Translational gearing motor with improved structure

A structure-improved, translational technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing the structural components and weight of the drive device, high precision requirements for parts, and complicated circuit control, so as to avoid magnetic circuit Saturation phenomenon, small output torque, and the effect of avoiding magnetic circuit coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

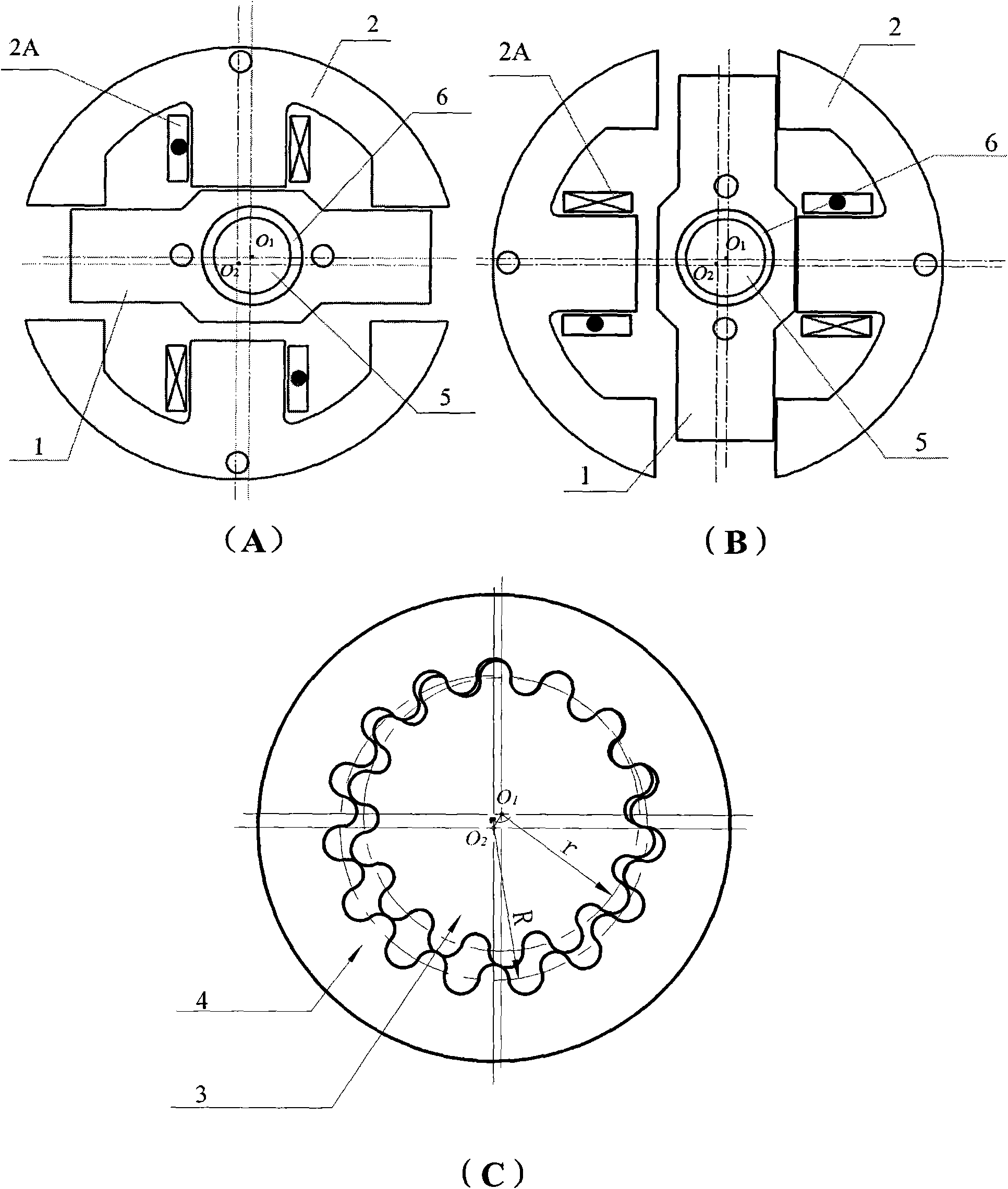

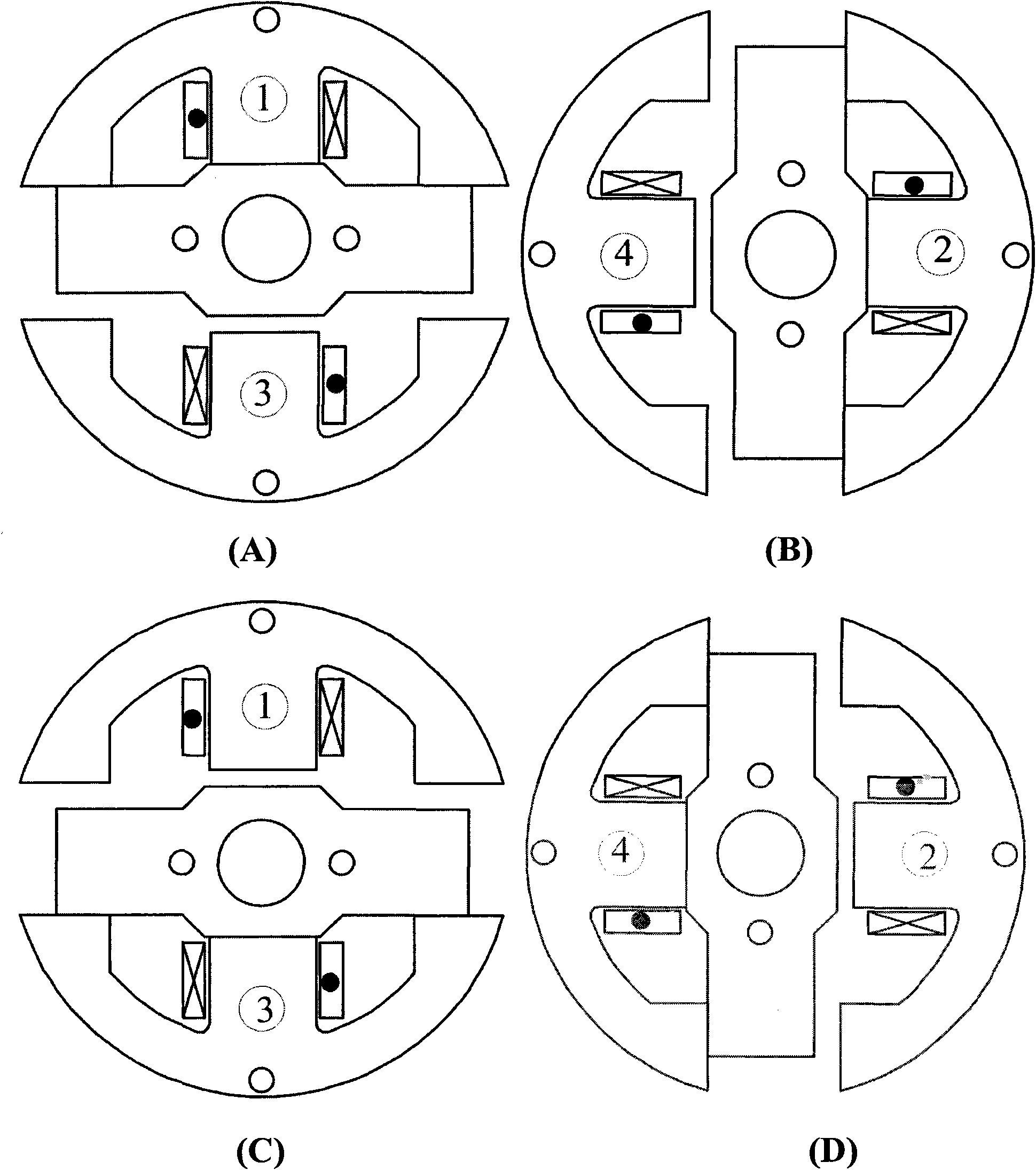

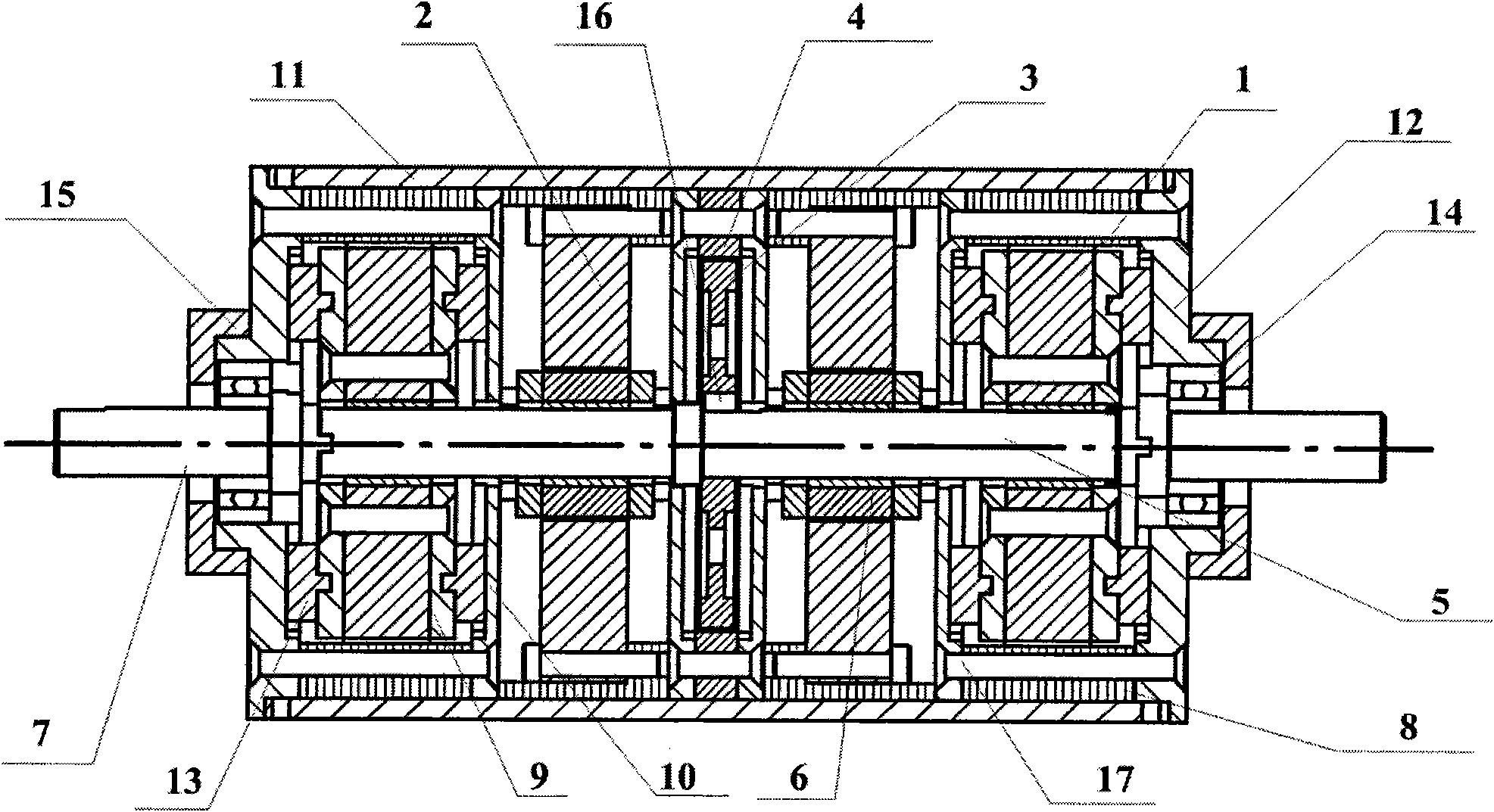

[0038] The invention is a translational meshing motor with improved structure, which integrates the motor and reducer, simplifies the mechanical transmission system, and can directly output low speed, high torque, and has certain self-locking and braking capabilities. electric motor. The motor is equipped with four sets of magnetic poles, and each set of magnetic poles is composed of a rotor in the middle and two stators on both sides. After the coil winding installed on the stator is powered on, it can drive the rotor to move left and right to form a one-way driving magnetic pole. ; The four sets of magnetic poles installed in the axial direction are divided into two pairs whose magnetic pole directions are staggered by 90° from each other. The sliding sleeve in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com