Patents

Literature

335results about How to "Fast tempo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

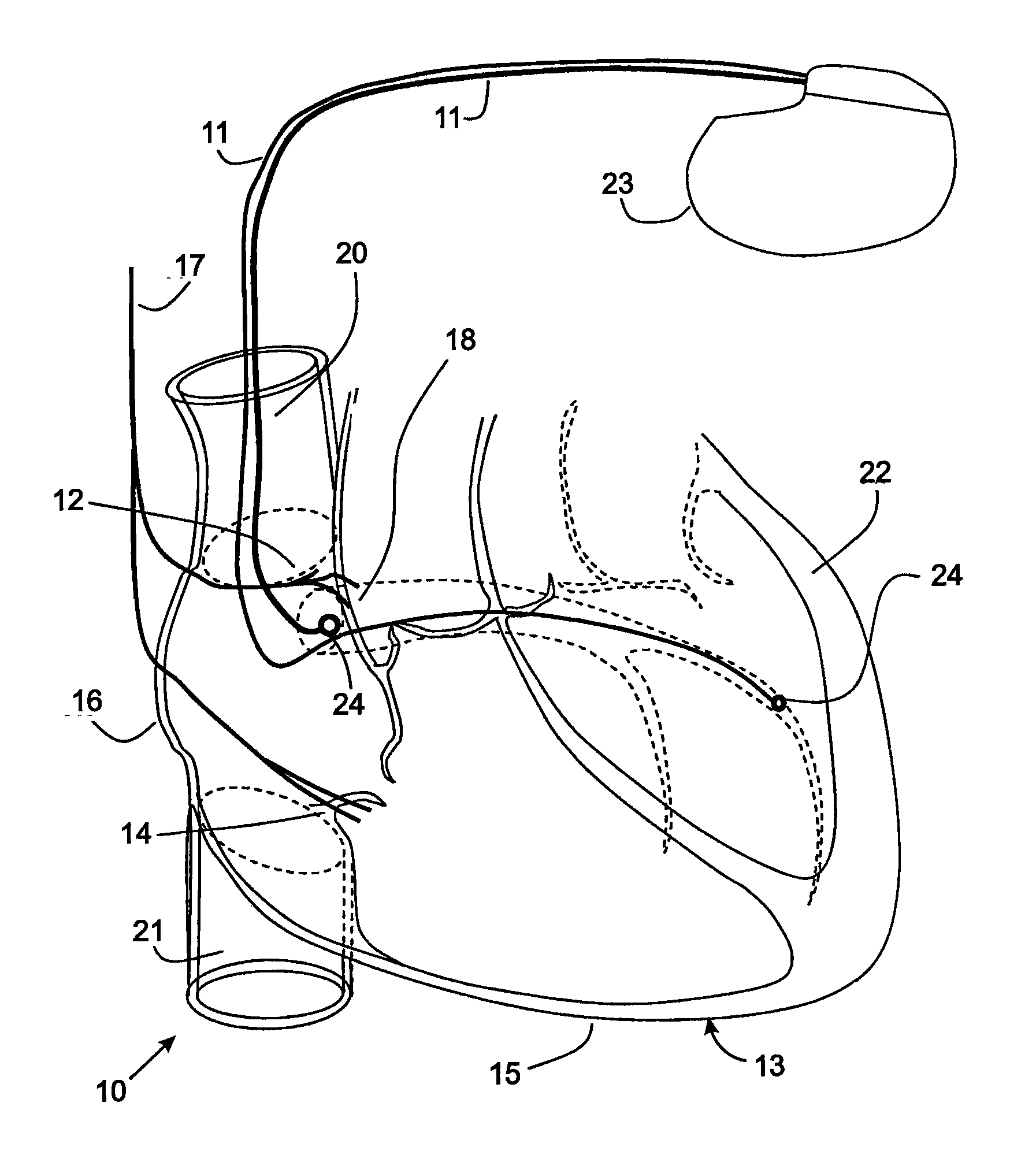

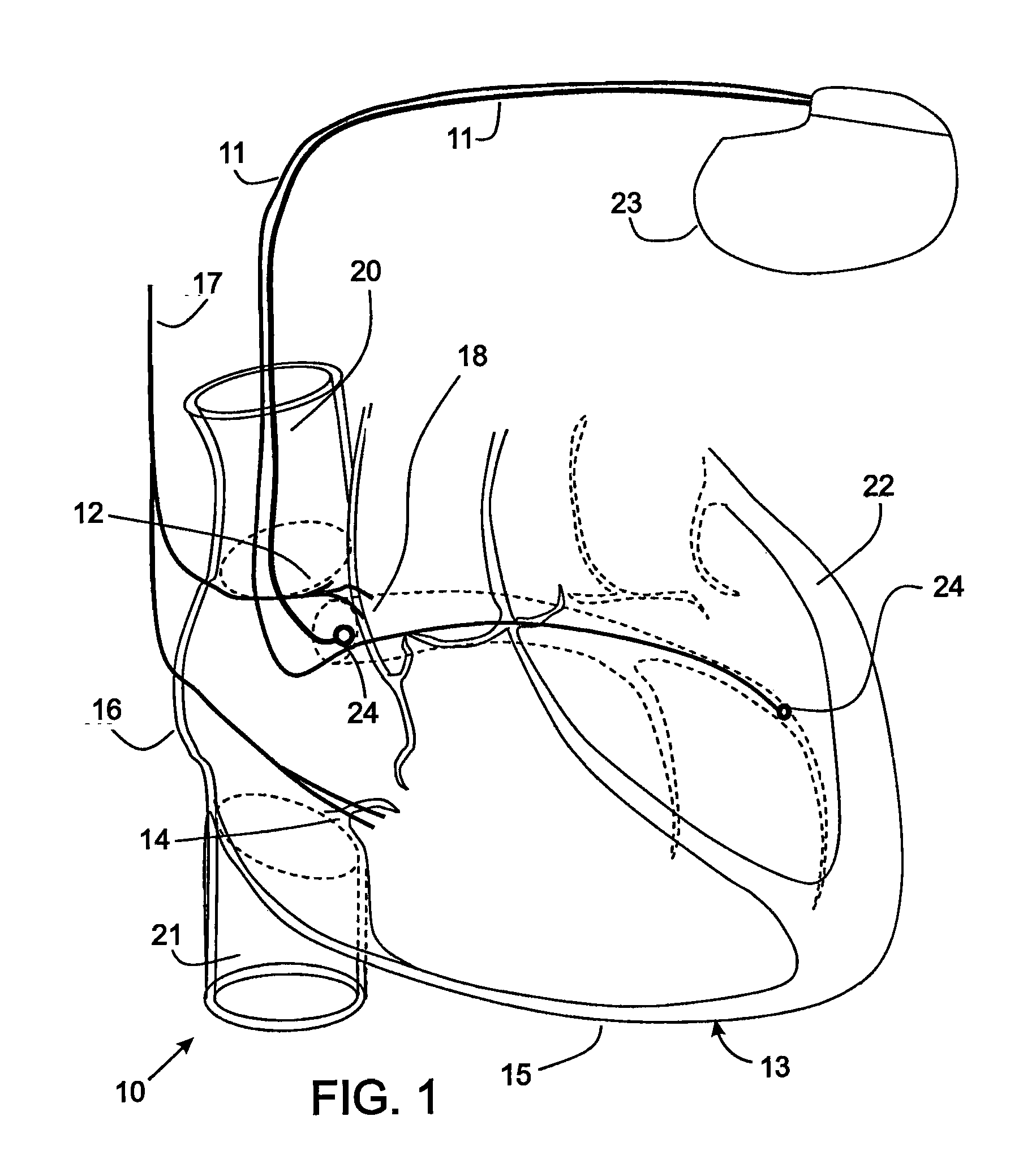

Implantable digital device for tissue stimulation

InactiveUS20080281368A1Power Loss MinimizationLower impedanceHeart defibrillatorsHeart stimulatorsHigh energyDigital device

An implantable vagal stimulation device with high-energy efficiency and novel data sensing is provided for use in a wide variety of applications where neural stimulation is required, including human heart rate control. The stimulation device uses low-impedance circuitry and digital waveforms to minimize energy losses, thereby requiring a relatively small battery. Front-loaded, passive filtering is employed to reduce electromagnetic noise sensitivity, leaving a clear physiological signal without degradations. This physiological signal is processed by a derivative zero transition detector (DZD), which is immune to variations in input signal dynamic range unlike traditional methods. Information that the DZD receives can be then interpreted and used along with an algorithm to execute appropriate vagal nerve stimulation.

Owner:KENERGY INC

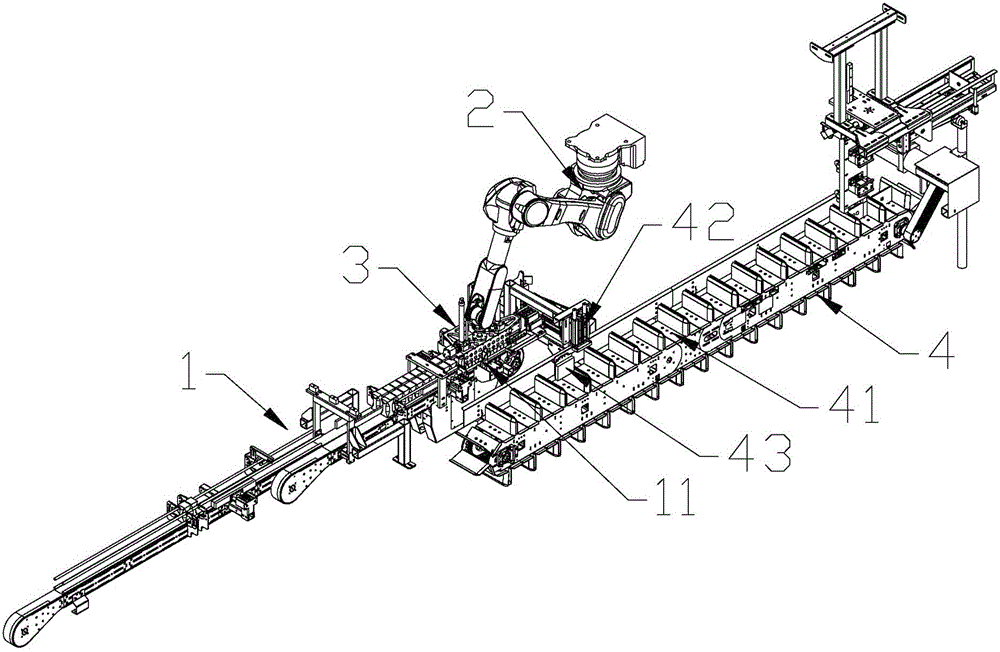

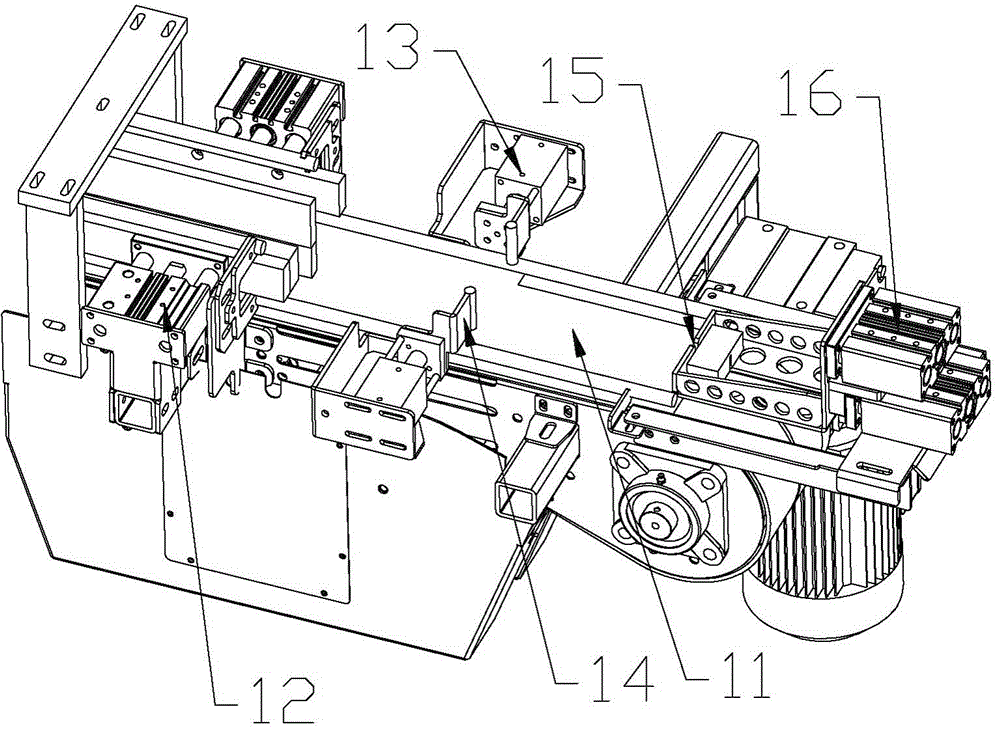

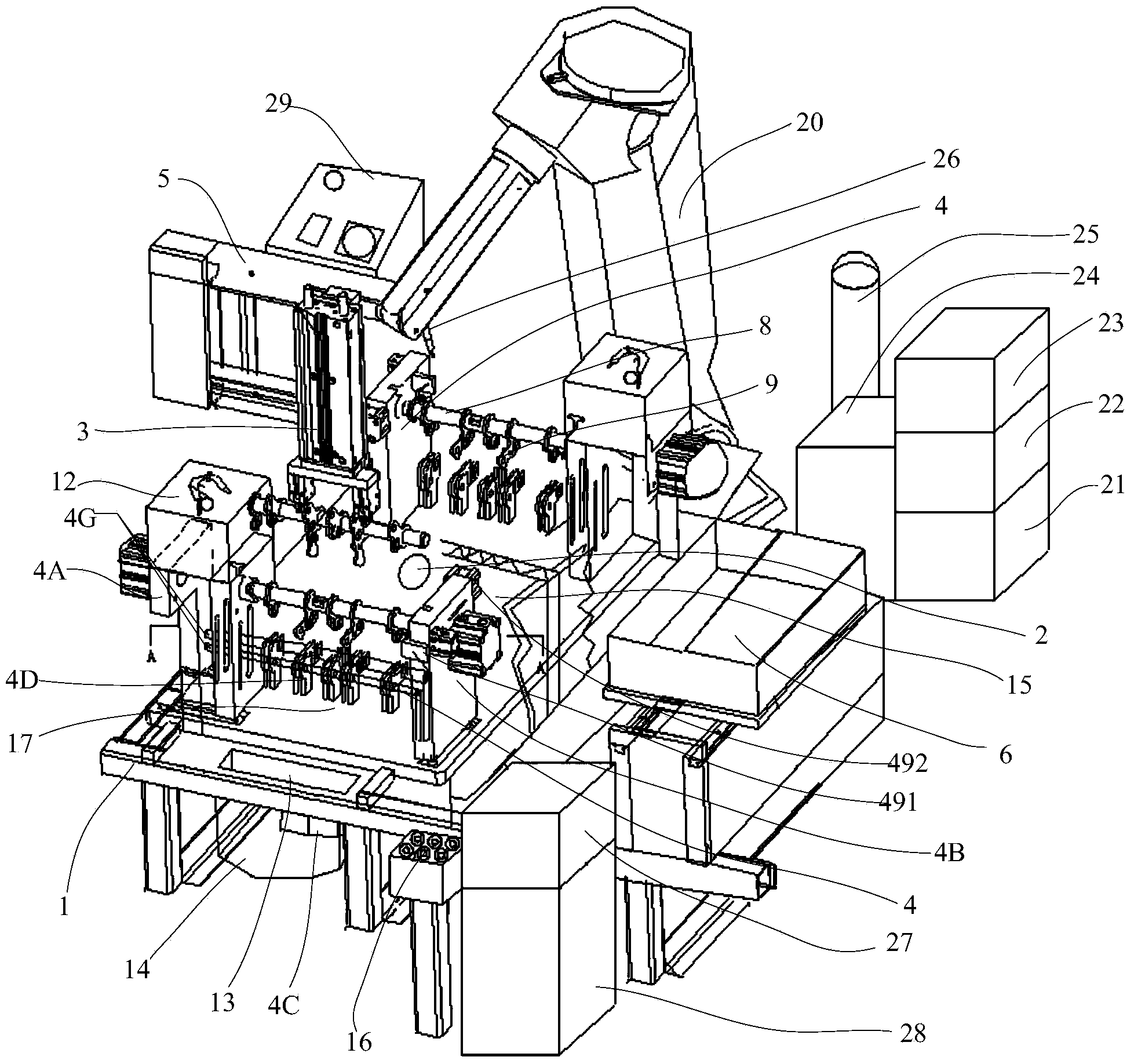

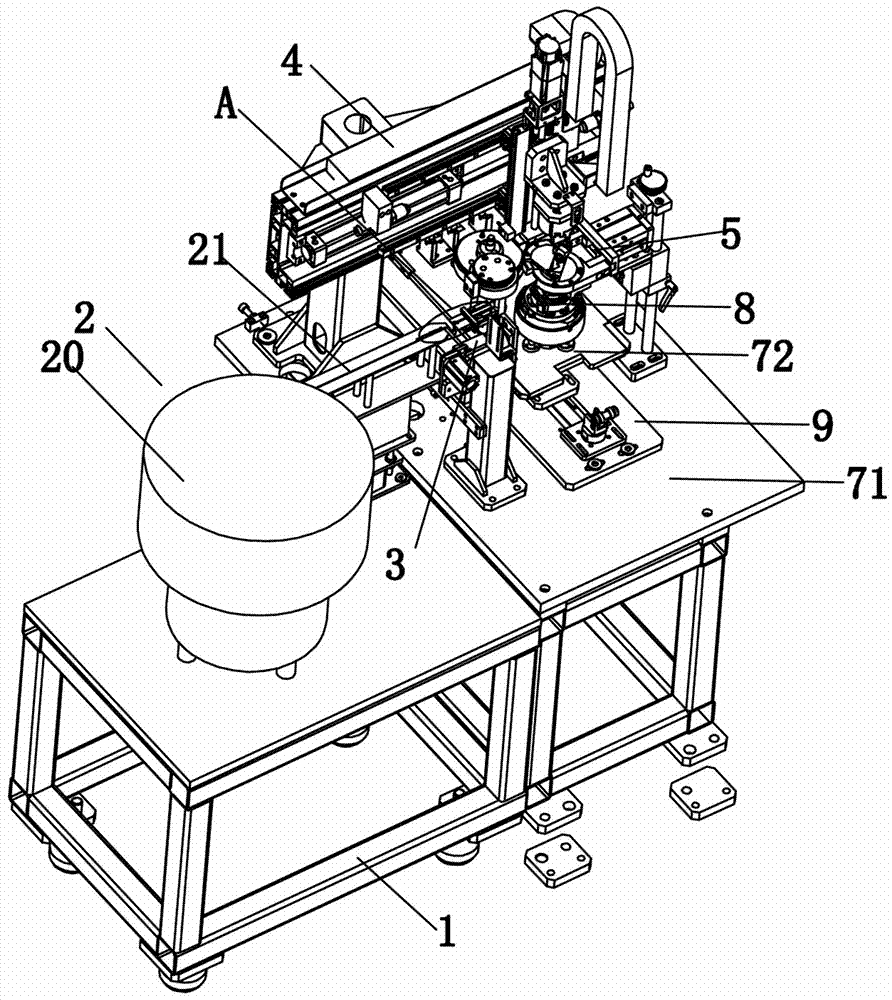

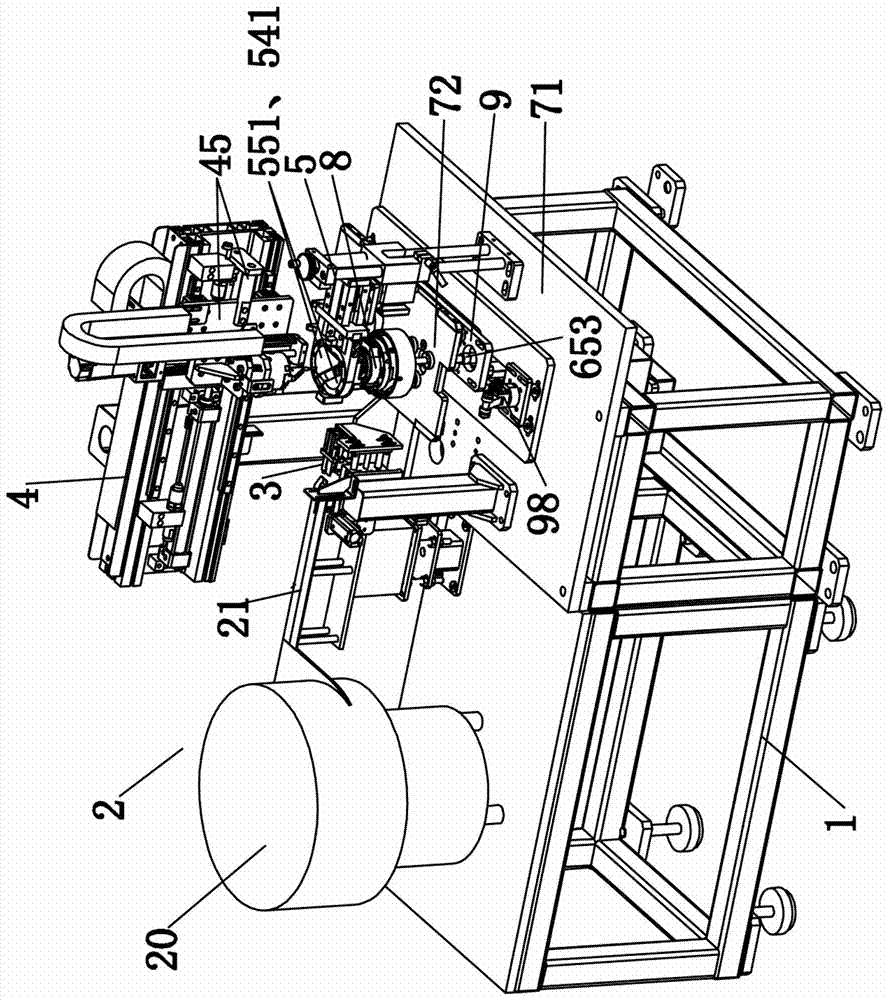

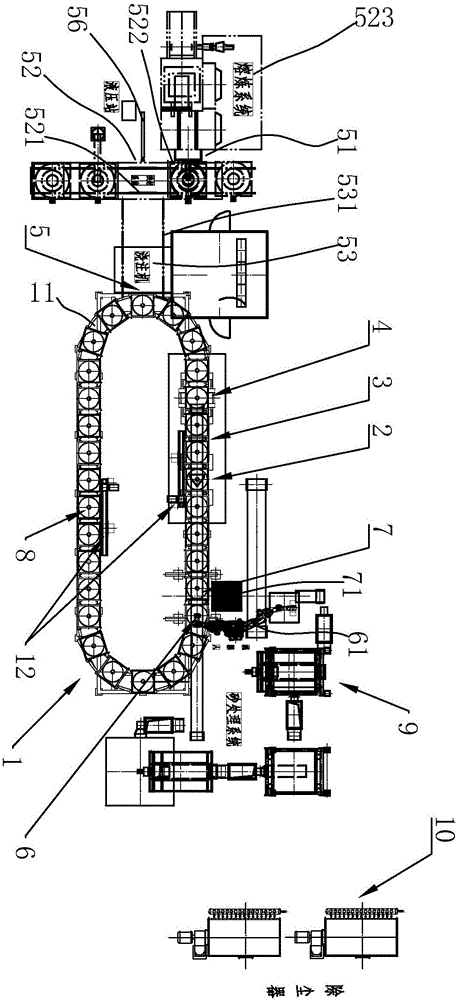

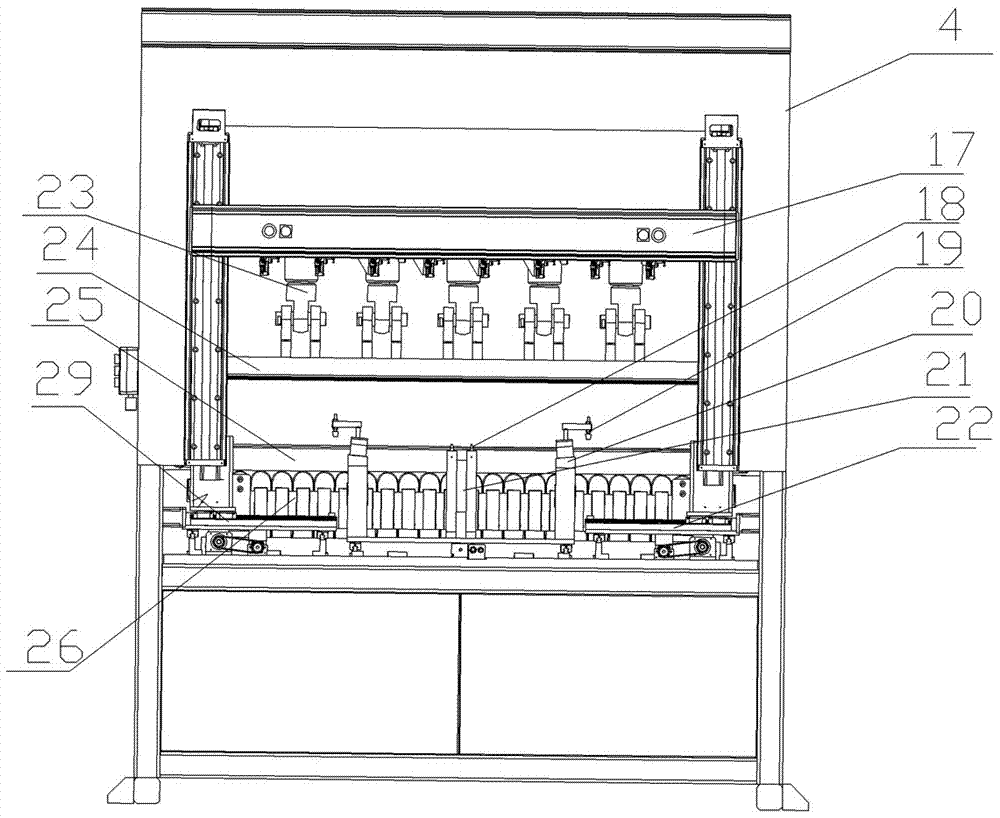

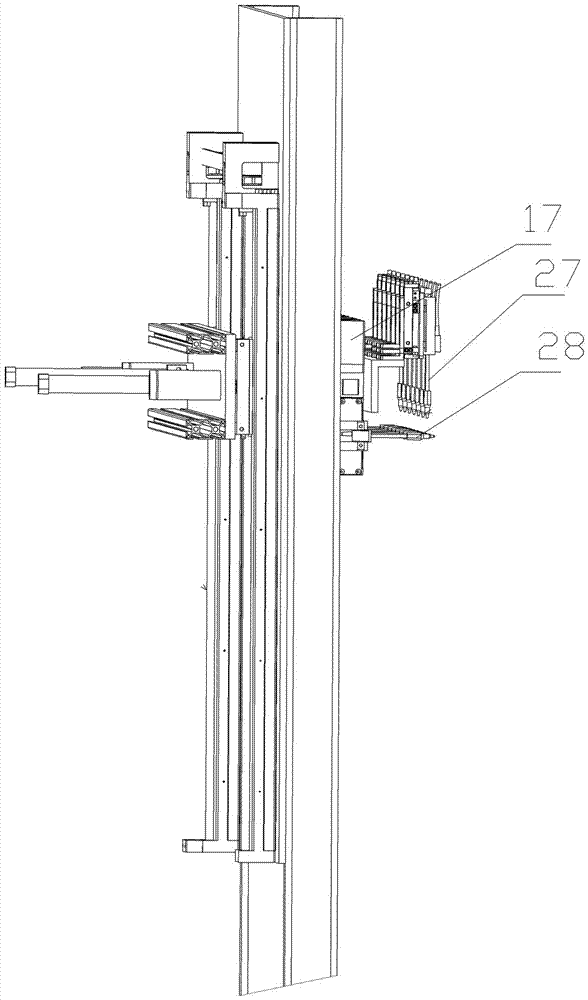

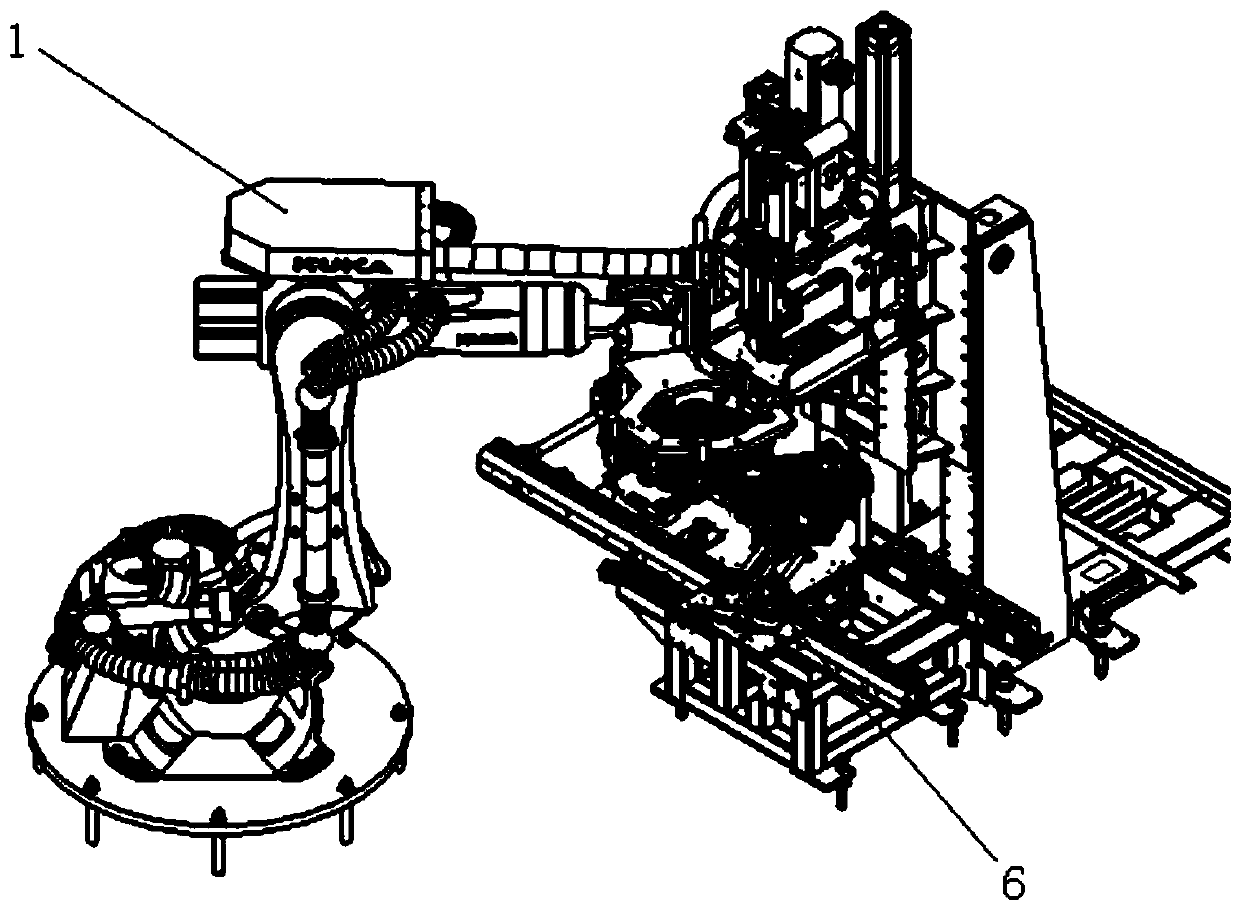

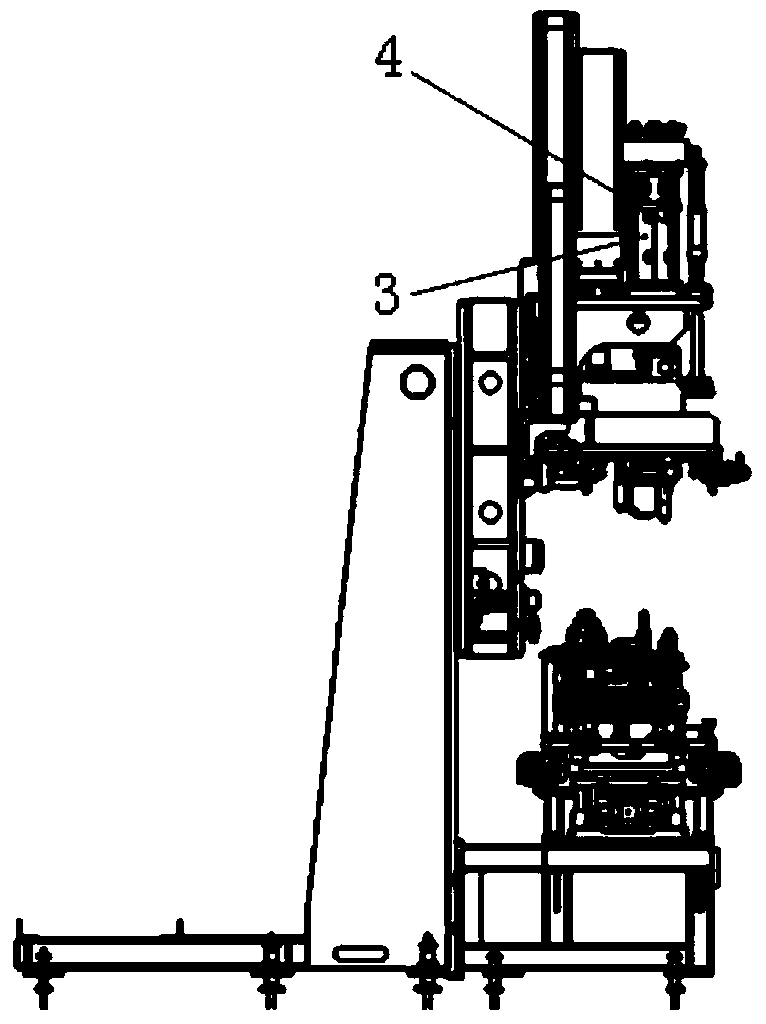

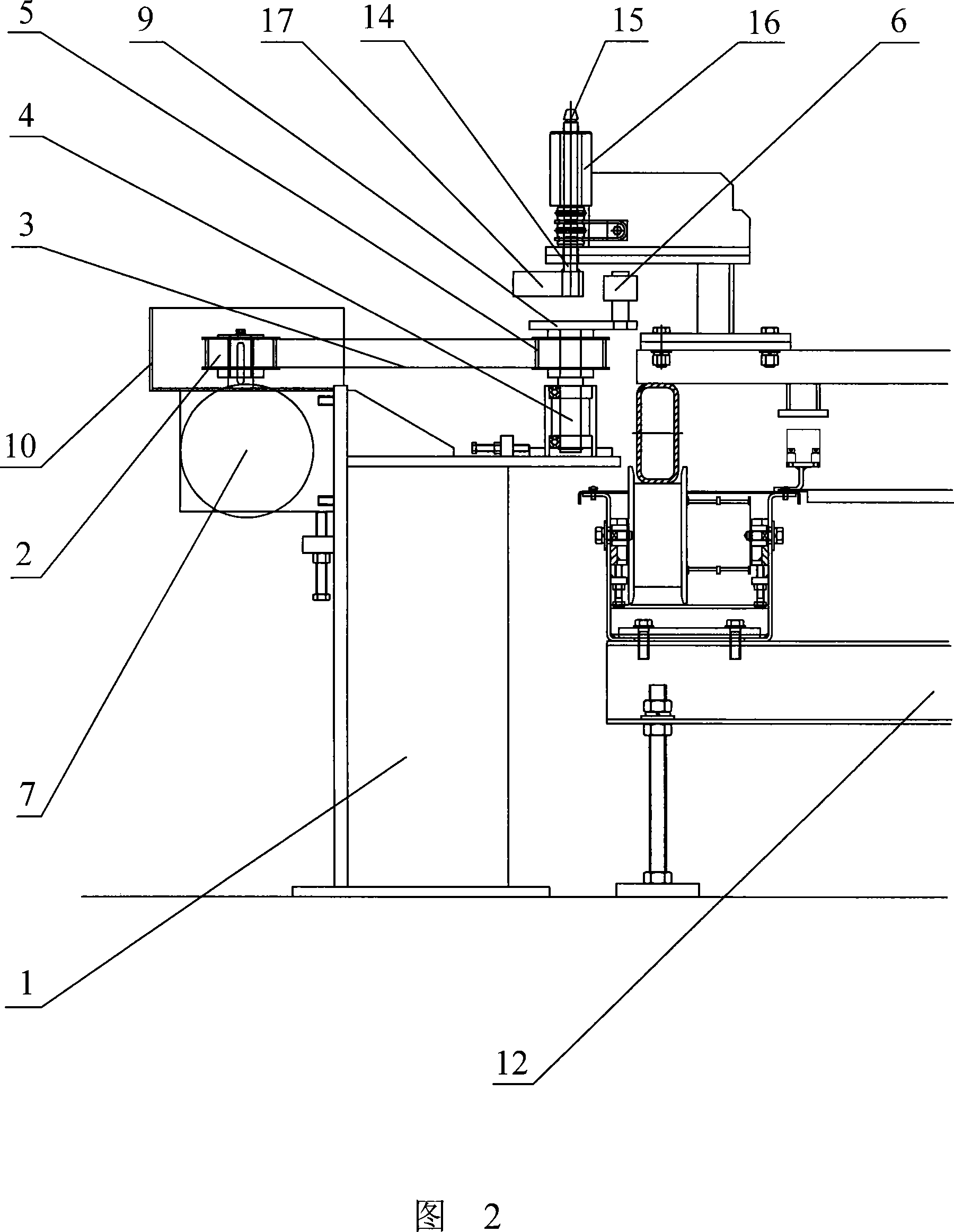

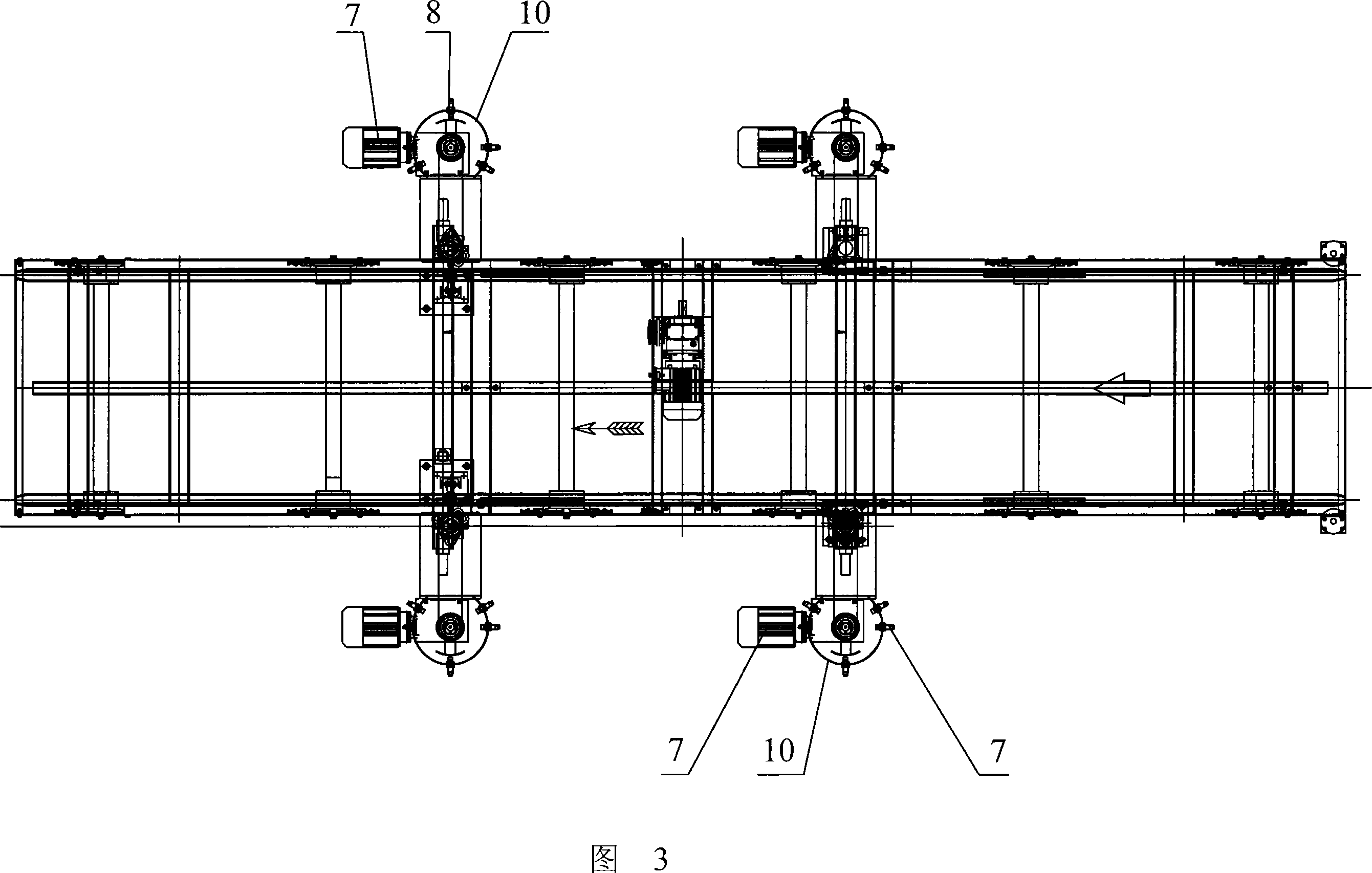

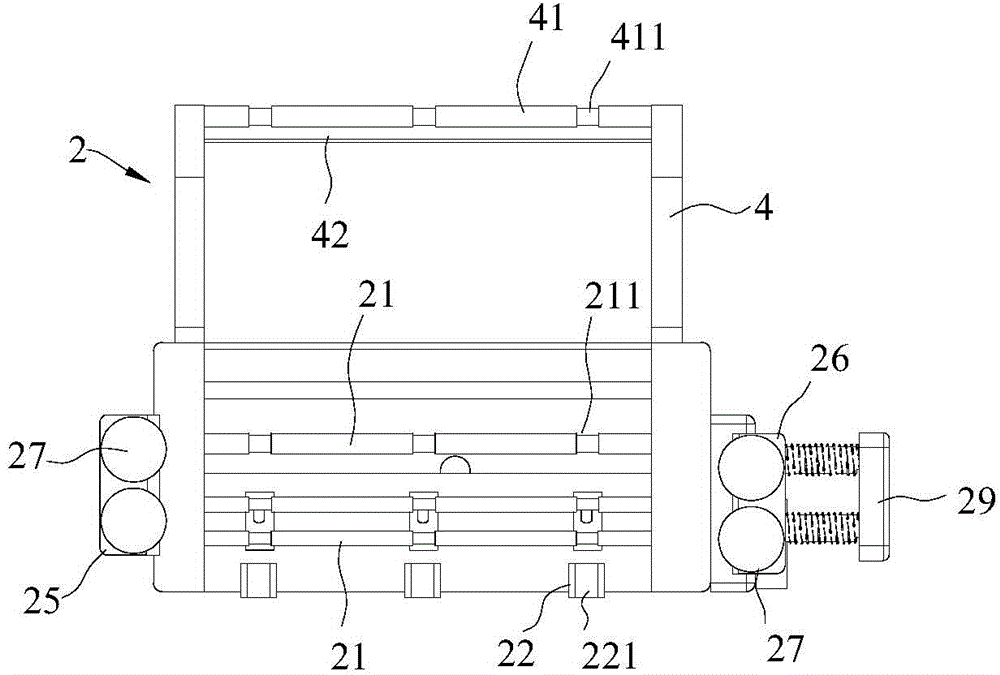

Automatic encasement system for Lilezuan milk bag gift boxes

ActiveCN104828288ASolve the problem that it is difficult to vertically transport automatic packingPrecise movement controlIndividual articlesEngineeringWorkload

The invention discloses an automatic encasement system for Lilezuan milk bag gift boxes. The automatic encasement system comprises a milk bag integration conveying line (1), a milk bag robot (2) and a milk bag unit conveying line (4), wherein a milk bag clamp (3) at the lower end of a manipulator of the milk bag robot (2) catches a milk bag unit on the milk bag integration conveying line (1) and pushes the milk bag unit into a corresponding milk bag unit separation slot (41) under the condition that the milk bag unit is in a horizontal state; then a small baffle plate insertion machine (5) inserts a small baffle plate into a middle clearance of the milk bag unit, and a horizontal pushing mechanism (6) is used for horizontally pushing the milk bag unit with the inserted small baffle plate into a packaging case already provided with a large lining plate on a packaging case conveying line (9); finally the packaging case already provided with the large lining plate, the small baffle plate and the milk bag unit is covered and encased to finish the whole automatic encasement process. According to the automatic encasement system for the Lilezuan milk bag gift boxes, the milk bag encasement operation is creatively changed from vertical encasement into horizontal encasement, so that the production operation is more stable, the maintenance is easy and convenient, and the workload can be reduced to the maximum extent.

Owner:苏州澳昆智能机器人技术有限公司

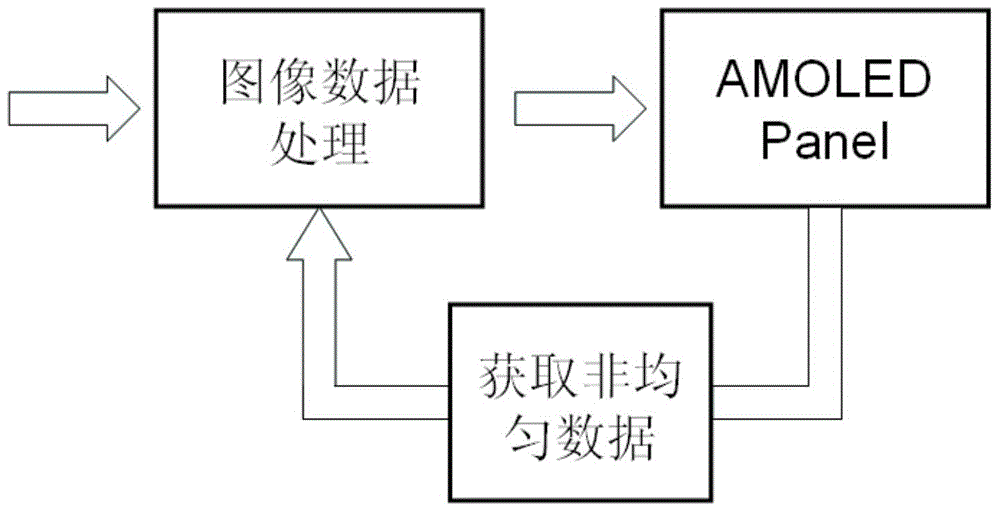

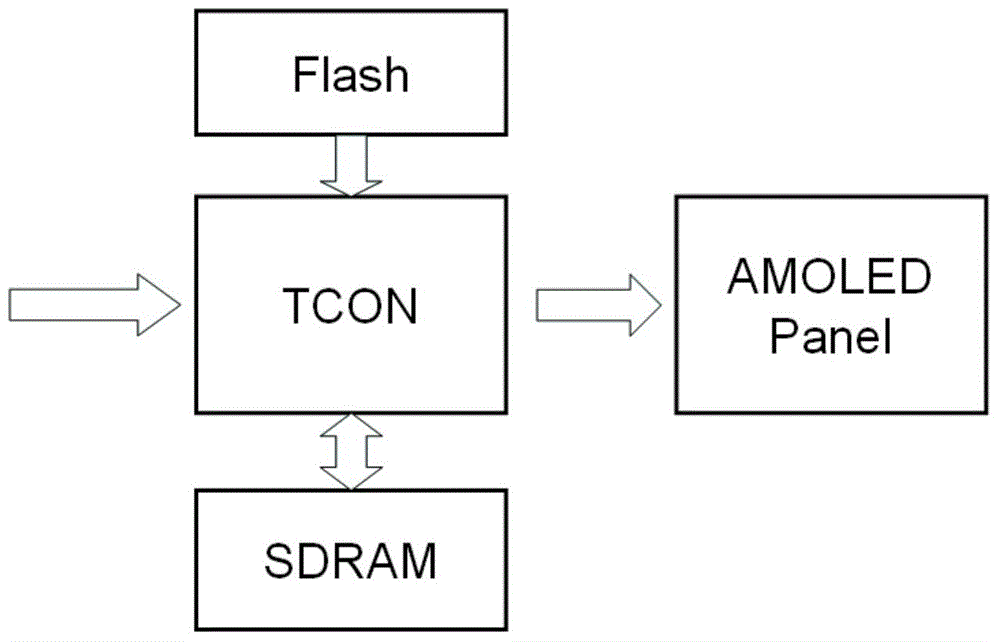

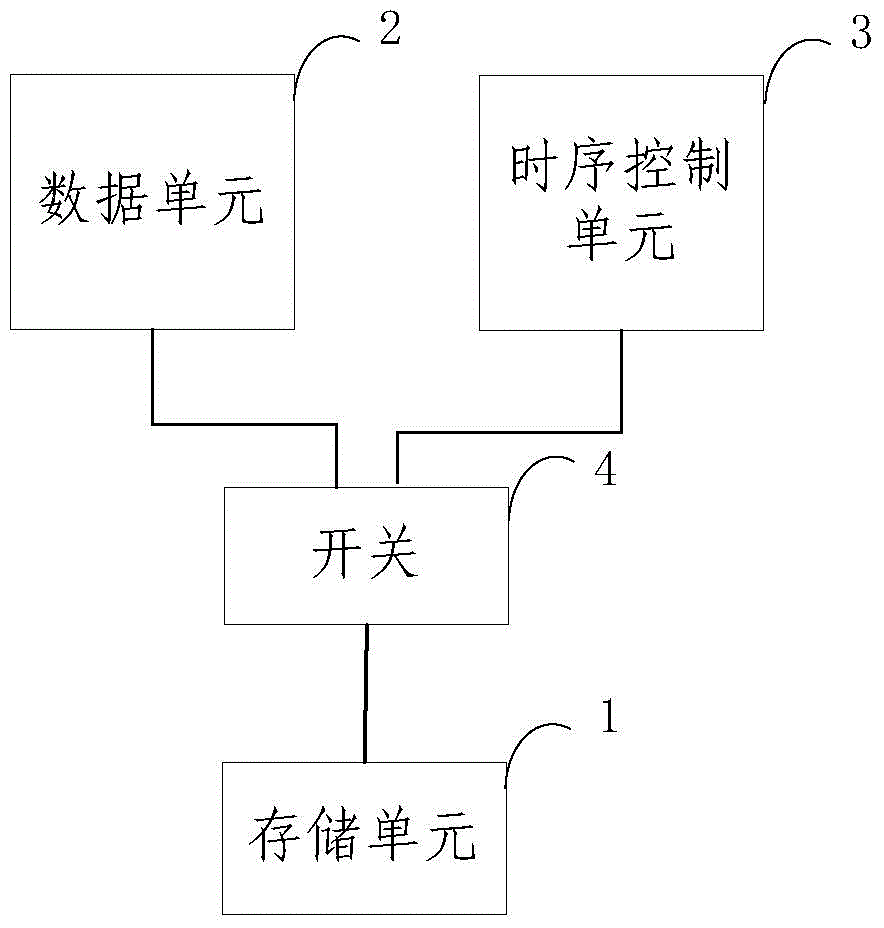

Display panel optical compensation device, display panel and optical compensation method

ActiveCN104064141ASimple structureFlexible operationStatic indicating devicesEngineeringData exchange

The invention provides a display panel optical compensation device, a display panel and a display panel optical compensation method. The display panel optical compensation device comprises a storage unit, a data unit, a time sequence control unit and a switch, wherein when the switch is in the first position, the time sequence control unit works in a non-compensation mode and carries out non-data exchange with the storage unit, and the data unit receives compensation data and burns the compensation data into the storage unit; when the switch is in the second position, the time sequence control unit works in a compensation mode, reads compensation data in the storage unit to carry out compensation operation on the display data and outputs the compensated display data. The display panel optical compensation device and the display panel are simple in structure, flexible to operate, high in stability, high in speed and suitable for mass production of products.

Owner:BOE TECH GRP CO LTD

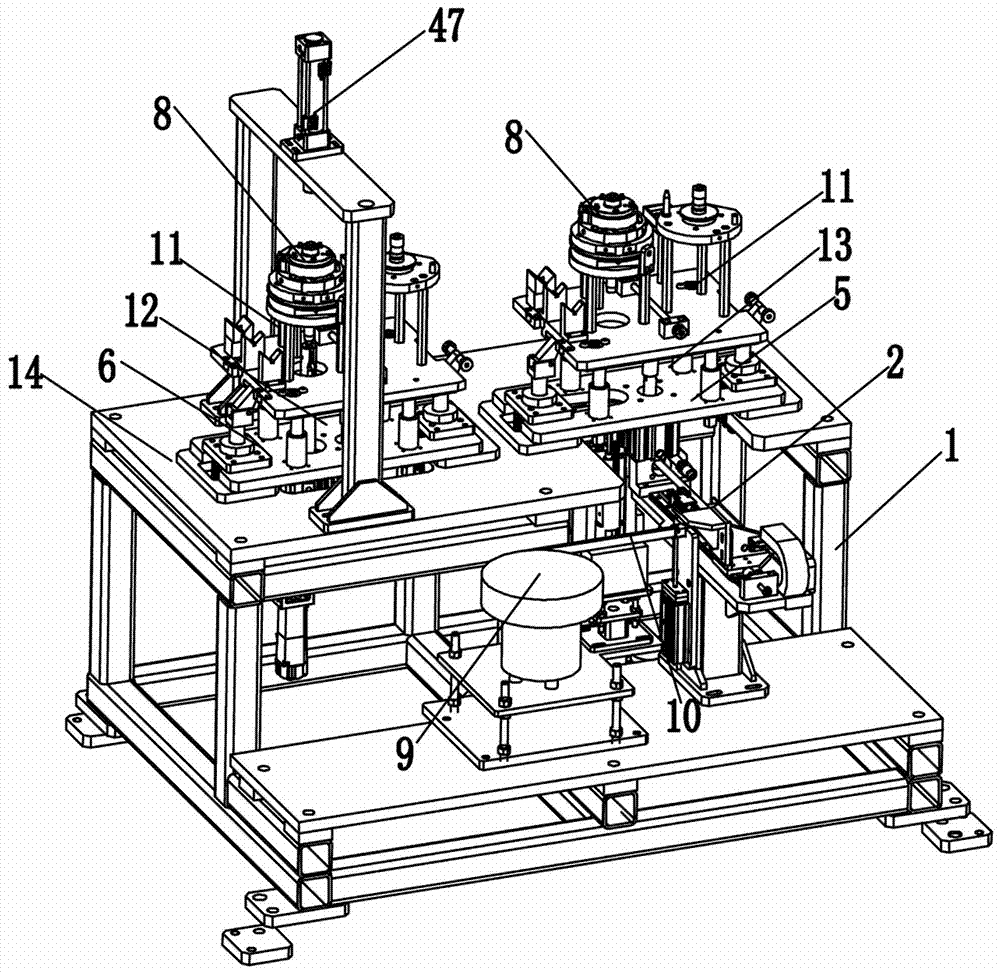

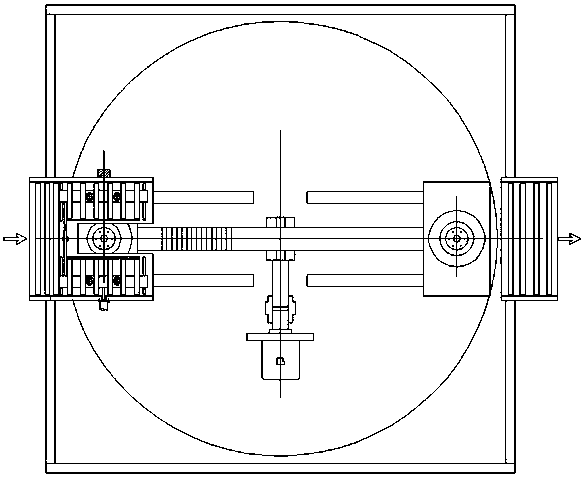

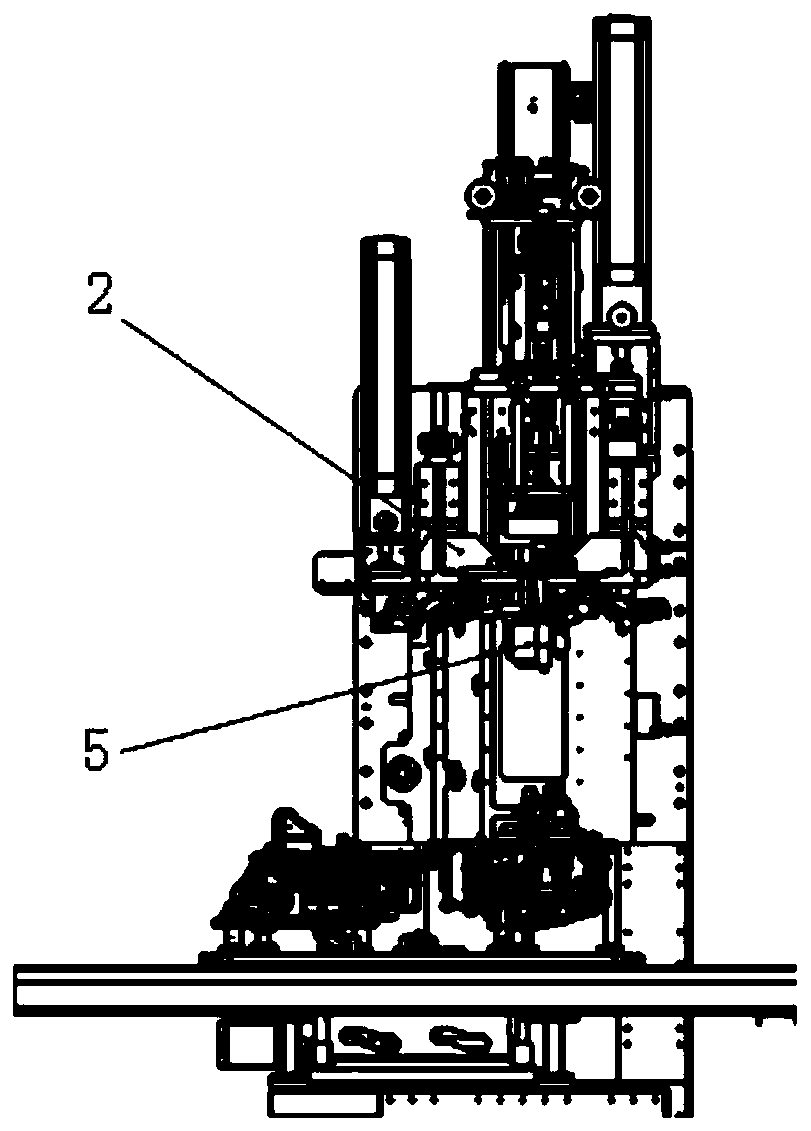

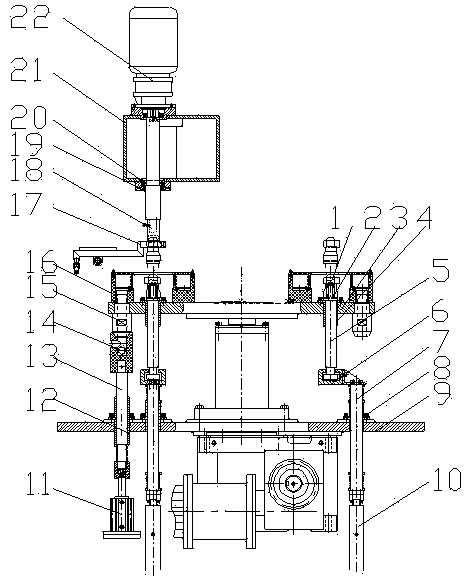

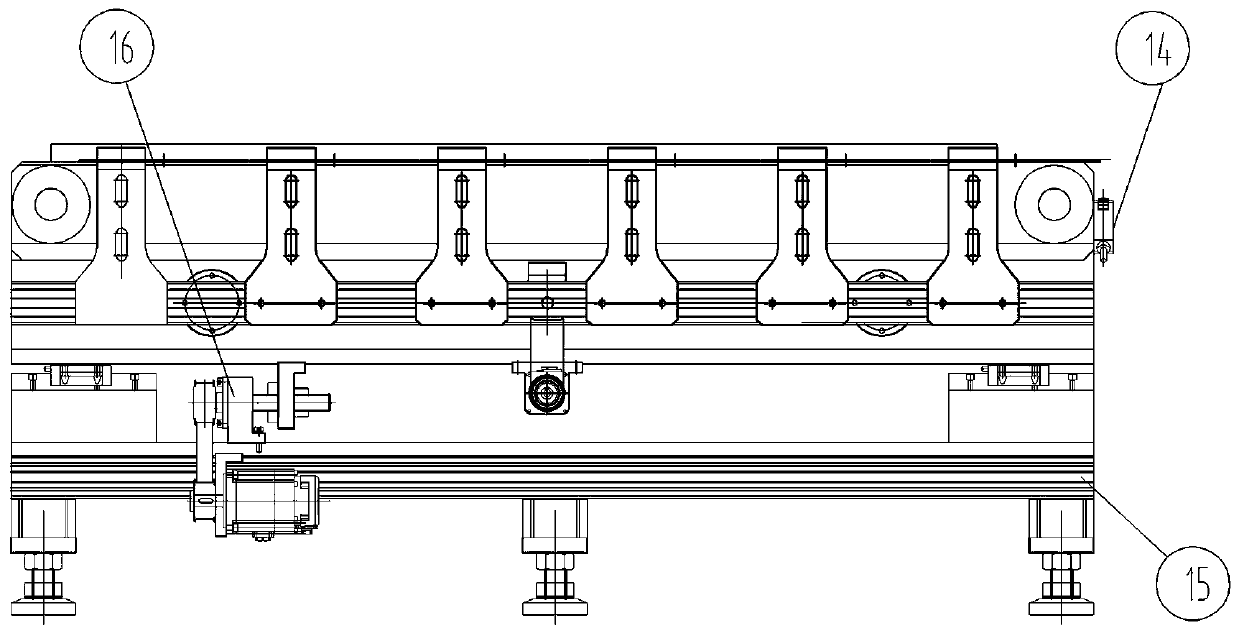

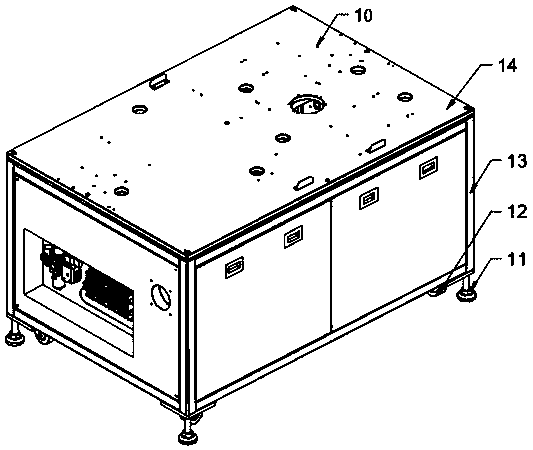

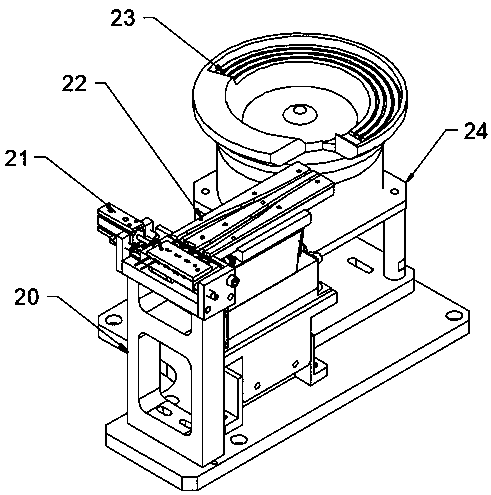

Online mounting equipment for crankshaft spring of pump body

ActiveCN107470890AAccurate control of jacking depthConsistent jacking depthMetal working apparatusEngineeringAssembly line

The invention relates to online mounting equipment for a crankshaft spring of a pump body. The online mounting equipment comprises a rack, a vibrating charging mechanism, a feeding mechanism, a first assembly disc jacking mechanism, a spring pre-jacking mechanism, a second assembly disc jacking mechanism, a spring jacking-in-place and detecting mechanism and a pressing mechanism, wherein a workbench is arranged on the rack. The online mounting equipment for the crankshaft spring of the pump body is of an online mounting form, and can realize whole-line automatic butt-joint for a compressor pump body assembly line. Work of charging, feeding, pre-mounting, mounting, detecting and the like of a crankshaft conical spring is separately realized through the vibrating charging mechanism, the feeding mechanism, the first assembly disc jacking mechanism, the spring pre-jacking mechanism, the second assembly disc jacking mechanism, the spring jacking-in-place and detecting mechanism and the pressing mechanism, and therefore, the online mounting equipment is high in production efficiency, is efficient and accurate in discharging and loading, improves rhythm of online mounting very well, and can meet large-scale production needs.

Owner:SANHE IND AUTOMATION EQUIP CO LTD SHUNDE DISTRICT FOSHAN CITY

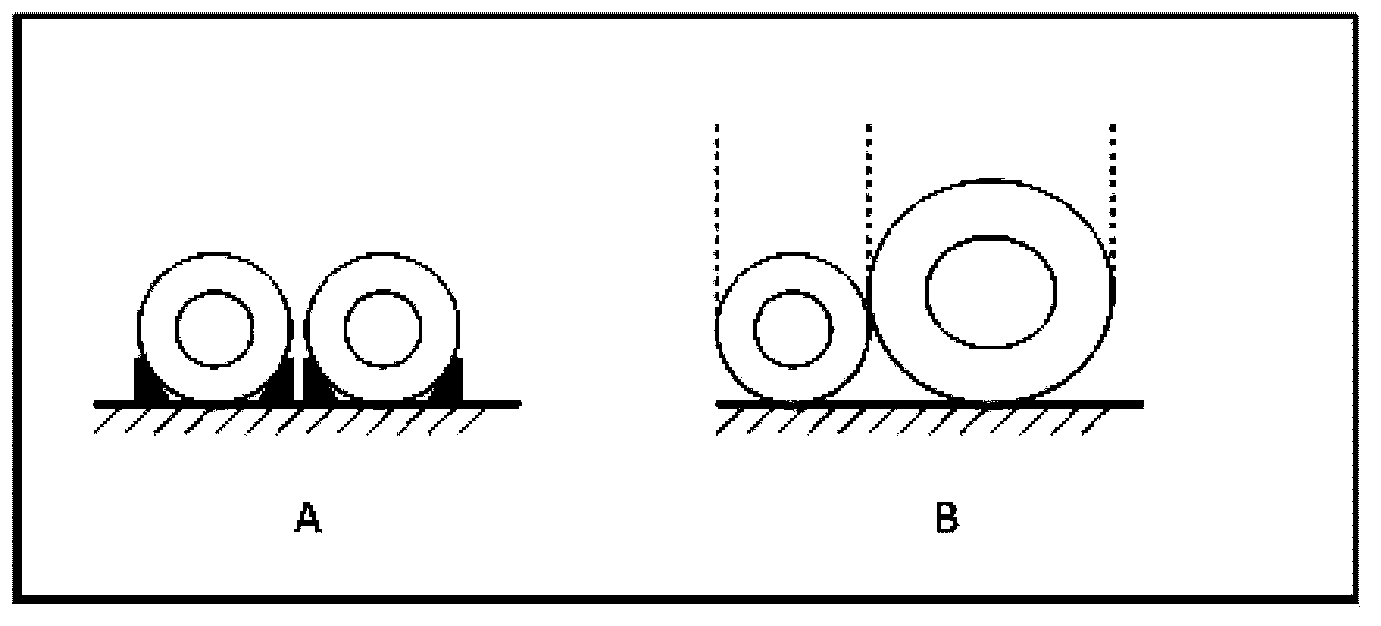

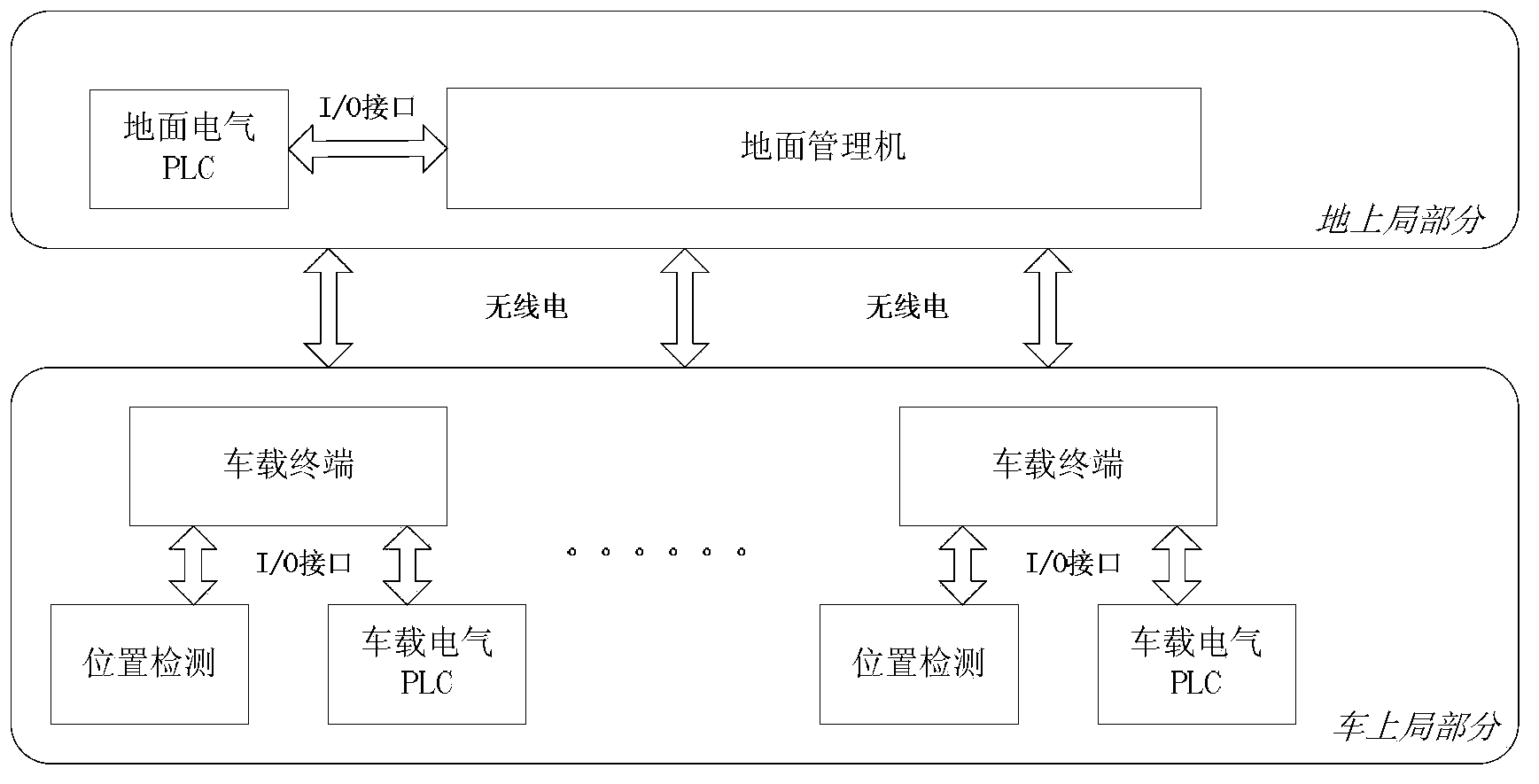

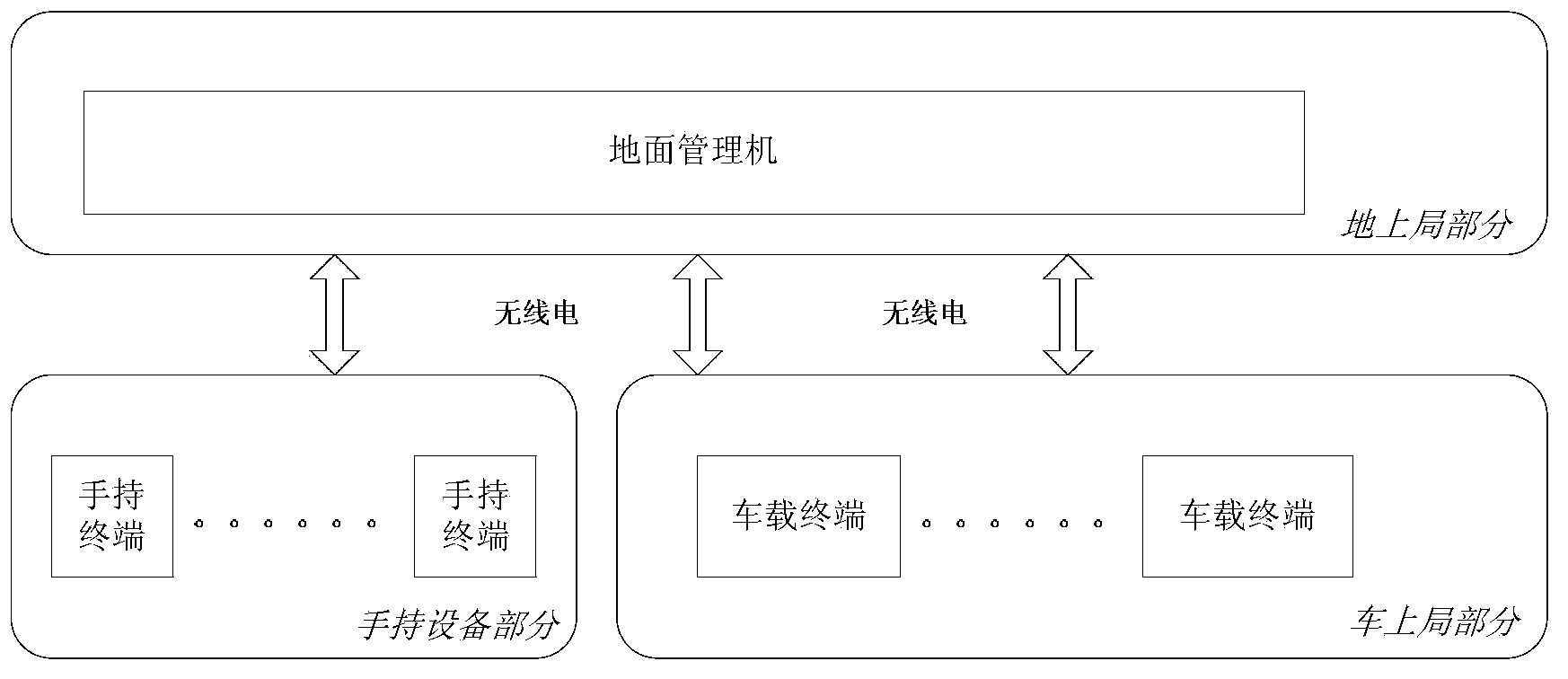

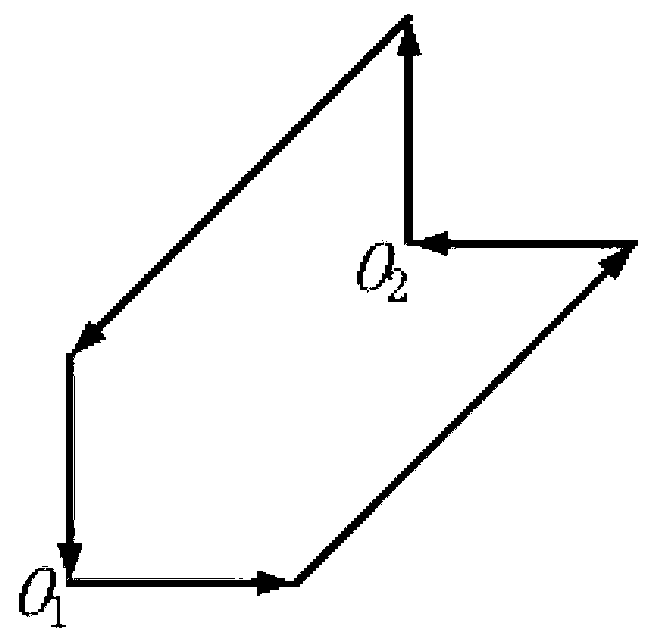

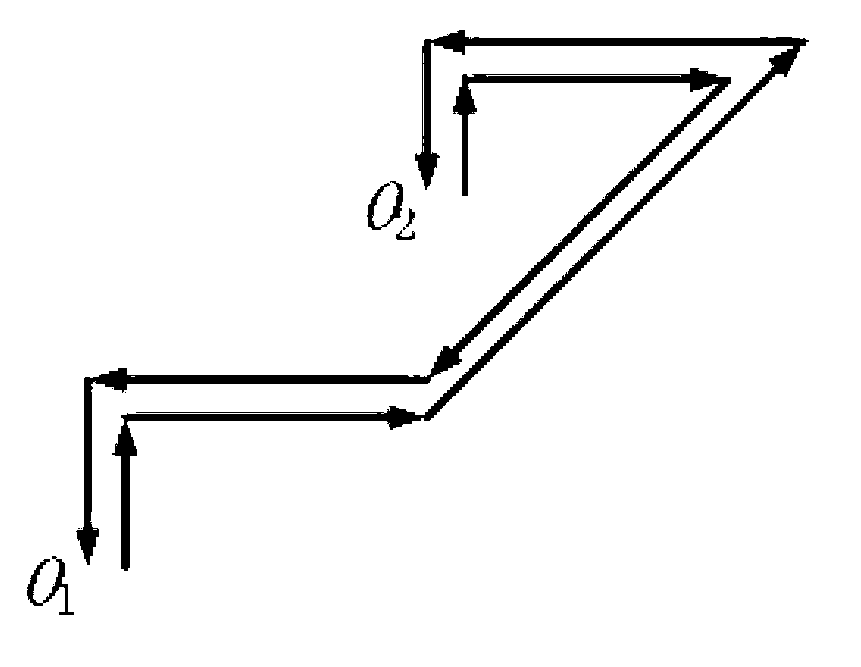

Steel coil storeroom position dynamic distribution method under position-data-reference-free condition

The invention discloses a steel coil storeroom position dynamic distribution method under a position-data-reference-free condition. The steel coil storeroom position dynamic distribution method includes the steps of dividing storeroom areas to form gridding structures, building a storeroom position distribution database in a management server of the storeroom areas, then determining a stacking rule of the storeroom areas, enabling each storeroom area to serve as a whole, carrying out stacking according to the same rule, carrying out stacking among the storeroom areas according to different demands and different user demand rules, dynamically modifying the user demand rule of the storeroom area to carry out stacking when the demands of the certain storeroom area are changed, and finally, after the steps are completed, carrying out management on steel coil storage, steel coil delivery, steel coil transferring and steel coil checking. According to the steel coil storeroom position dynamic distribution method, under the condition that a traveling positioning system is not provided, a dynamic storeroom position management mode is used for a steel coil storeroom, steel coils are reasonably and accurately stacked, the storeroom area use rate is improved, and the stack transferring quantity is reduced; meanwhile, the operation actual performance is collected, and therefore the position information of the steel coils inside the steel coil storeroom is accurate.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

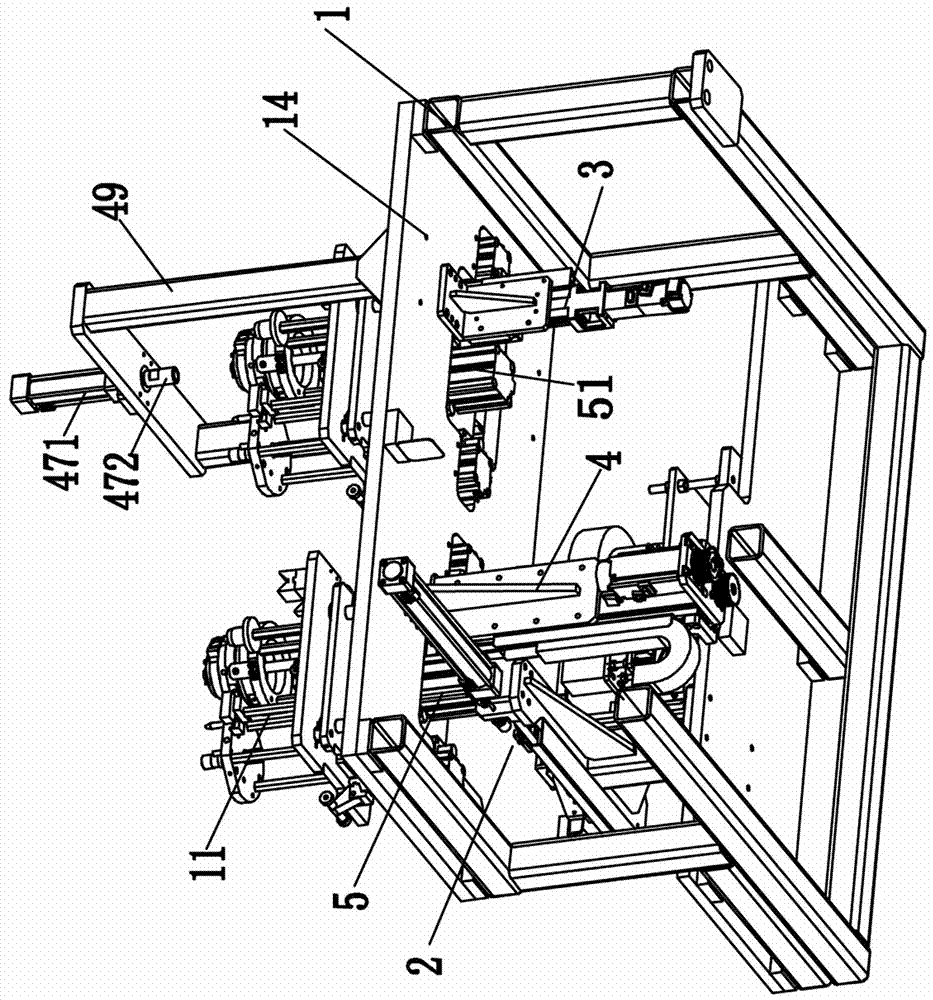

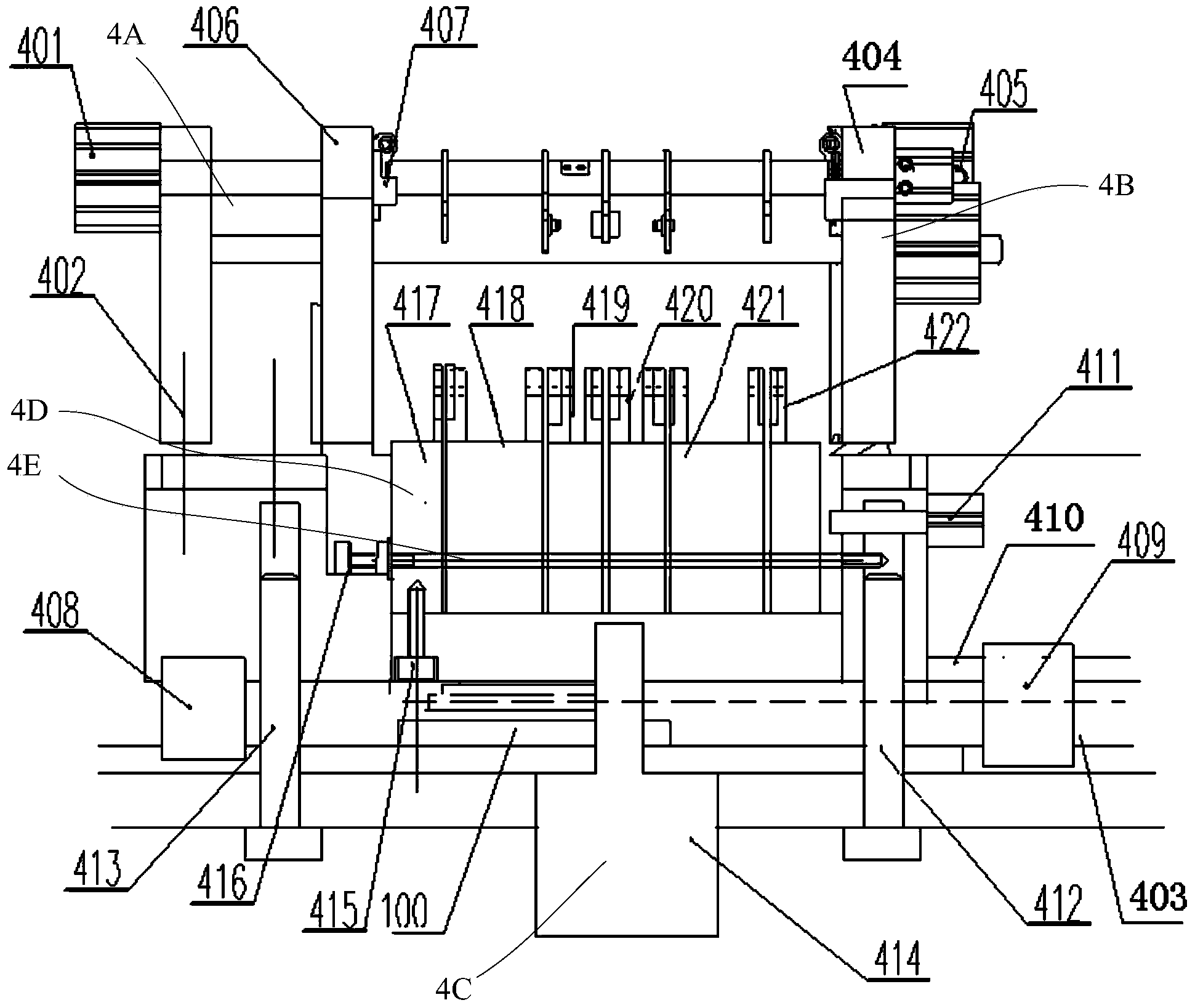

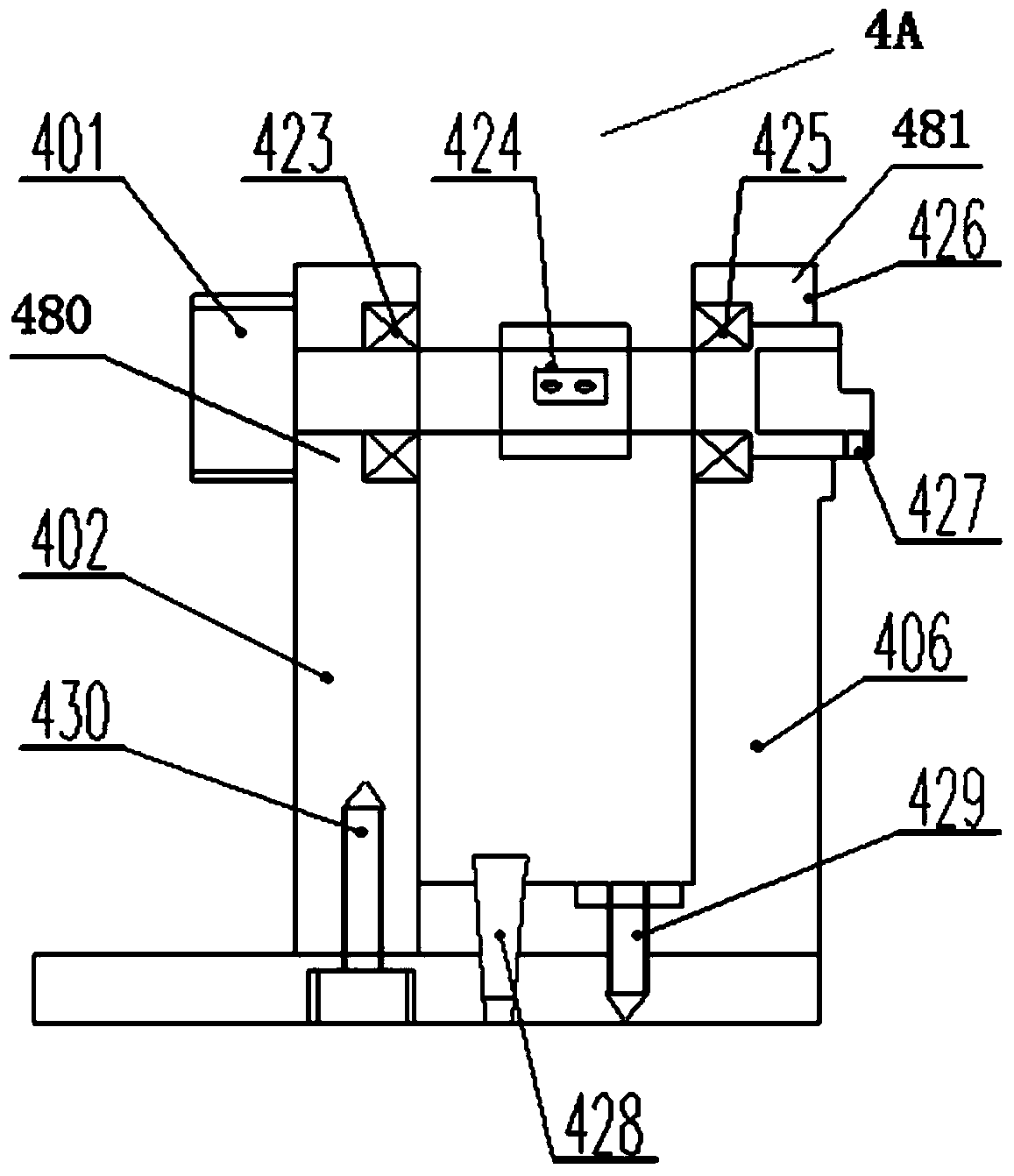

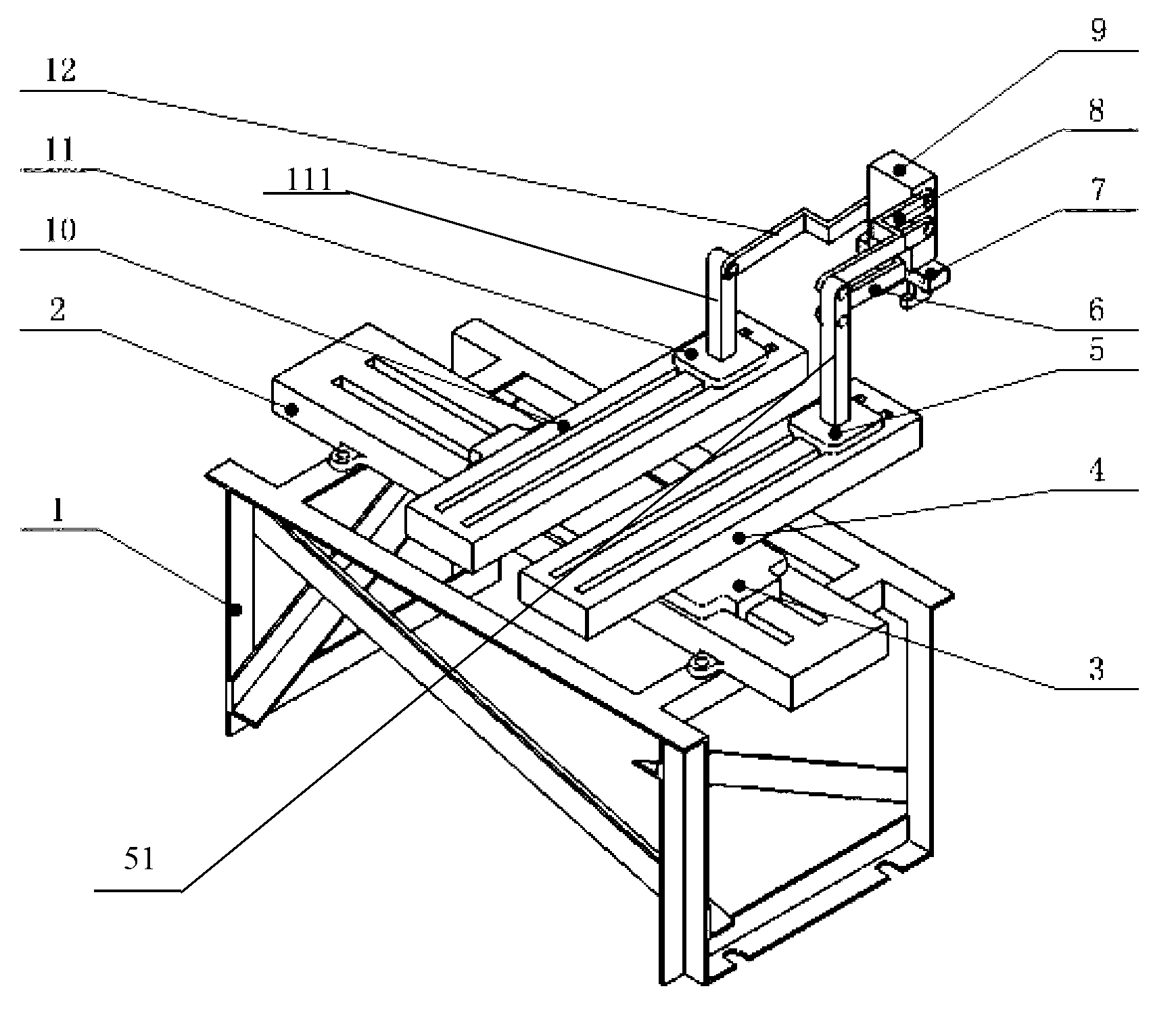

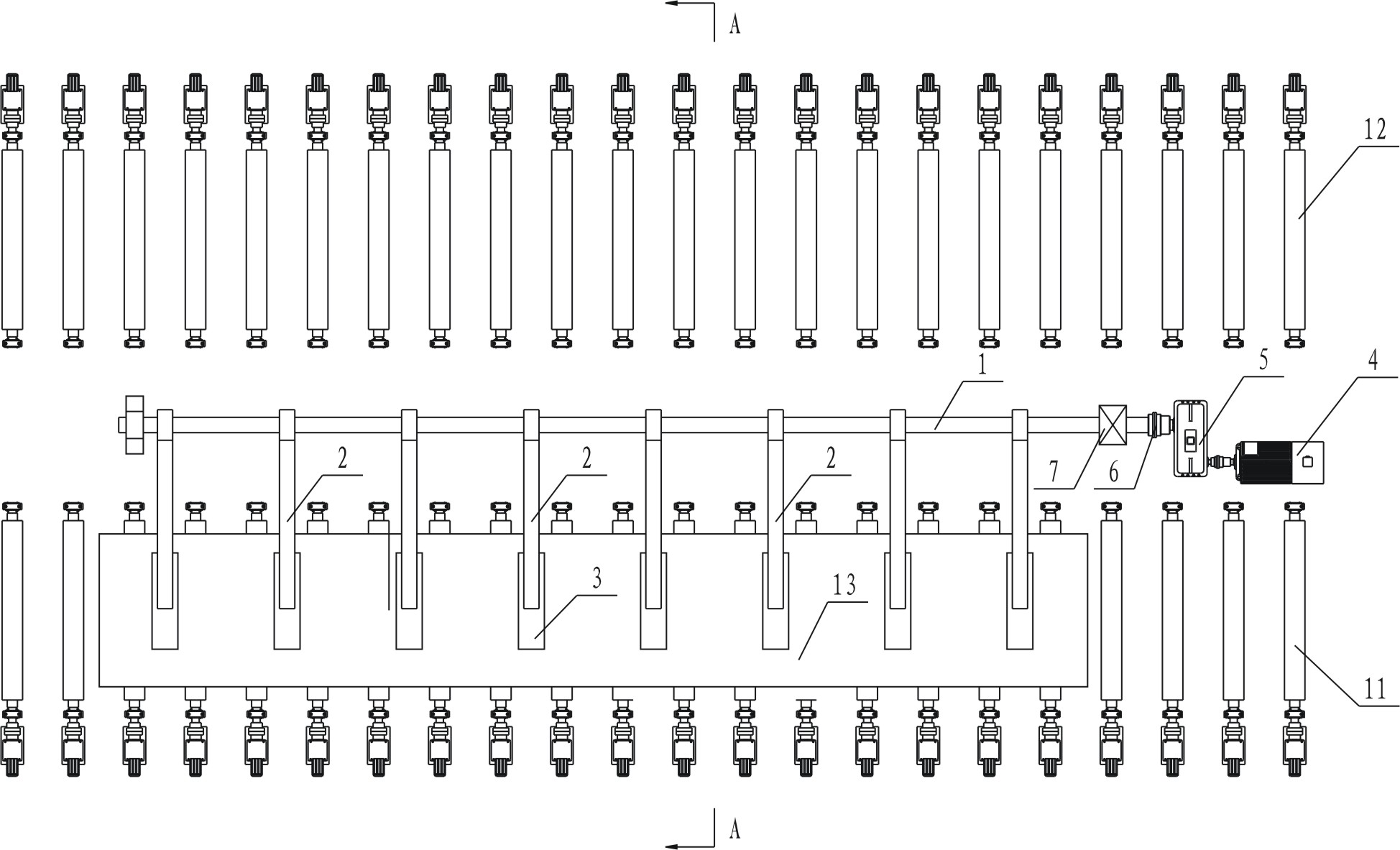

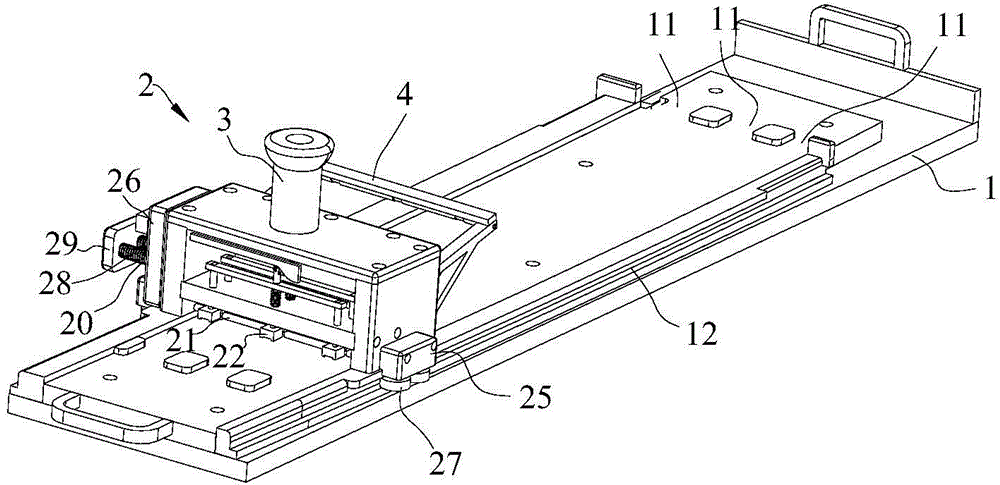

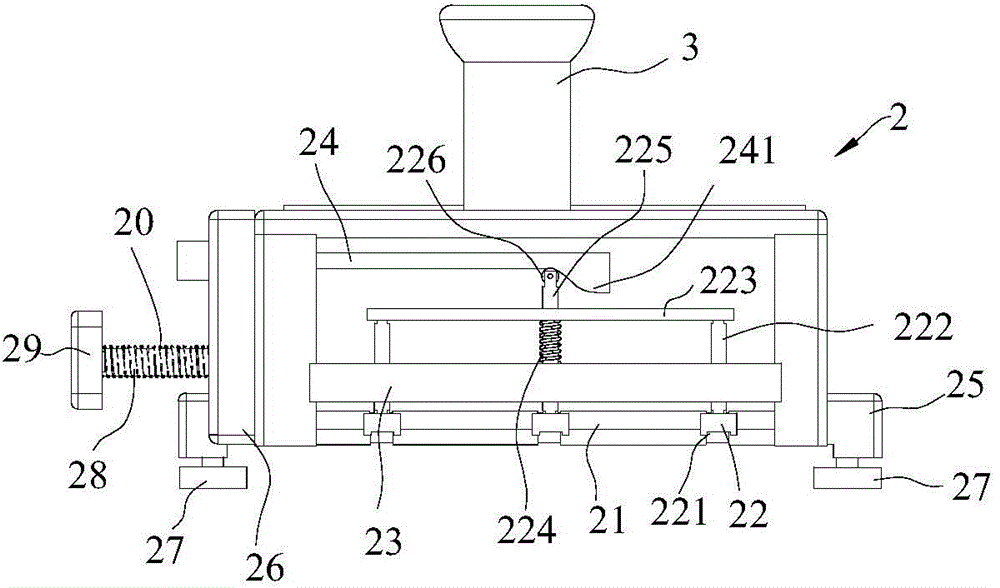

Rotating shaft welding jig, rotating shaft welding worktable and automatic rotating shaft welding system

ActiveCN103506797ASimple structurePrecise control of shape and positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a rotating shaft welding jig, a rotating shaft welding worktable and an automatic rotating shaft welding system. The rotating shaft welding jig comprises a rotating shaft clamp and a component fixing device, wherein the rotating shaft clamp is used for clamping a rotating shaft, and the component fixing device is used for fixing a rotating shaft component which needs to be welded to the rotating shaft. The rotating shaft clamp comprises a rotating shaft supporting and rotating mechanism and a rotating shaft supporting and clamping mechanism, wherein the rotating shaft supporting and rotating mechanism and the rotating shaft supporting and clamping mechanism are used for clamping the two ends of the rotating shaft respectively. The component fixing device is arranged between the rotating shaft supporting and rotating mechanism and the rotating shaft supporting and clamping mechanism and comprises a rotating shaft component clamping part and a clamping driving part. The rotating shaft component clamping part comprises a plurality of bases which are arranged on a base plate side by side, wherein the bases include at least one fixed locating base and a plurality of sliding bases. The clamping driving part is connected with the rotating shaft component clamping part and can drive the sliding bases to slide towards the locating base so that the adjacent bases can clamp and loosen the rotating shaft component. The rotating shaft welding jig can clamp the rotating shaft and the rotating shaft component at a time.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

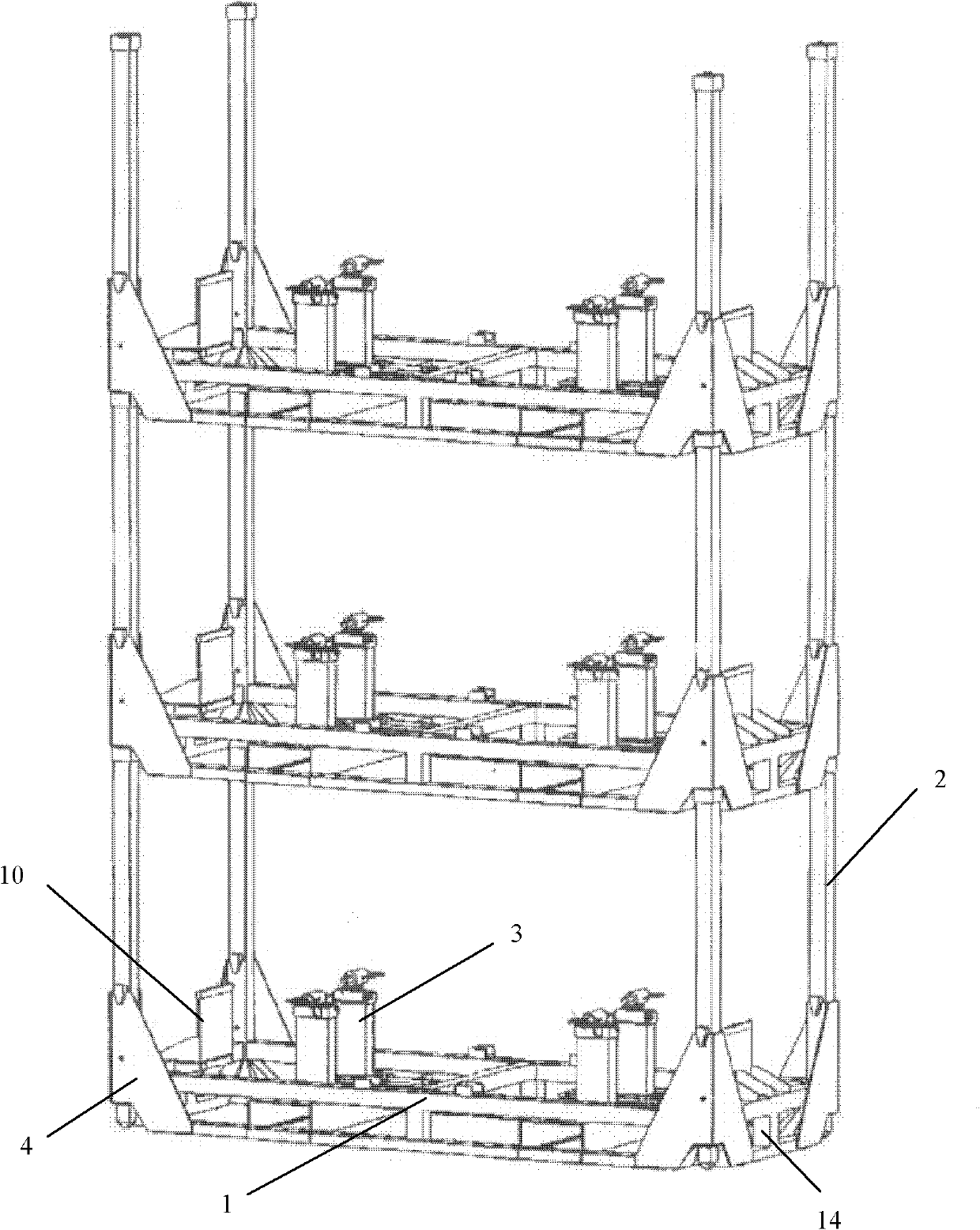

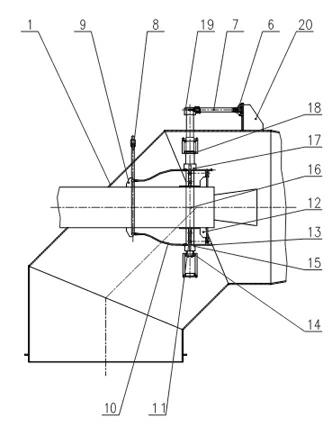

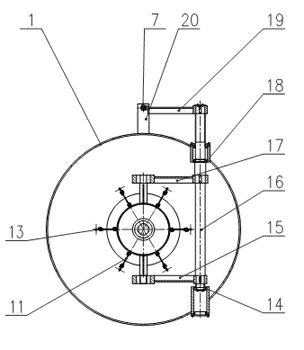

Foldable engine turnover frame

ActiveCN102476728AImprove corrosion resistanceComply with environmental standardsPackaging vehiclesContainers for machinesMechanical engineeringTransportation cost

The invention discloses a foldable engine turnover frame, which comprises a rectangular base (1), wherein both sides of the base are provided with polyurethane plates (10); two rows of base plates (13) are horizontally arranged at the bottom of the base; each row of base plates is provided with a plate type bracket (20); the bracket is provided with a roller (7) and a support plate (24); and the support plate is provided with a clamp. The foldable engine turnover frame is a device suitable for accommodation, storage, transportation and the like of a finished engine, a storage space is utilized effectively, and the surface and key positions of the finished engine can be prevented from being damaged. Due to the adoption of a foldable design in the invention, product quality is ensured effectively, a limited space is utilized more reasonably, the utilization ratio of the space is increased greatly, and transportation cost is reduced during recovery. A product is easy to use, and has high flexibility; and regardless of warehousing and turnover transportation, the space can be utilized effectively, transportation cost is reduced, and the turnover speed and quantity of product are increased.

Owner:DALIAN HONGYUN PACKAGING TECH

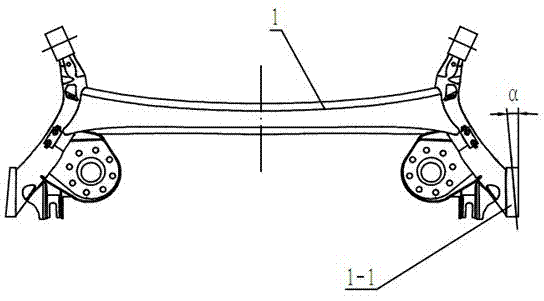

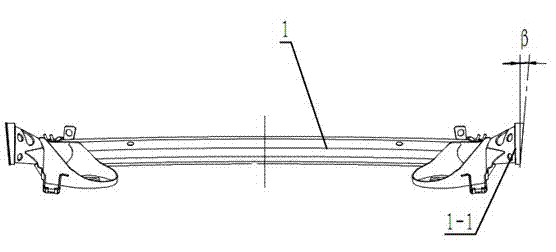

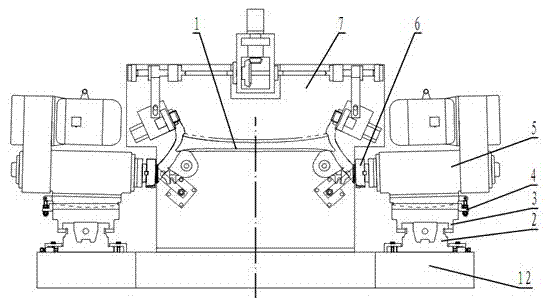

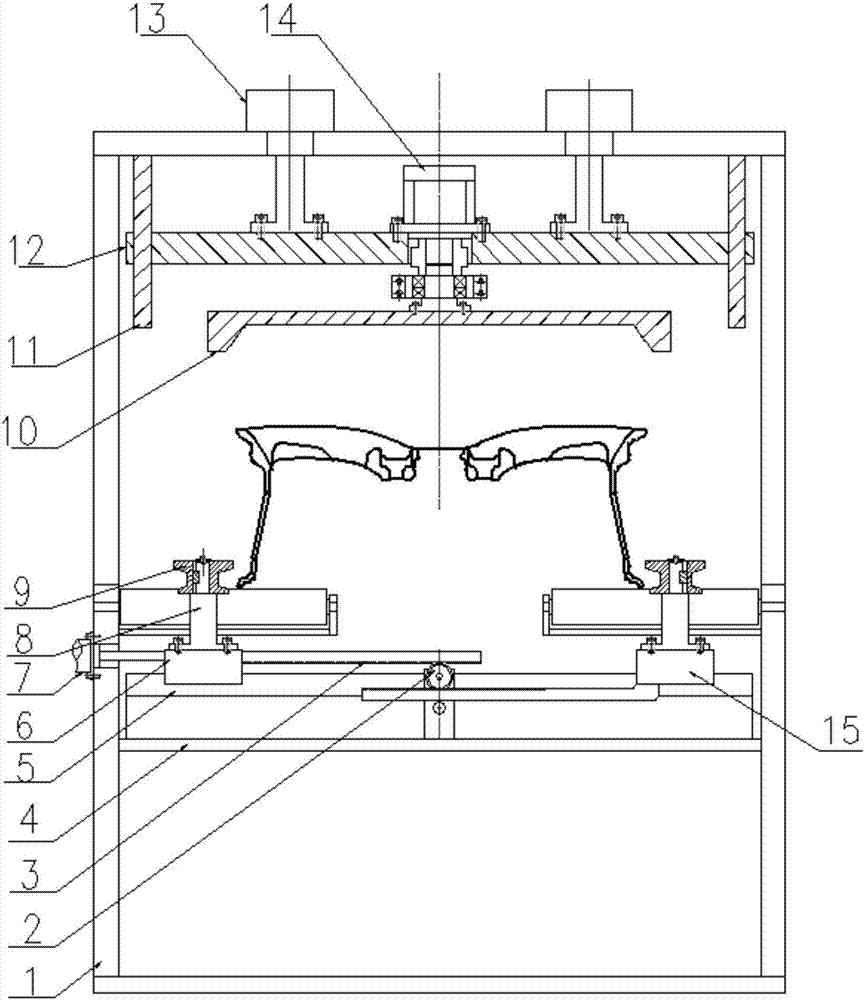

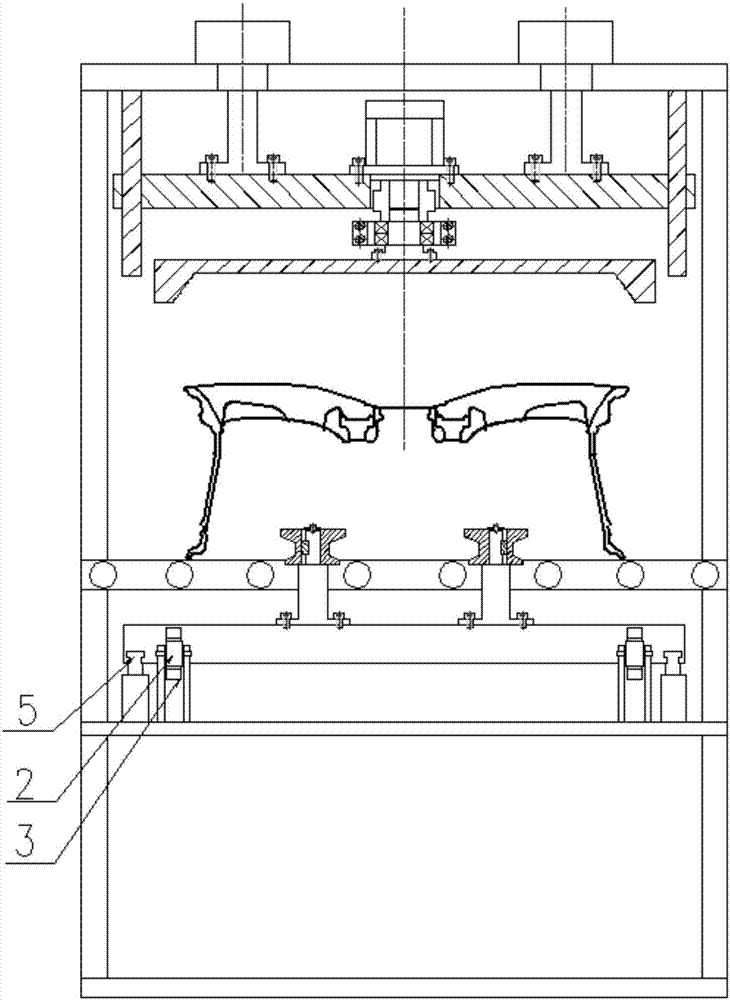

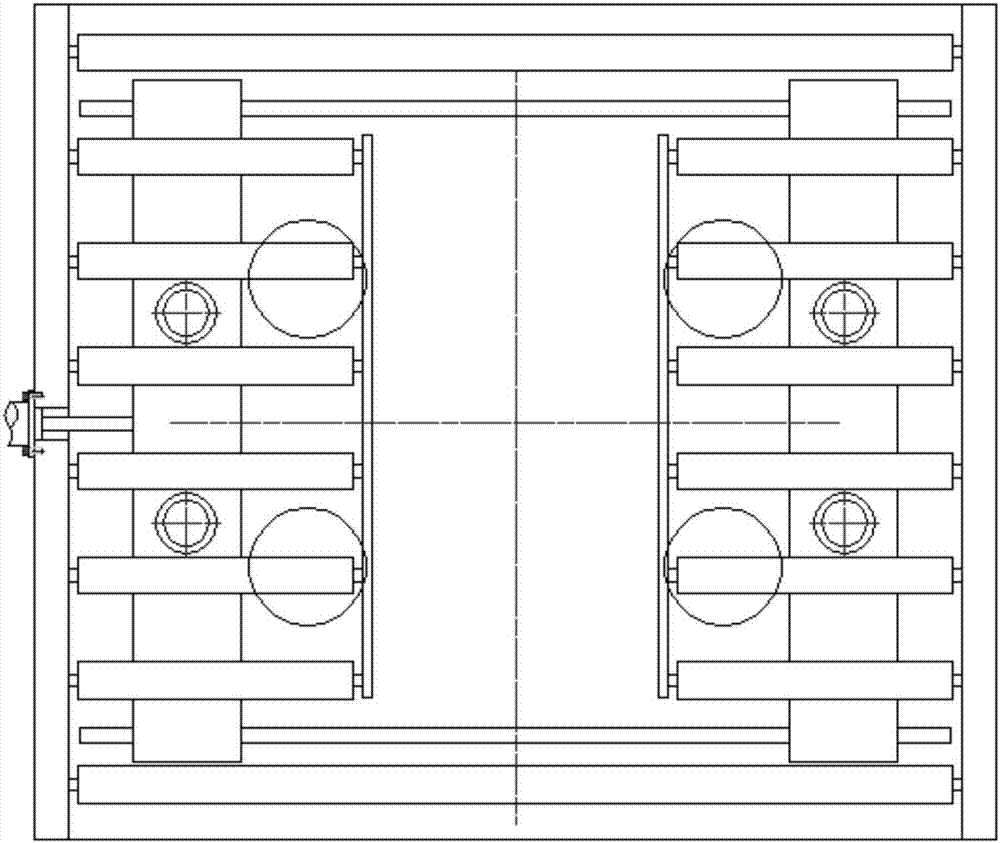

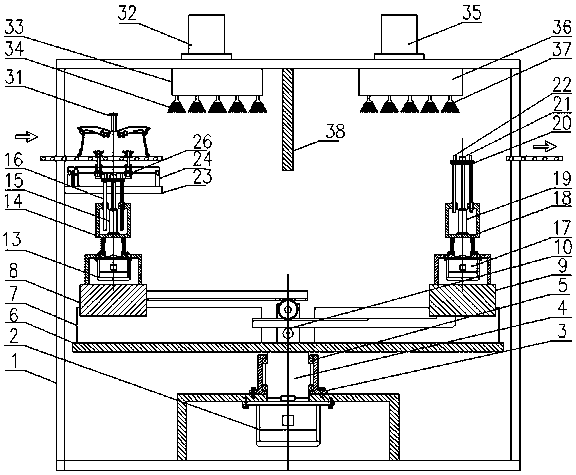

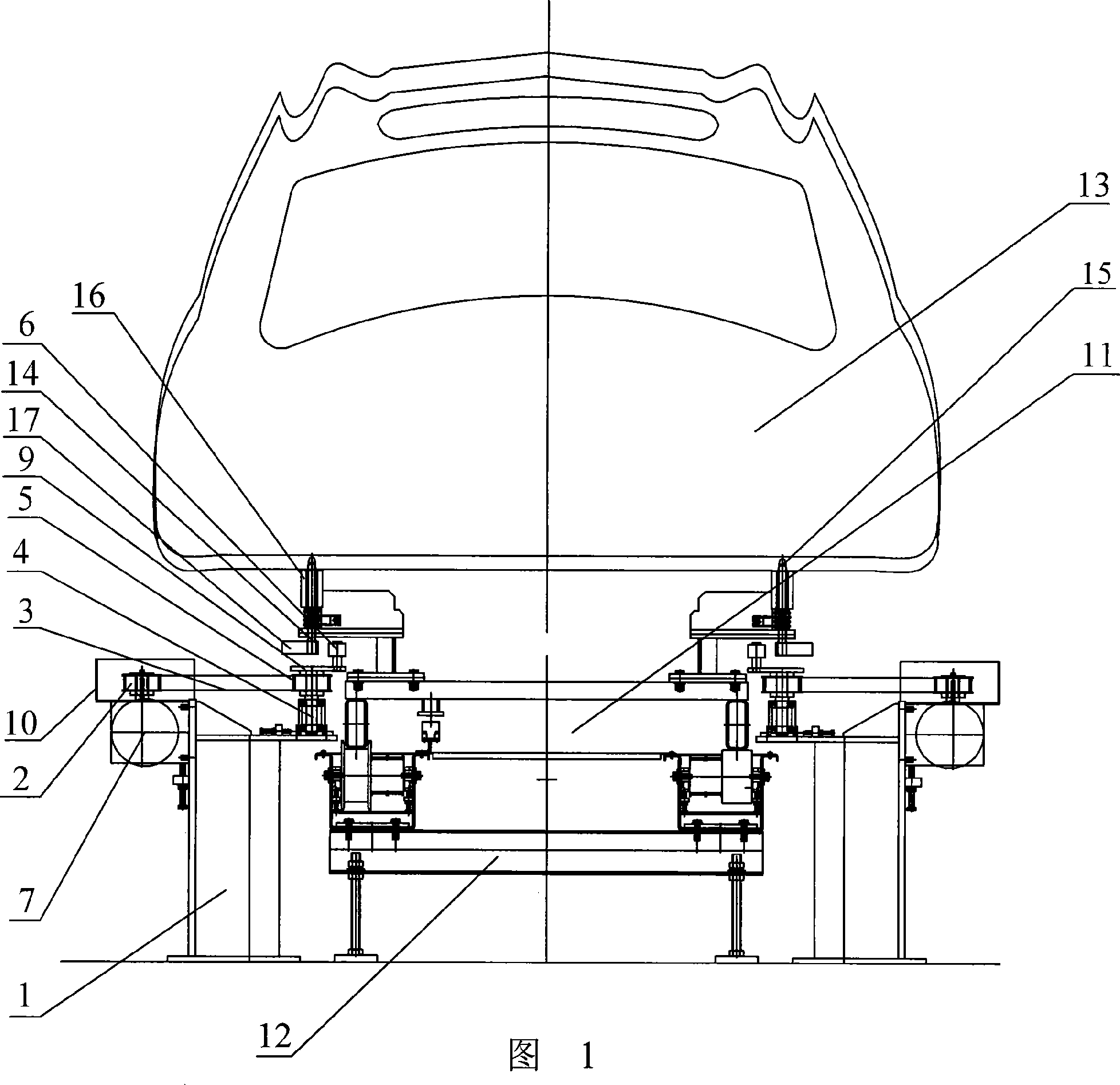

Automobile rear torsion beam hub connecting support assembling surface machining device

ActiveCN103084635AAdjust SymmetryMeet the requirements of assembly face millingAutomatic control devicesFeeding apparatusHigh volume manufacturingEngineering

The invention discloses an automobile rear torsion beam hub connecting support assembling surface machining device for milling and machining a plane containing two space angles. The automobile rear torsion beam hub connecting support assembling surface machining device comprises a fixture, a base and a milling and machining mechanism; the milling and machining mechanism comprises two parts which are arranged symmetrically at the left side and the right side of the fixture, wherein each part comprises a milling power head, a hydraulic sliding table, a guide rail, a milling power head tilt angle regulating mechanism and a guide rail angle regulating mechanism; the milling power head is installed on the hydraulic sliding table which is matched with the guide rail; and the guide rail is installed on the base. The automobile rear torsion beam hub connecting support assembling surface machining device provided by the invention has the characteristics of stable product machining quality, high guarantee capability and low manufacturing cost; the working efficiency is improved by 60% above compared with that of the traditional machining mode; the manufacturing cost is only one tenth of that of the traditional machining equipment; the mass production requirement is met; the automobile part production rhythm is accelerated; and the production capability of enterprises is improved.

Owner:长城汽车股份有限公司平湖分公司

Series-parallel combined three-freedom-degree translation carrying mechanism

ActiveCN103264384ACompact layoutSimple structureProgramme-controlled manipulatorEngineeringElectrical and Electronics engineering

A series-parallel combined three-freedom-degree translation carrying mechanism comprises a base, a first linear driving unit, a first slider, a second linear driving unit, a third linear driving unit, a first connection rod, a second connection rod, a third connection rod, a second connection member and an operation tail end. A second slider is arranged on the second linear driving unit, a third slider is arranged on the third linear driving unit, the first linear driving unit is in series connection with the second linear driving unit and the third linear driving unit, and the second linear driving unit is in parallel connection with the third linear driving unit. The series-parallel combined three-freedom-degree translation carrying mechanism is of a series-parallel combined structure, enables distribution of the driving units to be compact, simplifies the structure, meanwhile reduces load inertia and is favorable for improving efficiency.

Owner:SHANGHAI JIYI ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH CO LTD +1

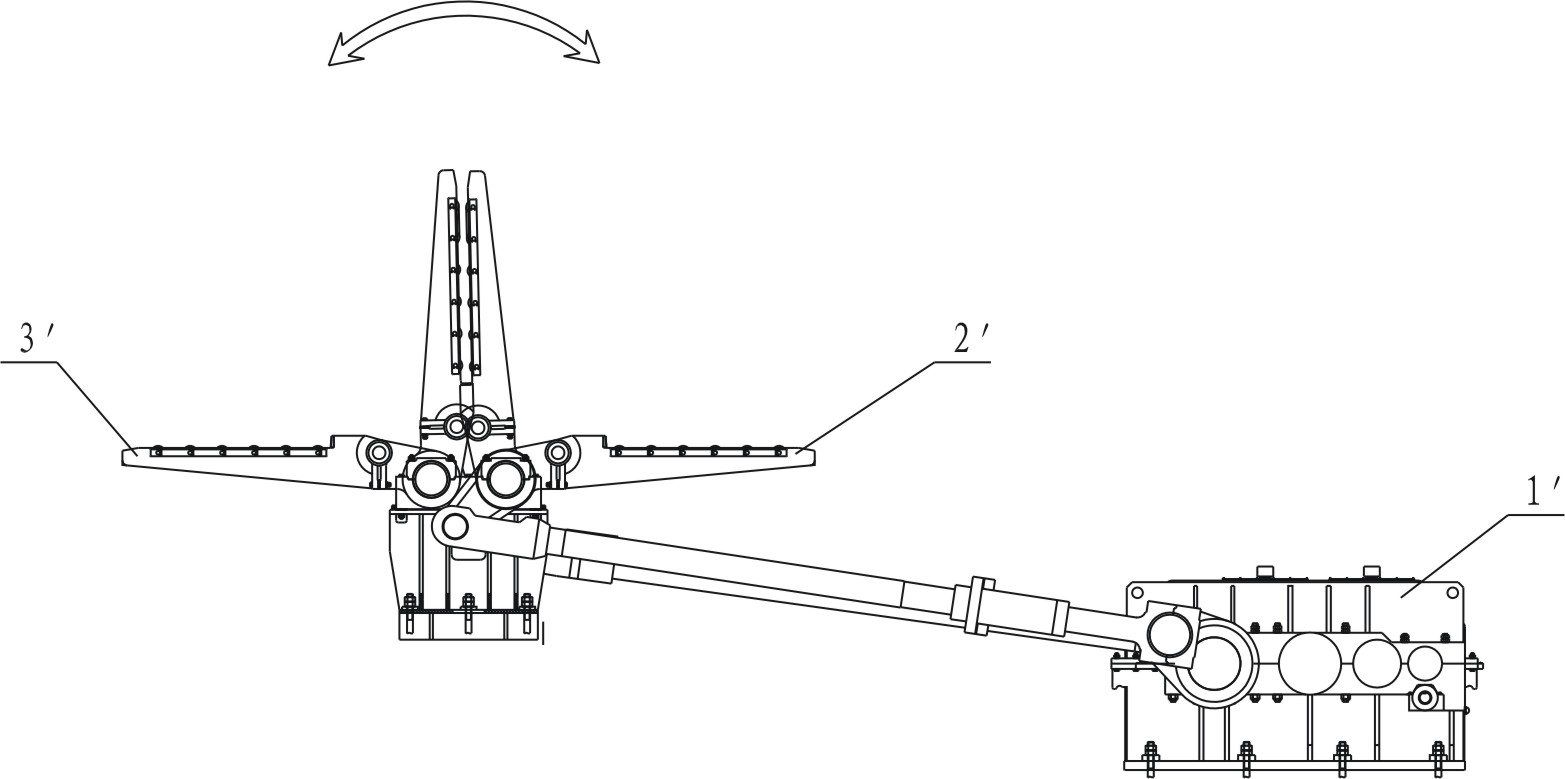

Magnetic steel plate turnover machine

InactiveCN102051466AFast tempoNo risk of scratchesFurnace typesHeat treatment furnacesSingle plateSmall footprint

The invention provides a magnetic steel plate turnover machine, belonging to the field of heat treatment of steel plates. The machine is used for solving the problems in the existing plate turnover machines. The machine comprises a transmission mechanism and plate turnover arms. The machine is characterized in that at least one plate turnover arm is arranged; the fixed ends of the plate turnover arms are connected with the output end of the transmission mechanism; and electromagnets are arranged at the movable ends of the plate turnover arms and are used for adsorbing or releasing a steel plate. The machine has the following beneficial effects: (1) single plate turnover transverse equipment is not needed, the plate turnover speed is high, and the whole operations comprising turned-over plate checking and sending back to approach tables can be completed within 30 seconds; (2) in the plate turnover process, relative sliding can not appear between the steel plate and the plate turnover arms, so the steel plate can not be scratched; (3) in the plate turnover process, the steel plate always horizontally leaves off or is contacted with the approach tables, is placed in the designated position and can not align close to the side; (4) when the steel plate is subjected to small angle check, the lower surface of the steel plate is unshaded, thus ensuring thorough check; and (5) the whole magnetic steel plate turnover machine has the advantages of simple structure, small floor area and less investment.

Owner:WISDRI WUHAN WIS IND FURNACE

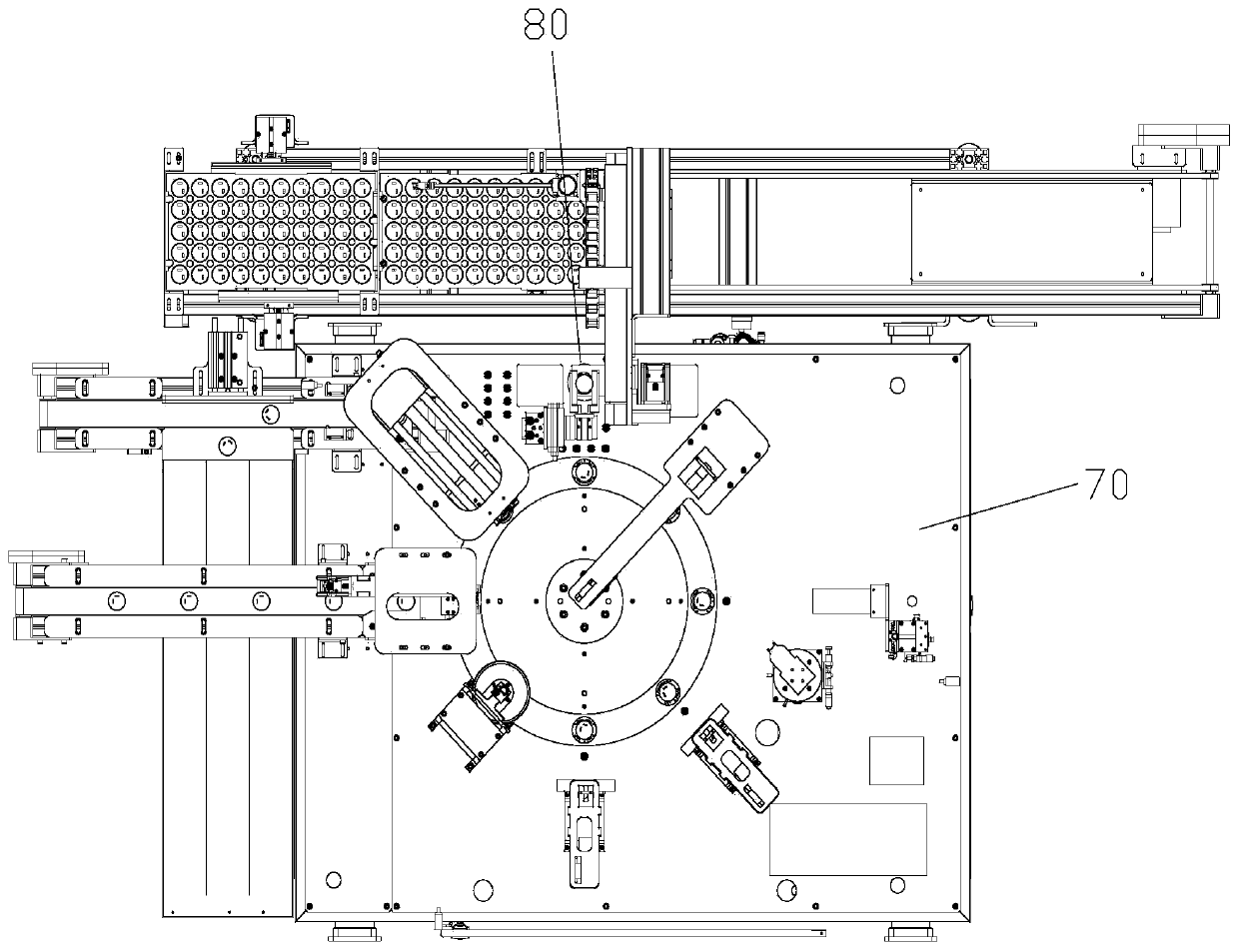

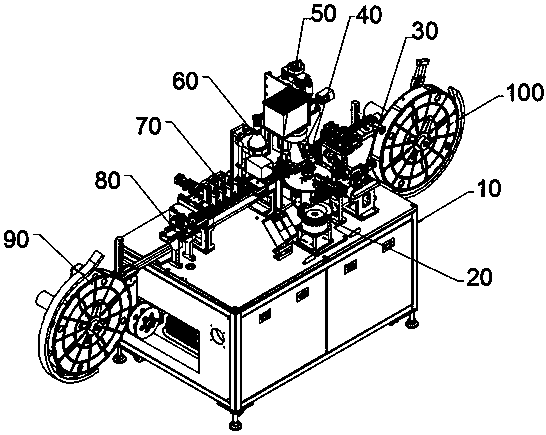

Capacitor detection device

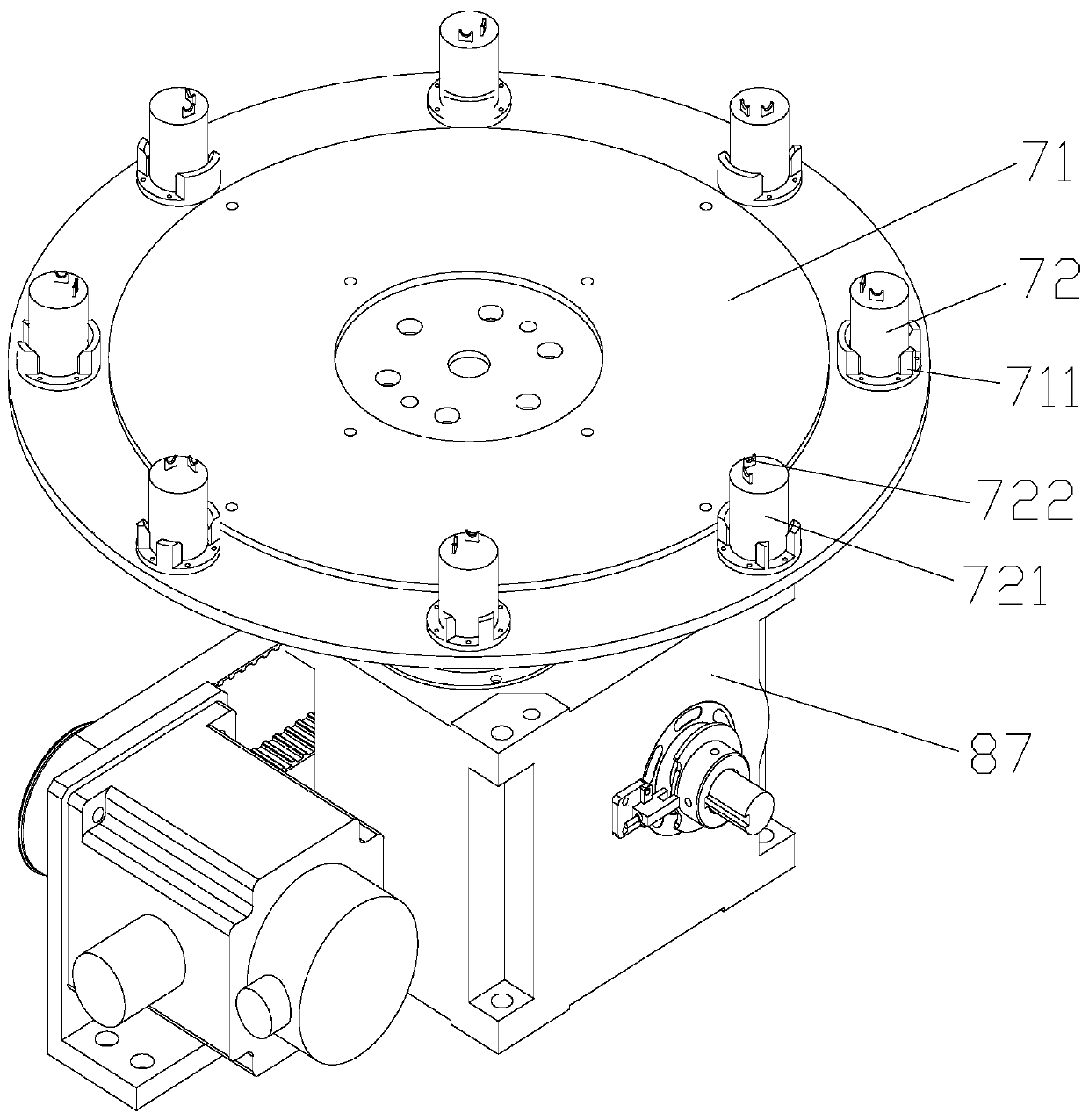

PendingCN110346375AComprehensive detectionFast tempoOptically investigating flaws/contaminationSortingCapacitanceCapacitor

The invention provides a capacitor detection device. The device comprises a rack, a turntable and a plurality of rotation mechanisms, wherein the rack is provided with a plurality of stations; the plurality of stations are alternately arranged around the center of the turntable; a support seat for supporting a capacitor is arranged on the turntable so that the capacitor passes through the stationsin sequence under the driving of the turntable; the turntable has a turntable initial position and a rotation position which is lifted for a predetermined height relative to the turntable initial position, so that the turntable can rotate when moving to the rotation position and move to the turntable initial position when finishing the rotation; the plurality of rotation mechanisms are arranged to correspond to the plurality of detection stations one by one and each rotation mechanism is arranged on the corresponding detection station; and the rotation mechanisms are arranged below the turntable so that the rotation mechanisms are connected with the capacitor through through holes of the support seat and through holes of the turntable so as to drive the capacitor to rotate when the turntable moves to the turntable initial position. The device is capable of solving the problem that the capacitor detection devices are relatively low in detection efficiency in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

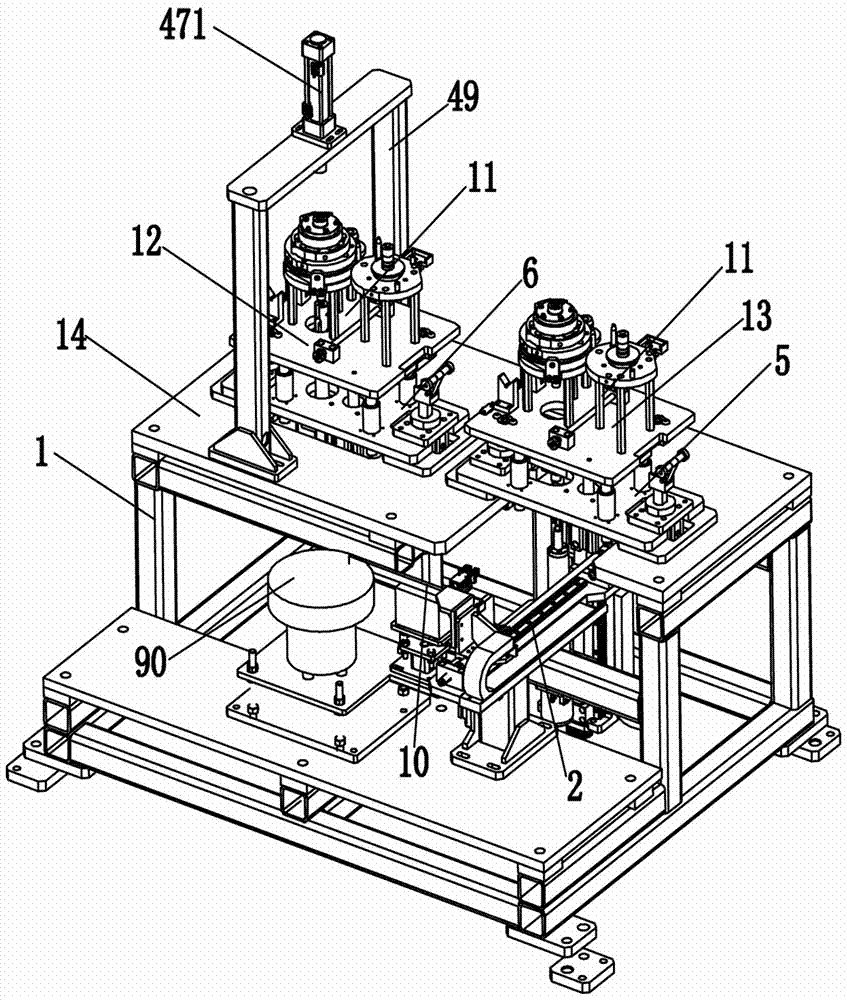

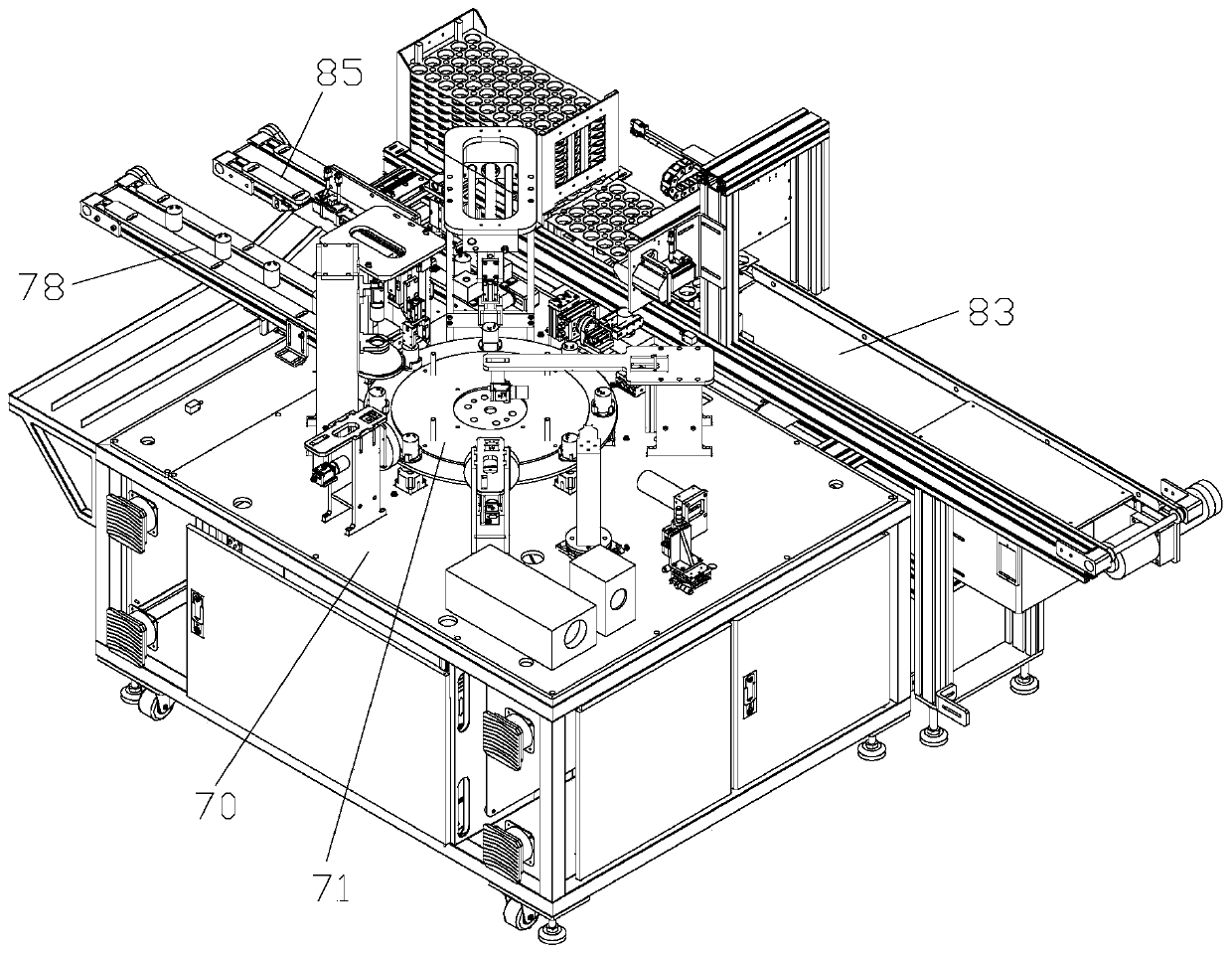

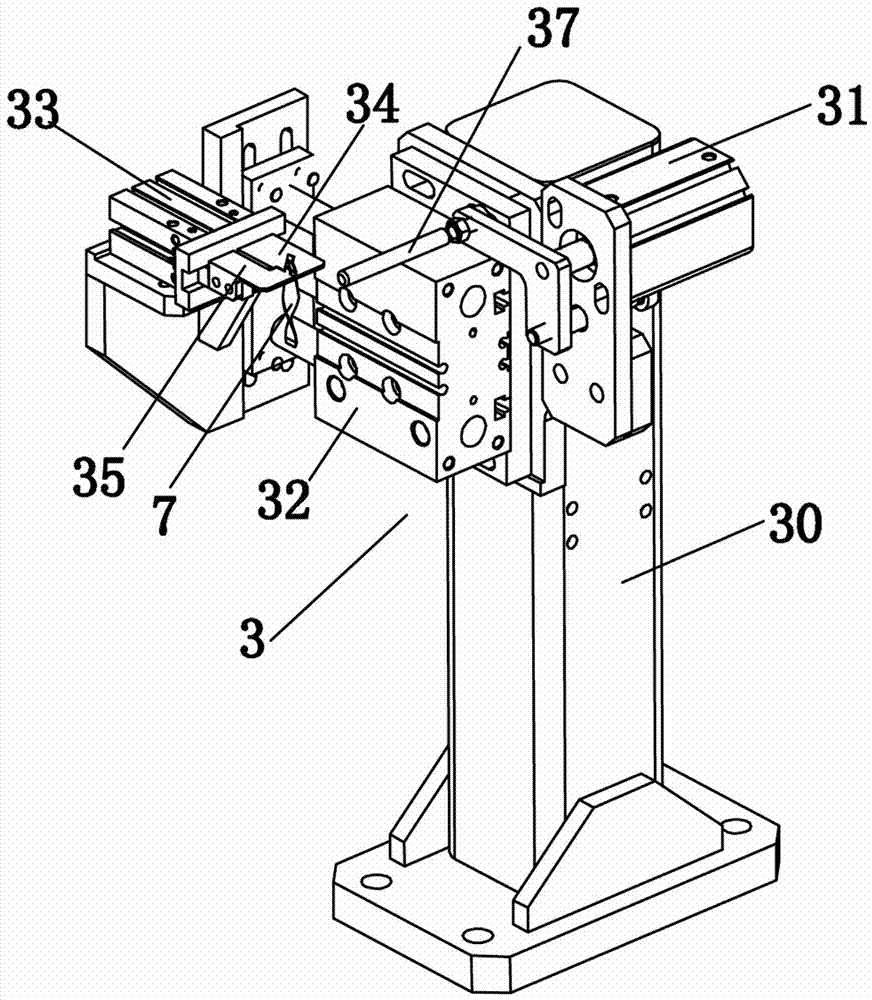

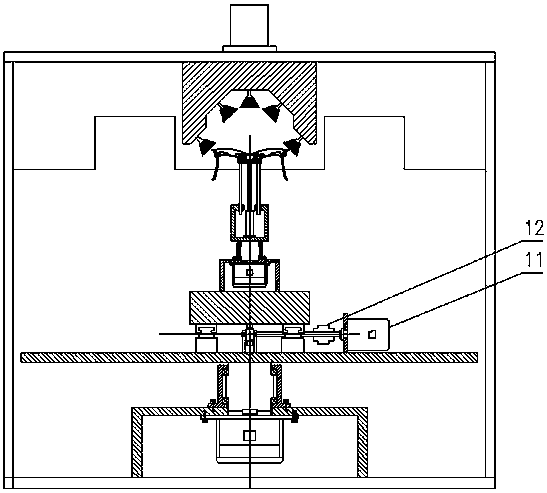

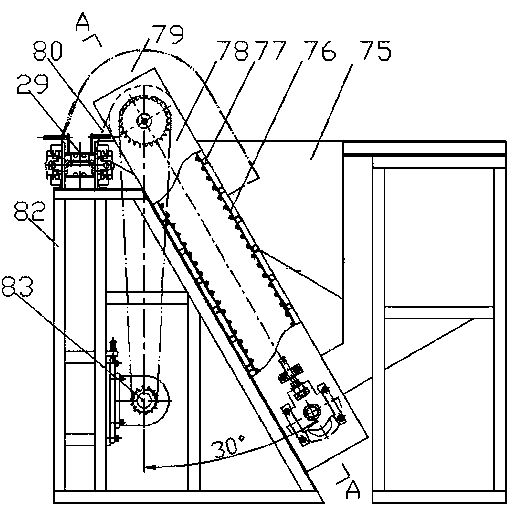

Full-automatic installation equipment for oil blades of compressor pump body

ActiveCN107378461AIncrease productivityHigh degree of automationWind energy generationMetal working apparatusRobot handControl engineering

The invention relates to the technical field of assembling of a compressor pump body, in particular to full-automatic installation equipment for oil blades of the compressor pump body. The full-automatic installation equipment comprises a rack, a vibration feeding mechanism, an oil blade distributing mechanism, an oil blade conveying mechanical arm, an oil blade guiding mechanism, a tool disk positioning and jacking mechanism and a crankshaft aligning mechanism. The full-automatic installation equipment for the oil blades of the compressor pump body is in an online installation manner and can be combined to a compressor pump body assembly line to achieve automatic butt connection of the whole line. According to the full-automatic installation equipment, by means of the vibration feeding mechanism, the oil blade distributing mechanism, the oil blade conveying mechanical arm, the oil blade guiding mechanism, the tool disk positioning and jacking mechanism and the crankshaft aligning mechanism, directional discharging, distributing, feeding, charging and other actions of the oil blades are achieved correspondingly, and therefore the full-automatic installation equipment is high in production efficiency and automation degree, discharging and charging are efficient and accurate, the online installation takt can be improved well, and the requirement for large batch production can be met.

Owner:GUANGDONG SHUNDE SANHE IND AUTOMATION EQUIP CO LTD

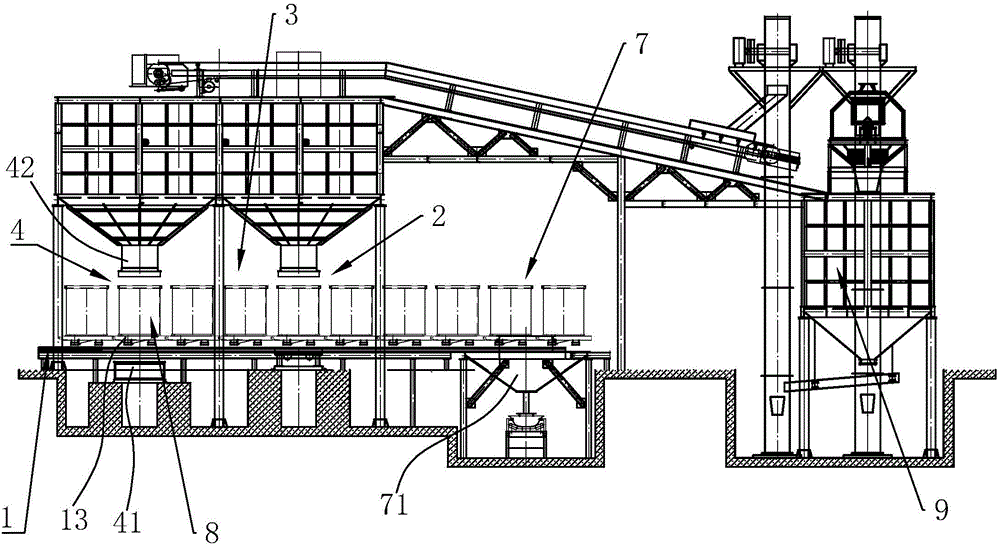

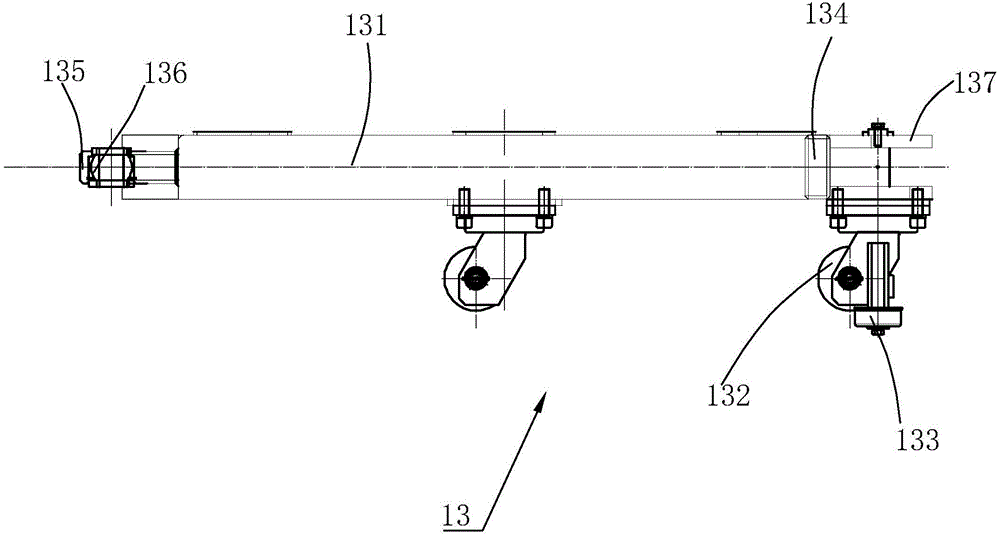

High-efficiency and energy-saving aluminum alloy evaporative pattern casting production line

The invention discloses a high-efficiency and energy-saving aluminum alloy evaporative pattern casting production line. The high-efficiency and energy-saving aluminum alloy evaporative pattern casting production line comprises a sand box automatic circular line, wherein a plurality of box bearing carts which move along a conveying line and are used for bearing sand boxes are arranged on the sand box automatic circular line; the sand boxes are borne on the box bearing carts; the box bearing carts sequentially pass through a bottom sand adding station, a model cluster storing station, a sand filling and modeling station, a pouring station, a casting discharging station and a sand falling station on the conveying line through a servo box pushing system; the pouring station comprises a pouring machine and a tundish changing system; a casting taking robot for taking out castings in the sand boxes is arranged at the casting discharging station; and a bottom-dump type sand falling device for dumping molding sand in the sand boxes from the bottoms of the sand boxes is arranged at the sand falling station, or a box turning machine is adopted for automatically turning over the boxes to finish the sand falling. The production line has the characteristics of high degree of automation, high production efficiency, stability, reliability, energy conservation, environment friendliness and the like.

Owner:北京天哲消失模铸造技术有限公司

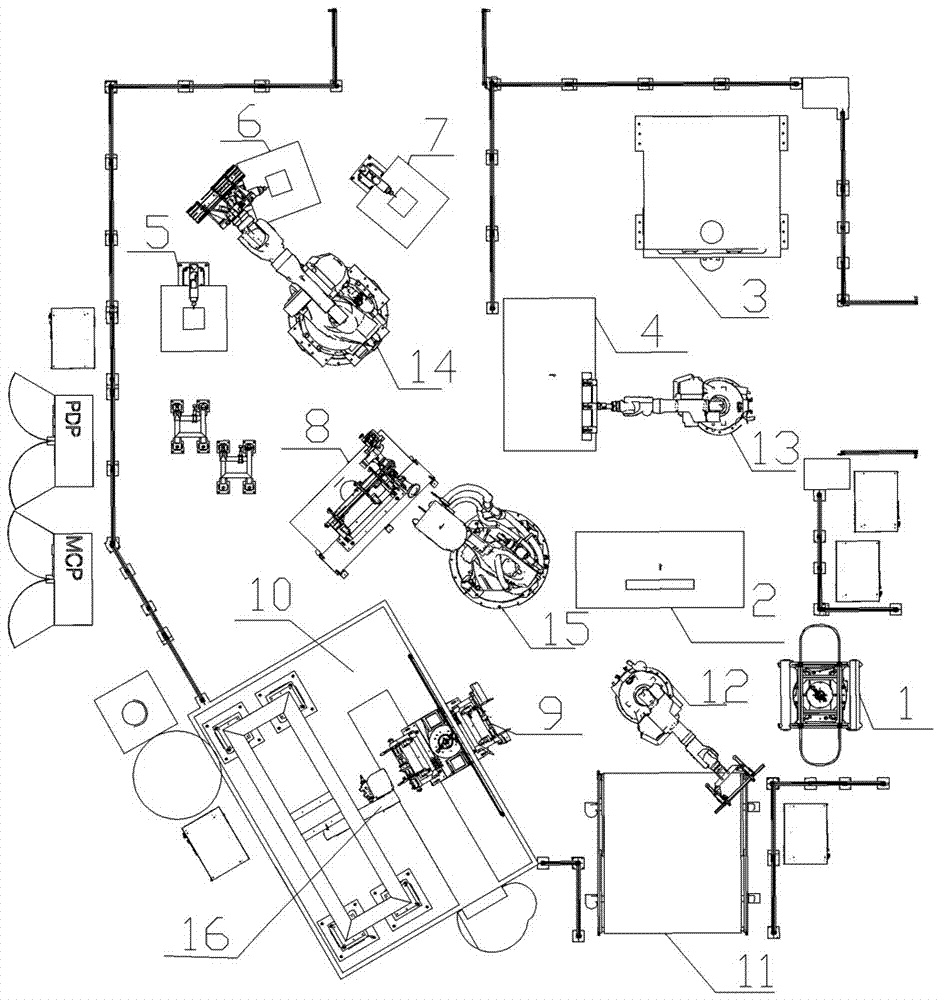

Guide rail machining technology for automobile skylight

ActiveCN107309360AFast tempoReduce manufacturing costOther manufacturing equipments/toolsVehicle componentsEngineeringSkylight

The invention relates to a guide rail machining technology for an automobile skylight. Parts are grasped and conveyed to different stations through a robot and different operations are carried out. A whole guide rail production technology flow and equipment are improved, so that the production pace is reduced, the yield of production is improved and a process of producing and detecting synchronously is realized. The guide rail machining technology can be switched through one key according to different project guide rails, different radians and pre-adjusted parameters.

Owner:NINGBO HENGHE PRECISION INDUSTRY CO LTD

Novel loratadine oral quickly soluble film and preparation method thereof

InactiveCN106619577AImprove complianceQuick releaseOrganic active ingredientsPharmaceutical non-active ingredientsLoratadineEthanol

The invention relates to a novel loratadine oral quickly soluble film and a preparation method thereof. The oral quickly soluble film comprises the following components: loratadine, a surfactant, a film-forming material, a flavoring agent, a corrigent and a small amount of ethanol. The invention further provides a preparation method of the novel loratadine oral quickly soluble film. The oral quickly soluble film is small in size and convenient to carry; the dosage is convenient to control, a preparation process is simple and controllable, special production equipment is not required, the novel loratadine oral quickly soluble film is suitable for industrial massproduction, can be quickly dissolved in the oral cavity of a patient who does not need to drink water or chew, and tastes good; compliance of medication for children is greatly improved; the dissolution condition of the novel loratadine oral quickly soluble film in a citric acid-disodium hydrogen phosphate buffer solution with pH of 4.0 is remarkably better than the dissolution condition of commercially available tablets; and the novel loratadine oral quickly soluble film has significance on gerontal patients and other patients with achlorhydria.

Owner:CHINA PHARM UNIV

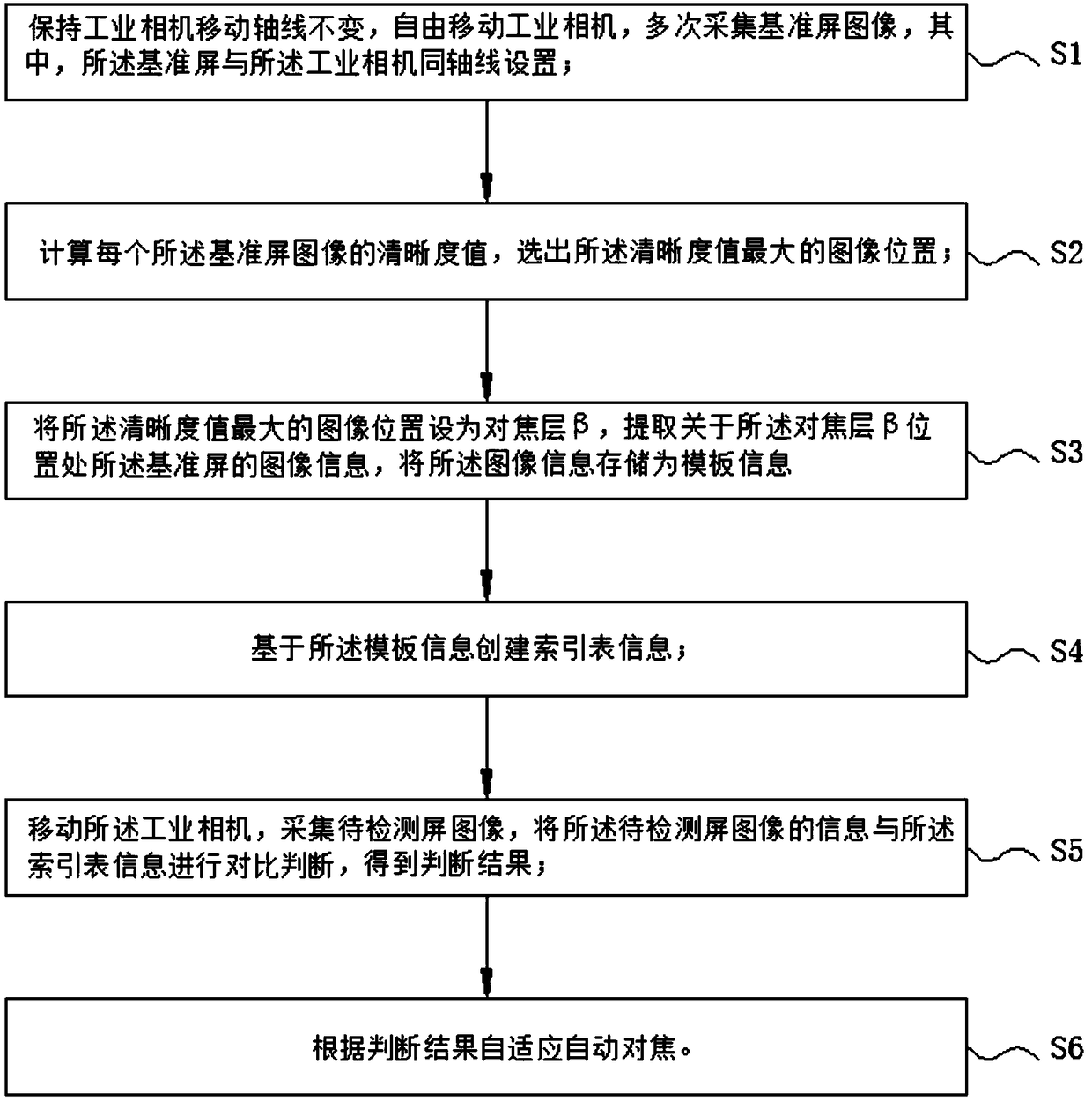

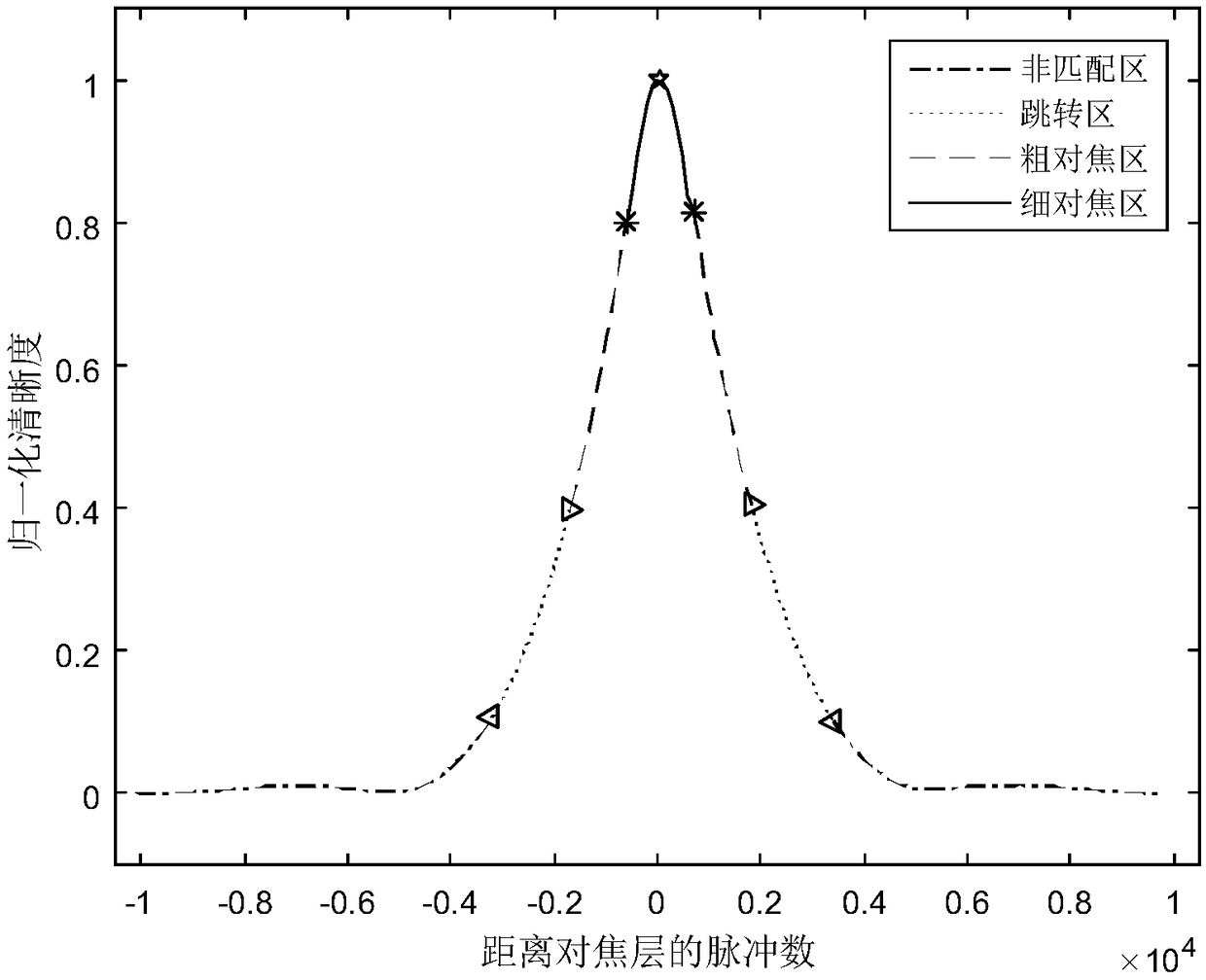

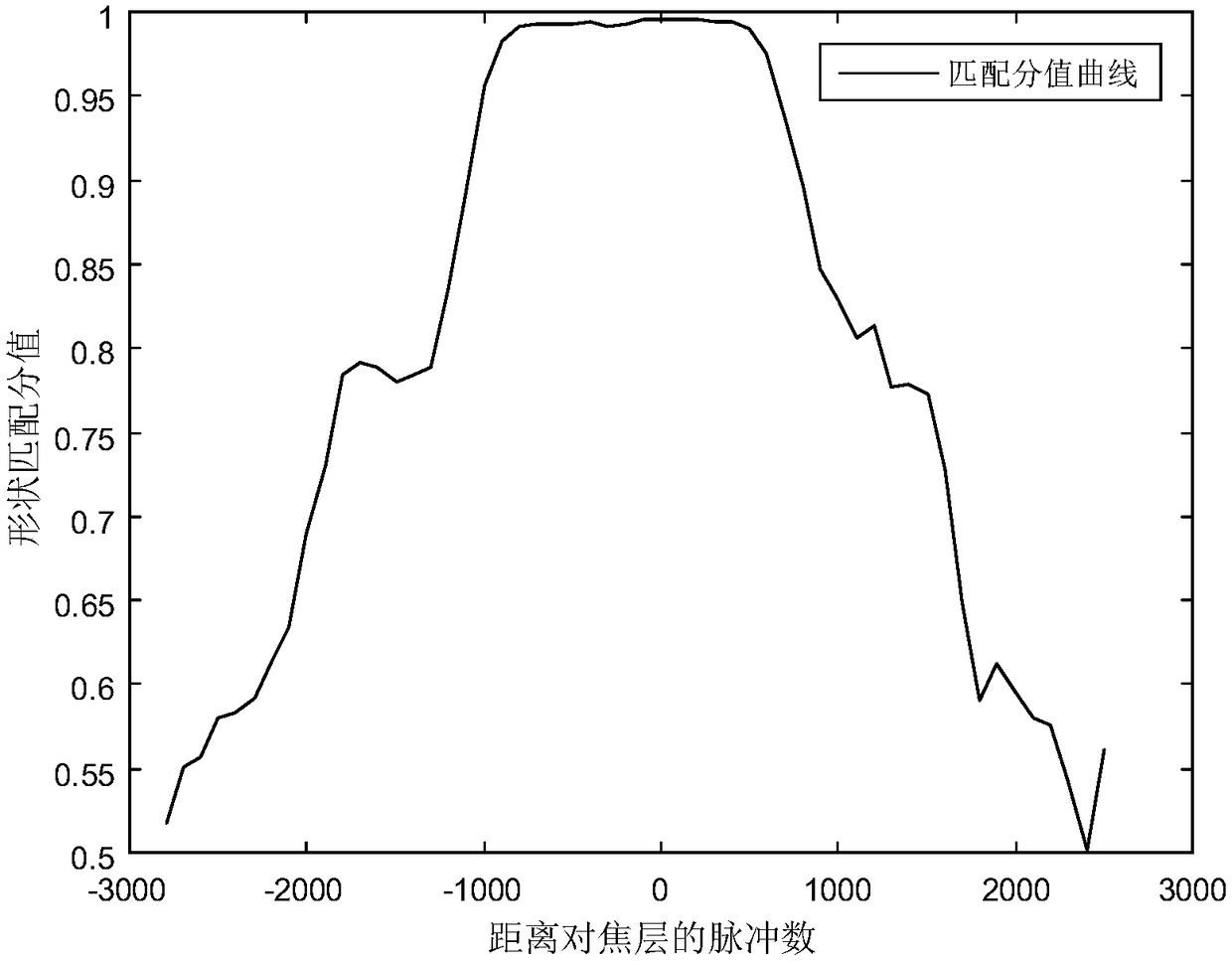

Industrial camera adaptive automatic focusing method and industrial camera adaptive automatic focusing device

The invention provides an industrial camera adaptive automatic focusing method and an industrial camera adaptive automatic focusing device, which relate to the technical field of automatic detection.The method comprises the following steps: keeping a moving axis of an industrial camera constant, freely moving the industrial camera, acquiring benchmark screen images for many times; calculating a definition value of each benchmark screen image, screening out a benchmark screen image position with highest definition value, taking the benchmark screen image position as a focusing layer beta, extracting information about the benchmark screen image at the focusing layer beta, storing the information as template information; creating index table information based on the template information; moving the industrial camera, acquiring a to-be-detected screen image, and performing comparing and judging for the to-be-detected screen image and the index table information; and performing adaptive automatic focusing according to a judging result. The method is simple and fast in focusing, has high robustness for being suitable for variation of outside lighting conditions, is suitable for different types of LCD screens and the screens of different working procedure stages, has high detection precision, can improve automation degree of detection equipment and can improve working efficiency.

Owner:BEIJING LUSTER LIGHTTECH

Device for automatically removing rim burrs

PendingCN106938417AHigh degree of automationImprove efficiencyEdge grinding machinesEngineeringSlide plate

The invention provides a device for automatically removing rim burrs. The device is formed by a machine frame (1), gears (2), racks (3), a fixed supporting plate (4), a guide rail (5), a left sliding plate (6), a clamping air cylinder(7), vertical columns (8), clamping wheels (9), a rotary cutter plate (10), guide columns (11), a movable supporting plate (12), upper air cylinders (13), a servo motor (14) and a right sliding plate (15). The device is characterized in that the clamping wheels (9) are fixed to the vertical columns (8), the two vertical columns (8) are fixed to the left sliding plate (6), the other two vertical columns (8) are fixed to the right sliding plate (15), and the left sliding plate (6) is structurally connected with the right sliding plate (15) through the gears (2) and the racks (3). The device can meet the requirement of automatic removal of burrs on a rim on the outer side of a wheel, the automation degree is high, the takt is short, efficiency is high, the burr removal effect is good, labor cost is reduced, and labor intensity is relieved. The device has the advantages of being compact in structure, stable in running, easy to operate and the like.

Owner:CITIC DICASTAL

Wheel washing and blow-drying device and method

InactiveCN108097640AFast tempoImprove efficiencyDrying gas arrangementsVehicle cleaning apparatusHigh pressure waterPositioning system

The invention discloses a wheel washing and blow-drying device, comprising: a wheel positioning system for initially positioning wheels on a roller bed and finding valve holes; a wheel advancing and dry-wet conversion system allowing the wheels to advance so as to perform dual-station dry-wet conversion on the wheels; a high-pressure water washing system cooperating with the wheels in advancing and rotating to wash them clean; a compressed air blowing system cooperating with the wheels in advancing and rotating to evenly blow them dry. The invention also discloses a wheel washing and blow-drying method. The wheel washing and blow-drying device and method have the advantages that wheels are kept moving forward during washing and blow drying, the rhythm is short, the efficiency is high, washing and blow drying are integrated, and dry-wet separation is also attained.

Owner:CITIC DICASTAL

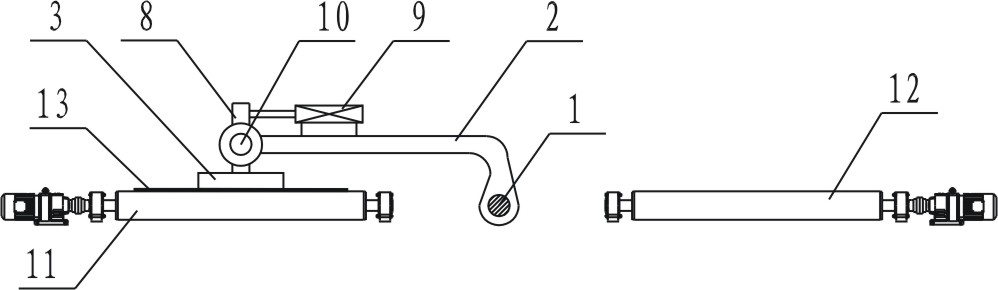

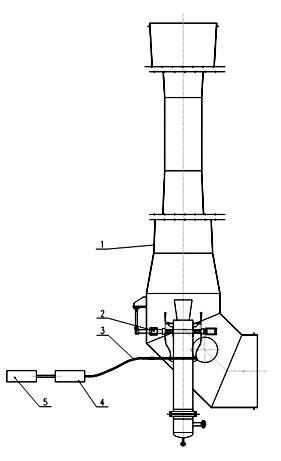

Design method for automatic high-pressure water cleaning device

InactiveCN102094109AFast pacedImprove productivityHollow article cleaningEngineeringElectromagnetic valve

The invention belongs to the technical field of secondary refining of molten steel, in particular to a design method for an automatic high-pressure water cleaning device used for cleaning accumulated dust on the inner wall of a pump body of a steam ejection pump. The design method is characterized in that: the designed automatic high-pressure water cleaning device controls an ejection angle of a high pressure nozzle through the reciprocating movement of an adjustment connecting rod, namely a hydraulic cylinder rotationally connected with the pump body controls bidirectional extension through an electromagnetic valve, and the hydraulic cylinder drives a swing arm three, a rotating shaft, a swing arm one and a swing arm two and finally drives and controls the reciprocating movement of the adjustment connecting rod, so that the ejection angle of the high pressure nozzle is changed; moreover, the change speed of the ejection angle of the high pressure nozzle can be adjusted by controlling the oil feeding speed of the hydraulic cylinder, the most reasonable oil feeding speed is selected according to the diameter of the pump body and the distribution of high pressure nozzles and the best cleaning effect is achieved. The designed automatic high-pressure water cleaning device can automatically clean the accumulated dust on the inner wall of the pump body of the steam ejection pump in an interval of molten steel vacuum treatment.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Automatic box closing assembly device

ActiveCN110961891APrevent rotationSave manpower and material resourcesMetal working apparatusControl engineeringEngineering

The invention discloses an automatic box closing assembly device. The automatic box closing assembly device is characterized by comprising an automatic feeding mechanism, a lifter press-fitting body mechanism, an input shaft holding mechanism, a hybrid shaft tensioning mechanism and a type position-changing mechanism. A robot is used for automatically feeding workpieces, the takt is saved, and themanual cost is reduced; a lifting air cylinder cooperates with a servo press machine, and therefore press-fitting action is smoother; the output shaft holding structure is changed, and therefore theholding mechanism is more flexible, the telescopic quantity is increased, wear is reduced, and the equipment maintenance failure rate is reduced; and the servo press machine cooperates with a tensionsensor, press fitting is precisely monitored to be achieved in place by adjusting the in-place positions of different shafts, and press-fitting reliability and stability are increased.

Owner:COMAU SHANGHAI ENG

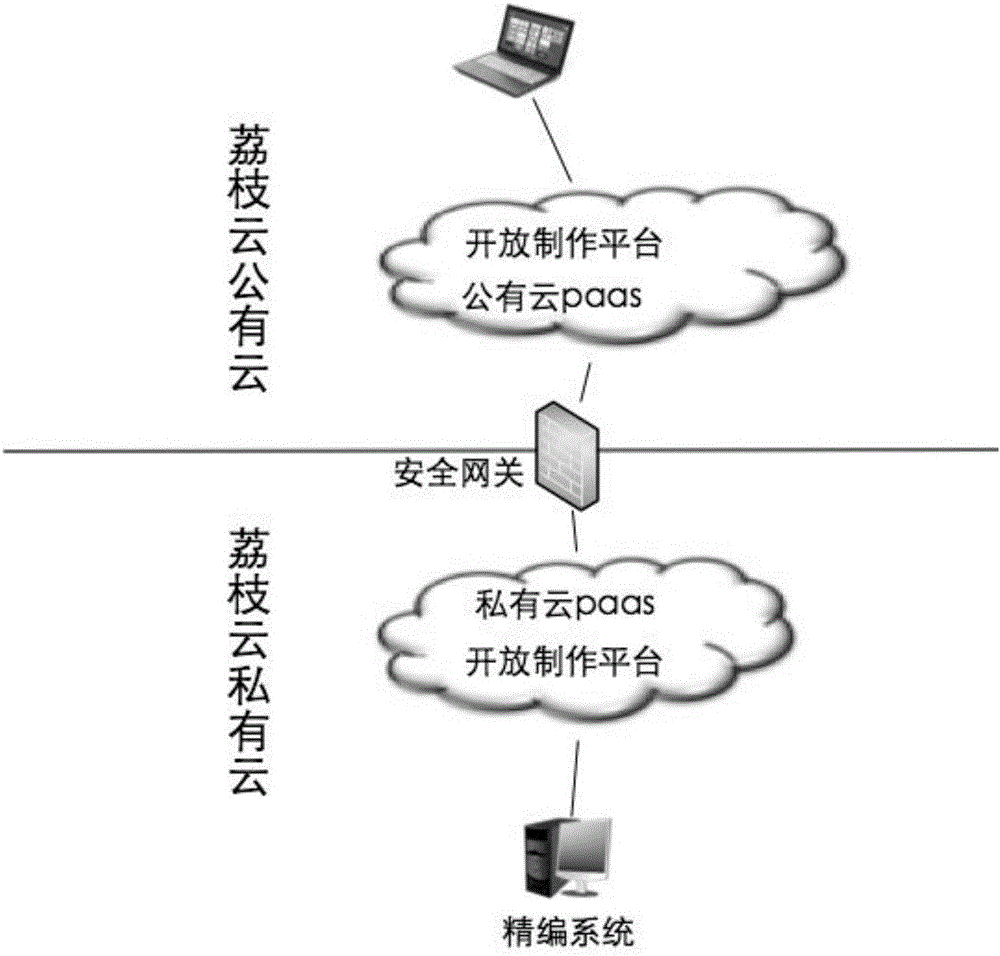

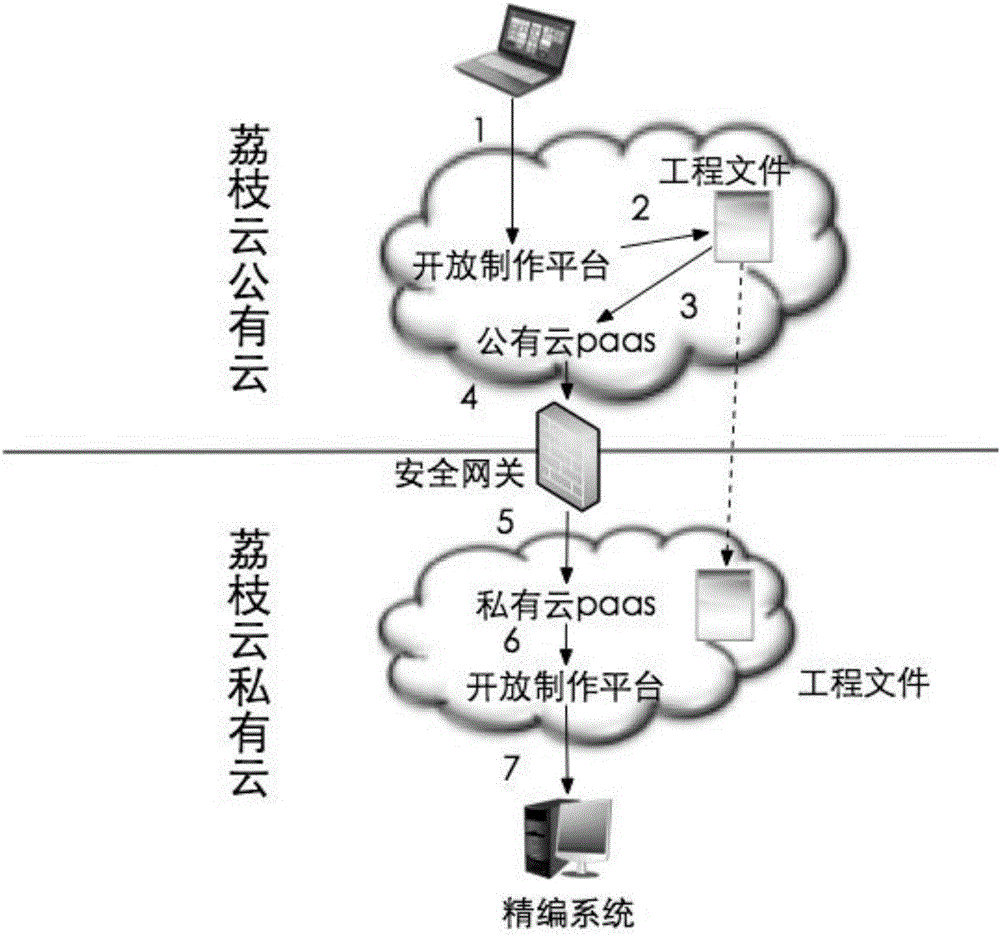

Hybrid cloud service platform based pass-while-encoding PaaS (platform as a service) capability application system and method

InactiveCN106227728AFast tempoImprove production efficiencyTransmissionSpecial data processing applicationsFile transferFile storage

The invention discloses a hybrid cloud service platform based pass-while-encoding PaaS (platform as a service) capability application system which comprises a hybrid-cloud public cloud, a security gateway and a hybrid-cloud private cloud. The hybrid-cloud public cloud comprises a hybrid-cloud open production platform and public-cloud PaaS, the hybrid-cloud open production platform is used for compiling low-bit files stored on the public cloud by a user, well-compiled project files are stored in the public-cloud PaaS of the hybrid cloud; the security gateway is used for transmitting the project files on the public-cloud PaaS to private-cloud PaaS; the hybrid-cloud private cloud comprises the private-cloud PaaS and the hybrid-cloud open production platform, and the hybrid-cloud open production platform of the private cloud finds corresponding high-bit files from the private-cloud PaaS for processing through the project files. By the arrangement, efficiency from live recording of video-audio program to completion can be effectively improved.

Owner:JIANGSU BROADCASTING CORPORATION

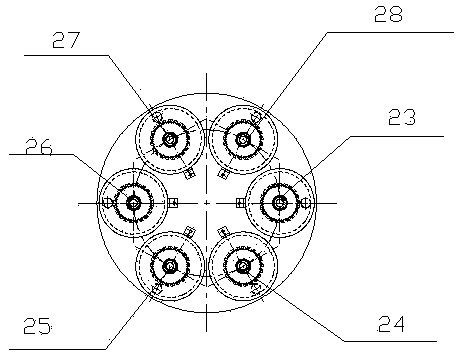

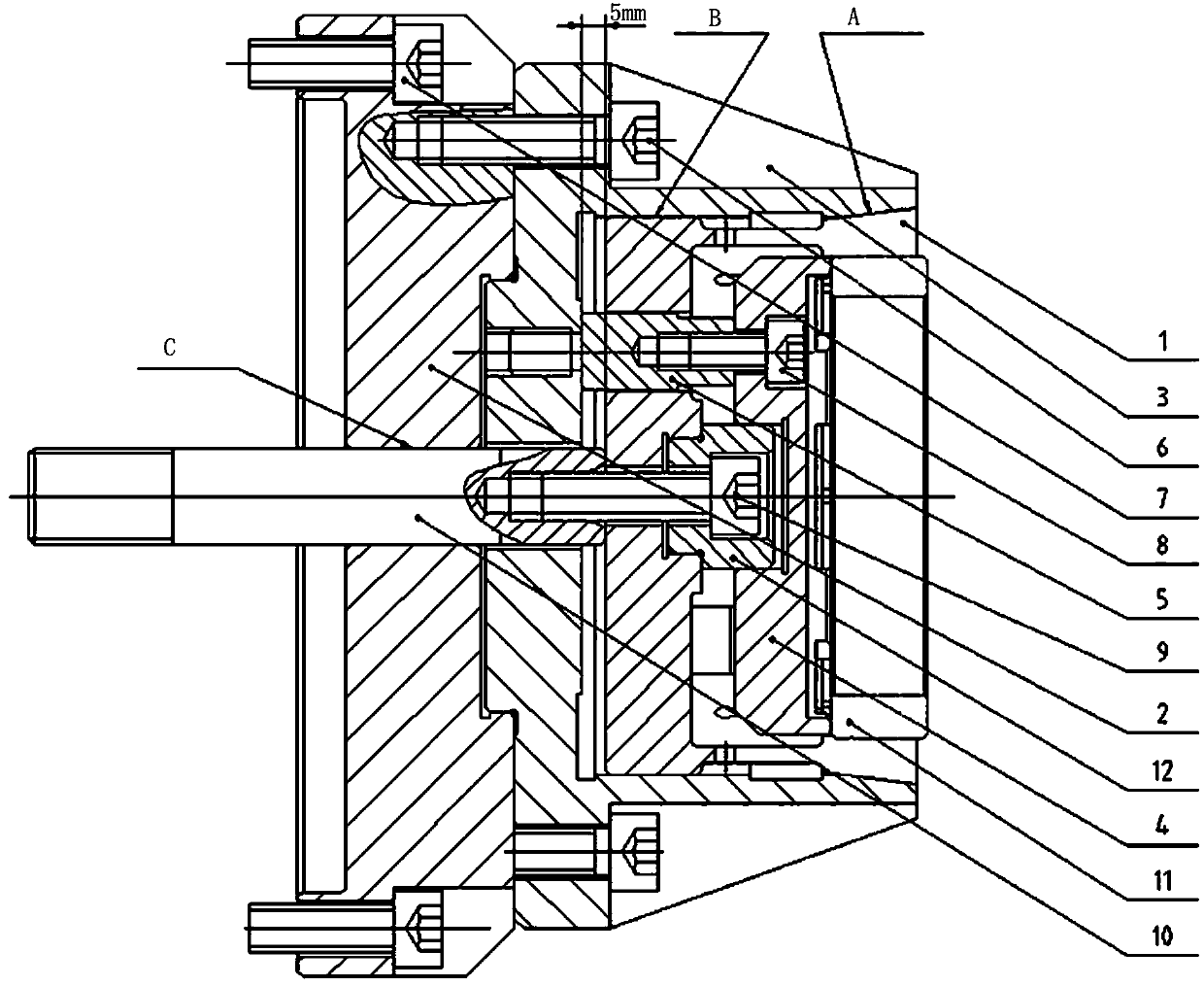

Induction quenching machining tool for flake workpieces

ActiveCN103898291AAutomatic feeding is lightweightSort easilyFurnace typesHeat treatment furnacesInduction hardeningMachine tool

The invention belongs to the field of induction quenching technology, and particularly relates to an induction quenching machining tool for flake workpieces. The induction quenching machining tool for the flake workpieces comprises a machining tool body (9), a rotary disk (3), an automatic feeding mechanism, a material sorting ranking mechanism, a locating pushing mechanism, a feeding and discharging mechanism and a swing mechanism, wherein the rotary disk (3) is of a disc structure arranged on the machining tool body (9), and has six uniformly and circumferentially distributed work stations-a feeding station (23), a transition station I (24), a transition station II (25), a quenching station (26), an air injection station (27), and a discharging station (28), the automatic feeding mechanism, the material sorting ranking mechanism, the locating pushing mechanism, the feeding and discharging mechanism and the swing mechanism are arranged in front of the feeding station (23), and a loading regulating device for regulating a quenching inductor is arranged at the position corresponding to the quenching station. The induction quenching machining tool meets the technological requirement of quenching, and has the characteristics of high automation degree and simple and convenient operation.

Owner:LUOYANG SHENGHUA INDUCTION HEATING

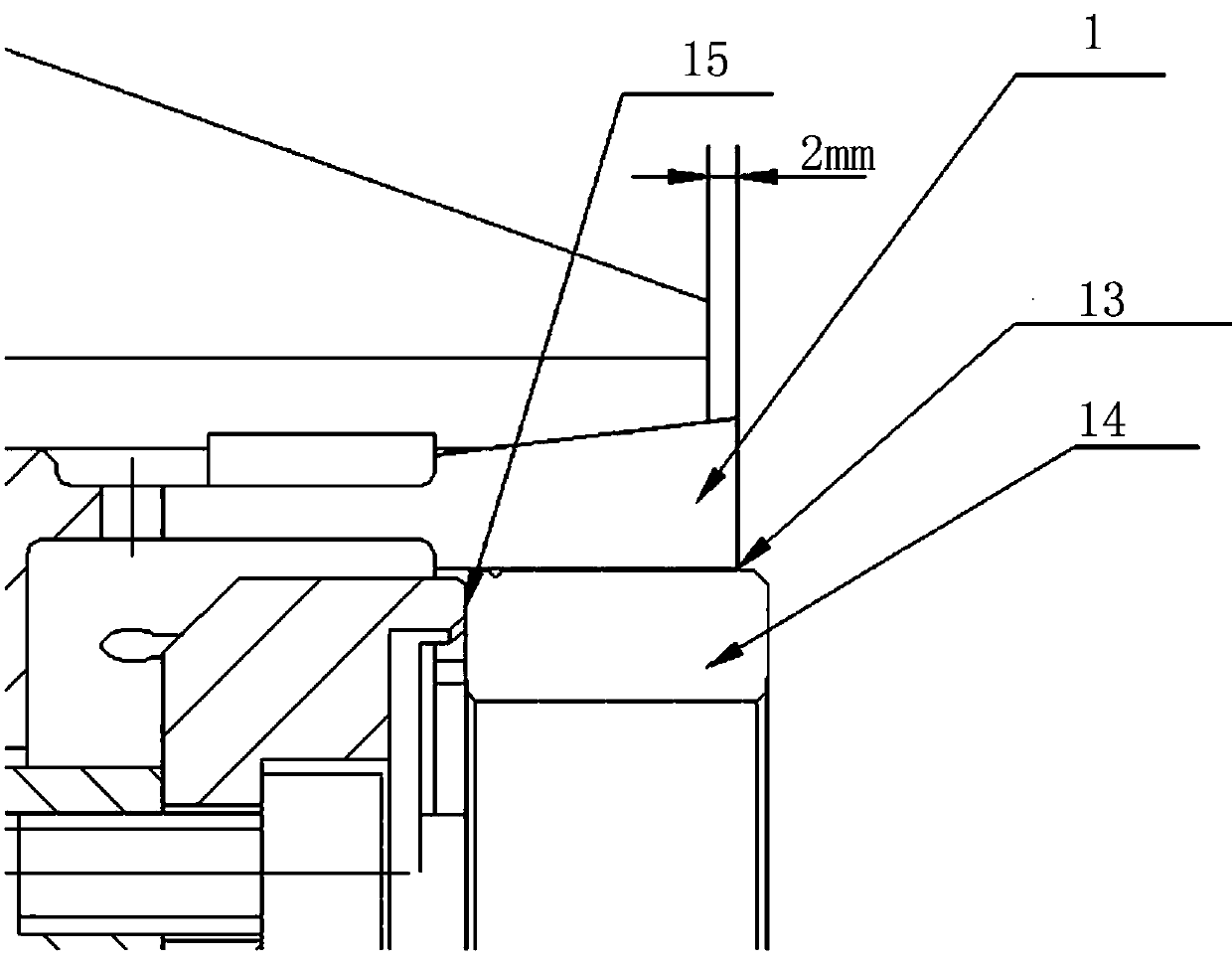

Rearward pull clamping type lathe fixture for processing of inner hole and end faces of thin-walled part

ActiveCN104191296AAvoid deformationReduce distortionPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a rearward pull clamping type lathe fixture for processing of an inner hole and end faces of a thin-walled part. The rearward pull clamping type lathe fixture comprises a tubular base; one end face, which is tapered, of the tubular base is as tapered as the outside of one end of an elastic collet; the tubular base which is a disc base is fixed while the elastic collet is slidable; the inside of the elastic collet clamps the outside of a workpiece, and a gap remains between the inside of the elastic collet and the outside of the workpiece so as to favor clamping of the workpiece. When a cylinder drives a pull rod to pull the elastic collet to slide rearward, the elastic collet contracts to clamp the workpiece; while the elastic collet moves rearward and gradually clamps the workpiece, the workpiece is driven to move rearward to tightly attach to a positioning seat. A positioning sleeve is arranged among the positioning seat of the fixture, the elastic collet and the pull rod so that coaxiality of the positioning seat, the elastic collet and the pull rod is guaranteed. The rearward pull clamping type lathe fixture has the advantages that deformation of the thin-walled part can be effectively reduced, clamping is facilitated, positioning is reliable, and batch production of parts is facilitated.

Owner:JIANGSU SAIC AUTOMOBILE SYNCHRONIZER WORKS

Automatic adhesive tape tearing equipment

The invention discloses automatic adhesive tape tearing equipment which is adapted to the processing process of photovoltaic products. The automatic adhesive tape tearing equipment comprises a conveying mechanism adapted to assembly line work in a linear feeding mode, an adhesive tape tearing mechanism erected on the upper side of the photovoltaic products through a transfer mechanism, a material receiving mechanism and a discharging mechanism; the adhesive tape tearing mechanism can respectively generate displacement actions of tearing an adhesive tape / a covering film in the width and / or length direction of the products; the material receiving mechanism is configured to be a winding structure driven by the transfer mechanism and can wind the torn adhesive tape / covering film while the adhesive tape tearing mechanism acts; and the discharging mechanism comprises a clamping assembly arranged relative to the material receiving mechanism so as to take down the wound adhesive tape / covering film from the material receiving mechanism. According to the equipment and the structure, the automatic implementation and control of the film tearing action are realized, the rhythm of the whole line is improved, the labor cost is reduced, and the efficiency of the whole station is improved.

Owner:苏州鑫本智能科技有限公司

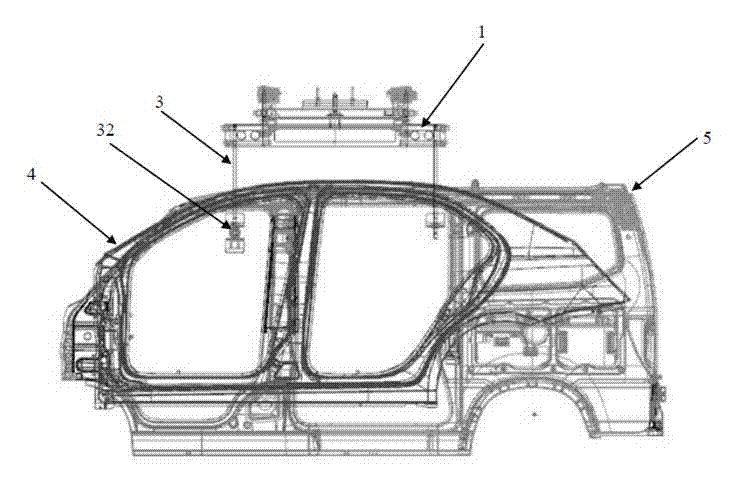

Prized body automatic locking device

The present invention relates to one kind of automatic locking unit for the automatic locking between vehicle body and sledge before pre-treatment and surface electrophoresis treatment. According to the technological scheme of the present invention, there are locking rotation shafts set on the frame in the positions corresponding to the locating holes of the workpiece, one rotation driving unit connected to the locking rotation shafts, locking sheets capable of being inserted into the locating hole, and one workpiece supporting unit. After the workpiece is supported with the supporting unit, it is locked to the frame via rotating the locking rotation shafts driving the locking sheets. The present invention can realize automatic locking between the vehicle body and sledge, and has compact structure, high reliability, low cost and other advantages.

Owner:MIRACLE AUTOMATION ENG CO LTD

Tape adhering jig for door frame decorating strip

The invention discloses a tape adhering jig for a door frame decorating strip. The tape adhering jig for the door frame decorating strip comprises a fixed base, and a moving sliding seat which can transversely slide on the fixing base; a plurality of mounting stations which are transversely distributed to position the decorating strip are arranged at the upper side of the fixing base; transverse shafts which transversely cross each mounting station are mounted at the bottom part of the moving sliding seat; a tape guide groove corresponding to each mounting station is formed in each transverse shaft; a pressing block corresponding to each mounting station is arranged a the rear side of each transverse shaft, on the moving sliding seat; a tape pressing groove is formed in the bottom part of each pressing block. According to the tape adhering jig for the door frame decorating strip, the decorating strip and a tape can be effectively adhered by the moving sliding seat transversely sliding on the fixing base; the plurality of tapes and decorating strips can be adhered synchronously through the plurality of mounting stations at a time, and therefore, the frequency is increased; the operation is standard, the adhering force is uniform, the adverse effect caused by manmade factors can be reduced, and as a result, the quality defect can be removed.

Owner:GUANGZHOU MINHUI AUTOMOBILE PARTS

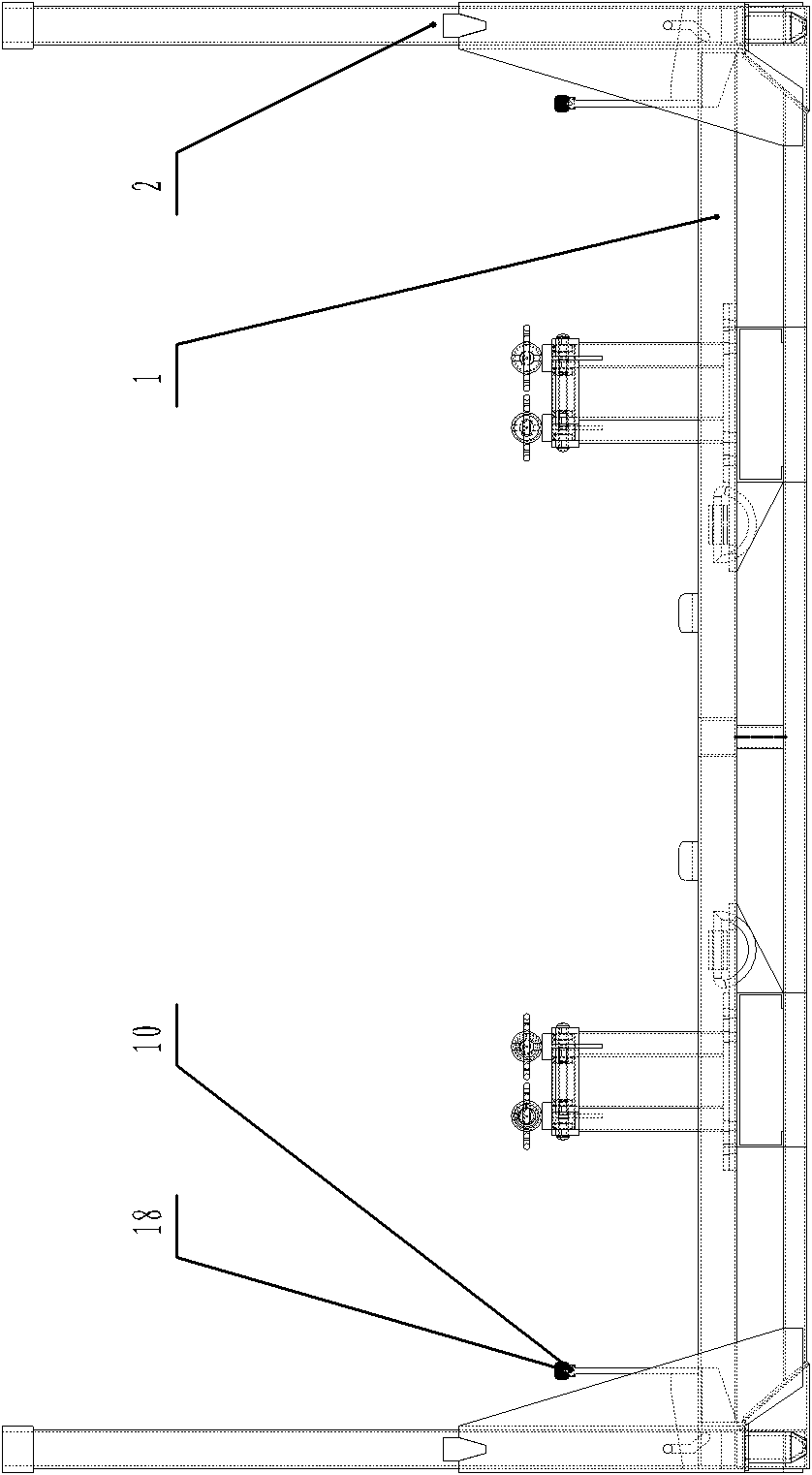

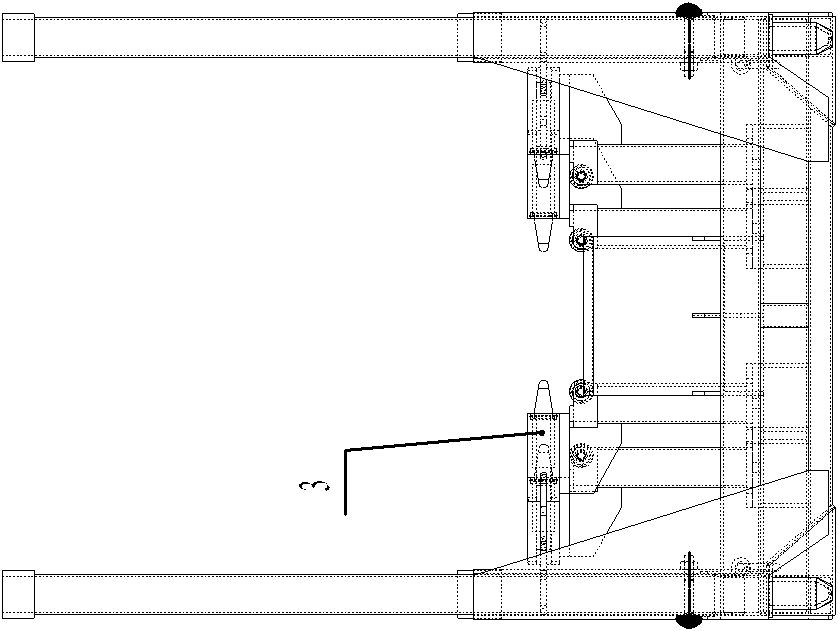

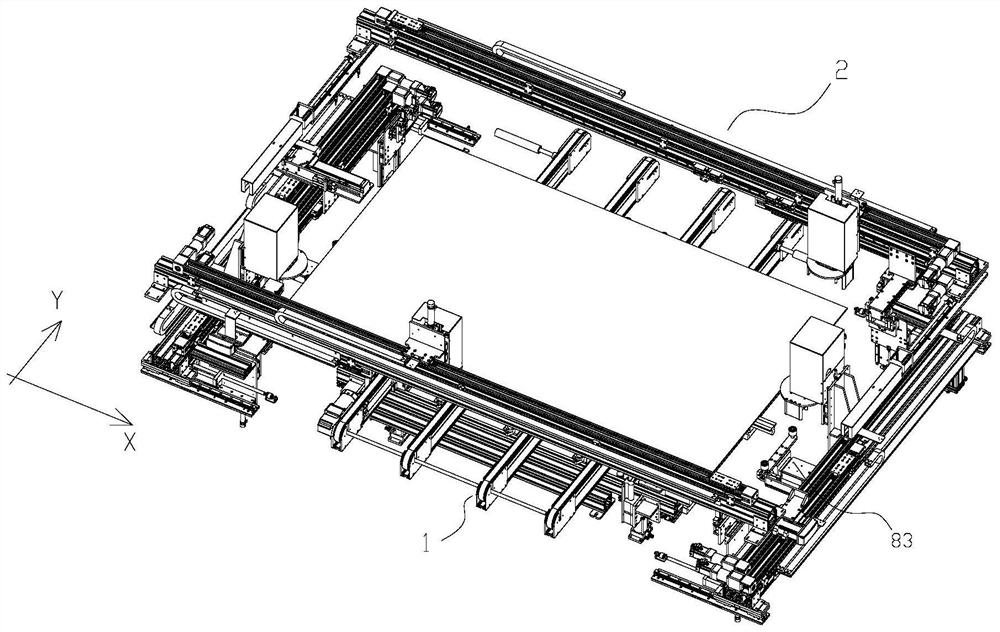

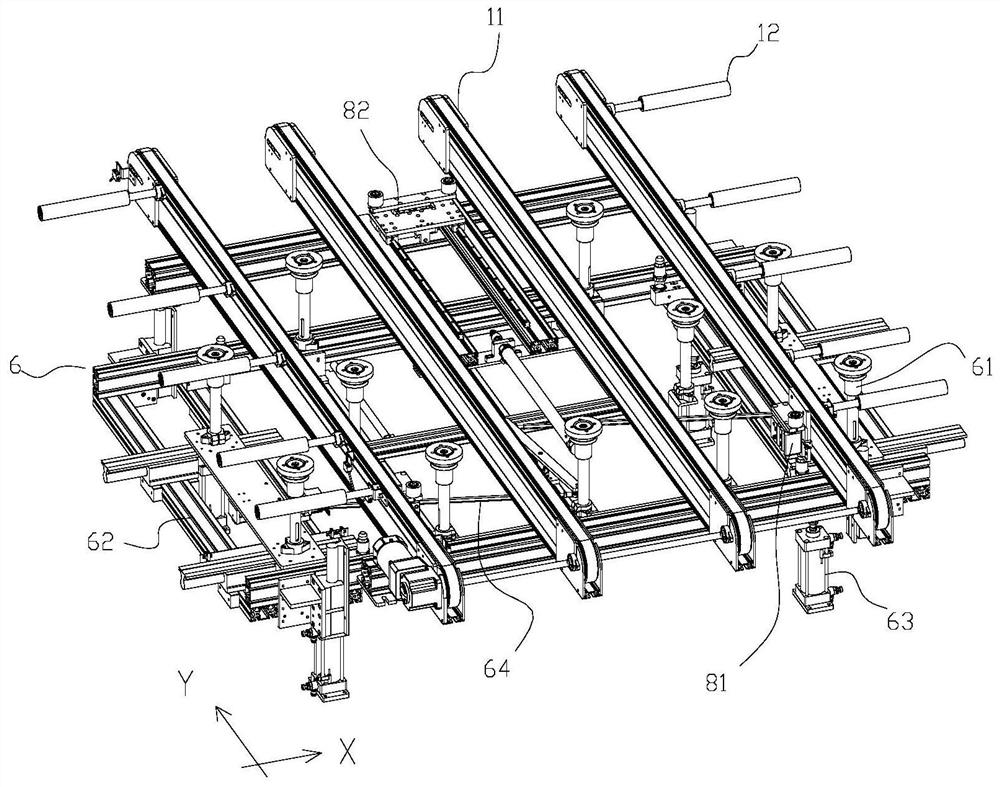

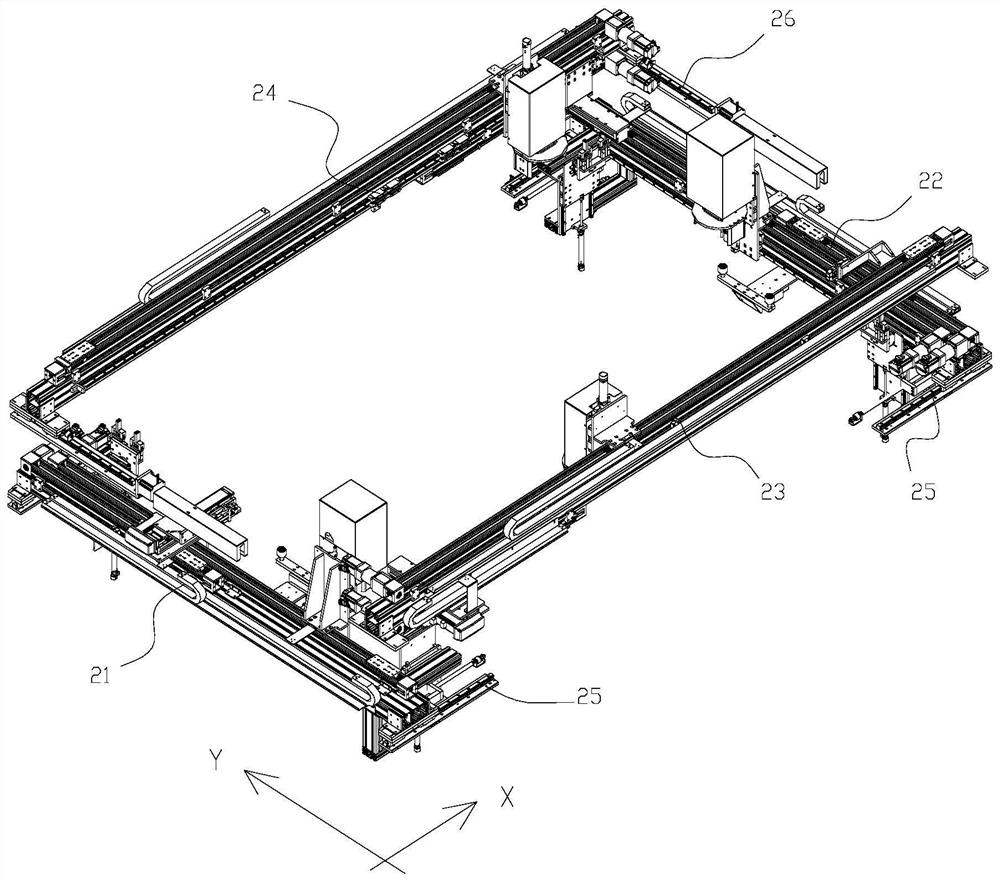

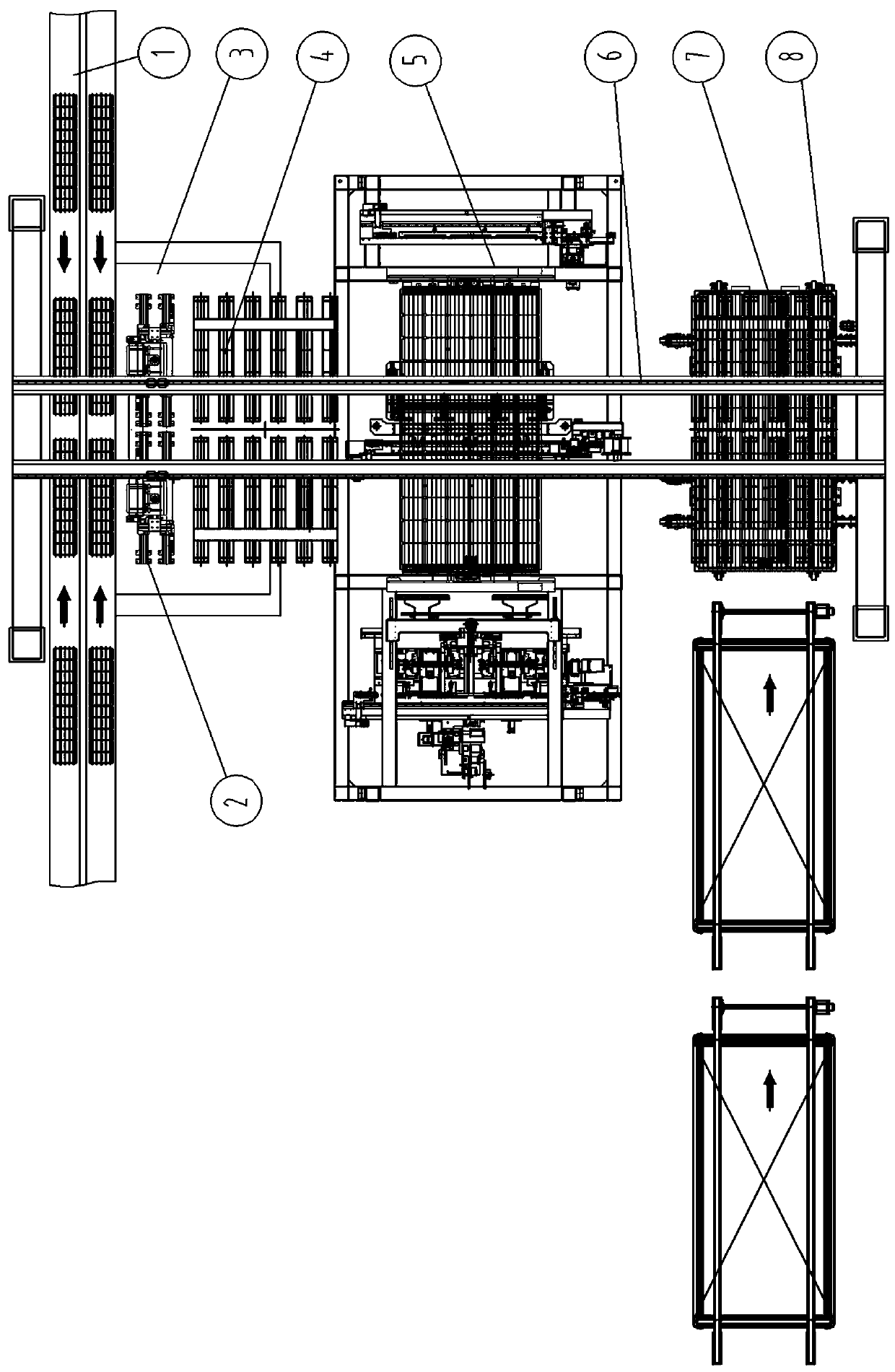

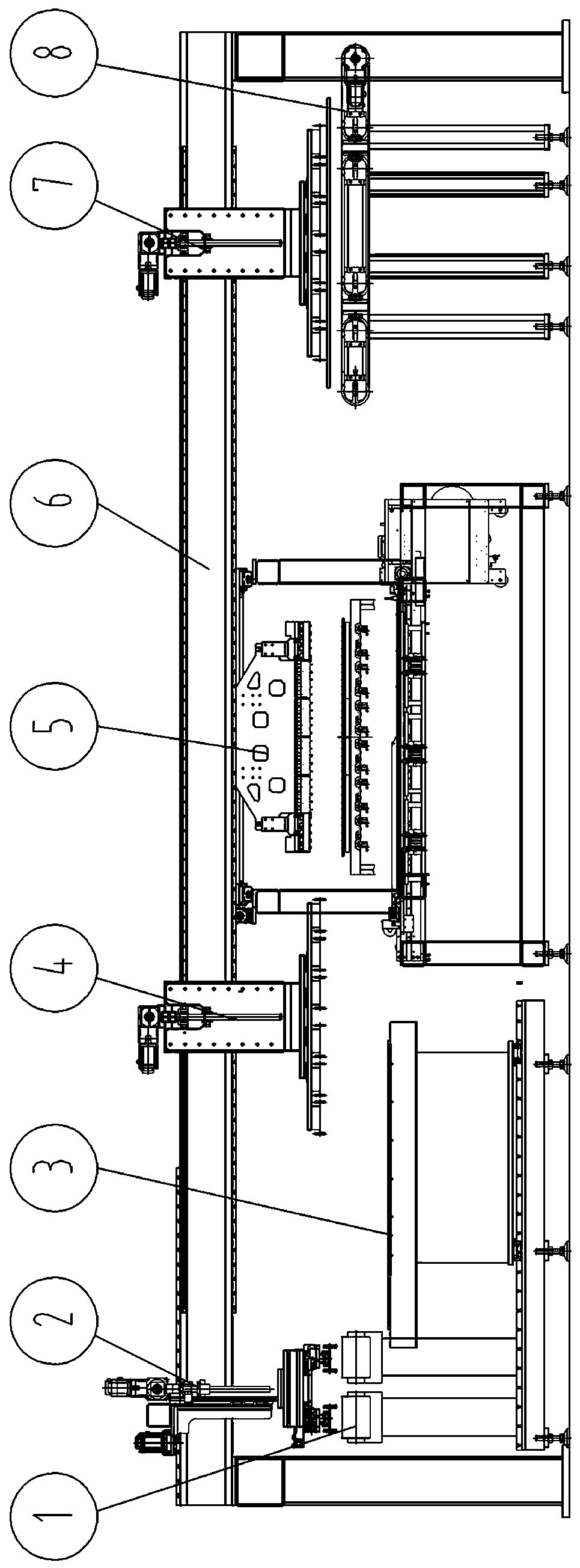

Photovoltaic assembly battery string precise layout and bus bar efficient welding machine

PendingCN110660720AExactly rightReduce movementFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringManipulator

The invention belongs to the technical field of photovoltaic module manufacturing equipment, and particularly relates to a photovoltaic assembly battery string precise layout and bus bar efficient welding machine. The photovoltaic assembly battery string precision layout and bus bar efficient welding machine is high in working efficiency. The machine comprises a conveying and positioning device (1), a battery string translation and adjustment manipulator (2), a buffer platform (3), an assembly feeding manipulator (4), a bus bar welding machine (5), a truss (6), an assembly discharging manipulator (7) and a receiving and conveying platform (8), and is characterized in that the conveying and positioning device (1) is arranged below the front end of the truss (6) in the length direction, thebattery string translation and adjustment manipulator (2) is arranged on the truss (6) above the conveying and positioning device (1), and the buffer platform (3) is arranged below the rear end of theconveying and positioning device (1).

Owner:大连昊霖智能装备有限公司

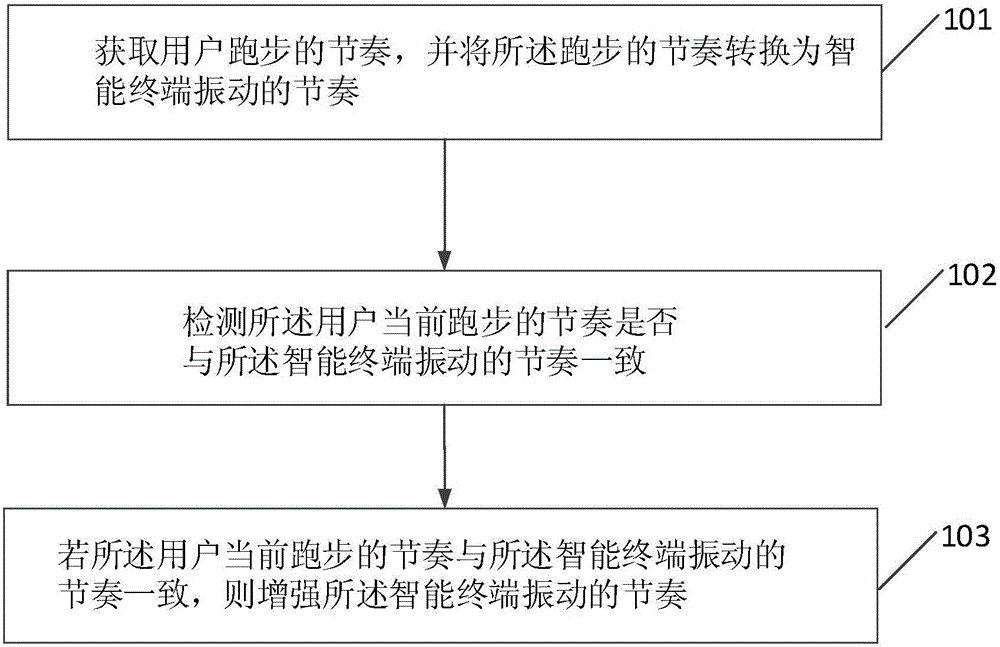

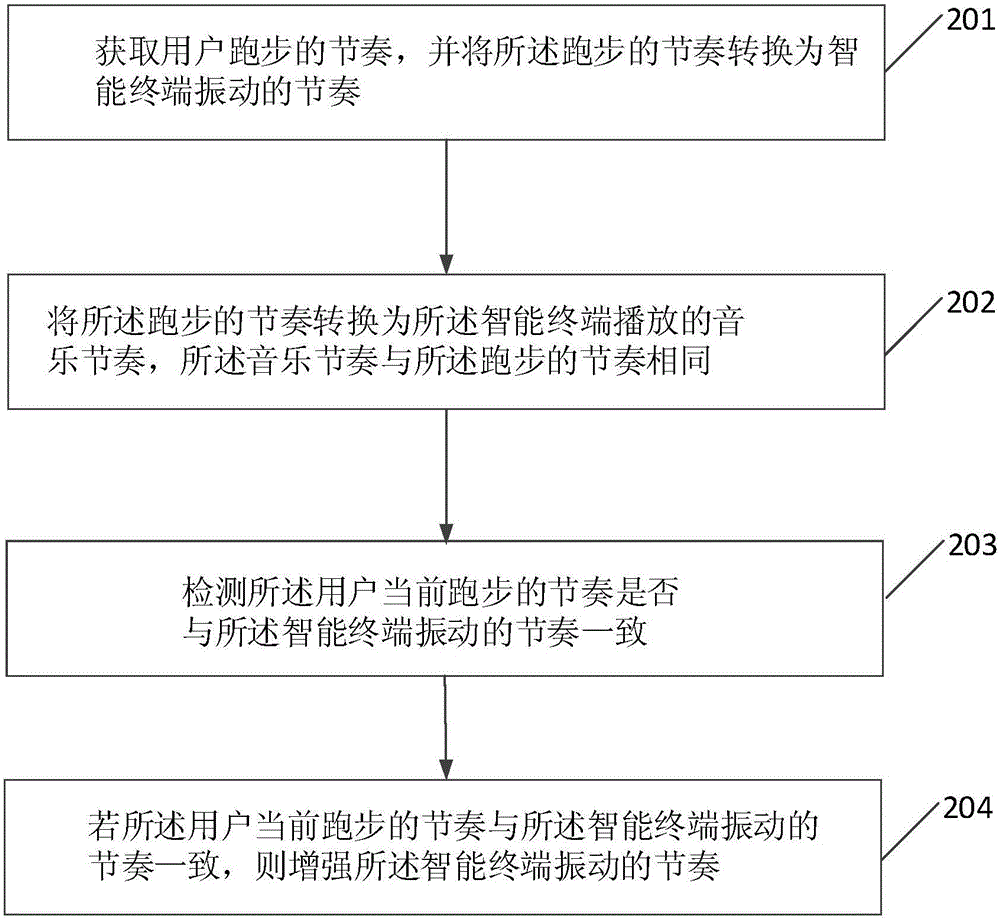

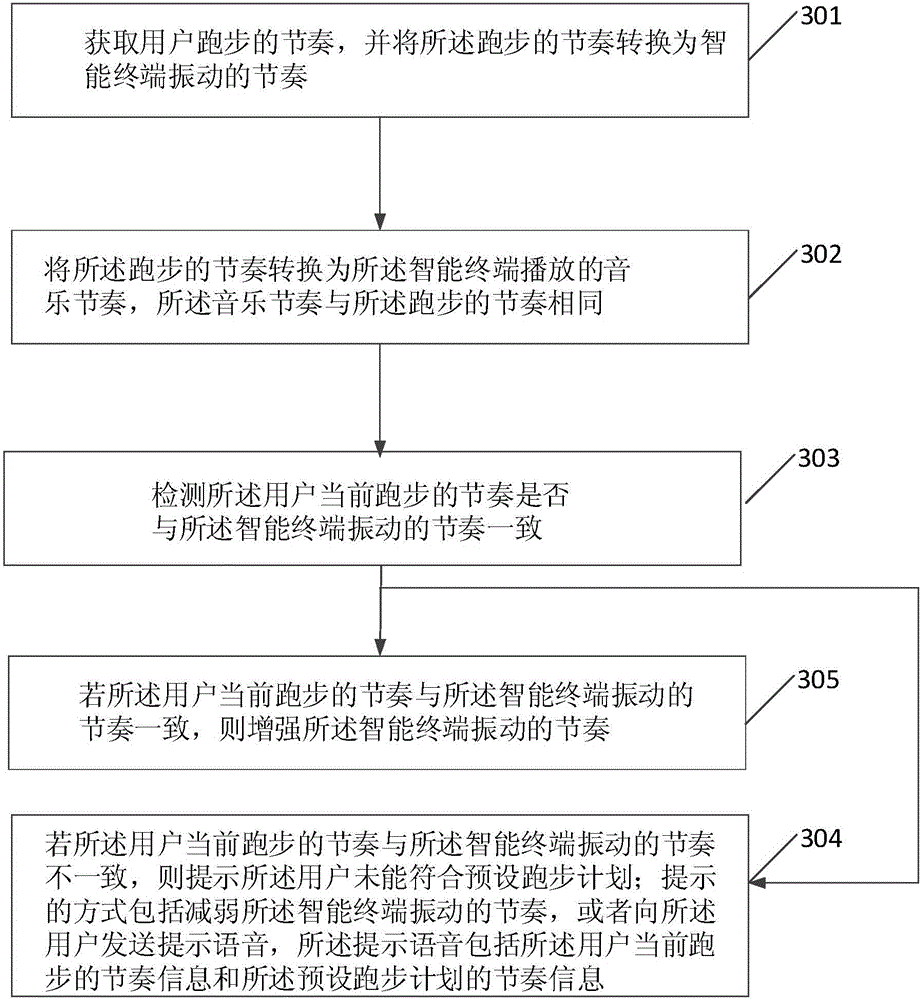

Method and device for displaying running rhythm

The invention discloses a method and a device for displaying running rhythm. The method comprises the steps of acquiring running rhythm of a user, and converting the running rhythm into vibration rhythm of an intelligent terminal; detecting whether the current running rhythm of the user is consistent with the vibration rhythm of the intelligent terminal or not; and if yes, strengthening the vibration rhythm of the intelligent terminal. Compared with voice guiding, the method is more convenient, and the user does not need to wear earphones, so that the method has a high valve for dressing products without loudspeakers, such as bracelets, and leg speed information in the training plan of running is externalized, and easy to percept; and therefore, the method has an effective guiding effect.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

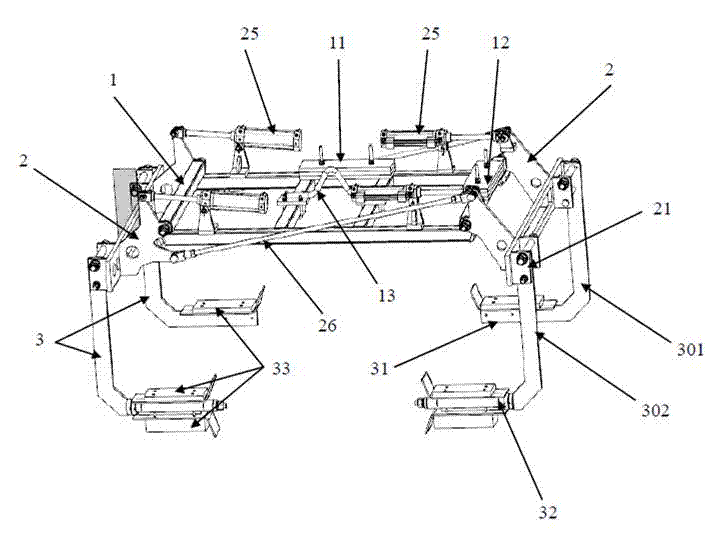

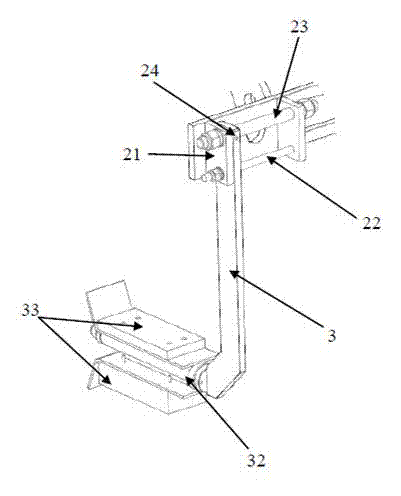

Main assembly unloading flexible sling device

The invention relates to an automobile sling, in particular to a main assembly unloading flexible sling device. The main assembly unloading flexible sling device comprises a sling framework (1), at least two swing arms (2) and at least two movable arms (3), the swing arms (2) are hinged to the two ends of the sling framework (1) respectively, the lower ends of the swing arms (2) are provided with swing arm fixing plates (21) which are provided with guiding rods (22) in the horizontal longitudinal direction, the movable arms (3) are provided with movable arm guiding holes, and the upper ends of the movable arms (3) are connected with the guiding rods (22) through the movable arm guiding holes. The main assembly unloading flexible sling device solves the problem that a traditional special sling can only be matched with one automobile type and cannot be suitable for flexile lines of multiple automobile types, the field occupation is reduced under the situation that the production requirement is met, and takt is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Device for metal material strip automatic feeding welding

InactiveCN109848552AFast tempoReduce the requirement for rotational positioning accuracyLaser beam welding apparatusEngineeringMetal

The invention relates to a metal material strip welding device, in particular to a device for metal material strip automatic feeding welding. The device for metal material strip automatic feeding welding comprises a rack component, a nut vibrating plate feeding component is mounted on the rack component, a nut feeding mechanism is mounted on the side edge of the nut vibrating plate feeding component, a station turntable mechanism is mounted on the inner side of the nut feeding mechanism, a welding jig mechanism is mounted on the inner side of the station turntable mechanism, an image detectionmechanism is mounted on the side edge of the welding jig mechanism, an unwinding mechanism, a defective product neaten mechanism, and a material strip feeding mechanism are mounted on the other sideedgeof the welding jig mechanism, and a winding mechanism is mounted on the side wall of the rack component. According to the device for metal material strip automatic feeding welding, the takt is high, the defect rate is low, and the stability is good; the device for metal material strip automatic feeding welding has the simple structure, the low manufacturing cost, and high cost performance; andthe disadvantages of low takt, inaccurate welding positioning, high defect rate after welding and poor stability generallyexisting inan existing production device areovercome.

Owner:SHANGHAI SHARETEK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com