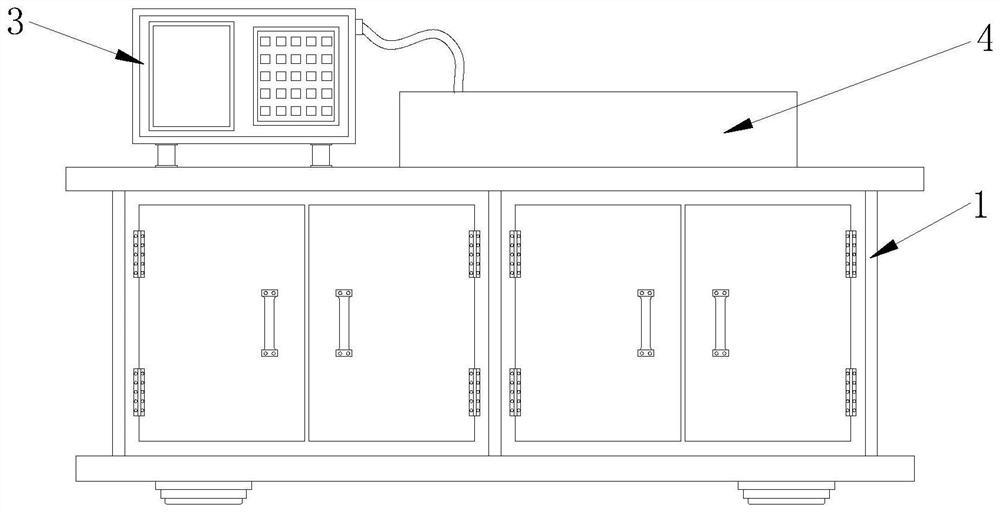

Patents

Literature

108results about How to "Realize automatic tightening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

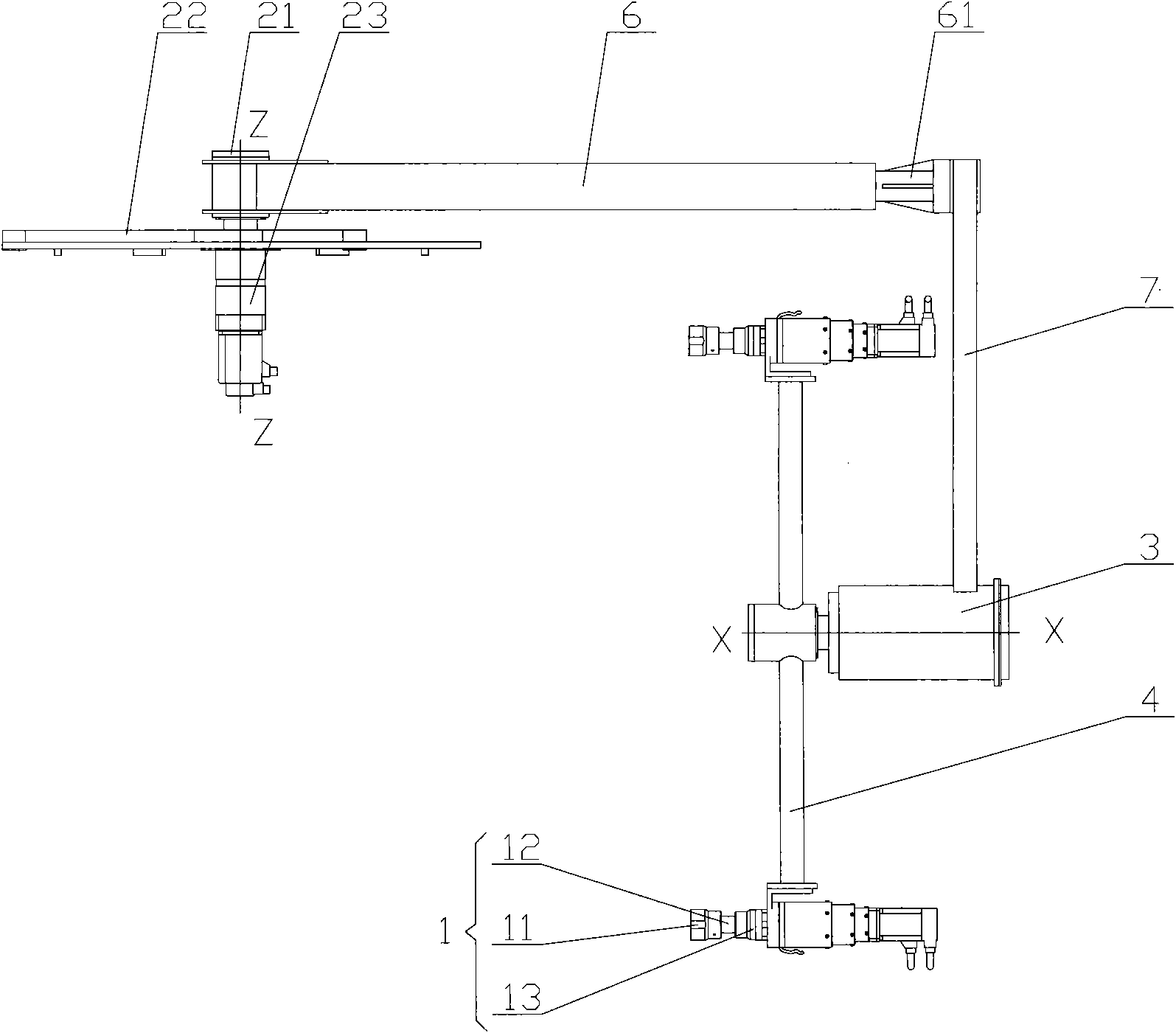

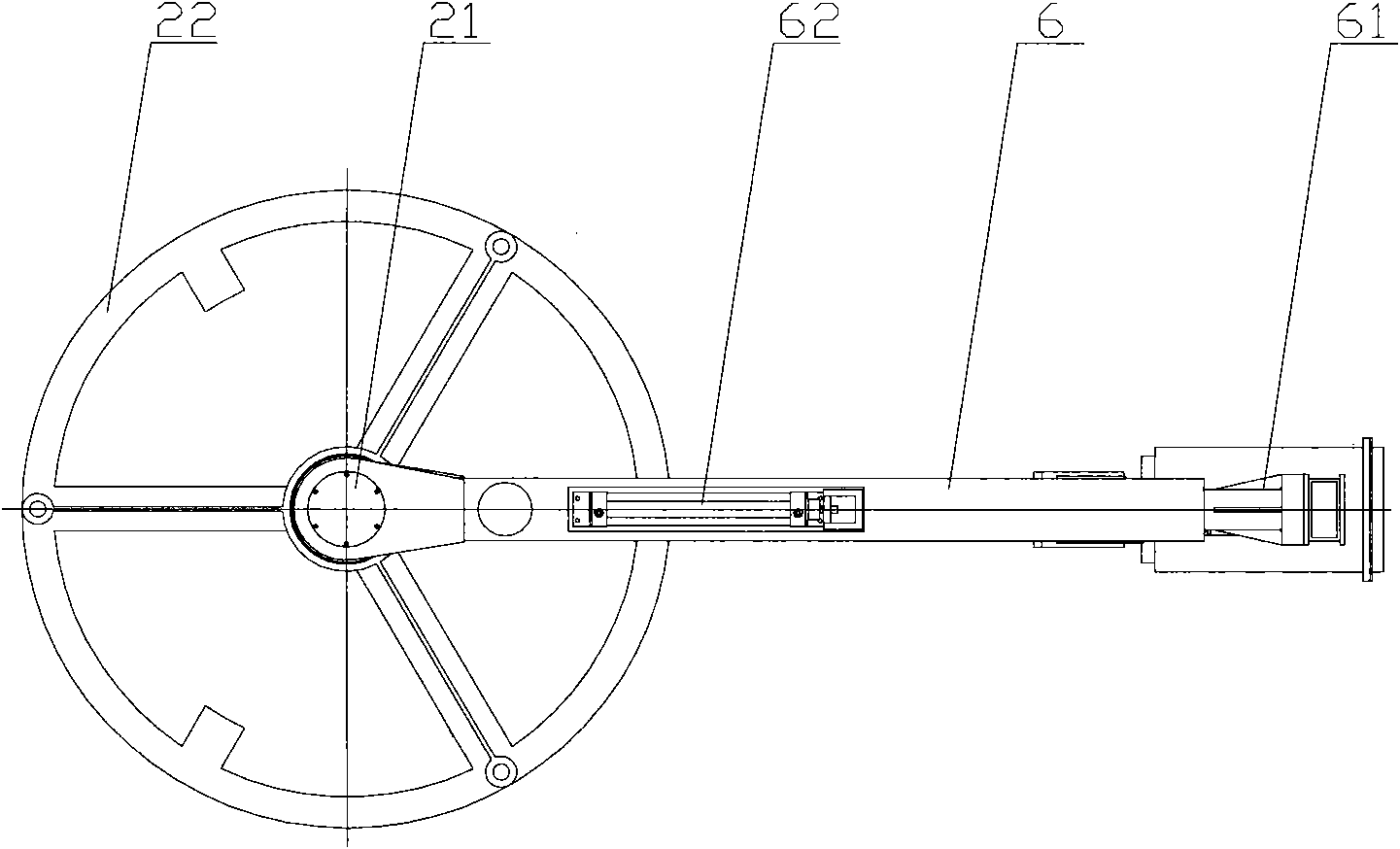

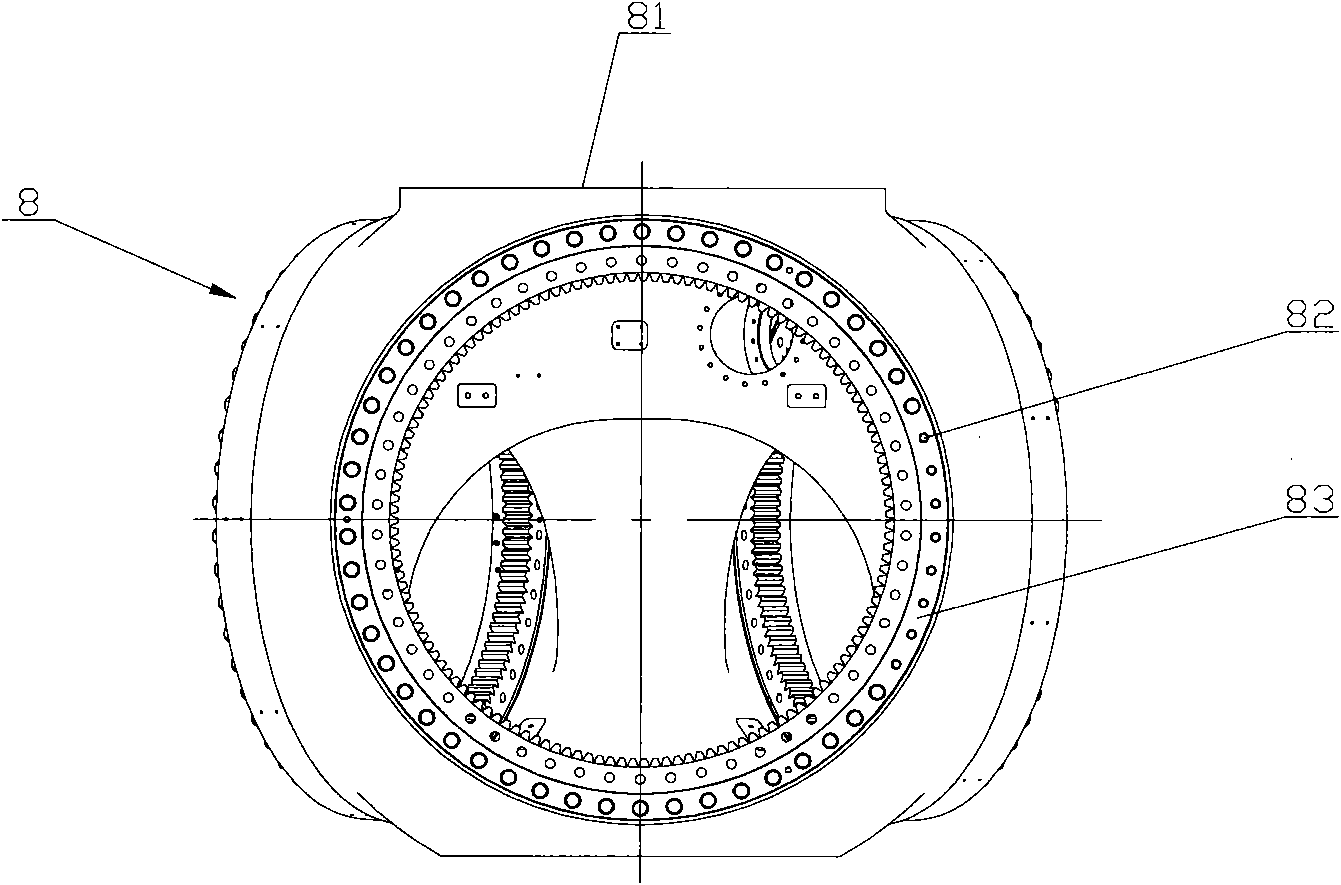

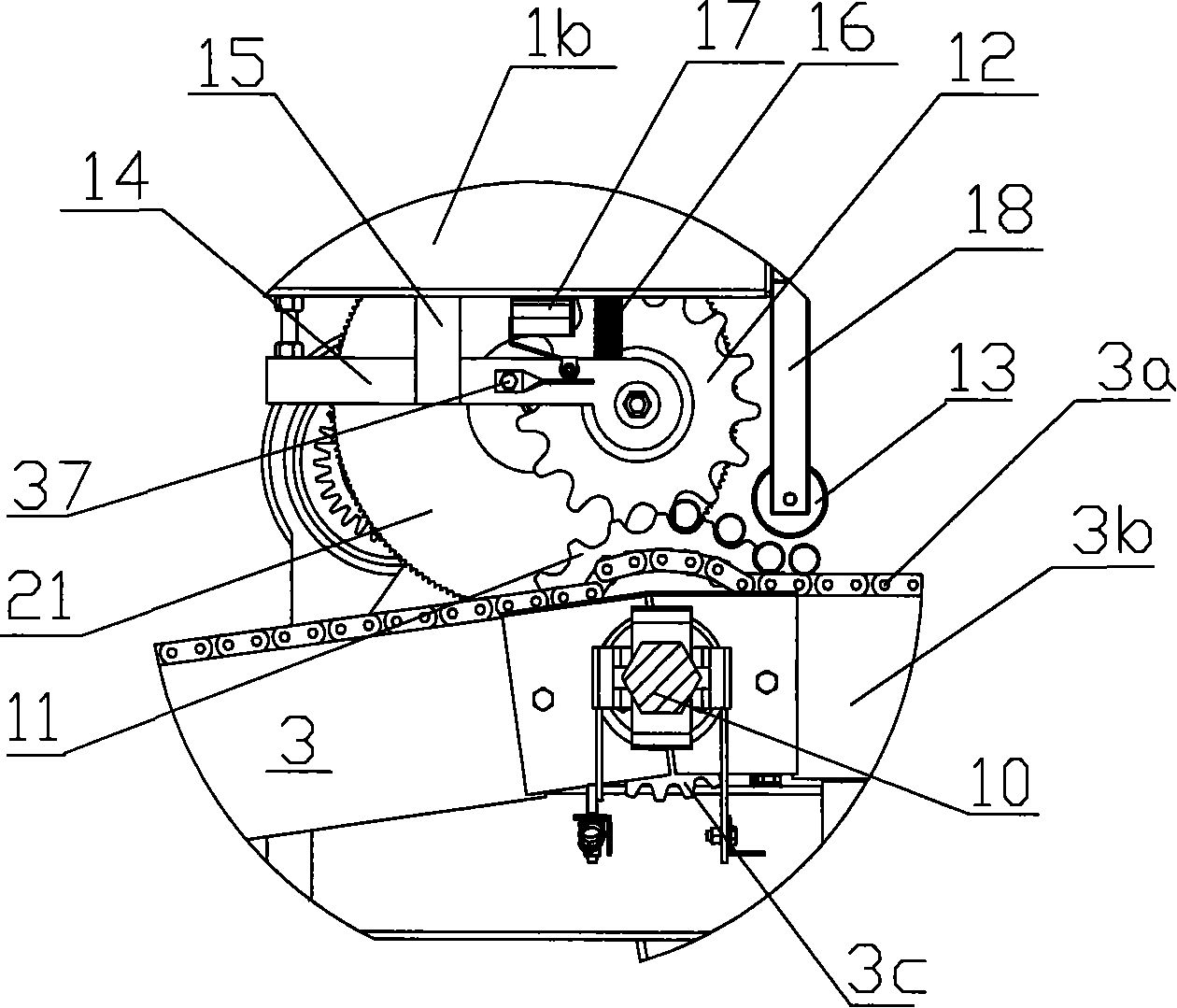

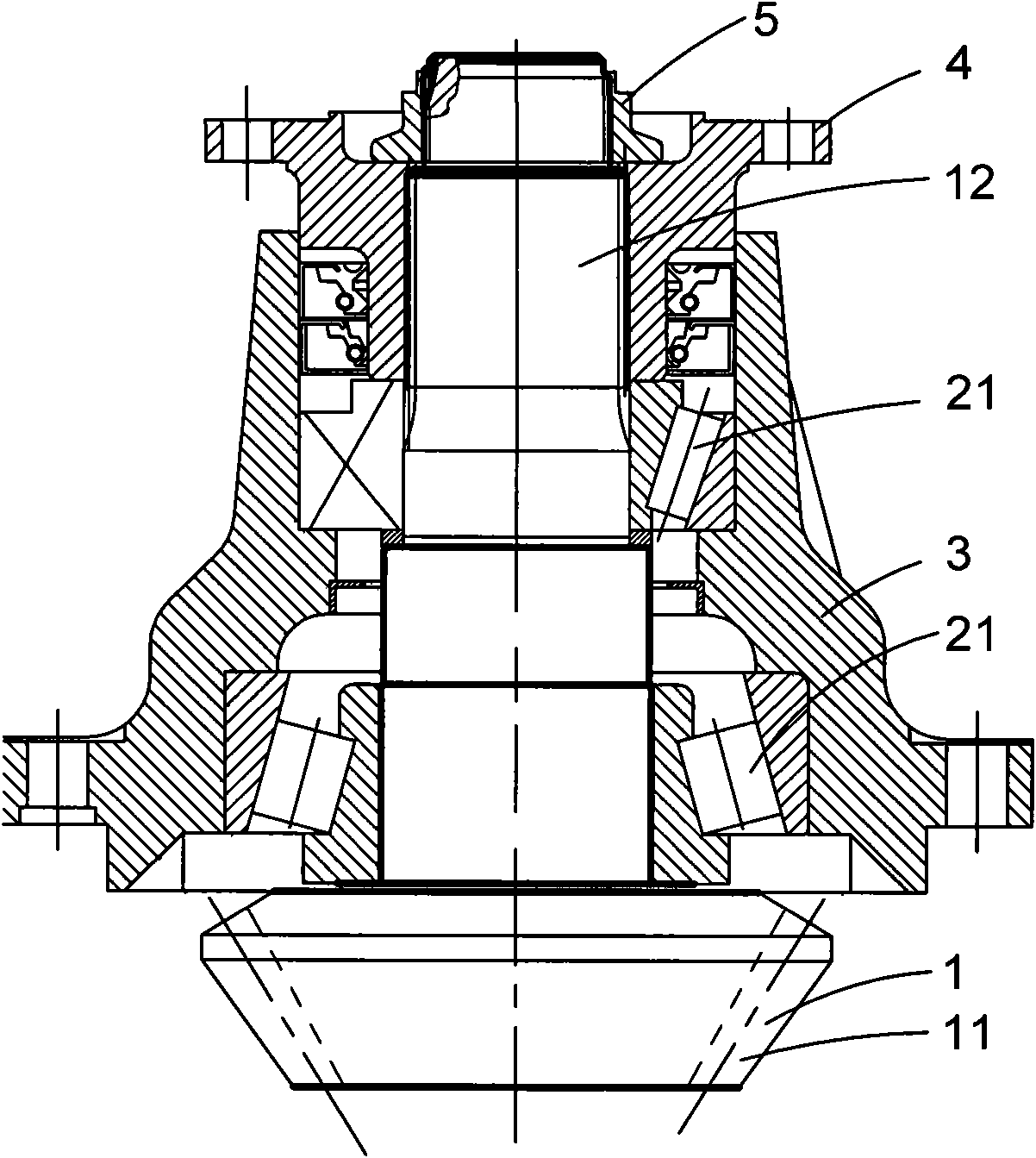

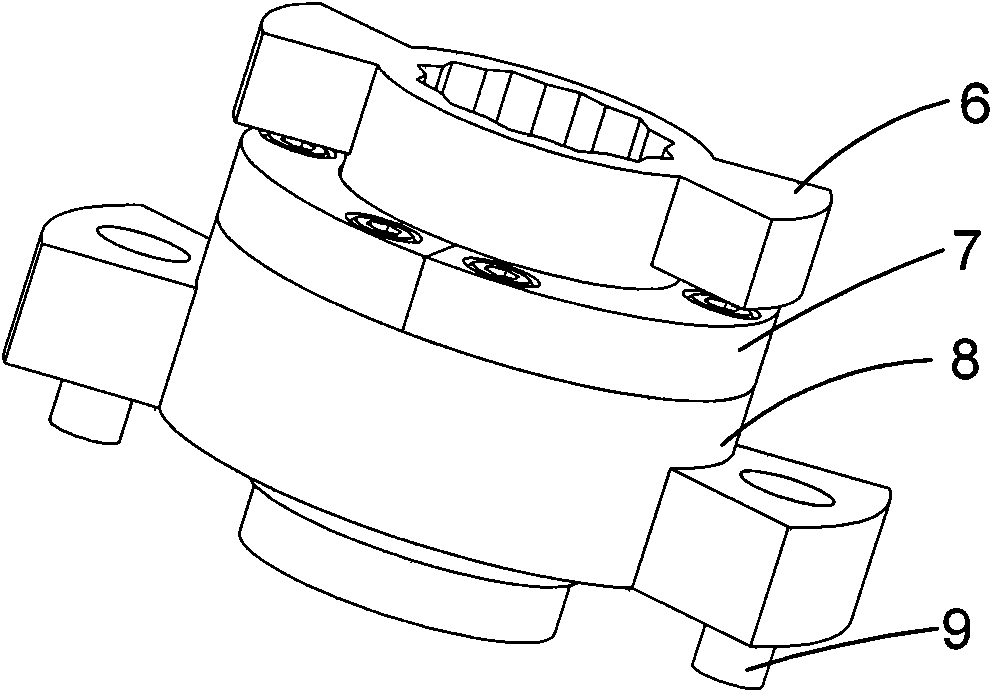

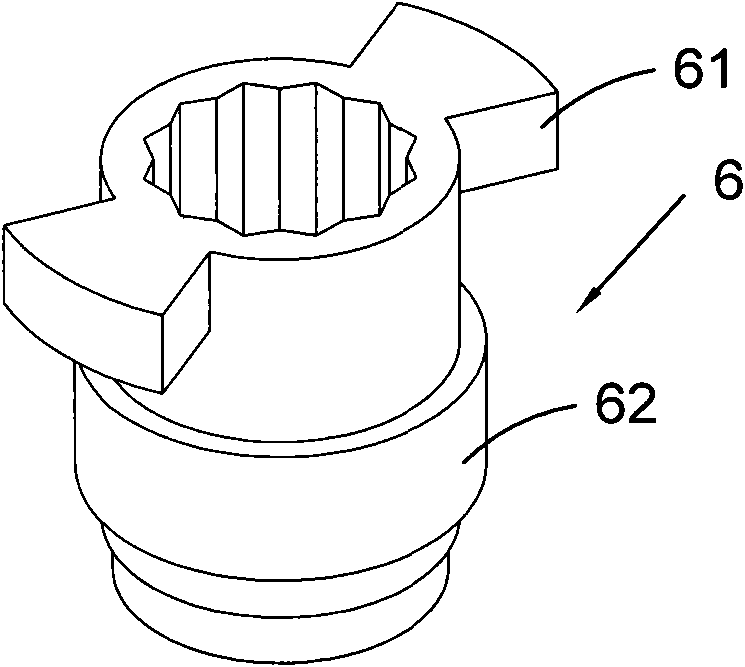

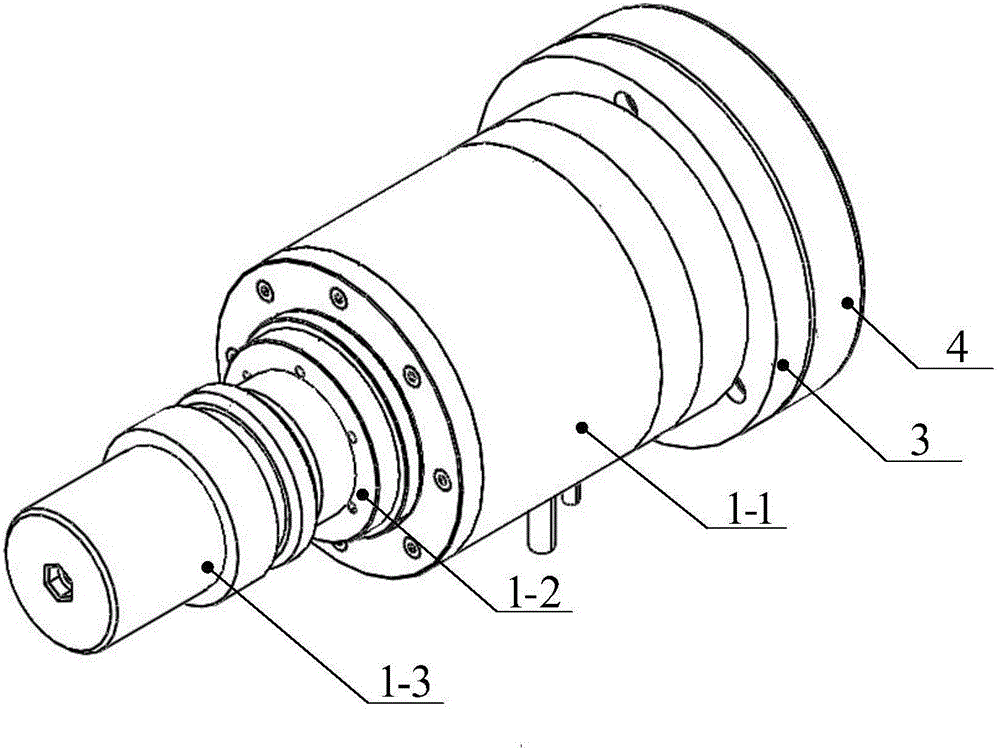

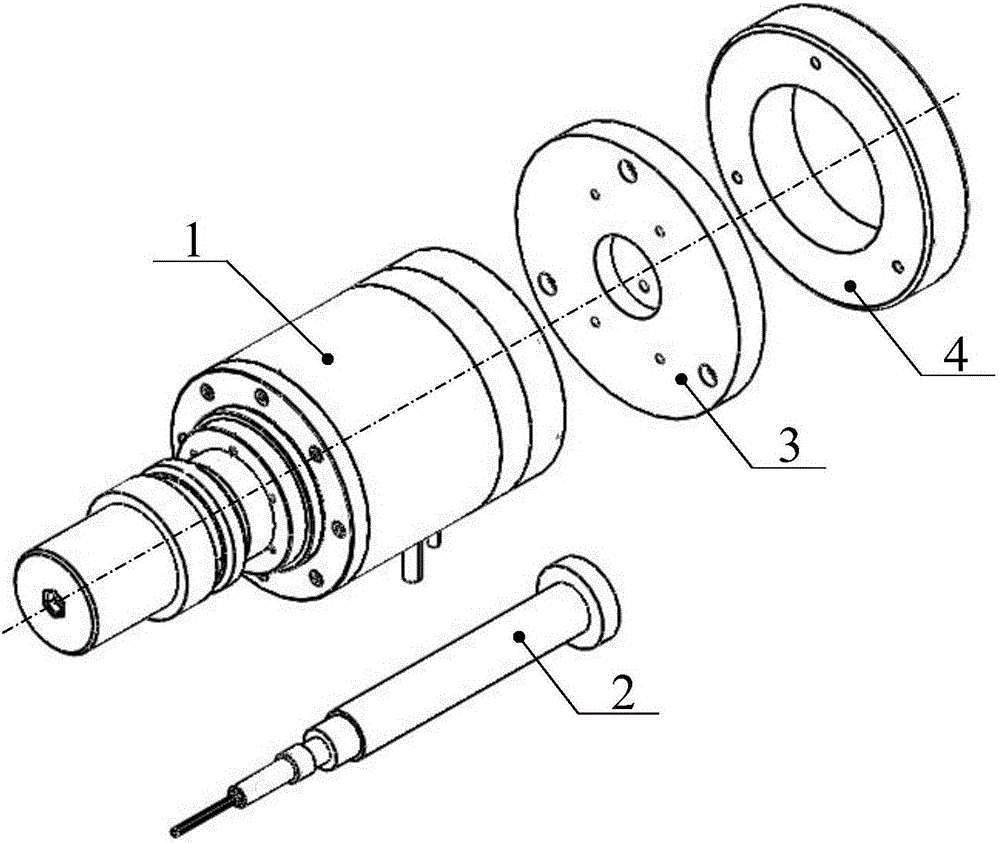

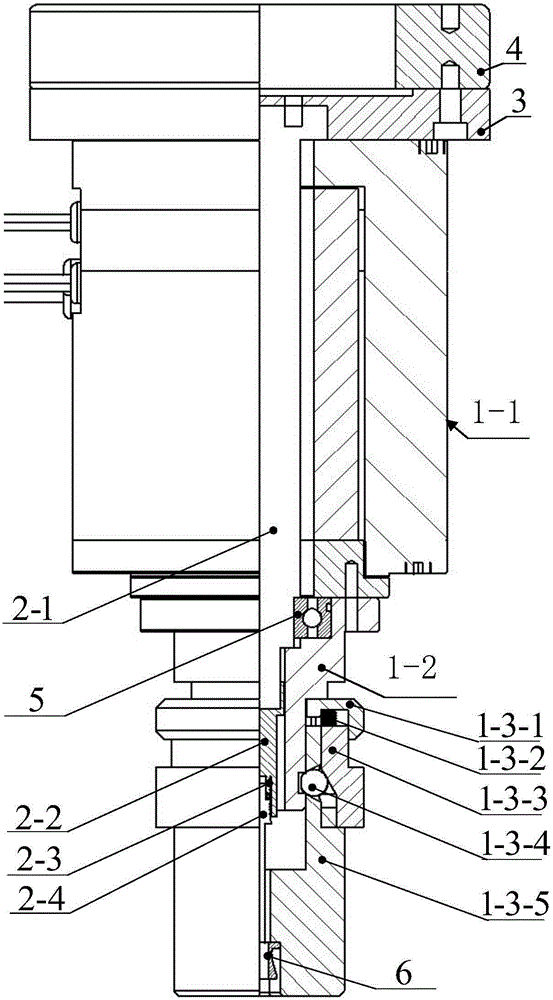

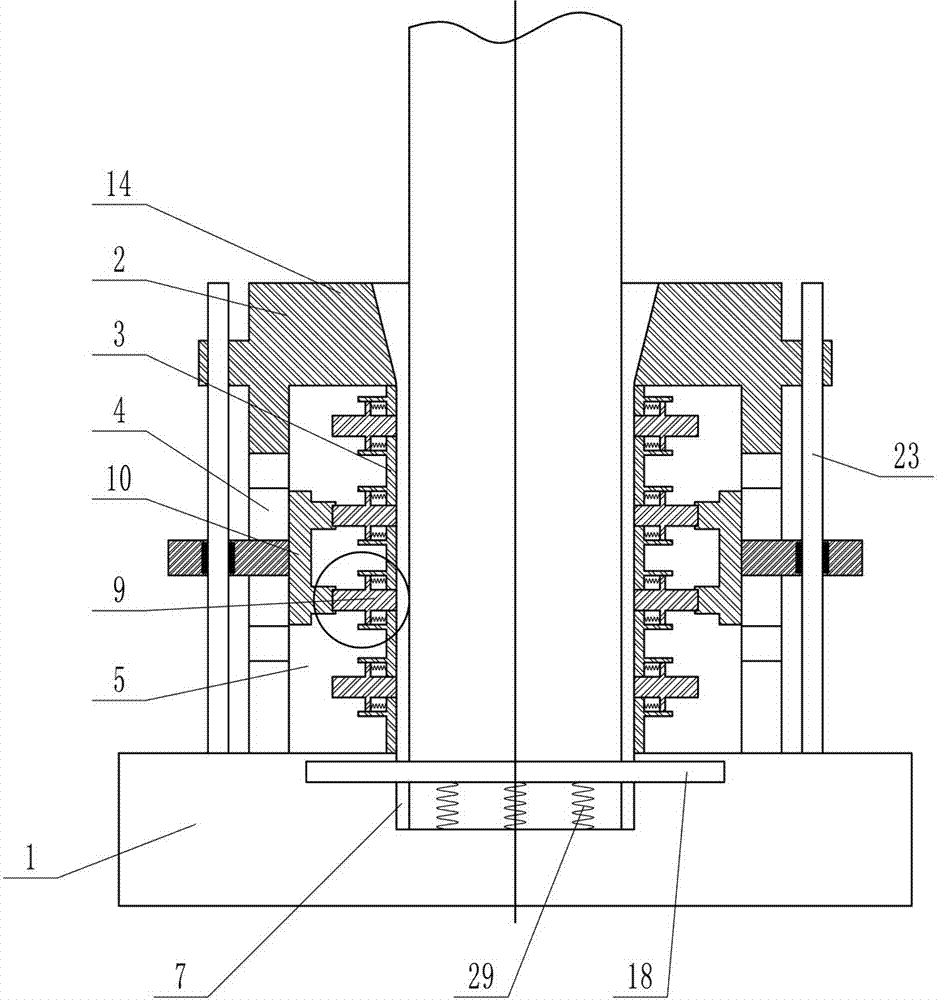

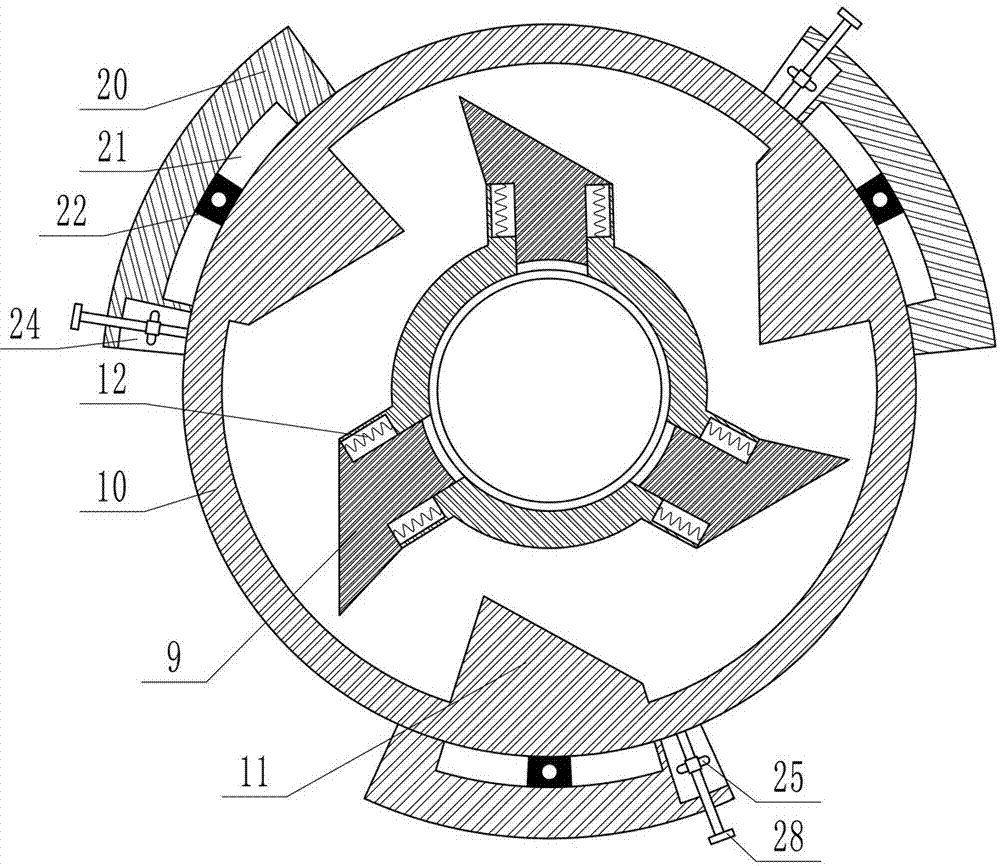

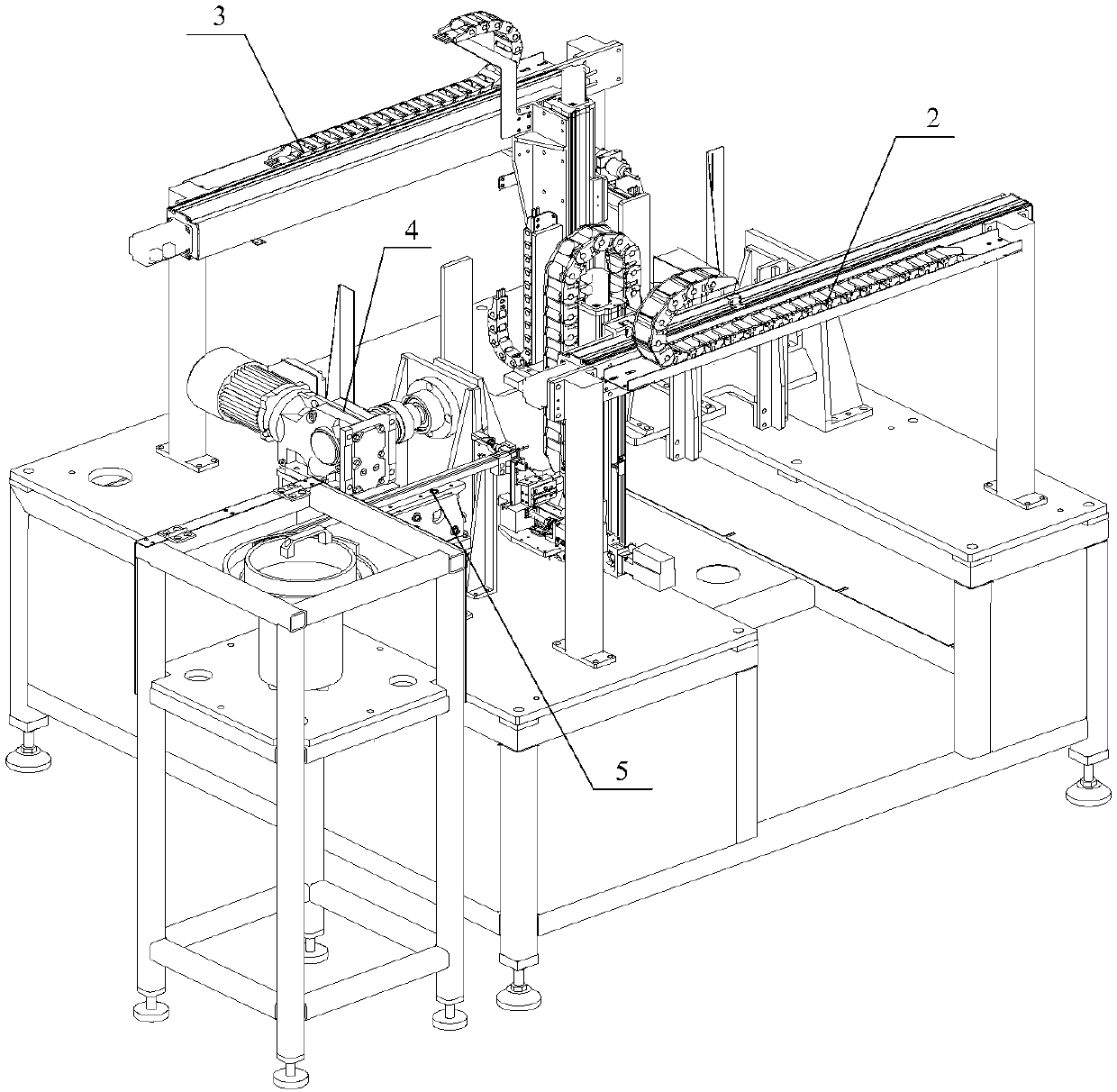

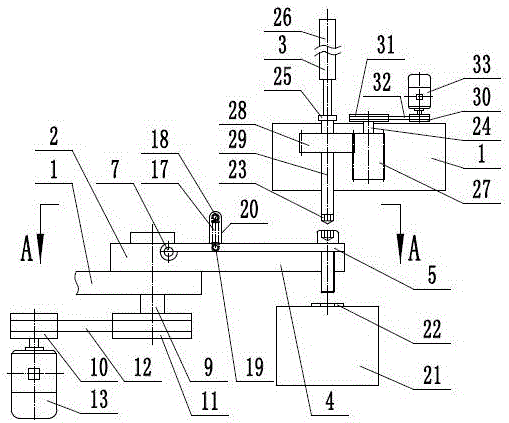

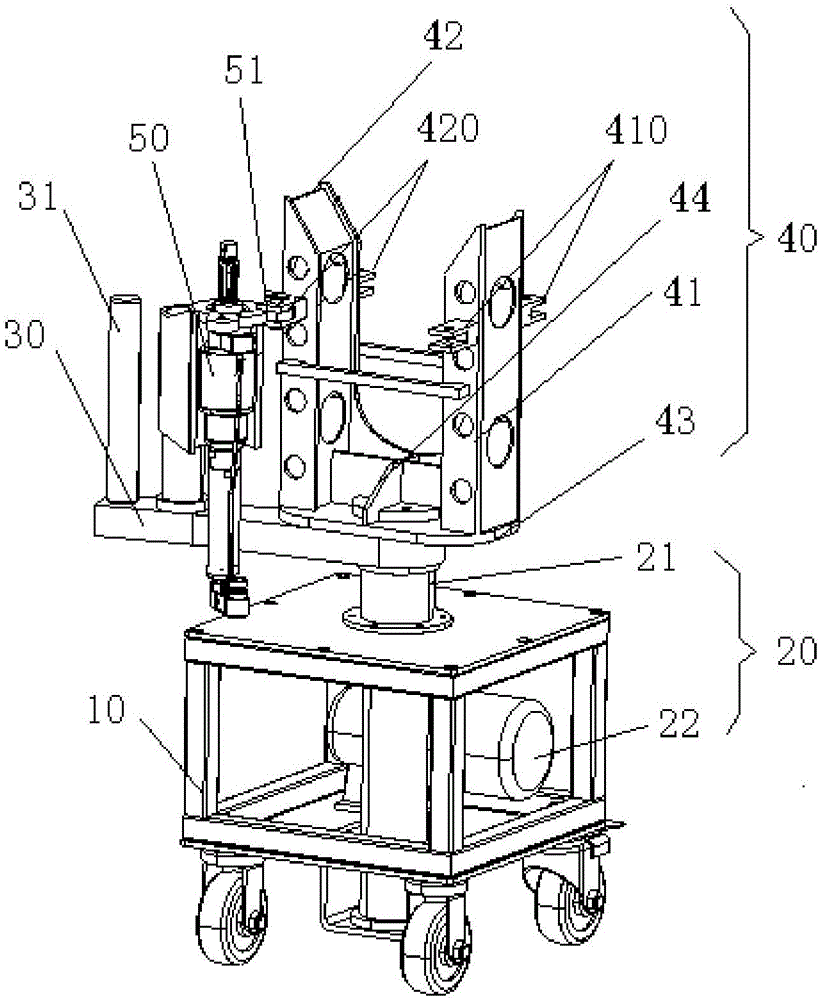

Bolt tightening machine for connecting slewing bearing and hub

ActiveCN101890635AImprove work efficiencyImprove tightening efficiencyMetal working apparatusEngineeringSlewing bearing

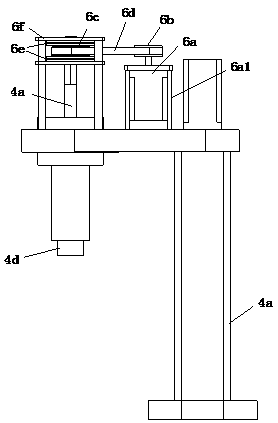

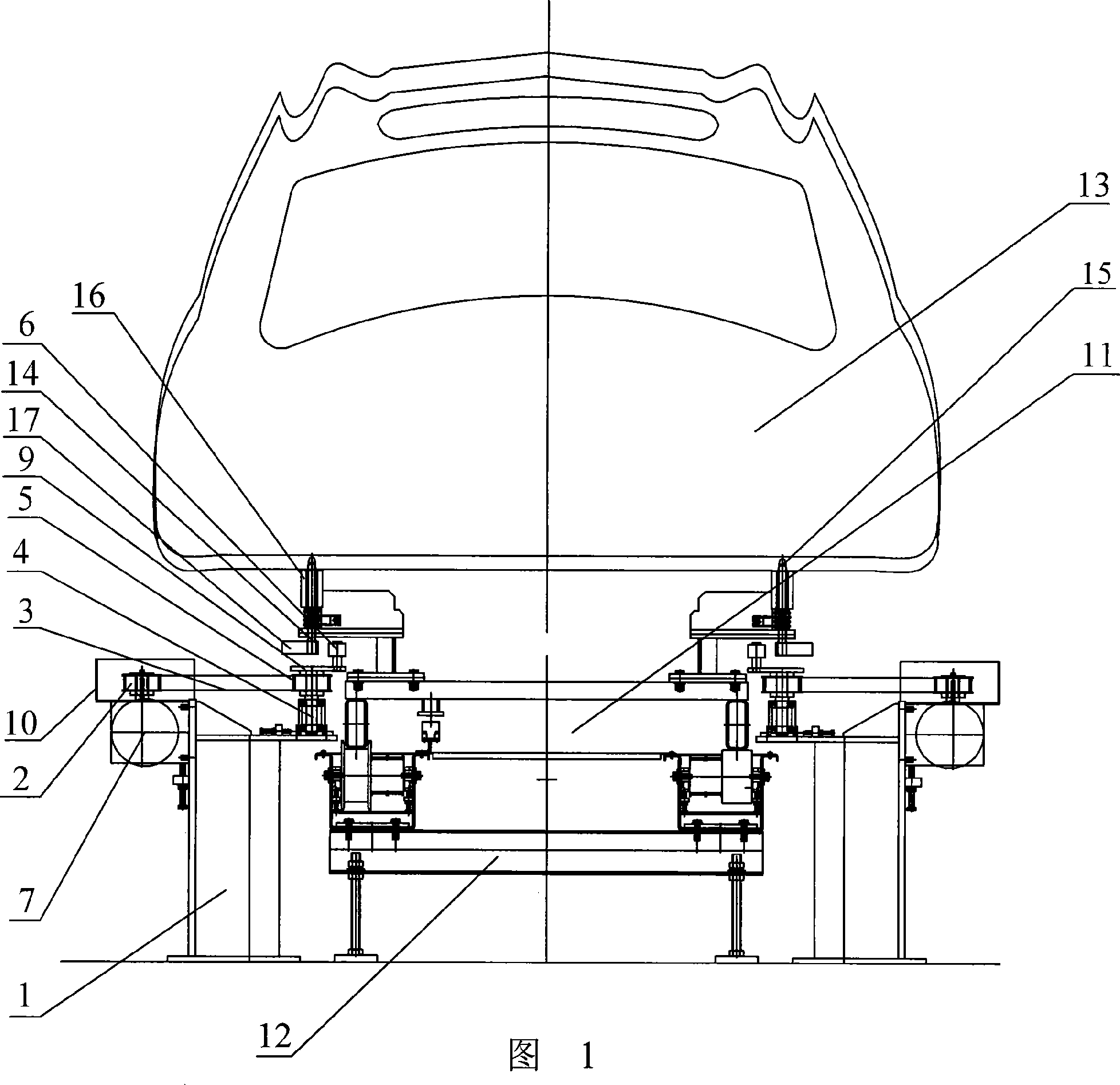

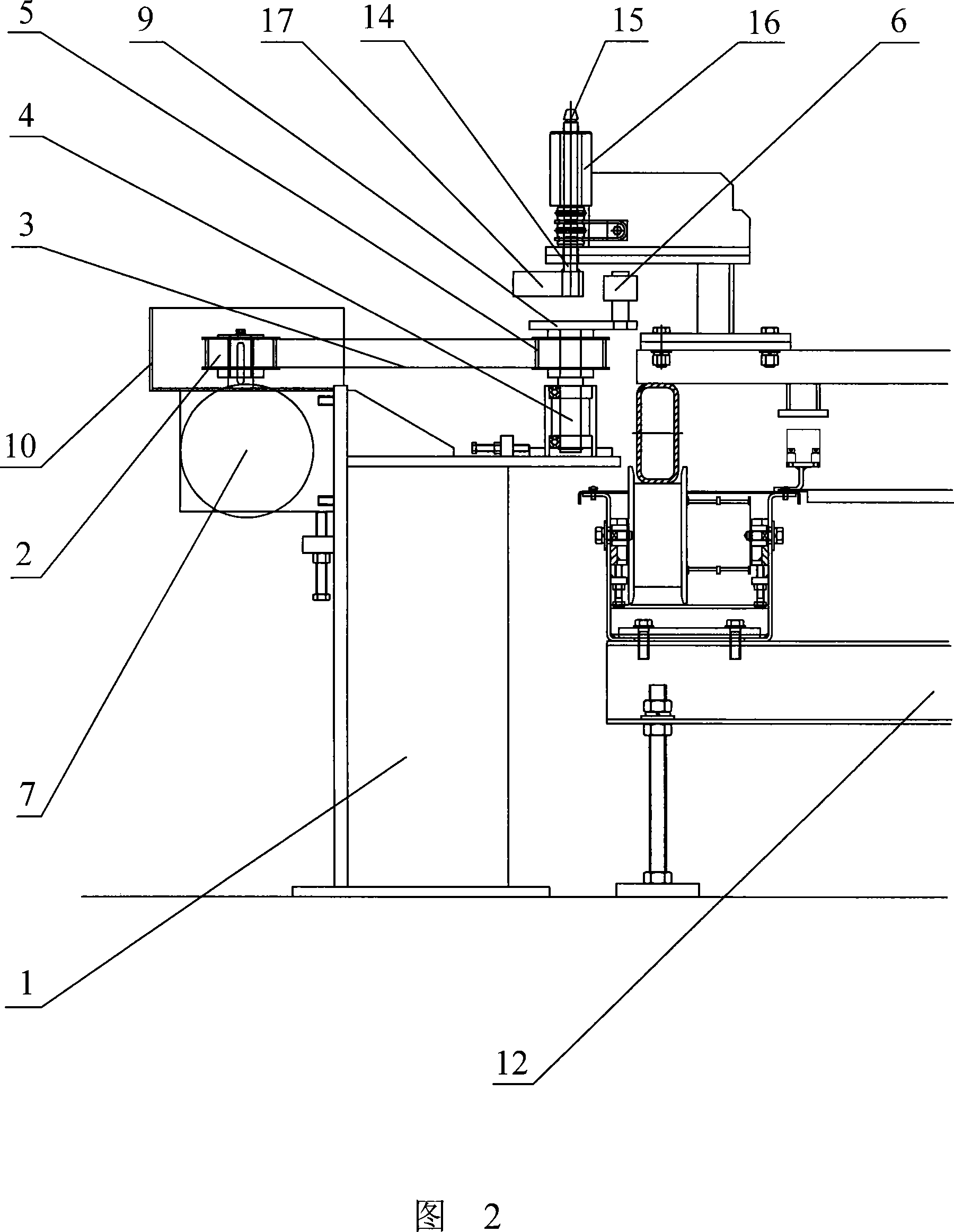

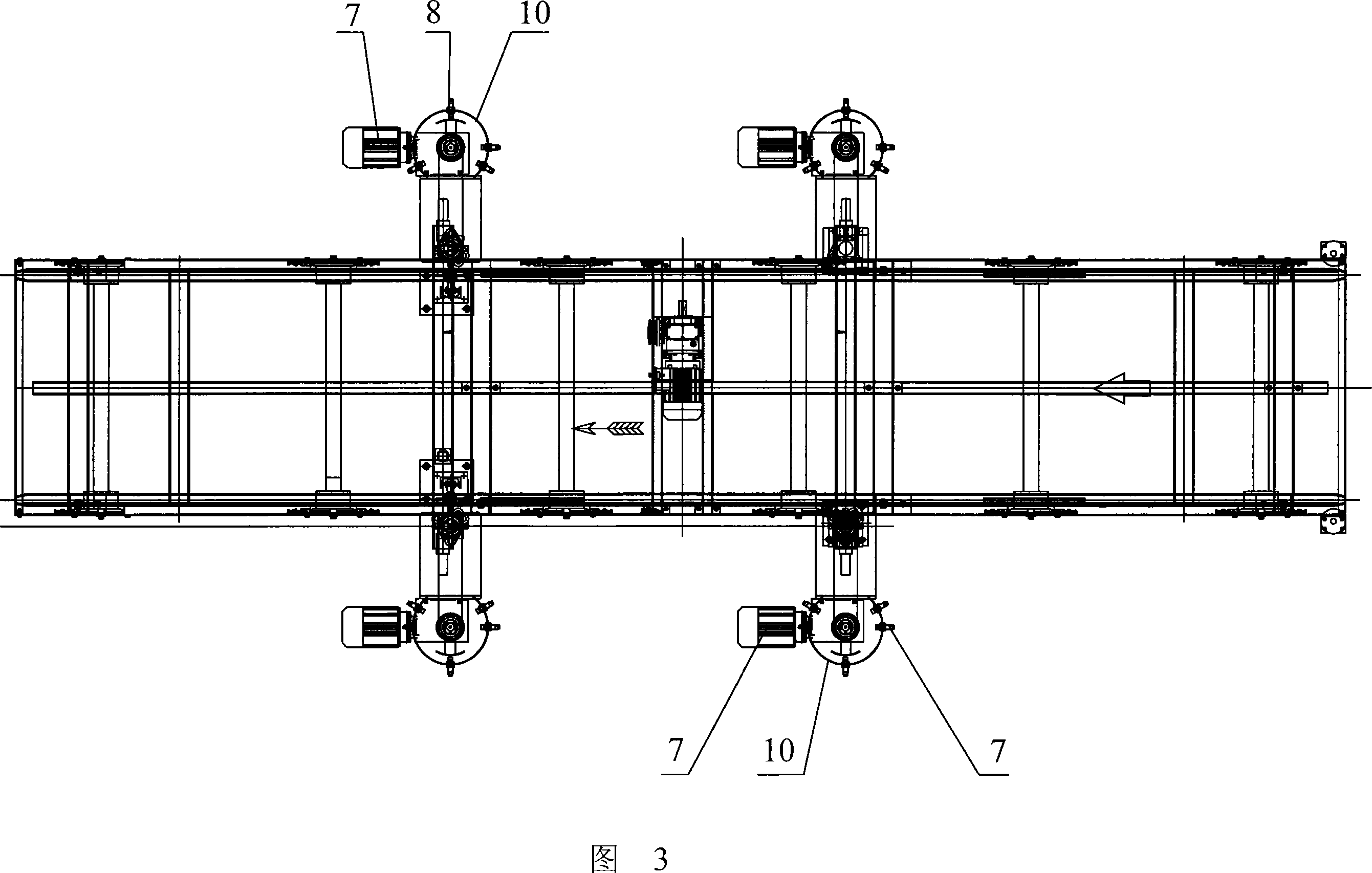

The invention discloses a bolt tightening machine for connecting a slewing bearing and a hub. The bolt tightening machine comprises a tightening shaft device (1) and a central rotating shaft (21), wherein the central rotating shaft (21) is connected with a positioning bracket rotating with the central rotating shaft (21); the positioning bracket is provided with a circumferential rotation drive device (3); the circumferential rotation drive device (3) is connected with a tightening shaft bracket (4) rotating with the circumferential rotation drive device (3); and the tightening shaft device (1) is arranged on the tightening shaft bracket (4). The bolt tightening machine also comprises a control device connected with the circumferential rotation drive device (3) and the tightening shaft device (1), so that the control device controls the tightening shaft device (1) to move to the position of each bolt needing tightening and completes the tightening action of the bolt. The bolt tightening machine can improve the efficiency of tightening the bolt on one hand, and can improve the quality of tightening the bolt on the other hand.

Owner:SANY ELECTRIC CO LTD

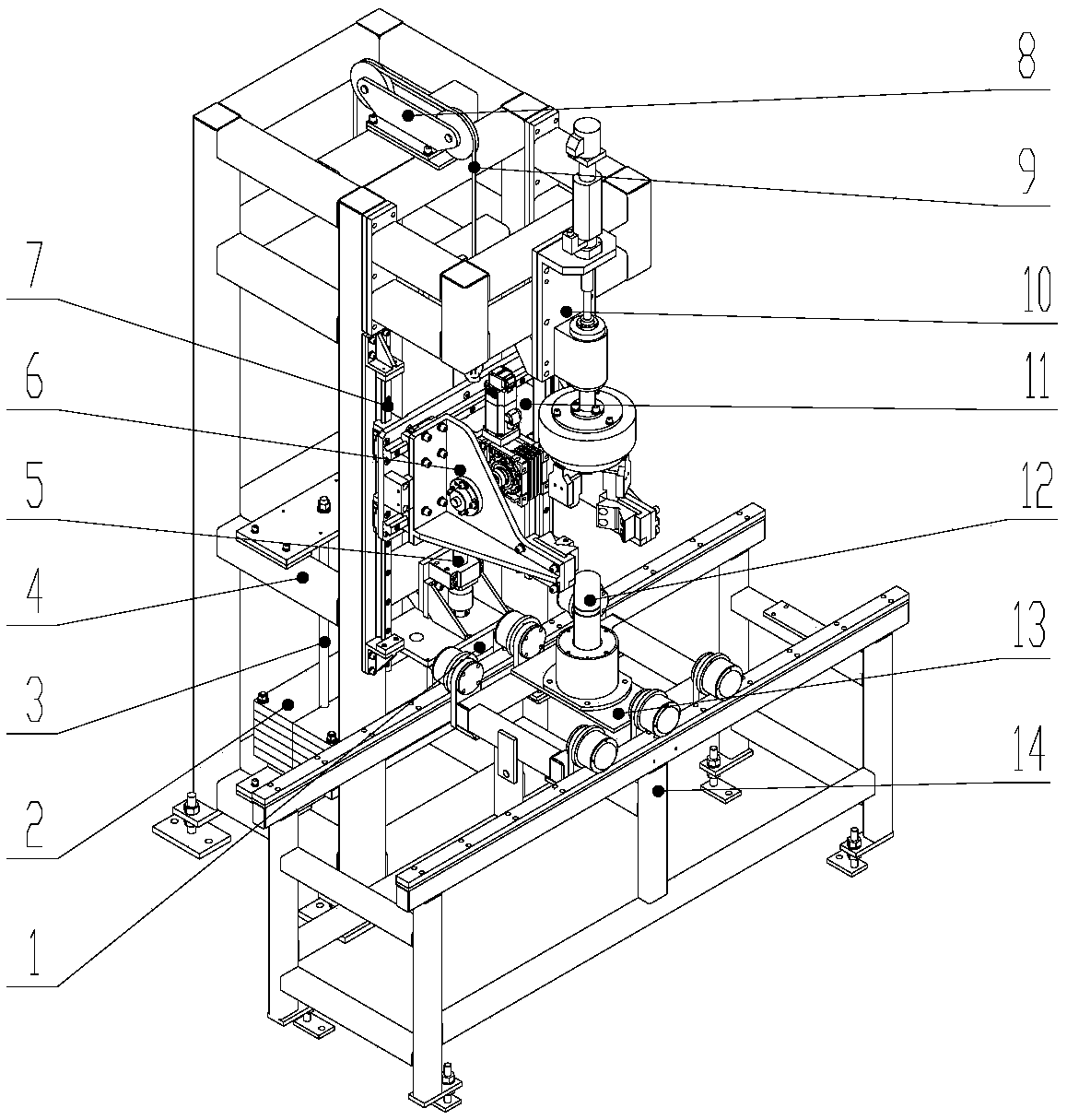

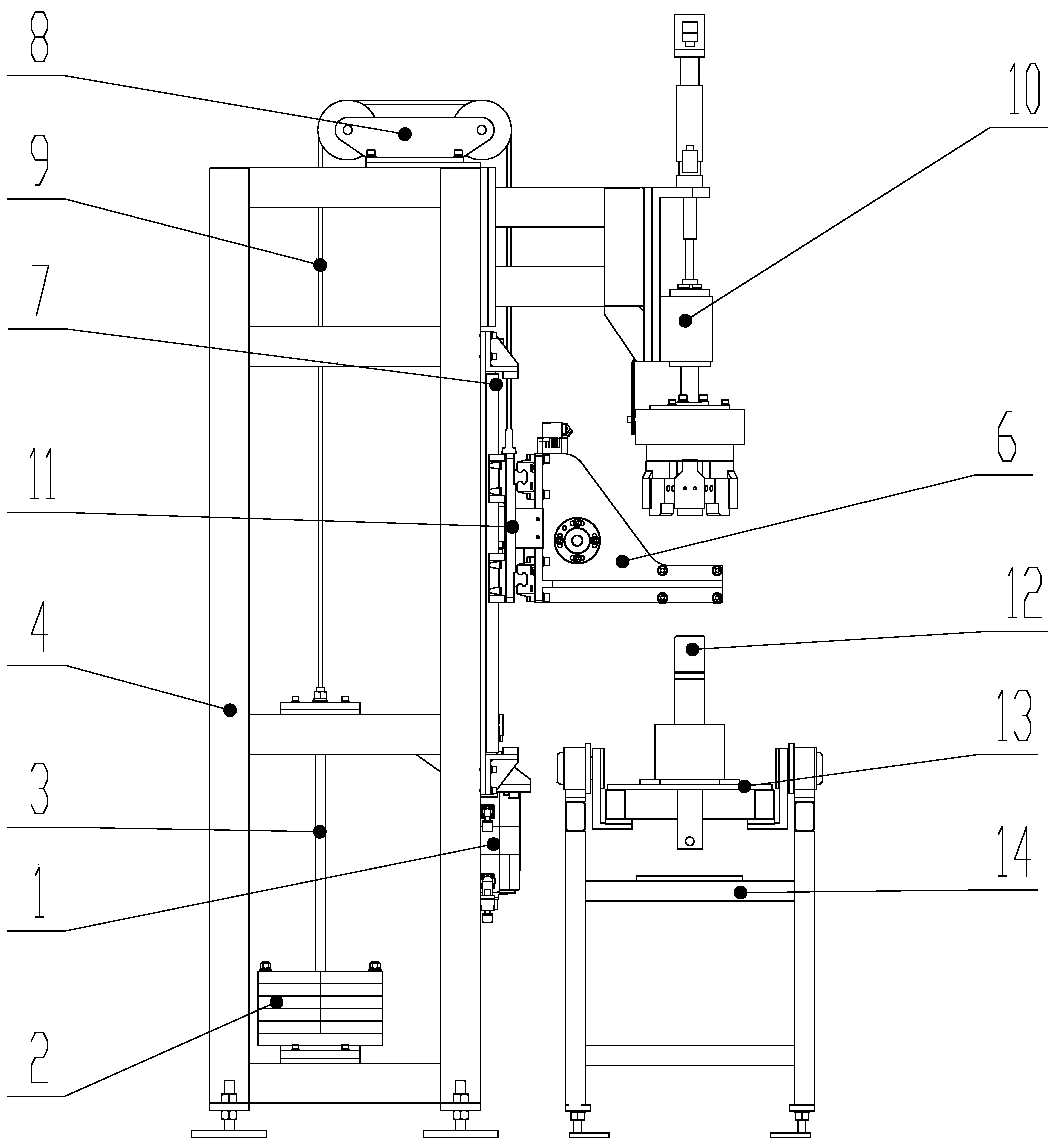

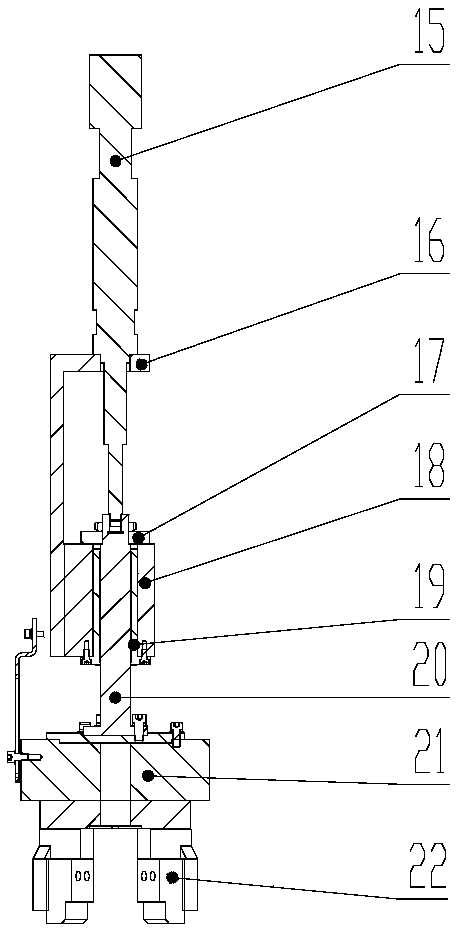

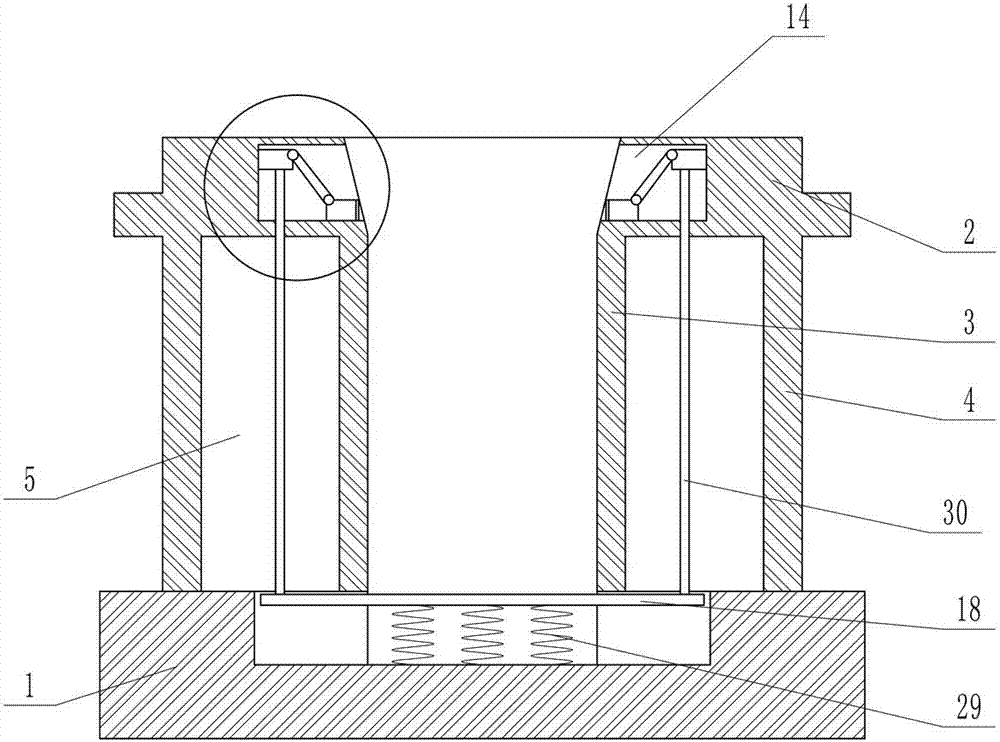

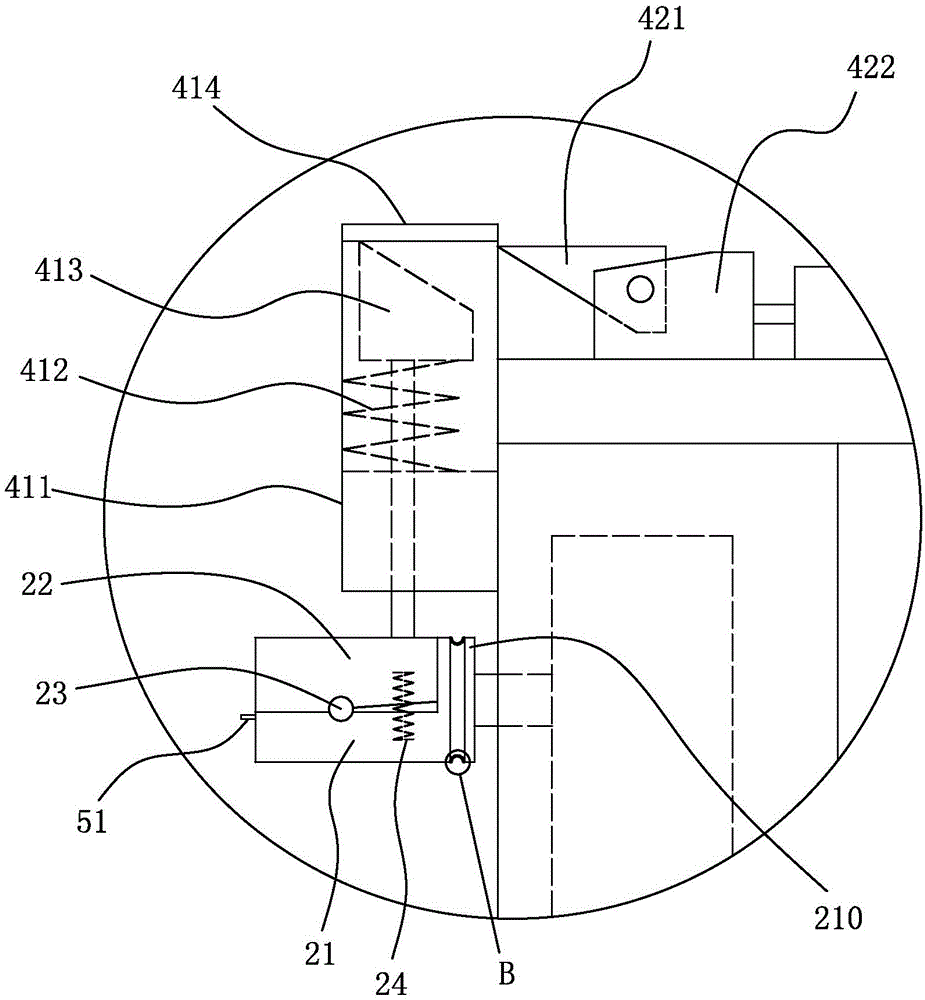

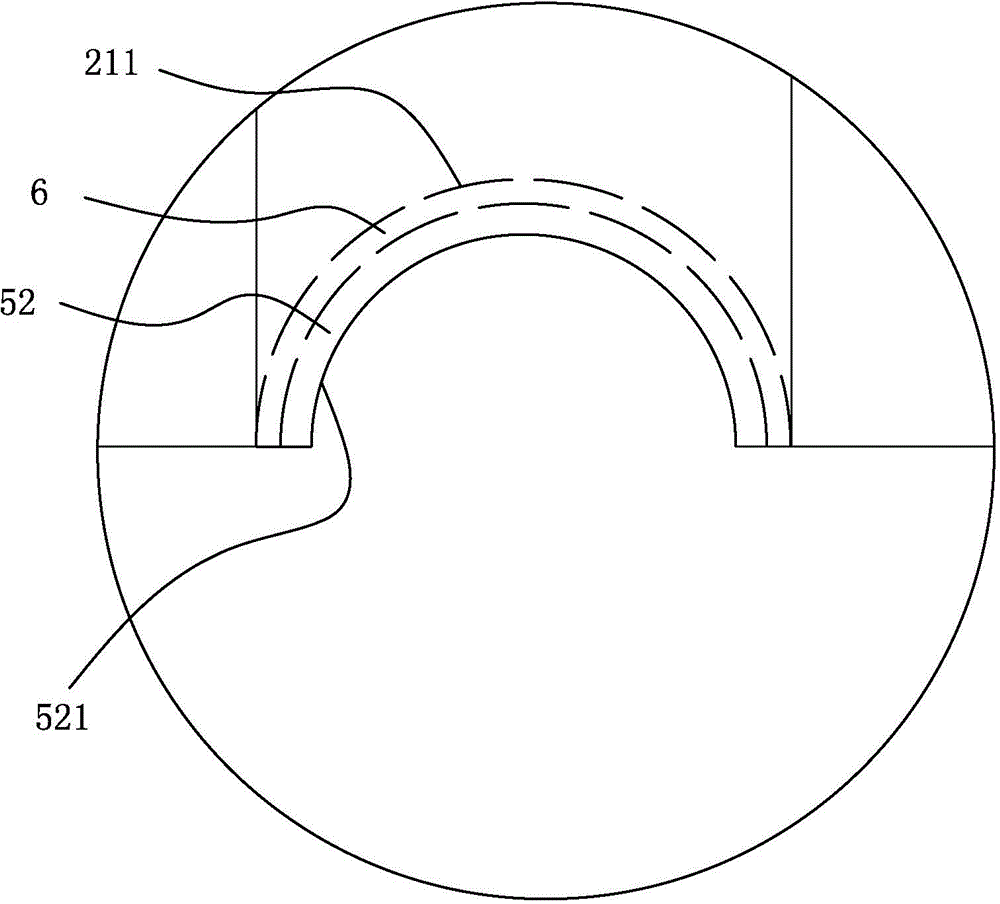

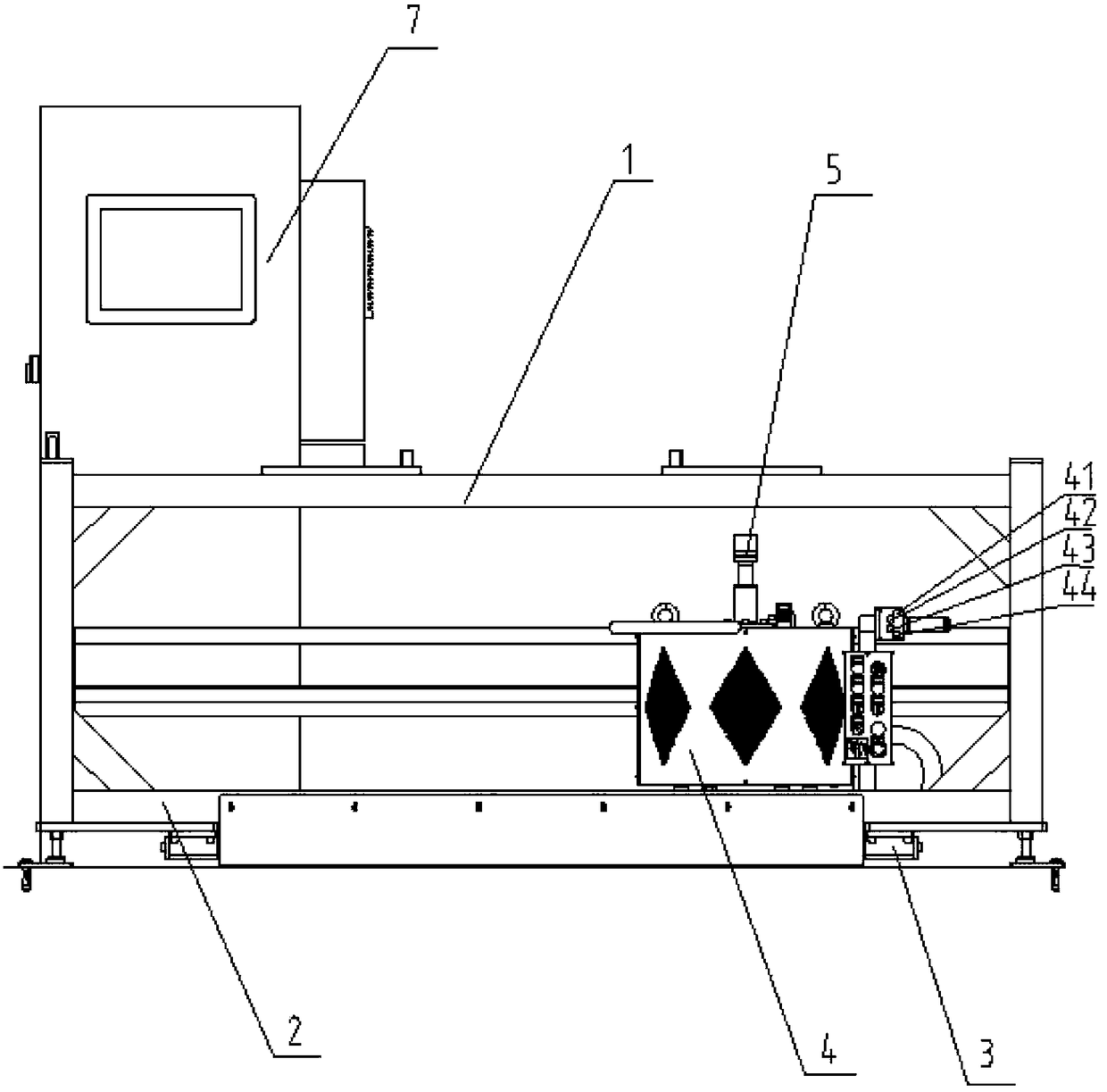

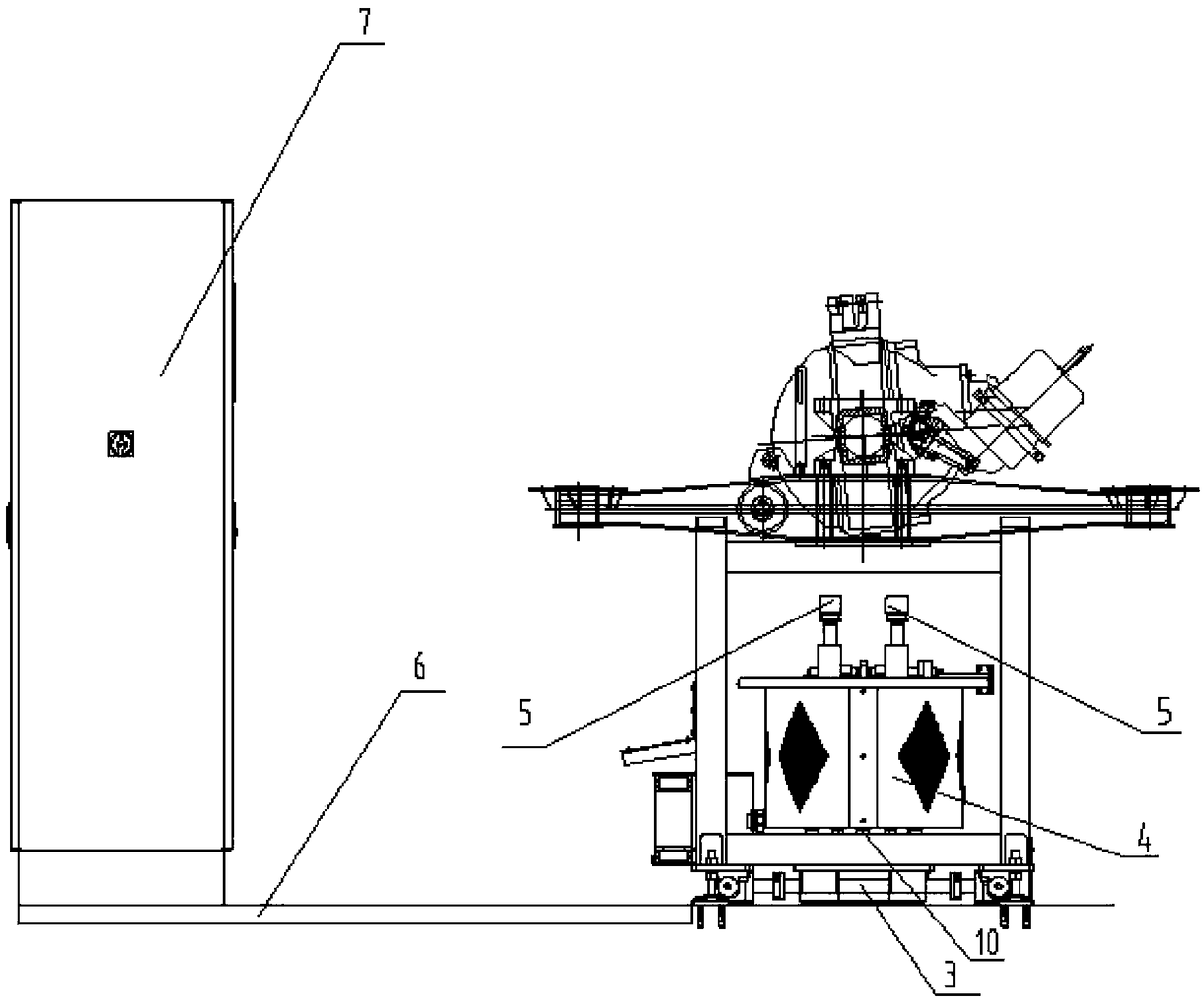

Automatic tightening machine

ActiveCN109158865ARealize automatic tighteningCompact structureMetal working apparatusProduction lineSmall caliber

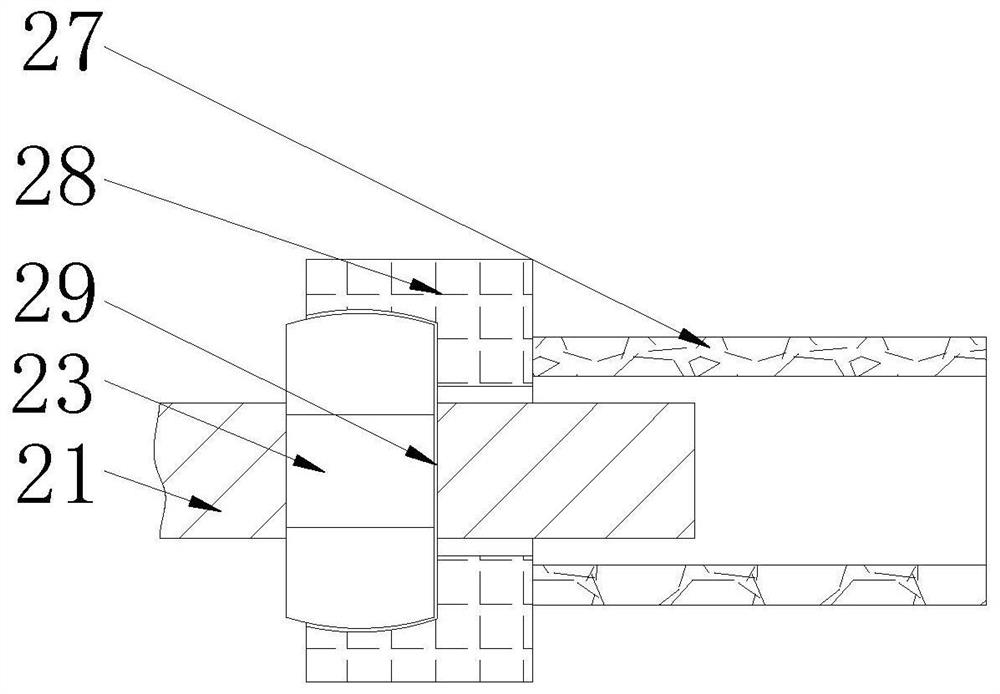

The invention relates to a tightening machine, in particular to the tightening of large threads between different sections of a projectile and a small-caliber missile. The tightening machine includesa rack, a tightening unit, a clamping unit, a lifting slide table and a lifting drive mechanism, wherein the lifting slide table is slidably connected to the rack, the lifting drive mechanism is arranged on the rack and connected with the lifting slide table, and the clamping unit or the tightening unit is arranged on the lifting slide table; when the clamping unit is disposed on the lifting slidetable, the tightening unit is fixed to the upper end of the rack; when the tightening unit is disposed on the lifting slide table, the clamping unit is disposed on a transmission line body, and the tightening unit and the clamping unit achieve the tightening of a workpiece by mutual cooperation. The automatic tightening machine can realize automatic tightening and solve the problems of high laborintensity, low work efficiency and certain risk in the existing tightening process. The automatic tightening machine has the advantages of compact structure, reasonable layout and wide adaptability,and can be used for direct operation in a product pallet station of a production line.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

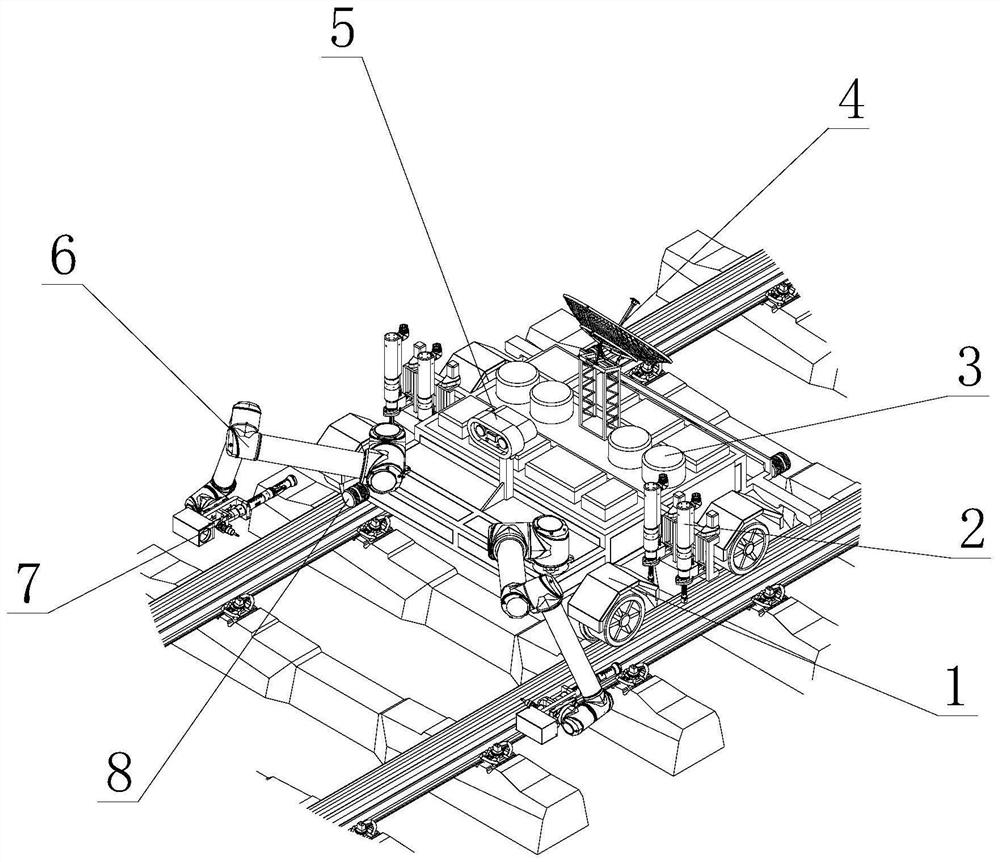

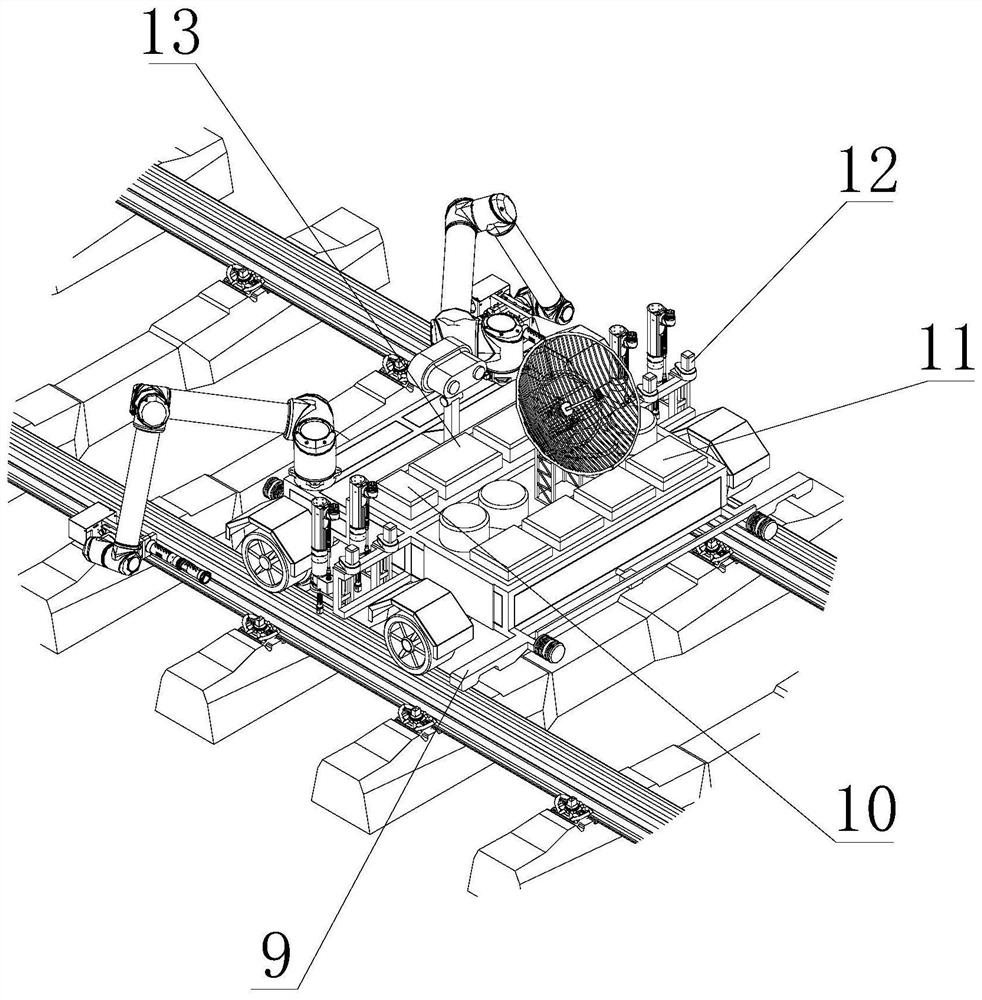

Automatic tightening system and method for rail fastener robot

ActiveCN112025281ARealize automated detectionImprove work efficiencyMetal working apparatusMachineServo

The invention belongs to the technical field of rail maintenance, and particularly discloses an automatic tightening system and method for a rail fastener robot. The system comprises a rail car, a rail car positioning module, a fastener and rail detection module, a servo electric tightening machine module, an elbow tightening robot module, a communication module, a workstation module and a management server module, the rail car positioning module is used for positioning position information of the rail car, the fastener and rail detection module is used for detecting crack damage of a steel rail to be detected and locking torque of a rail fastener bolt, the workstation module is used for judging the rail fastener bolt to be tightened according to position information of the rail car and the locking torque value of the rail fastener bolt and calculating the position information of the rail fastener bolt to be tightened and controlling a corresponding tightening machine to tighten or replace the rail fastener bolt to be tightened according to the direction of the rail fastener bolt. According to the system, automatic detection of rail flaw detection, rail fastener state and bolt locking torque is realized, and the working efficiency and the operation precision are high.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

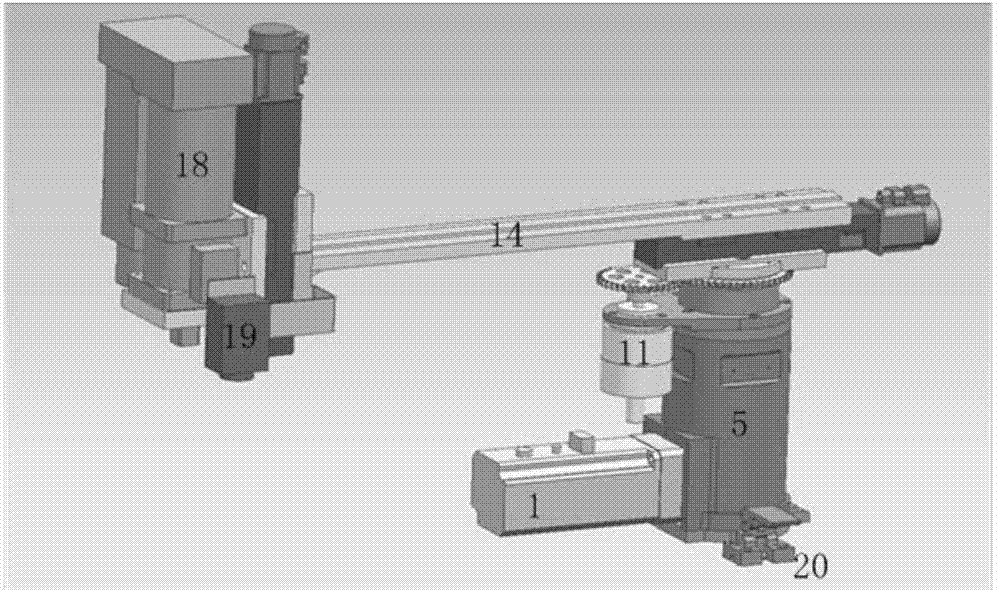

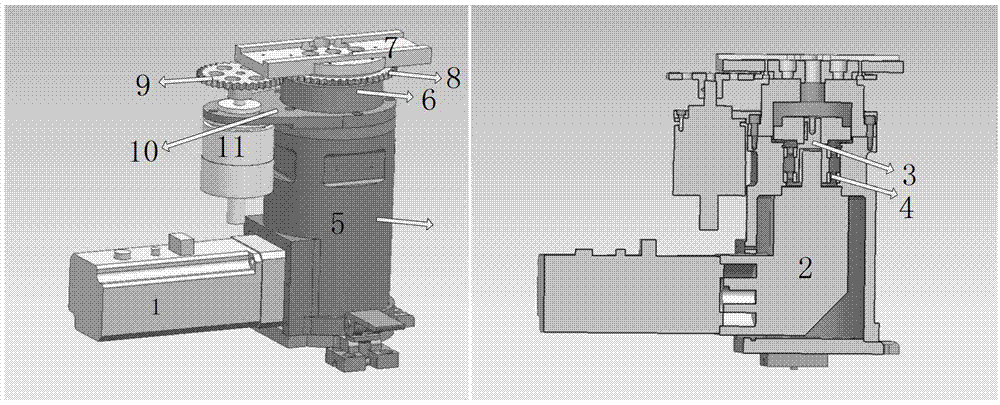

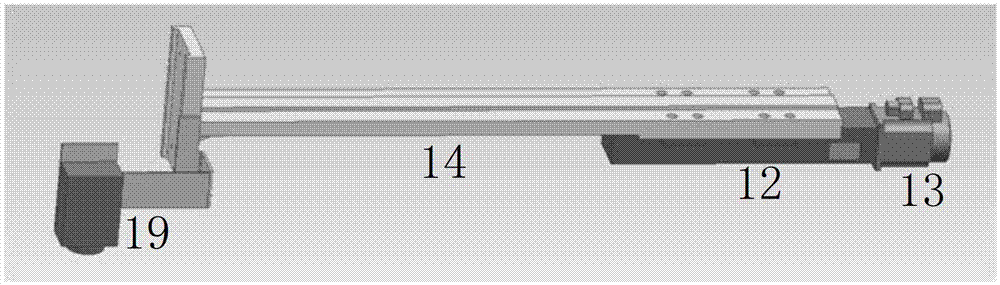

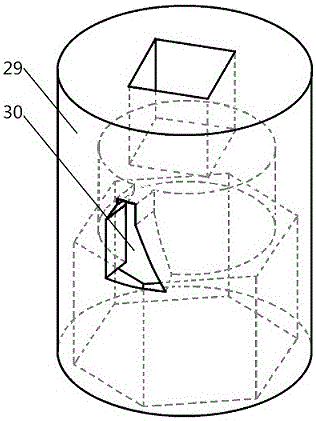

Vapor generator primary side baffle operation robot

ActiveCN103111837ARealize automatic tighteningMinimize workProgramme-controlled manipulatorMetal working apparatusIntelligent lightingVideo monitoring

The invention provides a vapor generator primary side baffle operation robot which is capable of completing fastening and disassembly of a vapor generator primary side baffles in a nuclear power plant. The vapor generator primary side baffle operation robot is composed of a bolt fastening mechanical arm capable of rotating at an angle of 360 degrees, a force moment feedback sensing system and a video monitoring system. Intelligent location, automatic route planning, self judging of bolt fastening torque and process real-time monitoring are achieved. The vapor generator primary side baffle operation robot is simple in designed structure, small in occupied space, convenient to operate, high in accuracy, convenient to popularize and apply, and capable of reducing working time.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

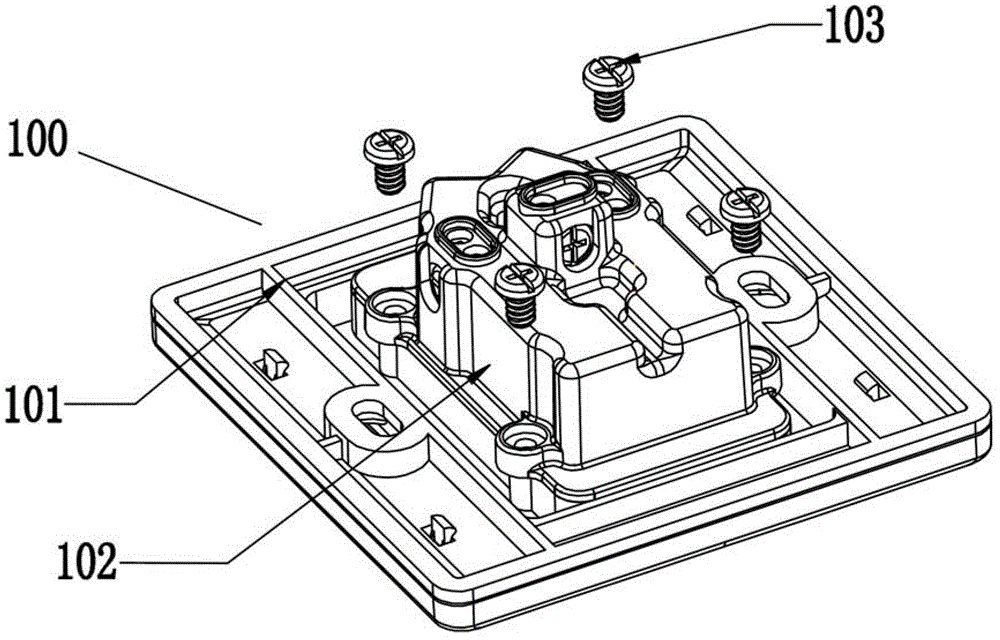

Online automatic screwing system

InactiveCN103143927ARealize automatic tighteningReduce labor intensityMetal working apparatusScrew systemEngineering

The invention relates to an online automatic screwing system. An electric screwing device is mounted in a mounting bracket; a first drive device is mounted above the mounting bracket and connected with the mounting bracket; a vertical channel is formed in a limiting block; a screw falling channel is obliquely and downwardly formed in the limiting block and communicated with the vertical channel; the limiting block is mounted below the mounting bracket; a rotary head of the electric screwing device can be inserted into the vertical channel by moving up and down; a tray is positioned below the limiting block; a second drive device is mounted below the tray and connected with the tray; a control device is connected with the first drive device, the electric screwing device and the second drive device through circuits; and preferably, the mounting bracket comprises an upper sliding plate, a lower sliding plate, at least two guide rods and an elastic part. The online automatic screwing system is smart in design and simple in structure, can perform the automatic screwing operation, reduce the labor intensity of workers, improve the working efficiency and guarantee the assembly quality, and is suitable for large-scale popularization and application.

Owner:SIMON ELECTRIC CHINA

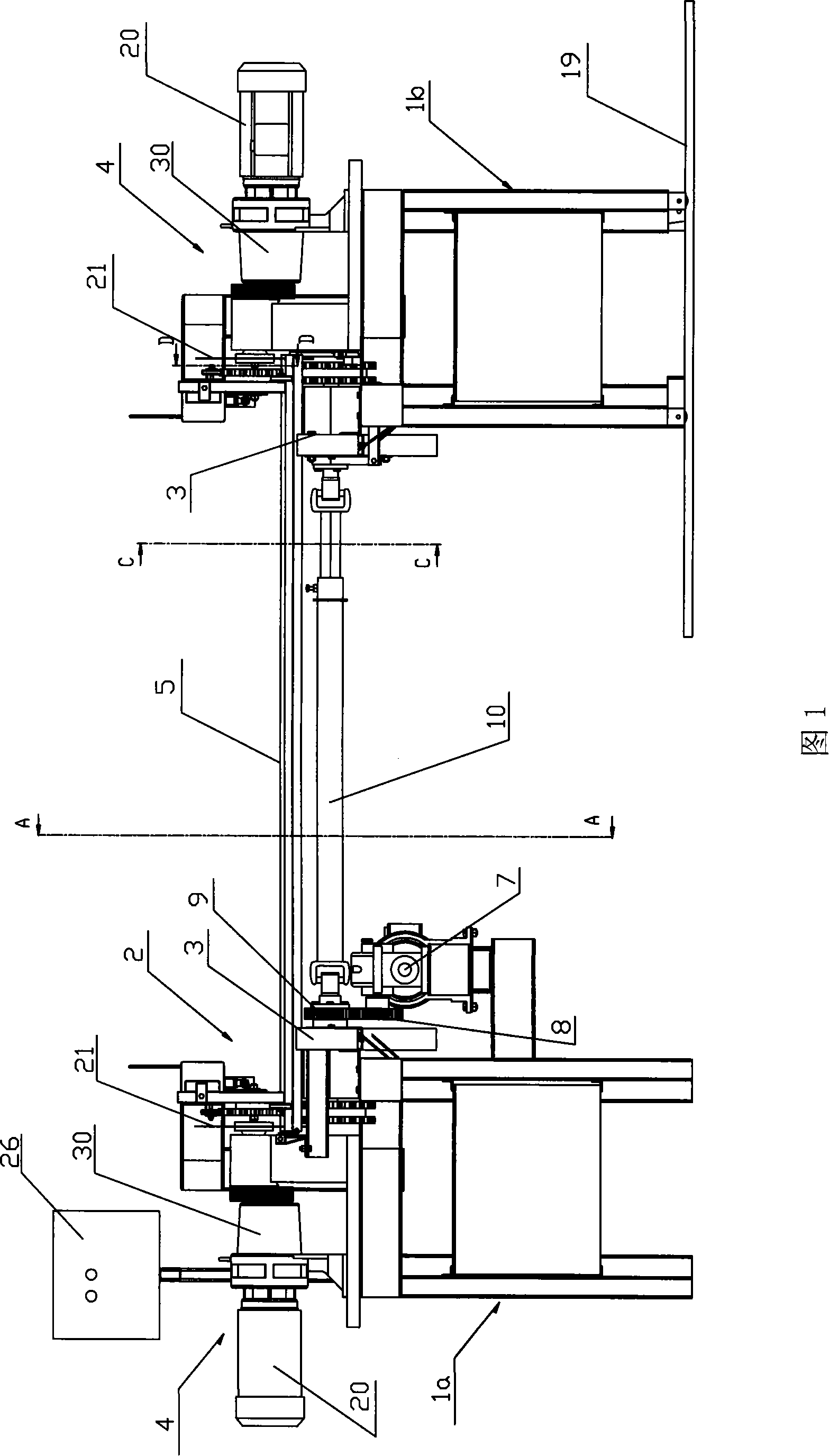

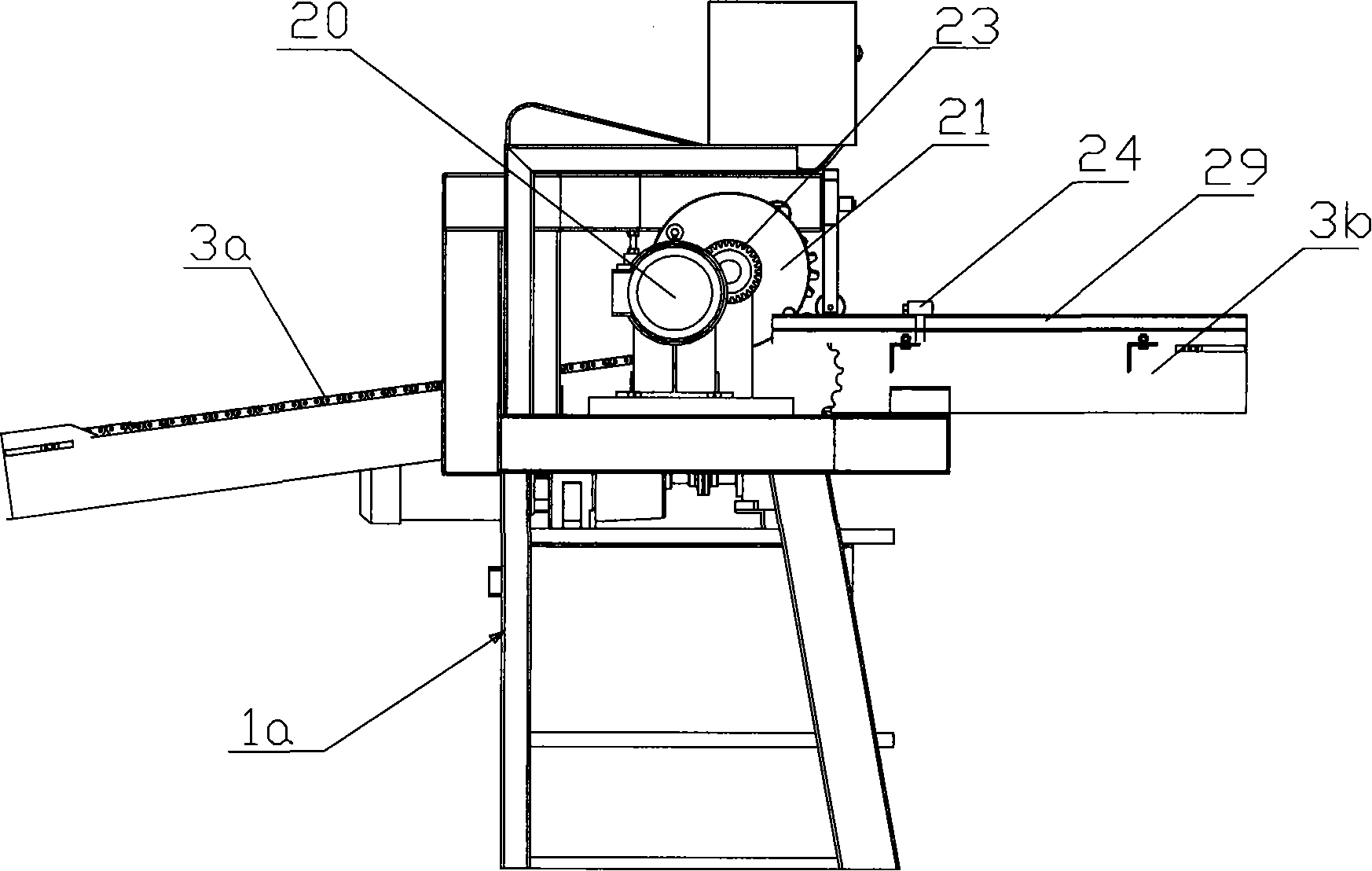

Straight pipe double-ended automatic non-bur cutter device

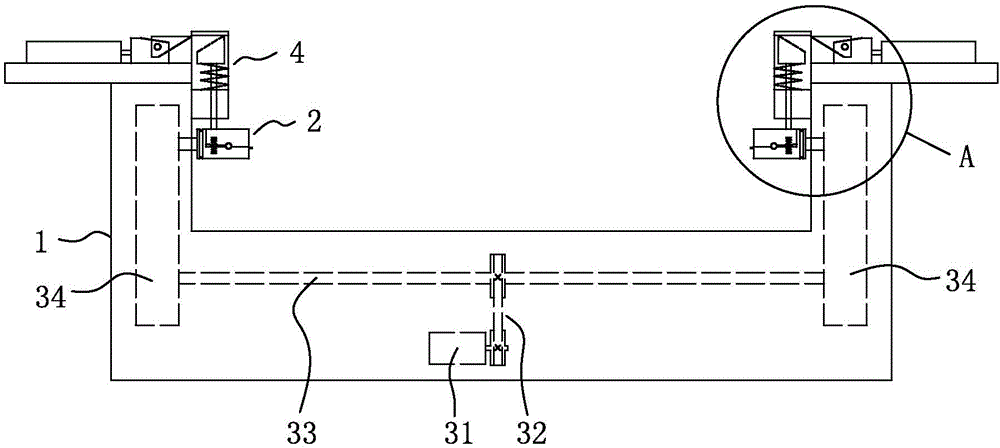

InactiveCN101249574AImprove work efficiencyRealize large-scale continuous productionMetal sawing devicesDeformation ProblemThin walled

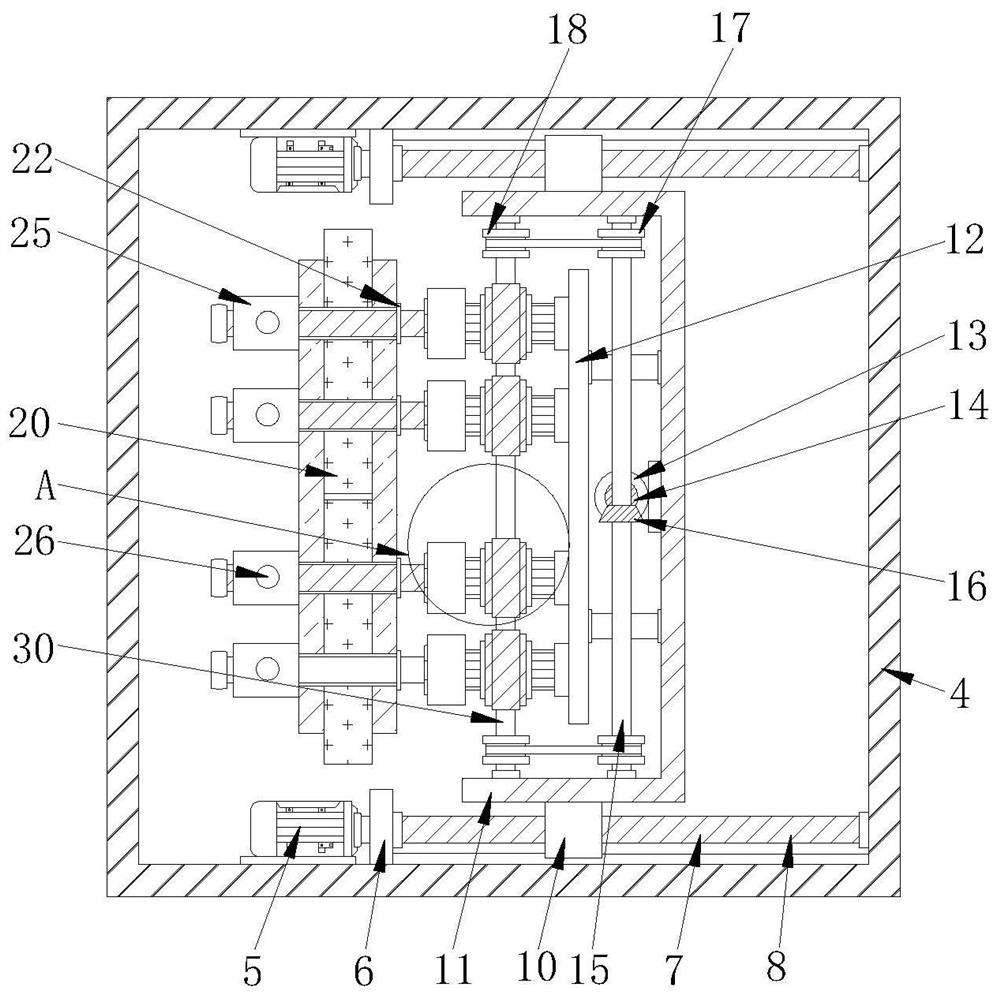

A double-end automatic burr-free cutting device for straight pipes comprises a first and a second supports correspondingly arranged on both sides, pipe clamping structures positioned on the supports on both sides for fixing both ends of a pipe to be cut, and pipe transport rails respectively linked with the pipe clamping structures on both sides for supporting and transporting the pipe to be cut, wherein pipe cutting structures are correspondingly arranged on the supports on both sides and outside the pipe clamping structures and the pipe transport rails. The pipe clamping structure comprises a drive motor, a gear box, a pipe clamping drive gear and a transmission shaft fixed on the axis of the pipe clamping drive gear, which are sequentially connected with each other, wherein lower pipe clamping gears are respectively connected with both ends of the transmission shaft, and upper pipe clamping gears engaged with the lower pipe clamping gears are arranged thereon. The cutting device can achieve automatic double-end clamping, automatic feeding and simultaneous cutting, thus greatly improving the work efficiency and achieving large-scale continuous production. The cutting device can overcome the deformation problem of thin-wall pipes during clamping and cutting, and can be operated by users away from saw blades, thus obviating the occurrence of industrial accident.

Owner:鲍洪文

Adaptor device for synchronous butt joint of main cone nut and flange of automobile drive axle assembly

InactiveCN102000967ARealize automatic tighteningImprove work efficiencyMetal working apparatusButt jointFlange

The invention relates to an adaptor device for the synchronous butt joint of a main cone nut and a main cone flange of an automobile drive axle assembly. The adaptor device comprises an adaptor inner cylinder, a splitting gland and an adaptor outer cylinder; inner bores are formed on the adaptor inner cylinder and the adaptor outer cylinder; the shape of the inner bore of the adaptor inner cylinder is meshed with that of the outer diameter of the main cone nut; a cylindrical shaft shoulder is arranged on the middle part of the outer circumferencial surface of the adaptor inner cylinder; the outer circumference of the cylindrical shaft shoulder is matched with the inner circumference of the adaptor outer cylinder, so that the adaptor inner cylinder is embedded into the adaptor outer cylinder concentrically; and the splitting gland has a semicircular step structure and is fixedly connected with the adaptor outer cylinder, so that the adaptor outer cylinder is prevented from being fallenout of the adaptor inner cylinder and can rotate relative to the adaptor inner cylinder. The adaptor device has the advantage that: compared with the main cone flange needing to be fixed in the priorart, the main cone nut which is screwed tightly by rotating has better accurate control effect and higher work efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Automatic screwing robot for high-locking-force bolt and end effecter of automatic screwing robot

ActiveCN106426175AAchieve separationAchieve positioningProgramme-controlled manipulatorGripping headsEngineeringActuator

The invention discloses an automatic screwing robot for a high-locking-force bolt and an end effecter of the automatic screwing robot. The end effecter comprises a bolt screwing mechanism, a bolt positioning mechanism and a base; the bolt screwing mechanism and the bolt positioning mechanism are fixed to the base; the bolt screwing mechanism is of a hollow structure; the bolt positioning mechanism is coaxially positioned in a hollow space of the bolt screwing mechanism. The automatic screwing robot for the high-locking-force bolt comprises the end effecter disclosed by the invention. The automatic screwing robot disclosed by the invention is capable of realizing separation of rotation motion and twisting motion of the positioning mechanism and the bolt screwing mechanism by virtue of a simple structure.

Owner:北京中科万盛智能装备科技有限公司

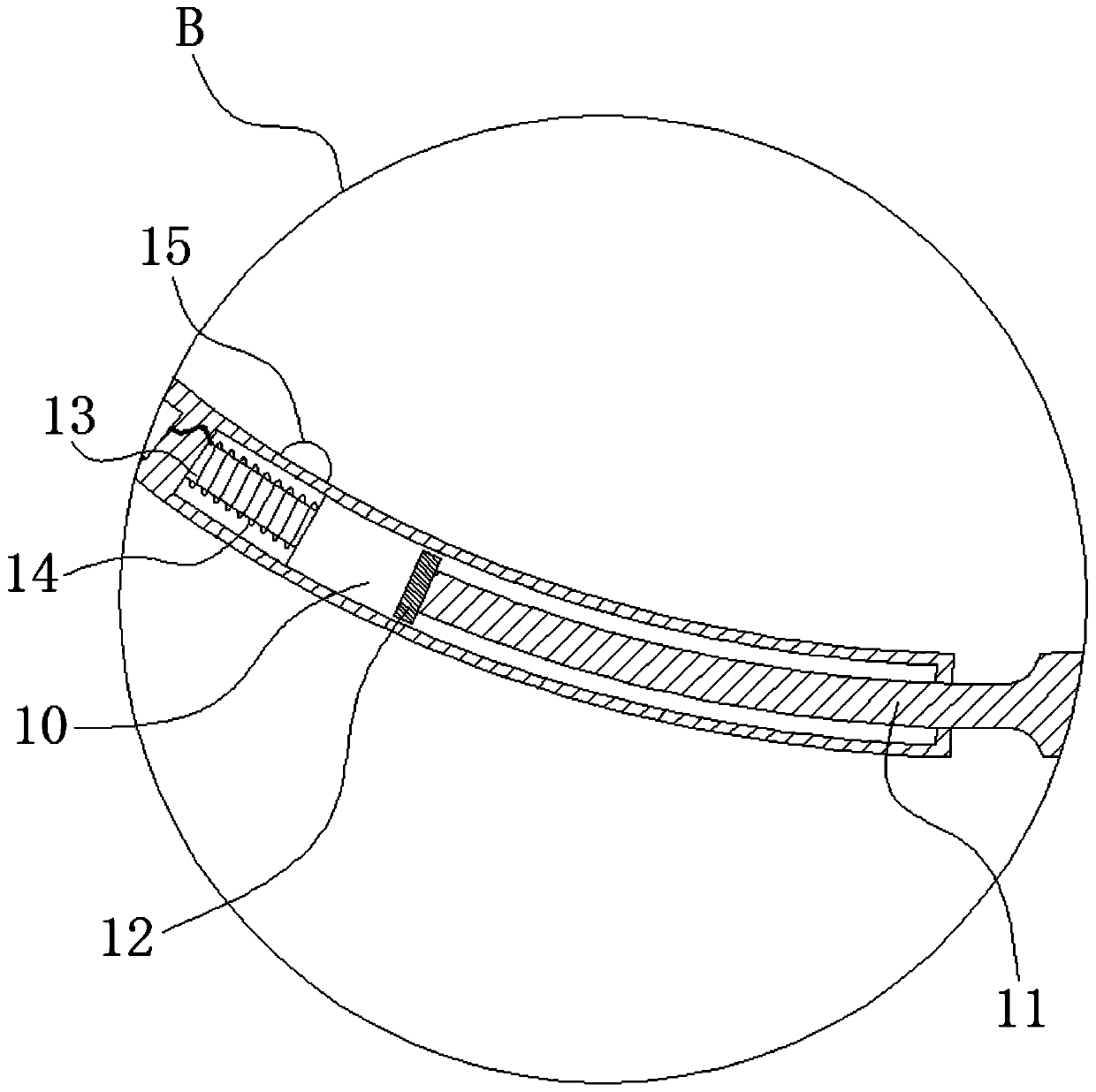

Intelligent bracelet with conveniently-disassembled and replaceable wrist strap

InactiveCN111184320AEasy to maintainGuaranteed comfortBraceletsWrist-watch strapsInductive chargingEngineering

The invention provides an intelligent bracelet with a conveniently-disassembled and replaceable wrist strap, and relates to the technical field of intellligent bracelets. The intelligent bracelet witha conveniently-disassembled and replaceable wrist strap comprises a wrist strap. A groove is formed in the top of the wrist strap. A guide rail groove is formed in the periphery of the groove, a display is fixedly connected to the interior of the groove, a wireless charging receiving patch is fixedly installed at the bottom of the display, a limiting column is fixedly installed on the periphery of the display, a spring is fixedly connected to the bottom of the groove, and a wireless charging base is fixedly connected to the top end of the spring. According to the intelligent bracelet with a conveniently-disassembled and replaceable wrist strap, the display and the wrist strap can be switched, maintenance is convenient, attraction is better achieved, the wrist strap can be automatically tightened to a certain degree, the comfort degree during wearing is guaranteed while body data collection of the bracelet is not affected, the storage battery in the wrist strap can wirelessly charge the display, and the cruising ability of the bracelet is improved.

Owner:李兆和

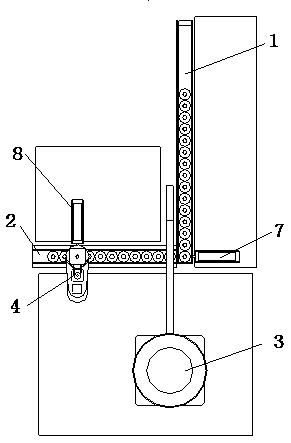

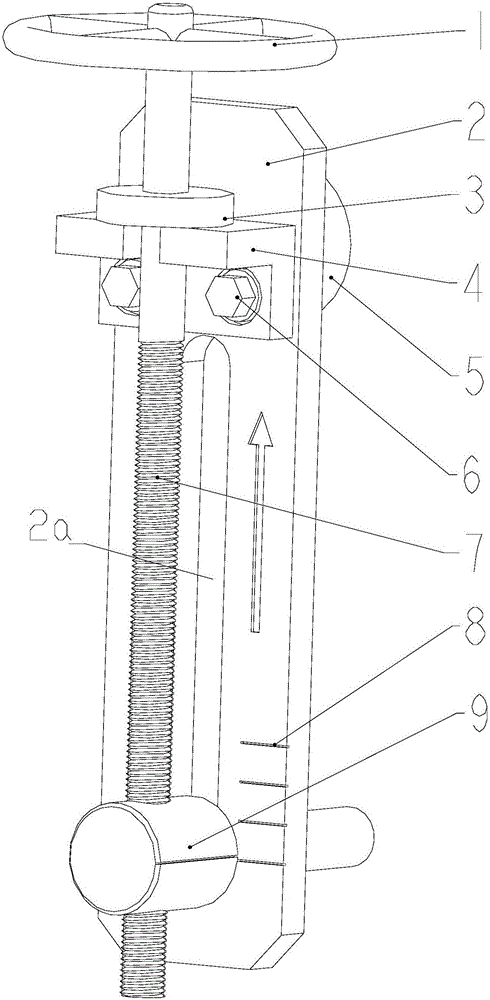

Bottle cap tightening machine

InactiveCN107792821ATighten to achieveRealize automatic tighteningClosing machinesThreaded caps applicationDrive shaftEngineering

The invention relates to the field of automation equipment, in particular to a bottle cap tightening machine, comprising a conveyor belt, a material rail, a feeding mechanism and a tightening mechanism, the conveying direction of the conveyor belt is perpendicular to the guide of the material rail, and the discharge end of the conveyor belt It is connected with the feeding end of the material rail, and the side of the discharge end of the conveyor belt is provided with a pushing device matched with the material rail. The feeding mechanism and the tightening mechanism are distributed along the guiding interval of the material rail. One side of the material rail A positioning device arranged opposite to the tightening mechanism is provided. The invention can realize the automatic tightening of bottle caps. The tightening mechanism adopts a rotatable rotating shaft installed inside the lifting screw rod, and a tightening head is installed at the bottom of the rotation. The lifting of the screw rod drives the rotating shaft to go up and down synchronously, and the rotation drives the tightening. The head rotates to tighten the bottle cap. The mechanism for driving the screw rod up and down and the mechanism for driving the rotating shaft are independent of each other, so that the structure is simpler, the cost is lower, and the maintenance is easier.

Owner:乔合祥

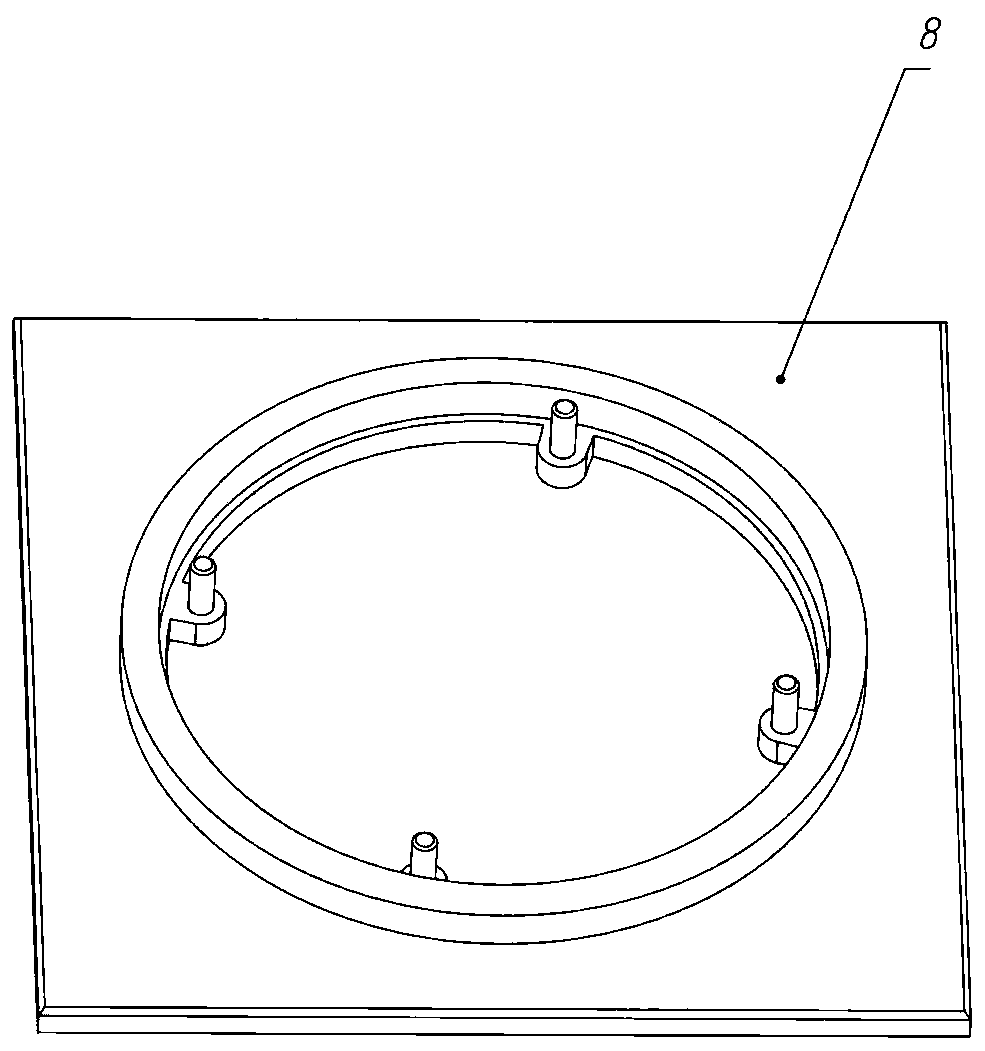

Prized body automatic locking device

The present invention relates to one kind of automatic locking unit for the automatic locking between vehicle body and sledge before pre-treatment and surface electrophoresis treatment. According to the technological scheme of the present invention, there are locking rotation shafts set on the frame in the positions corresponding to the locating holes of the workpiece, one rotation driving unit connected to the locking rotation shafts, locking sheets capable of being inserted into the locating hole, and one workpiece supporting unit. After the workpiece is supported with the supporting unit, it is locked to the frame via rotating the locking rotation shafts driving the locking sheets. The present invention can realize automatic locking between the vehicle body and sledge, and has compact structure, high reliability, low cost and other advantages.

Owner:MIRACLE AUTOMATION ENG CO LTD

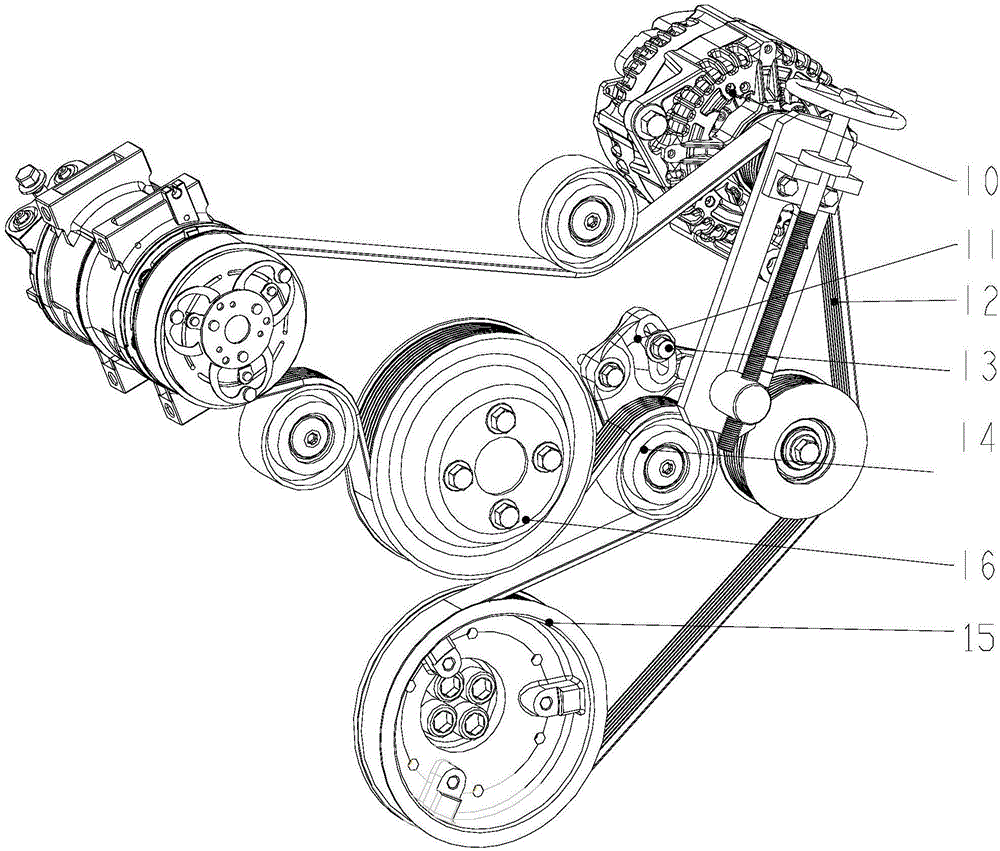

Engine belt tensioning adjusting mechanism

ActiveCN106641140AGuarantee the quality of workRealize automatic tighteningGearingMechanical engineeringKidney

The invention discloses an engine belt tensioning adjusting mechanism. The mechanism comprises a fixing plate; a long kidney-shaped through groove is formed in the fixing plate; an adjusting shaft is arranged in the through groove of the fixing plate; the front shaft end of the adjusting shaft penetrates through the through groove and can slide in the length direction of the through groove with the inner wall of the through groove as a guide; the rear shaft end of the adjusting shaft is arranged to be a feed screw nut with an internal thread structure; an adjusting screw rod in threaded fit with the feed screw nut of the adjusting shaft is arranged on the front surface of the fixing plate by utilizing an L-shaped connecting plate, a rotary hand wheel is arranged at one end of the adjusting screw rod and is used for driving the adjusting screw rod to rotate so as to enable feed the screw nut to move in the length direction of the through groove, and therefore the position of the adjusting shaft in the length direction of the through groove can be adjusted; and the front shaft end of the adjusting shaft is linked with a tensioning wheel, and therefore the tensioning degree of a belt can be adjusted. The engine belt tensioning adjusting mechanism has the advantages that the tensioning degree of the belt can be accurately adjusted, and the working quality of the engine can be ensured.

Owner:ANHUI JIANGHUAI NAVISTAR DIESEL ENGINE CO LTD

Automatic-held shaft part safety protection frame

ActiveCN107322549ASave production spaceAchieve fixationWork tools storageEngineeringMechanical engineering

The invention relates to an automatic-held shaft part safety protection frame, and effectively solves the problems of large floor area of shaft parts, inconvenience in use and easy deformation in transverse placement of shafts. The automatic-held shaft part safety protection frame comprises an annular cavity formed between an inner sleeve and an outer sleeve; a first through groove is formed in the inner sleeve; pressing blocks are arranged in the first through groove; the pressing blocks on the same periphery form a clamping unit; a pressing disc is arranged in the annular cavity; multiple projection blocks are arranged on the inner wall of the pressing disc; first springs are connected between the pressing blocks and the side walls of the inner sleeve; a pressing plate is mounted in a blind hole; a first slide block capable of sliding up and down is mounted on the outer side wall of a first groove; a pull rod is fixed below the first slide block; the pressing plate moves up and down to drive the first slide block to downwards move through the pull rod; the first slide block is hinged with a second slide block capable of sliding inwards and outwards by a connecting rod; and a second spring is connected between the pressing plate and the bottom of the blind hole. The automatic-held shaft part safety protection frame is skillful in structure, convenient in operation and safe and reliable in use.

Owner:ANHUI WANNAN ELECTRIC MACHINE

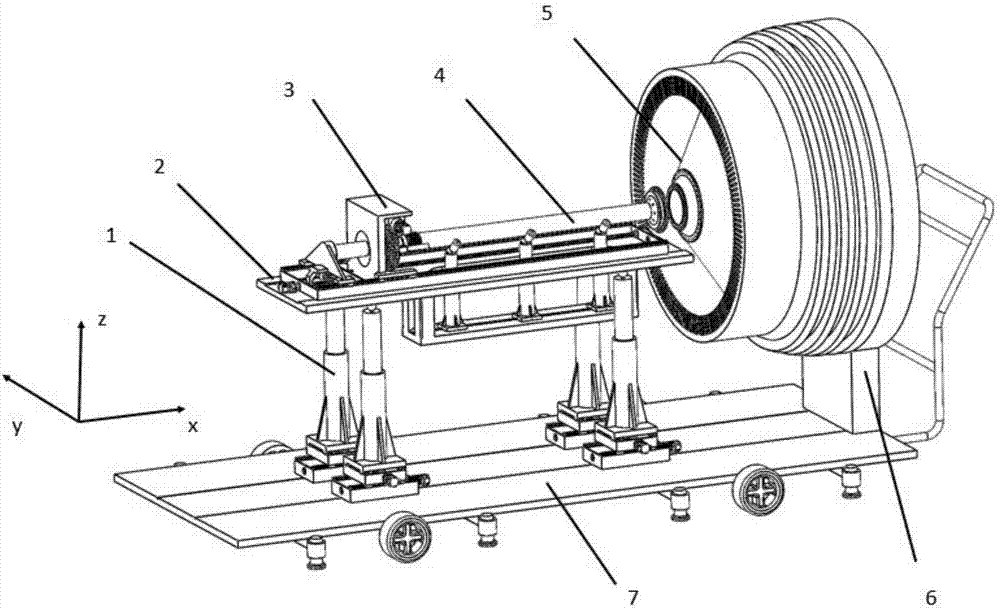

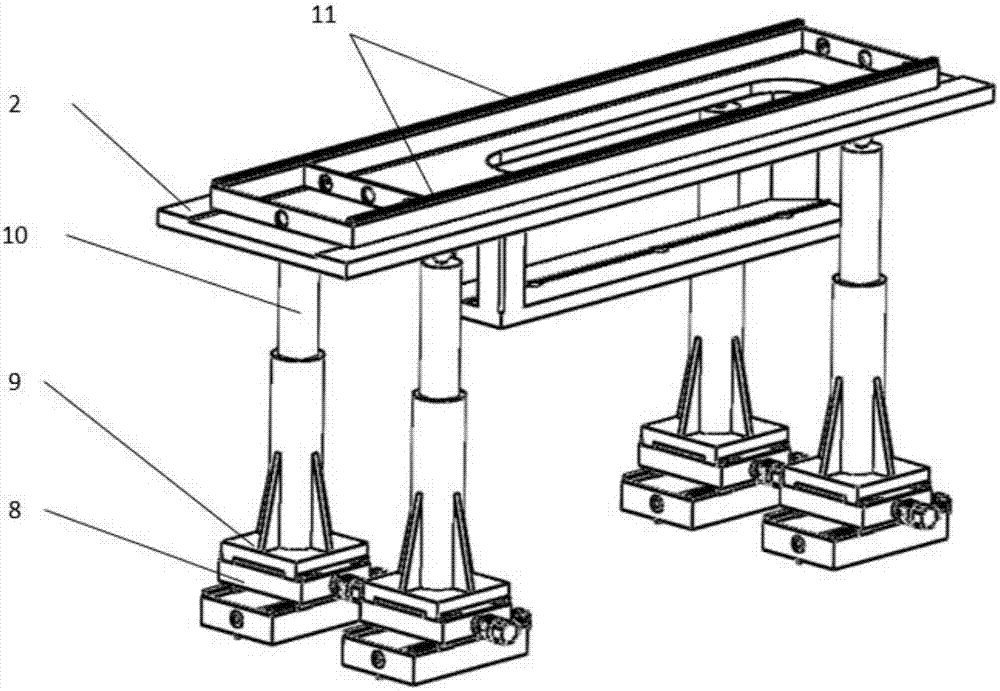

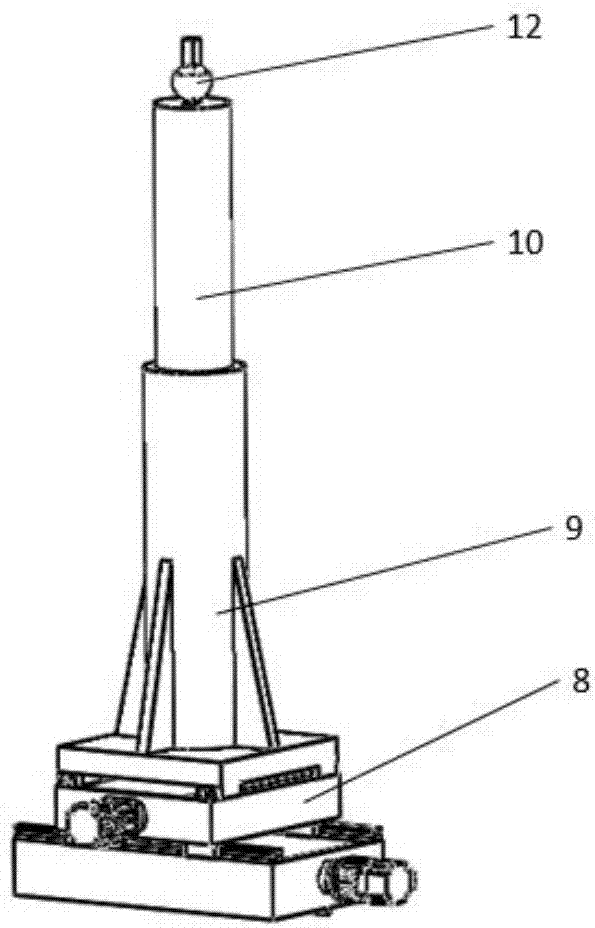

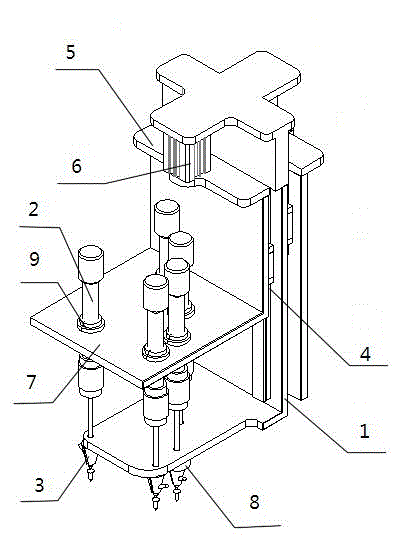

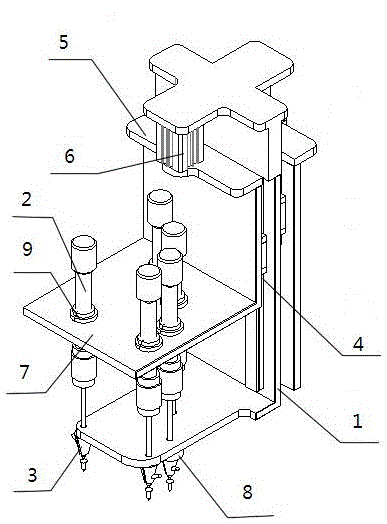

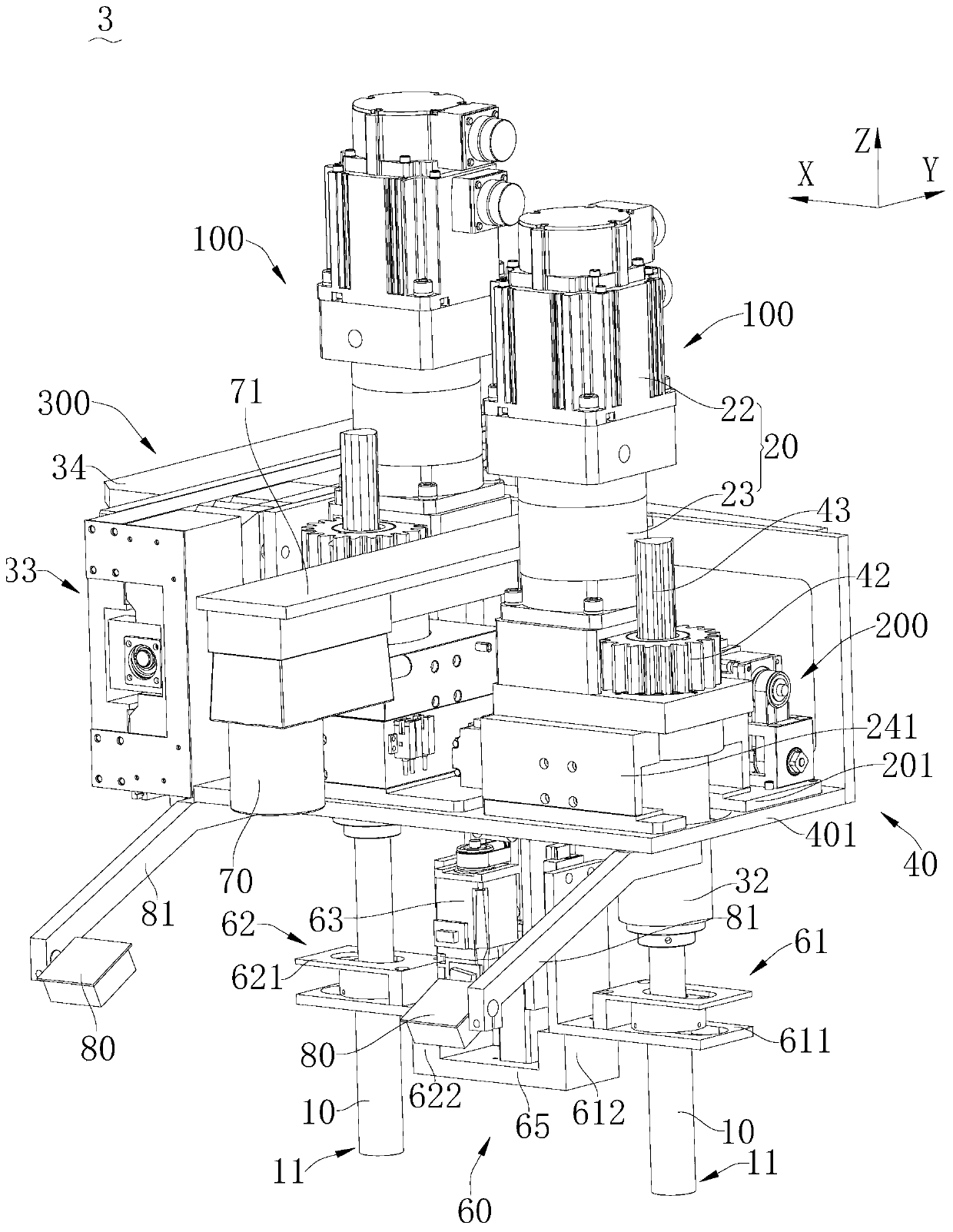

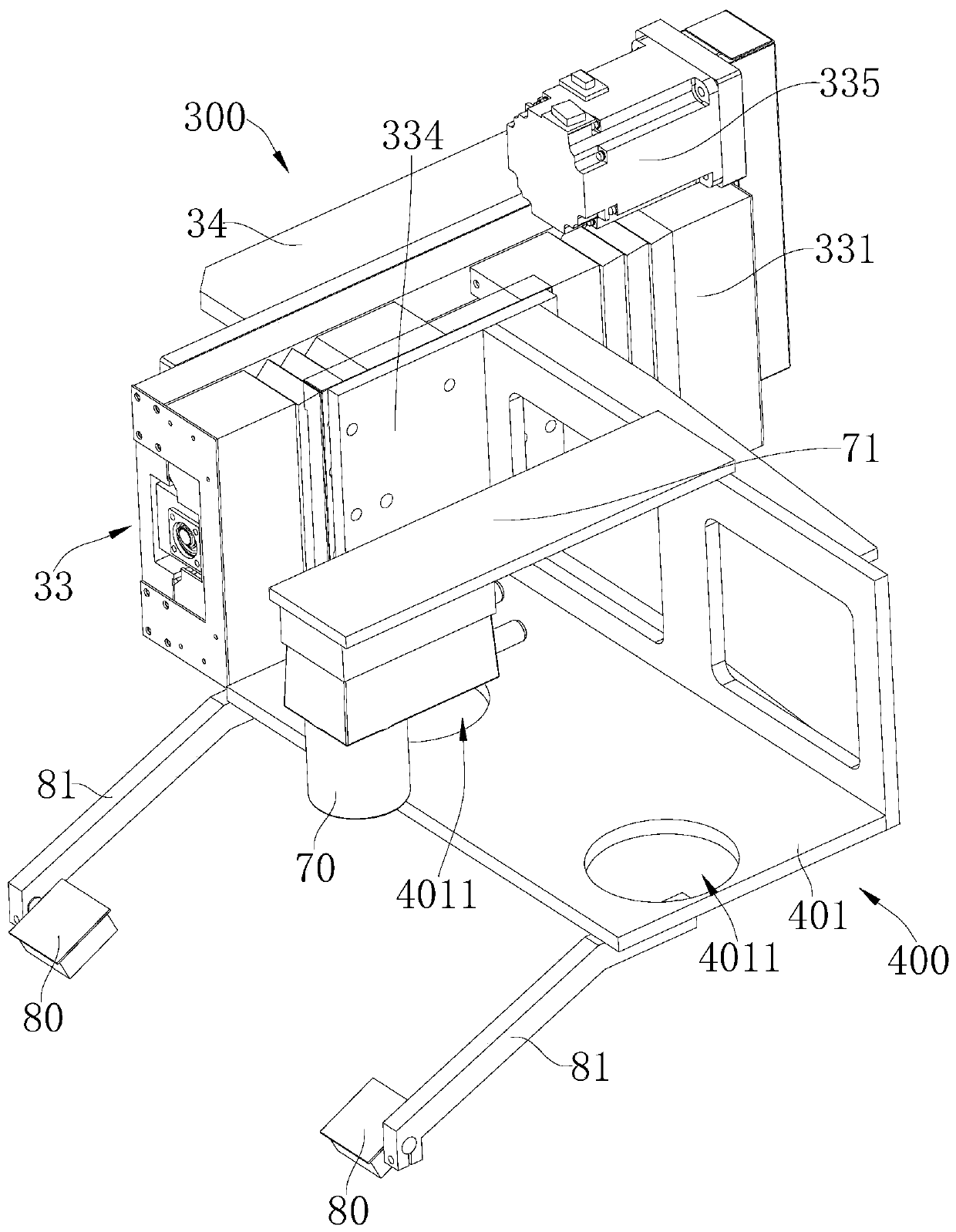

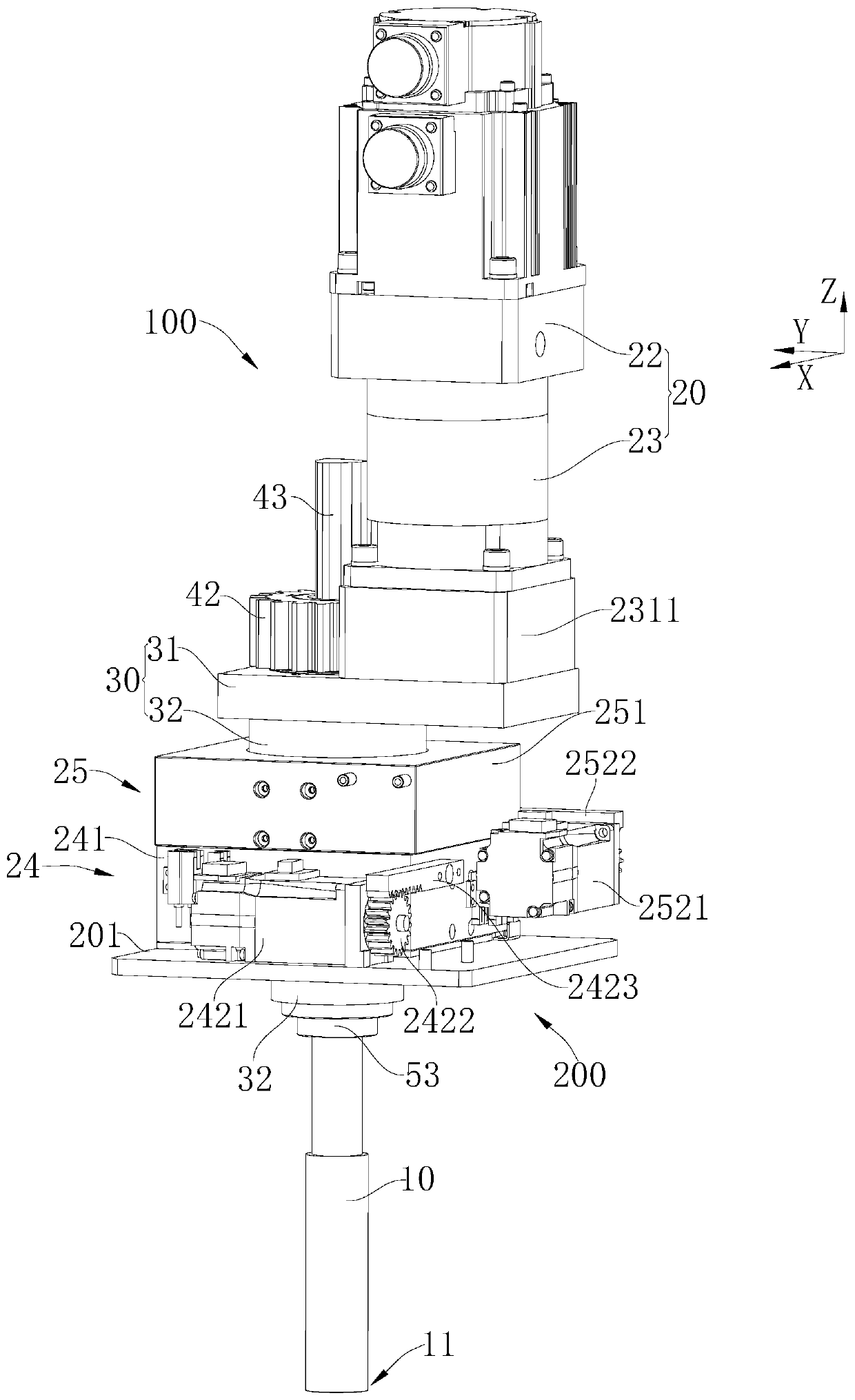

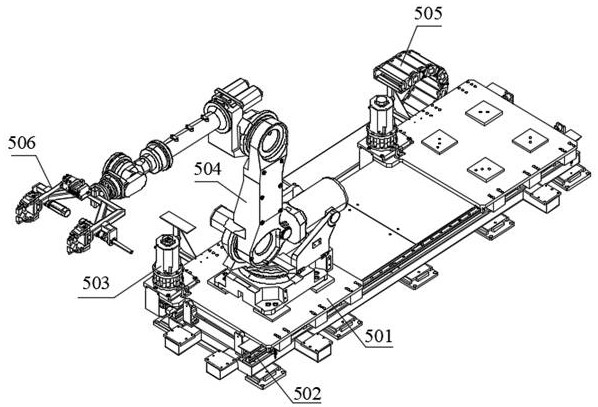

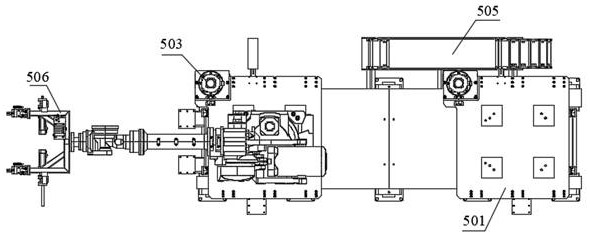

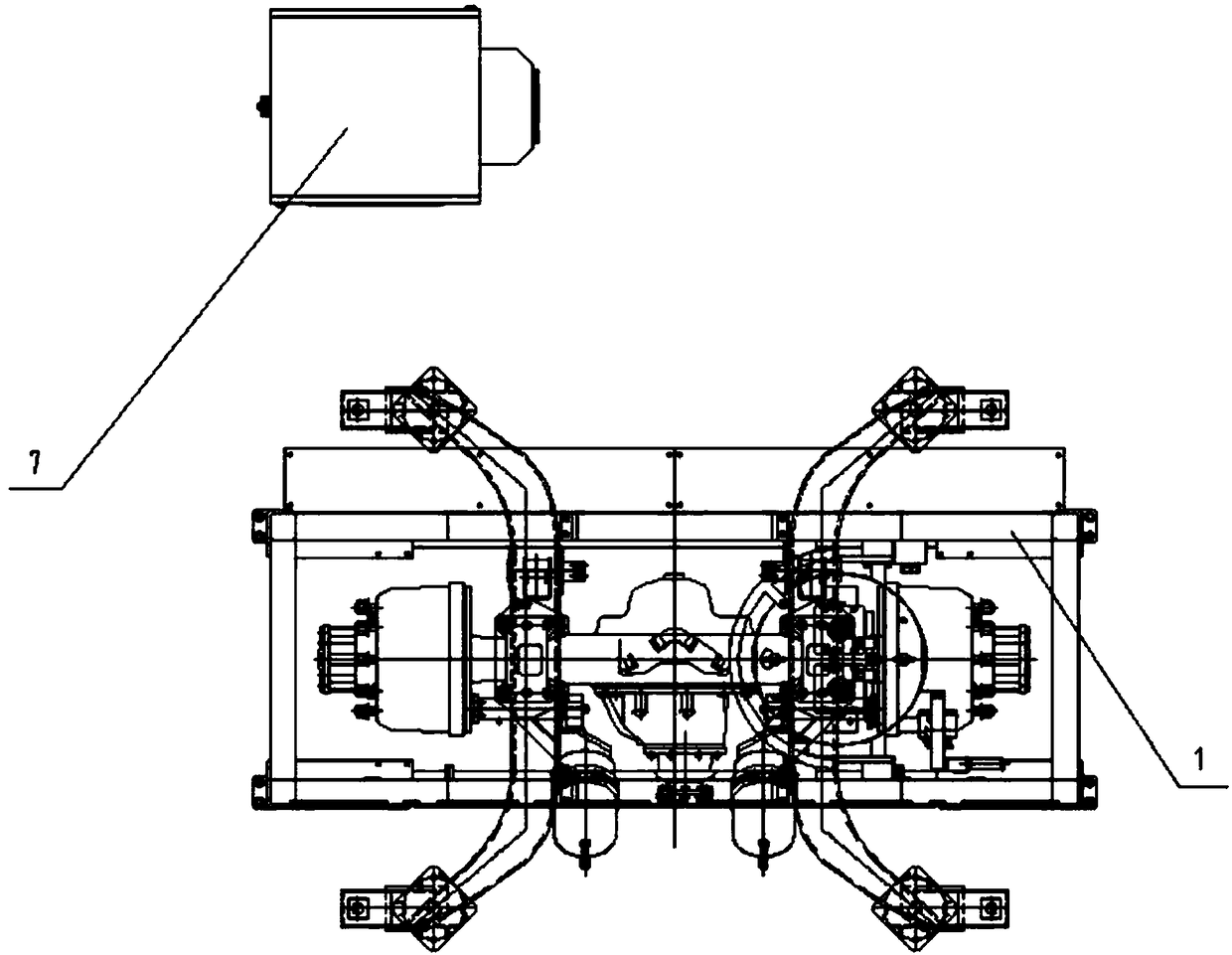

Automatic assembly equipment with collaborative gesture adjustment, collision prevention and tightening functions

ActiveCN107984203AStrong posture adjustment abilityHigh precision in posture adjustmentWork benchesMetal working apparatusButt jointSimulation

The invention discloses automatic assembly equipment with collaborative gesture adjustment, collision prevention and tightening functions. The automatic assembly equipment comprises at least two pairsof POGO column mechanisms arranged on a base through two-dimensional motion mechanisms, and gesture adjustment movable platforms and screw tightening devices arranged on the POGO column mechanisms, wherein parts to be assembled are arranged in the screw tightening devices, and are aligned to fixed parts. The automatic assembly equipment has the advantages of high gesture adjustment motion capacity, high gesture adjustment motion precision, high bolt tightening efficiency and full automation, and can realize precise butt joint of the parts and bolt fastening. The automatic assembly equipment greatly reduces the part assembly difficulty and potential safety hazards, improves the butt joint efficiency, and meets the assembly process requirements.

Owner:SHANGHAI JIAO TONG UNIV

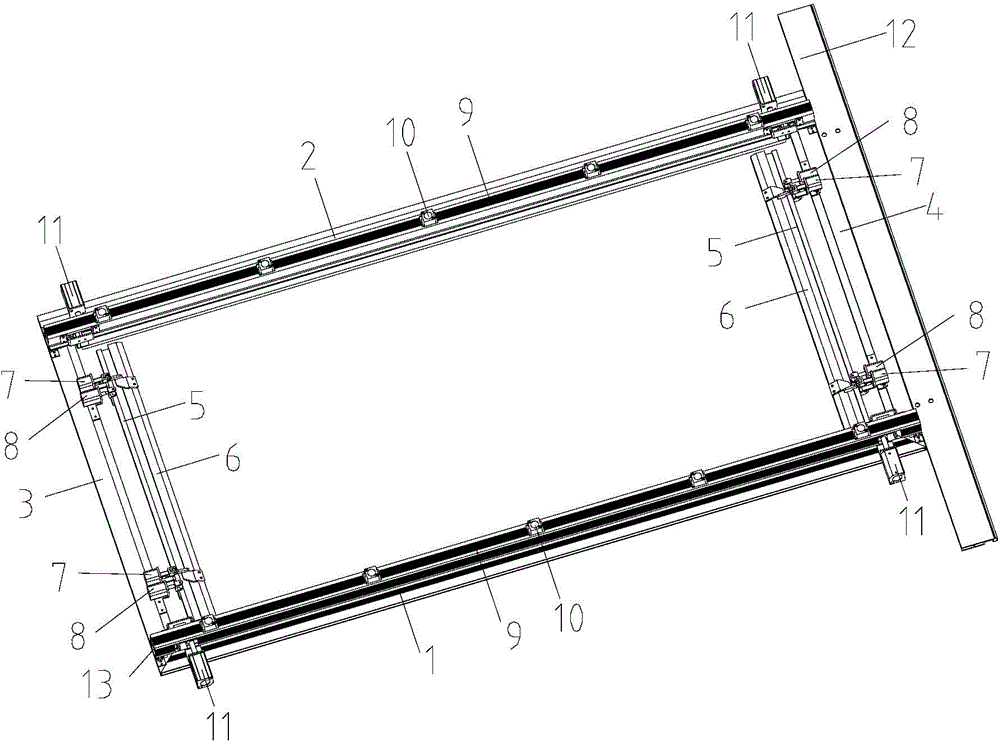

Special embroidery box for embroidered cloth

The invention discloses a special embroidery box for embroidered cloth. The special embroidery box comprises a front beam, a rear beam, a left beam, a right beam, a supporting beam, five pneumatic devices c, two cylinder connecting rod mechanisms, a pneumatic device a, a pneumatic device b, a rear edge strip and left and right beam cover plates, wherein the front beam, the rear beam, the left beam and the right beam form an embroidery box frame; the supporting beam, the five pneumatic devices c and the two cylinder connecting rod mechanisms are mounted on the front beam and the rear beam; the pneumatic device a, the pneumatic device b, the rear edge strip and the left and right beam cover plates are mounted on the left beam and the right beam; a cylinder a of each of the cylinder connecting rod mechanisms is fixed on the front beam through an angle plate, and a cylinder joint is positioned at the threaded end of a piston rod of the cylinder a; each of the two cylinder connecting rod mechanisms and a fixing plate are mounted on the front beam through a two-eye connecting rod; the two-eye connecting rod is positioned on the left side of a three-eye connecting rod and is connected with a middle hole of the three-eye connecting rod through a pin shaft; one end of the cylinder joint is connected to the threaded end of the piston rod of the cylinder a, and the other end of the cylinder joint is connected with an upper end hole of the two-eye connecting rod through a pin shaft and is positioned on the right side of the three-eye connecting rod; the pneumatic devices are adopted for pressurization; the structure is simple; the automatic clamping and tensioning of the cloth in the embroidery process can be realized, so that the embroidery process becomes very simple and quick.

Owner:上工富怡智能制造(天津)有限公司

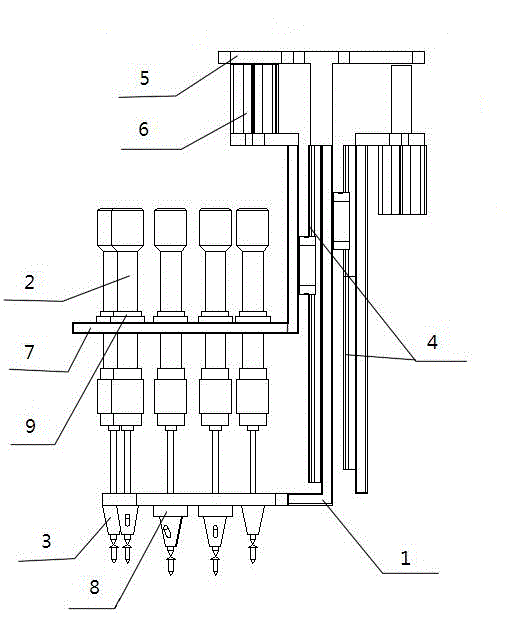

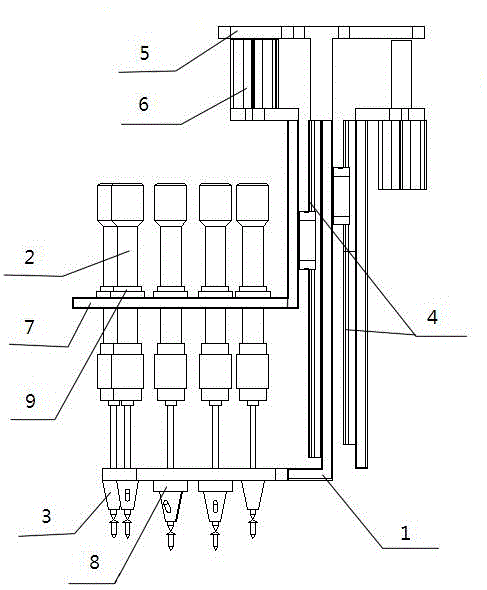

Automatic screw tightening machine

InactiveCN104999264ARealize automatic tighteningReduce labor intensityMetal working apparatusEngineeringScrew thread

The invention provides an automatic screw tightening machine. In order to solve the above technical problems, the following technical scheme is adopted: the automatic screw tightening machine comprises a machine base, screw tightening devices, screw tightening device heads, a slideway, a cylinder fixing plate and a cylinder. The automatic screw tightening machine is characterized by also comprising a detachable fixing plate, at least two holes for inserting the screw tightening devices are formed in the fixing plate; the positions of holes for inserting the screw tightening devices are different on different fixing plates; the upper end of each screw tightening device head is provided with a screw tightening device head cushion block; the tail end of each screw tightening device head is magnetic; limiting mechanisms are arranged on each screw tightening device on and below the fixing plate; the limiting mechanisms of the screw tightening devices on the fixing plate are nuts; and an external screw thread is arranged on each screw tightening device and is matched with an internal screw thread which is arranged on the corresponding hole in the fixing plate. The automatic screw tightening machine has the following beneficial effects: the automatic tightening of screws is realized; the labor intensity is reduced; and furthermore, multiple screws can be tightened at a time, so that the production efficiency is improved.

Owner:苏州金牛精密机械有限公司

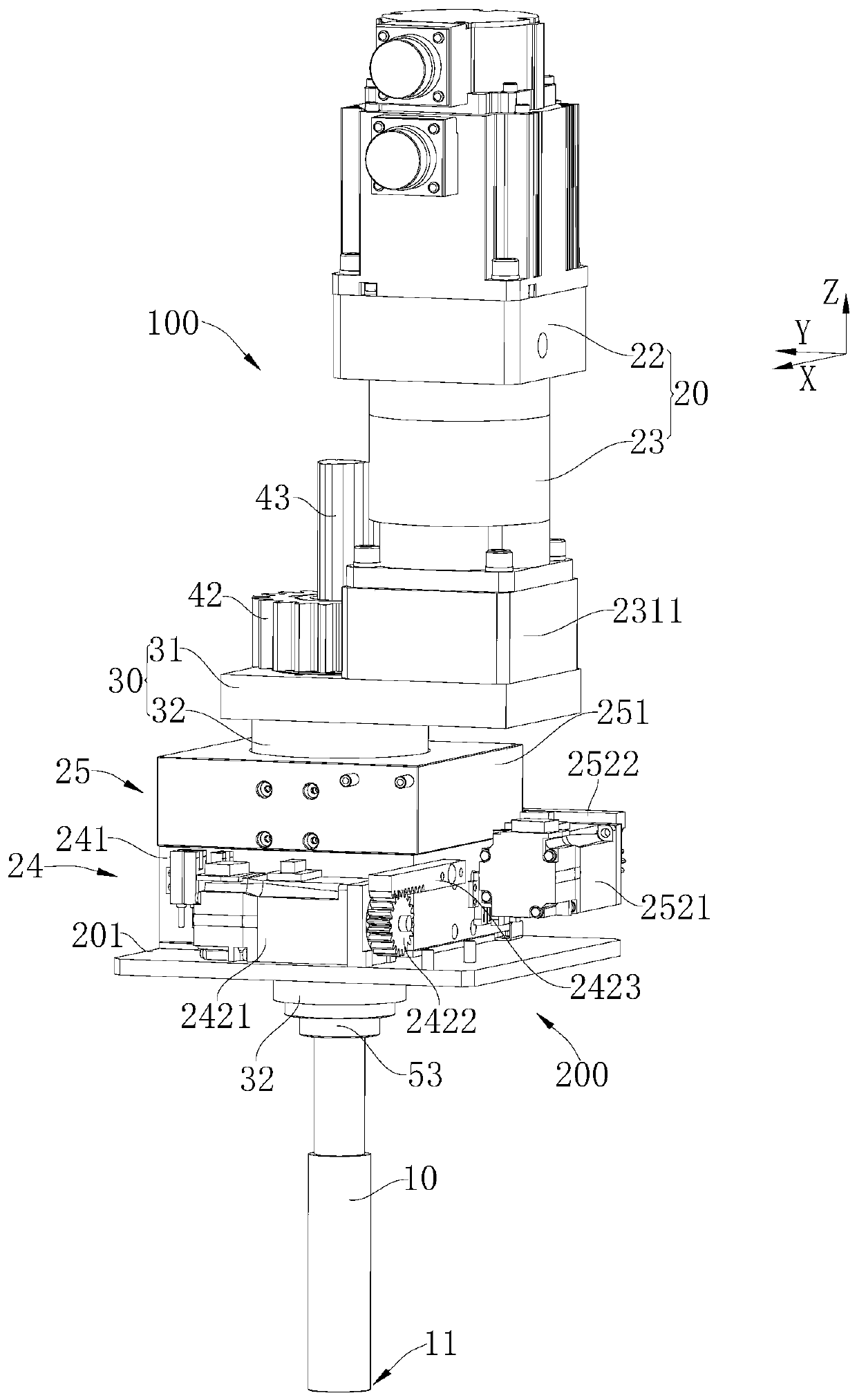

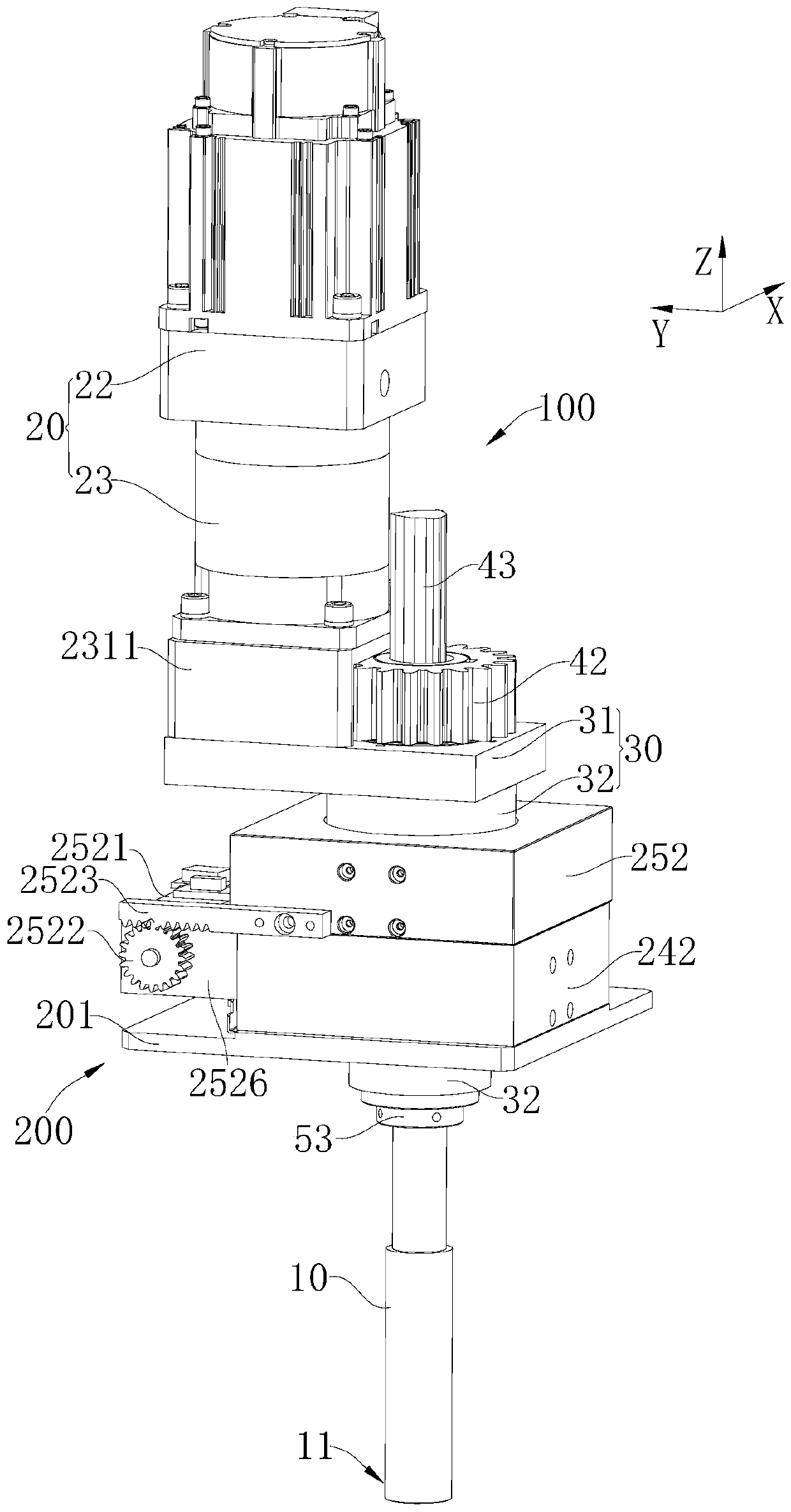

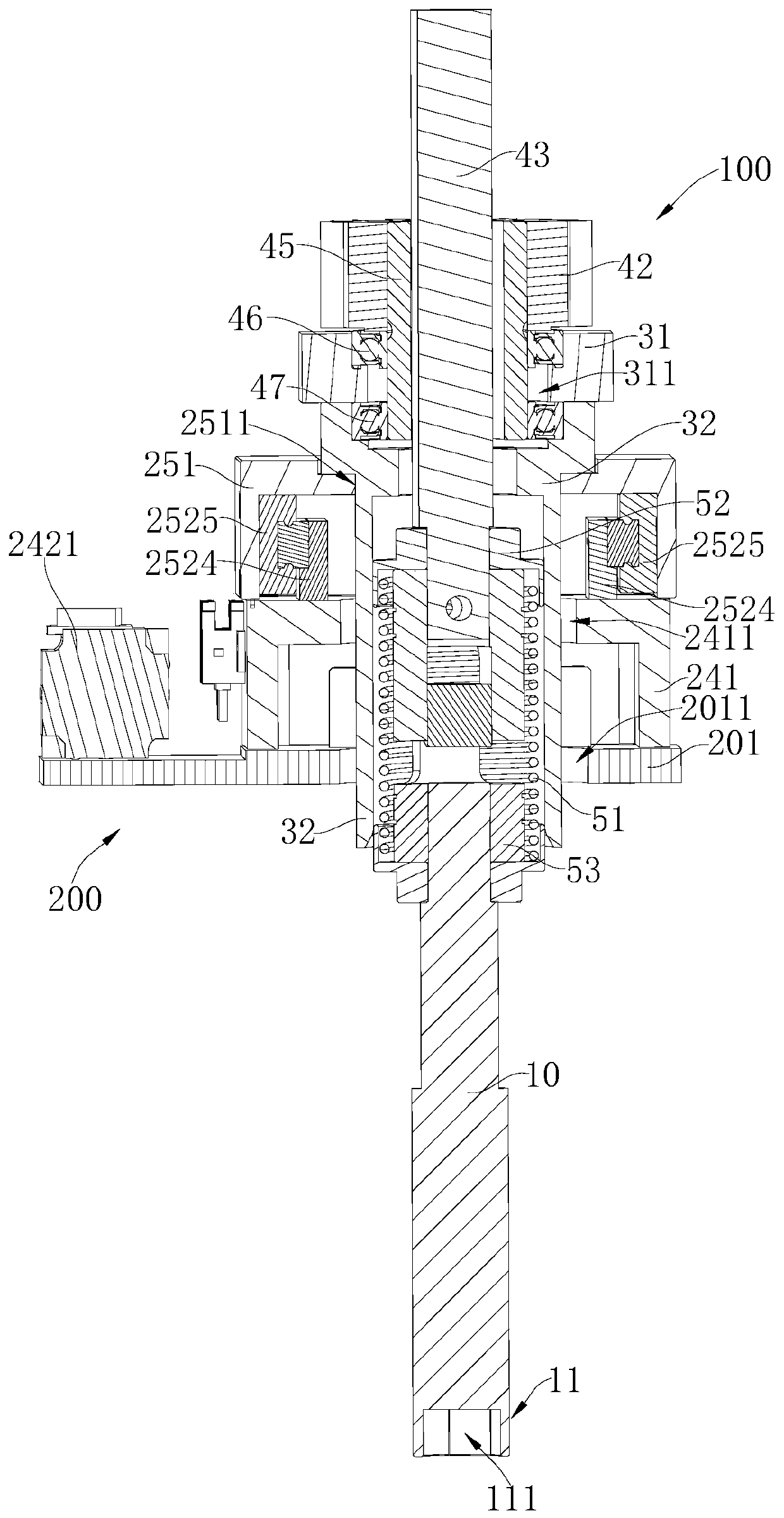

Nut screwing device

PendingCN110757140ARealize automatic tighteningImprove work efficiencyMetal working apparatusControl engineeringAutomation

The invention belongs to the technical field of fasteners, and particularly relates to a nut screwing device. The device comprises a frame, and a nut screwing mechanism and a position adjusting mechanism which are mounted on the frame, wherein the nut screwing mechanism comprises a mounting seat, a sleeve and a rotary driving part; one end of the sleeve is provided with a nesting part; the rotarydriving part is in driving connection with the sleeve to drive the sleeve to rotate, so that a nut is rotated and screwed driven by the nesting part; and the position adjusting mechanism is used for adjusting the position of the nut screwing mechanism relative to the nut so as to move the nesting part over the nut. According to the nut screwing device, the nut can be screwed automatically, the position adjusting mechanism can automatically adjust the position according to the position of the nut before the nut screwing mechanism operates, and thus it is ensured that the nut screwing mechanismis moved to the accurate position first and then the screwing operation is performed; and the movement and the positioning of the nut screwing mechanism are automatically adjusted through the positionadjusting mechanism without manual participation, the automation degree is high, the labor intensity of operators can be effectively reduced, and the operation efficiency of nut screwing is improved.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

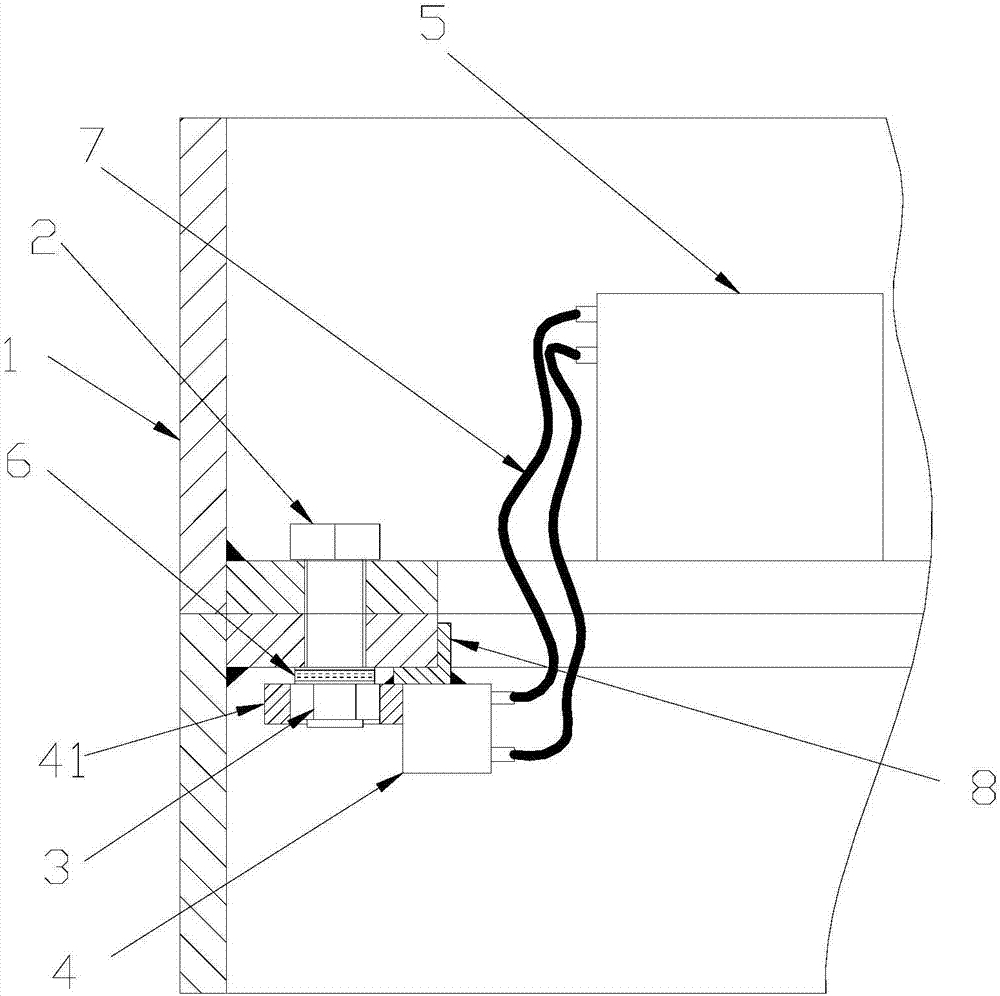

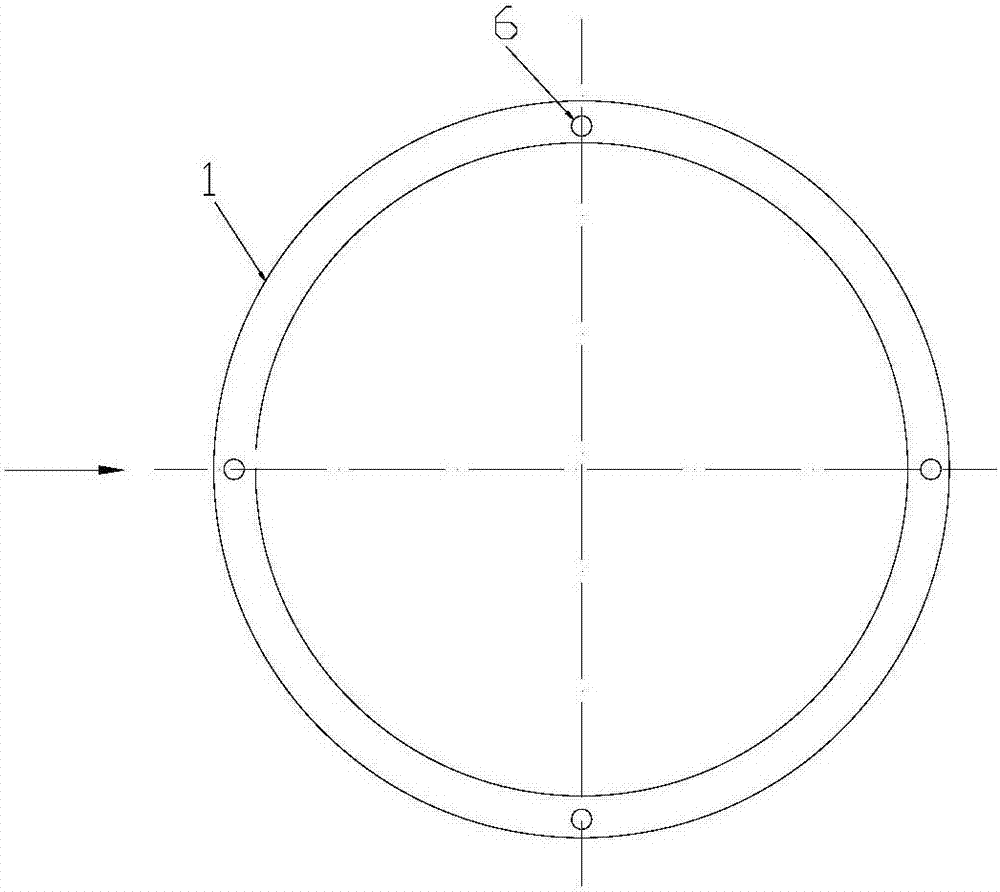

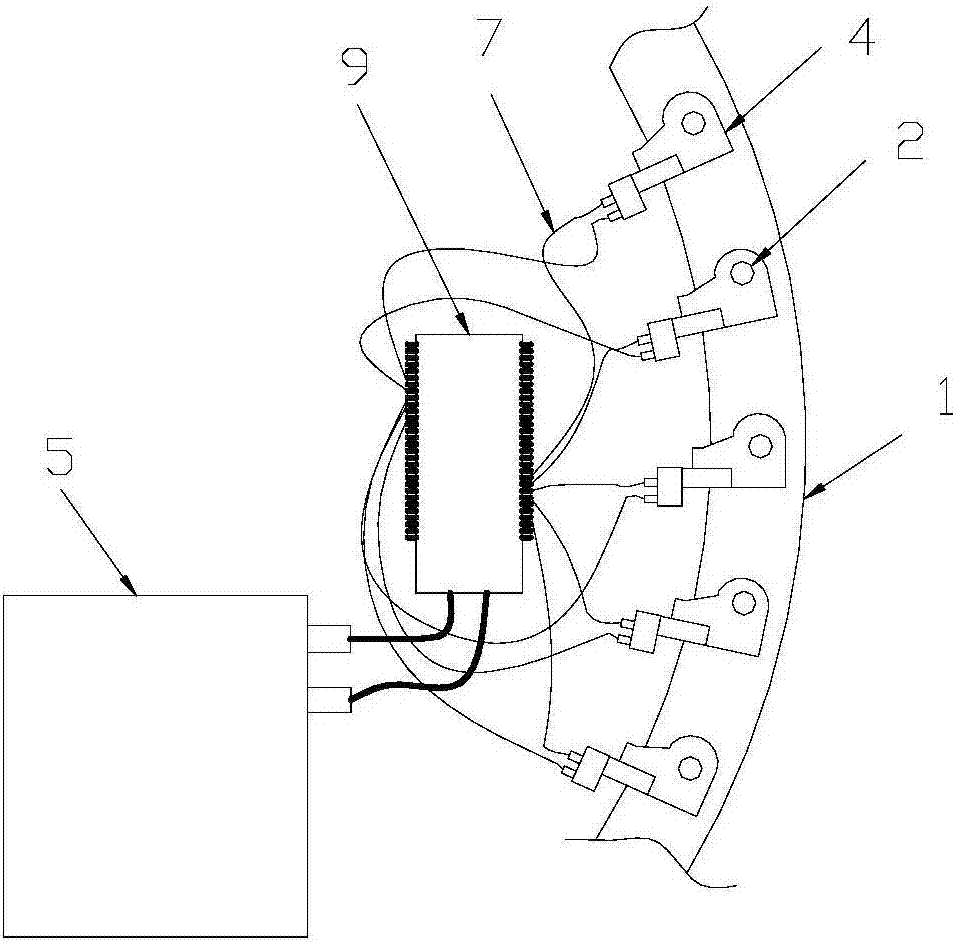

Bolt pre-tightening device and bolt tightening method on draught fan tower barrel

InactiveCN106925987AImplement automatic detectionTime-consuming and laborious to solveMeasurement of torque/twisting force while tighteningMetal working apparatusAutomatic controlEngineering

The invention relates to a bolt pre-tightening device on a draught fan tower barrel. The bolt pre-tightening device comprises a stress detection device and a bolt tightening device which are installed in the tower barrel connection position. The stress detection device comprises a plurality of pressure sensors which are arranged in the circumferential direction of the tower barrel. The pressure sensors are arranged on the sides, making contact with the tower barrel, of the ends of bolts. The pressure sensors are connected with the bolt tightening device so as to produce electric signals for controlling the bolt tightening device to act. The invention further relates to a bolt tightening method on the draught fan tower barrel. The numerical value of the pressure sensors is detected, and the blots are tightened through automatic control. According to the bolt pre-tightening device and bolt tightening method on the draught fan tower barrel, the tower barrel connection bolts are monitored in real time, the loose bolts can be tightened in time, thus, the draught fan tower barrel connection stability is greatly improved, and the labor burden of overhauling personnel is eased.

Owner:BEIJING PUHUA YINENG WIND POWER TECH

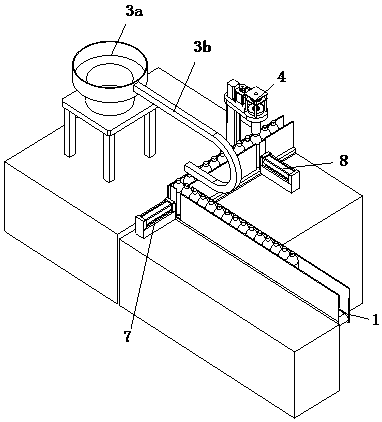

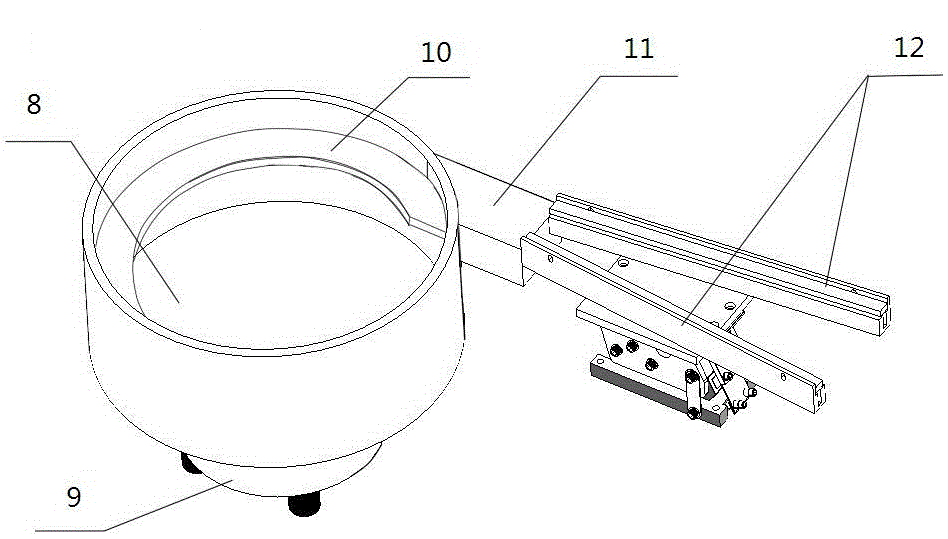

Automatic screw driving device with vibration disc discharging mechanism

InactiveCN105058033ARealize automatic tighteningImprove efficiencyMetal working apparatusEngineeringUltimate tensile strength

The invention provides an automatic screw driving device with a vibration disc discharging mechanism. According to the technical scheme, the automatic screw driving device comprises a base, a screw driving machine, a screwing machine head, a sliding rail, a cylinder fixing plate and a cylinder. The automatic screw driving device is characterized by further comprising a detachable fixing plate and a multi-outlet vibration disc discharging mechanism, at least two holes for insertion of the screw driving machine are formed in the fixing plate, and the positions of the holes, for insertion of the screw driving machine, in different fixing plates are different. The multi-outlet vibration disc discharging mechanism comprises a hopper and a bottom disc. A spirally rising advance channel is formed in the inner wall of the hopper, and a discharger is arranged at the tail end of the advance channel and is provided with two outlet channels. The automatic screw driving device has the following beneficial effects that products can be discharged from a mechanism outlet in any required state and screwed automatically after entering automatic assembly equipment, and accordingly efficiency is high, labor is not needed, the device is safe, rapid and convenient to use, labor intensity is relieved, and production efficiency is improved.

Owner:苏州金牛精密机械有限公司

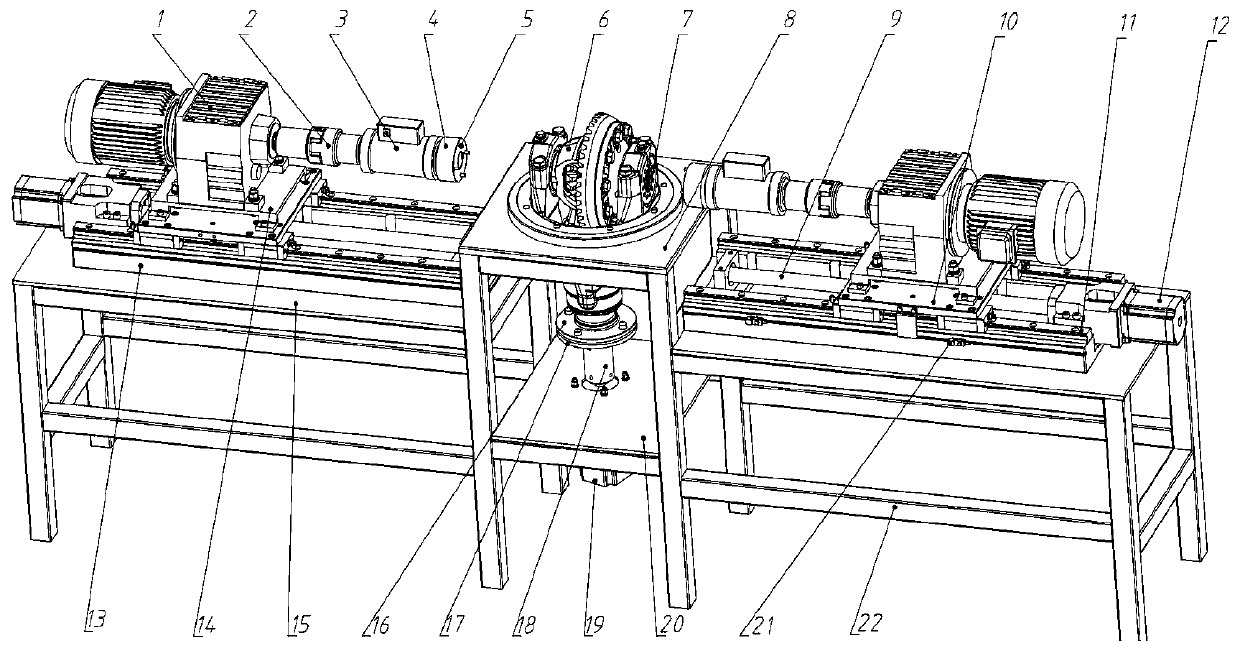

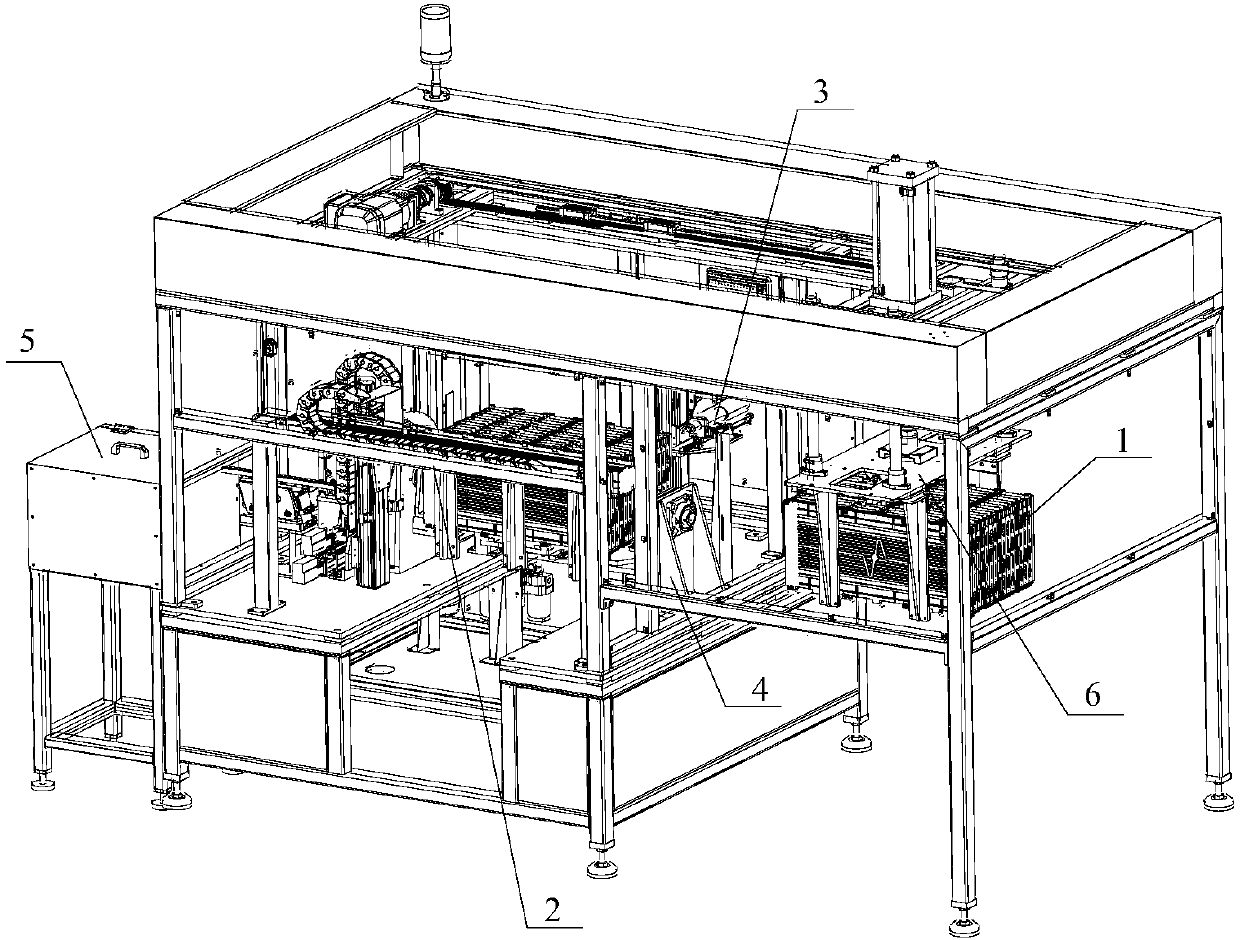

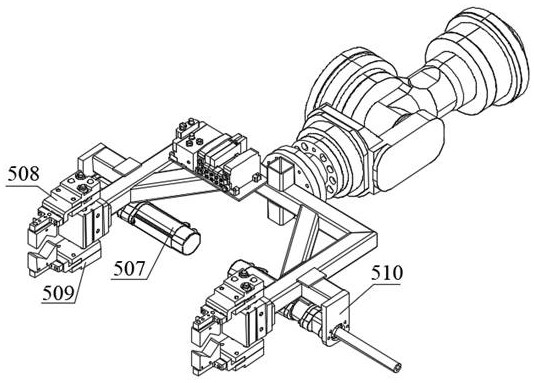

Automatic tightening and mark rolling inspection and assembly system of spline nuts of rear axle main speed reducer

InactiveCN110216459ARealize automatic tighteningHigh degree of automationMetal working apparatusReduction driveGear wheel

The invention discloses an automatic tightening and mark rolling inspection and assembly system of the spline nuts of a rear axle main speed reducer. The automatic tightening and mark rolling inspection and assembly system of the spline nuts of the rear axle main speed reducer comprises a positioning mechanism, tightening devices, a moving device, a mark rolling inspection driving device and a matched servo control system. The positioning mechanism is used for installing and fixing the main speed reducer, the tightening device is used for providing torque for the spline nuts on the two sides of the main speed reducer, and the moving device used for driving the tightening device to move along the axis direction of the spline nuts; the main speed reducer is arranged on the positioning mechanism, the tightening device is provided with two groups, the tightening device are symmetrically arranged on the two sides of the main speed reducer, and the tightening device can be coaxially connected with the spline nuts on the two sides of the main speed reducer respectively; each tightening device is provided with the moving device, and the tightening device and the moving device are arrangedthe working table, and output end of the mark rolling inspection driving device is connected with a connecting flange of the driving gear of the main speed reducer. The automatic tightening and mark rolling inspection and assembly system of the spline nuts of the rear axle main reducer has the advantages of being high in automation degree, high in precision, fast and reliable, intelligent and controllable, greatly improving the working efficiency and the assembly precision, and saving the labor cost.

Owner:WUHAN UNIV OF TECH

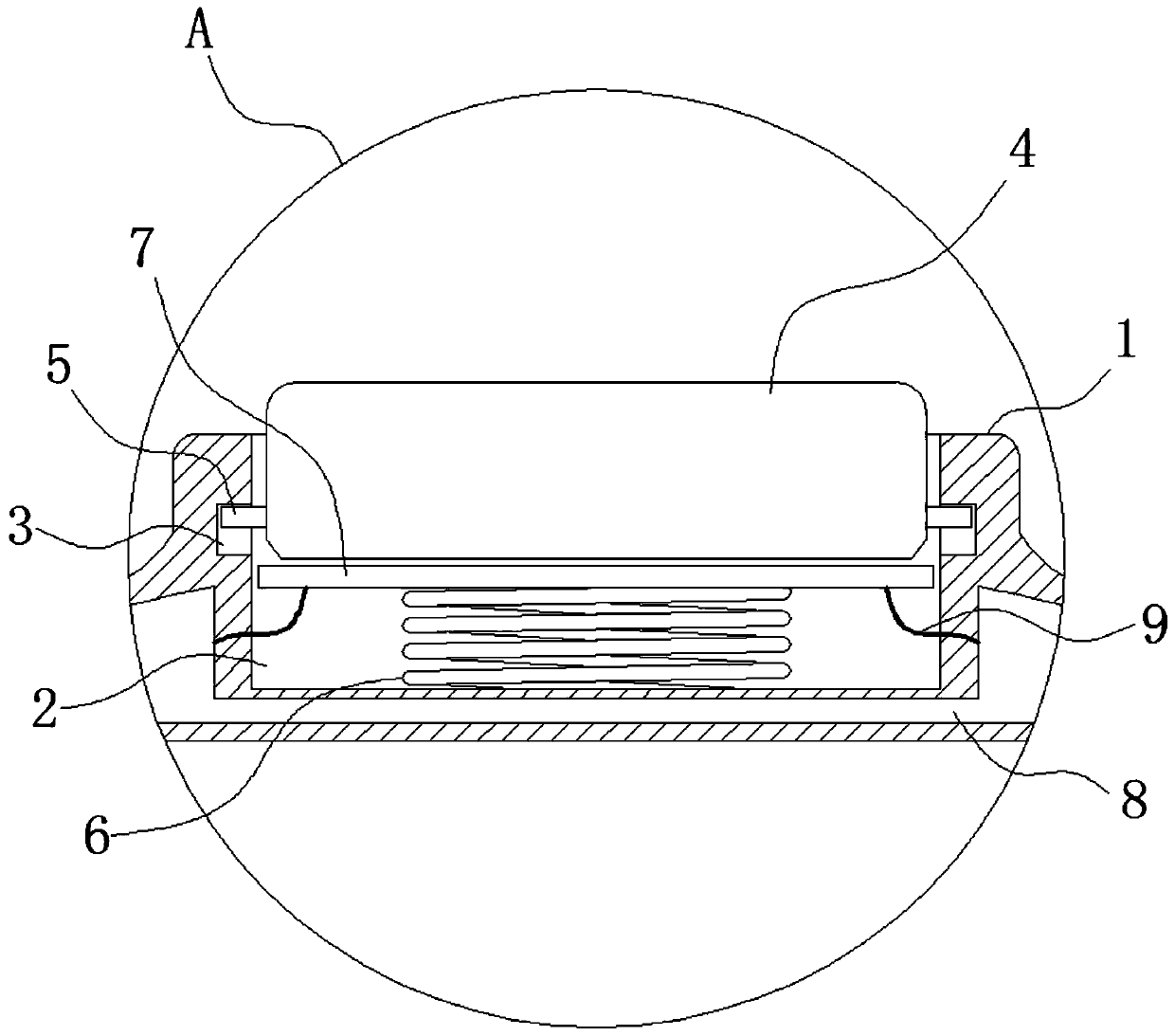

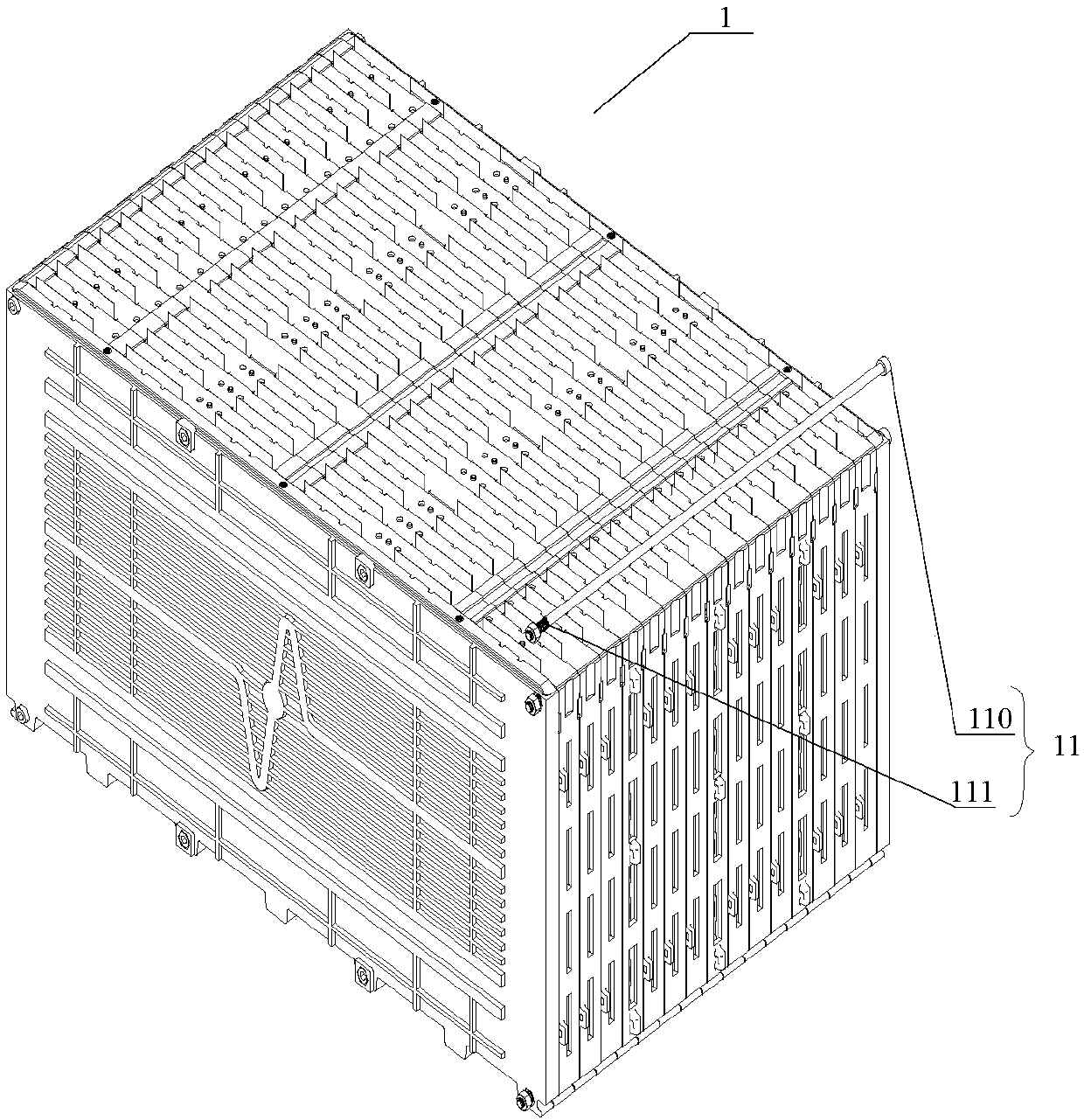

Full-automatic battery module locking device

ActiveCN108054329ARealize automatic tighteningAvoid inconsistent thicknessCell component detailsLocking mechanismEngineering

The invention discloses a full-automatic battery module locking device, which comprises a battery module, a nut positioning mechanism and a torque-adjustable screw locking mechanism, wherein the battery module is provided with a plurality of screws; each screw penetrates through the battery module and comprises a top end part and a thread part; the nut positioning mechanism is arranged at one sideclose to the thread parts and is used for positioning to-be-installed nuts, so that the to-be-installed nuts are overlapped with the axes of the screws; each to-be-installed nut corresponds to one screw; and the torque-adjustable screw locking mechanism is arranged at one side close to the top end parts, and is used for determining locking torque and driving the screws to rotate around the axes of the screws under the action of the locking torque, so that the to-be-installed nuts are arranged at preset positions of the corresponding thread parts. According to the full-automatic battery modulelocking device, automatic tightening of the screws and the nuts is achieved through the nut positioning mechanism and the torque-adjustable screw locking mechanism, tightening missing is avoided, theinconsistency of the locking torque is avoided and the thickness of the locked battery module is consistent, thereby reducing the labor cost and improving the quality and the production efficiency ofthe battery module.

Owner:SHENZHEN CLOU ELECTRONICS

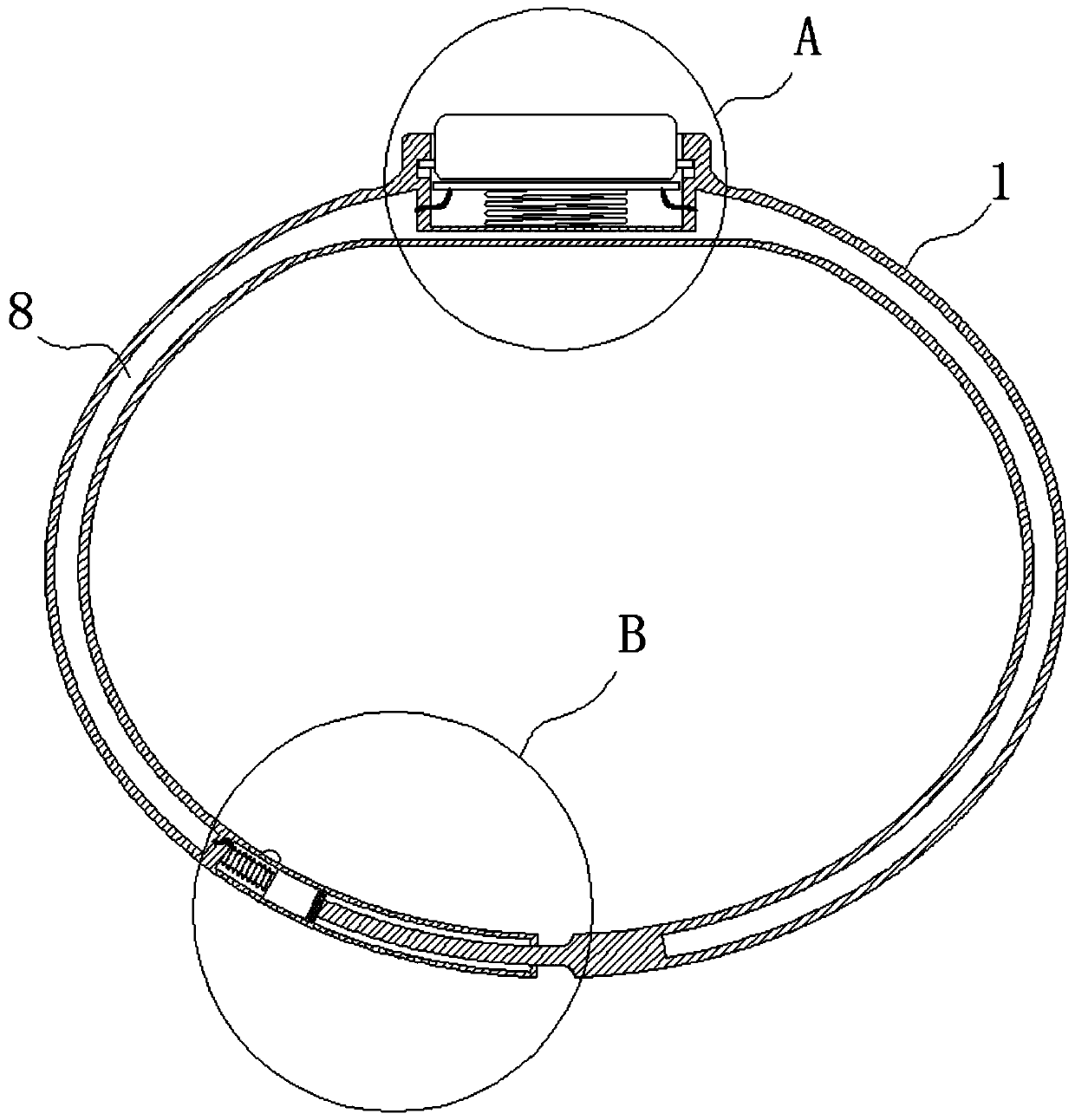

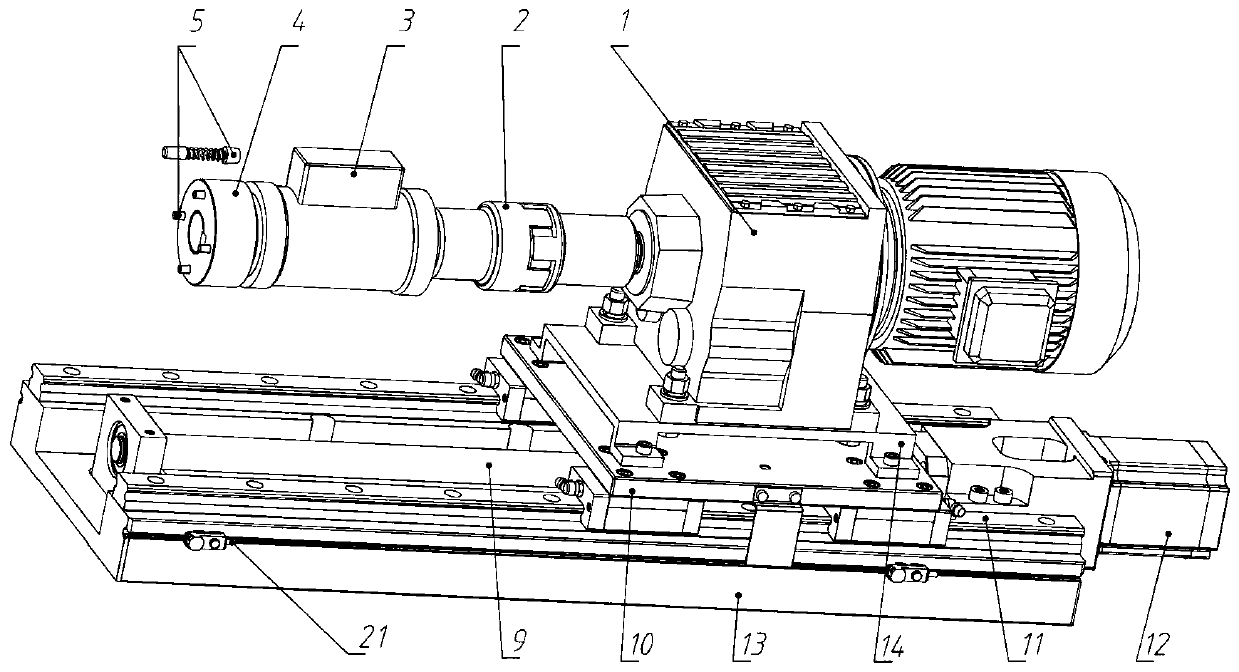

Workpiece clamping device of filament winder

The invention discloses a workpiece clamping device of a filament winder. The workpiece clamping device comprises a rack and an automatic loosening and tightening clamping mechanism. The automatic loosening and tightening clamping mechanism comprises rotating clamping heads located at the two ends of the rack and used for clamping a filament winding plate, and clamping head rotating driving devices driving the rotating clamping heads to rotate. Each rotating clamping head comprises a first clamping block fixed to the rack, wherein the first clamping block and a second clamping block are hinged, a clamping head closing elastic piece for driving the first clamping block and the second clamping block to be closed at the other side of the hinged position is arranged between the side, located at the hinged position, of the first clamping block and the second clamping block, and a clamping head loosening driving device used for exerting pressure on the second clamping block to enable the clamping head closing elastic piece to be compressed and releasing the pressure to enable the clamping head closing elastic piece to be expanded is arranged above the rotating clamping head. According to the structure, automatic loosening and tightening of the rotating clamping heads can be achieved, the loosening and tightening operation can be achieved without manual operation, time and labor are saved, and the production efficiency is high.

Owner:何雲彬

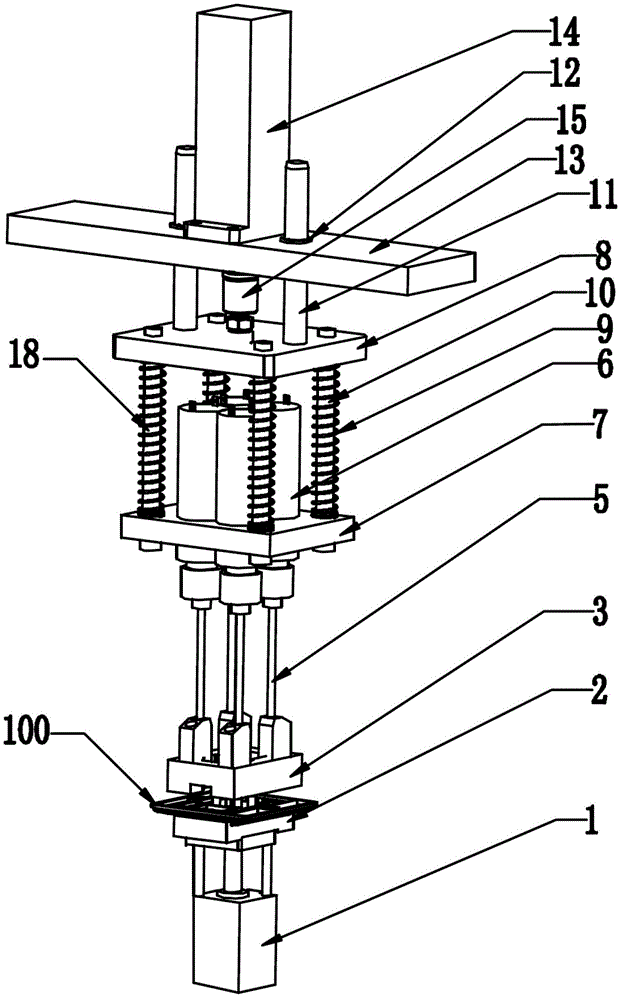

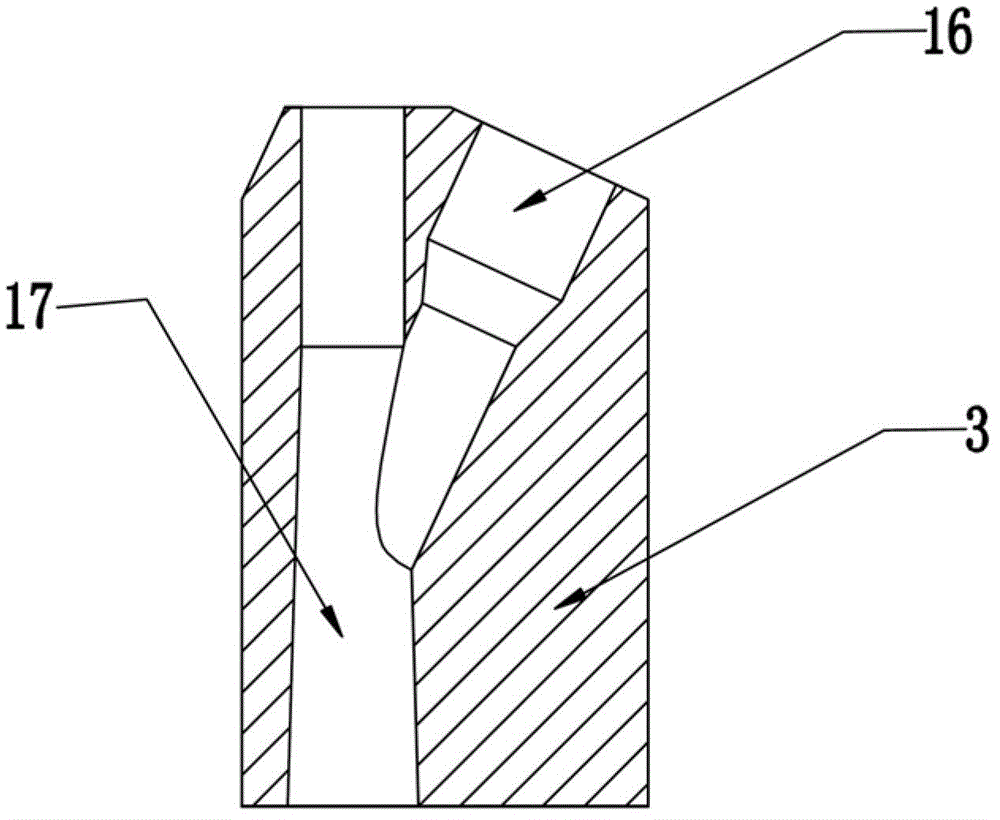

Screw automatic feeding and screwing device

InactiveCN106736355AReasonable structureHigh degree of automationMetal working apparatusEngineeringScrew head

The invention provides a screw automatic feeding and screwing device and belongs to the technical field of feeding machines. The device comprises a feeding mechanism and a screwing mechanism; one end of a sector plate of the feeding mechanism is installed on an upper side of a rotating shaft; a material passage is installed at one side of the sector plate obliquely; the sector plate is provided with an U-shape groove; a spacing rod is inserted in the U-shape groove of the sector plate; one end of a material taking plate is installed on the side end of the sector plate through a material taking pin in a up-down swing mode; the end part of the material taking plate is provided with a material taking opening; two ends of a return extension spring of a return assembly are respectively connected to an upper extension spring pillar and a lower extension spring pillar; a first gear of the screwing mechanism is installed at the lower end of a first fulcrum shaft coaxially; a second gear is installed on a second fulcrum shaft coaxially; the first gear and the second gear are mutually meshed; a screwdriver blade is mounted at the lower end of the second fulcrum shaft; the lower end of a driving cylinder is connected to the second fulcrum shaft through a screwing head. The device of the invention can realize automatic feeding and screwing; the structure is reasonable and the automation degree is high; the work efficiency is greatly increased.

Owner:TONGXIANG GREENCITY FLOCKING

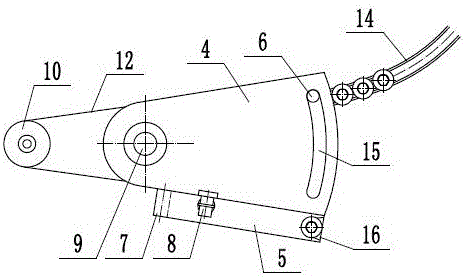

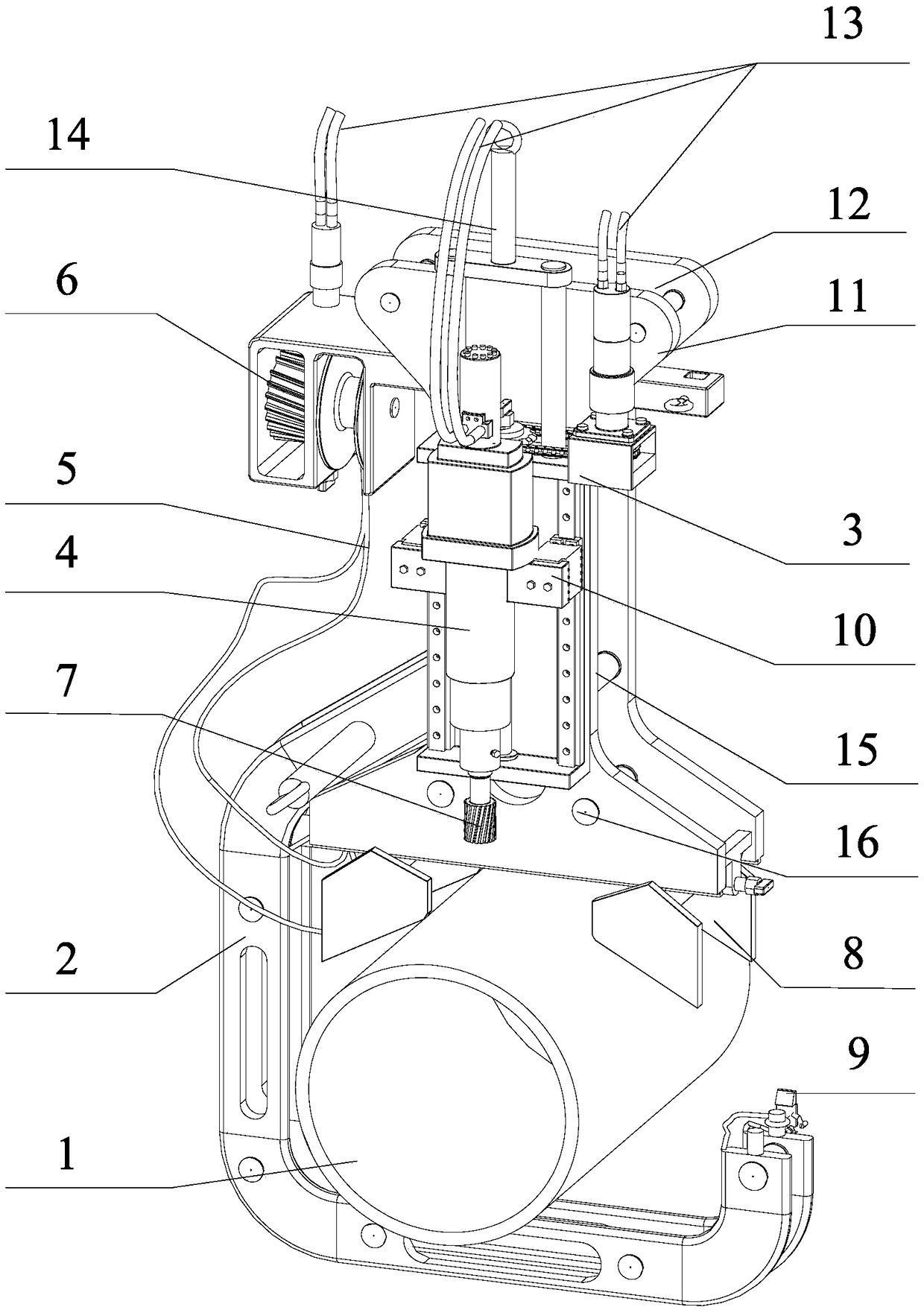

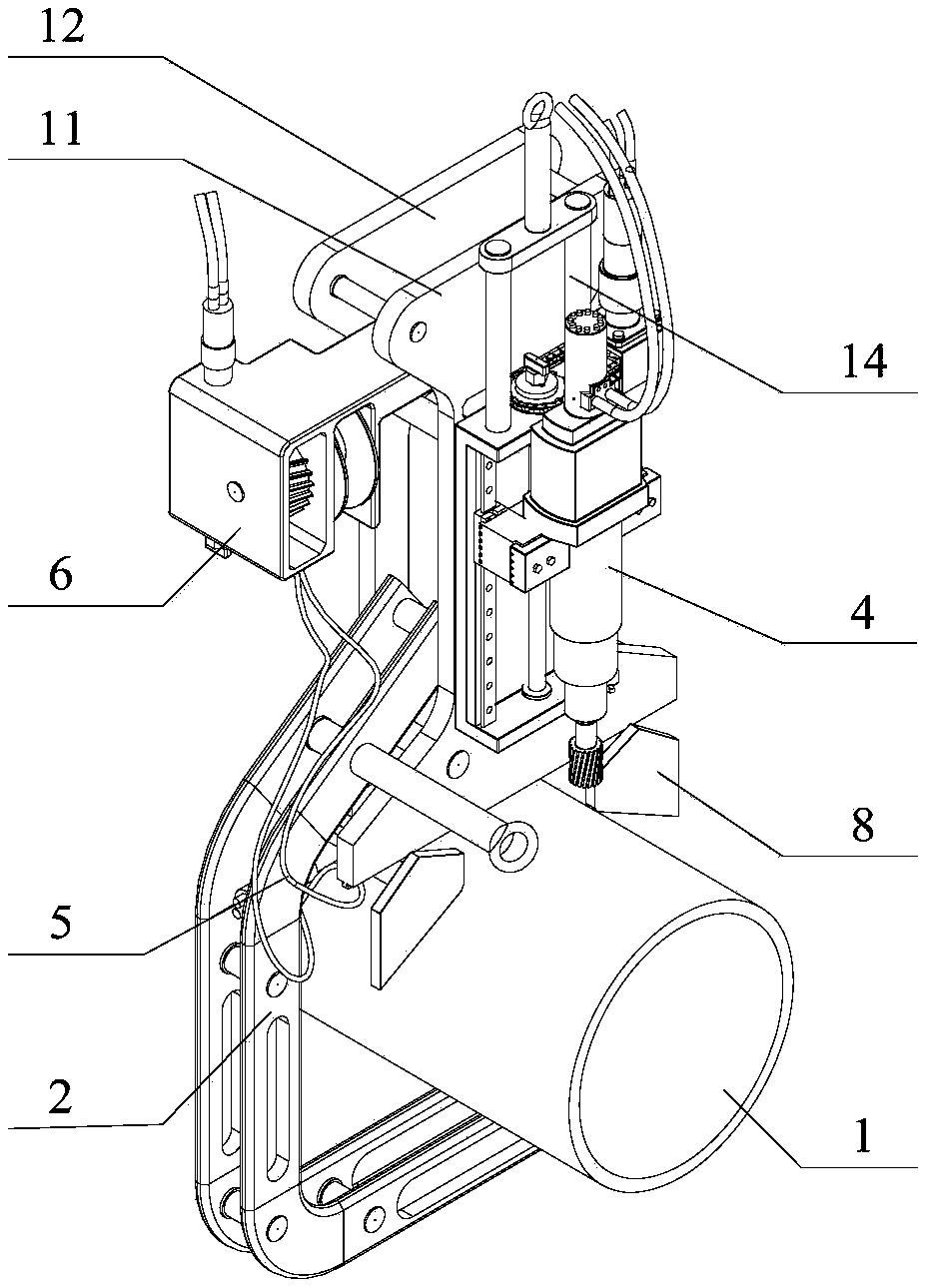

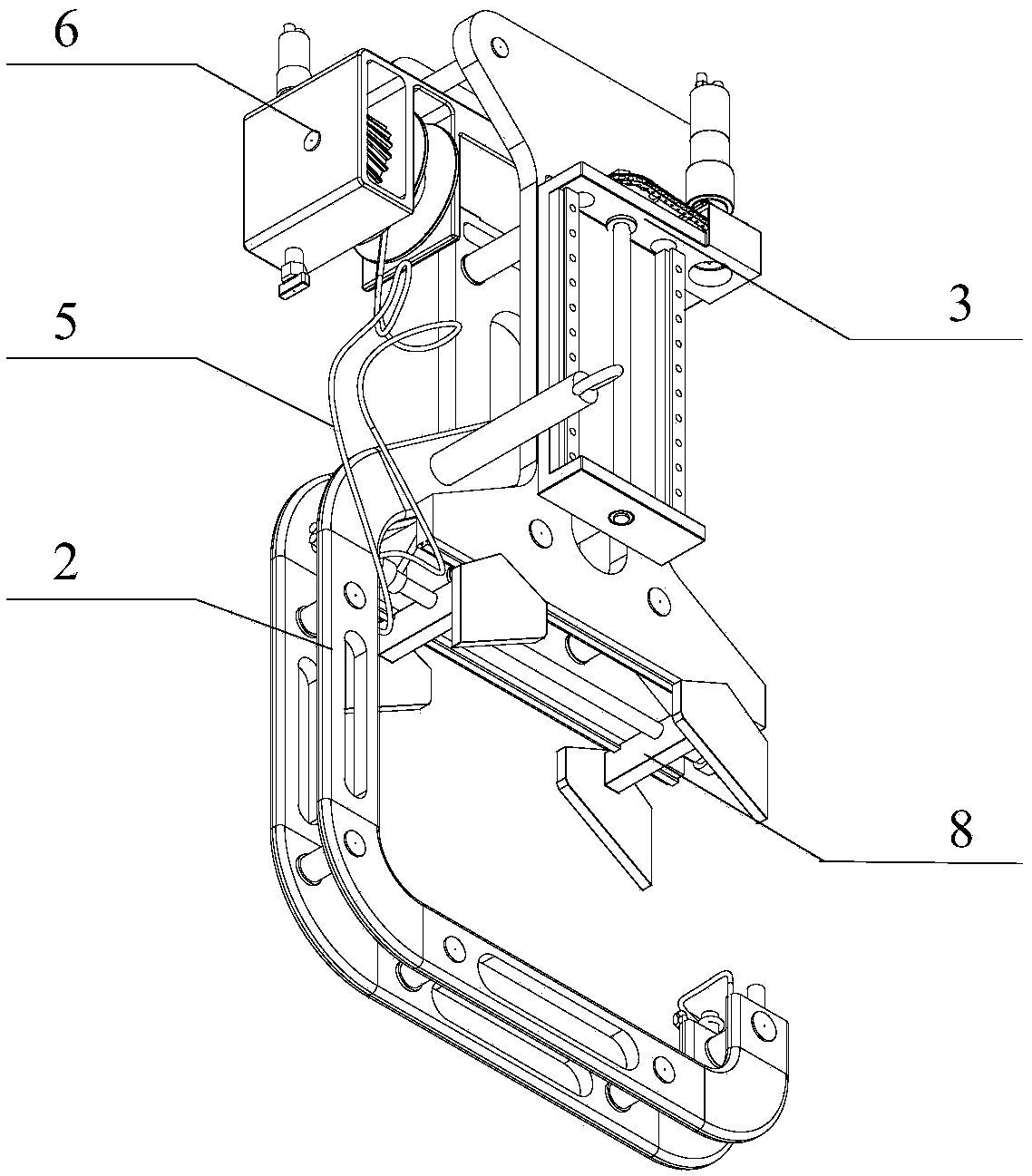

Underwater pipeline automatic drilling machine

ActiveCN109047854ARealize drilling operationsConvenient for underwater workBoring/drilling machinesAutomatic controlWorking environment

The invention provides an underwater pipeline automatic drilling machine. The underwater pipeline automatic drilling machine comprises a steel wire rope guiding mechanism, a feeding driving mechanism,a drilling driving mechanism, a clamping mechanism, a pipeline positioning mechanism and an upper and lower bracket, wherein the upper and the lower support form a machine body main body part througha pin shaft, the steel wire rope guide mechanism, the pipeline positioning mechanism, the feeding driving mechanism and the drilling driving mechanism are arranged on the body part of the machine body. The underwater pipeline automatic drilling machine are used for achieving drilling work of pipelines with different sizes at one time; the system can be automatically controlled and can be operatedby an ROV, the pipeline positioning mechanism, a steel wire rope tightening mechanism can select different driving modes under different working conditions, the application is flexible, and underwater operation is facilitated; and the underwater pipeline automatic drilling machine can adapt to the narrow working environment of the seabed pipeline and the ground space.

Owner:HARBIN ENG UNIV

Nut twisting equipment

PendingCN110773992AHigh degree of automationReduce labor intensityMetal working apparatusEngineeringAutomation

The invention belongs to the technical field of nut tightening, and particularly relates to nut twisting equipment. The nut twisting equipment comprises a rack, a nut twisting mechanism, a position coarse adjusting mechanism and a position fine adjusting mechanism. The rack comprises a supporting plate, the nut twisting mechanism is mounted on the supporting plate, the nut twisting mechanism comprises a mounting seat, a sleeve and a rotation drive part, the sleeve is provided with a nesting portion capable of nesting a nut, the rotation drive part drives the sleeve to rotate, thus, the nestingportion drives the nut to rotate, and the nut is tightened. The position coarse adjusting mechanism is used for coarsely adjusting the position of the nut twisting mechanism, the position fine adjusting mechanism is used for finely adjusting the position of the sleeve, and therefore the nesting portion is moved over the nut. By means of the nut twisting equipment, the nut on a rail can be automatically tightened, the position coarse adjusting mechanism and the position fine adjusting mechanism can automatically adjust the position of the nut twisting mechanism relative to the nut according tothe specific position of the nut, the position of the nut twisting mechanism is autonomously adjusted, and the equipment is high in automation degree and high in tightening working efficiency.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

Fastening device

Owner:CRRC QINGDAO SIFANG CO LTD

Robot flexible unit for clamping cantilever pipe fitting of overhead line system

PendingCN111906801ASolve the work of manual loading and unloadingRealize loading and unloading workTrolley linesMetal working apparatusRobot handPipe fitting

The invention discloses a robot flexible unit for clamping a cantilever pipe fitting of an overhead line system. A sliding table unit is arranged on a working table top and can slide along guide railsarranged on the two sides; the sliding table unit is fixedly connected with the bottom of a six-axis robot, the end portion of the other end of the six-axis robot is fixedly connected with a mechanical arm, and the pipe fitting is clamped through the mechanical arm; the mechanical arm comprises a truss directly connected with the six-axis robot, a first clamping end and a second clamping end which are vertically arranged are arranged at the end portions of the two ends of the truss, servo tightening guns are arranged at the bottoms of the two sides of the truss respectively, and the corresponding servo tightening guns are fixedly connected with the truss in a rotatable mode; and the tightening ends of the servo tightening guns achieve torque automatic tightening of accessories on the pipefitting. By means of the robot flexible unit, manual feeding and discharging work can be achieved, standard torque automatic installation of the accessories on the pipe fitting can be achieved, and the situation that tightening is not in place or torque is excessive due to the fact that a manual torque wrench is adopted is avoided.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

Anti-slip coefficient detector and working method thereof

PendingCN111912780ARealize tightening and fixingImprove practicalityUsing mechanical meansMaterial analysisFixed frameDisplay device

Owner:湖北科规检测有限公司

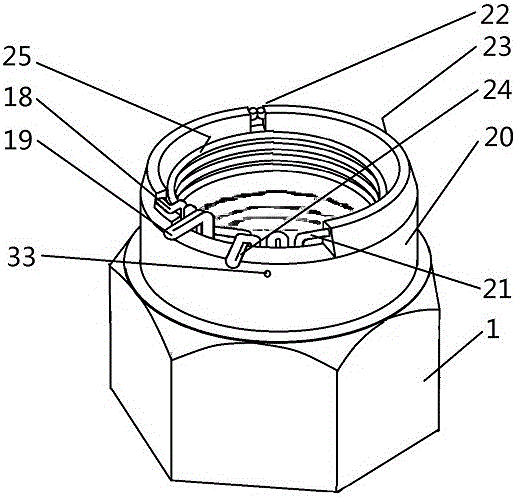

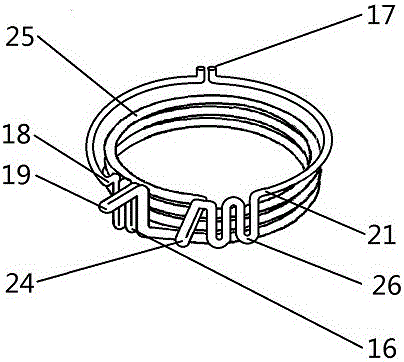

Active torque anti-loose nut

The invention discloses an active torque anti-loose nut. The active torque anti-loose nut is characterized by comprising a locking nut (1), a screw sleeve (25) is mounted on the locking nut (1), one end of the screw sleeve (25) is connected with one end of an elastic anti-loose body, and the other end of the screw sleeve (25) is connected with an elastic tension body; the other end of the elastic anti-loose body is connected with an anti-loose head (21); and in the work process, when normal-state tightening force is larger than loosening force and friction force borne by the locking nut, the locking nut moves in the tightening direction, and therefore reduction of the nut to the axial clamping force of a workpiece is achieved, and loosening is prevented.

Owner:常州市武进大众标准件有限公司

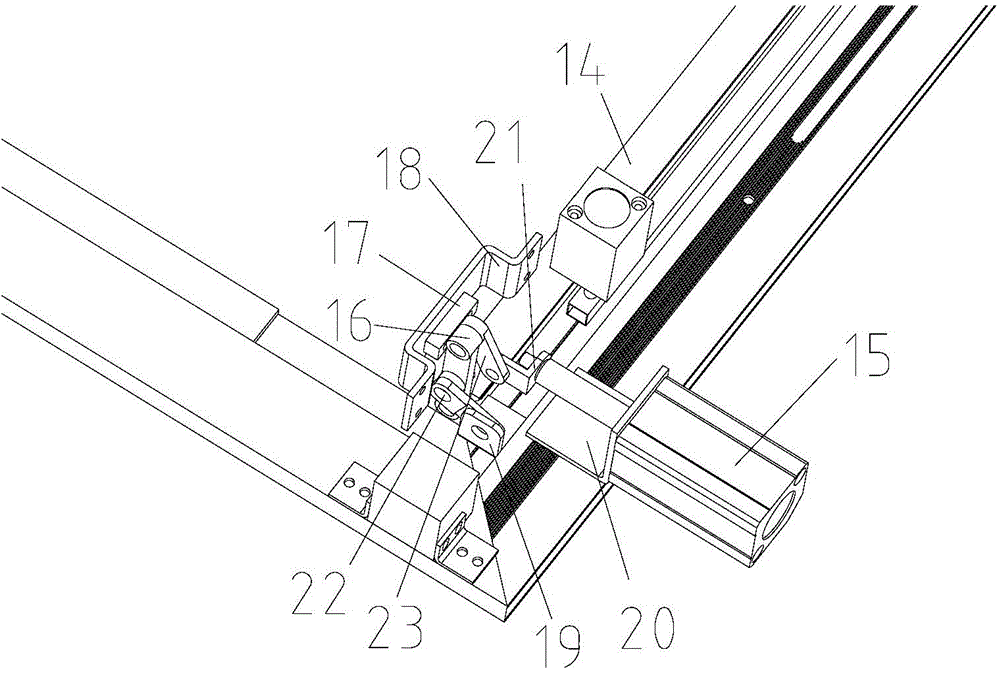

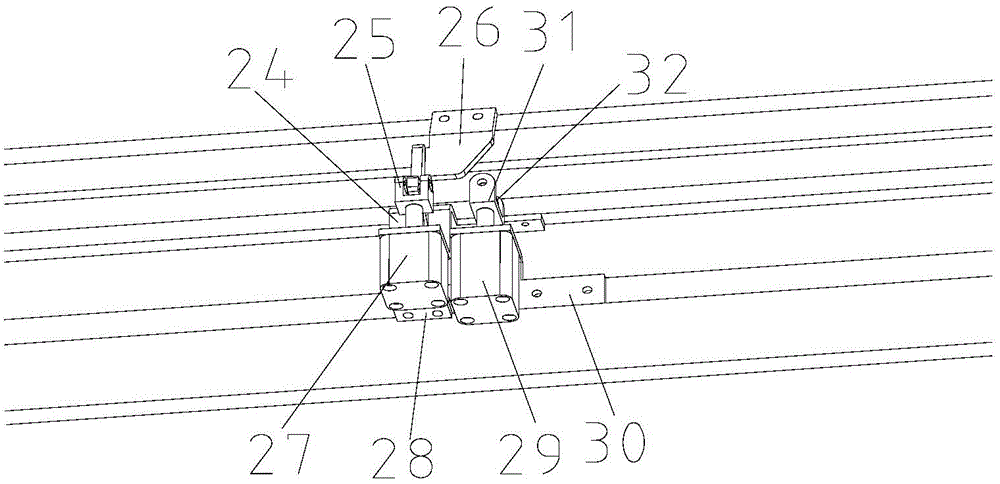

Air suspension U-bolt tightening device

PendingCN108500605ARealize automatic tighteningImprove operational flexibilityMetal working apparatusEngineeringUltimate tensile strength

The invention discloses an air suspension U-bolt tightening device. The air suspension U-bolt tightening device comprises a supporting frame, a lateral guide rail, a longitudinal guide rail, an operating body, two tightening shafts connected with the operating body, a cable bridge and an electric cabinet, and the lateral rail is arranged on the inner side of the bottom of the supporting frame, thelongitudinal rail is slidably connected to the lateral rail through first sliders at both ends of the longitudinal rail, and a base of the operating body is slidably connected to the longitudinal rail through second sliding blocks; a turntable is arranged at the bottom of the operating body, and the operating body realizes adjustment within the circumferential range by the rotation of the turntable; and the cable bridge is a signal transmission carrier for connecting the electrical cabinet and the operating body. The tightening torque of the tightening device and a tightening shaft head are adjustable, the operation flexibility is high, automatic tightening of two U-bolts is realized, the quality of products is ensured, the production efficiency is improved, the labor intensity is reduced, and the defects of an existing U-bolt tightening device with poor operability and low production efficiency are overcome.

Owner:ANHUI ANKAI AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com