Patents

Literature

189 results about "Corrosion behavior" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

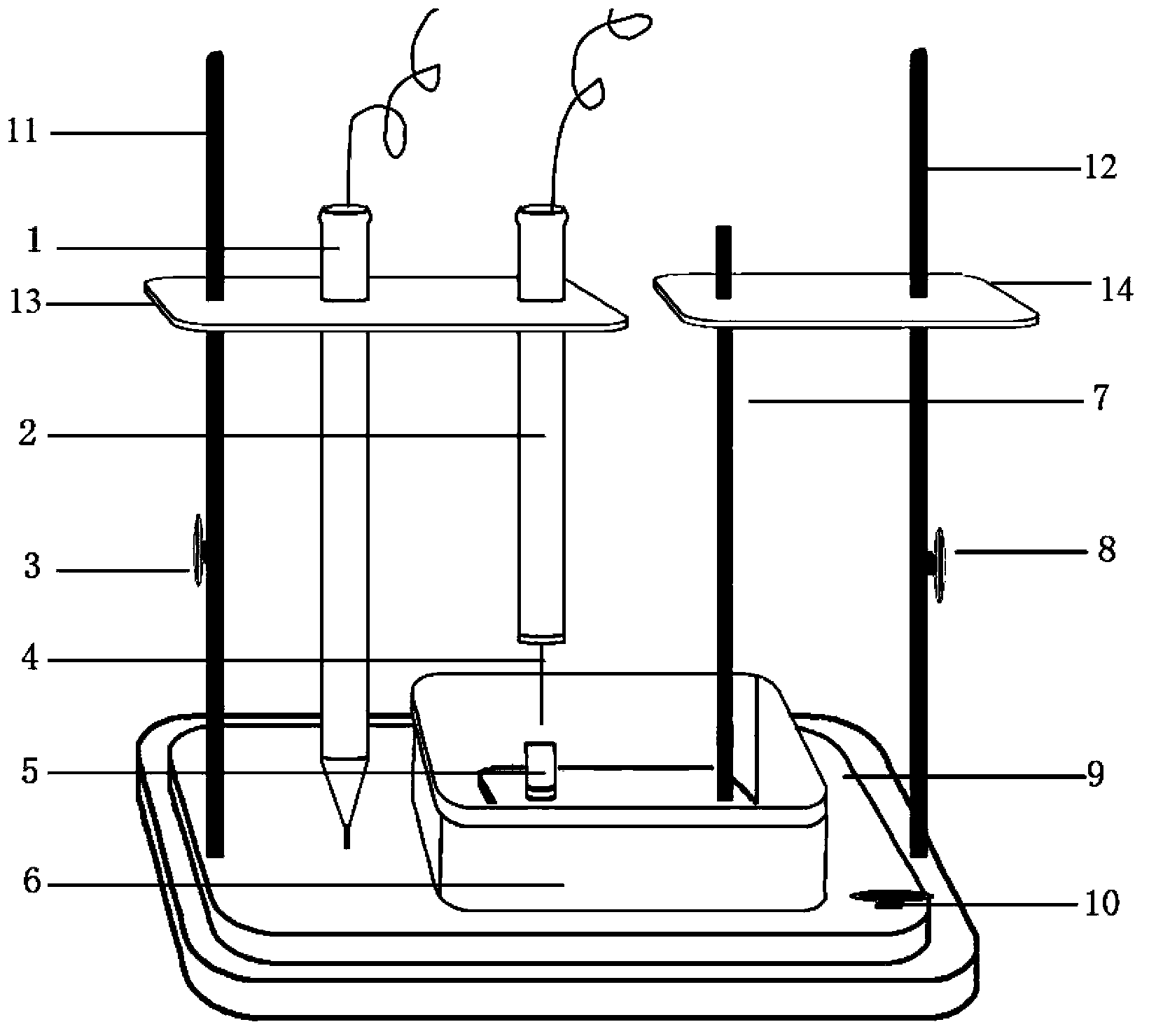

Erosion-corrosion experiment device for simulating spray splashing area

InactiveCN104849198AClarify the law of actionWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceElectricityTemperature control

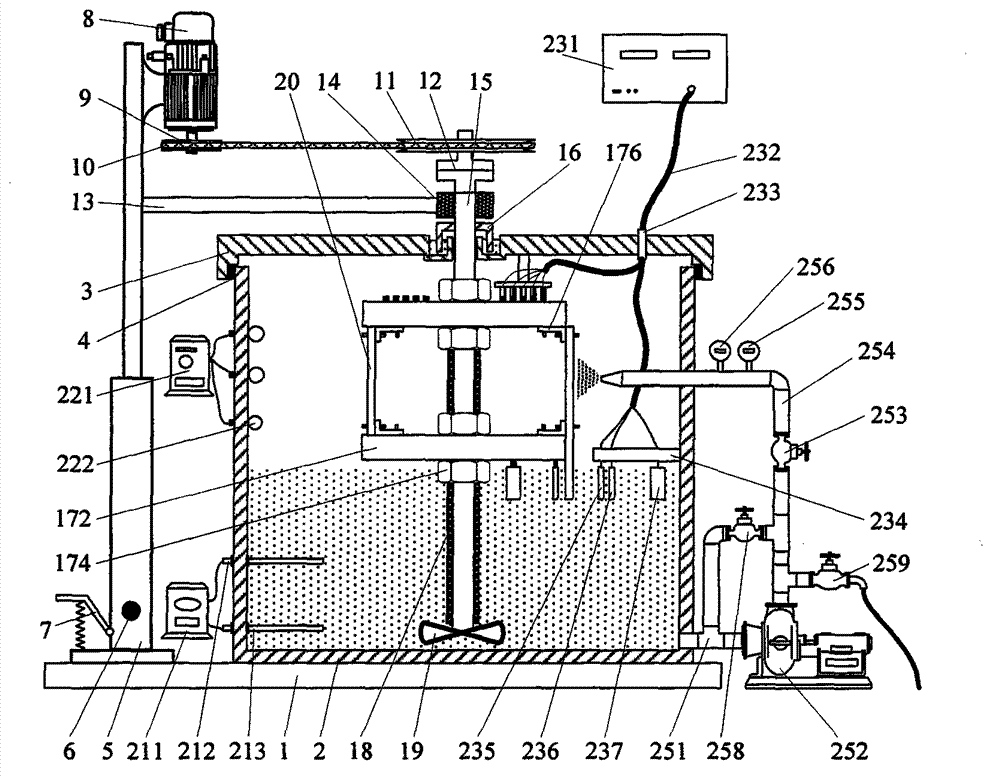

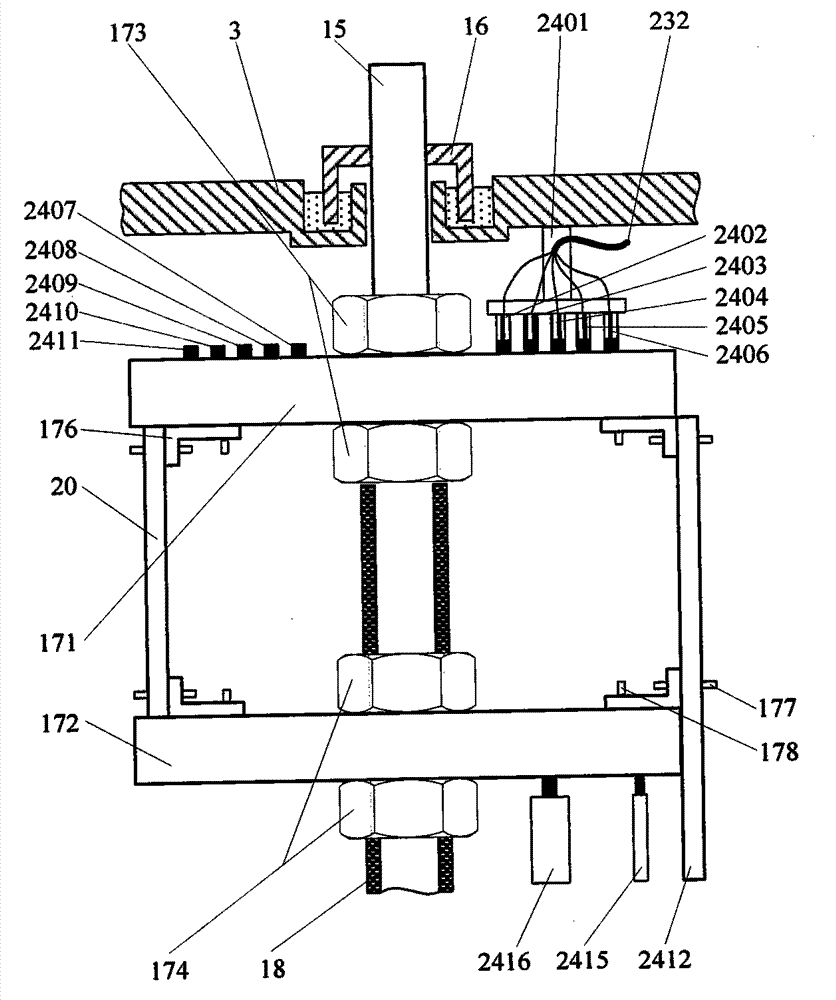

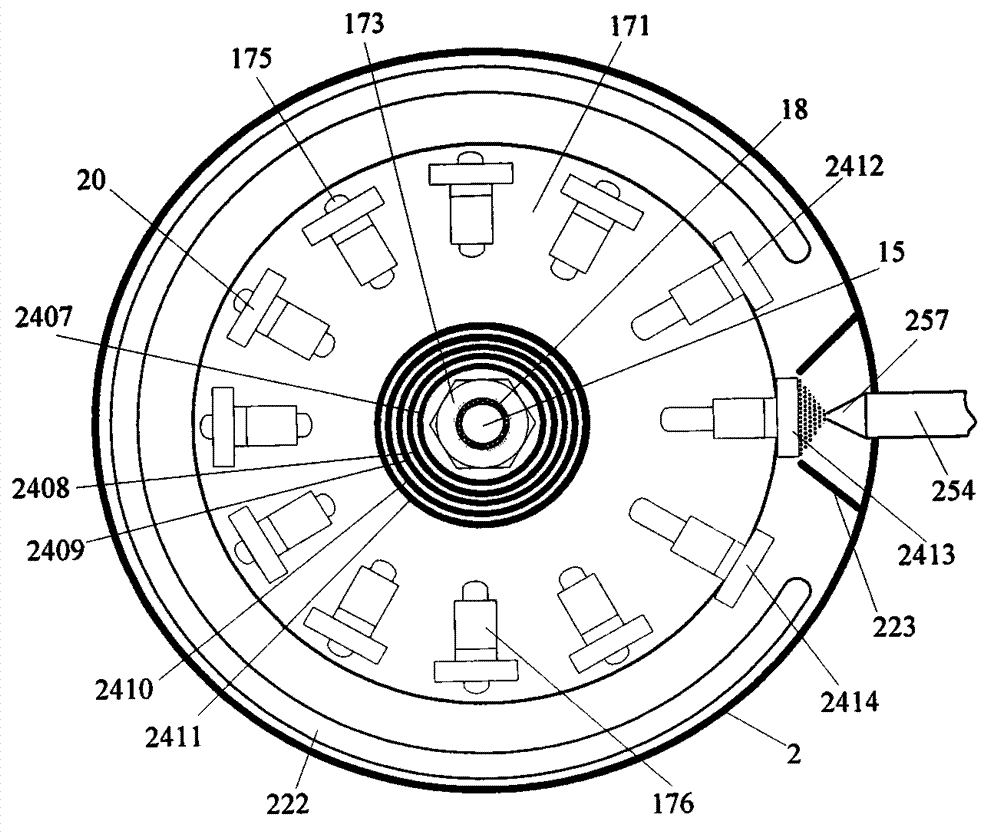

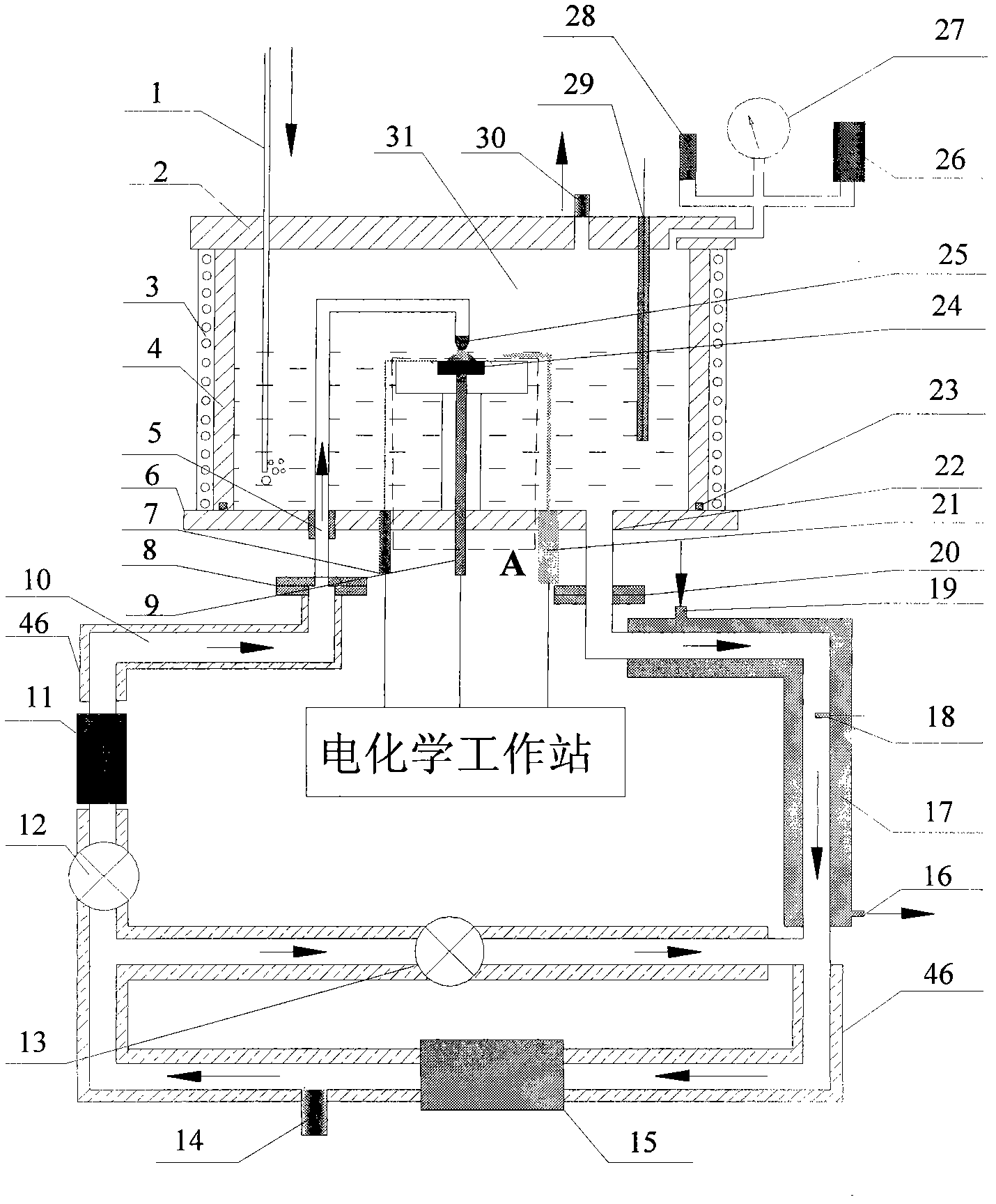

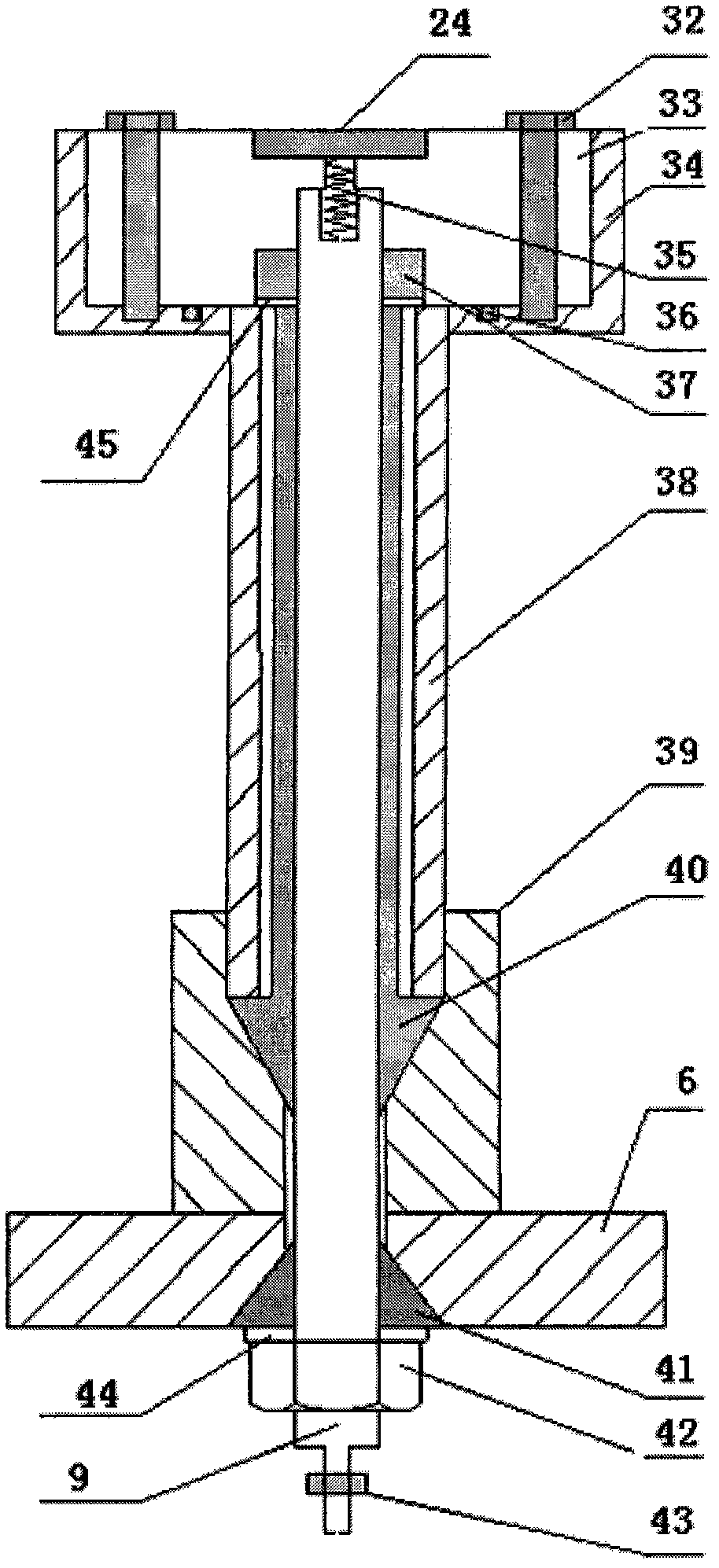

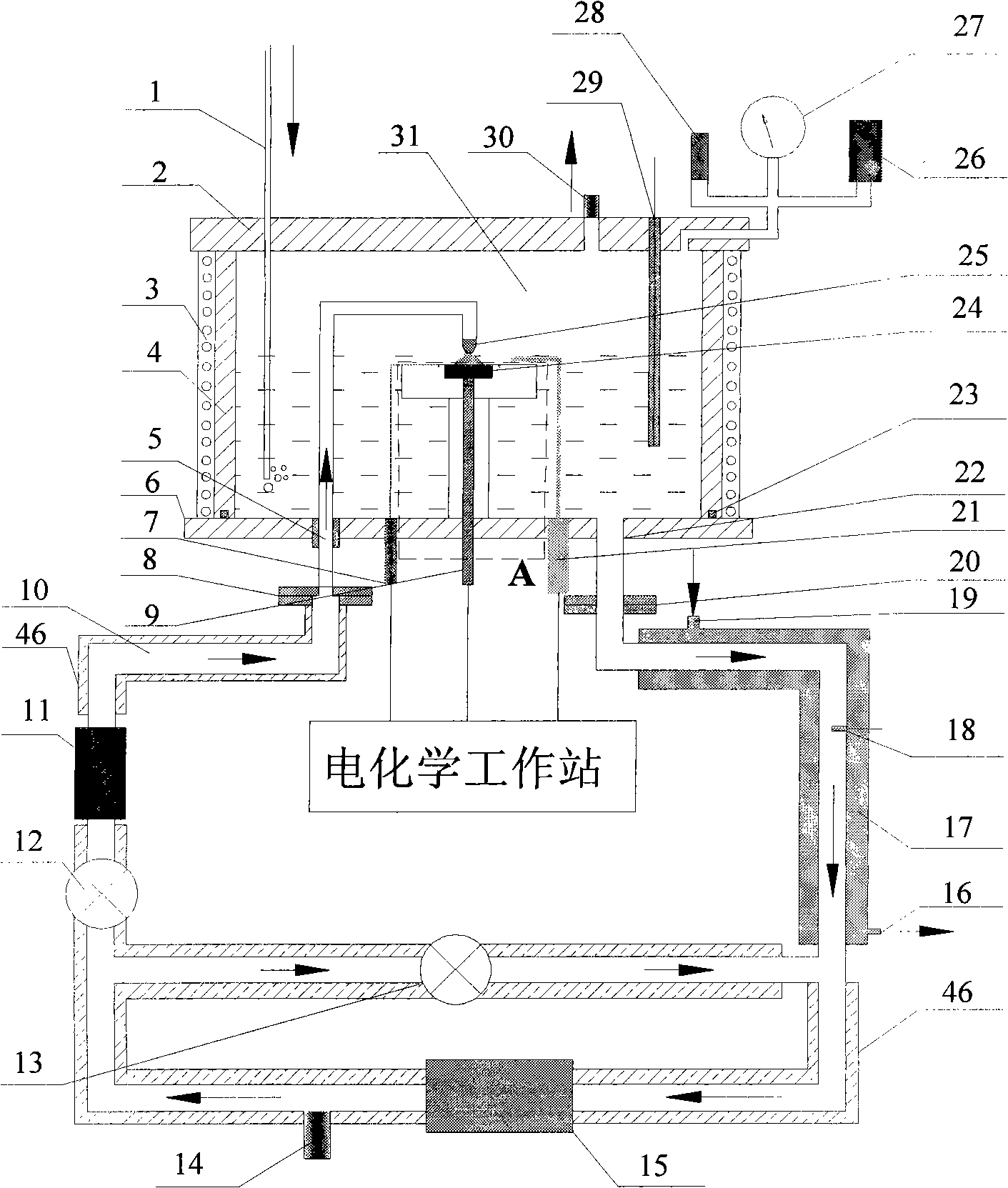

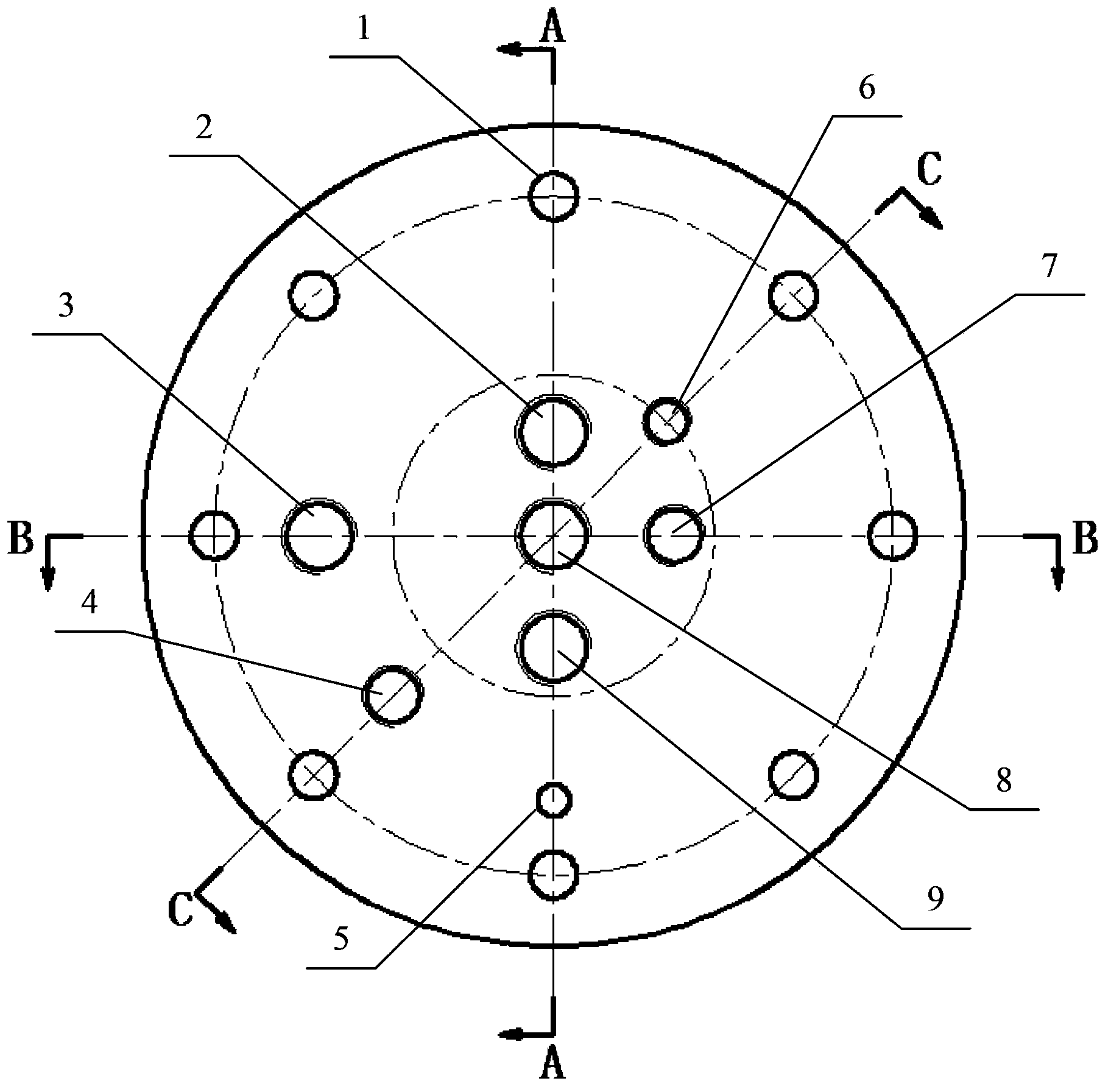

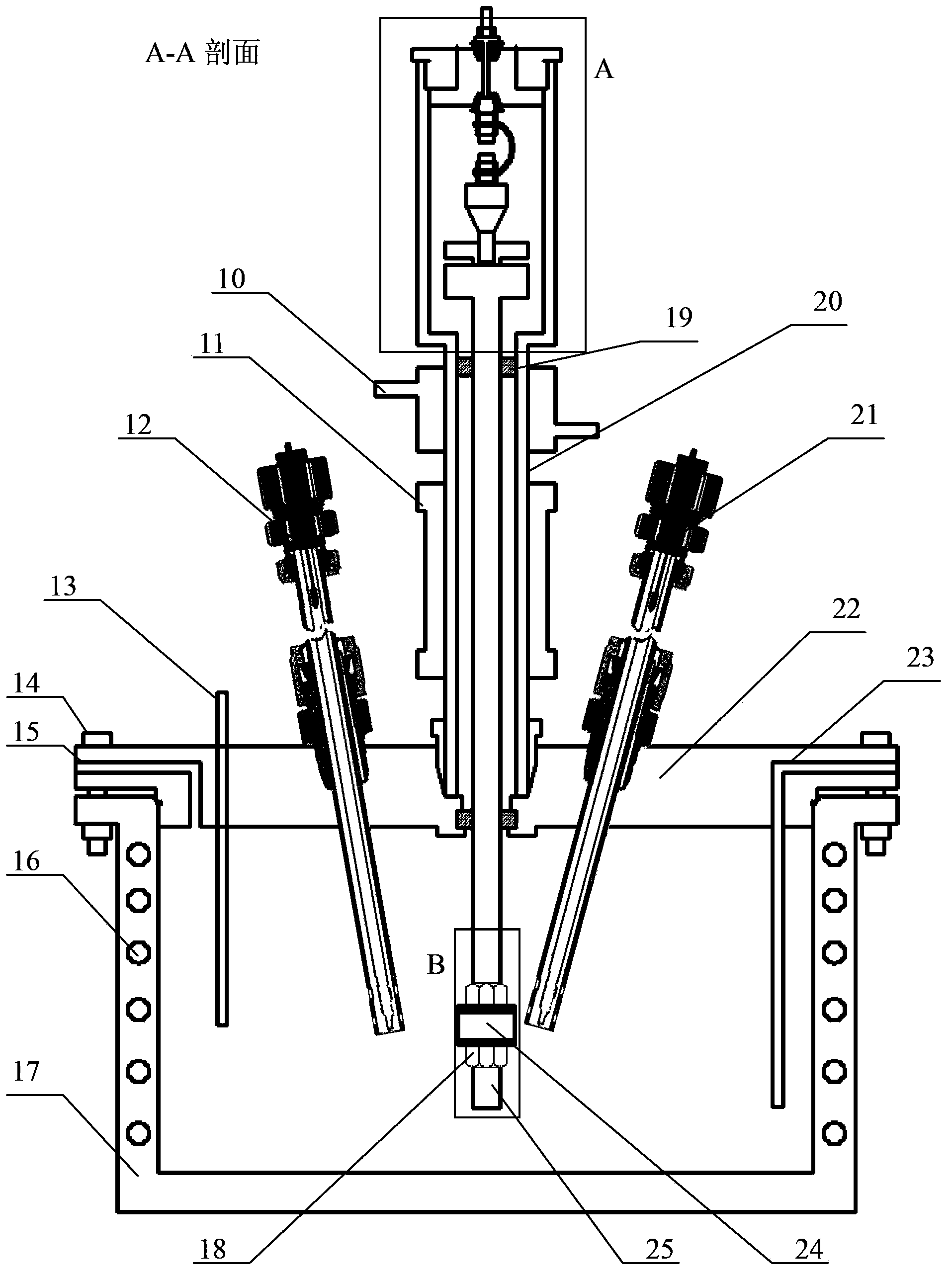

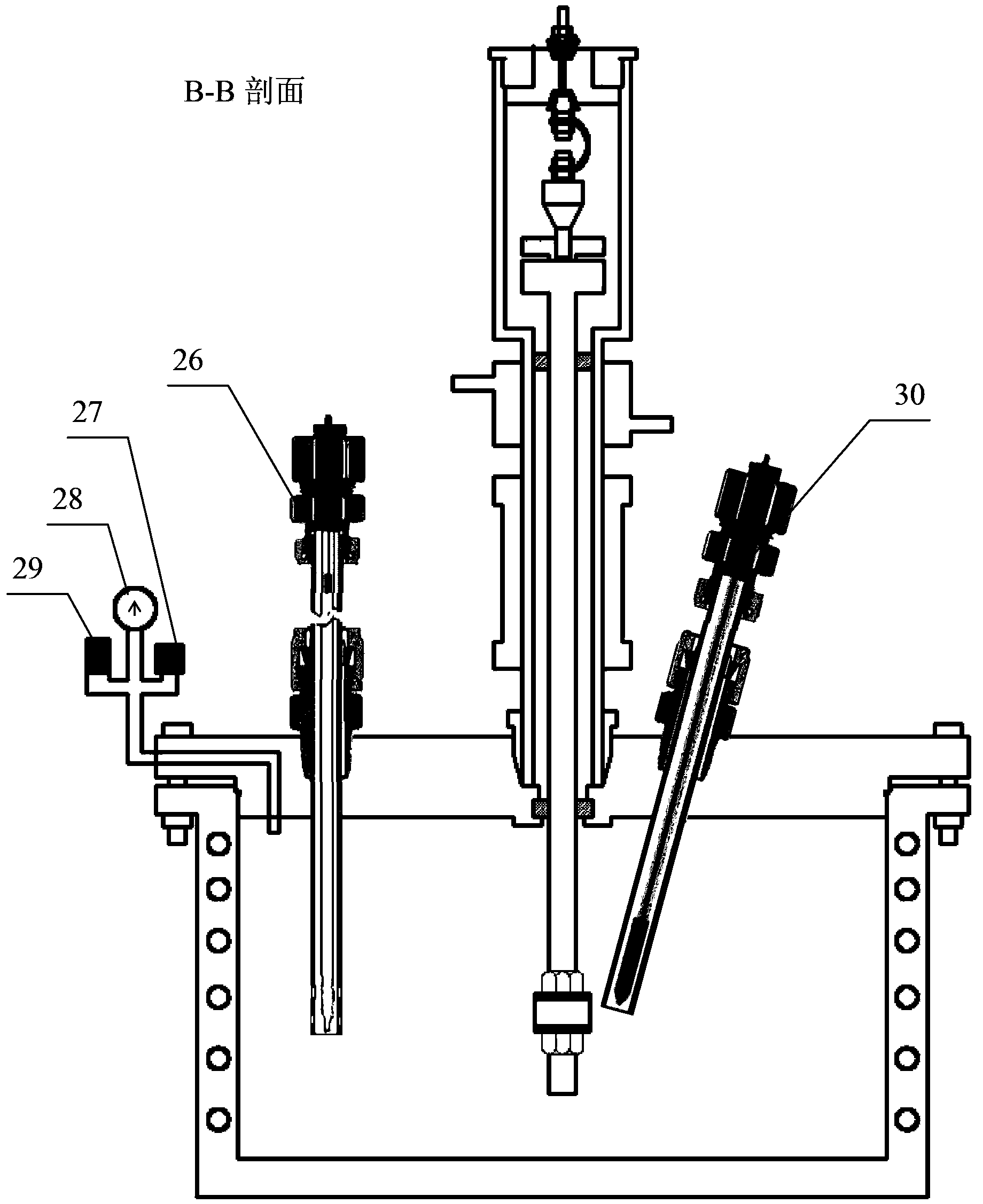

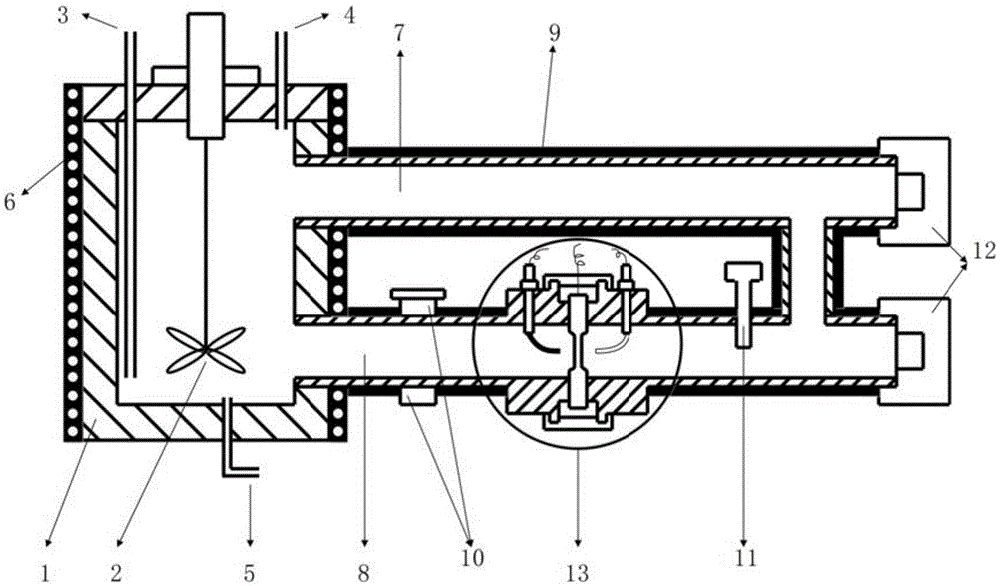

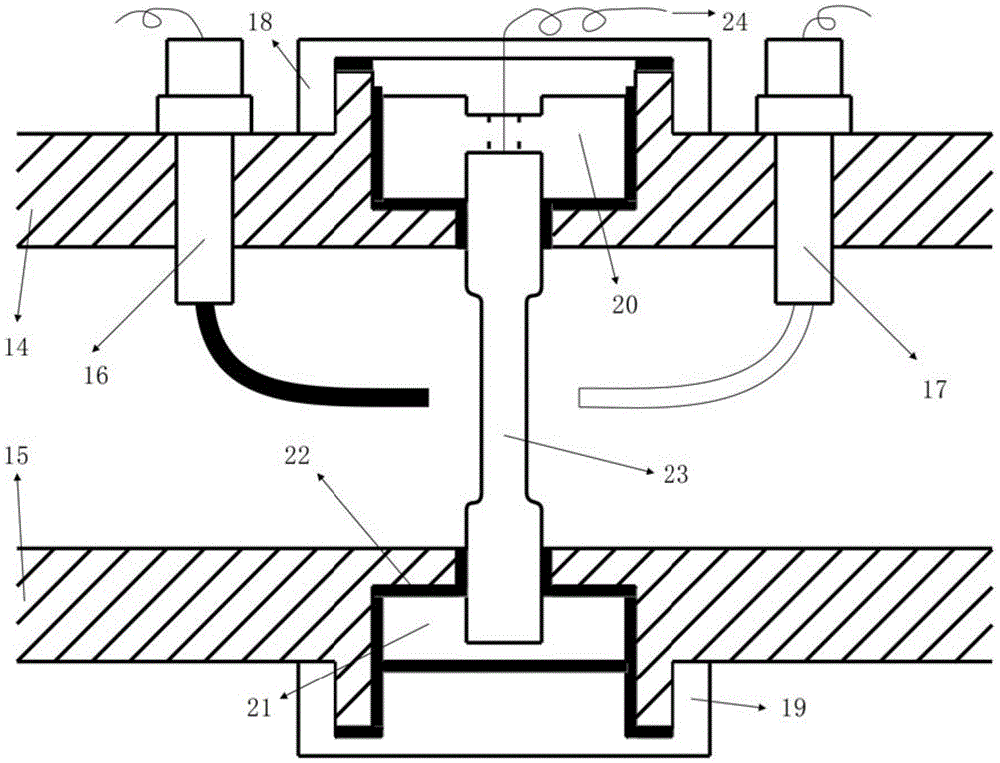

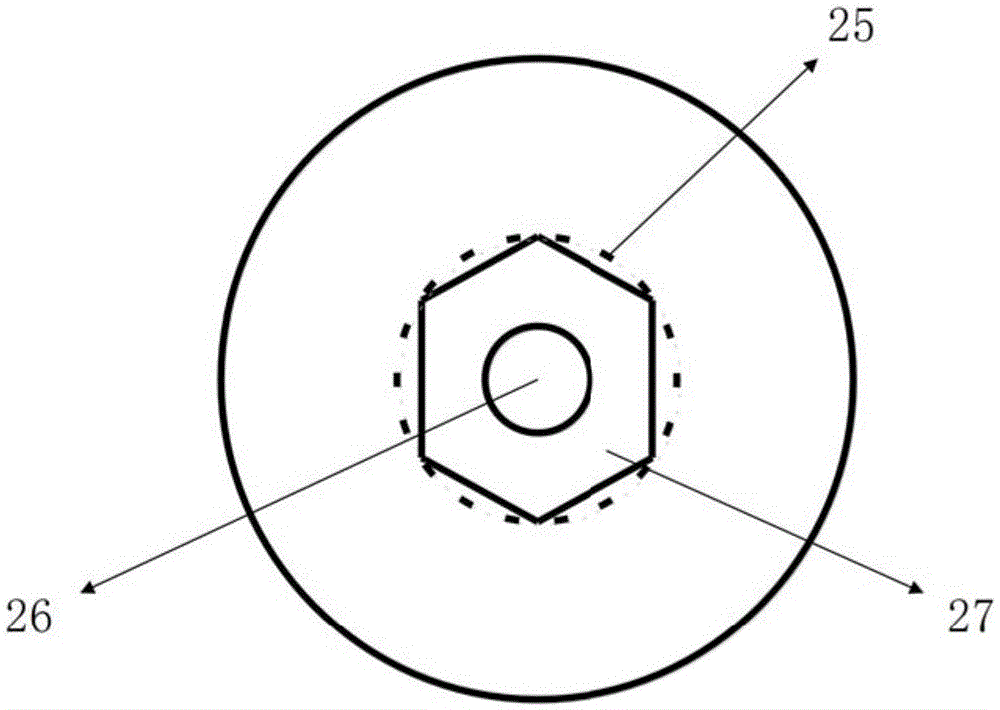

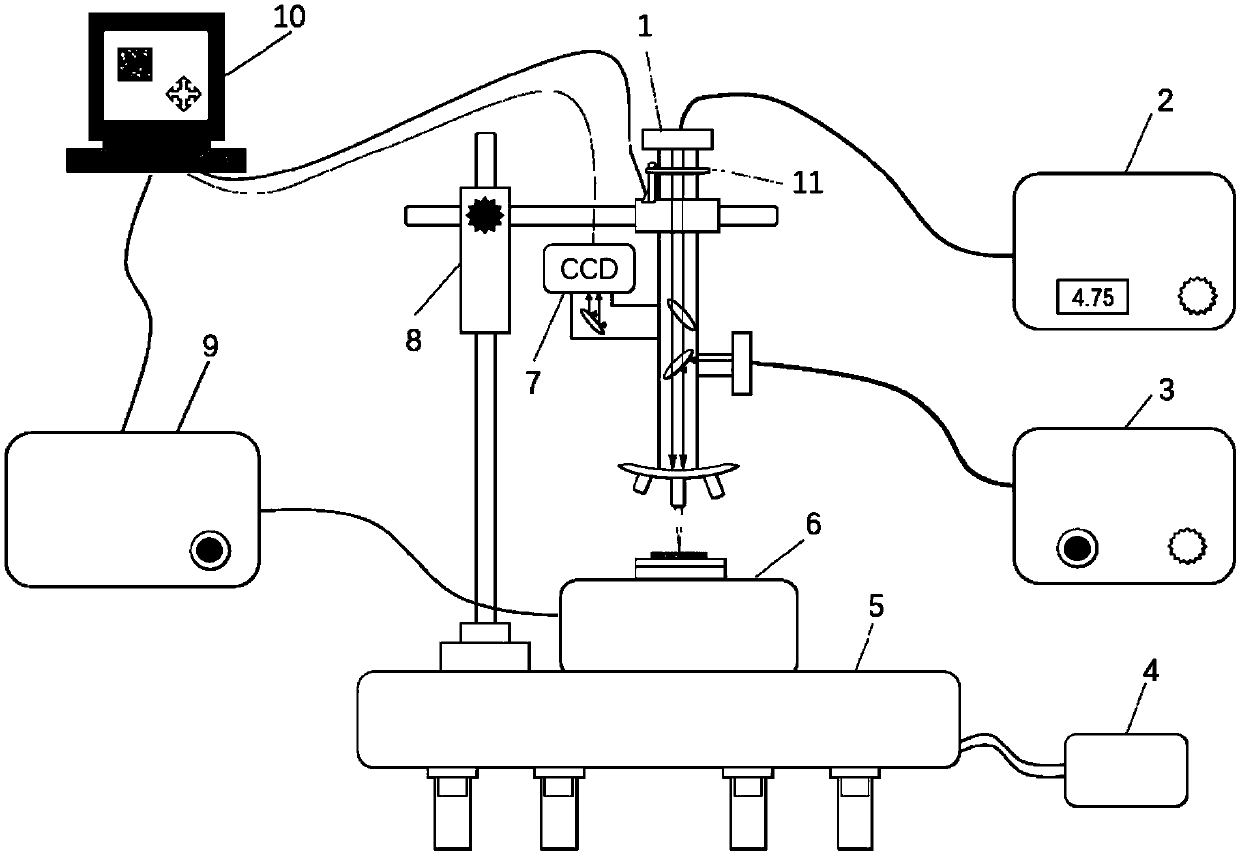

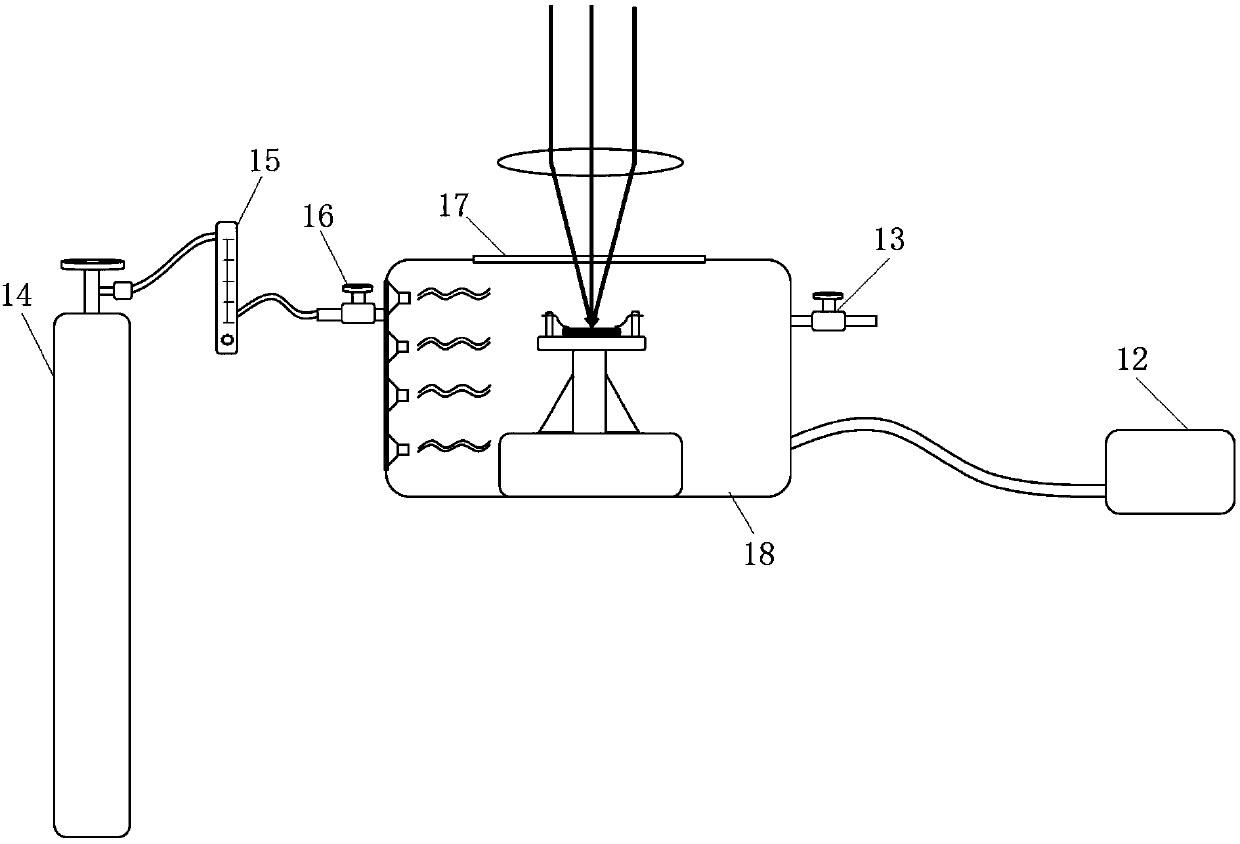

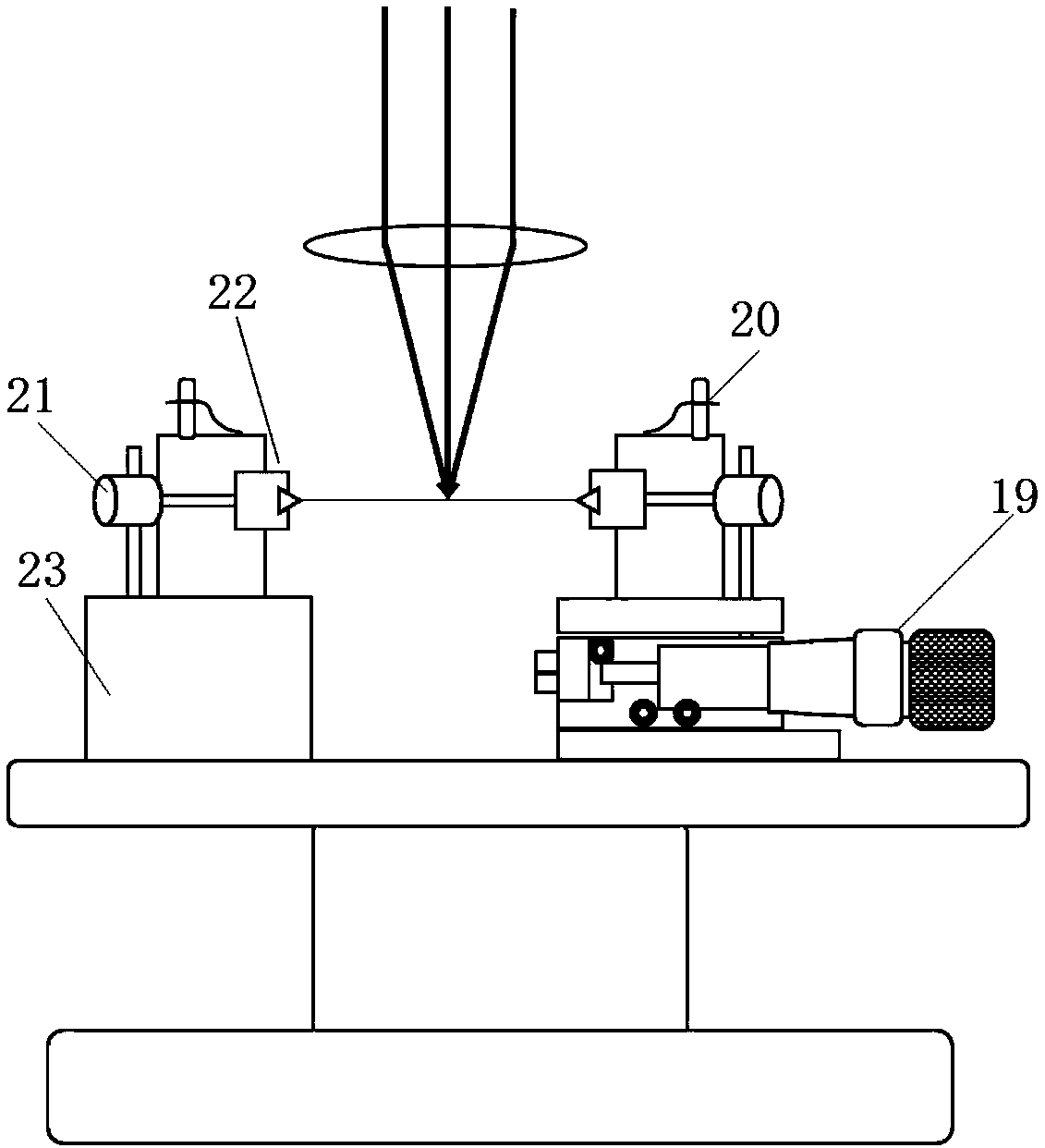

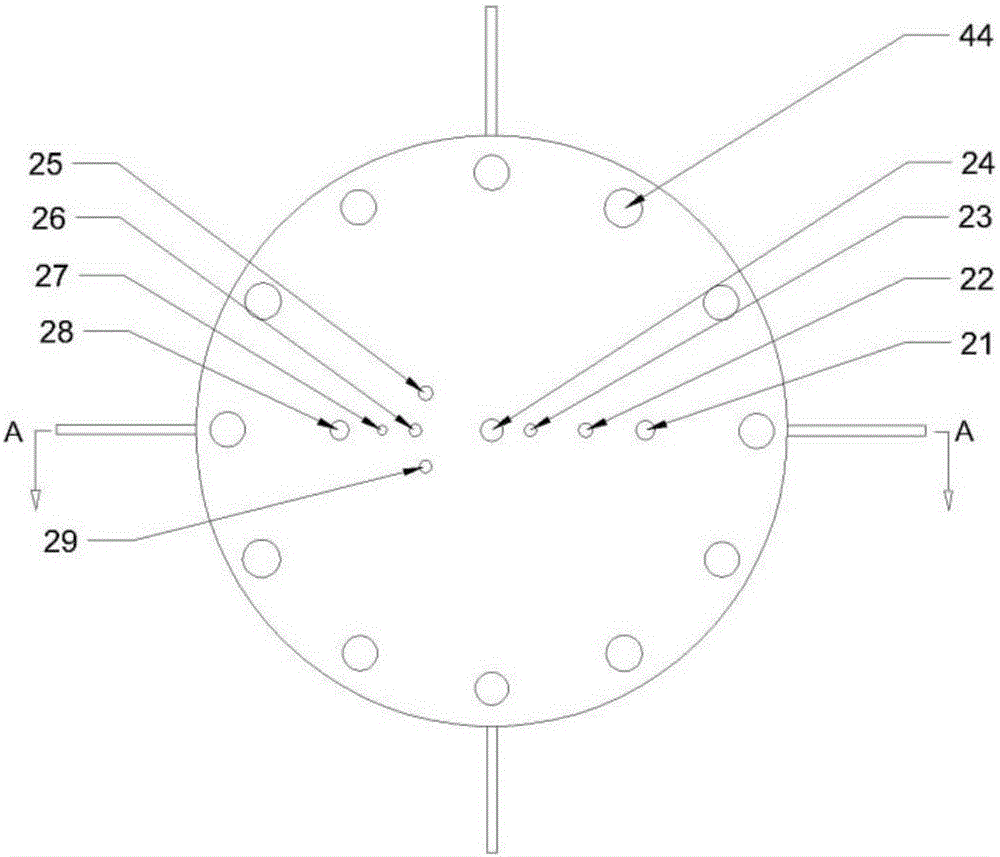

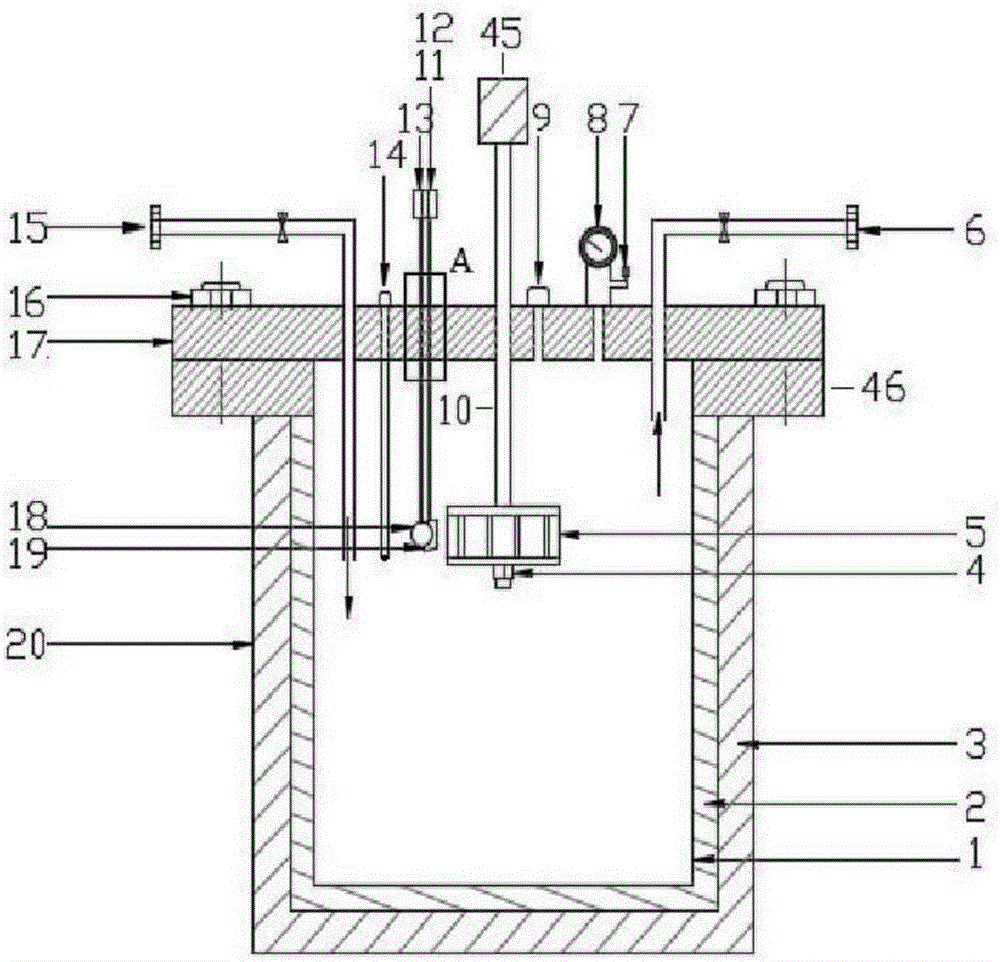

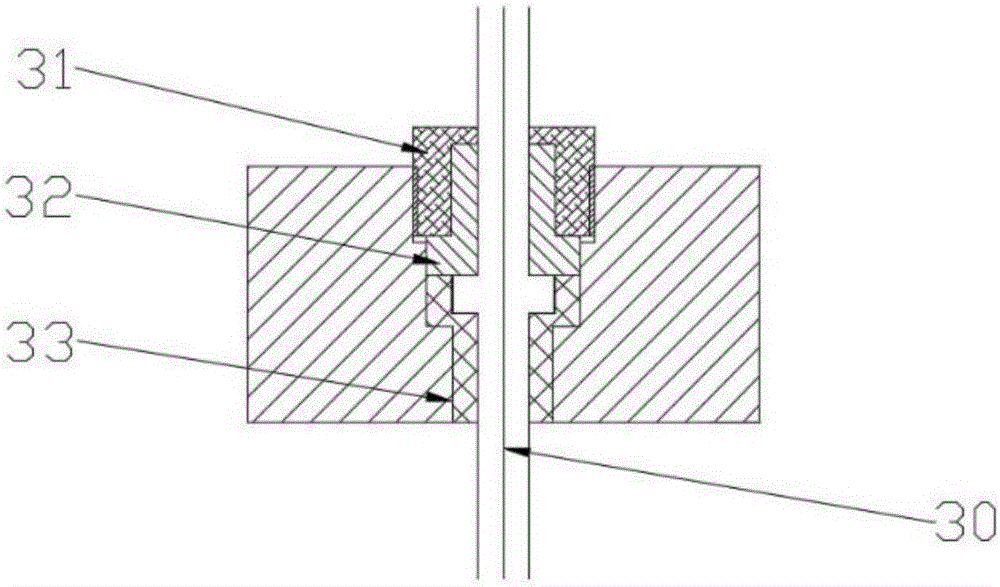

The invention discloses an erosion-corrosion experiment device for simulating a spray splashing area. The experiment device is supported by a base and comprises a lifting system, a sample clamping system, a power system, an injection system, an ultraviolet illumination aging system, an electrochemical testing system and a temperature control system, wherein a hydraulic lifting frame is fixedly arranged on the base and is controlled to ascend or descend by a pedal or a pressure relief knob; the sample clamping system and the power system are mounted on the hydraulic lifting frame; a medium groove is formed in one side of the hydraulic lifting frame; the sample clamping system is arranged inside the medium groove; the upper part of the medium groove is sleeved by a sealing cover, and the sealing cover and the medium groove are sealed through a rubber sealing ring. According to the erosion-corrosion experiment device, the influence on a material erosion-corrosion behavior caused by factors such as wave impact strength, impact period, sand content, oxygen content, temperature and illumination can be researched, the failure process of an ocean spray splashing area structure is accurately simulated, and the defects of a conventional material erosion-corrosion research device for simulating a splashing area are overcome.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

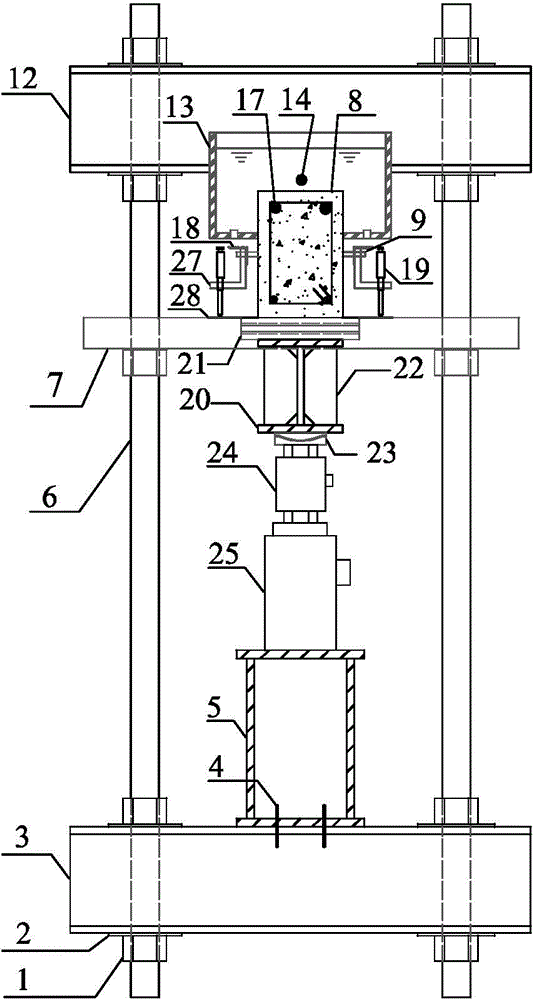

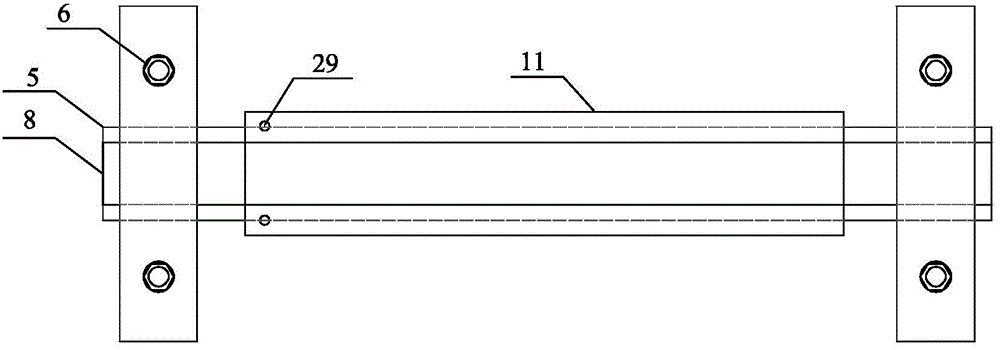

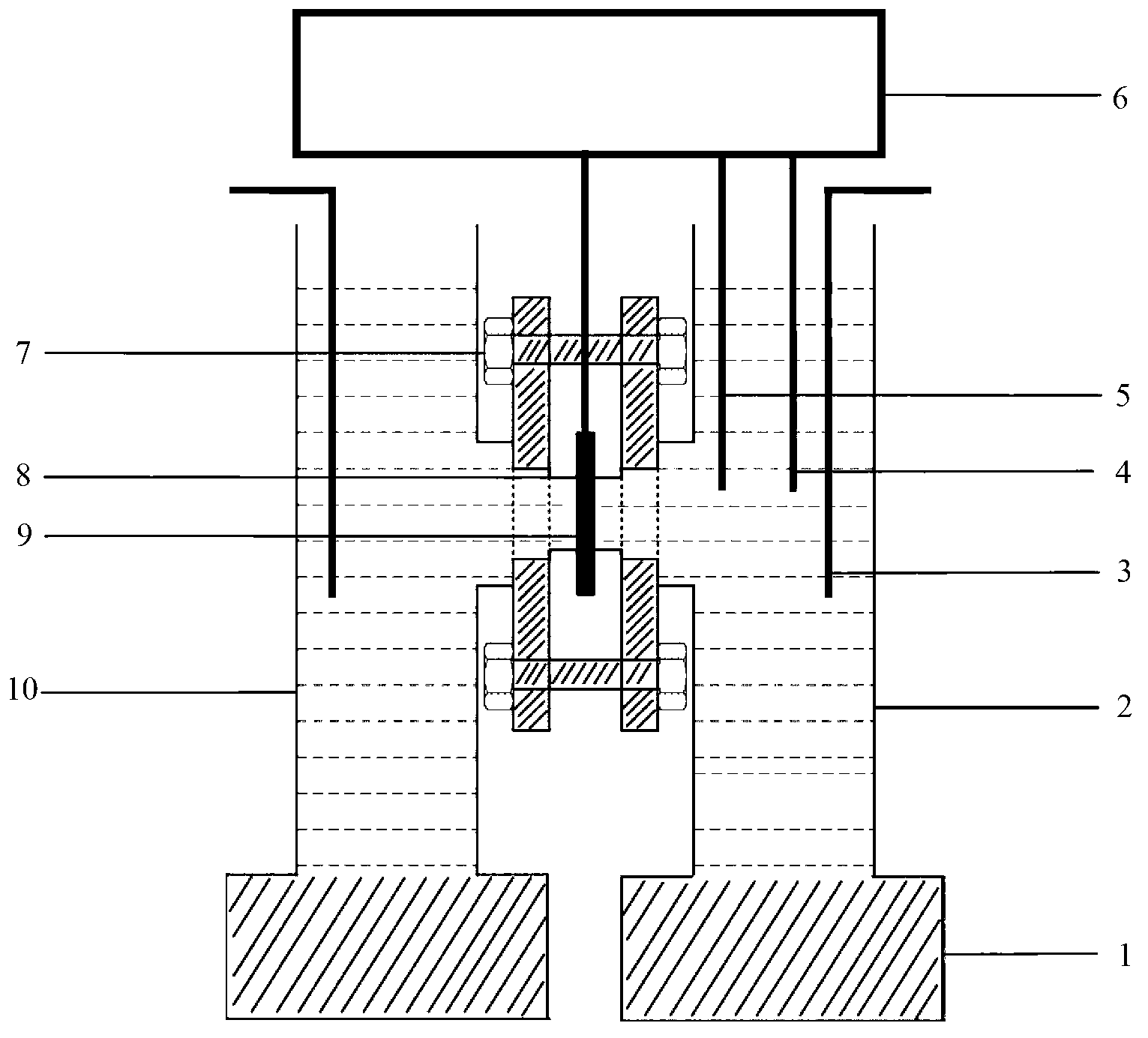

Device and method for testing chloride corrosion of reinforced concrete member under continuous load

ActiveCN104132847ATroubleshoot test setup issuesSolve the real problemMaterial strength using tensile/compressive forcesMicrocontrollerData acquisition

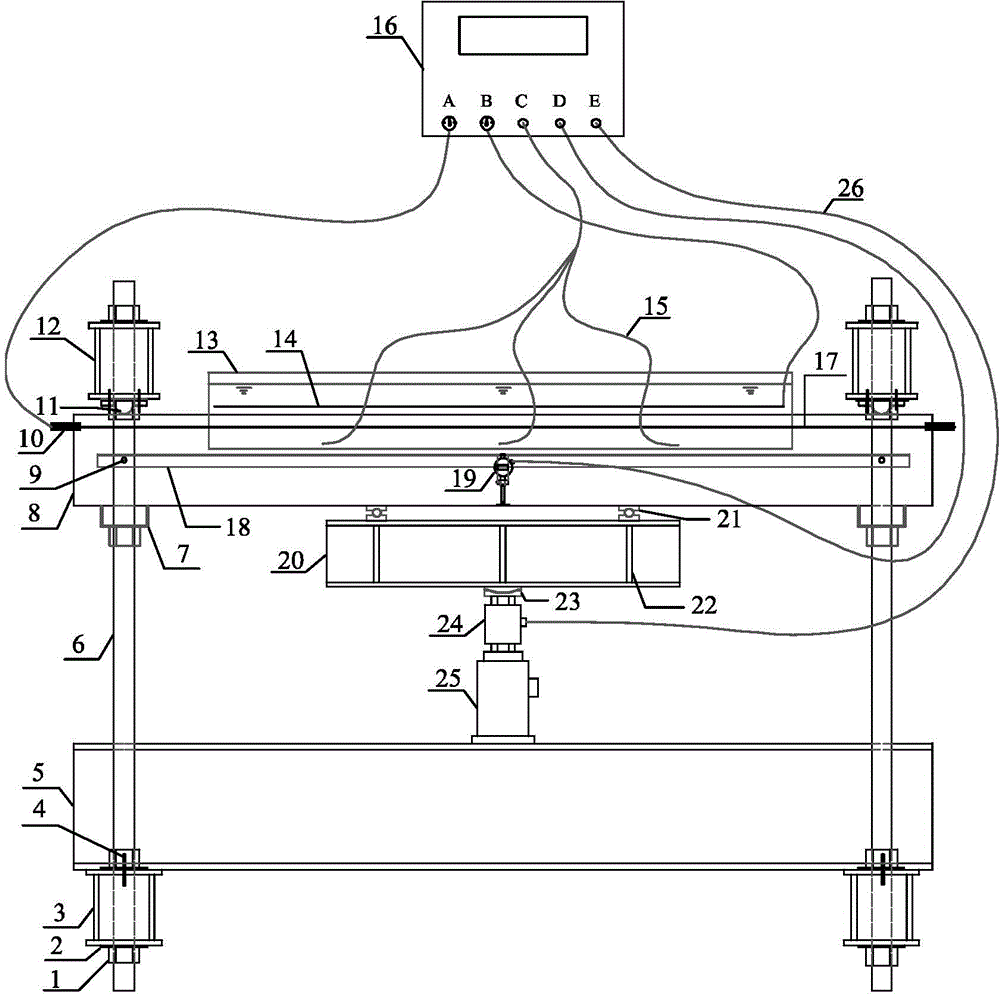

The invention provides a device and method for testing chloride corrosion of a reinforced concrete member under a continuous load. The device comprises a continuous load loading device, a rapid chloride corrosion device and a measurement and control device. A continuous load is applied by a loading frame and a drive device, a frame body is filled with a chloride solution and is fixed at the upper-middle part of a test beam in a sealing manner, air is continuously injected in the chloride solution by adopting an air pump, and direct current is introduced into reinforced steel bars of the test beam to implement the rapid corrosion. Relevant data acquirers, electrochemical testers and output equipment which are controlled through a single chip microcomputer in a unified manner are integrated in the main control box, the continuous load is measured in real time, and periodically corrected to a target level, corrosion behaviors of a corroded member are periodically tested, and data are acquired, displayed, stored, printed and output in real time. The device is capable of effectively simulating an actual corrosion working condition of the on-active service reinforced concrete structure member under the coupling effect of a chloride environment and the load, and provides a scientific basis for evaluating the durability of engineering structures under chloride environments such as sea and salt lakes.

Owner:HOHAI UNIV

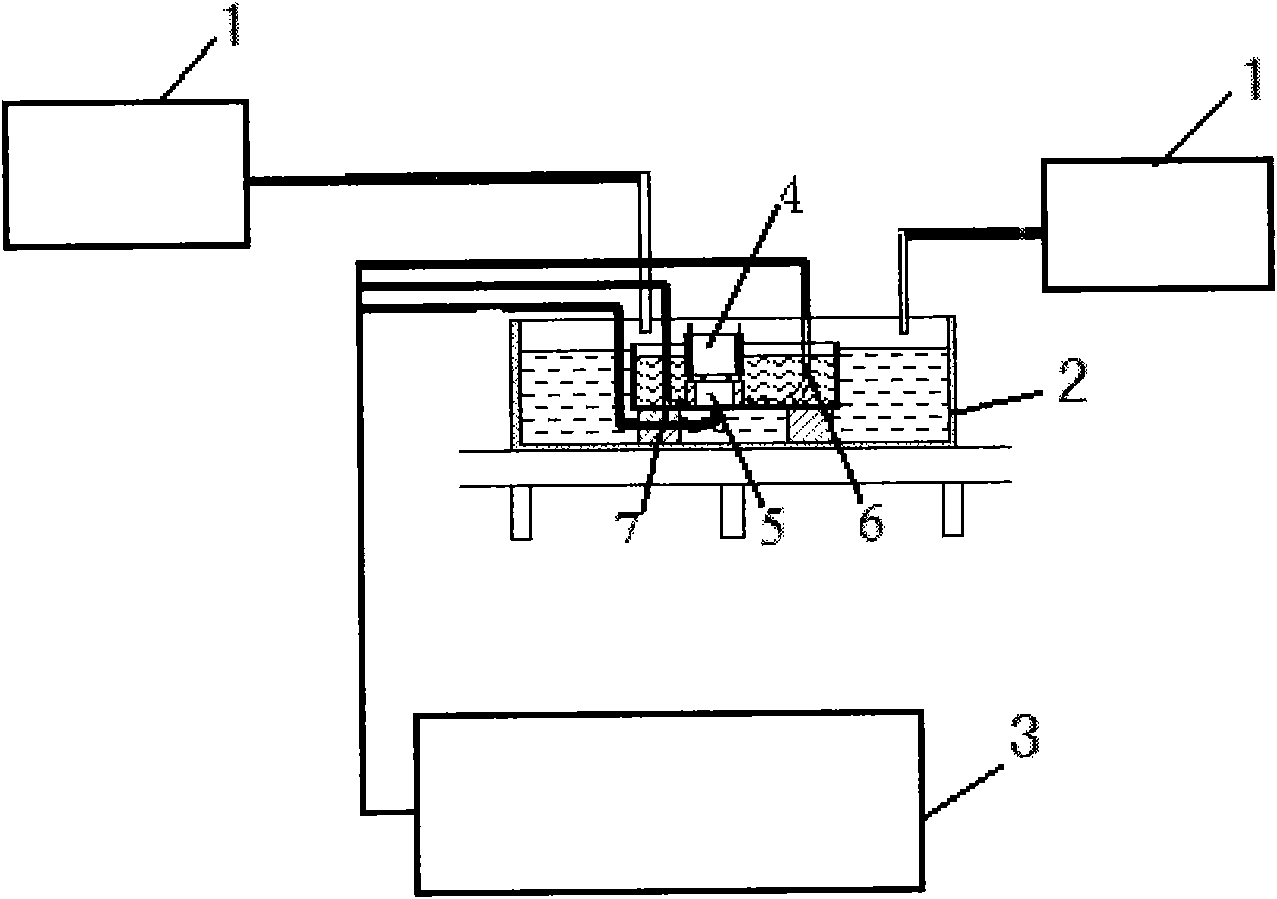

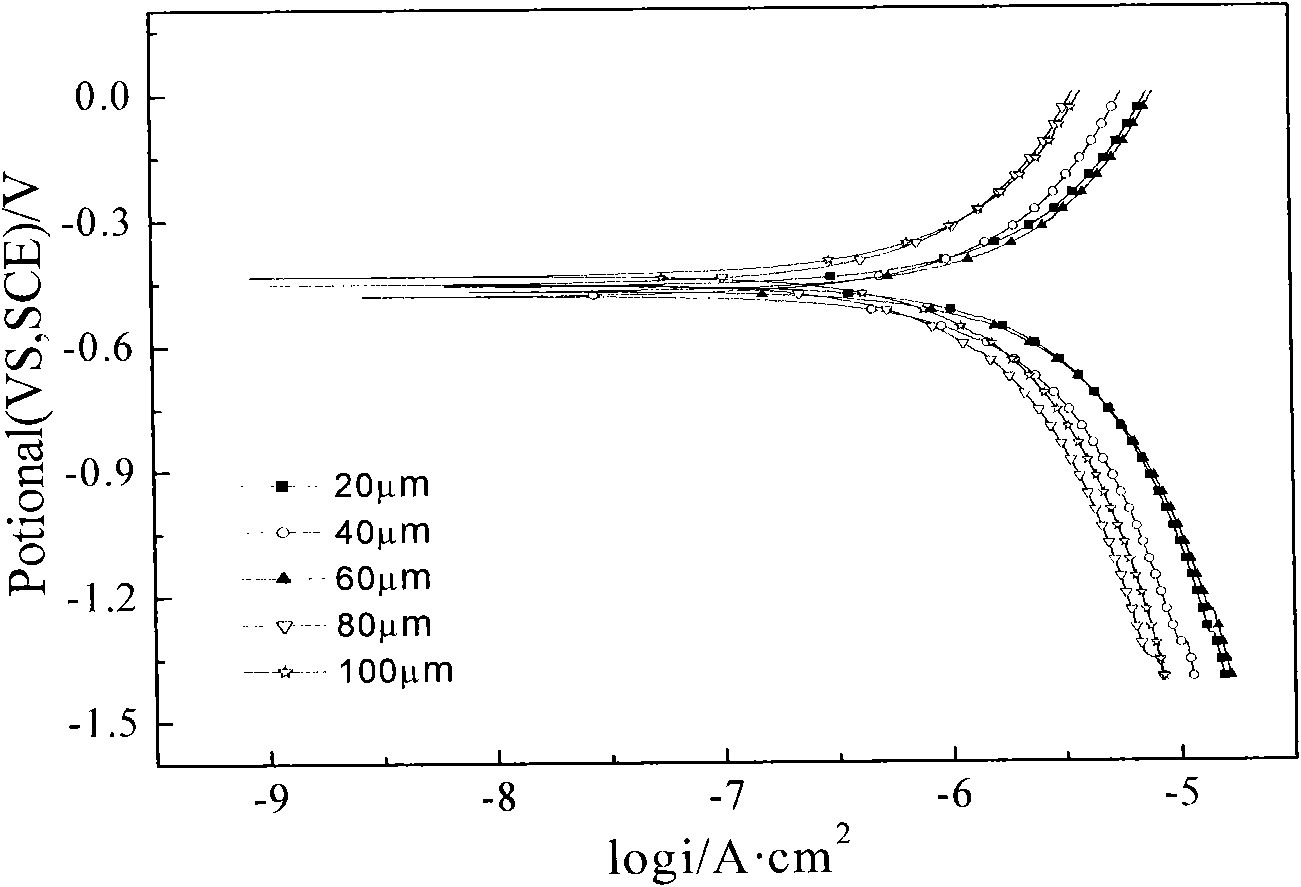

Method for testing corrosion behavior under thin liquid film in gas environment

InactiveCN101788454AControl thicknessSolve difficult to set preciselyWeather/light/corrosion resistanceEpoxyCopper wire

The invention relates to a method for testing the corrosion behavior under a thin liquid film in a gas environment, which is characterized in that the method comprises the following steps that: (1) one end of a cylindrical metal sample is encapsulated with epoxy resin after being welded with a copper wire; (2) all the wires which are connected with an electrode penetrate through a corrosion test case to form small holes which are sealed by glass glue; (3) the thickness between waterproof breathable films on the bottom part of a device is controlled by setting and adjusting the thickness of the metal sample and the thin liquid film; (4) a corrosive gas is generated by using a corrosive gas generation system and is fed into a solution; (5) the corrosive gas must be always fed during the experiment process to ensure the concentration of the corrosive gas; and (6) electrochemical parameters of the metallic corrosion under the thickness of thin liquid film are obtained. The invention has the advantages that the difficulty that the thickness of the liquid film is difficult to accurately set and control is solved, the control accuracy of the think liquid film can reach plus or minus 0.5 Mum, and the method has good stability when being tested.

Owner:NANCHANG HANGKONG UNIVERSITY

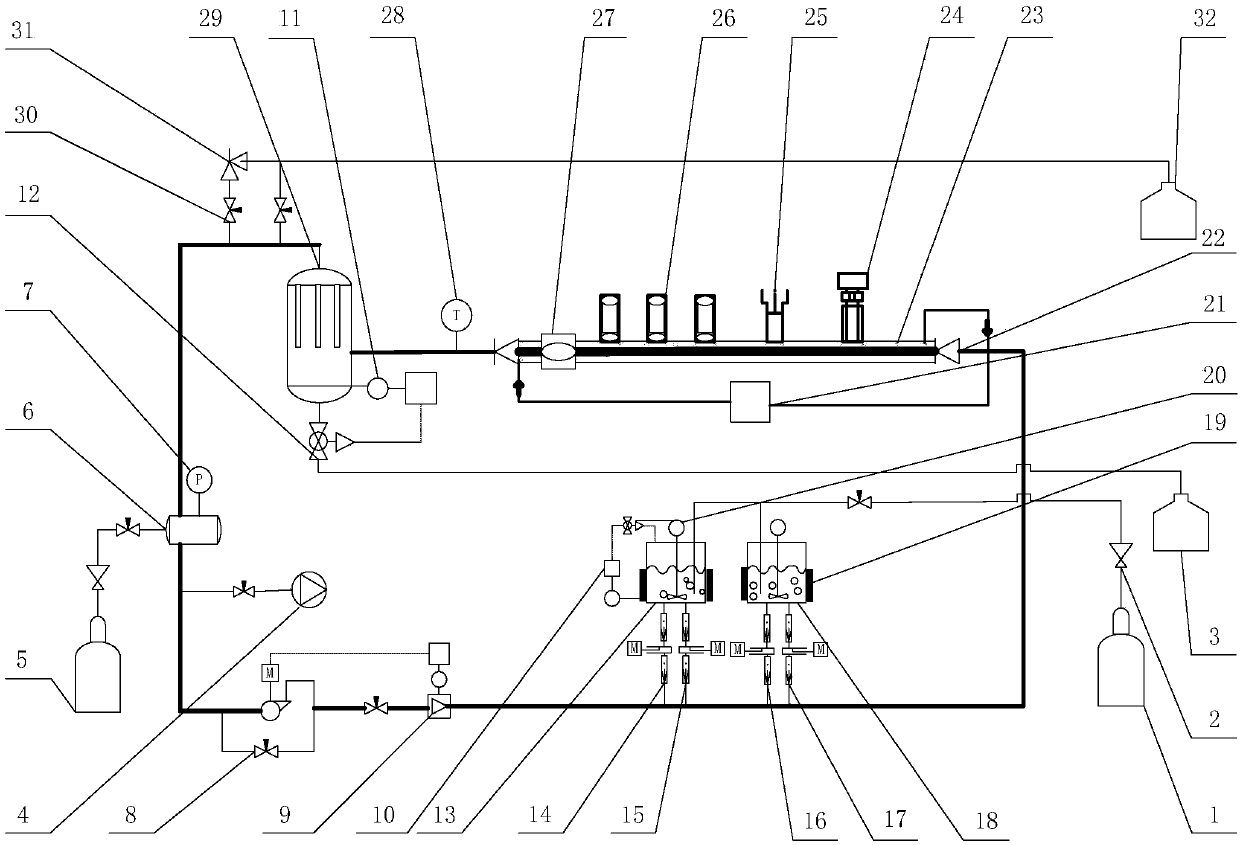

Gas and liquid two-phase flow loop corrosion experiment device

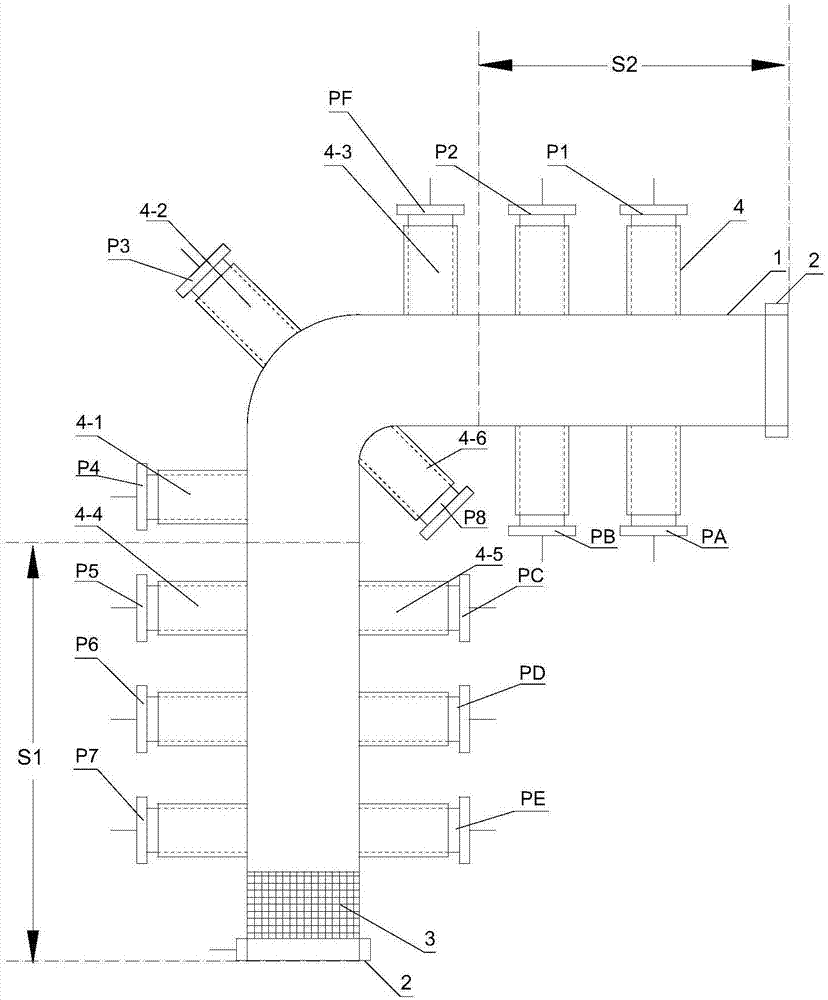

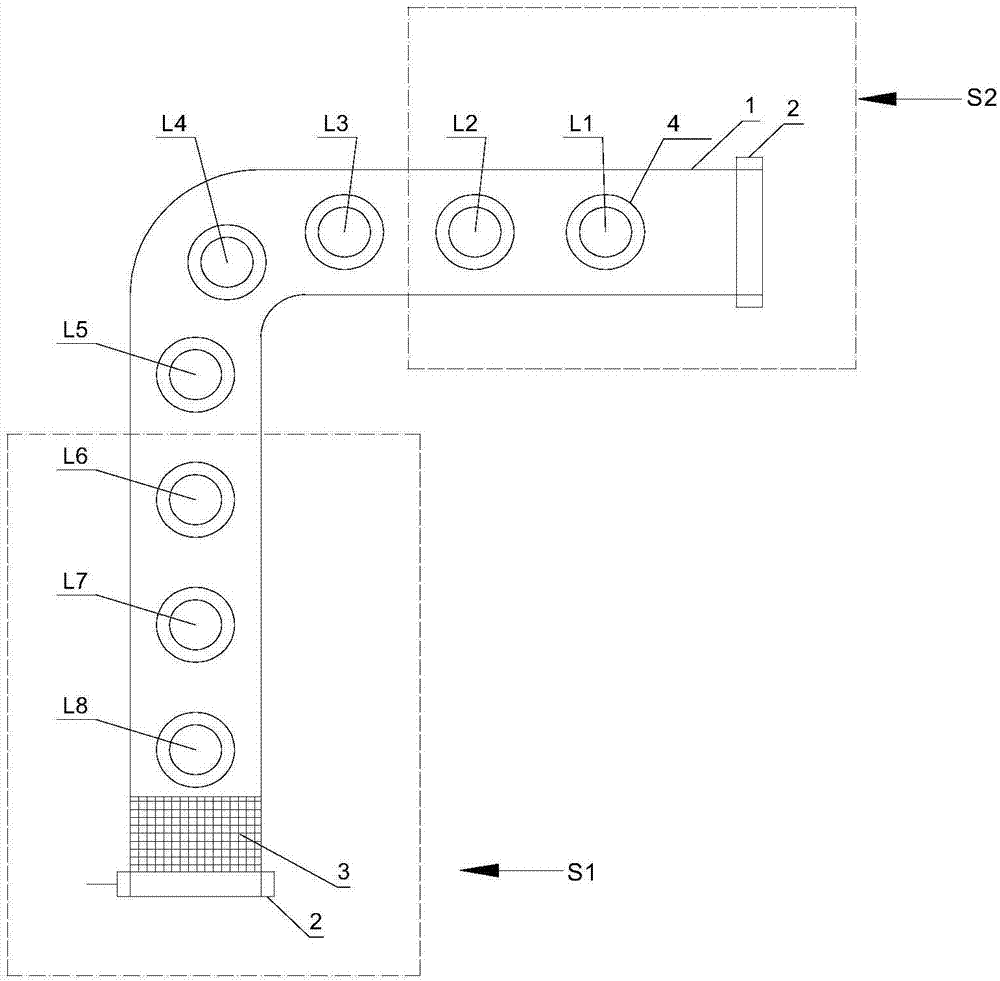

The invention relates to the field of oil and gas field corrosion research, in particular to a gas and liquid two-phase flow loop corrosion experiment device, which is applicable to coupon corrosion experiment and in-situ corrosion electrochemical test of gas and liquid two-phase flow of an oil and gas field production system on an oil pipe under the simulated working condition. An experiment testing module is arranged in a horizontal pipeline, and oil and gas field high-temperature and high-pressure fluid simulated by an experiment device is subjected to loop corrosion experiment by using an electrochemical workstation and a three-electrode electrochemical corrosion measuring device, so that flow accelerated corrosion weight loss and appearance features are obtained; an 'in-situ' electrochemical signal of a working electrode in simulated high-temperature and high-pressure fluid is monitored, so that the corrosion behavior and mechanism of the gas and liquid two-phase flow loop are mastered.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

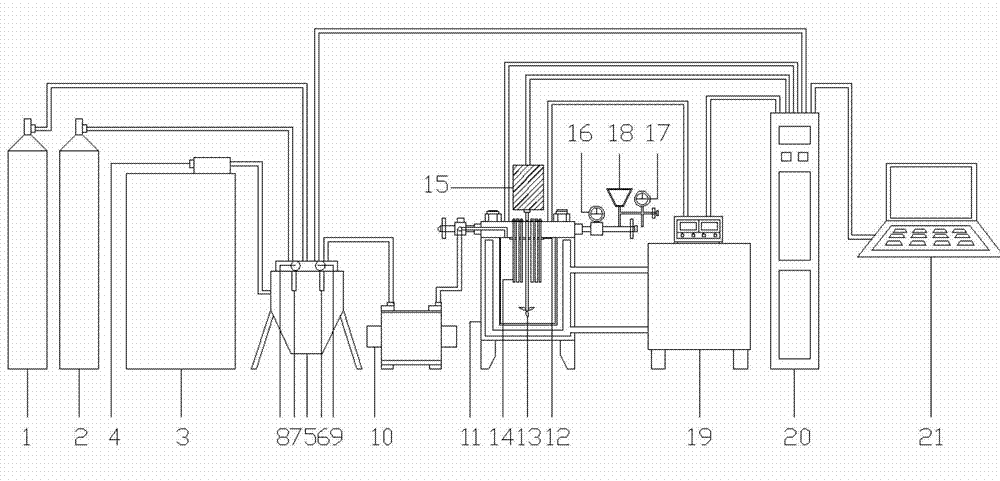

Experimental device for jet etching simulation and electrochemical test of high-temperature high-pressure loop

ActiveCN102121896AWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceGas cylinderWorkstation

Owner:CHINA NAT OFFSHORE OIL CORP +3

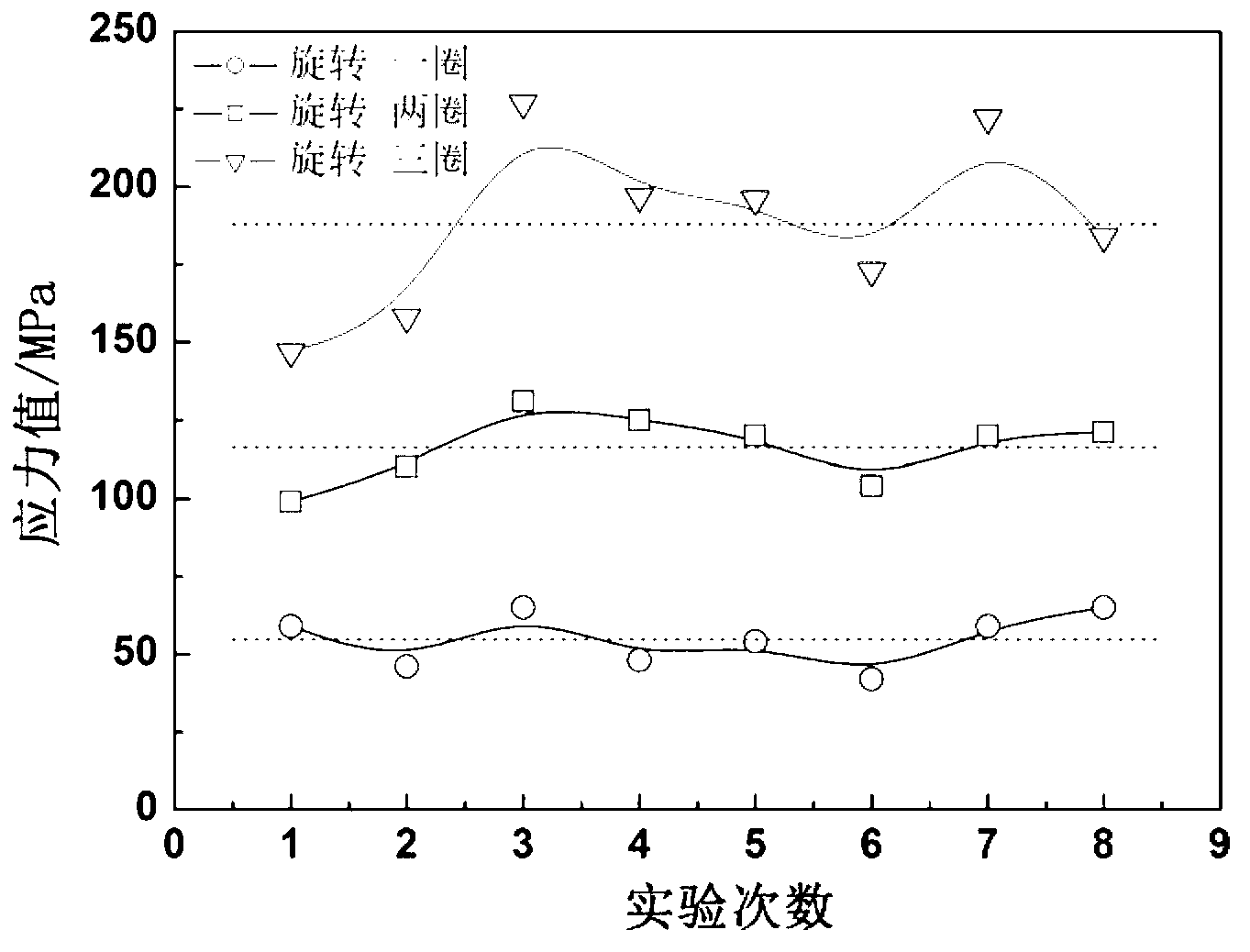

Loop test device for imitating gas phase erosion corrosion of natural gas

ActiveCN102980823ADeficiencies of changing flushing circuits with low flow ratesEasy to controlWeather/light/corrosion resistanceInvestigating abrasion/wear resistancePilot systemGas phase

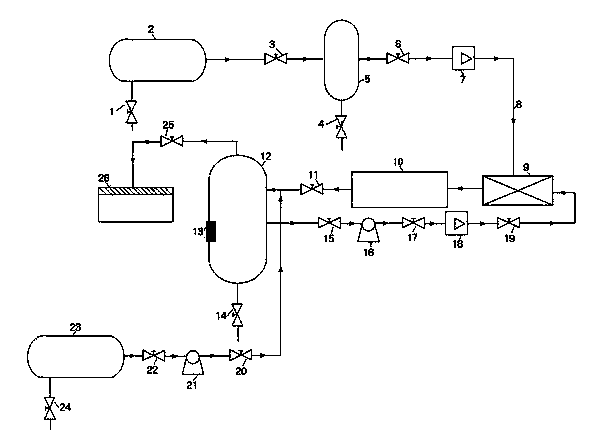

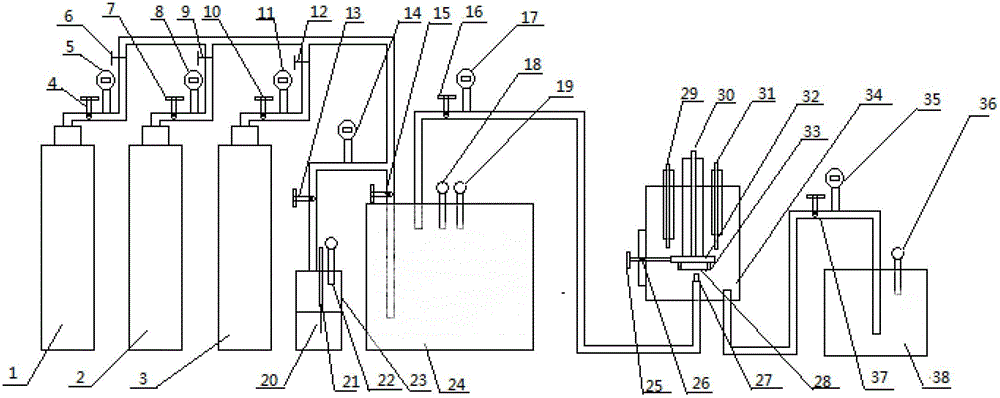

The invention discloses a loop test device for imitating gas phase erosion corrosion of natural gas, and belongs to the technical field of imitating experiment devices. The loop test device for imitating gas phase erosion corrosion of natural gas is suitable for imitating conditions of medium components, humidity, flow speed and the like of natural gas gathering pipelines during the actual operation process, and is especially suitable for simulating the erosion corrosion situation caused by the flowing of gases containing trace moisture and corrosion media and having high-speed flowing in natural gas pipes, and testing electrochemistry and corrosion behaviors. The device is composed of three parts including a control system, a test system and a recovery system, wherein the control system comprises a high-pressure air bottle, a high-pressure kettle, a high-pressure flow meter, a regulating valve, a stop valve, an electric heater, a humidity probe, a pressure probe and pipelines; the test system comprises the high-pressure kettle, a three-electrode system, a rotary working bench, a test sample jig and a pressure probe; and the recovery system comprises a recovery tank, a regulating valve, a high-pressure flowmeter and a pressure probe. The device can well imitate the erosion corrosion situation of parts including pipe walls, elbows, tee joints and reducing parts by high-flow-speed wet gases under natural gas intra-pipe environment, can test electrochemistry signals, and has important significances for the research on erosion corrosion behavior rules under the natural gas intra-pipe environment as well as main influence factors of the erosion corrosion behavior rules.

Owner:UNIV OF SCI & TECH BEIJING

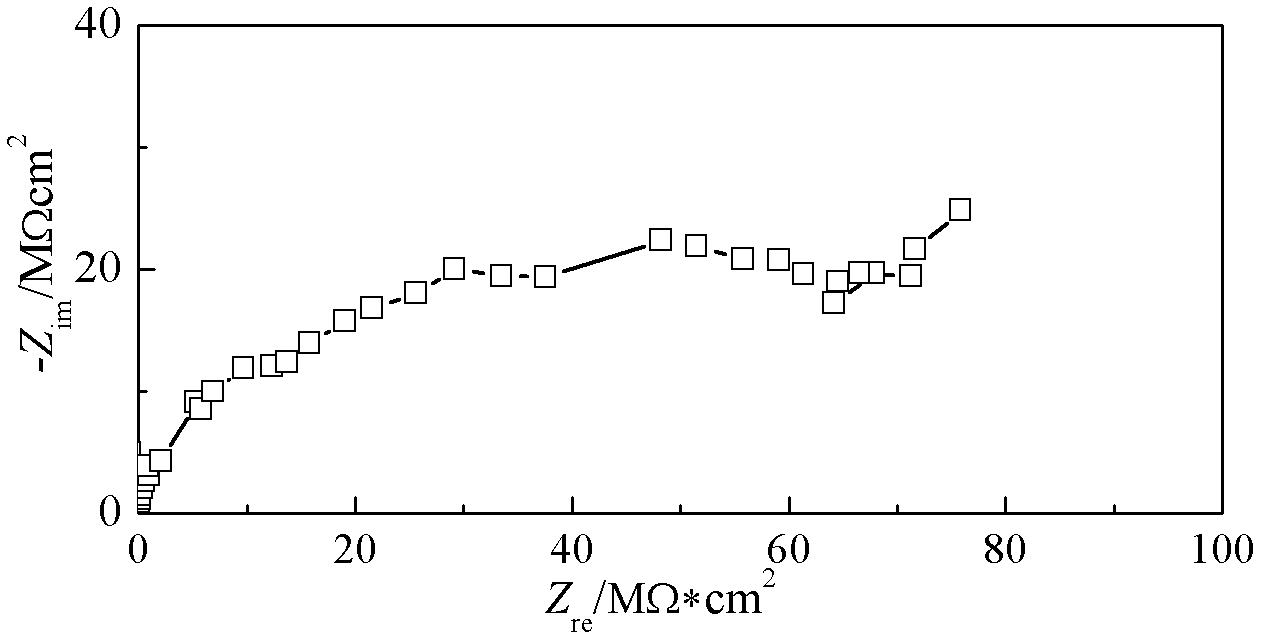

Sensor for measuring corrosion of inner wall of metal tank body and monitoring method

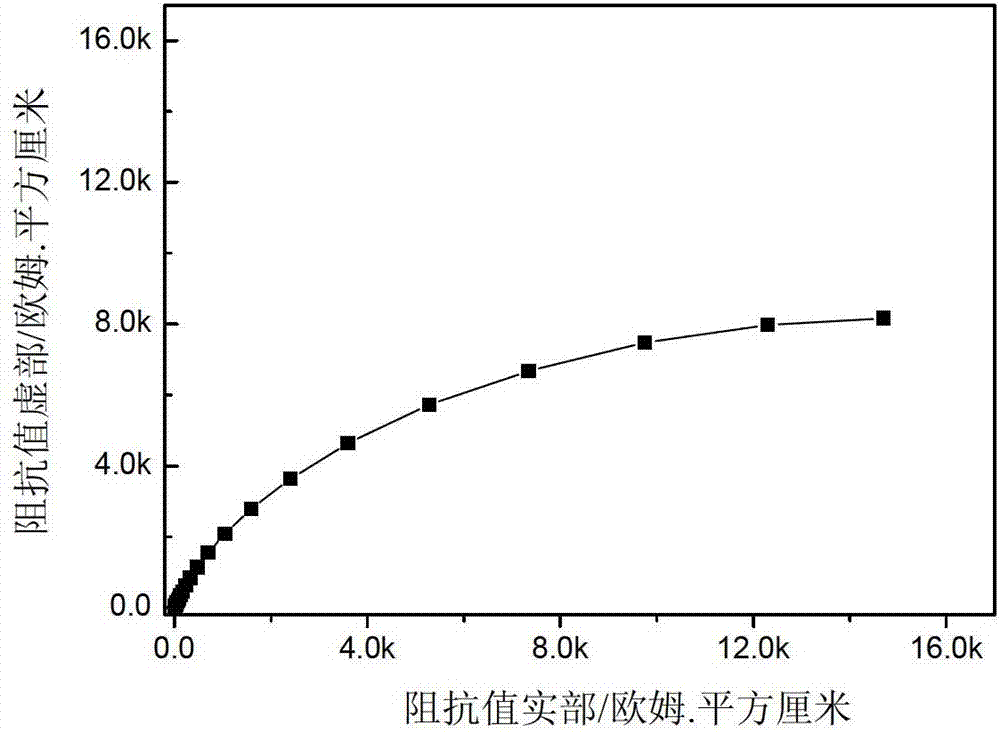

ActiveCN102494990AJudgment integrityDetermine the type of damageWeather/light/corrosion resistanceSpectroscopyAuxiliary electrode

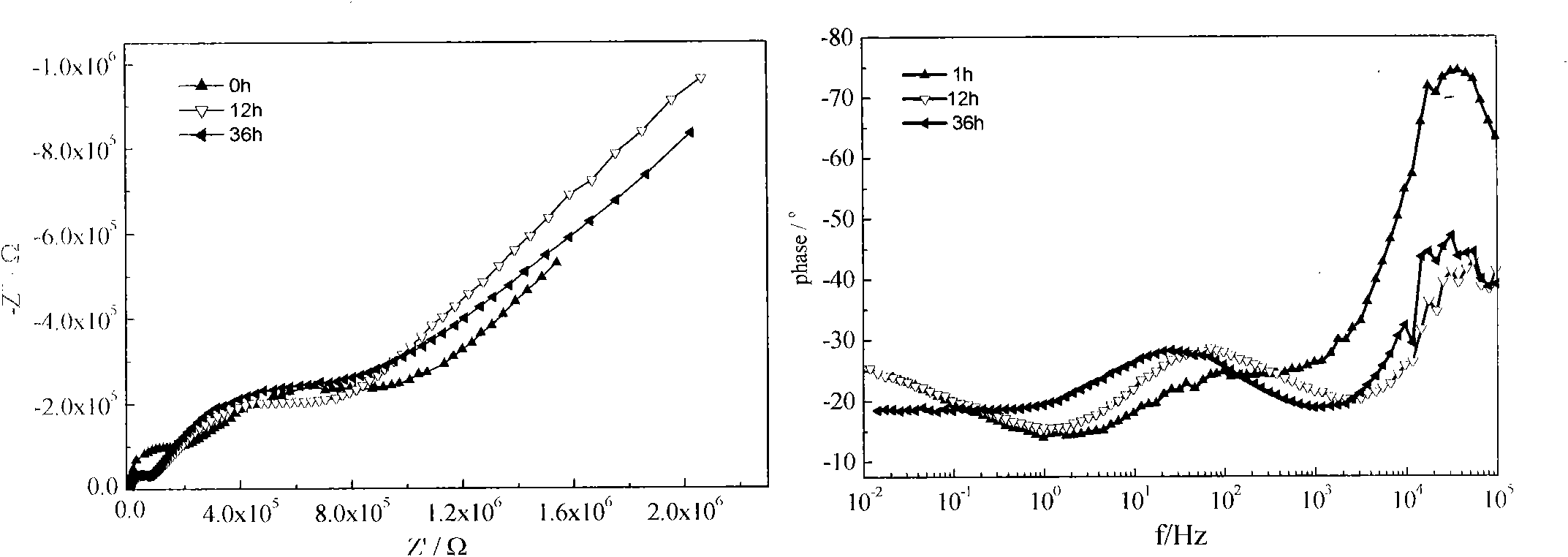

The invention discloses a sensor for measuring the corrosion of the inner wall of a metal tank body and a monitoring method. The sensor is of the following structure that the sensor comprises a fixing device, a sleeve, a reference electrode, an auxiliary electrode and a working electrode; and in the measuring process, the sensor is arranged at the top of a metal tank, the metal tank and the sensor are fixed and are tightly contacted through magnets, the electrodes partly extend into the tank to be in contact with a solution for performing an electrochemical detection, and a contact of the working electrode is attracted by the magnets to be fixed on the outer surface of the tank body. In the monitoring process, the corrosion behavior and degree of the inner wall of the metal tank are tested by utilizing an electrochemical low-frequency impedance spectroscopy technology. In the technical scheme disclosed by the invention, the sensor has simple manufacturing process, is sensitive to response, is convenient to carry and is simple to operate; the monitoring method is simple and convenient and has high data resolvability; the breakage condition, the breakage type and the corrosion degree of a coating on the inner wall of the metal tank can be rapidly judged in the service environment by the monitoring method; and the monitoring method is suitable for carrying out rapid detection andevaluation on the corrosion degree of the coatings on the inner walls of the metal tanks with various sizes.

Owner:TIANJIN UNIV

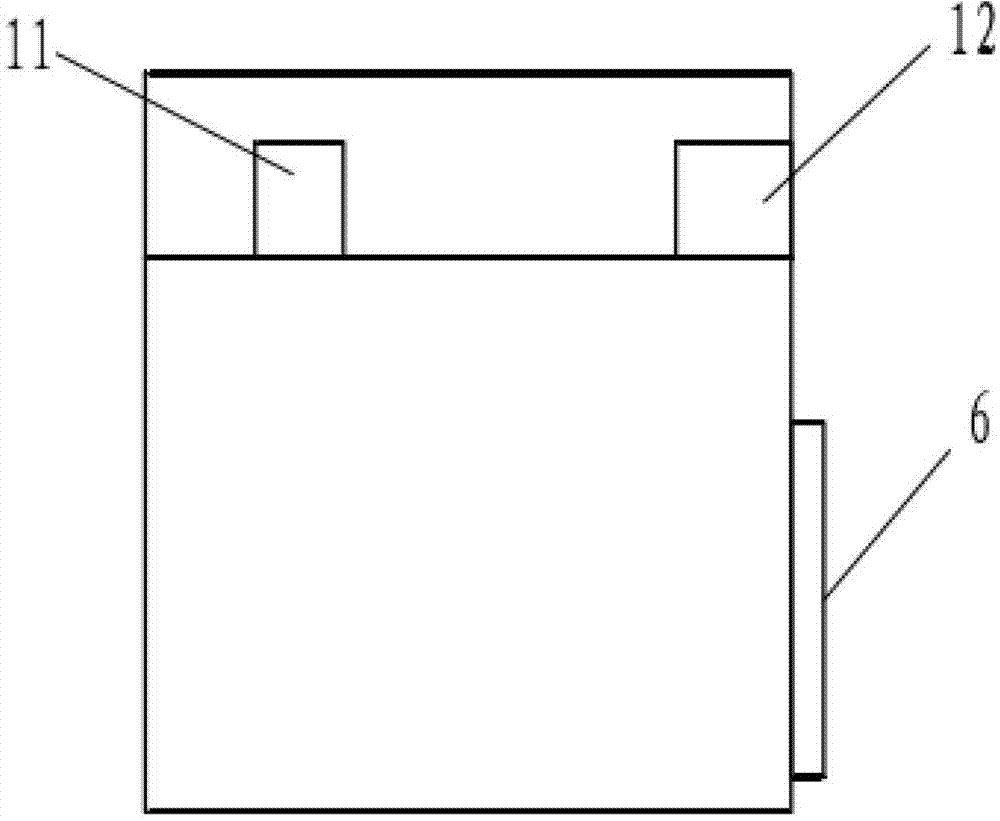

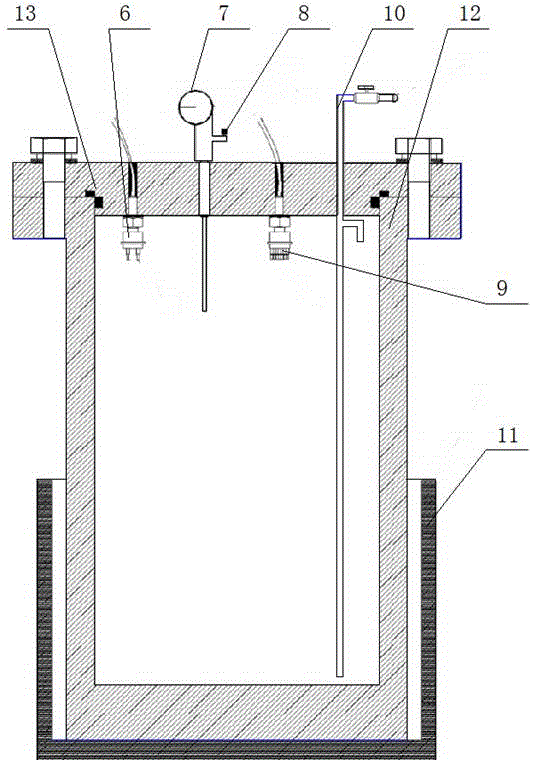

Abyssal environment simulation device suitable for testing material corrosion behavior

InactiveCN103196819AEasy to useDissolved oxygen content stable controlWeather/light/corrosion resistanceHydraulic pumpNitrogen gas

The invention provides an abyssal environment simulation device suitable for testing material corrosion behavior. The abyssal environment simulation device comprises a high pressure autoclave, a hydrostatic pressure control system of simulated abyssal environment and a simulated environment monitoring control system. The hydrostatic pressure control system of simulated abyssal environment comprises a nitrogen cylinder, an oxygen cylinder, a water tank, a liquid supply tank and a hydraulic pump, artificial sea water is stored in the water tank, a water pump injects the artificial sea water into the liquid supply tank, the nitrogen cylinder and the oxygen cylinder are connected with the liquid supply tank, and the hydraulic pump is connected between the liquid supply tank and the high pressure autoclave so as to inject the artificial sea water meeting the dissolved oxygen content into the high pressure autoclave; the simulated environment monitoring control system comprises a compound sensor, a working electrode, a reference electrode, a temperature control device, a singlechip signal processor and a computer. The abyssal environment simulation device can simulate the characteristic environment parameters, such as the hydrostatic pressure, the environment temperature, the dissolved oxygen content, the pH value, the flow rate and the salinity, of the corrosive medium for the material in the abyssal environment, and is used for testing the related corrosion electrochemistry behaviors of the material in the simulated abyssal environment.

Owner:三亚哈尔滨工程大学南海创新发展基地

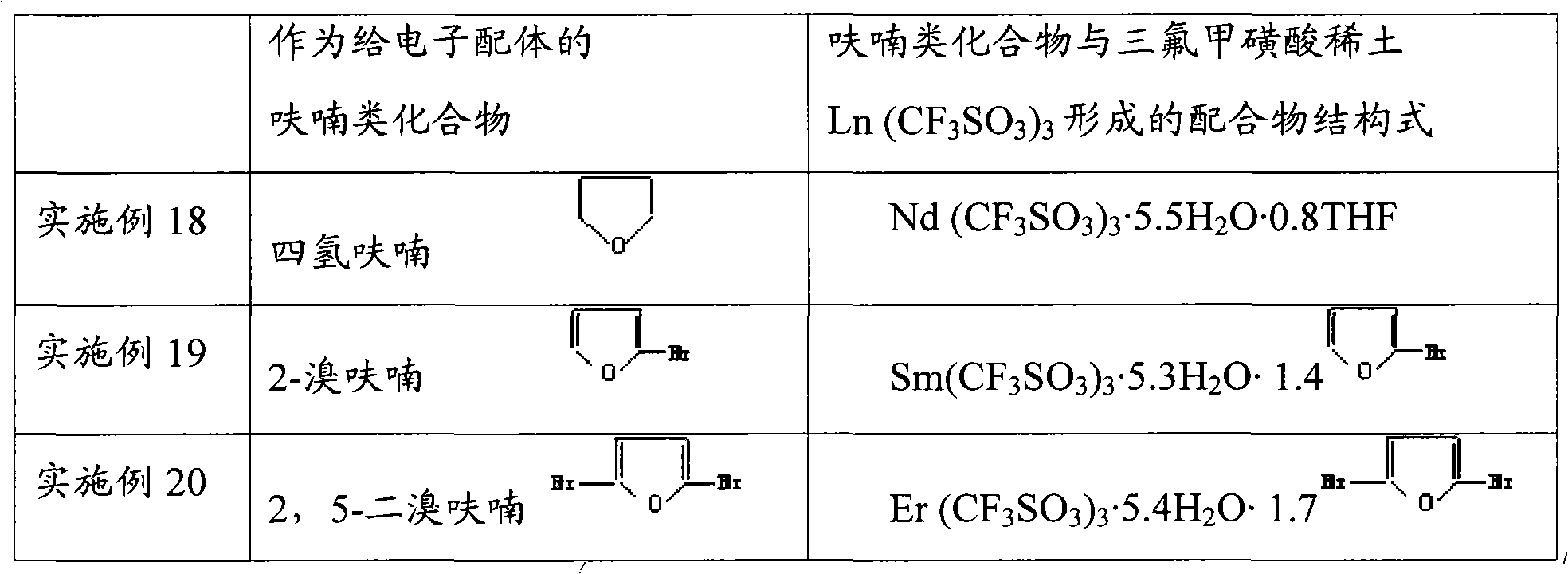

Rare earth complex, catalyst, preparation method thereof and preparation method of polybutadiene

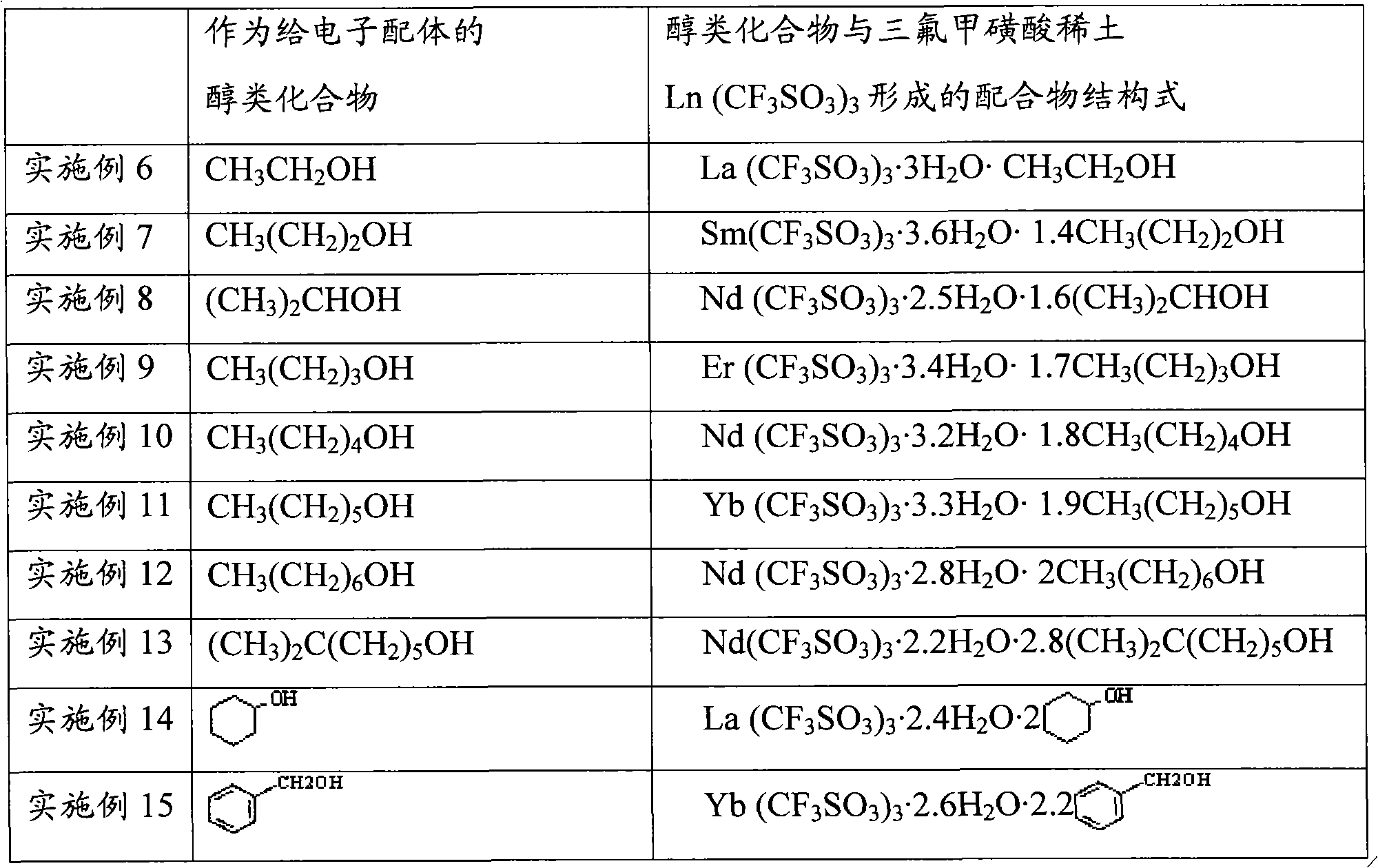

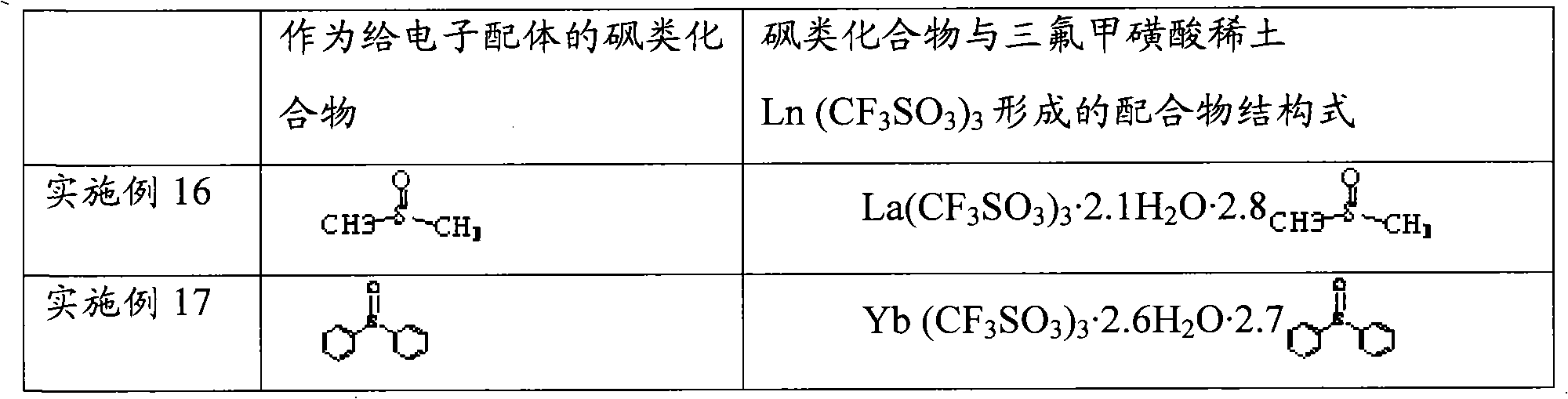

ActiveCN101974023AReduce corrosionHigh cis contentGroup 3/13 element organic compoundsSulfonateRare earth

The embodiment of the invention discloses a rare earth complex the molecular formula of which is Ln(CF3SO3)3.xH2O.yL. The invention also provides a rare earth sulfonate catalyst and a preparation method thereof. The rare earth sulfonate catalyst comprises aluminum alkyls and the rare earth complex, wherein the mol ratio of the aluminum alkyls to the Ln is 10-60:1. Besides, the invention also provides a preparation method of polybutadiene. The rare earth sulfonate catalyst provided by the invention has small corrosion behavior, thereby being environment friendly. The rare earth sulfonate catalyst provided by the invention provides a new catalysis system for the field of synthetic rubber. Experimental results indicate that the cis-content of the polybutadiene obtained by using the prepared rare earth sulfonate catalyst in the invention is high and can be up to 97% or above, and the weight-average molecular weight of the prepared polybutadiene is 4*10<5>-20*10<5>.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

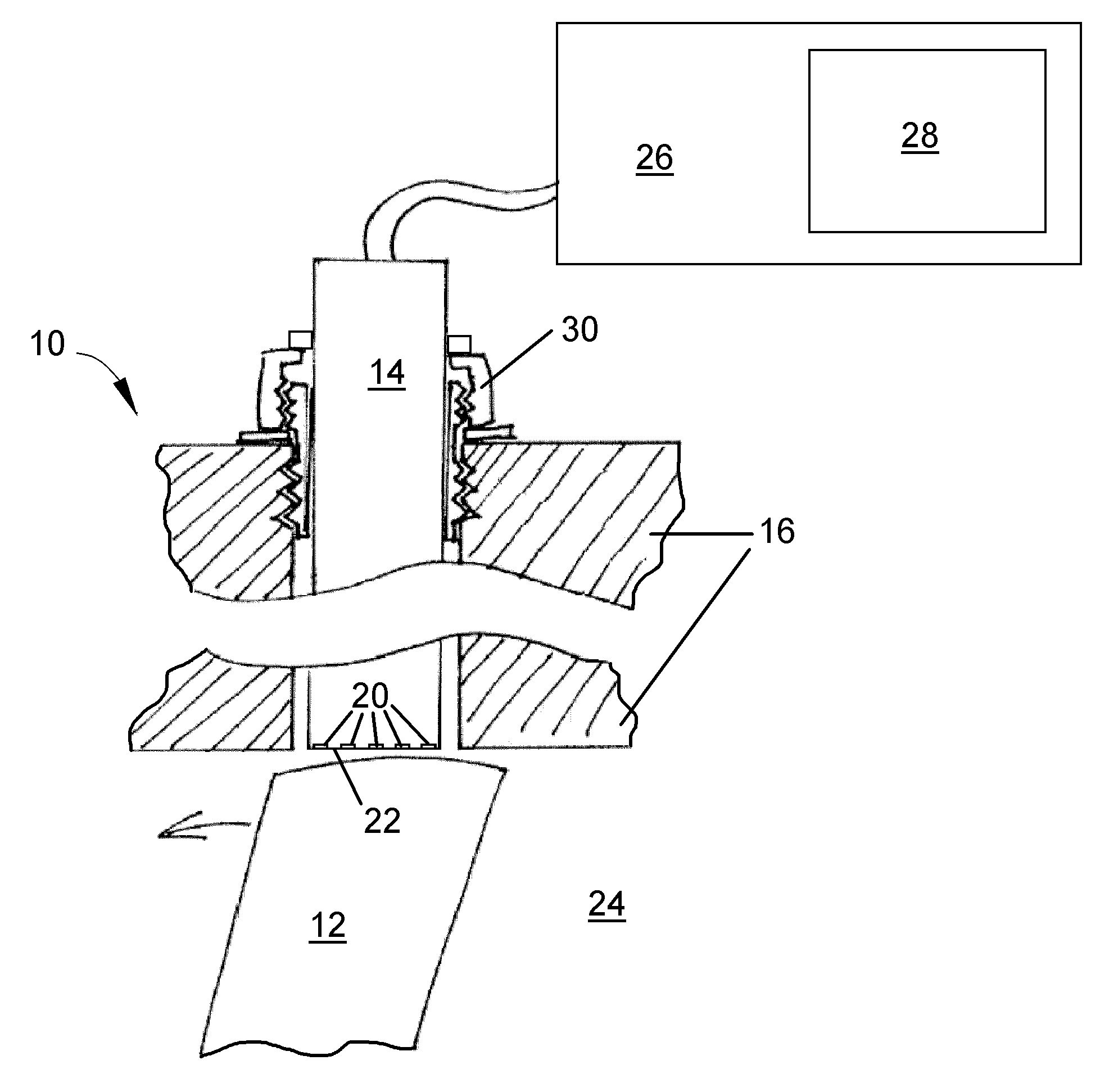

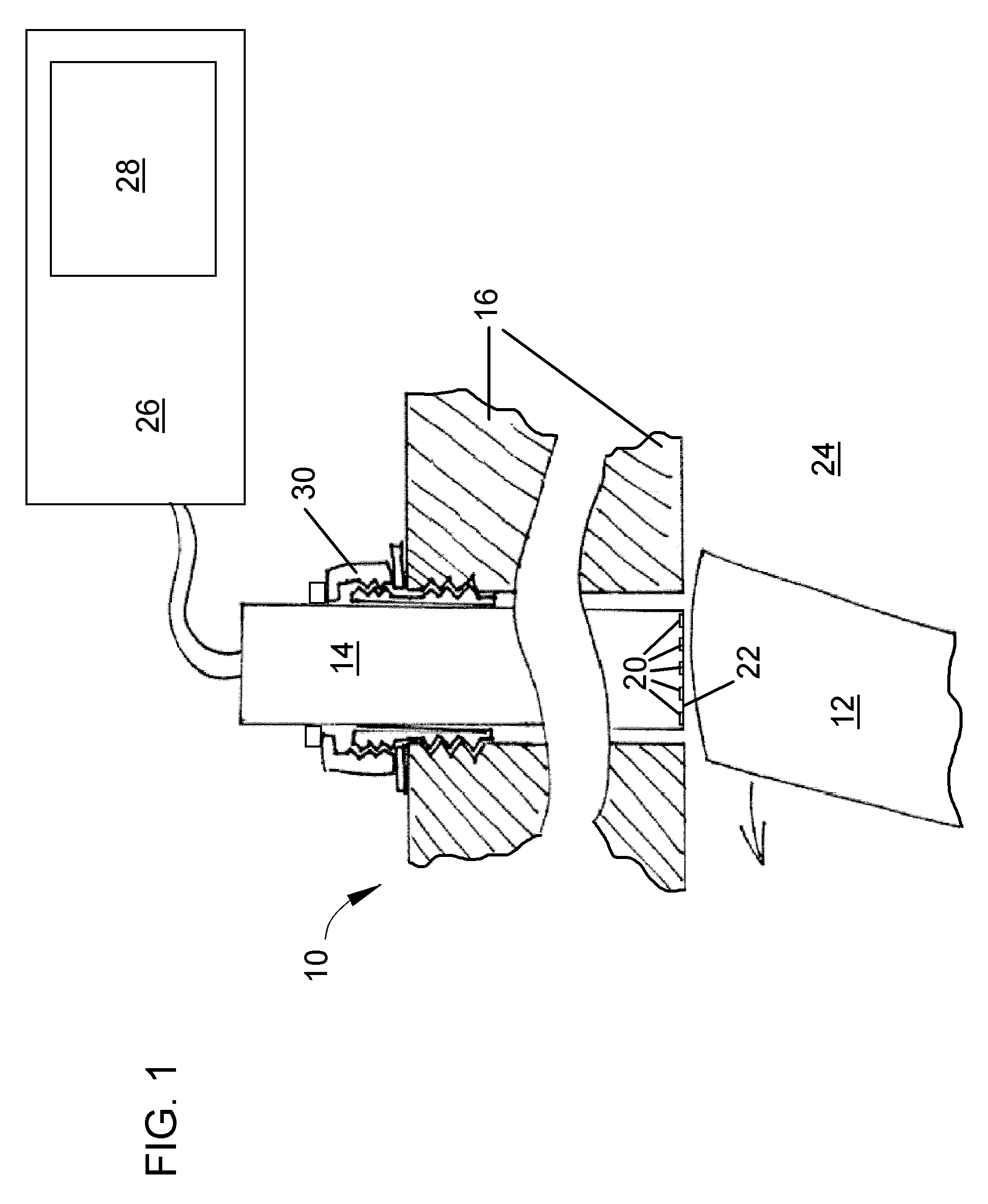

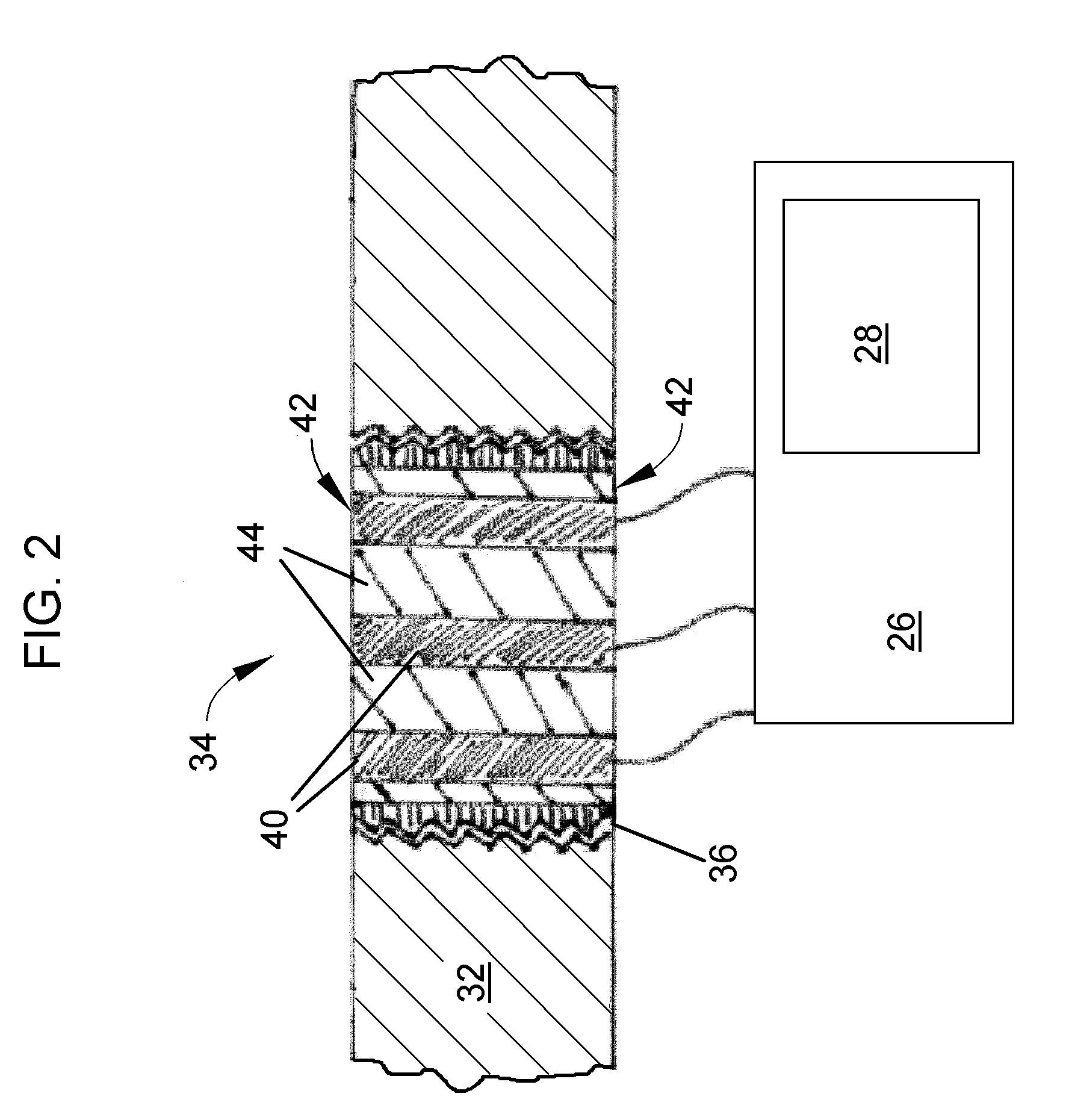

System and method for online monitoring of corrosion of gas turbine components

ActiveUS8475110B2Accurate predictionPropellersVolume/mass flow measurementEngineeringCorrosion behavior

Owner:GENERAL ELECTRIC CO

High-speed moisture corrosion loop experimental device for simulating corrosion environment in natural gas pipeline

PendingCN109668824AMake up for the shortcomings that cannot meet the actual working conditionsEasy to operateWeather/light/corrosion resistanceGas phaseEngineering

The invention provides a high-speed moisture corrosion loop experimental device for simulating corrosion environments in a natural gas pipeline, and belongs to the technical field of corrosion tests.The device comprises a deaerating system, an external gas supply system, a gas phase circulating system, a liquid phase filling system, an external control system, a heating and insulating system, anexperimental test system, a waste liquid and waste gas treatment system and the like. The device has the advantages that the conditions such as internal medium flow state, flow speed, pressure and temperature of the natural gas pipeline can be simulated; the operating corrosion environments of low water content, high gas phase flow speed and high wall surface shear force station are represented tothe maximum extent, and corrosion behavior study and corrosion inhibitor evaluation can be realized by an inductance probe, electrochemical testing and a corrosion coupon; and the high-speed moisturecorrosion loop experimental device has an important significance for application of corrosion mechanism study of the natural gas pipeline and protecting methods for corrosion inhibitors and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

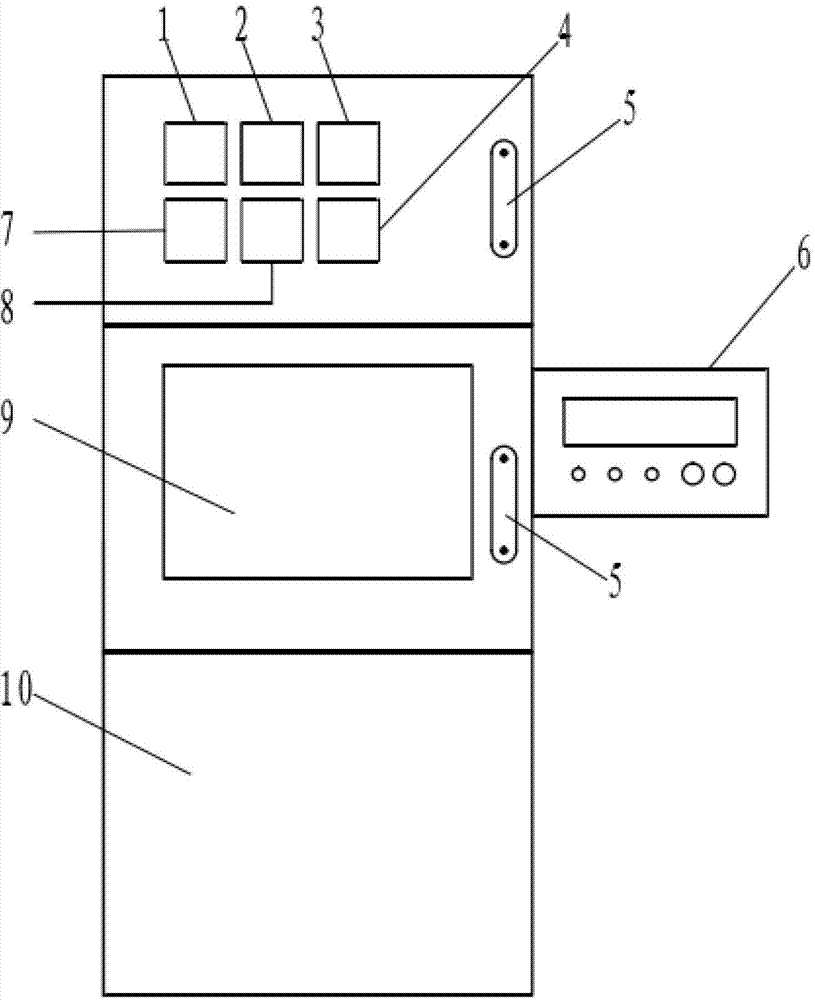

Indoor simulation/rapid assessment device for comprehensive atmospheric environment corrosion

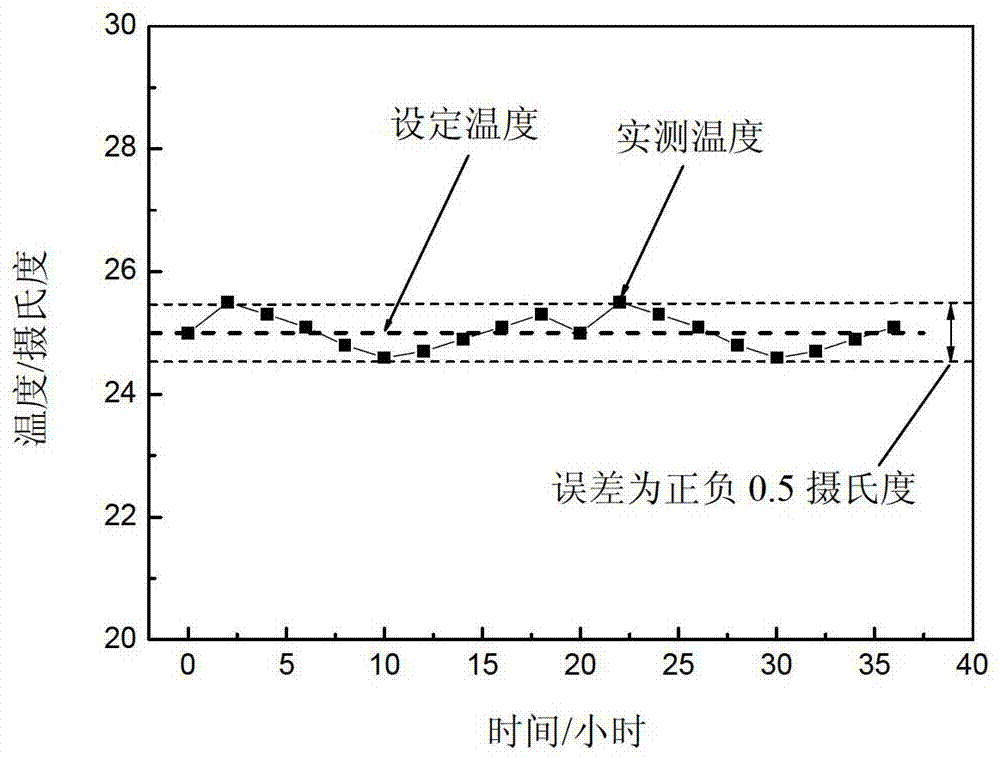

ActiveCN103115864AEasy to controlCompact structureWeather/light/corrosion resistanceTemperature controlCold air

The invention relates to an indoor simulation / rapid assessment device for comprehensive atmospheric environment corrosion, and belongs to the technical field of indoor simulation / rapid assessment devices for the corrosion of materials. The device comprises a control panel, a main work box, an ultraviolet lamp tube, a lifting mechanism, a temperature control and feedback system, a humidity control and feedback system and a hot and cold air system. The temperature control and feedback system, the humidity control and feedback system, the ultraviolet lamp tube and the hot and cold air system are controlled by the control panel to carry out environmental simulation on a test sample in the main work box. The device is simple in structure, low in manufacturing cost, high in work stability and accurate in test parameter control, not only can simulate the corrosion process of a material component under single conditions, such as constant temperature and constant humidity, alternation of wetting and drying and ultraviolet irradiation, but also can simulate the corrosion behaviors and processes of the material component under the synergistic action of multiple factors, and is particularly applicable to the indoor simulation and rapid assessment of the corrosion under the comprehensive action of the multiple factors in an atmospheric environment.

Owner:河北维立方科技有限公司

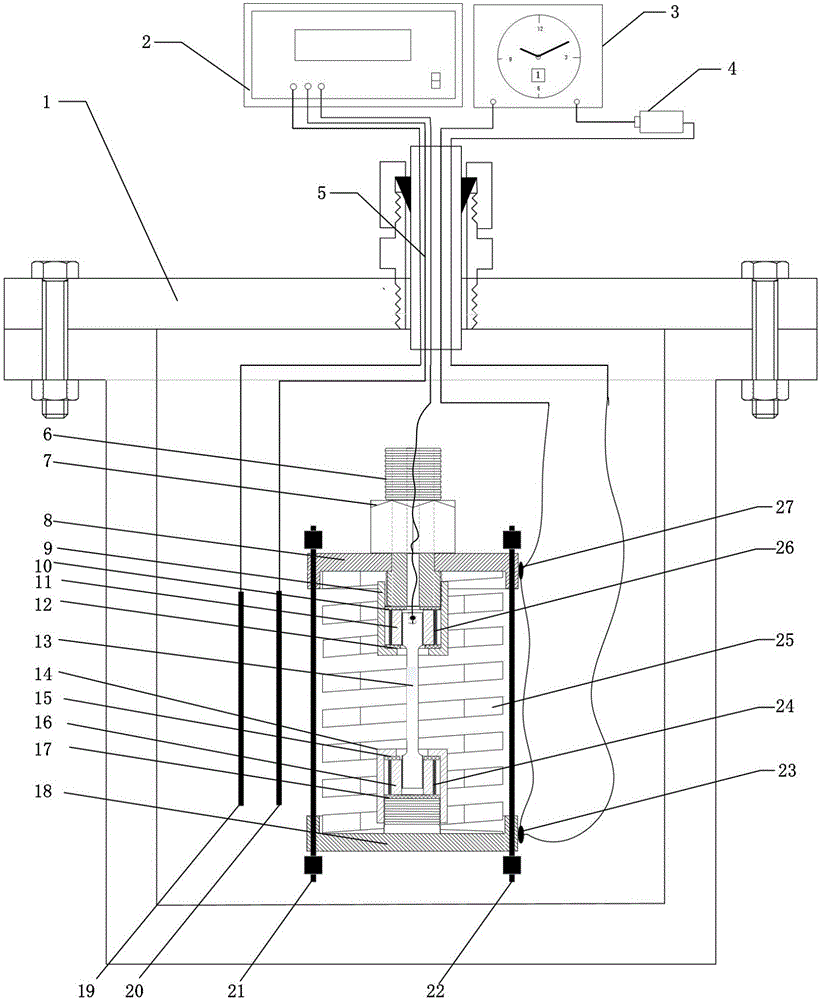

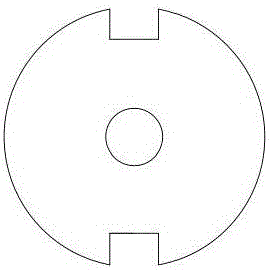

Device for testing stress corrosion behavior of metal material under fluid high pressure

ActiveCN106442136AImprove insulation reliabilitySolve the problem of high stress conduction sealing requirementsWeather/light/corrosion resistanceNuclear energy generationAdhesiveAuxiliary electrode

The invention provides a device for testing the stress corrosion behavior of a metal material under fluid high pressure, belonging to the technical field of metal material test equipment. The device comprises a high-pressure kettle, an electrochemical workstation, a timer, a bundled wire, a stud, a loading nut, a loading device top plate, a closed threaded sleeve, a high-strength insulating spacer, a threaded sleeve, a loading device bottom plate, an auxiliary electrode, a reference electrode, a steel wire rope, a powerful instant adhesive, an insulating coating layer and a rectangular spring and is used for testing the stress corrosion behavior of the metal material under fluid high pressure. The loading way is a constant-load loading way which is implemented by a spring and the stress magnitude of which can be conveniently adjusted. The device can solve the problems of high requirement on stress conduction air tightness between the loading equipment and the high-pressure kettle in the prior art, inconvenience in adjusting the loading stress and electrochemical performance study in a stress corrosion test process of a high-pressure environment.

Owner:UNIV OF SCI & TECH BEIJING

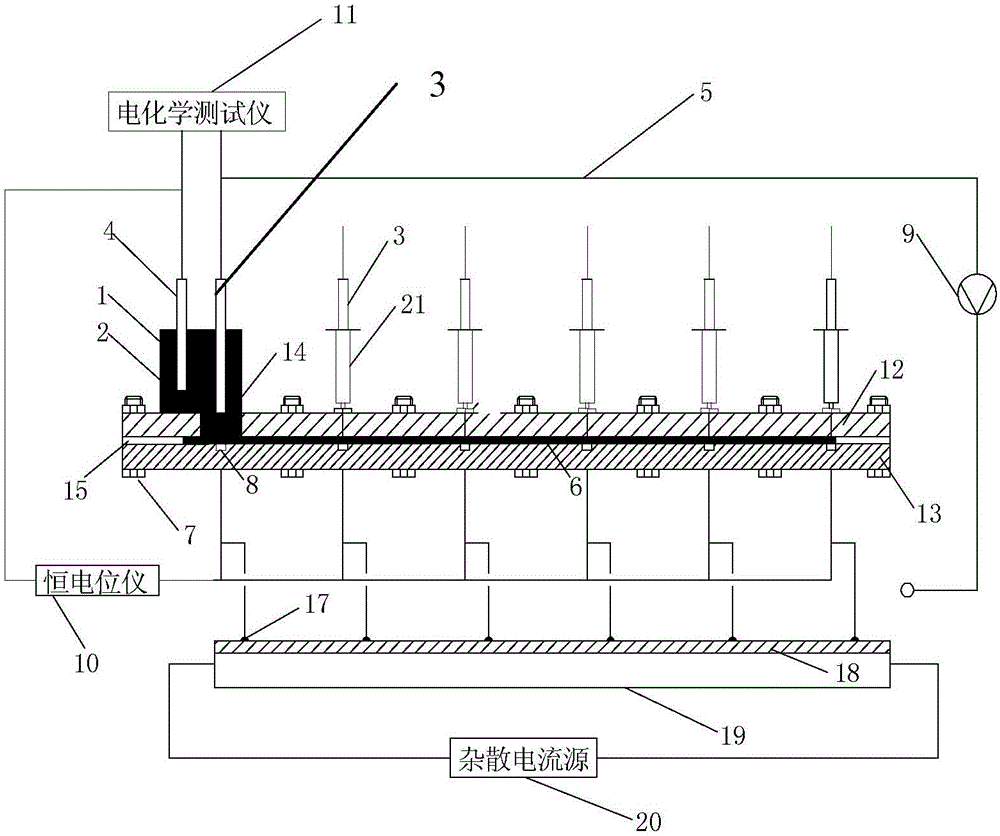

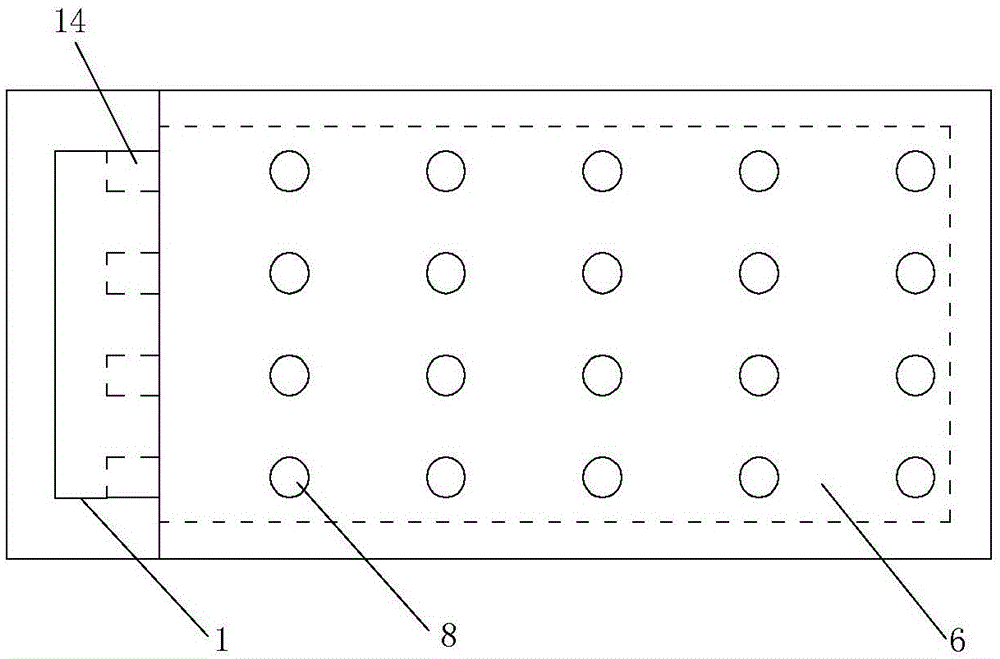

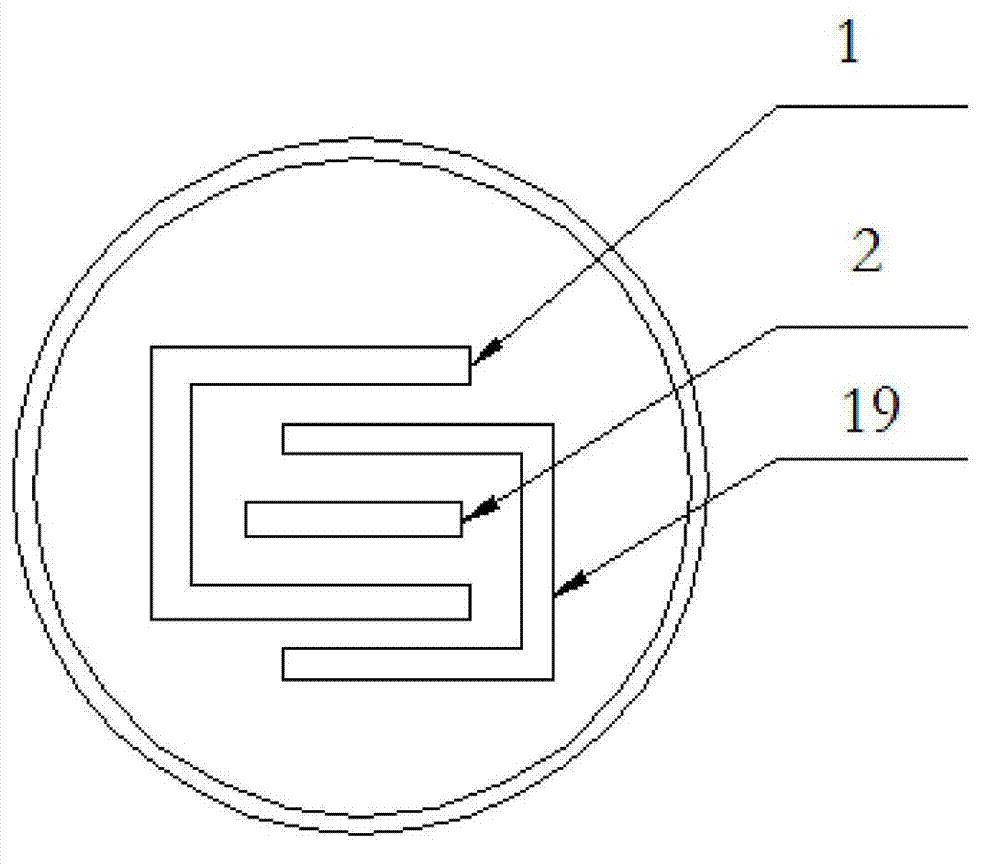

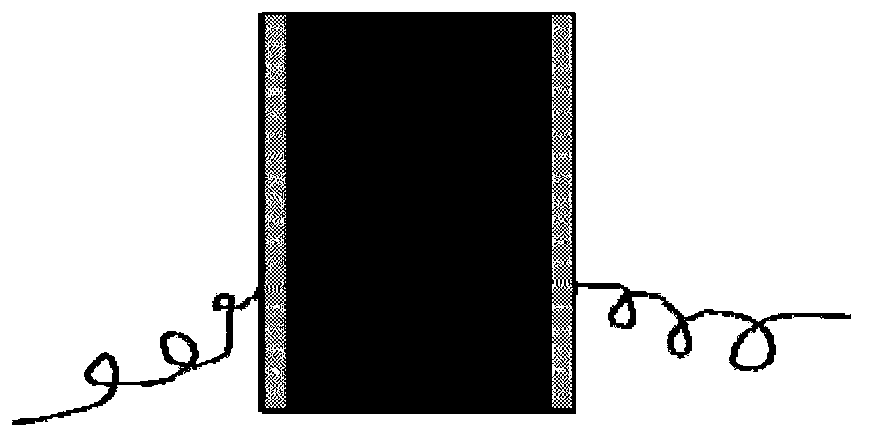

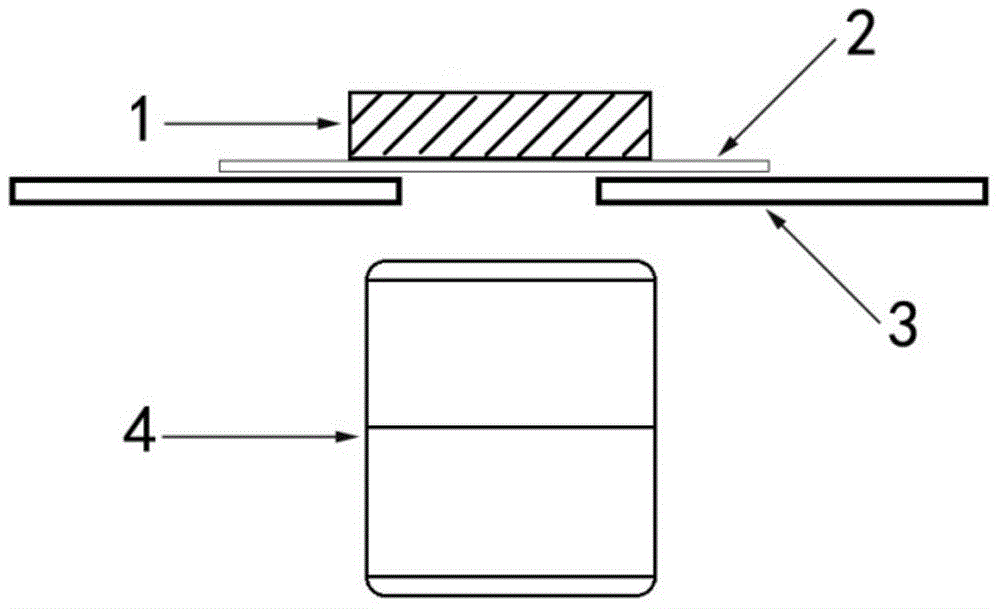

Experiment device for research on corrosion behavior of metal substrate beneath peeling coating

InactiveCN105043971AEasy to buildEasy to repeat experimentsWeather/light/corrosion resistanceEpoxyVoltmeter

The invention discloses an experiment device for research on the corrosion behavior of a metal substrate beneath a peeling coating. The experiment device comprises an epoxy resin plate, an organic glass plate, a plurality of work electrode, at least one auxiliary anode, a plurality of reference electrodes, a plurality of needle tubes, a plurality of lead wires, a plurality of bolts, a steel pipe, gaskets, a voltmeter, a constant potential rectifier, an electrochemical tester, and a stray current source. In the provided equipment, the organic glass plate and epoxy resin plate are used to simulate the medium environment beneath a peeling coating, wherein a gap exists between the organic glass plate and the epoxy resin plate, and the gap thickness can be controlled by adjusting the number of gaskets; multiple work electrodes are arranged on the damaged parts and different positions beneath the peeling coating to simulate the metal substrates on the damage parts and positions beneath the peeling coating. Only one experiment device can carry out many indoor experiments on the corrosion behavior of metal substrate under factors of stray currents, gap thickness, and cathode protection potential, and the like.

Owner:CIVIL AVIATION UNIV OF CHINA

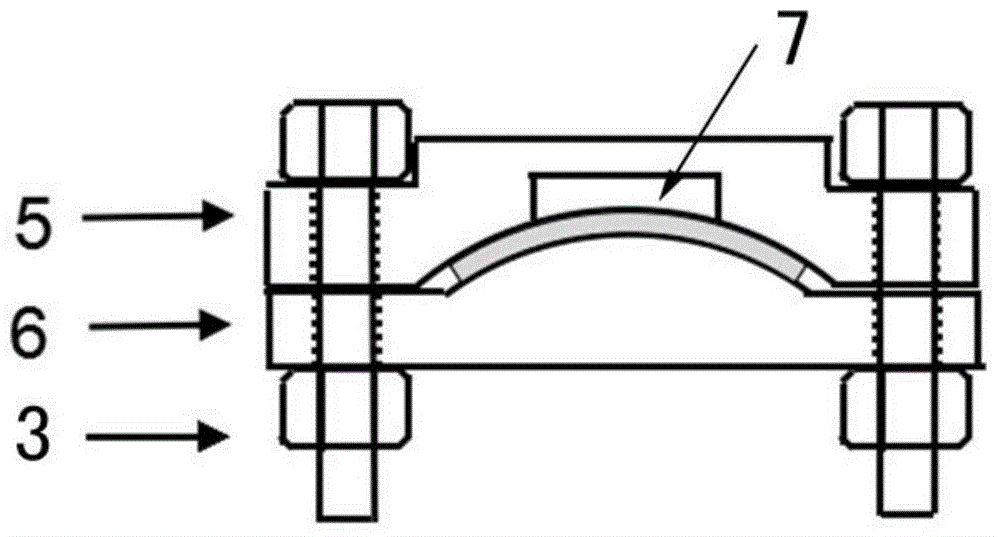

Deep-sea stress corrosion and seepage hydrogen experimental simulation device

InactiveCN103293093ASolve fit problemsAvoid problems such as poor airtightness and air pressure leakageWeather/light/corrosion resistanceHydrogenCorrosion behavior

The invention provides a deep-sea stress corrosion and seepage hydrogen experimental simulation device which comprises an oxidizing chamber and a corrosion chamber, as well as a stress application device, wherein testing ports are formed in one sides of the oxidizing chamber and the corrosion chamber; a fastening device is arranged at the testing ports; a testing sample is positioned between the testing ports of the oxidizing chamber and the corrosion chamber; the oxidizing chamber is connected with the corrosion chamber through the fastening device; the stress application device comprises two stress application steel plates and two stress application screw rods; one end of each stress application screw rod is fixed with one stress application steel plate; the other end of each stress application screw rod penetrates through the other stress application steel plate, and a rotating nut is arranged on the inner side of the stress application steel plate; two ends of the testing sample respectively penetrate through the two stress application steel plates; barrier plates are arranged between two ends of the testing sample and the stress application steel plates. The device can be used for testing the influence of the simulated external tensile stress in a deep sea environment on the material stress corrosion behavior.

Owner:HARBIN ENG UNIV

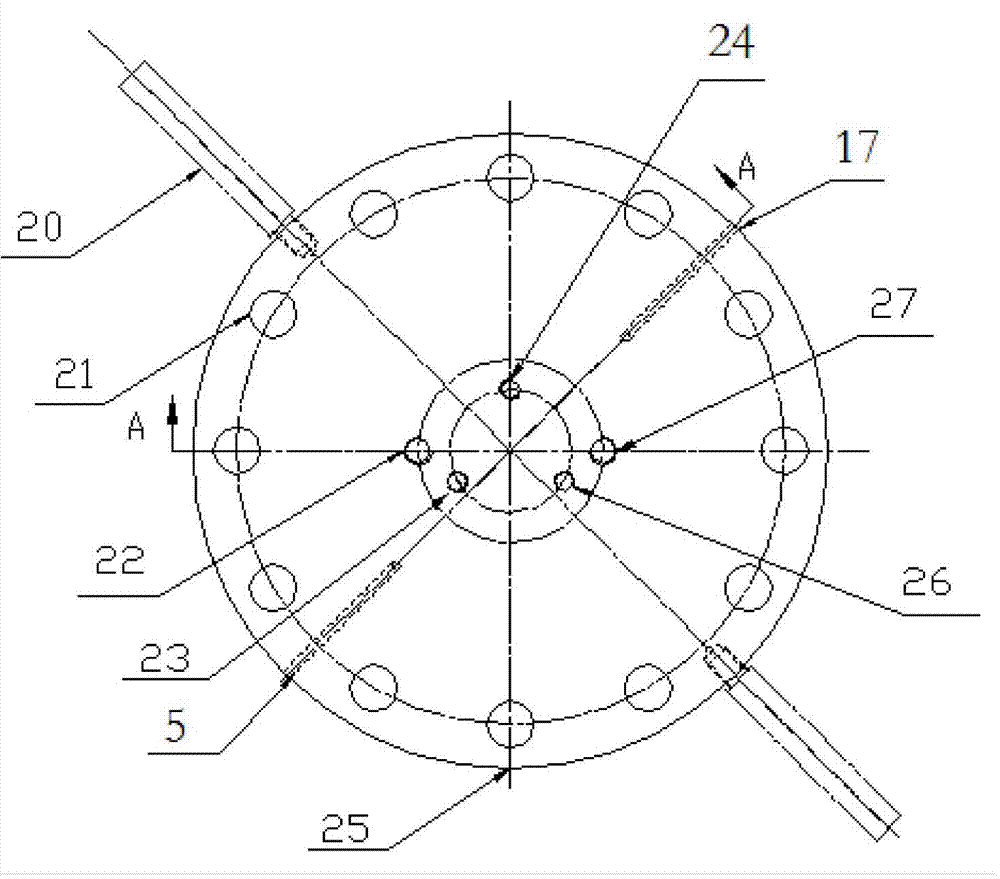

High temperature and high pressure dynamic electrochemical test and pH in situ monitoring experimental device

InactiveCN103411879AEliminate the effects of resistance changesIncrease speedWeather/light/corrosion resistanceInsulation systemHigh pressure

The invention relates to a high temperature and high pressure dynamic electrochemical test and pH in situ monitoring experimental device. The device includes a high temperature and high pressure reaction kettle, a rotation system, a heating insulation system, an external air supply system, a three-electrode system, a first pH composite electrode system, a second pH composite electrode system, a signal transduction pathway, a control box, an external electrochemical workstation, an external pH instrument and a computer. The device utilizes the high temperature resistance, cold resistance, wear resistance, corrosion resistance, anti-magnetoelectric insulation, oil-free self-lubricating, high rotation speed, high strength and other characteristics of a ceramic bearing, can be used in a severe corrosion environment, and also improves the rotation speed and concentricity precision of a rotary working electrode. A collector ring is employed to realize connection of a moving lead and a static lead. The electrochemical signal of a working electrode under a high temperature and high pressure dynamic state can be tested. A high temperature and high pressure pH composite electrode system is employed to realize in situ continuous monitoring and record the pH change of a solution in the vicinity of the rotary working electrode and a bulk solution. The device can be used for high temperature and high pressure dynamic corrosion behavior and mechanism study.

Owner:UNIV OF SCI & TECH BEIJING

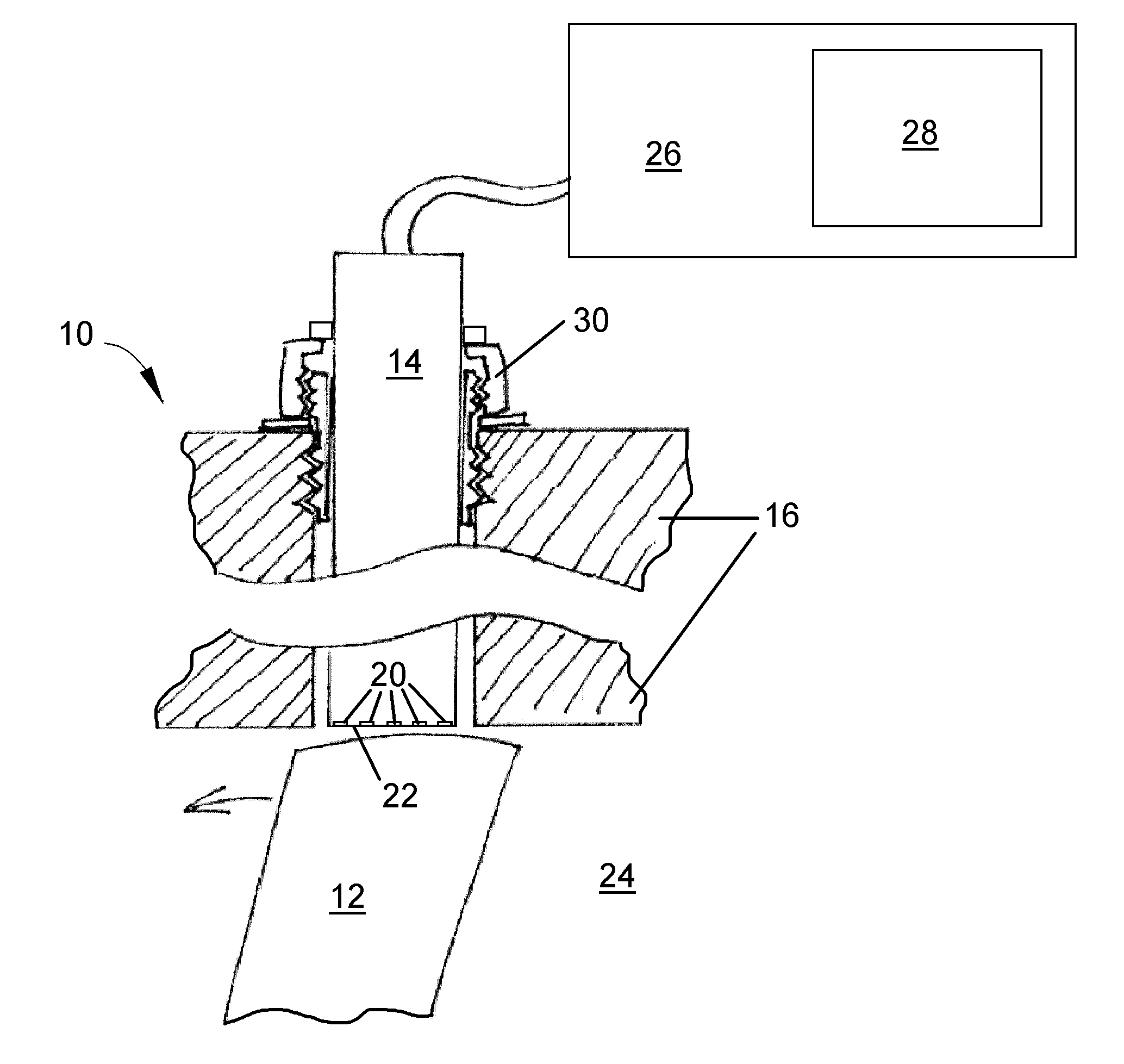

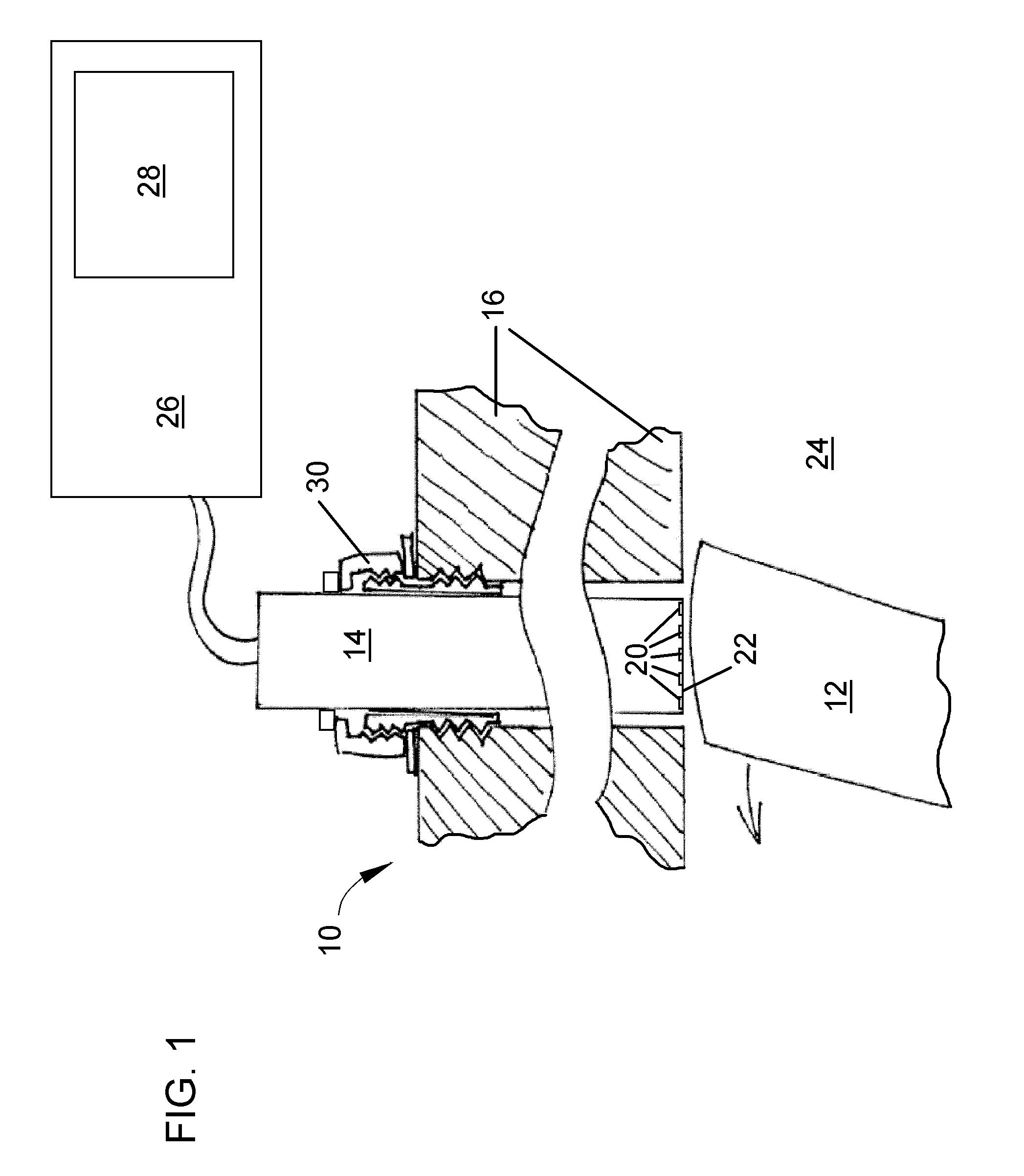

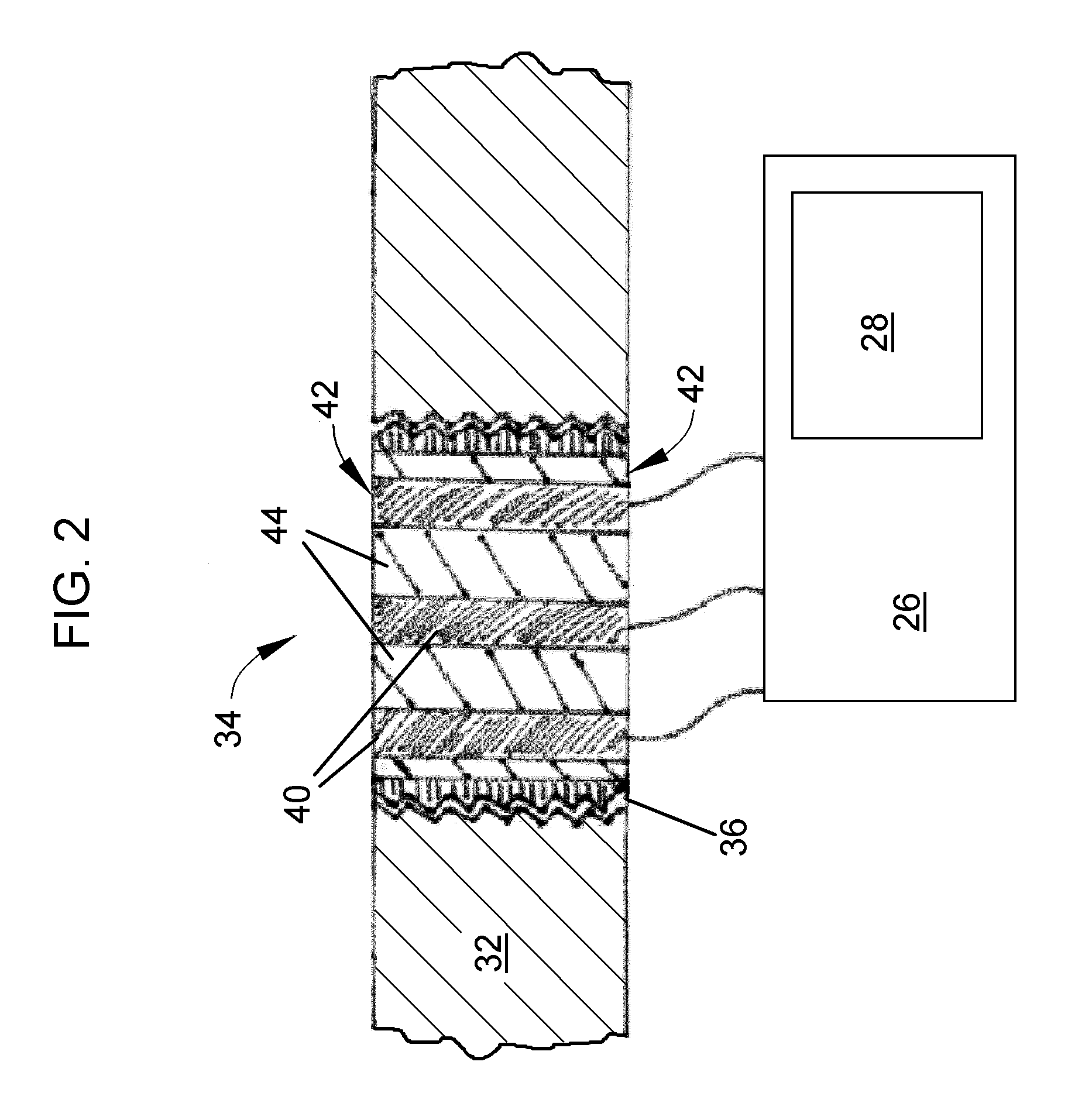

System and method for online monitoring of corrosion of gas turbine components

ActiveUS20110027063A1Accurate predictionPropellersVolume/mass flow measurementElectricityEngineering

A system and method capable of performing online corrosion monitoring of a component installed in a gas turbine. A sensing device is located so that electrodes thereof are exposed to an operating environment within the gas turbine section containing the component. The electrodes are formed of a material so that the component and electrodes similarly respond to corrosive agents within the gas turbine section. The electrodes are electrically insulated from each other and each electrode is operable as an anodic electrode or a cathodic electrode, depending on the extent of corrosion thereat, so that each electrode has an electrical potential value, voltages exist across the electrodes, electric currents flow between the electrodes, and the electrical potential / current values correspond to corrosion behaviors at the anodic electrodes. During gas turbine operation, output signals are obtained from the sensing device and indications are provided as to when certain maintenance operations should be performed on the gas turbine.

Owner:GENERAL ELECTRIC CO

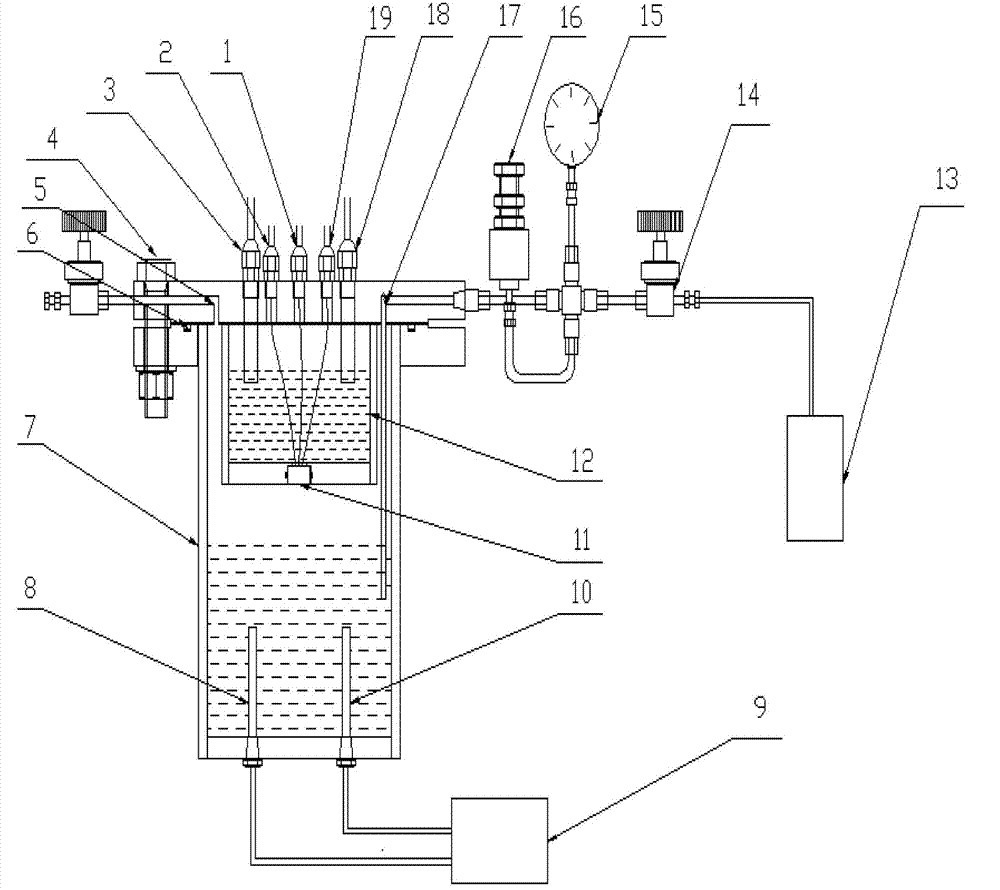

Top-corrosion electrochemical testing device in high-temperature and high-pressure environments

ActiveCN104502264AOriginalEasy to operateWeather/light/corrosion resistanceElectrochemical responseChemical reaction

The invention provides a top-corrosion electrochemical testing device in high-temperature and high-pressure environments, belongs to the field of corrosive electrochemistry, and is suitable for top-corrosion simulation experiments and corrosion behavior mechanism research in high-temperature and high-pressure working conditions. The top-corrosion electrochemical testing device comprises a high-temperature and high-pressure reaction kettle, a heating and heat preservation system, a circulating condensate water tank refrigerating system, a three-electrode system, a signal conduction pathway, a control box, an external air supply system and a computer. The device has the advantages that actual high-temperature and high-pressure working conditions can be achieved; top-corrosion in-situ electrochemical signal testing can be carried out; and the method is of great significance on mechanism research on high-temperature and high-pressure top-corrosion behaviors and electrochemical reaction.

Owner:UNIV OF SCI & TECH BEIJING +1

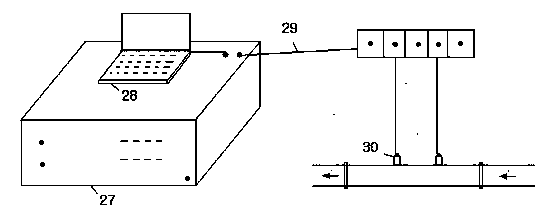

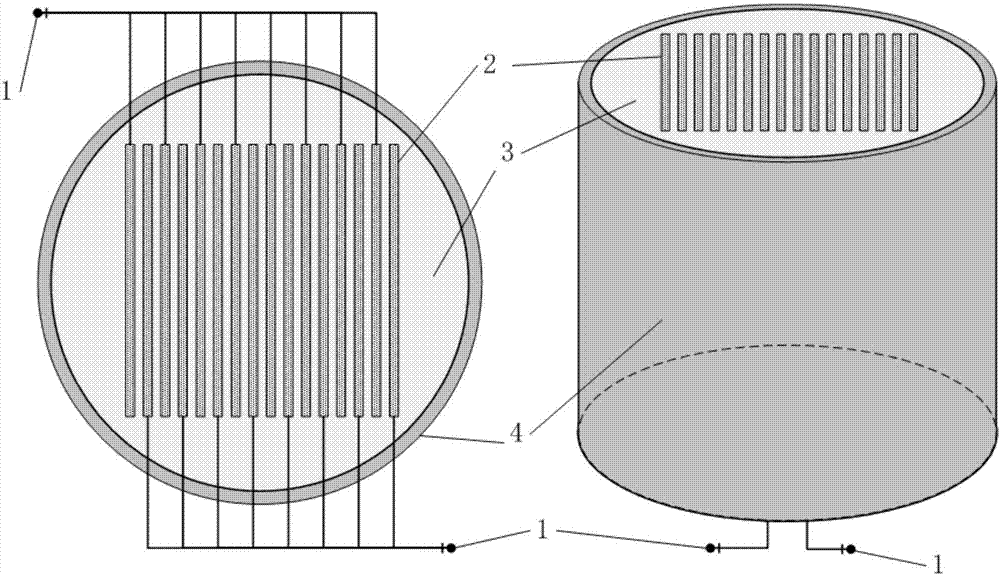

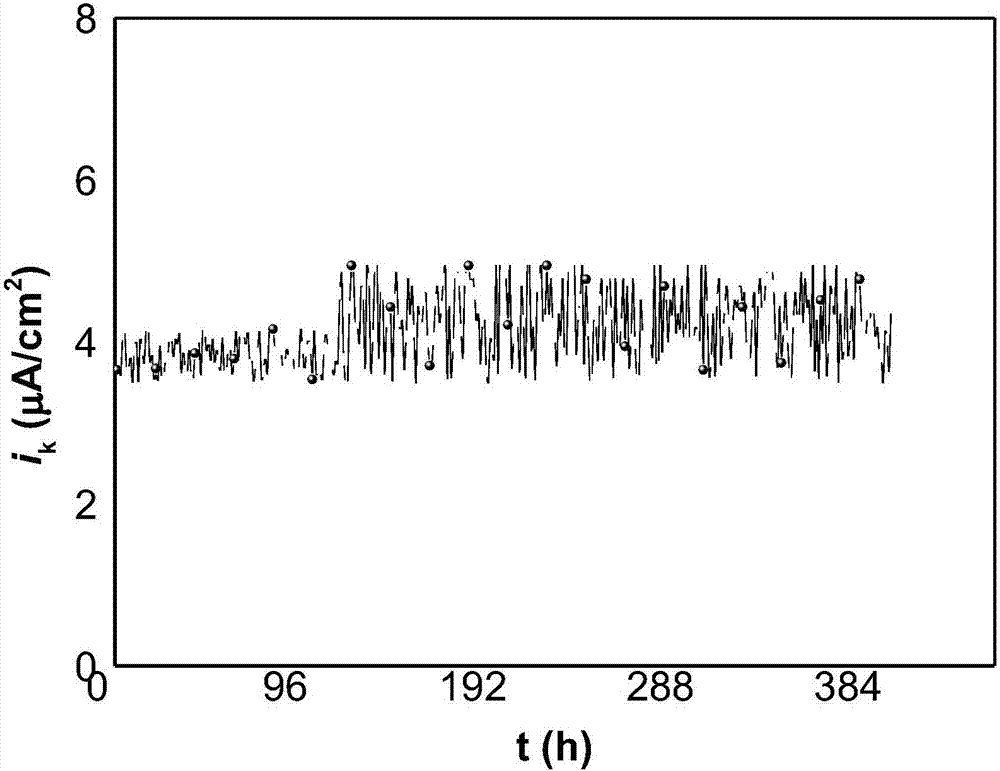

Method for continuously monitoring corrosivity of field environment by utilizing corrosion sensor

ActiveCN107449727ALong-term useExtended service lifeWeather/light/corrosion resistanceWorkstationContinuous monitoring

The invention discloses a method for continuously monitoring corrosivity of a field environment by utilizing a corrosion sensor, and belongs to the field of atmosphere corrosion monitoring. The method comprises the following steps: firstly, selecting metal which can generate a response in time when the environment corrosivity is changed to prepare the corrosion sensor; then converting data recorded by the corrosion sensor into parameters representing the environment corrosivity, transmitting the parameters to an electrochemical workstation, controlling the electrochemical workstation to constantly input a direct current voltage signal (delta E), and recording an output current signal ia in a loop; controlling the electrochemical workstation again to constantly input a negative value (-delta E) of the direct current voltage signal after the test is completed for a period of time, and recording an output current signal ic in the loop. By using an ik value calculated by an equation that ik is equal to (ia multiplies by ic) / (ic minus ia) as a y-coordinate and testing time as an x-coordinate, a curve of ik and time is drawn; continuous monitoring on the corrosivity of the field environment can be realized according to the curve. The method disclosed by the invention has the characteristics that the service life is long and the corrosivity of the environment can be truly represented according to the monitoring data, and atmosphere corrosion behaviors in different regions of the country can be monitored for a long time.

Owner:浙江钱浪智能信息科技有限公司

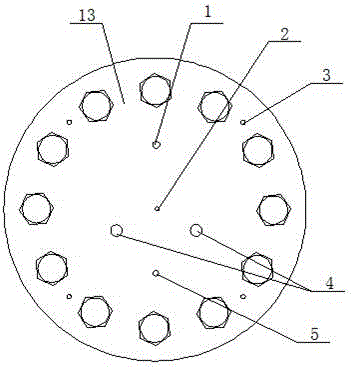

Device and method for testing local corrosion in deep-sea simulation environments

InactiveCN106501168ASimple structureEasy to installWeather/light/corrosion resistanceButt jointAuxiliary electrode

The invention provides a device and a method for testing local corrosion in deep-sea simulation environments, and belongs to the field of simulation test equipment for deep-sea environments. The device comprises a test cabin, a test cabin cover and an electrode assembly. The electrode assembly is based on a three-electrode system and is fixed onto the test cabin cover by the aid of an electrode water-tight connector, the electrode water-tight connector is provided with a wire-wire butt-joint needle bed, a working electrode is an electrode array, the electrode array comprises a plurality of micro-electrodes, and the micro-electrodes are matched with a working electrode water-tight connector; a reference electrode is fixedly connected onto a plug-in cable matched with a reference electrode water-tight connector, and an auxiliary electrode is fixedly connected onto a plug-in cable matched with an auxiliary electrode water-tight connector. The method is based on the device. The device and the method have the advantages that the device is simple in structure, convenient to mount and high in universality, requirements on testing array electrodes in simulation deep-sea high-pressure environments can be met, and-sealing requirements of test environments can be met; the device and the method can be used for research on local corrosion behavior and mechanisms in the deep-sea simulation environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

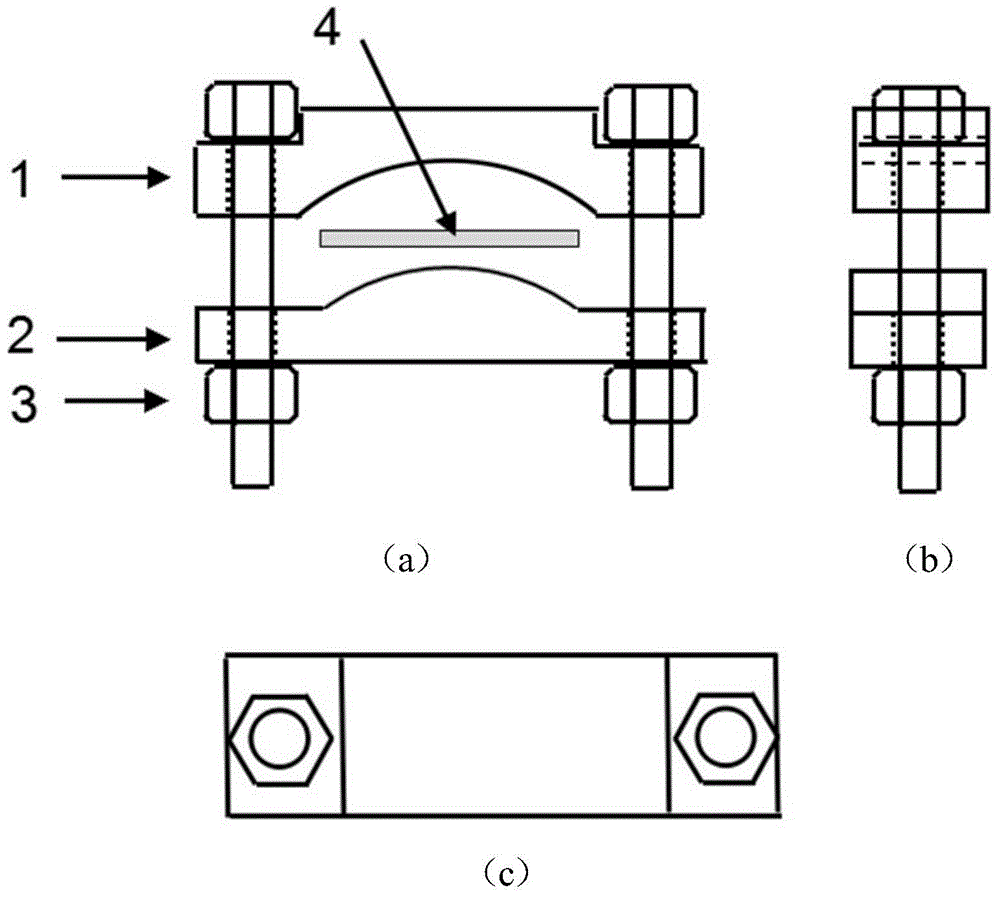

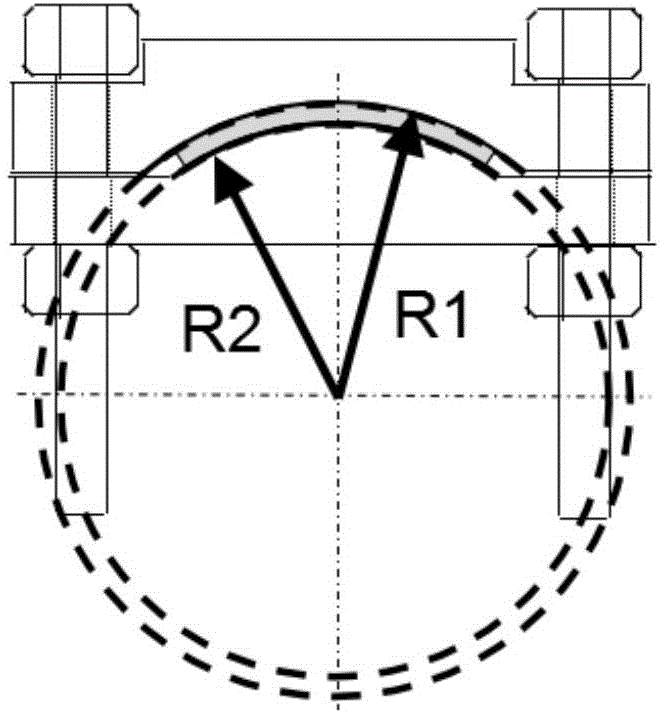

Device and method for bending crossbeam stress corrosion test

InactiveCN105716944AJudging stress corrosion performanceReduce riskWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesAlloyStressed state

Belonging to the field of corrosion science and protection technologies, the invention discloses a device and method for bending crossbeam stress corrosion test, and mainly studies the stress corrosion behavior of metals (including alloys, also be applicable to other materials). The method includes a loading deformation part and an experimental part. Mainly a groove equipped concave clamp with a predesigned fixed deformation amount and a convex clamp are used in coordination, loading bolts apply force, and retain the force in an experimental environment. A same fixed strain can be applied effectively to different samples to safely, conveniently and efficiently assess the material's stress corrosion susceptibility, including the influence of sample composition, microstructure, stress state or corrosive environment and other factors' changes to stress corrosion susceptibility.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-tensile, malleable molded bodies of titanium alloys

The object of the invention is to create high-tensile molded bodies that are made of titanium alloys and are malleable at room temperature and that, compared with the metallic glasses, have macroscopic plasticity and work hardening, without other properties, such as breaking resistance, elastic elongation or corrosion behavior being thus greatly impaired. The molded bodies according to the invention are characterized in that they are made of a material that in its composition conforms to the formula Tia E1b E2c E3d E4e, where E1 comprises one or more elements of the group containing the elements Ta, Nb, Mo, Cr, W, Zr, V, Hf and Y, E2 comprises one or more elements of the group containing the elements Cu, Au, Ag, Pd and Pt, E3 comprises one or more elements of the group containing the elements Ni, Co, Fe, Zn, Mn and E4 comprises one or more elements of the group containing the elements Sn, Al, Ga, Si, P, C, B, Pb and Sb, where a=100−(b+c+d+e), b=0 to 20, c=5 to 30, d=5 to 30, e=1 to 15 (a, b, c, d, e in atomic %). The molded bodies have a homogenous microstructure, mainly comprising a glassy or nanocrystalline matrix with ductile dendritic body-centered cubic phase embedded therein. A third phase with low volumetric proportion can be present. Such molded bodies can be used as high-stress components, e.g., in the aircraft industry, space aviation and the automobile industry, but also for medical technical equipment and implants in the medical field.

Owner:INST FUER FESTKOERPER & WERKSTOFFORSCHUNG DRESDEN EV

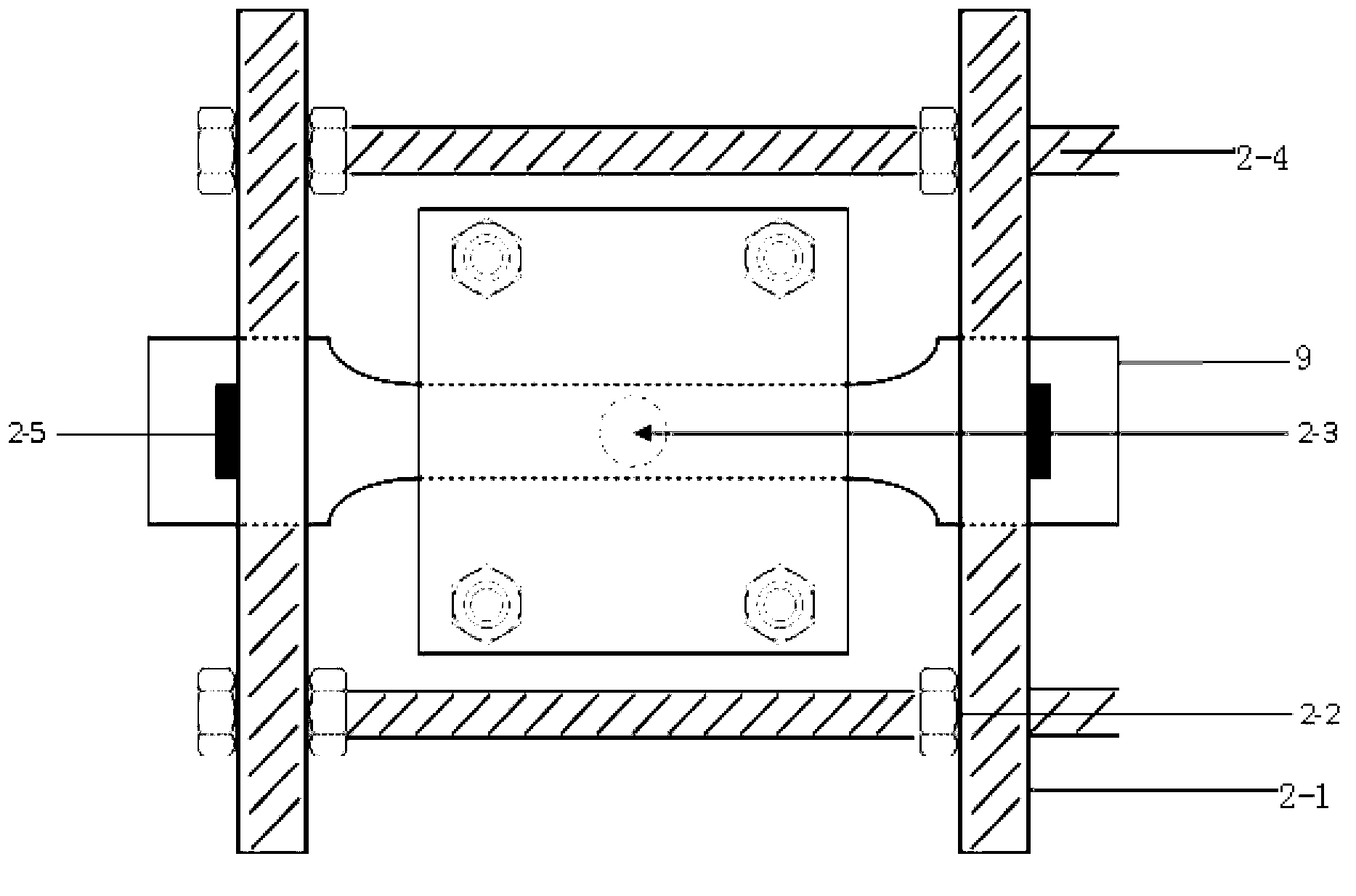

Electrochemical experiment apparatus and test method for corrosion of samples with tensile stress loaded in high-temperature and high-pressure fluid environment

InactiveCN105675481AStability test methodReliable experimental methodWeather/light/corrosion resistanceEngineeringChemical test

The invention discloses an electrochemical experiment apparatus and test method for corrosion with tensile stress loaded in high-temperature and high-pressure fluid environment. The apparatus comprises an autoclave, a branch pipe with circular flow and an electrochemical test system with tensile stress loaded; one side of the autoclave is connected to the branch pipe with circular flow, and the branch pipe with circular flow is provided with the electrochemical test system with tensile stress loaded. The apparatus and the test method can be used for researching corrosion behaviors of metal materials with the interaction of high temperature, high pressure, liquid phase fluid, loading of tensile stress, and other factors.

Owner:SOUTHWEST PETROLEUM UNIV

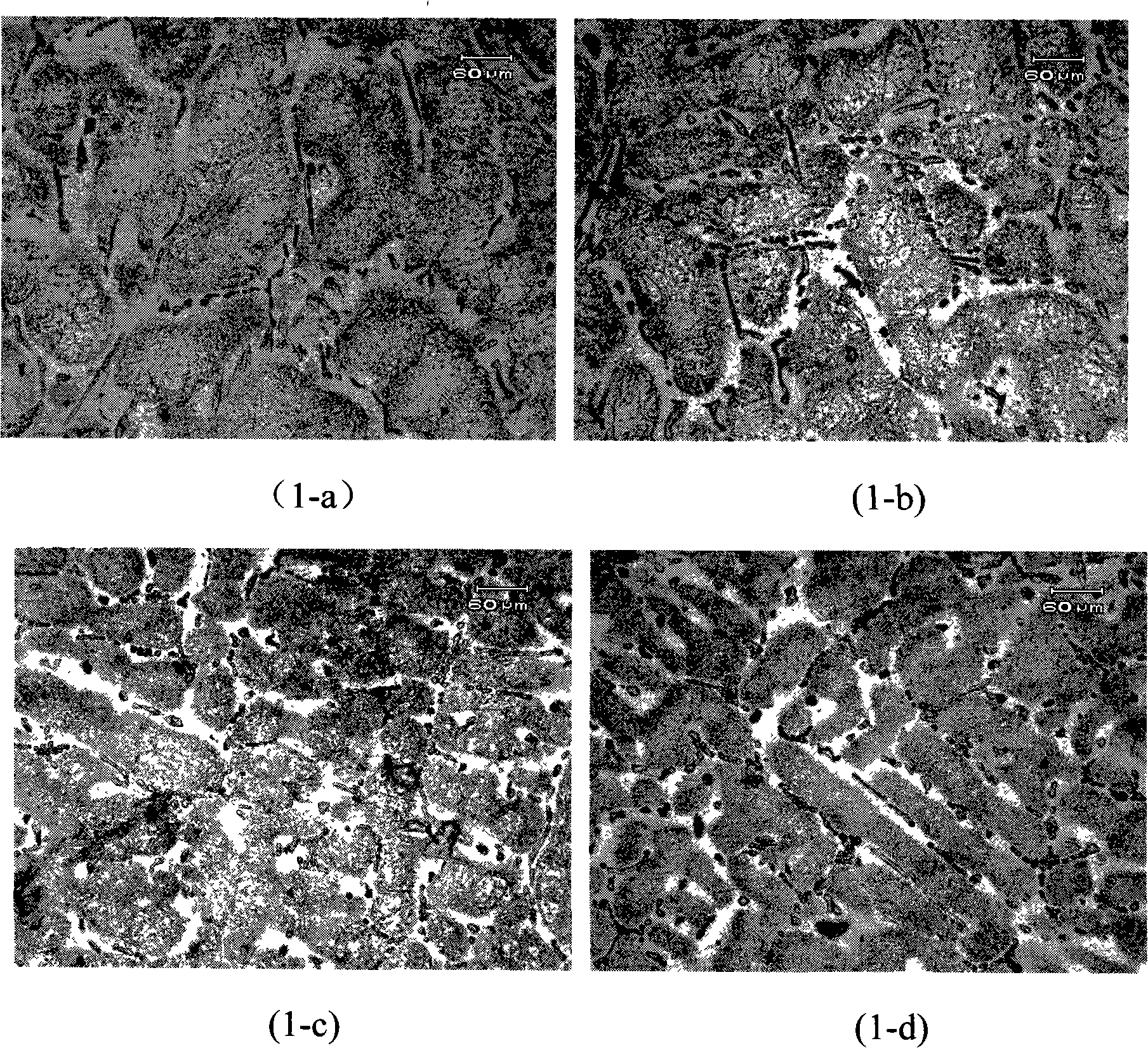

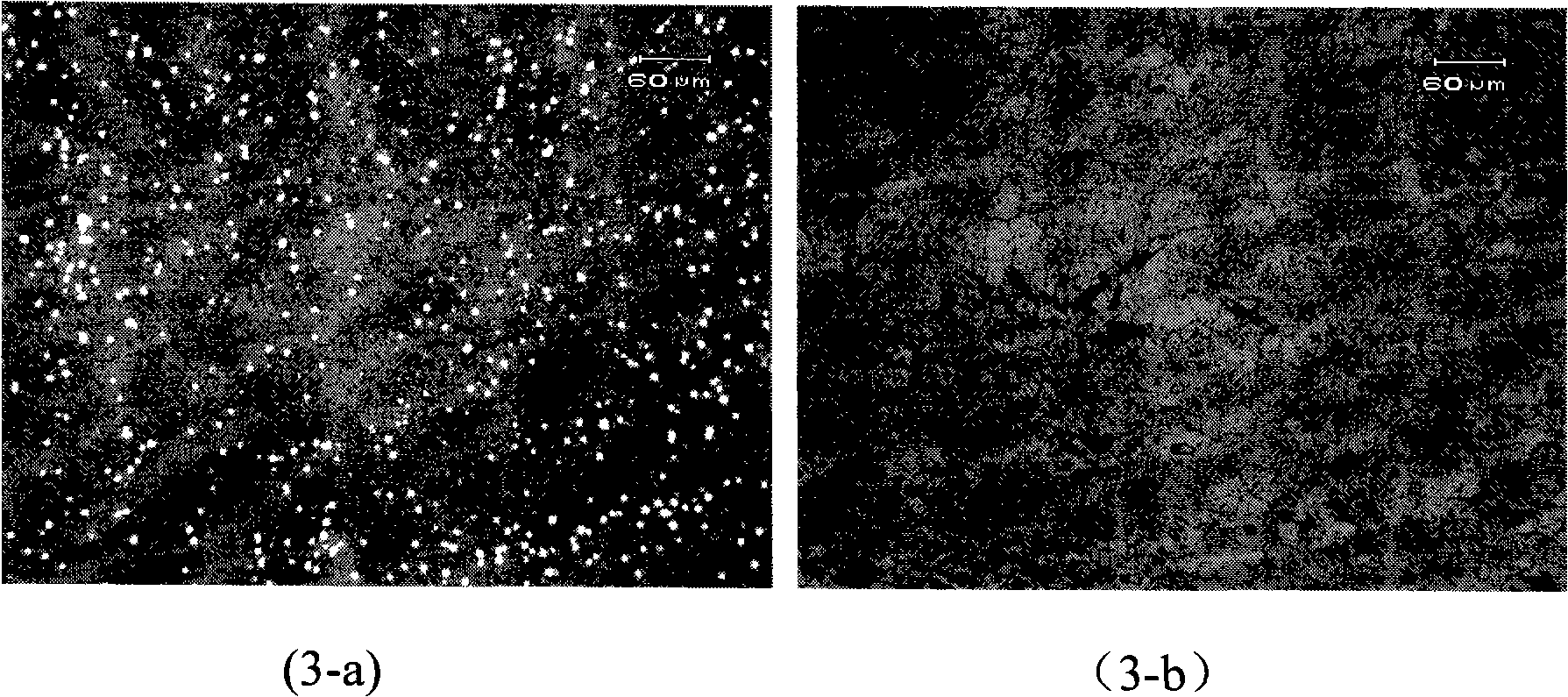

Aluminium alloy material for car radiator cooling flat tube

ActiveCN101328552AImprove corrosion resistancePromote spheroidizationZeta potentialRare-earth element

The invention relates to an aluminum alloy material for a radiator cooling flat pipe used in an automobile, belonging to the aluminum alloy material technical field. The material is mainly characterized in that aluminum-manganese alloy with a certain component is added with proper amount of mixed type rare earth(RE) taking Ce as main materials for smelting and casting. Experiments show that the rare earth element has refined action on secondphase such as eutectic phase and exsolution precipitate phase by observing fine texture of the aluminum alloy material containing the mixed type rare earth, and a plurality of small pits of electrochemical corrosion are not found in the texture of the aluminum-manganese alloy added with rare earth, which means that the corrosion resistance of the aluminum-manganese alloy added with rare earth is improved; and the corrosion behavior of the alloy material is tested by the zeta potential scanning polarization curve test technology, which shows that the corrosion resistance of the aluminum-manganese alloy added with rare earth is improved to some extent. The aluminum material provided by the invention can be directly made into the aluminum flat pipe by drawing, and also be used to process plate materials to be manufactured into radiator ribs, and the radiator ribs are not collapsed in the high temperature brazing.

Owner:JIANGSU JIAHE THERMAL SYST RADIATOR +1

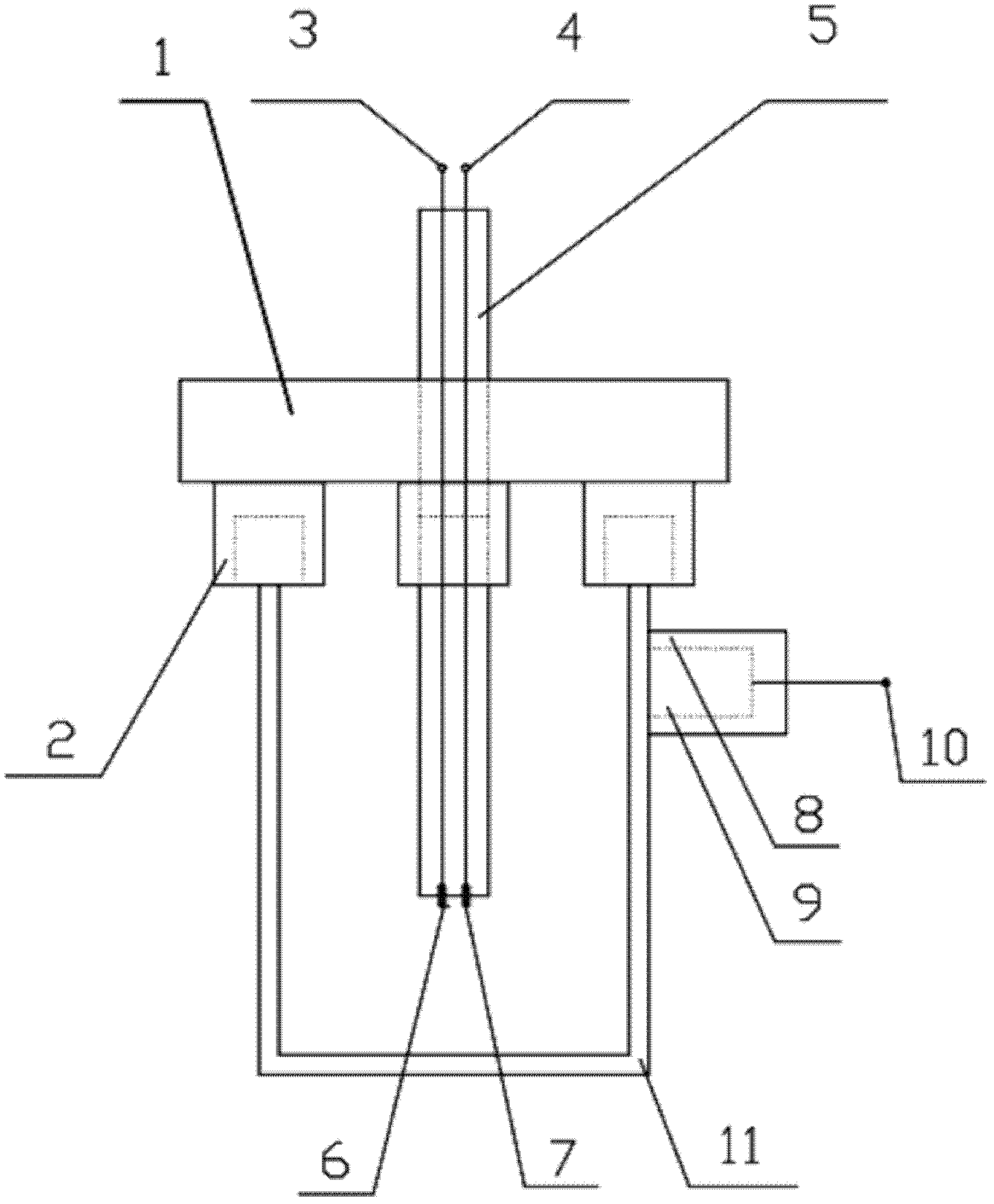

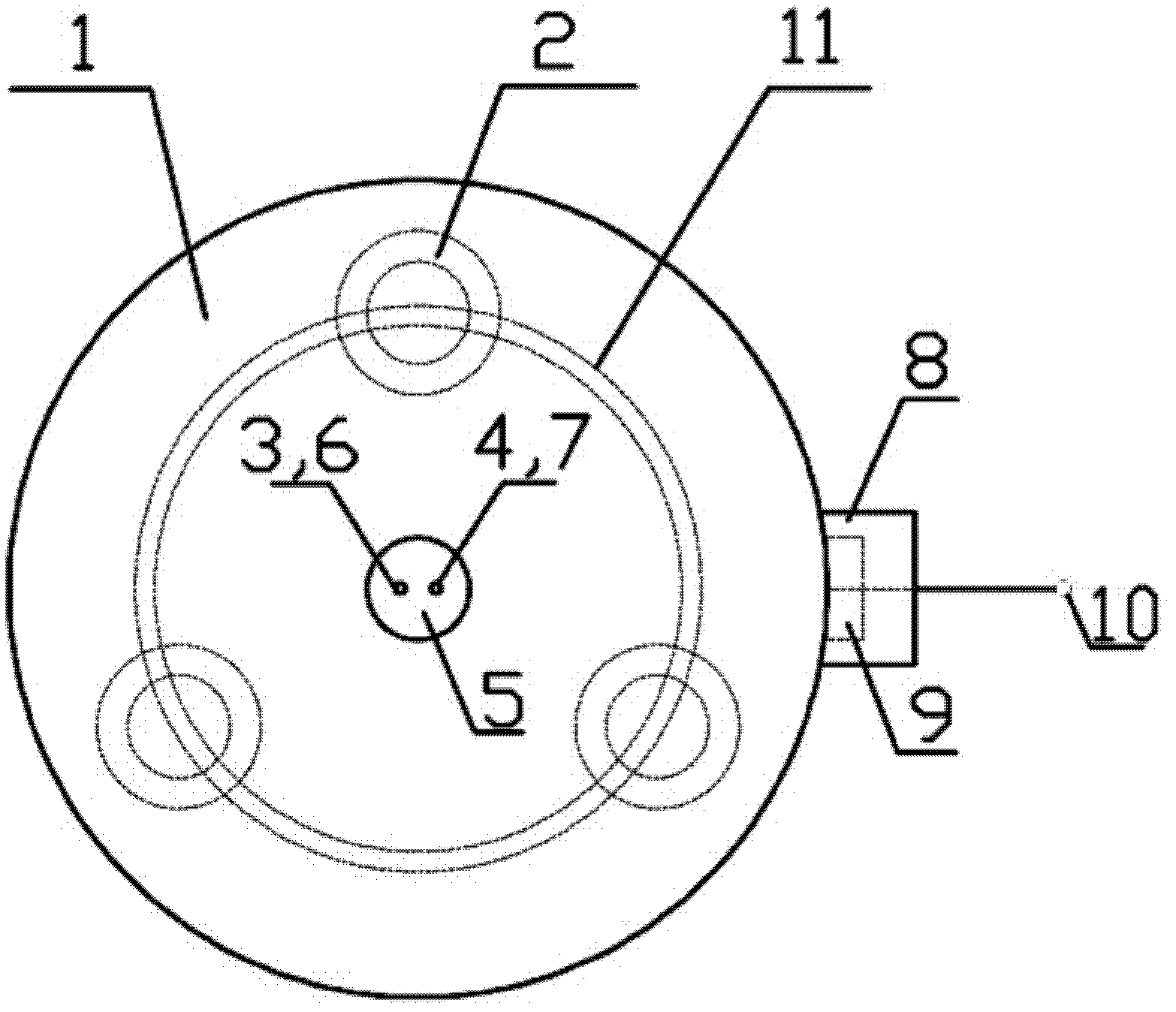

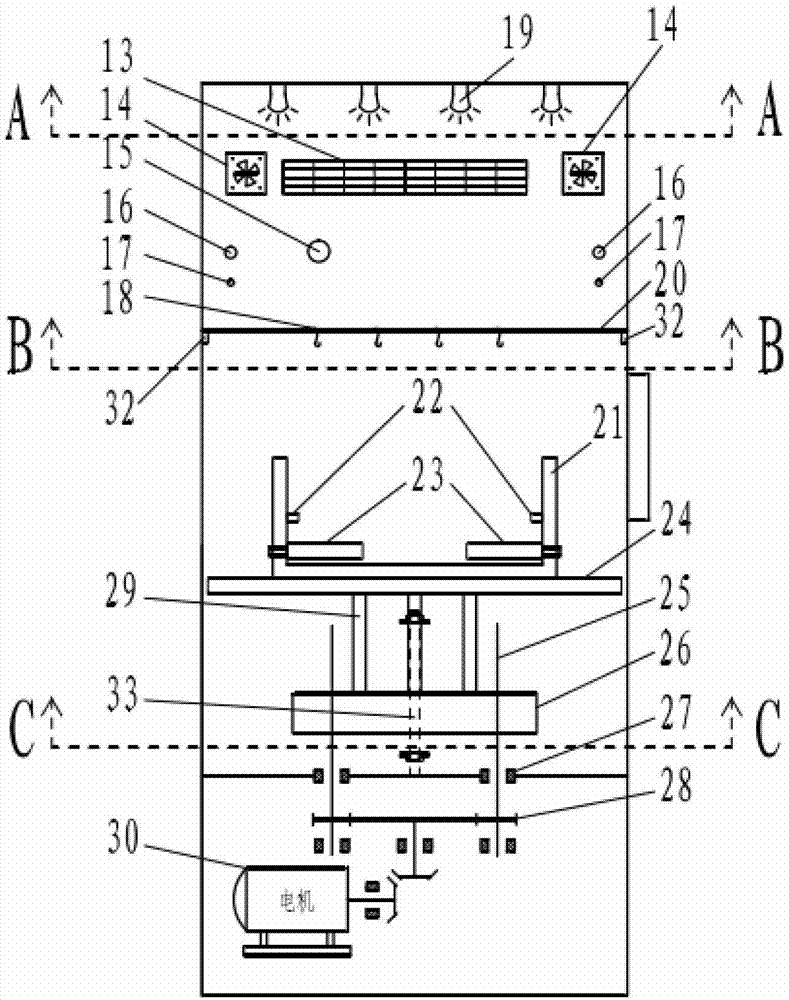

Researching device and researching method of corrosion electrochemistry behavior in splashing zone

InactiveCN104132885AGuarantee authenticityGuaranteed accuracyWeather/light/corrosion resistanceElectrical/magnetic thickness measurementsThin layerEngineering

The invention relates to a researching device and a researching method of a corrosion electrochemistry behavior in a splashing zone. The device includes a first guide rail support, a second guide rail support, an X-Y axial moving bench, a displacement sensor, an insulating cylinder, a high-precision digital-display meter, a multi-channel data recorder, a platinum wire probe, a working electrode, a T-shaped electrode carrying bench, a bottom bench and a container. With the multi-channel data recorder, a displacement change and abrupt voltages during contact of the platinum wire probe to a liquid film and the working electrode are recorded at the same time, thereby ensuring authenticity, accuracy and reliability of data. By means of change of a relative position of the working electrode to a liquid level, a thickness of a thin-layer liquid film can be adjusted so that the thickness of the thin-layer liquid film can be adjusted continuously, thereby providing a convenient and effective method for researching a corrosion behavior under the thin-layer liquid film during a researching process of the corrosion electrochemistry behavior in the splashing zone. The method and the device are simple in operation and high in precision.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

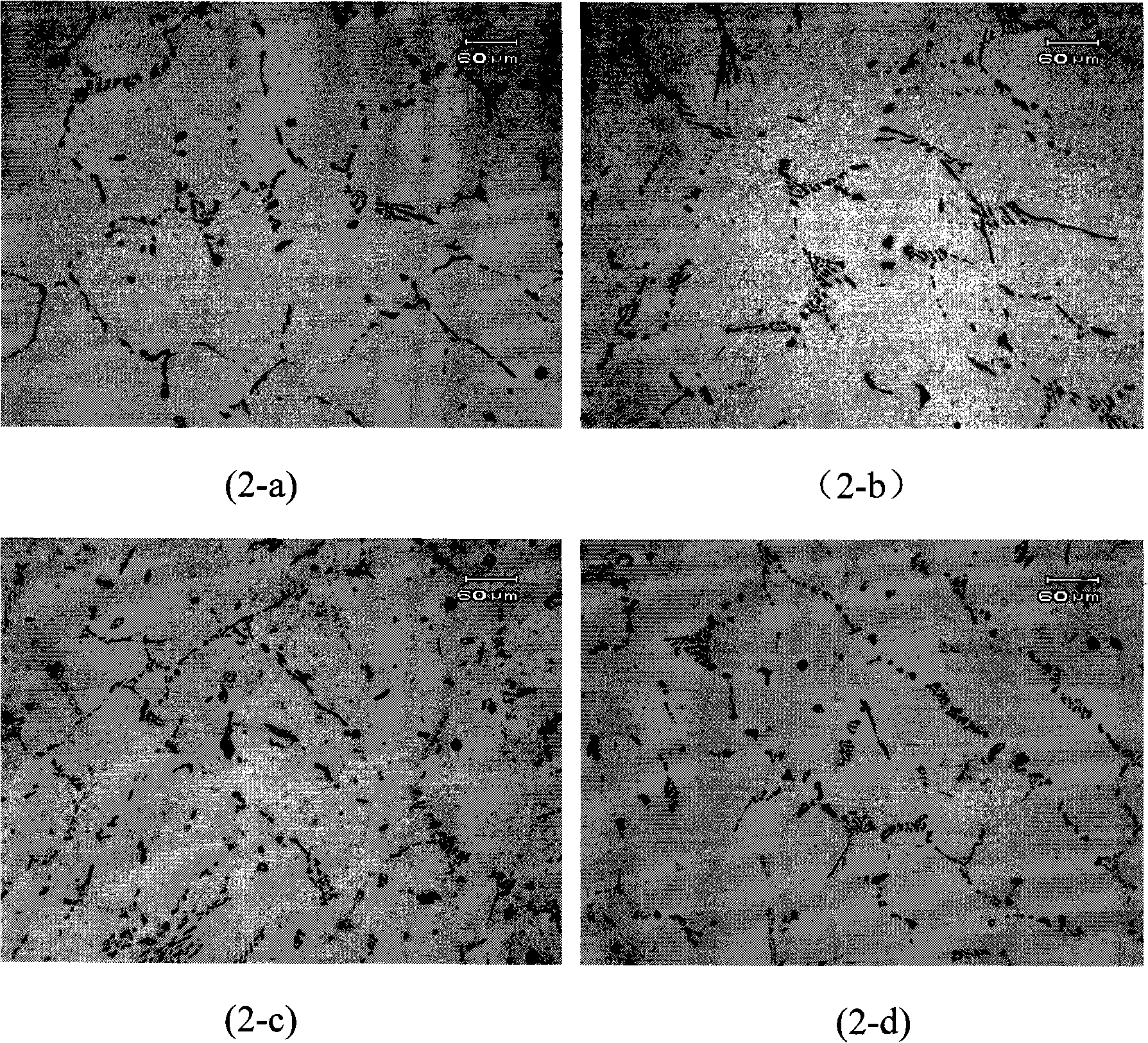

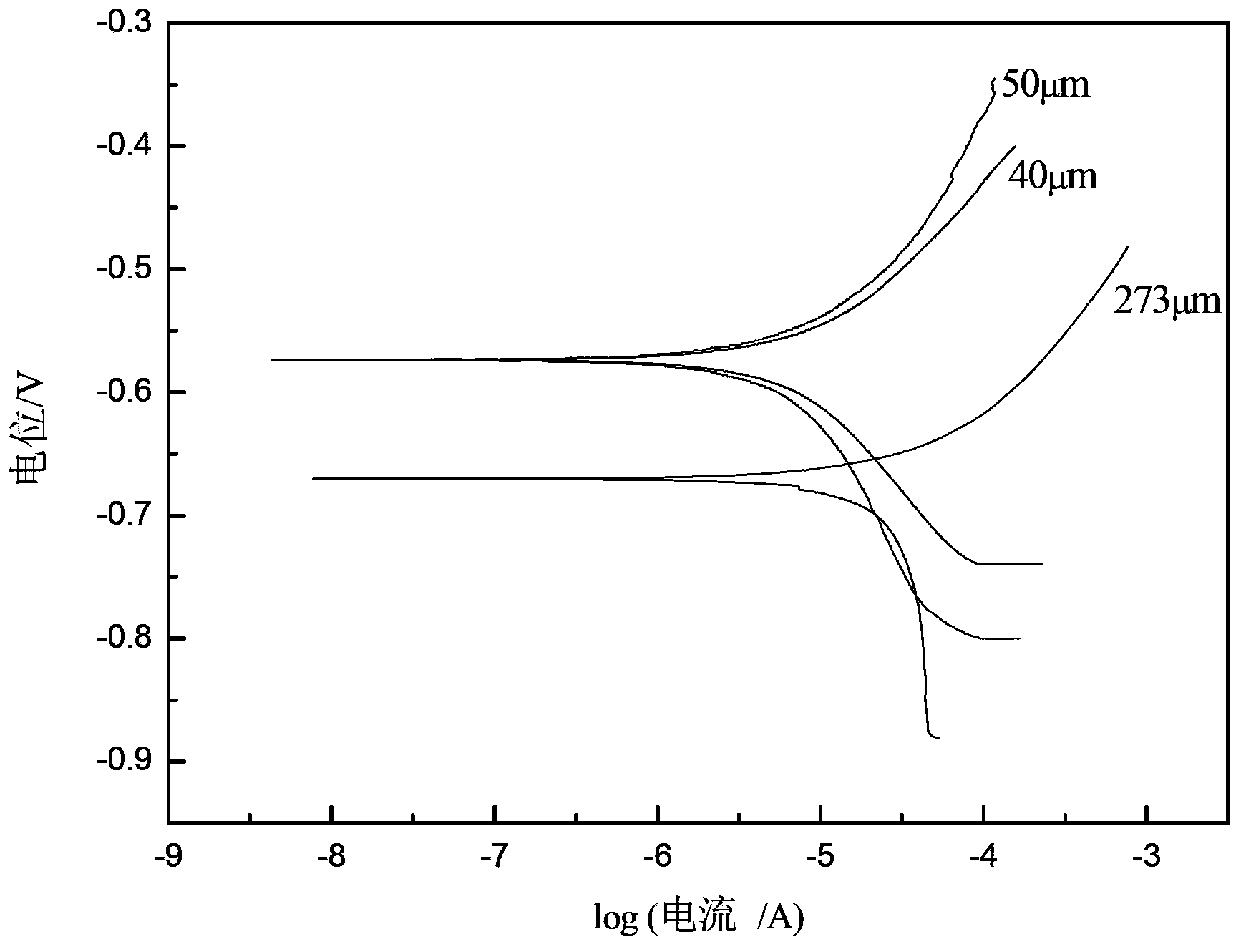

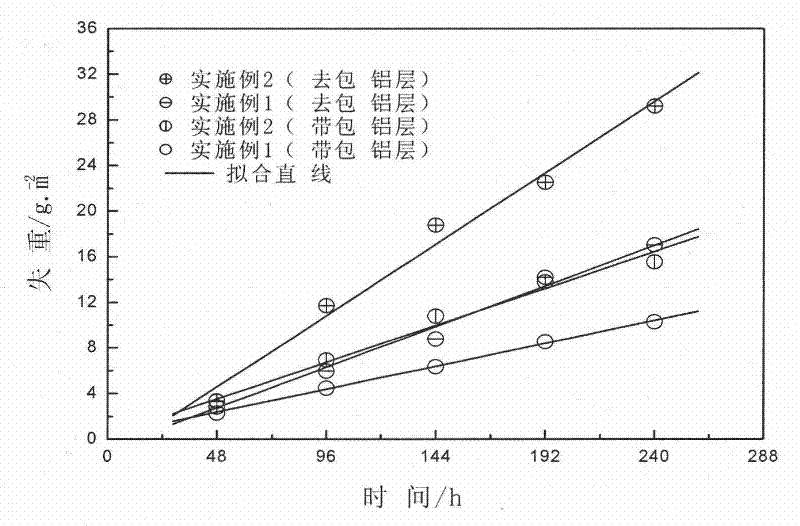

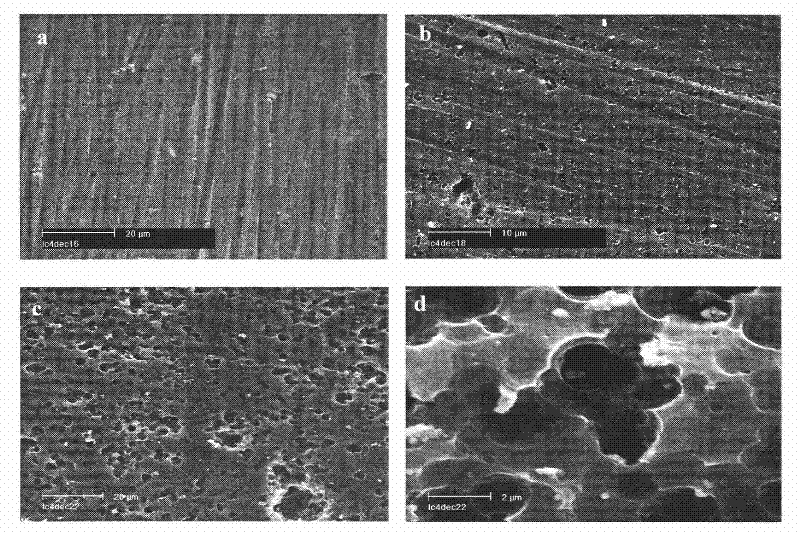

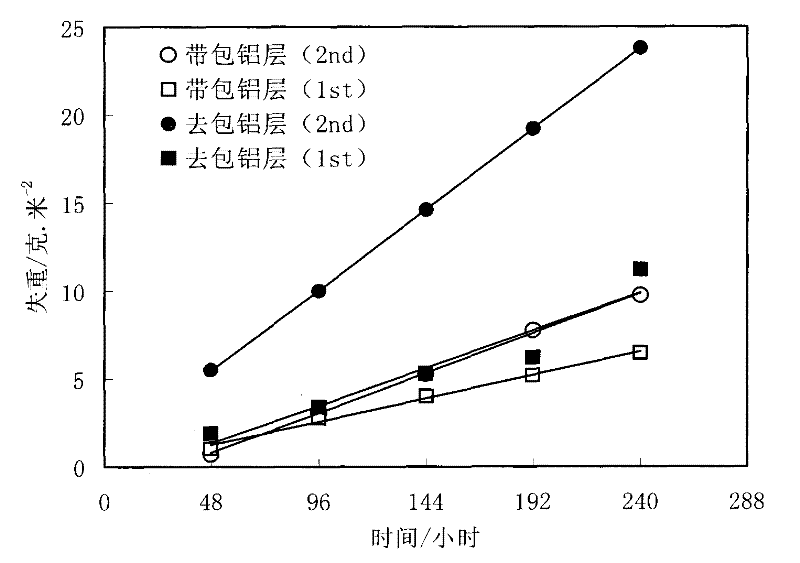

Test method for simulating corrosion process of aluminum and aluminum alloy in industrially polluted atmospheric environment

InactiveCN102128781ARapid evaluation of atmospheric corrosion resistanceHigh magnificationWeather/light/corrosion resistanceTested timeTest material

The invention relates to aluminum and aluminum alloy atmospheric corrosion simulation technique, in particular to a test method for simulating the corrosion process of aluminum and aluminum alloy in an industrially polluted atmospheric environment. In the method, aluminum or aluminum alloy is used as a tested material; aqueous solution containing NaHSO3 at a concentration of 0.02mol / L and NaCl at a concentration of 0 to 0.006mol / L is used as corrosive liquid; and soaking, drying and wetting are carried out in turn and are circulated every 10 to 20 minutes, wherein soaking is performed at 45 to 50 DEG C for 1 to 2 minutes, drying is performed at 50 to 60 DEG C for 8 to 15 minutes, wetting is performed at 40 to 50 DEG C for 1 to 3 minutes, and the test time is 48 to 240 hours. The method has simulating performance, accelerating performance and repeatability, can be used in study on the corrosion behaviors of the aluminum and aluminum alloy in the industrially polluted atmospheric environment to evaluate and predict the atmospheric corrosion of the aluminum and aluminum alloy quickly, and can solve the problems of long test period, high cost, difficult environmental factor control and the like of the conventional atmospheric exposure test.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

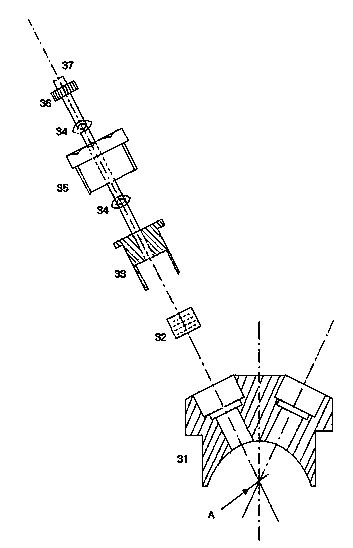

Device and method for preparing in-situ electron microscopy sample by adopting converged femtosecond laser

PendingCN107745197APulse width adjustableImprove machining accuracyLaser beam welding apparatusNumerical controlHeat-affected zone

The invention relates to the field of laser micro-area machining and preparation of electron microscopy in-situ samples, in particular to a device and method for fine machining and forming an electronmicroscopy sample by utilizing a converged laser. The device comprises a femtosecond laser device and converging scanning system, a sample table mechanical numerical control moving system, a coaxialmicroscopic observation and positioning system, a computer centralized data monitoring and visualization system, a damping system and a protective system. The device can be utilized to quickly and conveniently use femtosecond laser to conduct fine machining such as numerical control cutting and punching on various electron microscopy samples such as a metal sheet, an alumina ceramic block and transparent quartz glass, thereby the in-situ electron microscopy sample with the specific shape and notch can be prepared through the device; combining with an in-situ observation technology through an electron microscope, in-situ observation research such as mechanics, electrics and corrosion behaviors can be conducted on some special tissues and structures; and the device has the advantages of being wide in machining area, and high in precision, having no heat-affected zone and no pollution and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-temperature and high-pressure dynamic electrochemical testing experimental device and testing method

ActiveCN105806774AAchieving tightnessGuaranteed accuracyWeather/light/corrosion resistanceEngineeringAuxiliary electrode

Provided is a high-temperature and high-pressure dynamic electrochemical testing device and testing method.A high-temperature and high-pressure reaction kettle comprises a high-pressure kettle body, a high-pressure kettle cover, a gas inlet pipe, a gas outlet pipe, a rotating shaft, a pressure sensor, a pressure meter, a temperature sensor, a heating device and a heat insulating layer; a three-electrode system comprises a reference electrode, a working electrode column, an auxiliary electrode column and a stabilizing device; an external control box is connected with the heating device and the rotating shaft, an external gas supply system is connected with the gas inlet pipe of the device, an external electrochemical workstation is connected with terminals of the auxiliary electrode, the reference electrode and the working electrode, and a computer is connected with the external electrochemical workstation.The high-temperature and high-pressure dynamic electrochemical testing device meets the requirements of the sealing property and high-temperature-resistance property of a testing environment, proves a high-temperature and high-pressure environment and can be used for research of dynamic high-temperature and high-pressure corrosion behaviors and mechanisms.

Owner:TIANJIN UNIV

Electrochemical test device for metallic corrosion of 90-degree elbow in flowing corrosive medium

ActiveCN107449730AComplete and accurate simulationComplete and Accurate ResearchWeather/light/corrosion resistanceNuclear energy generationStraight tubeStructural engineering

The invention discloses an electrochemical test device for metallic corrosion of a 90-degree elbow in a flowing corrosive medium. The device comprises a glass pipeline which is in same structure and size with a to-be-tested 90-degree elbow, wherein the glass pipeline is horizontally arranged; the glass pipeline is composed of a 90-degree bent pipeline section, a first straight pipeline section and a second straight pipeline section; the first straight pipeline section and the second straight pipeline section are vertical to each other and are respectively connected with the ports at the two ends of the 90-degree bent pipeline section; and a plurality of glass branches are connected with the glass pipeline. The electrochemical test device for metallic corrosion of the 90-degree elbow in the flowing corrosive medium disclosed by the invention is used for performing real-time electrochemical corrosion measurement on the to-be-tested metal at the pipeline elbow in the flowing corrosive medium and breaks through the limitation of the present electrochemical test device for researching the corrosion test of the straight pipe section, so that the running condition and corrosion behavior of the whole water supply pipeline can be more completely and accurately stimulated and researched.

Owner:TIANJIN UNIV

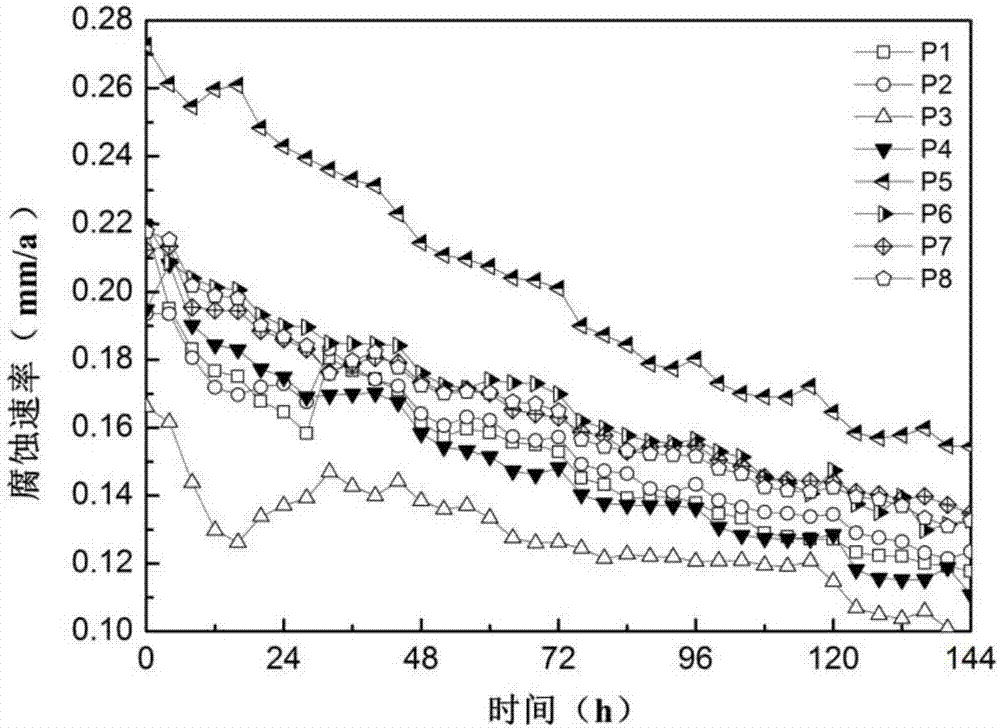

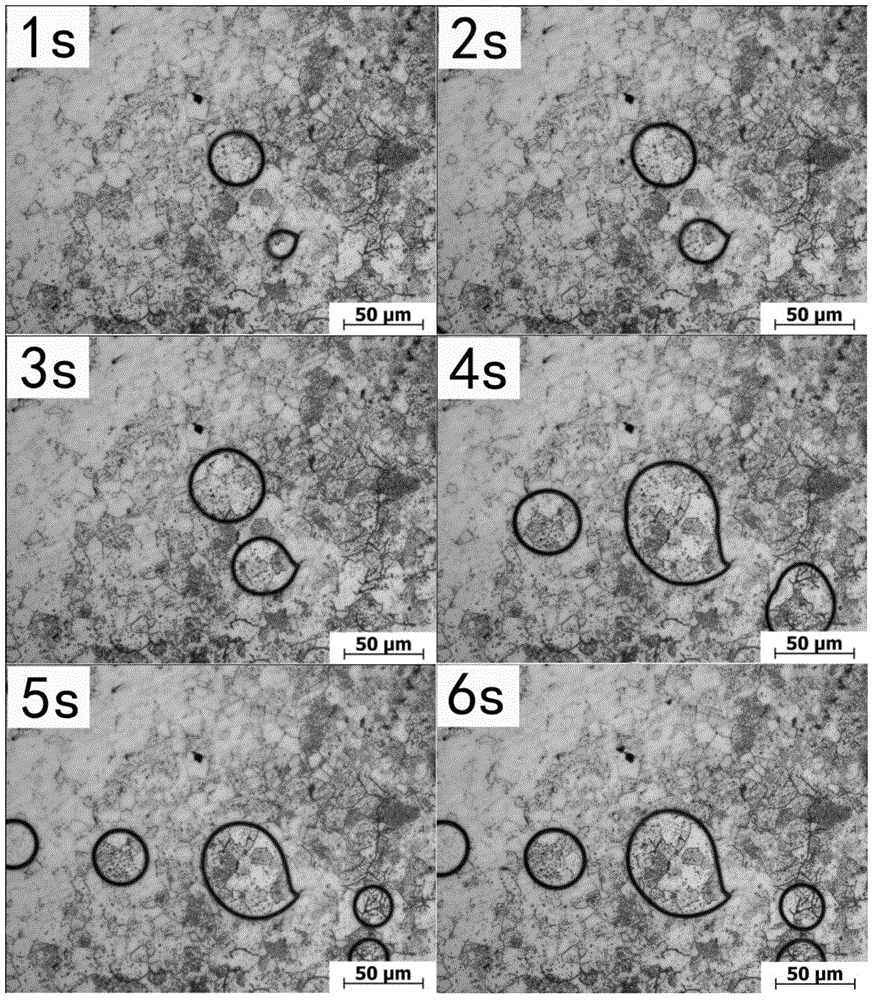

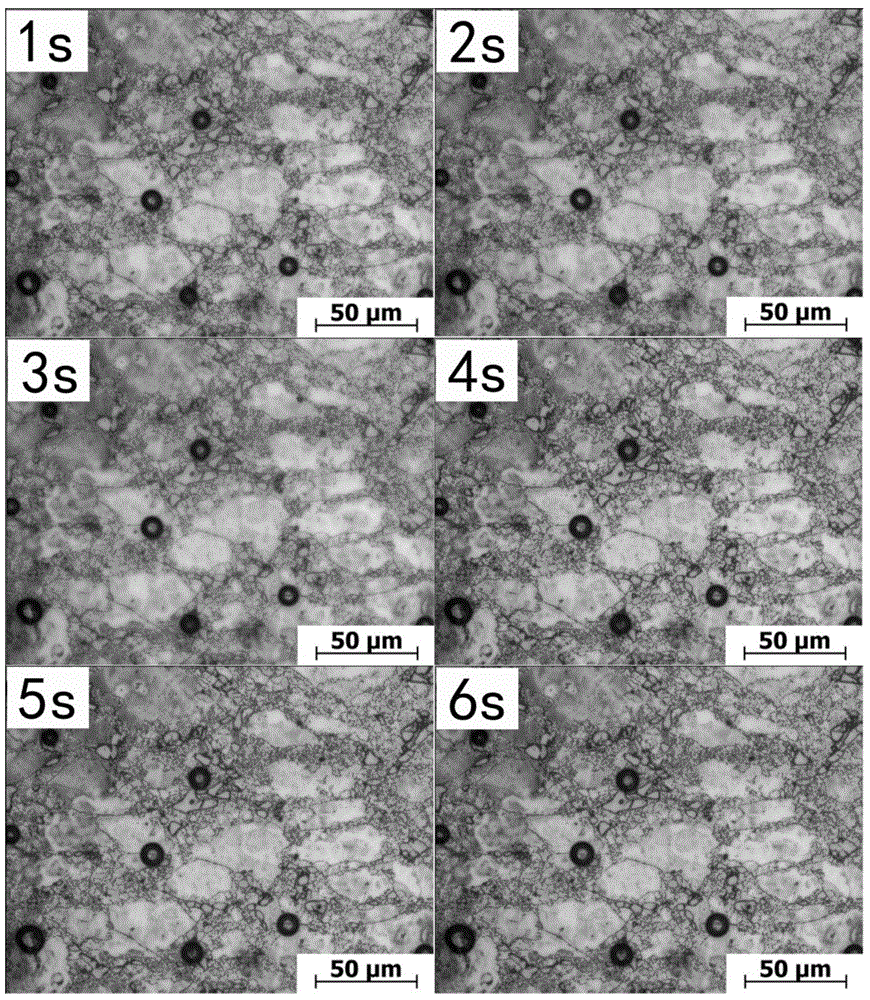

Method for recording and observing corrosion behavior of magnesium alloy microstructure in situ

ActiveCN104677715AEasy and reliable determinationAccurately determineWeather/light/corrosion resistancePreparing sample for investigationMicroscopic observationCover glass

The invention relates to a method for recording and observing the corrosion behavior of a magnesium alloy microstructure in situ, and belongs to the field of material corrosion analysis. The method comprises the following steps: firstly, sampling, taking a metallographic specimen from a to-be-analyzed magnesium alloy material, carrying out rough grinding, fine grinding, polishing and corroding for later use; putting a cover glass with good light transparency on a shelving unit of a metallographic microscope, wherein the cover glass can completely cover a microscope observation hole; putting a processed sample on the cover glass, and adjusting a lens so as to obtain a clear metallographic structure; dipping a cotton swab in a corrosion salt solution, wiping the observation surface of the specimen lightly for multiple times, and putting the specimen on the cover glass; observing and recording the corrosion behavior of the specimen by the microscope, and recording the crystal boundary, the crystal grain and the second phase corrosion status at each time interval by observing and recording the corrosion behavior of the specimen by the microscope. According to the invention, the sampling is simple, the cycle is short, and the analysis speed is high; the priority corrosion region can be determined accurately by comparing, observing and analyzing the corrosion behavior of the magnesium alloy microstructure, so that the corrosion mechanism of the material can be judged.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com