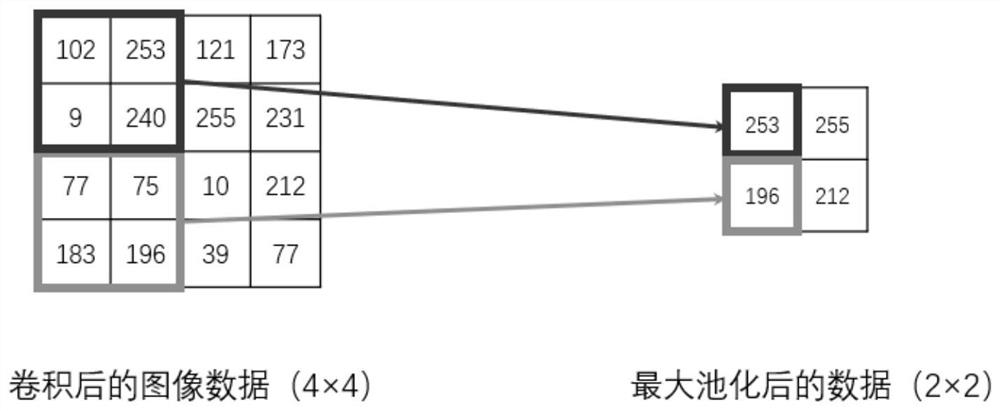

Corrosion level information processing method and system based on image recognition

PendingCN111862093AReduce overfittingAvoid difficultiesImage enhancementImage analysisInformation processingData set

The invention belongs to the technical field of metal corrosion morphology grade judgment, and discloses a corrosion grade information processing method and system based on image recognition, and themethod comprises the steps: obtaining a labeled laboratory metal morphology picture as a data set; carrying out the de-duplication on the obtained training data set, randomly selecting a half of images of each category as a test set, and taking other images as training set images; expanding the training data set, namely carrying out the data enhancement; building a convolutional neural network model by using a Keras framework, carrying out model training, and storing optimal model parameters; and analyzing the grade of the corrosion morphology of the metal surface by utilizing the trained optimal model. According to the method, the judgment of the metal corrosion morphology grade is realized by using a computer vision technology, so the judgment efficiency is greatly improved and the judgment uniformity and objectivity are ensured under the condition of ensuring the judgment accuracy. The method can assist engineers engaged in material research in judging the metal corrosion grade, andvarious difficulties of a previous judgment method are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

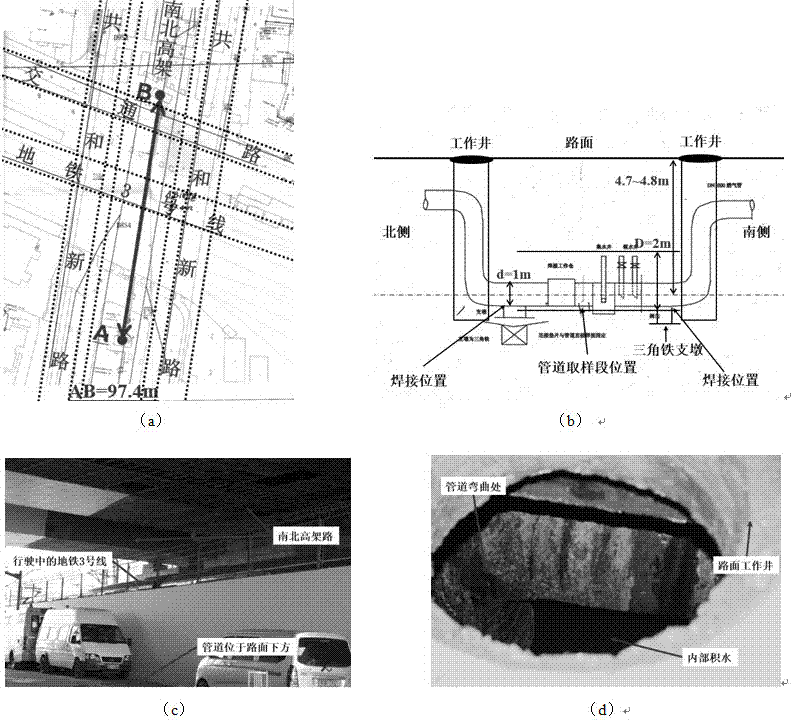

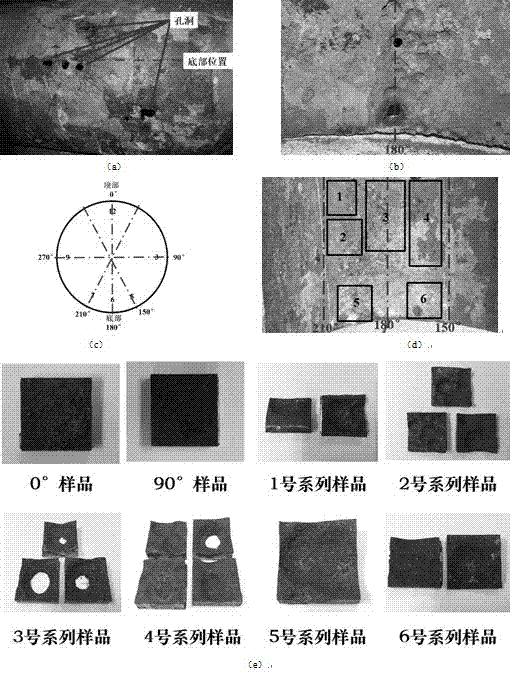

Comprehensive judgment method for buried gas metal pipeline corrosion caused by stray current nearby subway lines

InactiveCN107271359AAccurately determine the failure mechanismDetermining the Cause of Corrosion FailureWeather/light/corrosion resistanceEngineeringSubway line

The invention discloses a comprehensive judgment method for buried gas metal pipeline corrosion caused by stray current nearby subway lines. The method comprises steps as follows: 1, arrangement and analysis of background and general situation: technological parameters, past operation conditions and the like of a pipeline are known; 2, inspection and test analysis: after a faulted pipeline with abnormal leakage is sampled, the sample is subjected to check analysis with various devices and multiple physical and chemical test means; 3, comprehensive discussion, analysis and judgment: an acting form of the stray current on pipeline corrosion morphology is judged, a mutual relation between failure mechanisms is discussed, a failure reason is found out and a solution is given. By means of comprehensive analysis for corrosion failure, caused by the stray current nearby the subway lines, of the buried gas metal pipeline, new stray current corrosion morphology feature reference and failure mechanism theoretical support are provided, the failure reason of the pipeline can be accurately judged, and an effective solution is proposed. The method has great reference significance and practical application value for failure analysis of various oil and gas transmission pipelines and pipelines with different diameters, model and textures in different environments.

Owner:FUDAN UNIV

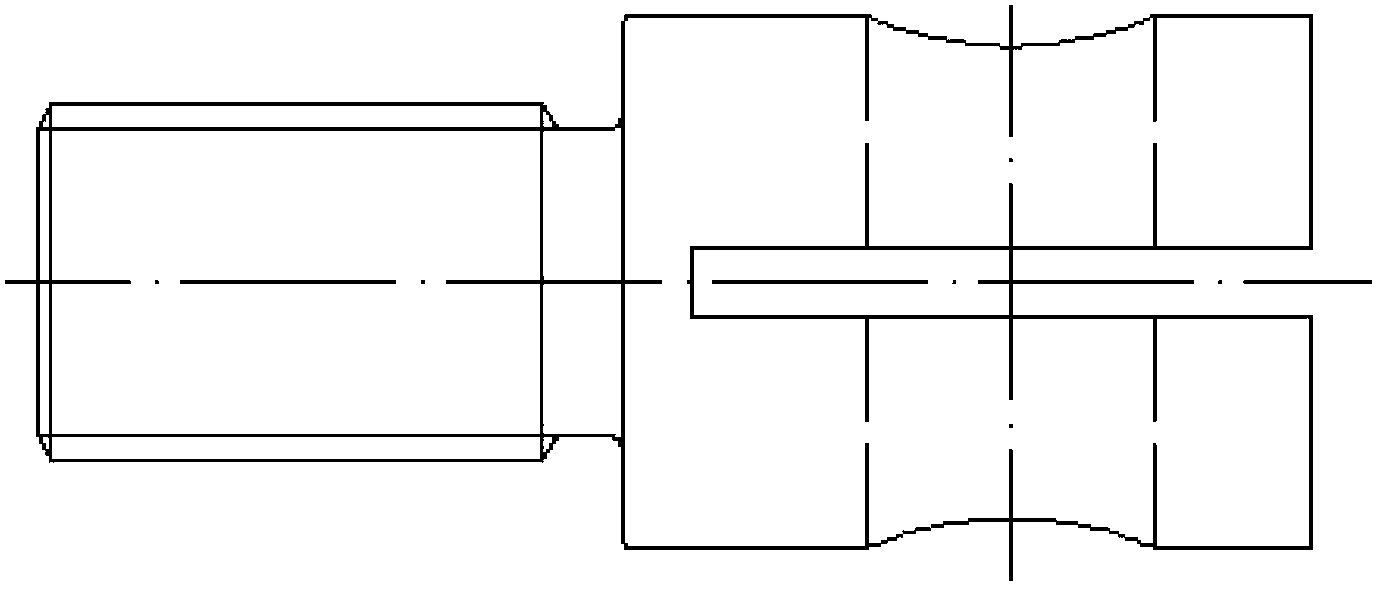

Aluminum alloy local corrosion evaluation device

ActiveCN107228823AEnables localized corrosion evaluationReal-time observation of local corrosion morphologyWeather/light/corrosion resistanceObservation unitAuxiliary electrode

The invention provides an aluminum alloy local corrosion evaluation device. The device comprises an environment simulation unit and a corrosion real-time observation unit. The environment simulation unit comprises an occluded anode, a macroscopical cathode, an auxiliary electrode, a reference electrode device and a simulated solution tank. The corrosion real-time observation unit comprises a real-time observation microscope and a corrosion real-time observation system main body. The device realizes aluminum alloy material local corrosion simulation and local corrosion morphology real-time observation simultaneously, acquires local corrosion generation and development processes and a form change process of an aluminum alloy material in the simulative environment and realizes local corrosion evaluation of the aluminum alloy material in a marine environment and other simulative environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

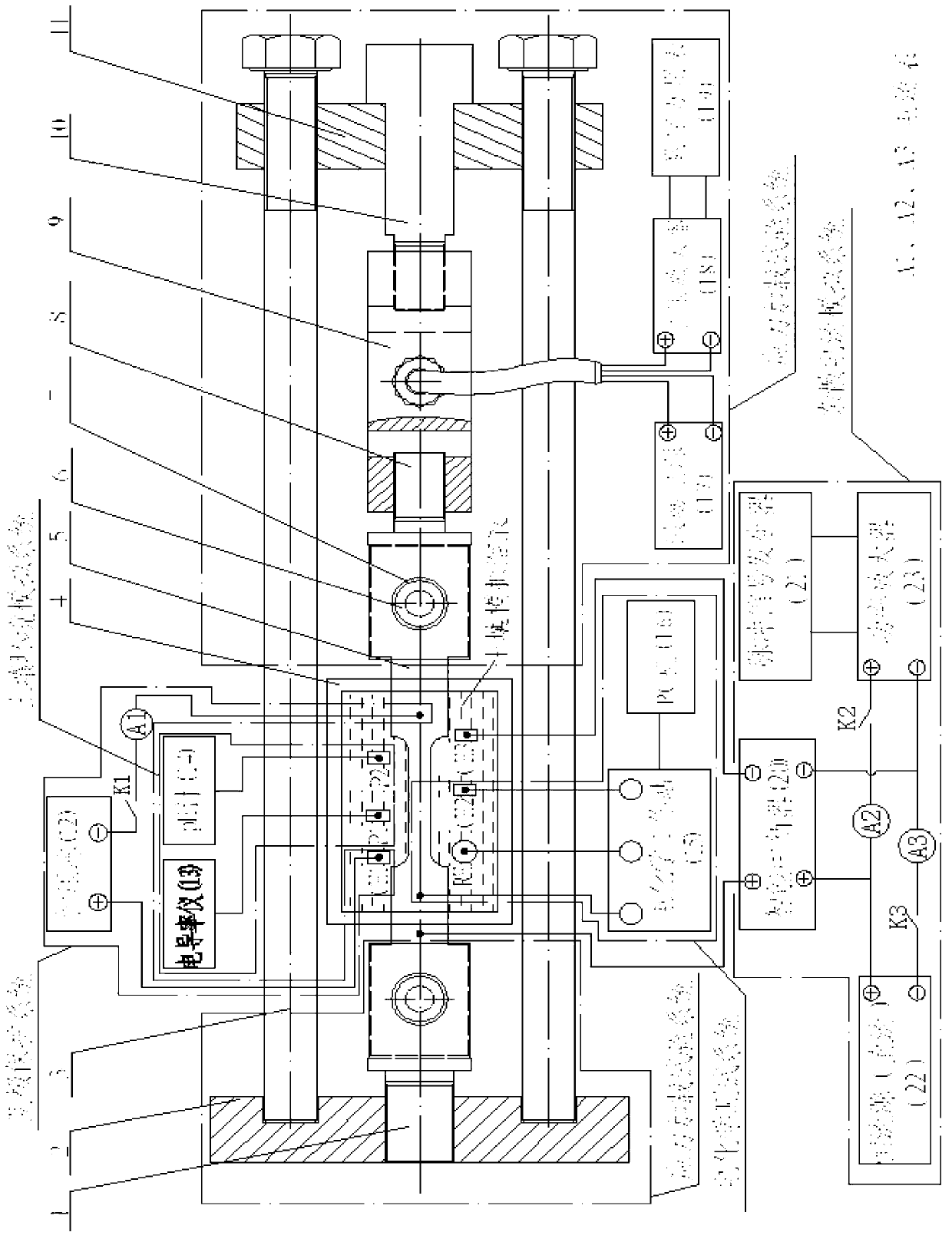

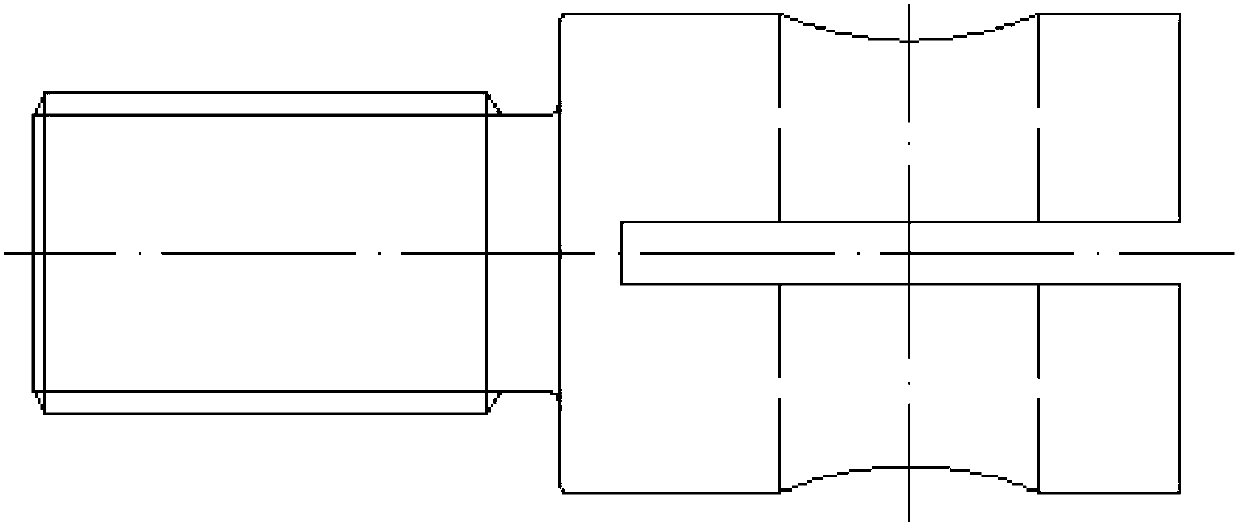

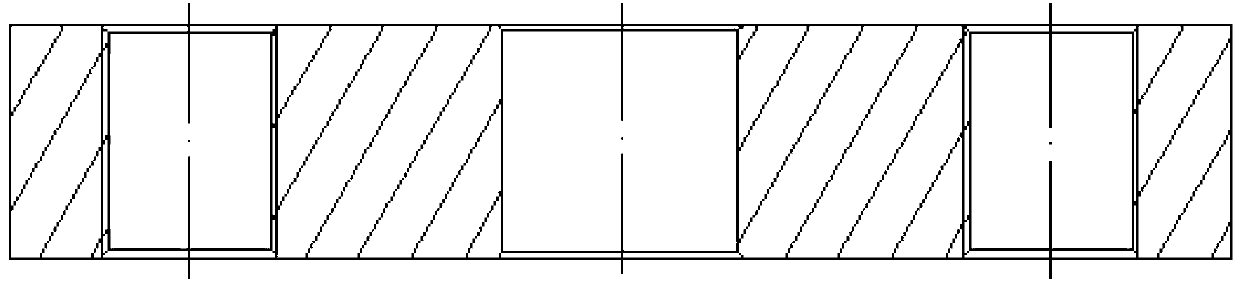

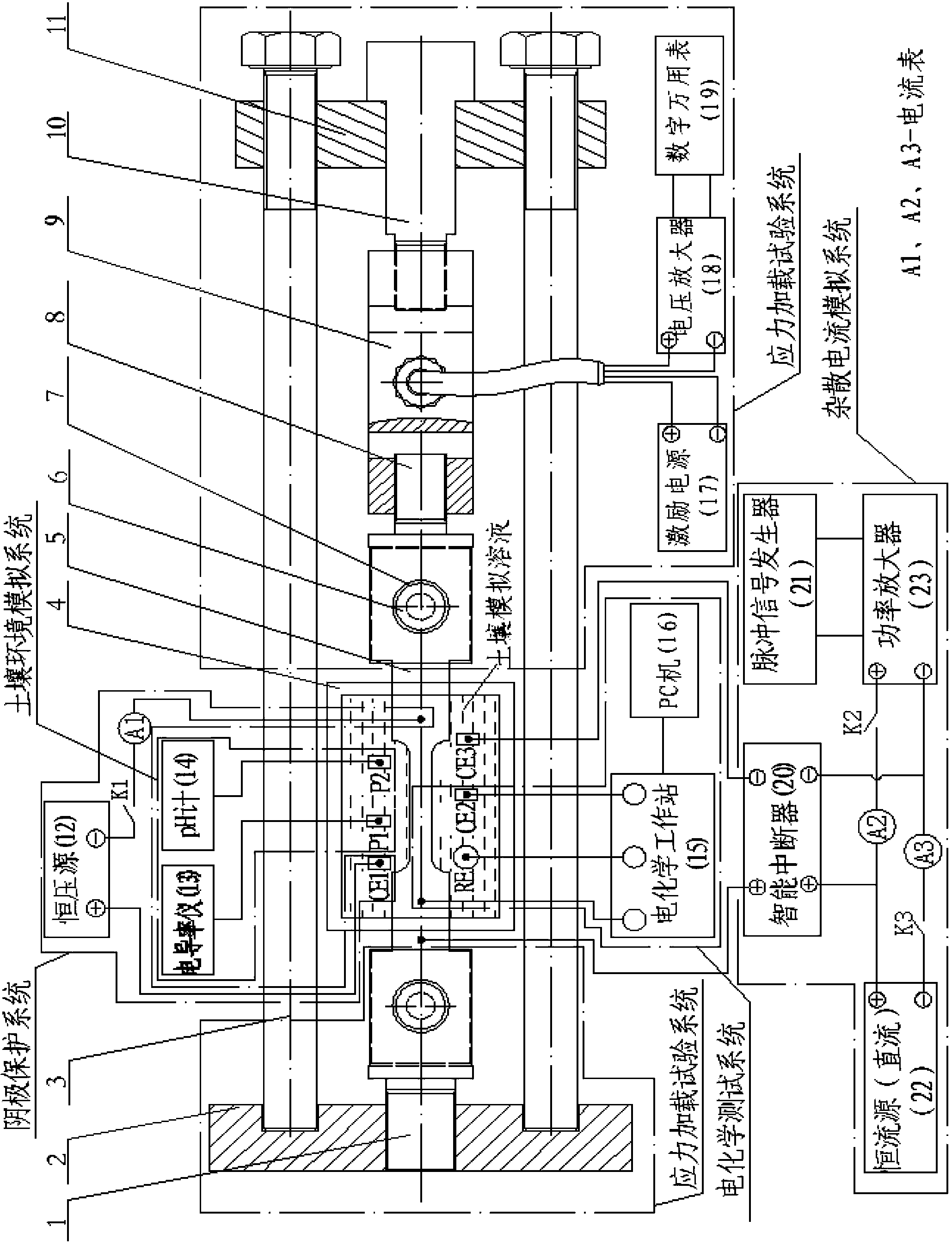

System for testing stray current corrosion of buried steel pipeline under function of tensile stress

InactiveCN103344548ACapable of measuring weightlessnessWeather/light/corrosion resistanceSteel qualityCorrosion morphology

The invention discloses a system for testing stray current corrosion of a buried steel pipeline under the function of a tensile stress, belonging to the field of corrosion and protection of materials. The system comprises a stress loading experiment system, a soil environment simulating system, a stray current simulating system, a cathodic protection system and an electrochemical testing system. The stress loading experiment system generates a pressure required by a sample experiment; the soil environment simulating system simulates a soil environment in which a buried metal is, and soil solutions with different powers of hydrogen and conductivities are provided; the stray current simulating system generates a direct current, an alternating current and an alternating-current and direct-current mixed stray current; the cathodic protection system provides a cathodic protection potential for the sample; and the electrochemical testing system tests corrosion potentials of the sample under different influence factors. The system is capable of measuring weightlessness, obtaining corrosion morphology, generating the direct current, the alternating current and the alternating-current and direct-current mixed stray current, providing the stress required by the experiment according to the actual running condition, simulating the cathodic protection, and carrying out corrosion rule experiments under different influence factors.

Owner:BEIJING UNIV OF TECH +1

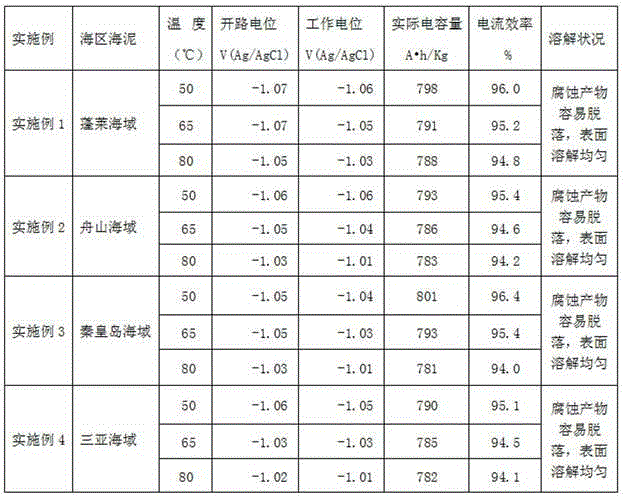

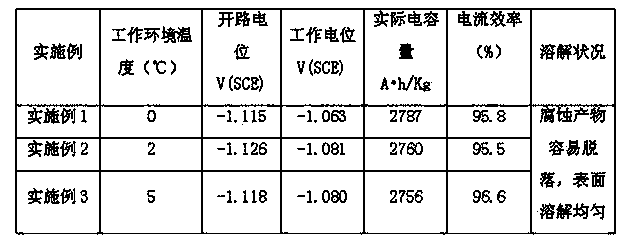

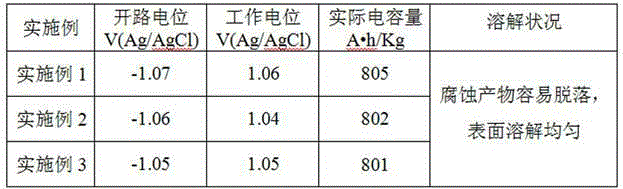

Zinc alloy sacrificial anode applicable to hot seabed mud environment

The invention discloses a zinc alloy sacrificial anode applicable to a hot seabed mud environment. Zinc is taken as a raw material, and alloy elements such as aluminum, magnesium, indium and gallium are added to eliminate the influence of impurity elements to the chemical property of a sacrificial anode. The zinc alloy sacrificial anode comprises the following components in percentage by mass: 0.1-0.4% of Al, 0.1-0.8% of Mg, 0.005-0.03% of In, 0.01-0.02% of Ga, less than or equal to 0.003% of an impurity element Fe, less than or equal to 0.006% of Pb, less than or equal to 0.002% of Cu, less than or equal to 0.002% of Cd, and the balance of Zn. The electric chemical properties of the zinc alloy sacrificial anode are that the working potential in the hot seabed mud environment of 50-80 DEG C is stabilized to be minus 1.00 V-minus 1.06V (relative to an Ag / AgCl reference electrode), corroded products can be easily dropped off, the corrosion morphology can be uniformly dissolved, the capacitance is greater than or equal to 780A.h / Kg, the current efficiency is greater than or equal to 94%, and the zinc alloy sacrificial anode is applied to anode protection of metal structures in the hot seabed mud environment.

Owner:SUNRUI MARINE ENVIRONMENT ENG

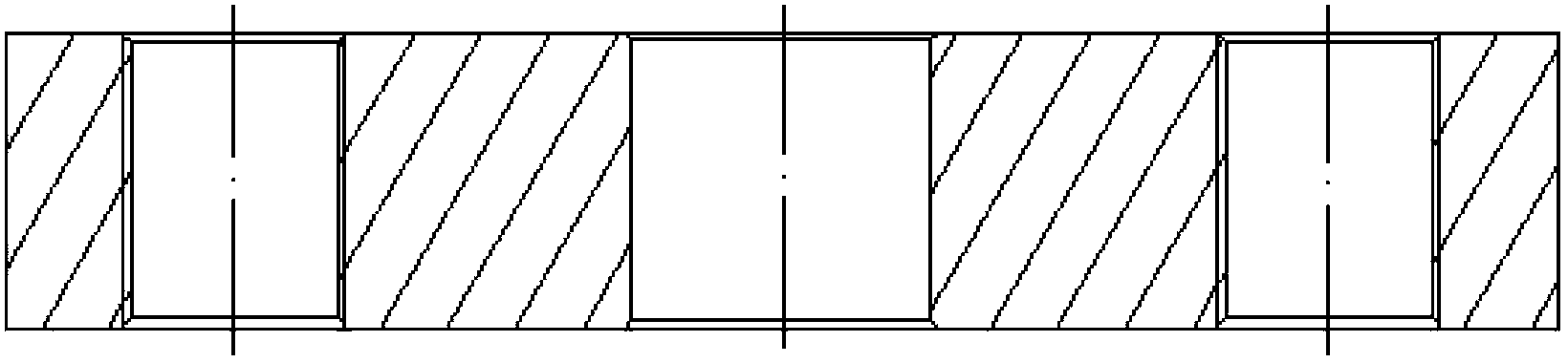

Electrolytic capacitor low impedance anode aluminum foil erosion method and its chemical processing fluid

InactiveCN101211696AReduce sizeControl distributionElectrolytic capacitorsCapacitor manufactureChemical treatmentAluminium chloride

The invention relates to a method for corroding the low-impedance anode aluminum foil for electrolytic capacitor and the chemical pretreatment solutions. The method comprises the following steps: the first step of primary electrolytic corrosion, the second step of chemical treatment and the third step of secondary electrolytic corrosion; the chemical pretreatment solutions consist of 4.0N to 5.0N of hydrochlorides, 0.15N to 5.0N of sulfates, 0.05N to 0.15N of phosphoric acids, 0.01N to 0.05N of nitric acids and 1.0N to 2.0N of aluminium chlorides. The invention forms the uniformly distributed pits with larger clearances and passive films enduring the corrosion on the surface of the clean aluminium foil and then implements the expanding treatment, so the impendance of the obtained etching foil is outstandingly lowered and in particular the invention has outstanding effects on the electrode foil with a voltage ranging from 50 to 100V. The use of the method controls the size, distribution and clearance of the pits to a certain extent, improves the corrosion morphology and increases the clearance of the pits and distribution uniformity so as to lower the impedance of the anode foil. The invention is suitable for the corrosion of the low-voltage aluminium foil with a voltage ranging from 25V to 100V, can lower the impedance of the anode foil by a great amount and can be used for preparing the low-impedance electrolytic capacitor anode aluminium foil.

Owner:XINJIANG JOINWORLD CO LTD

Method for stray current corrosion test of buried steel pipeline under tensile stress action

InactiveCN103411878ACapable of measuring weightlessnessWeather/light/corrosion resistanceAlternating currentSteel pipeline

The invention relates to a method for the stray current corrosion test of a buried steel pipeline under the tensile stress action, and belongs to the material corrosion and protection fields. A system used by the method comprises a stress loading test system, a soil environment simulation system, a stray current simulation system, a cathode protection system and an electrochemical test system. The stress loading test system generates a pressure required by a sample test, the soil environment simulation system stimulates the soil environment in which a buried metal is positioned to prepare soil solutions having different pH values and conductivities, the stray current simulation system generates direct current, alternate current and direct and alternate mixed stray currents, the cathode protection system provides a cathode protection potential for the sample, and the electrochemical test system tests the corrosion potentials of the sample under different influence factors. The system used by the method can measure the weight loss, can obtain the corrosion morphology, can generate the direct current, alternate current and direct and alternate mixed stray currents, can provide the stress required by the test according to the practical running condition, can stimulate the cathode protection, and can realize the corrosion rule experiments under different influence factors.

Owner:BEIJING UNIV OF TECH

Efficient Al alloy sacrificial anode suitable for low-temperature seawater environment and preparation process thereof

The invention discloses an efficient Al alloy sacrificial anode suitable for a low-temperature seawater environment, and belongs to the field of corrosion and protection. The efficient Al alloy sacrificial anode is characterized in that Al is taken as a raw material, and Zn, In, Sn and Bi alloy elements are added so as to eliminate the influence of impurity elements to the electrochemical performance of the sacrificial anode; the efficient Al alloy sacrificial anode comprises the following components by weight percent: 3.2% to 5.8% of Zn, 0.005% to 0.01% of In, 0.016% to 0.02% of Sn, 0.01% to 0.2% of Bi, less than or equal to 0.10% of impurity element Fe, less than or equal to 0.1% of impurity element Si, less than or equal to 0.005% of impurity element Cu and the balance of Al. The efficient Al alloy sacrificial anode has the electrochemical performance that the working potential of the sacrificial anode is stabilized within -1.05V to -1.1V (relative to SCE (Saturated Calomel Electrode)), corrosion products easily fall off, the corrosion morphology is evenly dissolved, the capacitance of the sacrificial anode is greater than or equal to 2700A.h / kg and the current efficiency of the sacrificial anode is greater than or equal to 95% under the conditions that the seawater temperature is within 0 DEG C to 5 DEG C. Thus, the efficient aluminum alloy sacrificial anode can be used for the cathode protection of a metal-structured article under the low-temperature seawater environment.

Owner:SUNRUI MARINE ENVIRONMENT ENG

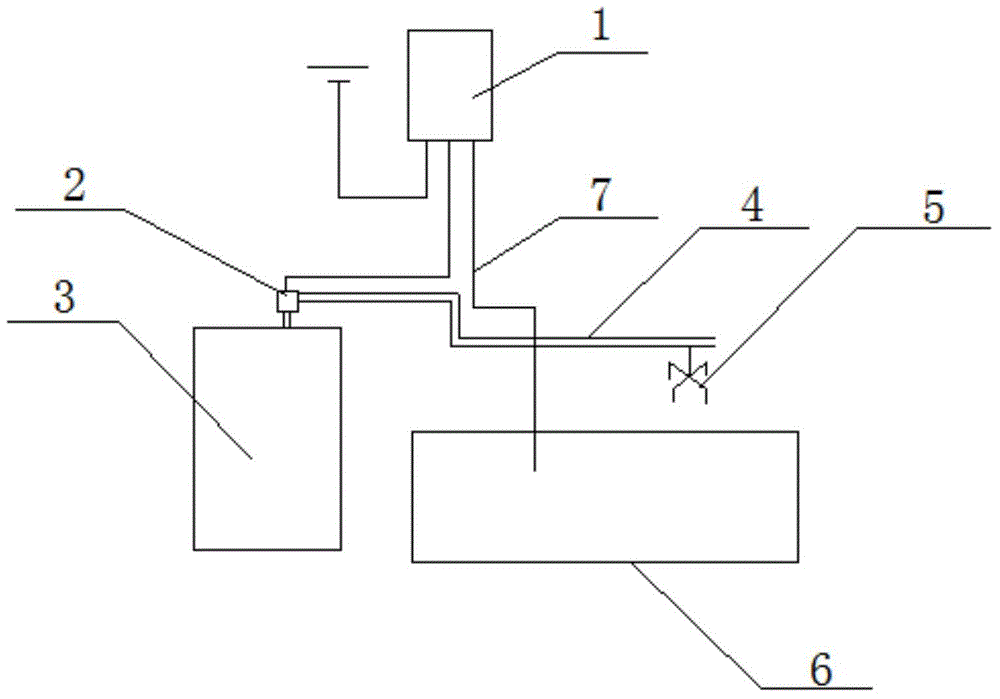

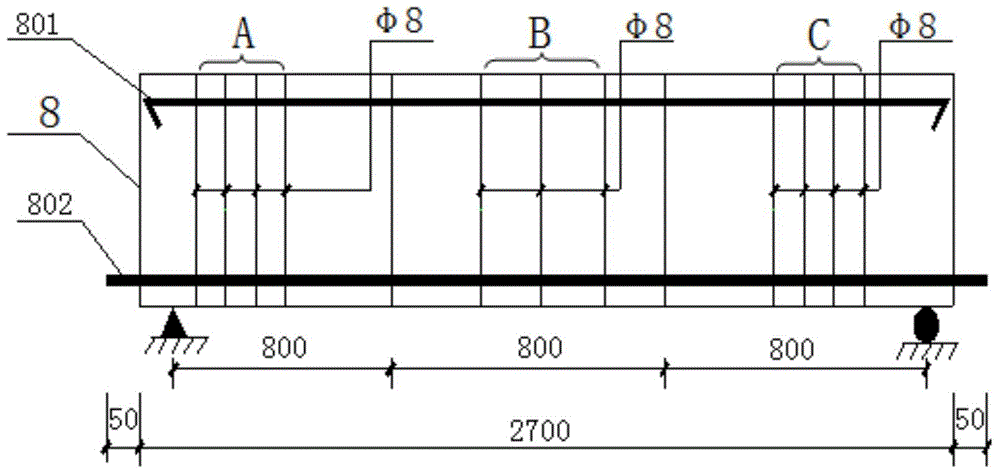

Apparatus and method for simulating natural corrosion of reinforced concrete

ActiveCN104964920ASolve the problem of easy dissolution lossThe simulation effect is accurateWeather/light/corrosion resistanceAutomatic controlSolenoid valve

The invention discloses an apparatus and method for simulating natural corrosion of reinforced concrete and especially relates to an automatic control device for simulating natural corrosion of reinforcing steel bars in the reinforced concrete and a method for testing durability of the reinforced concrete. The automatic control device for simulating natural corrosion of reinforcing steel bars in the reinforced concrete comprises a power supply, a controller, a solenoid valve, a sensor, a main water pipe, a spraying sprinkler, an electrode, an electrolyte storage tank, a testing tank, a direct-current voltage stabilizer and a reinforced concrete sample. According to the invention, through adjusting the concentration of a NaCl solution, humidity of wet salty sand and current intensity, the effect of a natural corrosion environment can be simulated under laboratory conditions; data is acquired by using test time history, monitoring is controlled in real time, and a deteriorated reinforced concrete test piece in a corrosion environment is obtained; and the corrosion test piece can be used for research on endurance properties like corrosion morphology of the reinforcing steel bars and corrosion depth of corrosives and mechanical properties of the test piece after performance degradation of the reinforced concrete.

Owner:西安建筑科大工程技术有限公司

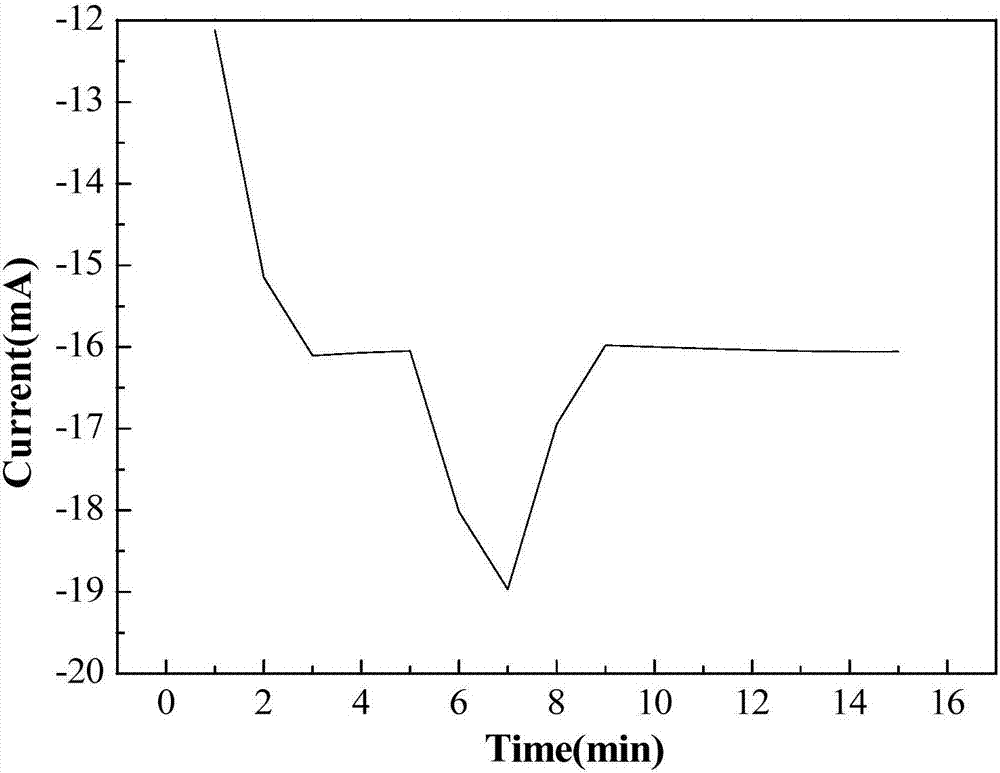

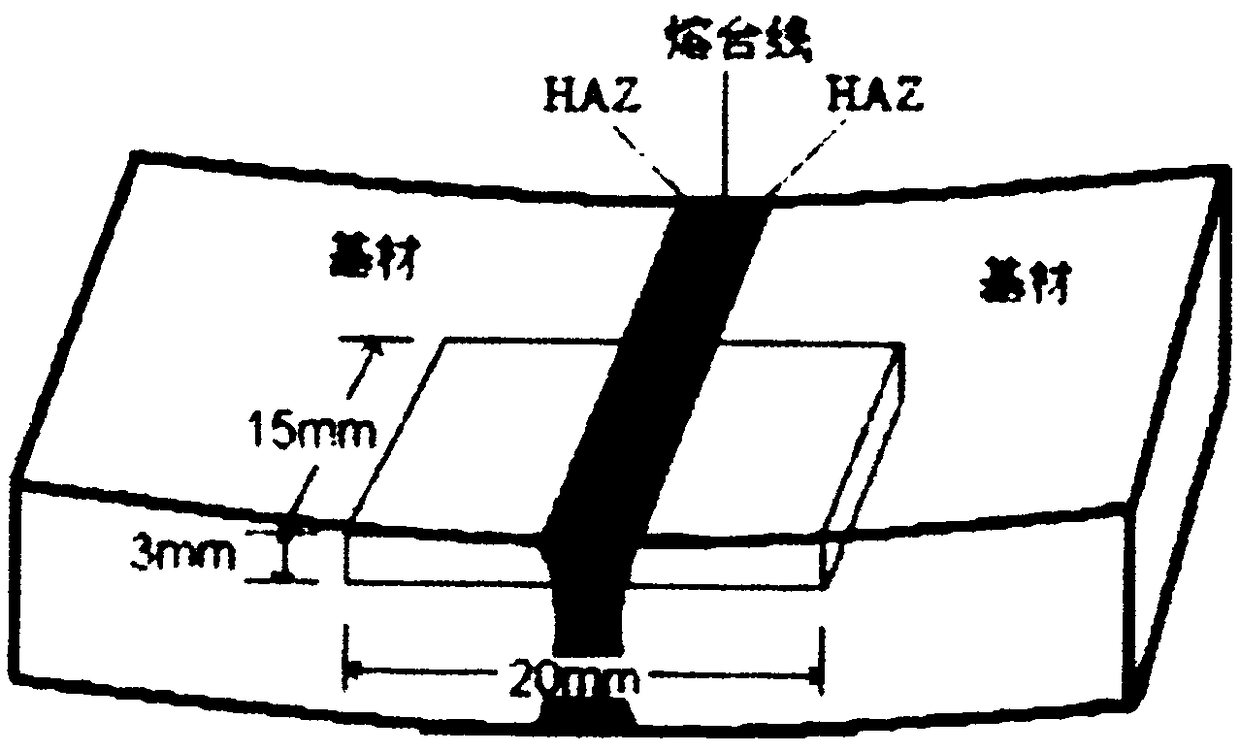

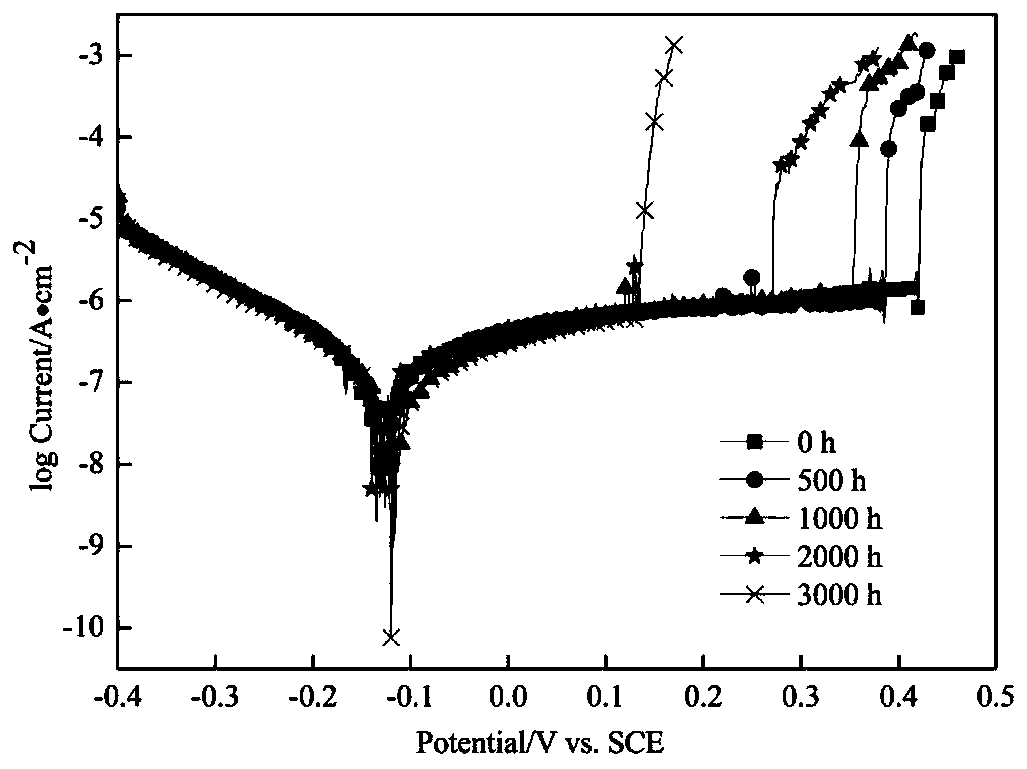

Electric chemical method for accelerated corrosion on stainless steel welding seam region

InactiveCN108072602ASpeed up corrosionJudging the strength of corrosion resistanceWeighing by removing componentWeather/light/corrosion resistanceWeld seamCorrosion morphology

The invention discloses an electric chemical method for accelerated corrosion on a stainless steel welding seam region. The method comprises the following experiment steps of work electrode preparation, stable corrosion potential test and electrochemical accelerated corrosion. The method provided by the invention solves the problems that the existing electrochemical accelerated corrosion cannot beused for accelerated corrosion on stainless steel to obtain the practical corrosion morphology. The test method can be used for performing electrochemical accelerated corrosion on the stainless steelregion; the corrosion speed of the stainless steel is accelerated; the corrosion resistance performance weakness relationship of different regions of the welding seam in the corrosion media can be judged; the correct judgment is made on the corrosion behavior of a welding joint used in engineering in the use environment.

Owner:TIANJIN UNIV

Environment-friendly sacrificial zinc alloy anode

The invention discloses an environment-friendly sacrificial zinc alloy anode, and belongs to the technical fields of corrosion and protection. The environment-friendly sacrificial zinc alloy anode disclosed by the invention comprises the following components in percentage by weight: 0.1%-0.5% of Al, 0.25%-1.5% of Mg, 0.01%-0.05% of Ca, not more than 0.003% of an impurity element Fe, not more than 0.006% of an impurity element Pb, not more than 0.002% of an impurity element Cu, not more than 0.003% of Cd and the balance of Zn. The invention further provides a preparation method of the sacrificial zinc alloy anode. According to the sacrificial zinc alloy anode prepared by the preparation method provided by the invention, the working potential is minus 1.00 to minus 1.06V; a corrosion product easily falls off; the corrosion morphology is uniformly dissolved; and the electric capacity is greater than or equal to 800A.h / Kg. The sacrificial zinc alloy anode disclosed by the invention is wide in application range, small in environmental pollution, simple in preparation method and low in cost, and has obvious economic benefits and environmental benefits.

Owner:SUNRUI MARINE ENVIRONMENT ENG

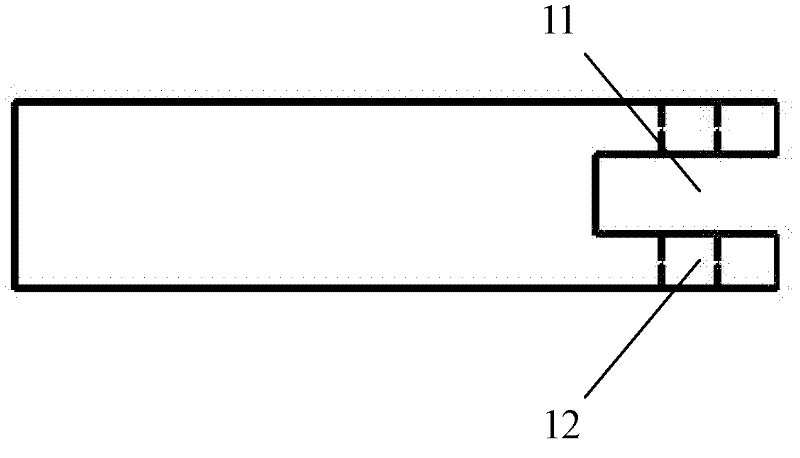

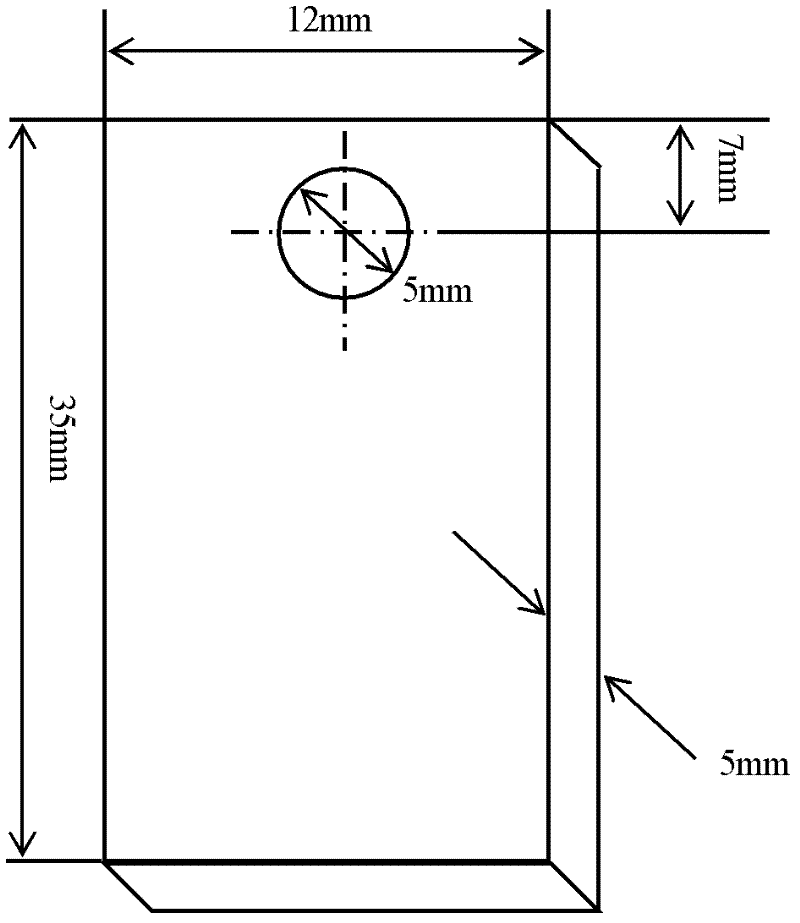

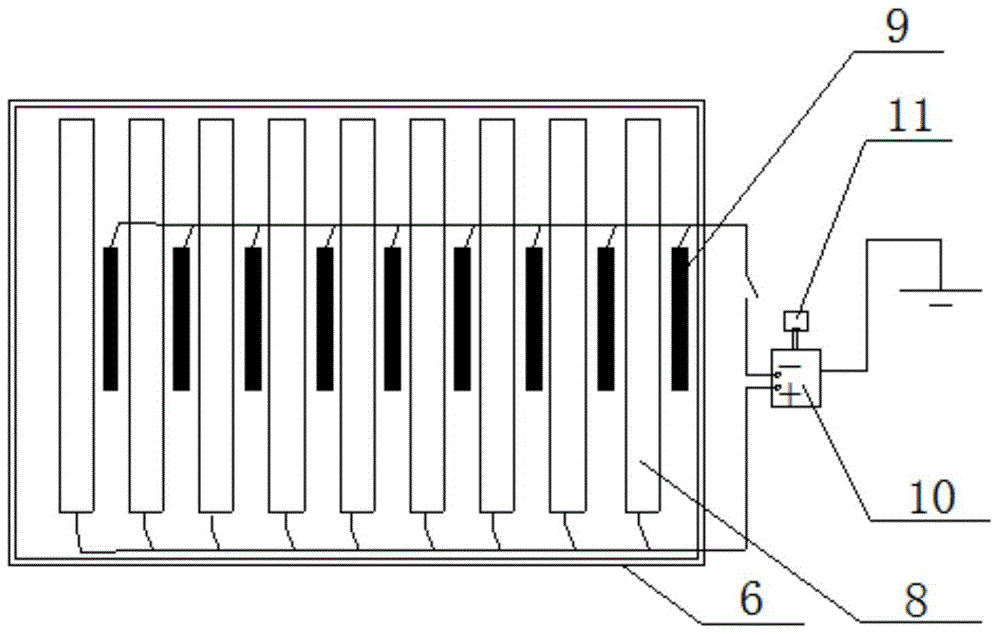

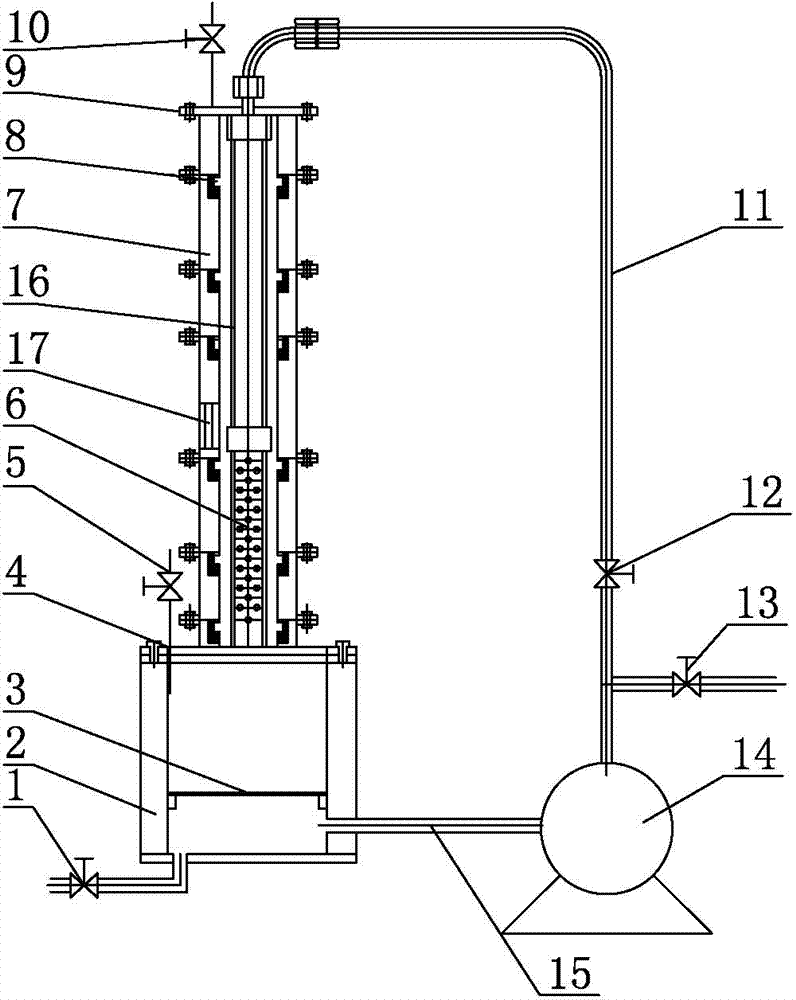

In-situ observation device for corrosion morphology of stray current

ActiveCN108982343AEasy to observeImprove accuracyWeather/light/corrosion resistanceMaterial analysis by optical meansPower flowFixed frame

The invention discloses an in-situ observation device for corrosion morphology of stray current. The in-situ observation device comprises a container, an electrode bracket, a sample fixing frame, auxiliary electrodes, a stray current interference power source and a microscope, wherein the electrode bracket is arranged in the container and can be fetched out of the container; the sample fixing frame is detachably connected with the electrode bracket; the sample fixing frame is used for fixing a metal sample; at least two auxiliary electrodes are symmetrically arranged on the electrode bracket corresponding to the metal sample; the auxiliary electrodes and the metal electrodes are respectively connected with one electrode of the stray current interference power source; the container is usedfor accommodating a transparent corrosive medium; an observing hole is formed in the electrode bracket; the microscope is arranged above the observing hole; the metal sample can be observed by an objective lens of the microscope via the observing hole. The in-situ observation device has the advantages that the change of corrosion morphology of metal surface in the stray current corrosion experiment can be observed in real time and in situ; the detachment and installation are easy; the use and cleaning are convenient; the auxiliary electrodes are symmetrically arranged corresponding to the metal sample; the influence to the experiment results due to nonuniformity of the electric field is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

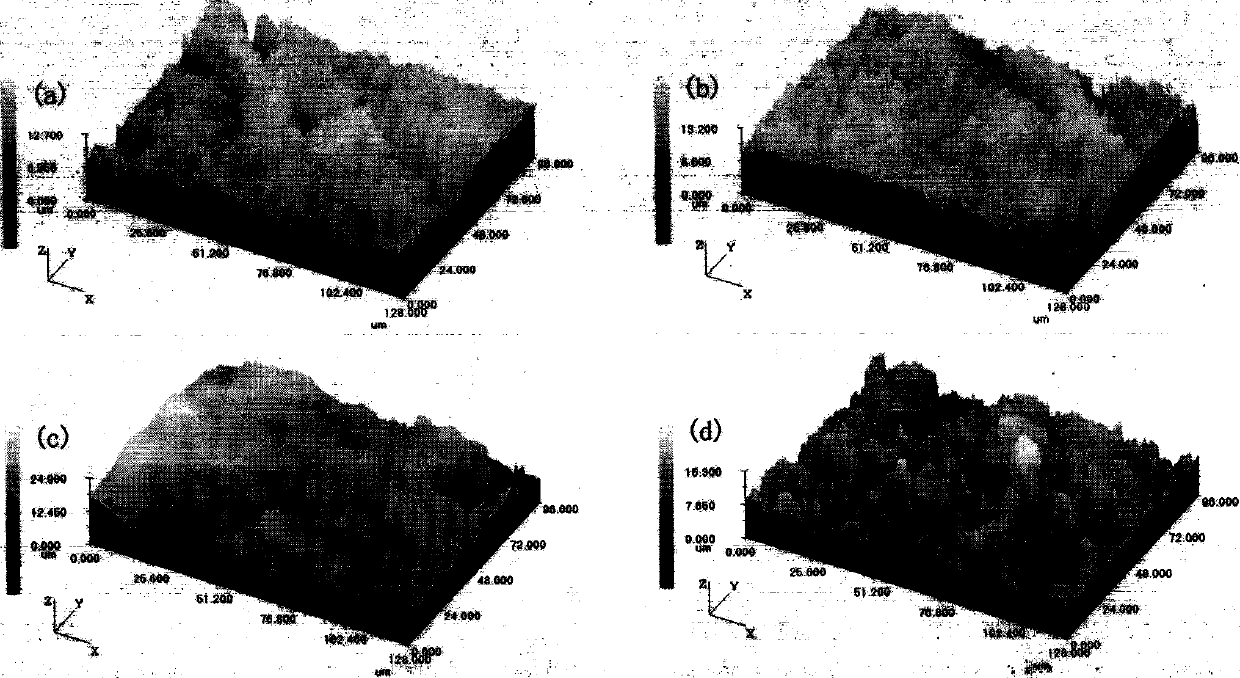

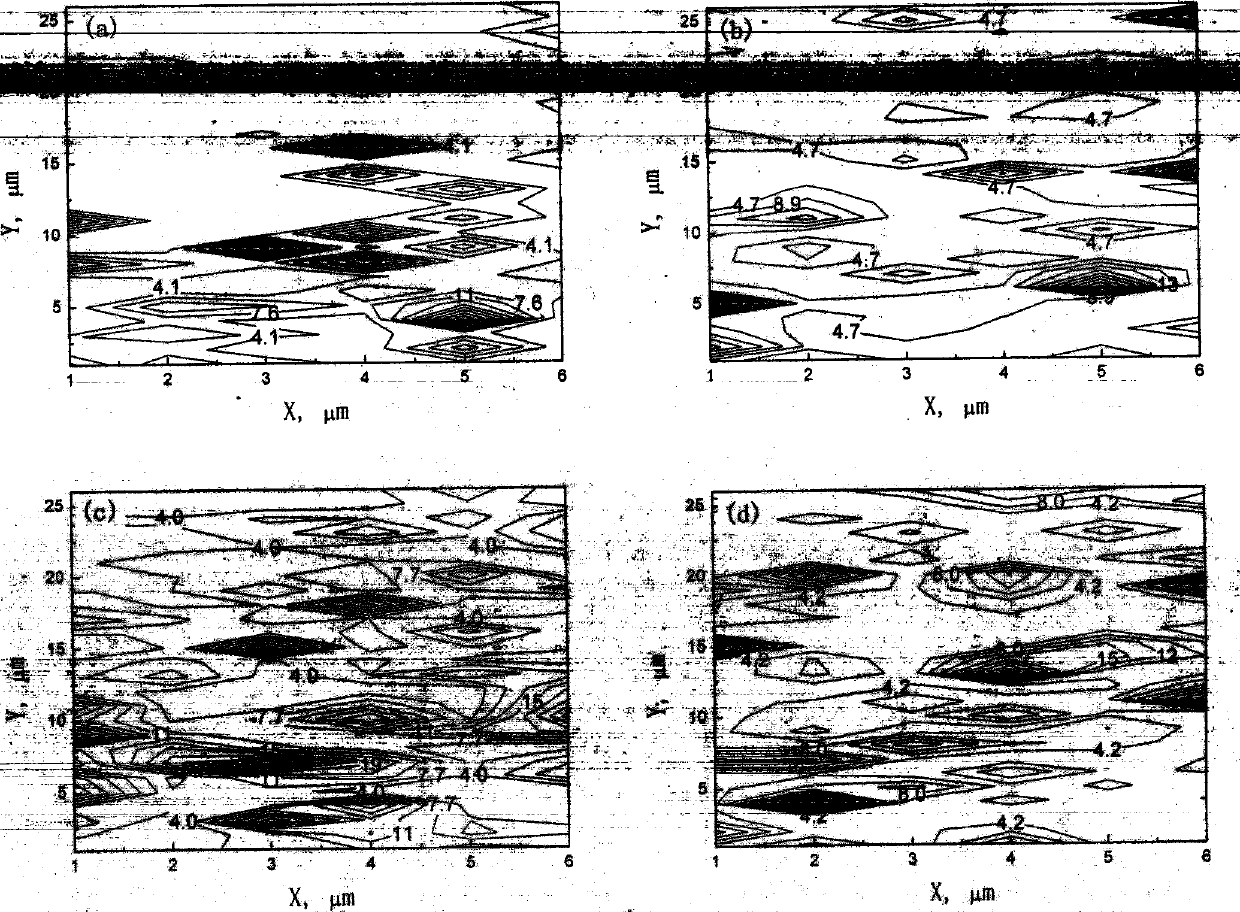

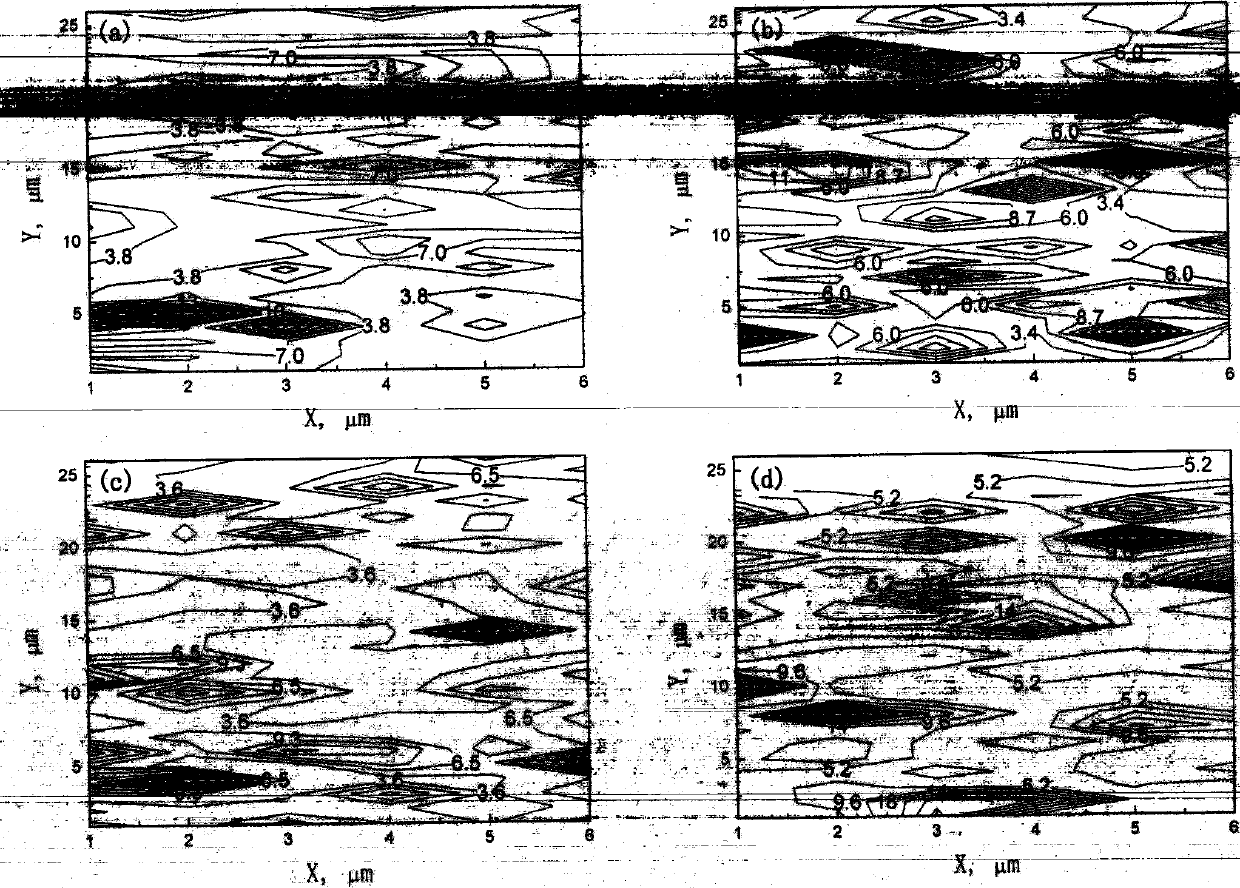

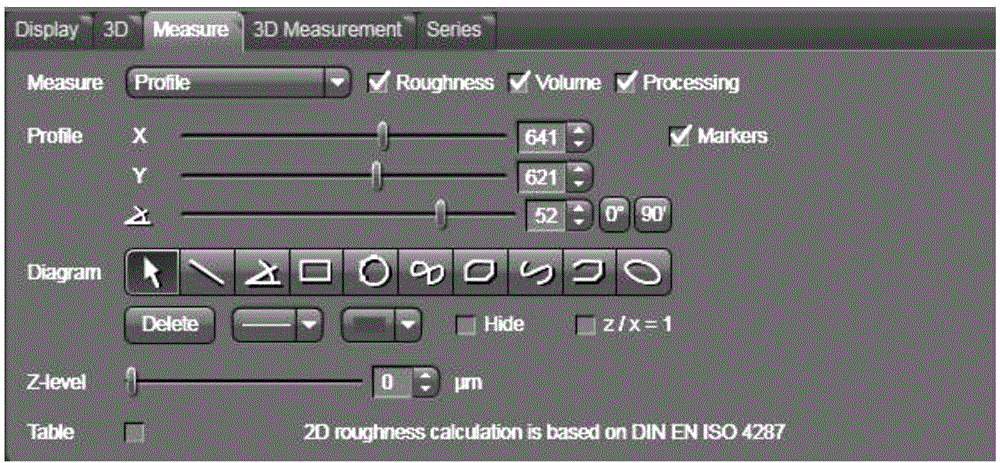

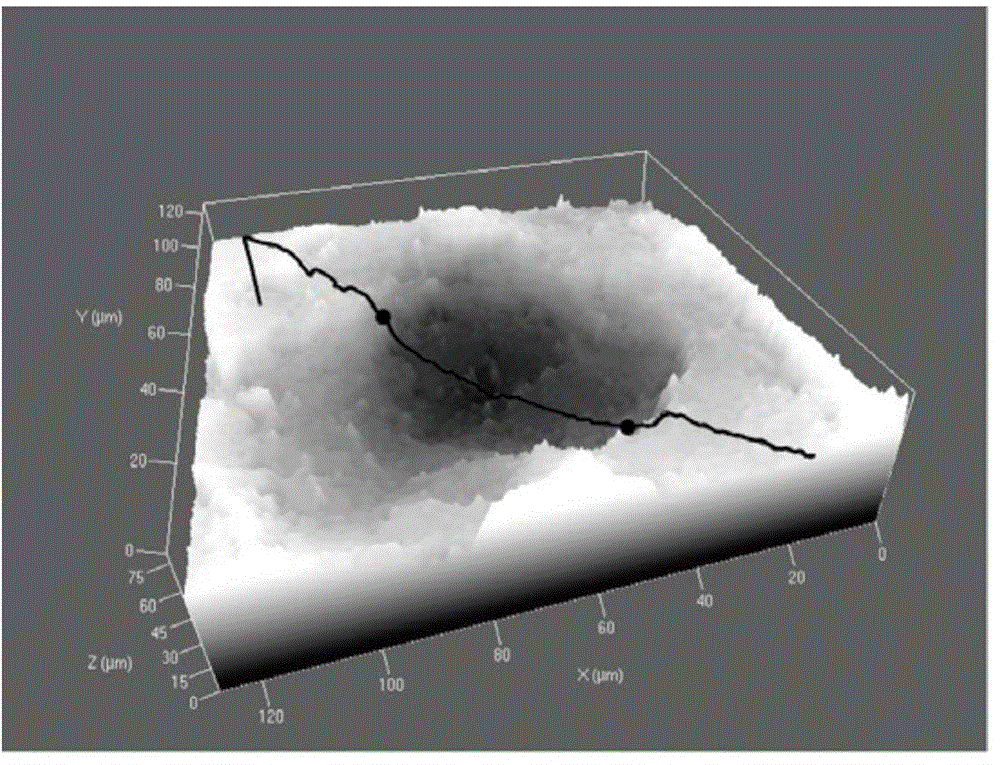

Method for testing and evaluating dynamic morphology features of material during corrosion process

InactiveCN103487366AEasy to handleAccurate feature judgmentWeather/light/corrosion resistanceUsing optical meansTest samplePhases of clinical research

A method for testing and evaluating the dynamic morphology features of a material during the corrosion process comprises the following steps: firstly, trimming in-service samples in different stages into test samples with certain sizes; conducting ultrasonic cleaning on the test samples with acetone after the test samples are cleaned with deionized water; blow-drying the test samples for later use after the test samples are cleaned with ultrapure water; conducting surface imaging on the test samples through an image acquisition tool and recording three-dimensional coordinate data; judging the flow condition of a corrosive medium according to the Reynolds number of the corrosive medium; calculating the boundary layer thickness of the corrosive medium in the flow condition; processing the data according to the Gaussian evaluation criterion; drawing a contour line-type corrosion morphology graph; calculating the change degrees of the surface areas of the test samples during the corrosion processes; judging the corrosion features of the material. According the method, the treating processes of the testing and evaluating of the dynamic morphology features of the material during the corrosion process are simple and convenient, and the acquired dynamic information of the corrosion process is complete. The method can effectively evaluate the morphology evolution of the material during the corrosion process and accurately judge the corrosion features of the material.

Owner:HARBIN INST OF TECH AT WEIHAI

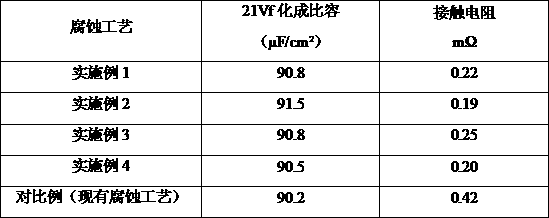

Electrode foil corrosion method of low-contact resistance low-voltage aluminium electrolytic capacitor

InactiveCN107591247AUniform Corrosion MorphologyReduce contact resistanceElectrolytic capacitorsIon contentLow voltage

The invention discloses an electrode foil corrosion method of a low-contact resistance low-voltage aluminium electrolytic capacitor. The electrode foil corrosion method of a low-contact resistance low-voltage aluminium electrolytic capacitor includes the steps: performing pretreatment by means of immersion in sodium hydroxide solution; performing power-on corrosion for 10-85 seconds in hydrochloric acid and sulfuric acid solution; immersing in the hydrochloric acid and sulfuric acid solution for 10-85 seconds, rinsing by means of tap water, and repeating the corrosion, immersion and rinsing steps for 4 times; performing pore broadening power-on corrosion for 10-85 seconds in the hydrochloric acid, sulfuric acid and phosphoric acid corrosion liquid, immersing for 10-85 seconds in the hydrochloric acid, sulfuric acid and phosphoric acid corrosion liquid, rinsing by means of tap water, and repeating the corrosion, immersion and rinsing steps for 8 times; and immersing by means of the hydrochloric acid solution, immersing by means of nitric acid solution, rinsing by means of clean water, and then performing annealing treatment. The electrode foil corrosion method of a low-contact resistance low-voltage aluminium electrolytic capacitor utilizes multi-level pore-forming multi-level low frequency pore broadening to control the corrosion morphology, and correspondingly performs multiple steps of treatment in bath solution and warm rinse to enable the aluminium powder and foreign ion during the corrosion process to be fully rinsed to finally obtain an electrode foil for a low-contact resistor low-voltage aluminium electrolytic capacitor, wherein the electrode foil is uniform in the thickness of the residual core layer, is suitable in the aluminium content in the corrosion layer,and is low in the aluminium powder and foreign ion content, and the contact resistance can be reduced more than 40%.

Owner:NANTONG HAIXING ELECTRONICS +1

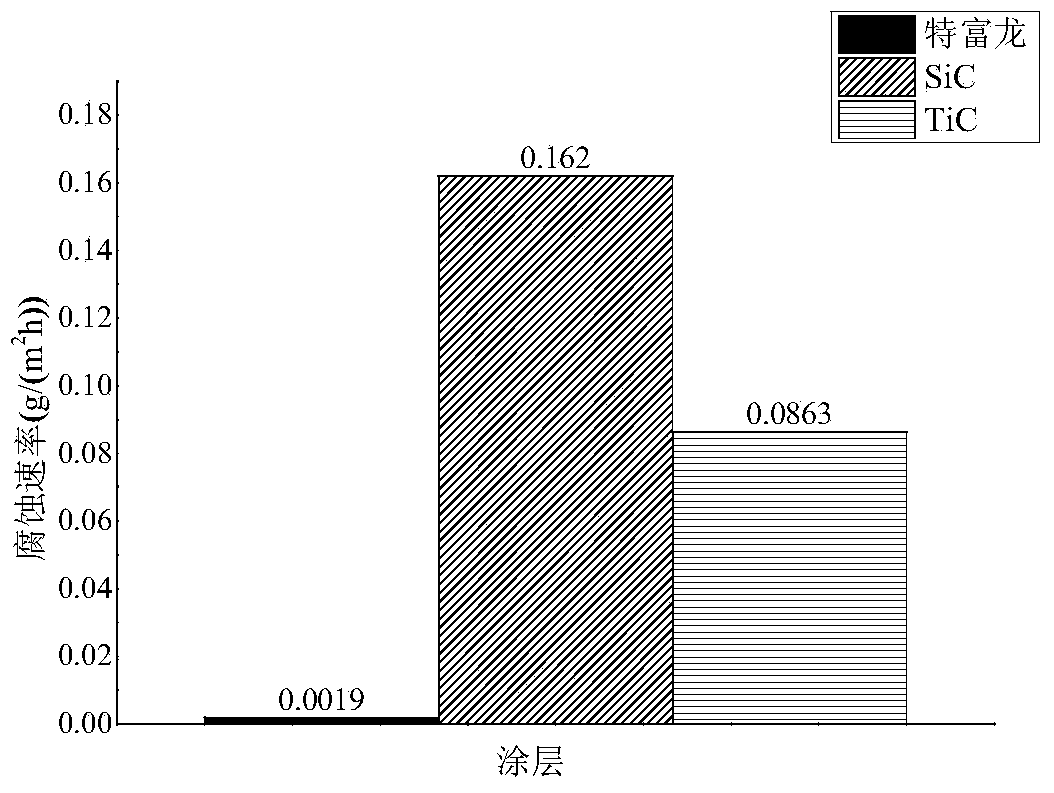

Test method for evaluating corrosion resistance of coating

InactiveCN104266958AEasy for initial screeningEvaluation of Corrosion ResistanceWeather/light/corrosion resistanceBrominePre treatment

The invention provides a test method for evaluating corrosion of a coating in a bromine-containing corrosive solution. The test method comprises the following steps: firstly, cutting a steel plate into a test sheet with a certain size, and pretreating the surface of the test sheet; secondly, coating the surface of the pretreated test sheet with an anticorrosive coating to obtain a test sheet 1, photographing, recording the coating morphology and measuring the size and the quality of the test sheet 1; thirdly, preparing the corrosive solution, putting the test sheet 1 therein for testing, taking out the test sheet 1 after a period time, and drying to obtain a test sheet 2; and finally, weighing the test sheet 2, observing the corrosion morphology, and calculating the weight loss and the corrosion rate of the test sheet 1 so as to evaluate the corrosion resistance of the coating. By the test method, corrosion resistances of different coatings in a bromine solution can be evaluated, preliminary screening for the coatings resistant to the corrosion of the bromine solution is facilitated, and a basis for selecting the anticorrosive coating in the bromine solution environment is provided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

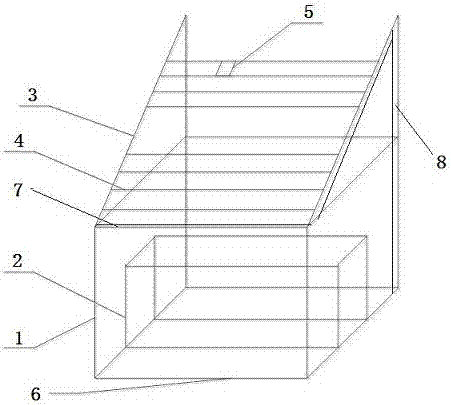

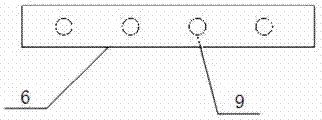

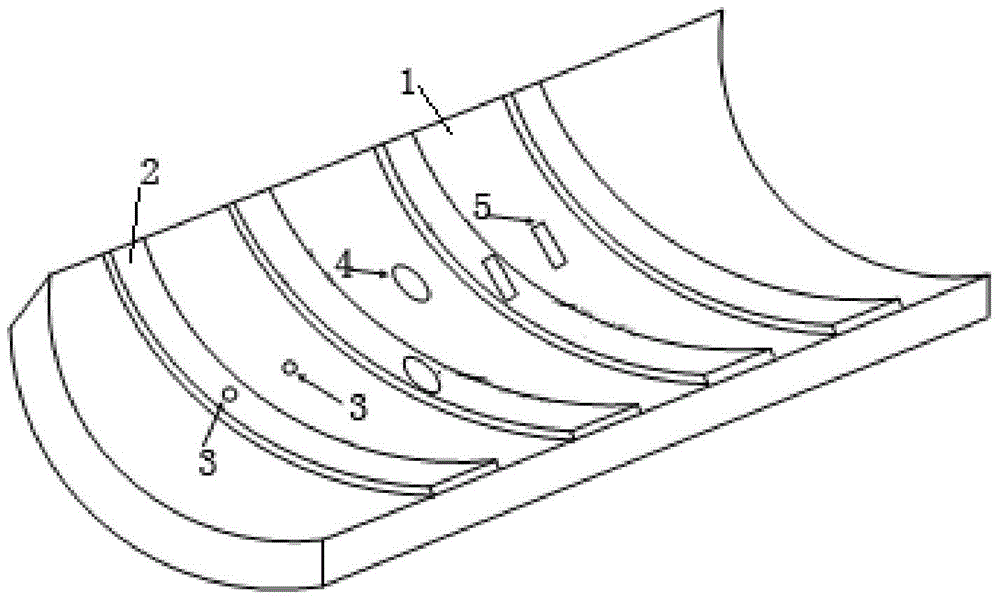

Atmospheric corrosion exposure test device and method for metal test samples

The invention relates to an atmospheric corrosion exposure test device for metal test samples. The device comprises a base fixing bracket (1), two inclined beams (3), a plurality of cross beams (4), two back vertical beams (8) and an atmospheric corrosion detector mounting box (2). One ends of the two inclined beams are separately mounted at two ends of a rotatable shaft (7) at the front end of the upper portion of the fixing bracket while the other ends are separately mounted on the two back vertical beams; the plurality of cross beams are parallelly and vertically mounted on the two inclinedbeams separately; the cross beams are divided into upper and lower regions; metal test samples (5) are symmetrically placed in the upper and lower regions separately; an atmosphere temperature / humidity inductor is mounted in the lower region, and an atmospheric corrosion detector monitors, records and stores couple corrosion currents and atmosphere temperature / humidity of special metal test samples. The device can analyze the relationship between atmospheric metal galvanic corrosion and lighting angle by means of corrosion weight loss, corrosion products, corrosion morphology, corrosion current and the like of the metal test samples in the regions at different angles.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +2

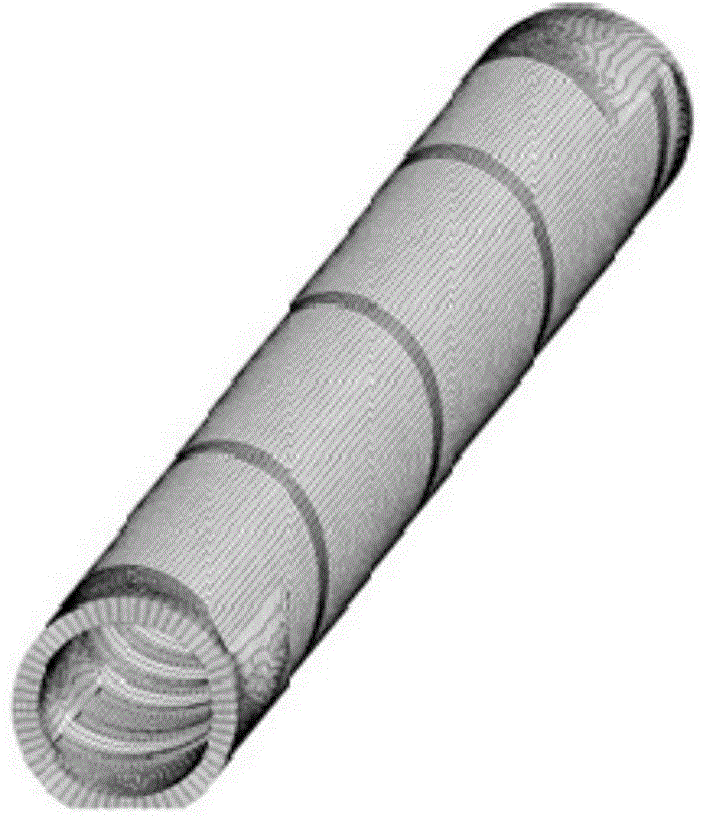

Gas-liquid two-phase flow corrosion test device for mountain moisture pipeline

ActiveCN111624153ASafe and economicalReduce energy consumptionWeather/light/corrosion resistanceSoil scienceEnvironmental engineering

The invention discloses a gas-liquid two-phase flow corrosion test device for a mountain moisture pipeline, and relates to the field of wet natural gas pipeline transportation, and aims at the currentsituation that the existing moisture pipeline gas-liquid two-phase flow corrosion test cannot truly restore the working condition of the pipe flow. The invention provides the mountain moisture pipeline gas-liquid two-phase flow corrosion test device, which not only restores the flowing state of the moisture pipeline gas-liquid two-phase flow, but also can simulate the fluctuation change of the mountain pipeline; an electrochemical test, a corrosion weightlessness test and corrosion morphology characterization can be carried out at the same time, the test period is shortened, and thereby the corrosion condition of the mountain moisture pipeline under the gas-liquid two-phase flow working condition is effectively predicted.

Owner:SOUTHWEST PETROLEUM UNIV

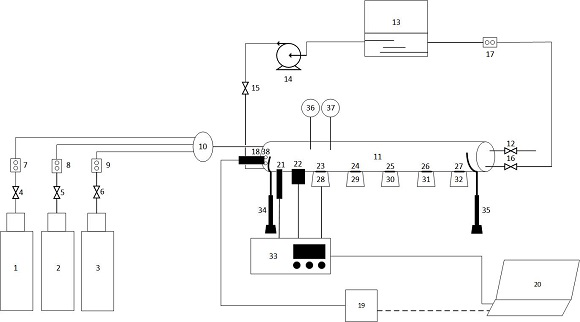

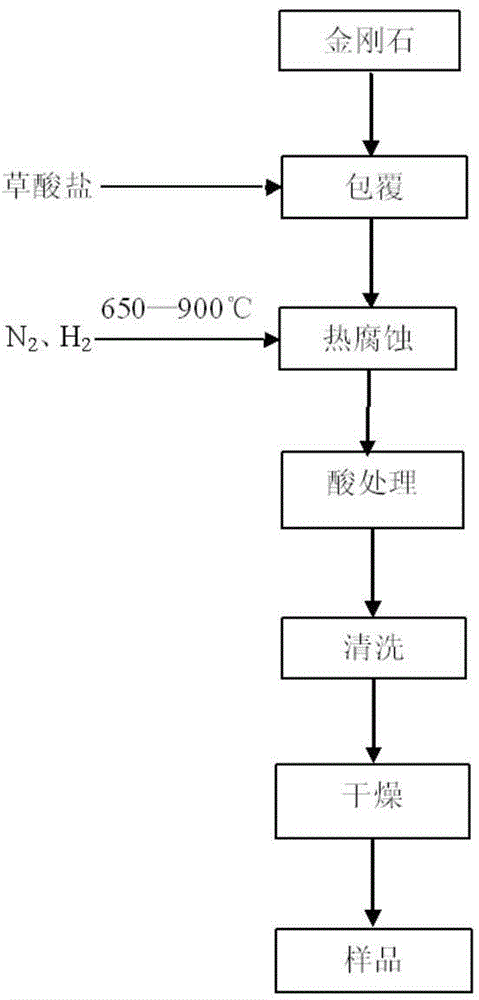

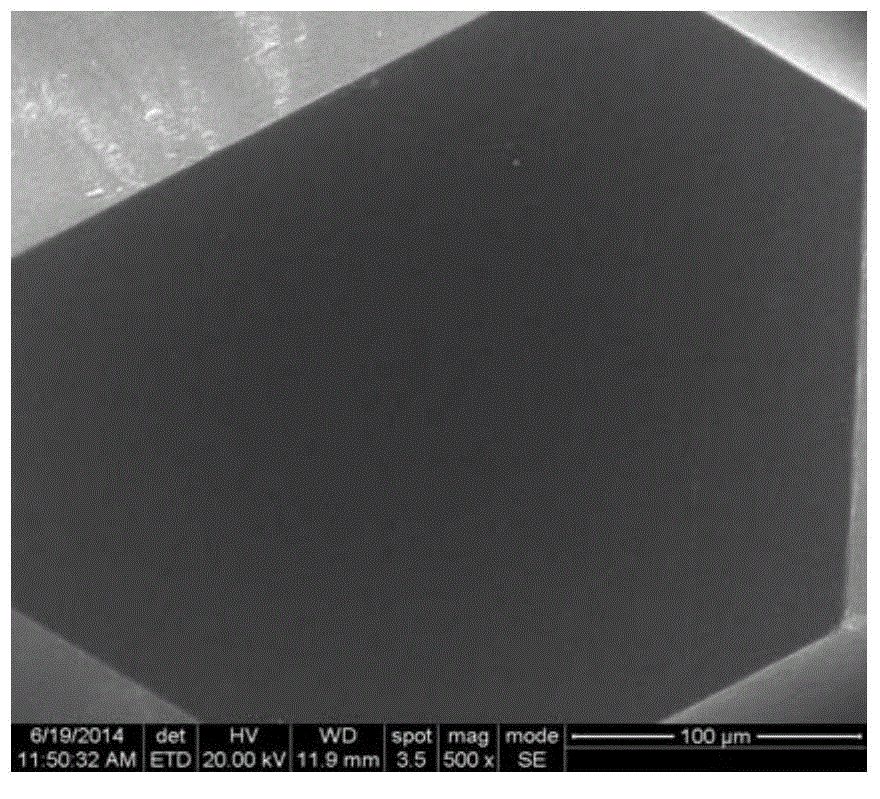

Method for increasing surface roughness of man-made diamond single crystal

The invention discloses a method for increasing surface roughness of a man-made diamond single crystal. The method comprises the following steps: packaging a diamond with oxalate, putting the packaged diamond in a reducing atmosphere, heating and sintering, pickling, washing and drying sintering products, thereby obtaining diamond with improved surface roughness. The method is used for processing the diamond surface, so that the uniformly-distributed corrosion morphology is shown in the surface, the surface roughness of the diamond is increased, the specific surface area and the surface energy of the diamond are improved, the mechanical holding force of a binder in a diamond tool on the diamond surface is strengthened, the condition that the diamond is easy to separate in a practical grinding process is improved, and the service life of the diamond tool is prolonged. The method has the advantages of being low in equipment requirement, simple in operation process, economical and practical, obvious in effect, and the like.

Owner:HUNAN UNIV

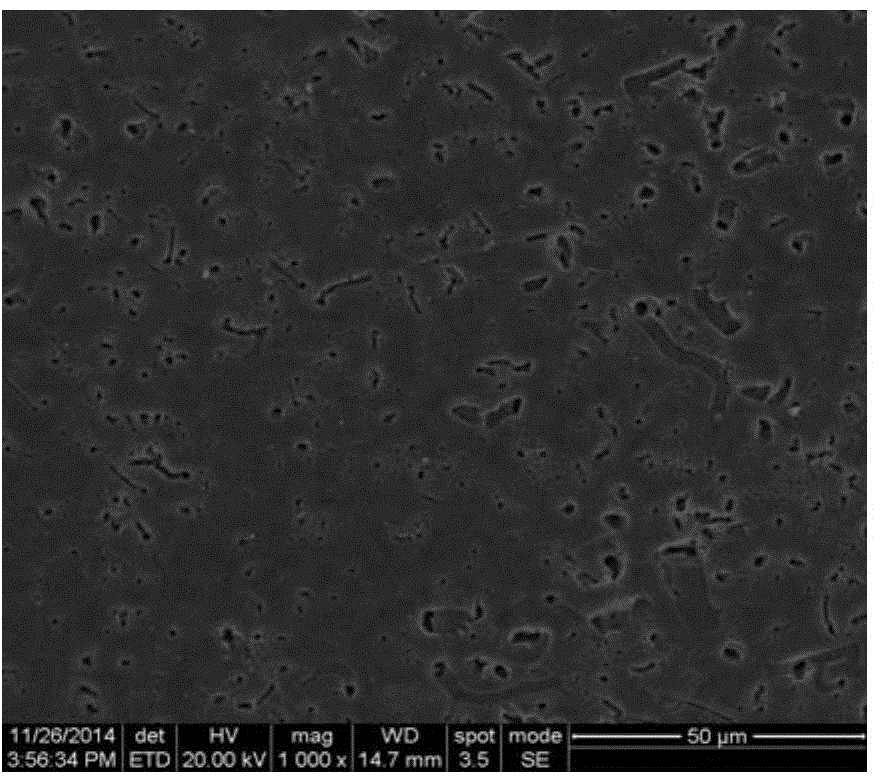

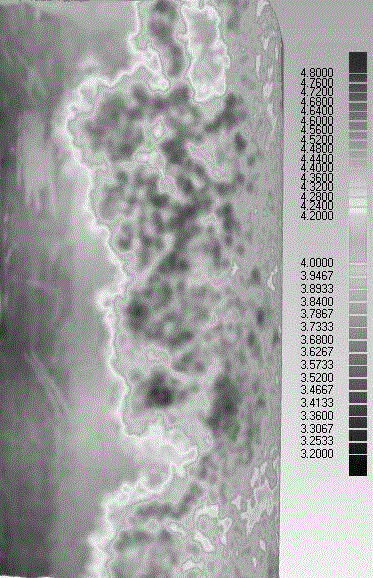

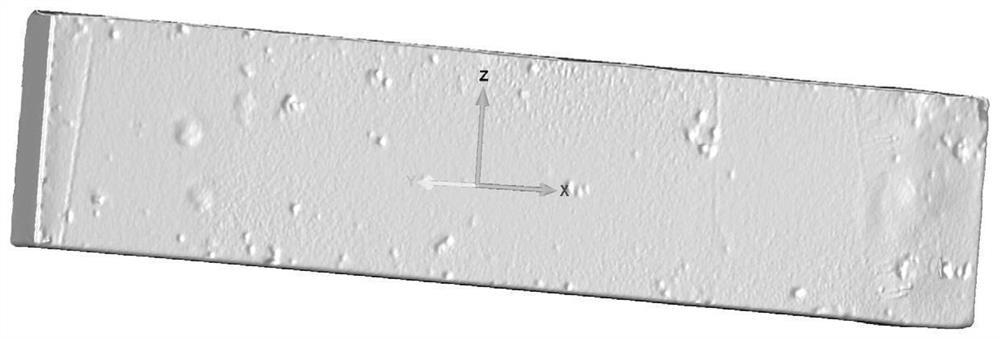

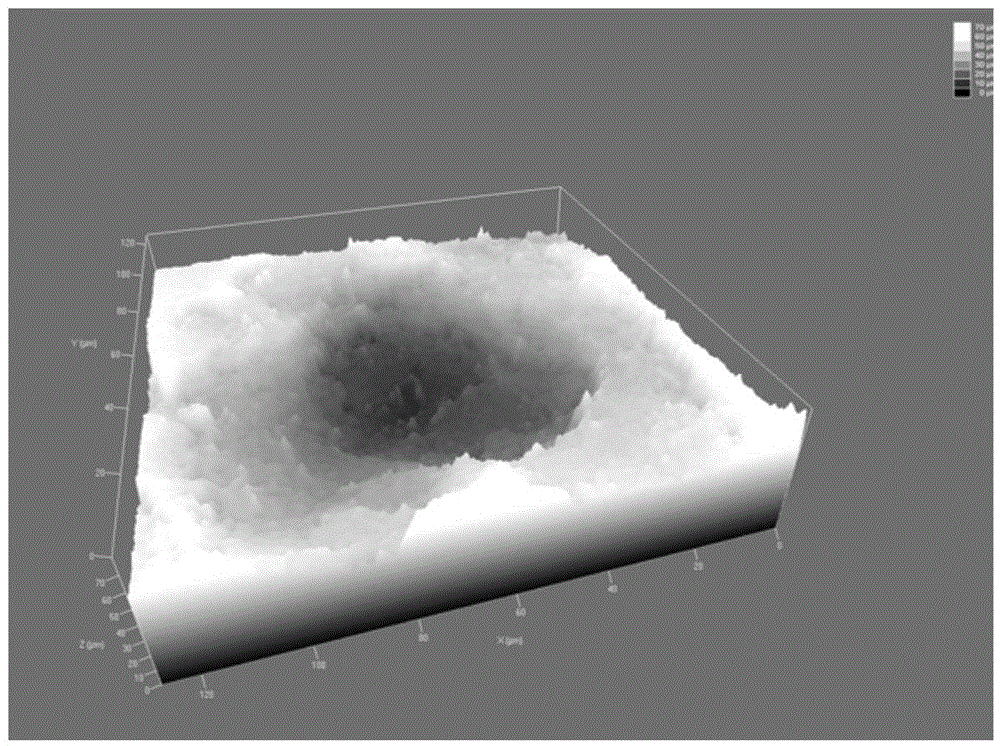

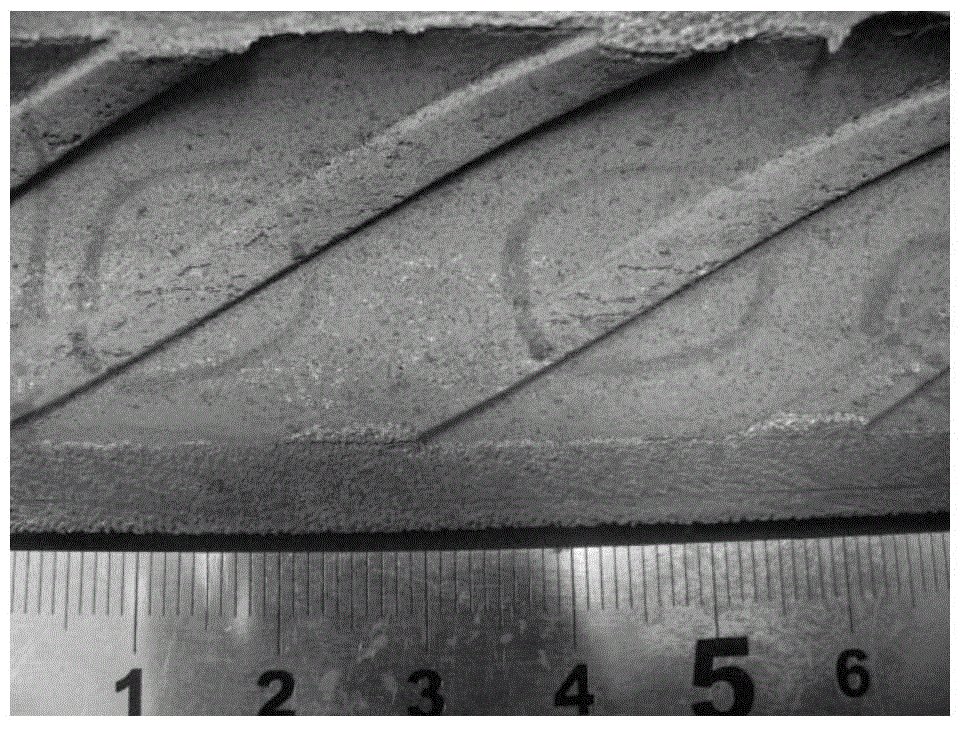

Corrosion morphology quantitative detection method of outer wall of pipeline

ActiveCN105486240AEffective Visual Quantitative CharacterizationIntuitive Quantitative CharacterizationOptically investigating flaws/contaminationUsing optical meansPoint cloudComputer science

The present invention provides a corrosion morphology quantitative detection method of the outer wall of a pipeline. The method provided by the invention comprises the following steps: 1) point cloud acquisition; 2) three-dimensional entity image reduction; 3) analysis of a three-dimensional entity image at the surface of a pipeline. The method provided by the invention is able to visually reflect the corrosion degrees of different areas of the outer wall, the deviation of the inner surface and the outer surface is highlighted through establishing of marks at special positions, and the quantitative analysis of the variation trend of the corrosion degree at the cross section is realized.

Owner:PETROCHINA CO LTD

Method for testing hydrogen sulfide stress corrosion resistance of oil well pipe

InactiveCN109813612AMaterial strength using steady bending forcesUsing optical meansLaser scanningOil well

The invention discloses a method for testing hydrogen sulfide stress corrosion resistance of an oil well pipe. The method comprises the steps that after a sample which does not lose efficacy in bending loading is subjected to surface derusting treatment, sample surface morphology observation and corrosion pit depth measurement are conducted on the sample by adopting a laser scanning confocal microscope, and the stress corrosion resistance of the oil well pipe material is evaluated according to the corrosion pit depth of the surface of the tensile stress side of the sample. According to the method, the stress corrosion sensitivity of the oil wall pipe is evaluated through corrosion morphology observation and corrosion pit depth measurement, quantifiable grading is conducted on the sample which does not lose efficacy in bending loading without adding extra tests, accordingly, the corrosion resistance of the oil well pipe material is evaluated in a specific working condition environment,and guidance is provided for material selection and equipment maintenance.

Owner:ANGANG STEEL CO LTD

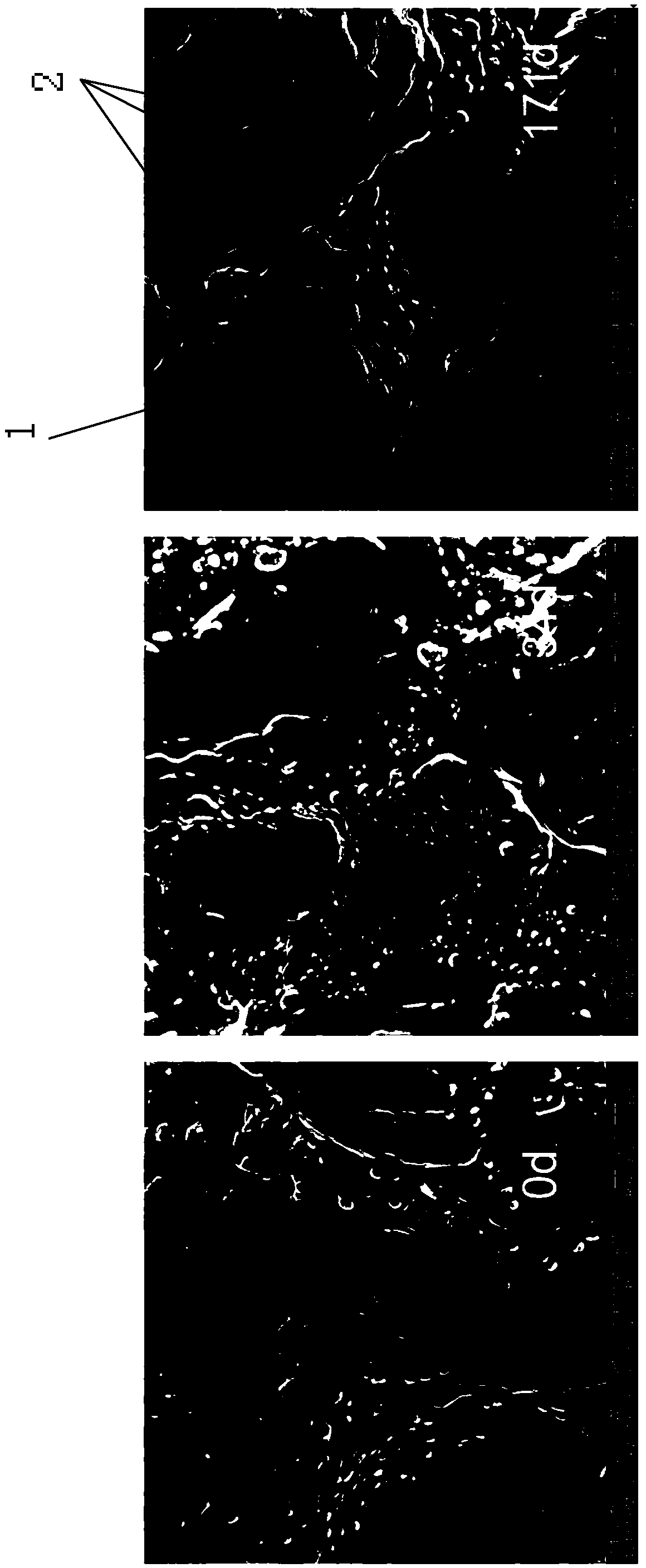

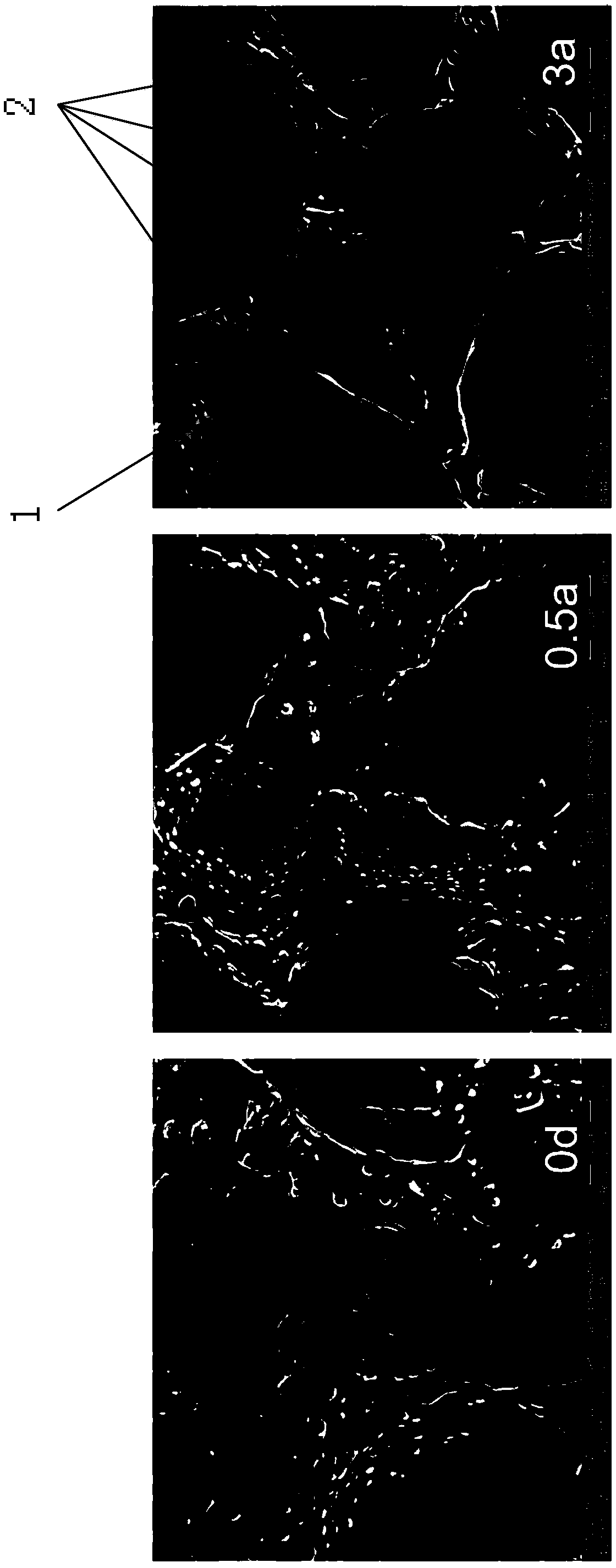

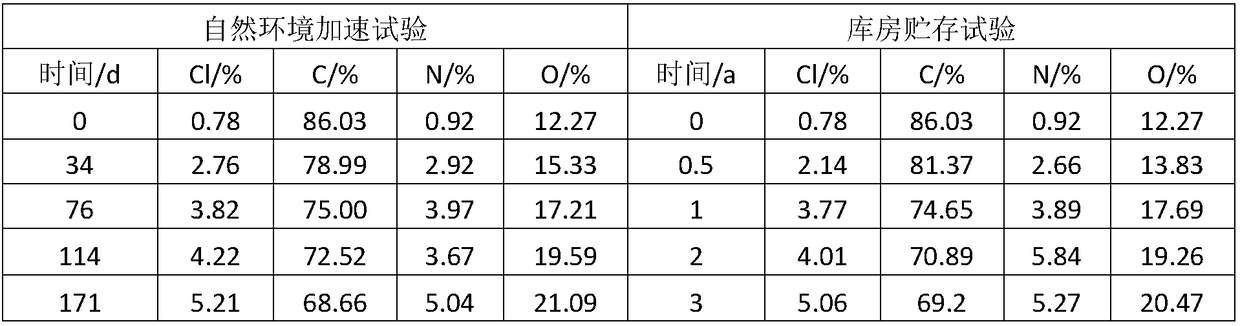

Method for evaluating consistency of aging mechanism of composite solid propellant

ActiveCN109297896AQuickly reflect storage aging performanceReflect storage aging performanceWeather/light/corrosion resistanceComputer scienceCorrosion morphology

The invention discloses a method for evaluating the consistency of aging mechanism of a composite solid propellant. The method comprises the steps that composite solid propellant samples are subjectedto a natural environment accelerated test and a warehouse storage test separately in the same climatic environment; after the prescribed aging days and years are reached, the storage modulus, the pure gel content, relative atomic content of elements and corrosion morphology of the samples are tested separately; and the change rule of the storage modulus, the pure gel content, the relative atomiccontent of the elements and the corrosion morphology of the samples under the natural environment accelerated test and warehouse storage test conditions are compared and analyzed. By synergistically characterizing the variation trend of parameters such as the storage modulus, the pure gel content, the corrosion morphology and the relative atomic content of elements of the samples under the naturalenvironment accelerated test and the warehouse storage test, the method for evaluating the consistency of the aging mechanism of the composite solid propellant under the two test conditions is established, and the storage aging performance of the composite solid propellant under the warehouse storage test condition is reflected in a true and rapid manner.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

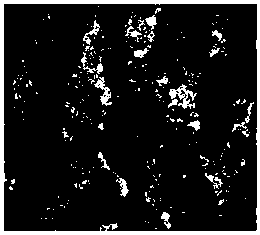

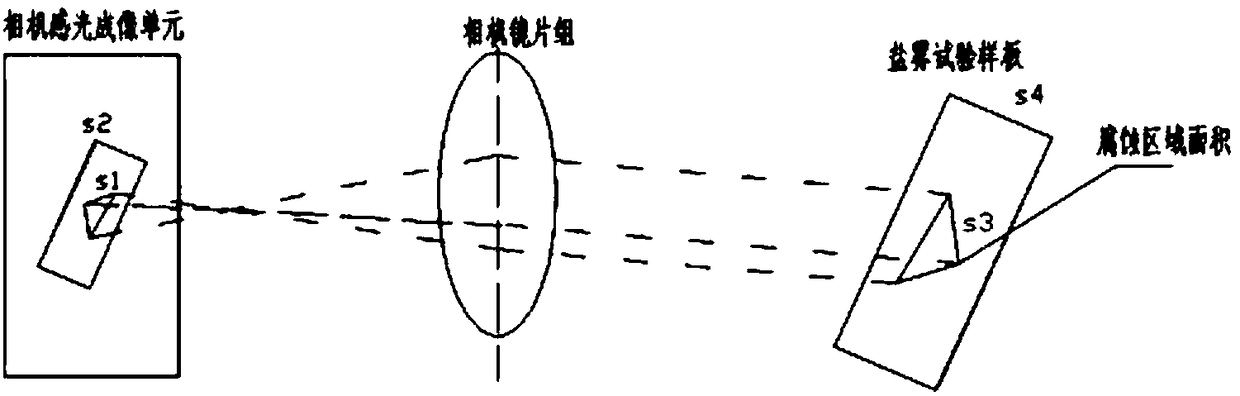

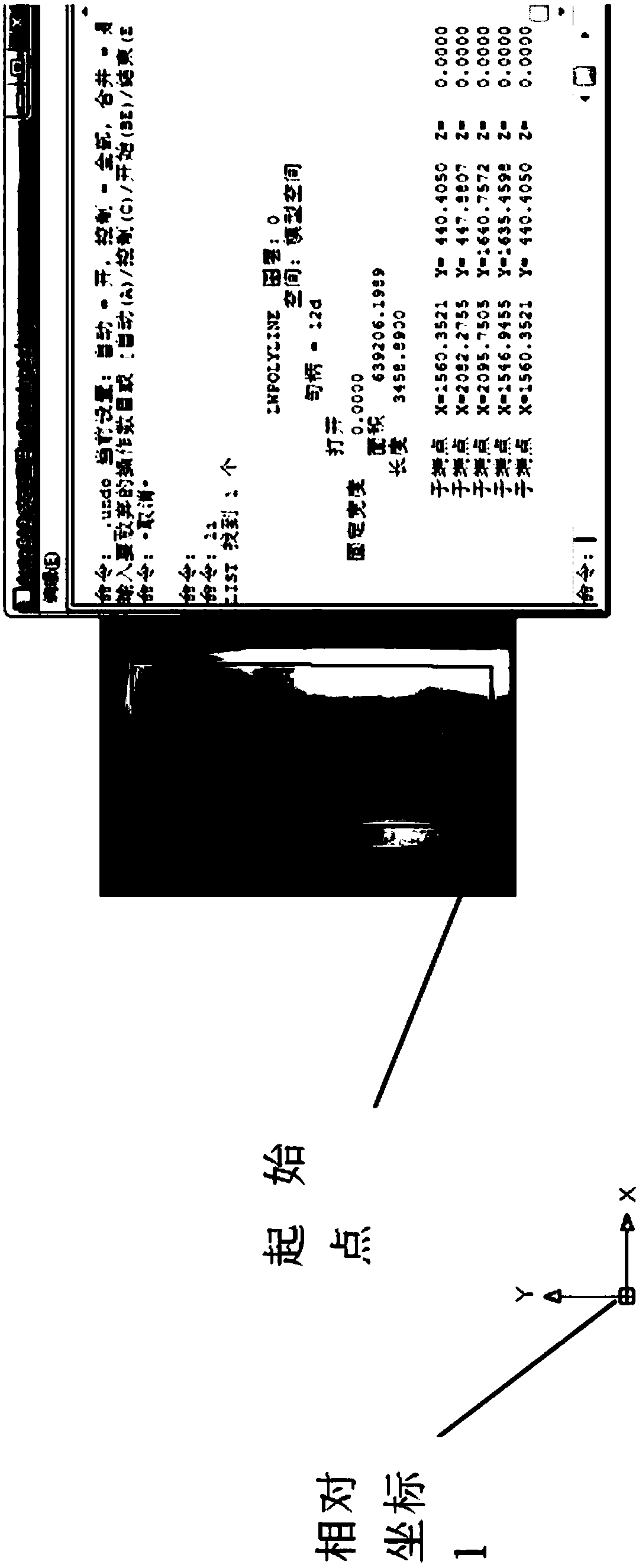

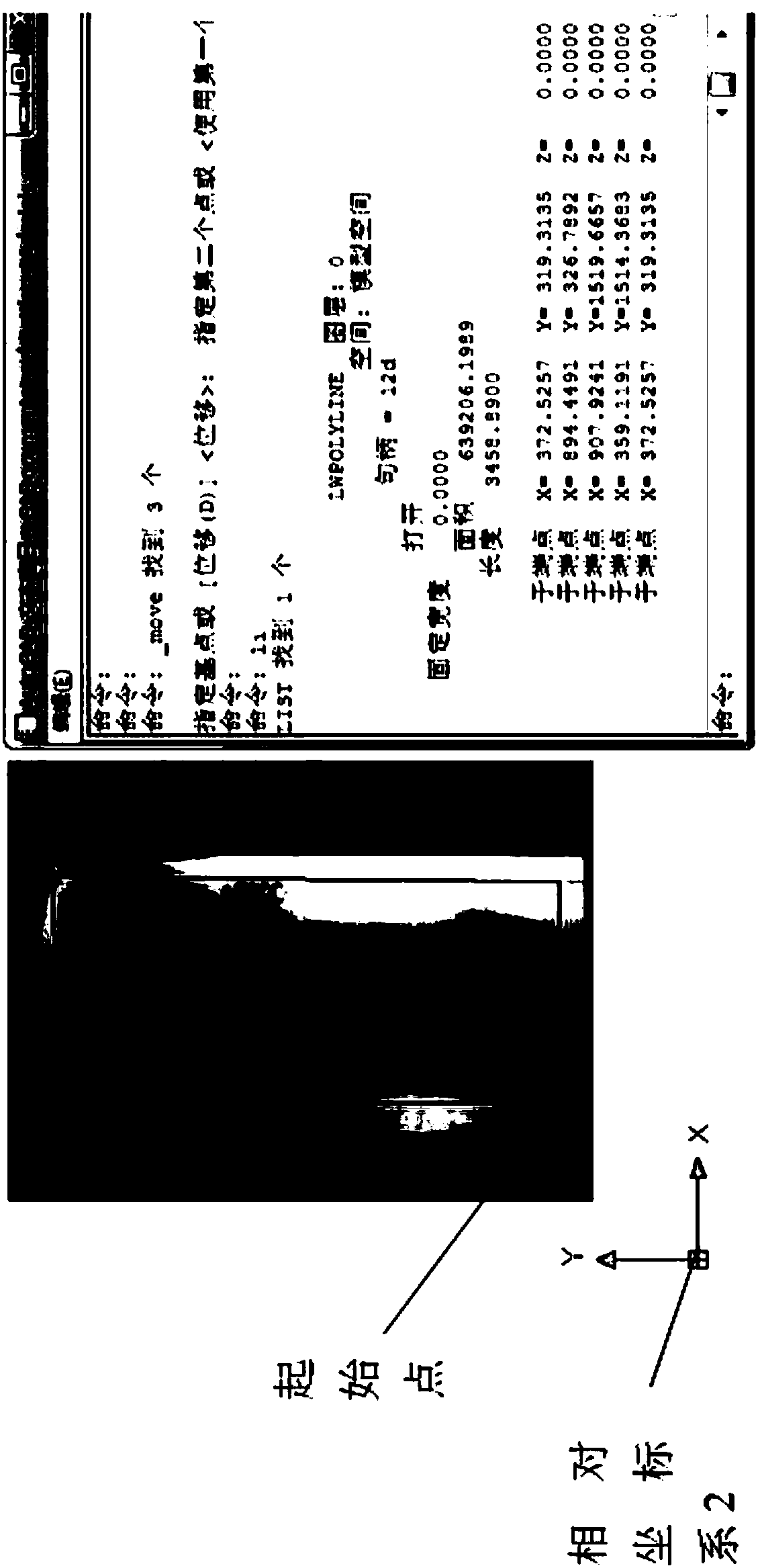

Salt spray test relative corrosion area measurement method

InactiveCN108414430AReduce dependenceSimple and fast operationWeather/light/corrosion resistanceUsing optical meansSalt spray testPhysical chemistry

The invention relates to a salt spray test relative corrosion area measurement method and belongs to the technology of coating relative corrosion area measurement. The salt spray test relative corrosion area measurement method comprises the steps of taking a passivated galvanized plate as a salt spray test sample plate, after salt spray test is performed for 72 h, standing the sample plate for 0.5-1 h, washing the salt spray test sample plate through desalted water, blow-drying the salt spray test sample plate through a blow dryer, and wiping the salt spray test sample plate through test paperuntil no residue remains; taking photos of the salt spray test sample plate, ensuring clearness of images so that a user can identified corroded zones and uncorroded zones by naked eyes; adhering theimages to a white background of the software of AUTOCAD; drawing limited closed polygons through PL command to separately fit every corroded zone and the overall zone of the salt spray test sample plate; computing the area of every corroded zone and the area of the entire salt spray test sample plate through LI command; comparing the sum of the areas of the corroded zones and the overall area ofthe salt spray test sample plate to calculate a relative corrosion area. The salt spray test relative corrosion area measurement method saves ruler measurement and is simple in operation, low in dependence on pixel and capable of distinguishing corrosion morphology of various salt spray tests.

Owner:TANGSHAN GUOFENG IRON & STEEL

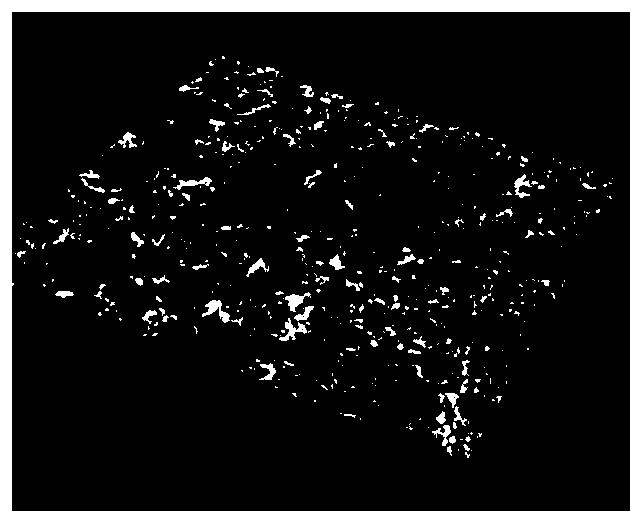

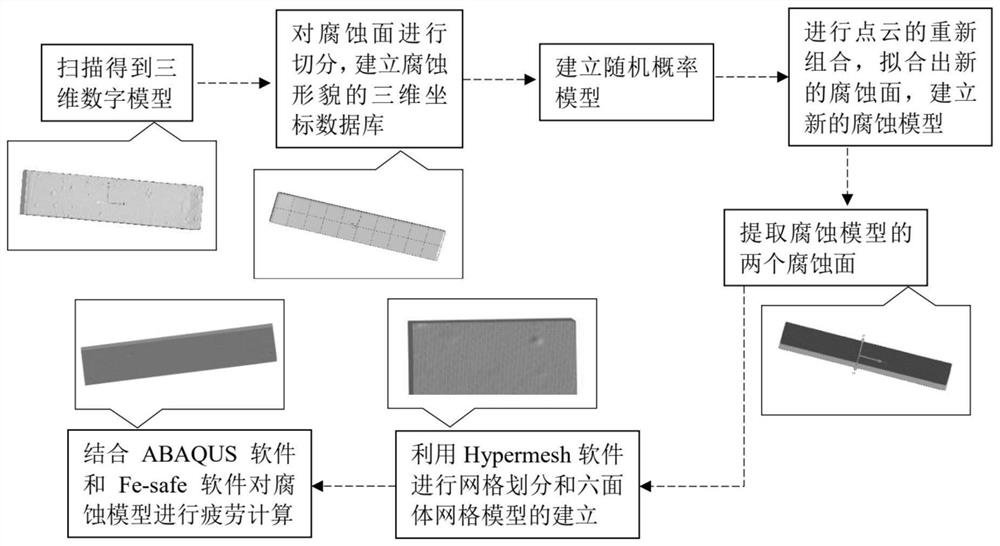

Finite element numerical simulation and parameter analysis method for fatigue after corrosion of metal material

ActiveCN113177272AShorten the timePredicting Residual Fatigue LifeGeometric CADDesign optimisation/simulationMetallic materialsEngineering

The invention provides a finite element numerical simulation and parameter analysis method for fatigue of a metal material after corrosion, which comprises the following steps of: scanning an existing corroded metal material test piece to obtain a corrosion three-dimensional digital model, and establishing a three-dimensional coordinate database of corrosion morphology; establishing a random probability model, randomly selecting three-dimensional coordinate points, recombining point clouds, fitting a new corrosion surface, and establishing a new corrosion model; extracting two corrosion surfaces of the obtained new corrosion model, utilizing Hypermesh software to carry out grid division and establishment of a hexahedral grid model, and then combining ABAQUS software and Fe-safe software to carry out fatigue calculation on the corrosion model. By the adoption of the technical scheme, the problems that corrosion and fatigue tests are long in consumed time and large in test result discreteness are effectively solved, time is effectively saved through the finite element fatigue calculation method, and compared with the test result, the fatigue simulation result is accurate and effective.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

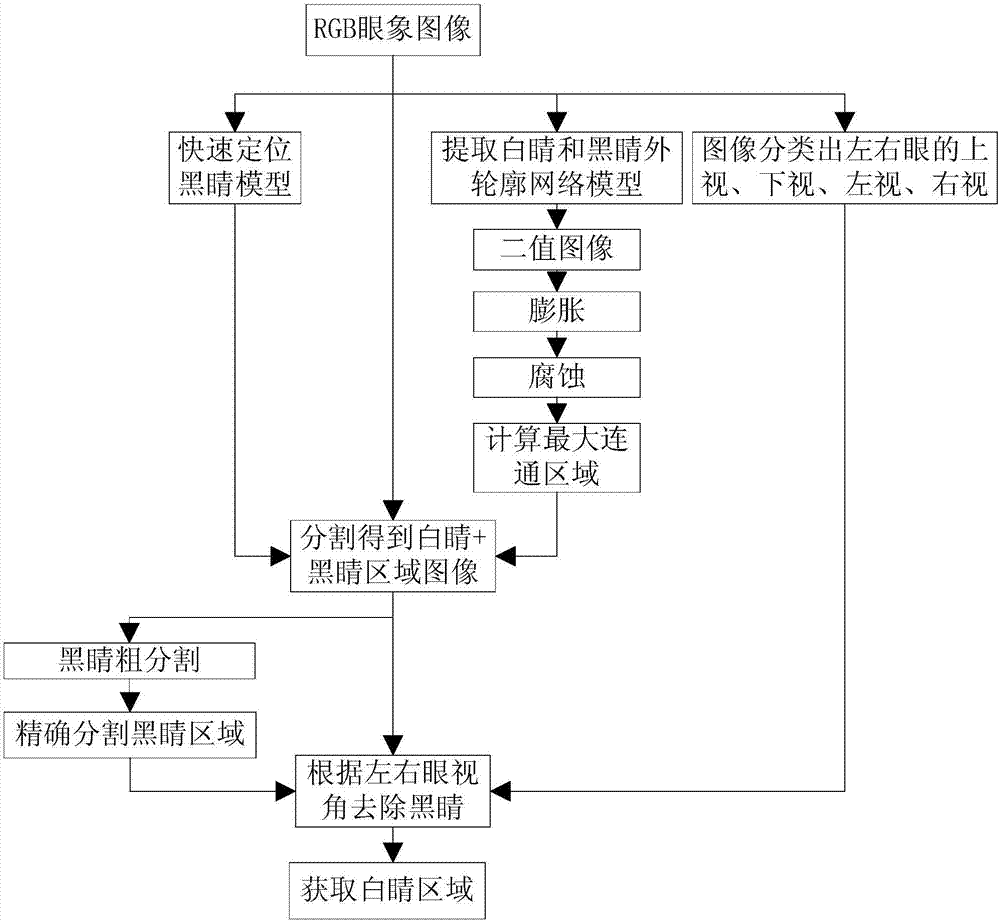

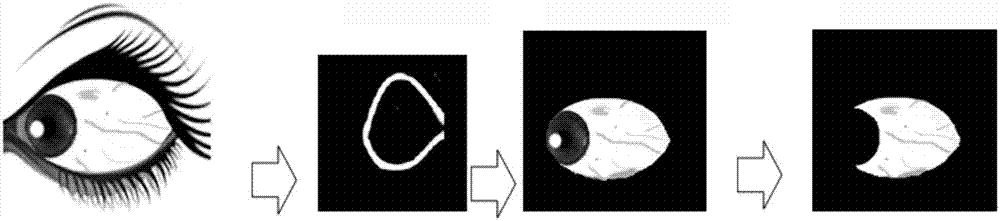

Complete extraction method of true color eye image graph white eye area

ActiveCN106960199AImprove applicabilityRapid positioningImage enhancementImage analysisEdge extractionEye position

The invention relates to a complete extraction method of a true color eye image graph white eye area. The method comprises the following steps of using a trained edge extraction model to carry out edge extraction of white-eye and black-eye complete areas on different-visual-angle 24-bit true color eye image graphs of natural light; after expansion and corrosion morphology conversion, acquiring a completely-enclosed edge binary image, calculating a maximum connection area, mapping the binary image to an original 24-bit true color eye image graph and acquiring the white-eye and black-eye complete areas; using a trained black-eye position prediction model to calculate position coordinate information of a black-eye external connection rectangle, and rapidly positioning a black-eye position; in the white-eye and black-eye complete areas, using the black-eye position coordinate information to roughly segment a black-eye area, using a Hough detection circle to calculate and acquire a black-eye center and a radius, and accurately segment the black-eye area; and according to visual angle orientation information of an eye image and the acquired black-eye area, removing a black-eye area image in the white-eye and black-eye complete areas and acquiring a white-eye area. In the invention, the white-eye area can be accurately, effectively and completely extracted.

Owner:CAPITALBIO CORP

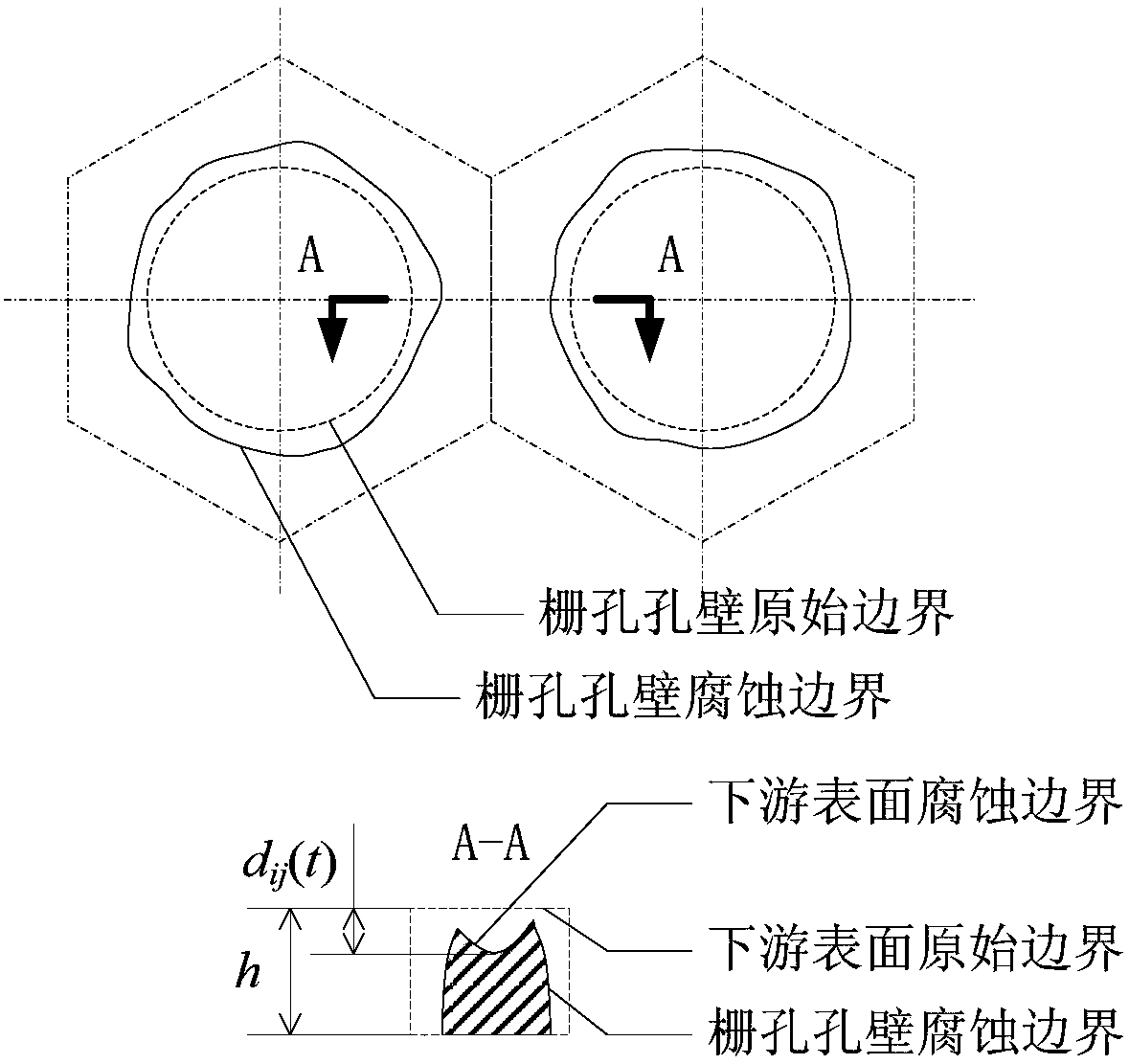

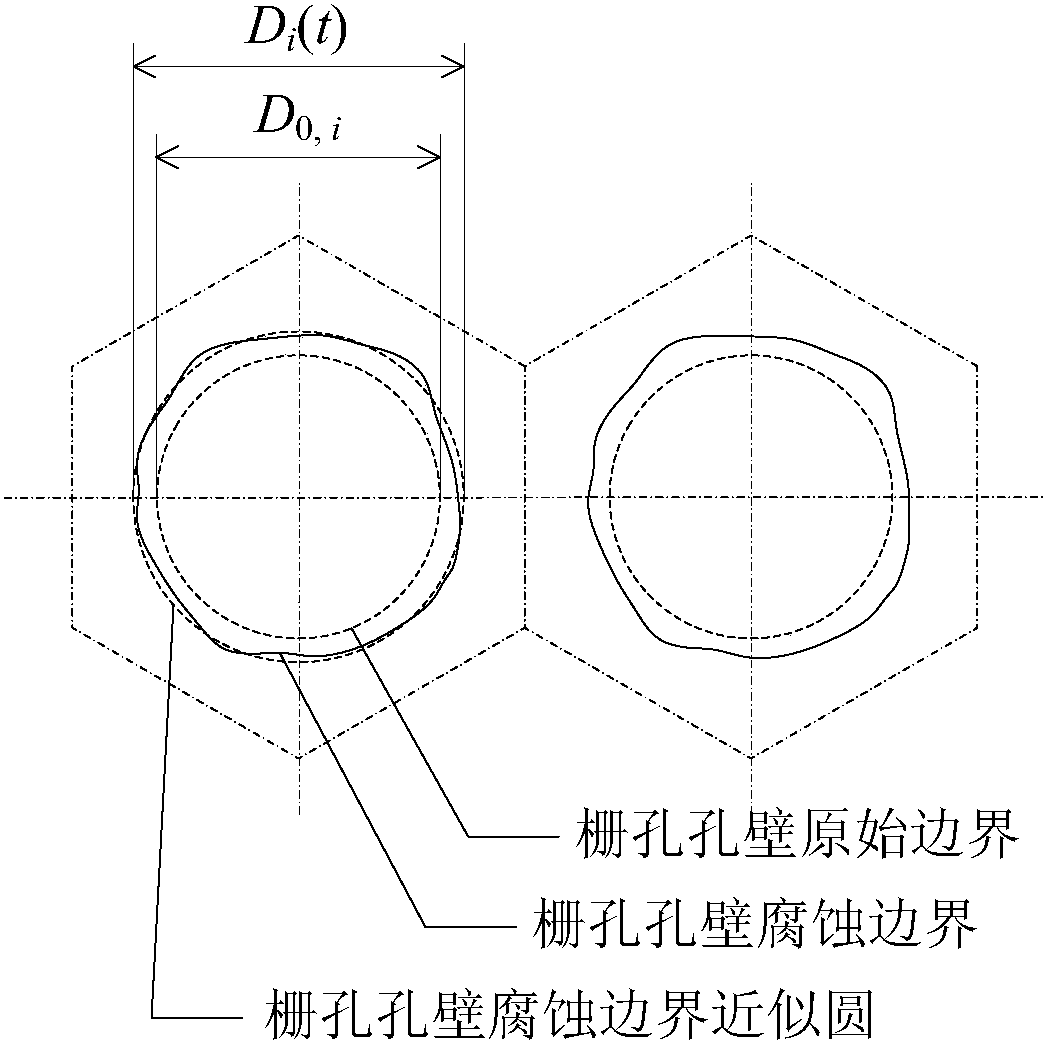

Ion thruster service life evaluating method based on grid corrosion morphology and electronic backflow

ActiveCN108280253ASolve the problem that life needs long-term test verificationGuaranteed accuracyDesign optimisation/simulationSpecial data processing applicationsModel parametersElectron

The invention discloses an ion thruster service life evaluating method based on grid corrosion morphology and electronic backflow. The method comprises the steps of firstly collecting the corrosion depth of a groove in the surface of the downstream of an accelerating grid and the diameter of a grid hole of the accelerating grid, building a grid corrosion degradation model, determining grid corrosion degradation model parameters, obtaining a grid corrosion fitting degradation model, then, estimating the service life of an ion thruster, collecting electronic backflow limit voltage data under different testing times, building an electronic backflow limit voltage degradation model, determining grid corrosion degradation model parameters, obtaining a grid corrosion fitting degradation model, estimating the service life of the ion thruster, and finally comprehensively estimating the service life of the ion thruster.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Corrosion pit depth determining method by use of confocal microscope

ActiveCN104897063AReliable data sourceIncrease credibilityUsing optical meansMacroscopic scaleMeasuring instrument

The invention discloses a corrosion pit depth determining method by use of a confocal microscope. The method makes full use of original corrosion information on the surface of a sample, the data source is real and reliable, and the credibility of a determined result is quite high. The method transforms a minimal difficult-to-distinguish corrosion morphology from a macro perspective into a visual and vivid Profile graph of a corrosion pit, such that more complete attention is given to corrosion details, and the accuracy of a measuring result is greatly improved. The method effectively makes up for the disadvantages of poor measuring precision, limited measuring scope and the like of a conventional depth measuring instrument, further enlarges the measuring scope of the corrosion pit, can be used for measuring the depth of the corrosion pit and can also be used for measuring the width of the corrosion pit. The method is simple and convenient to operate, small in consumed time and high in experiment efficiency, thereby being an important experiment means for a sample local corrosion condition evaluation and a local corrosion resistance capability evaluation.

Owner:NANJING IRON & STEEL CO LTD

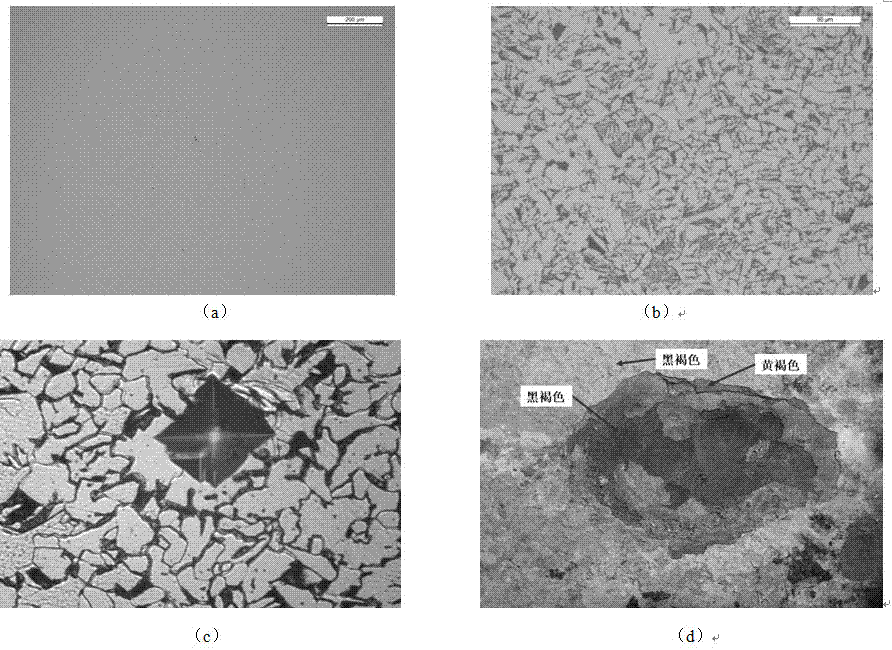

Method for carrying out half-in-site observation on initiation position of point corrosion pit

ActiveCN110108731AAccurate representationIncrease credibilityPreparing sample for investigationMaterial analysis by transmitting radiationThermal ageingRoom temperature

The invention relates to a method for carrying out half-in-site observation on an initiation position of a point corrosion pit, and belongs to the technical field of corrosion. Firstly, Z3CN20.09M cast austenite-ferrite stainless steel is subjected to thermal ageing to obtain thermally aged samples containing a nanoscale Cr-rich alpha' phase, a Fe-rich alpha phase and a G phase. The samples thermally aged for different time are soaked in FeCl3 acid solution, and after ultrasonic pickling treatment, a corrosion morphology is observed under a metallographic microscope. Finally, thinning is carried out by utilizing an automatic twin-jet electropolisher and an ion thinner. The prepared thermally-aged samples are placed into a transmission electron microscope to carry out a first round of histological observation, a ferrite structure is found at a thin region position close to a thinned hole, and a G phase morphology in ferrite is observed. The samples are taken out of the transmission electron microscope and cleaned with a plasma cleaner, and the samples are placed into NaCl solution to soak under the condition of the room temperature, cleaned with deionized water, air-dried and then placed into the transmission electron microscope again so as to determine the preferential initiation position of the point corrosion pit. According to the method disclosed by the invention, the initiation position of the point corrosion pit can be rapidly and accurately represented, and credibility is high.

Owner:UNIV OF SCI & TECH BEIJING

Membrane wall tube inner wall corrosion failure critical judging method

ActiveCN104318010AReduce the number of replacementsGuaranteed safe operationSpecial data processing applicationsElement modelUltimate tensile strength

The invention relates to a membrane wall tube inner wall corrosion failure critical judging method. The method includes the steps of firstly, building the finite element model of a membrane wall tube to obtain the horizontal relationship form of the defect morphology and defect depth and the partial equivalent stress of a tube; secondly, performing nondestructive testing on the corrosion degree of the inner wall of the to-be-judged membrane wall tube to obtain corrosion morphology and corrosion depth; thirdly, finding the partial equivalent stress corresponding to the tested corrosion morphology and corrosion depth according to the horizontal relationship form obtained at the first step; fourthly, comparing the partial equivalent stress obtained at the third step with the yield strength of the membrane wall tube at 400 DEG C, taking the safety coefficient as 1.5, and judging that the membrane wall tube is in a critical failure state when the obtained partial equivalent stress sigma is not smaller than the yield extreme sigma s / 1.5 of the membrane wall tube at 400 DEG C. The method is simple in field implementation and free of special equipment, membrane wall tube replacing number can be reduced greatly, and unit safety operation is guaranteed.

Owner:SUZHOU NUCLEAR POWER RES INST +3

Simulated test device and method for corrosion nearby suction port of downhole oil pump

ActiveCN103115863AAccurately reflectAccurate CorrosionWeather/light/corrosion resistanceExhaust valveEngineering

The invention discloses a simulated test device and method for corrosion nearby a suction port of a downhole oil pump, and belongs to the field of oil production test devices. The device comprises a buffer container, wherein an air entrapping valve is arranged on the buffer container, a heater is arranged in the buffer container, the buffer container is connected with an outlet of a plunger type metering pump through a liquid return pipe, the top of the buffer container is connected with a sieve pipe which is arranged uprightly, the upper end of the sieve pipe is connected with an oil pipe, the upper end of the oil pipe is communicated with an inlet of the plunger type metering pump through a high-pressure double-layer hose, the sieve pipe and the oil pipe are arranged in a main vertical pipe, and the main vertical pipe is formed in a manner that a plurality of single vertical pipes with sample grooves are in superimposed connection; an exhaust valve is arranged at the top of the main vertical pipe; the single vertical pipe corresponding to the upper end of the sieve pipe is provided with an observation window; and a cut-off valve is arranged on the high-pressure double-layer hose, and a liquid charging valve is connected between the cut-off valve and the inlet of the plunger type metering pump in a bypass manner. The device can be used for simulating the flowing state of fluid nearby the suction port of the downhole oil pump and researching the corrosion morphologies and regulation of sleeves.

Owner:CHINA PETROCHEM & CHEM JIANGSU OILFIELD BRANCH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com