Patents

Literature

47 results about "Joint acceleration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for generating a motion of a human type link system

InactiveUS7136722B2Easy to understandSimple interfaceProgramme-controlled manipulatorComputer controlInverse dynamicsClassical mechanics

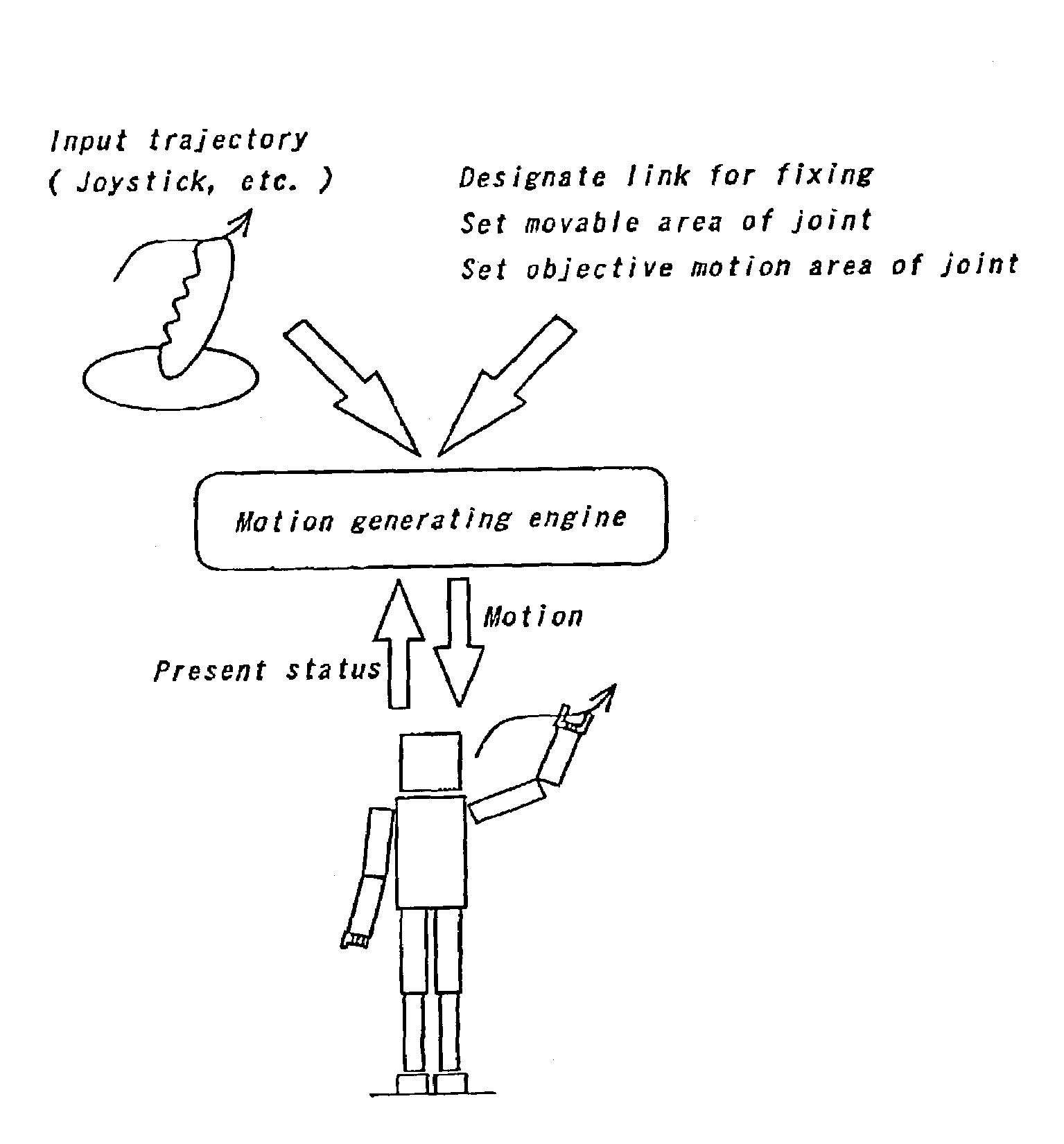

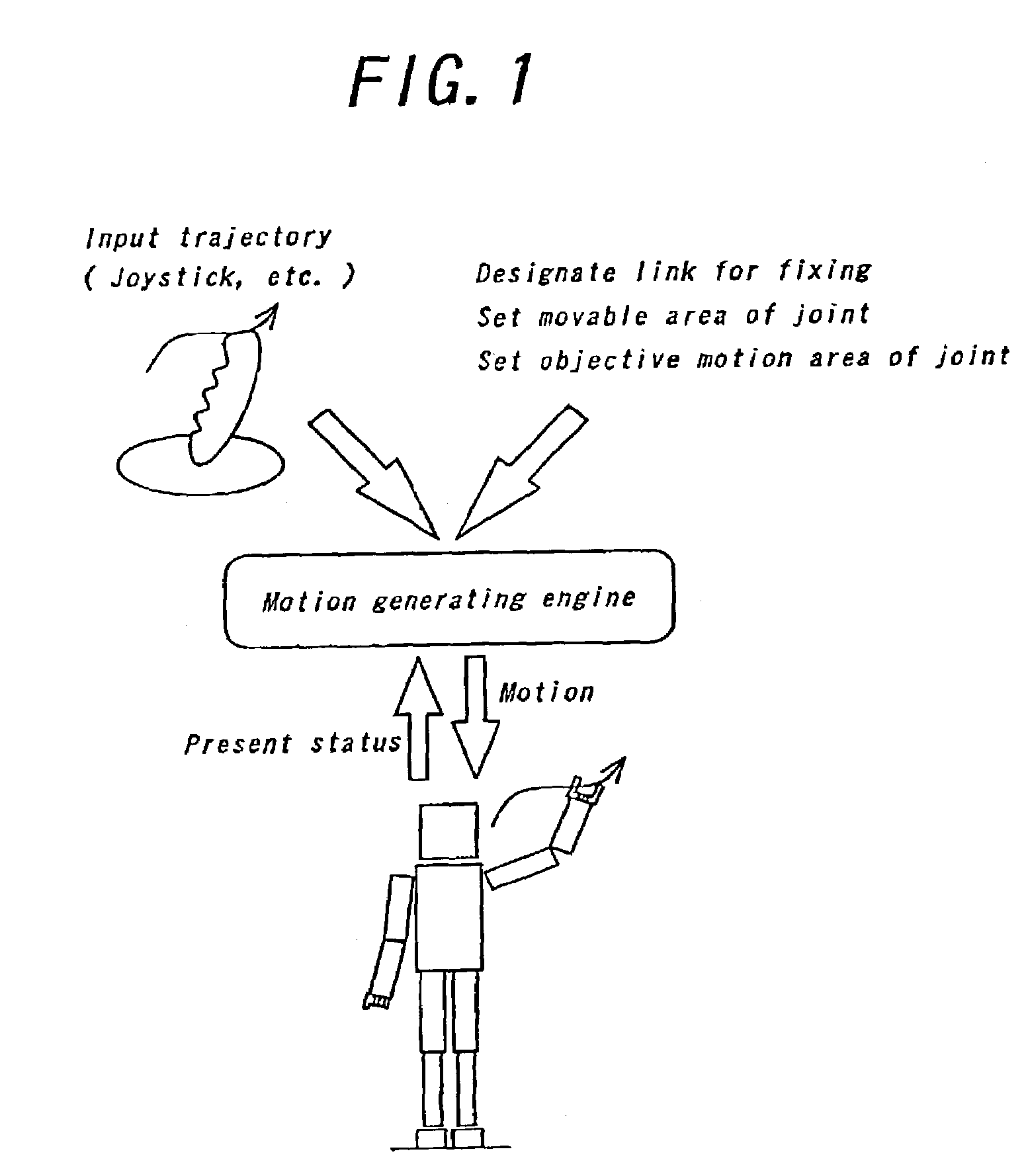

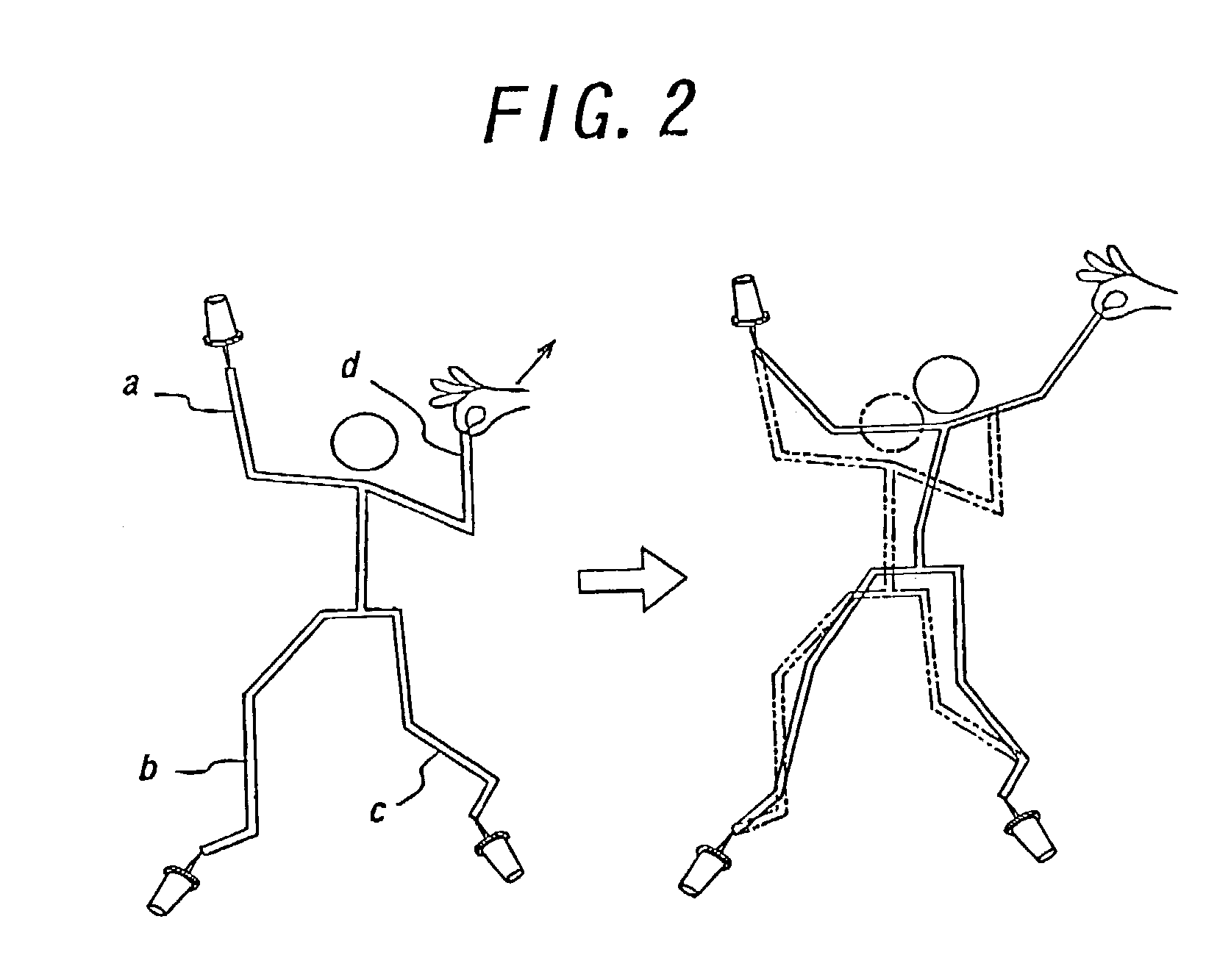

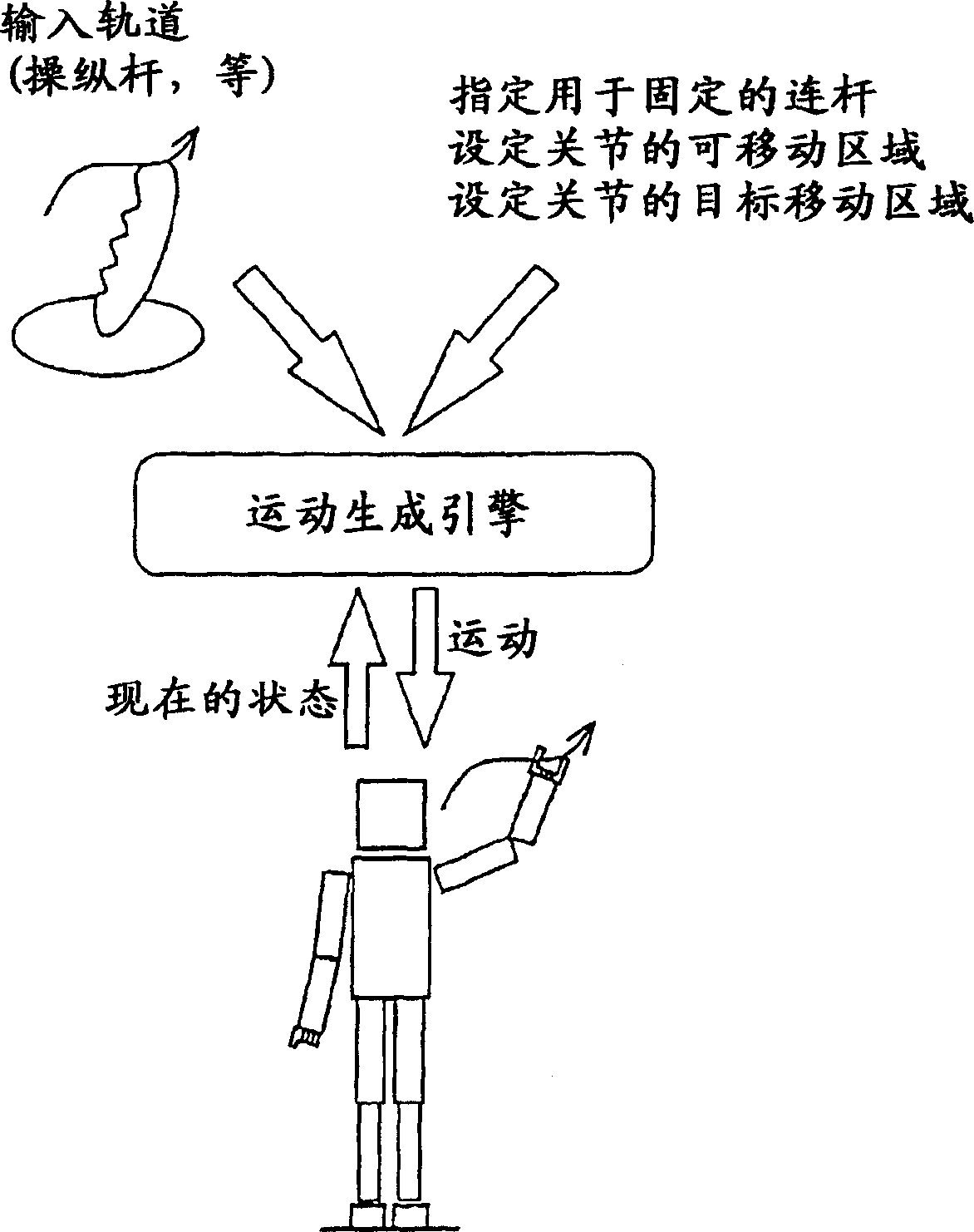

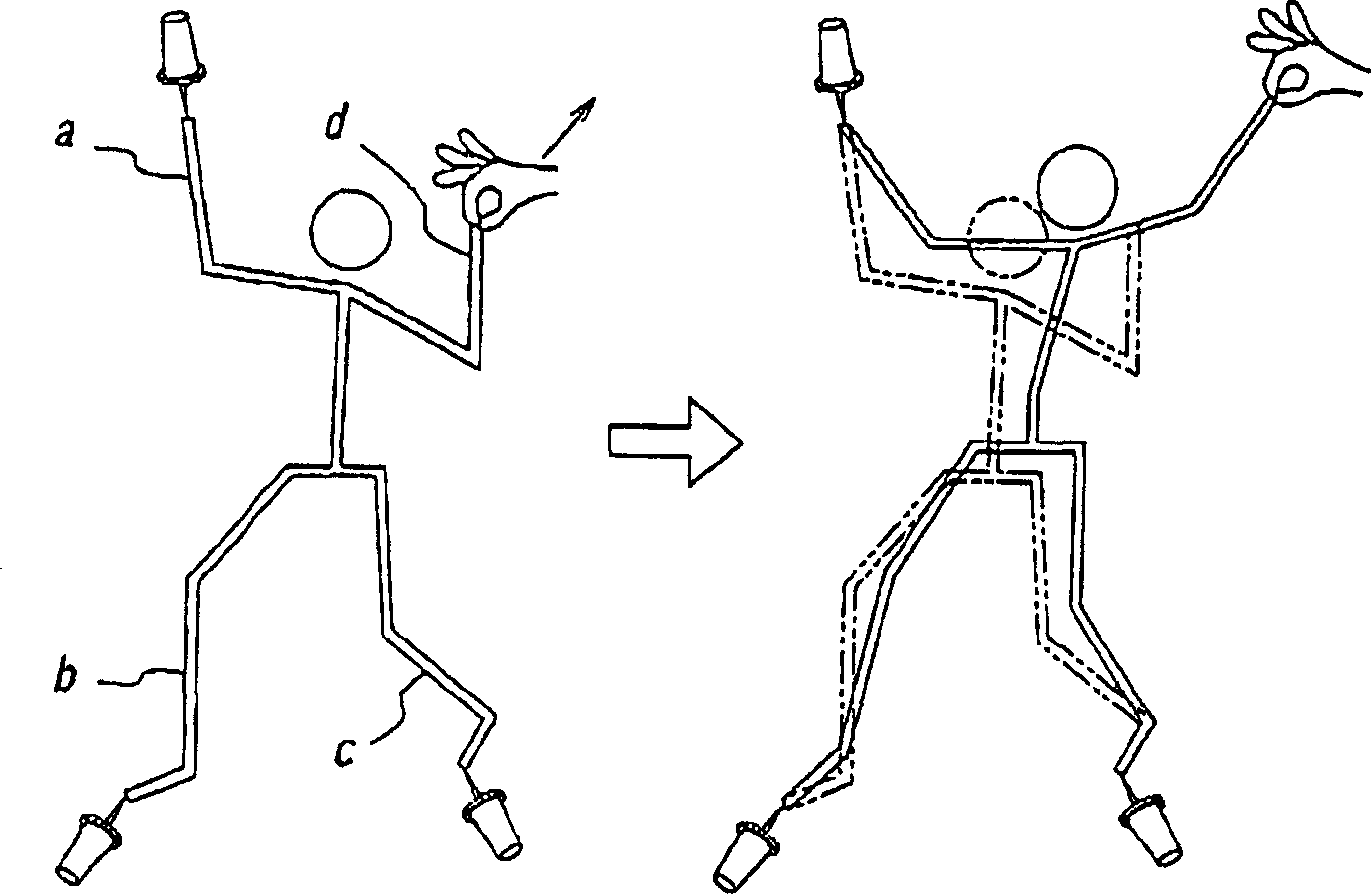

A human-type link system, such as a humanoid robot having a dynamically feasible motion of the link system that is generated when a reference joint acceleration that is only calculated from a kinematical constraint condition is determined not feasible by an evaluation of external force computed based on an inverse dynamics calculation, or is generated by calculating from a dynamic constraint condition and a kinematical constraint condition simultaneously, the dynamic constraint condition is formulated by using an actuation space inverse inertial matrix that represents the relation of force acting on the link system and the acceleration of the link system caused by the force.

Owner:THE UNIV OF TOKYO

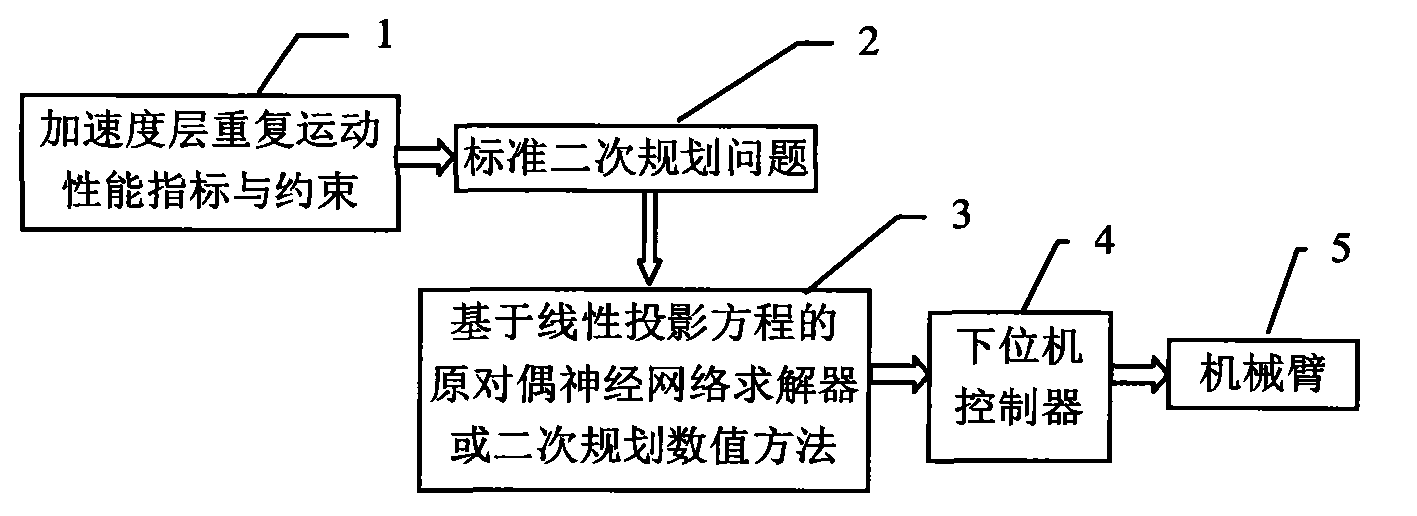

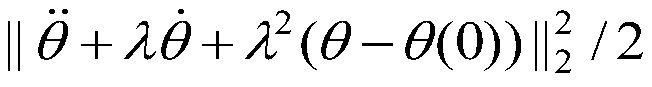

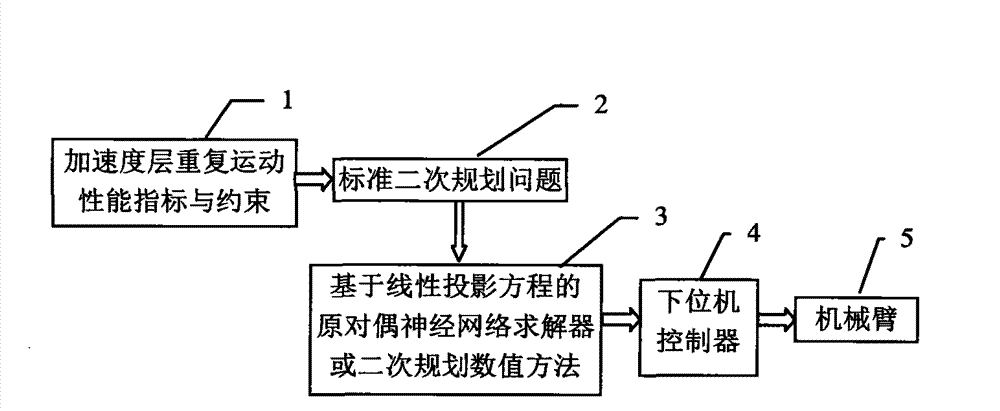

Repetitive motion planning method for redundant manipulator

The invention provides a repetitive motion planning method for a redundant manipulator, which comprises the following steps of: 1) resolving a manipulator repetitive motion scheme on an acceleration layer by adopting quadratic model optimization through an upper computer, designing the minimum performance index as repetitive motion, and restraining by an acceleration Jacobian equation, a joint angle limit, a joint speed limit and a joint acceleration limit; 2) converting the quadratic model optimization in the step 1) into standard quadratic programming; 3) solving the standard quadratic programming in the step 2) by using a linear projection equation-based primal-dual neural-network solver or quadratic programming numerical method; and 4) transmitting a solving result in the step 3) to acontroller of a lower computer for driving the manipulator to move. The method realizes the repetitive motion of the manipulator on the acceleration layer, has good control effect on the redundant manipulator inconvenient to control, and can effectively prevent the manipulator from exceeding the limits and being physically damaged according to various joint limits.

Owner:SUN YAT SEN UNIV

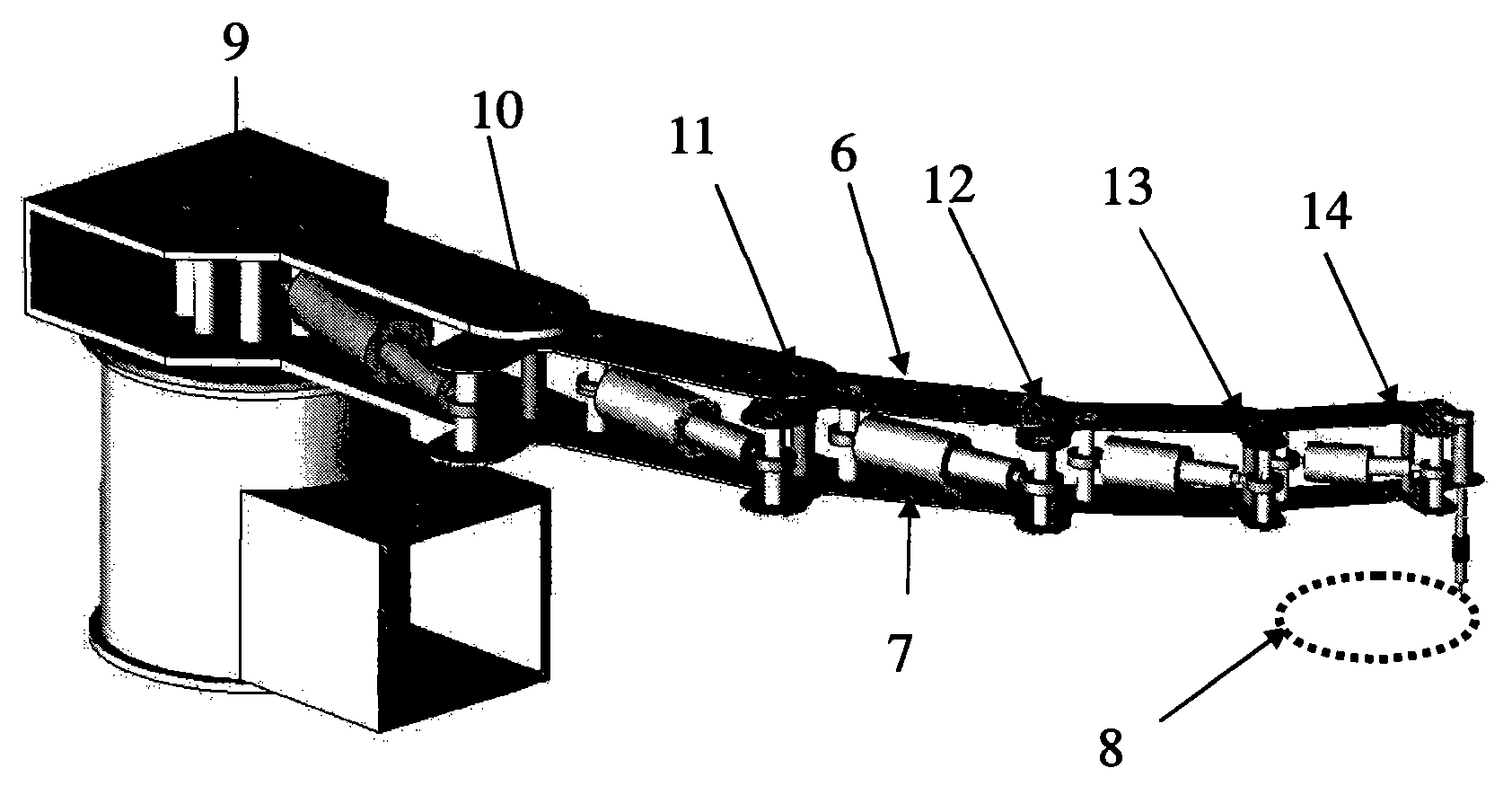

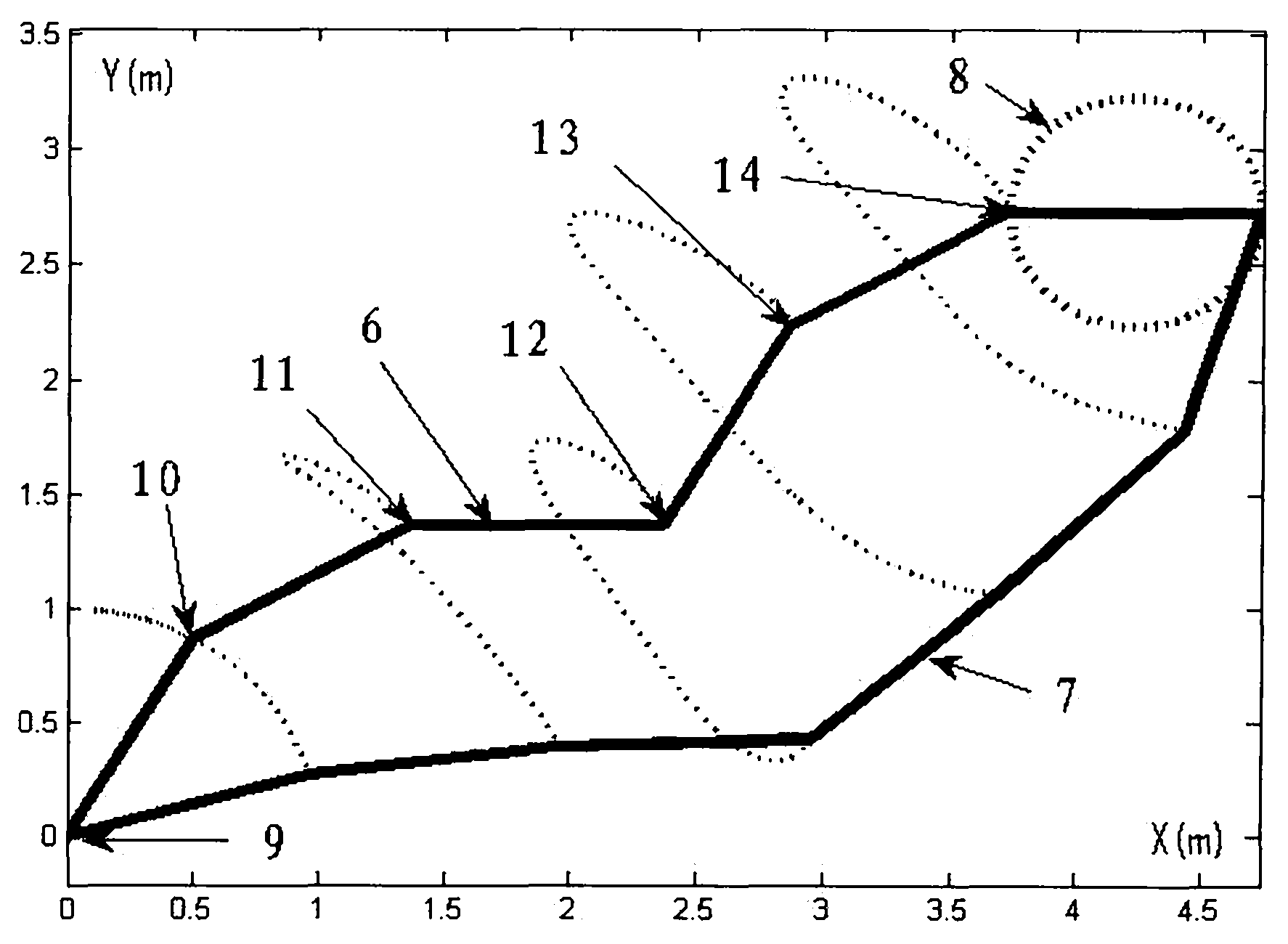

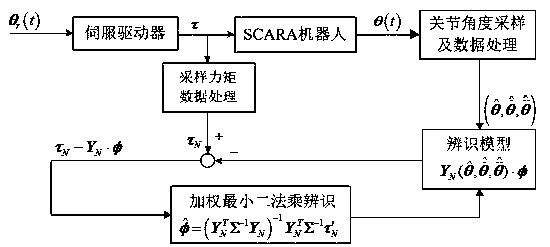

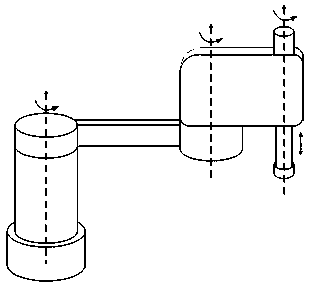

Improved SCARA robot kinetic parameter identification method

ActiveCN107671861AReduce condition numberImprove recognition accuracyProgramme-controlled manipulatorAngular degreesEngineering

The invention relates to the field of SCARA robot kinetic parameter identification, and discloses an improved SCARA robot kinetic parameter identification method. A Lagrange method is adopted for establishing an SCARA robot integral kinetic model comprising a friction term, and the SCARA robot integral kinetic model is subjected to linearization. The five-order fourier series is adopted as the stimulation track basic form, the polynomial with 5 degree is used for replacing the constant term in the traditional fourier series, and the joint angular velocity and angular acceleration are zero at the track start and stop time; and the minimum observing matrix conditional number serves as the target, and to enhance the global optimization capability, various coefficients of the stimulation trackare optimized through the niched pareto genetic algorithm based on the crowding-out mechanism. To avoid the transmission error directly caused to the joint angle two-time differential, the sampled joint angular velocity data are fitted into the fourier series form, and a joint acceleration signal is obtained through the differential. Considering the measuring noise influence, the WLS is adopted as the parameter estimation method.

Owner:WUXI XINJIE ELECTRICAL

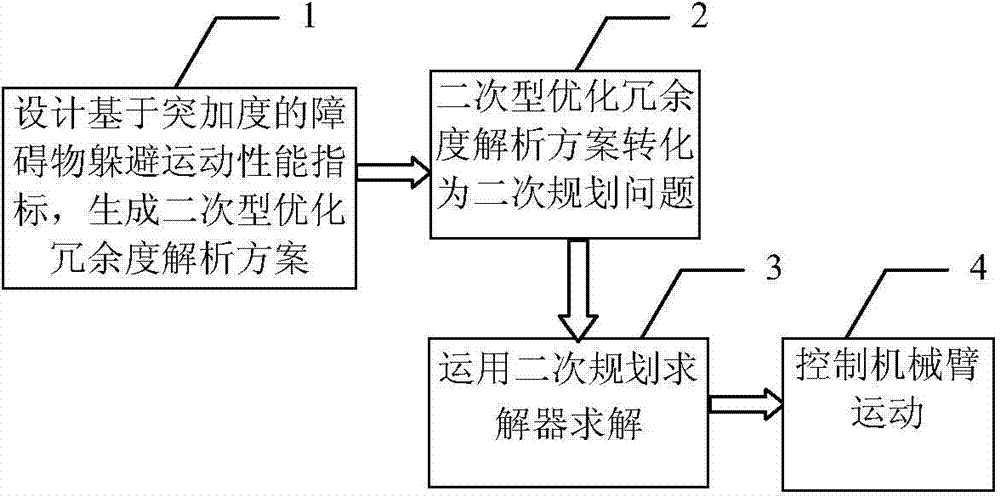

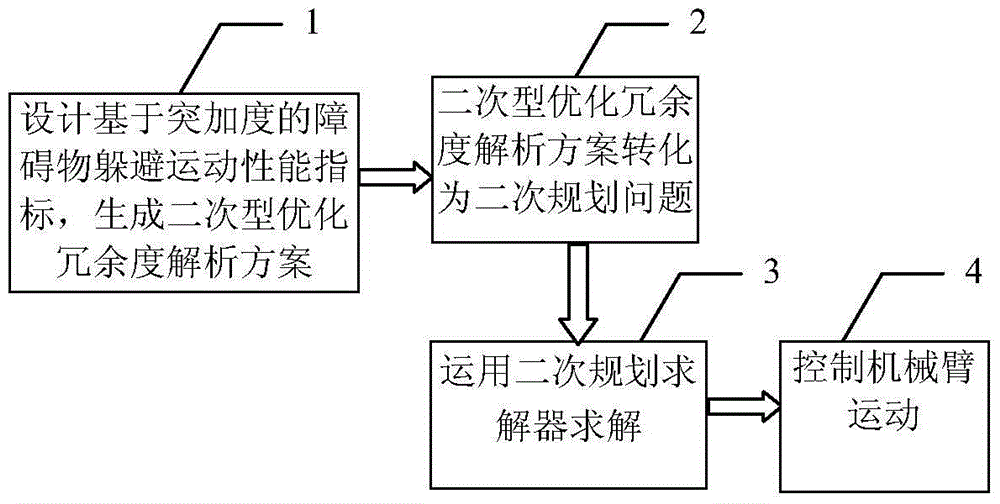

Barrier escaping motion planning method based on impact degree

The invention discloses a barrier escaping motion planning method based on an impact degree. The method comprises the steps of 1) designing barrier escaping motion performance indices based on the impact degree so that the designed motion performance indices are subject to a Jacobian matrix equation based on the impact degree, a barrier escaping inequation based on the impact degree, joint angle limitation, joint speed limitation, joint acceleration limitation and joint impact degree limitation, and generating a quadratic form optimization redundancy analysis scheme, 2) transforming the quadratic form optimization redundancy analysis scheme generated in the step 1) into a secondary planning problem, 3) solving the secondary planning problem in the step 2) by use of a secondary planning solver, and 4) transferring the solution result of the step 3) to a lower computer controller to drive a mechanical arm to move. According to the barrier escaping motion planning method, the barrier escaping motion performance indices based on the impact degree are designed, the mechanical arm is controlled to escape a barrier at an impact degree layer, and meanwhile, the mechanical arm is capable of completing a given tail end task.

Owner:SUN YAT SEN UNIV

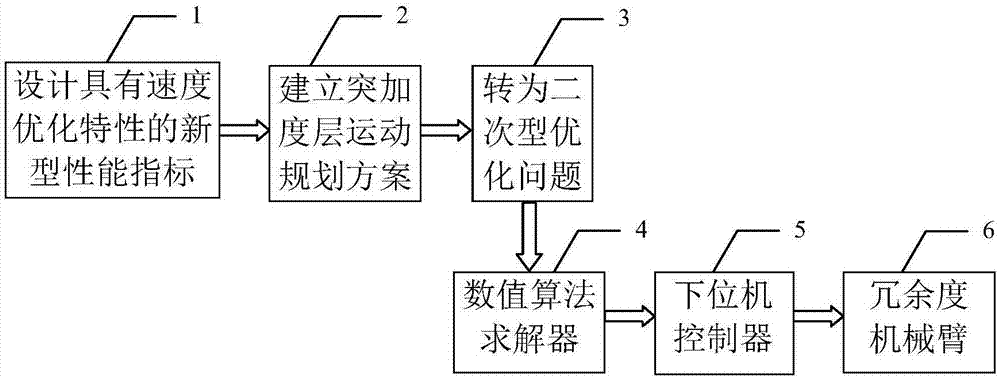

Movement planning method with speed optimizing characteristic and for acceleration derivative layer of redundant manipulator

ActiveCN107351081AHas speed optimization featuresProgramme-controlled manipulatorPerformance indexEngineering

The invention provides a movement planning method with the speed optimizing characteristic and for an acceleration derivative layer of a redundant manipulator. The movement planning method comprises the steps that a novel performance index with the speed optimizing characteristic is designed according to the performance index of the acceleration derivative layer of the redundant manipulator through two design parameters, namely the guiding-in speed and the acceleration speed; based on the novel performance index, a corresponding movement planning scheme for the acceleration derivative layer is established, and the planning scheme is restrained by the jacobian matrix of the speed, the acceleration speed and the acceleration derivative, the joint angle limit, the joint speed limit, the joint acceleration speed limit and the joint acceleration derivative limit; the planning scheme is converted into a quadratic optimization problem, and the quadratic optimization problem is solved through a solver according to a numerical algorithm; and a lower computer controller controls the manipulator to complete a given terminal task according to a solving result. According to the movement planning method with the speed optimizing characteristic and for the acceleration derivative layer of the redundant manipulator, speed optimization can be achieved on the acceleration derivative layer, and the speeds of all joints can be zero after the manipulator completes the given terminal task.

Owner:HUAQIAO UNIVERSITY

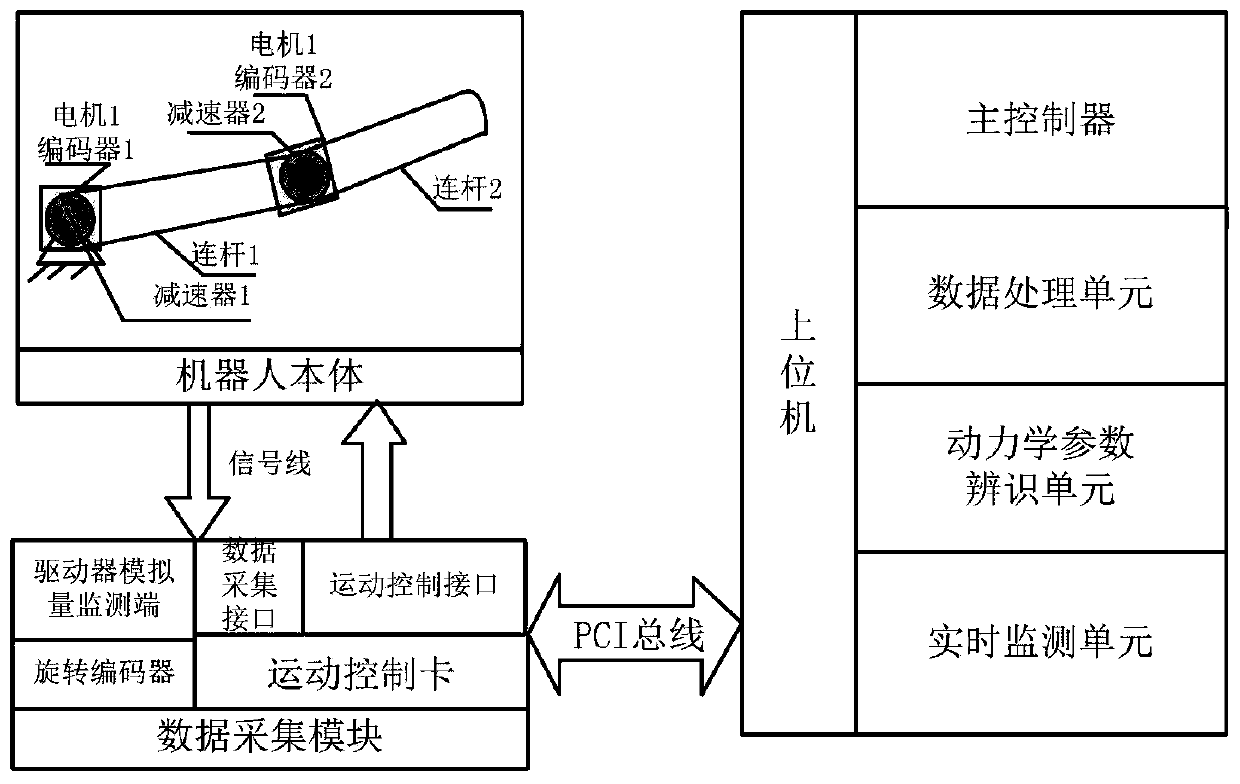

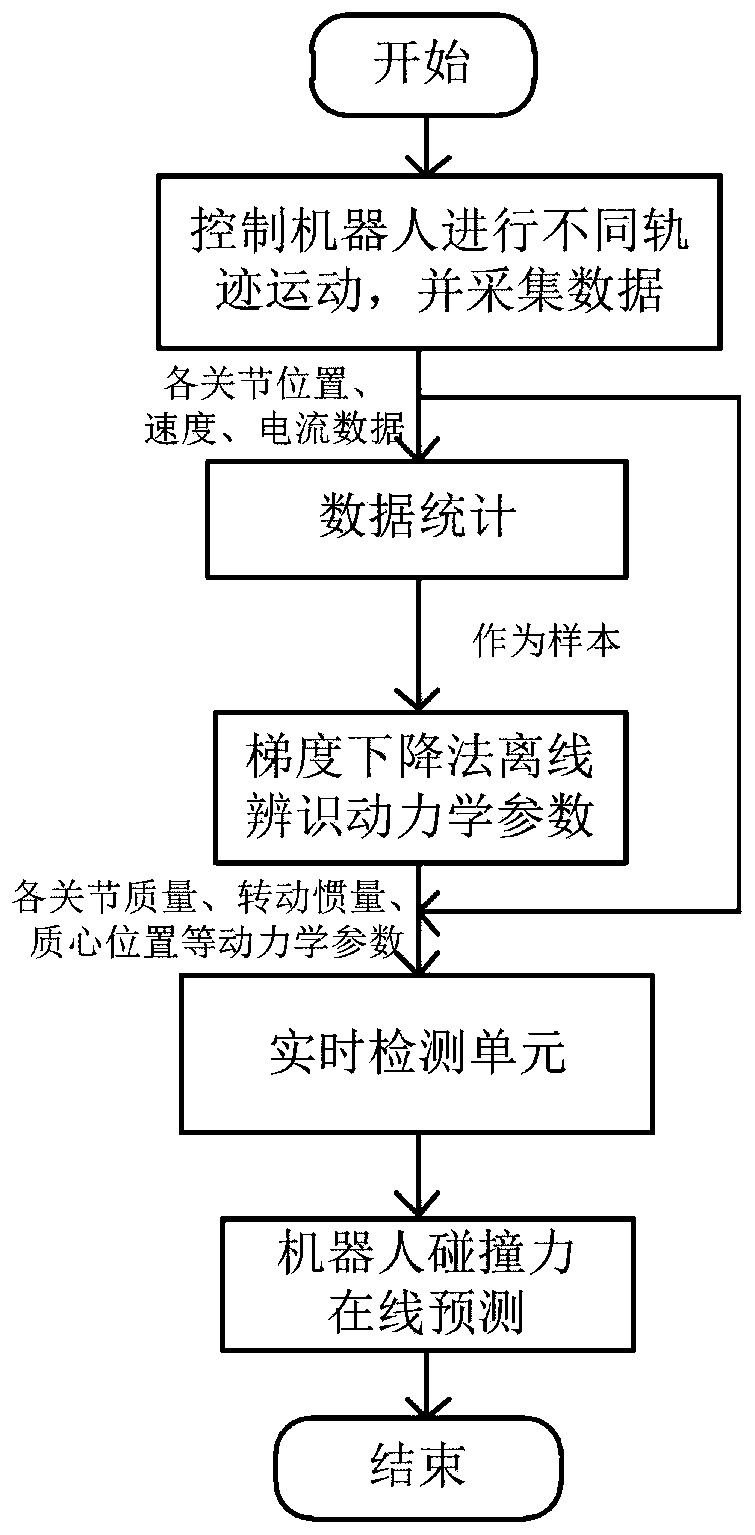

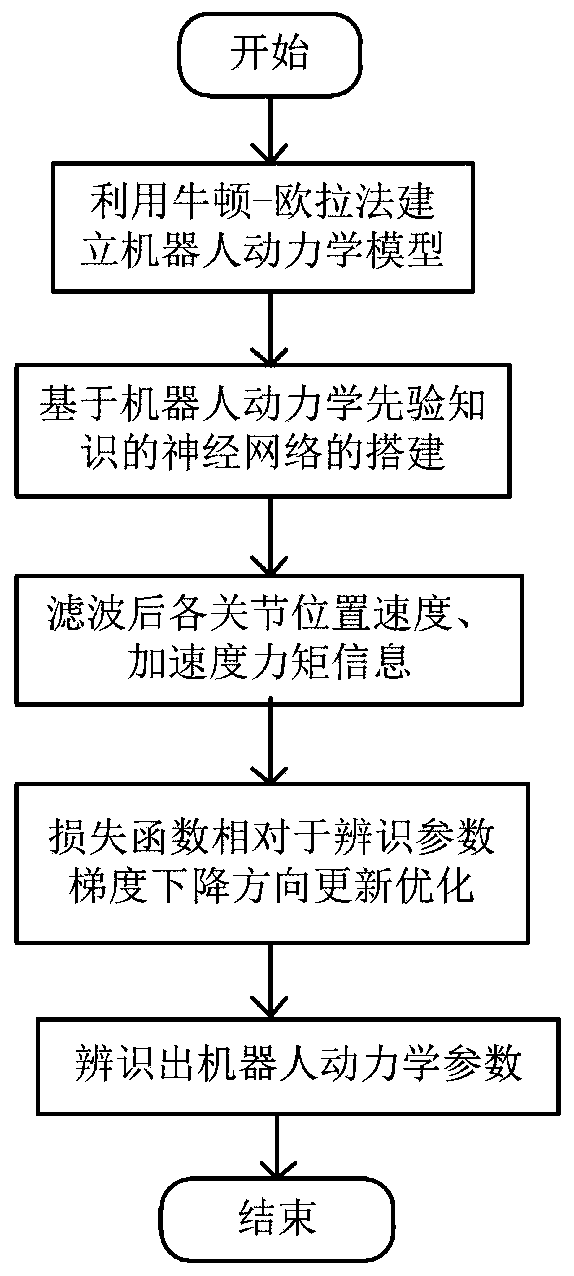

Robot parameter identification and contact force monitoring method based on prior kinetic knowledge

ActiveCN110716557AGeneralized workspaceEffective predictionPosition/course control in two dimensionsOffline learningSimulation

The invention discloses a robot parameter identification and contact force monitoring method based on prior kinetic knowledge. The method comprises the following steps: acquiring joint position and speed information and joint acceleration information of a robot through an encoder, and acquiring actual joint torque obtained after current information of an analog quantity monitoring end of a motor driver is processed in real time by a data acquisition card; controlling the robot to move along different tracks as many as possible in a space, acquiring angles, angular speeds, angular accelerationsand actual torque of the robot at different moments as samples, performing offline learning by a gradient descent method, identifying kinetic parameters of the robot, and obtaining an ideal kinetic model of the robot; in the real-time monitoring process, substituting the acquired and processed current information into the ideal kinetic model to obtain theoretical torque of the robot at the moment; and comparing the actual joint torque with the theoretical torque, and if the difference exceeds a threshold range, indicating that collision occurs. According to the method, contact force data canbe accurately acquired at low cost.

Owner:HEBEI UNIV OF TECH

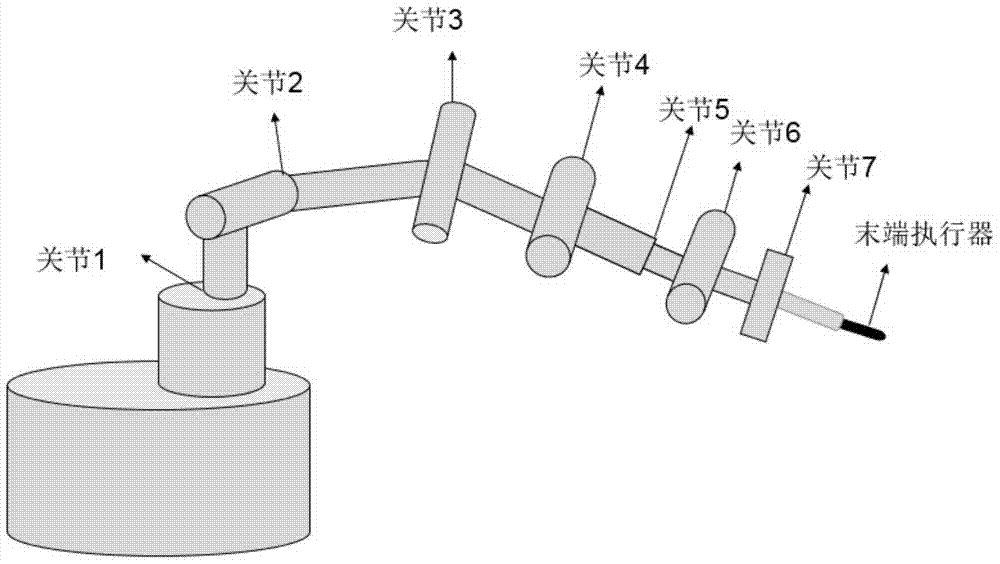

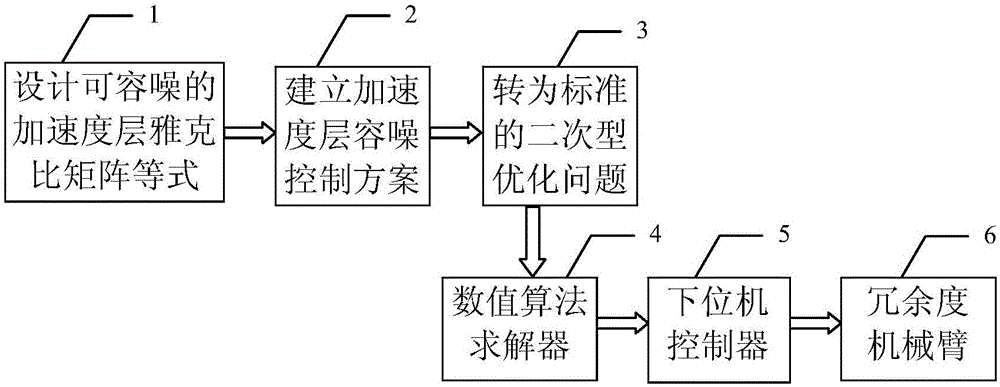

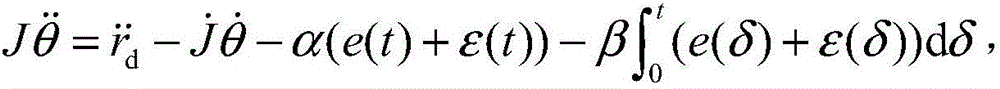

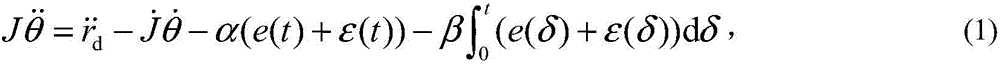

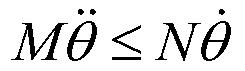

Redundant manipulator acceleration layer noise-tolerant control method

The invention provides a redundant manipulator acceleration layer noise-tolerant control method. The method comprises the following steps of: designing a noise-tolerant novel jacobian matrix equation by introducing position error and speed error feedback according to a manipulator acceleration layer jacobian matrix equation; and establishing an acceleration layer noise-tolerant control scheme in combination with a performance index needing to be optimized, wherein the control scheme is constrained in the novel jacobian matrix equation, the manipulator kinetic equation, the joint angle limit, the joint speed limit, the joint acceleration limit and the joint moment limit; the above mentioned control scheme is translated into a standard quadric form optimization problem, and a numerical algorithm solver is used for solving the standard quadric form optimization problem; a lower computer controller drives the manipulator to complete the given tail end task according to a solving result. The acceleration layer noise-tolerant control method disclosed by the invention not only can enable the manipulator to complete the given tail end task under the noise condition, but also can enable the final state speed of each joint of the manipulator to approach to zero.

Owner:HUAQIAO UNIVERSITY

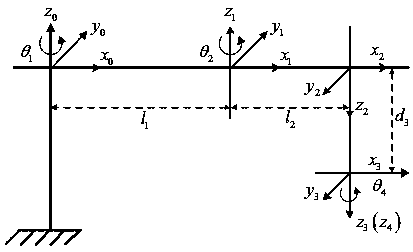

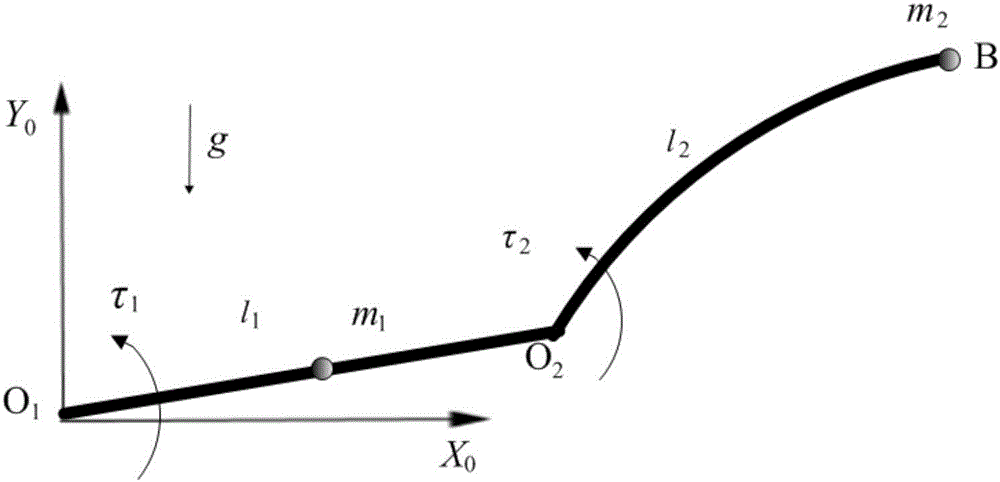

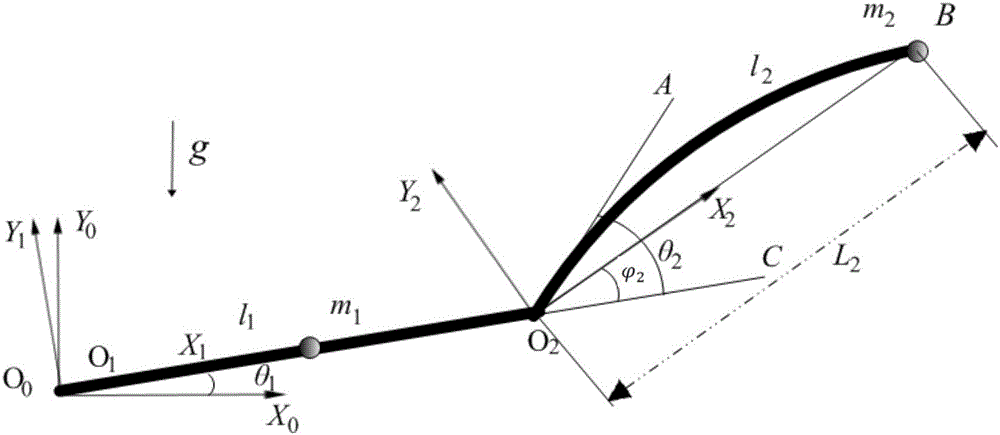

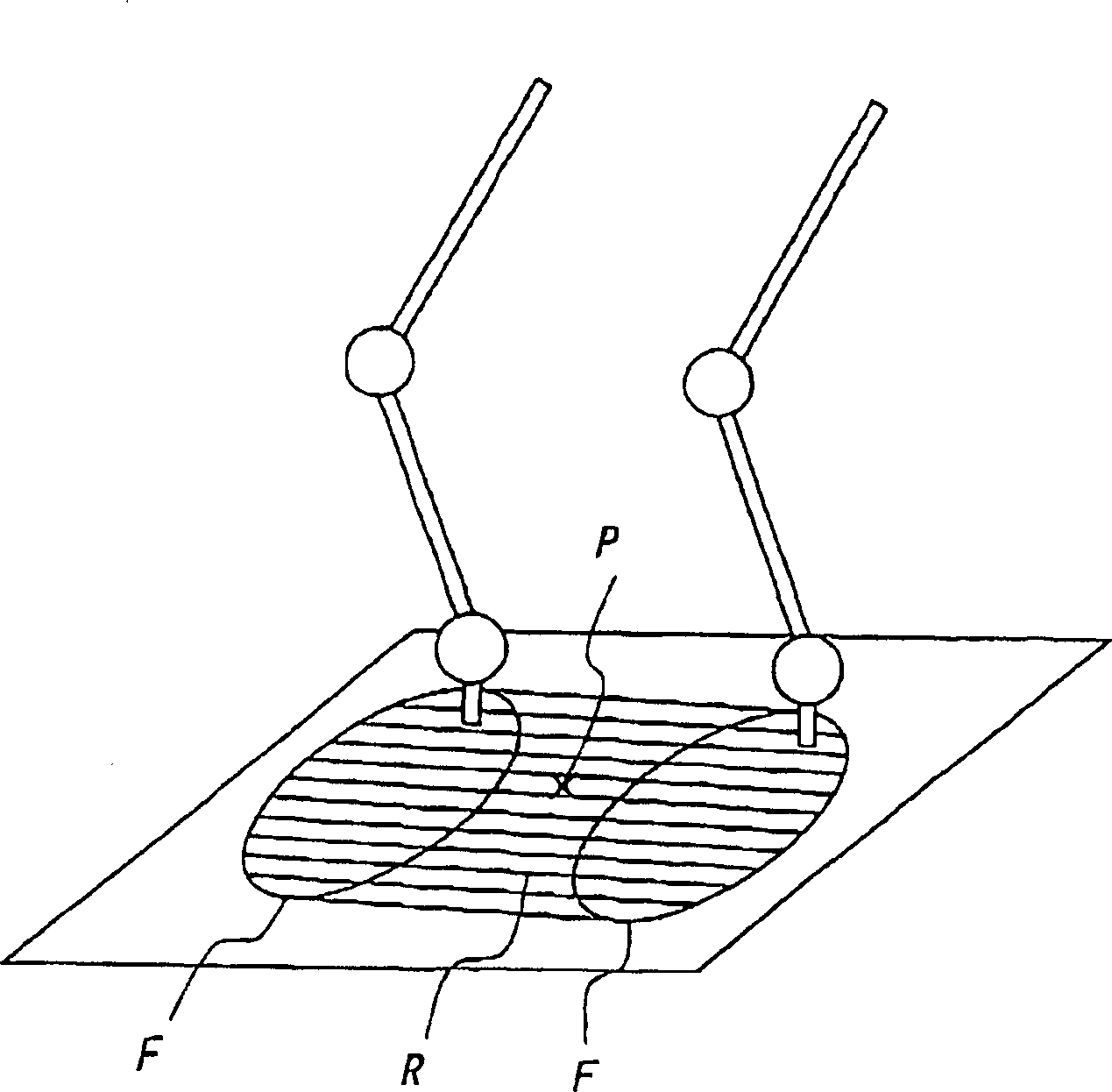

Control method of semiflexible mechanical arm system

The invention discloses a control method of a semiflexible mechanical arm system. The semiflexible mechanical arm system consists of a rigid mechanical arm and an additional flexible connecting rod, wherein the rigid mechanical arm consists of a series of rigid connecting rods and joints; each joint is a rotating joint or a moving joint. The method comprises the following steps that the rigid mechanical arm is totally provided with (n+1) rigid connecting rods; the additional flexible connecting rod is R; a fixed connection coordinate system of the (n+1) rigid connecting rods is built and obtained by an improved DH parameter method via the rigid mechanical arm; the connecting rod parameters of the (n+1) rigid connecting rods are obtained through calculation; the length of the flexible connecting rod R in the flexible connecting rod parameters is regarded as a variable value, and other parameters are invariable; a coordinate system transformation formula of the adjacent connecting rods between the rigid connecting rods and the flexible connecting rod R is determined according to the connecting rod parameters; then, the relationship between the joint moment, and the joint angle, the joint speed and the joint acceleration speed is built to serve as a kinetic equation; the semiflexible mechanical arm system is controlled according to a set control method in accordance with the kinetic equation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

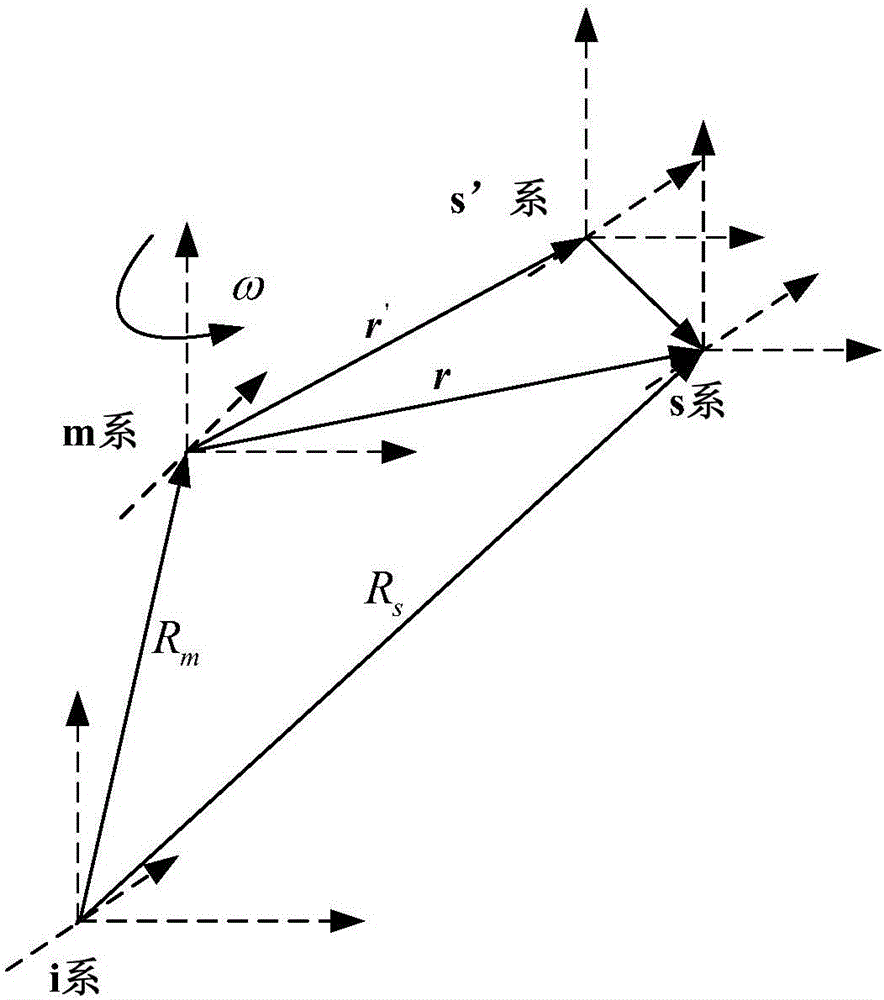

Inertial navigation system transfer alignment modeling method based on dual quaternion

ActiveCN106525034AImprove calculation accuracyImprove computing efficiencyNavigational calculation instrumentsNavigation by speed/acceleration measurementsGyroscopeAccelerometer

The invention provides an inertial navigation system transfer alignment modeling method based on dual quaternion. A nominal dual quaternion between a main inertial navigation system and an auxiliary inertial navigation system is constructed, the dual quaternion is calculated to describe an auxiliary inertial navigation system carrier system relative to a main inertial navigation system carrier system, rotation and translation motion of the carrier systems are calculated, and a normal dual quaternion differential equation of transfer alignment is constructed by reasoning spinor expressions of relative rotation and translation motion of the main inertial navigation system and the auxiliary inertial navigation system and calculated; a dual quaternion error equation is obtained in combination with an accelerometer parameter error equation and a gyroscope error differential equation; a systematic observation equation is constructed by using the linear velocity of an accelerometer and the angular velocity of rotation of a gyroscope, an initial calibration parameter of the auxiliary inertial navigation system is calculated through kalman filter iteration, the effects of rotation and translation separation calculation on coning errors and sculling errors are eliminated, and the calculation accuracy and the calculation efficiency are effectively improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

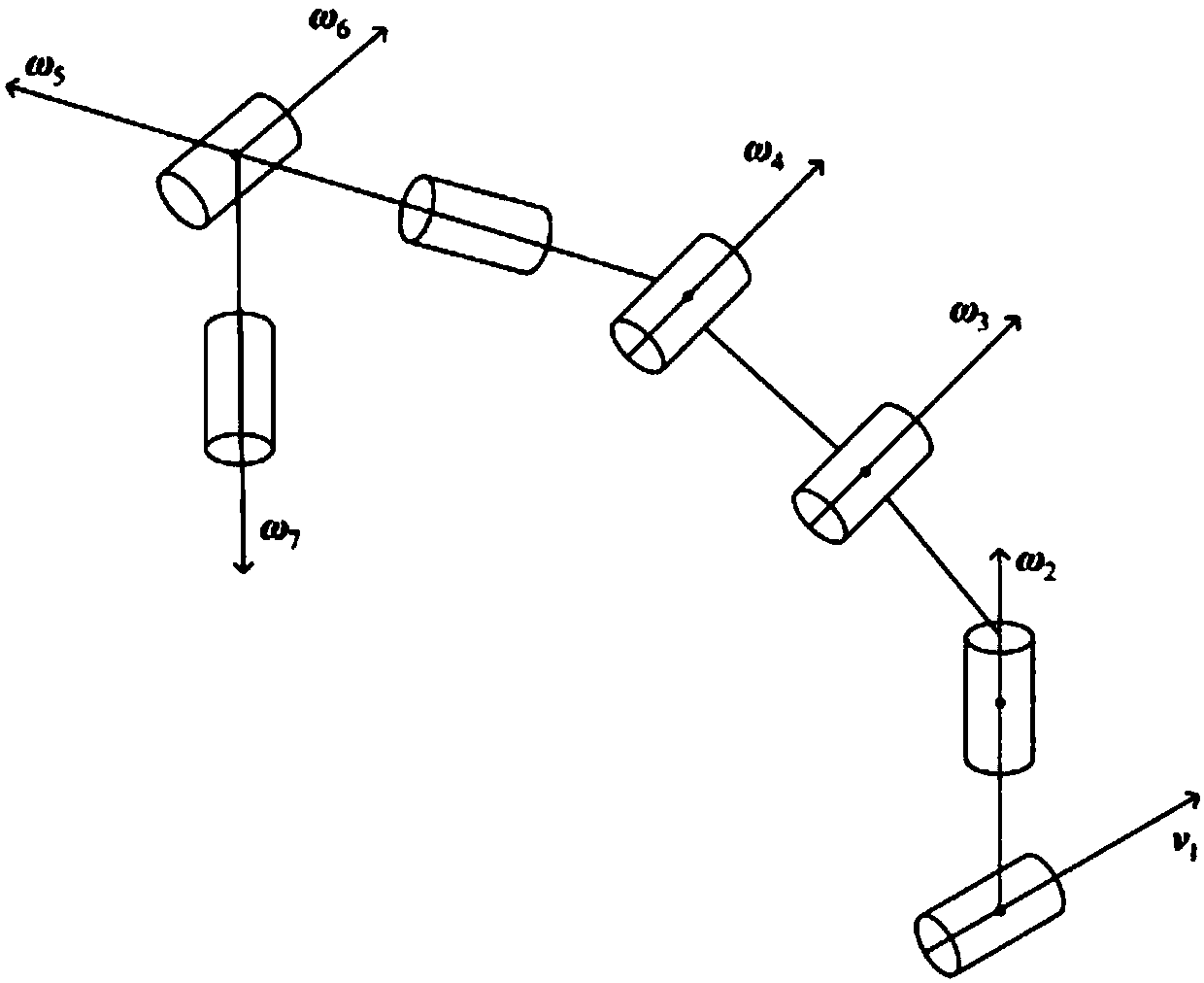

Time optimal trajectory planning method for robotic arm

InactiveCN107367938AExercise time optimizationReduce running timeAdaptive controlGenetic algorithmsInverse operationJoint acceleration

The present invention provides a time optimal trajectory planning method for a robotic arm, which has the following features: Step 1: discretizing a task space of the robotic arm into a plurality of trajectory difference points to obtain a pose matrix sequence Ti and a corresponding time node sequence ti, and performing an inverse operation on the pose matrix sequence Ti to obtain a corresponding joint position qi, wherein the relationship between the joint position qi and the time node sequence ti is as shown in the formula S = (qi, ti); Step 2: setting kinetics speed constraints; Step 3: according to the kinematic speed constraints, connecting points corresponding to each S in turn through the cubic polynomial curve interpolation to obtain a joint trajectory curve of the robotic arm; Step 4: establishing a target function according to the joint trajectory curve of the robotic arm; and Step 5: according to the target function, using a multi-population genetic algorithm to optimize the total movement time of the robotic arm to obtain a movement speed curve, a joint acceleration curve and a joint movement pulse curve of the robotic arm.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

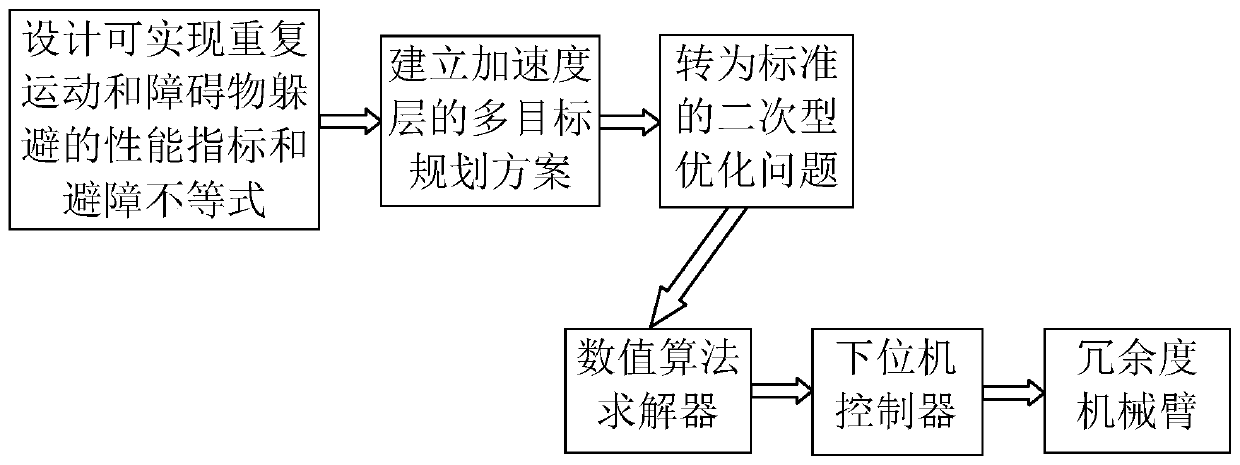

Redundant manipulator acceleration layer multi-objective programming method

ActiveCN110561440AAchieve repetitive motionProgramme-controlled manipulatorTotal factory controlEngineeringPerformance index

The invention relates to a redundant manipulator acceleration layer multi-objective programming method which comprises the steps of respectively designing an optimal performance index and inequation data of an acceleration layer; combining a programming task of a terminal of a manipulator and physical limits of joints of the manipulator, and building an acceleration layer multi-objective programming scheme, wherein the scheme is restrained by an acceleration layer jacobian matrix equation, a manipulator kinetic equation, an obstacle avoidance inequation, a joint angle limit, a joint speed limit, a joint acceleration limit and a joint torque limit; transforming the multi-objective programming scheme into a standard quadratic form optimization problem, and adopting a numerical algorithm forsolving the problem; using a lower computer controller for driving the various joints of the manipulator to fulfil a given terminal programming task according to a solving result of the algorithm. According to the acceleration layer multi-objective programming scheme designed by the invention, under the circumstances that the joints of the manipulator are restricted and obstacles exist, the giventerminal programing task can be fulfilled, and the aim of repetitively moving is achieved.

Owner:HUAQIAO UNIVERSITY

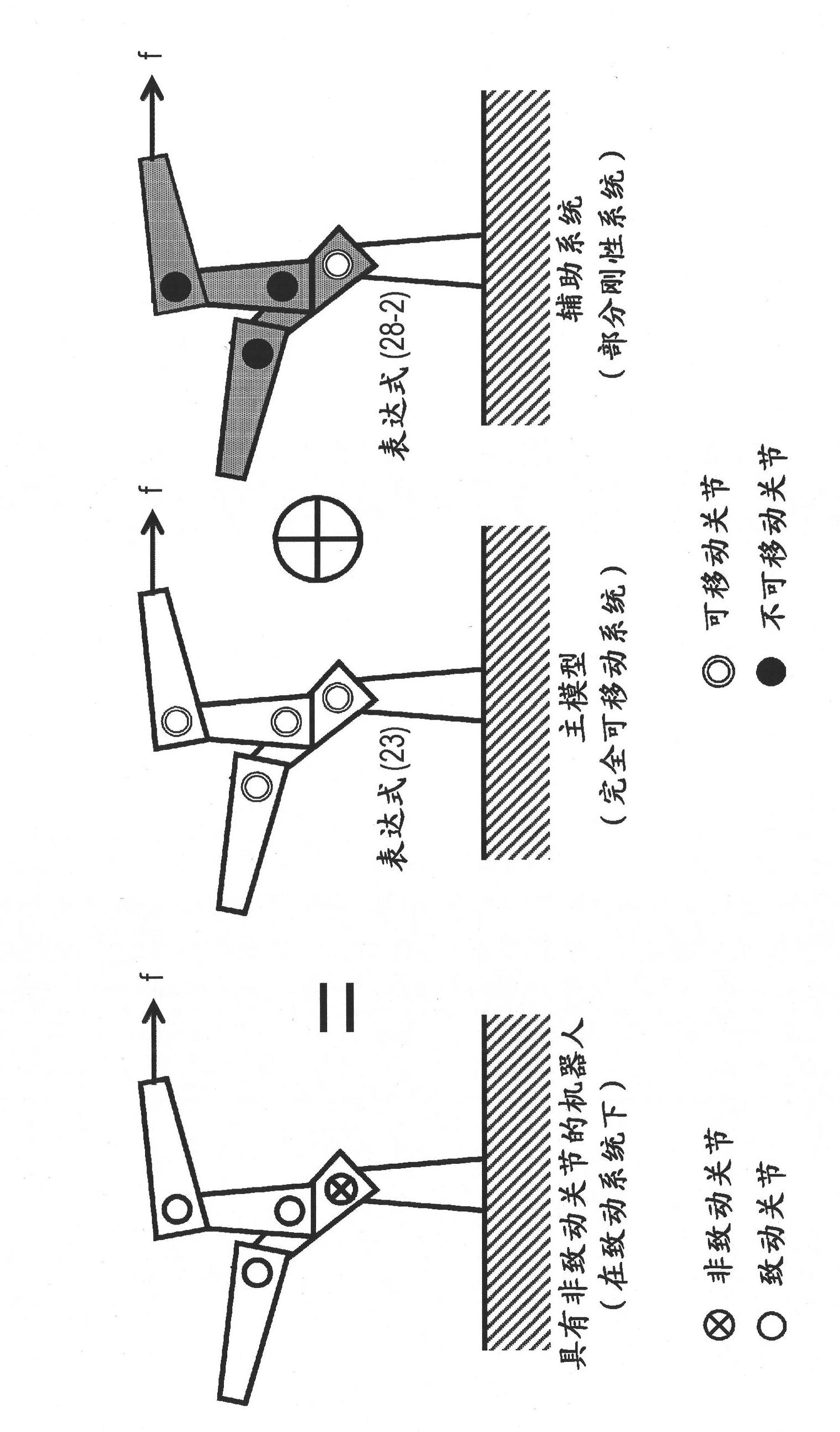

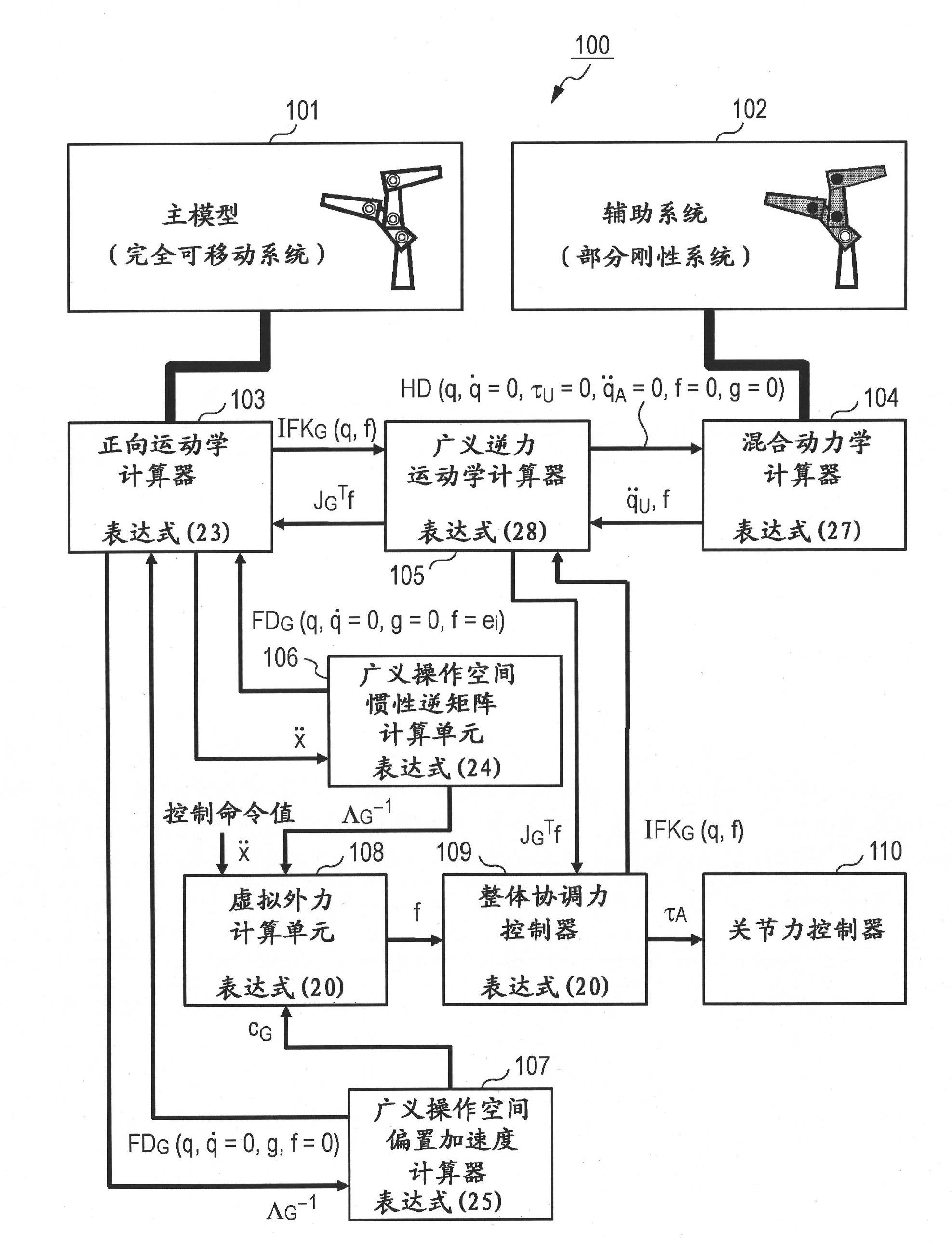

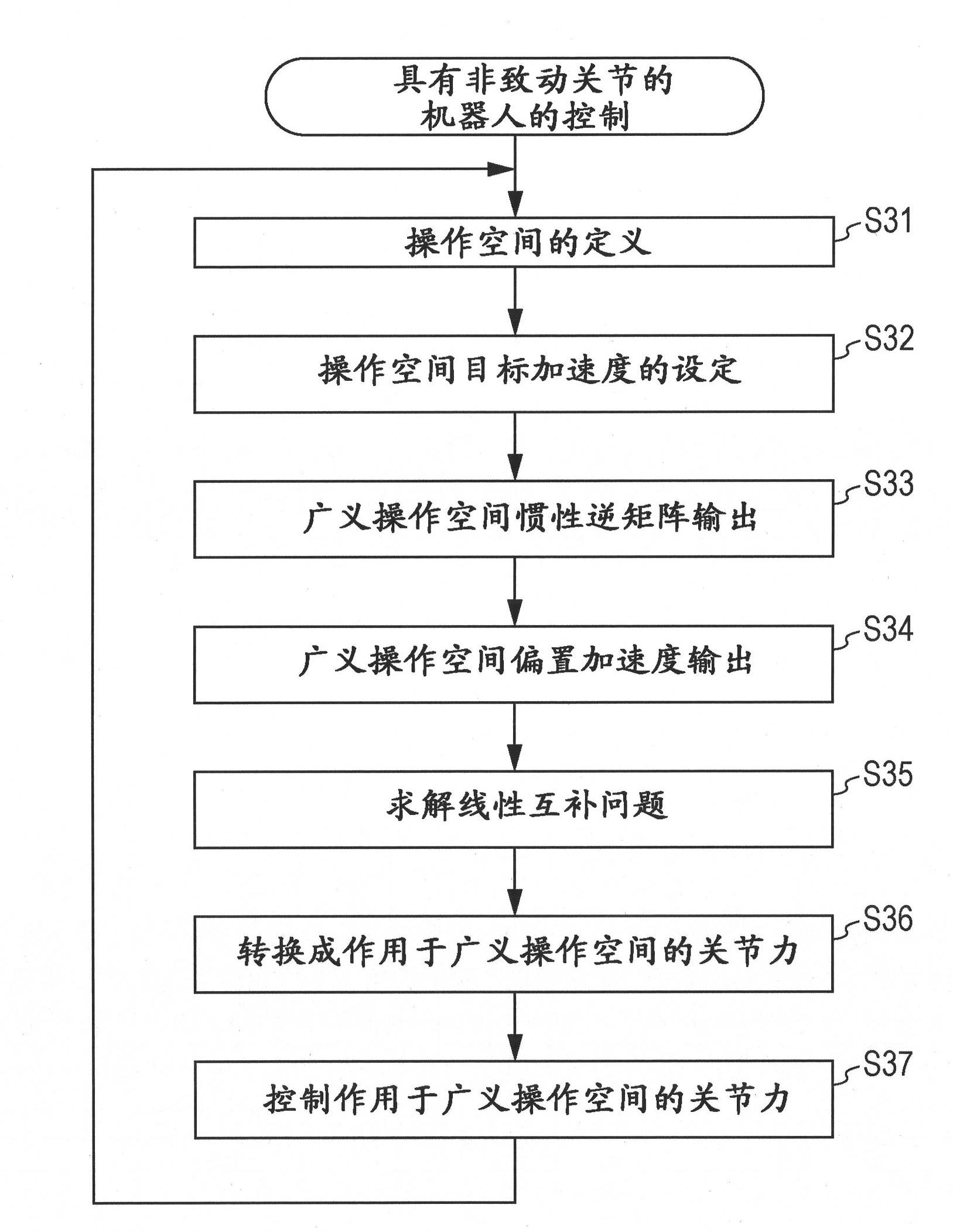

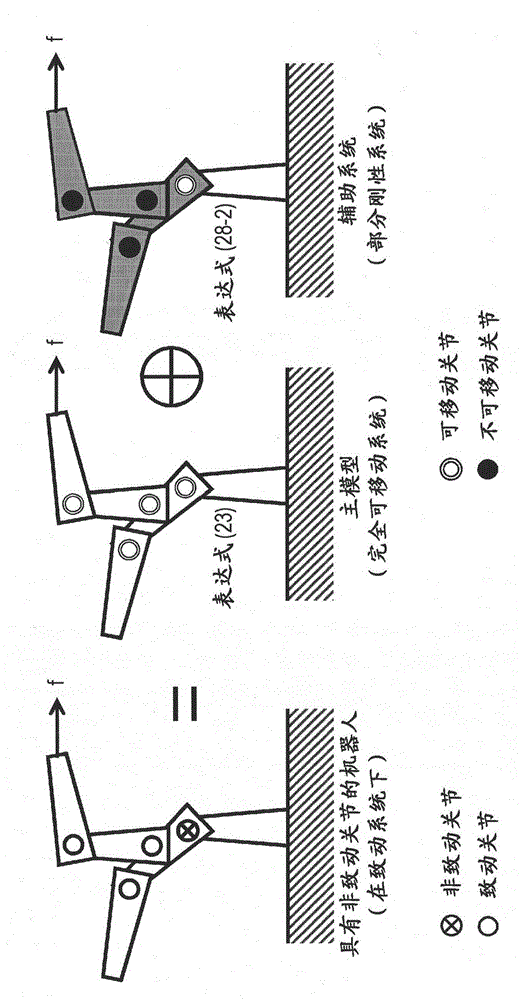

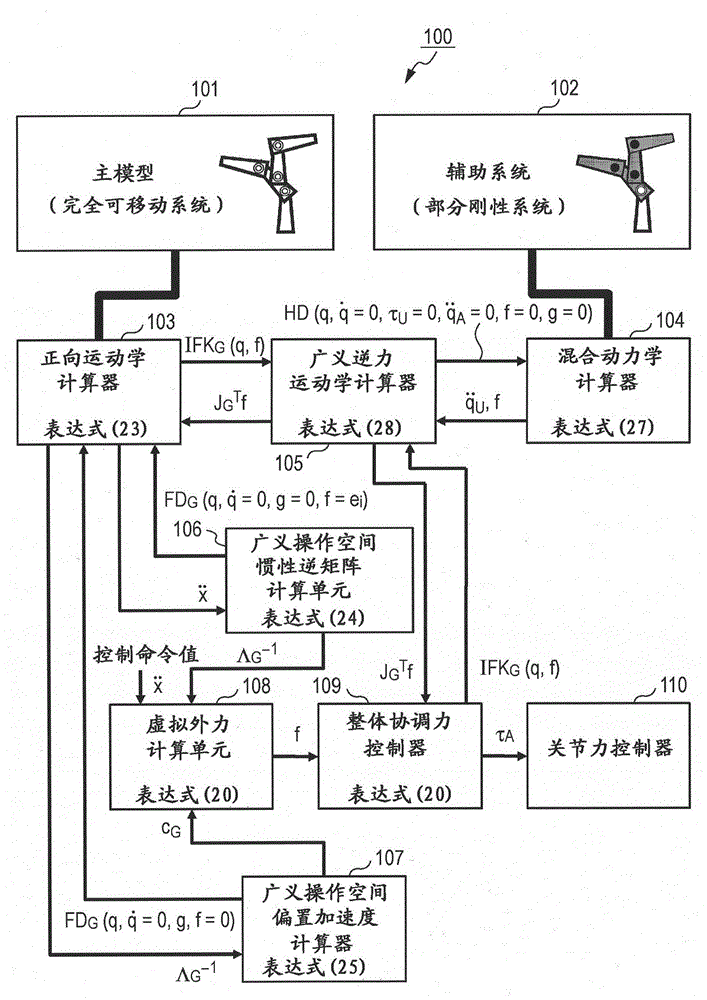

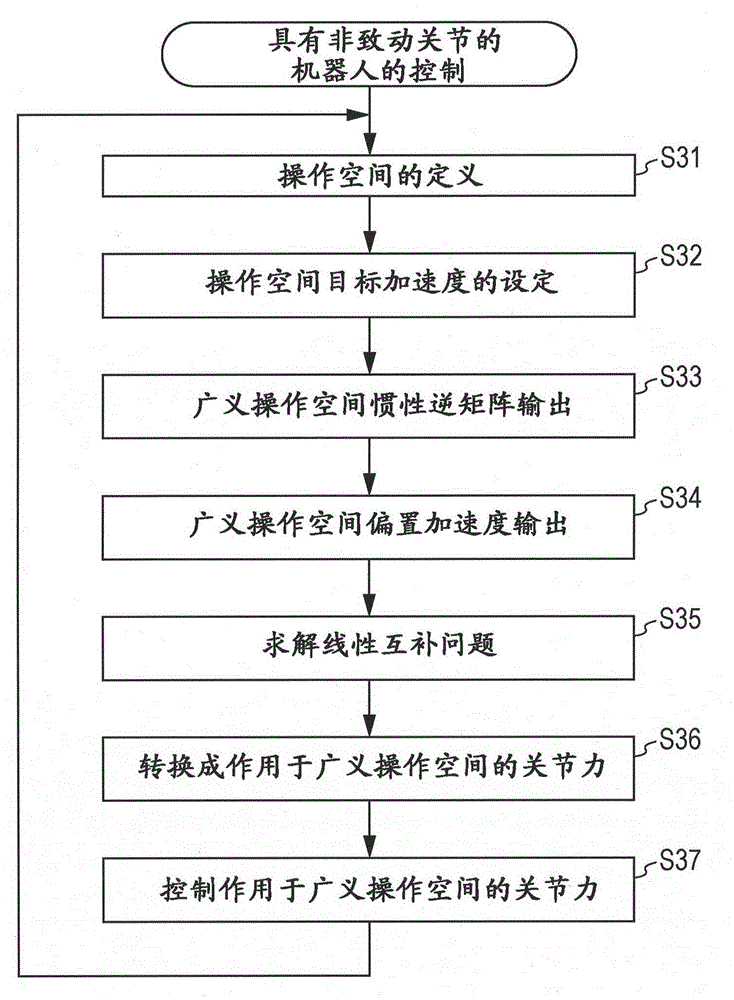

Control device for robot, control method and computer program

InactiveCN102452077AEasy to controlExcellent control equipmentProgramme controlProgramme-controlled manipulatorInverse dynamicsForward dynamic

A control device for a robot including: a hybrid dynamics calculator calculating joint forces that act on immovable joints and the joint accelerations that are generated at movable joints by performing a hybrid dynamics calculation that includes inverse dynamics and forward dynamics using an auxiliary model in which the actuated joints of the robot having the actuated joints and the unactuated joints are immovable; a forward dynamics calculator calculating the acceleration that is generated by known force that acts on the robot using a main model; a joint force determination unit determining the joint force; and a joint force controller controlling the joint force of each joint of the robot.

Owner:SONY CORP

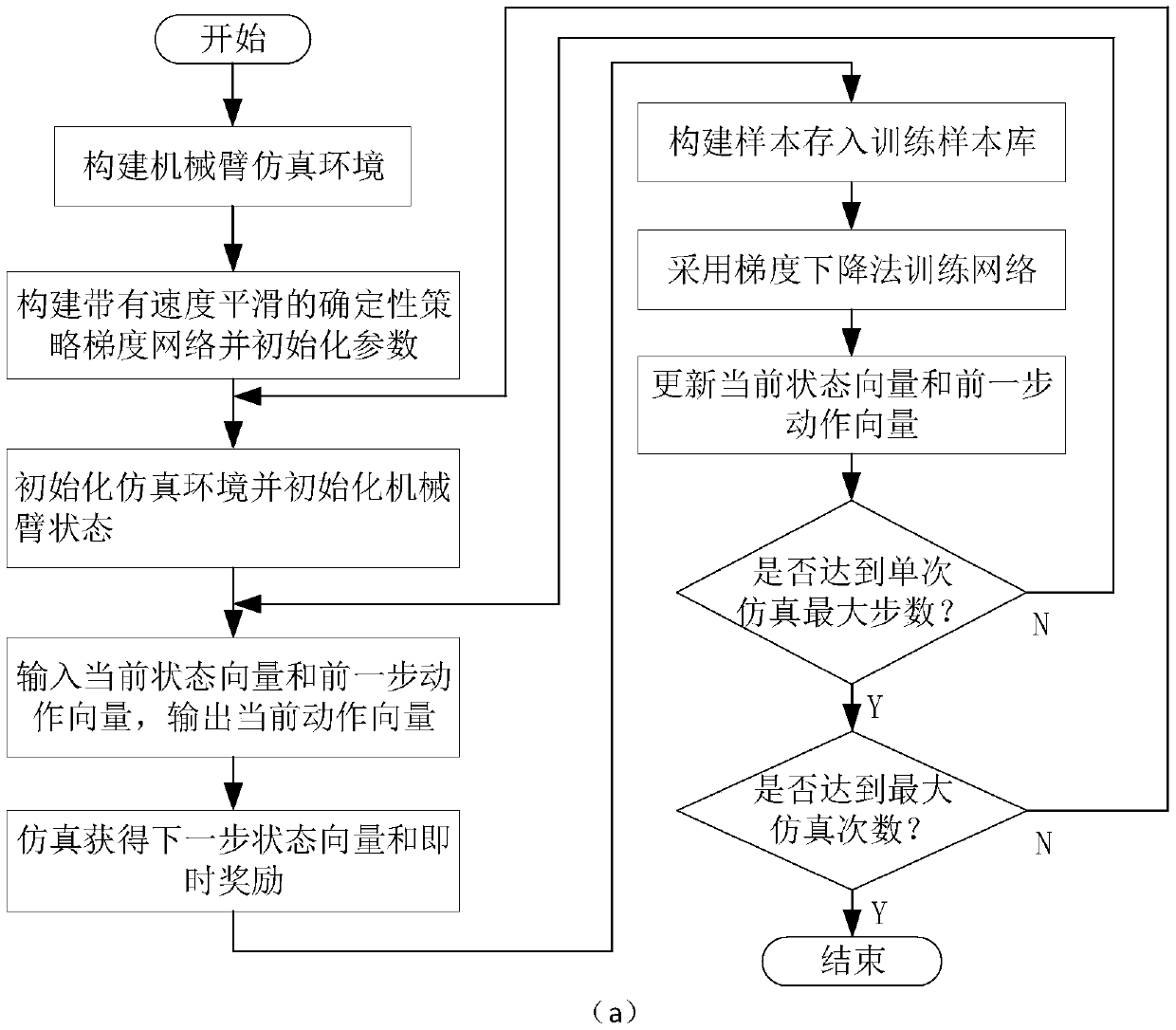

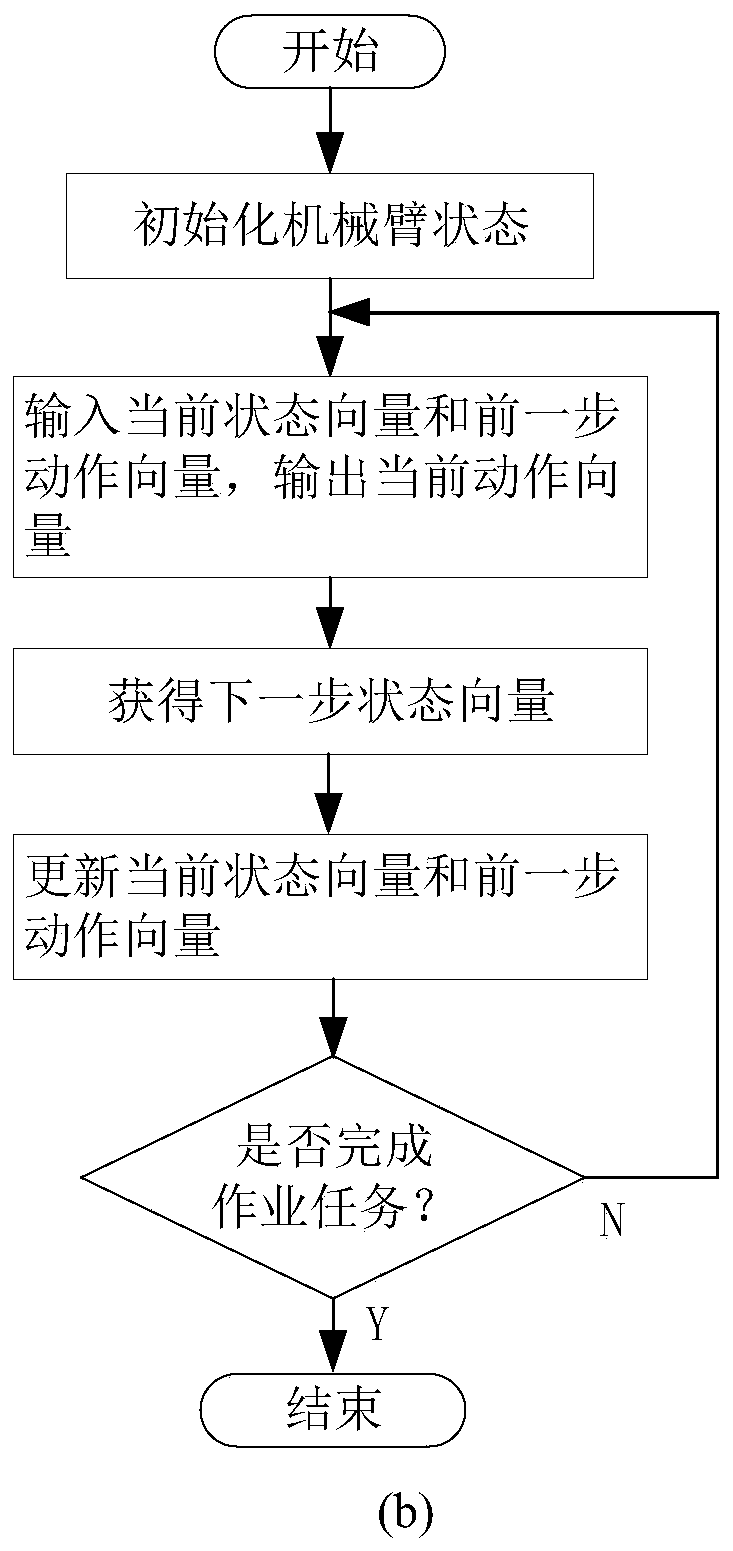

Mechanical arm path planning method based on velocity smoothing deterministic policy gradient

ActiveCN110328668AReduce jitterReduce joint accelerationProgramme-controlled manipulatorGradient networkSimulation

The invention discloses a mechanical arm path planning method based on velocity smoothing deterministic policy gradient. The method comprises the steps that a mechanical arm simulation environment with job task feedback is established in a training stage; a previous step mechanical arm action vector is introduced during inputting of a deterministic policy gradient network, and a reinforced learning network framework based on the velocity smoothing deterministic policy gradient is established; network training parameters and the mechanical arm simulation environment are initialized; and samplesare obtained based on the velocity smoothing deterministic policy gradient network and the simulation environment, a training sample database is established, if the training sample quantity reaches the maximum sample quantity, training samples are drawn from the training sample database according to the single time training sample quantity, the velocity smoothing deterministic policy gradient network is trained, and otherwise, next step or the next time of simulation is performed. According to the mechanical arm path planning method provided by the invention, the previous step velocity vectoris added as the network input on the basis of the deterministic policy gradient network, the joint acceleration is effectively decreased, and mechanical arm jitter is reduced.

Owner:NANJING UNIV OF SCI & TECH

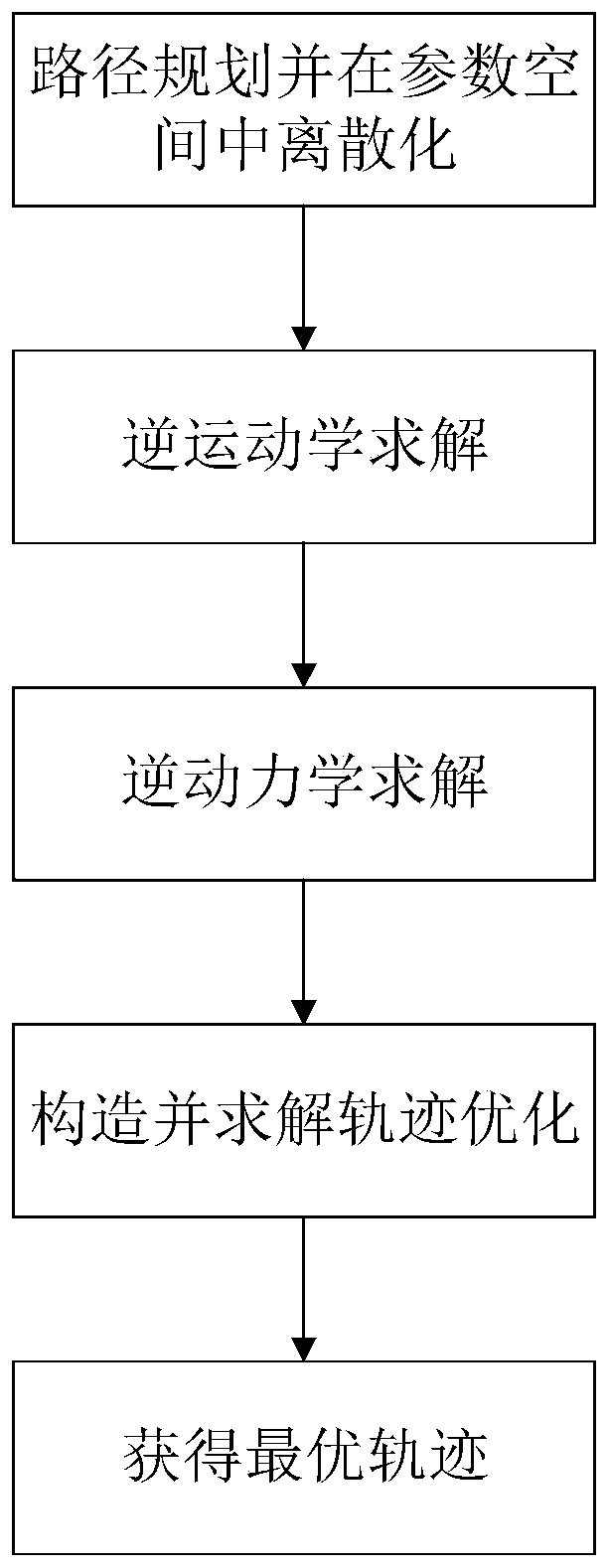

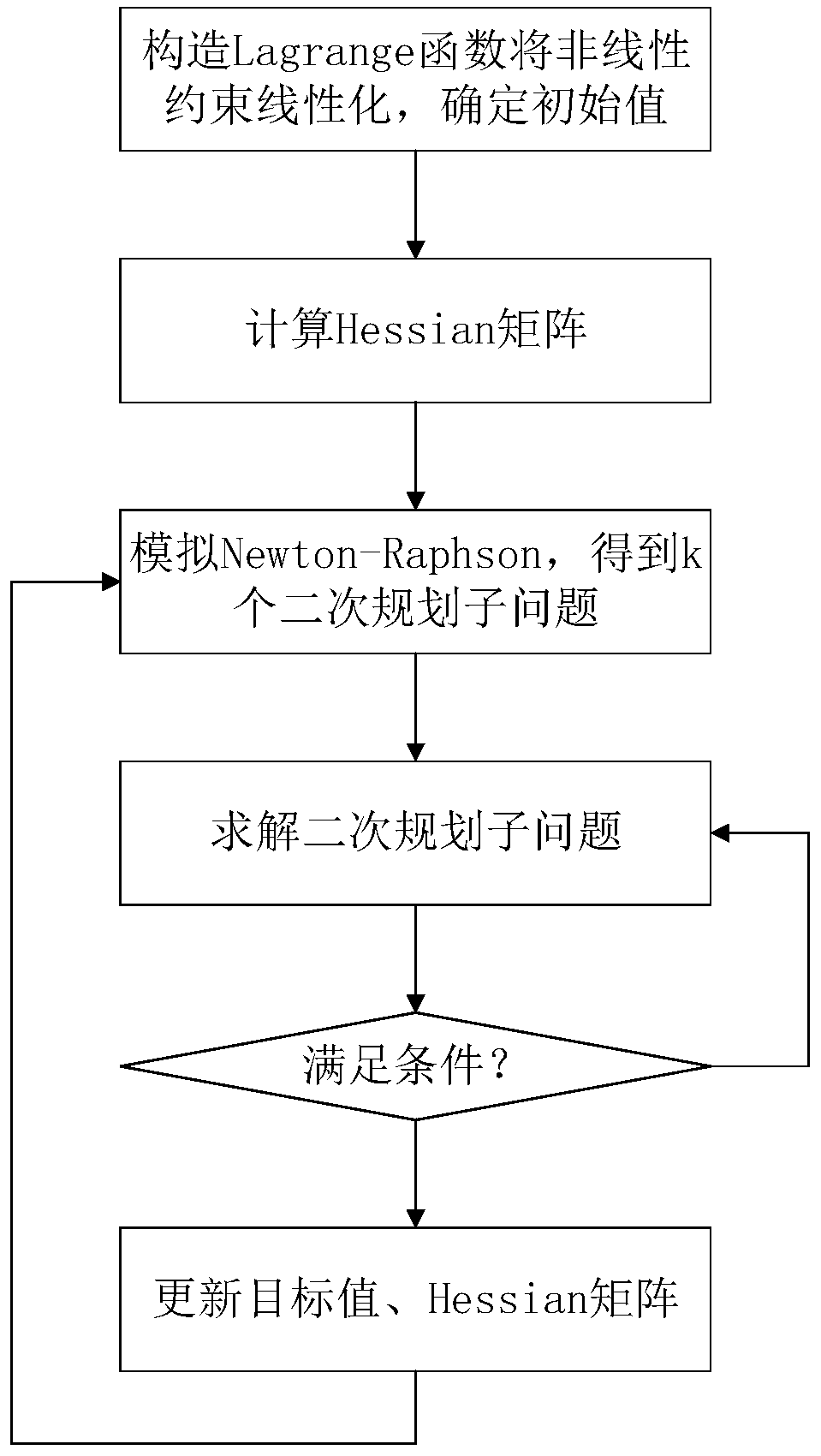

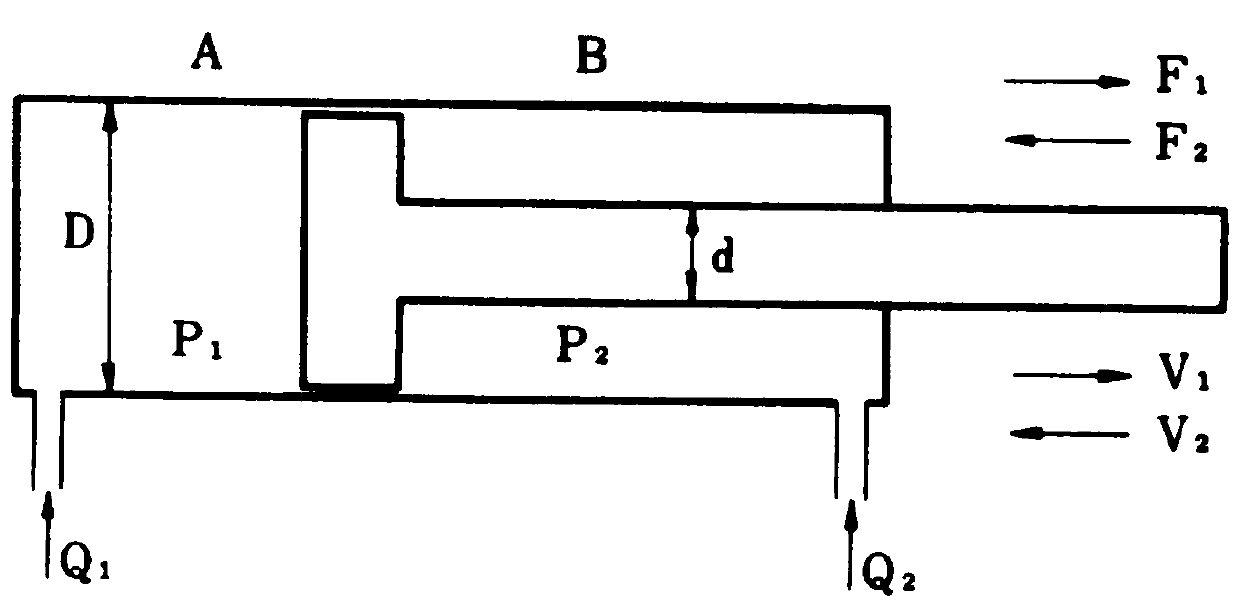

Optimal track planning method for intelligent hydraulic excavator

ActiveCN110455290AImprove work efficiencySmooth job trajectoryNavigational calculation instrumentsPosition/course control in two dimensionsControl systemTrajectory optimization

The invention relates to the technical field of excavator controlling, and particularly relates to an optimal track planning method for an intelligent hydraulic excavator. The method comprises steps of: solving time optimal track optimization by using a sequence quadratic programming method with a superlinear convergence property, and solving smoothest track optimization in consideration of a joint dynamic constraint, a joint acceleration semi-infinite constraint problem and a cumulative effect. Compared with the prior art, the optimal track planning method mainly optimizes round trip time andsmoothness of the round trip path of the excavator, and realizes time optimal track planning and smoothest track planning simultaneously, thereby improving working efficiency of an automatic controlsystem of an excavator, making an operation track smoother, remarkably reducing excavator vibration, and prolonging service life of an excavator.

Owner:爱克斯维智能科技(苏州)有限公司

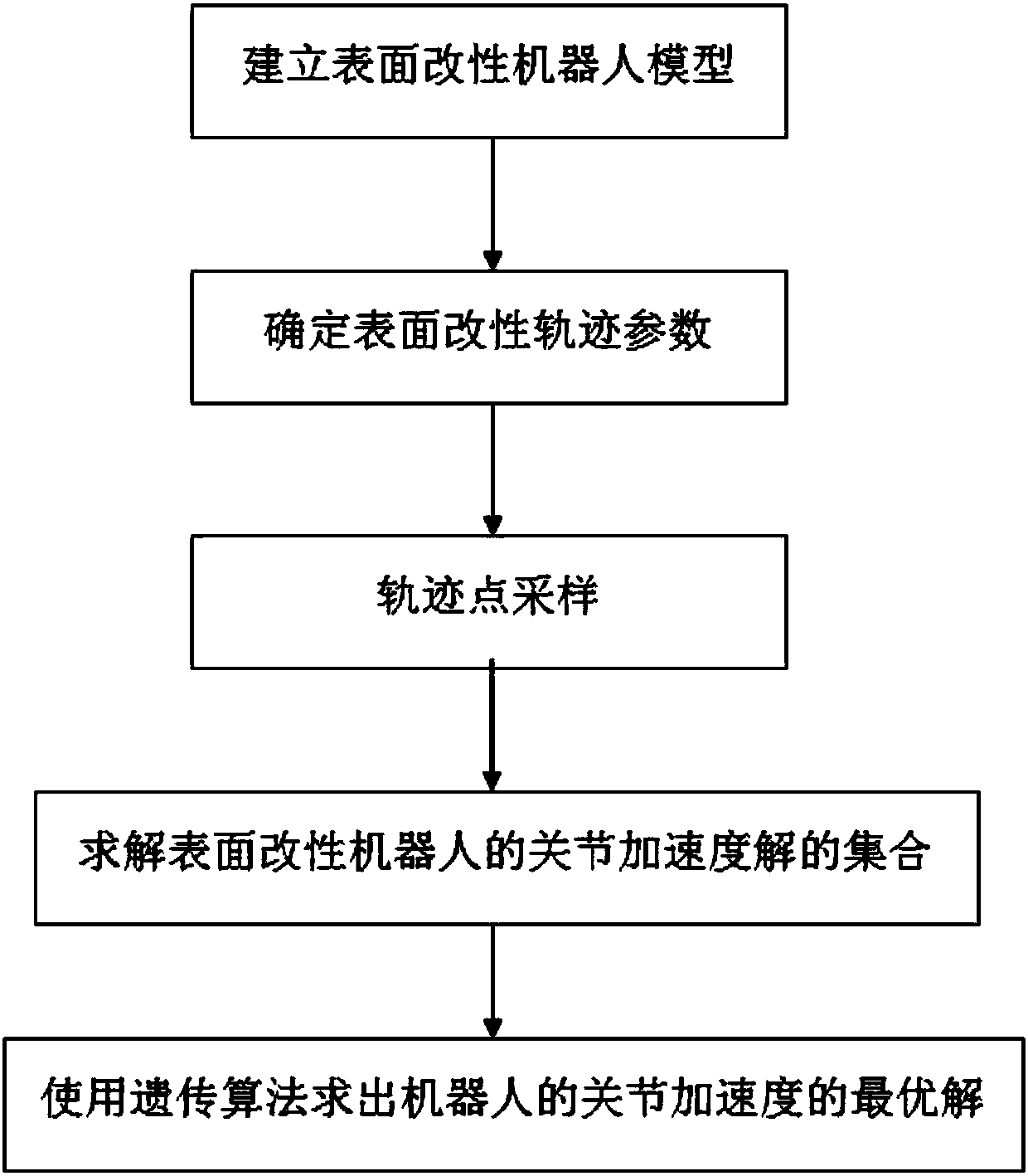

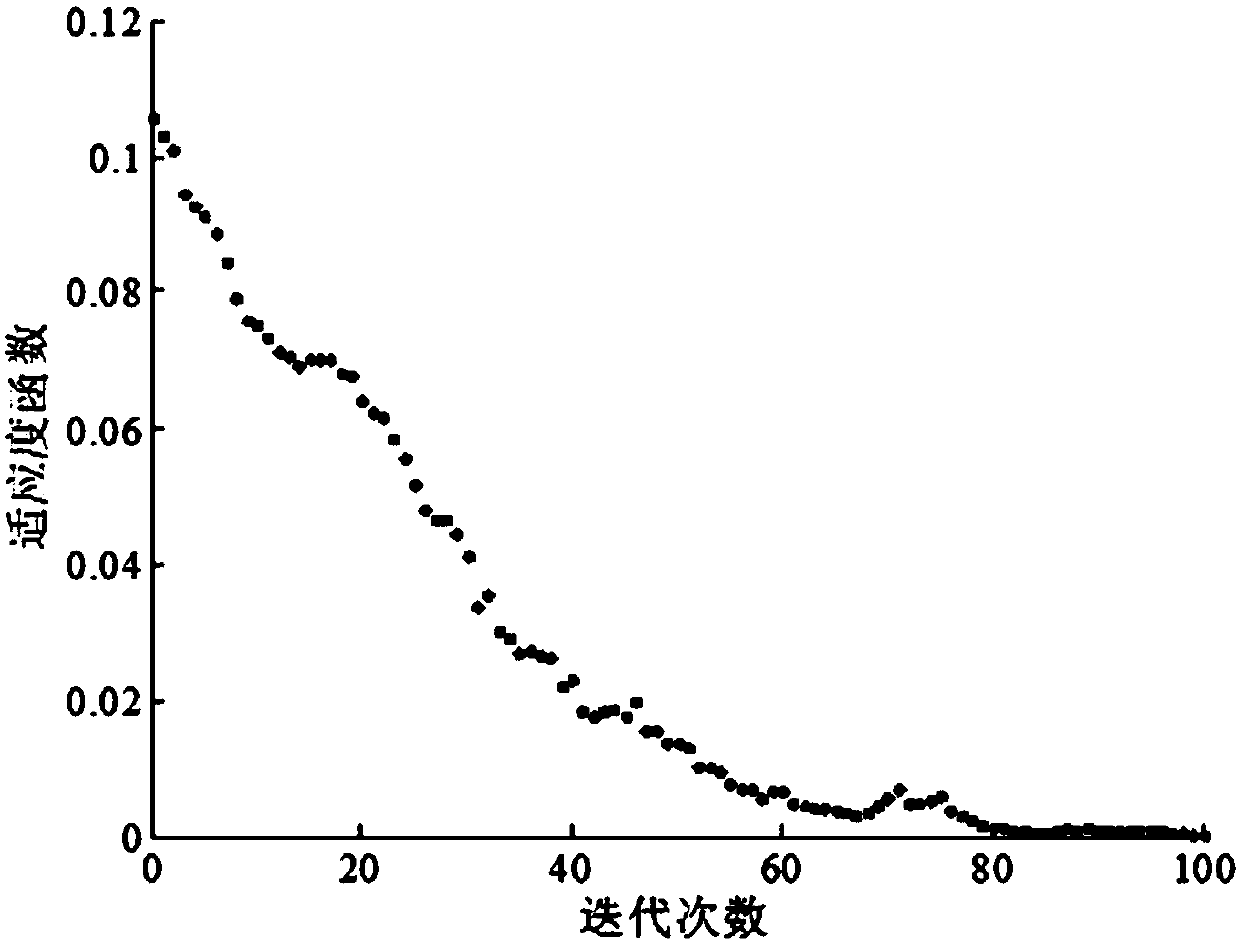

Joint space trajectory optimization method for surface modification robot

ActiveCN108393883AAchieve optimizationGuaranteed stabilityProgramme-controlled manipulatorGenetic algorithmEngineering

The invention discloses a joint space trajectory optimization method for a surface modification robot. The joint space trajectory optimization method for the surface modification robot comprises the following steps of 1, establishing a surface modification robot model; 2, determining the surface modification trajectory parameters, specifically, the surface modification trajectory parameters include the surface modification trajectory, the surface modification speed and the surface modification time span; 3, sampling trajectory spots, specifically, reference spots are selected from the surfacemodification trajectory at equal time intervals; 4, carrying out inverse kinematics solving according to the selected reference spots to obtain a joint acceleration solution set of the surface modification robot; and 5, obtaining the optimal solution of the joint acceleration of the robot by using a genetic algorithm according to the joint acceleration solution set of the surface modification robot.

Owner:SUZHOU INST OF INDAL TECH

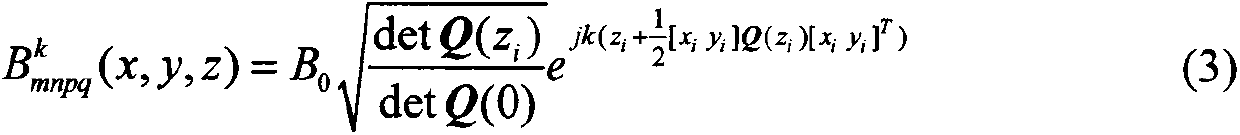

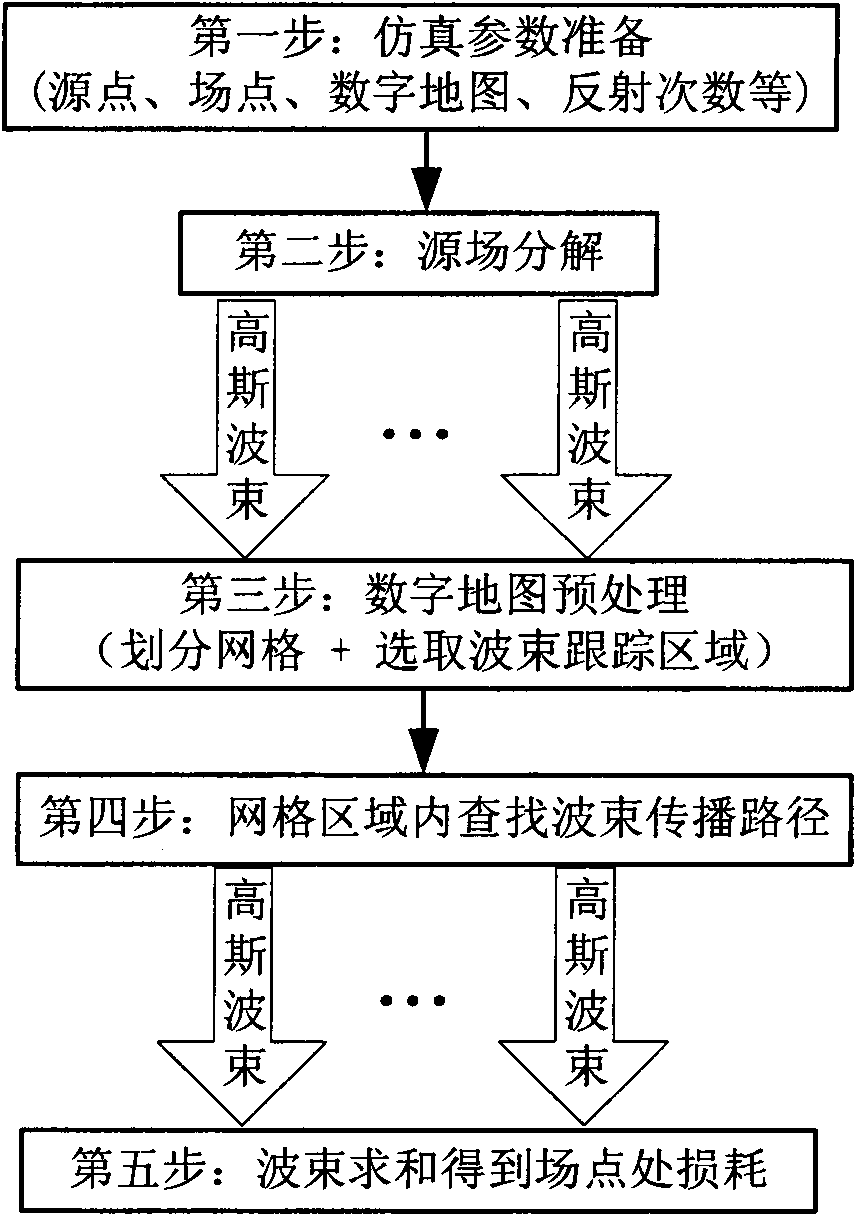

Rapid prediction method for radio wave propagation loss

InactiveCN103391139AEasy to implementEasy to handleTransmission monitoringDiffraction effectGaussian beam

The invention discloses a rapid prediction method for radio wave propagation loss. The rapid prediction method comprises the steps of first enabling a plane wave source field at the position of a source point to be decomposed into the weighting sum of a series of gaussian beams; performing preprocessing on a digital map; averagely dividing a whole scene area into a plurality of grid units, enabling buildings to belong to grids where the buildings are located, enabling the grids to serve as basic units, and selecting a rectangular region covering the source point and a receiving path to serve as a beam tracking region; searching building scene propagation paths of the gaussian beams emitted from the source point in the beam tracking region; and finally performing summation of all beams reaching a field point so as to obtain loss at the position of the field point. All the beams are uniformly processed through the method, complex diffraction effect does not need considering, receiving ball processing is not involved, and arithmetic implementation is simple; a grid region joint acceleration algorithm is adopted simultaneously, the beam tracking region is minimized, collision detection time of the beams and a barrier is greatly reduced, and prediction efficiency is further improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

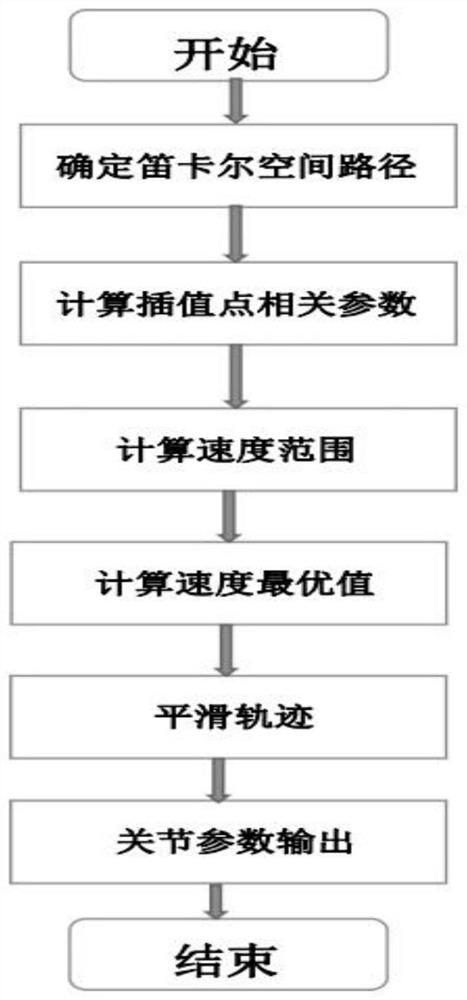

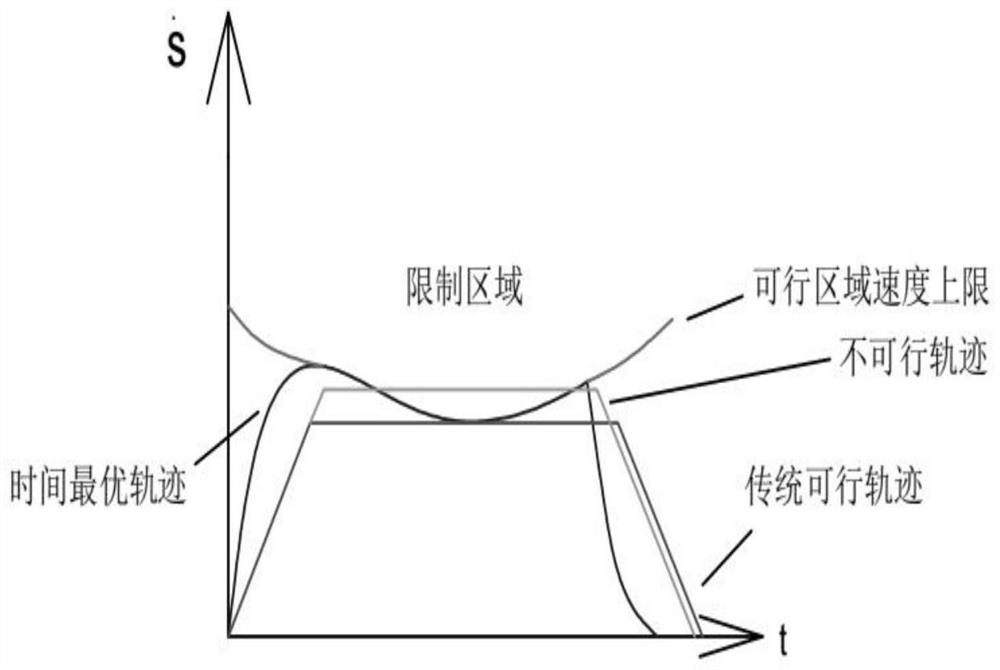

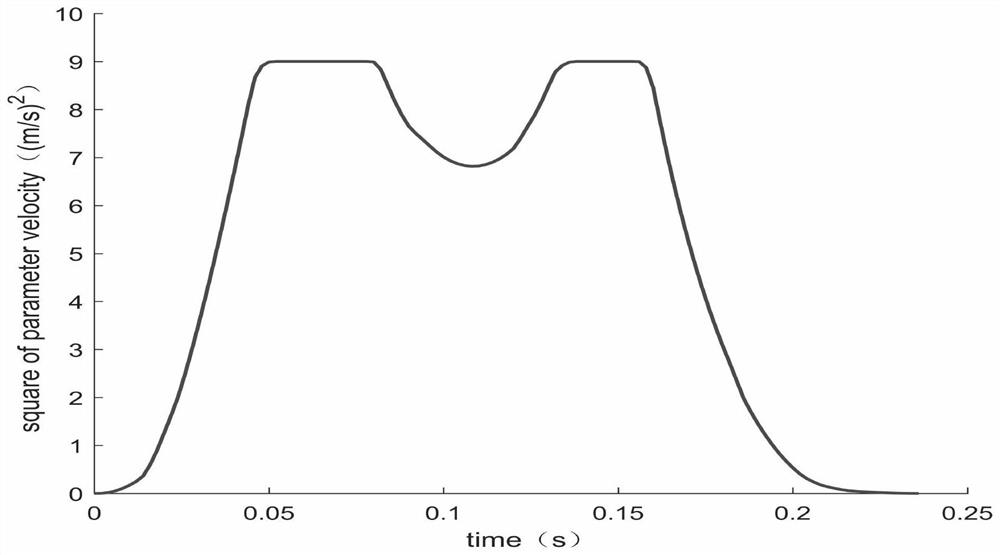

Spraying robot time optimal trajectory planning method based on dynamics

InactiveCN113084821AFull drive performanceUniversalProgramme-controlled manipulatorDynamic modelsSimulation

The invention discloses a spraying robot time optimal trajectory planning method based on dynamics, and relates to a robot trajectory planning method. The spraying robot time optimal trajectory planning method comprises the following steps that 1, a Cartesian space path is given; 2, relevant parameters of interpolation points are calculated, including the number of the interpolation points, Cartesian space parameters, joint space parameters and kinetic equation coefficients, the Cartesian space parameters include the position, the posture, the linear speed, the Euler angular speed, the linear acceleration and the Euler angular acceleration, and the joint space parameters include the joint angle, the joint speed and the joint acceleration; 3, a speed range is calculated; 4, an optimal speed value is calculated; 5, a track is smoothened; and 6, the joint parameters are output. Kinematic constraints are considered, a dynamic model is introduced to consider dynamic constraints, and compared with a traditional trajectory planning method, the method has obvious advantages in time, at least one joint motor reaches a limit operation state in the operation process, driving performance is brought into full play, all the joint parameters do not exceed limit values, the working efficiency is improved, and the universality is realized.

Owner:HARBIN INST OF TECH

Motion generating method for man-shape link system

This invention relates to a method for generating a motion of a human type link system, such as in a humanoid robot. In this invention, a dynamically feasible motion of the link system is generated when a reference joint acceleration that is only calculated from a kinematical constraint condition is determined not feasible from by an evaluation of external force computed based on an inverse dynamics calculation, or is generated by a calculating from dynamic constraint condition and a kinematical constraint condition simultaneously, the dynamic constraint condition is formulated by using an actuation space inverse inertial matrix that represents the relation of force acted on the link system and the acceleration of the link system caused by the said acceleration

Owner:THE UNIV OF TOKYO

A Motion Planning Method for Obstacle Avoidance Based on Sudden Acceleration

The invention discloses a barrier escaping motion planning method based on an impact degree. The method comprises the steps of 1) designing barrier escaping motion performance indices based on the impact degree so that the designed motion performance indices are subject to a Jacobian matrix equation based on the impact degree, a barrier escaping inequation based on the impact degree, joint angle limitation, joint speed limitation, joint acceleration limitation and joint impact degree limitation, and generating a quadratic form optimization redundancy analysis scheme, 2) transforming the quadratic form optimization redundancy analysis scheme generated in the step 1) into a secondary planning problem, 3) solving the secondary planning problem in the step 2) by use of a secondary planning solver, and 4) transferring the solution result of the step 3) to a lower computer controller to drive a mechanical arm to move. According to the barrier escaping motion planning method, the barrier escaping motion performance indices based on the impact degree are designed, the mechanical arm is controlled to escape a barrier at an impact degree layer, and meanwhile, the mechanical arm is capable of completing a given tail end task.

Owner:SUN YAT SEN UNIV

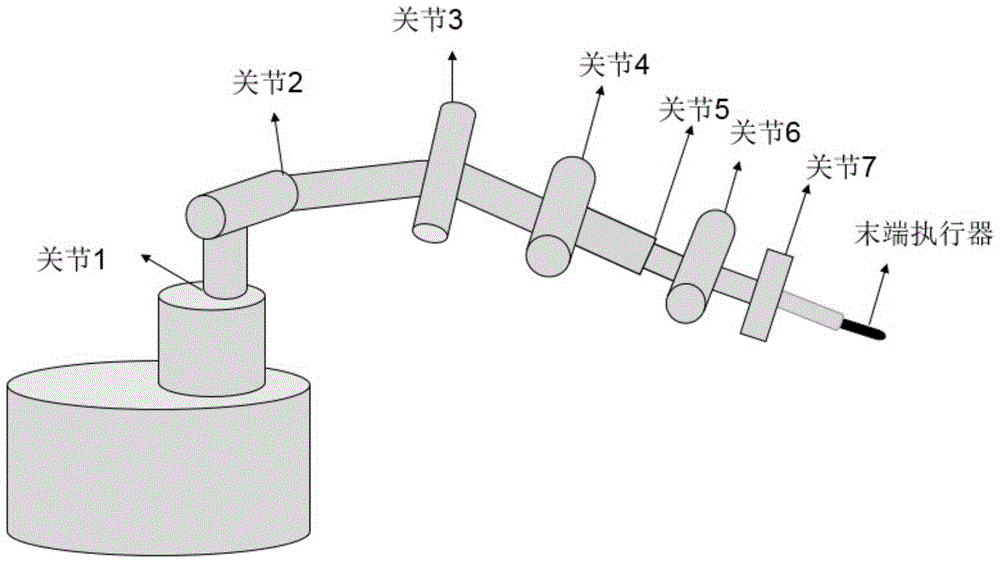

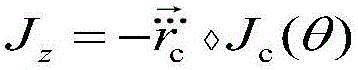

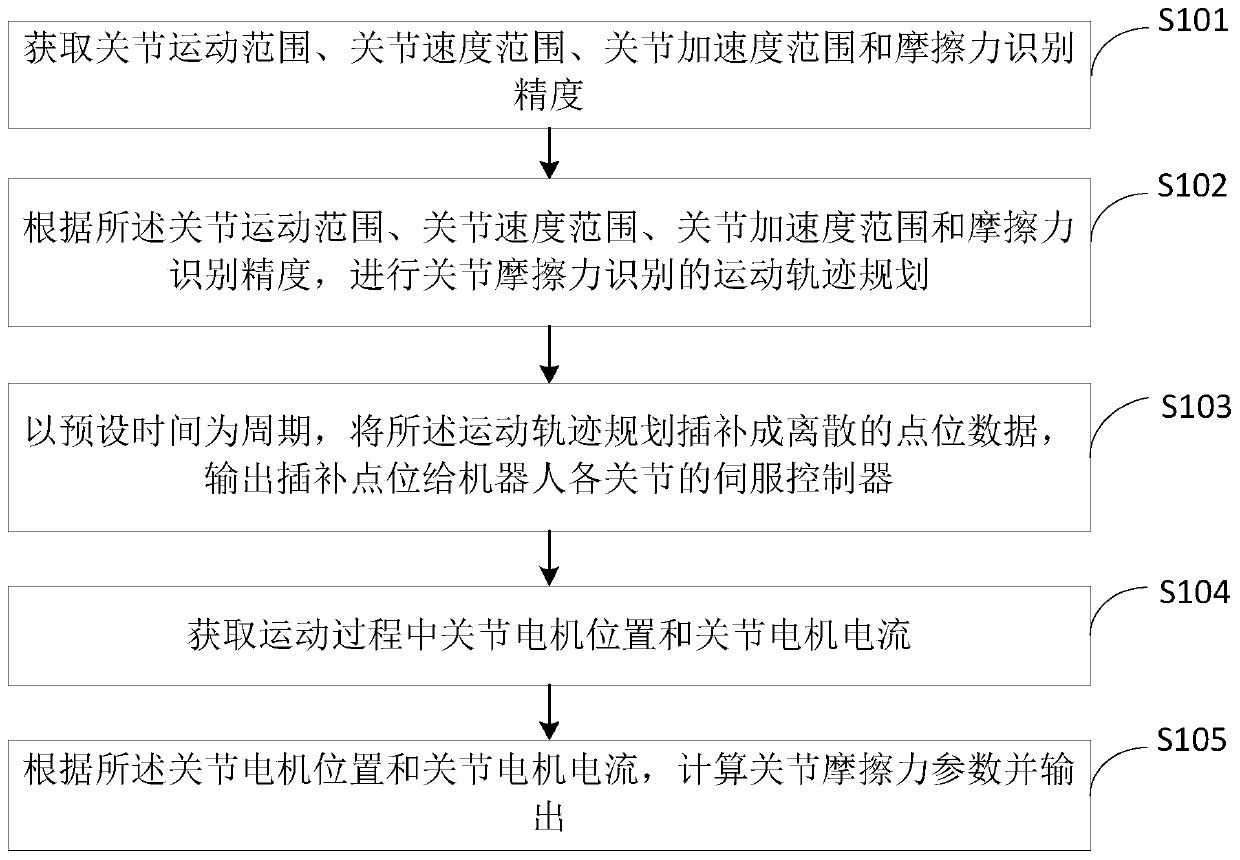

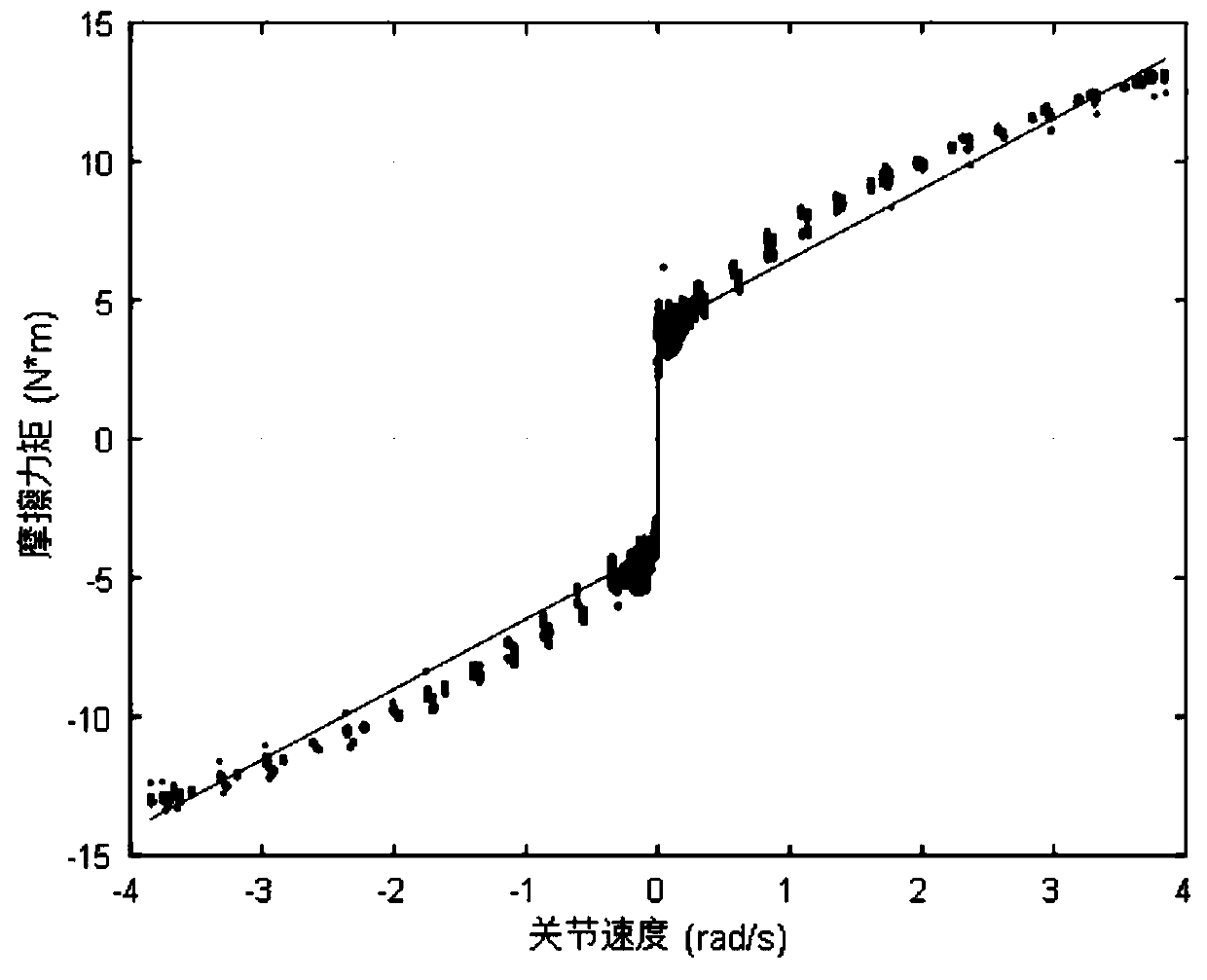

Robot control method and device for recognizing friction force, robot and storage medium

ActiveCN111185908AAccurate identification of friction forceProgramme-controlled manipulatorSimulationElectric machinery

The invention is applicable to the technical field of robots, and provides a robot control method for recognizing friction force. The method comprises the following steps of planning a motion trajectory of joint friction force recognition according to a joint motion range, a joint speed range, a joint acceleration range and friction force recognition precision; taking preset time as a period, planning and interpolating the motion trajectory into discrete point position data; outputting interpolation point positions to servo controllers of all joints of a robot; obtaining joint motor positionsand joint motor currents in the motion process; and calculating joint friction force parameters and outputting the parameters. According to the method, joint friction force in the whole motion processcan be accurately identified.

Owner:ADTECH SHENZHEN TECH

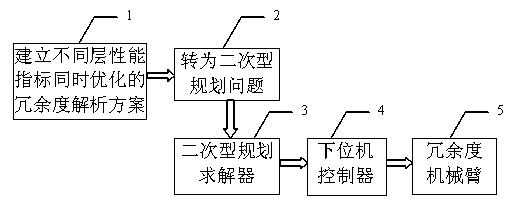

Method for optimizing performance indexes of different layers of redundancy mechanical arm simultaneously

InactiveCN102514008BEasy to operateReduce workloadProgramme-controlled manipulatorPerformance indexComputer science

The invention provides a method for optimizing performance indexes of different layers of a redundancy mechanical arm simultaneously. The method comprises the following steps: according to performance indexes of an angle layer, a speed layer and an acceleration layer which are to be optimized, establishing a corresponding redundancy analytical scheme by introducing a weight regulatory factor, wherein the analytical scheme is constrained by Jacobin matrix equation of speed and acceleration, a kinetic equation of a mechanical arm, joint angle limit, joint speed limit, joint acceleration limit and joint torque limit; converting the redundancy analytical scheme into a uniform quadratic problem by utilizing equivalence of the performance indexes of the three layers and introducing equivalence parameters; solving a quadratic planning problem by using a quadratic planning solver; and driving the mechanical arm to complete a given end task by a lower computer controller according to solution. According to the invention, the weight regulatory factor is intruded to optimize the performance indexes of different layers at the same time, and the mechanical arm can complete the given end task.

Owner:SUN YAT SEN UNIV

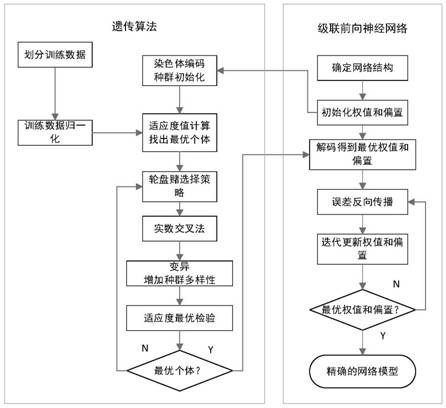

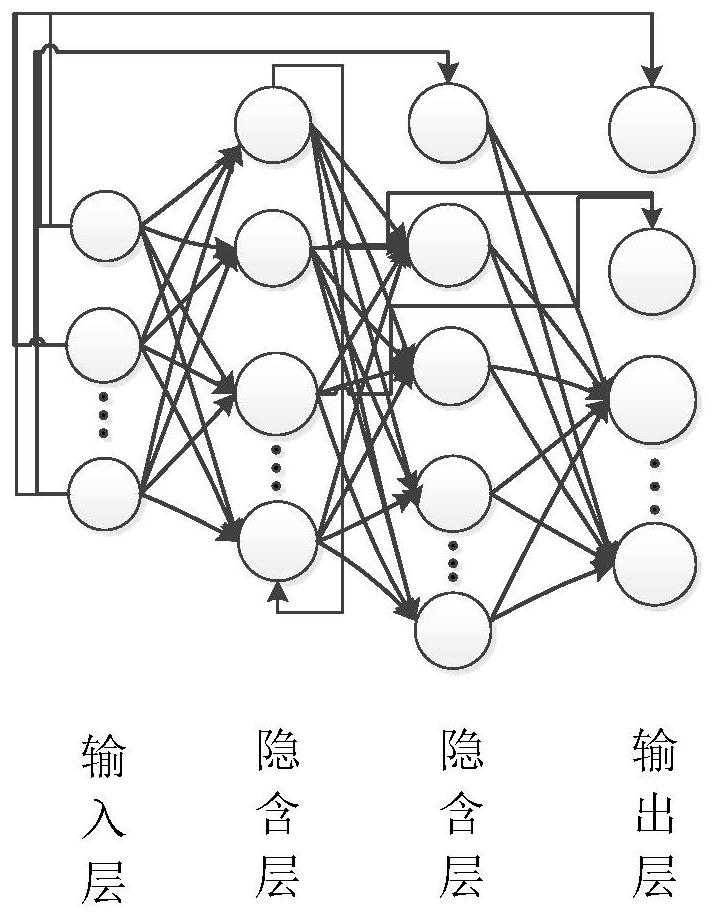

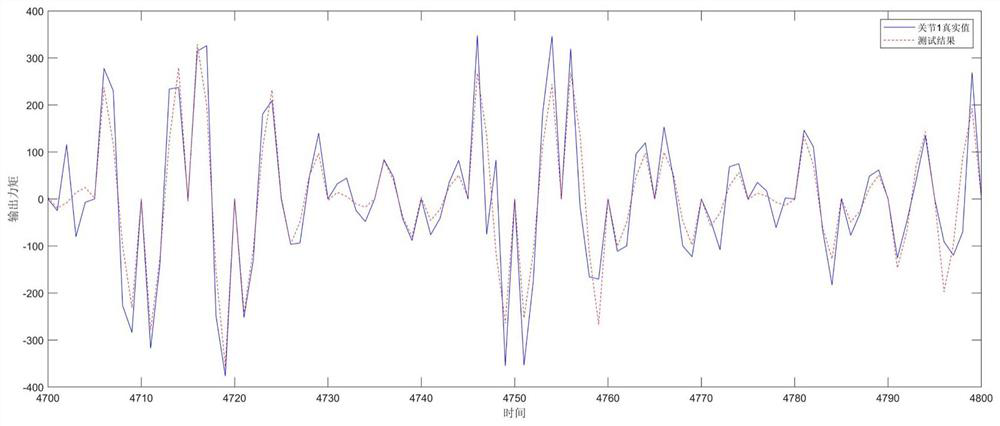

Neural network mechanical arm dynamics modeling method based on genetic algorithm optimization

PendingCN114417711ABig errorHigh precisionCharacter and pattern recognitionDesign optimisation/simulationAlgorithmDynamic models

The invention relates to a neural network mechanical arm dynamics modeling method based on genetic algorithm optimization, the modeling method relates to a joint motion variable of a mechanical arm and a relation between the joint motion variable and an output torque, and the joint motion variable comprises a joint angle, a joint speed and a joint acceleration. According to the modeling method, a cascade forward neural network structure and a genetic algorithm structure are adopted to construct a dynamic model of the mechanical arm, and the cascade forward neural network structure comprises a plurality of hidden layers. According to the neural network, parameters subjected to primary optimization are trained, the output of a more accurate network model is used as an evaluation index to carry out iterative updating on the evaluation index, deep optimization is carried out on the network parameters, and accurate construction of the network model is realized.

Owner:QINGDAO UNIV OF SCI & TECH

Repetitive motion planning method for redundant manipulator

Owner:SUN YAT SEN UNIV

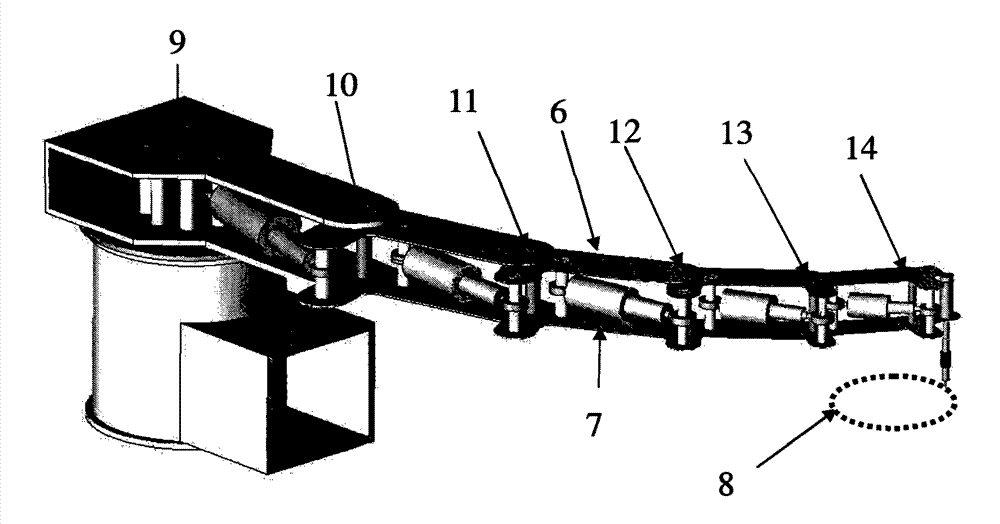

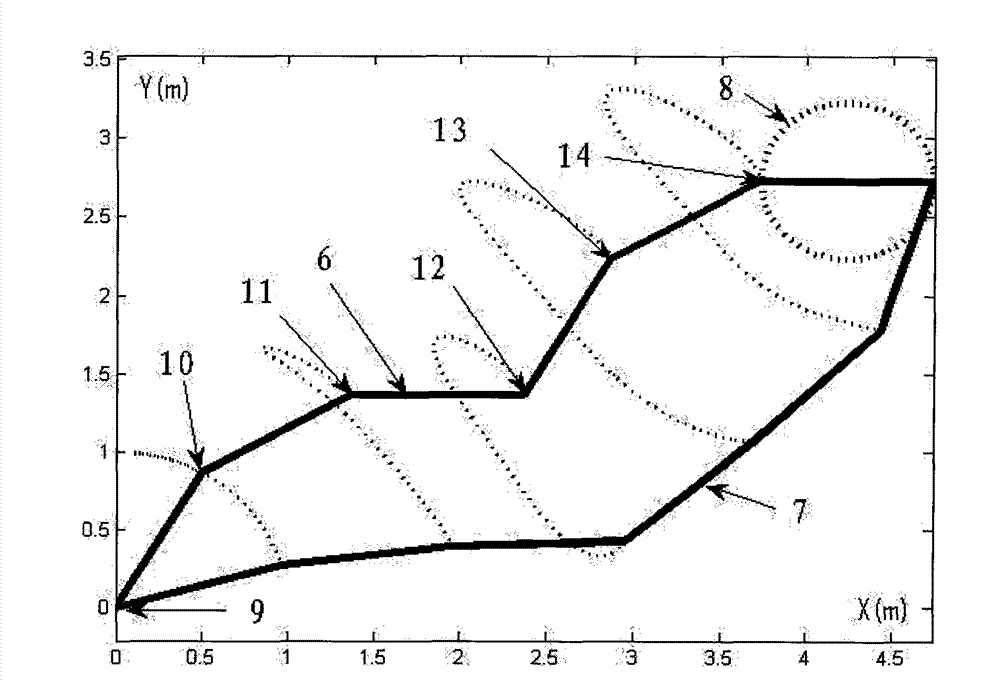

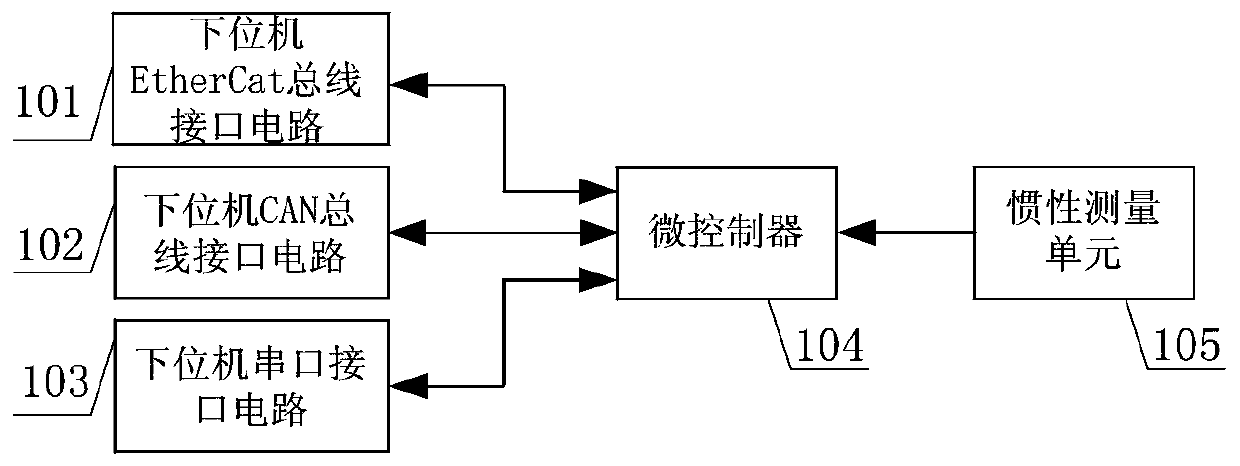

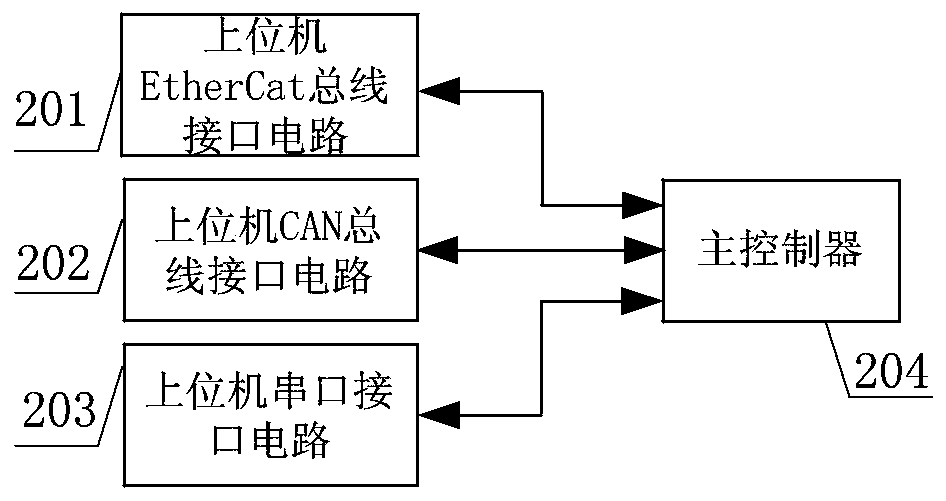

Robot joint information acquisition method

InactiveCN111421551AHigh speedQuality improvementProgramme-controlled manipulatorSimulationRobot control

The invention provides a robot joint information acquisition method, belongs to the field of robots, and mainly solves the problem that the control performance of a robot is influenced due to poor joint speed and joint acceleration signal quality of the existing robot. According to the robot joint information acquisition method, joint displacement, joint speed and joint acceleration information are obtained through the angular speed and acceleration information output by an inertia measurement unit, meanwhile, under the condition that the joint torque is known, the current load mass of a driver can be estimated in real time, and reliable state information is provided for driver control. The method is reasonable in structural design, small in size, diversified in sensor arrangement mode andcapable of improving the performance of the robot conveniently.

Owner:HARBIN UNIV OF SCI & TECH

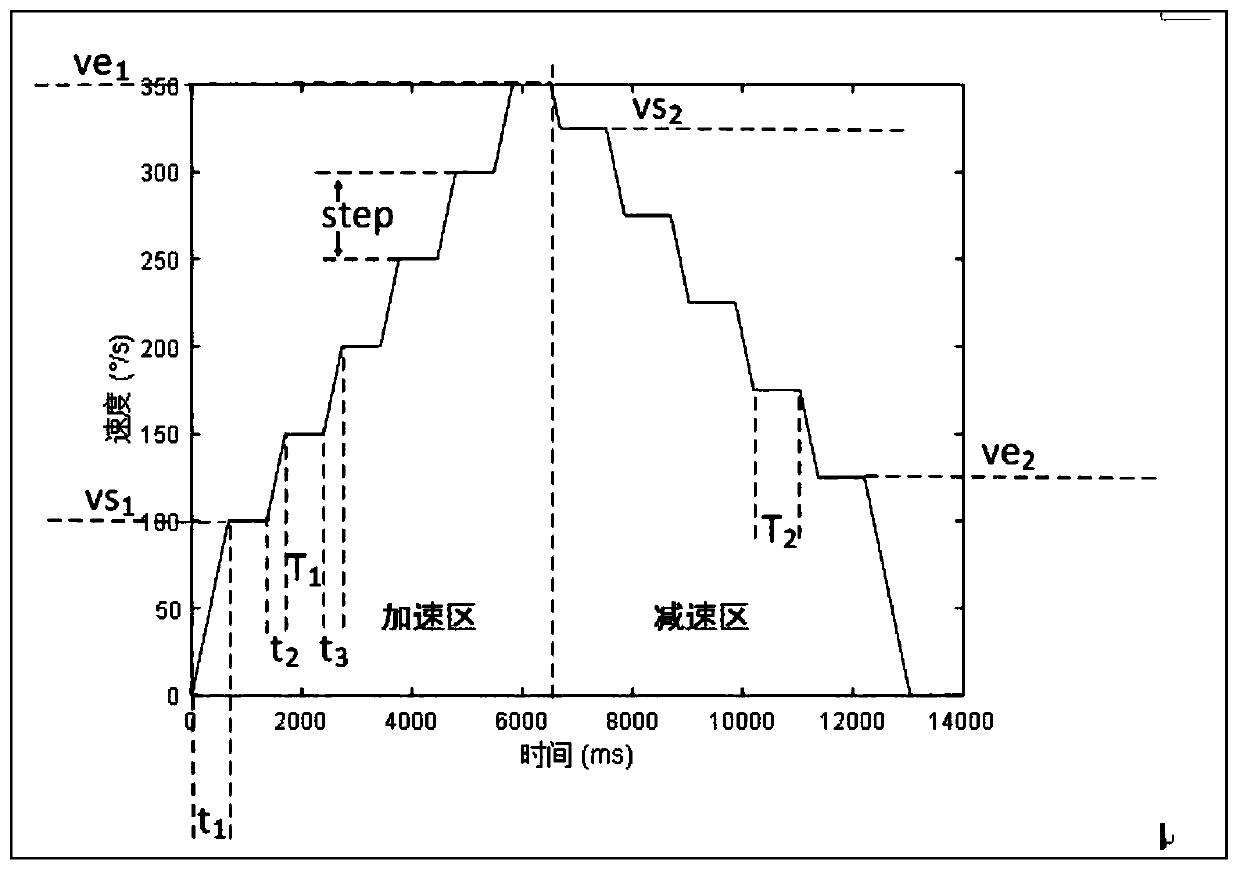

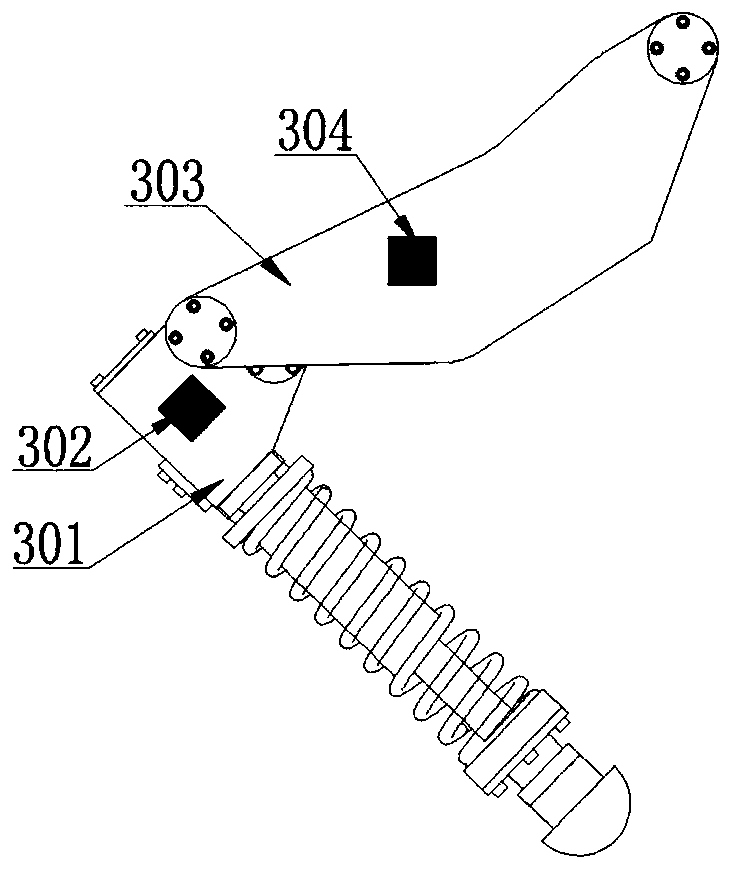

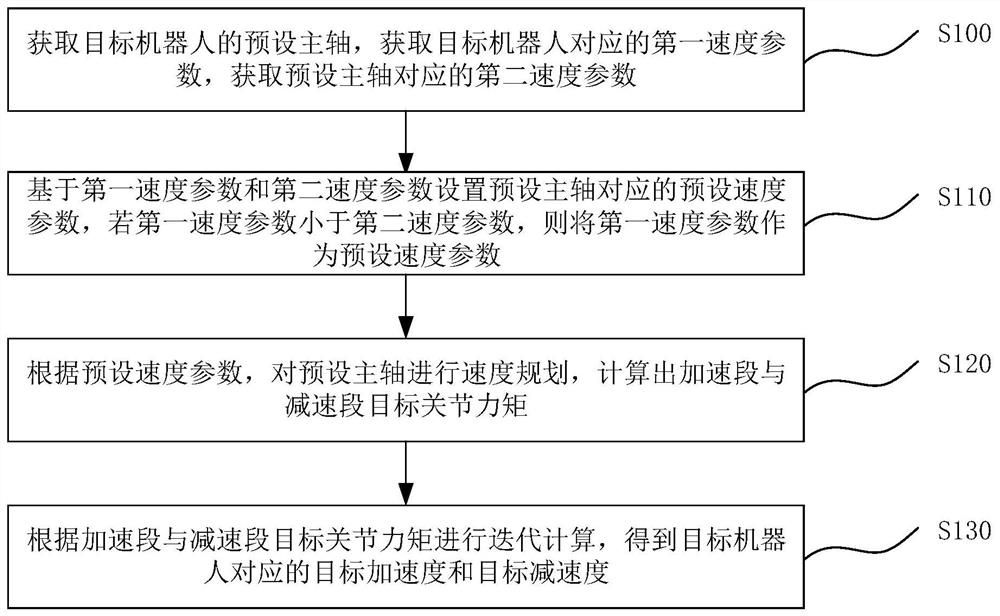

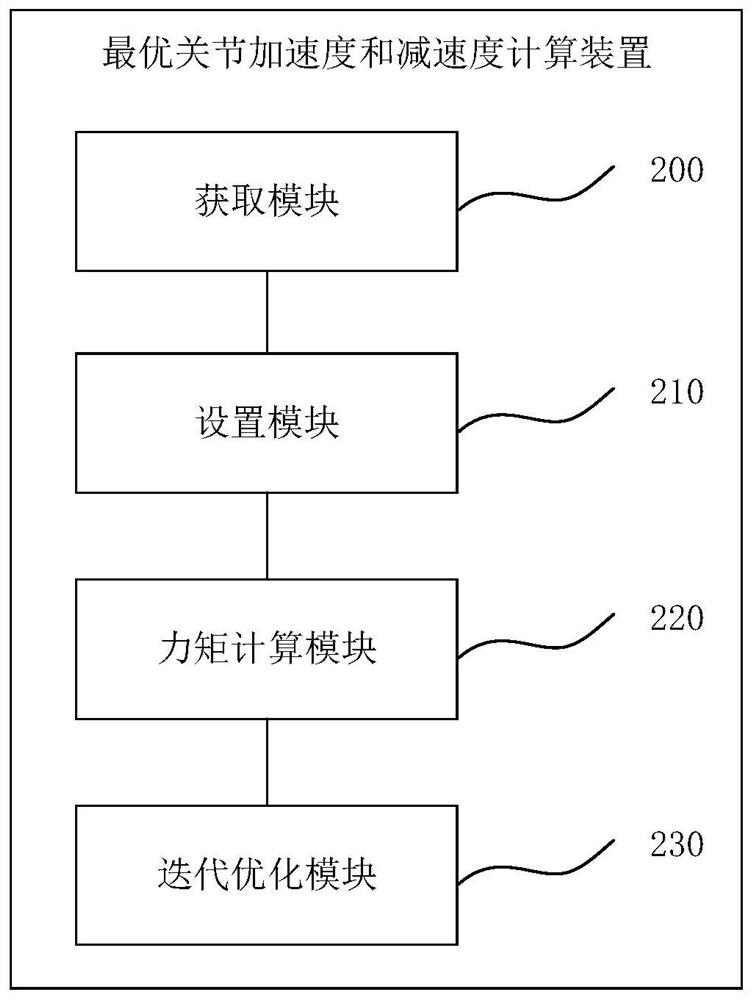

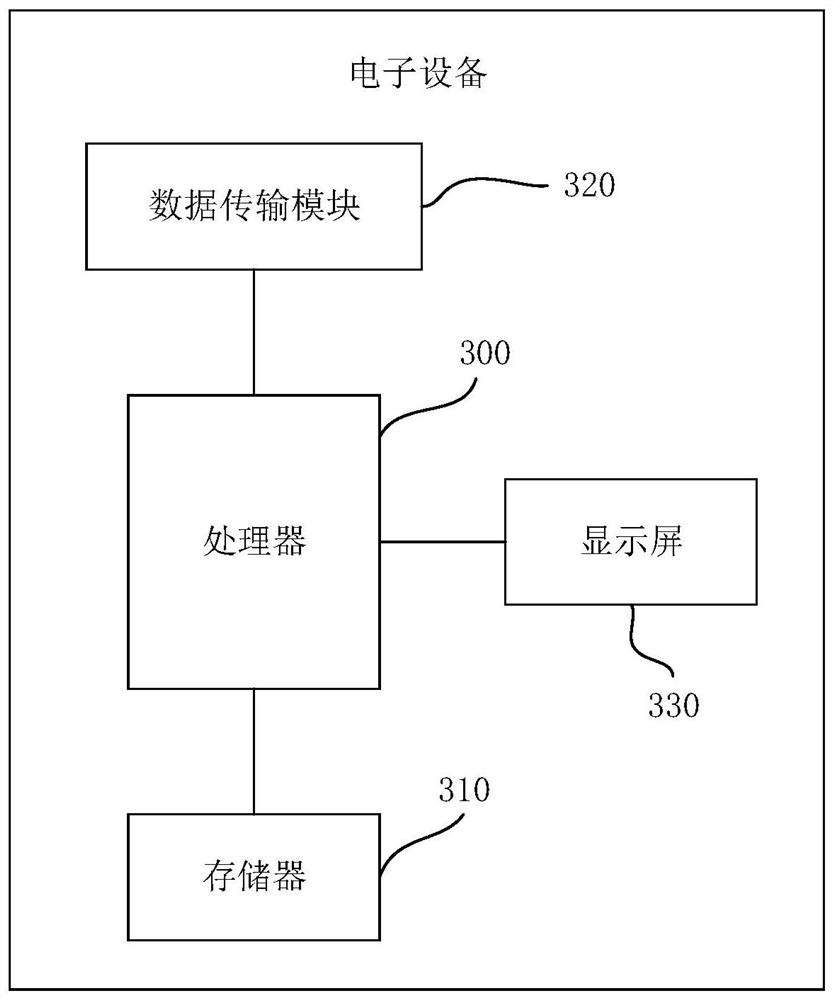

Optimal joint acceleration and deceleration calculation method and device, and application thereof

ActiveCN112720455ACalculation is automatic and fastFast tempoProgramme-controlled manipulatorDesign optimisation/simulationSimulationElectric machinery

The invention discloses an optimal joint acceleration and deceleration calculation method and device, and application thereof, and relates to the field of robot control. The optimal joint acceleration and deceleration calculation method comprises the steps: obtaining a preset main shaft of a target robot, obtaining a first speed parameter corresponding to the target robot, and obtaining a second speed parameter corresponding to the preset main shaft; setting a preset speed parameter corresponding to the preset main shaft based on the first speed parameter and the second speed parameter; conducting speed planning on the preset main shaft according to the preset speed parameter, and calculating target joint torques of an acceleration section and an deceleration section; and performing iterative calculation according to the target joint torques of the acceleration section and the deceleration section to obtain a target acceleration and a target deceleration corresponding to the target robot. Through the method, the optimal joint acceleration and deceleration can be automatically and quickly calculated under the constraint of relevant speed parameters of the robot joint, the performance of a motor is fully achieved, and the beat of the robot is improved.

Owner:ADTECH SHENZHEN TECH

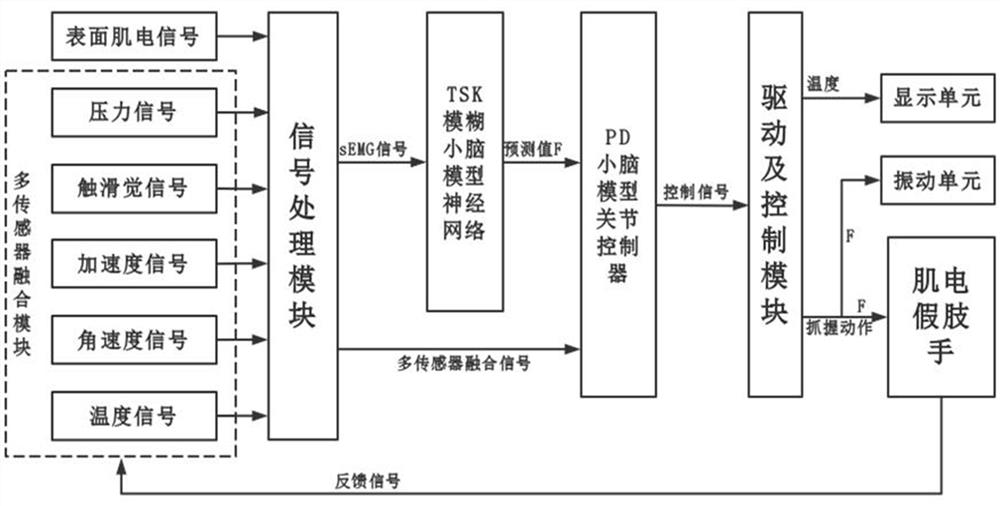

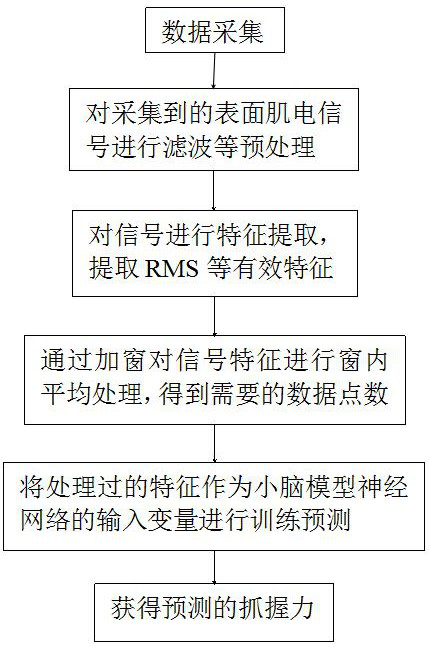

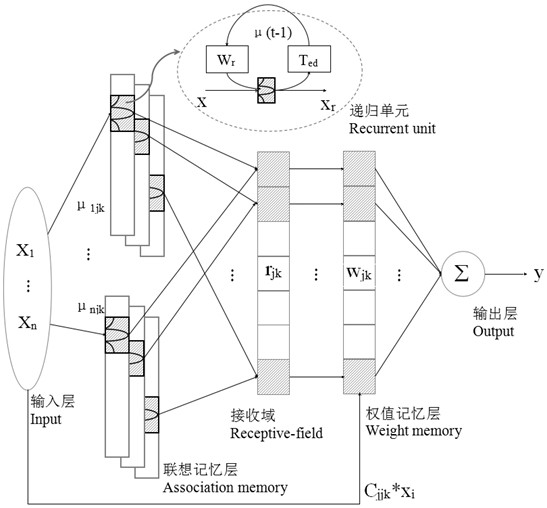

Multi-sensor fusion prosthetic hand grasping force feedback control method

PendingCN113952091AGuaranteed stabilityGuaranteed reliabilityInput/output for user-computer interactionCharacter and pattern recognitionPhysical medicine and rehabilitationTouch Senses

The invention provides a multi-sensor fusion prosthetic hand grasping force feedback control method. The method comprises a multi-sensor fusion and feedback method, a grasping force prediction method and a PD-based CMAC manipulator grasping control method, wherein the multi-sensor fusion and feedback method comprises the following steps: acquiring surface electromyogram signals of muscles, acquiring temperature, contact force and sliding state of an object grabbed by a prosthetic hand, acquiring joint acceleration and angular velocity corresponding to a grasp action, and acquiring actual grasping strength of the grasp action of the prosthetic hand; the grasping force prediction method is used for predicting the grasping force of the current grasping action; and according to the multi-sensor fusion and feedback method, data is fused to generate prosthetic end sensing information of the current grasping action. A user can adjust the actual grasping force and grasping action in time, an object is accurately and stably grasped, besides, the real-time temperature and contact force of the grasped object are detected in the grasping process, and touch information is fed back to the user through a vibration and display module.

Owner:FUZHOU UNIV

Control device and control method for robot

InactiveCN102452077BEasy to controlExcellent control equipmentProgramme controlProgramme-controlled manipulatorForward dynamicInverse dynamics

A control device for a robot including: a hybrid dynamics calculator calculating joint forces that act on immovable joints and the joint accelerations that are generated at movable joints by performing a hybrid dynamics calculation that includes inverse dynamics and forward dynamics using an auxiliary model in which the actuated joints of the robot having the actuated joints and the unactuated joints are immovable; a forward dynamics calculator calculating the acceleration that is generated by known force that acts on the robot using a main model; a joint force determination unit determining the joint force; and a joint force controller controlling the joint force of each joint of the robot.

Owner:SONY CORP

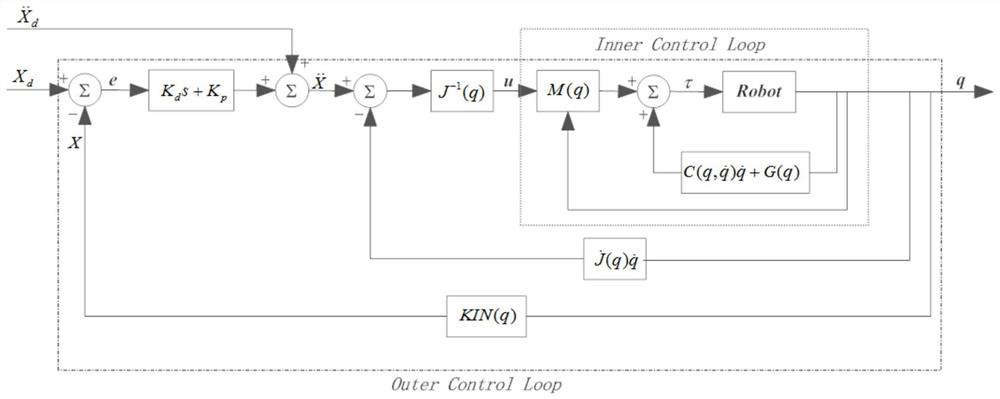

A kind of robot trajectory synchronization control method, computer readable storage medium

ActiveCN112847373BImprove trajectory accuracyAdjust motion in real timeProgramme-controlled manipulatorLoop controlSynchronous control

The invention discloses a robot trajectory synchronization control method. The linear acceleration and angular acceleration in space are converted into the joint speed and joint acceleration of the robot. If there is a deviation between the pose and joint speed of the robot end and the set value, the inner loop control loop is introduced to control each joint of the robot to increase according to the joint acceleration. Deceleration; in each control interpolation cycle of the robot, according to the deviation between the set pose and the actual pose of the robot end, the joint acceleration of each joint is calculated and applied to the controller of the inner loop control loop of the robot. The method of the invention adjusts the motion of each joint of the robot in real time according to the deviation between the robot end feedback pose and the theoretical pose, and improves the trajectory accuracy of the robot.

Owner:CHENGDU CRP ROBOT TECH CO LTD

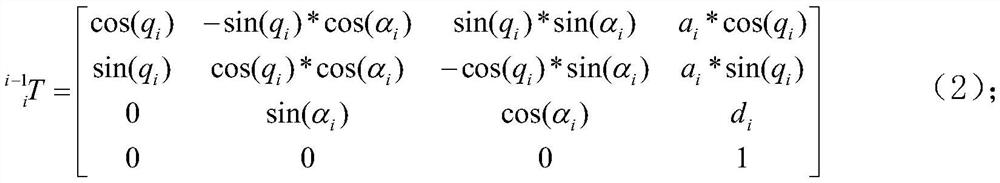

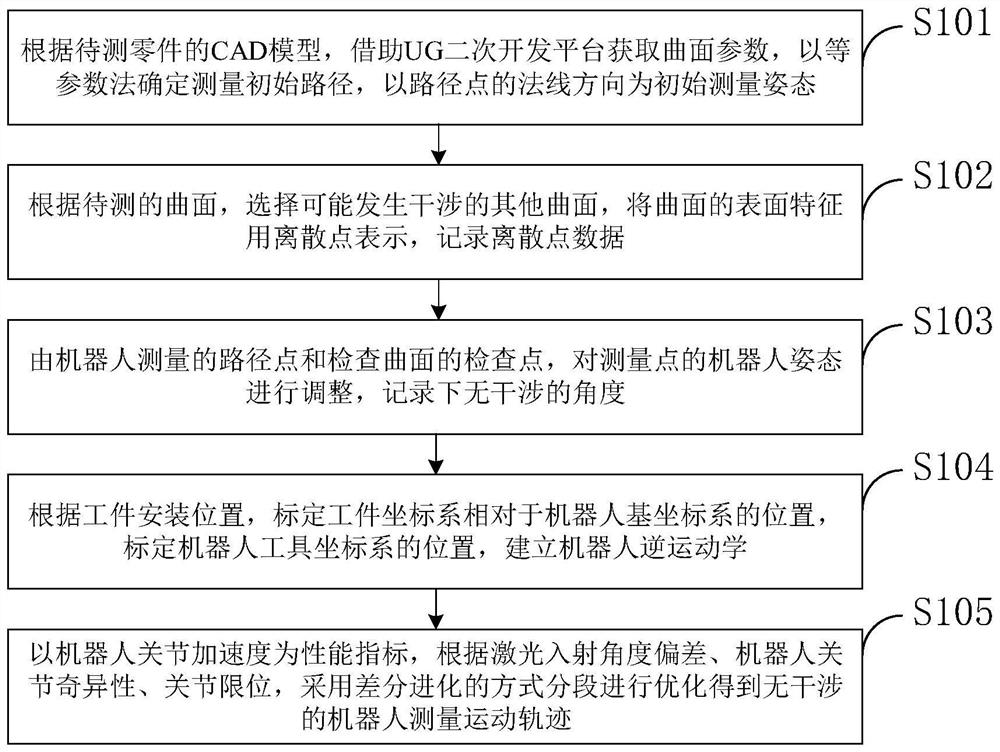

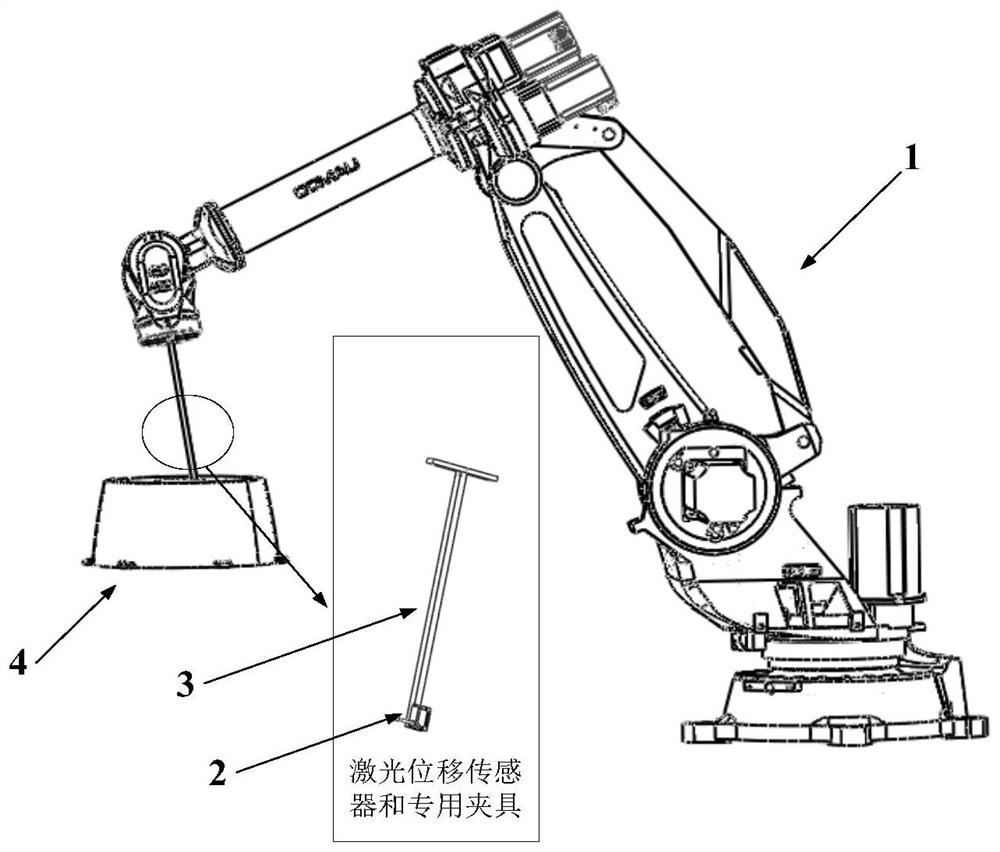

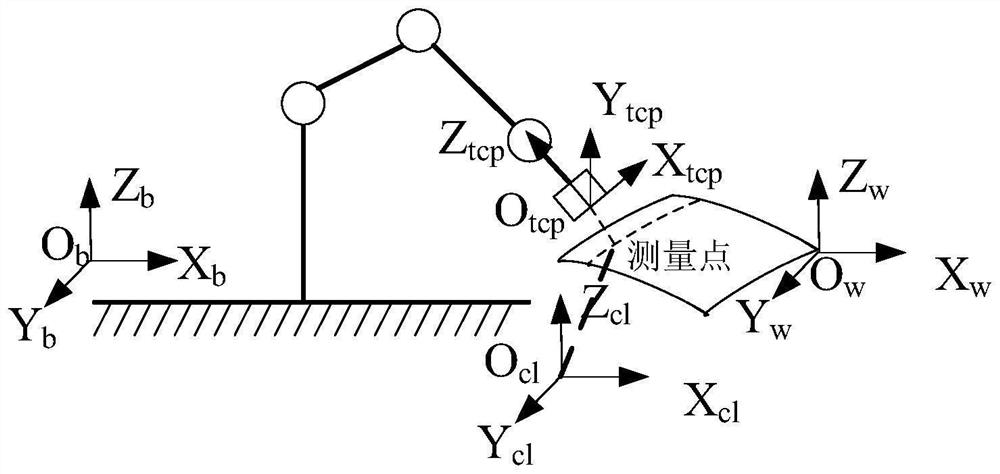

Pose optimization and motion fairing calculation method and system for robot measurement and application

PendingCN114310897AGuaranteed measurement accuracyImprove efficiencyProgramme-controlled manipulatorGenetic modelsSimulationPath generation

The invention belongs to the technical field of robot motion posture optimization, and discloses a robot measurement posture optimization and motion fairing calculation method and system and application, according to a CAD model of a to-be-measured part, curved surface parameters are obtained by means of a UG secondary development platform, and an equal parameter method is adopted to generate an initial path and posture information during robot measurement; selecting an interference inspection curved surface, and dispersing the inspection curved surface into data points; constructing a non-interference area for measuring the path points according to the path points measured by the robot and the feature points of the inspection curved surface; according to the workpiece mounting position, the end effector mounting position and the inverse kinematics of the robot, calculating the joint acceleration of the robot during measurement; the joint acceleration is used as an index, an axis deviation angle is measured to establish optimization, a measurement feasible area of each path point is used as a search domain, and segmented optimization is carried out by adopting a differential evolution algorithm. According to the invention, interference-free path generation and smooth movement are realized when the robot carries out measurement on the laser displacement sensor at the clamping point.

Owner:HUAZHONG UNIV OF SCI & TECH +1

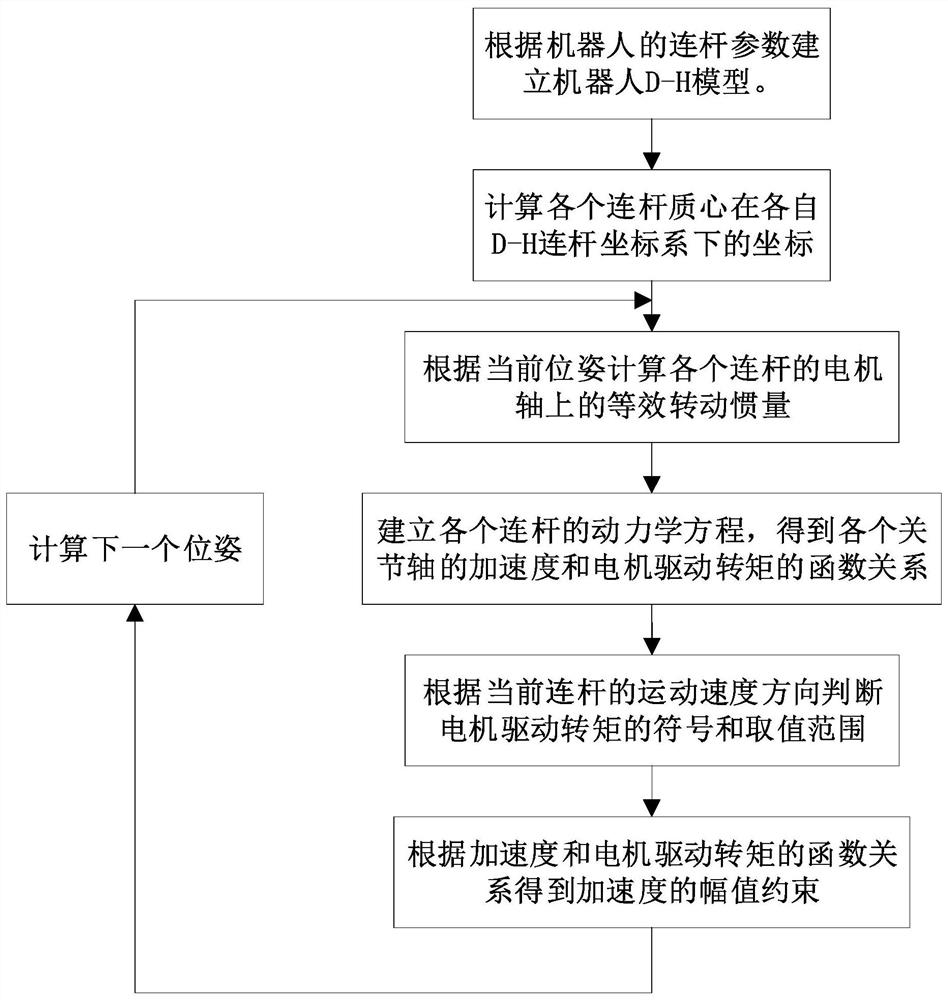

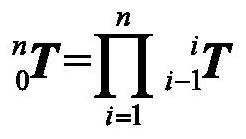

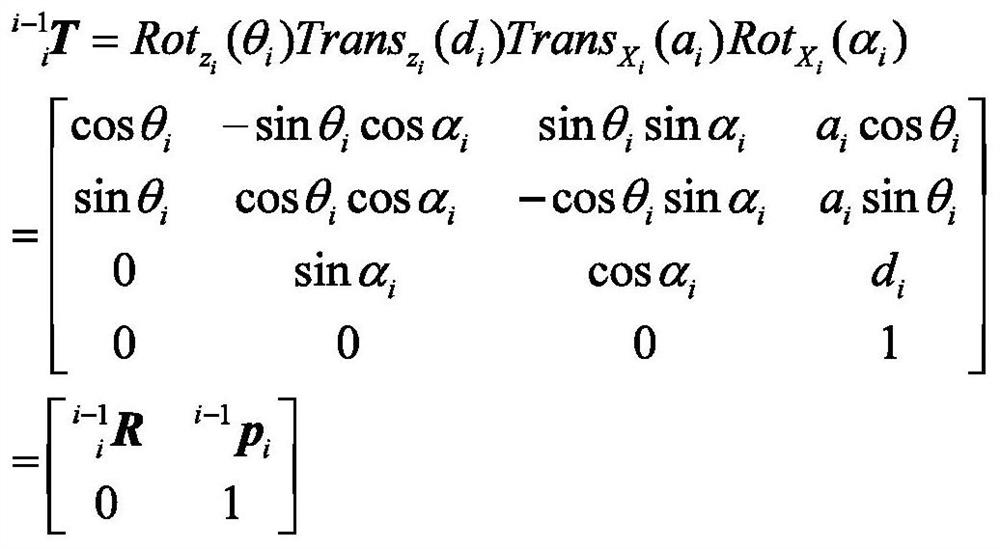

A robot joint acceleration constraint planning method and system

ActiveCN113510705BImprove exercise efficiencyProgramme-controlled manipulatorJointsDynamic equationKinetics equation

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com