Quenching system and method applied to workpiece induction quenching

An induction quenching and quenching system technology, applied in the field of workpiece or part quenching, can solve the problems of poor heating effect, high energy consumption, unfavorable installation, etc., and achieve the effects of convenient operation, compact equipment structure, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

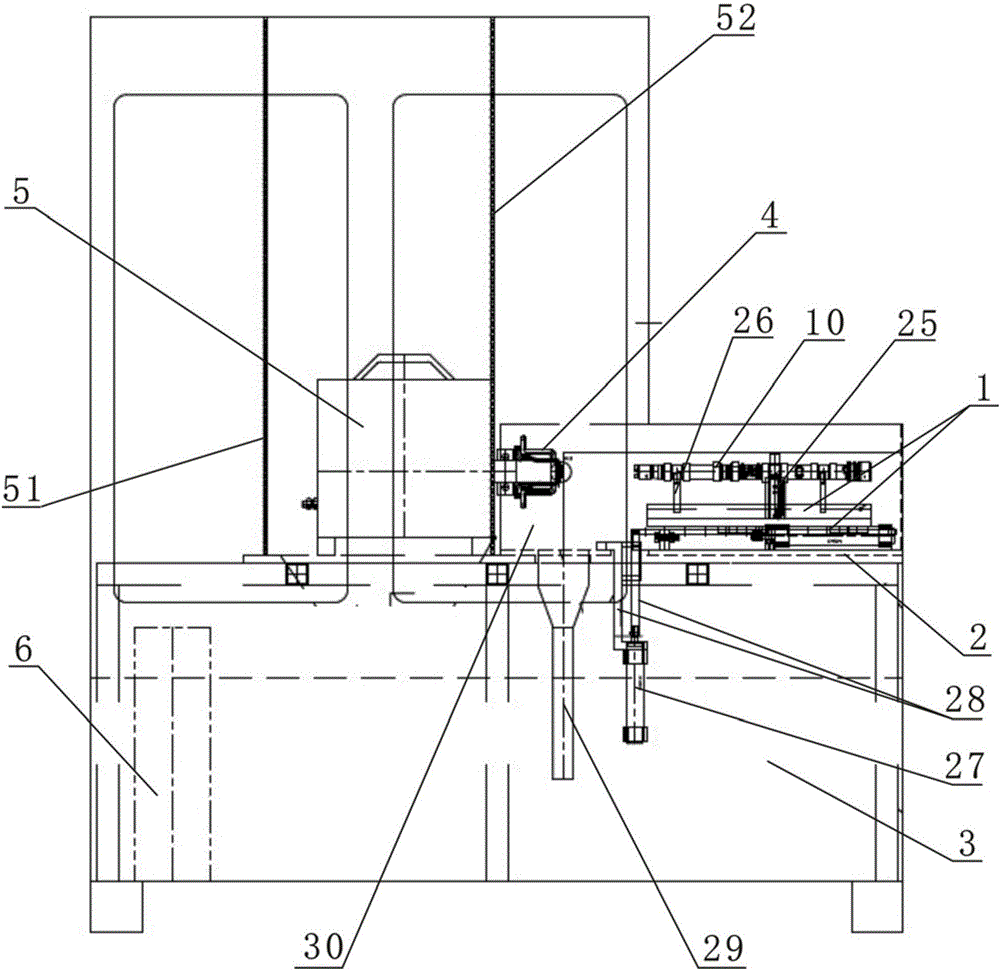

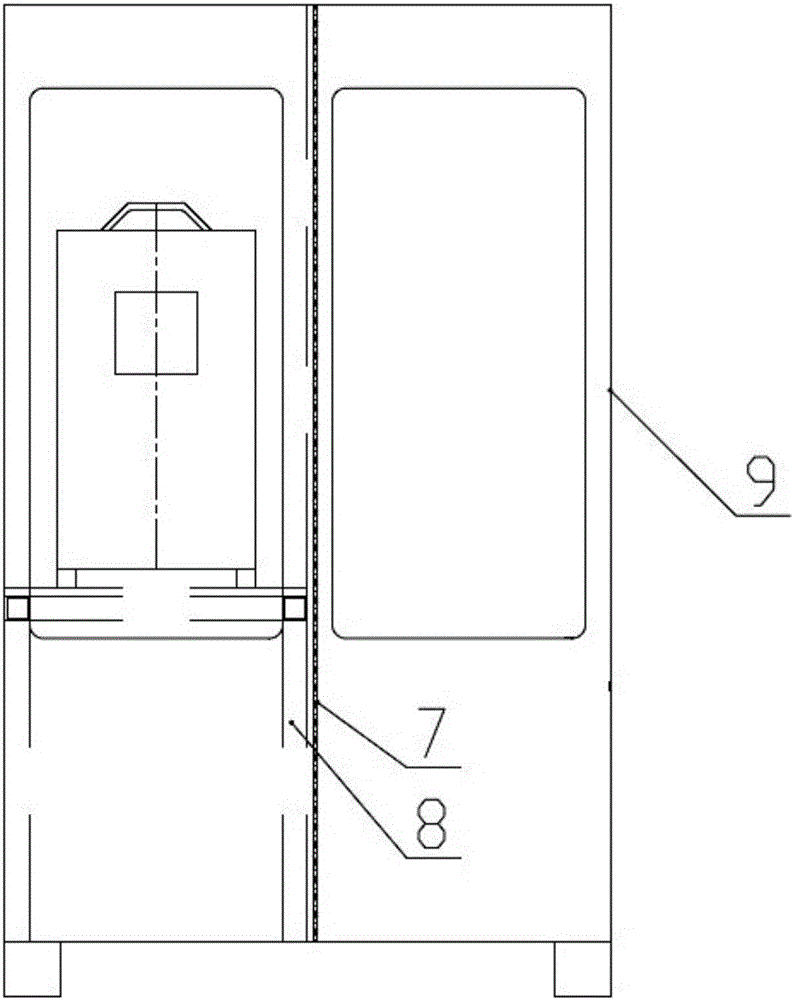

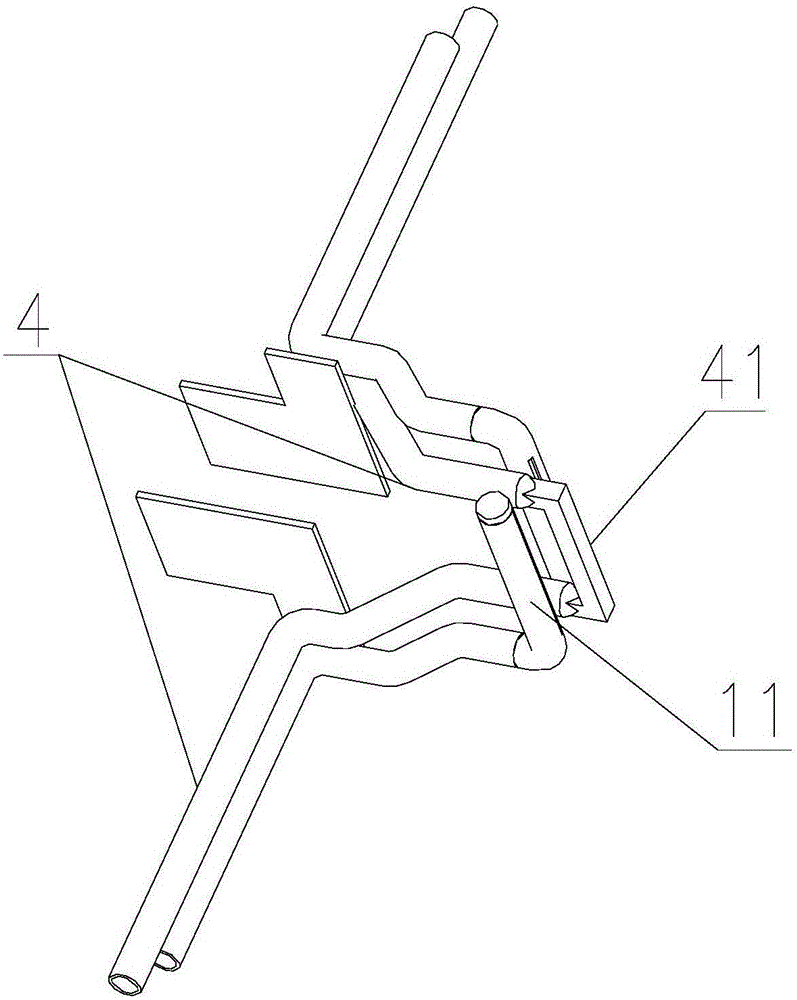

[0035] Such as Figure 1 to Figure 7 As shown, a quenching system applied to workpiece induction quenching, including a sliding assembly 1, a quenching bracket 2, a drainage pipe 29, a water tank 3, an induction coil heating device 4, a transformer 5, a quenching liquid tank 12, and a cooling water tank 13 And the refrigeration industrial air conditioner 15, the sliding assembly 1 is slidably installed on the quenching bracket 2, and the workpiece 10 is installed on the upper end of the sliding assembly 1, and the workpiece 10 in this embodiment is a camshaft or a camshaft tail groove. The induction coil heating device 4 is electrically connected to the transformer 5 , the transformer 5 provides electric energy for the induction coil heating device 4 , and the induction coil of the induction coil heating device 4 can inductively heat the workpiece 10 . The induction coil heating device 4 is set corresponding to the workpiece 10 on the sliding assembly 1; when the workpiece 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com