An electrochemical corrosion test device that realizes multiple in-situ monitoring

A technology of corrosion test and test device, which is used in measurement devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc. The effect of reducing sound wave attenuation and simplifying the test setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

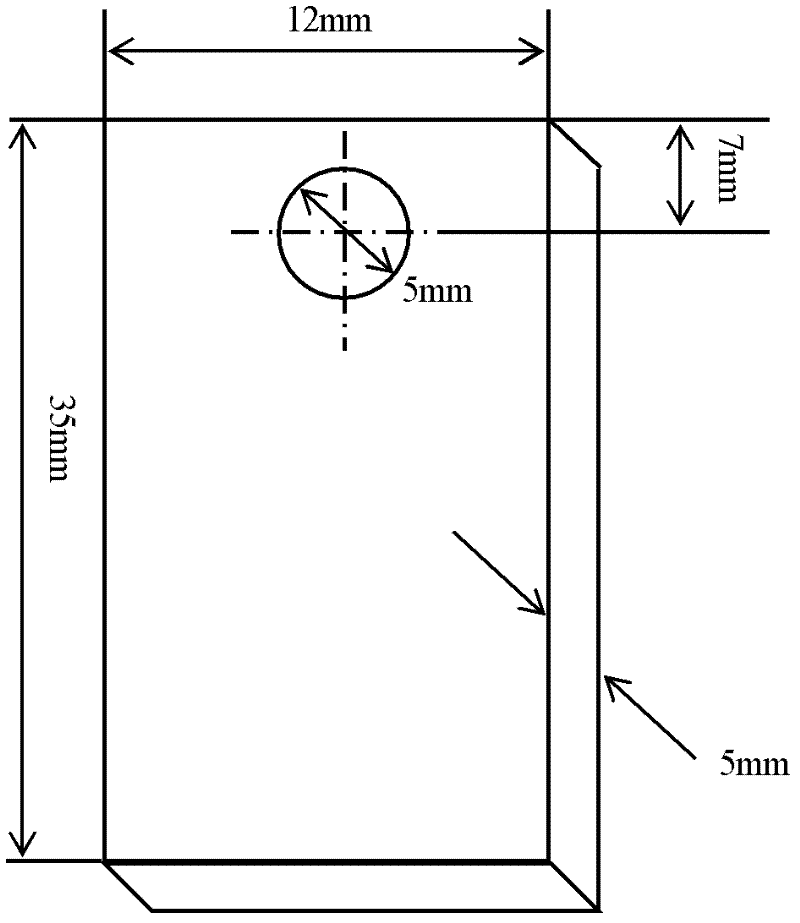

[0042] 304 stainless steel room temperature 0.05M H 2 SO 4 +0.5M Na 2 SO 4 Cathodic polarization test in solution.

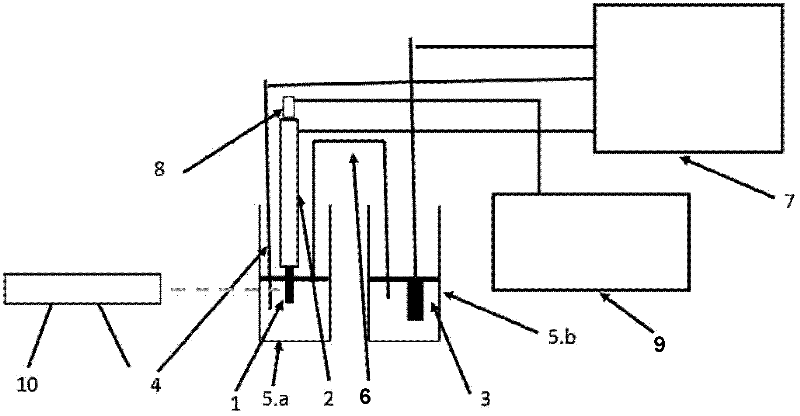

[0043] The working electrode size is as image 3 As shown, the lower end of the waveguide rod is connected to the working electrode through bolts, and the upper end of the waveguide rod is connected to the acoustic emission probe. Through three lead breaking tests on the surface of the working electrode, the signal amplitudes are 91dB, 91dB, and 92dB, which proves that the sound wave conduction is good and stable. .

[0044] Put the working electrode, counter electrode and reference electrode into two electrolytic cells respectively, and the two electrolytic cells are connected by a salt bridge.

[0045] Place the long focal length microscope on the side of the electrolytic cell, adjust the position so that the optical axis is perpendicular to the surface of the working electrode, and adjust the focal length so that the focus is on the surface of the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com