Optimal track planning method for intelligent hydraulic excavator

A hydraulic excavator and trajectory planning technology, applied in the field of excavator control, can solve the problems of obvious vibration, complicated calculation, and the movement trajectory is not smooth enough, and achieve the effect of avoiding the semi-infinite constraint problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with drawings and embodiments.

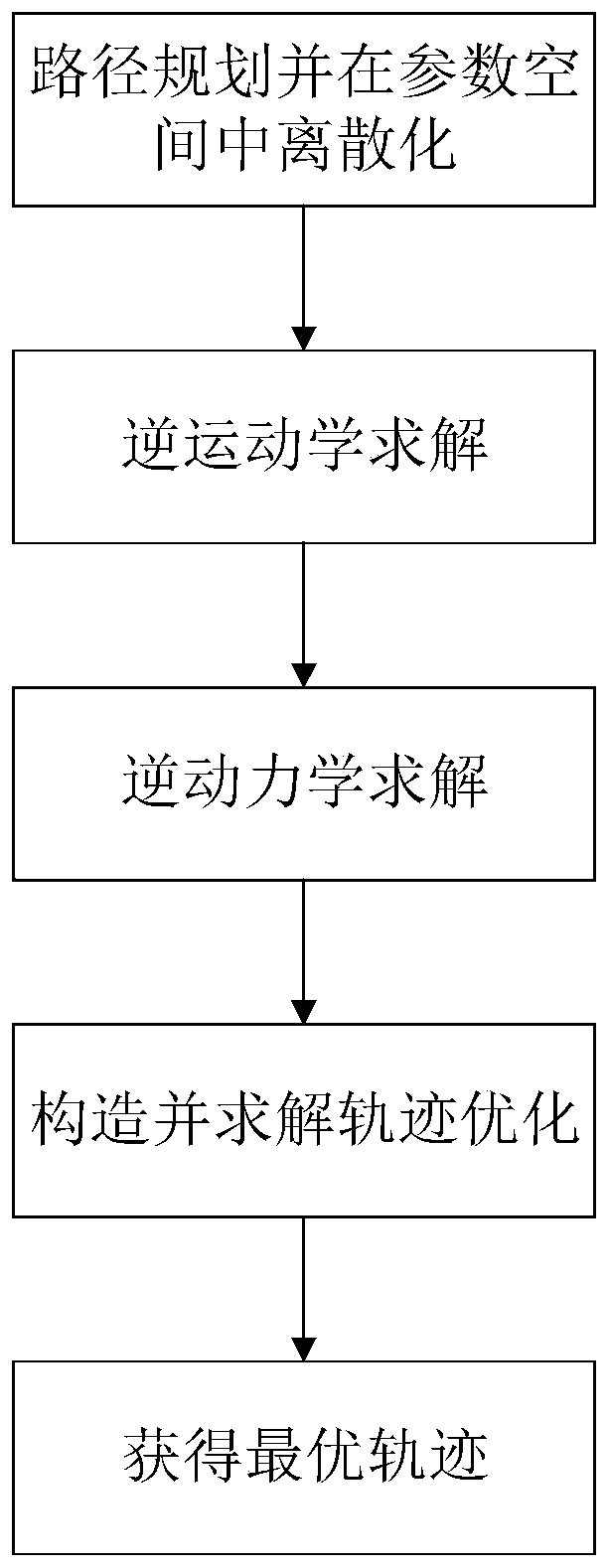

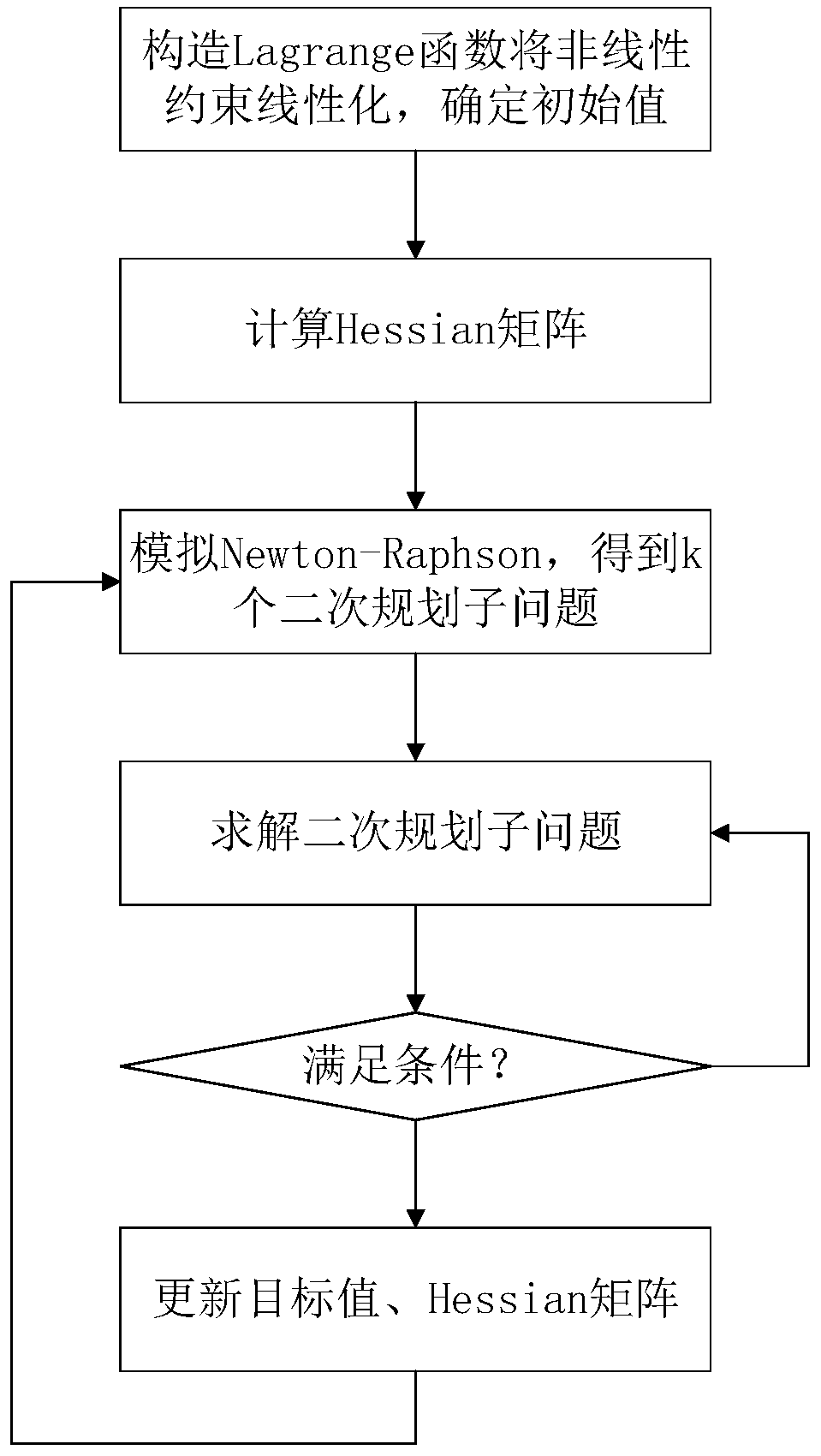

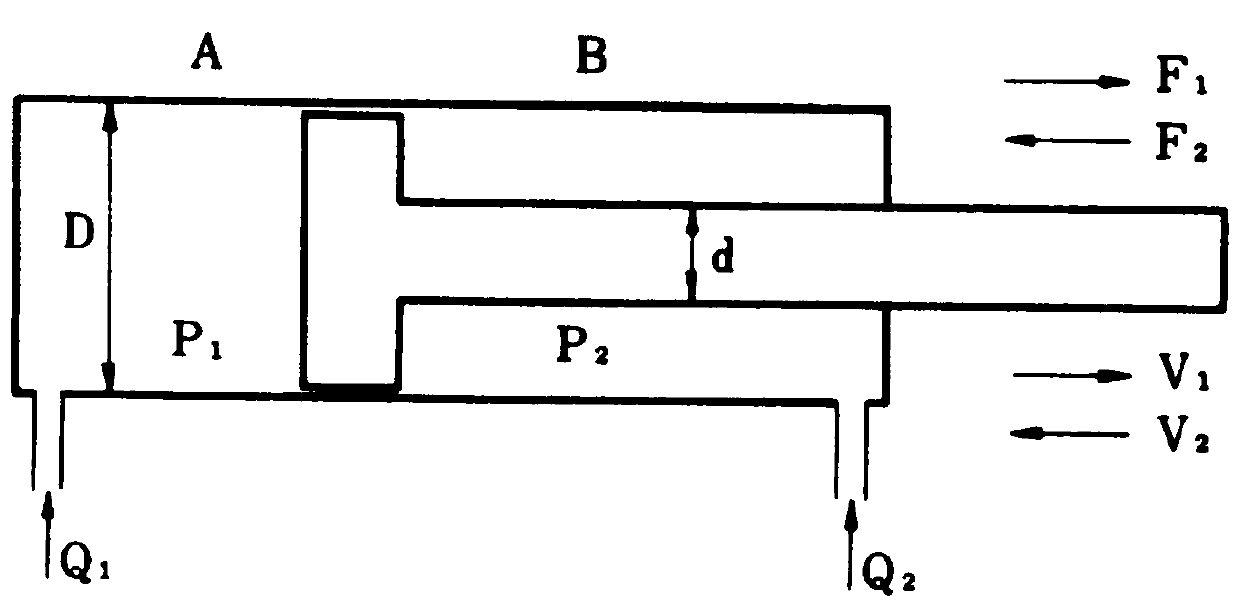

[0080] refer to Figure 1 to Figure 3 , taking the autonomous excavation operation of an intelligent hydraulic excavator as an example, the intelligent hydraulic excavator includes a central controller, a vision module, a working module, a power module, an electric proportional control multi-way valve, and an electric proportional control multi-way valve connected to the The main valve of the excavator, the electric proportional control multi-way valve is connected to the central controller; wherein: the vision module is used to provide image signals for the central controller, which includes an image processor connected to the central controller And the camera that is arranged on the body of the excavator, the camera is connected with the image processor; the working module is an actuator, which includes a slewing device, a boom, a stick and a working head, and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com