In-situ mechanical testing device used in lead-bismuth environment

A mechanical test and environmental technology, applied in the direction of applying stable tension/compression to test the strength of materials, measuring devices, and using applied repetitive force/pulsation force to test the strength of materials, etc., to save money, avoid unnecessary use, and be economical Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0033] An in-situ mechanical test device used in a lead-bismuth environment of the present invention can provide support for the measurement of mechanical property parameters of structural materials under a high-temperature lead-bismuth environment and a relatively large load, and contribute to the development of my country's nuclear industry and fill my country's Technical gaps in related fields are of great significance.

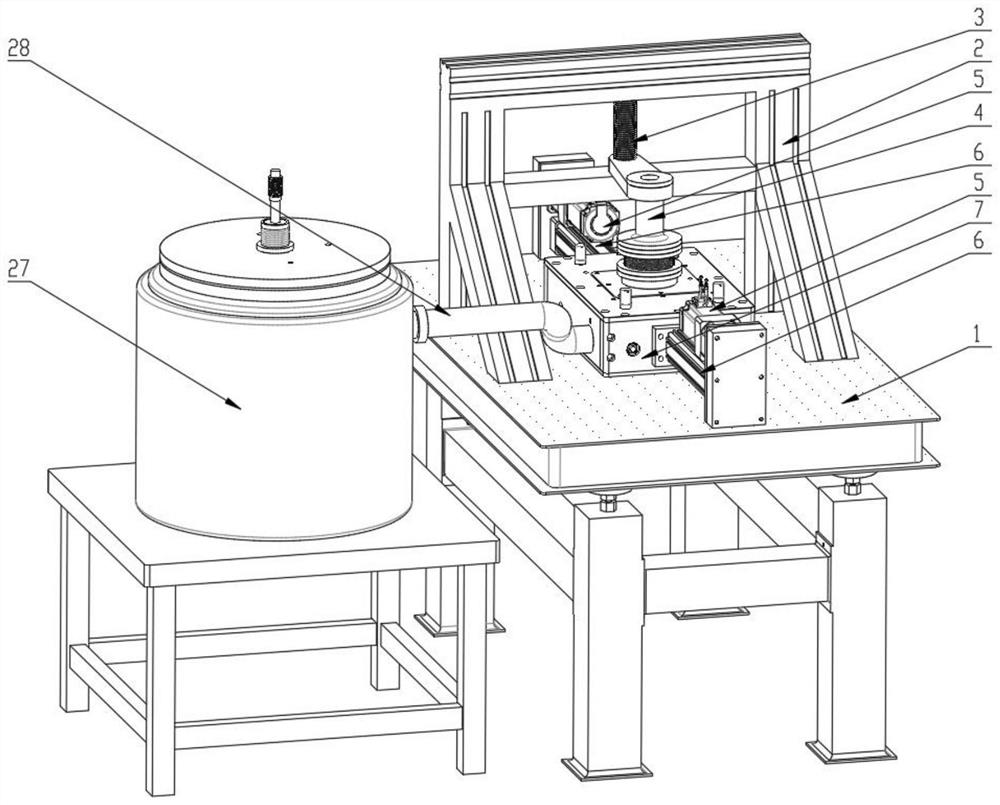

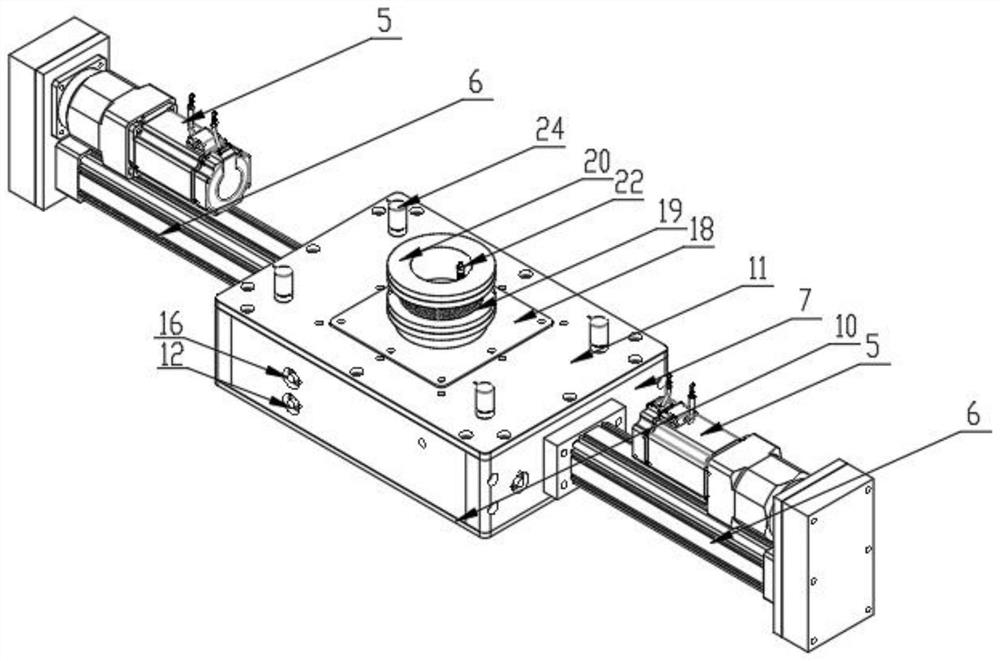

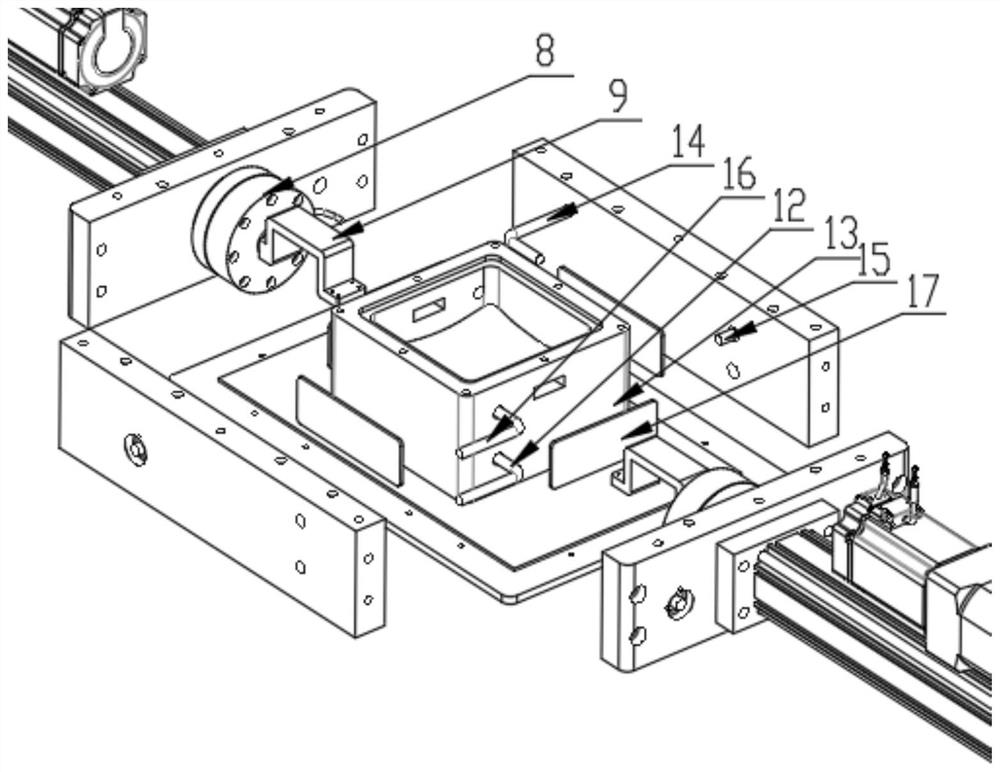

[0034] Such as figure 1 As shown, this embodiment provides an in-situ mechanical test device for use in a lead-bismuth environment, which mainly includes two parts: a testing machine and an oxygen control device.

[0035] The testing machine has a horizontal structure, and the whole is fixed on the optical table 1 by bolts. The opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com