Finite element numerical simulation and parameter analysis method for fatigue after corrosion of metal material

A metal material, numerical simulation technology, applied in the field of material corrosion, can solve the problems of quantitative analysis of corrosion amount and corrosion morphology of corrosion specimens, inability to obtain corrosion data of metal materials, long time consumption of corrosion and fatigue tests, etc., to improve calculation accuracy and calculation efficiency, avoid poor tetrahedral mesh accuracy, and solve the effect of long corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be further described in detail below.

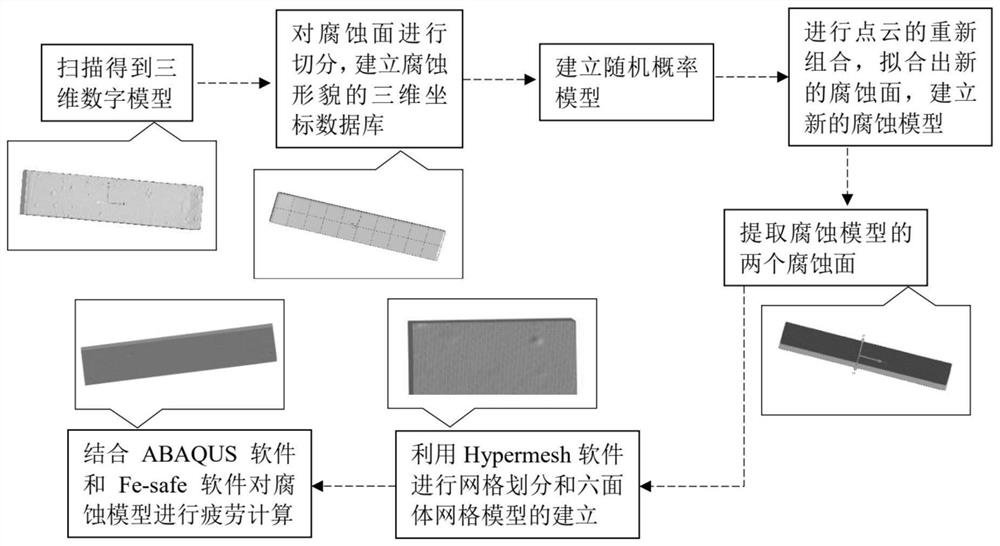

[0042] A method for finite element numerical simulation and parameter analysis of fatigue after corrosion of metal materials, such as figure 1 shown, which includes:

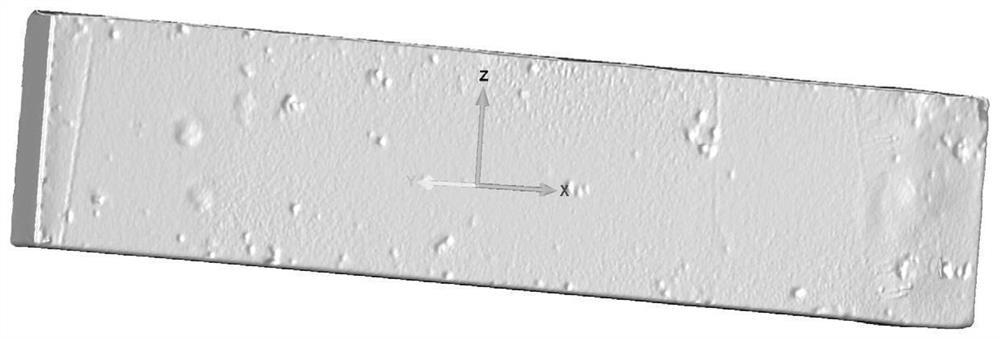

[0043] First, place the prepared metal material test piece in the marine environment or simulated marine environment for corrosion. After the corrosion test is completed, follow the "Removal of Corrosion Products on Corrosion and Corrosion Test Specimens of Metals and Alloys" (GB / T 16545-2015) According to the requirements in the specification, the corrosion products should be removed from the test pieces of metal materials. Since the corroded morphology of the metal material has a great influence on the fatigue performance of the metal material, in order to ensure the accuracy of the finite element simulation, it is necessary to establish an accurate three-dimensional model of the corroded metal material.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com