Prized body automatic locking device

A technology of automatic locking and rotating driving device, which is applied in the directions of motor vehicles, transportation and packaging, conveyor objects, etc., can solve the problems of long manual operation time, large safety hazards for operators, and low efficiency, and achieves a simple structure. , reliable performance, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

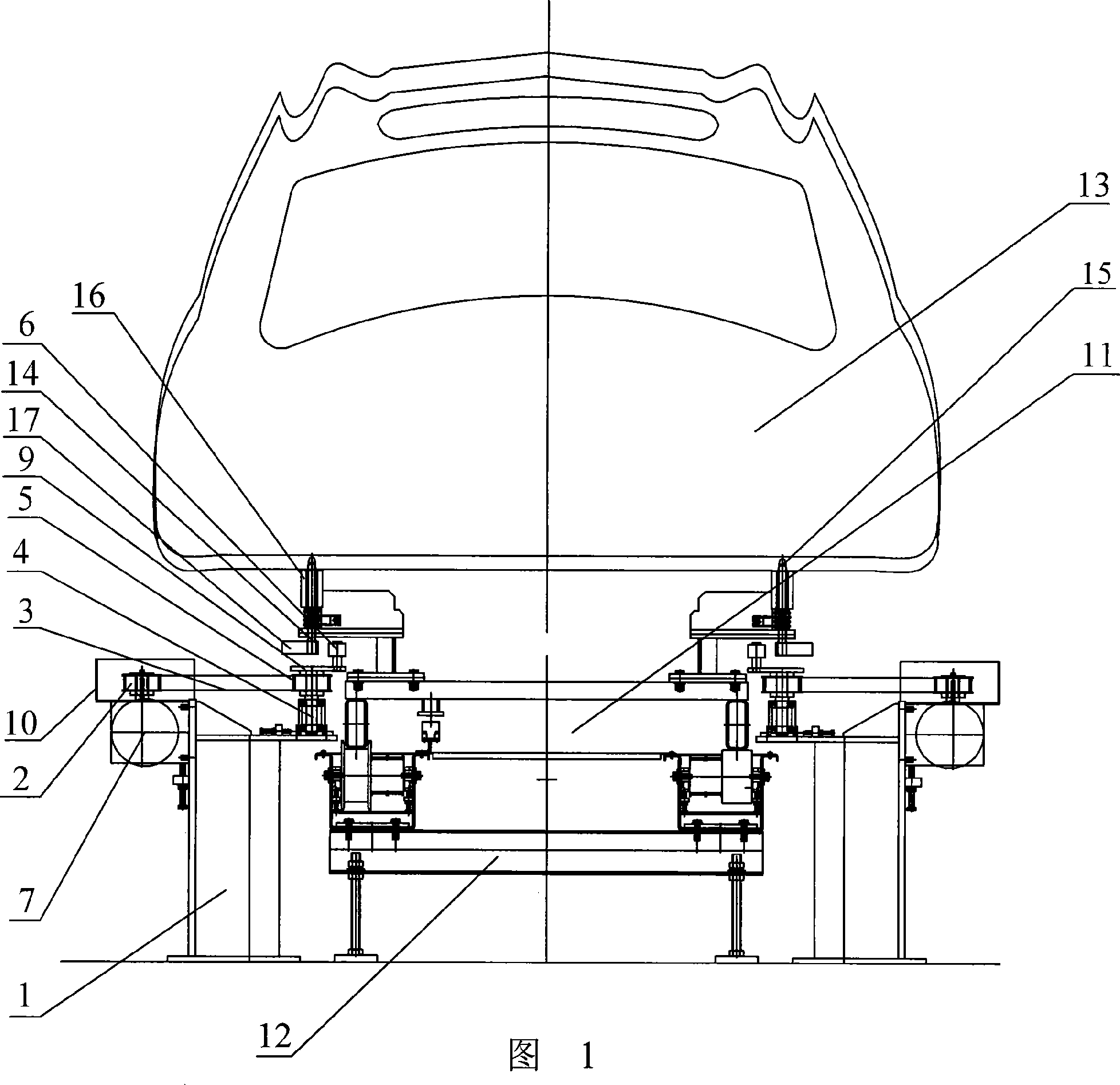

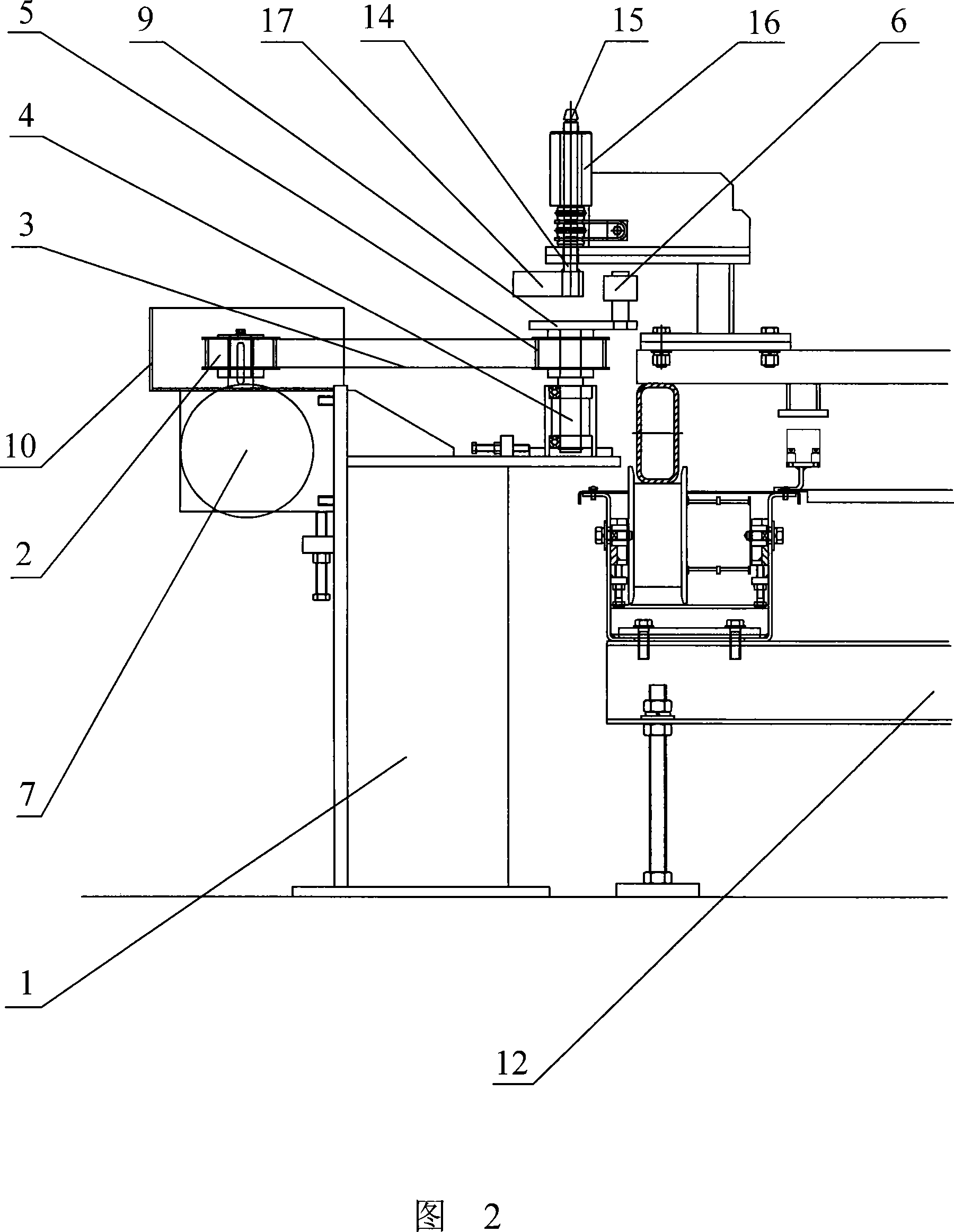

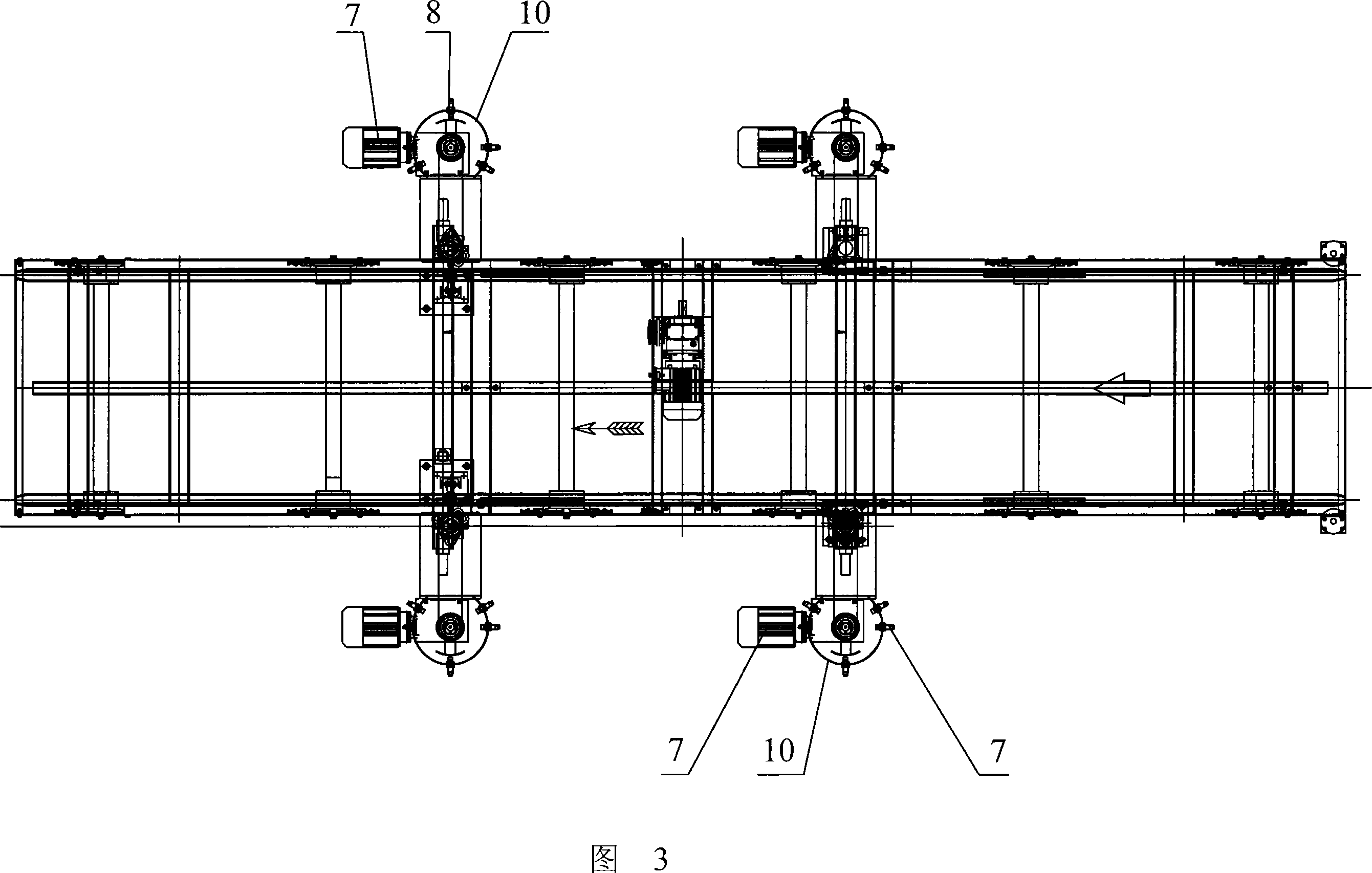

[0015] As shown in the figure: a locking shaft 14 is provided on the frame 1 below the positioning support hole of the corresponding workpiece, and the locking shaft 14 is connected with the rotating drive device arranged on the frame 1. The locking piece 15 that can be inserted into the positioning support hole and protrudes laterally is provided with a supporting device for the workpiece on the frame 1 below the workpiece or is set on the locking rotating shaft 14. During work, the supporting device supports the workpiece and locks it. After the rotating shaft 14 rotates, the locking piece 15 is driven to rotate at a certain angle, and the workpiece and the frame 1 are connected as one.

[0016] The supporting device is a supporting sleeve 16 sleeved outside the locking rotating shaft 14, and the lower end of the supporting sleeve 16 is pressed against the frame 1 below the workpiece. At the bottom end of the locking rotating shaft 14, there is provided a lug 17 protruding l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com