Steel coil storeroom position dynamic distribution method under position-data-reference-free condition

A dynamic allocation and database technology, applied in data processing applications, instruments, logistics, etc., to improve the overall quality, ensure accuracy, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

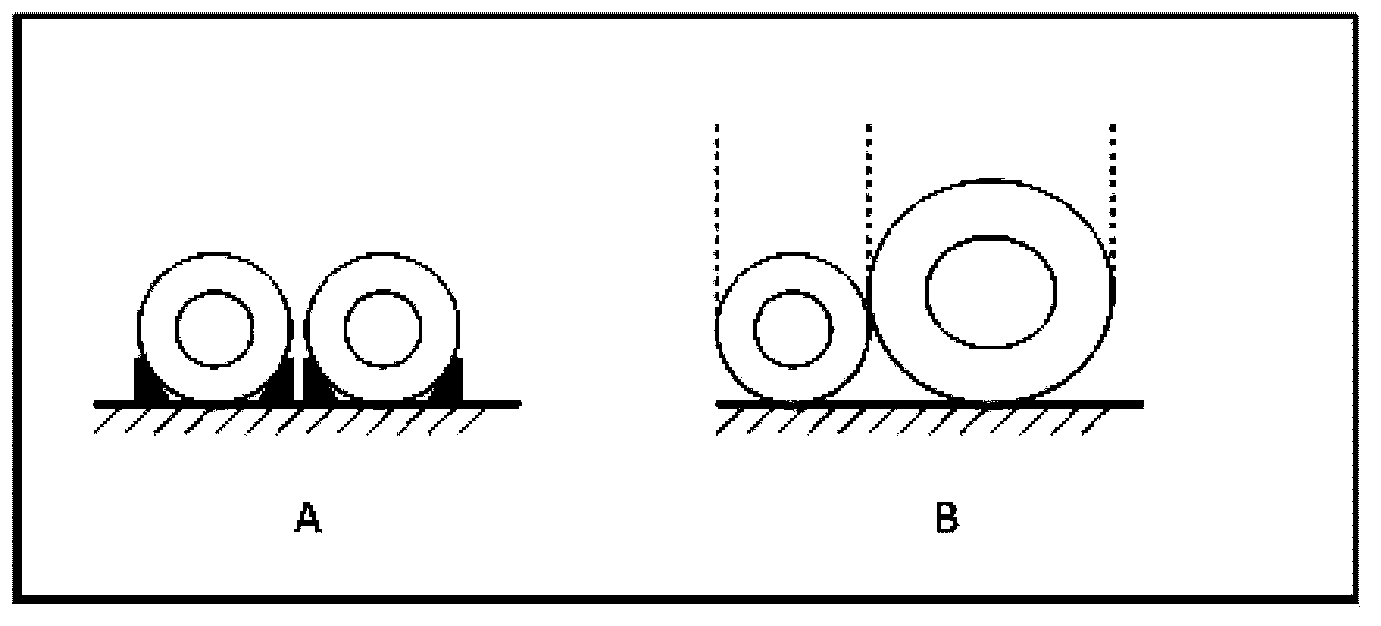

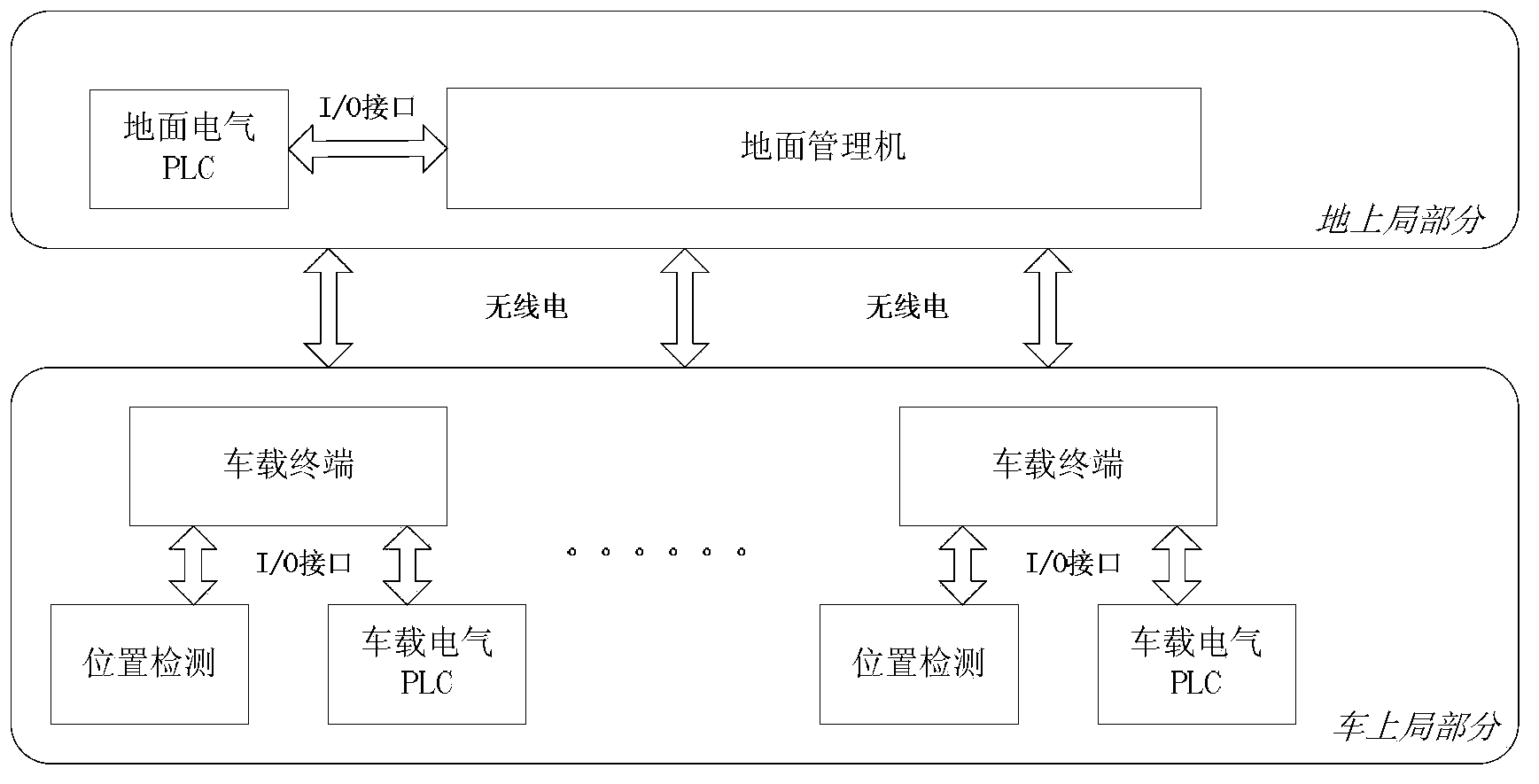

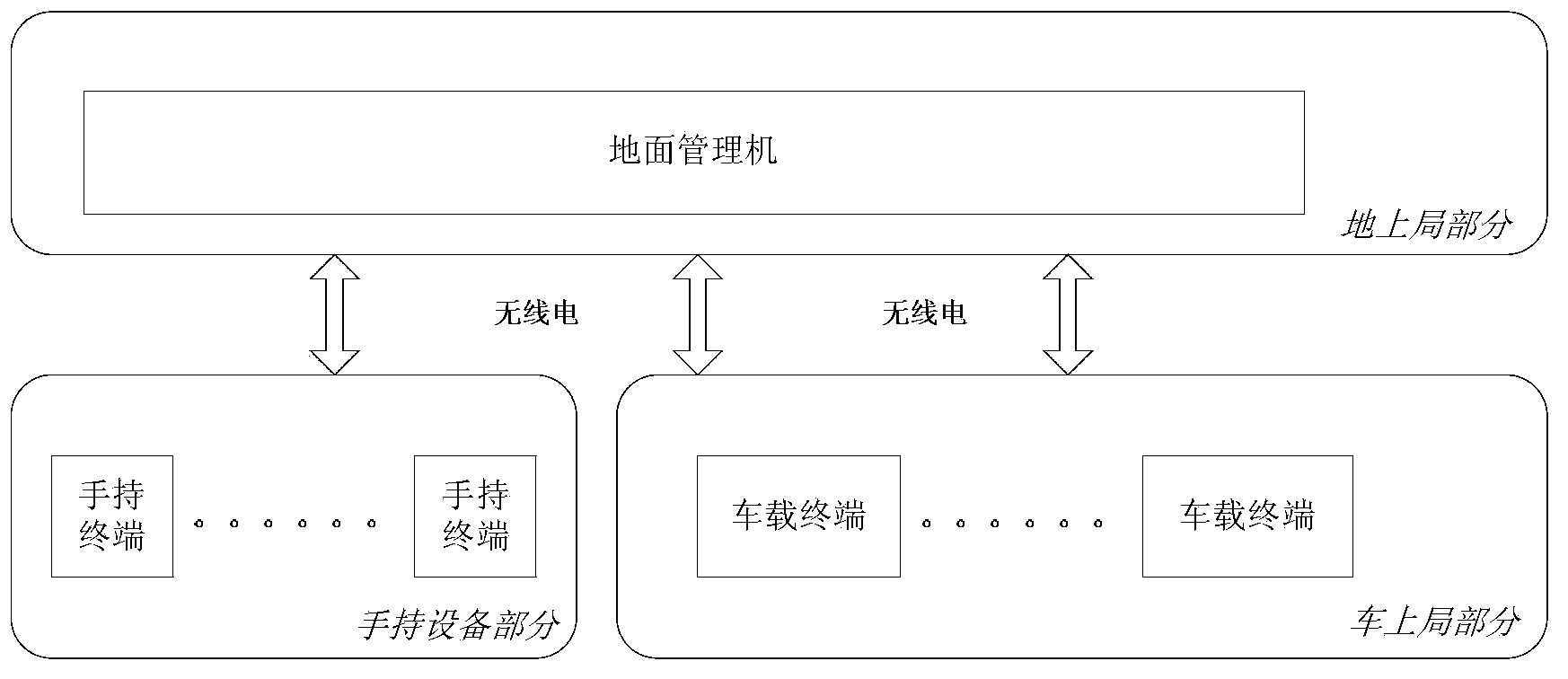

[0073] The physical conditions of the dynamic steel coil storage area are very different from those of the traditional static storage locations of the steel coil storage. According to the special requirements for stacking steel coils, the storage area of the steel coil warehouse adopts an open and dynamic storage location form, that is, there is no fixed stacking location, and the physical size of the storage location is based on the coil diameter of the storage steel coil. The physical position occupied by the steel coil is the way of storage location. This program requires certain hardware support: ground server computer, wireless base station, vehicle terminal computer and handheld scanning terminal. The block diagram of the system is at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com