Single-axis yaw electric bolt tightening machine

一种拧紧机、电动的技术,应用在风力发动机的装配、螺丝刀、风能发电等方向,能够解决噪音大、偏航部件变形、人力成本大等问题,达到减小噪音污染、压紧力均衡、拧紧精度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

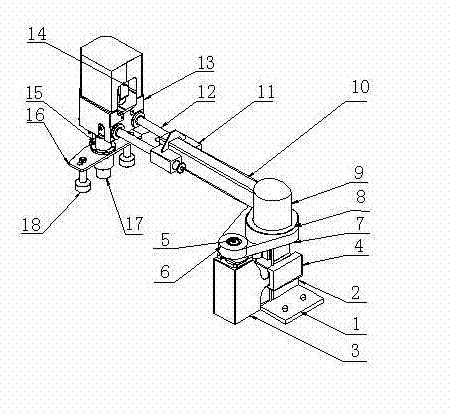

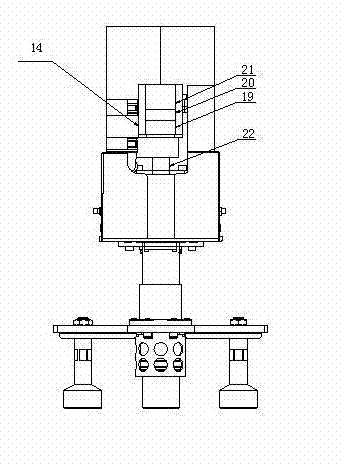

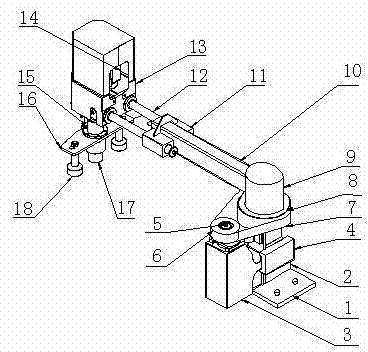

[0014] figure 1 , figure 2 The reference signs shown are as follows: base 1, bracket 2, rotary servo motor 3, encoder 4, output shaft 5, small pulley 6, toothed belt 7, large pulley 8, rotating shaft 9, rotating arm 10, Shaft sleeve 11, guide post 12, cover plate bracket 13, electric tightening shaft assembly 14, sleeve 15, reaction force support plate 16, special sleeve 17, reaction force sleeve 18, servo motor 19, torque sensor 20, angle sensor 21. The connecting shaft 22.

[0015] figure 1 , figure 2 In the schematic diagram of a single-axis yaw electric bolt tightening machine shown, it mainly includes: a base 1, a bracket 2, a rotary servo motor 3, an encoder 4, an output shaft 5, a small pulley 6, a toothed belt 7, Large pulley 8, rotating shaft 9, rotating arm 10, shaft sleeve 11, guide post 12, cover plate bracket 13, electric tightening shaft assembly 14, sleeve 15, reaction force support plate 16, special sleeve 17, reaction force Sleeve 18, servo motor 19, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com