Patents

Literature

33results about How to "Tighten to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

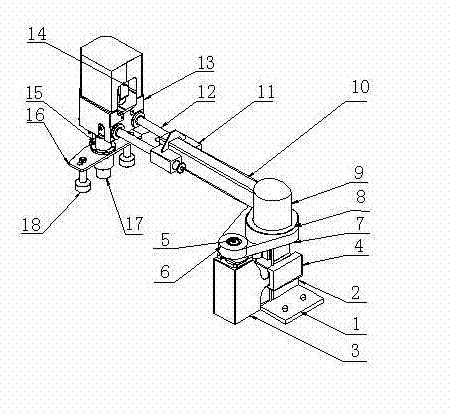

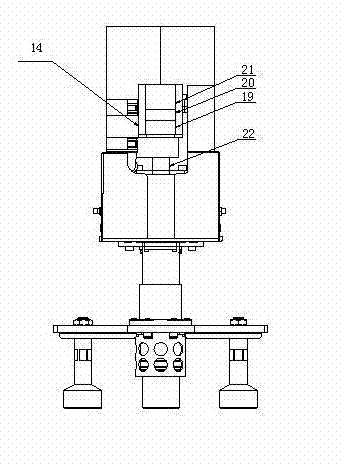

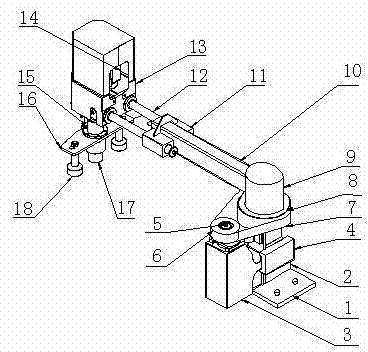

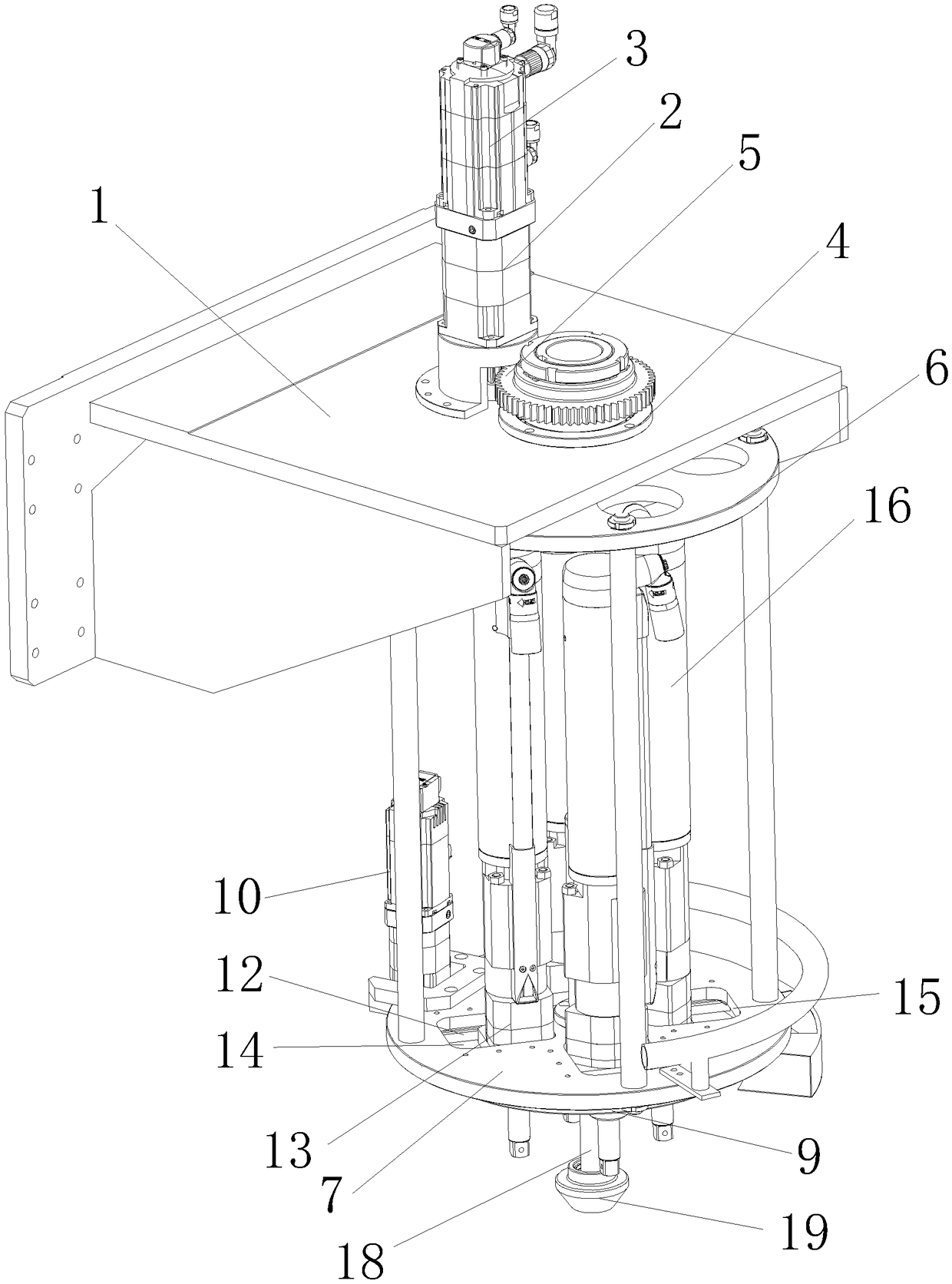

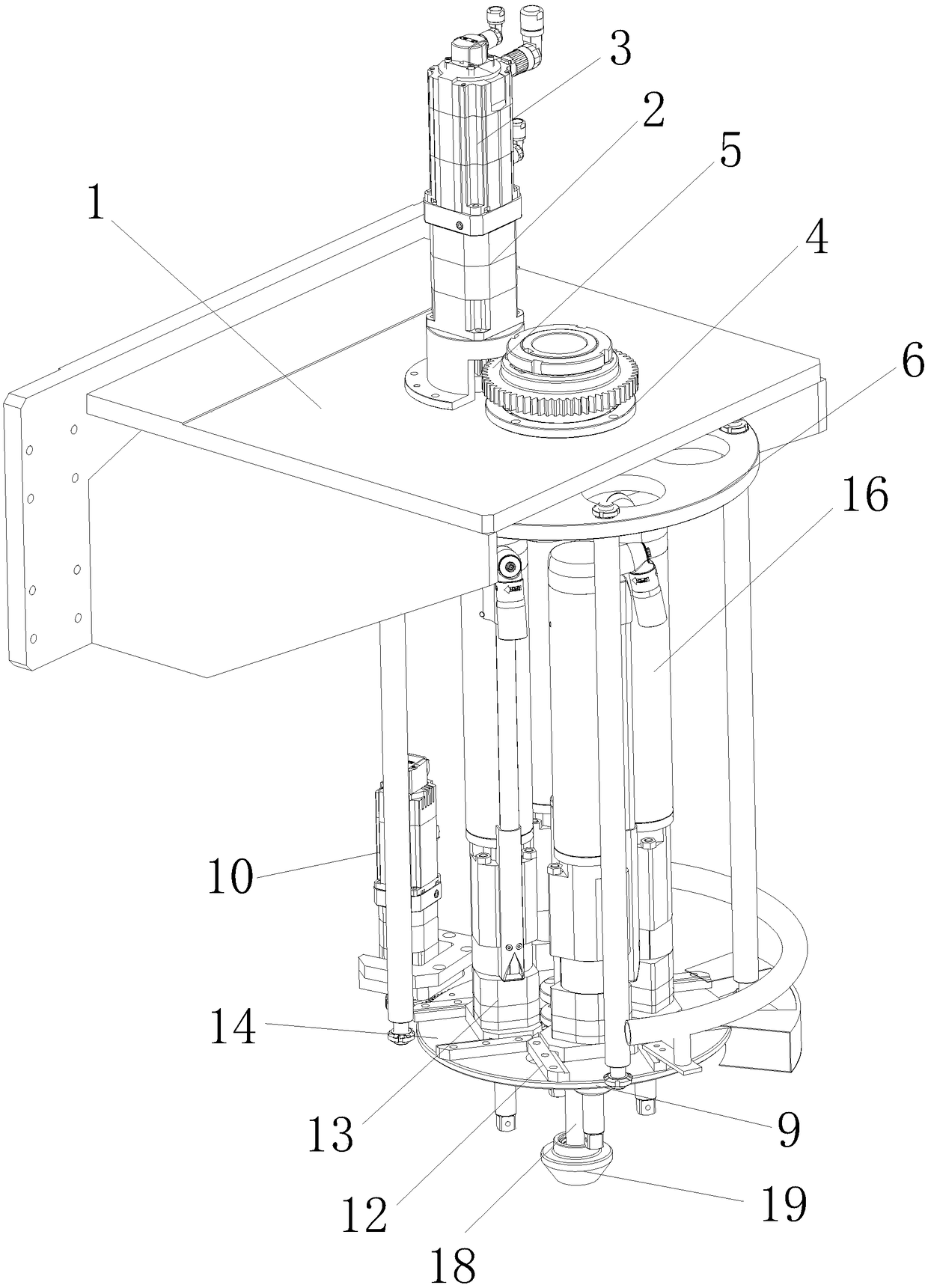

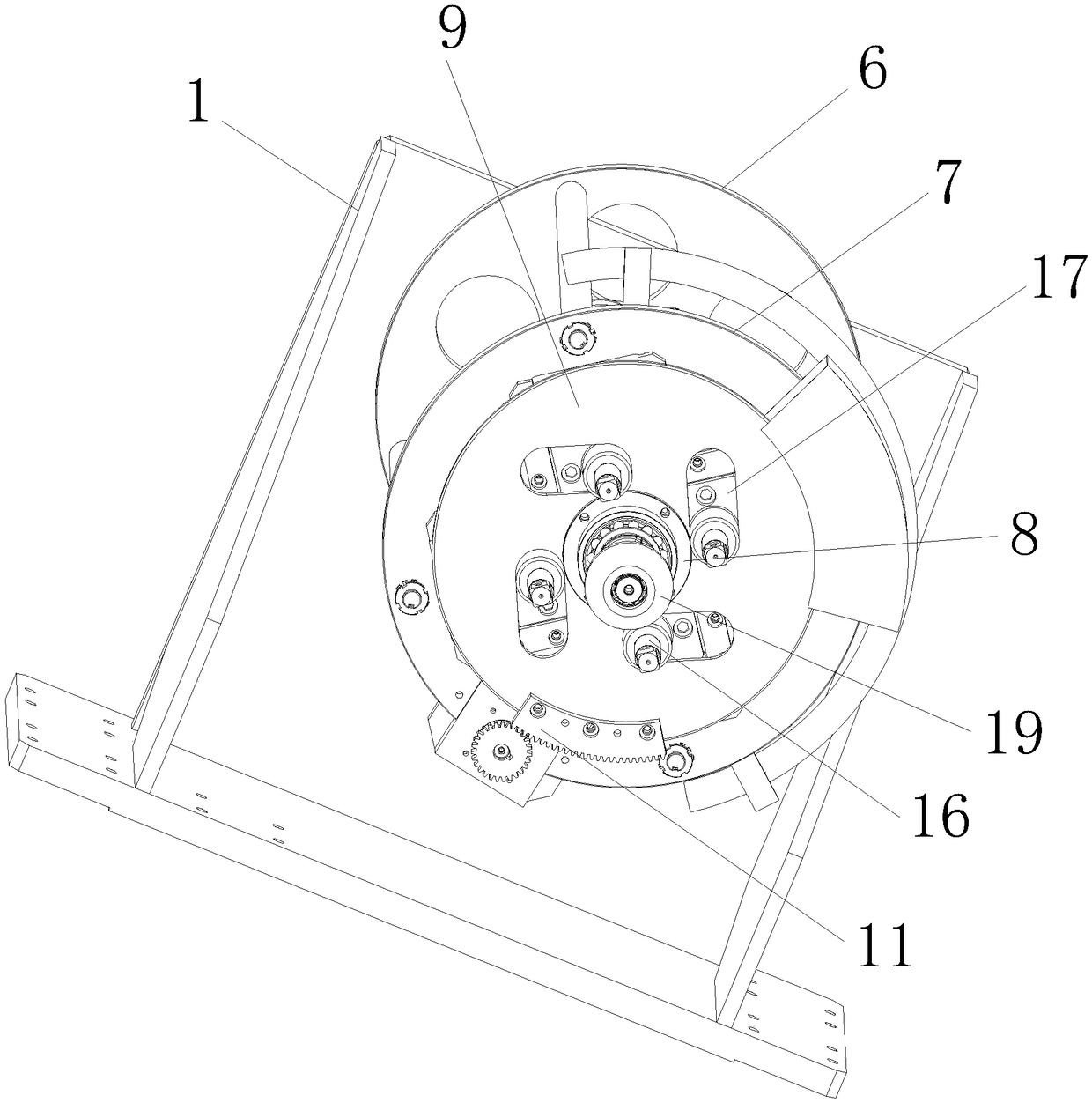

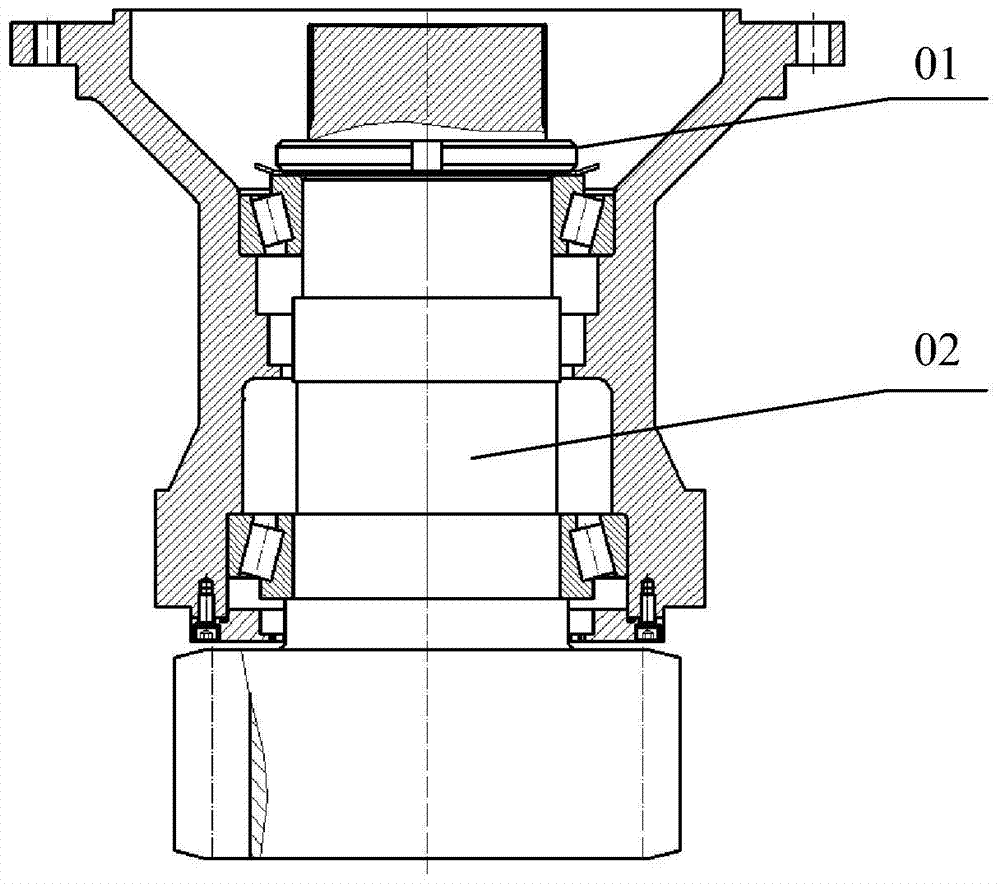

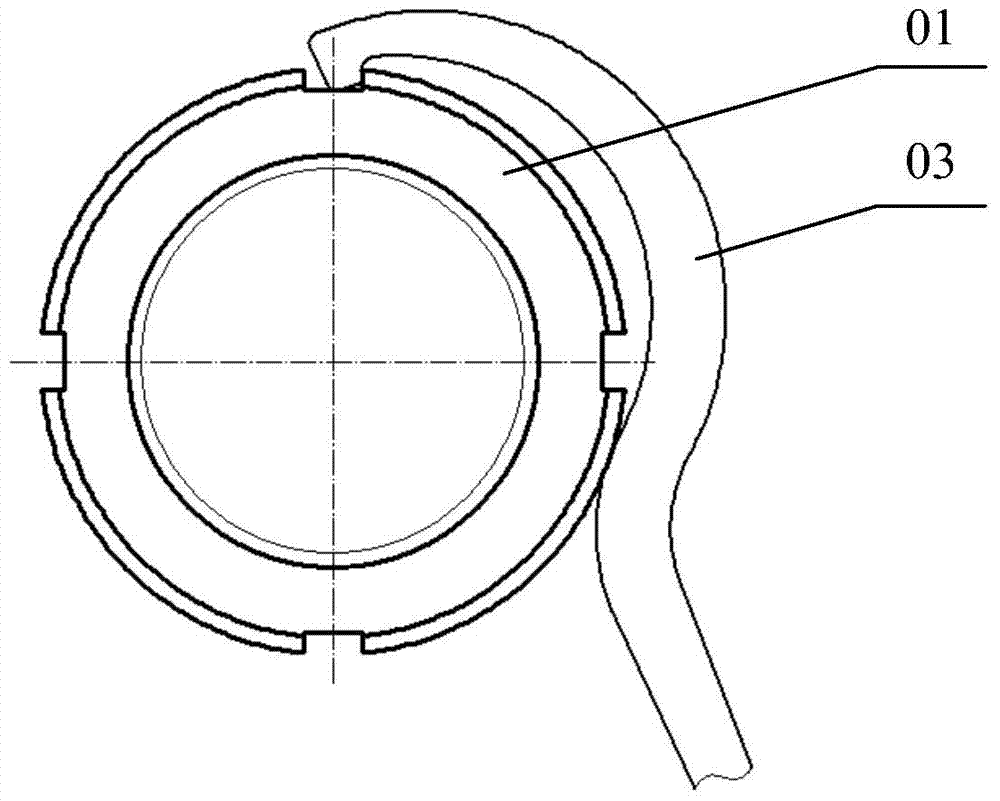

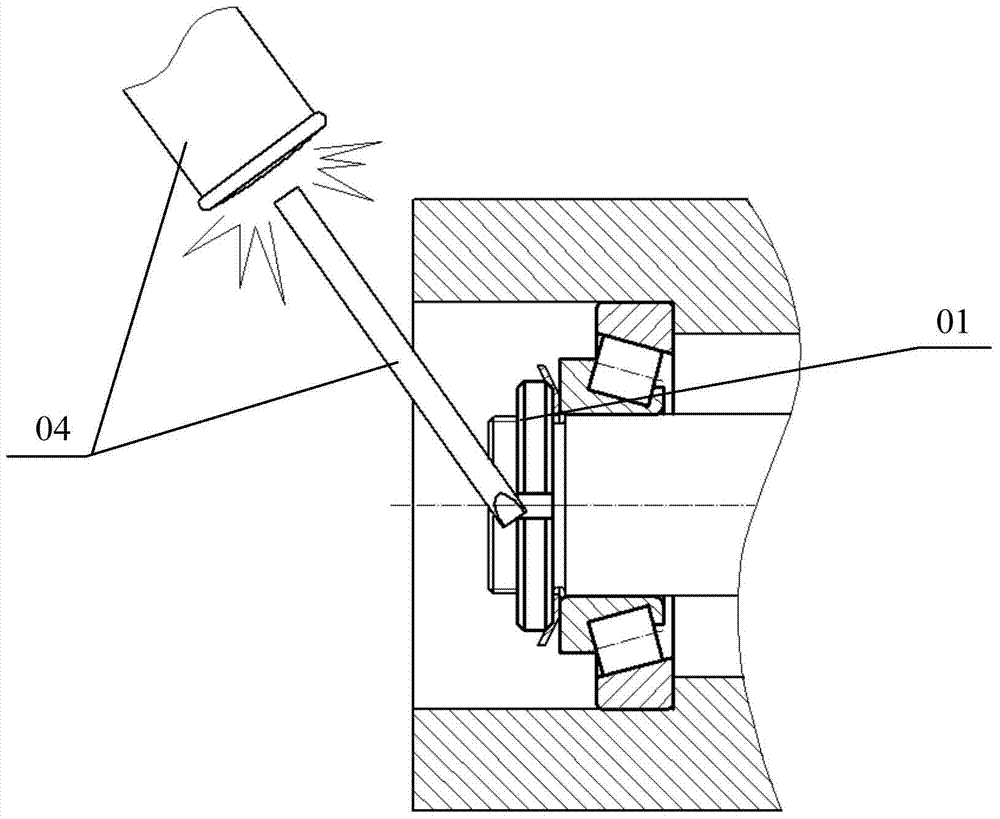

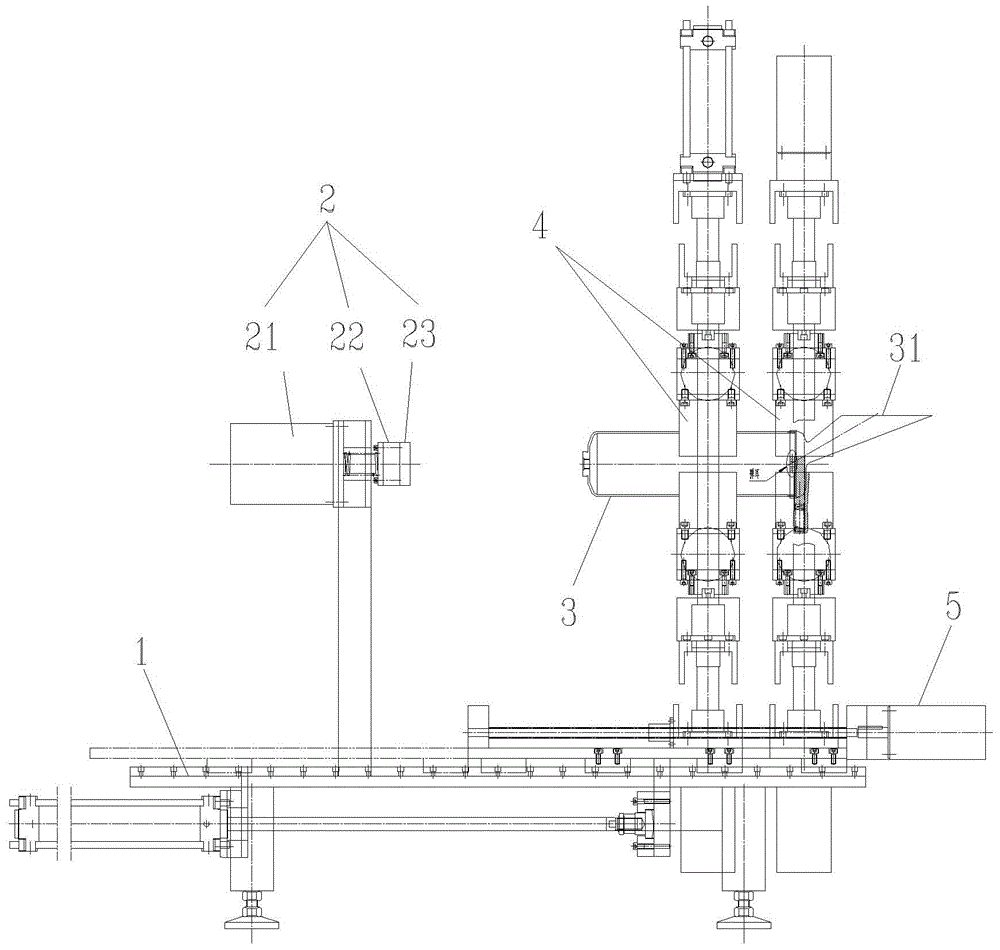

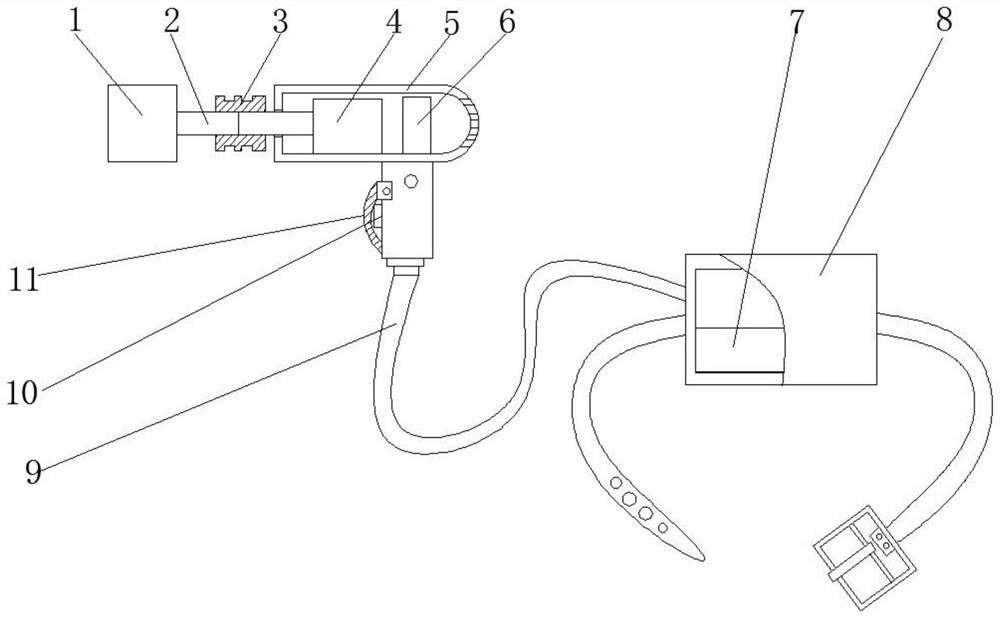

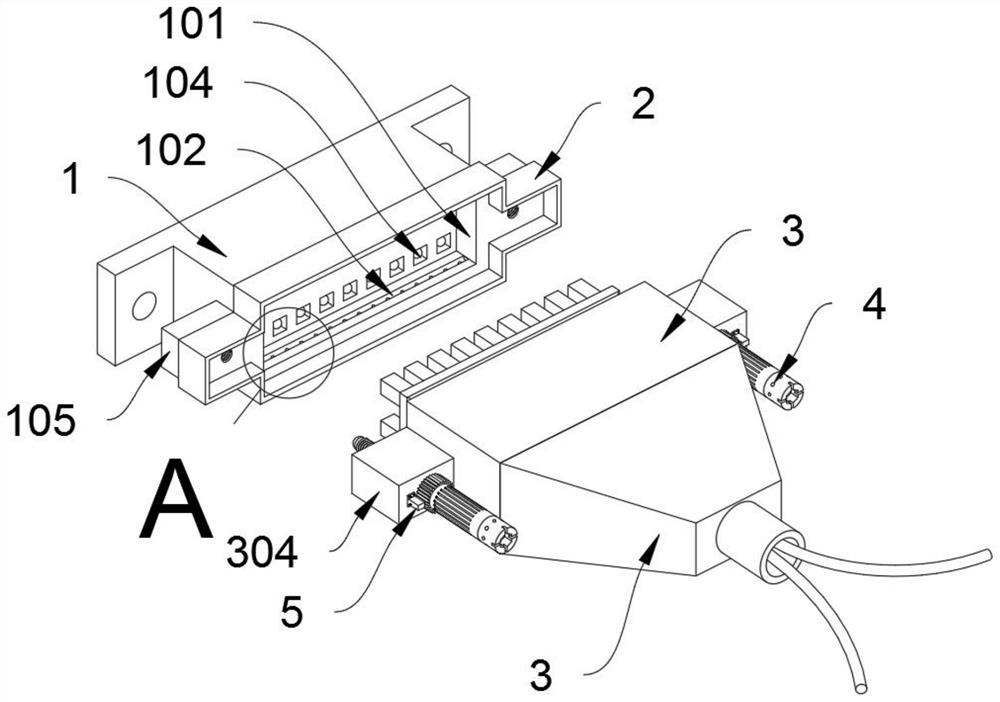

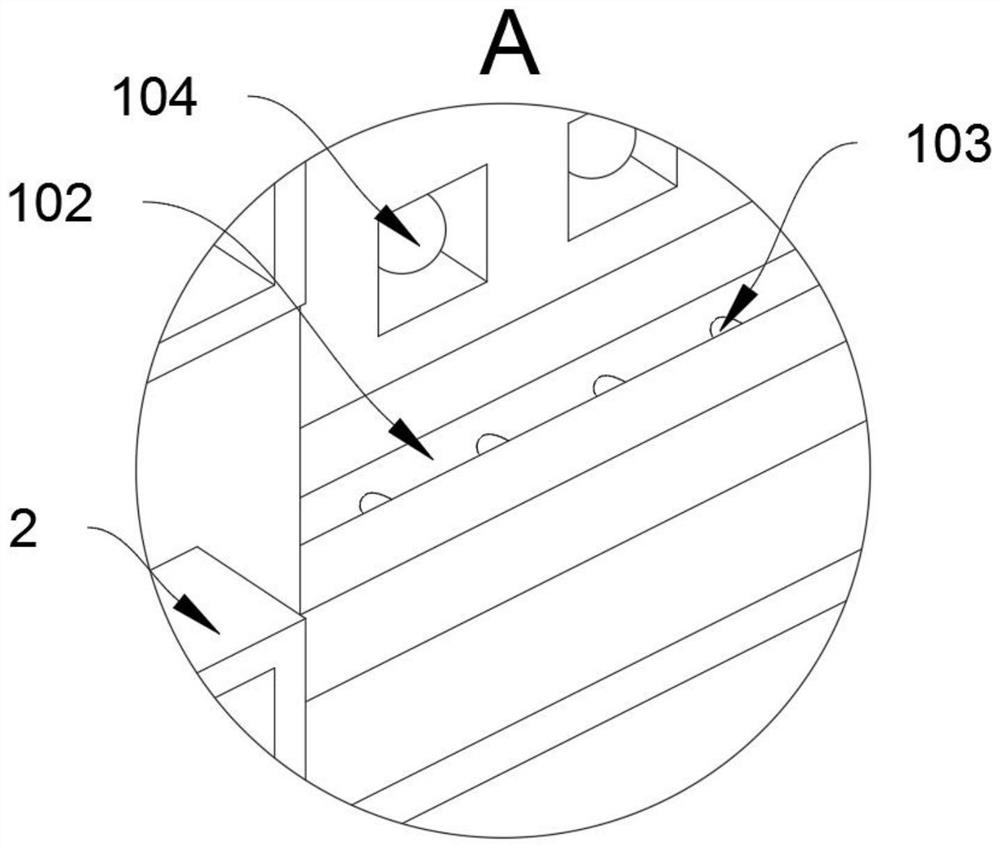

Single-axis yaw electric bolt tightening machine

ActiveCN102451993ATighten to achieveHigh precisionWind motor assemblySpannersCounterforceTorque sensor

The invention discloses a single-axis yaw electric bolt tightening machine, which comprises a base, a bracket, a revolving servo motor, an encoder, an output revolving shaft, a small belt wheel, a cog belt, a large belt wheel, a revolving shaft, a swiveling jib, a shaft sleeve, a guide post, a housing plate bracket, an electric tightening shaft assembly, a sleeve, a counterforce support plate, a special sleeve, a counterforce sleeve, a servo motor, a torque sensor, an angle sensor and a connecting shaft, wherein the bracket is fixed on the base, and is provided with the revolving servo motor and the encoder; the revolving servo motor is connected with the output revolving shaft; the output revolving shaft is provided with the small belt wheel; the small belt wheel is matched with the large belt wheel through the cog belt; the large belt wheel is connected with the revolving shaft; the guide post is connected with the swiveling jib through the shaft sleeve, and is fixed on the housing plate bracket; and the electric tightening shaft assembly is fixed in the housing plate bracket.

Owner:DALIAN DEXIN M&E TECH ENG

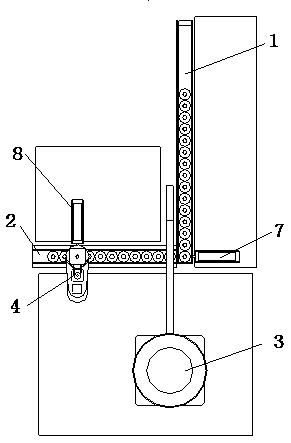

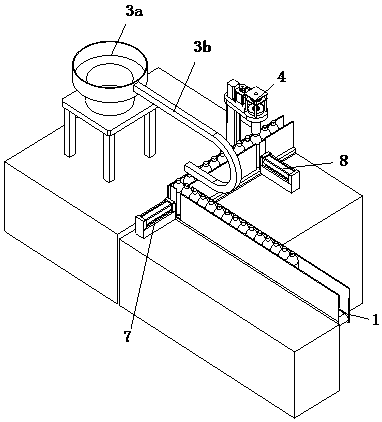

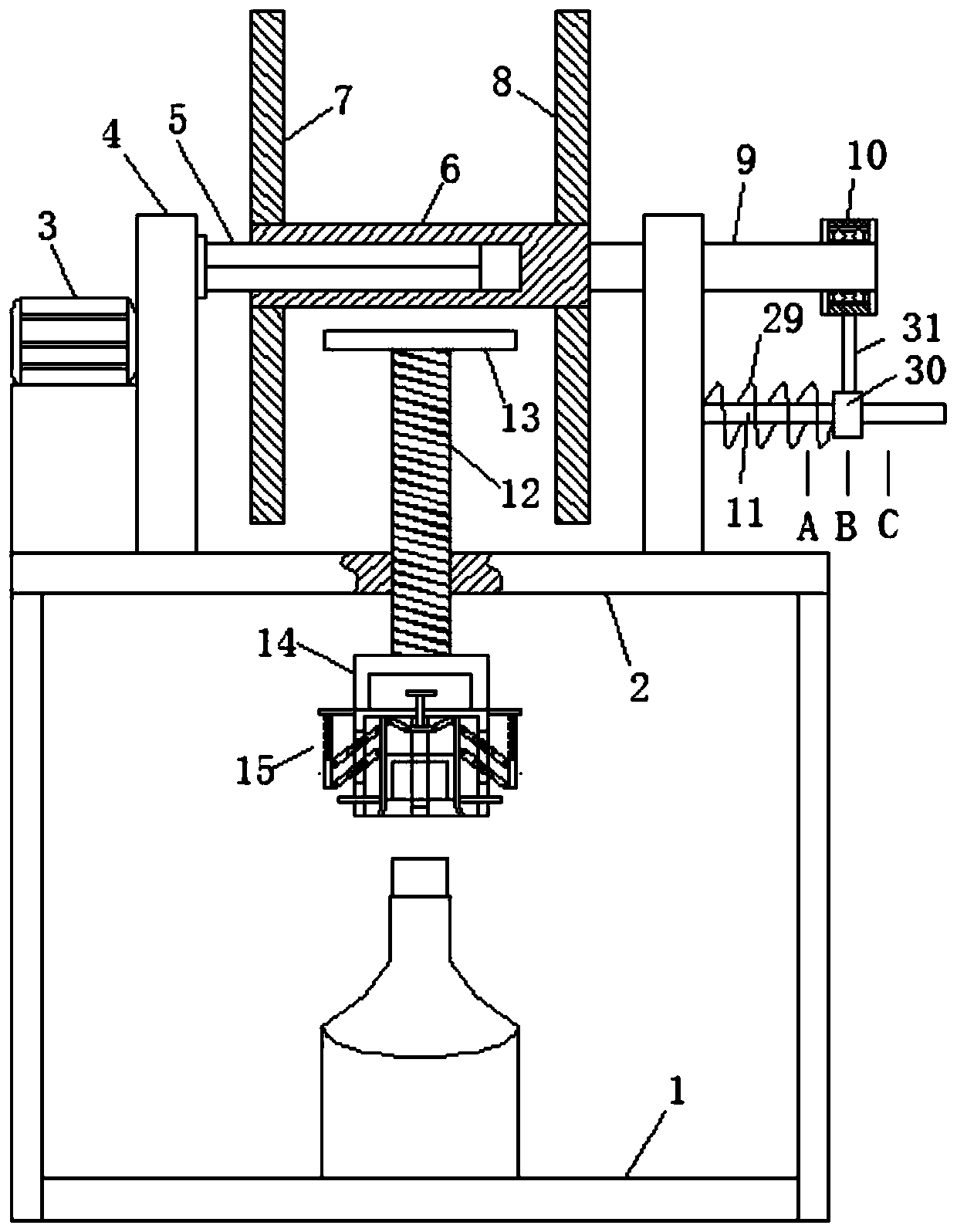

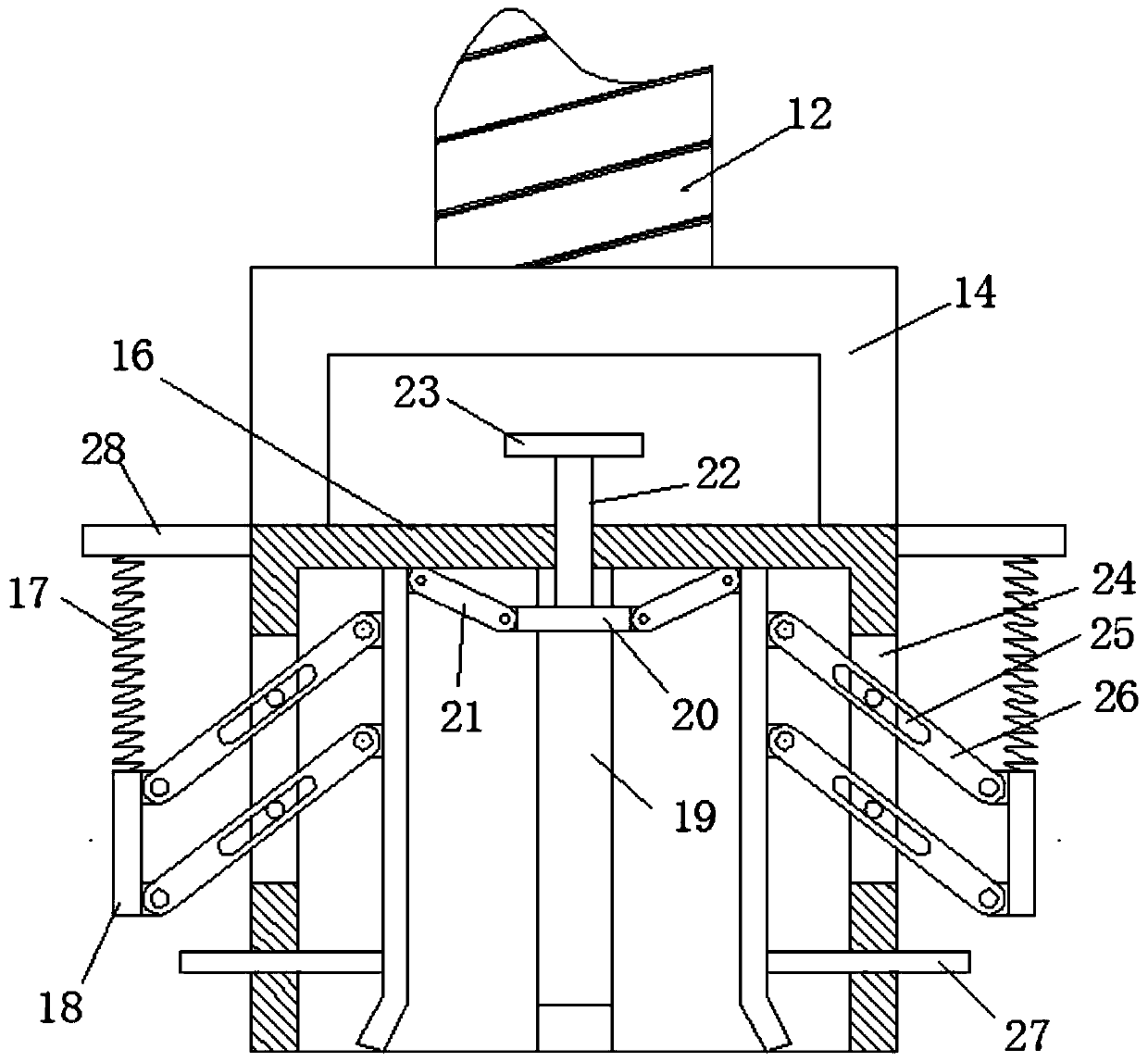

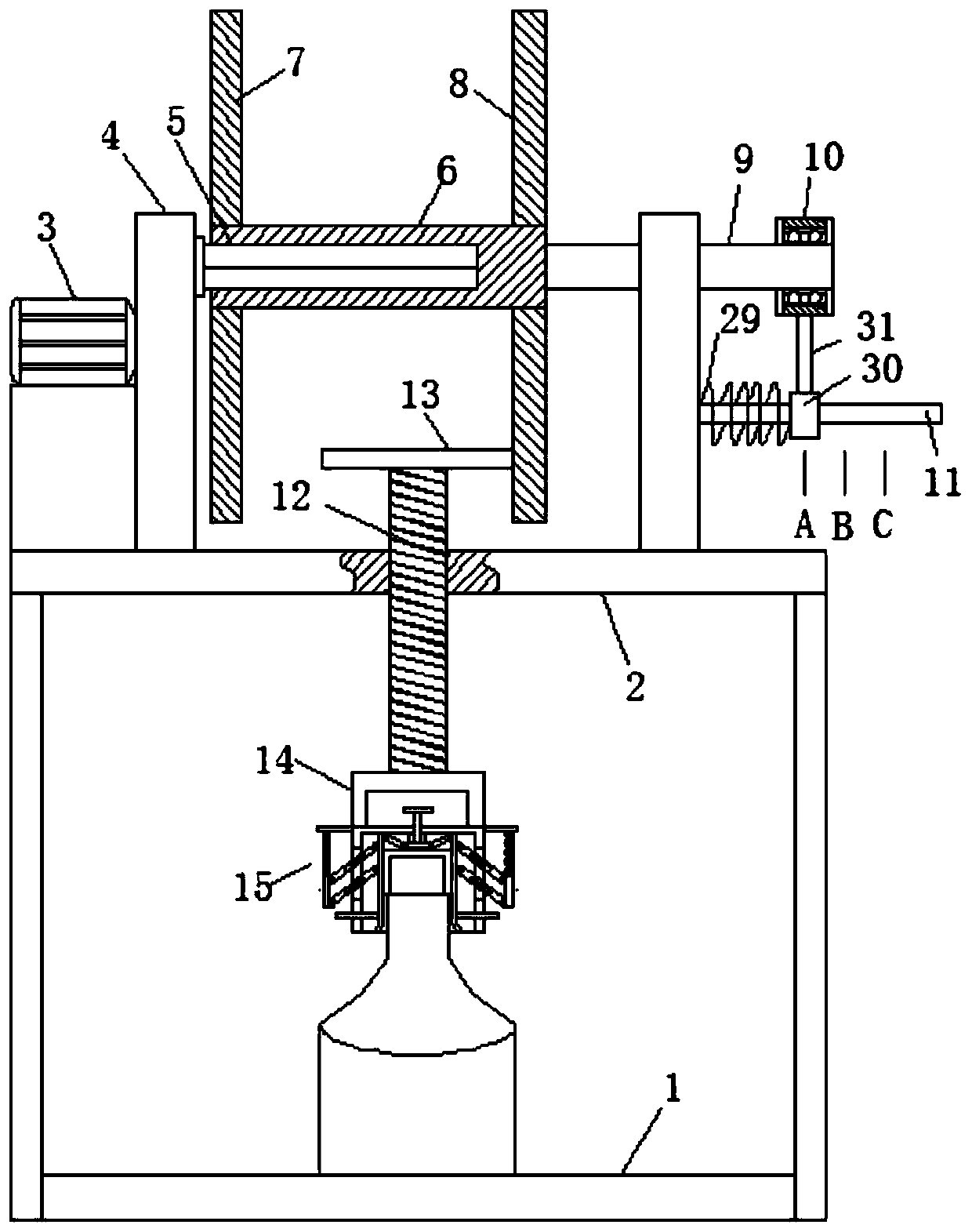

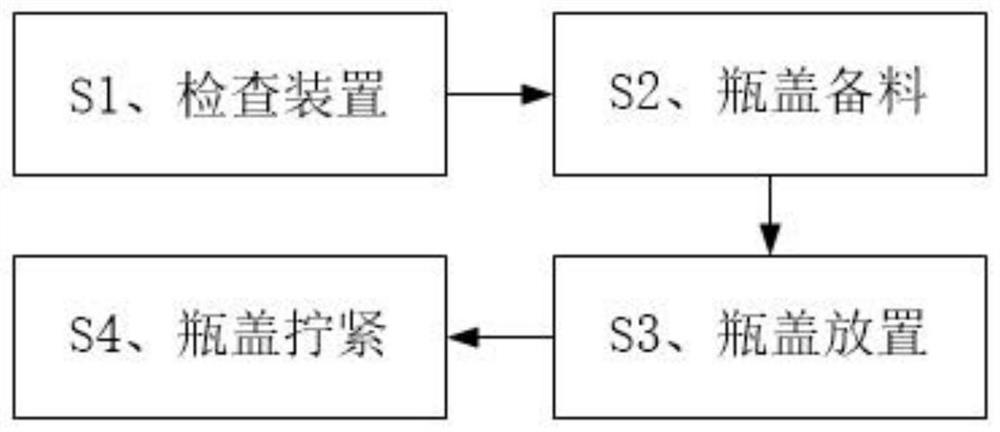

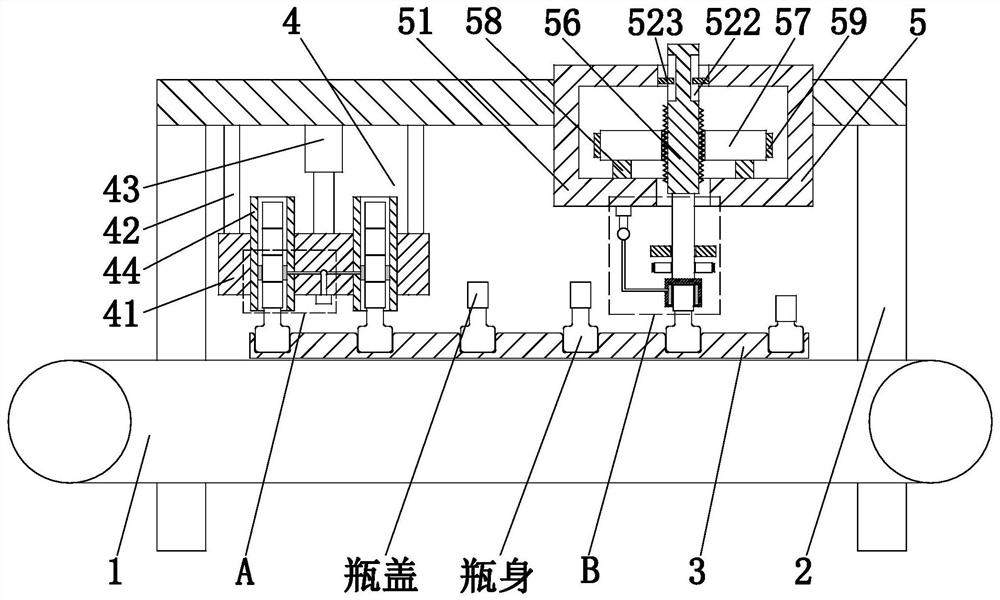

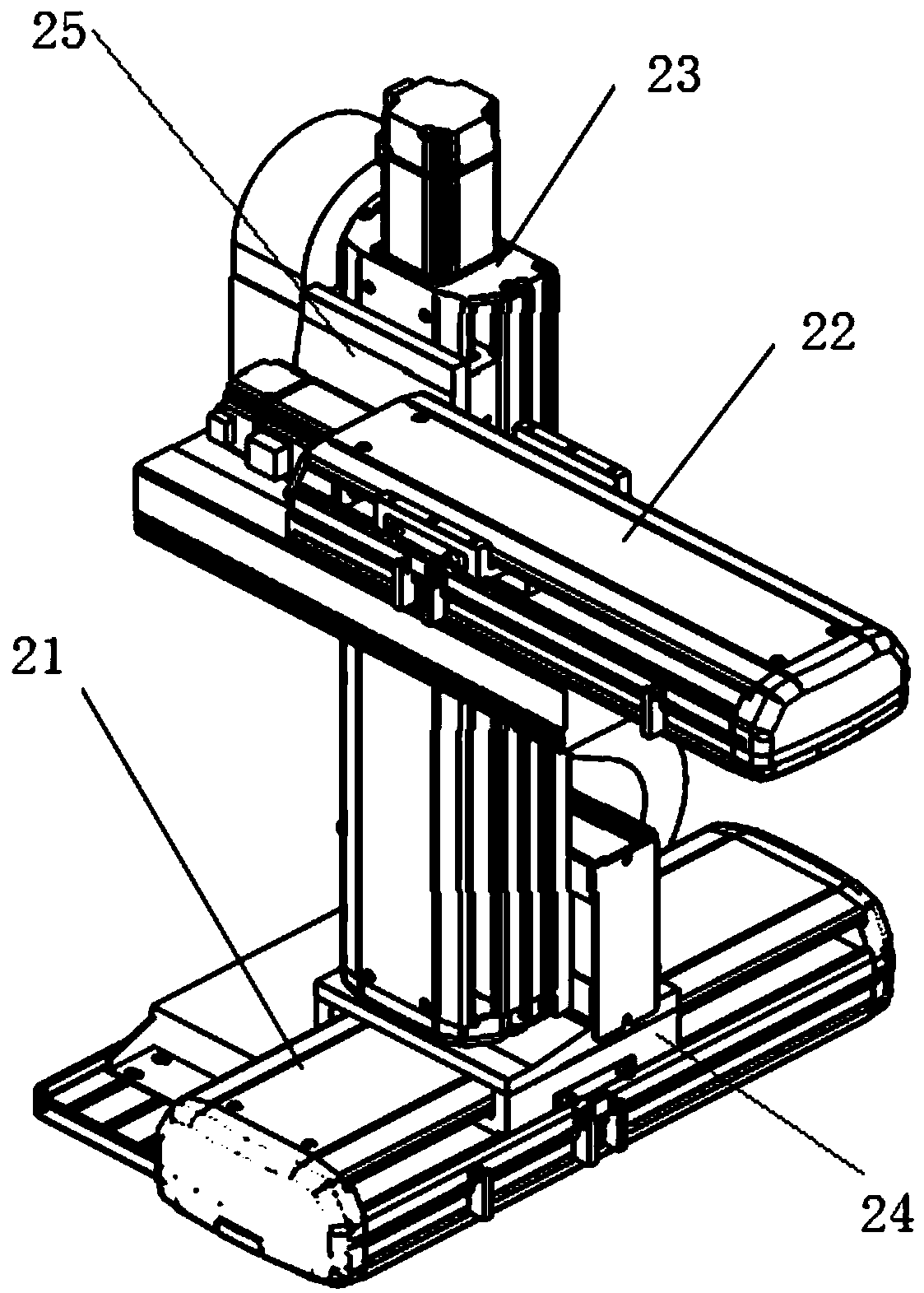

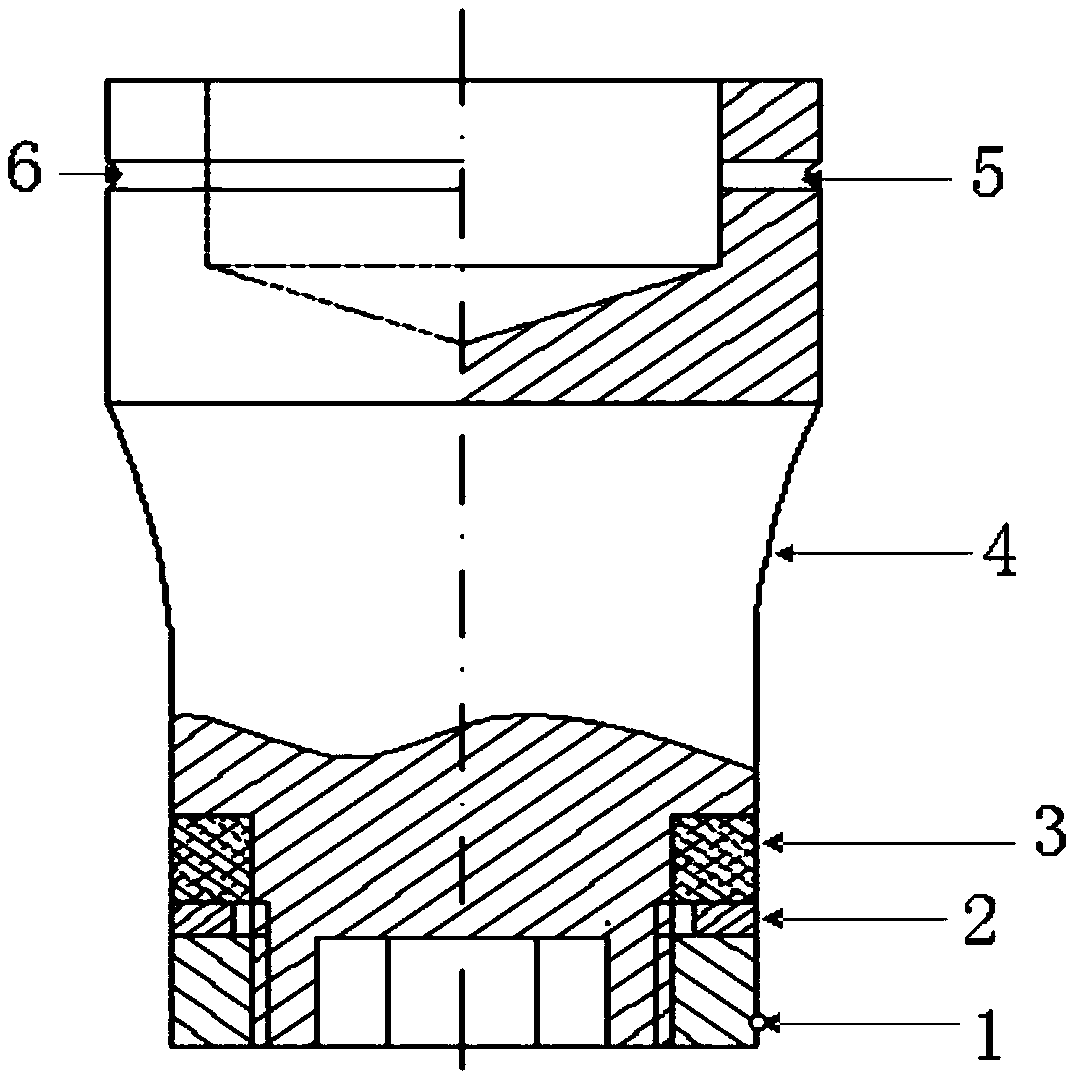

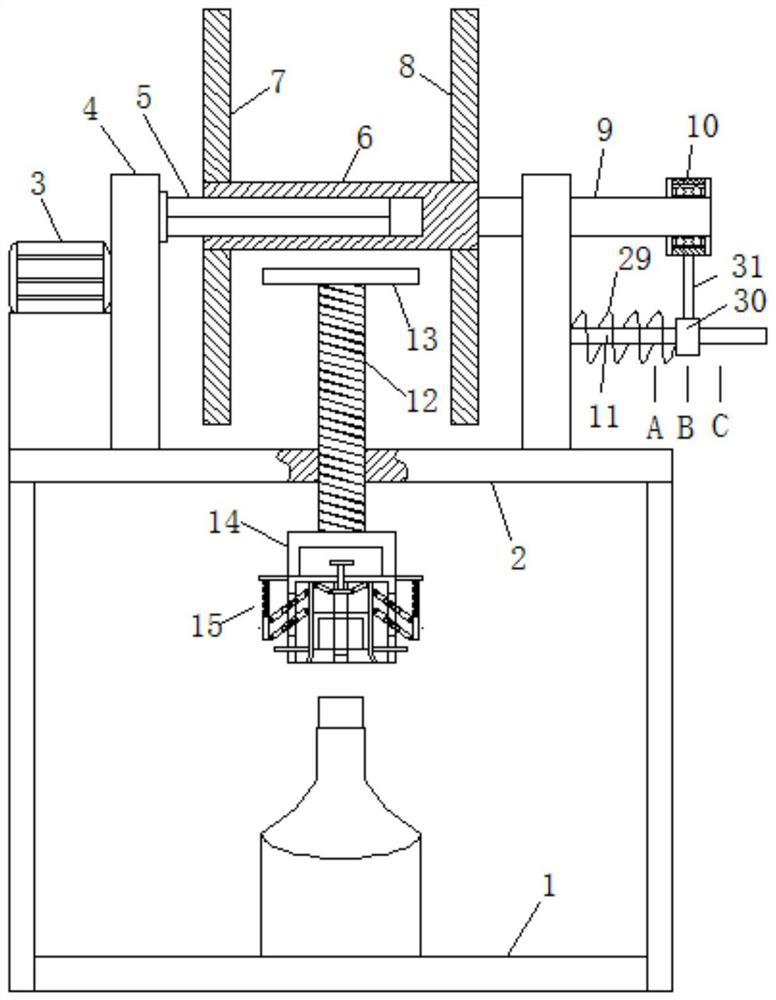

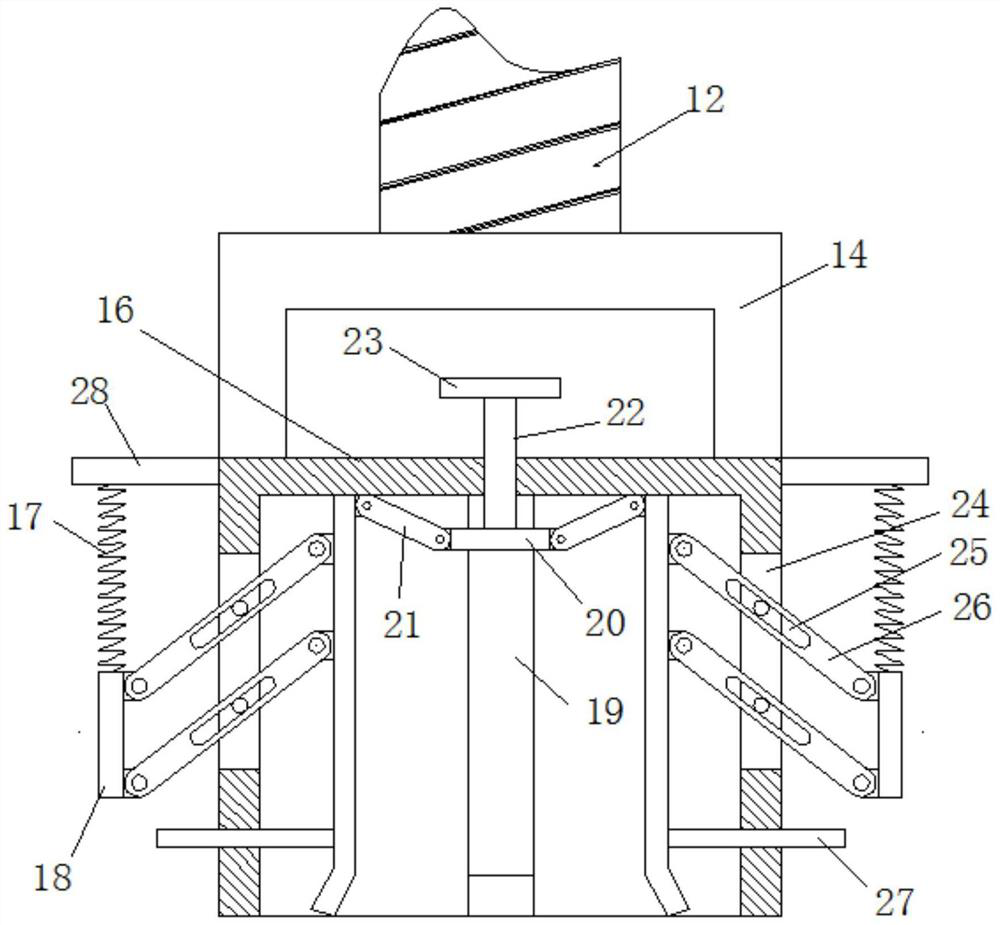

Bottle cap tightening machine

InactiveCN107792821ATighten to achieveRealize automatic tighteningClosing machinesThreaded caps applicationDrive shaftEngineering

The invention relates to the field of automation equipment, in particular to a bottle cap tightening machine, comprising a conveyor belt, a material rail, a feeding mechanism and a tightening mechanism, the conveying direction of the conveyor belt is perpendicular to the guide of the material rail, and the discharge end of the conveyor belt It is connected with the feeding end of the material rail, and the side of the discharge end of the conveyor belt is provided with a pushing device matched with the material rail. The feeding mechanism and the tightening mechanism are distributed along the guiding interval of the material rail. One side of the material rail A positioning device arranged opposite to the tightening mechanism is provided. The invention can realize the automatic tightening of bottle caps. The tightening mechanism adopts a rotatable rotating shaft installed inside the lifting screw rod, and a tightening head is installed at the bottom of the rotation. The lifting of the screw rod drives the rotating shaft to go up and down synchronously, and the rotation drives the tightening. The head rotates to tighten the bottle cap. The mechanism for driving the screw rod up and down and the mechanism for driving the rotating shaft are independent of each other, so that the structure is simpler, the cost is lower, and the maintenance is easier.

Owner:乔合祥

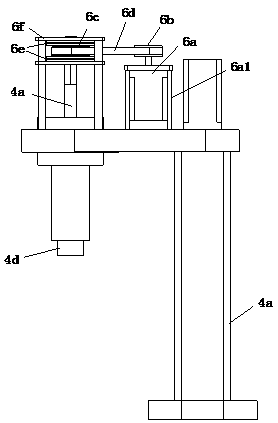

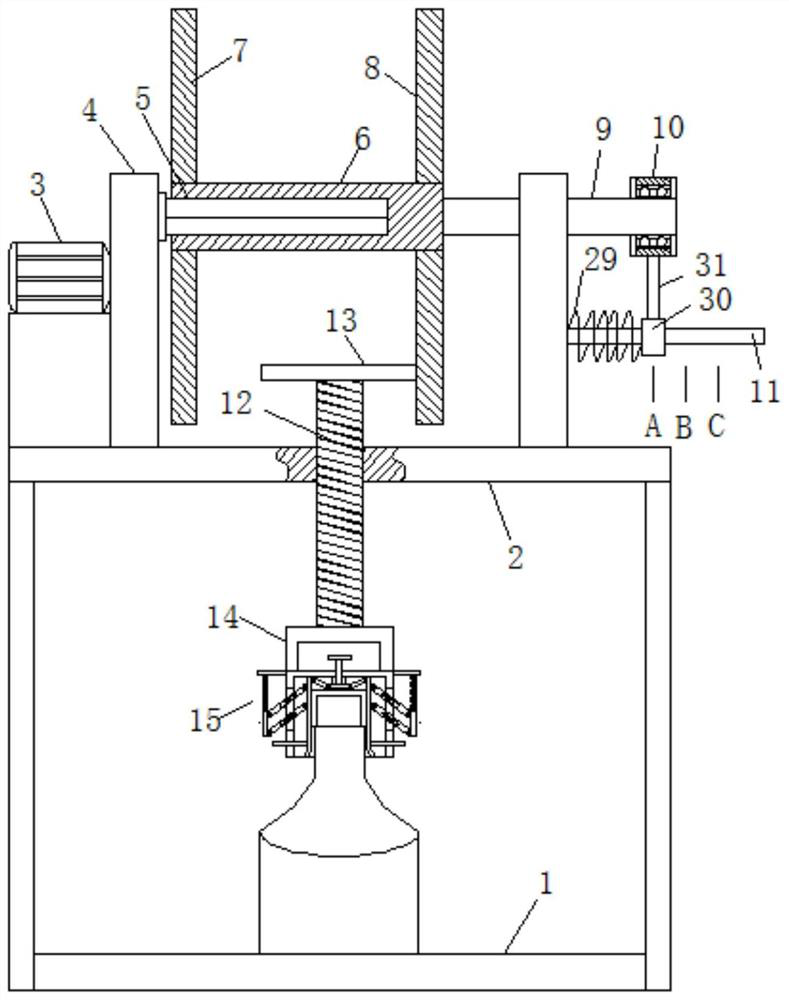

Bottle cap screwing device for filling food packaging and using method thereof

ActiveCN110540157ATighten to achieveEasy to tighten and loosenCapsThreaded caps applicationEngineeringFood packaging

The invention relates to the field of food filling, in particular to a bottle cap screwing device for filling food packaging and a using method thereof. The bottle cap screwing device comprises a base, wherein a cross beam is fixedly connected to the base through two vertical rods, a driving part is fixed to the cross beam, and a screw rod which is downward vertically is in threaded connection tothe middle of the cross beam; a rotating disc is fixed to the upper end of the screw rod, and the rotating disc can be connected with the driving part; and a hanging bracket is fixed to the lower endof the screw rod, and a clamping head is fixed to the lower end of the hanging bracket. According to the bottle cap screwing device for the filling food packaging and the using method thereof, the driving part is utilized to drive the clamping head to screw a bottle cap on a bottle body, so that screwing of the bottle cap is realized; and a reversing mechanism on the driving part conveniently screw and can loosen the bottle cap, so that the operation is convenient, the working procedure and the operation difficulty are simplified, and the working efficiency is improved.

Owner:汨罗市府源圣益食品科技有限责任公司

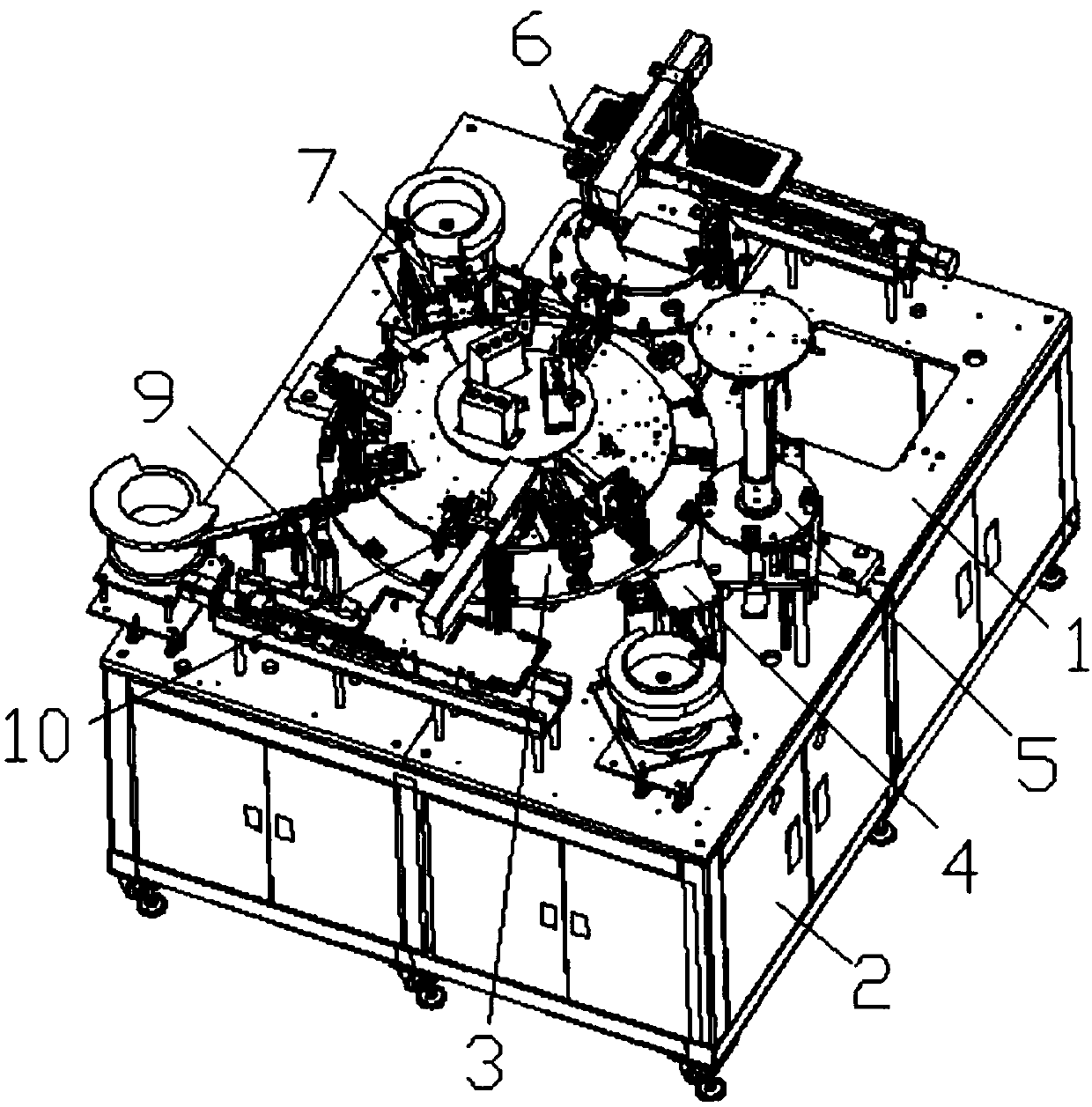

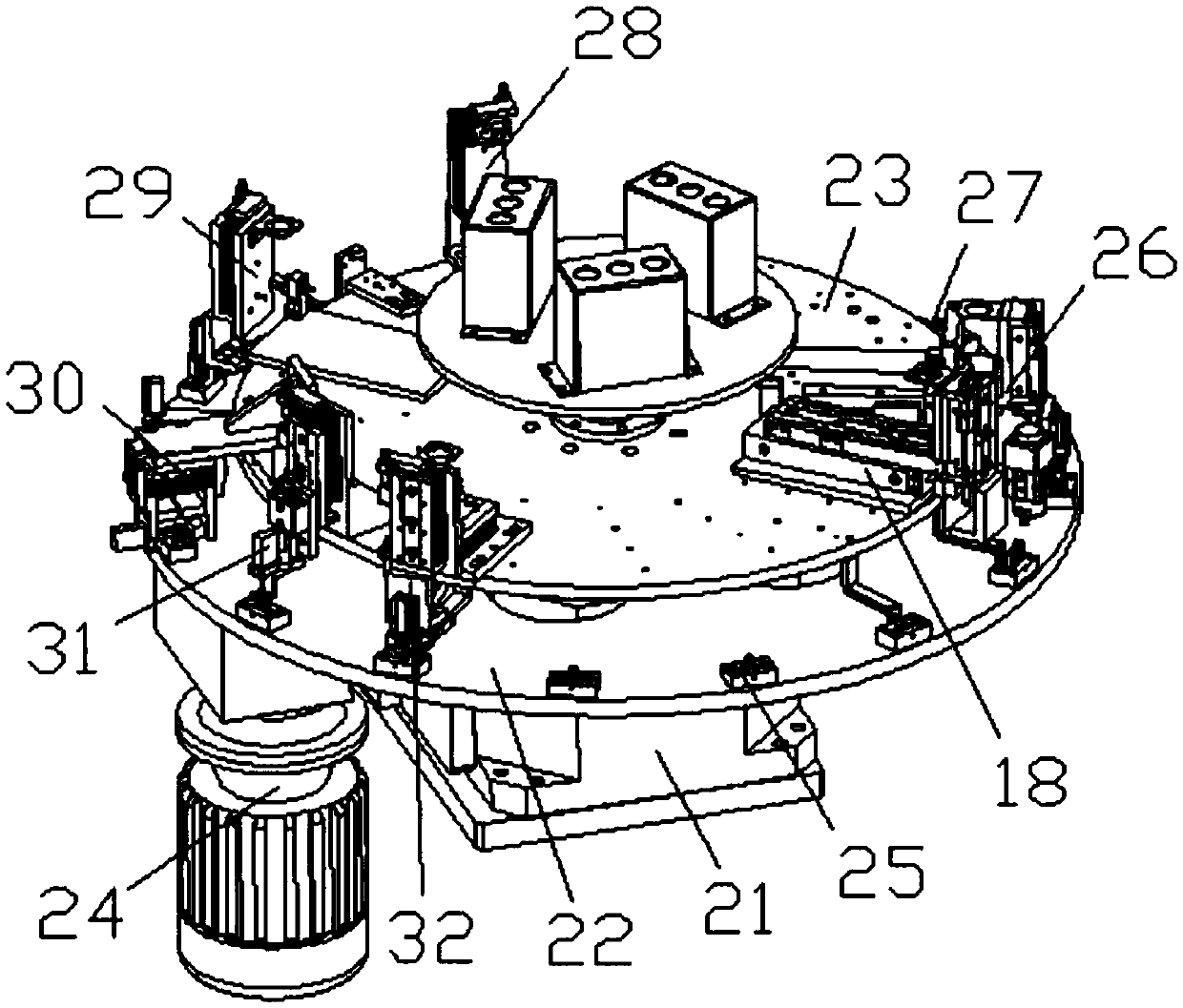

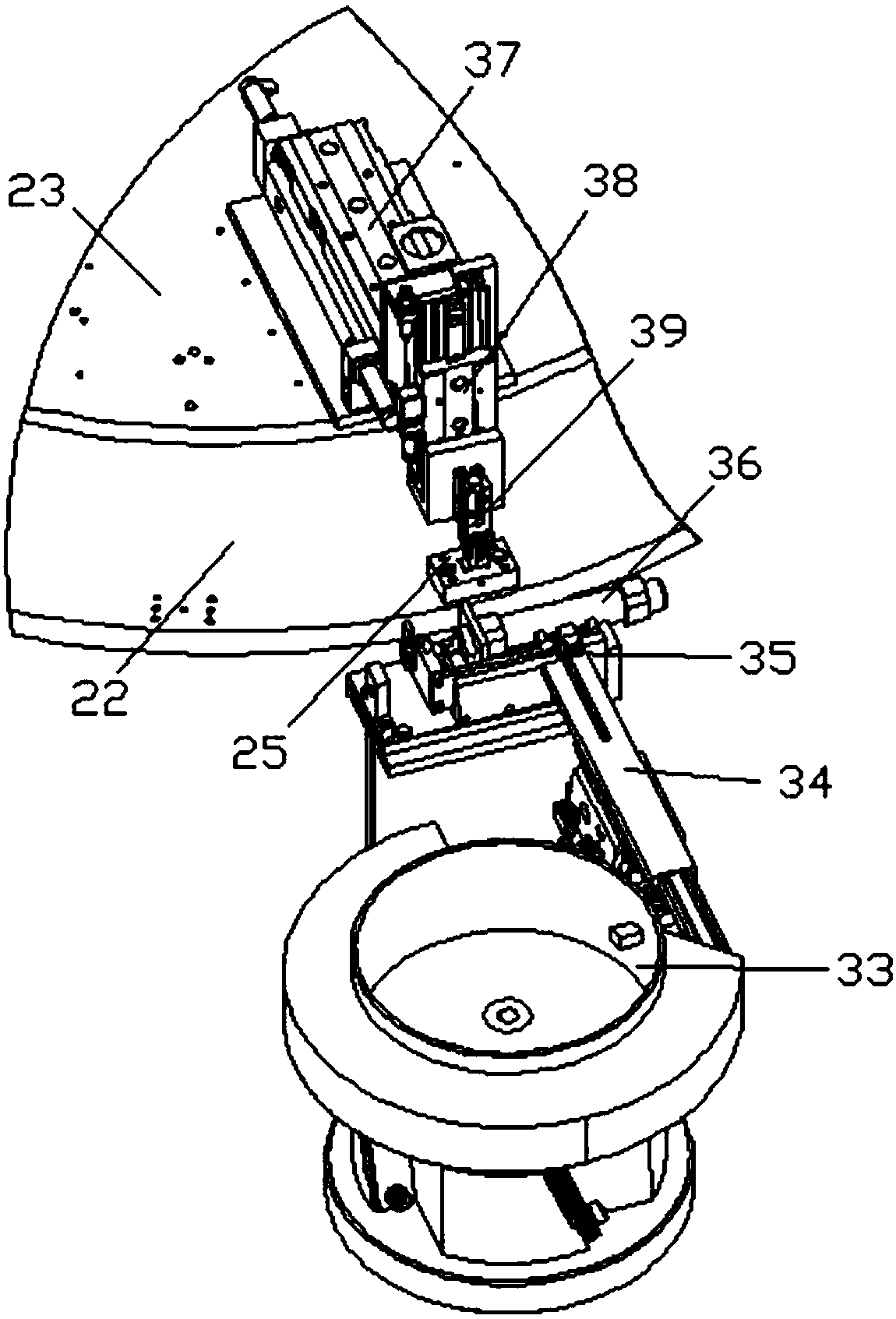

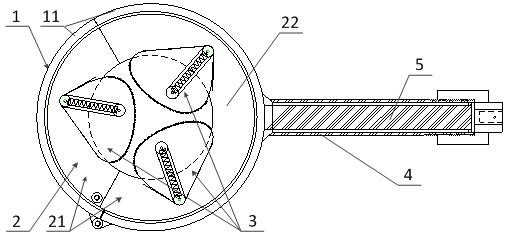

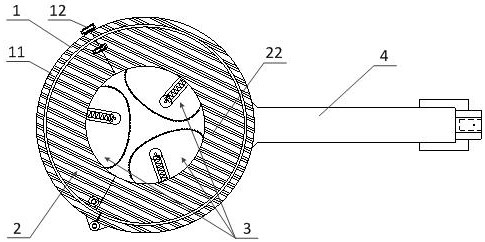

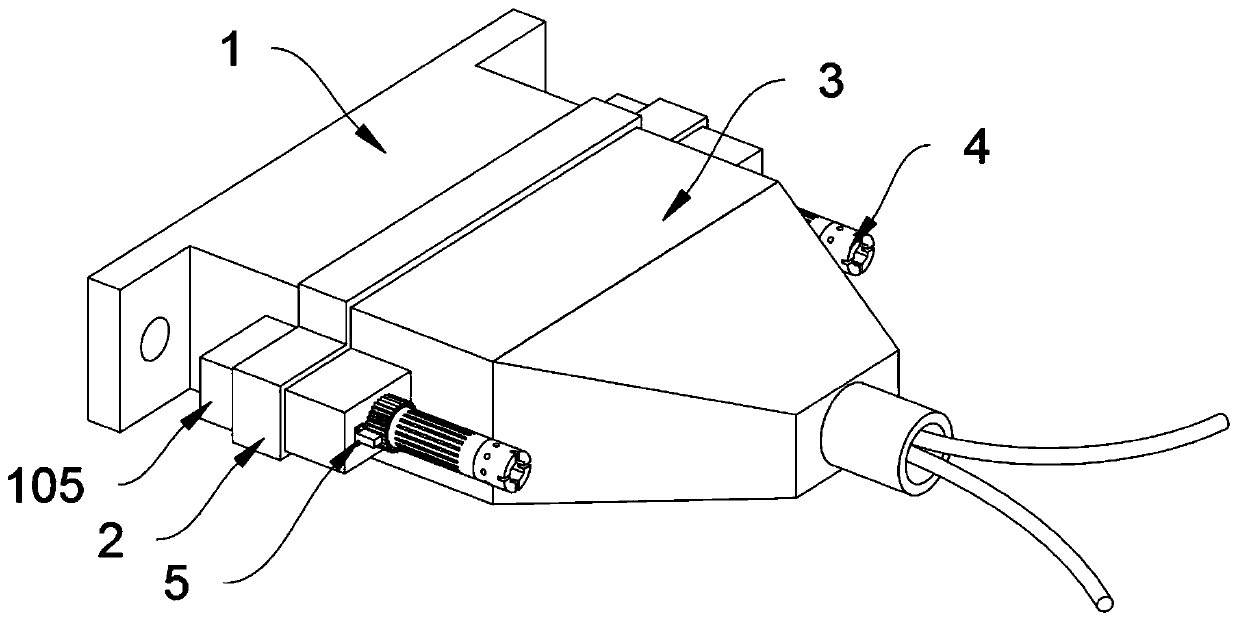

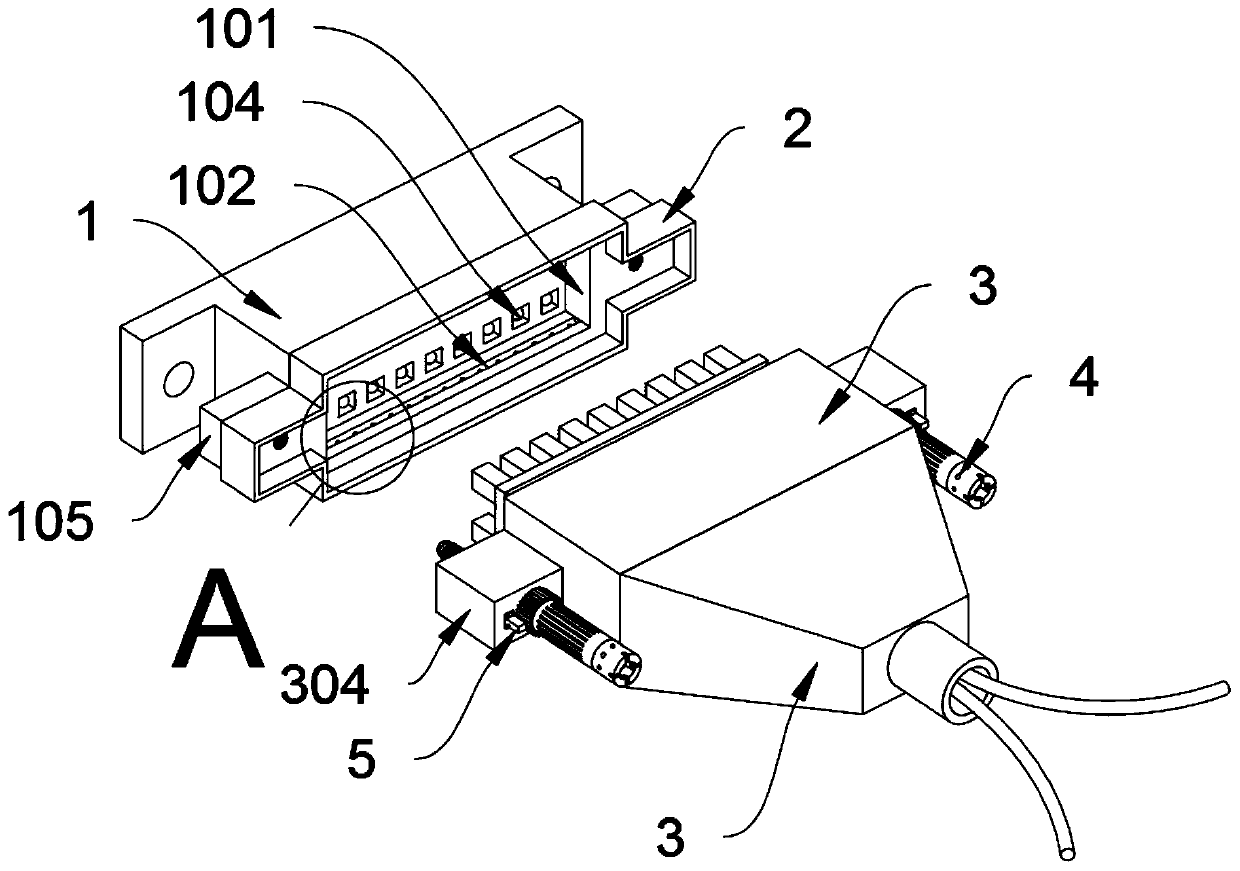

Full-automatic optical fiber head assembling machine capable of conducting insertion core assembling

ActiveCN107553130AImprove processing efficiencyTighten to achieveAssembly machinesDistribution controlButt joint

The invention relates to a full-automatic optical fiber head assembling machine capable of conducting insertion core assembling. The full-automatic optical fiber head assembling machine comprises a rack and a power distribution control box. The rack is provided with a rotary disc assembly, a base assembling mechanism, a spring assembling mechanism, a shell assembling mechanism, a cover sealing assembling mechanism and a discharging device, wherein the base assembling mechanism, the spring assembling mechanism, the shell assembling mechanism, the cover sealing assembling mechanism and the discharging device are matched with the rotary disc mechanism. A rotary disc rack comprises an assembling rotary disc installation base arranged on the rack, an assembling rotary disc and an assembling fixing disc which are concentric are installed on the assembling rotary disc installation base, the assembling rotary disc is matched with an assembling rotary disc motor, and assembling carriers are evenly arranged at the outer portion of the assembling rotary disc in an annular shape. An insertion core assembling mechanism is arranged between the spring assembling mechanism and the shell assemblingmechanism. By means of the full-automatic optical fiber head assembling machine capable of conducting insertion core assembling, an insertion core assembling rotary disc can be matched with an insertion core assembling part to synchronously machine the insertion core while all parts of the assembling rotary disc are used for assembling, meanwhile, unqualified products of insertion core sleeves can also be removed, in addition, the assembled insertion core and a rotary disc assembling part can be in seamless butt joint, and the overall machining efficiency of an optical fiber head is improved.

Owner:东莞鸿辉光联通讯技术有限公司

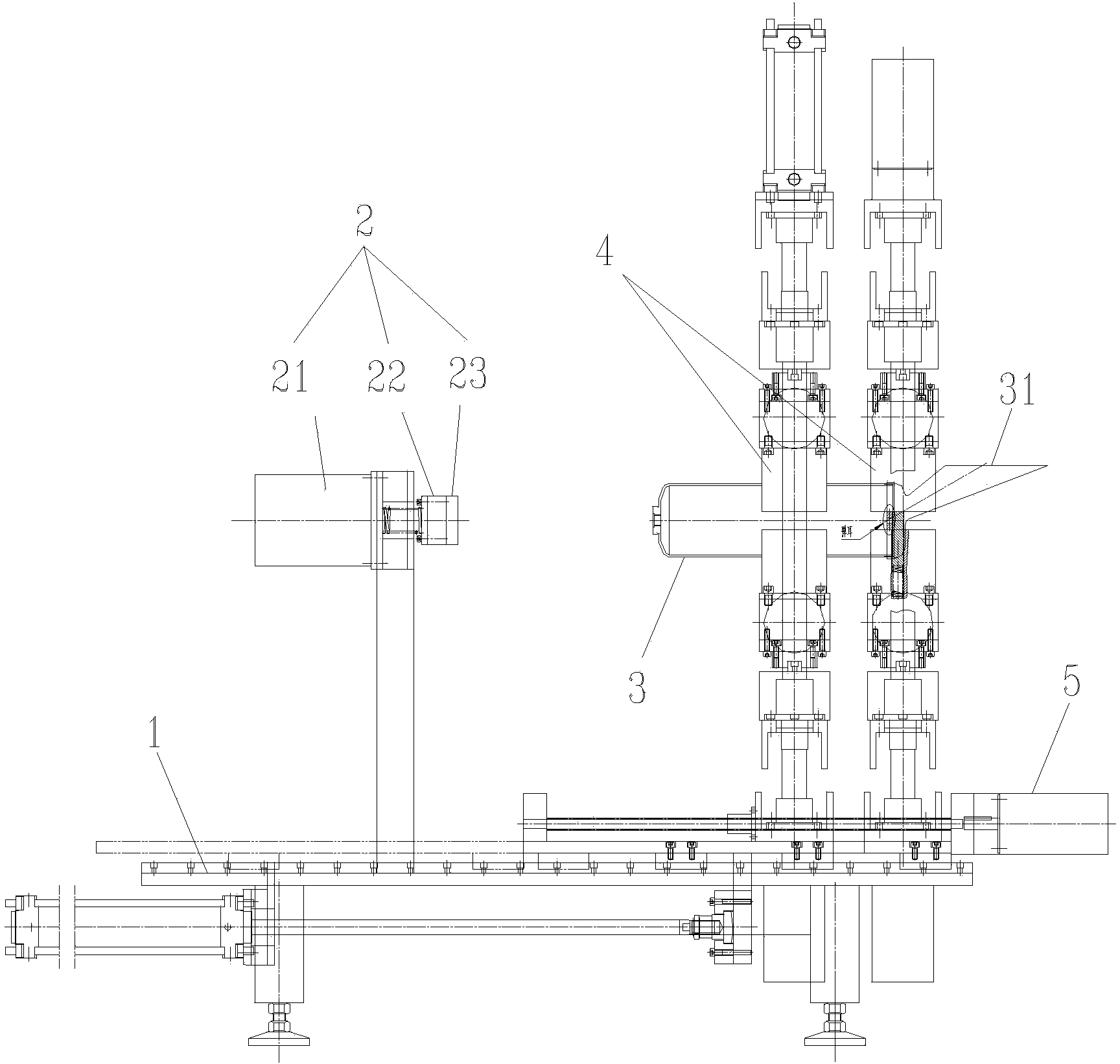

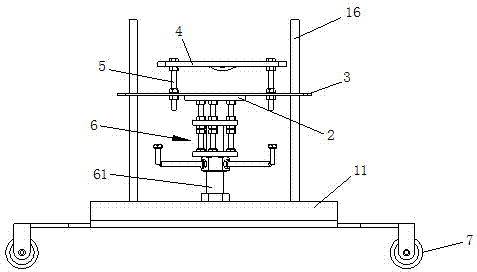

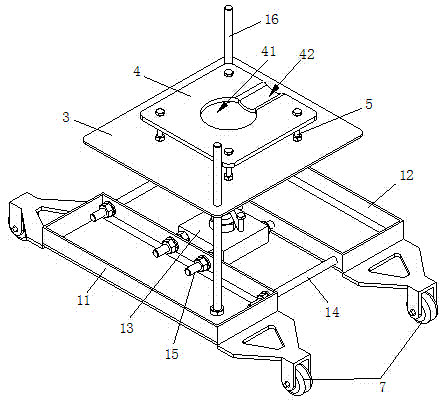

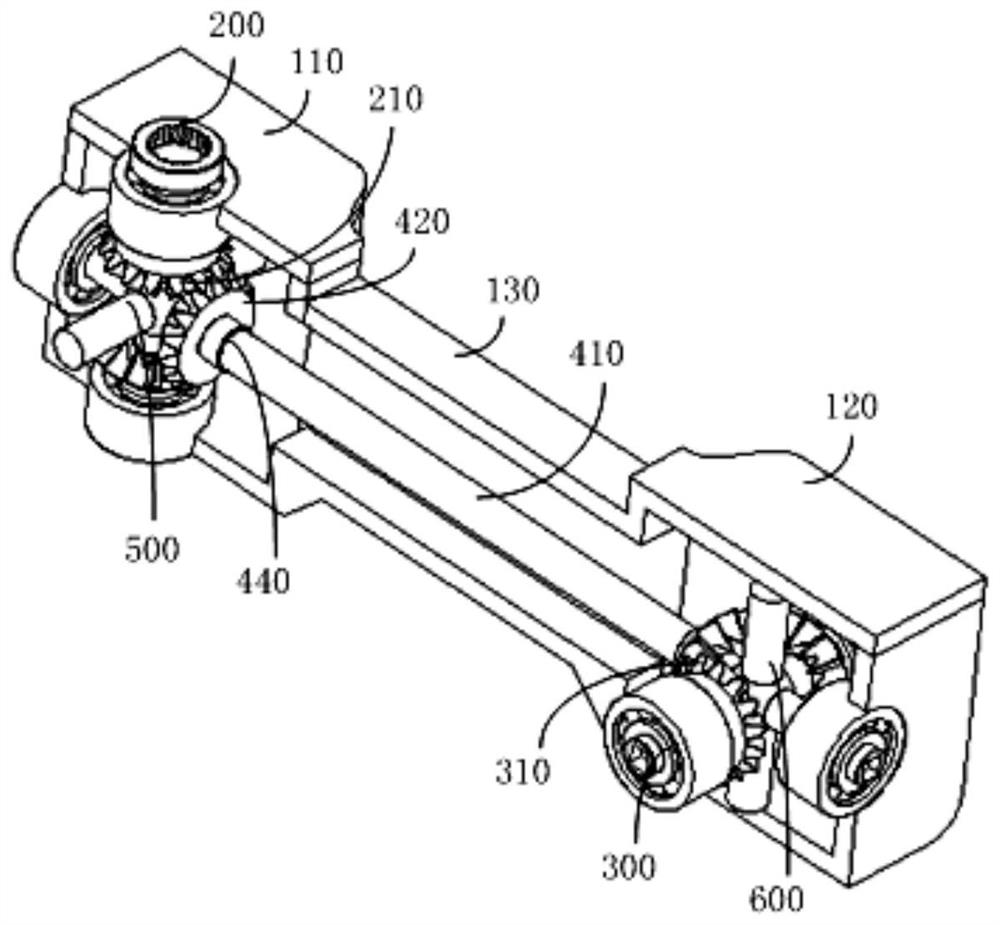

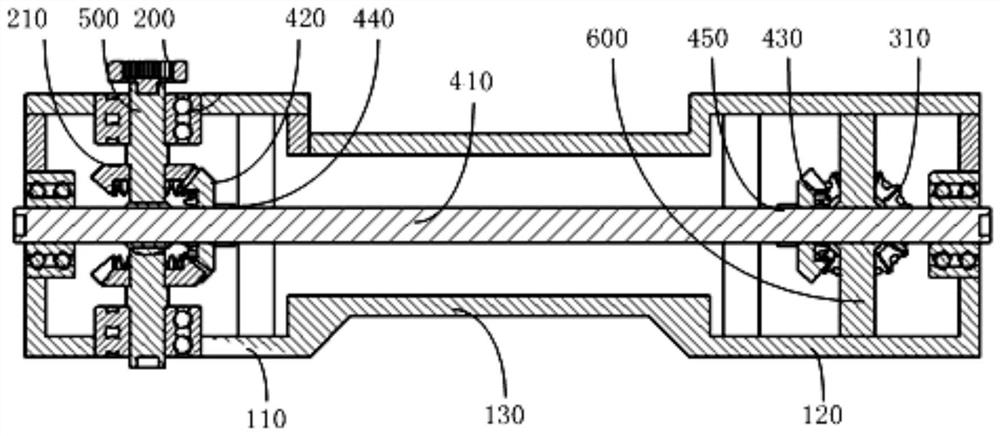

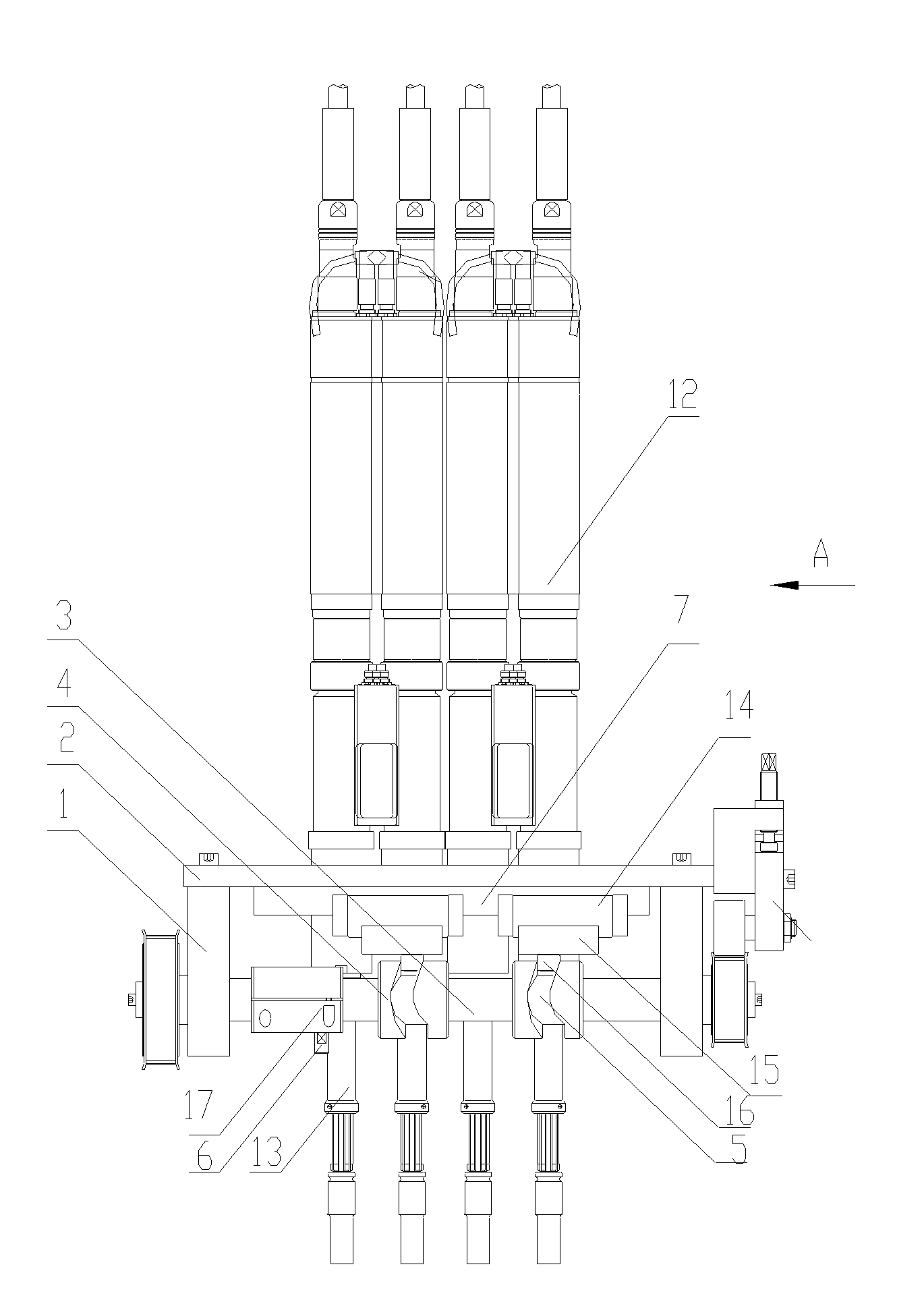

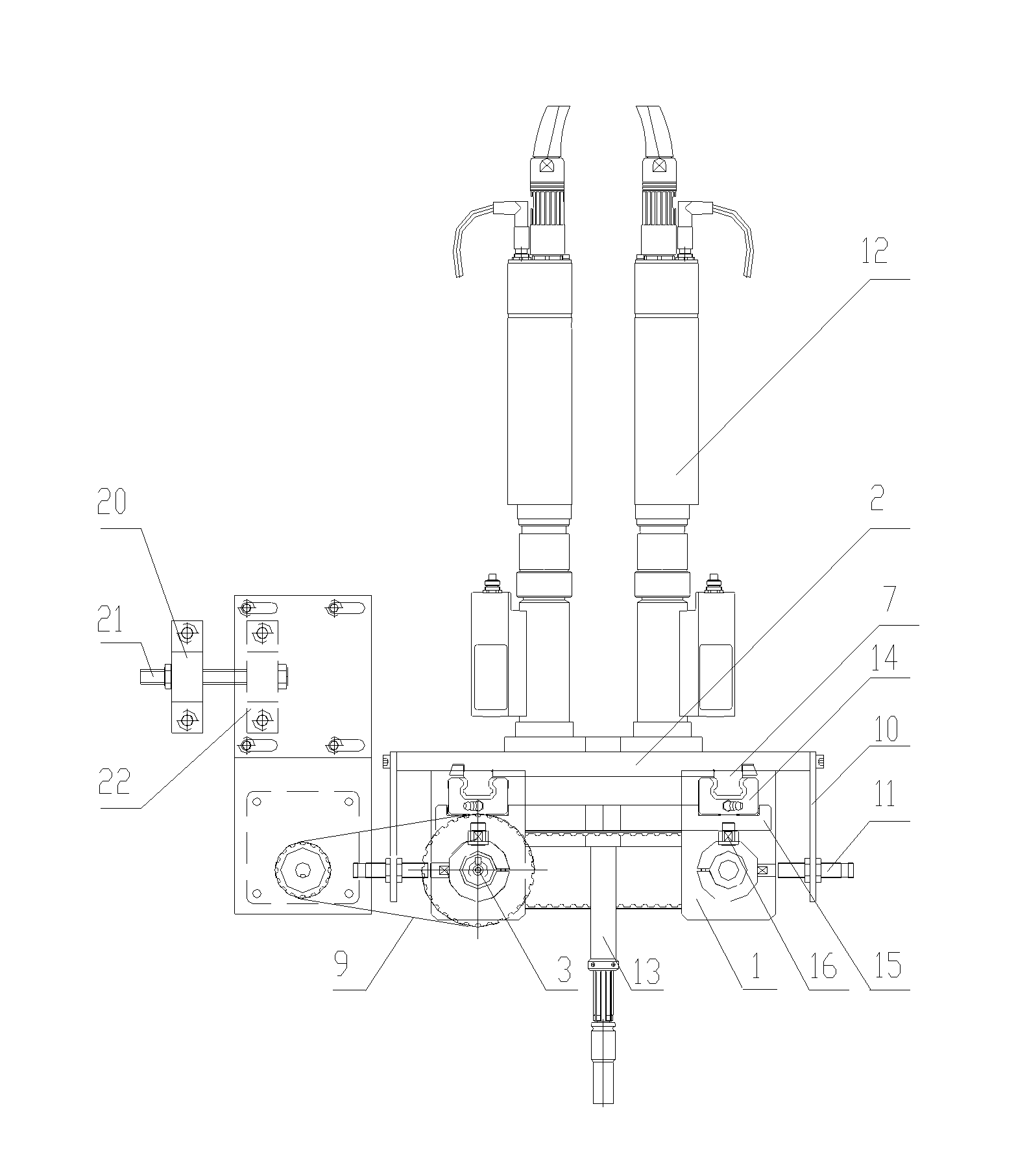

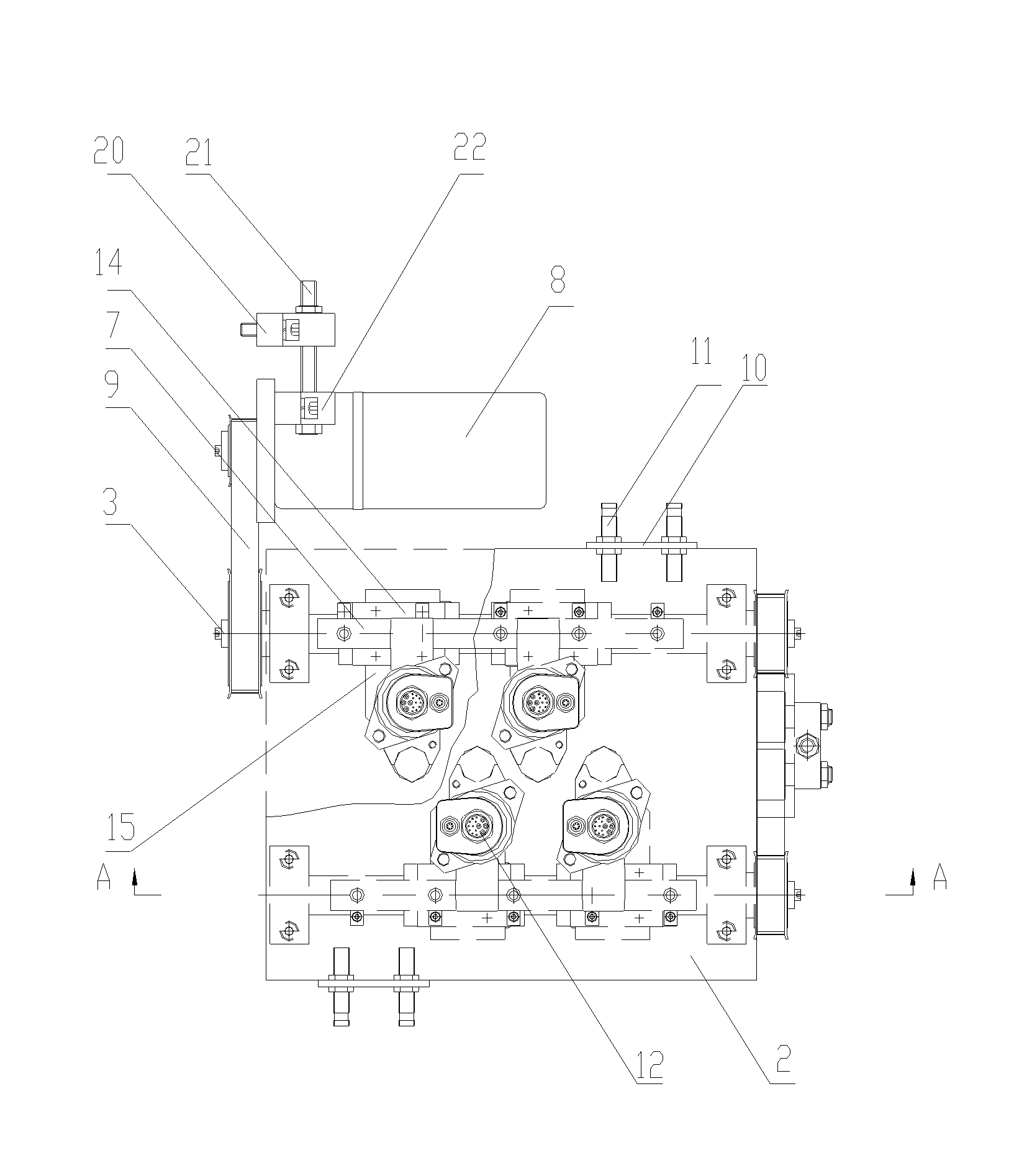

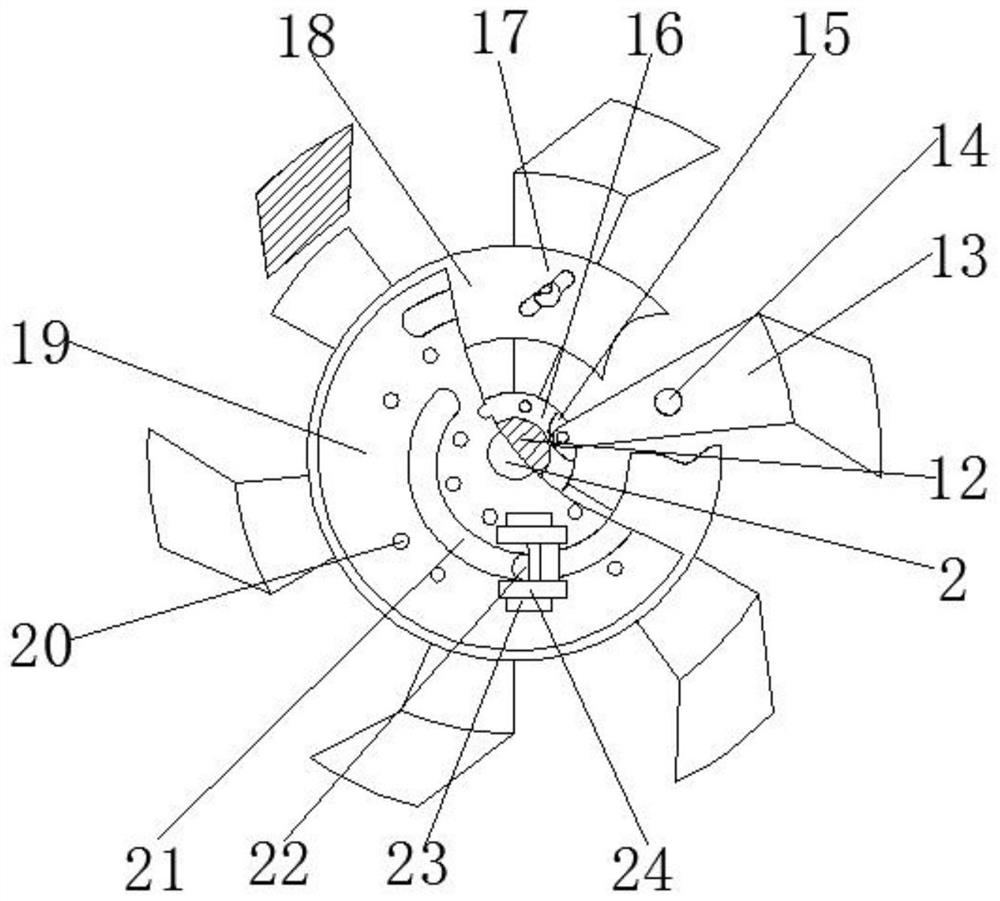

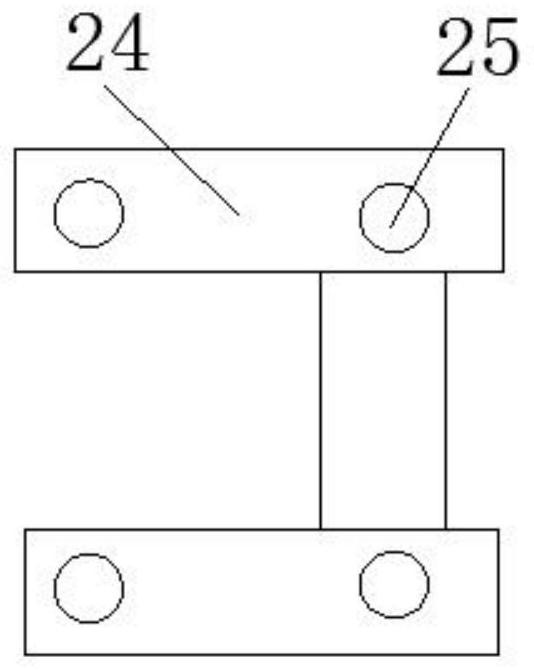

Multi-shaft tightening torque-changing and position-changing mechanism

PendingCN108971957AImprove compatibility and flexibilityImprove tightening qualityMetal working apparatusDrive motorEngineering

The invention relates to the technical field of automatic assembly, in particular to a multi-shaft tightening torque-changing and position-changing mechanism which comprises a mounting base, a position-changing drive speed reducer, a position-changing drive motor, a position-changing shaft assembly, a position-changing drive gear mechanism, position-changing shaft connecting base plates, a mechanism torque measuring buffer shaft assembly, a toque-changing plate, a torque-changing mechanism drive unit, a torque-changing drive gear mechanism, sliding limiting blocks, tightening shaft mounting seats, tightening shafts, a mechanism torque measuring buffer press rod and a mechanism torque measuring buffer head. According to the mechanism, the multiple tightening shafts can tighten circumferentially-distributed screws, the tightening shafts are precisely controlled within a certain range to move in the radial direction to any radius, tightening of the screws of different circumferential distribution radii is achieved, and compatibility and flexibility of tightening equipment are improved; and when the screws are tightened, the screw tightening depth can be monitored in real time, and thetightening quality can be improved better by combining angle and torque monitoring of the tightening shafts.

Owner:安徽航大智能科技有限公司

Elastic body flexible screwing device

ActiveCN103949876ATighten to achieveAvoid damageMetal working apparatusProtection mechanismEngineering

The invention discloses an elastic body flexible screwing device, which comprises a screwing platform, wherein a screwing mechanism and an elastic body protection mechanism are arranged on the screwing platform, the elastic body protection mechanism is used for clamping and positioning an elastic body, a screwing mechanism driving device used for driving the screwing mechanism to horizontally move is also arranged on the screwing platform, the screwing mechanism comprises a screwing servo motor, a torque sensor and a screwing head, the torque sensor and the screwing head are arranged at the output end of the screwing servo motor, the elastic body protection mechanism comprises an upper fixing beam, a lower fixing beam, an upper sliding beam, a lower sliding beam and a guide post, the upper fixing beam and the lower fixing beam are fixedly arranged on the guide post, the upper sliding beam and the lower sliding beam can respectively and vertically slide on the guide post, an upper press block and a lower press block are respectively arranged on the upper sliding beam and the lower sliding beam, an upper sliding beam driving device is arranged on the upper fixing beam, and a lower sliding beam driving device is arranged on the lower fixing beam. The elastic body flexible screwing device has the advantages that the elastic body screwing work efficiency and the screwing precision are improved, and in addition, the elastic body is prevented from generating unrecoverable obvious deformation and appearance damage.

Owner:贺州市八步区市场监督管理局

Preparation method of eye muscle bottom essence

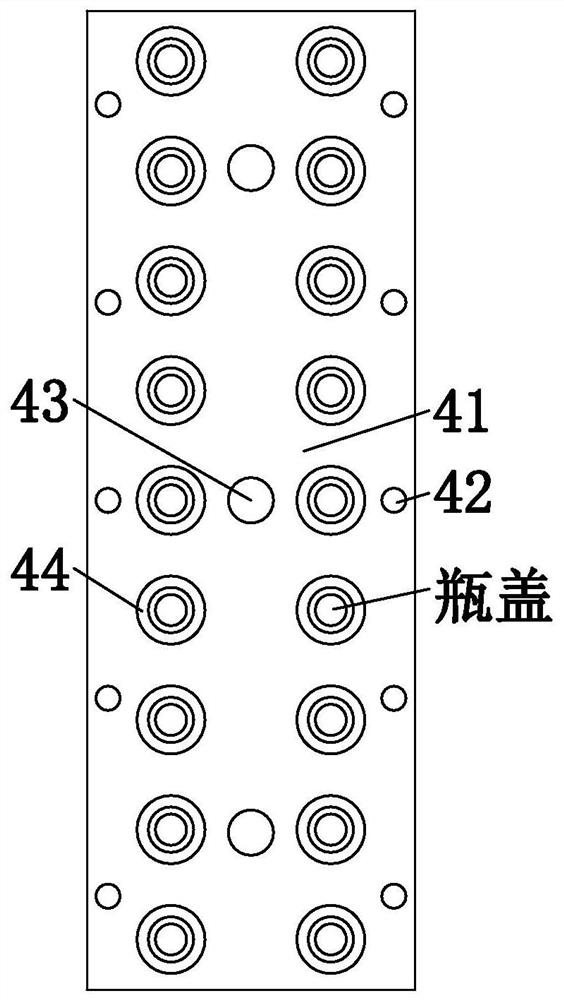

InactiveCN112456408AReduce production efficiencySingle functionThreaded caps applicationConveyorsOphthalmologyEngineering

The invention provides a preparation method of eye muscle bottom essence. The preparation method uses an eye muscle bottom essence preparation device, and the device comprises a conveying belt, a support frame, a containing plate, a placing mechanism and a tightening mechanism. The invention provides the preparation method of the eye muscle bottom essence, which can solve the following problems inthe preparation process of the eye muscle bottom essence that a, in traditional modes, the eye muscle bottom essence is filled in a bottle through equipment, and then the eye skin bottom essence is sealed and locked in the bottle through a bottle cap; however, most of traditional modes adopt manual bottle cap tightening, and the manual modes are low in production efficiency, relatively high in working intensity and not suitable for batch preparation; and b, according to an existing eye muscle bottom essence preparation device, the bottle caps are arranged at bottle openings in a sleeving modefirstly, then the bottle caps are tightened one by one through the device, batch tightening production cannot be achieved, and therefore the device is single in function and not high in practicability.

Owner:盐城拉边化妆品有限公司

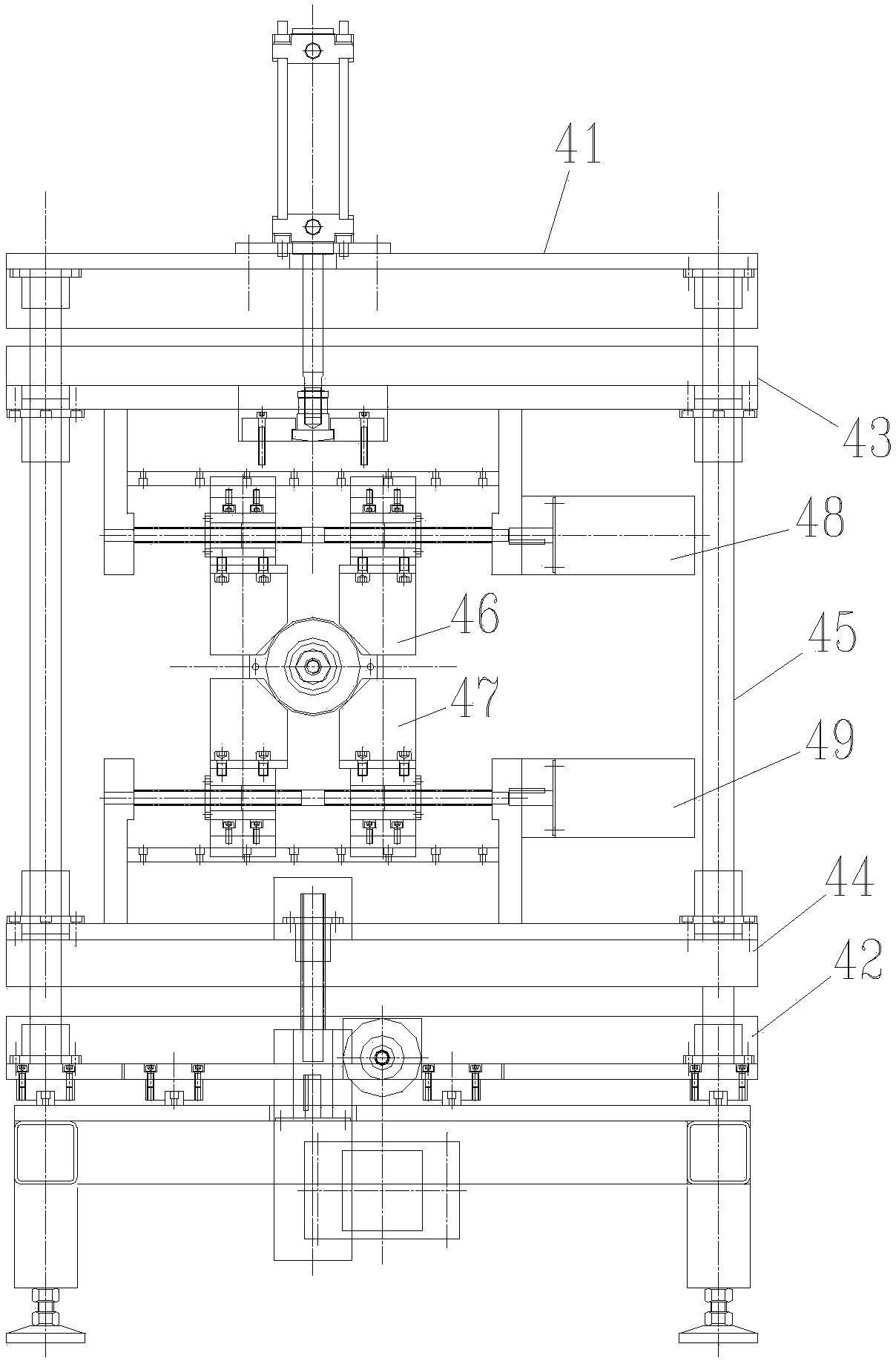

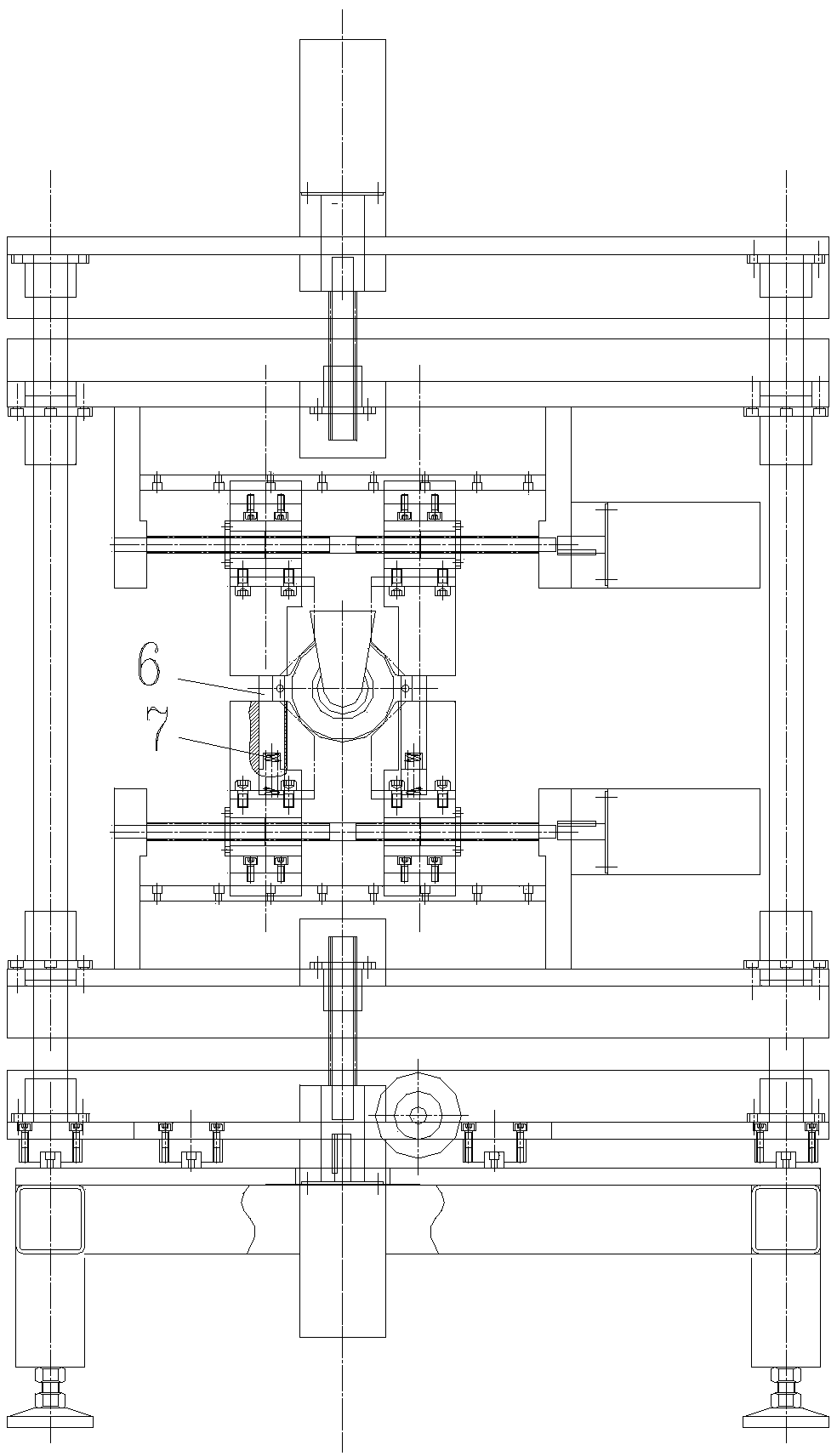

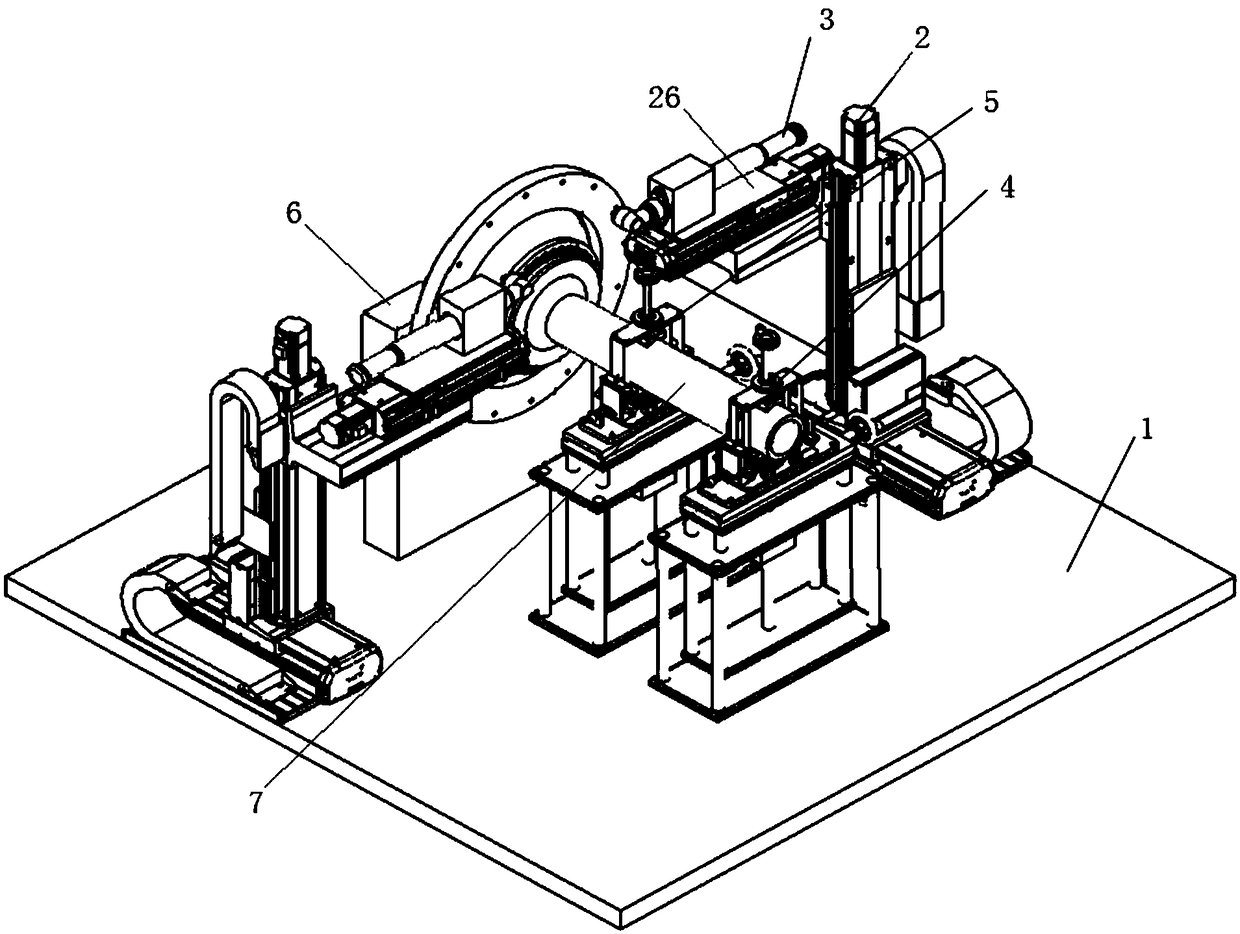

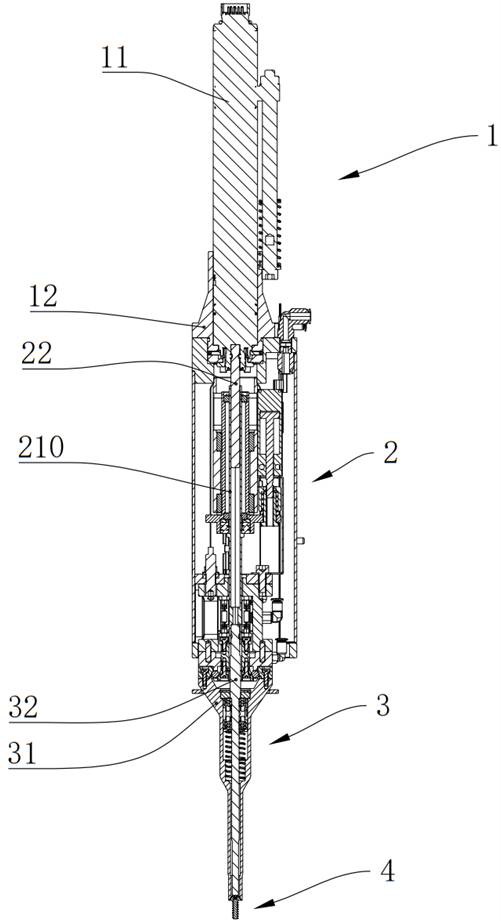

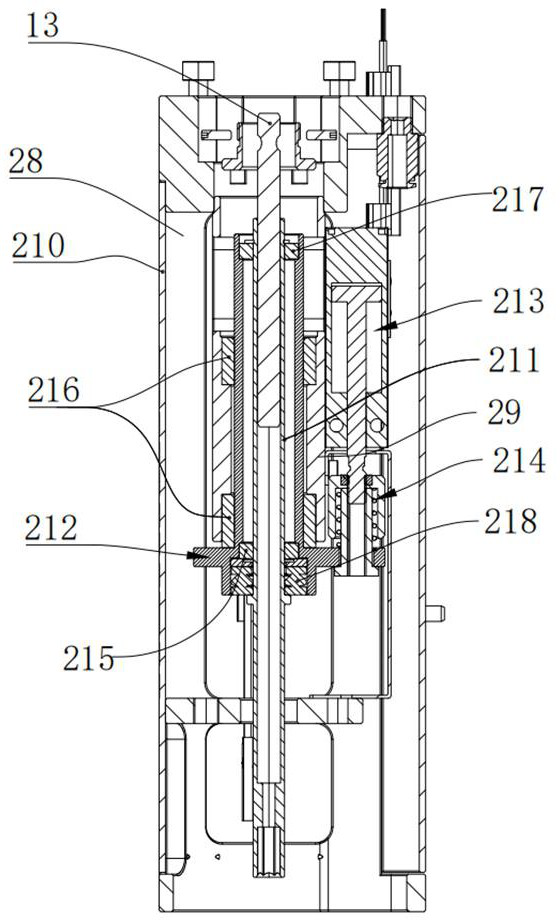

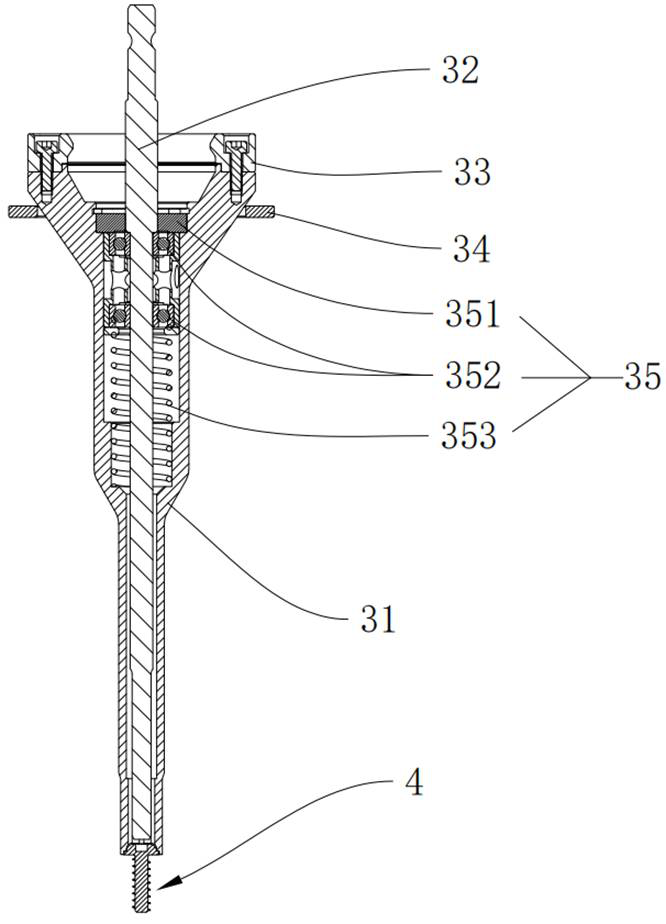

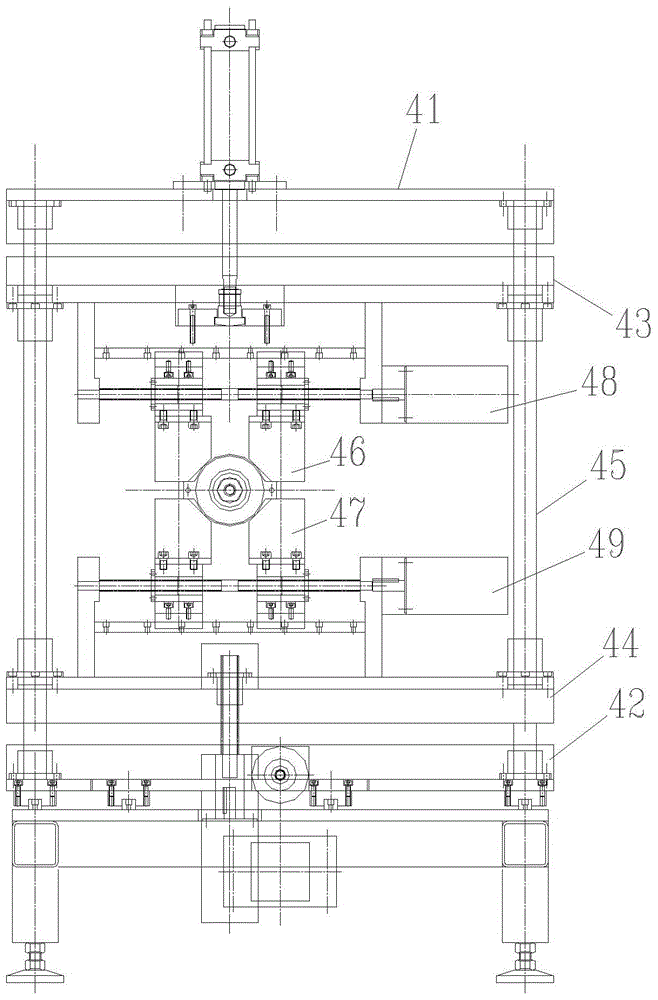

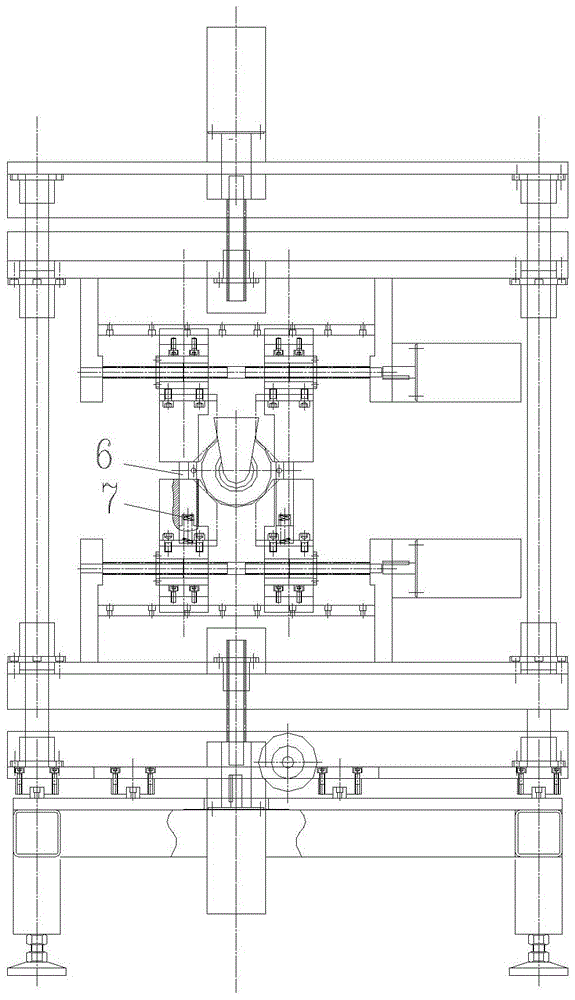

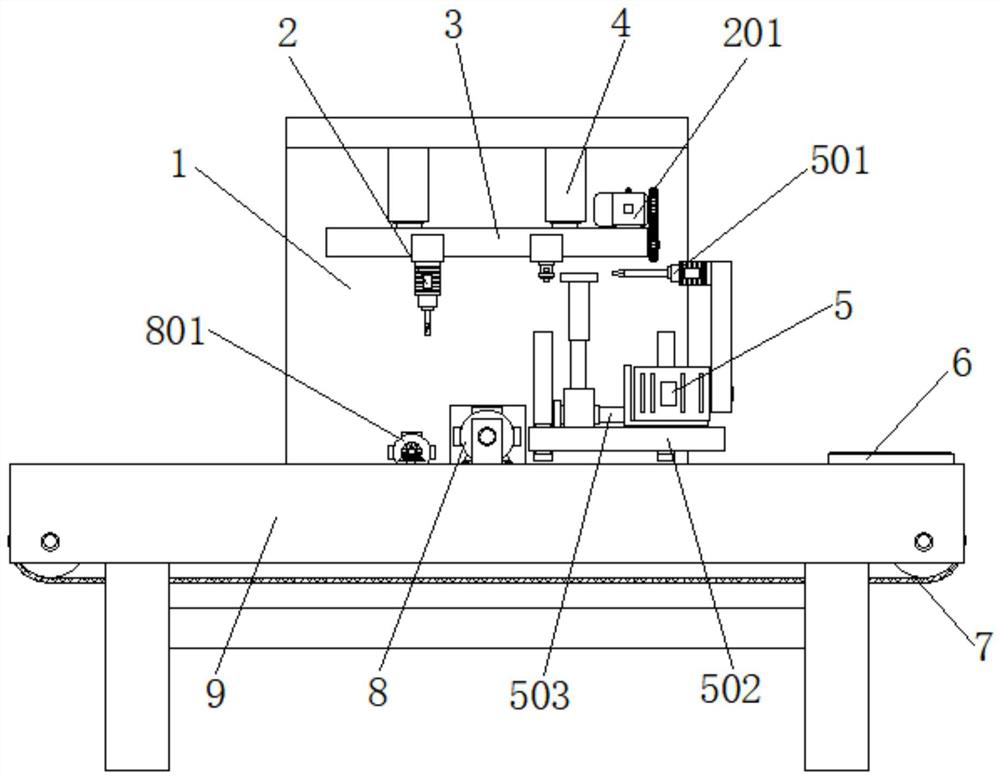

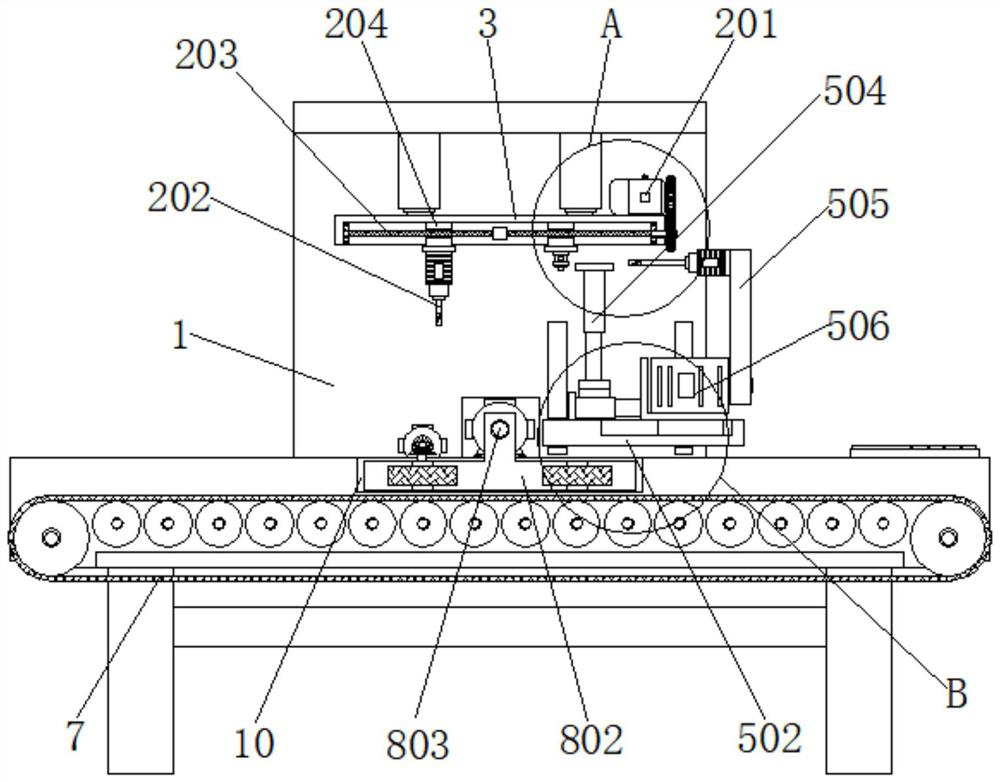

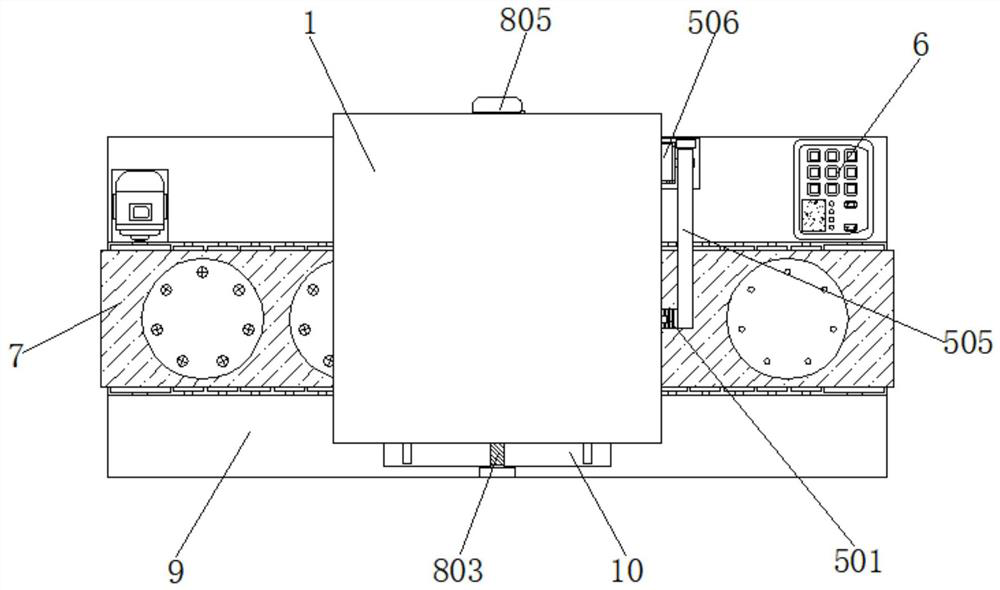

Automatic assembling system for rotor parts of rotary machine

InactiveCN108637651AEasy to controlTighten to achieveMetal working apparatusAxis of symmetryRectangular coordinates

The invention discloses an automatic assembling system for rotor parts of a rotary machine. The system comprises a base station and two rectangular coordinate system robots which are arranged in mirror symmetry. Each of the rectangular coordinate system robots comprises an X-axis slide rail, a Y-axis slide rail and a Z-axis slide rail, wherein the X-axis slide rail is fixedly connected to the upper surface of the base station, the lower end of the Z-axis slide rail is slidably connected to the X-axis slide rail through a Z-axis slide block, the side wall of one side of the Y-axis slide rail isslidably connected to the Z-axis slide rail through a Y-axis slide block, and the Y-axis slide rail is connected to an electric tightening shaft through an electric tightening shaft slide block. Theautomatic assembling system for the rotor parts of the rotary machine also comprises a first n-shaped clamp, a second n-shaped clamp and a third n-shaped clamp which are successively arranged along the direction of axis of symmetry of the two rectangular coordinate system robots. The system disclosed by the invention can tighten bolts according to different specifications of bolts, different reeldimensions, different tightening parameters and the like, and controls the bolt tightening process precisely.

Owner:DALIAN UNIV OF TECH

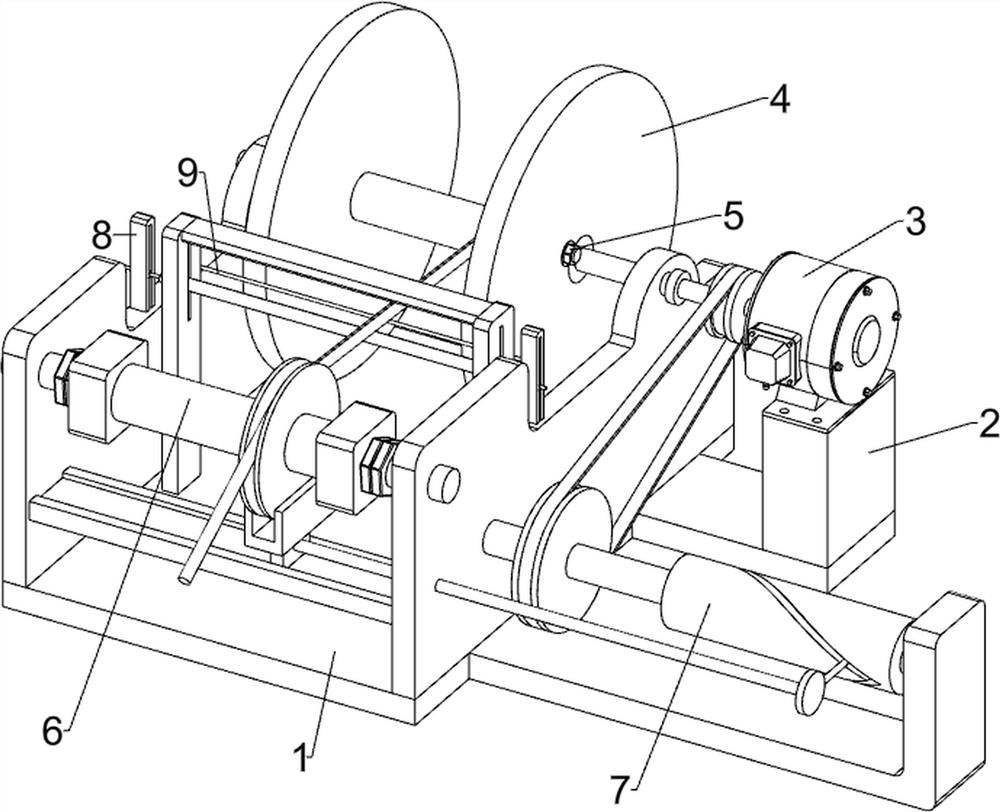

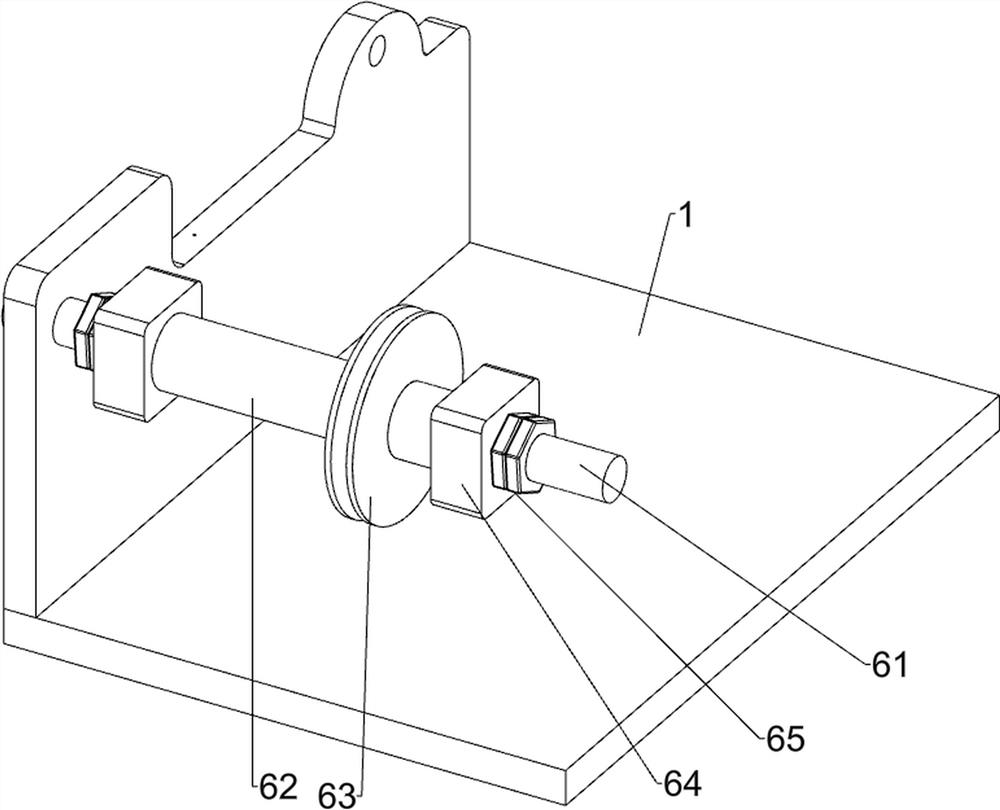

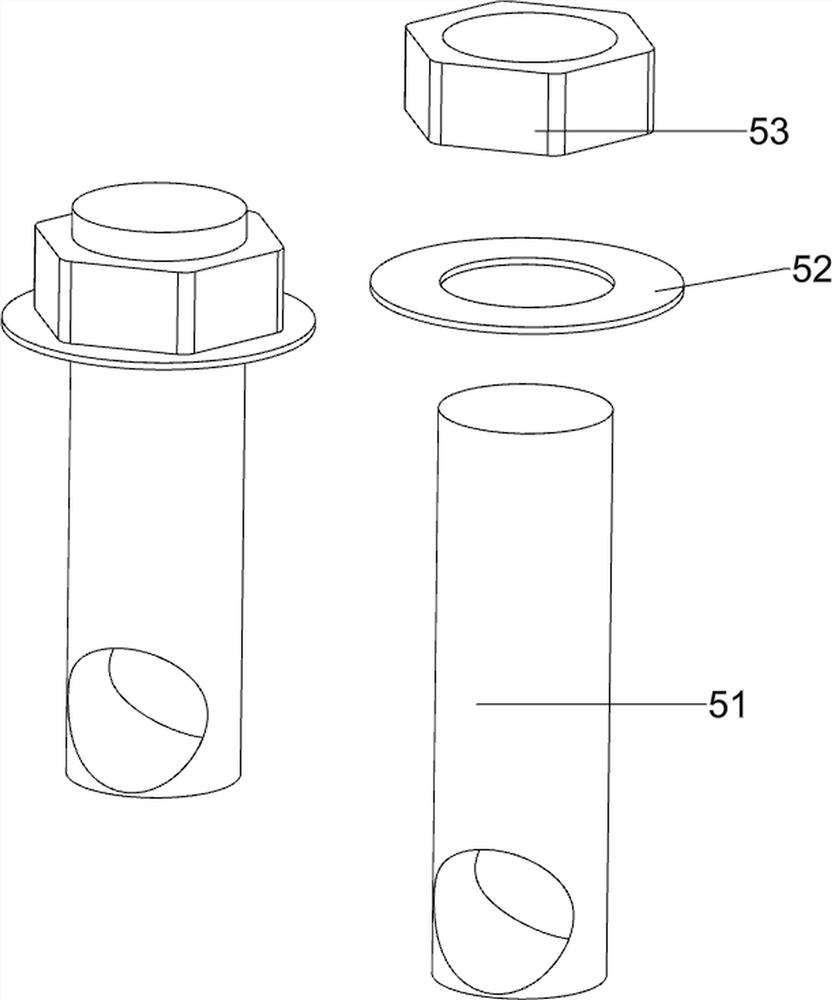

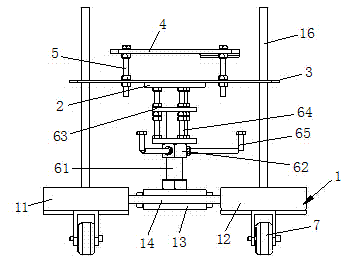

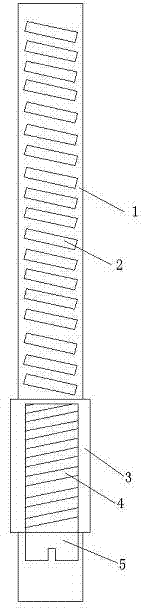

Electrical equipment winding device capable of uniformly arranging electric wires

ActiveCN112623861ATo achieve the effect of windingTighten to achieveFilament handlingElectric machineCoupling

The invention relates to a winding device, particularly relates to an electrical equipment winding device capable of uniformly arranging electric wires, and provides the electrical equipment winding device capable of uniformly arranging the electric wires, which is convenient and rapid in winding, capable of avoiding twining of the electric wires, and capable of automatically and uniformly arranging and cutting the electric wires. The electrical equipment winding device capable of uniformly arranging the electric wires comprises a lathe bed, a gear motor, a winding assembly and a clamping assembly, wherein the lathe bed is provided with a motor frame, the gear motor is mounted at the top of the motor frame, the lathe bed is provided with the winding assembly, the winding assembly is connected with an output shaft of the gear motor, and the clamping assembly is arranged on the winding assembly. According to the device, the output shaft of the gear motor rotates to drive a first rotating shaft to rotate, so that a coupler is driven to rotate, a second rotating shaft is driven to rotate, a first roller is driven to rotate, and the wire winding effect is achieved.

Owner:郑州市银河电线电缆有限公司

Air gun support

Owner:ANHUI HELI CO LTD

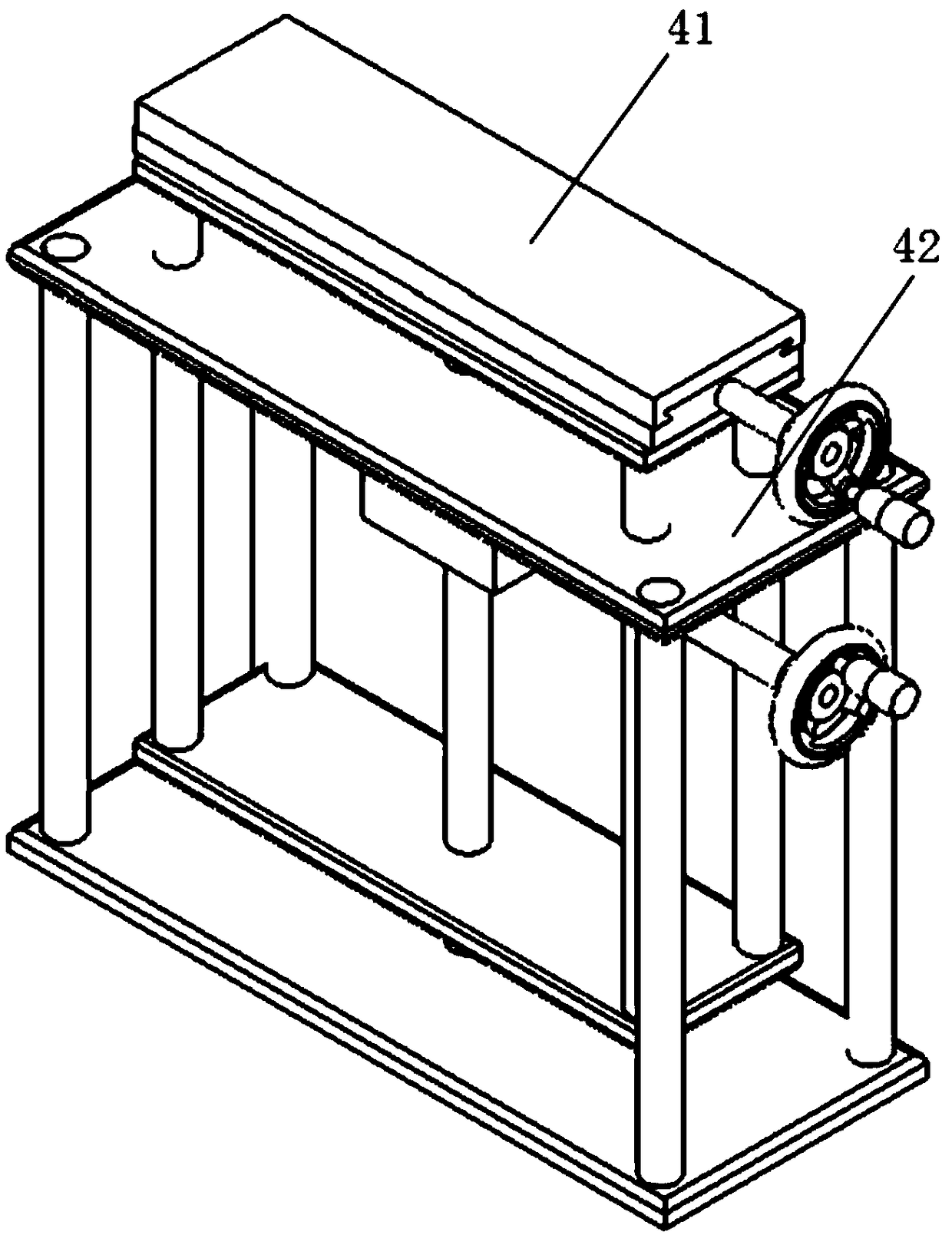

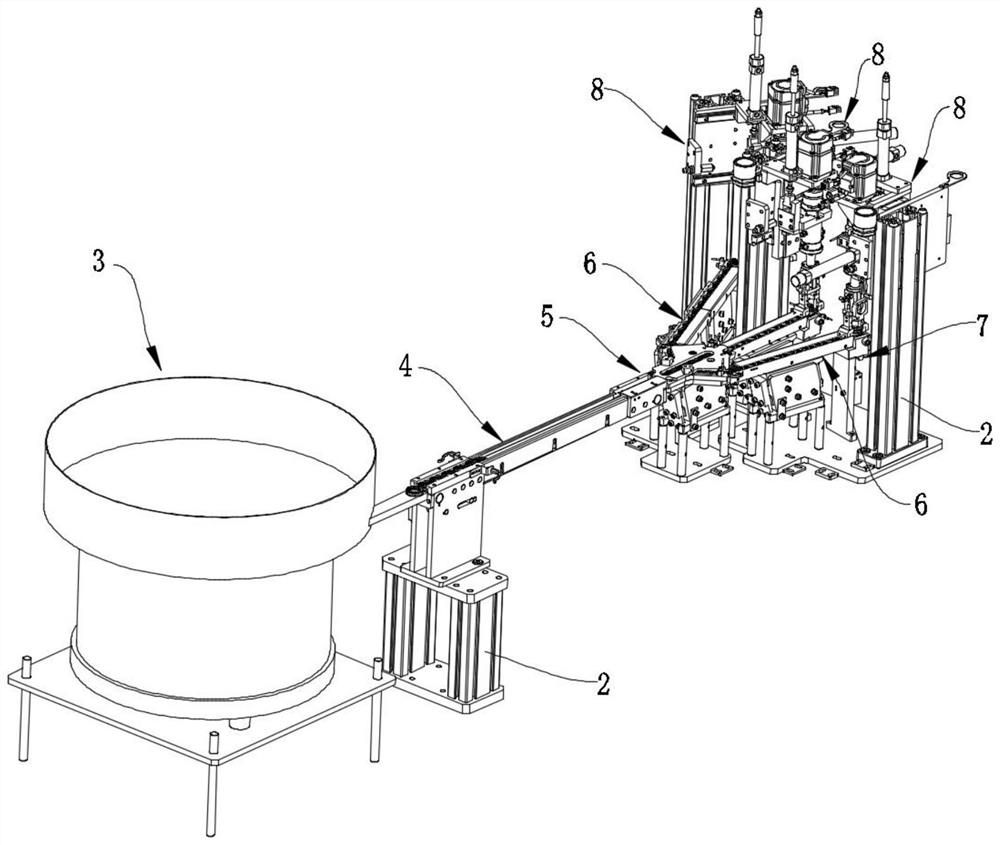

Tightening equipment for multi-path material distribution of cover body

PendingCN114770078AIncrease productivityReduce labor costs and equipment manufacturing costsMetal working apparatusConveyor partsStructural engineeringIndustrial engineering

The invention discloses a tightening device for multi-path material distribution of cover bodies. The tightening device comprises a rack, and a sorting output device used for orderly arranging and outputting the cover bodies in a row is arranged on the rack; one side of the sorting output device is connected with a first transverse conveying device used for transversely conveying the cover bodies arranged in order. The tail end of the first transverse conveying device is provided with a multi-path material distributing device used for dividing a row of fed cover bodies into multiple paths of discharged cover bodies. The tail end of the multi-path material distributing device is connected with a plurality of second transverse conveying devices used for transversely conveying the cover bodies, and the tail ends of the second transverse conveying devices are provided with material cutting devices used for cutting the cover bodies. A cover body tightening device used for transferring the cover body on the cutting device to the position above the base and tightening the base and the cover body is arranged on one side of the cutting device, a one-to-multiple-path conveying mode is adopted, the production efficiency can be improved, and the labor cost and the equipment manufacturing cost can be reduced.

Owner:DONGGUAN YI CHENG AUTOMATIC EQUIP

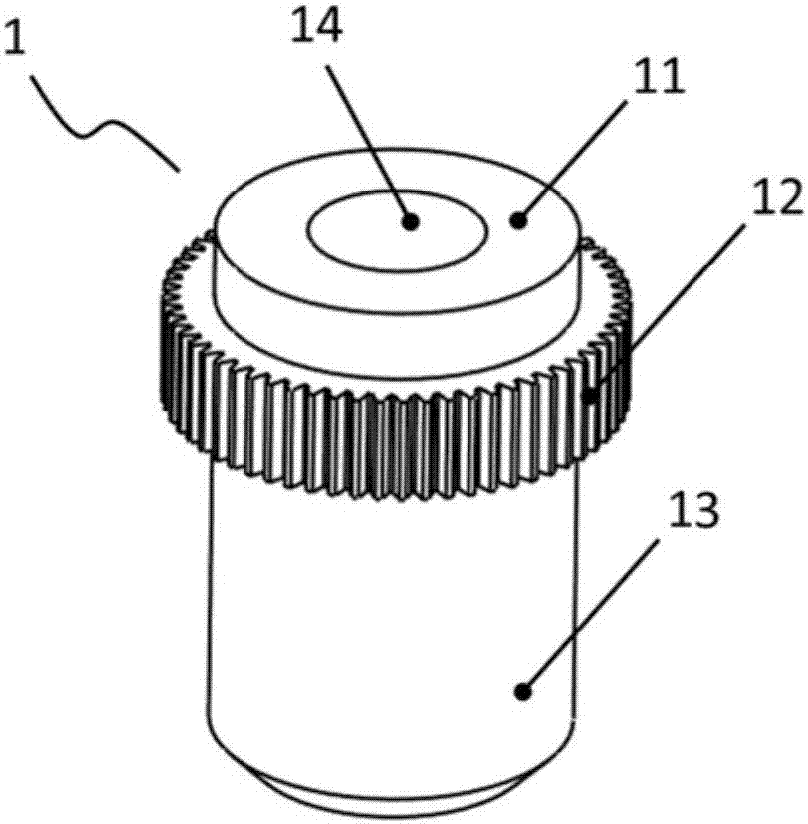

Cylinder head bolt tightening tool capable of absorbing iron filings

ActiveCN106141652BTighten to achieveAvoid Contamination CleanlinessMetal working apparatusCylinder headEngineering

The invention discloses a cylinder cap bolt tightening tool capable of sucking iron scraps. The cylinder cap bolt tightening tool is used for being installed on a tightening shaft of a tightening machine and comprises a cylindrical body and a magnetic ring. The diameter of the upper end head of the cylindrical body is larger than the diameter of the lower end head of the cylindrical body. The lower end head and the upper end head are connected in a gradually-changing manner. A square counter bore matched with the tightening shaft is formed in the upper end head, and an inner hexagonal counter bore matched with a cylinder cap bolt hexagon head is formed in the lower end head. The magnetic ring is arranged on the outer wall of the lower end head in a sleeving manner. According to the tool, cleanliness of the head of a cylinder cap bolt can be ensured.

Owner:GUANGXI YUCHAI MASCH CO LTD

Nut screwing device

PendingCN112975849ATighten to achieveEasy to tightenMetal-working hand toolsDrive shaftStructural engineering

Owner:KOCEL MACHINE

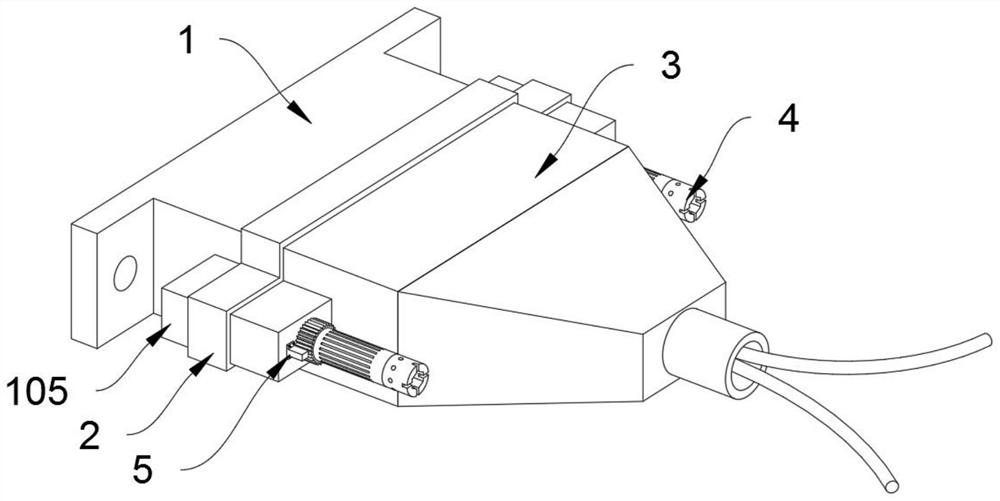

Automatic quick-change adsorption tightening device

ActiveCN114871747ATighten to achieveQuick disassembly and replacementVehicular energy storageMetal working apparatusClassical mechanicsStructural engineering

The invention relates to the field of dismounting and mounting equipment, and provides an automatic quick-change adsorption tightening device which comprises a tightening gun mounting module used for tightening, an adsorption tightening head used for adsorbing or tightening a screw and a quick-change connecting mechanism used for quickly replacing the adsorption tightening head. The tightening gun mounting module comprises a transmission connecting rod and a tightening gun which are in transmission connection with each other; the adsorption tightening head comprises a hollow nail suction pipe and a screw bit arranged in the nail suction pipe; the transmission connecting rod is movably connected to the screw bit and is driven by the tightening gun to rotate so as to tighten the screw; the pneumatic connecting pipe is communicated with the screw sucking pipe, and screws are sucked and released through air suction or air supply; the sliding traction assembly comprises a sliding telescopic piece and a driving piece driving the sliding telescopic piece to move, the sliding telescopic piece is connected with the movable limiting assembly, the sliding telescopic piece is connected to the installation support in a sliding mode, the movable limiting assembly is movably connected to the adsorption tightening head, and quick connection of the adsorption tightening head is achieved.

Owner:DEPRAG ASSEMBLY AUTOMATION TECH SUZHOU

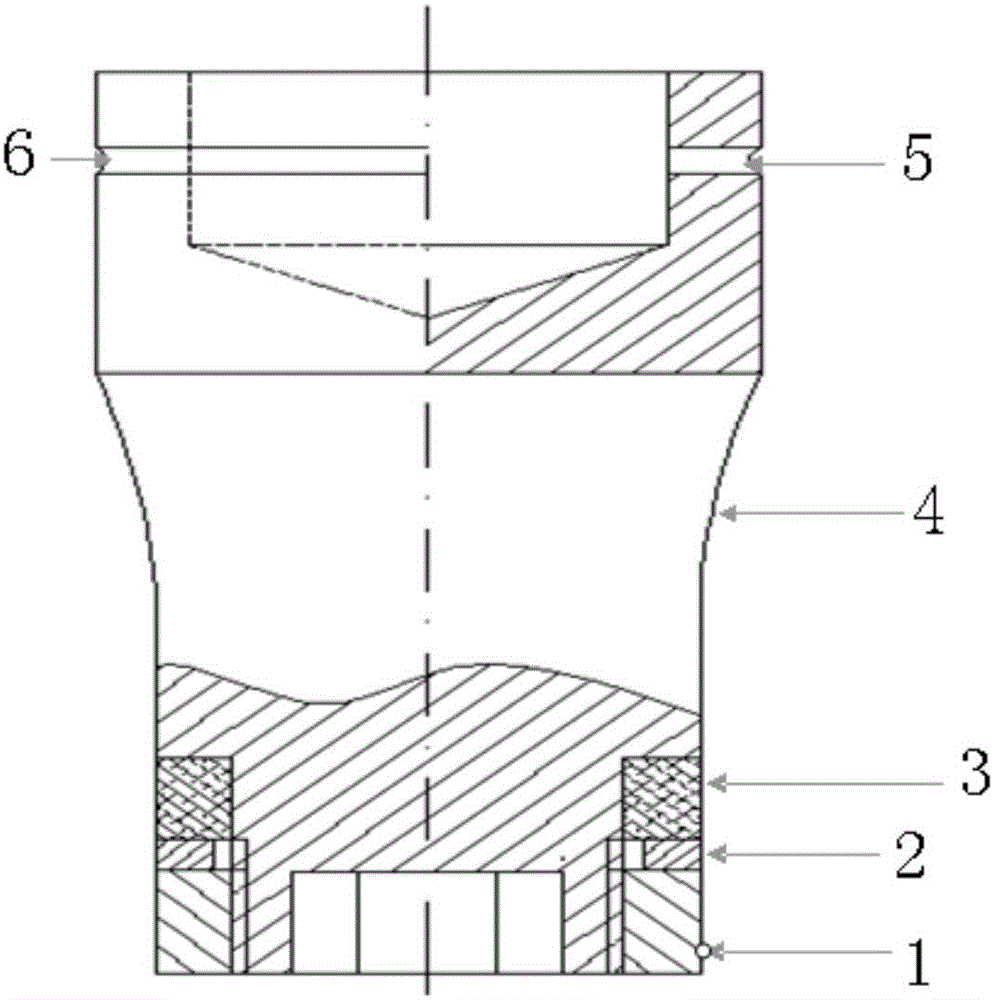

Nut tightening machine

ActiveCN104259837BTighten to achieveAvoid following rotationMetal working apparatusEngineeringMechanical engineering

An embodiment of the invention discloses a nut tightening machine comprising a machine body, a power system and a clamping mechanism. The power system and the clamping mechanism are arranged on the machine body, and the clamping mechanism is used for clamping an output shaft matched with a nut to be tightened. The power system comprises a shell arranged on the machine body, a driving head rotatably arranged on the shell, a sleeve matched with the to-be-tightened nut, and a first driving unit arranged on the shell and used for driving the driving head to rotate. By the nut tightening machine, the nut can be tightened without being knocked, so that the problem that the appearance of the round nut is damaged during assembly is avoided completely by the assembly form. The output shaft does not need to be fixed manually, labor intensity of workers is lowered substantially, and production efficiency is improved.

Owner:CHONGQING GEARBOX

Cylinder cap bolt tightening tool capable of sucking iron scraps

ActiveCN106141652ATighten to achieveAvoid Contamination CleanlinessMetal working apparatusScrapEngineering

The invention discloses a cylinder cap bolt tightening tool capable of sucking iron scraps. The cylinder cap bolt tightening tool is used for being installed on a tightening shaft of a tightening machine and comprises a cylindrical body and a magnetic ring. The diameter of the upper end head of the cylindrical body is larger than the diameter of the lower end head of the cylindrical body. The lower end head and the upper end head are connected in a gradually-changing manner. A square counter bore matched with the tightening shaft is formed in the upper end head, and an inner hexagonal counter bore matched with a cylinder cap bolt hexagon head is formed in the lower end head. The magnetic ring is arranged on the outer wall of the lower end head in a sleeving manner. According to the tool, cleanliness of the head of a cylinder cap bolt can be ensured.

Owner:GUANGXI YUCHAI MASCH CO LTD

Tightening wrench device for tightening sleeve connecting steel bar

PendingCN113400233AAchieve connectionTightening of connecting barsSpannersWrenchesWrenchIndustrial engineering

The invention provides a tightening wrench device for tightening a sleeve connecting steel bar. The device comprises a tightening shell, a clamping and supporting cylinder, at least three tightening and clamping assemblies and a driving assembly; the clamping and supporting cylinder is rotatably connected in the tightening shell; the at least three tightening and clamping assemblies are arranged in the clamping and supporting cylinder and distributed in the circumferential direction of the clamping and supporting cylinder, all the tightening and clamping assemblies are adjustably connected to the clamping and supporting cylinder in the radial position of the clamping and supporting cylinder, and the tightening and clamping assemblies are used for clamping a to-be-rotated part placed in the clamping and supporting cylinder; and the driving assembly is connected with the clamping and supporting cylinder and used for driving the clamping and supporting cylinder to rotate so as to drive the to-be-rotated part clamped by the tightening and clamping assemblies to rotate, and then tightening between a to-be-fixed part and the to-be-rotated part is achieved. According to the tightening wrench device, to-be-rotated part is clamped through the tightening and clamping assemblies; and the driving assembly drives the clamping and supporting cylinder to rotate so as to drive the to-be-rotated part clamped by the tightening and clamping assemblies to rotate, and tightening between the to-be-rotated part and the to-be-fixed part is achieved.

Owner:CHINA FIRST METALLURGICAL GROUP

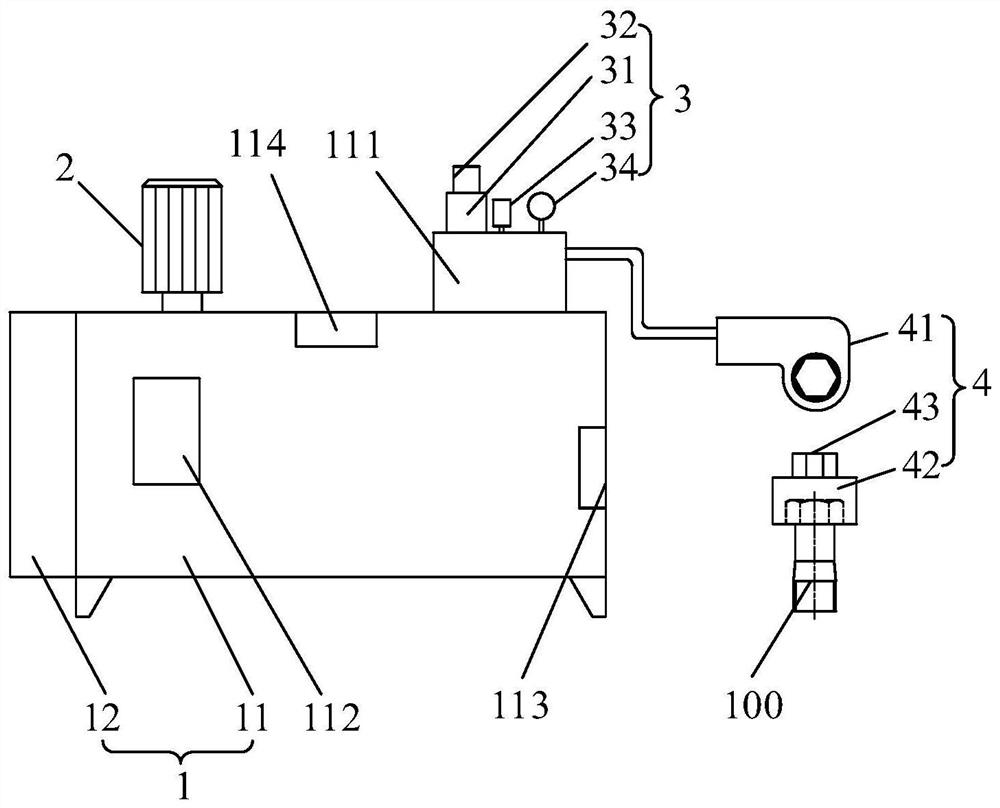

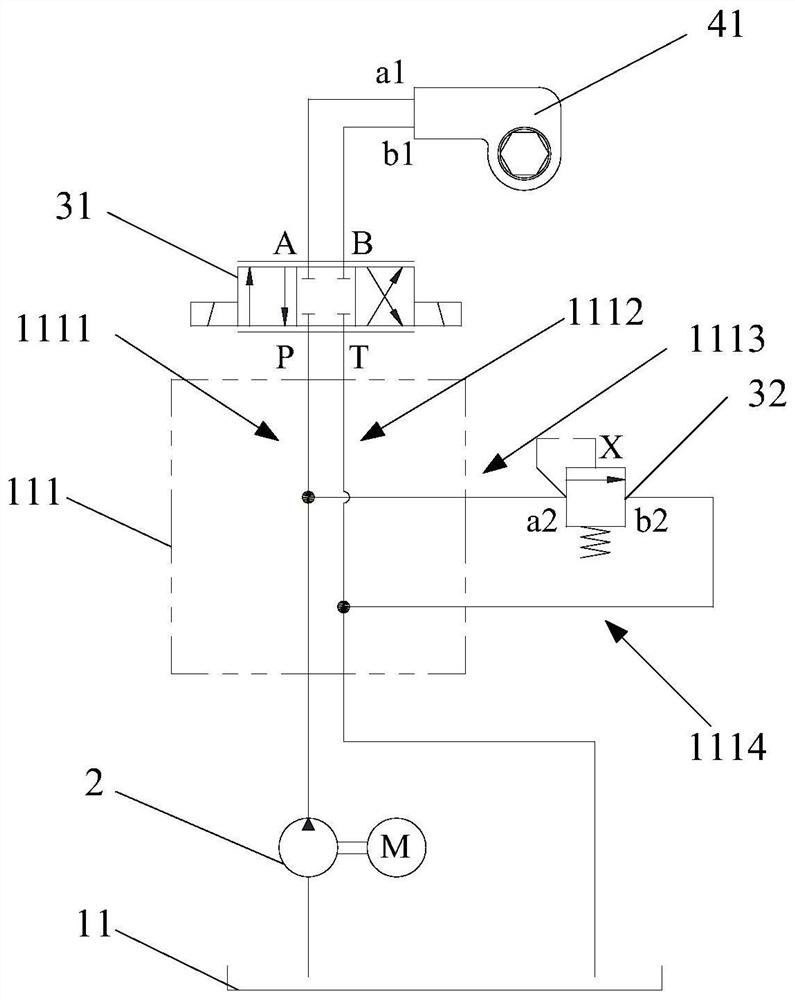

Bolt tightening device

PendingCN111810464ATighten to achieveGuaranteed accuracyFluid-pressure actuator testingServomotor componentsOil supplyElectrical and Electronics engineering

The invention provides a bolt tightening device, and belongs to the field of mechanical equipment. The bolt tightening device comprises an oil supply mechanism, an electric pump, a control mechanism and a force application mechanism, wherein the oil supply mechanism comprises an oil tank, the electric pump is located on the oil tank, and an oil inlet of the electric pump communicates with the oiltank; the control mechanism comprises a proportional reversing valve, the proportional reversing valve is located on the oil tank, an oil inlet of the proportional reversing valve communicates with anoil outlet of the electric pump, and an oil outlet of the proportional reversing valve communicates with the oil tank; and the force application mechanism comprises a working head and a sleeve, a first oil port of the working head communicates with a first working oil port of the proportional reversing valve, a second oil port of the working head communicates with a second working oil port of theproportional reversing valve, the sleeve is detachably inserted in the working head, and the working head is used for driving the sleeve to rotate. By means of the bolt tightening device, rotating torques in different directions can be output in a high-precision mode so as to tighten a bolt.

Owner:WUHAN MARINE MACHINERY PLANT

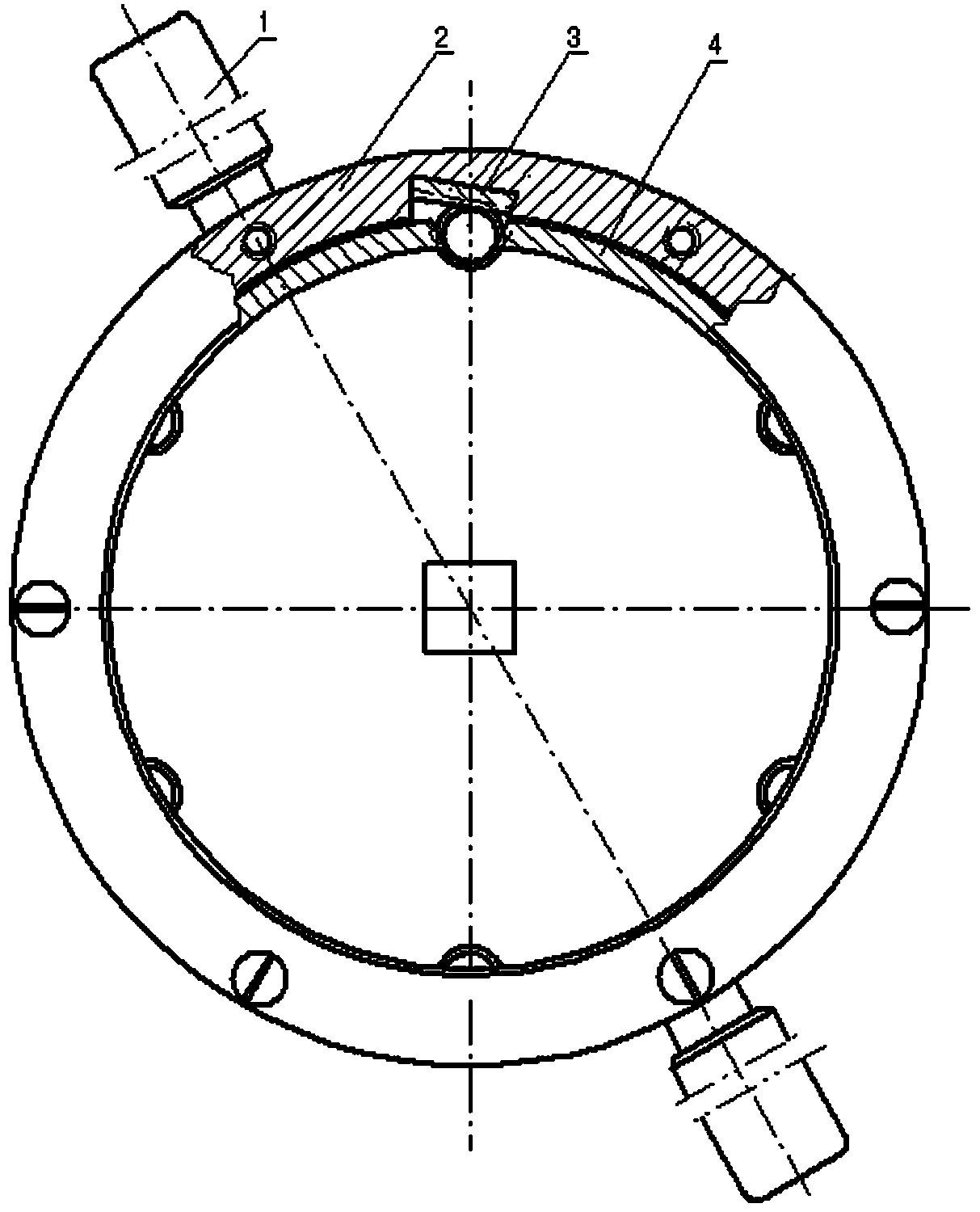

Grenade bottom-row stern screwing device and using method

PendingCN109668486AImprove tightening efficiencyGuaranteed accuracyAmmunitionSpannersCircular coneEngineering

The invention discloses a grenade bottom-row stern screwing device and a using method. The grenade bottom-row stern screwing device comprises handles, a frame body, an oblique block, a retaining frame, M6*16 screws, an upper end cover, cone rolling columns, a lower end cover and M6*10 screws. When the device is used, the lower end cover faces downwards to enable a wrench to sleeve on the externalconical surface of a bottom-row stern, and the handles which are symmetrically welded to the external circular surface of the frame body is manually used, so that the cone rolling columns rotate alongthe axial line of the bottom-row stern in the frame body; meanwhile, the cone rolling columns move in the axial direction of the bottom-row stern under the action of the oblique block, the conical surface of each cone rolling column is clamped on the external conical surface of the bottom-row stern in a fastened manner, and the bottom-row stern is driven to be screwed together with a projectile assembly; and the force moment set on the mechanical torque wrench is exerted on the bottom-row stern, so that it is guaranteed that the screwing force of the bottom-row stern and the projectile assembly meets the requirement of a set value. According to the grenade bottom-row stern screwing device and the using method, screwing of the bottom-row stern and the projectile assembly under the action of the force moment can be achieved, the screwing efficiency of the bottom-row stern is improved, and the accuracy and reliability of screwing of the bottom-row stern are guaranteed.

Owner:HENAN NORTHERN HONGYANG ELECTROMECHANICAL CO LTD

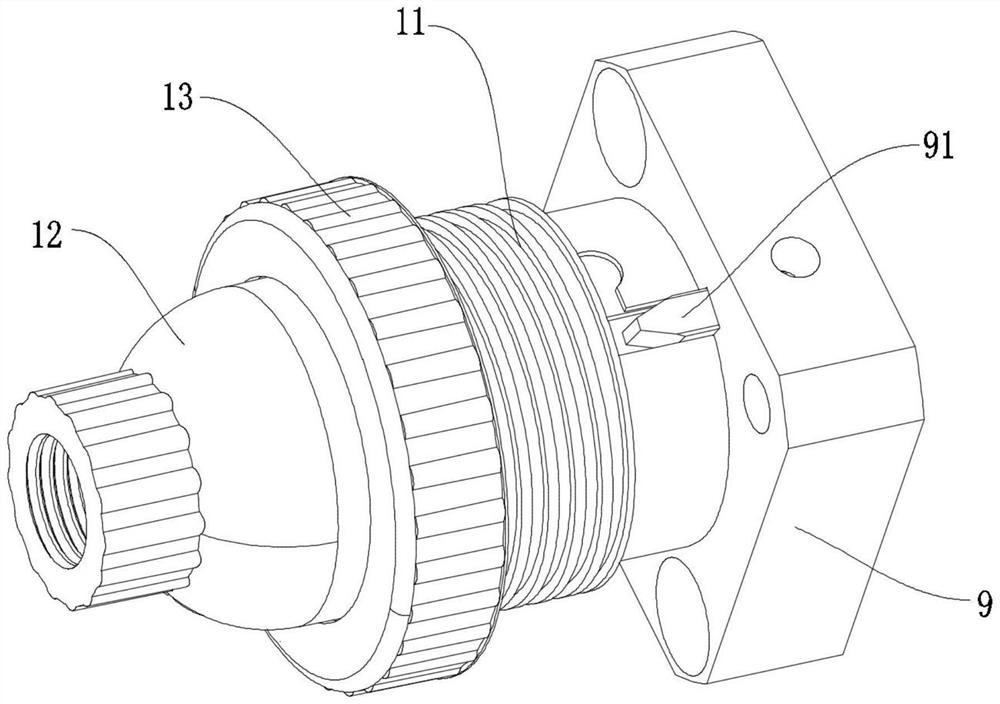

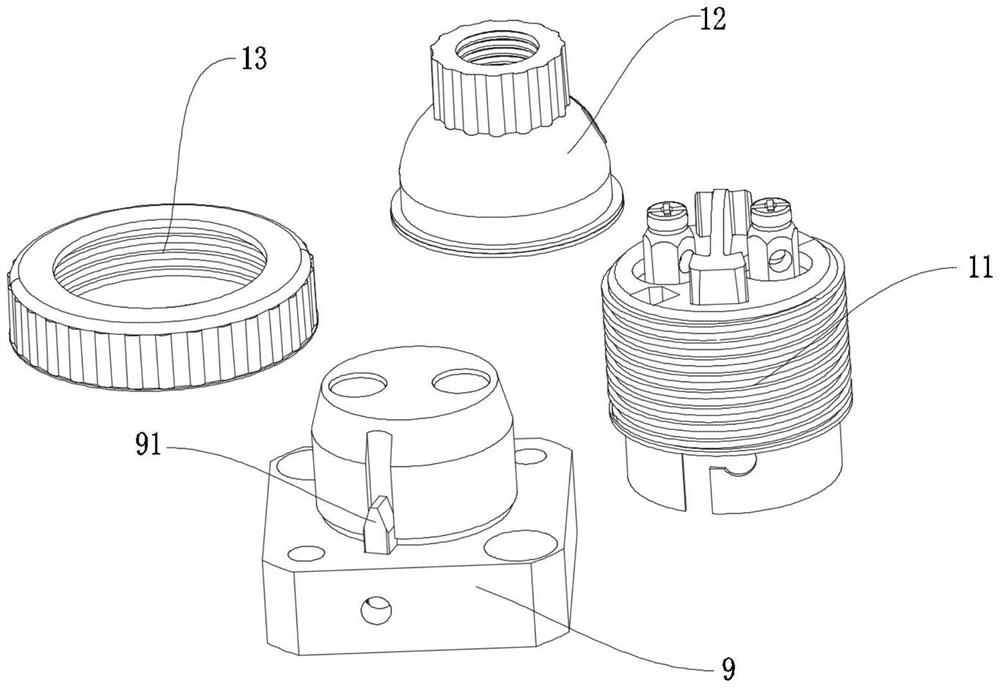

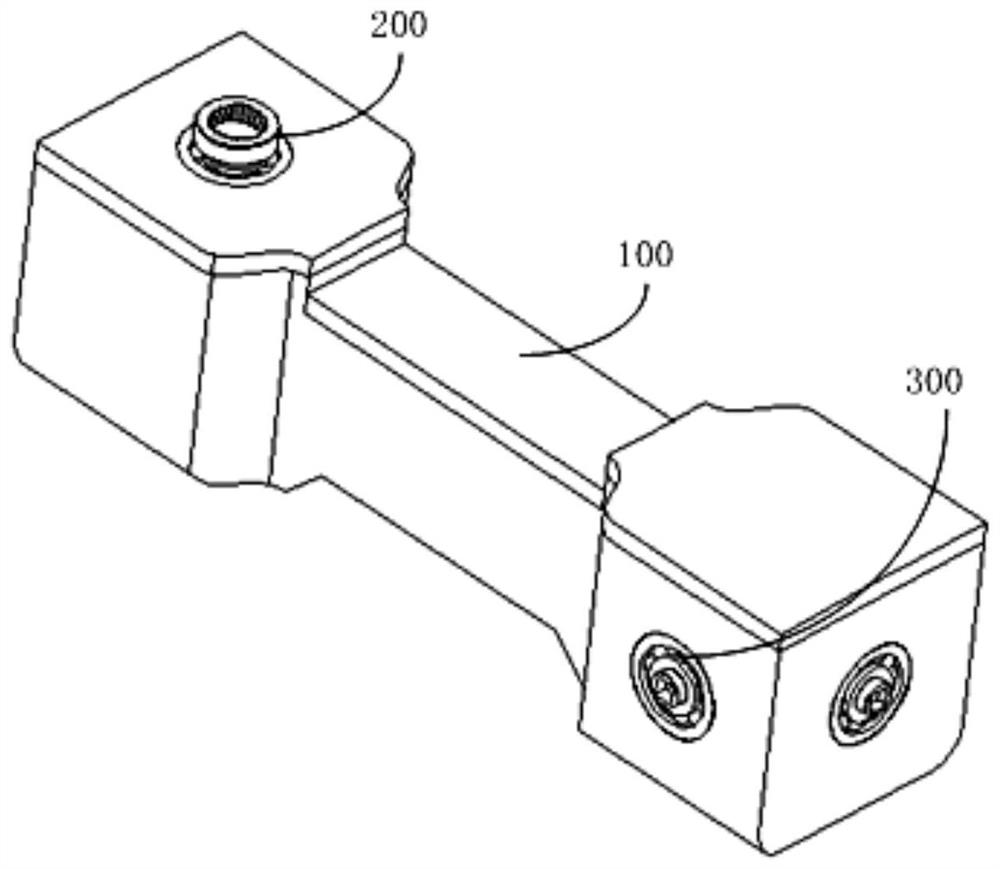

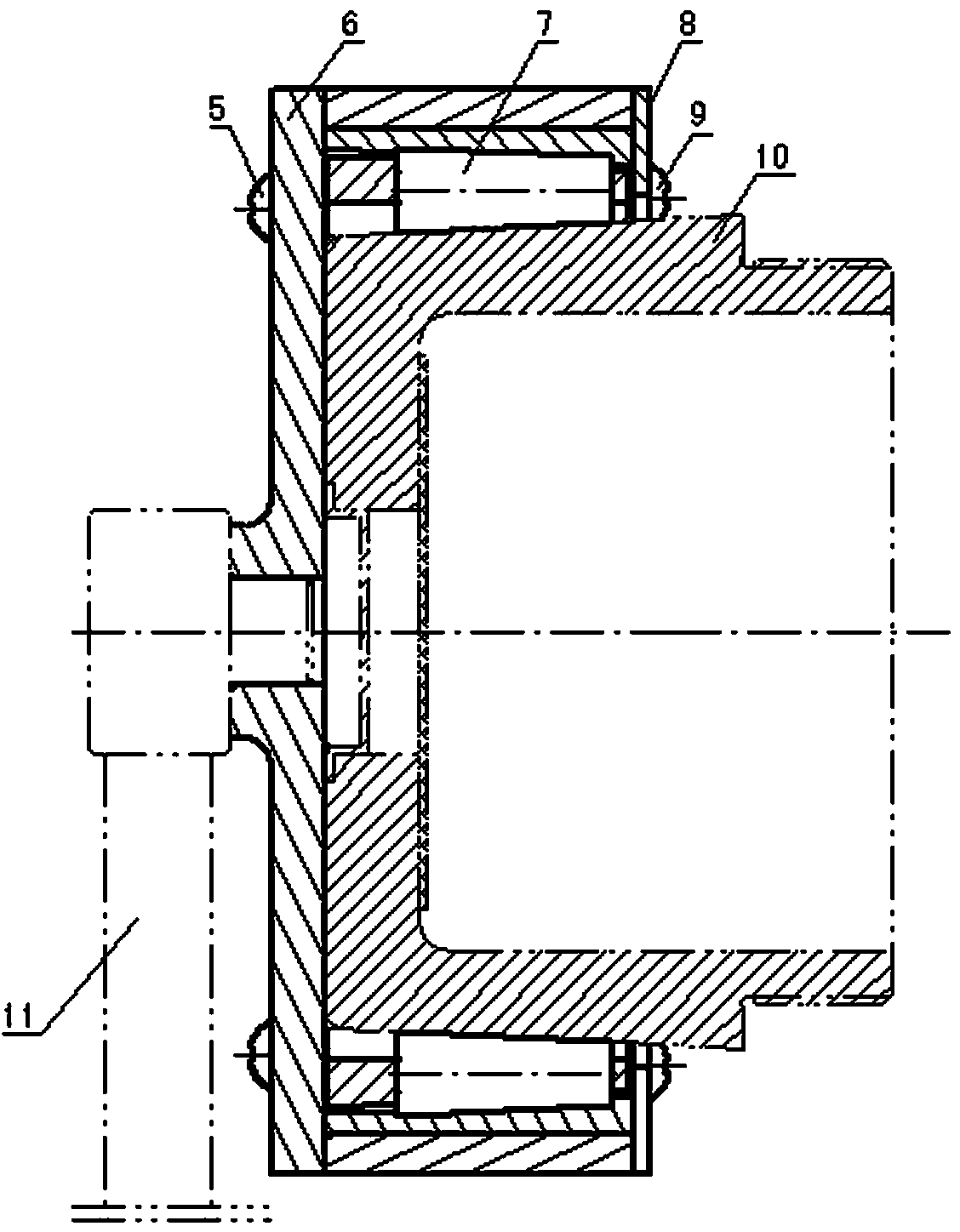

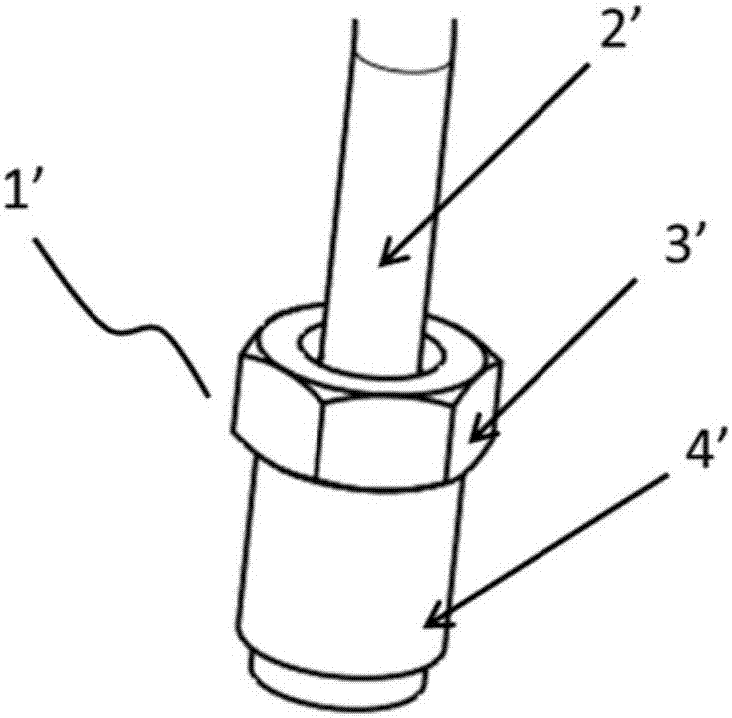

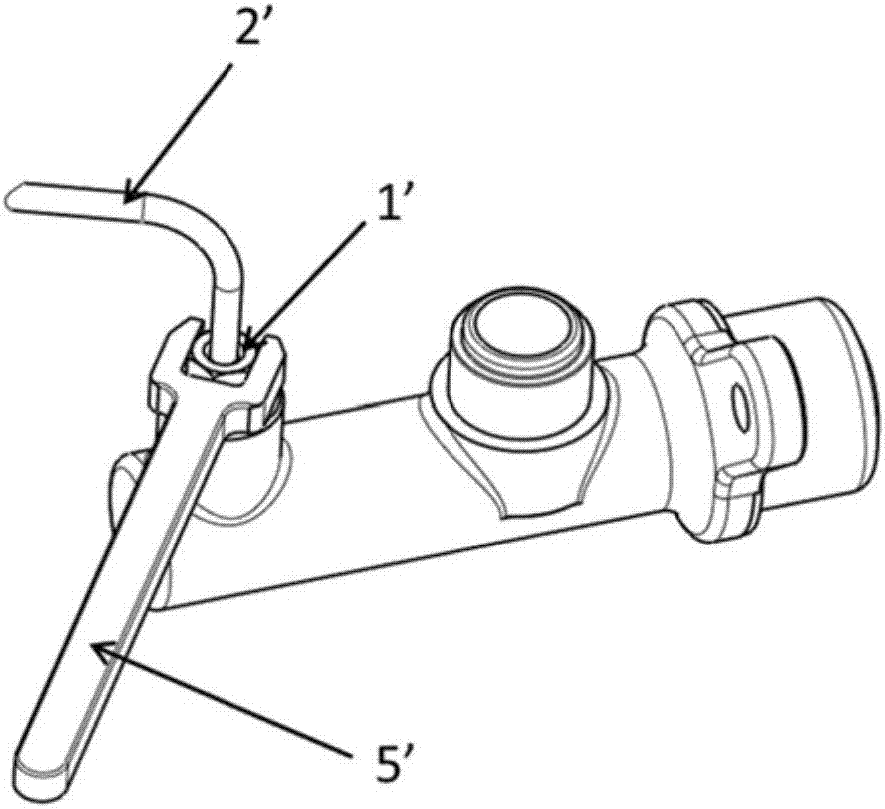

Pipe joint tightening components

ActiveCN105945856BTighten to achieveImprove assembly efficiencyMetal-working hand toolsEngineeringTransfer mechanism

The invention provides a pipeline joint tightening module. The pipeline joint tightening module comprises a pipeline joint module and a tightening sleeve module, wherein the pipeline joint module has a joint gear part; the tightening sleeve module has a force transfer mechanism, and a cylinder hole for clamping the joint gear part therein; the force transfer mechanism has a force transfer gear part; and after the joint gear part is clamped in the cylinder hole, the joint gear part is engaged with the force transfer gear part. When the pipeline joint tightening module is used, an output end of an electric bolt gun is connected with the force transfer mechanism; the electric bolt gun is started; the force transfer gear part in the force transfer mechanism is engaged with the joint gear part; the torque of the bolt gun is transferred to the pipeline joint module to realize tightening of a joint; and when the pipeline joint is assembled, the electric bolt gun can be used for improving the assembly efficiency, and the labor intensity is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Elastomer flexible tightening device

ActiveCN103949876BTighten to achieveAvoid damageMetal working apparatusElastomerProtection mechanism

Owner:贺州市八步区市场监督管理局

Special cable adapter device for electrical engineering

InactiveCN111092336AImprove waterproof performanceStrong bending resistanceCouplings bases/casesTwo-part coupling devicesContact failureStructural engineering

The invention provides a special cable adapter device for electric appliance engineering, relates to the field of cable connecting pieces, and solves problems that a fastening bolt is easy to loosen after an adapter on mobile joint equipment is utilized for a period of time and a rain-proof structure and the connection strength cannot be organically combined. The special cable adapter device for electrical engineering comprises a socket main body and a rectangular plug, wherein a waterproof sleeve is welded on the socket main body. On one hand, the sleeve main body is drawn outwards and rotated, so a bolt rod and a fastening connecting seat can be screwed through threads, the sleeve main body can be locked by loosening the sleeve main body through an elastic bayonet lock, on the other hand, due to arrangement of the elastic bayonet lock, when the position is narrow, the sleeve main body is inconvenient to draw, the sleeve main body can be directly made to rotate, a bolt rod can be screwed down and the sleeve main body can be locked so that a phenomenon of poor contact caused by loosening of a fastening bolt structure in the use process can be prevented.

Owner:LONGYAN UNIV

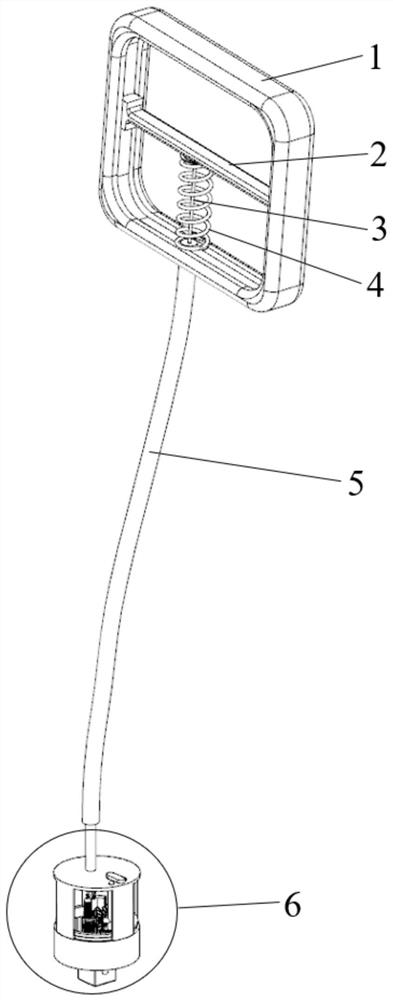

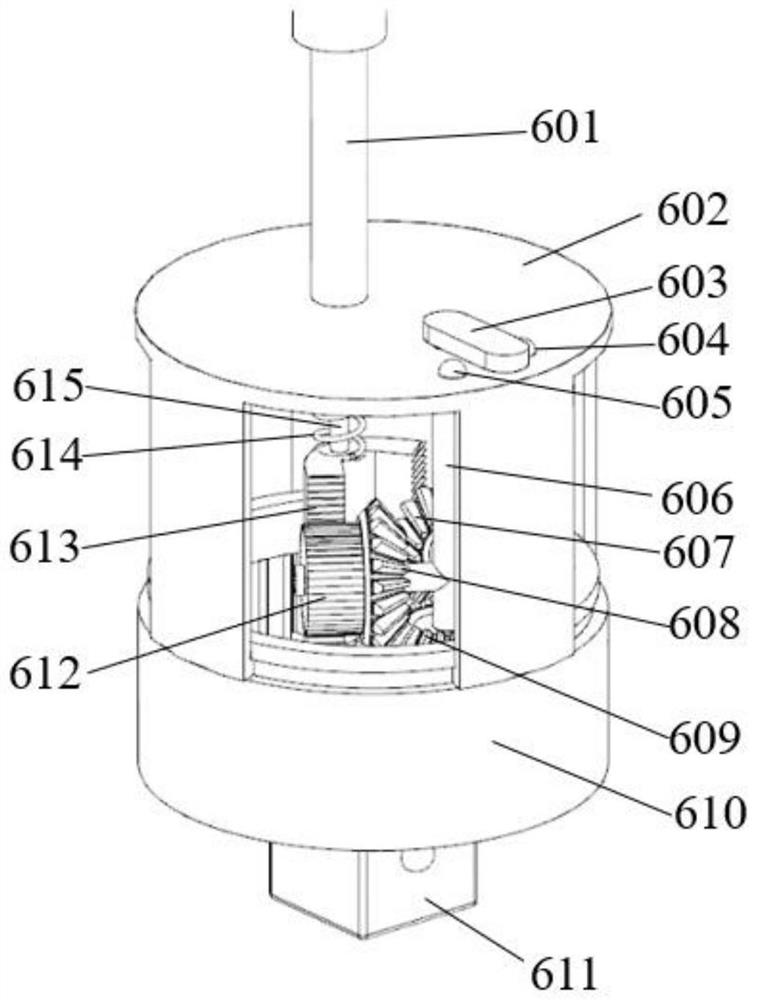

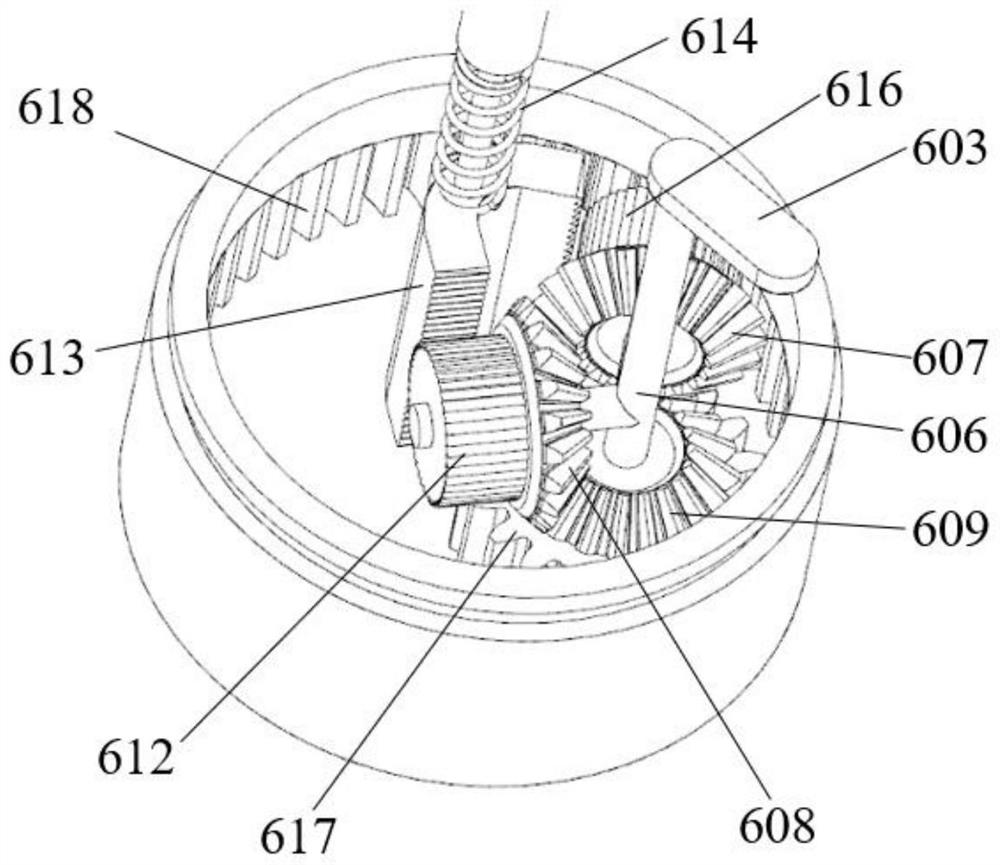

A flexible socket wrench

ActiveCN110170951BPlay a role of protective isolationFlexible and easy to disassembleWrenchesScrewdriversRatchetGear wheel

The invention discloses a flexible socket wrench, which comprises a handle, a sliding rod, a drawing wire, an elastic part, a flexible sleeve and a connecting head. The structure of the connecting head is composed of a ratchet mechanism and a gear mechanism inside. When working, the flexible sleeve is used to ensure that the socket wrench can bend in and out on the path of disassembly, making the disassembly flexible and convenient. After the direction is determined by the reversing mechanism, the ratchet mechanism is driven by wire drawing, thereby driving the gear mechanism , and finally drive the connecting square head at the lower part of the connecting head to drive the sleeve to tighten or disassemble the nut.

Owner:NANNING UNIV

Automatic camshaft shifting device for tightening wrench

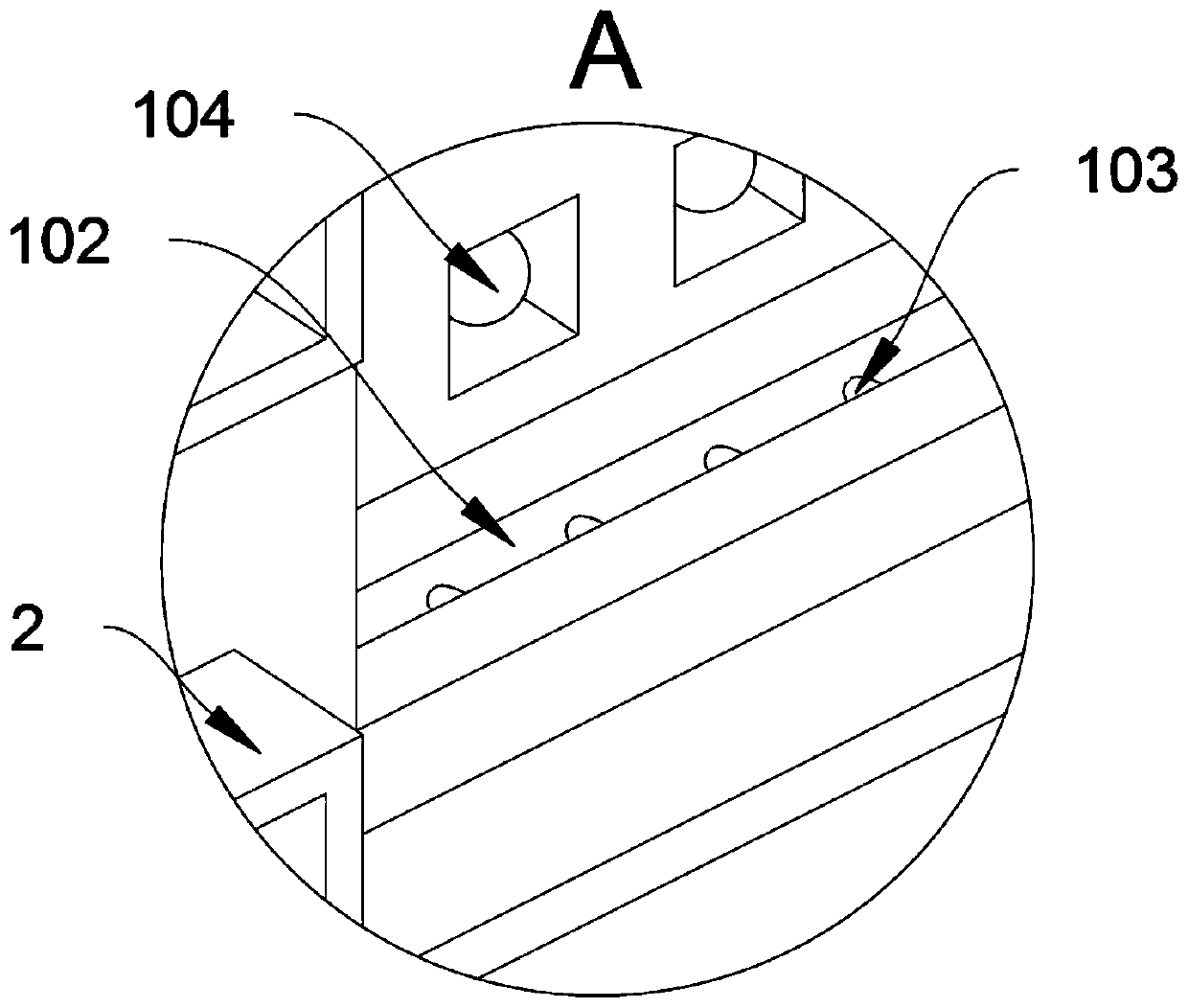

ActiveCN102416563BTighten to achieveAvoid tightening spindle position errorsMetal working apparatusProduction rateElectric machine

The invention relates to an automatic camshaft shifting device for a tightening wrench. The device comprises an upper support plate fastened with a support integrally, wherein at least two camshafts are parallelly arranged in the support; at least two sections of cams and an induction block are arranged on each camshaft; a circumferential curve groove is formed on each cam; at least two linear guide rails are fixed on the lower surface of the upper support plate and positioned above each camshaft; a motor is connected with one end of one camshaft through one driving belt, and the other end of one camshaft is connected with one end of the other camshaft adjacent to one camshaft through the other driving belt; a tightening shaft and the tightening wrench are fixed above and below a support plate; a sliding block which is in sliding fit with each linear guide rail is fastened with the support plate; and bumps are formed at the end of the support plate downwards and are inserted into the circumferential curve grooves on the camshafts. The whole device is not provided with pneumatic equipment, and only electric control is needed. The device has a simple and compact structure, and the number of equipment is reduced while functions are realized, so that production cost is reduced, the production rate is improved, and energy, field and fund are saved.

Owner:DALIAN ZHIYUN AUTOMATION

A bottle cap tightening device for filling food packaging and its application method

ActiveCN110540157BTighten to achieveEasy to loosen and tightenCapsThreaded caps applicationEngineeringFood packaging

The invention relates to the field of food filling, in particular to a bottle cap screwing device for filling food packaging and its use method, including a base, on which a crossbeam is fixedly connected by two vertical rods, a driving part is fixed on the crossbeam, and the crossbeam The middle part is threadedly connected with a vertically downward screw rod, the upper end of the screw rod is fixed with a turntable, and the turntable can be connected with the driving part, the lower end of the screw rod is fixed with a hanger, and the lower end of the hanger is fixed with a collet. The bottle cap tightening device for filling food packaging and its use method use the driving part to drive the chuck to tighten the bottle cap on the bottle body, thereby realizing the tightening of the bottle cap, and the reversing mechanism on the driving part It is convenient to tighten and loosen the bottle cap, so as to facilitate operation, simplify the process and operation difficulty, and improve work efficiency.

Owner:汨罗市府源圣益食品科技有限责任公司

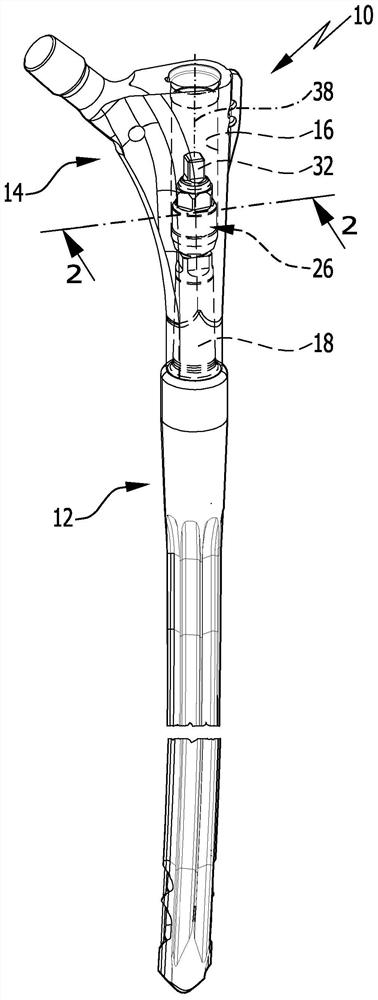

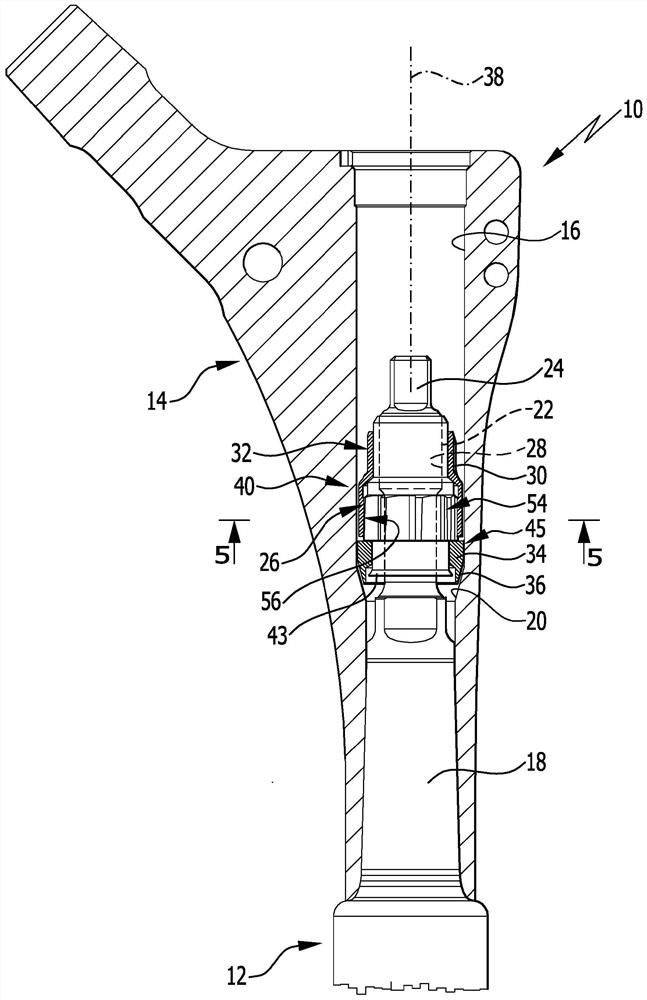

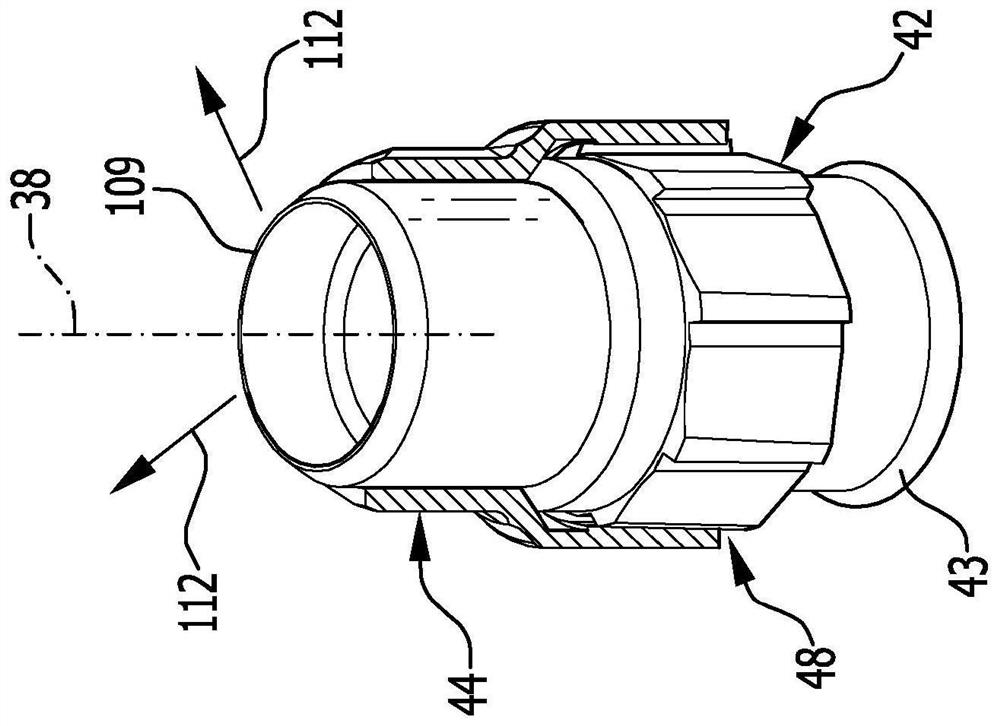

Implant

PendingCN112004501AEmbedded implementationTighten to achieveJoint implantsFemoral headsMechanical engineeringBiomedical engineering

The invention relates to an implant with a first implant part and with a second implant part, wherein the first implant part and the second implant part are connected to each other in a connection position via a screw connection comprising a nut, wherein the nut is configured in the form of a medical-type nut which defines a longitudinal axis and has an inner thread and a polygonal outer shape. Inorder to improve the implant such that the nut can be easily and safely tightened with a predefined tightening torque, it is proposed that the nut comprises at least one inner part and at least one outer part surrounding the inner part at least partially, in particular completely or substantially completely, that the at least one inner part comprises the inner thread, that the at least one outerpart comprises the polygonal outer shape, that the nut comprises a torque limiter which is configured in such a way that, if a torque acting on the at least one outer part in a tightening rotation direction is less than a limit torque, the at least one outer part and the at least one inner part are non-rotatable relative to each other in the tightening rotation direction, and that, if a torque acting on the at least one outer part in the tightening rotation direction at least corresponds to the limit torque, the at least one outer part and the at least one inner part are rotatable relative toeach other in the tightening rotation direction, and that the at least one inner part and the at least one outer part are coupled non-releasably to each other.

Owner:阿斯卡拉波股份有限公司

A desktop robot automatic locking screw machine

ActiveCN113043008BTighten to achieveImprove practicalityMetal working apparatusControl engineeringStructural engineering

The invention discloses a desktop type robot automatic locking screw machine, which comprises a mounting platform, an L-shaped main frame is installed at the middle position of one end of the mounting platform, and a second An electric lifting rod, the output ends of the two groups of the first electric lifting rods are jointly installed with a long bar, the bottom of the long bar is provided with a longitudinal processing assembly, and the middle position of the top of the installation platform is installed with a conveyor belt device . In the present invention, the L-shaped main frame, the longitudinal processing assembly, the clamping assembly, the mounting table and the mounting groove are used together. After the clamping assembly is used to drive the parts to rotate, the first screw gun can be accurately positioned on the top of the screw. Then the screw is gradually tightened on the part by the first screw gun, so as to realize the tightening of the screws at different positions on the top of the circular part, which greatly improves the practicability and use effect of the entire automatic screw locking machine.

Owner:星河智源(深圳)科技有限公司

An electric wrench for electric tower construction

ActiveCN110842838BStrong torqueTighten to achieveSpannersWrenchesElectric machineArchitectural engineering

The invention discloses an electric wrench for building an electric tower, which includes a casing, the inner surface of the casing is provided with a motor, and the output end of the motor passes through one end of the left side wall of the casing and is fixedly connected to a second end through a connecting sleeve. A connecting rod, the end of the first connecting rod far away from the connecting sleeve is fixedly connected with a clamping head, the inner surface of the casing is provided with a fan on the right side of the motor, and the lower part of the casing is a gripping part. In the present invention, the motor can provide a strong torque, which can make the connection of high-strength bolts more reliable after tightening. The clamping head has an adjustment function, which can be adjusted to match the state of various high-strength bolt sizes, so as to realize the adjustment of different sizes. With the tightening of high-strength bolts, the user does not need to bring too many tools during the construction of the tower, which is more convenient for the user to work at high altitudes. It is easy to carry and has strong battery life, which is very practical.

Owner:东台市新杰科机械有限公司

Special cable adapter device for electrical engineering

InactiveCN111092336BTighten to achieveDeadlock implementationCouplings bases/casesTwo-part coupling devicesContact failureStructural engineering

Owner:LONGYAN UNIV

Locking device for gas path connecting pipe

InactiveCN103322345AEasy to pass throughThe clip strips that pass through are easy to touch and tightenSleeve/socket jointsState of artEngineering

The invention belongs to the field of parts used for a color selector, and particularly relates to the field of locking of a connecting pipe on a gas path system on the color selector. The locking device of the gas path connecting pipe comprises a clamp strip, wherein a sleeve body is arranged at one end of the clamp strip, a screw is arranged in the sleeve body, and clamp grooves are uniformly formed in the part, where the sleeve body is not arranged, of the clamp strip. The locking device of the gas path connecting pipe adopts the technical scheme provided by the invention, has certain rigidity as well as certain elasticity and toughness simultaneously, and can connect, lock and fix the gas path connecting pipe, so that the phenomena that a pipeline in gas path pipeline connection in the prior art is prone to be damaged or loosen and fall off by impact force and air pressure generated in the gas path pipeline are prevented.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com