Induction quenching machining tool for flake workpieces

A sheet-shaped workpiece, induction hardening technology, applied in the field of induction hardening, can solve the problems that cannot meet the process requirements, the lift of the sheet-shaped workpiece is small, different, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in conjunction with accompanying drawing and specific embodiment:

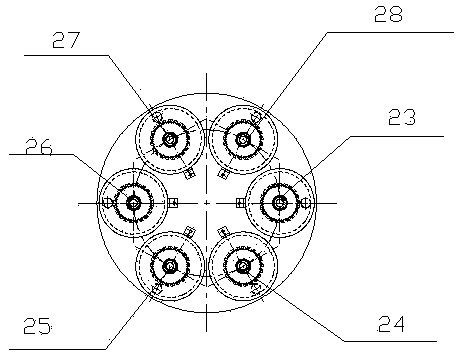

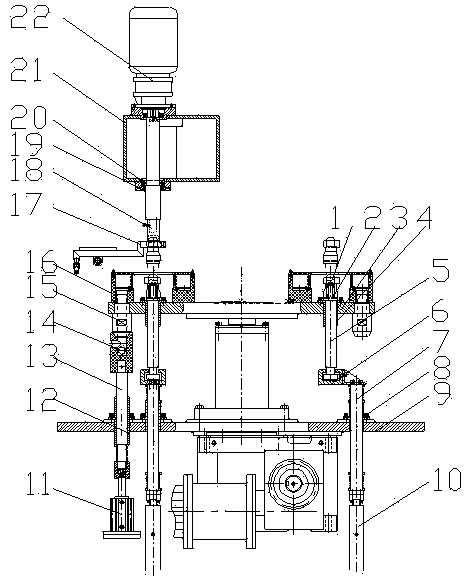

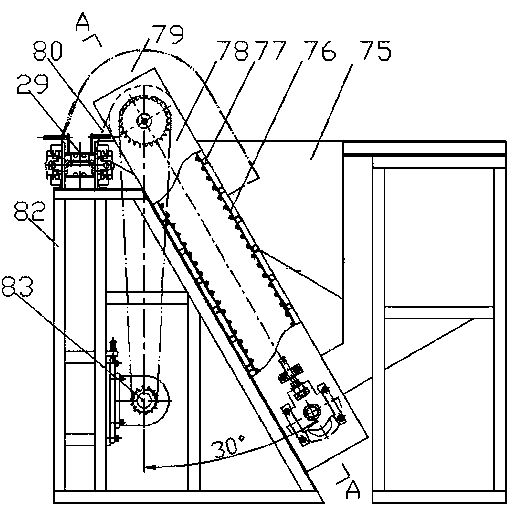

[0036] Such as figure 1As shown, a sheet workpiece induction hardening machine tool, said sheet workpiece induction hardening machine tool includes a bed, a rotary table 3, an automatic feeding mechanism, a material selection and sorting mechanism, a positioning and pushing mechanism, a loading and unloading mechanism, and a rotary mechanism; The rotary table 3 is a disc structure arranged on the bed 9; the rotary table 3 has six stations uniformly distributed along the circumference: feeding position 23, transition position I 24, transition position II 25, Quenching position 26, air injection position 27, and material discharge position 28; the automatic feeding mechanism, material selection and sorting mechanism, positioning and pushing mechanism, loading and unloading mechanism and rotary mechanism are arranged at the front of the material loading level 23; corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com