Device and method for bending crossbeam stress corrosion test

A stress corrosion and beam technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, and application of stable tension/pressure to test the strength of materials, etc. problem, to reduce misleading effect and reduce risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The bending beam test with gap in this embodiment includes the following contents:

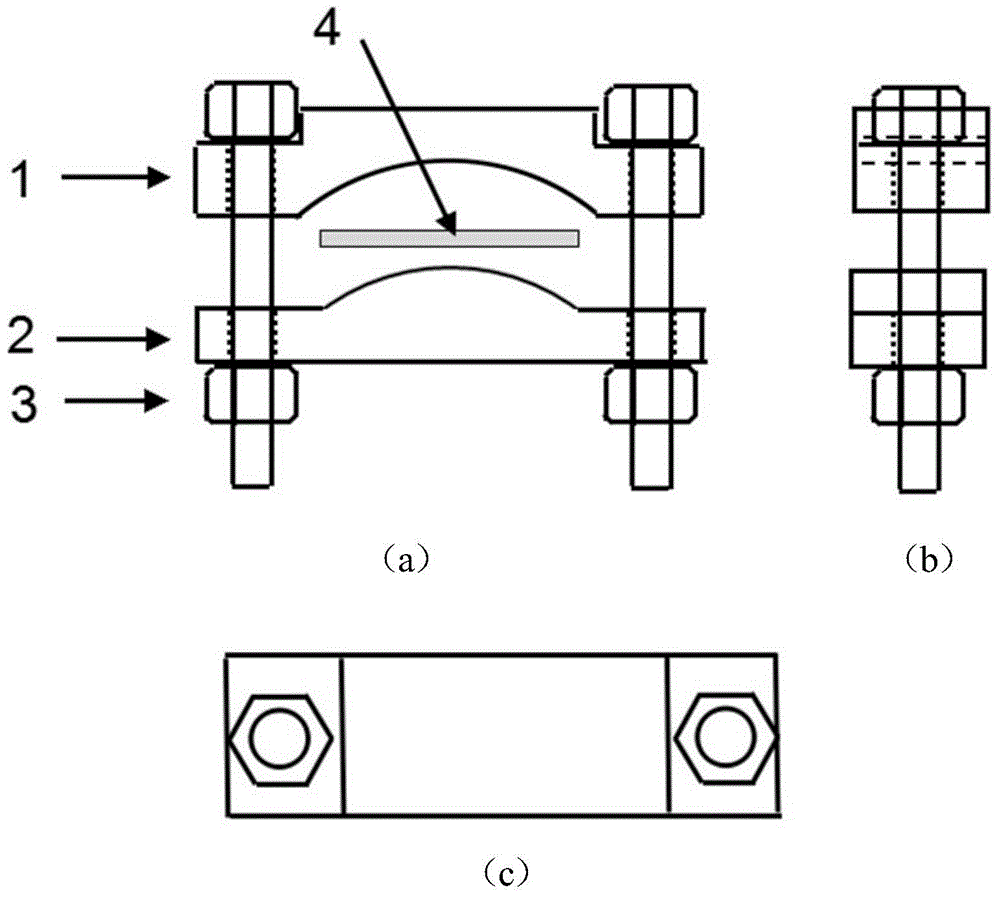

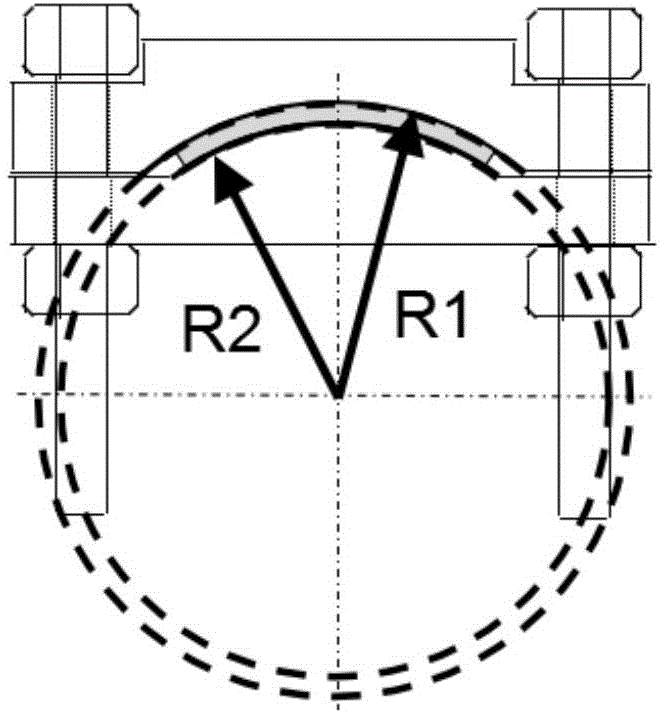

[0069] The design of the fixture in the present invention. The materials used in experimental sample 4 are 316L stainless steel and 308L stainless steel for welding, which belong to the face-centered cubic structure and have good shaping, so the surface strain is selected as 3%. The sample size is selected as 35mm×10mm×2mm. Using the simple estimation method, the arc radii required for the test are calculated as follows: the arc radius of the concave surface of the concave fixture is 34.3mm, and the arc radius of the convex surface of the convex fixture is 32.3mm. The fixture material is 316L stainless steel. In order to ensure that the sample is in a proper position in the fixture, the arc length of the convex surface is selected as 40mm, and the corresponding arc length of the concave surface is calculated as 47.8mm. The width of the fixture is selected as 10mm, and the length is s...

Embodiment 2

[0074] The main difference between Embodiment 2 of the present invention and Embodiment 1 lies in the test fixture, and other contents may refer to Embodiment 1.

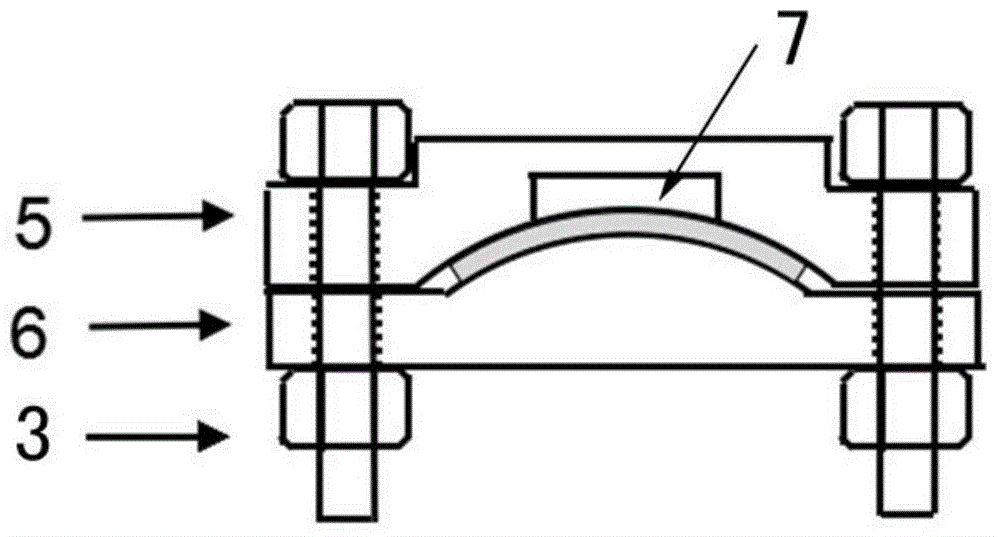

[0075] The schematic diagram of the test fixture structure of the present invention is Figure 5 , consists of two concave clamps II5 with 7 grooves, one male clamp II6 and two loading bolts 3. The male grip II6 in the test fixture consists of two convex faces. Each convex surface corresponds to a concave fixture II5 with a groove 7, and coincides with the center of its arc surface, and its radius is consistent with the size of the sample preparation fixture, namely 34.3mm and 32.3mm. Bolt holes with a diameter of 8.5mm are left on both sides of the concave fixture II5 and the convex fixture II6 of the test fixture respectively. The central axes of the holes coincide and have the same size, and M8 bolts are used. The minimum distance between the bottom of the groove 7 and the surface of the sample in the two groov...

Embodiment 3

[0077] The main difference between Embodiment 3 of the present invention and Embodiment 1 lies in the test fixture, and other contents may refer to Embodiment 1.

[0078] The schematic diagram of the test fixture structure of the present invention is Image 6, consisting of a concave clamp II5 with double grooves 7, a male clamp II6 and two loading bolts 3. The convex fixture II6 in the test fixture can be the same as the convex fixture I2 of the sample preparation fixture in Example 1. The center of the arc surface of the convex fixture II6 coincides with the arc surface of the concave fixture II5 with double grooves 7, and its radius is consistent with the size of the sample preparation fixture, namely 34.3mm and 32.3mm. Bolt holes with a diameter of 8.5mm are left on both sides of the concave fixture II5 and the convex fixture II6 of the test fixture respectively. The central axes of the holes are coincident and the same size, and M8 bolts are used. The minimum distance b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com