Polymerizable chiral compound

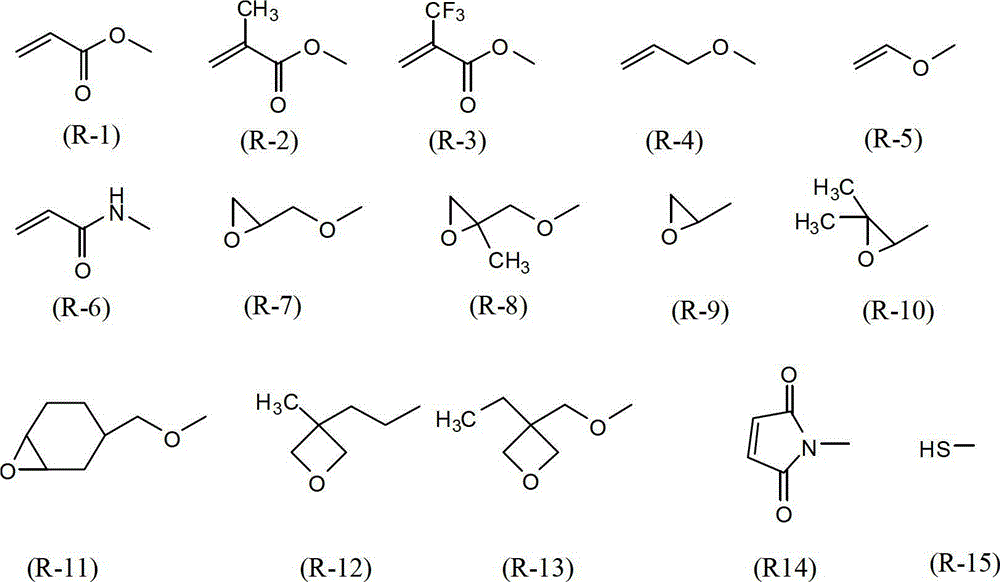

A chiral compound and polymerizable technology, applied in the field of polymerizable liquid crystal compositions and optical anisotropic bodies, can solve the problems of low compatibility, complicated manufacturing, high price of optical anisotropic bodies, etc., and achieve excellent optical properties, Simple production method and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0138] Add 33.2g (240mmol) of 3-(p-hydroxyphenyl)benzoic acid, 4g of potassium iodide, 1g of tetrabutylammonium bromide, 400ml of ethanol to a reaction vessel equipped with a stirring device, a cooler and a thermometer, and heat at room temperature Stir. A 25% aqueous solution of 24 g of sodium hydroxide was slowly added dropwise. After the dropwise addition, the reaction vessel was kept at 50° C., and 50 g (288 mmol) of benzyl bromide was slowly added dropwise. After completion of the dropwise addition, the reaction container was heated to 70° C. and further reacted for 3 hours. After the reaction, neutralize with 10% hydrochloric acid, extract with ethyl acetate, dry with sodium sulfate, and then concentrate the solvent to synthesize 38 g of the compound represented by formula (1).

[0139] [chem 27]

[0140]

[0141] Next, 28 g (123 mmol) of the compound represented by the formula (1) synthesized above, 7.7 g (55 mmol) of isosorbide, 1.8 g of dimethyl Aminopyridine, ...

Embodiment 2)

[0159] Add 4g (10.3 mmol) of the compound represented by formula (3) synthesized in Example 1 and 4.6 g (24 mmol) of 4-acryloyloxybenzoic acid to a reaction vessel equipped with a stirring device, a cooler and a thermometer , 200 mg dimethylaminopyridine, 500 ml dichloromethane, and keep the reaction vessel below 5° C. with an ice bath. 3.6 g (28 mmol) of diisopropylcarbodiimide was slowly added dropwise under a nitrogen atmosphere. After the dropwise addition was completed, the reaction container was returned to room temperature, and reacted for 5 hours. After filtering the reaction solution, 200 ml of dichloromethane was added to the filtrate, washed with 10% aqueous hydrochloric acid, and then washed with saturated brine, and the organic layer was dried over anhydrous sodium sulfate. After the solvent was distilled off, it was purified through a 5-fold amount (weight ratio) of silica gel column to obtain 5.2 g of the target compound represented by the formula (5).

[0160...

Embodiment 3)

[0169] Add 4g (10.3 mmol) of the compound represented by formula (3) synthesized in Example 1, 7.4g (24 mmol) of 4-(4-methylpropene) into a reaction vessel equipped with a stirring device, a cooler and a thermometer Acyloxy)phenyl cinnamic acid, 200mg dimethylaminopyridine, 500ml dichloromethane, keep the reaction vessel below 5°C with an ice bath. 3.6 g (28 mmol) of diisopropylcarbodiimide was slowly added dropwise under a nitrogen atmosphere. After the dropwise addition was completed, the reaction container was returned to room temperature, and reacted for 5 hours. After filtering the reaction solution, 200 ml of dichloromethane was added to the filtrate, washed with 10% aqueous hydrochloric acid, and then washed with saturated brine, and the organic layer was dried over anhydrous sodium sulfate. After the solvent was distilled off, it was purified through a 5-fold amount (weight ratio) of silica gel column to obtain 6.4 g of the target compound represented by the formula (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com