Device for metal material strip automatic feeding welding

A technology of automatic feeding and metal strips, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high product defect rate, inaccurate welding positioning, poor stability, etc., to reduce processing and procurement costs. , fast tempo, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

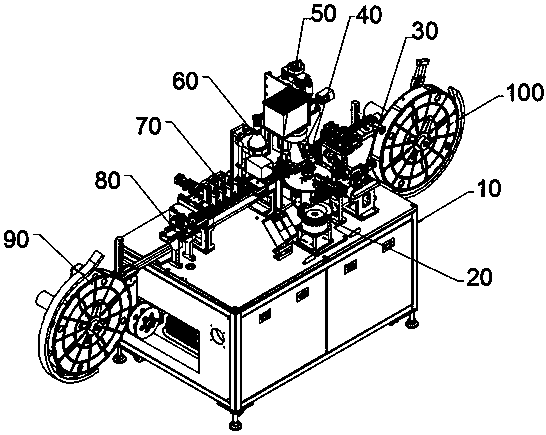

[0029] see figure 1 , in the embodiment of the present invention, a kind of equipment that is used for the automatic feeding welding of metal strip, comprises frame part 10, and nut vibrating plate feeding part 20 is installed on described frame part 10, and nut vibrating plate feeding part A nut feeding mechanism 30 is installed on the side of 20, a station turntable mechanism 40 is installed on the frame part 10 inside the nut feeding mechanism 30, and a welding jig is installed on the frame part 10 inside the station turntable mechanism 40. Mechanism 50, a laser welding head is installed on the upper end of the welding jig mechanism 50, an image detection mechanism 60 is installed on the side of the welding jig mechanism 50, and an unwinding mechanism 100 is installed on the other side of the welding jig mechanism 50. A defective product marking mechanism 70 is installed on the side of the detection mechanism 60 , a material tape feeding mechanism 80 is installed on the sid...

Embodiment 2

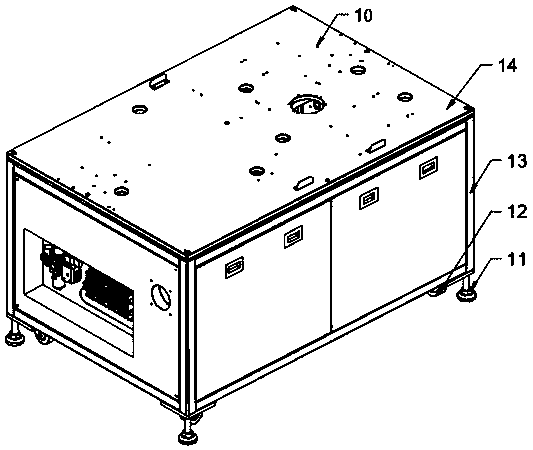

[0032] A kind of equipment for automatic feeding and welding of metal strips, please refer to figure 2 , the embodiment of the present invention is further defined on the basis of embodiment 1.

[0033] Further, the frame part 10 is provided with a square steel welding frame 13, and the bottom of the square steel welding frame 13 is fixed with an array of supporting cups 11 and casters 12, and the square steel welding frame 13 is surrounded by outer cover doors. , The top of the square steel welding frame 13 is provided with a table panel 14 .

Embodiment 3

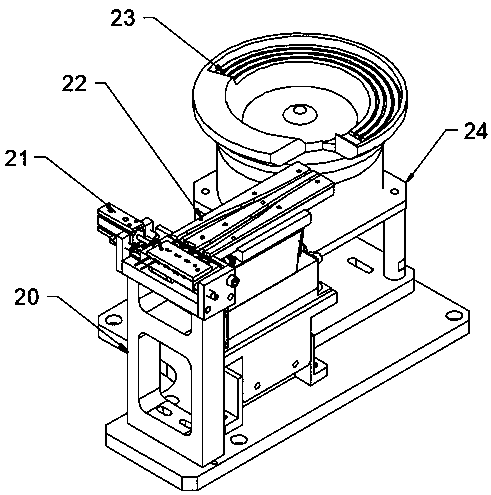

[0035] A kind of equipment for automatic feeding and welding of metal strips, please refer to image 3 , the embodiment of the present invention is further defined on the basis of embodiment 1.

[0036] Further, the nut vibrating plate feeding part 20 is provided with a vibrating plate 23, the vibrating plate 23 is fixed by a vibrating plate mounting frame 24, a linear vibrating track 22 is installed on the side of the vibrating plate 23, and the side of the linear vibrating track 22 Cylinder 21 is installed on the limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com