Patents

Literature

95results about How to "Strong torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

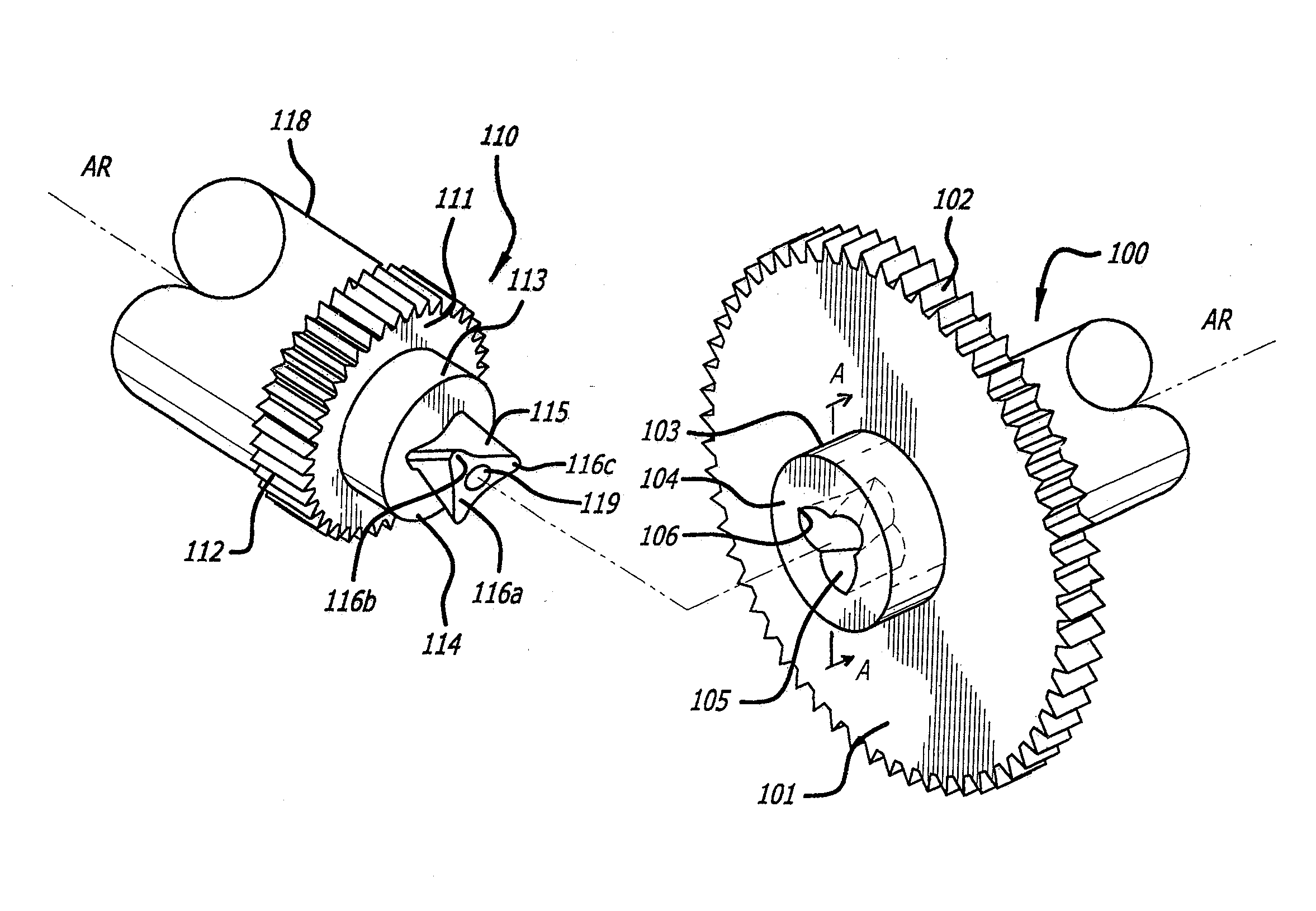

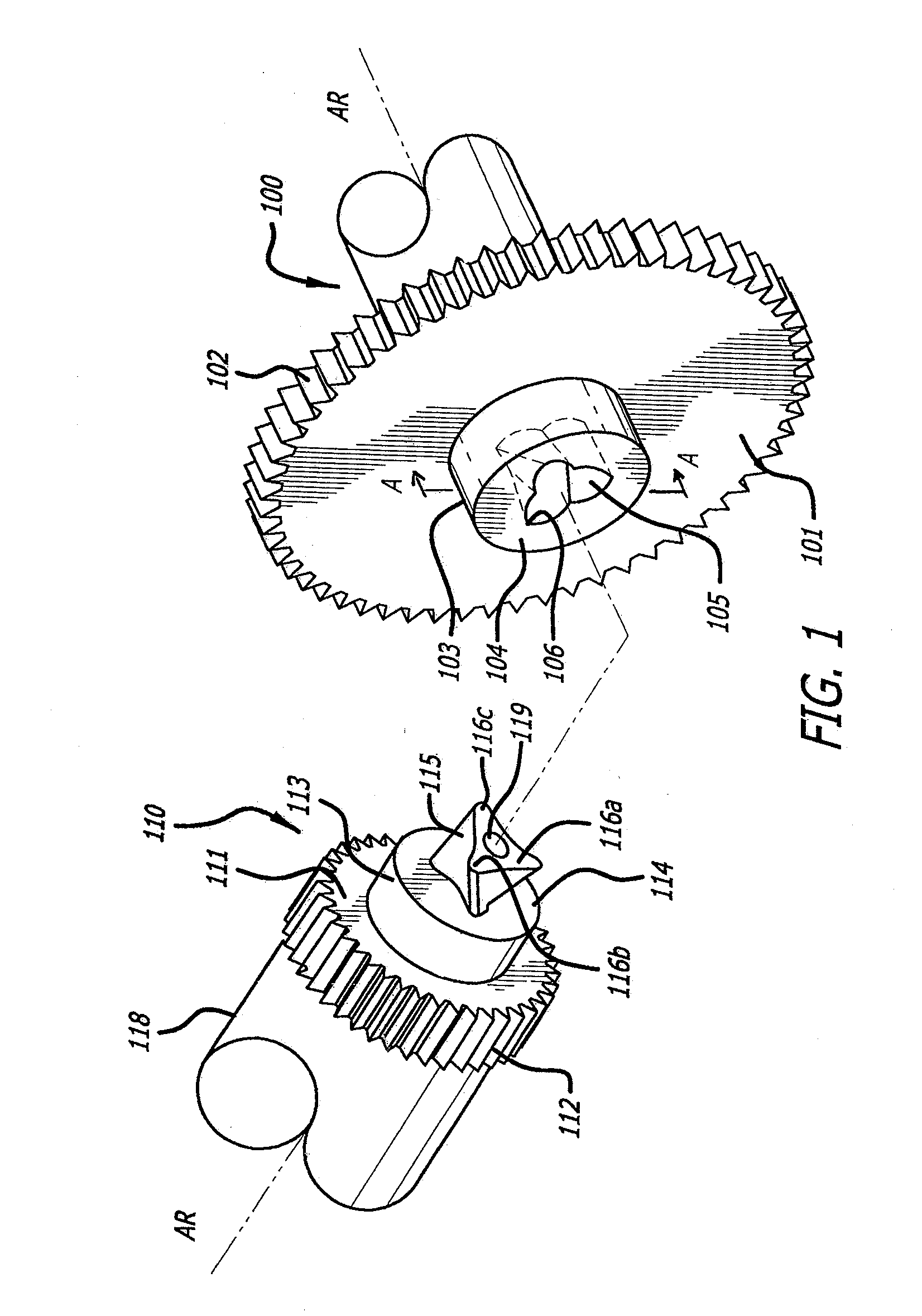

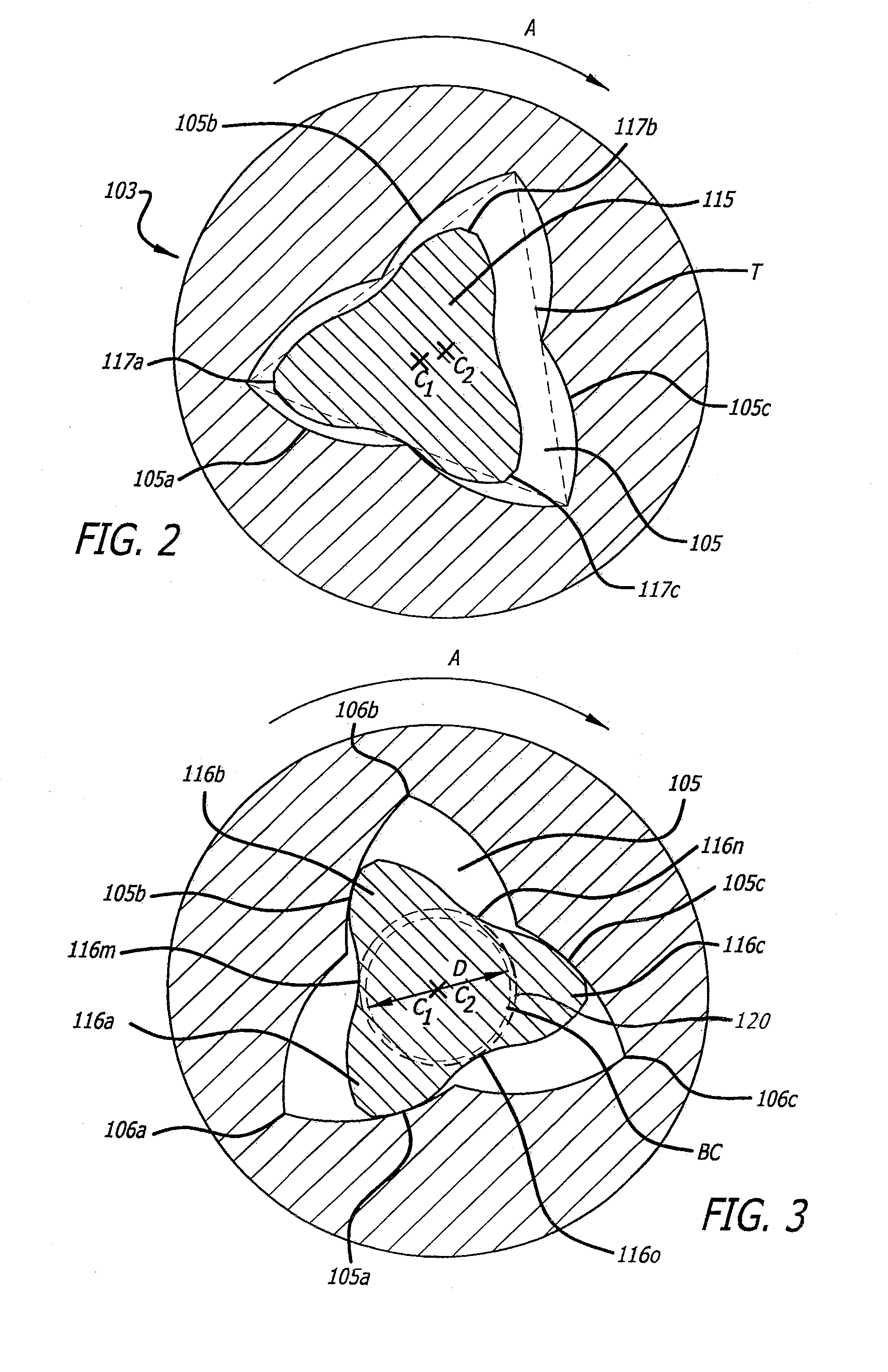

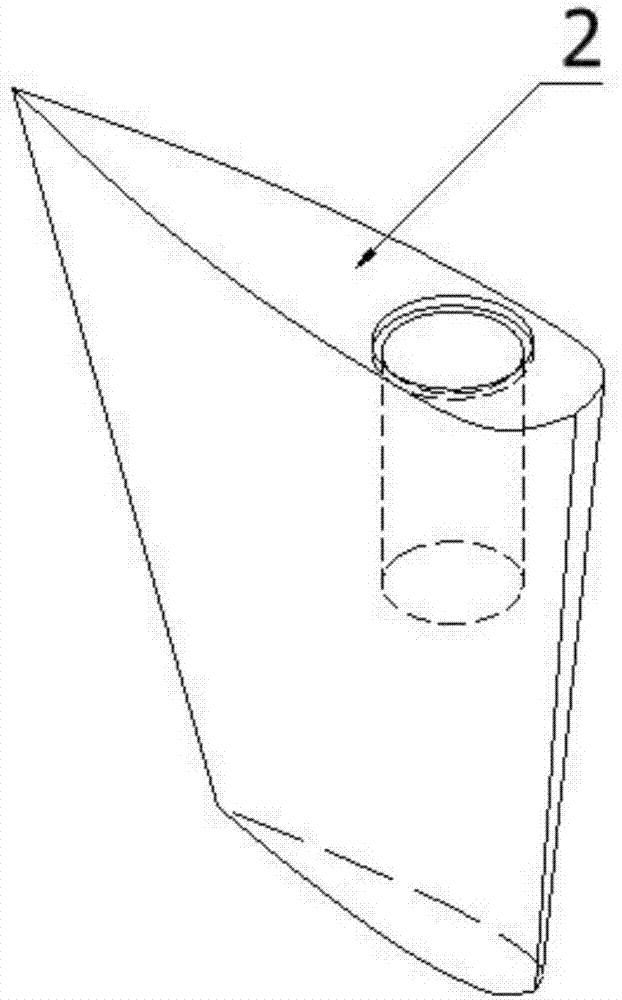

Rotating Drive Shaft Coupling

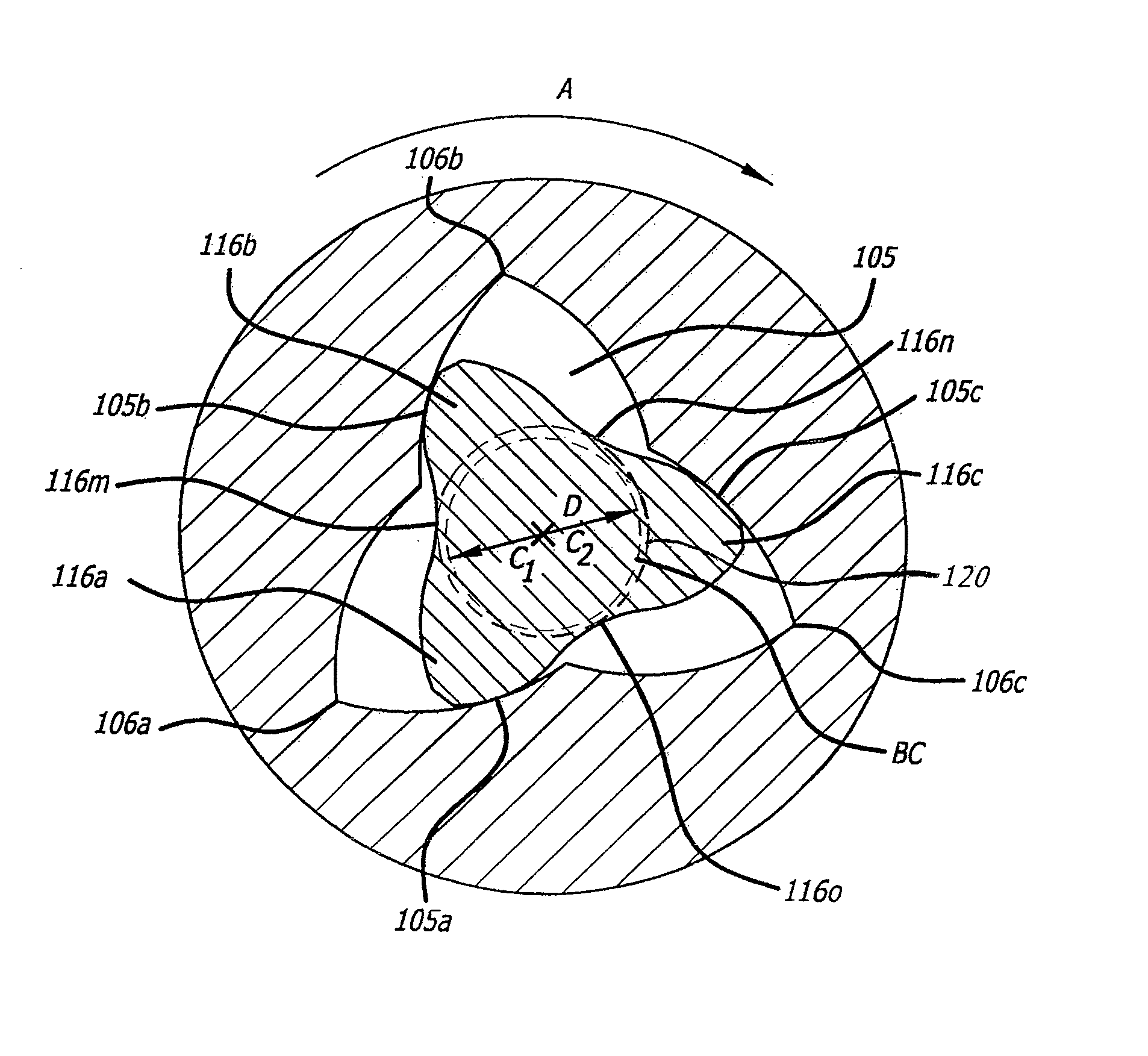

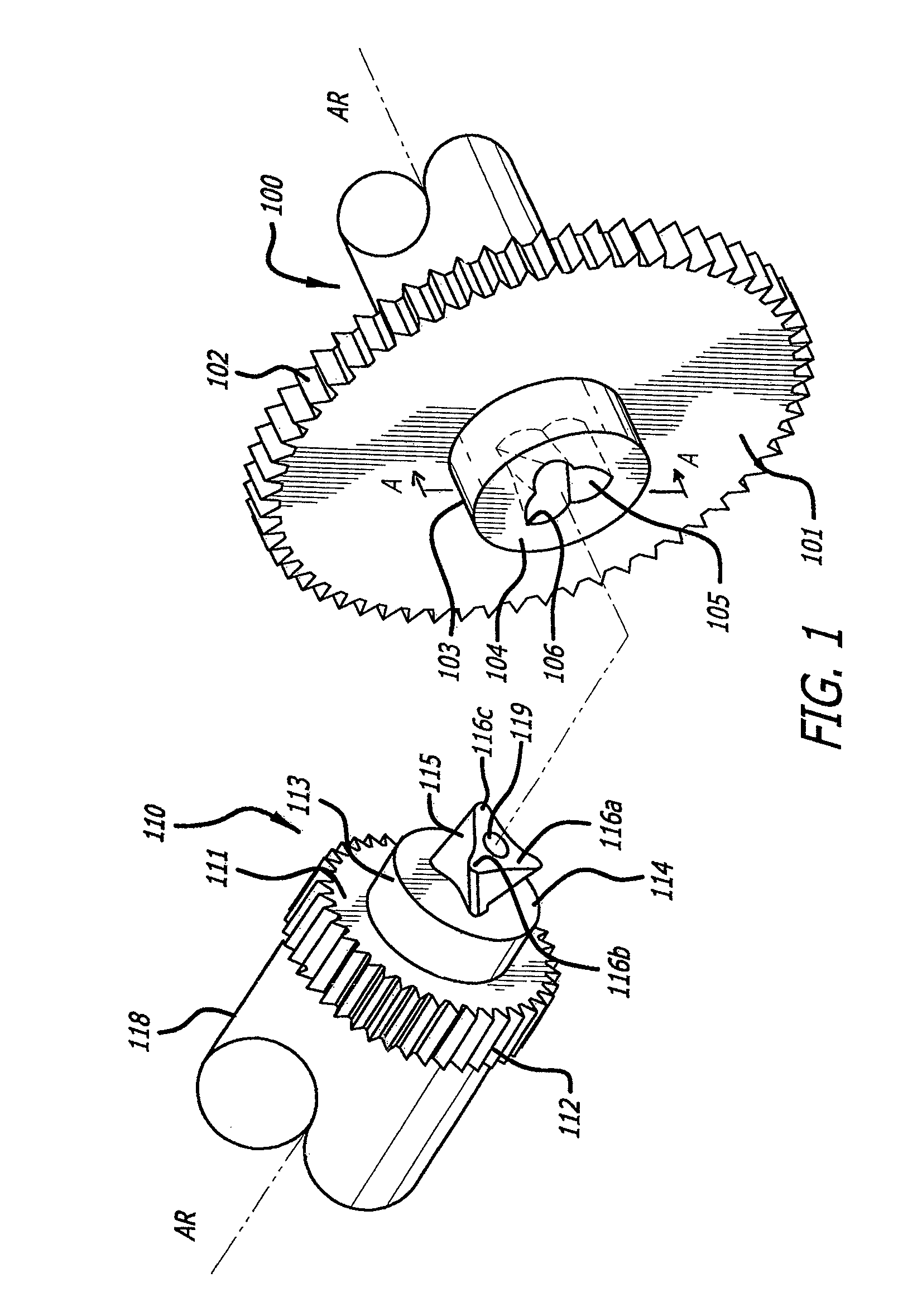

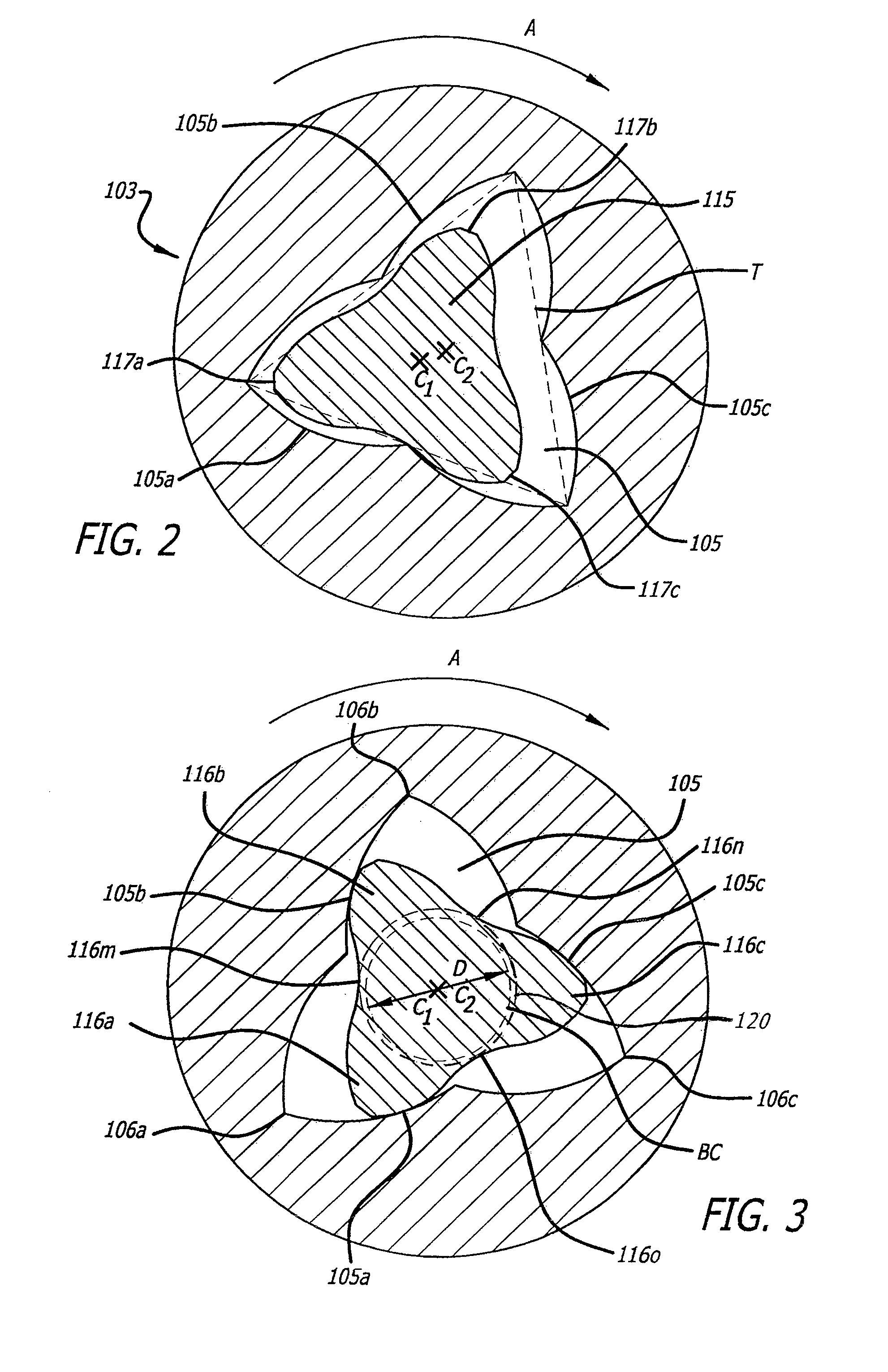

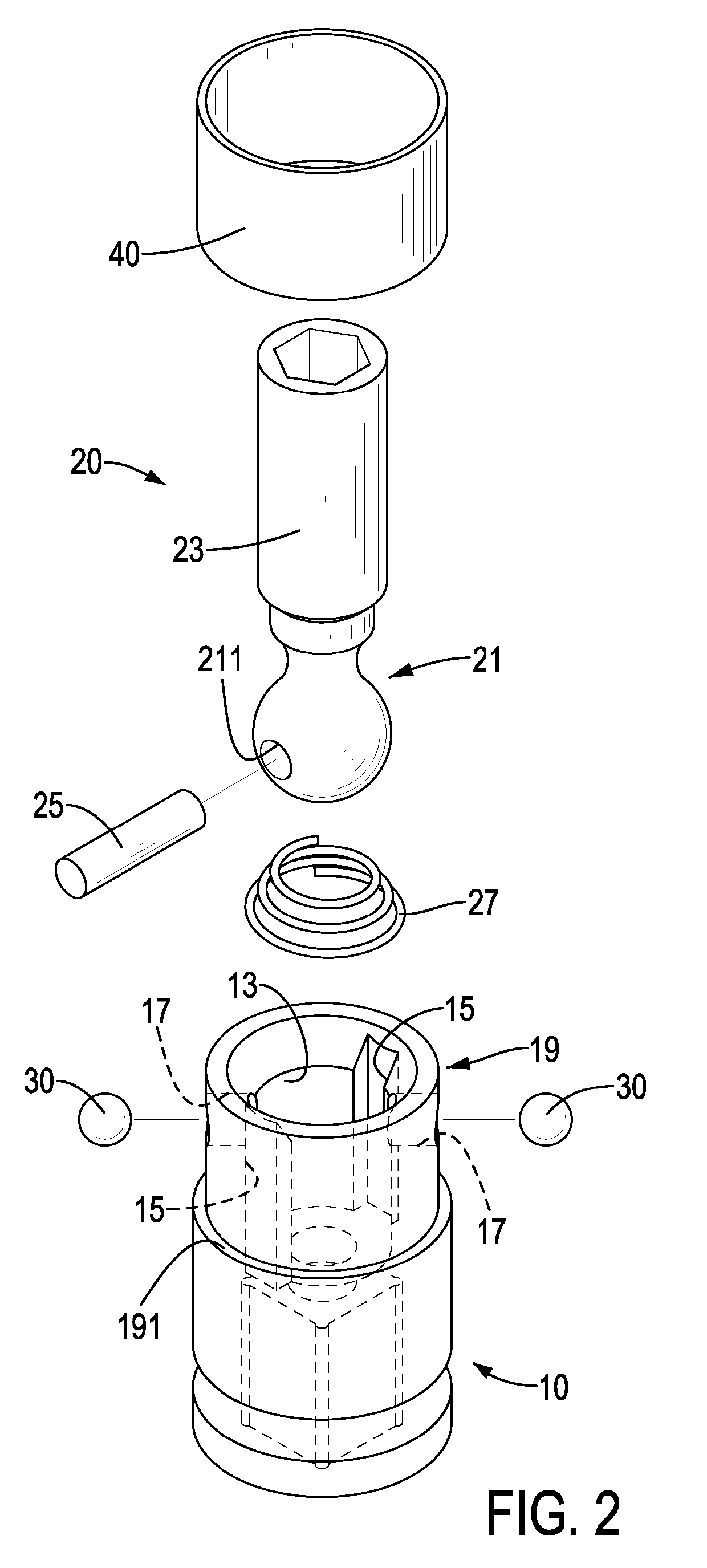

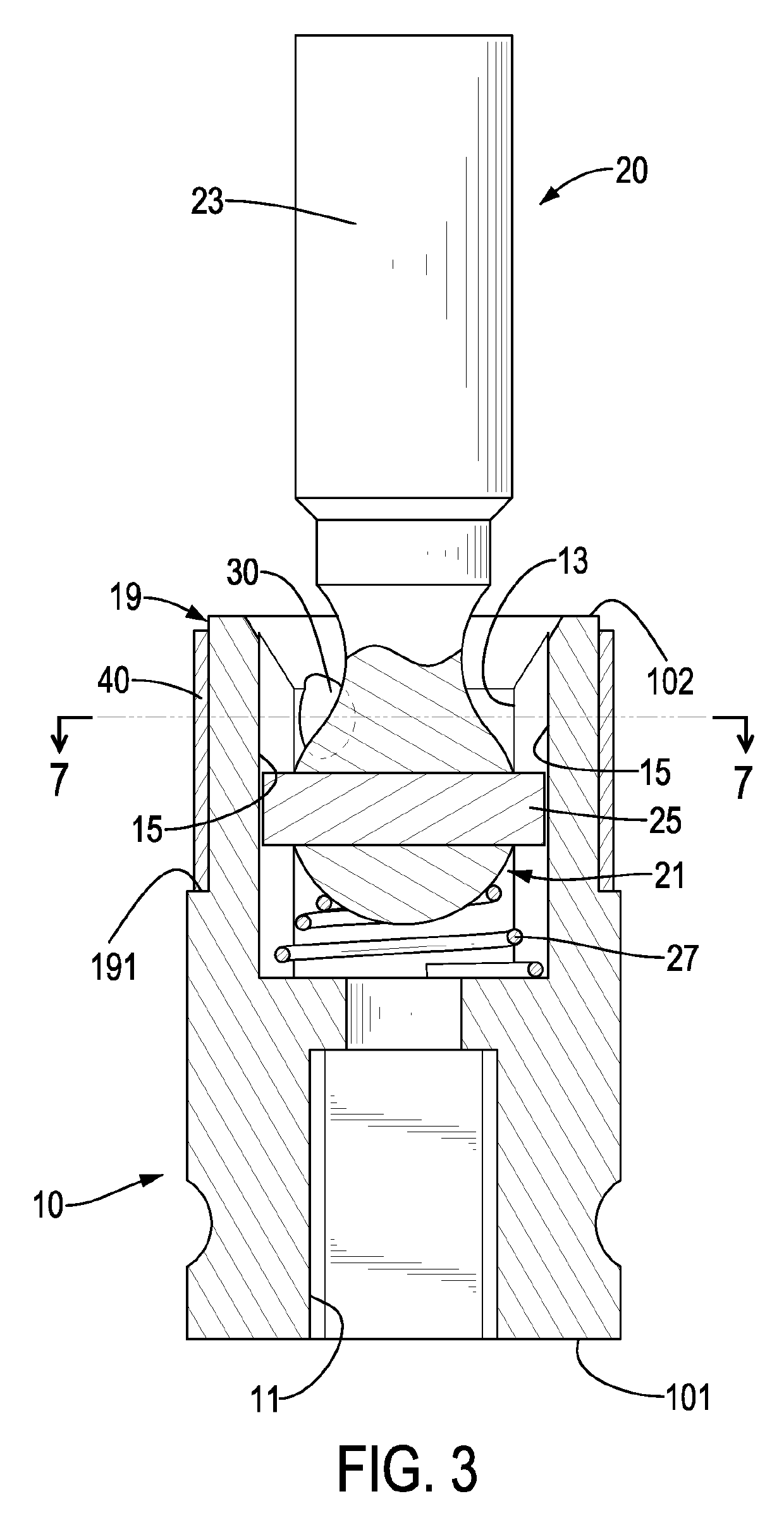

ActiveUS20130058710A1Reduce maintenanceLower manufacturing requirementsCouplings for rigid shaftsElectrographic processDrive shaftCoupling

A rotatable coupling is used with a replaceable developer cartridge and electrostatographic image devices. The coupling has a driven portion and a driving portion. The driven portion has a shaft with a connecting portion that has a plurality of helical involute teeth extending outwardly. The driving portion has an end with a gear shaft and a twisted petaline recess in the gear shaft. The sides of the recess are engageable with the helical involute teeth so that the driving portion drives the driven portion and transmit torque.

Owner:RAINBOW TECH INT LTD

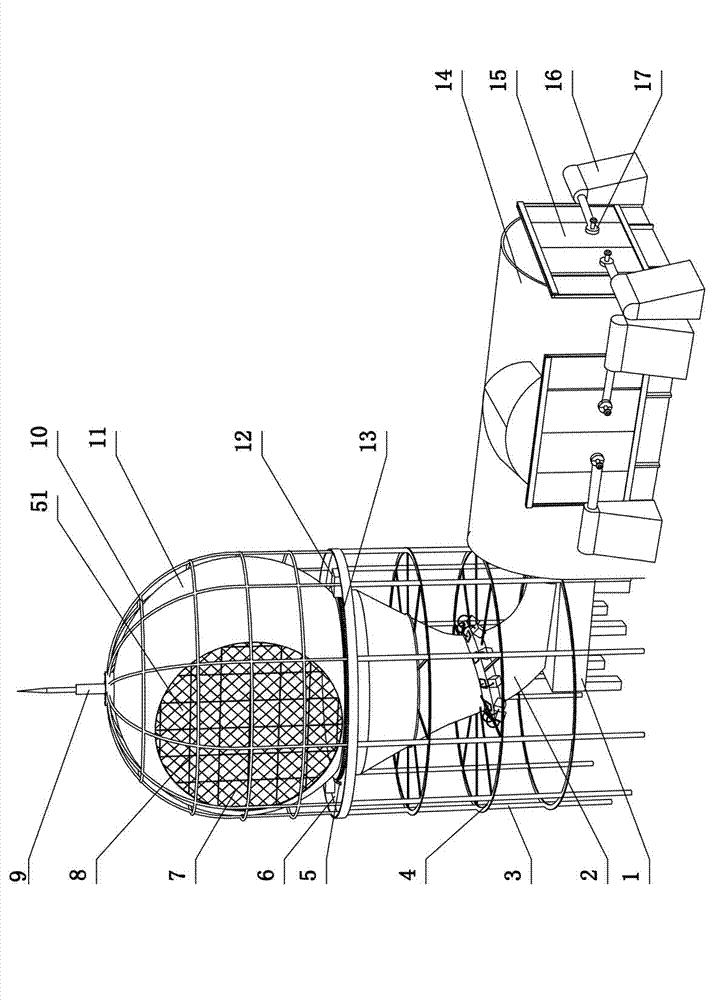

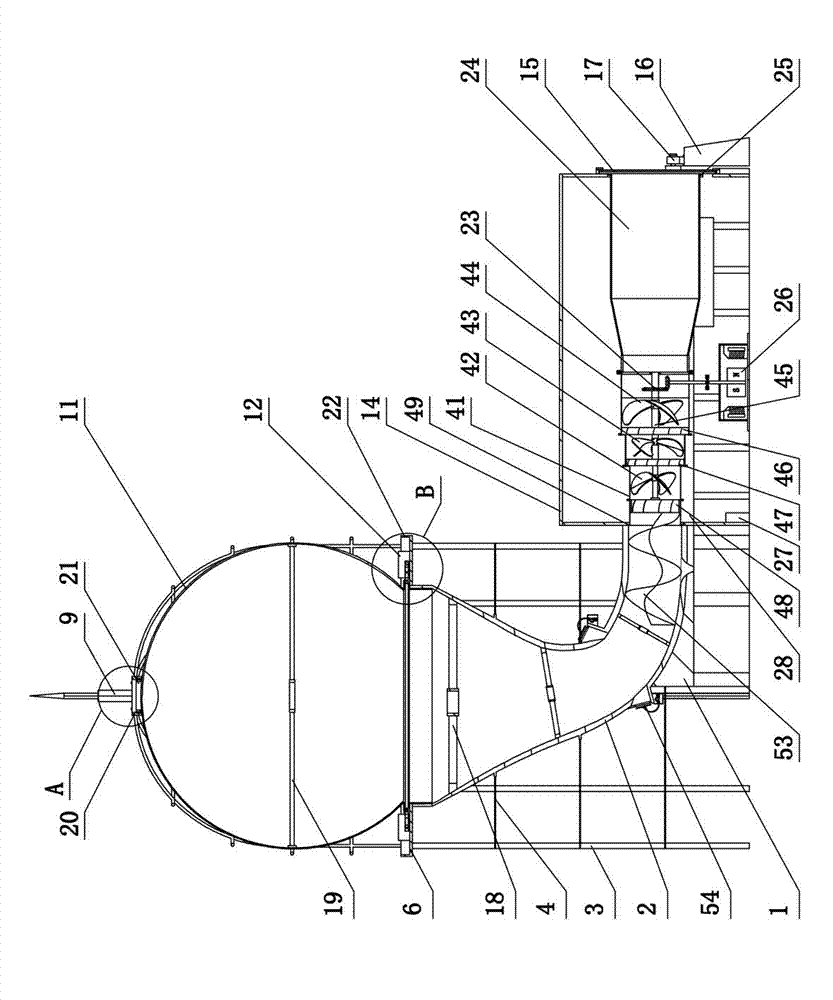

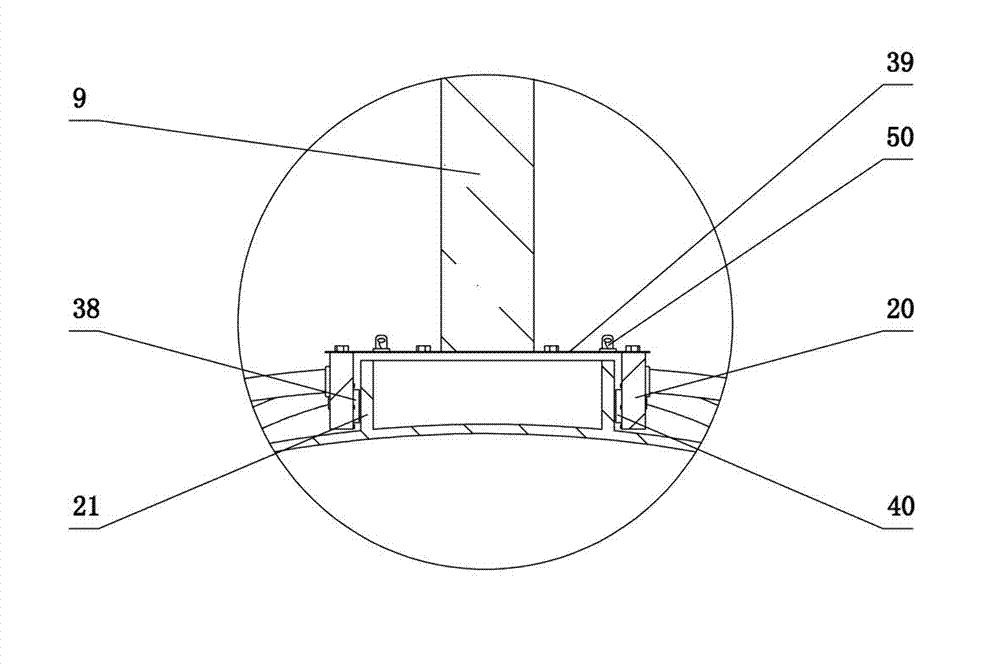

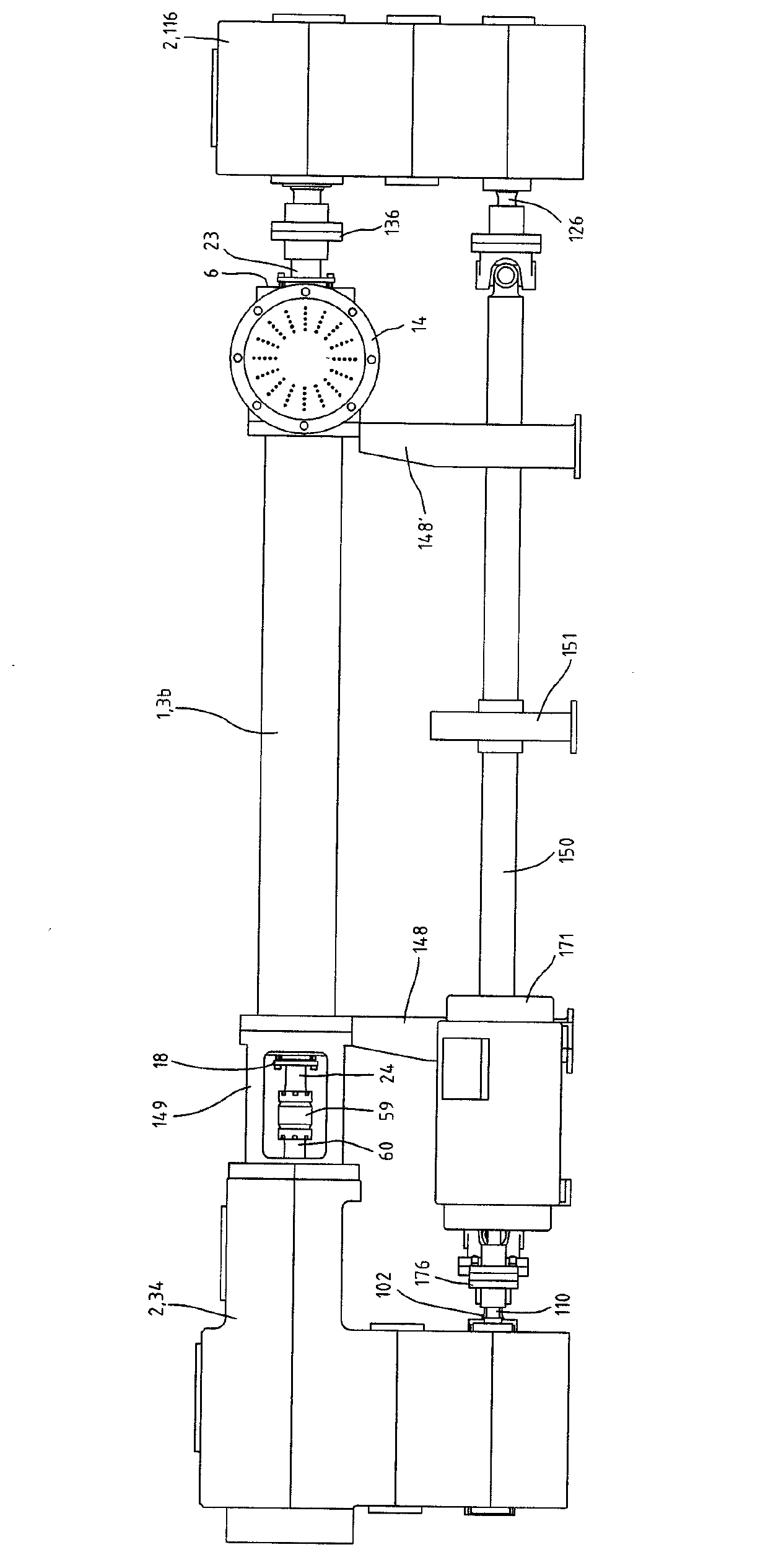

Self-starting funneling wind concentration wind power generation system

ActiveCN102777062AHigh fastnessImprove wind resistanceWind motor combinationsMachines/enginesElectric generatorWind power generation

The invention provides a self-starting funneling wind concentration wind power generation system, relates to important comprehensive core technologies such as wind concentration structure, wind tunnel characteristics, fluid transition, the funneling effect, infrastructure material, aerodynamics, structural mechanics, turbine effect, electric energy conversion and belongs to the technical field of funneling wind concentration wind power generation systems. The system consists of a bowler hat type wind concentration device assembly, a strong storm avoidance deflection closing device assembly, a multi-level gradual-expansion air turbine generator device assembly, a funneling type working medium speeder assembly, a reinforced rib anti-seismic component device assembly, an intelligent control man-machine integrated assembly and accessories. The assembled bowler hat type wind concentration device assembly, the strong storm avoidance deflection closing device assembly, the multi-level gradual-expansion air turbine generator device assembly, the funneling type working medium speeder assembly and the reinforced rib anti-seismic component device assembly are sequentially arranged in place, and an intelligent control system and an accessory part are respectively positioned and arranged in place, thereby forming a set of complete self-starting funneling wind concentration wind power generation system.

Owner:苏州奕方华知识产权运营有限公司

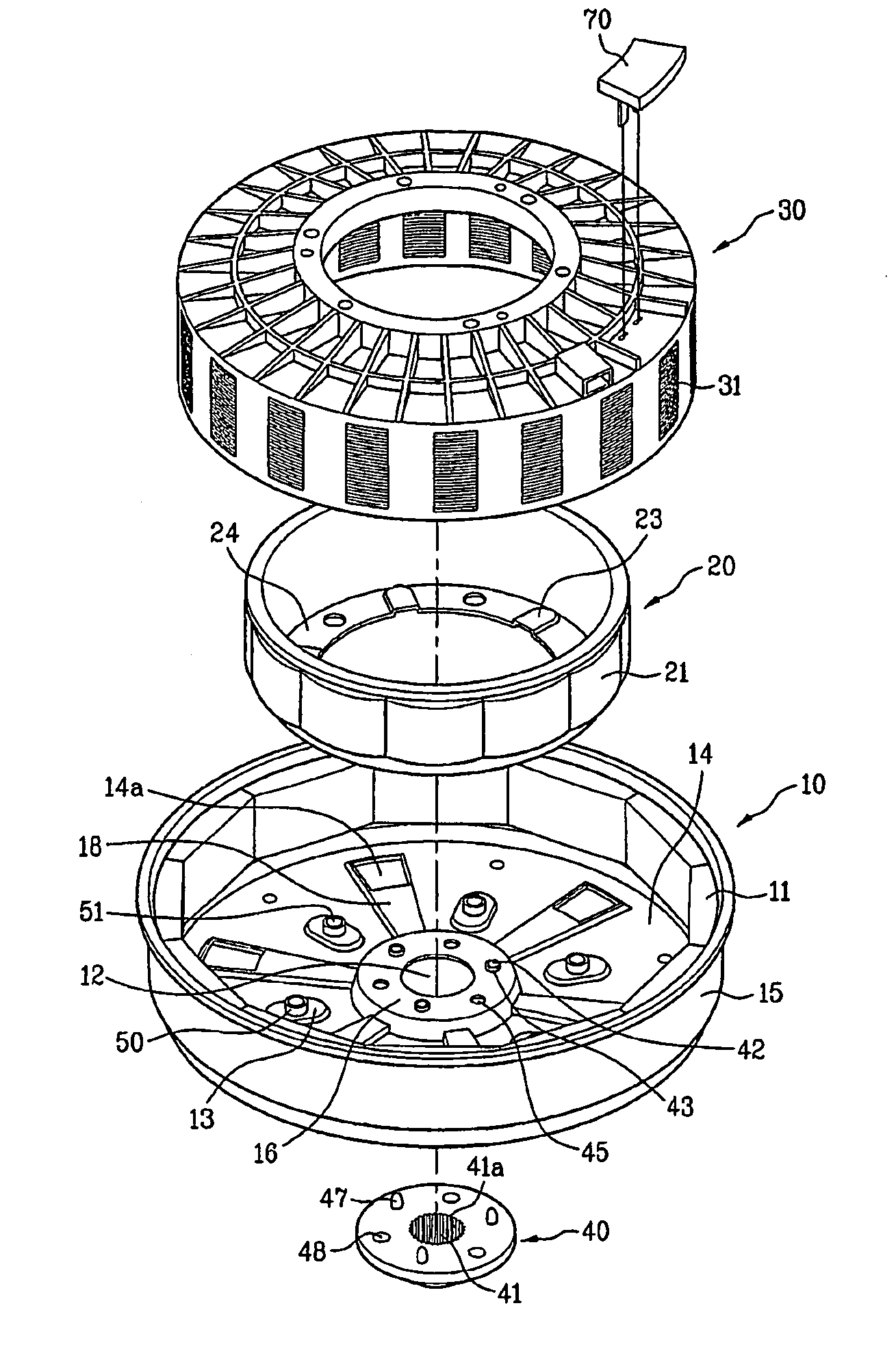

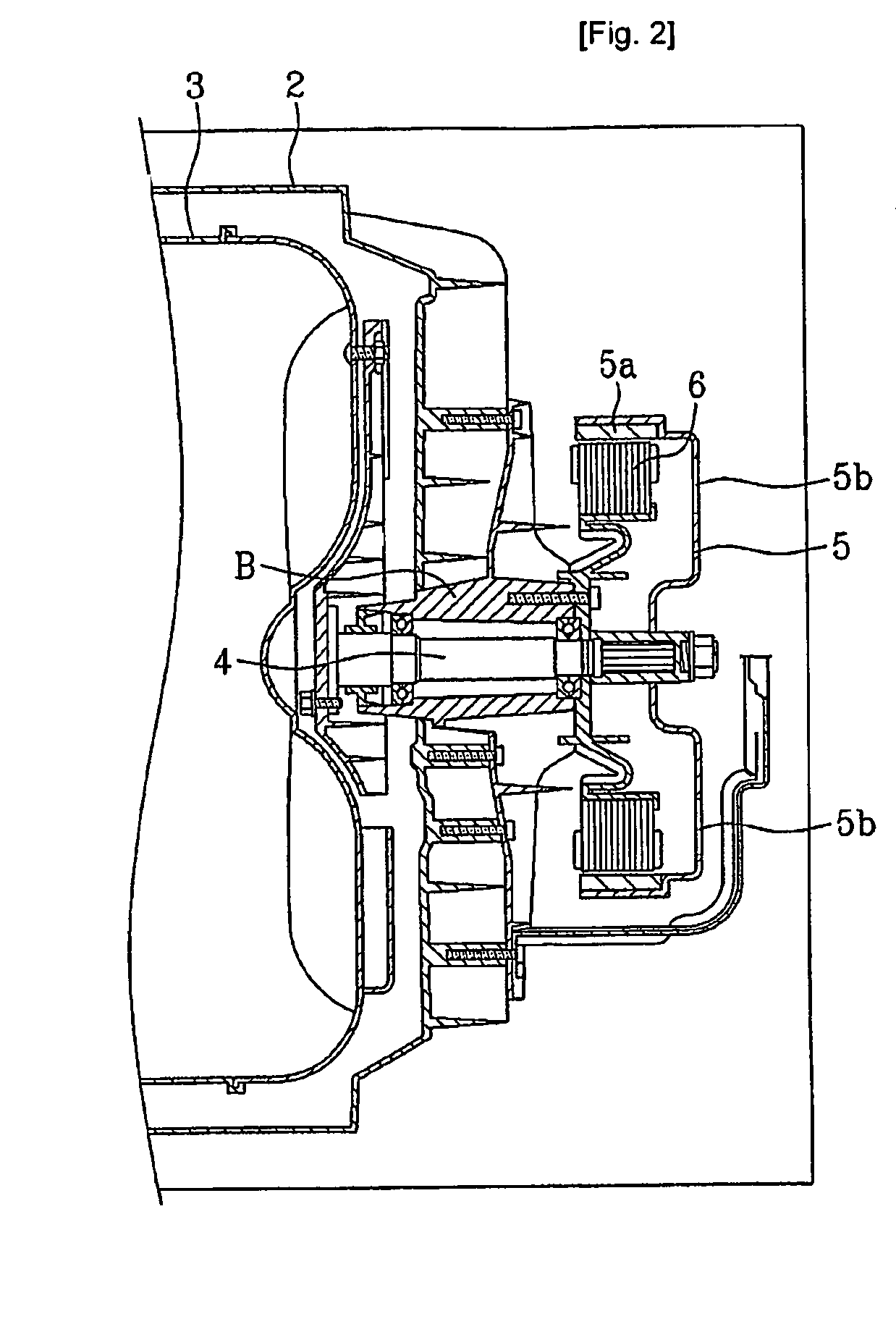

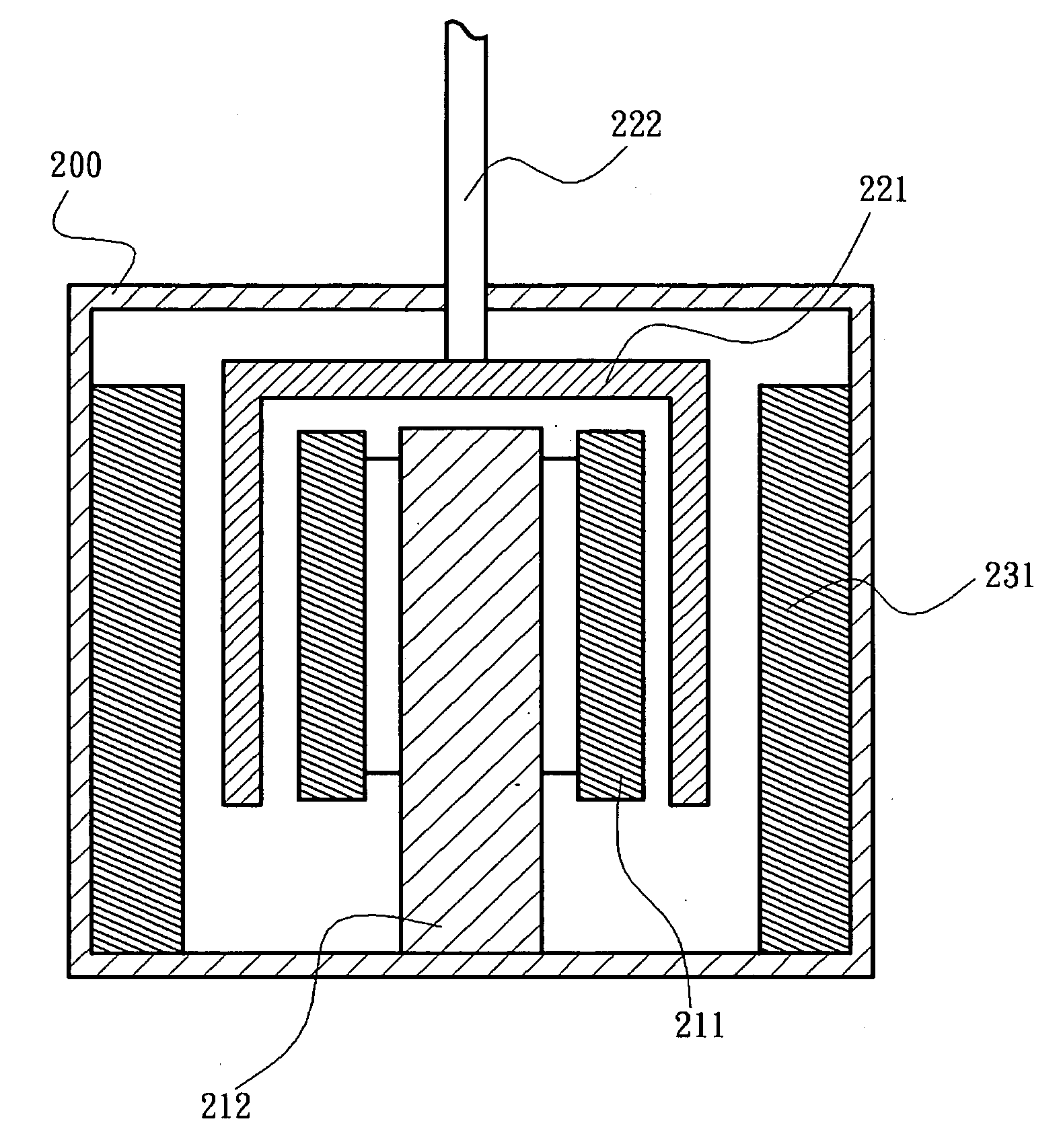

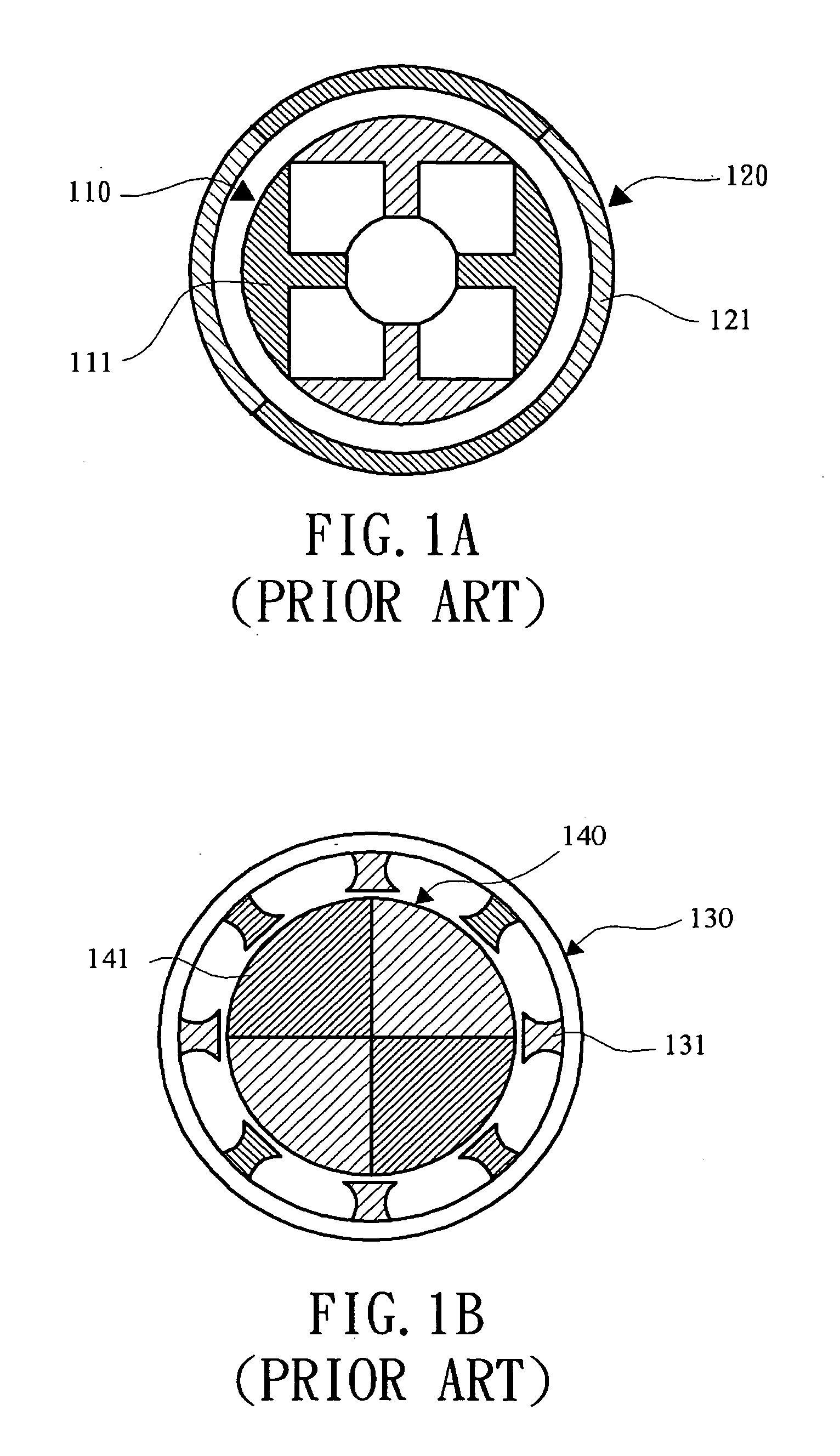

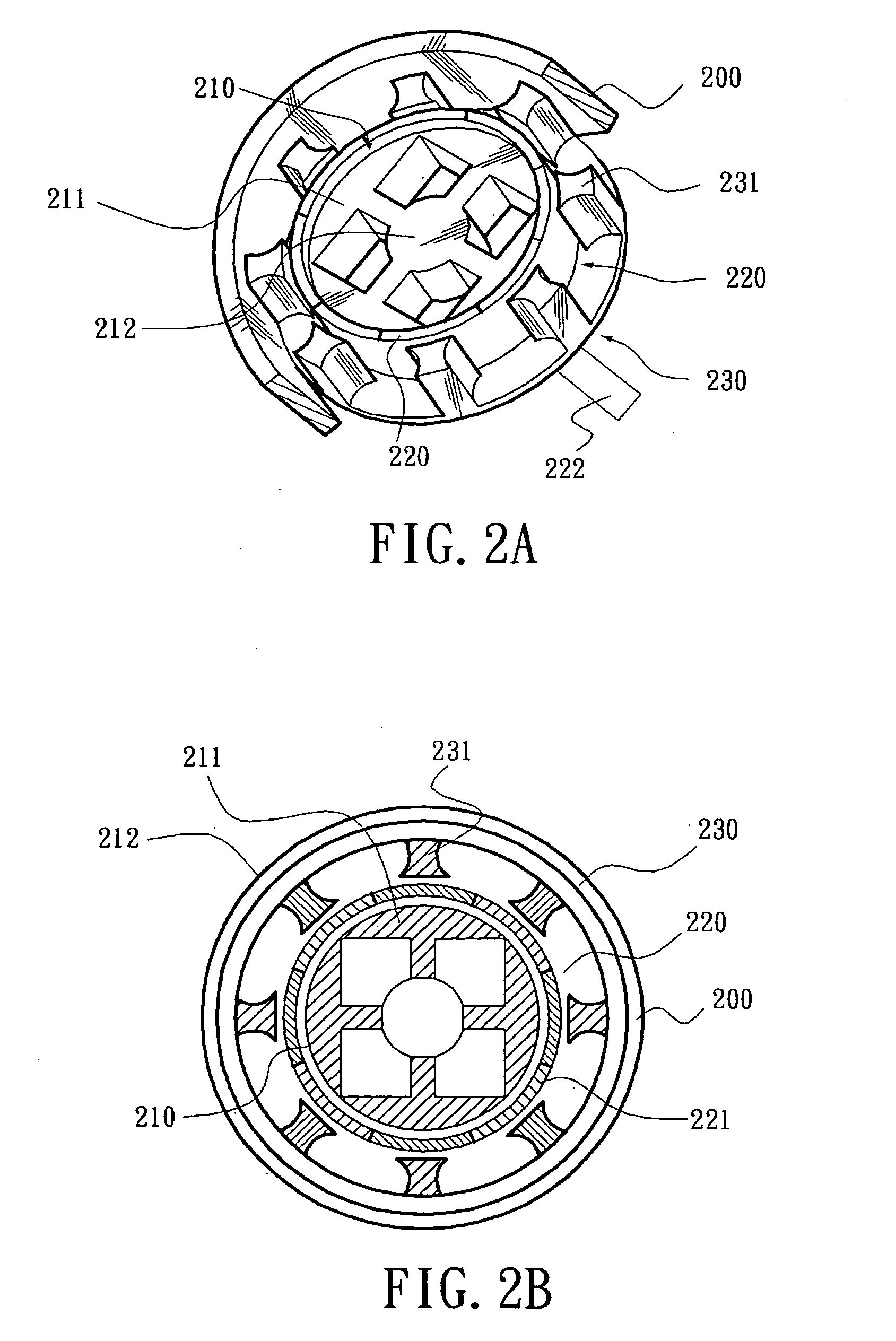

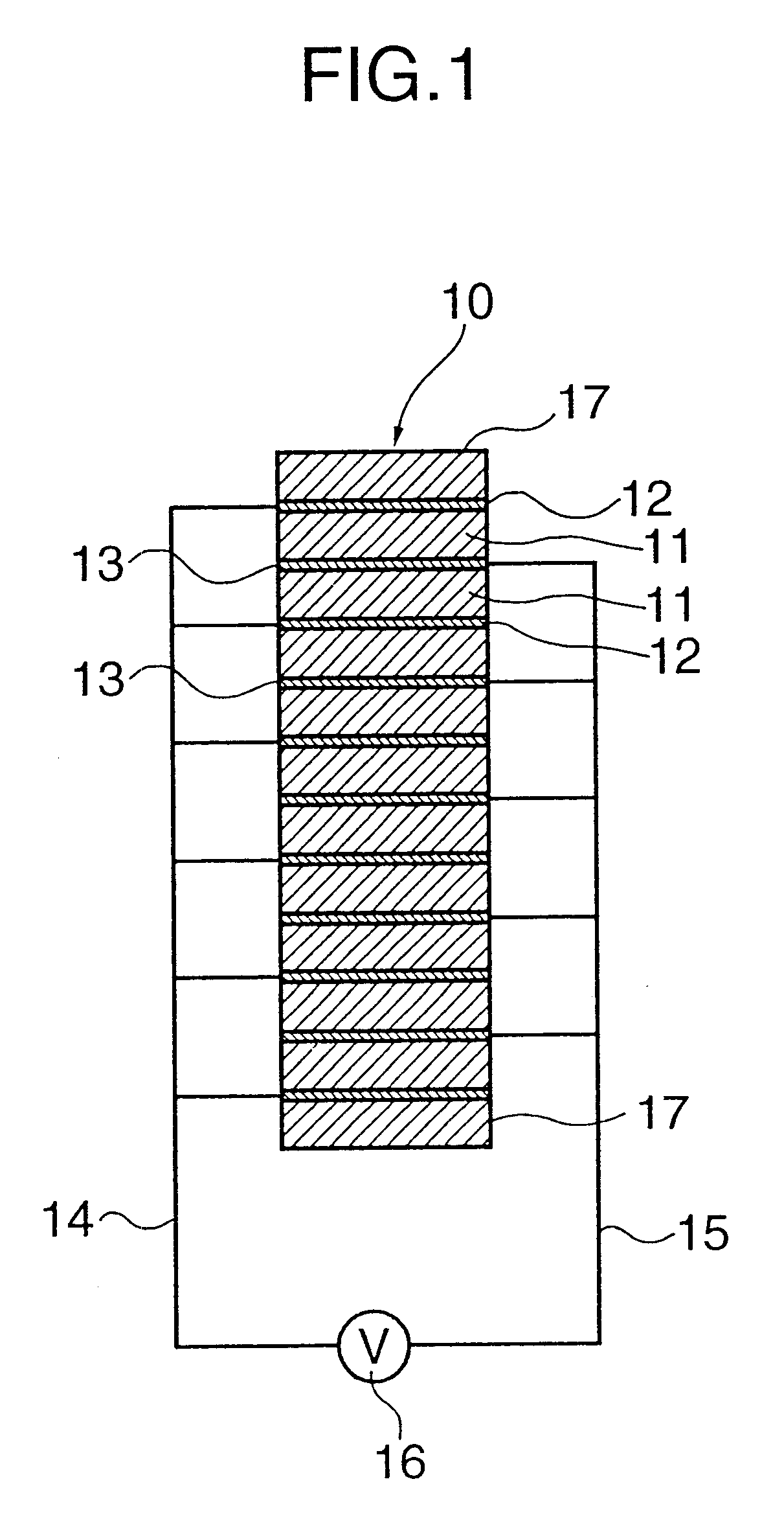

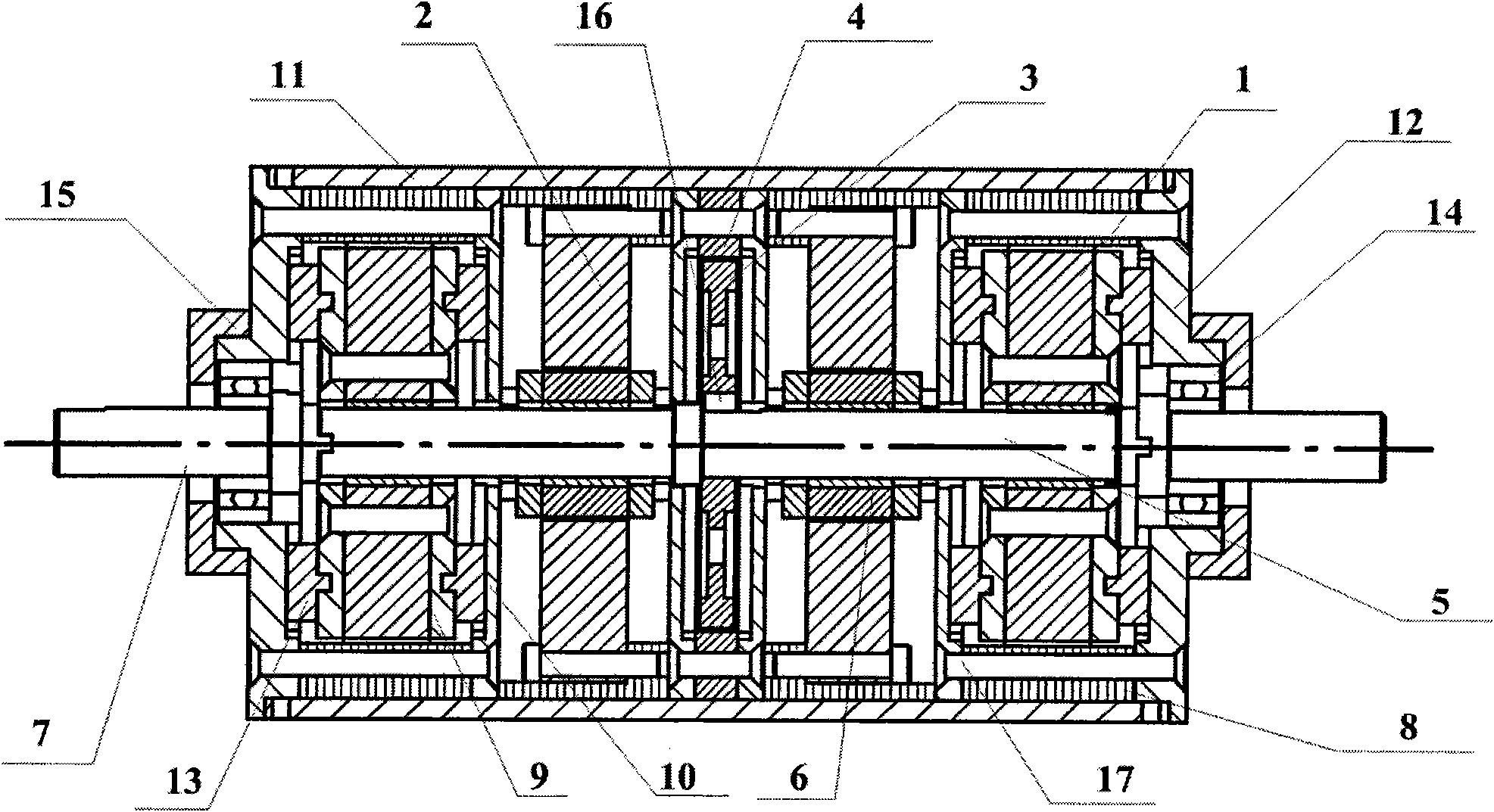

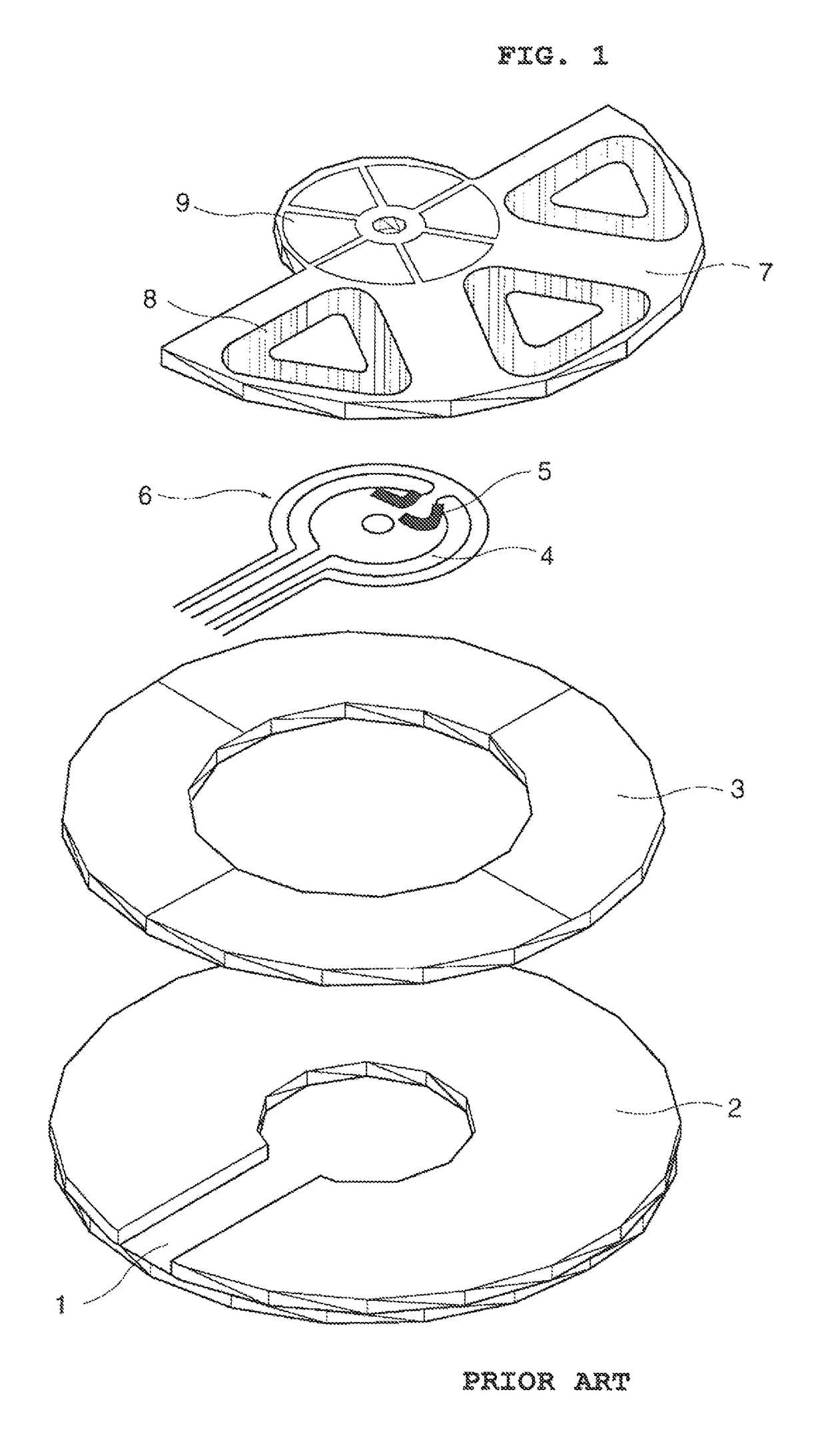

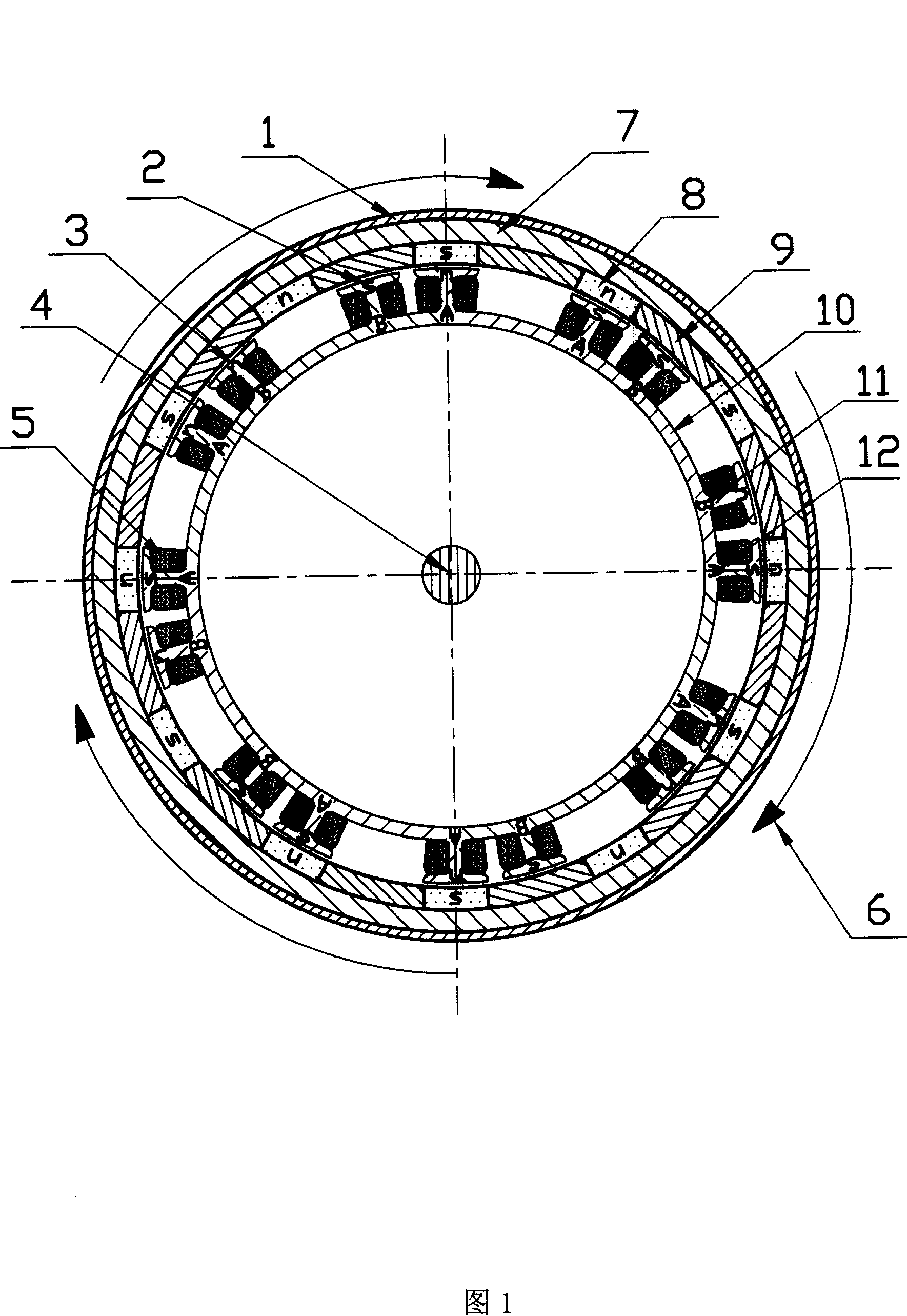

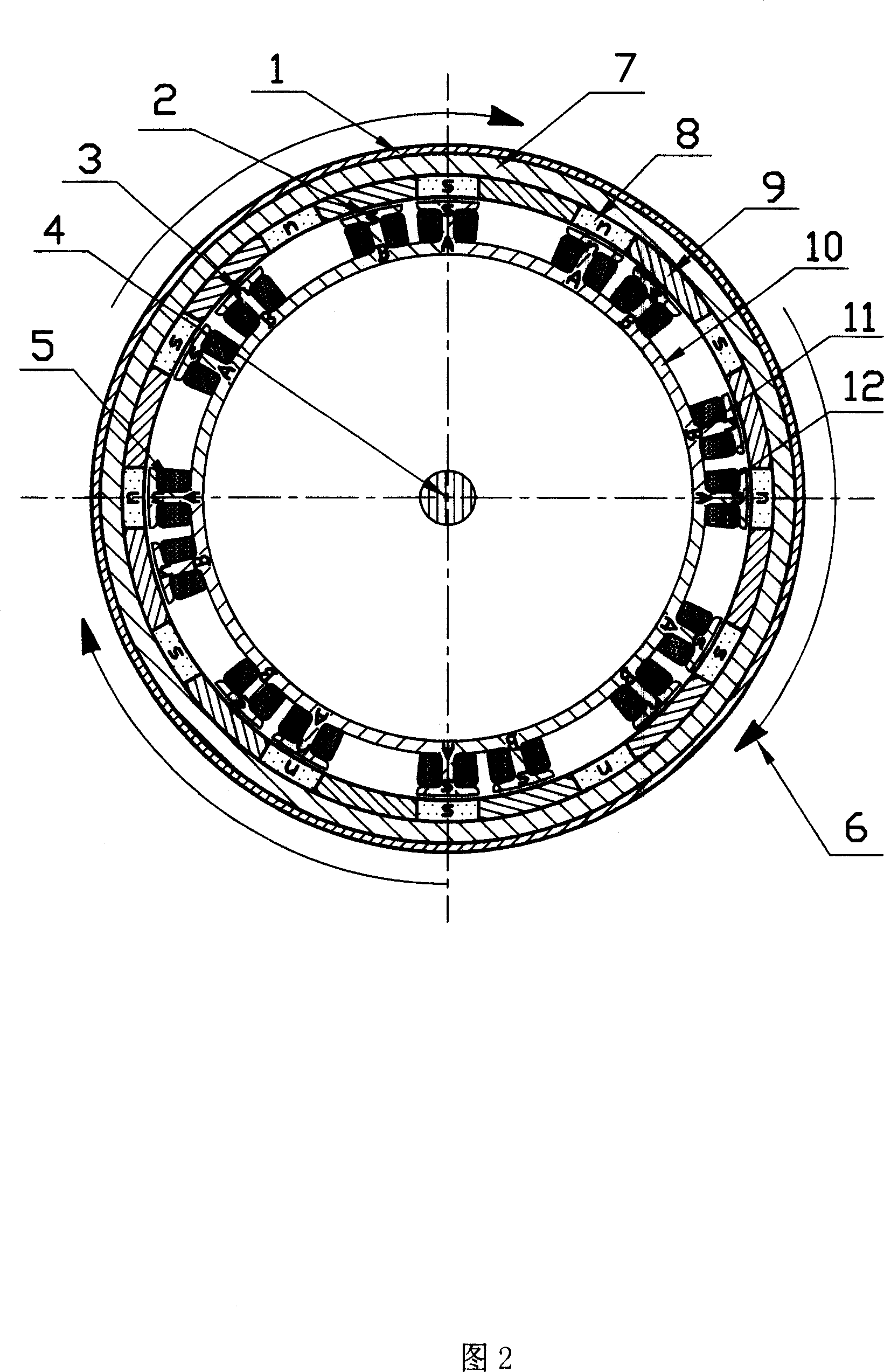

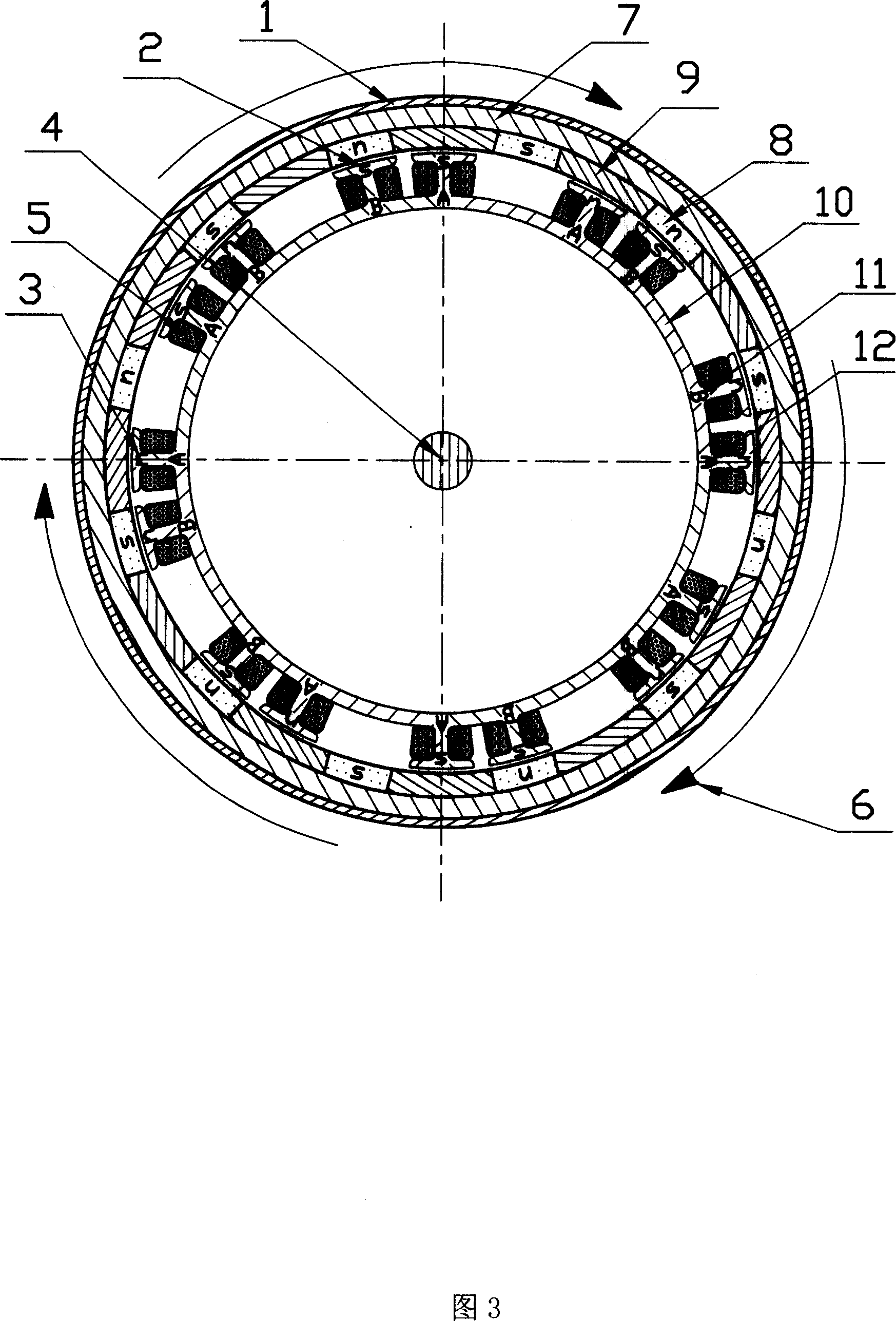

Double rotor type motor

ActiveUS7911110B2Strong torquePrecise positioningMagnetic circuit rotating partsOther washing machinesEngineeringMagnet

The present invention relates to motors, and more particularly, to a double rotor type motor applicable to a washing machine or the like. The double rotor type motor includes an outer rotor having first base, and a first extension extended from a circumference of the first base substantially perpendicular thereto, the first extension having outer magnets mounted on an inside circumferential surface, an inner rotor having a second base mounted on an upper surface of the first base concentric to the first base, and a second extension extended from a circumference of the second base so as to be opposite to the first extension with a predetermined gap toward an inner side of the first extension, the second extension having inner magnets mounted on an outside circumferential surface, and a bushing at a center of the first base and the second base, for transmission of rotation force both from the outer rotor and the inner rotor to a rotating shaft.

Owner:LG ELECTRONICS INC

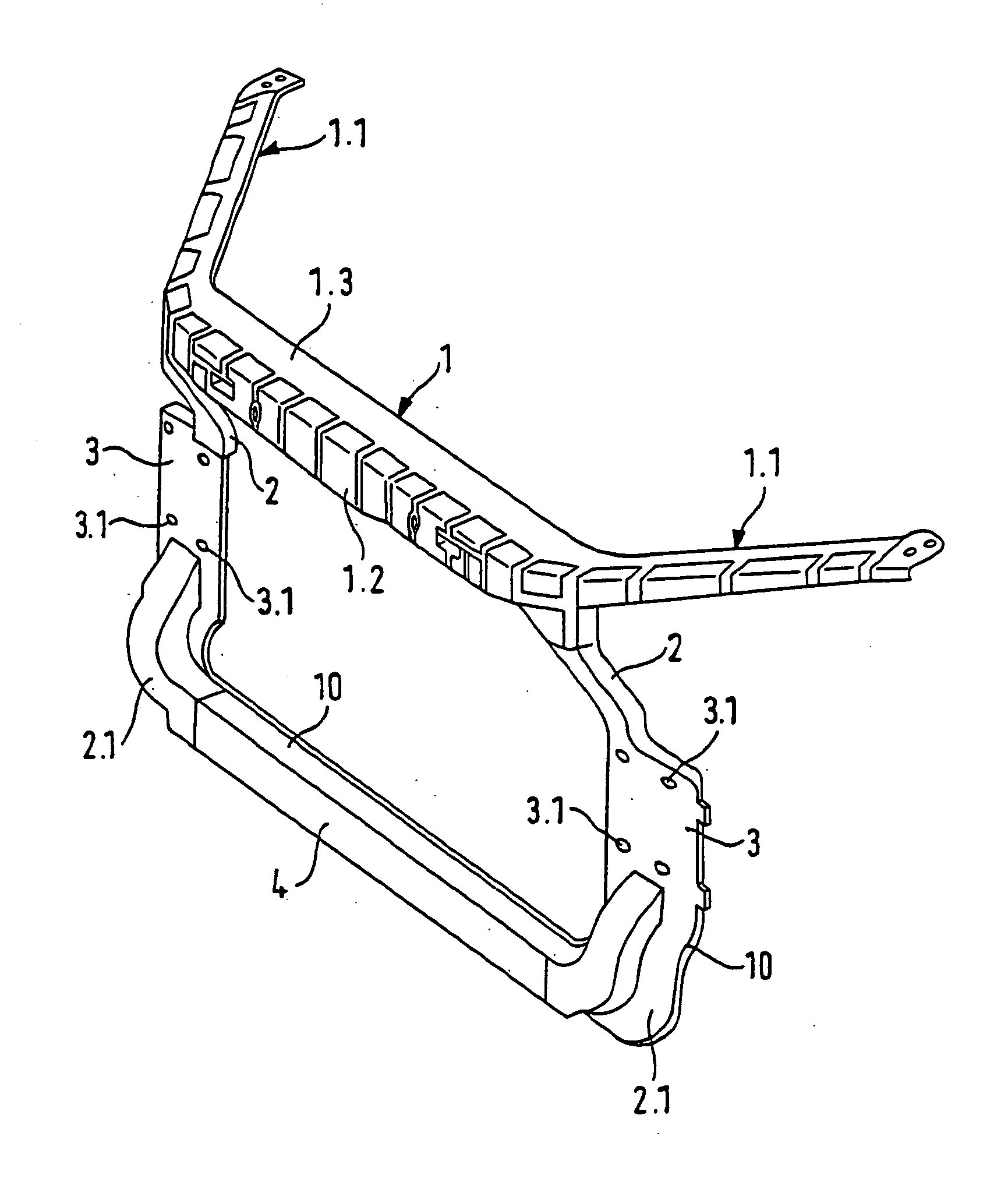

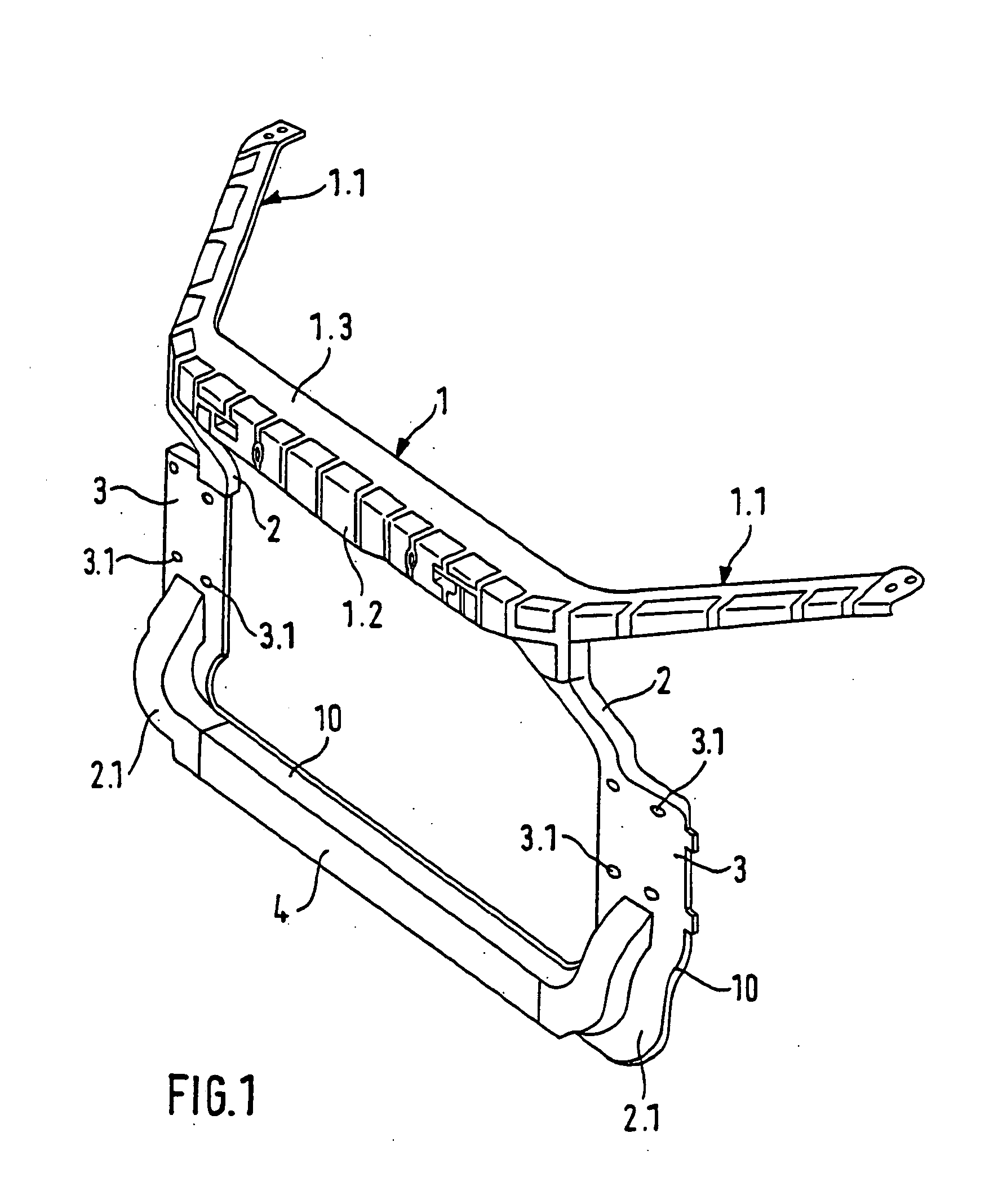

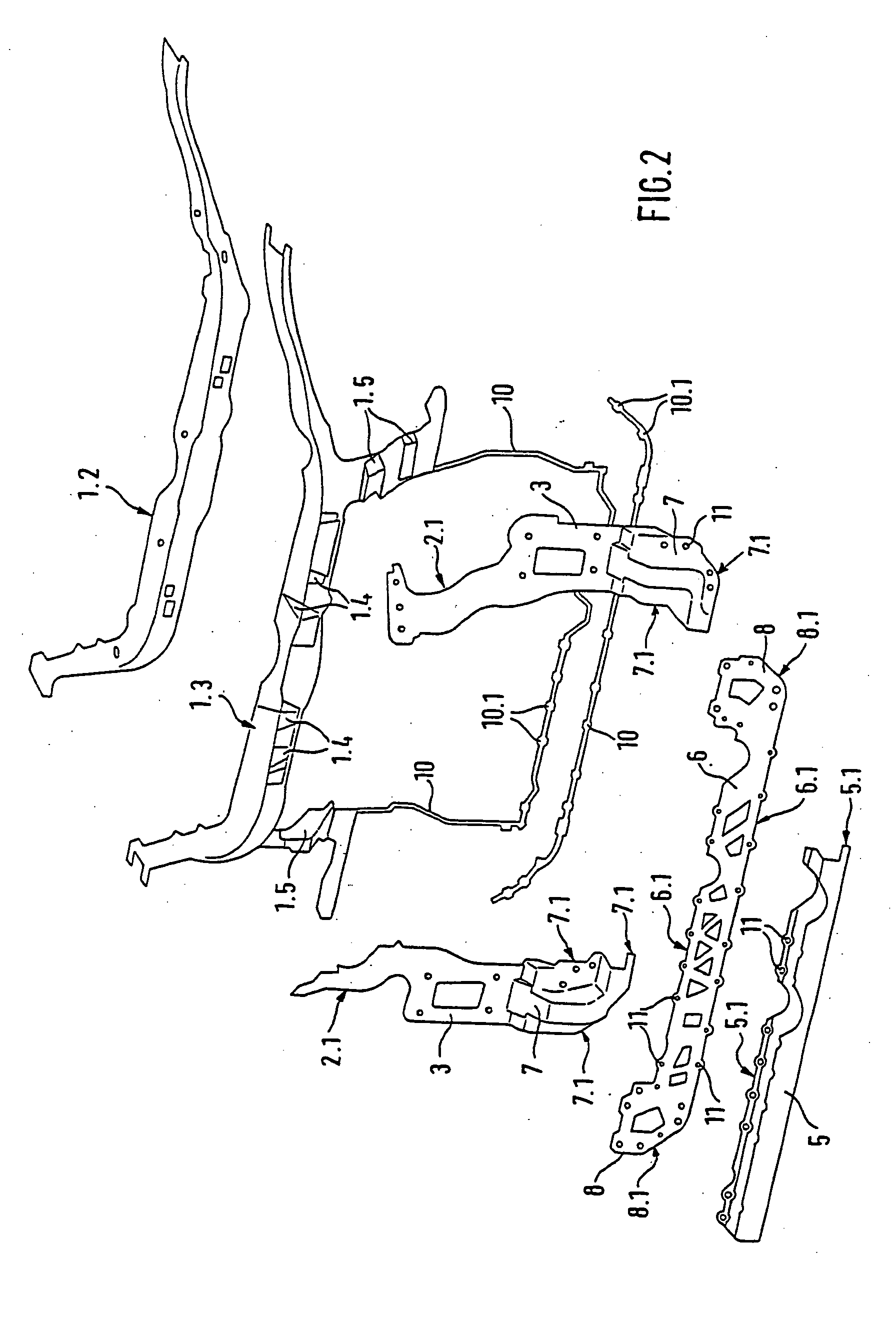

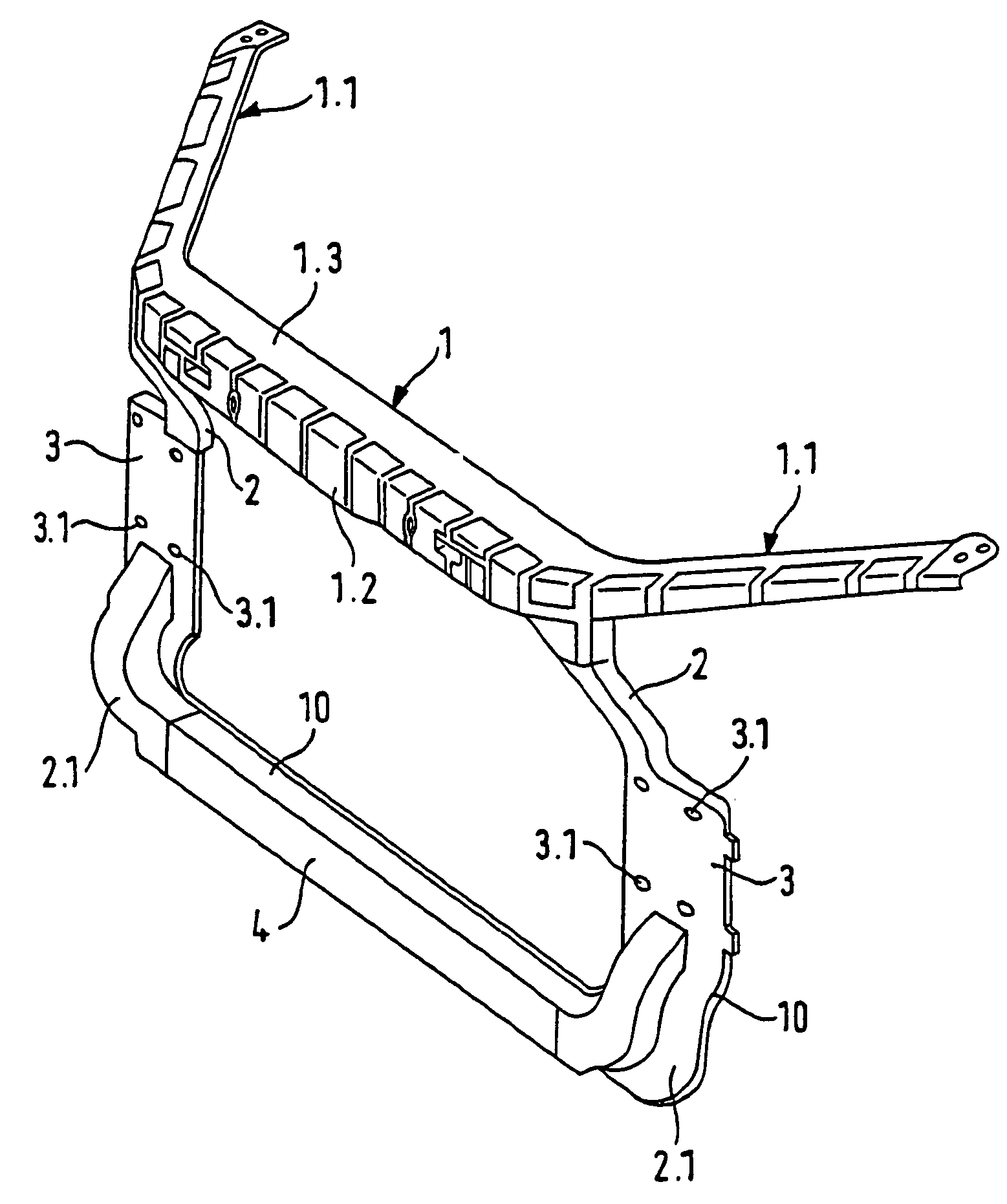

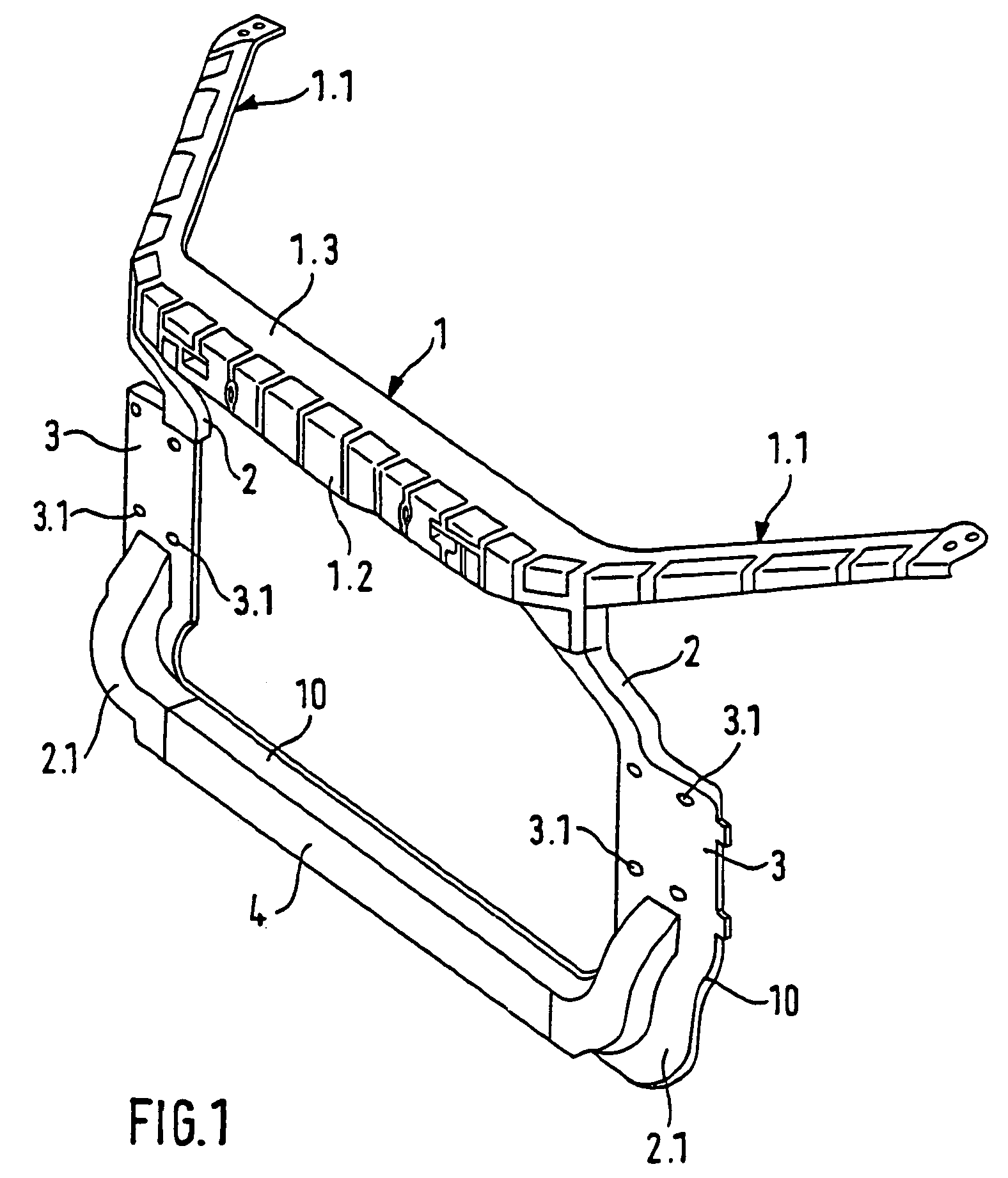

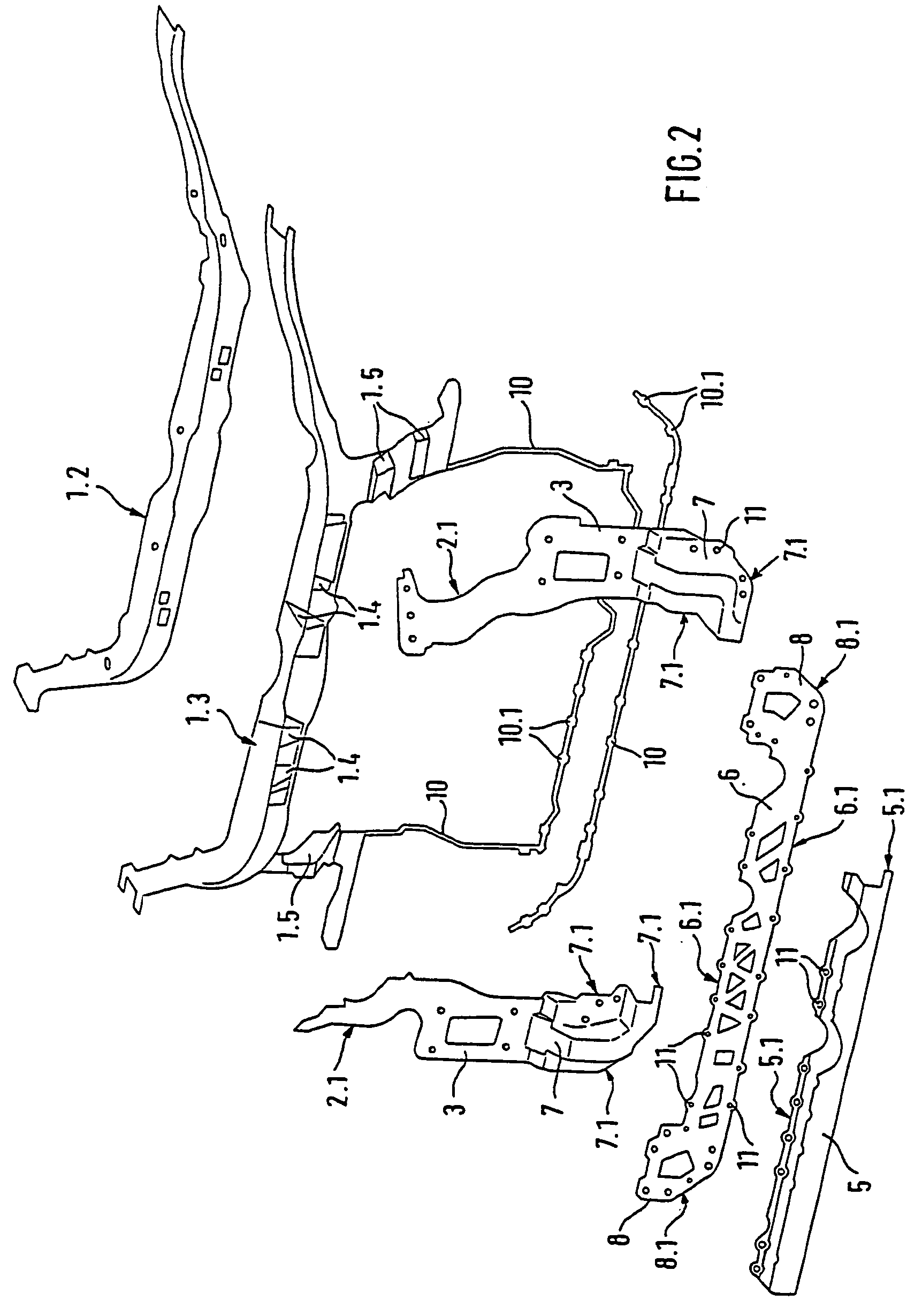

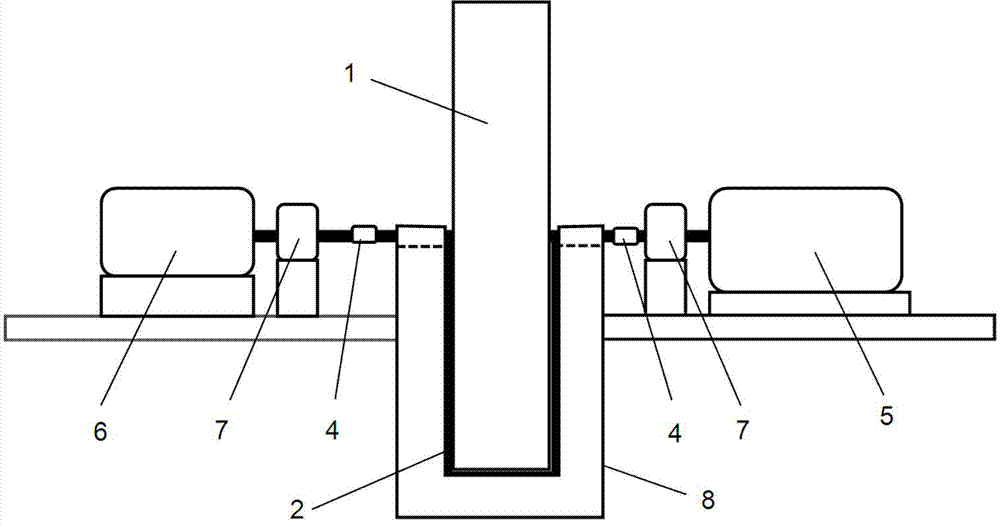

Hybrid-structure assembly support

An assembly support with hybrid structure for front ends of passenger vehicles and light trucks includes an upper cross member (1), a lateral member (2) attached to it from below with a flange plate (3) for connection with the face ends of vehicle longitudinal members and a lower cross member (4) connecting the lower sections (2.1) of these lateral members (2). In order to reinforce the assembly support in the area of the lower cross member (4), the lower cross member (4) consists of a shell body (5) with a flange (5.1) running along its edge and projecting outward, and of a sealing part (6) whose edge area overlaps it. The shell body (5) and the sealing part (6) are made of a stiff material, whereby the flange (5.1) and edge areas (6.1) of the above-mentioned components are surrounded by injected plastic used for the hybrid structure, and are thus bound together with the lateral members (2).

Owner:HBPO

Rotating drive shaft coupling

ActiveUS8628269B2Reduce maintenanceLower manufacturing requirementsRod connectionsCouplings for rigid shaftsCouplingDrive shaft

Owner:RAINBOW TECH INT LTD

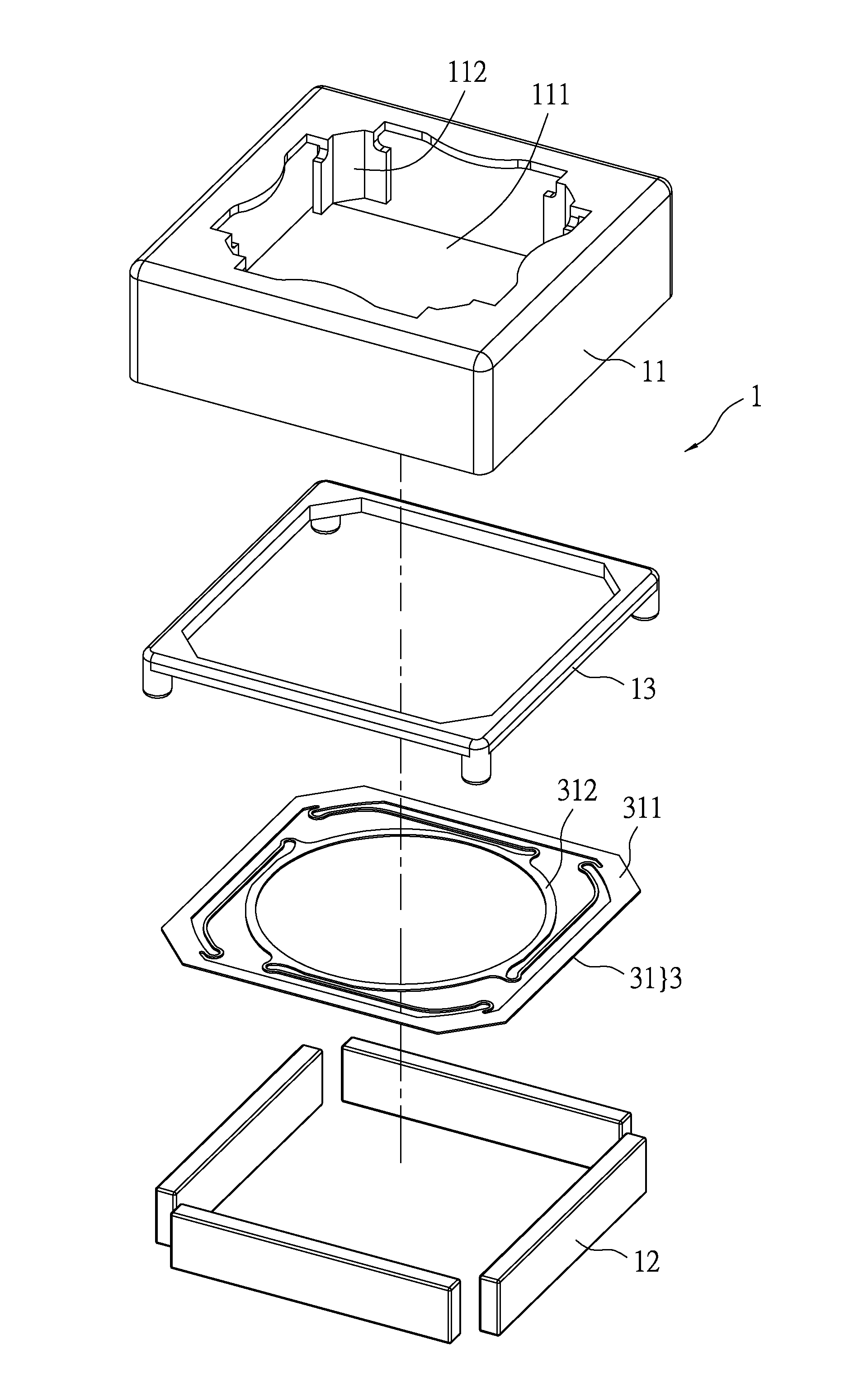

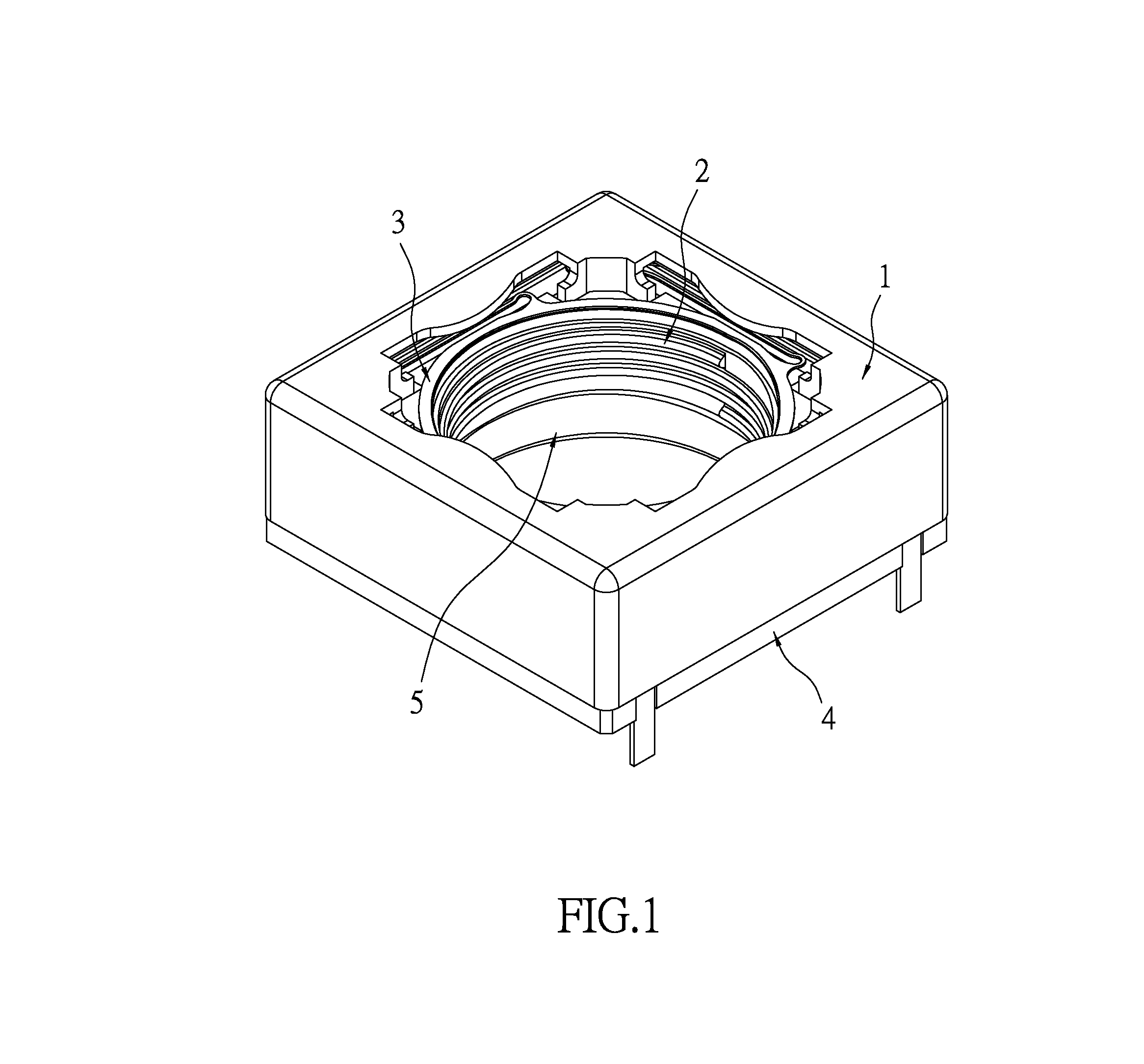

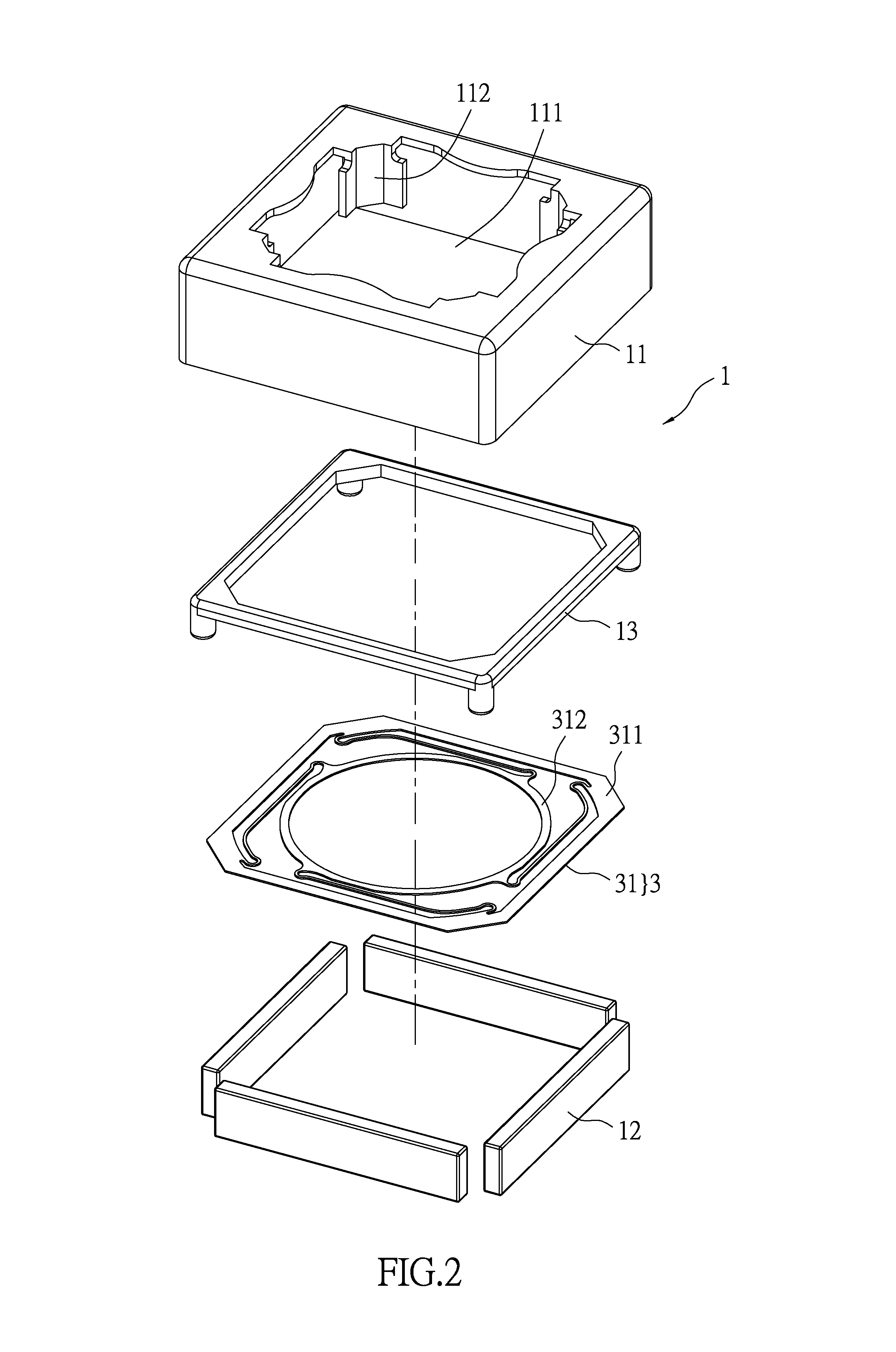

Voice coil motor

InactiveUS20140355142A1Stable and powerful pushing forceStrong torquePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersActuatorVoice coil

A VCM actuator for a lens and driving the lens for focusing includes a fixed module, a mobile module and a spring module. The fixed module includes a case and the magnet module is disposed along the inner side of the case. The mobile module includes a lens holder and a coil looping the lens holder. The lens holder is movably disposed in the case and the coil is fastened to the lens holder positioning to the magnet module. The spring module abuts the fixed module and mobile module. The case has an opening and along the rim of each corner of the opening a magnet guiding tab is formed. The guiding tabs extend between the lens holder and coil and are positioned toward the gaps between the magnet module, and each magnet guiding tab has a backbone and two wing portions extending from the backbone.

Owner:SILITECH TECH CORP

Motor structure

InactiveUS20080129135A1Increase rotation speedIncrease torqueMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesElectric motor

Owner:INVENTEC CORP

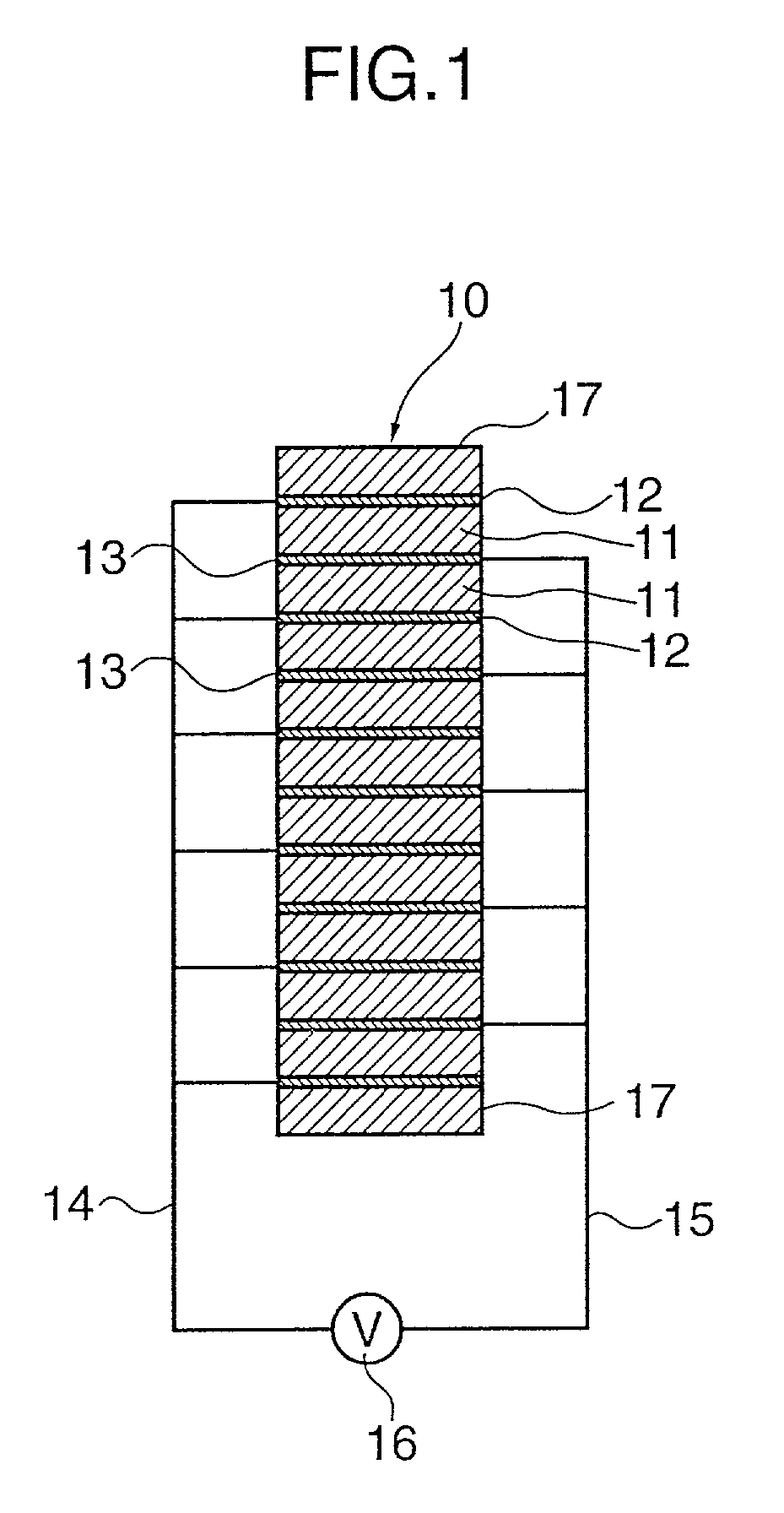

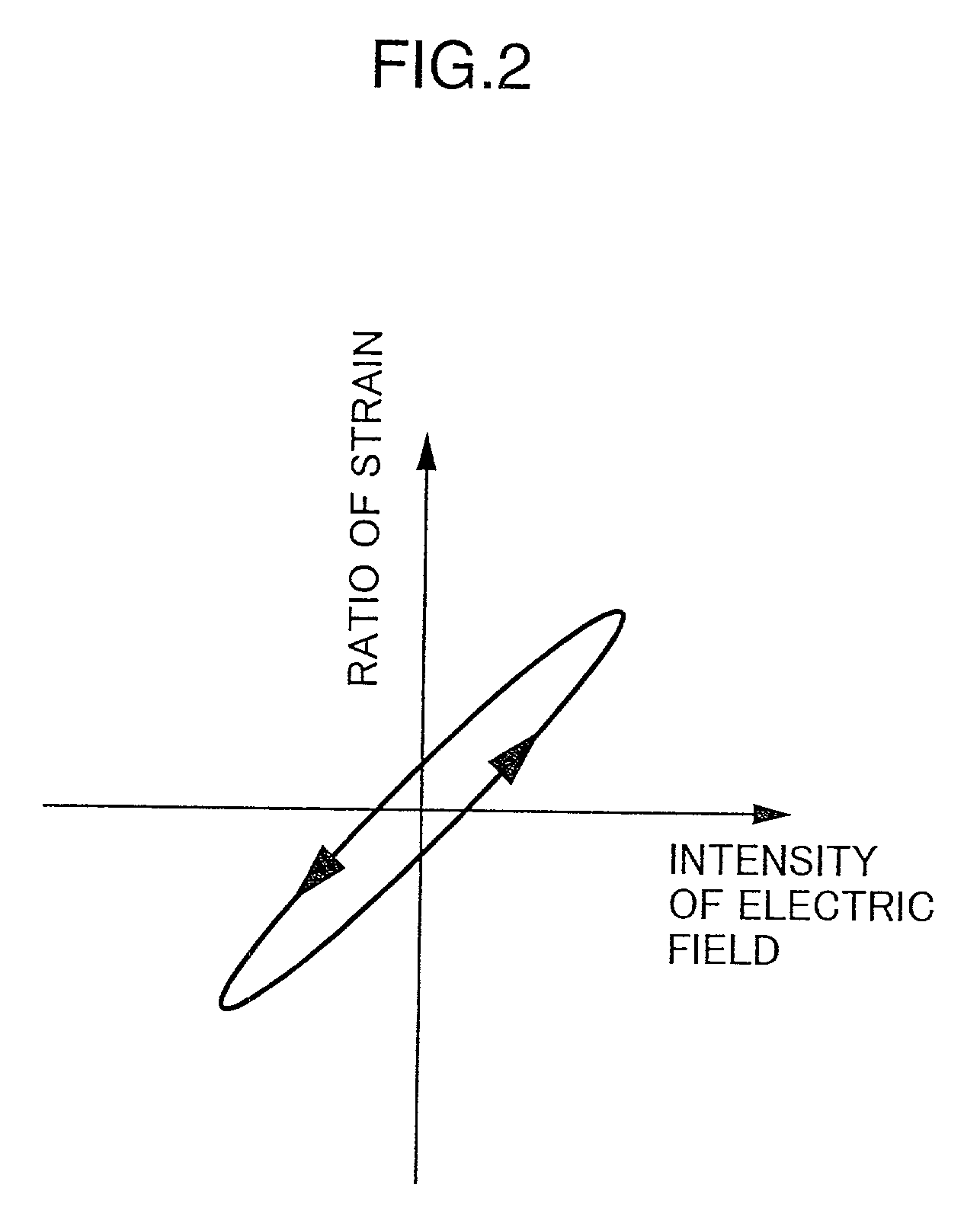

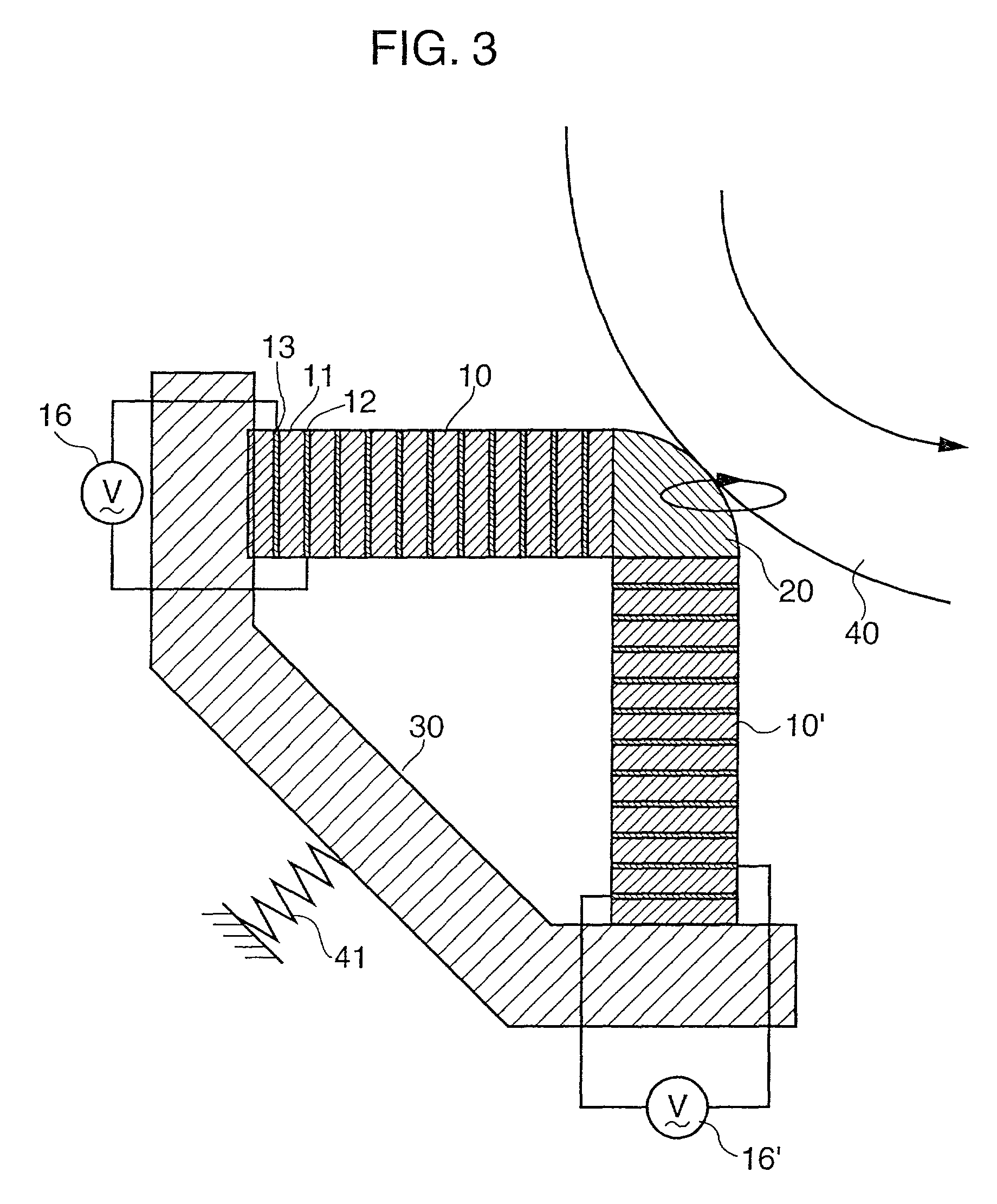

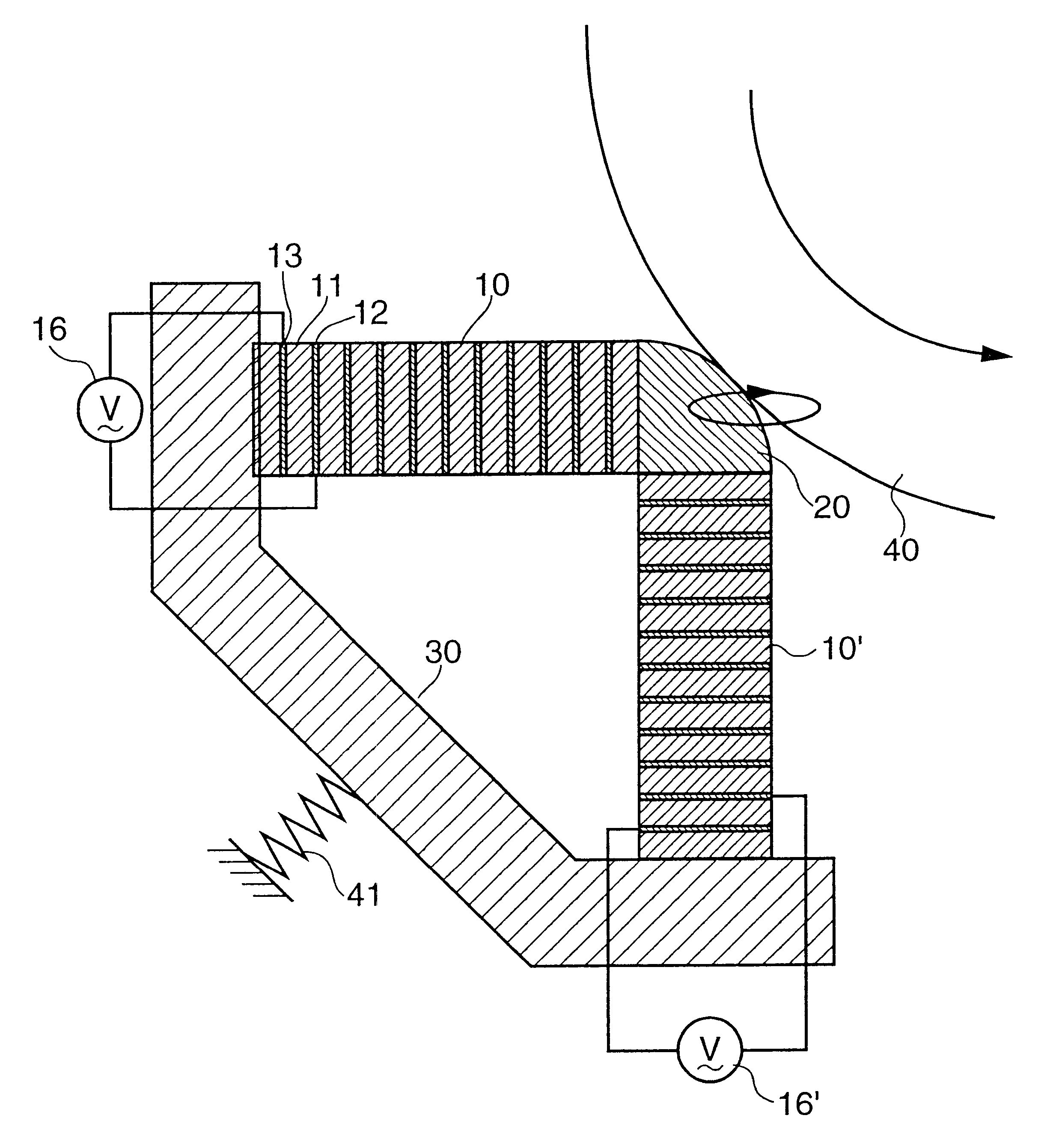

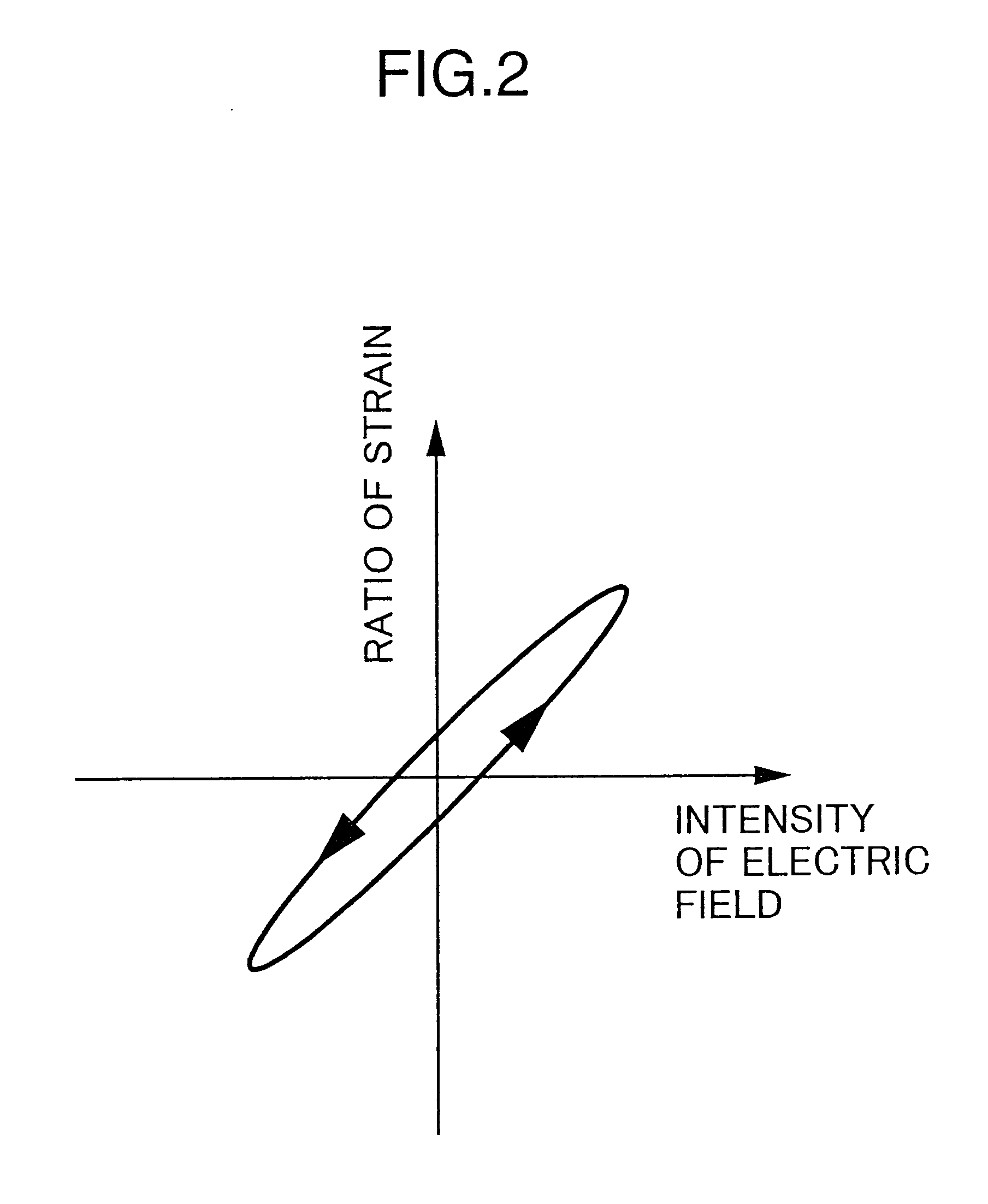

Actuator and driving method thereof

InactiveUS20010020809A1Make fastMade very strongPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsRotation velocityEngineering

An actuator includes at least two piezoelectric devices arranged for crossing displacing directions thereof at a predetermined angle, a chip member provided at a coupling point of the piezoelectric devices, and a spring for contacting the chip member to a rotor driven by the actuator. The piezoelectric device is driven for moving the chip member trailing an elliptical trail. The rotation velocity or the driving torque of the rotor is controlled by varying at least one of a length of a major axis or a minor axis of the elliptical trail and an inclination angle of the major axis or the minor axis with respect to a normal at a contacting point of the chip member and the rotor.

Owner:MINOLTA CO LTD

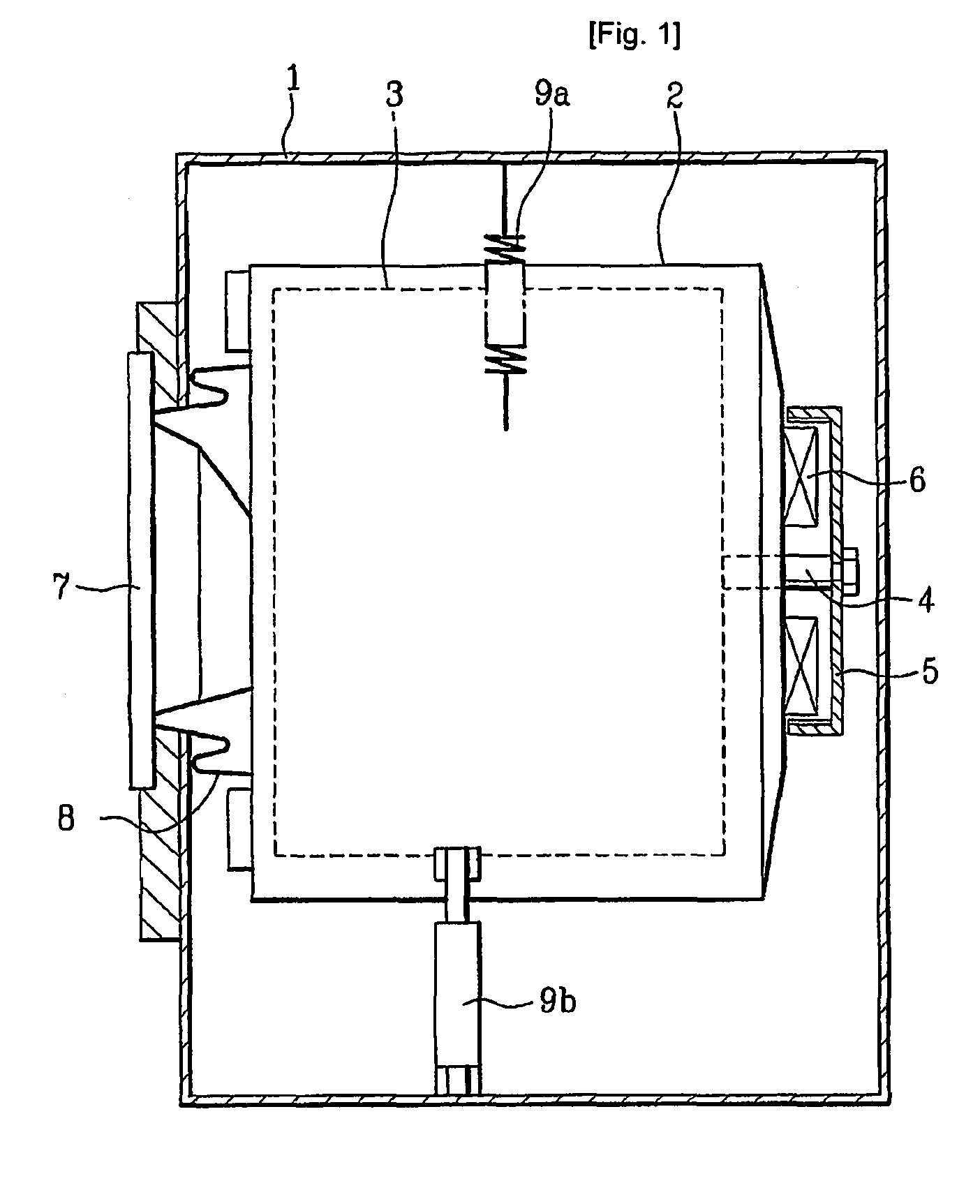

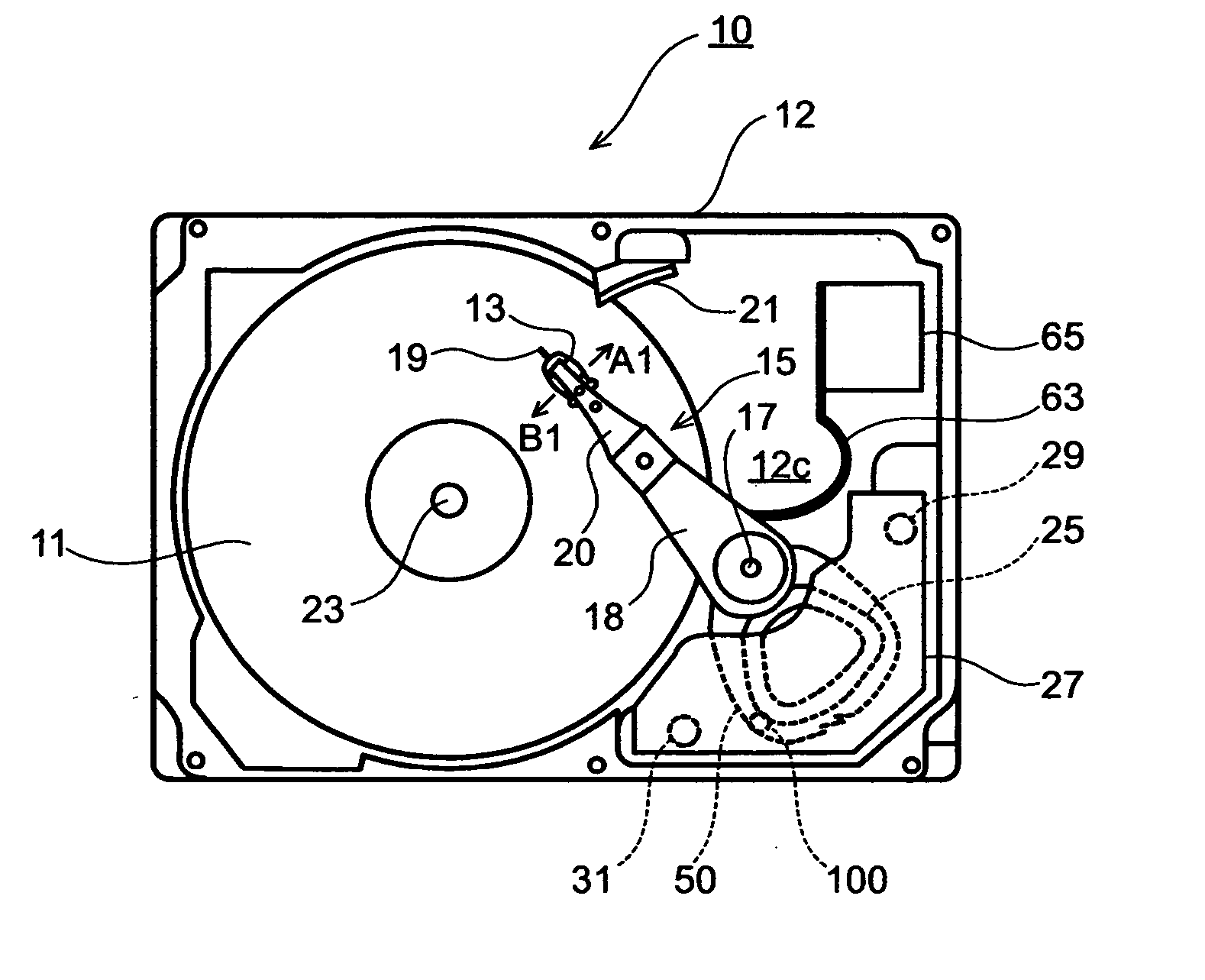

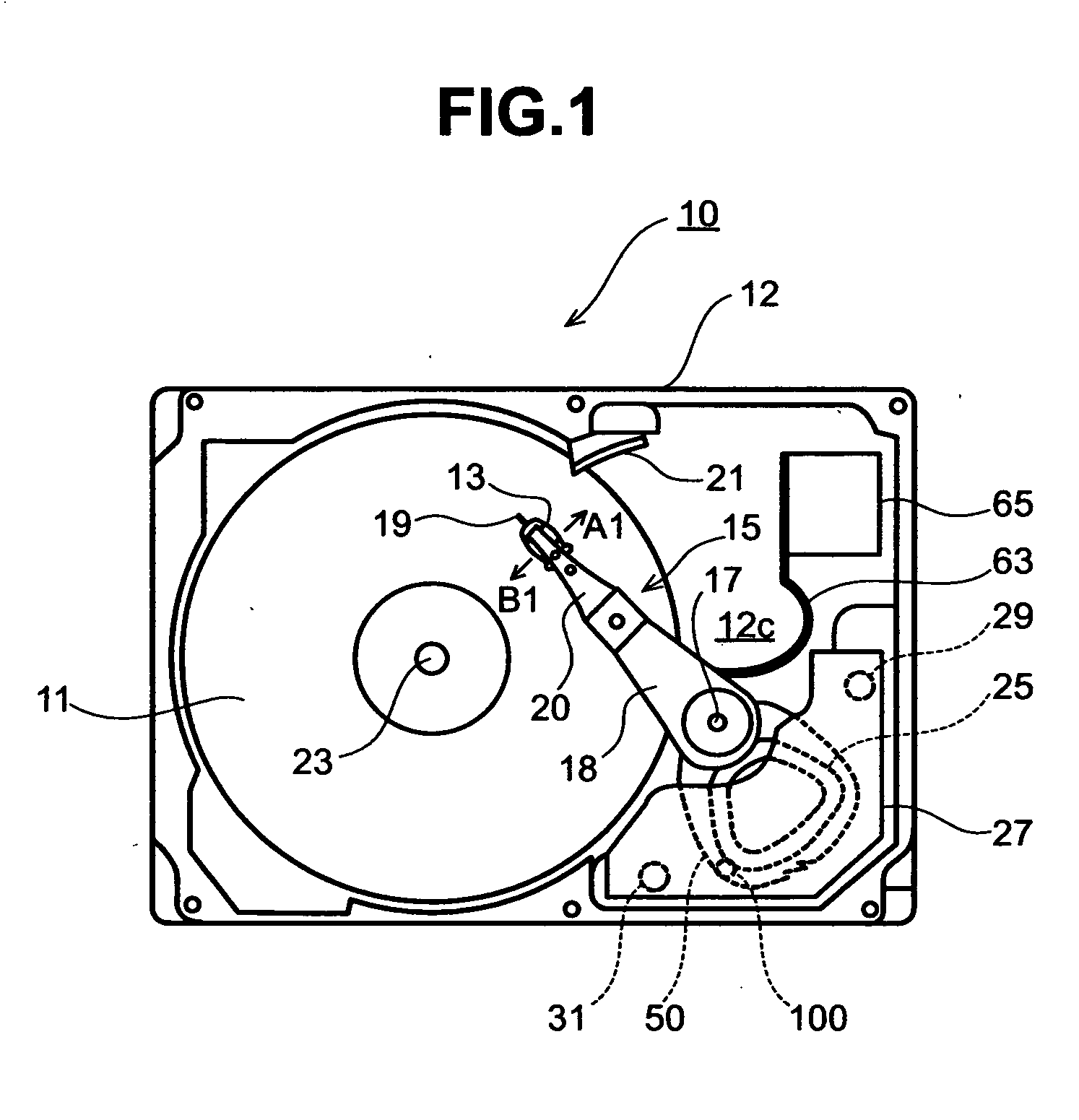

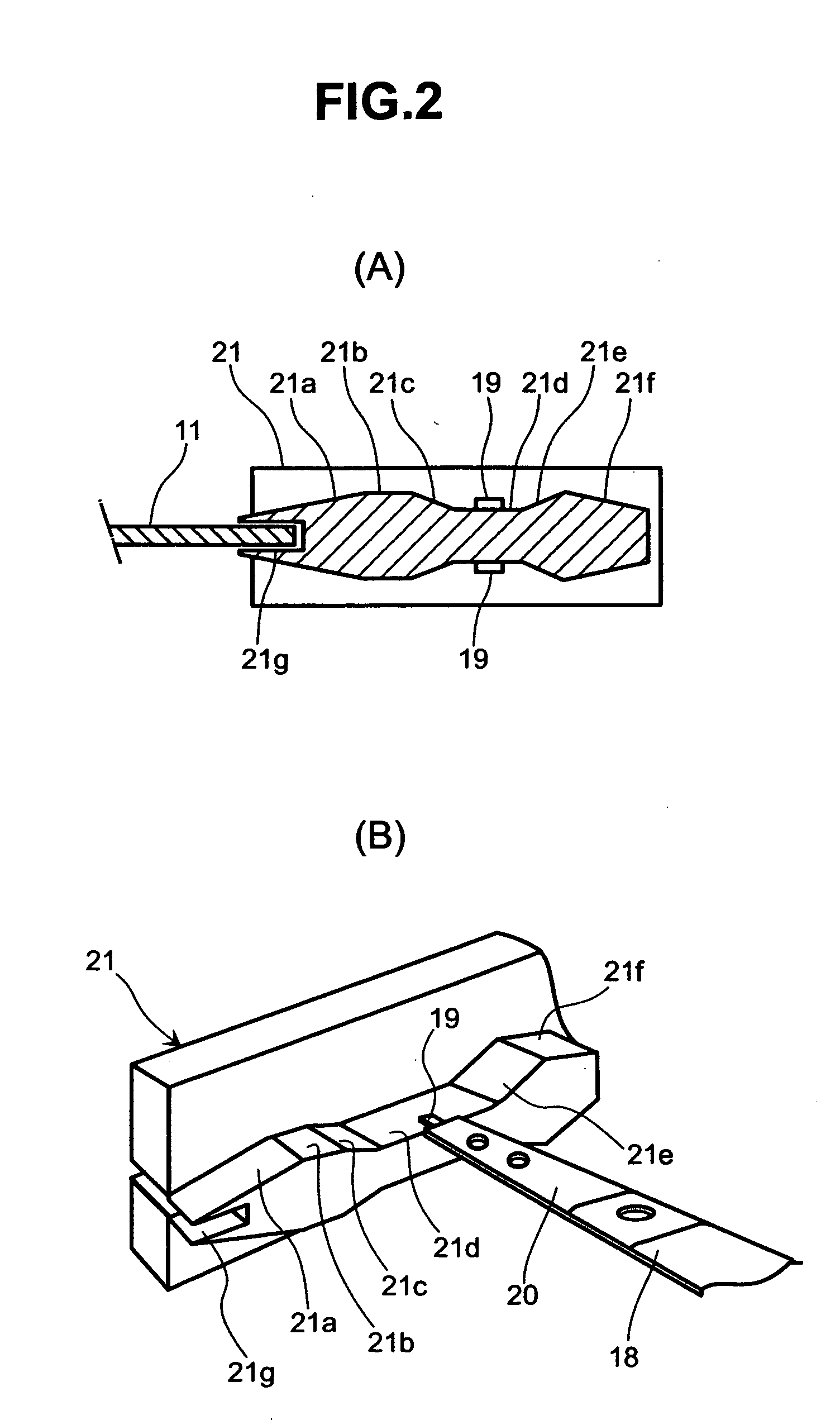

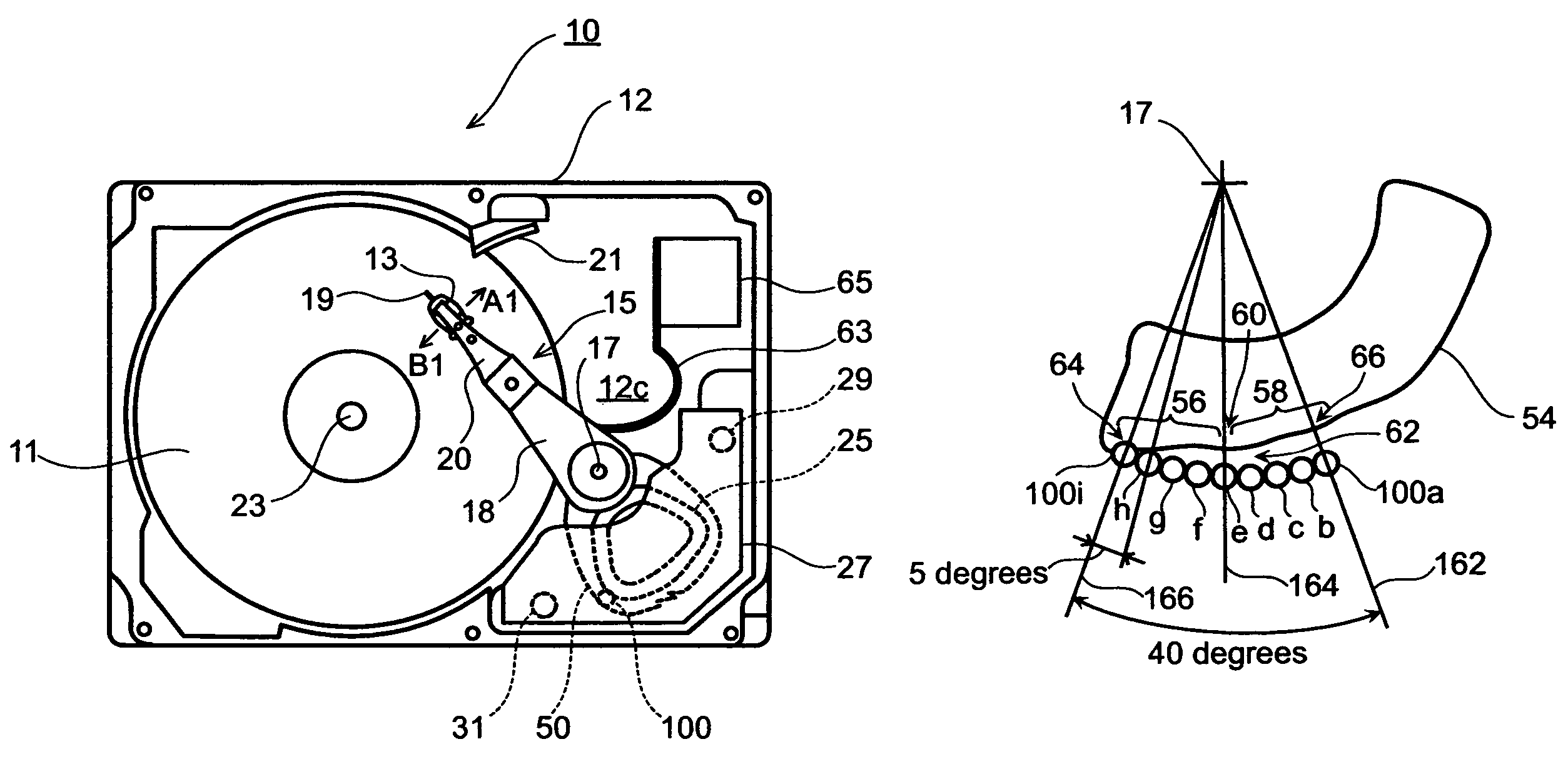

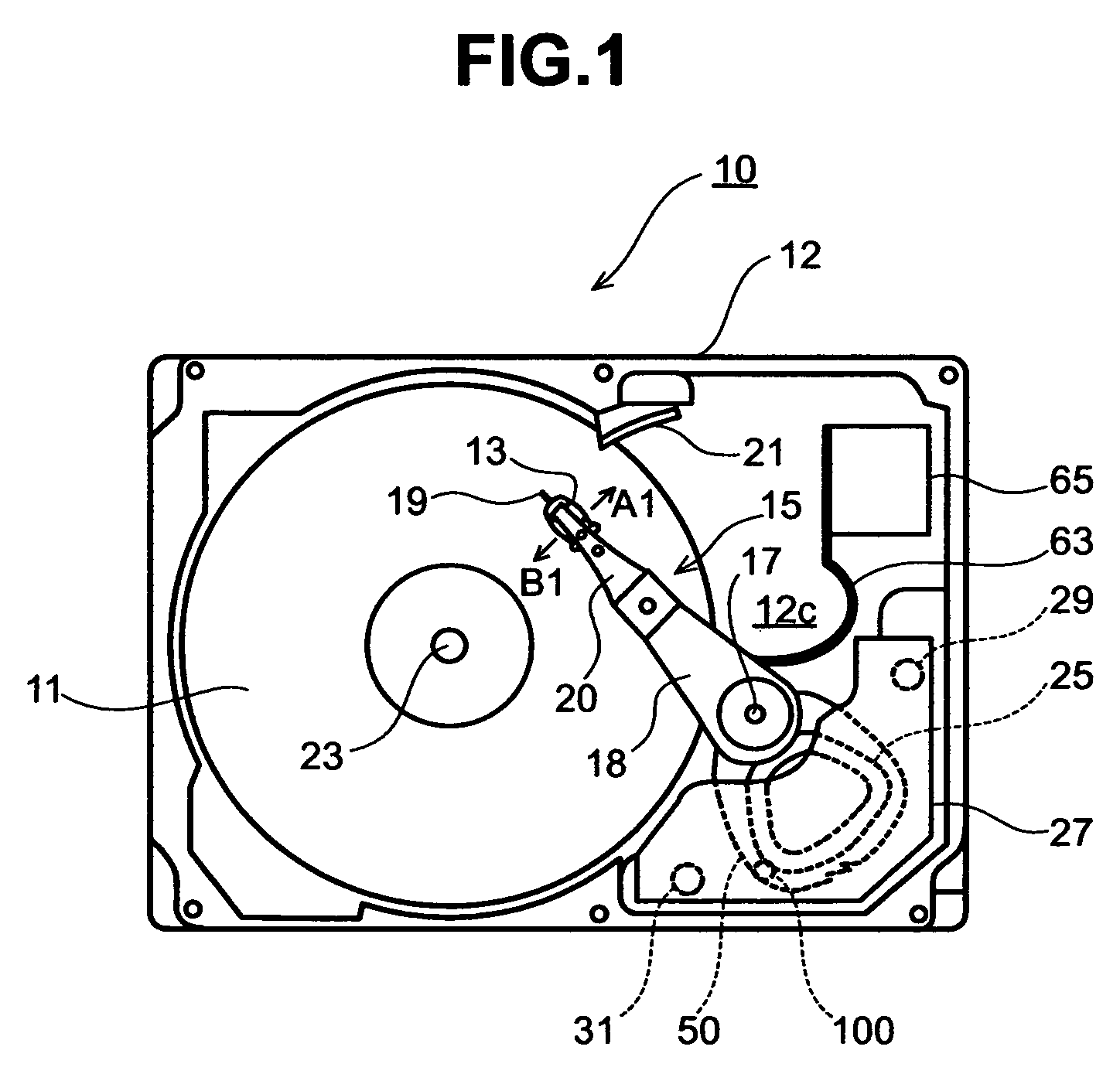

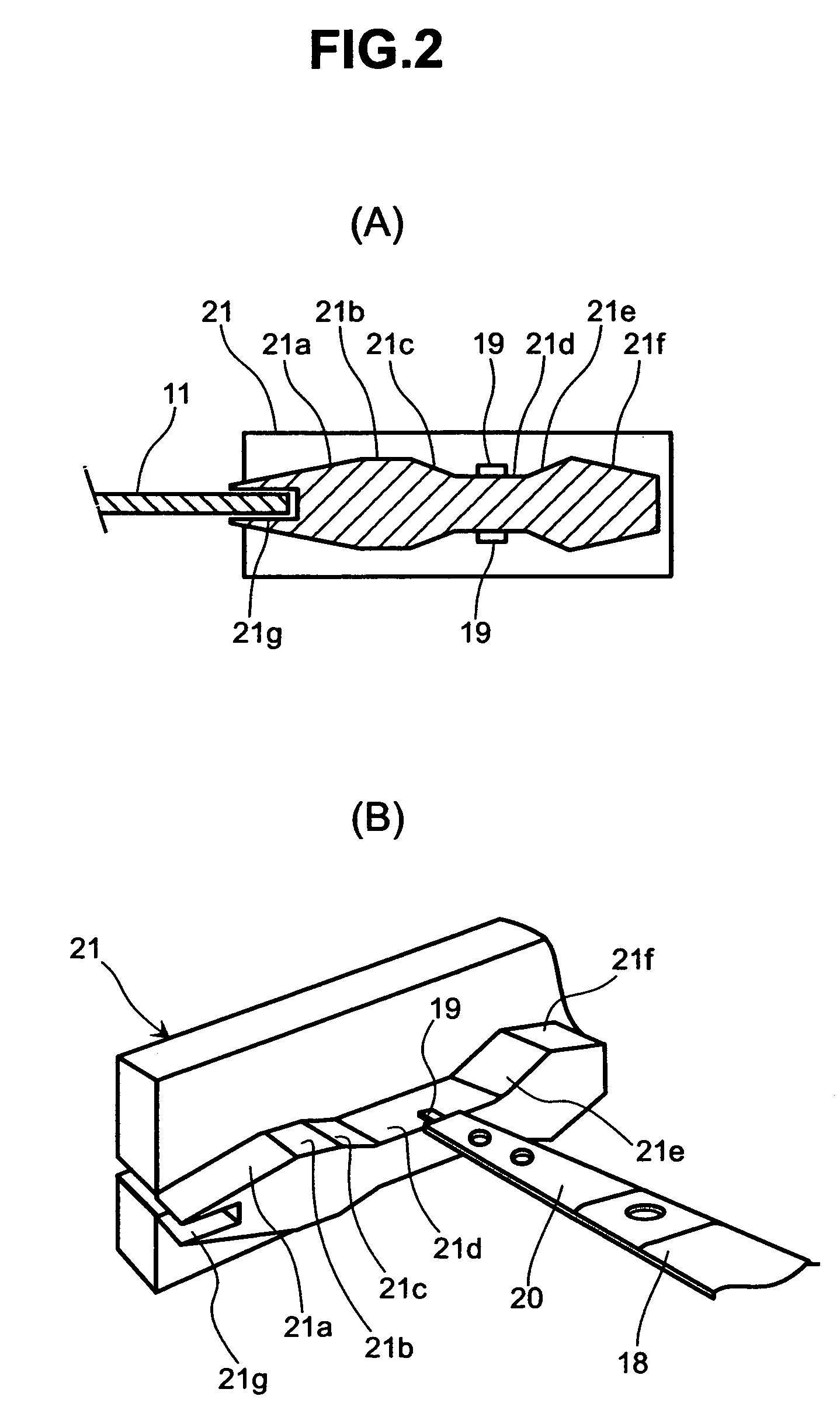

Rotating disk storage device

InactiveUS20050063098A1Simple structureReliable holdDisposition/mounting of recording headsDriving/moving recording headsActuatorControl theory

Embodiments of the present invention provide a rotating disk storage device having a mechanism to reliably retract an actuator into a retraction area in the event that the power supply is suddenly interrupted. A bias chip is embedded in a coil support that supports the voice coil. When a head stays in an access area, the bias chip is away from an end of the voice coil magnet. Therefore, no influence of the magnetic leakage flux is exerted on the bias chip. When the head is in a retraction area, the bias chip is attracted under the influence of the magnetic leakage flux of the voice coil magnet, which thereby produces bias torque causing an actuator to pivotally move in a retraction direction. Accordingly, the bias torque can be utilized as energy for retracting the actuator immediately after power shutdown.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

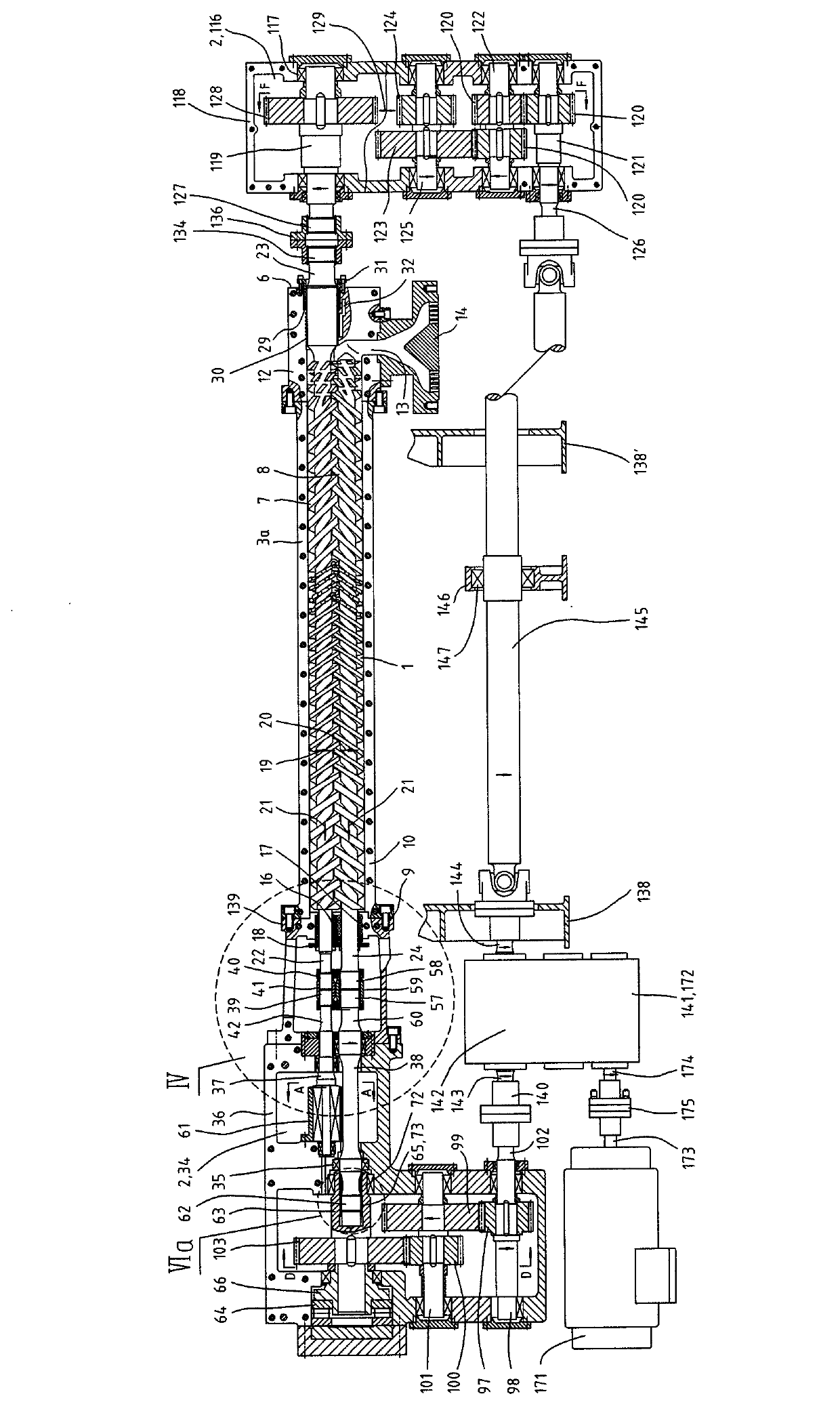

Parallel counter-rotating intermeshing twin-screw extruder

The invention discloses a parallel counter-rotating intermeshing twin-screw extruder used for compounding or compounding extrusion of plastic materials such as plastic. The parallel counter-rotating intermeshing twin-screw extruder comprises a parallel counter-rotating intermeshing twin-screw continuous extrusion device, a tail side transmission case, a head side transmission case, and at least one motor; the parallel counter-rotating intermeshing twin-screw continuous extrusion device comprises a combined type or an integral housing; the housing comprises two cavities which are parallel in longitudinal direction and are intercross along longitudinal direction; each cavity is provided with a pair of counter-rotating intermeshing screws, one of the counter-rotating intermeshing screws is protruded out of the head end and the tail end of the housing respectively, the forward protruded end is driven to rotate by the head side transmission case, and thrust supporting of the backward protruded end is realized by the tail side transmission case reelingly in longitudinal direction i.e. in axial direction; the other counter-rotating intermeshing screw is protruded out of the tail end of the housing, and thrust supporting and driving of the backward protruded end is realized by the tail side transmission case reelingly in longitudinal direction i.e. in axial direction, so that torque density (M / a<3>) is capable of exceeding 10Nm / cm<3> economically and serviceably, and is capable of exceeding 25Nm / cm<3> significantly.

Owner:陈克俭

Plastic foamed sheet with antistatic and flame-retardant functions and manufacturing technique thereof

The invention relates to an environment-friendly plastic foamed sheet with antistatic and flame-retardant functions and a manufacturing technique thereof. The manufacturing technique comprises the following steps: preparing bamboo carbon powder, kaolin, plastic, antistatic agent, flame retardant and other chemical assistants, banburying, mixing, discharging from a guillotine to obtain a sheet semi-finished product, and foaming to form with a foaming machine. The plastic foamed sheet is prepared from the following raw materials in parts by mass: 5.5-6 parts of plastic, 1.0-1.5 parts of bamboo carbon powder, 1.5-3.5 parts of kaolin, 1.0-2.5 parts of antistatic agent, 1.5-3.5 parts of flame retardant and 0.5-1.0 part of chemical assistants. The manufacturing technique produces the plastic foamed sheet with high-standard antistatic and flame-retardant functions, overcomes the defects and shortcomings in the prior art, has important and profound significance for solving the problems above, and has very wide market potential.

Owner:冼冰

Actuator and driving method thereof

InactiveUS6448694B2Make fastMade very strongPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsCouplingRotation velocity

An actuator includes at least two piezoelectric devices arranged for crossing displacing directions thereof at a predetermined angle, a chip member provided at a coupling point of the piezoelectric devices, and a spring for contacting the chip member to a rotor driven by the actuator. The piezoelectric device is driven for moving the chip member trailing an elliptical trail. The rotation velocity or the driving torque of the rotor is controlled by varying at least one of a length of a major axis or a minor axis of the elliptical trail and an inclination angle of the major axis or the minor axis with respect to a normal at a contacting point of the chip member and the rotor.

Owner:MINOLTA CO LTD

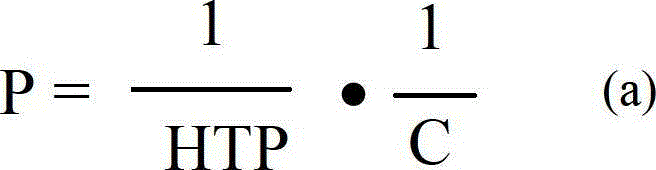

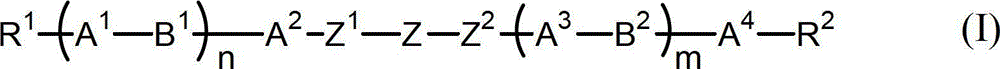

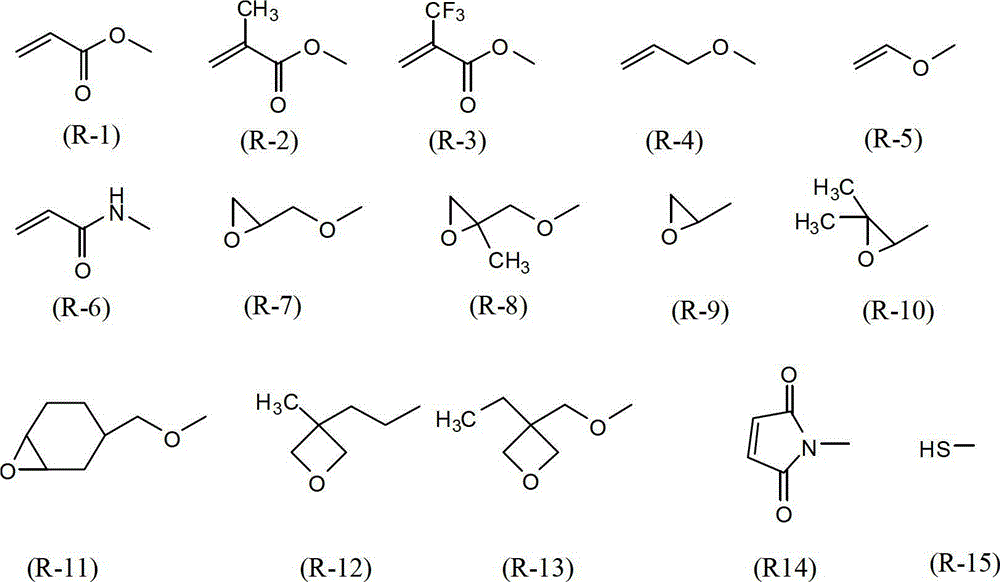

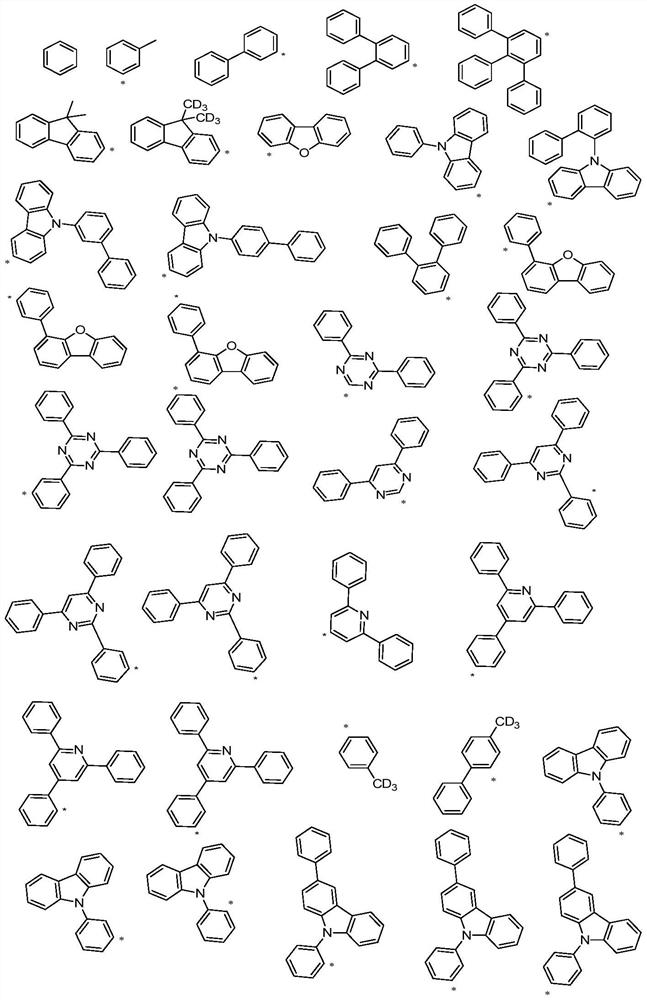

Polymerizable chiral compound

ActiveCN103059036AImprove solubilityStrong torqueLiquid crystal compositionsOrganic chemistrySolubilityOptical property

The invention provides a polymerizable chiral compound which has strong HTP and is excellent in solubility. The polymerizable chiral compound shown in a general form (I) has strong HTP and a low melting point. As the melting point is low, the polymerizable chiral compound has excellent solubility with other liquid crystal compounds and is useful to be a composition material of polymerizable liquid crystal composition. In addition, as the polymerizable chiral compound has a strong torque force, the polymerizable chiral compound can be used to manufacture optical anisotropy of excellent optical properties. The optical anisotropy can be used in deflection plates, phase difference plates, selective reflection plates, etc.

Owner:DIC CORP

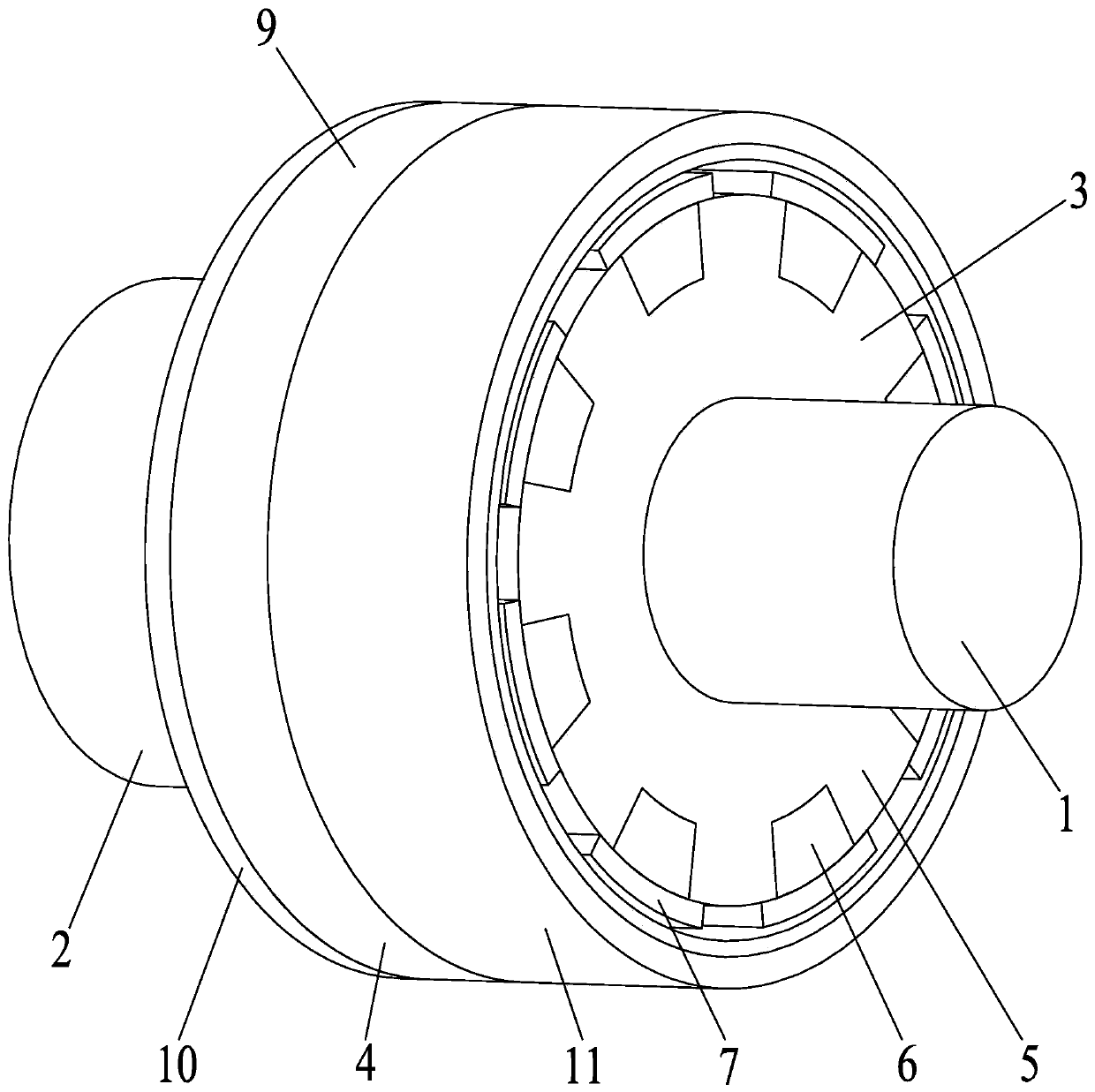

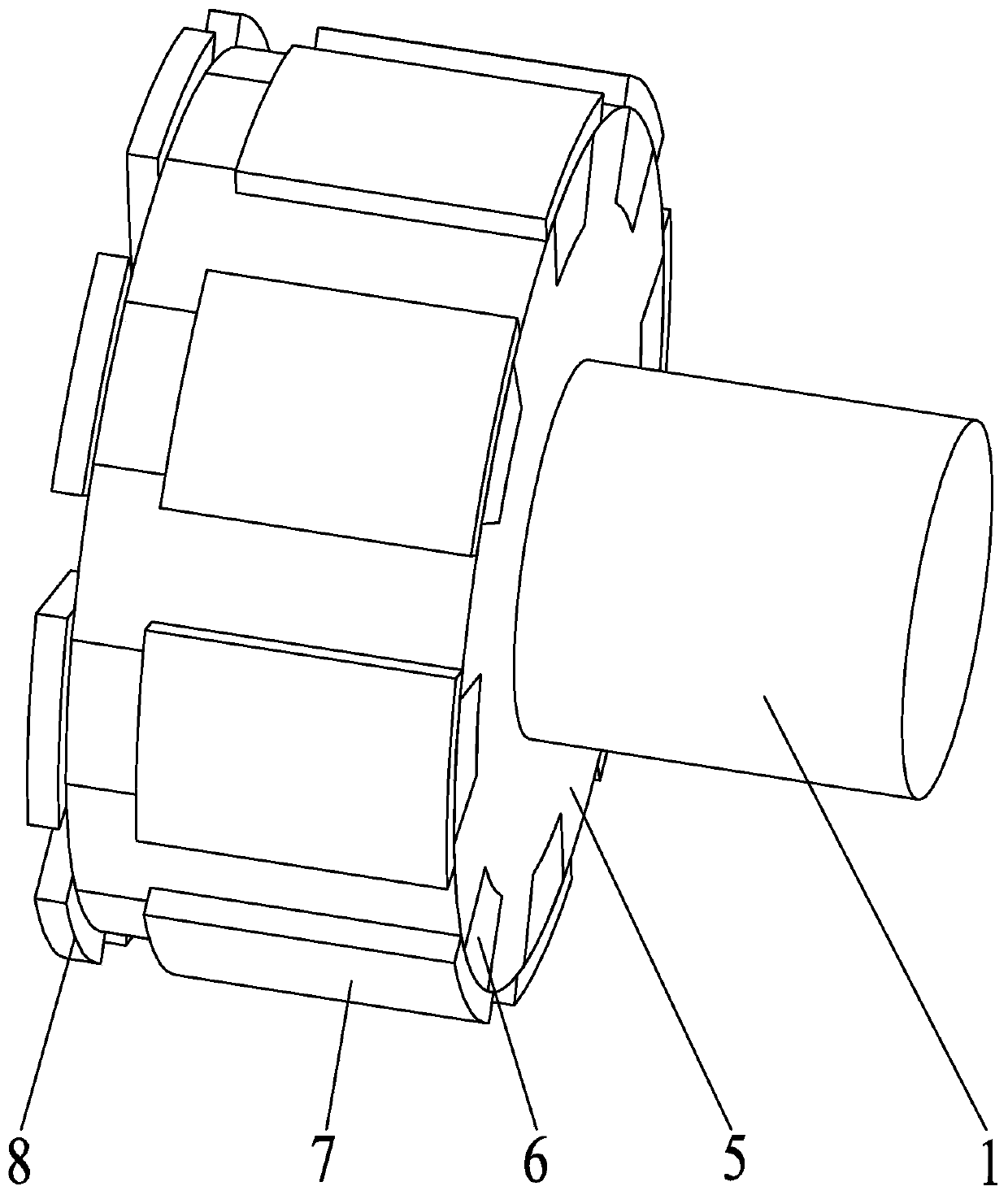

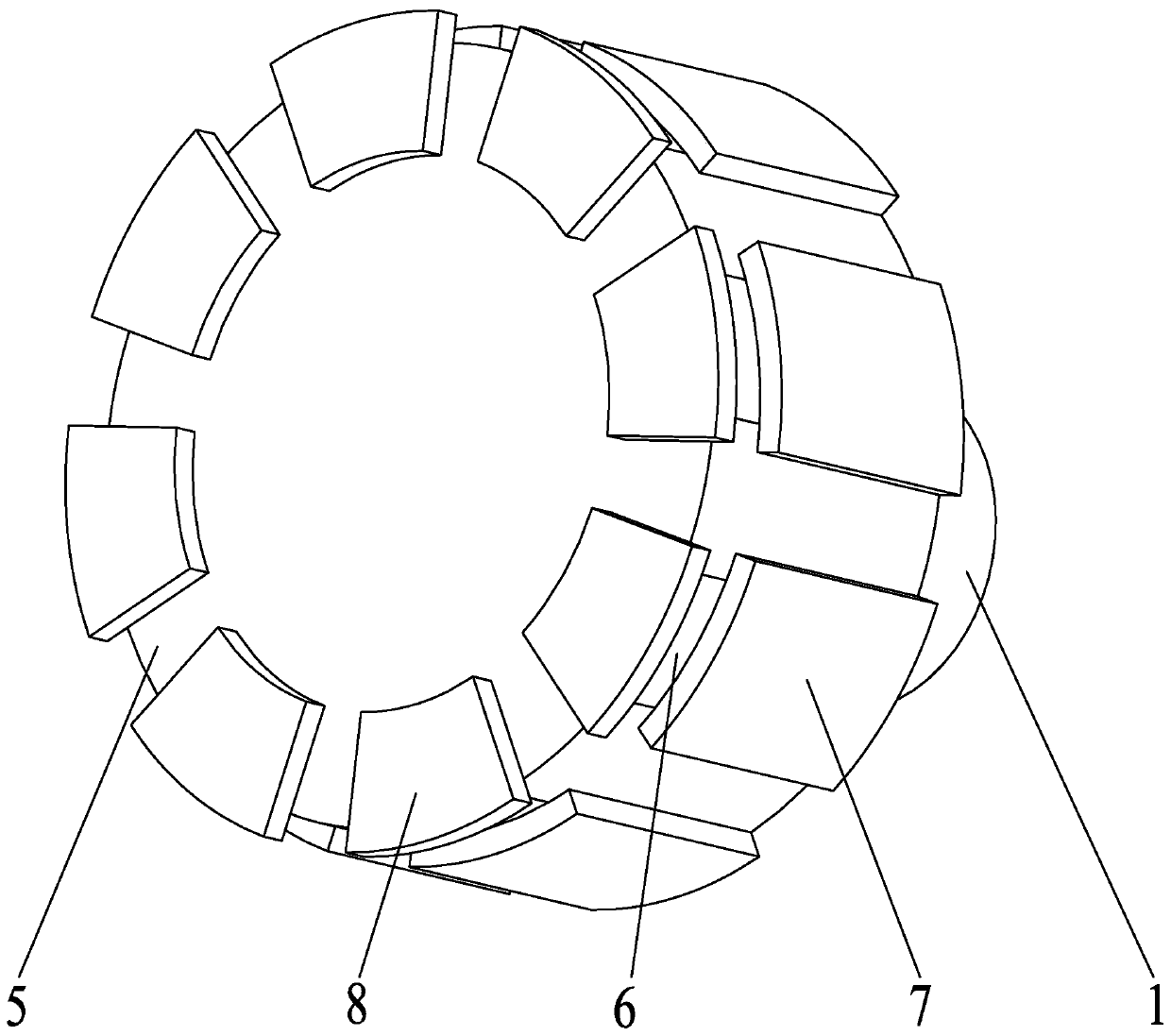

Hybrid coupling and assembling method thereof

ActiveCN111211663AIncrease forceSolve assembly difficultiesAsynchronous induction clutches/brakesManufacturing dynamo-electric machinesDrive shaftCoupling

The invention discloses a hybrid coupling and an assembling method thereof. The coupling comprises a driving disc and a driven disc. The driving disc comprises a connecting cylinder, back iron blocks,first magnetic rings and second magnetic rings. The driven disc comprises a connecting sleeve, a back iron disc, a back iron sleeve and third magnetic rings. The connecting cylinder is fixedly connected with a driving shaft. The back iron block is embedded into the connecting cylinder. The first magnetic rings are fixed to the connecting cylinder and cover the back iron blocks. The second magnetic rings are fixed to the end face of the connecting cylinder and connected with the back iron blocks. The connecting sleeve is fixedly connected with a driven shaft. An annular groove is formed in theconnecting sleeve. The back iron sleeve sleeves the connecting sleeve and is positioned in the annular groove. The connecting sleeve sleeves the connecting cylinder, so that the driving shaft and thedriven shaft are coaxially arranged. The third magnetic rings are distributed on the side, facing the second magnetic ring, of the back iron disc. The magnetic poles of every two adjacent third magnetic rings are arranged oppositely. The magnetic field intensity of the coupling is improved; the grooves and magnetic leakage amount of the coupling are reduced; collaboration is improved; the assembling difficulty of the coupling is reduced; a torque is increased through vortexes formed through speed changing; and combination is accelerated.

Owner:HEFEI UNIV OF TECH

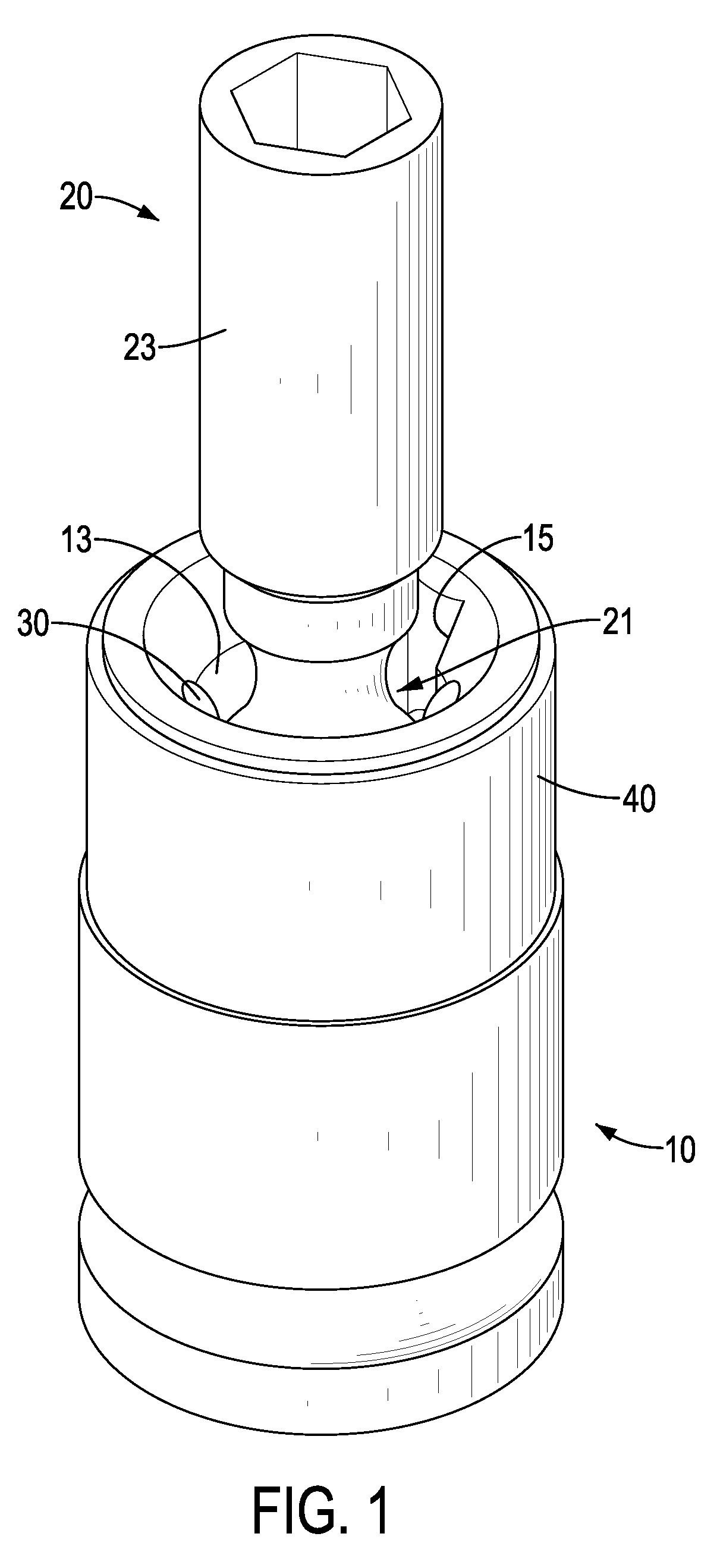

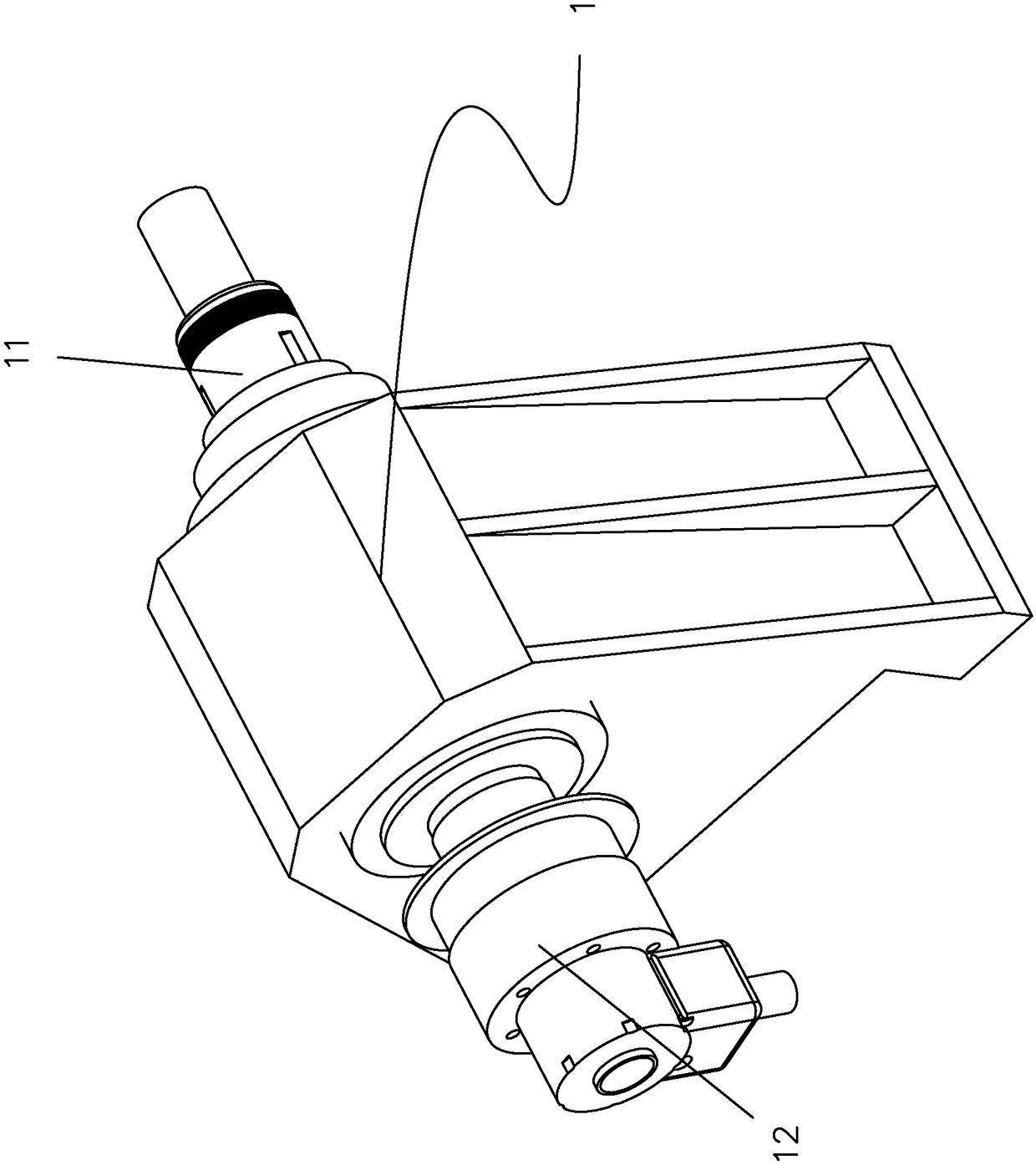

Universal joint socket

InactiveUS20190293112A1Reduce riskProne to damagePivotal connectionsPivotsBiomedical engineeringOperating life

A universal joint socket has a socket unit, a joint unit, multiple balls, and a collar. The socket unit has a cavity, multiple grooves and multiple ball holes. The joint unit has a spherical joint, and a pin inserted in the spherical joint. The spherical joint is placed inside the cavity of the socket unit with an elastic element inside for supporting the spherical joint, and two ends of the pin are located respectively on the grooves of the socket unit. The balls are respectively disposed in the ball holes of the socket unit for positioning the spherical joint. The collar is mounted around the peripheral wall of the socket unit and closes openings of the ball holes of the socket unit. The universal joint socket has a long operating life and can provide a large torque.

Owner:TSAI JHIH SHENG

Hybrid-structure assembly support

An assembly support with hybrid structure for front ends of passenger vehicles and light trucks includes an upper cross member (1), a lateral member (2) attached to it from below with a flange plate (3) for connection with the face ends of vehicle longitudinal members and a lower cross member (4) connecting the lower sections (2.1) of these lateral members (2). In order to reinforce the assembly support in the area of the lower cross member (4), the lower cross member (4) consists of a shell body (5) with a flange (5.1) running along its edge and projecting outward, and of a sealing part (6) whose edge area overlaps it. The shell body (5) and the sealing part (6) are made of a stiff material, whereby the flange (5.1) and edge areas (6.1) of the above-mentioned components are surrounded by injected plastic used for the hybrid structure, and are thus bound together with the lateral members (2).

Owner:HBPO

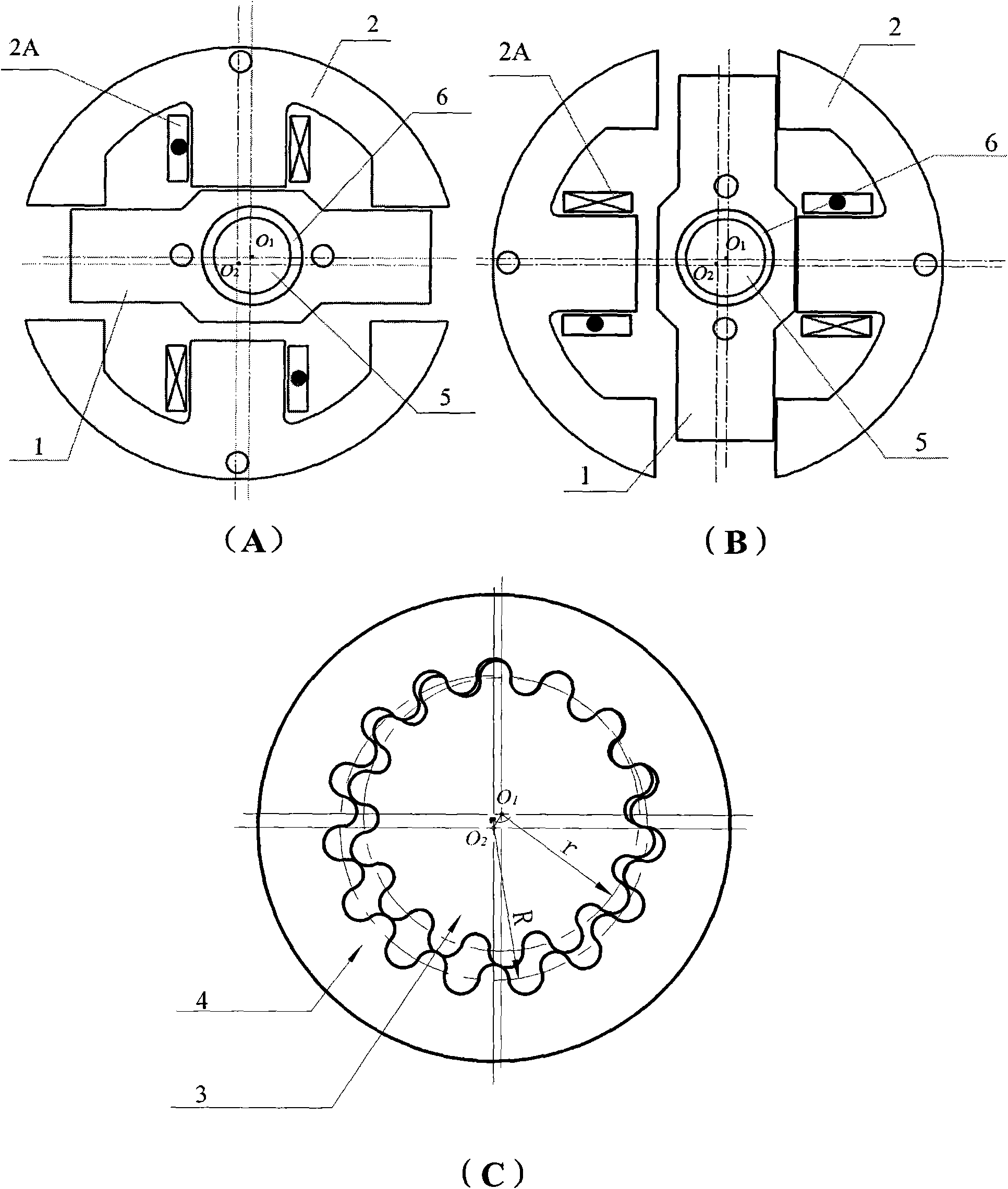

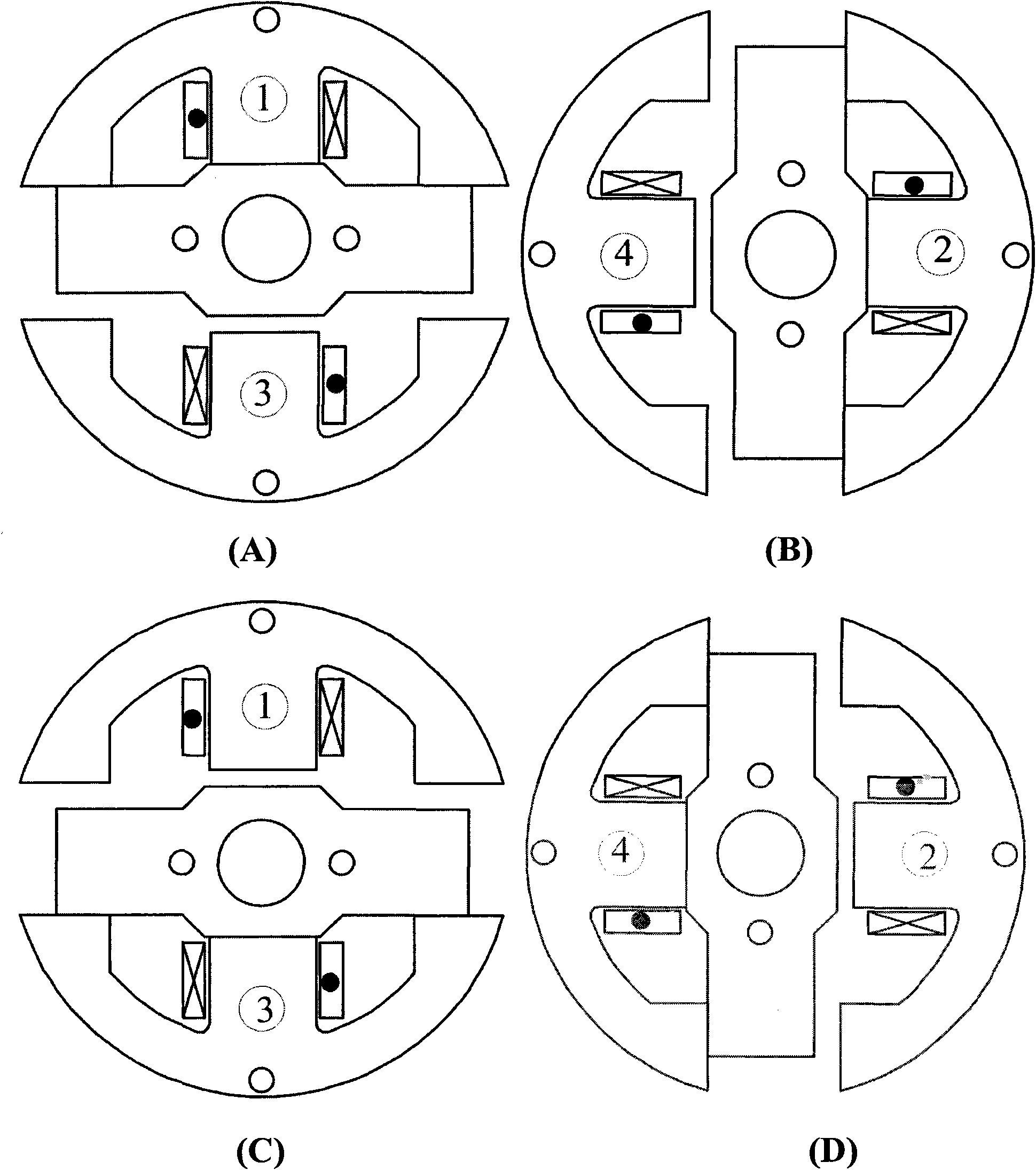

Translational gearing motor with improved structure

InactiveCN101662181AReduce output torqueAvoid Magnetic Circuit CouplingMechanical energy handlingWork statusRevolute joint

A translational gearing motor with improved structure is a low-speed large-torque motor integrating a motor with a speed reducer. 4 sets of magnetic poles are arranged in the axial direction, each setof magnetic poles consists of a rotor in the middle and stators at two sides, a coil winding is arranged on the stator, and after being electrified, the winding drives the rotor to move left and right so as to form a unidirectional drive magnetic pole. The four sets of magnetic poles are divided into two pairs with the installation directions vertically intersecting. A slide bush and a main shaftof a through hole in the middle of the rotor form a slide revolute joint and the main shaft is connected with a cycloid external gear through a connecting key. By controlling the working status of the windings of the four sets of magnetic poles, the rotor can be driven to drive the main shaft to generate translation of revolution mode in radial direction and to drive the cycloid external gear anda cycloid annular gear fixed on a machine shell to do gearing motion. According to theory of engagement, the cycloid external gear drives the main shaft to output low-speed large-torque motion. The motor is characterized by not only improving the winding fill rate of a single magnetic pole, but also reducing the control difficulty of magnetic field force of distributed windings by arranging a plurality of unidirectional drive magnetic poles in axial direction.

Owner:无锡威而纳电机有限公司

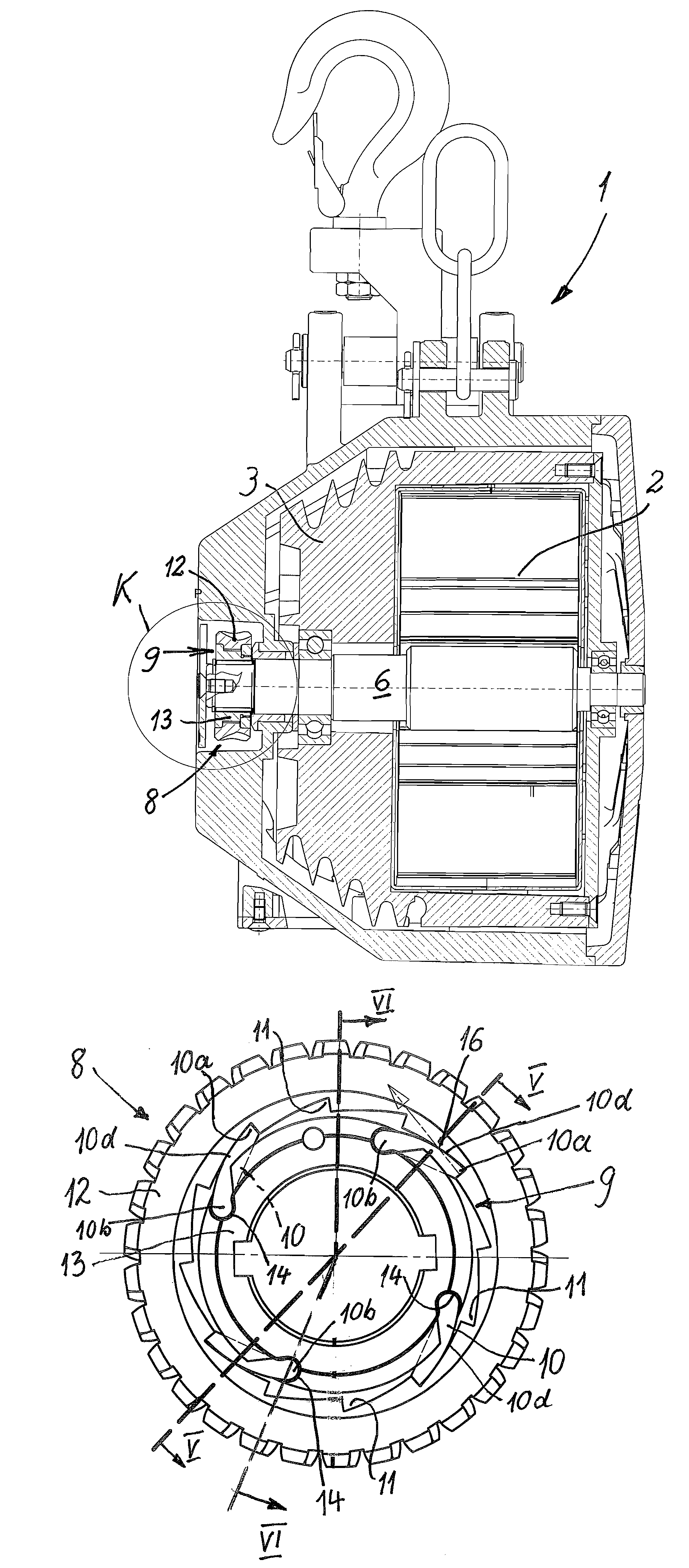

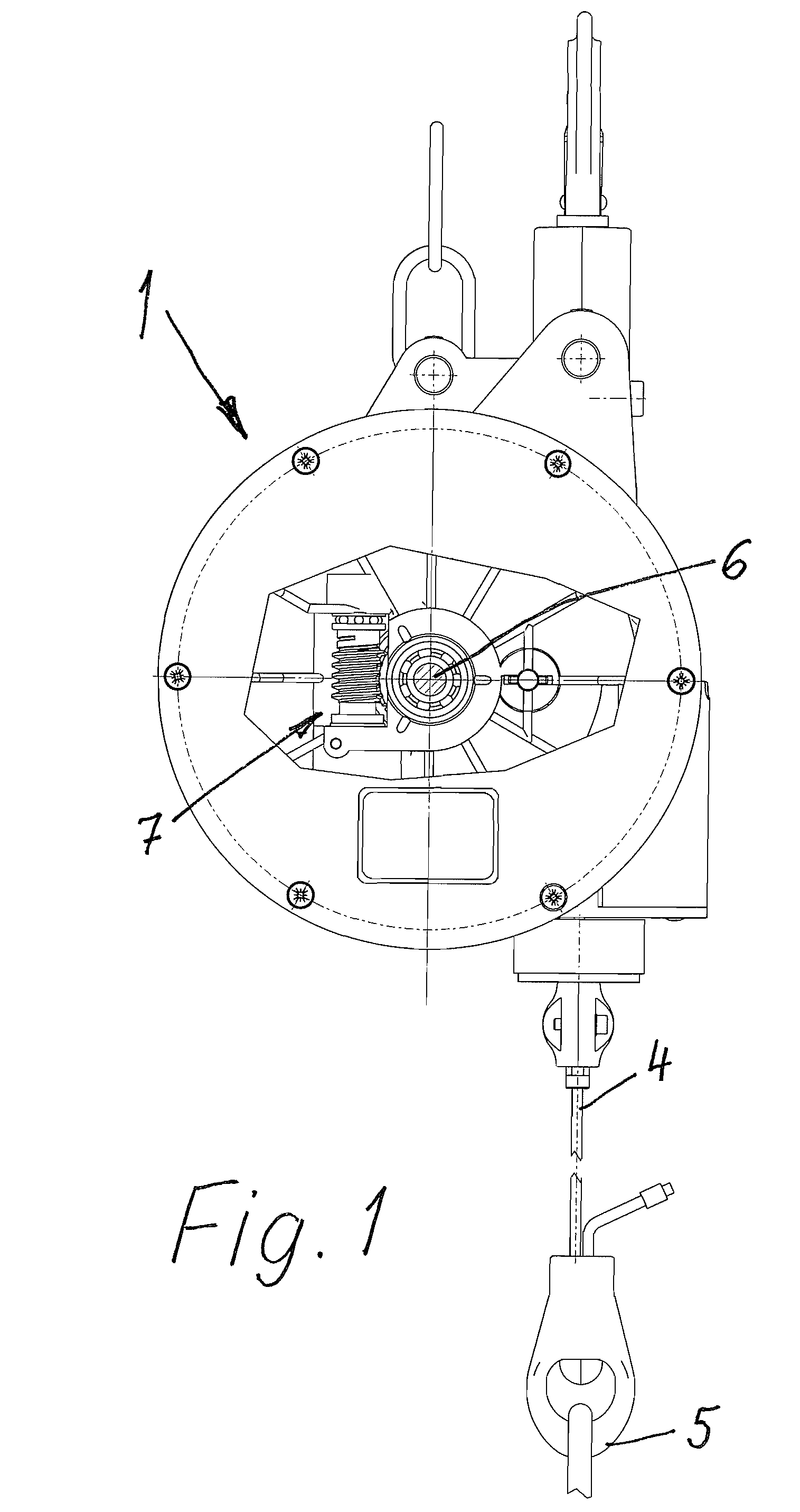

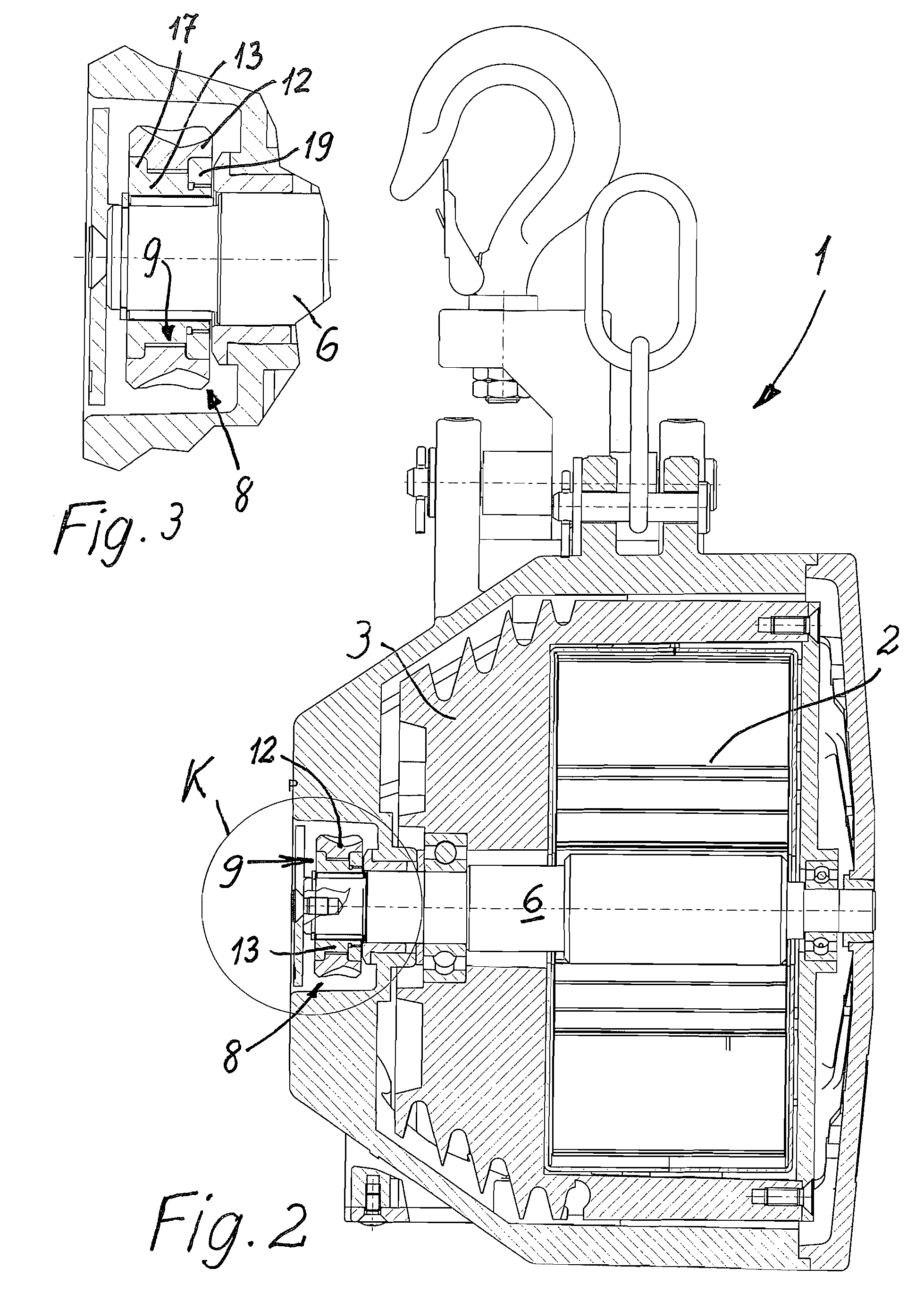

Device for compensating the weight of a suspended load

ActiveUS7424997B2Transfer strongLow production costWork benchesWinding mechanismsFreewheelPull force

A device (1) that compensates the weight of a suspended load, for example a tool or welding tongs, is provided as a spring tensioner with at least one barrel (4) or supporting wire that can be reeled off a barrel (3) against the force of a spring (2). The barrel (3) is supported on a shaft (6), to which the spring (2) engages directly with its interior end or via a sheath connected to the shaft (6), while the opposite exterior end of the spring (2) is mounted to the barrel (3) at the inside. A shaft drive (7) can be activated to change the pull force at the spring (2) via the shaft (6). The spring (2) is connected to the shaft drive (7) or to a drive wheel (8) allocated thereto via a freewheel. The freewheel is embodied with a catching latch arrangement (9) which, in the blocking direction has at least three or four latches (10) that simultaneously engage the recesses or catching recesses (11) which receive them, said latches being arranged at the inside at a circular drive wheel (12) allocated to a drive wheel (8). An interior body (13) of the catching latch arrangement located inside the circular drive wheel (12) supports the latches (10) and is simultaneously a part of a slide bearing for the circular drive wheel (12) for rotation in the freewheel direction. In this way, in a small space strong forces can be transferred.

Owner:CARL STAHL KROMER

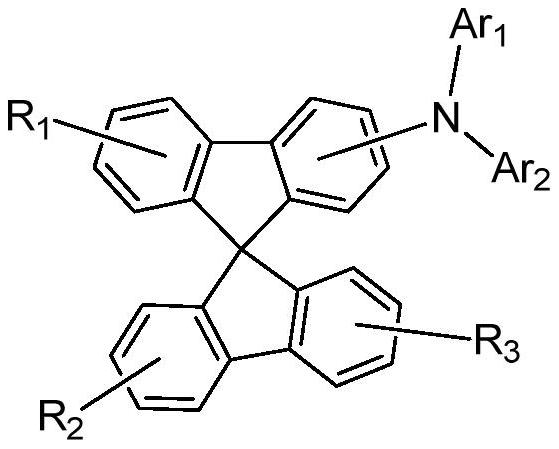

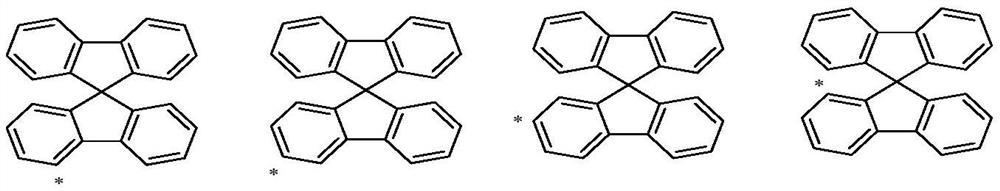

Spirobifluorene organic electroluminescent compound and organic electroluminescent device

ActiveCN112010760AUnique optoelectronic propertiesLower HOMO levelOrganic chemistrySolid-state devicesPhysical chemistryOrganic electroluminescence

The invention discloses a spirobifluorene organic electroluminescent compound and an organic electroluminescent device. The structural formula of the spirobifluorene organic electroluminescent compound is shown as a formula I, the compound can be used as an organic electroluminescent material. Compared with the techniques in the prior art, the planarity of material molecules is reduced so that theuse effect and the use range of the material can be effectively improved; the increase of the molecular torque and degree of freedom of the material effectively improves the hole transport capabilityof the material, and adjusts the HOMO energy level of the hole transport material, thereby greatly reducing the driving voltage of the organic electroluminescent device, effectively reducing the energy consumption, and greatly prolonging the service life of the organic electroluminescent device.

Owner:NANJING TOPTO MATERIALS CO LTD

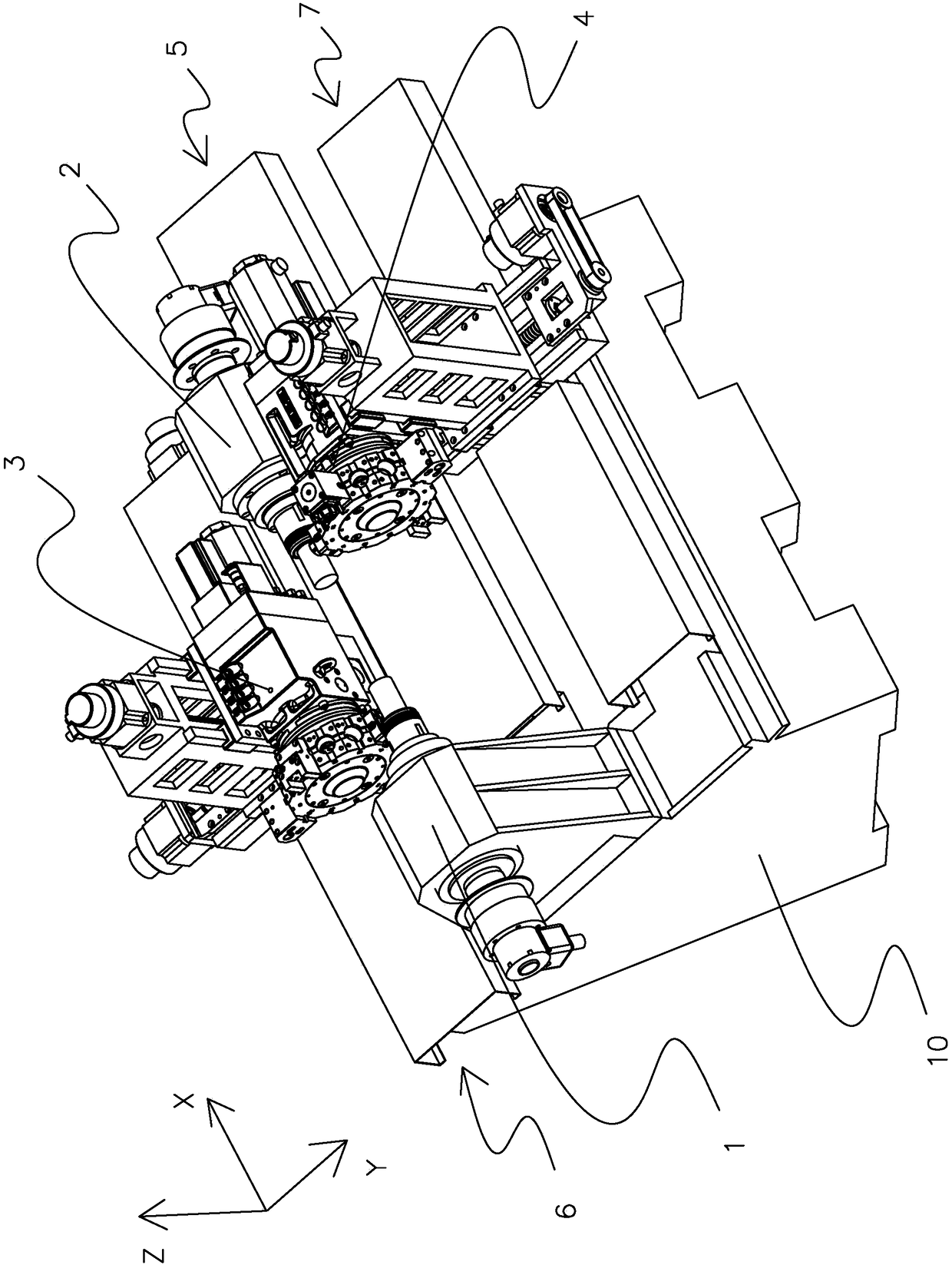

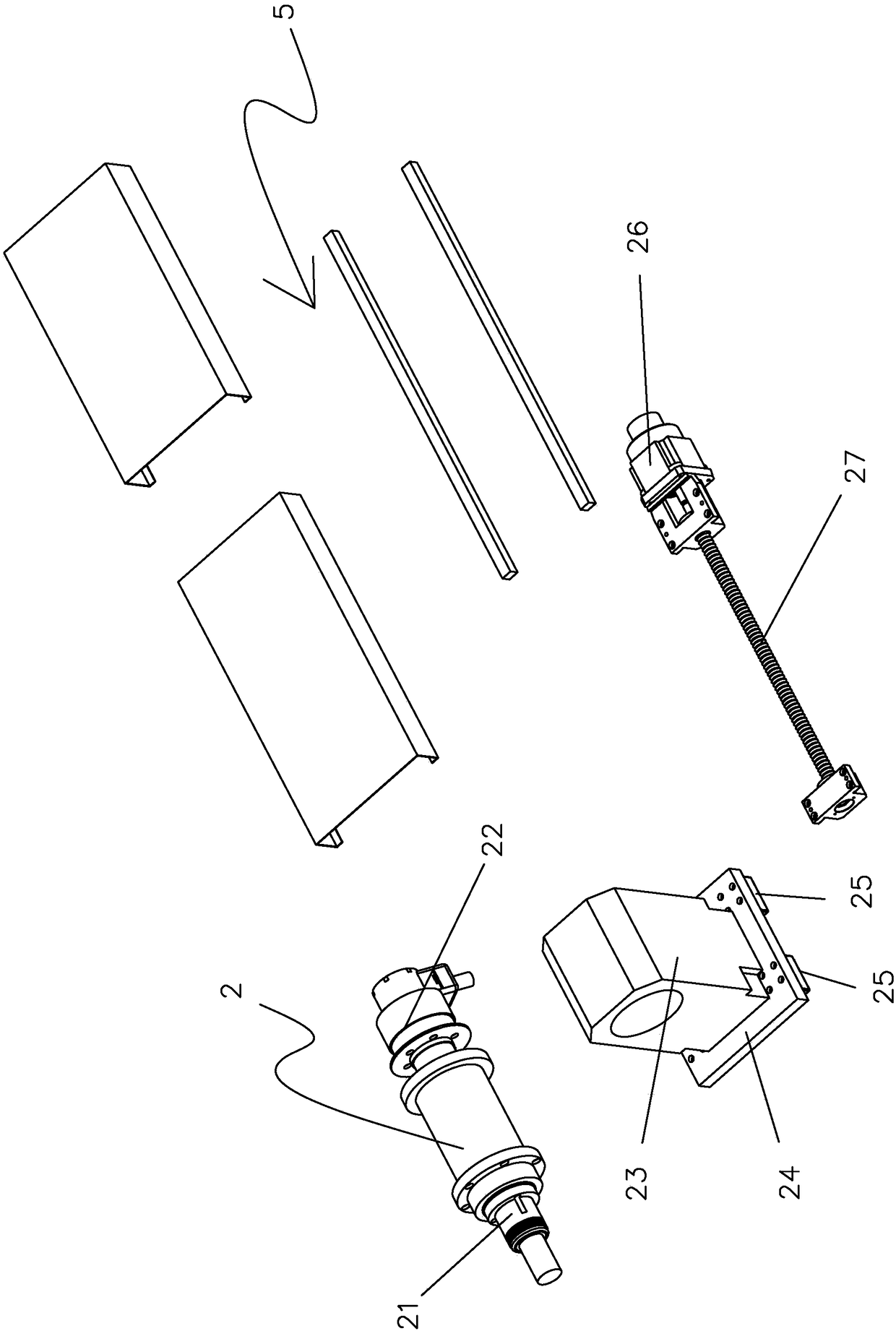

Double-spindle turn-milling compound numerical control machine

PendingCN108555695APowerfulImprove processing efficiencyMetal working apparatusNumerical controlEngineering

The invention provides a double-spindle turn-milling compound numerical control machine capable of significantly improving processing efficiency. The machine comprises a machine base, a first spindle,a second spindle, a first knife tower and a second knife tower, the first spindle is arranged on the machine base, a first clamping sleeve is arranged at the output end of the first spindle, and a first driving oil cylinder used for driving the first clamping sleeve to be loosened or tightened is arranged at the other end of the first spindle; the second spindle is arranged on the base, a secondclamping sleeve is arranged at the output end of the second spindle, a second driving oil cylinder used for driving the second clamping sleeve to be tightened or loosened is arranged at the other endof the second spindle, and the second spindle can slide to reach the first spindle along the machine base so that the first and second clamping sleeves can clamp workpieces of each other; the first knife tower is arranged on one side of the first spindle and can process the workpiece on the first or second spindle; the second knife tower is arranged on the other side of the first spindle and can process the workpiece on the second spindle or the first spindle.

Owner:中山市洪泉数控设备有限公司

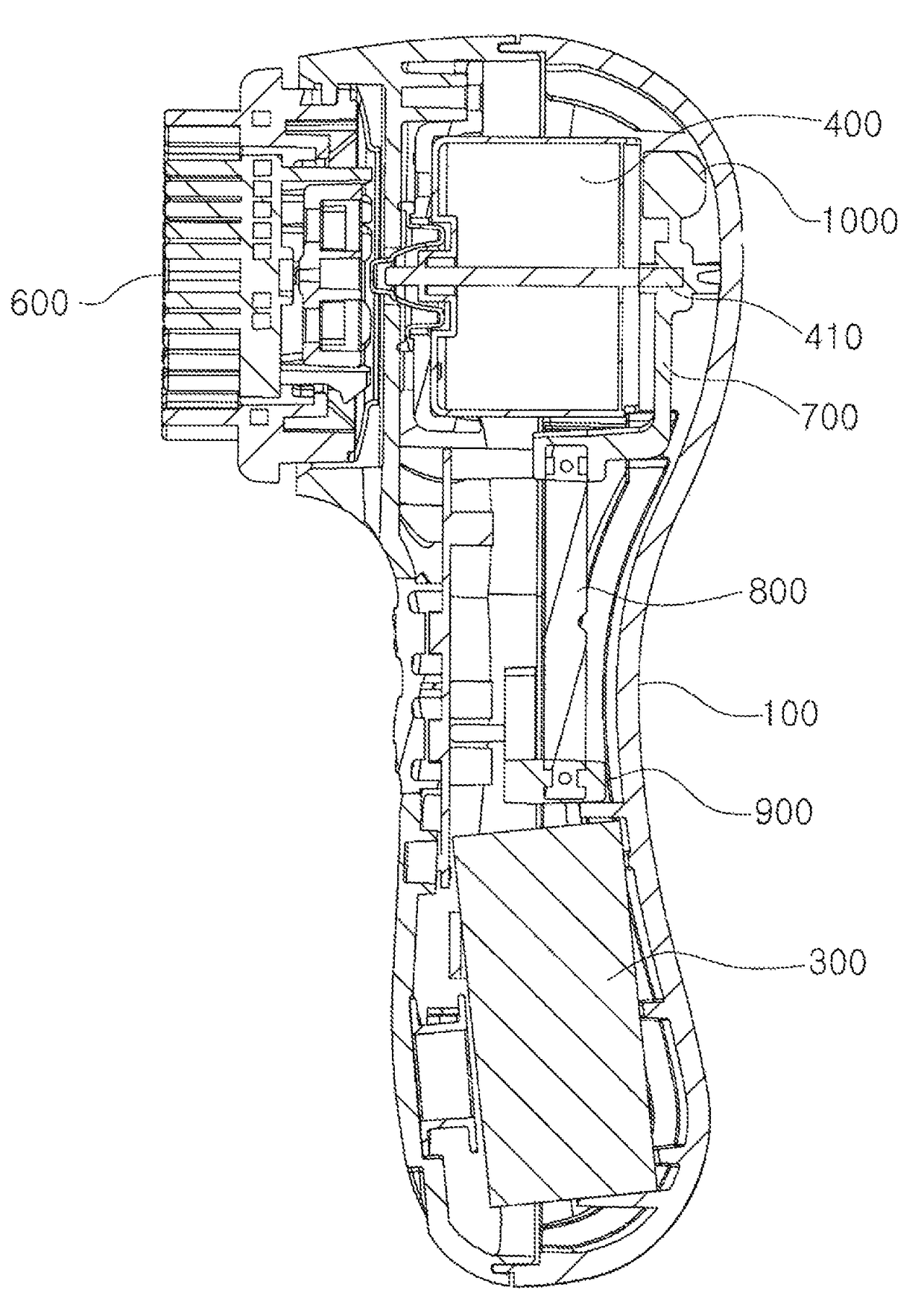

Facial cleansing apparatus using electric motor and spring, control method therefor, and recording medium recording program for performing control method

InactiveUS9717376B2Easy to cleanStrong torqueElectronic commutation motor controlAC motor controlExecution controlElectric signal

An apparatus for washing skin uses a brushless electric motor and a spring. The apparatus may include a case; an operation unit installed outside the case; a power supply unit installed at one end inside the case; the brushless electric motor installed inside the case; a control unit to output an electric signal; a face-washing brush fitted with a shaft of the brushless electric motor to be rotated forward and reverse as the brushless electric motor is operated; a holder and a spring.

Owner:AMOREPACIFIC CORP +1

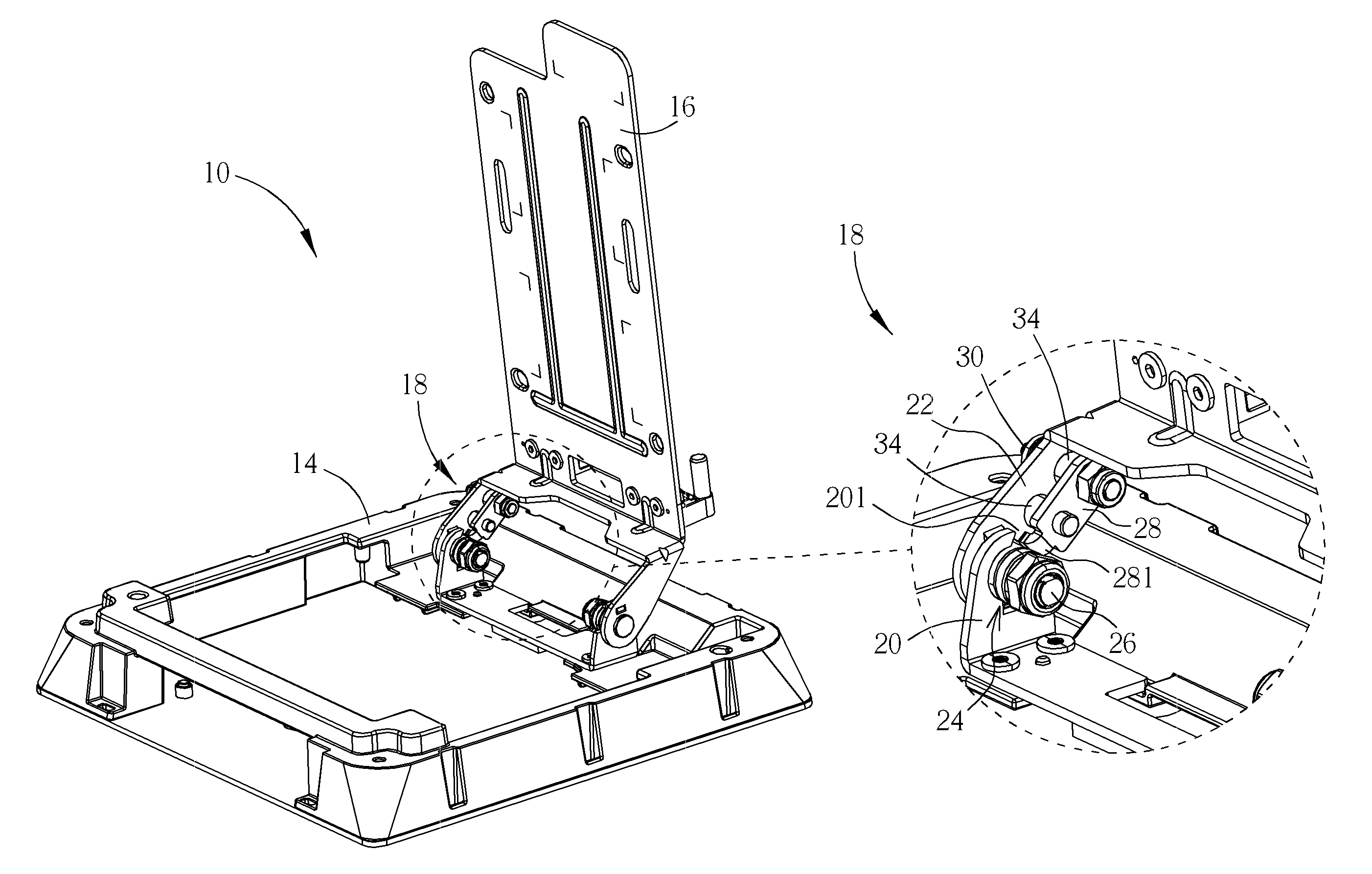

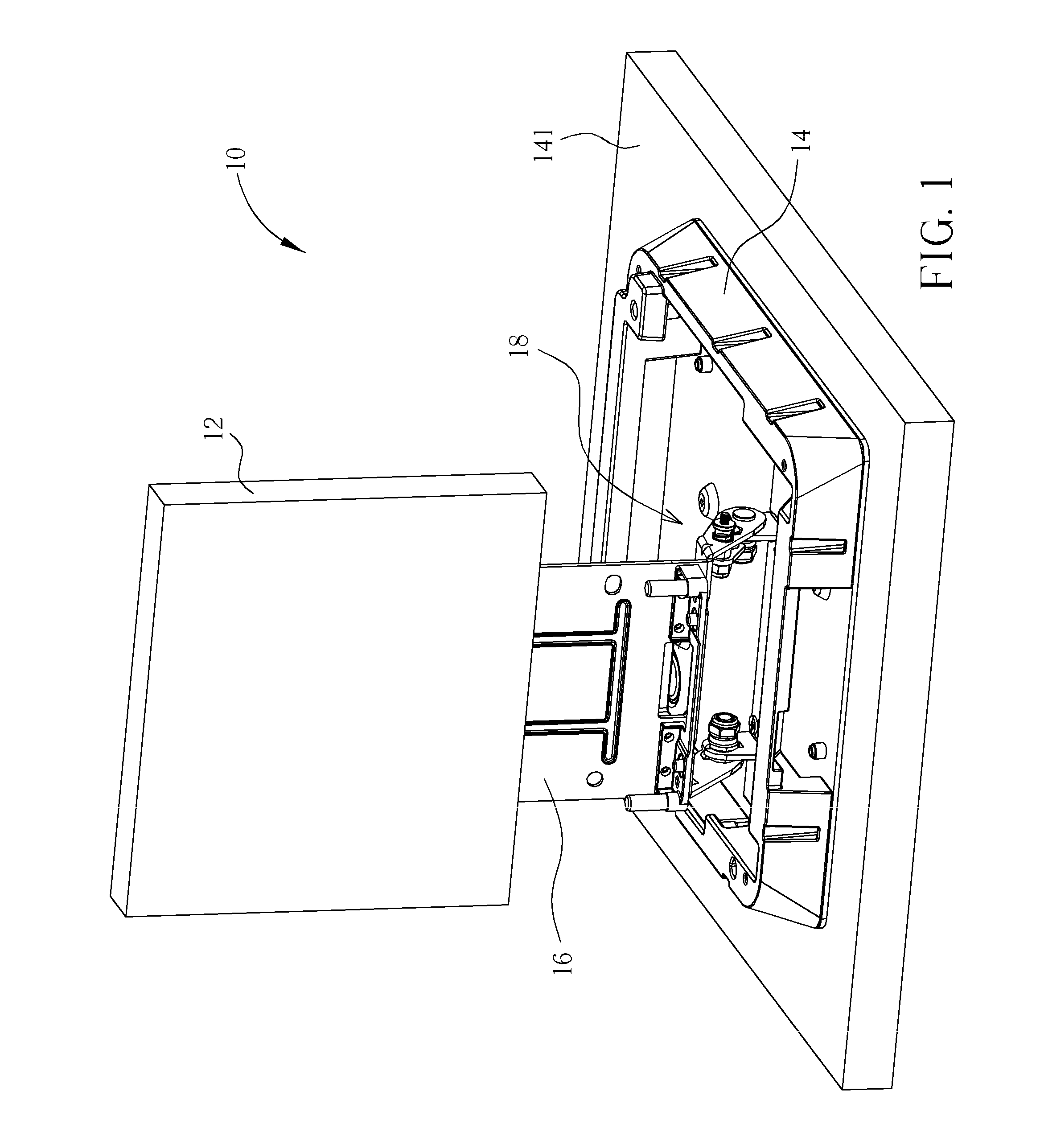

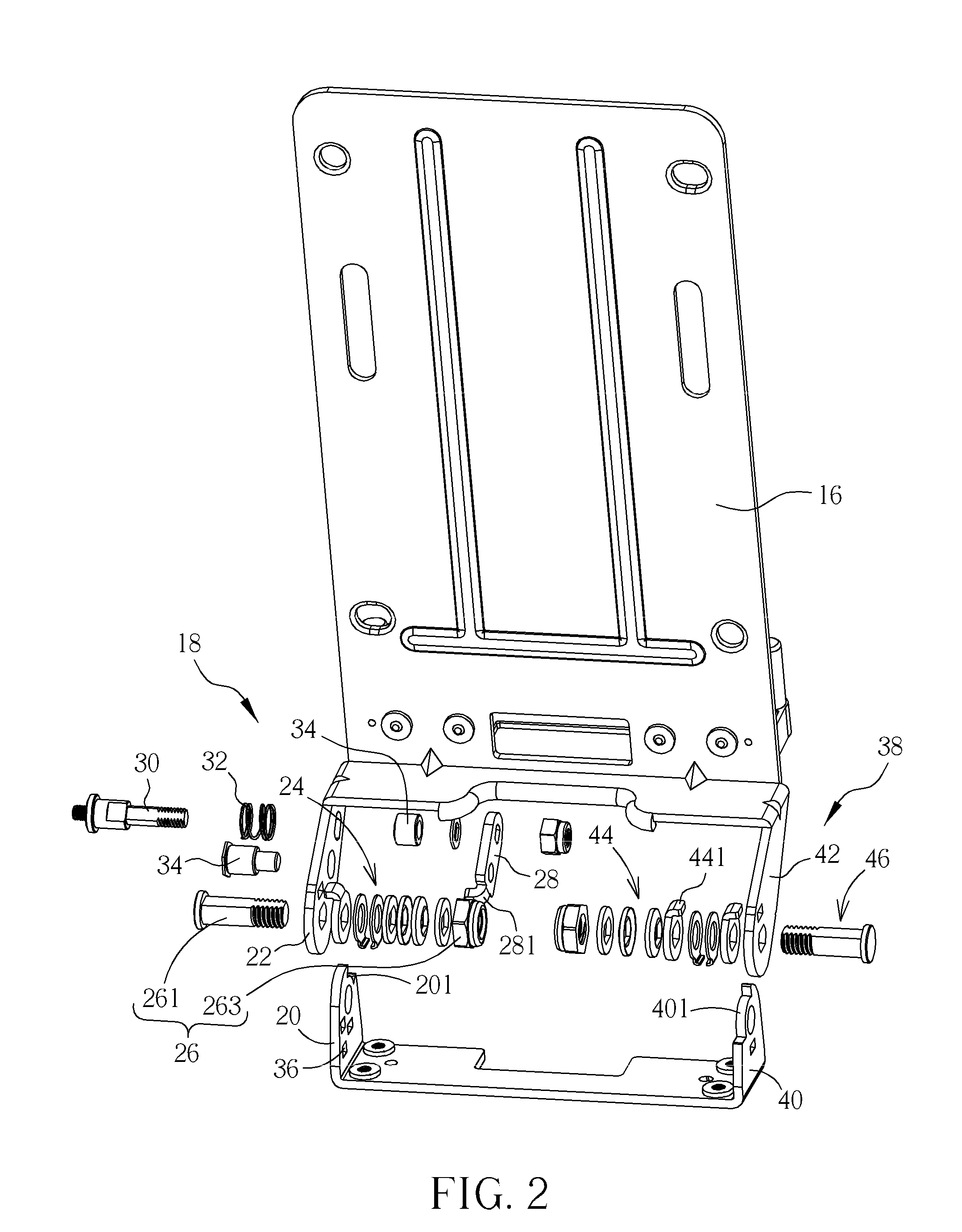

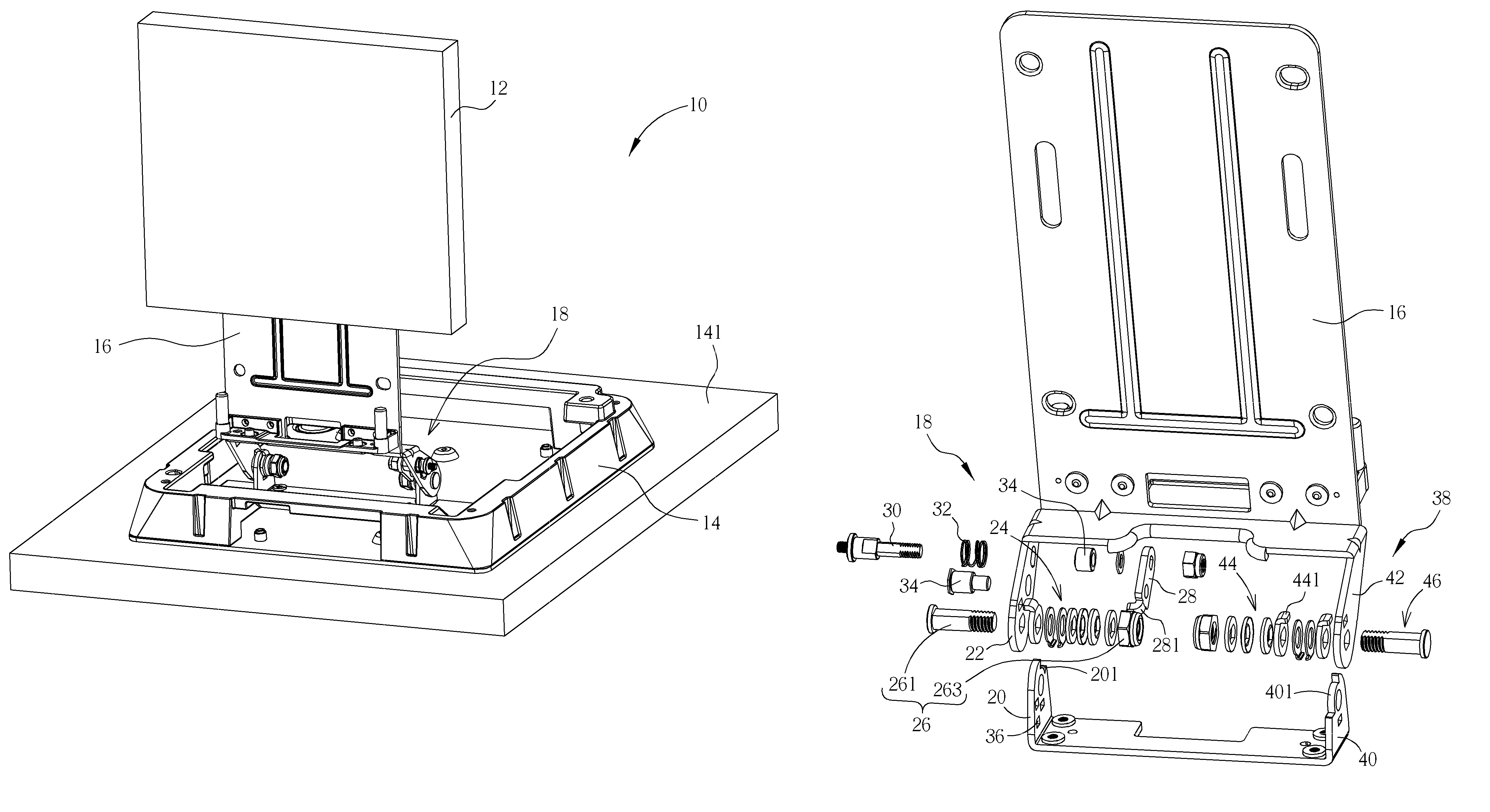

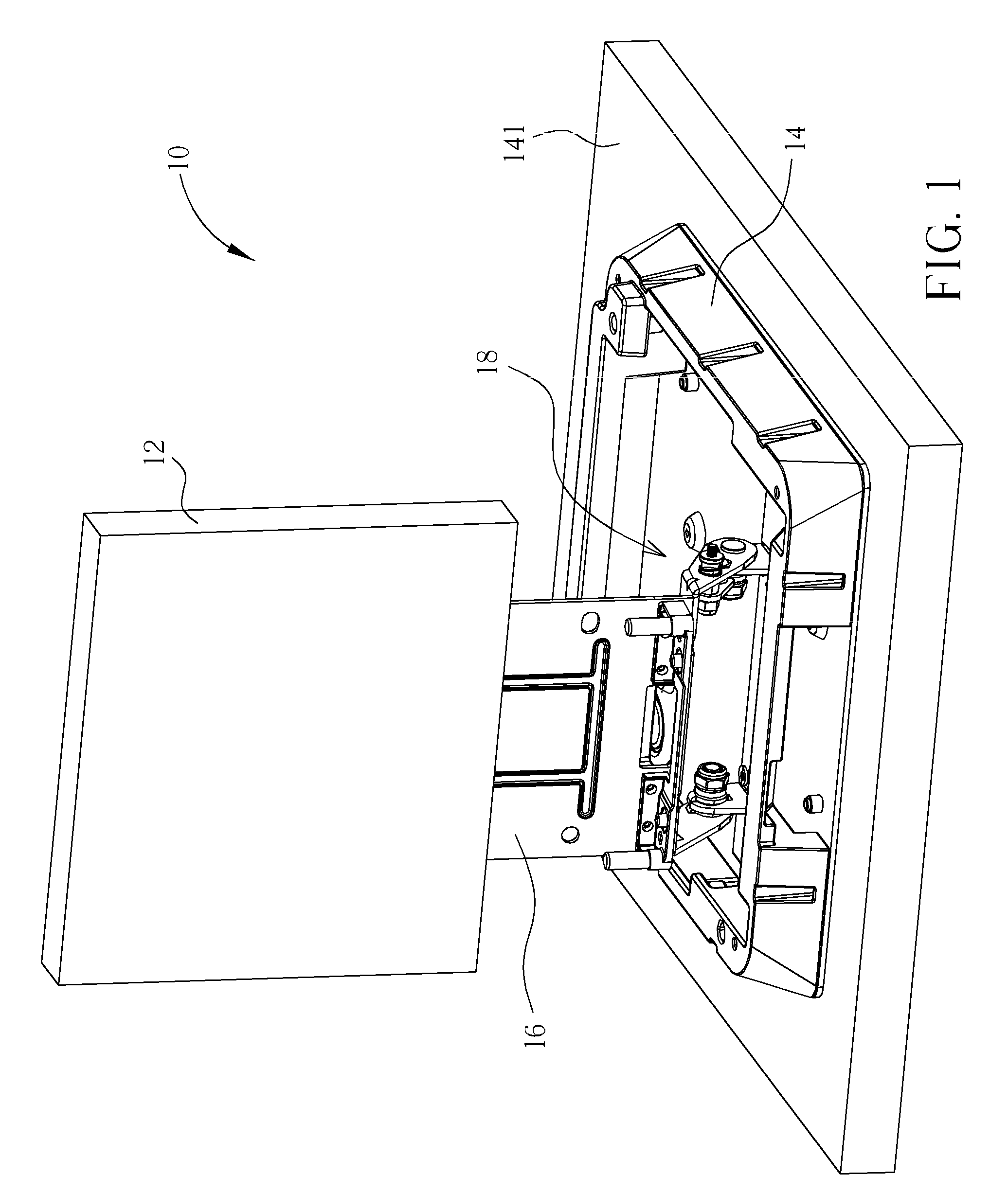

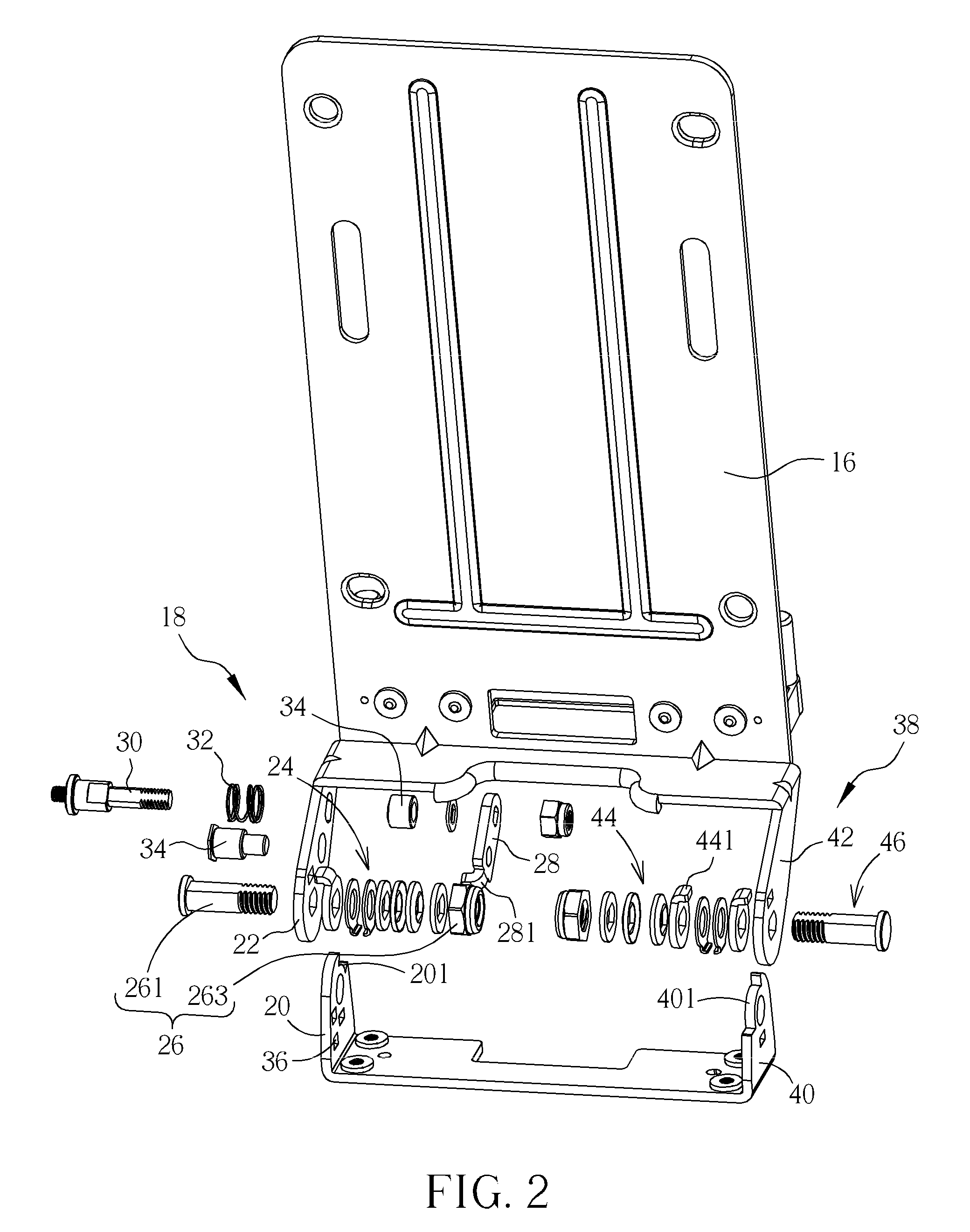

Panel positioning mechanism and display device with different positioning modes

ActiveUS8308113B2Low costStrong torqueDigital data processing detailsStands/trestlesDisplay deviceEngineering

Owner:WISTRON CORP

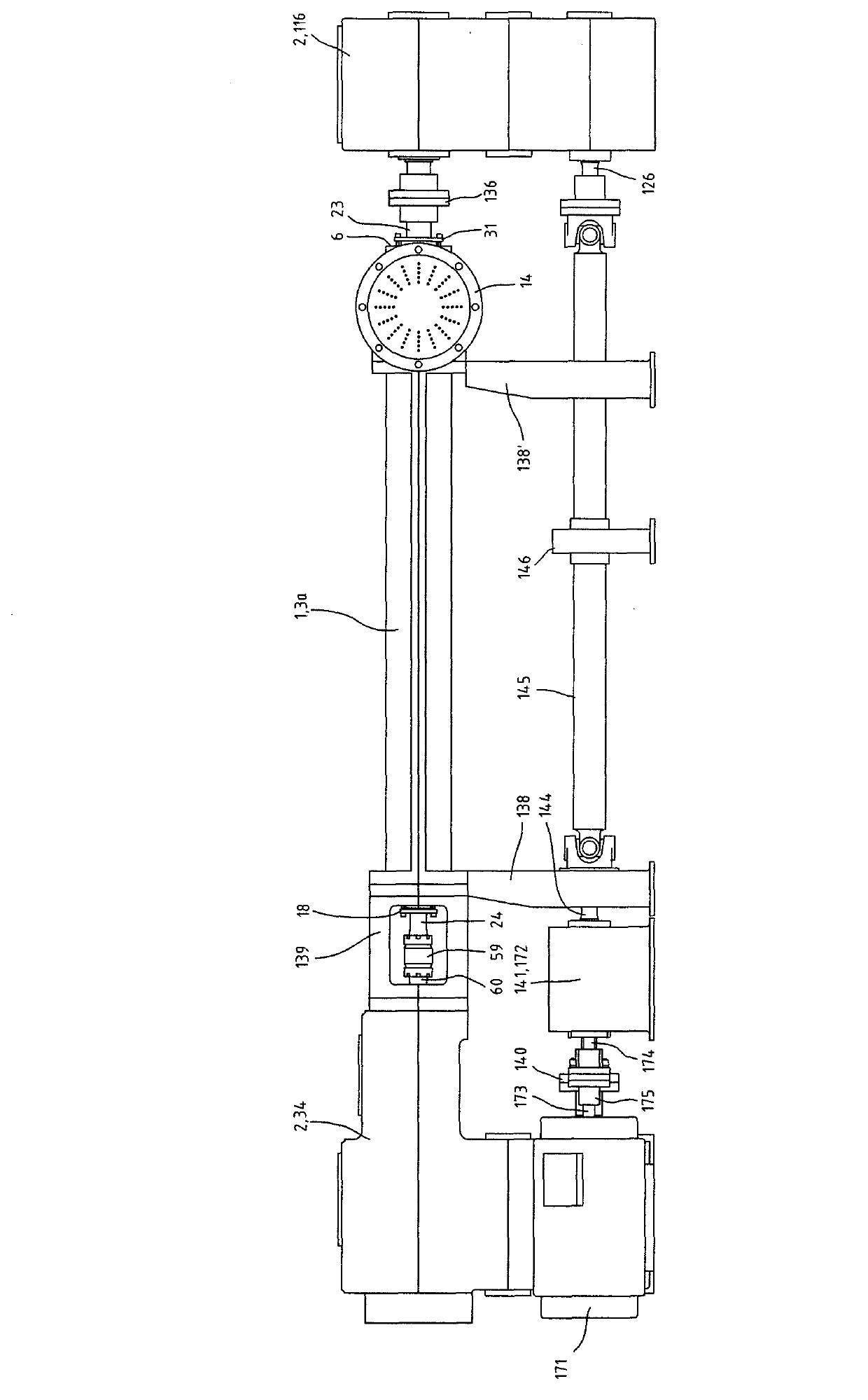

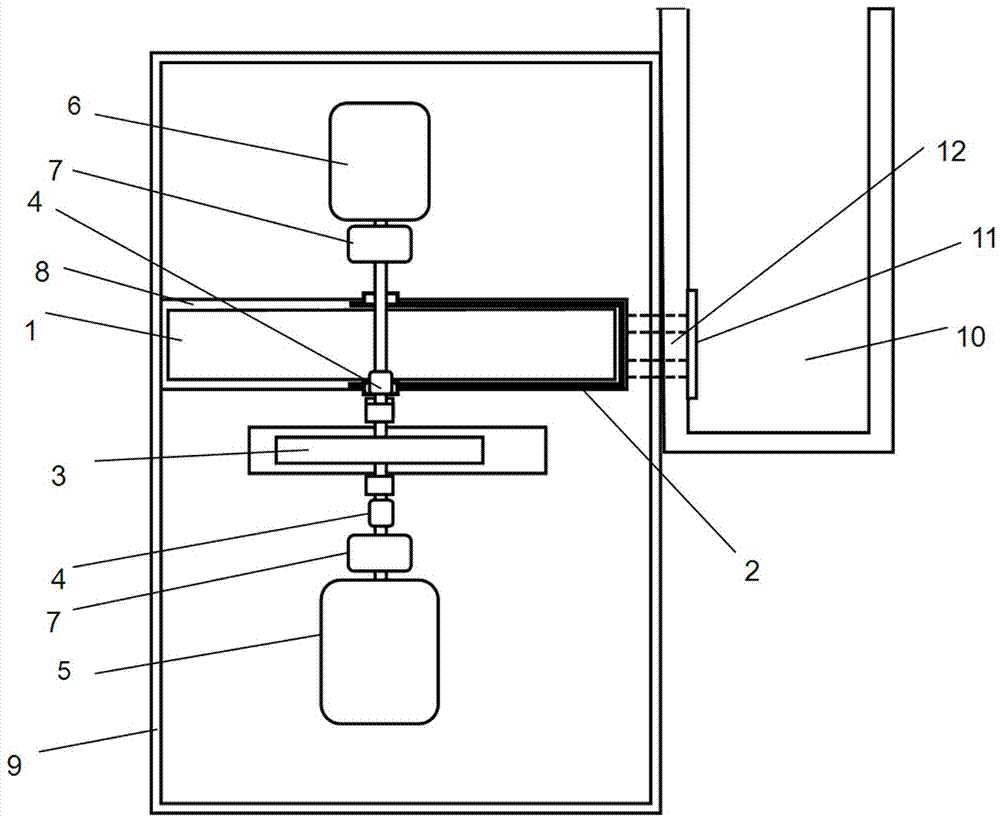

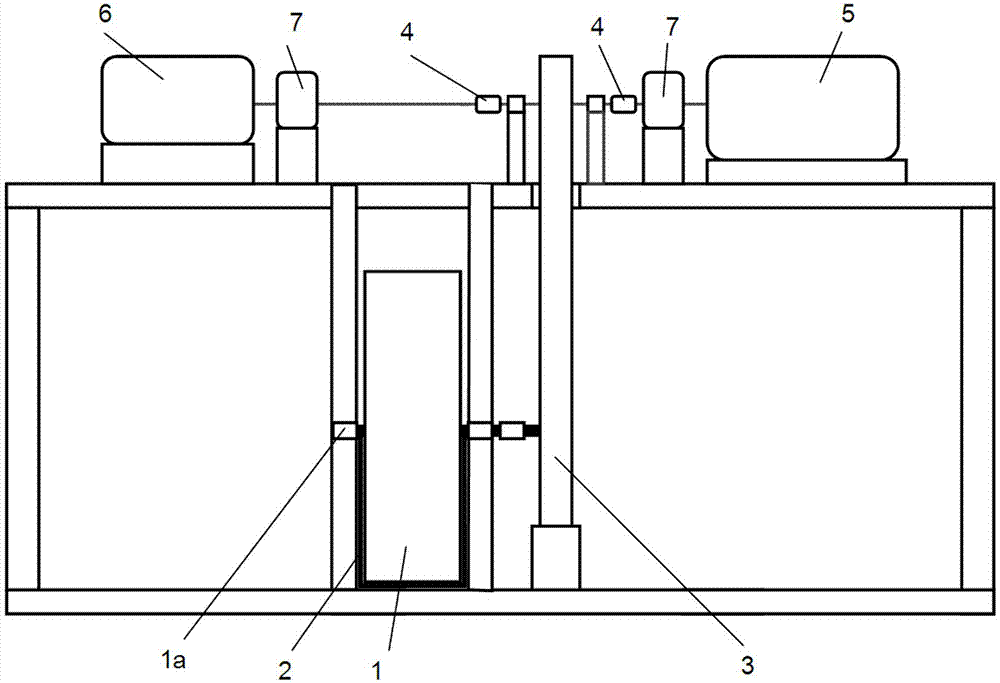

Water wheel-shaped washdown type hydraulic turbine generator set

InactiveCN104747354ASmooth rotationGuaranteed uptimeEngine componentsImpulse enginesImpellerWater wheel

The invention discloses a water wheel-shaped washdown type hydraulic turbine generator set. The water wheel-shaped washdown type hydraulic turbine generator set comprises a metal water wheel (1), a metal water wheel groove (2), a transmission case (3), a large capacity generator set (5) and a small capacity generator set (6), wherein the metal water wheel (1) is capable of rotating along a center rotary shaft (1a), the metal water wheel groove (2) leads water flow to the blades of a metal water wheel impeller (1b) of the metal water wheel, the transmission case (3) is connected to the outer end of the metal water wheel center rotary shaft, and the large capacity generator set (5) and the small capacity generator set (6) are connected to the two ends of an output shaft of the transmission case through a coupling (4) respectively. The water wheel-shaped washdown type hydraulic turbine generator set can efficiently use water energy, and the generating efficiency is high.

Owner:贵州道轮水电科技开发有限公司

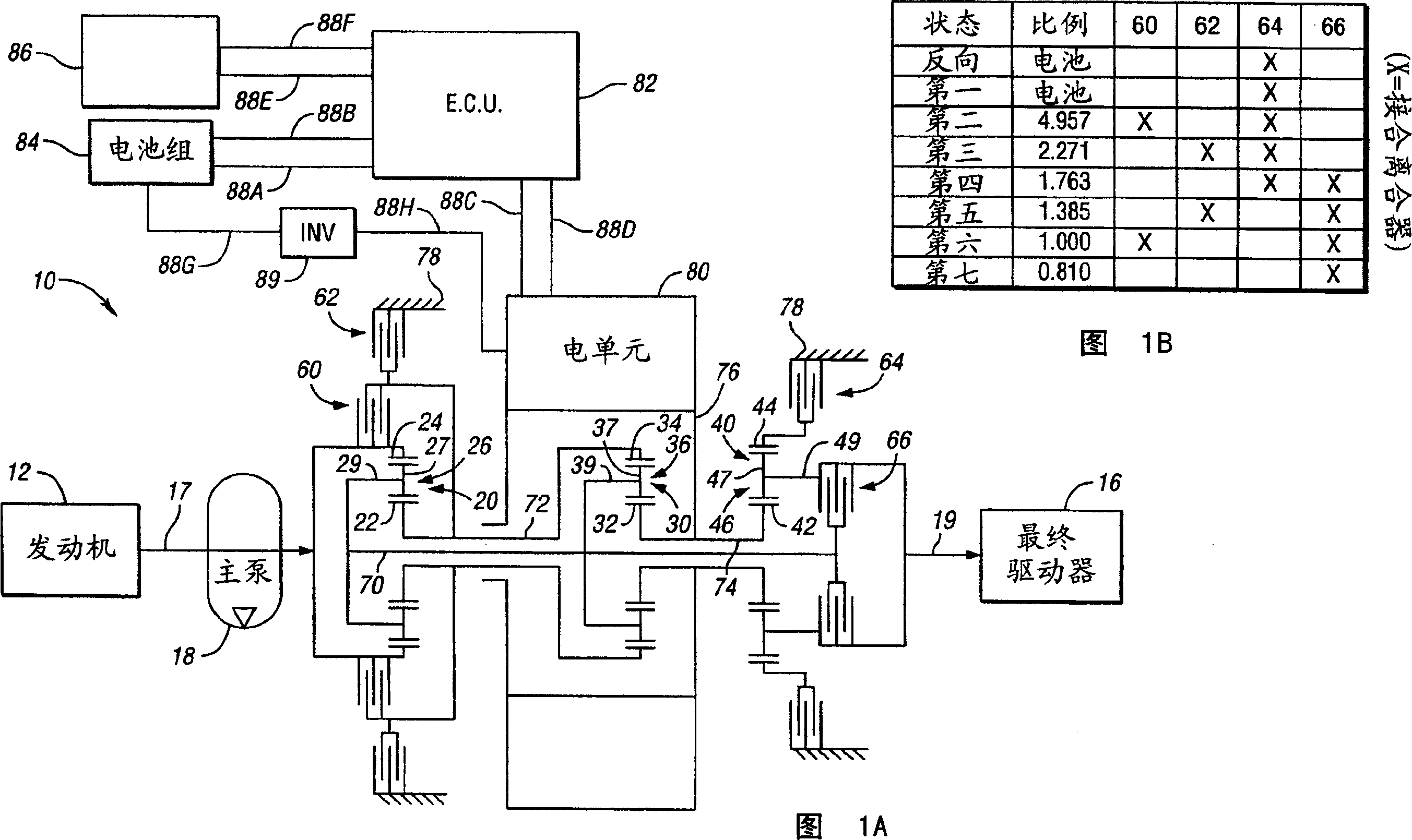

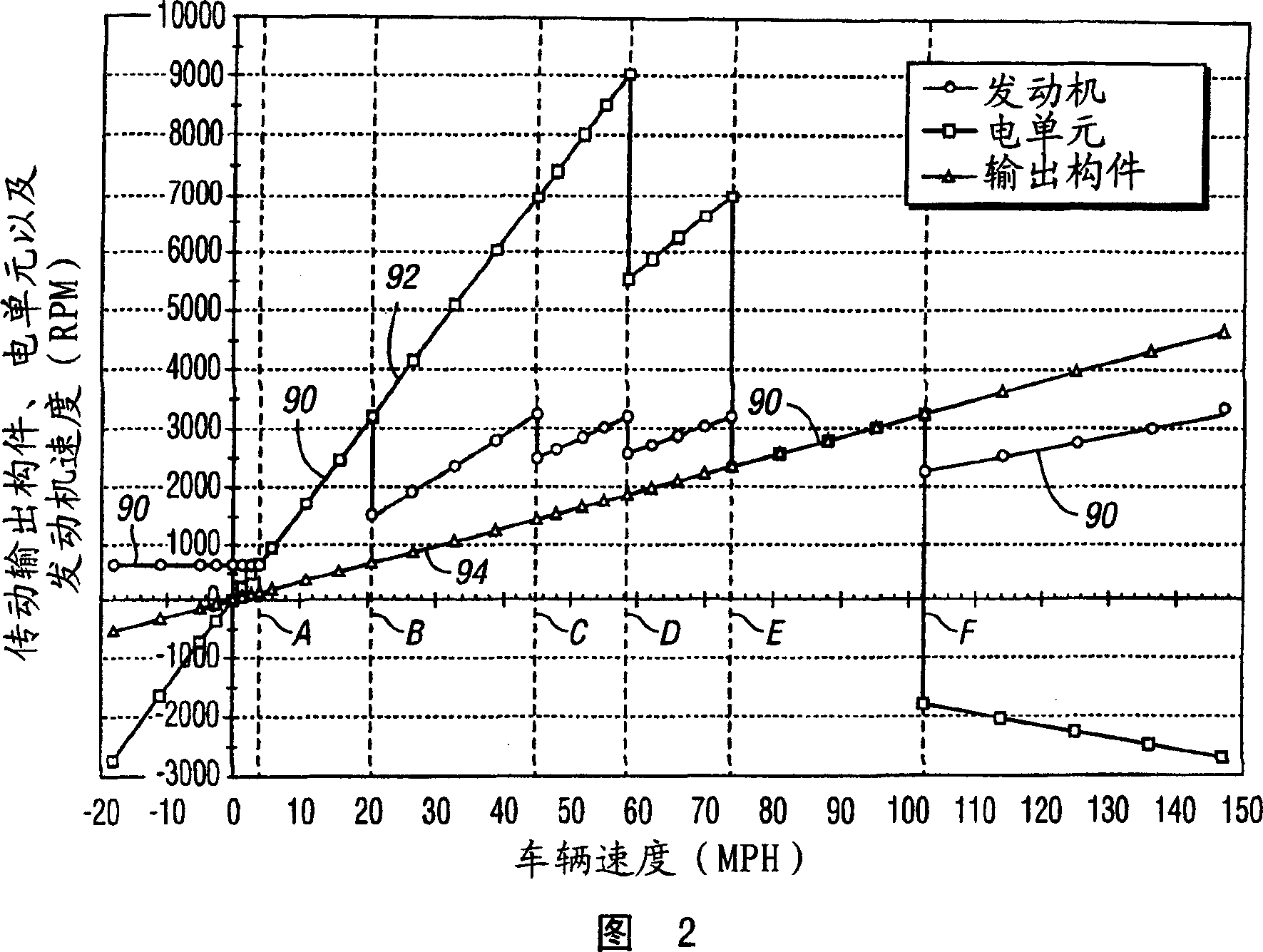

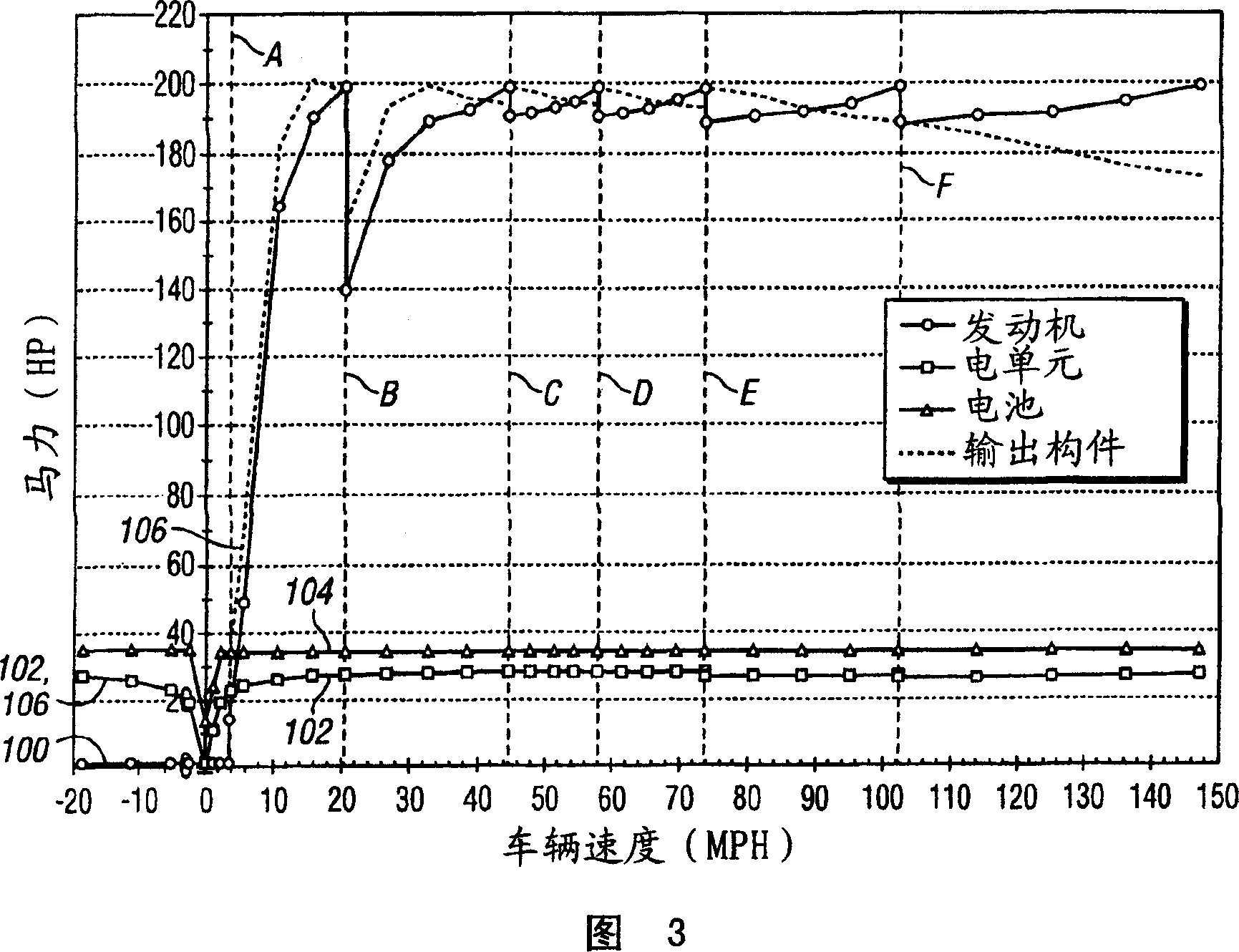

Parallel hybrid transmission having a single motor/generator

InactiveCN1924401AReduce transmission costsStrong torqueToothed gearingsTransmission elementsEngineeringForward speed

A reduced cost, compact parallel hybrid transmission having only a single motor / generator is provided. The transmission utilizes a reduced number of components, preferably only three interconnecting members and four torque-transmitting mechanisms, to provide a reverse speed mode and seven forward speed modes (i.e., operating states achieved by engagement of a particular torque-transmitting mechanism or torque-transmitting mechanisms, whether encompassing a continuous range of speed ratios or only a fixed speed ratio). At least five of the forward modes are fixed speed ratios.

Owner:GENERAL MOTORS CORP

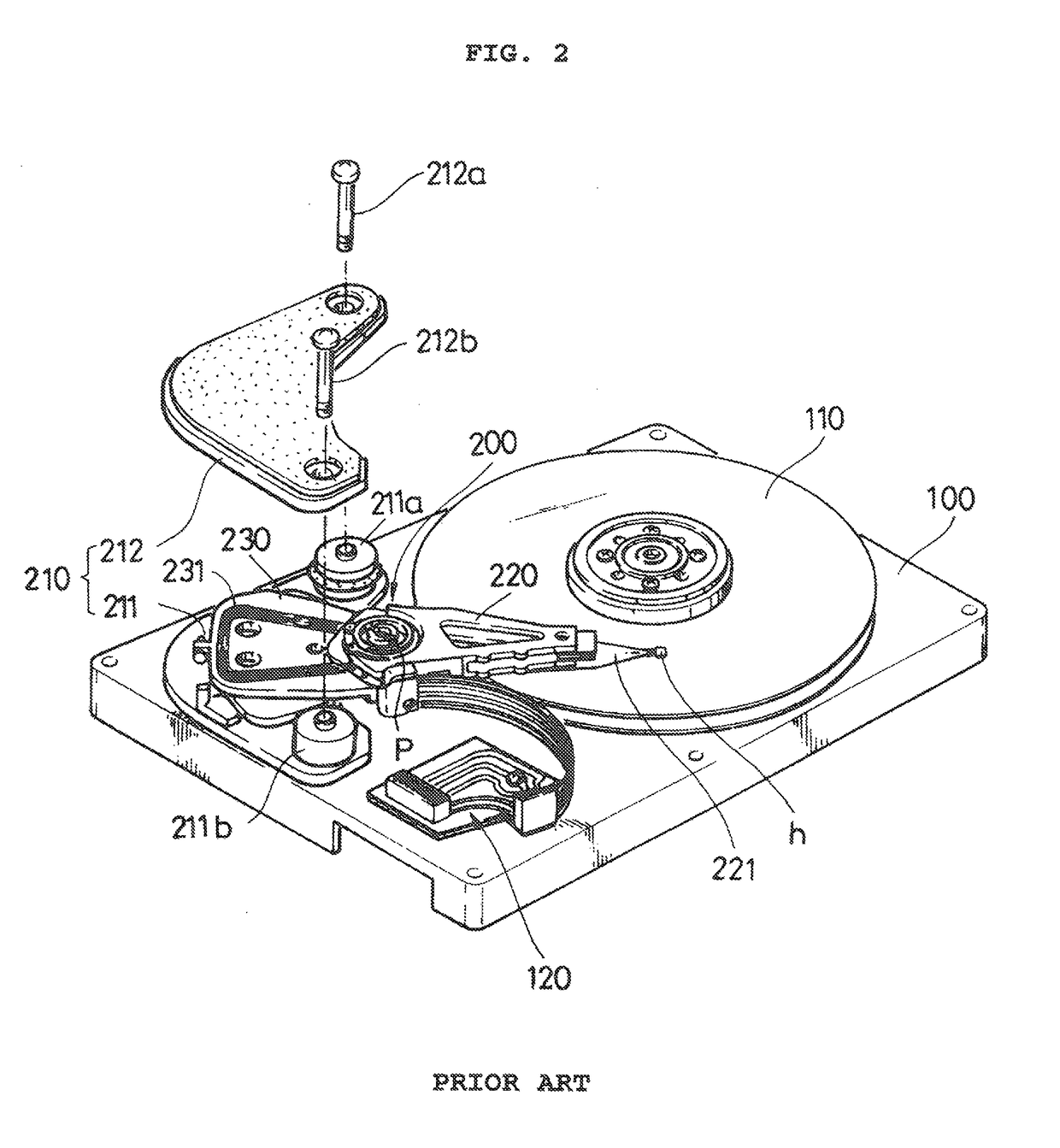

Rotating disk storage device with a retracting actuator head suspension assembly

InactiveUS7298591B2Simple structureTorque characteristics of the bias torque can be controlledDisposition/mounting of recording headsDriving/moving recording headsActuatorControl theory

Embodiments of the present invention provide a rotating disk storage device having a mechanism to reliably retract an actuator into a retraction area in the event that the power supply is suddenly interrupted. A bias chip is embedded in a coil support that supports the voice coil. When a head stays in an access area, the bias chip is away from an end of the voice coil magnet. Therefore, no influence of the magnetic leakage flux is exerted on the bias chip. When the head is in a retraction area, the bias chip is attracted under the influence of the magnetic leakage flux of the voice coil magnet, which thereby produces bias torque causing an actuator to pivotally move in a retraction direction. Accordingly, the bias torque can be utilized as energy for retracting the actuator immediately after power shutdown.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Non negative torque outer-rotor permanent magnet motor

InactiveCN101026327AReduce power consumptionLow costElectric machinesDC commutatorPermanent magnet motorMagnetic energy

Comparing with same kind of electrical motor, the disclosed permanent magnet motor uses less conduction wire, magnet material, and permanent magnetic material. The disclosed permanent magnet motor possesses features of low cost, high magnetic energy transform, small starting up current, no negative moment, powerful torsion, small power consumption. The motor is applicable to electric automobile, and other dynamical power.

Owner:阮桂林

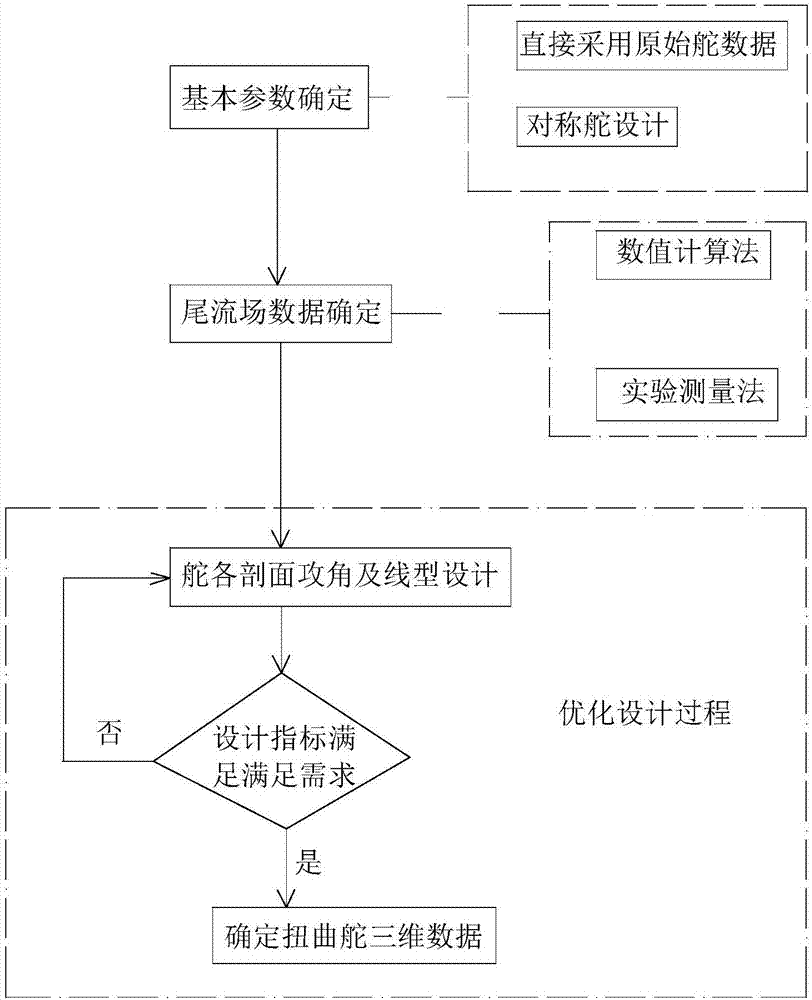

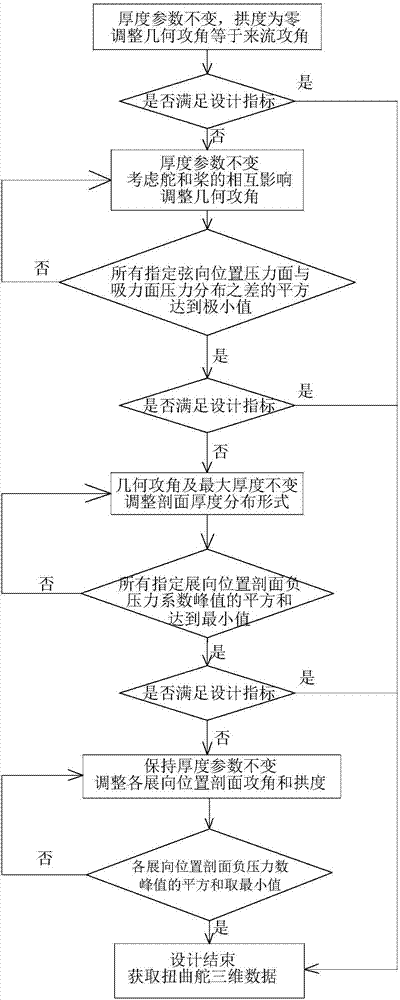

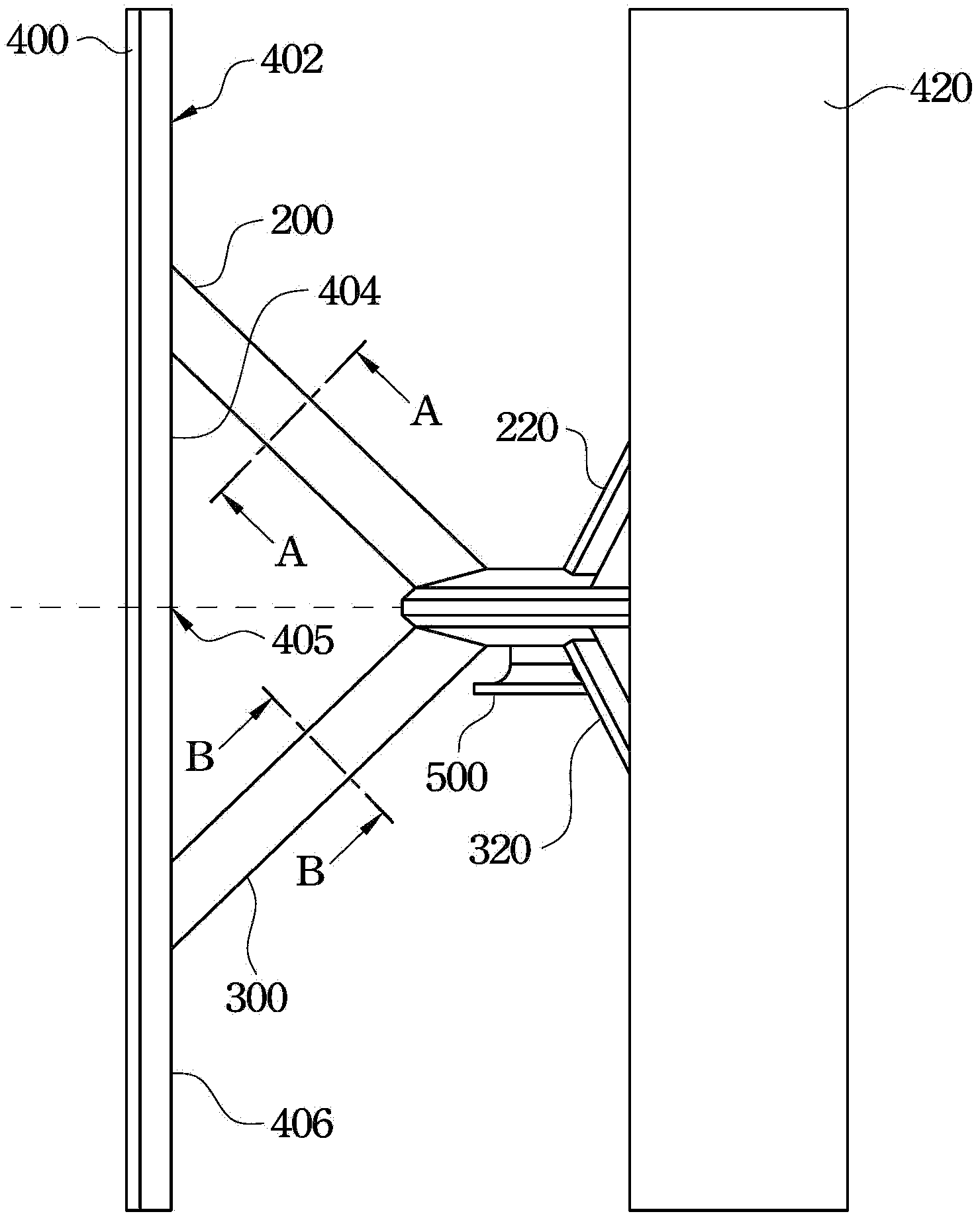

Anti-cavitation twisted rudder and design method thereof

ActiveCN107264763AImprove pressure distributionIncrease critical speedSteering ruddersVessel designingCavitationPropeller

The invention belongs to the field of ship or rudder design and particularly relates to an anti-cavitation twisted rudder and a design method thereof. On the basis that the influence of various factors such as the rotational speed in the ship propeller wake flow on the rudder is fully considered, the geometrical attack angles and line types of all the spanwise position sections are designed and determined through the distribution characteristic of a propeller rear wake flow field in direct sailing of a ship, so that the geometrical shape of the rudder is matched with that of the propeller wake flow field, and the purposes that the pressure distribution of the rudder surface is improved, the cavitation starting sailing speed of the rudder is increased, the time of rudder cavitation is shortened, the area of rudder cavitation is decreased, vibration and noise caused by the rudder are reduced, cavitation denudation of the rudder surface is restrained, the maintenance cost of the rudder is saved, the force state of rudder blades is improved, the rudder efficiency is improved, and the load of the rudder is reduced are achieved.

Owner:NAVAL UNIV OF ENG PLA

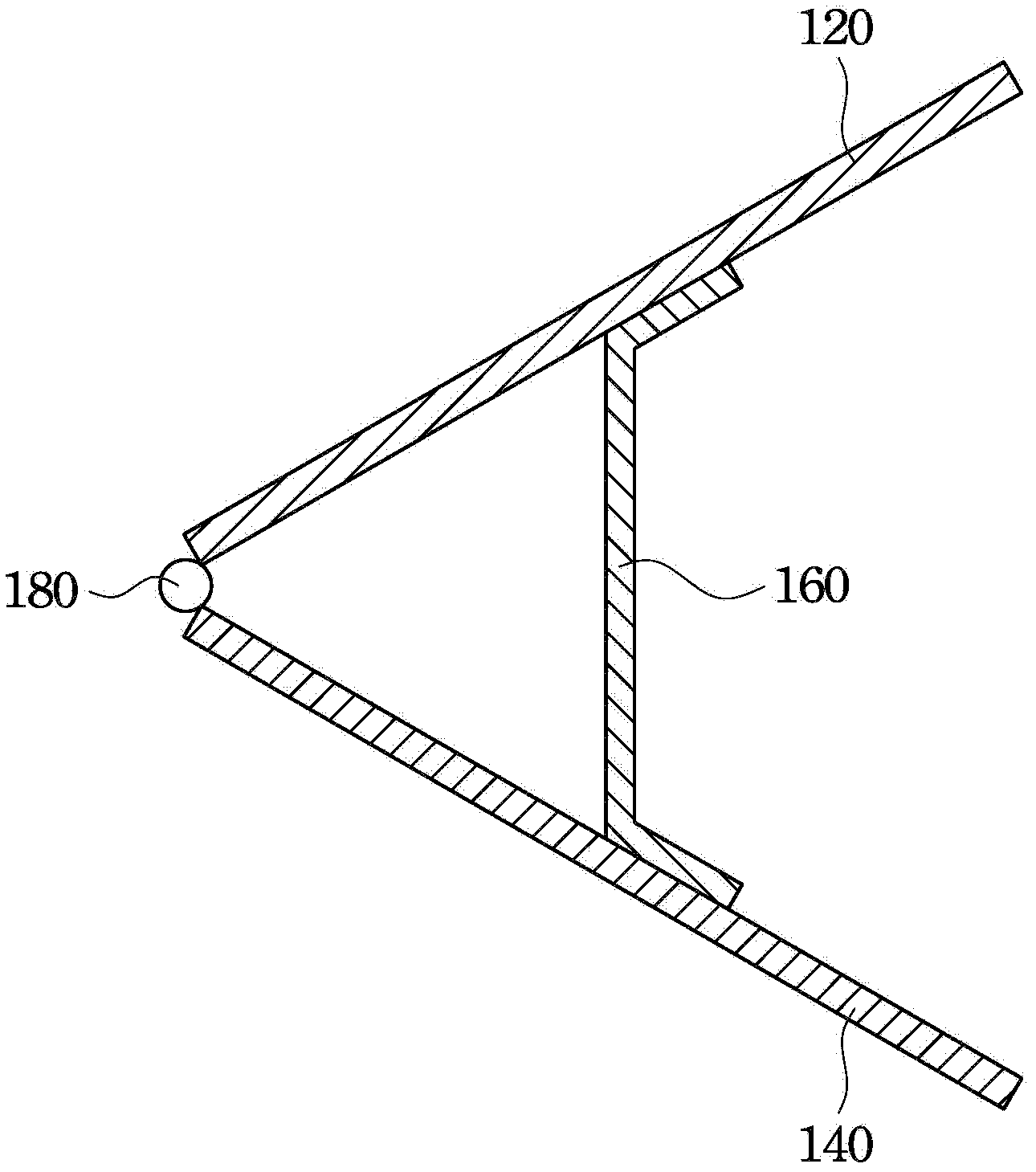

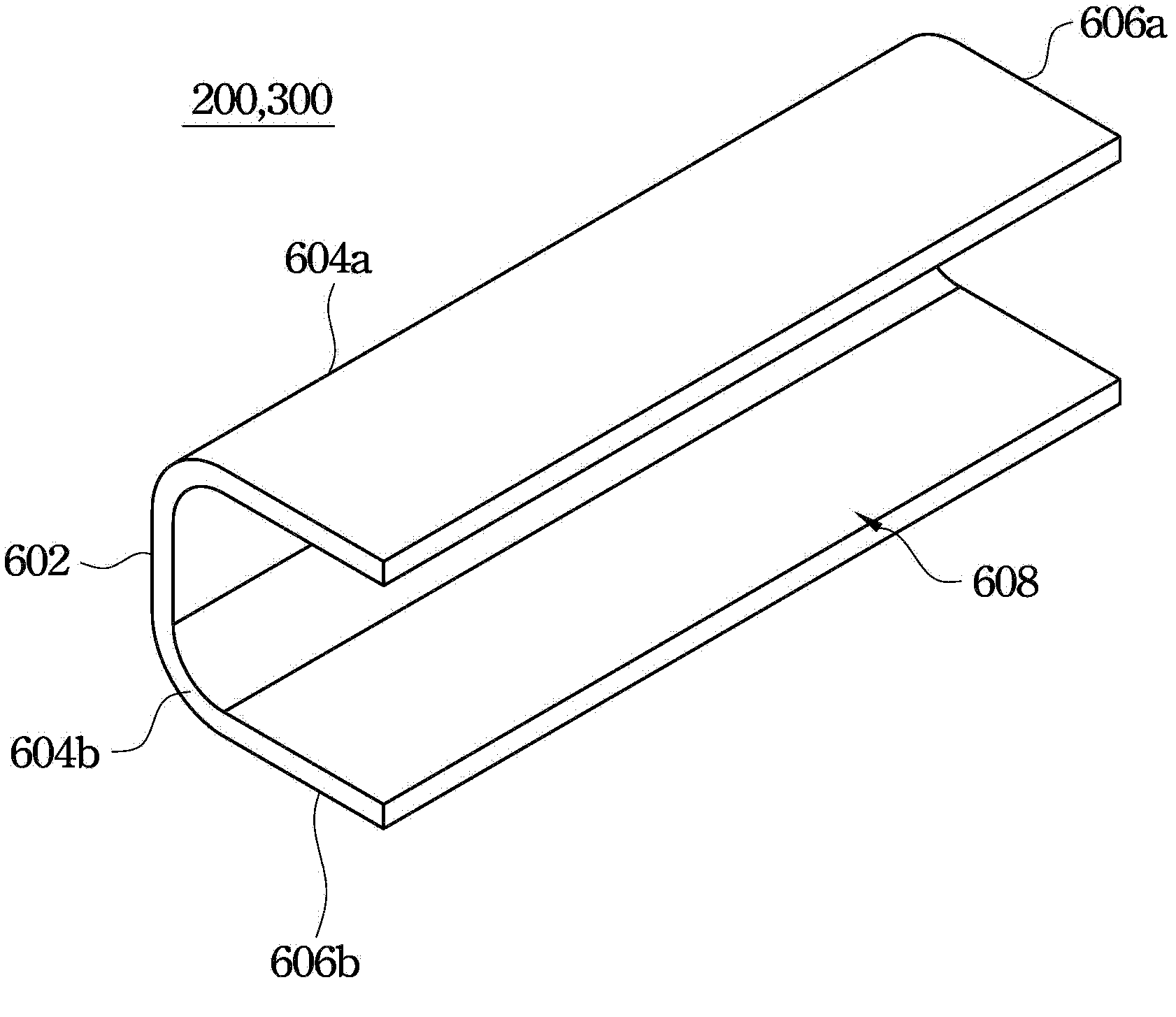

Vertical-axis wind driven generator and blade arm thereof

InactiveCN103216382AEliminate stress concentrationStrong torqueRenewable energy generationMachines/enginesWind drivenWind force

The invention discloses a vertical-axis wind driven generator and a blade arm thereof. The vertical-axis wind driven generator comprises a generator body, at least one first blade arm and at least one blade. One end of the first blade arm is connected to one surface of the generator body; the other end of the first blade arm is connected with the blade; the first blade arm comprises a baseplate, two arc parts and two side plates; the two arc parts respectively extend from the two ends of the baseplate; the two side plates are respectively connected with the two arc parts; and the baseplate, the two arc parts and the two side plates define a groove space together. The blade arm of the vertical-axis wind driven generator can form an arc section without any acute angle in general, so the problems of stress concentration, fragile structure and the like can be effectively prevented. In addition, as the wind area of the arc section is lager than that of a V-shaped section, the increased torsion is stronger, and the starting wind speed required by the wind driven generator can be further lowered.

Owner:DELTA ELECTRONICS INC

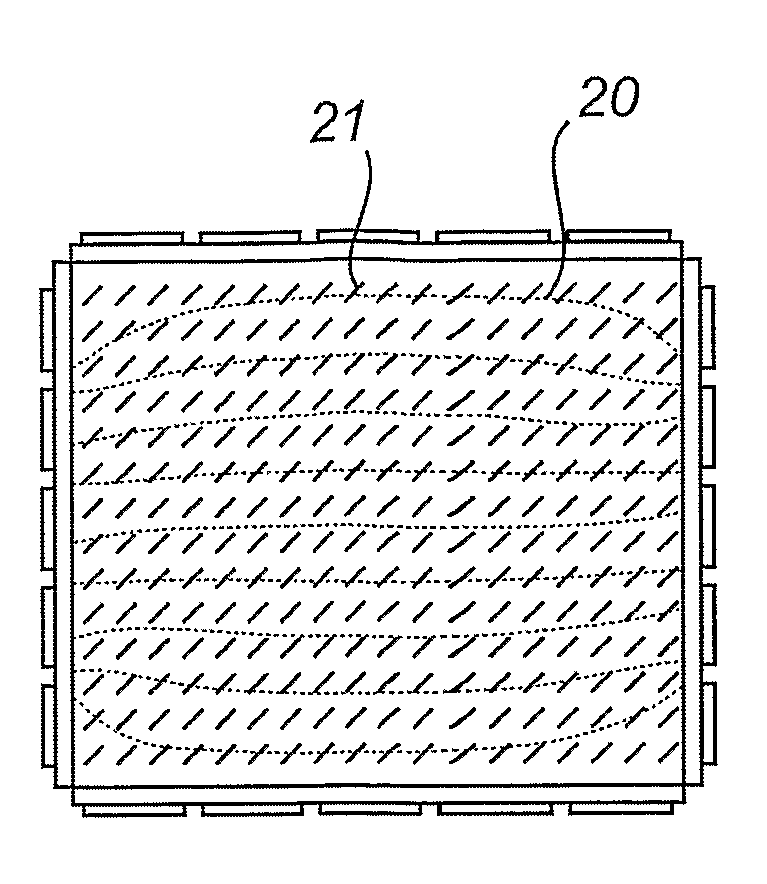

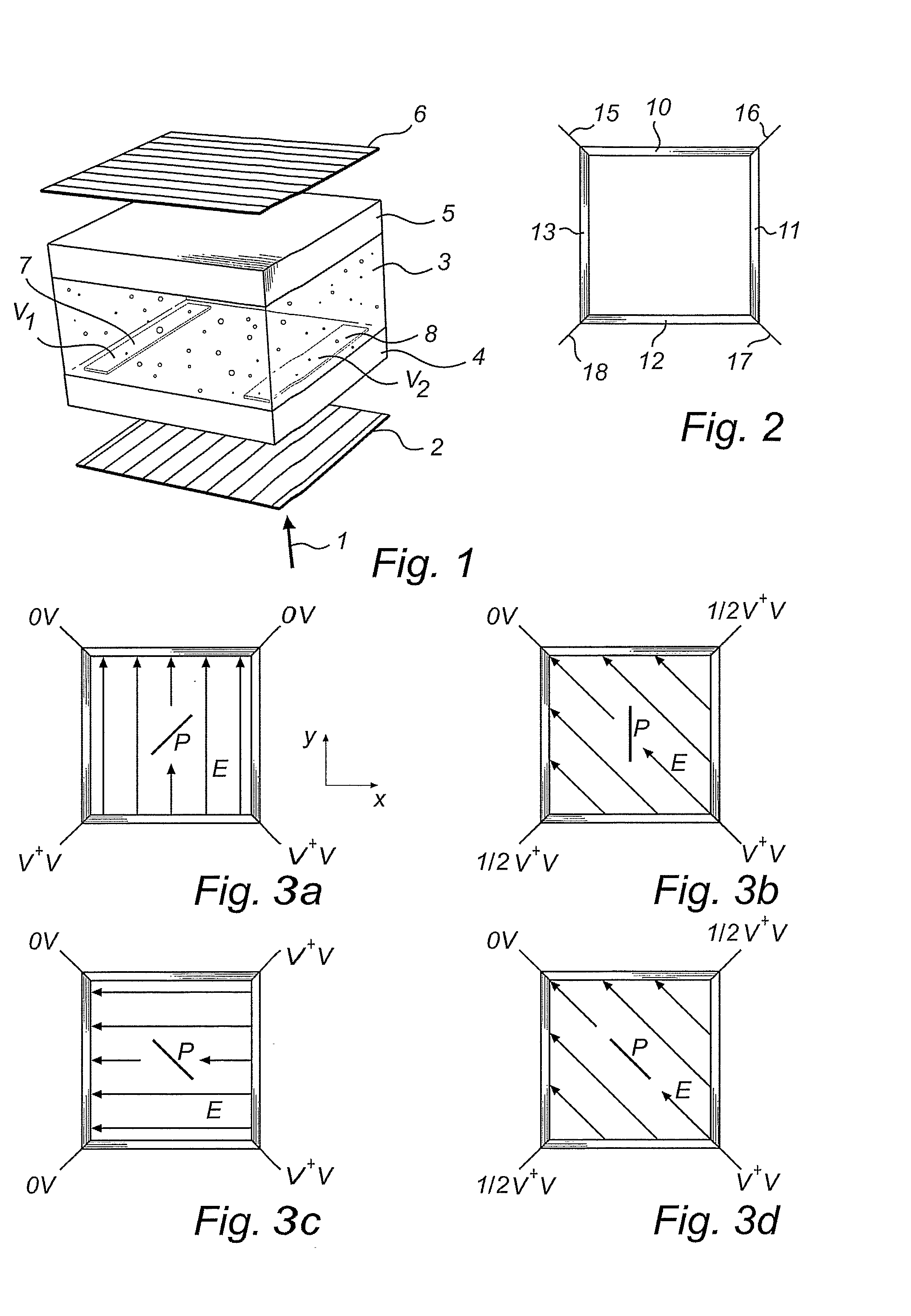

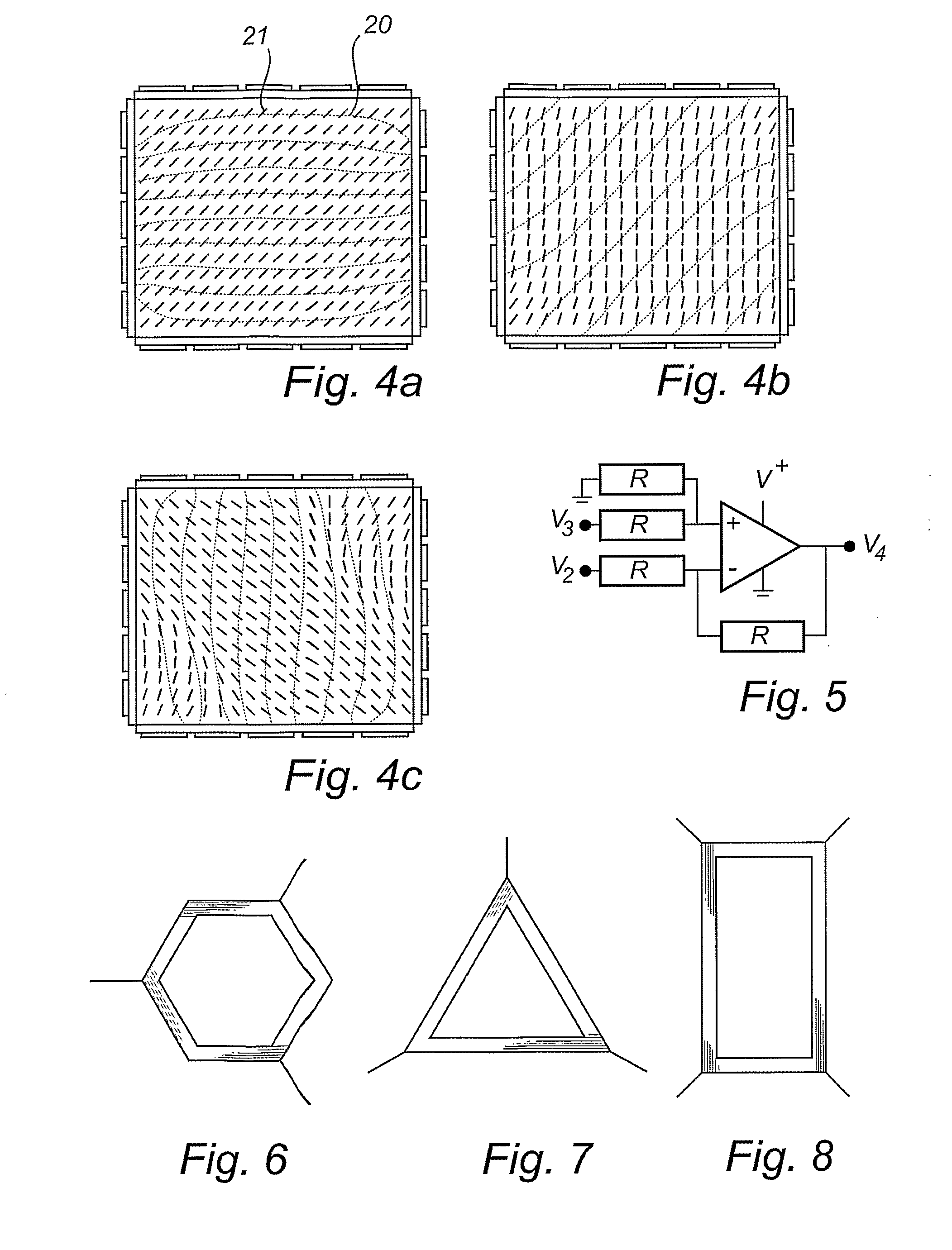

Liquid Crystal Display Device

InactiveUS20070195042A1Improve contrast and brightness propertyImproved contrast and brightness propertyStatic indicating devicesNon-linear opticsElectric fieldEngineering

The present invention relates to an in-plane switching liquid crystal display device. In order to enhance the switching characteristics of the display and to improve contrast in displayed images, each pixel area on a substrate in the display is surrounded by strips of resistive material. By applying driving signals to at least three connection terminals, connected to the resistive material strips at different locations, an electric field may be obtained that is homogenous over the pixel area and that may be changed dynamically during the switching process in order to exert maximum torque on liquid crystal molecules in the pixel throughout the switching process.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com