Patents

Literature

110 results about "Fill rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

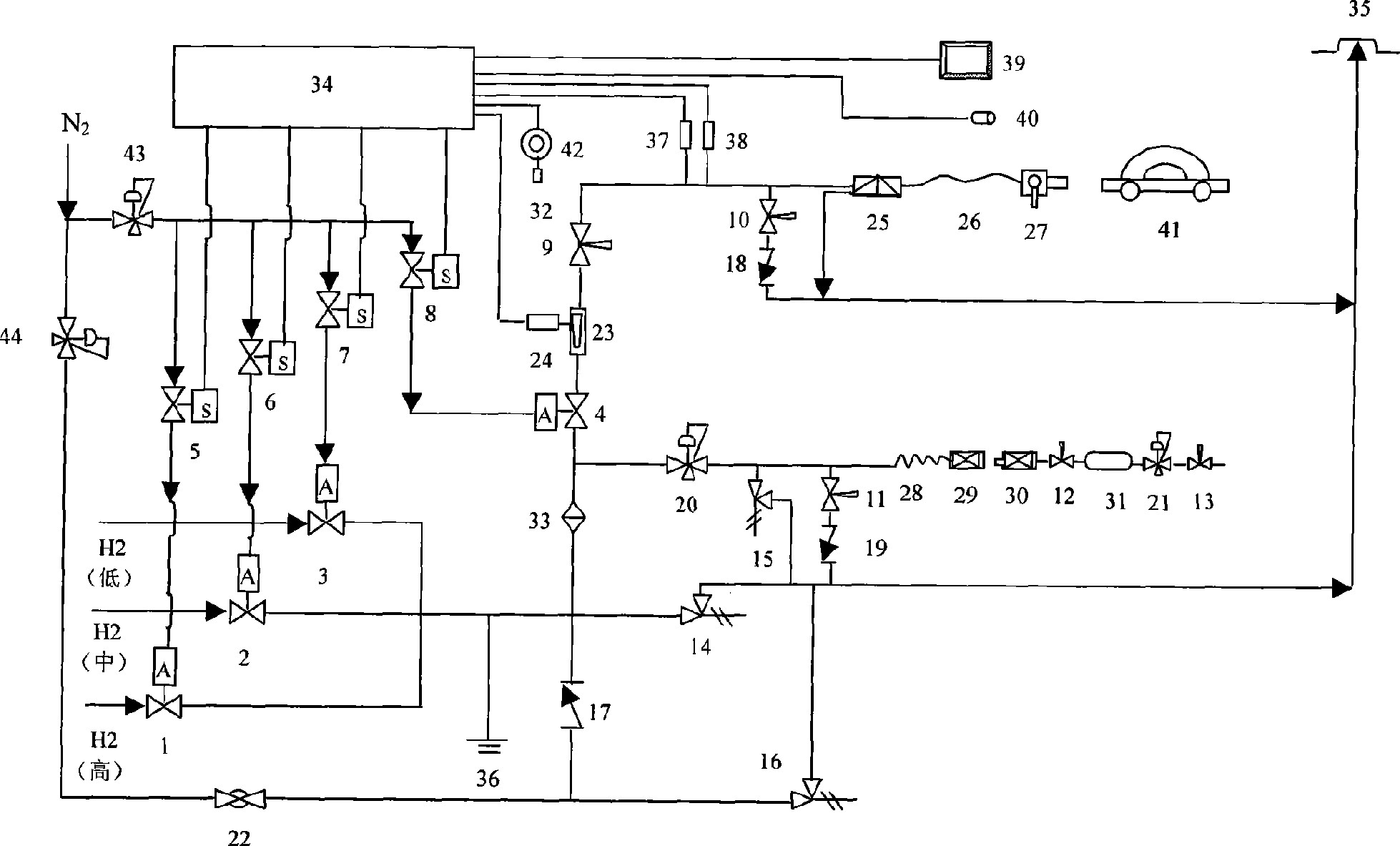

Air entraining system for high-pressure hydrogenation stations

ActiveCN101418908ASimple structureImprove reliabilityContainer filling under pressureFill rateFuel cells

The invention relates to a gas filling system for a high-pressure hydrogen filling station, which comprises a control system, a sampling system, a filling system, an alarm system and a nitrogen purging system, and is the gas filling system which can collect hydrogen sample of the hydrogen filling station and fill high-pressure hydrogen for fuel cell powered vehicles. The gas filling system has the functions of temperature automatic compensation of filling measurement, selectable gas taking procedure in three-stage order, reasonable control of filling rate, alarm of hydrogen leakage and automatic power-down, pulling out prevention and automatic static release in the filling process, overpressure protection of the system, and so on. The sampling points are designed at the tail end of the whole flow of the hydrogen filling station, so that the acquired hydrogen sample can have more representativeness in quality; and through the design of pressure regulation treatment on the high-pressure hydrogen for sampling, the sampling operation is more simple, convenient and quick, and a regular gas sampling steel bottle can also be used together, thereby the sampling cost is low. The gas filling system can improve the gas taking rate of the hydrogen filling station and ensure that the temperature rise of a filled vehicle hydrogen storage tank is strictly controlled within the required temperature range in the quick hydrogen filling process.

Owner:TONGJI UNIV

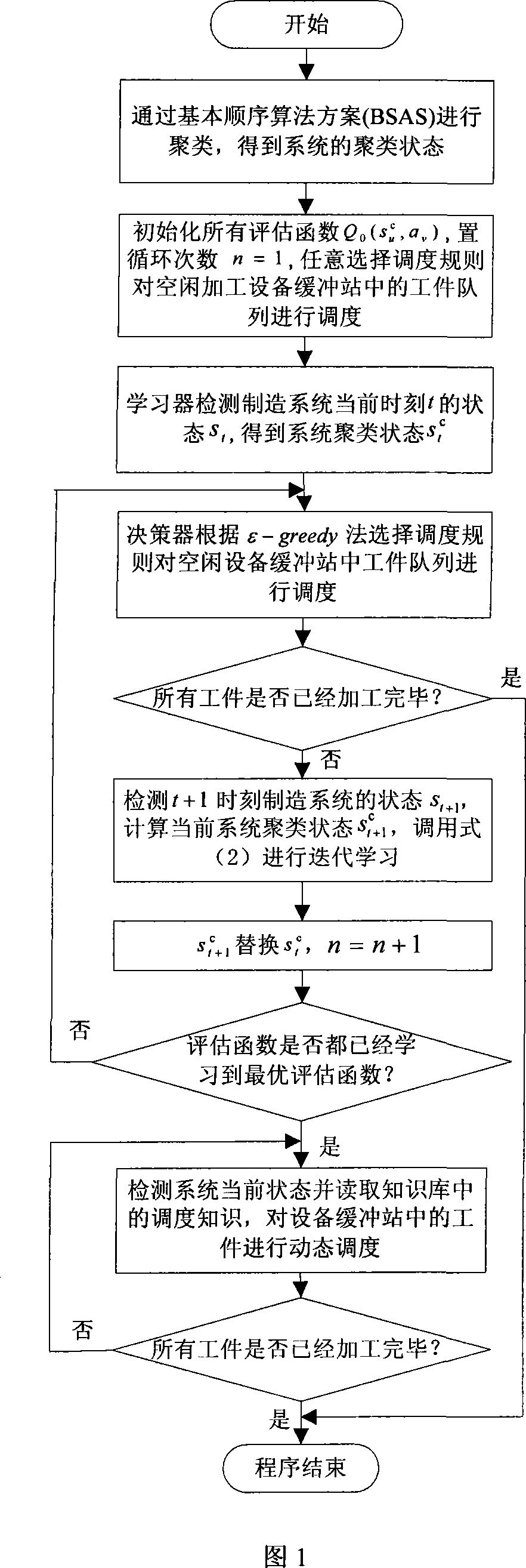

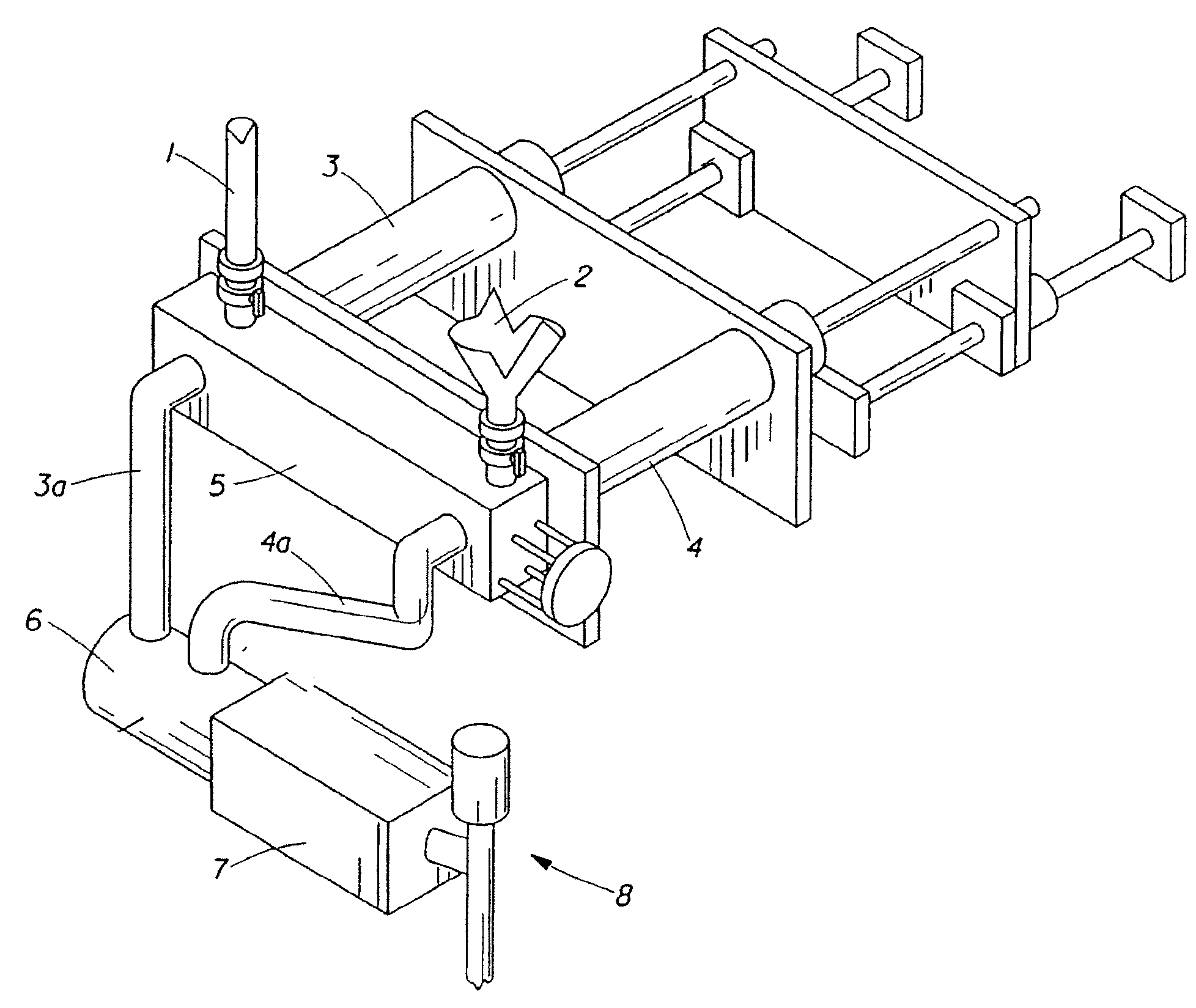

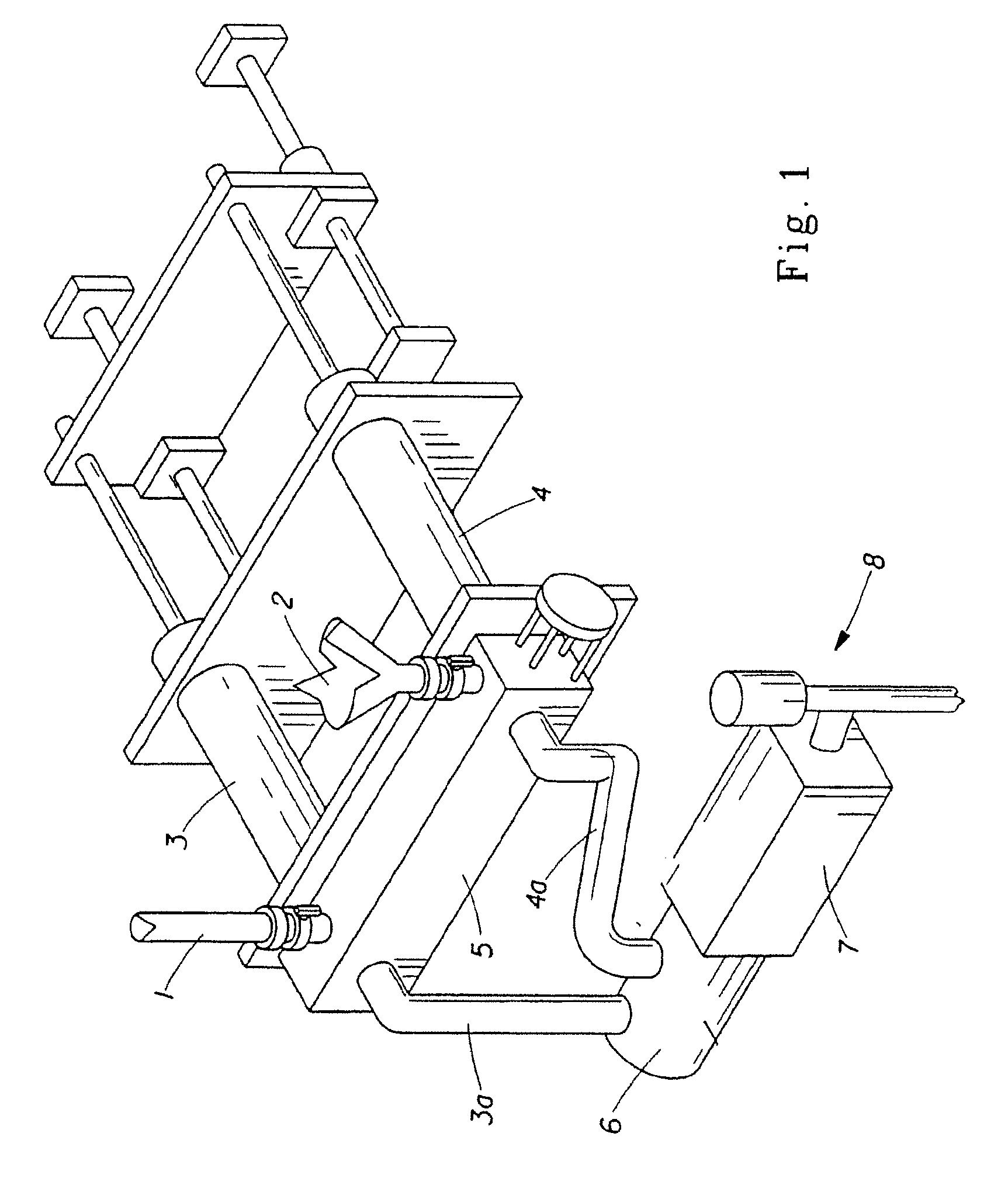

Self-adapting selection dynamic production scheduling control system accomplished through computer

InactiveCN101216710AReduce delaysReduce average time overdueTotal factory controlProgramme total factory controlLearning machineProduction schedule

A self-adaptive selection dynamic production scheduling control system, which is realized via a computer, is characterized in that: the system comprises a system emulator, a learning machine, a decision-making machine, a scheduling rules base, a scheduling knowledge base, a carrier, processing equipments and a buffer station thereof; the buffer station is provided with an optical grating, a sensor and a detection equipment; when a working piece reaches the buffer station and is processed, the learning machine detects the current system status for learning, so as to acquire dynamic scheduling knowledge about the system and update the knowledge in the scheduling knowledge base; when one processing equipment needs to be scheduled, the decision-making machine reads corresponding scheduling knowledge in the scheduling knowledge base according to the detected system status, acquires new scheduling knowledge through continuous interactive learning with the processing system, dynamically selects the scheduling rules based on the status of the processing equipments and the working piece in the system, and chooses the optimized scheduling rules to schedule the processing equipments. The invention can adapt to instable time-varying workshop dynamic production environments, obtain a better working-piece arrangement than prior rule-based scheduling technology, effectively reduce the process waiting time, and improve the fill rate of product delivery time.

Owner:SOUTHEAST UNIV

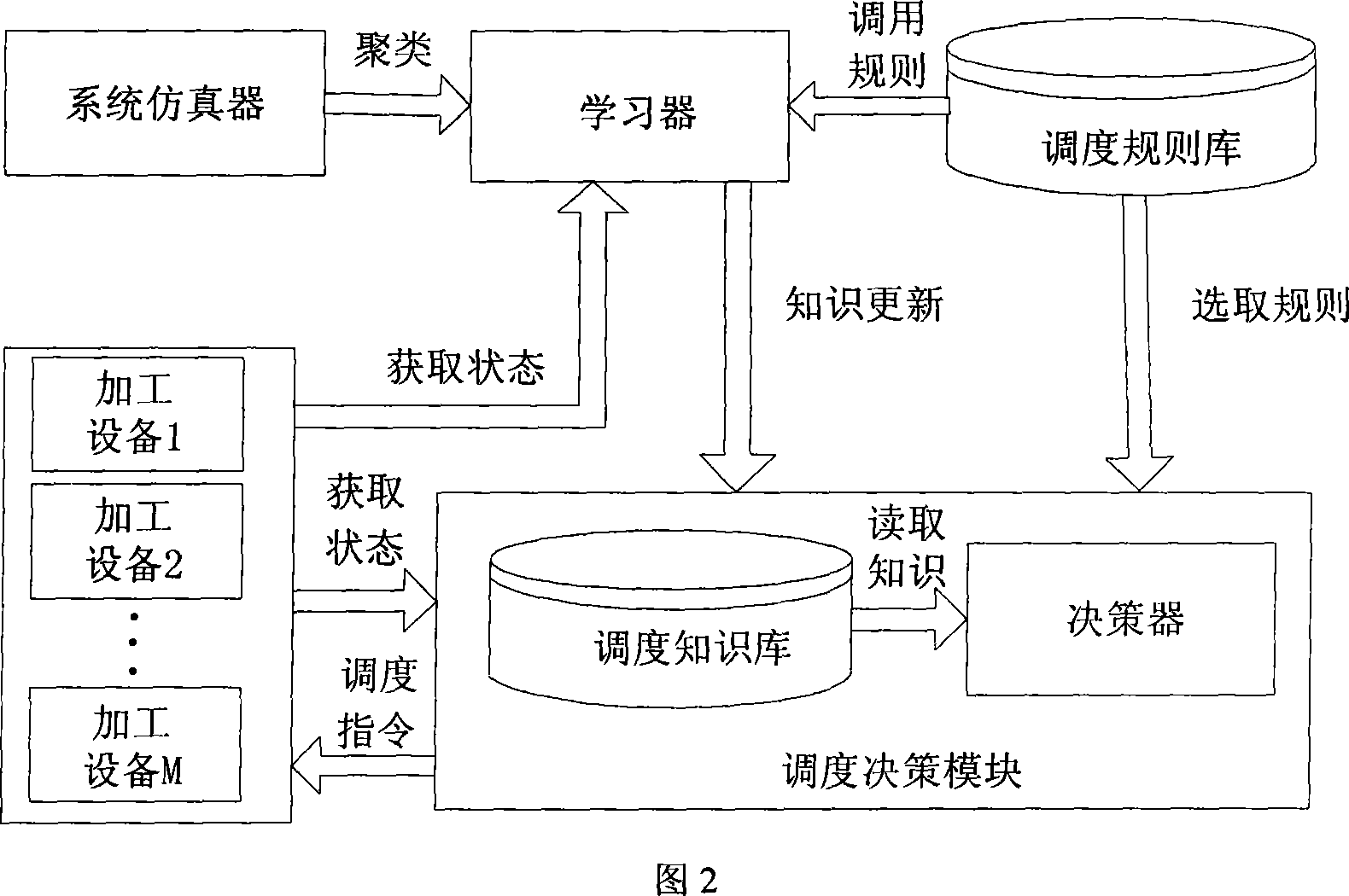

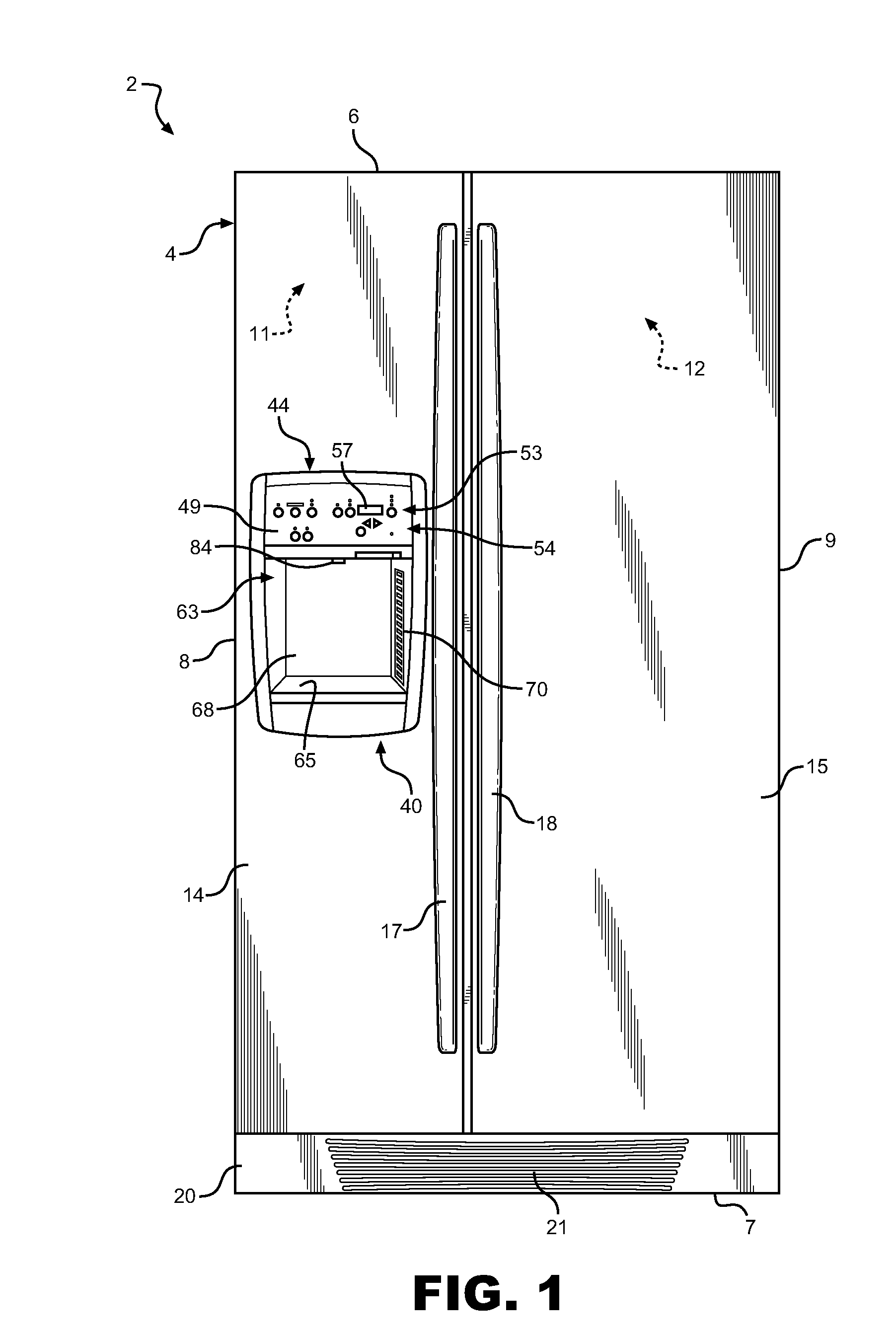

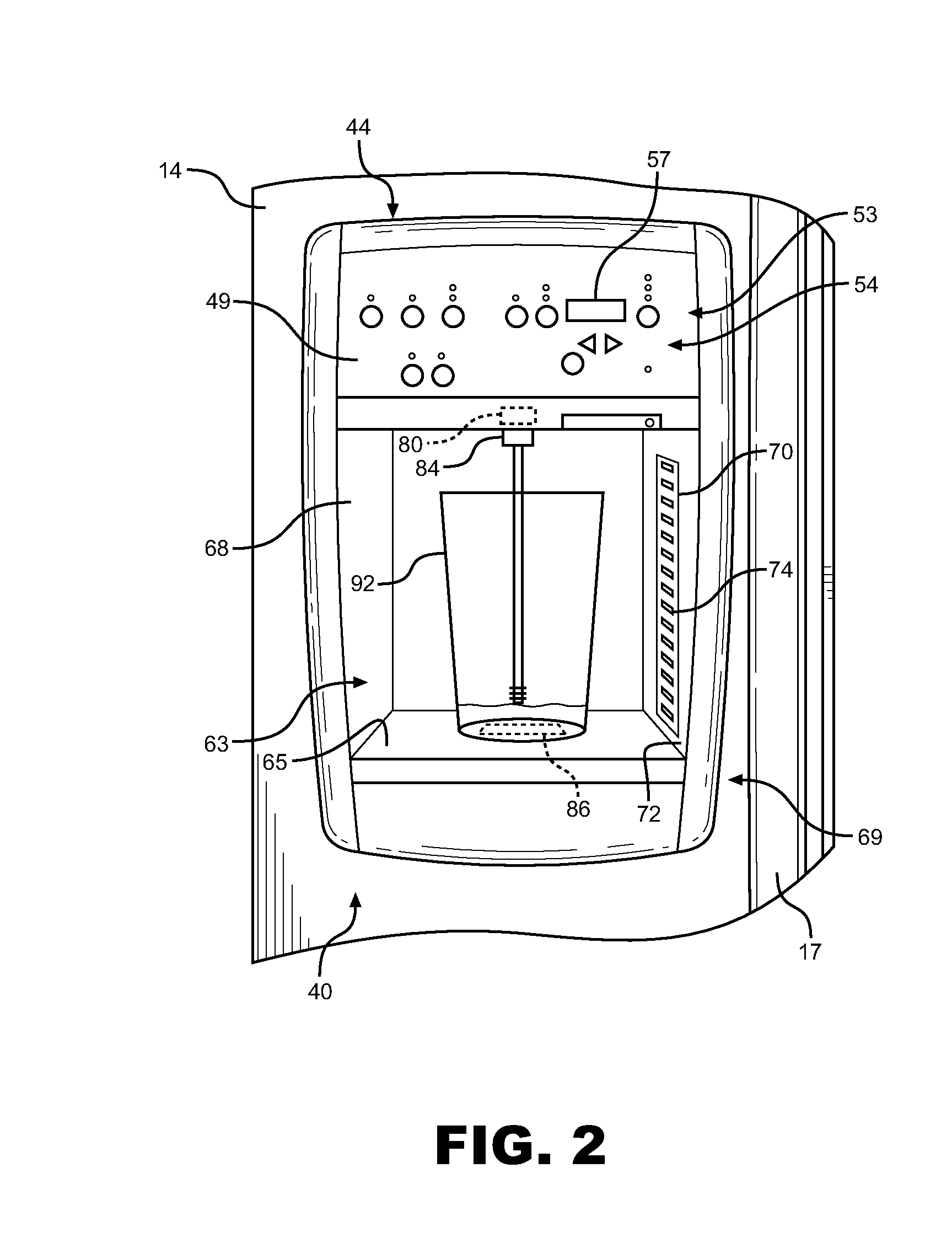

Select fill sensor system for refrigerator dispensers

ActiveUS20100155415A1Optimize fill ratePower operated devicesLighting and heating apparatusFill rateProcess engineering

Owner:WHIRLPOOL CORP

Process for Making Non-Uniform Patterns of Multiphase Compositions

A method of filling a container with a liquid composition, which comprises at least two visually distinct phases, comprising the steps of: a.) transferring said liquid composition to a container using a dispenser which has an initial fill rate; b.) rotating said container during said step a. at an initial speed of rotation and in an initial direction of rotation; c.) changing a feature selected from the group consisting of: the speed of rotation of said container, the fill rate of the dispenser, and the direction of rotation of said container; and mixtures of said features, each independently from the geometry of said container; and d.) completing the transfer of said liquid composition to said container.

Owner:THE PROCTER & GAMBLE COMPANY

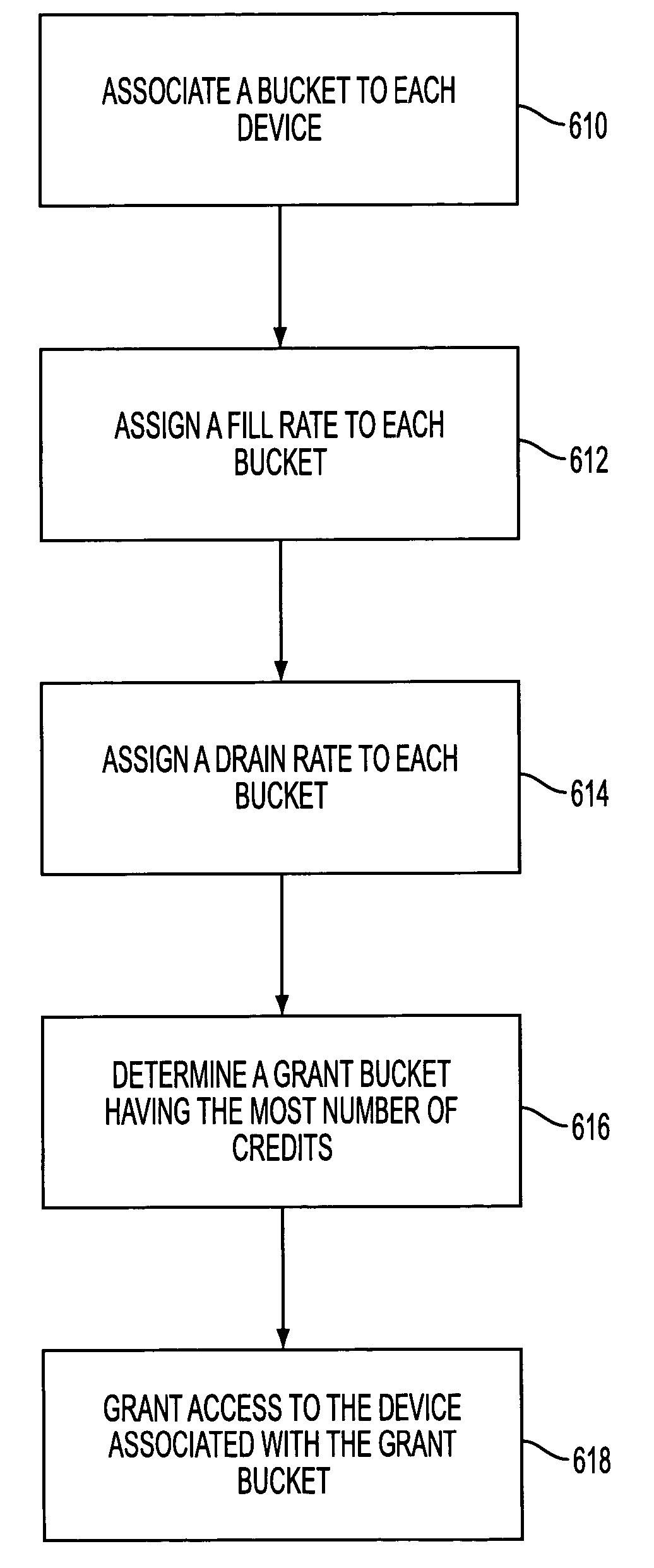

Method and system for allocating bandwidth

InactiveUS7474670B2Overcome problemsEnhanced advantageError preventionFrequency-division multiplex detailsFill rateShared resource

The present invention is directed to methods and systems for allocating bandwidth (or other shared resource) among multiple masters. According to an aspect of the present invention, an arbiter assigns a bucket to each CPU (or other device) where each bucket holds the credits for that CPU. Each bucket has a predetermined fill rate and a drain rate. Depending on the priority given to a particular CPU, the corresponding bucket will drain (or fill) at a particular rate. For example, CPUs with a higher priority will drain at a slower rate. For each clock tick (or other period of time) that a CPU is stalled, a number of credits is accrued. The bucket with the highest number of credits has priority and will be given access to the shared resource (e.g., DRAM, SDRAM, SRAM, EPROM, etc.).

Owner:IKANOS COMMUNICATIONS

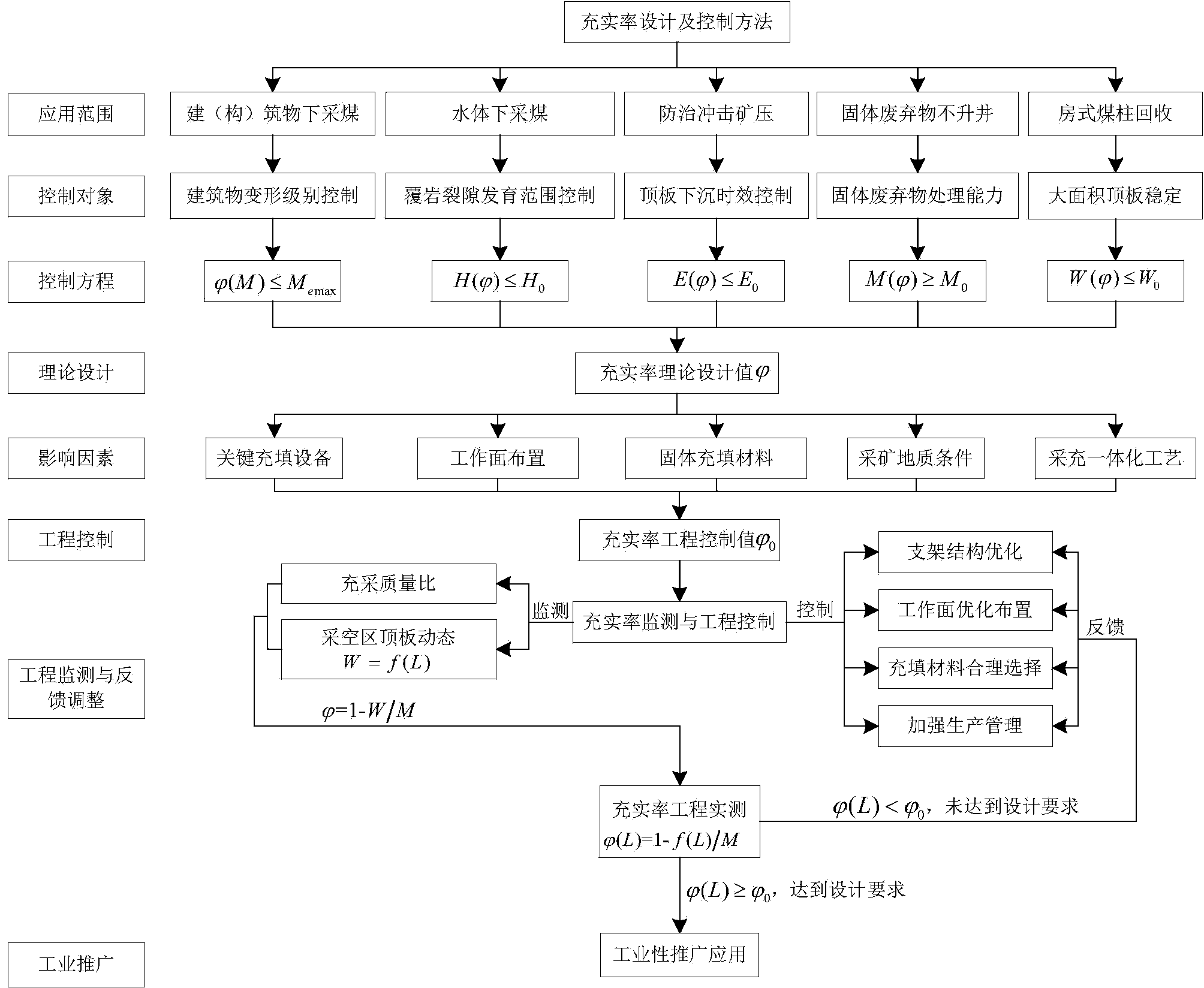

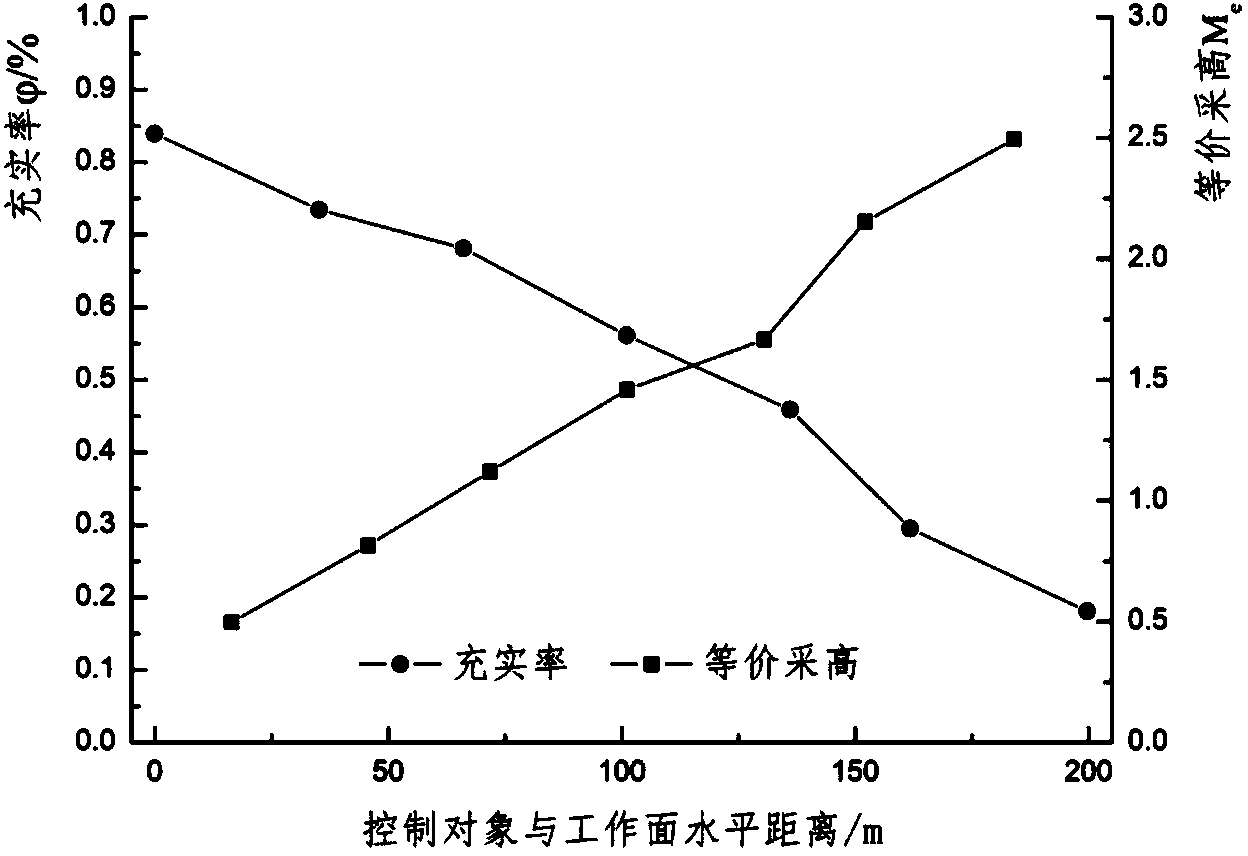

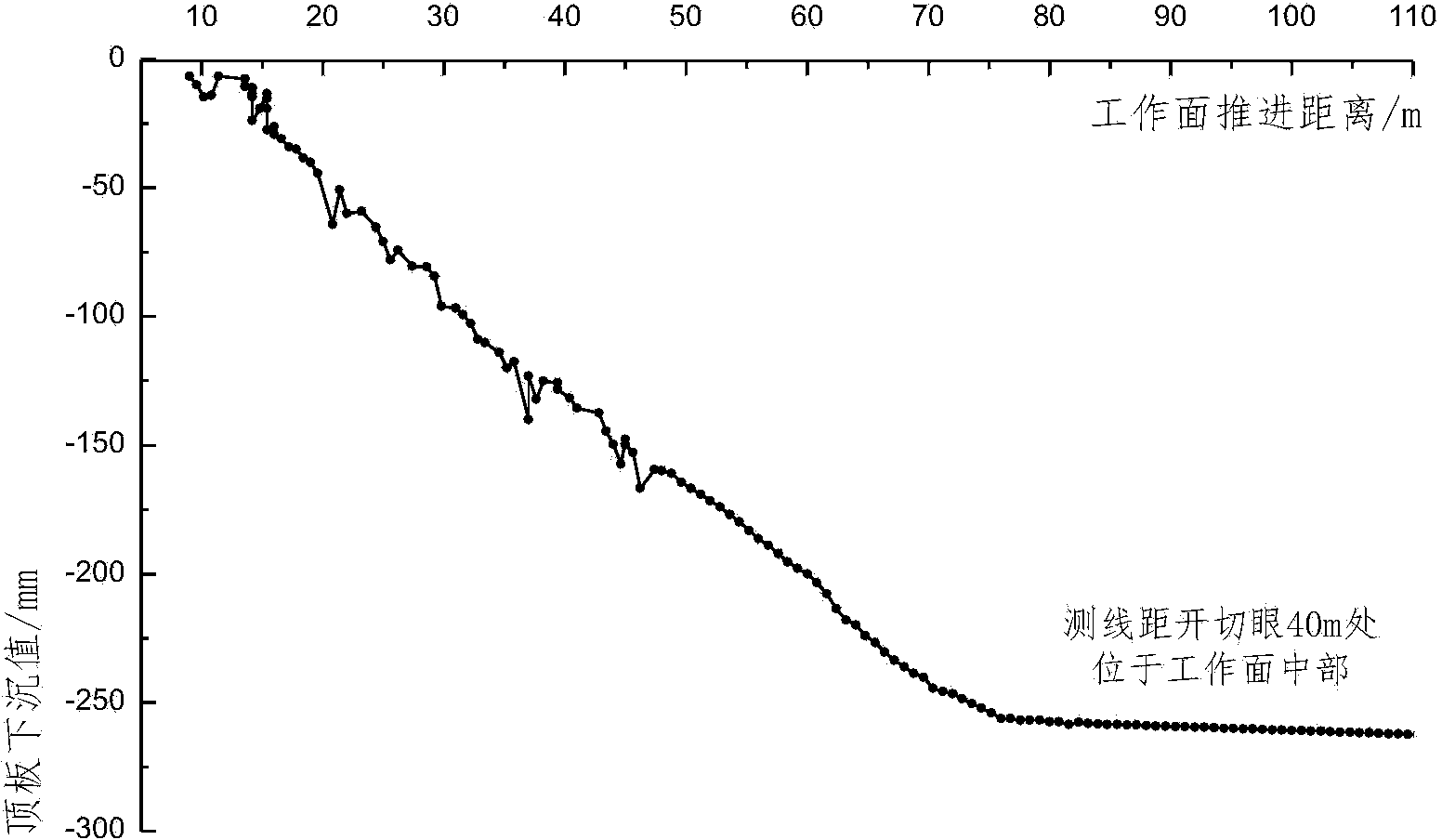

Filling rate design and control method for solid filing in coal mining

The invention discloses a filling rate design and control method for solid filing in coal mining, and belongs to filling rate design and control methods in cut and fill. The filling rate design and control method includes firstly, acquiring a theoretical design value phi of a solid filling coal mining filling rate according to cut and fill objectives and control objects; comprehensively analyzing influences of main controlling factors including key filling equipment, working face arrangement, solid filling materials, mining geological conditions and cut and fill integrated technologies on the filling rate to design an engineering control value of the filling rate phi0; during engineering practice, mounting a roof dynamic monitoring device in a gob to acquire measured filing rate curves phi(L) of different advancing positions of an on-site working face through actual measurement; comparing the engineering control value phi0, and adjusting the technology and the management method to ensure a measured filling value to meet engineering design requirements and guarantee filling effect. The method provides reference for design and control of the solid filling coal mining filling rate, and provides theoretical support for on-site popularization and application of the solid cut and fill technology.

Owner:CHINA UNIV OF MINING & TECH

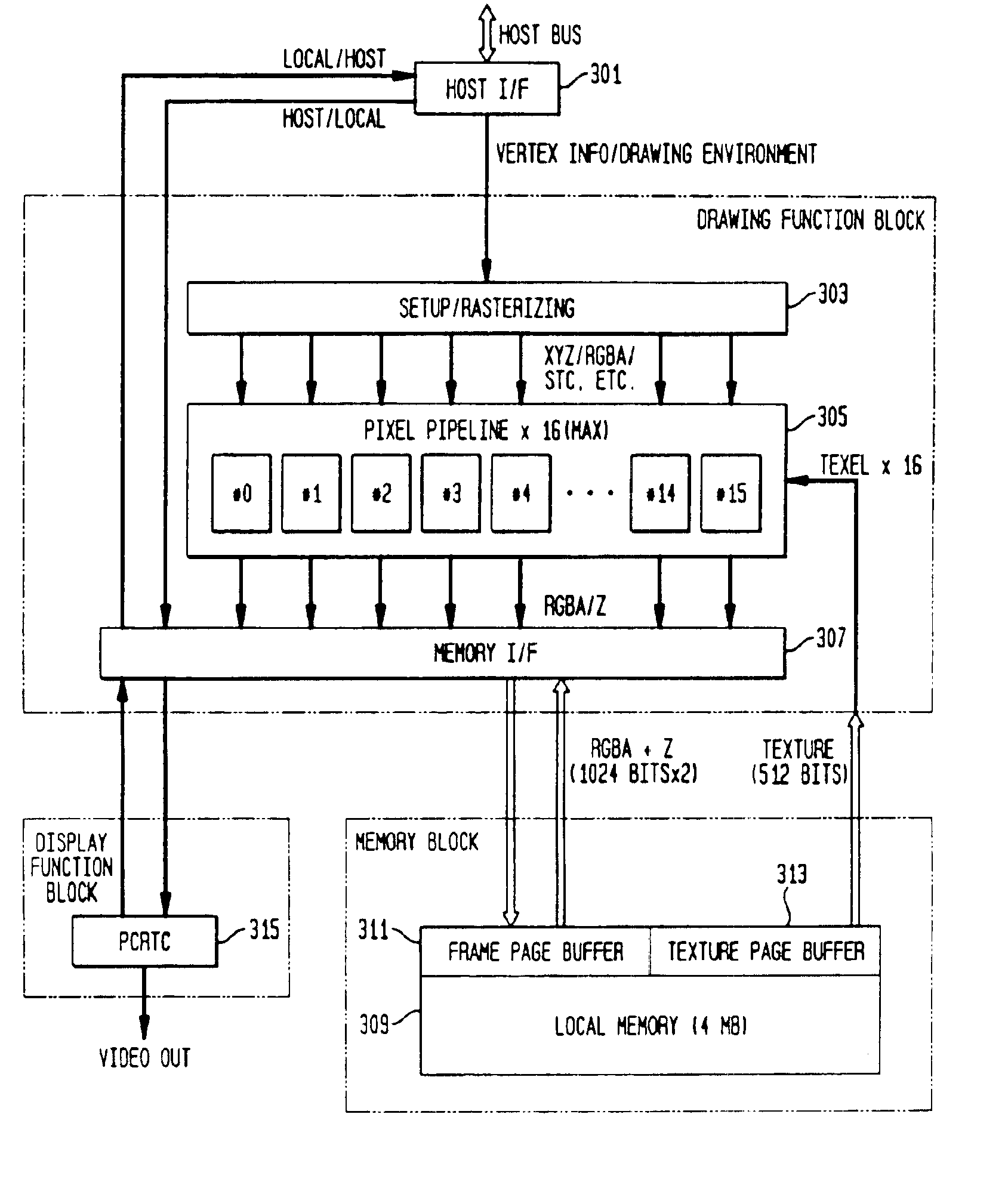

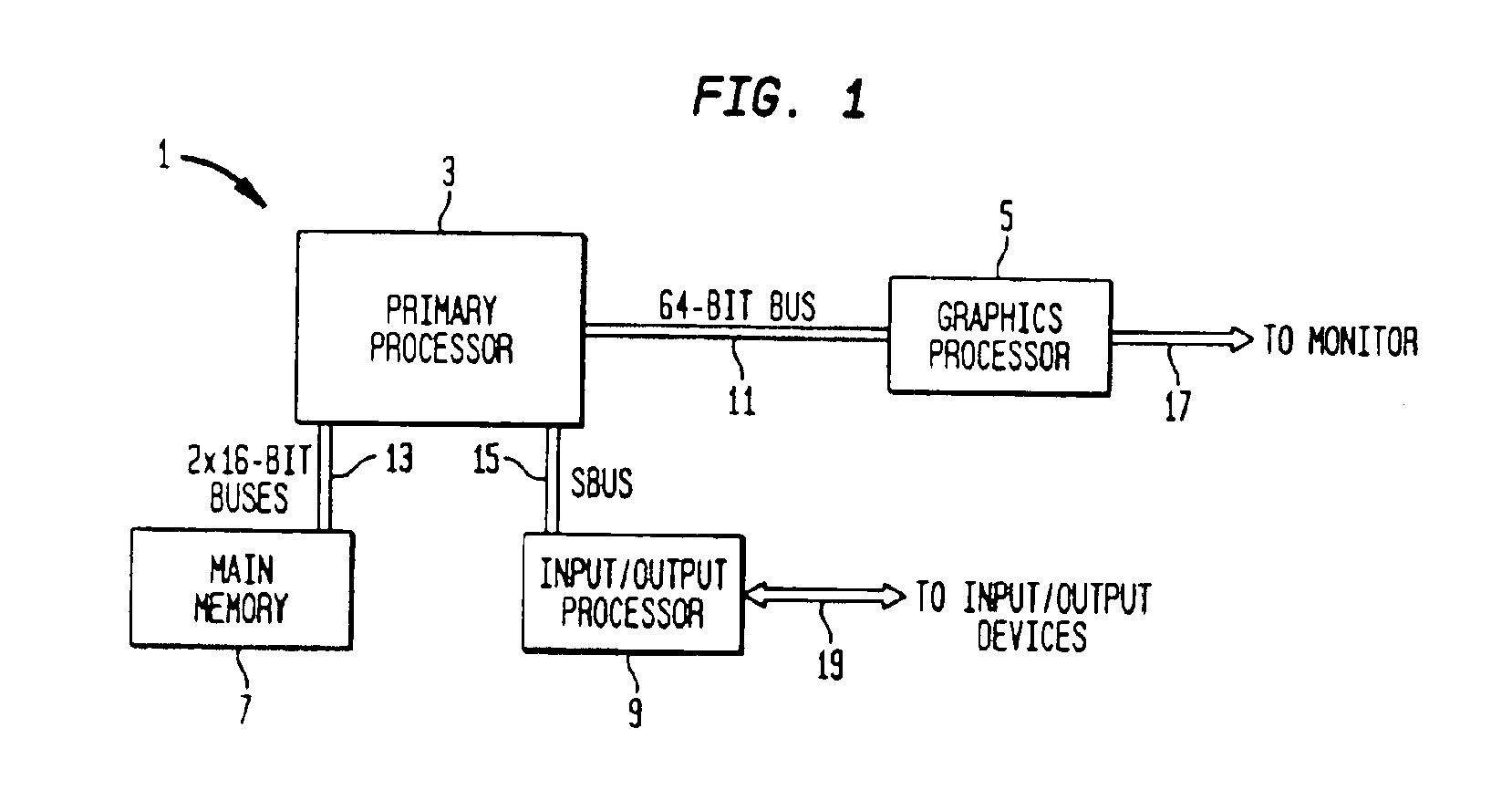

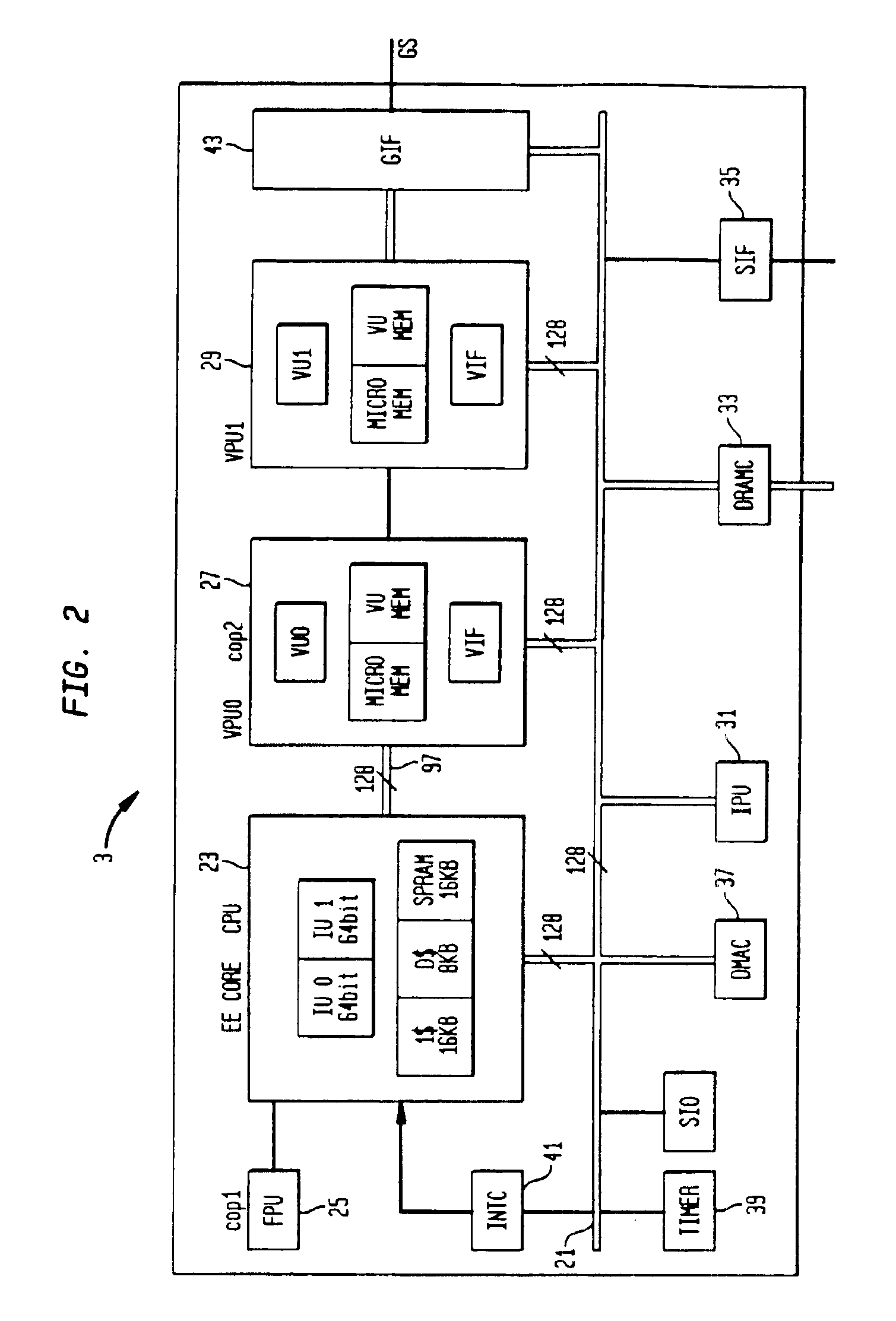

Game system with graphics processor

InactiveUS6891544B2Reduce data volumeHide main memory latencyIndoor gamesDigital computer detailsFill rateData stream

The present invention relates to the architecture and use of a computer system optimized for the efficient modeling of graphics. The computer system has a primary processor and a graphics processor. The primary processor has two vector processor units within it, one which is closely connected to central processor unit. Simultaneously performing complex modeling calculations on the first vector processor and CPU, and geometry transformation calculations on the second vector processor, allows for efficient modeling of graphics. Furthermore, the graphics processor is optimized to rapidly switch between data flows from the two vector processors. In addition, the graphics processor is able to render many pixels simultaneously, and has a local memory on the graphics processor chip that acts as a frame buffer, texture buffer, and z buffer. This allows a high fill rate to the frame buffer.

Owner:SONY COMPUTER ENTERTAINMENT INC

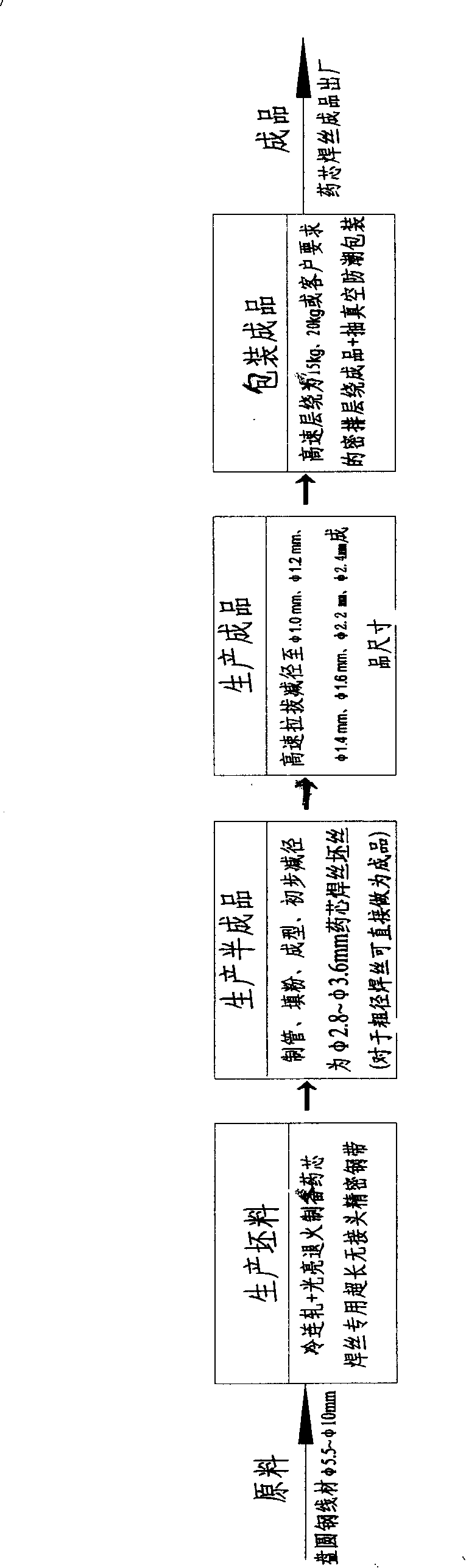

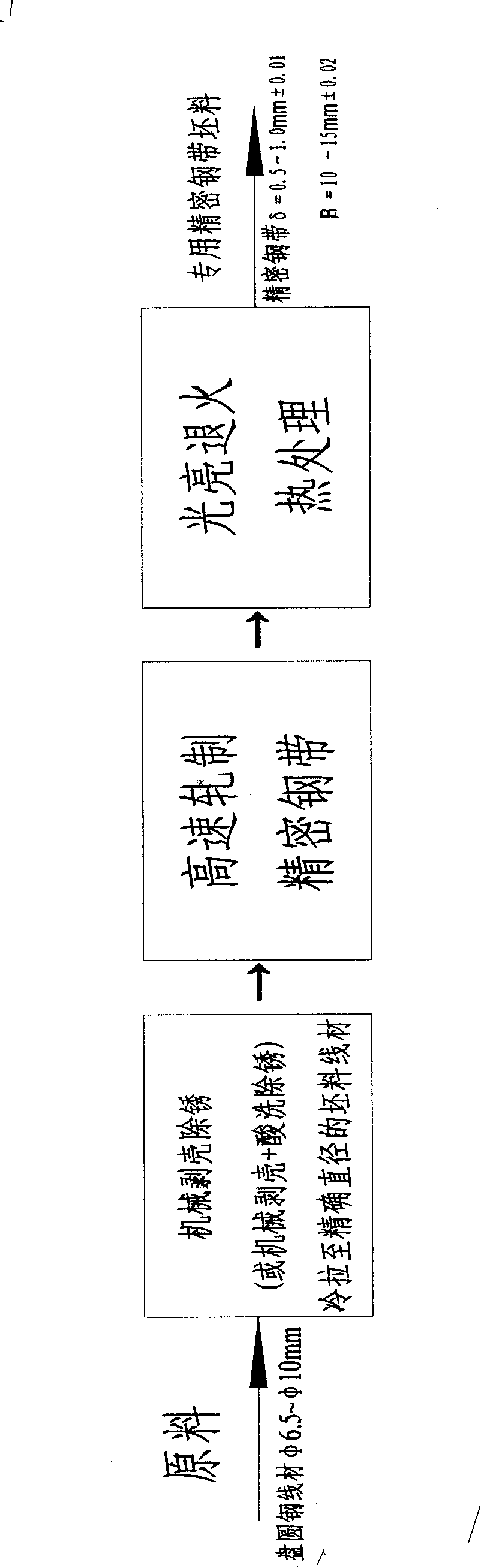

Technique for manufacturing flux-cored wire from disk round steel wire bar

InactiveCN101239430ASufficient bending radiusPrevent space warpingFurnace typesRollsFill rateBreakage rate

A technique for producing flux-cored wires by using disc round steel wire bars is characterized by comprising following steps: using disc round steel wire bars as raw materials; producing accurate steel bands used for flux-cored wires exclusively; producing semi-finished products which are flux-cored wire blank tubes by using accurate steel bands; producing termination products by drafting to reduce the diameter thereof with a high speed; packaging the termination products by winding with a high speed. The advantages of the invention are: the invented technique uses high-speed hot-rolling disc round steel wire bars to replace broad cold-rolled steel strip, so that the raw material cost is reduced greatly; the continuous overlong endless accurate steel bands are used to save assistant procedure time for welding steel band joints, reduce end breakage rate during rolling and drafting procedures, improve continuous operation rate, and further reduce production cost; the invented technique uses high-speed accurate cold tandem rolling machine group to solve the problem that the sheet iron rolling precision is difficult to be controlled when rolling flux-cored wires by using disc round steel wire bars directly, and the filling precision is improved greatly since size accuracy of the flux-cored wire exclusive use accurate steel bands is high.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

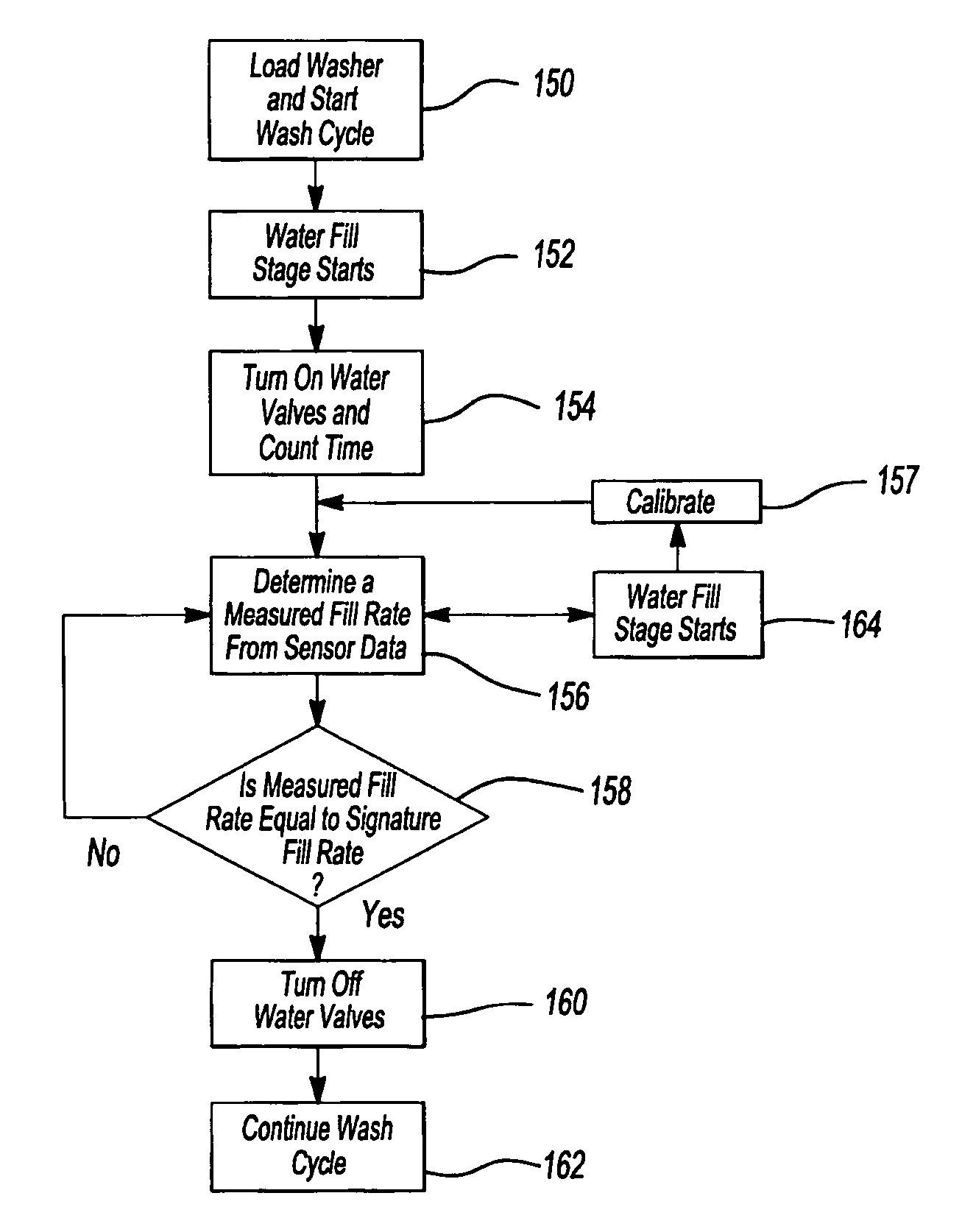

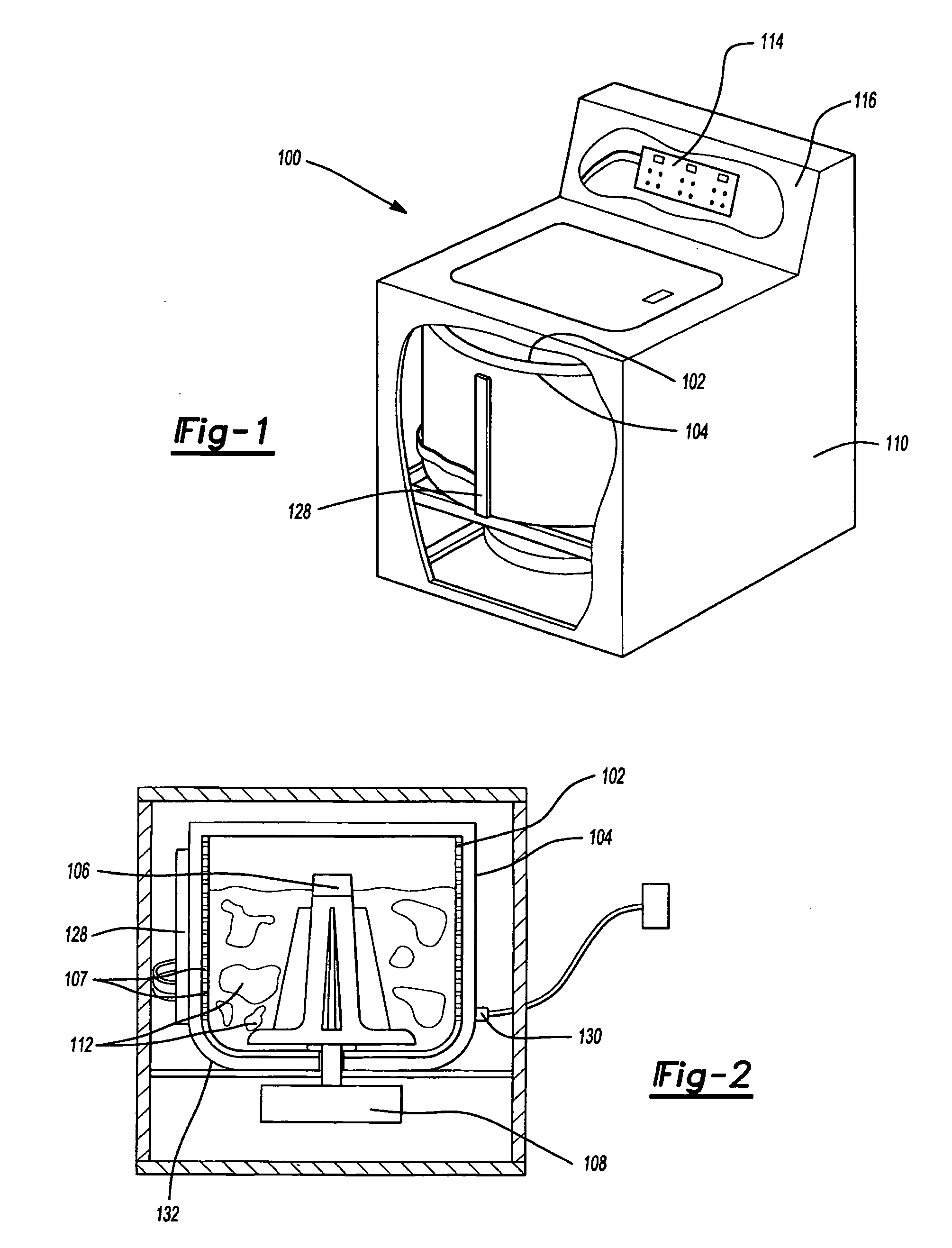

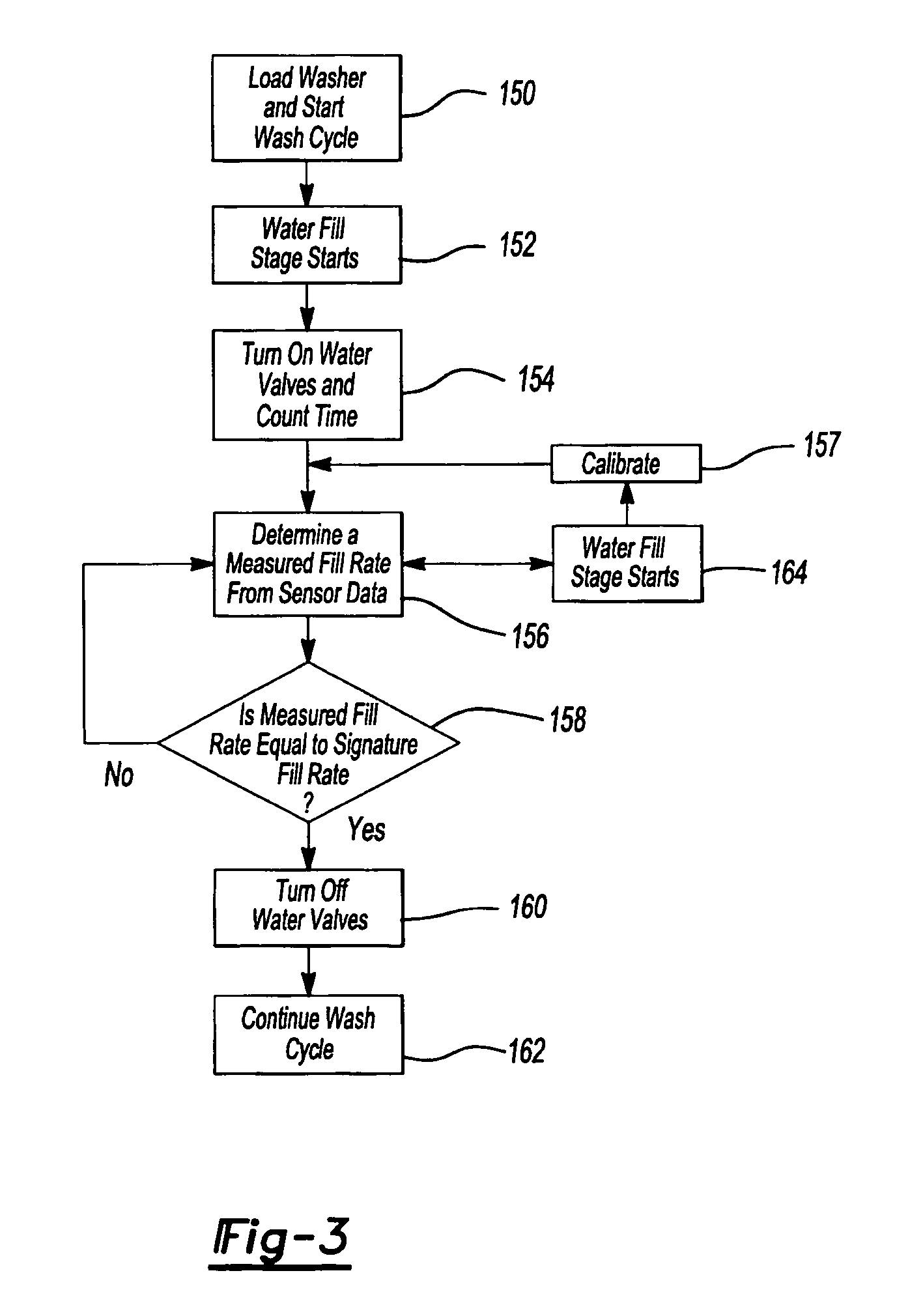

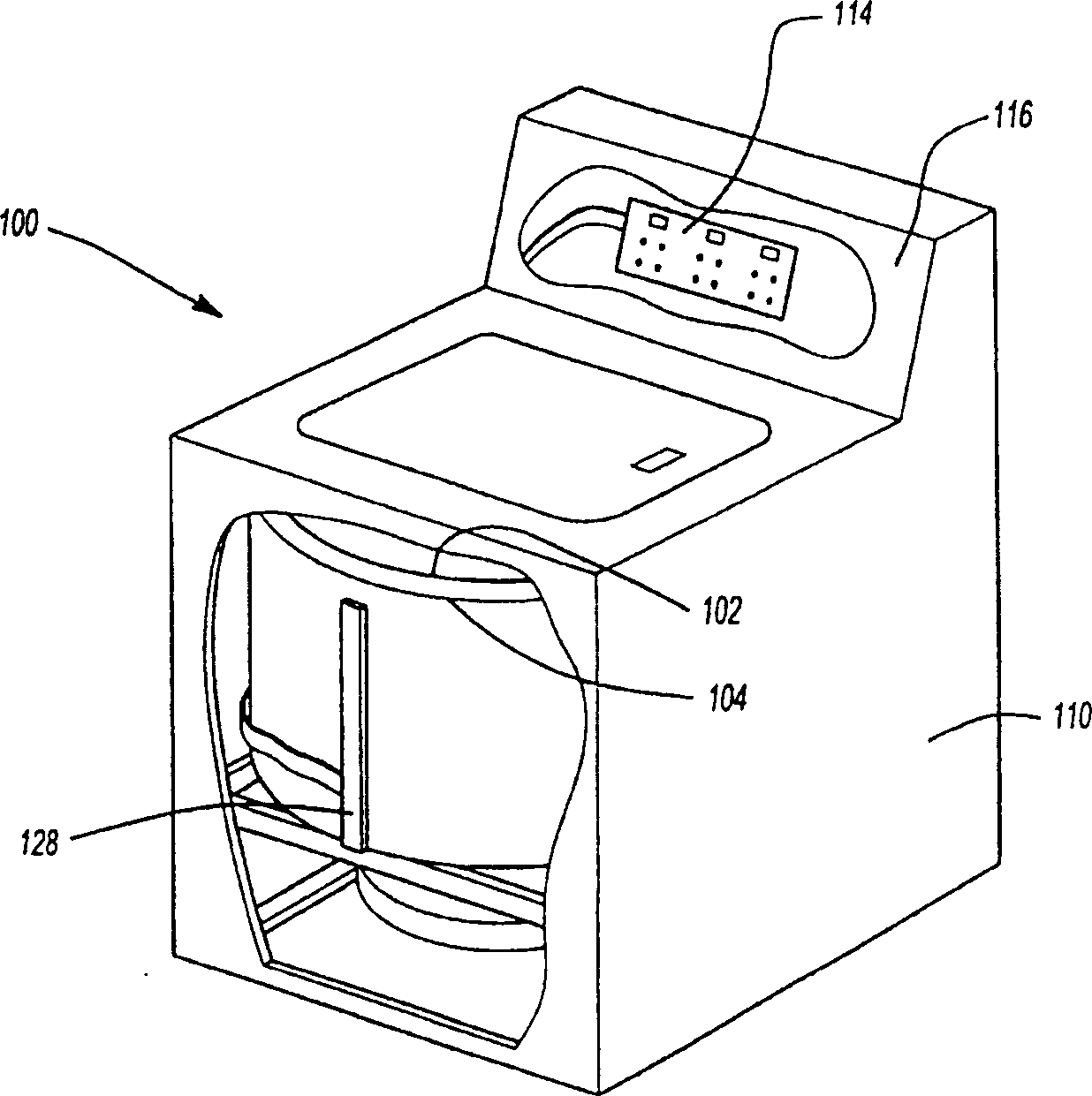

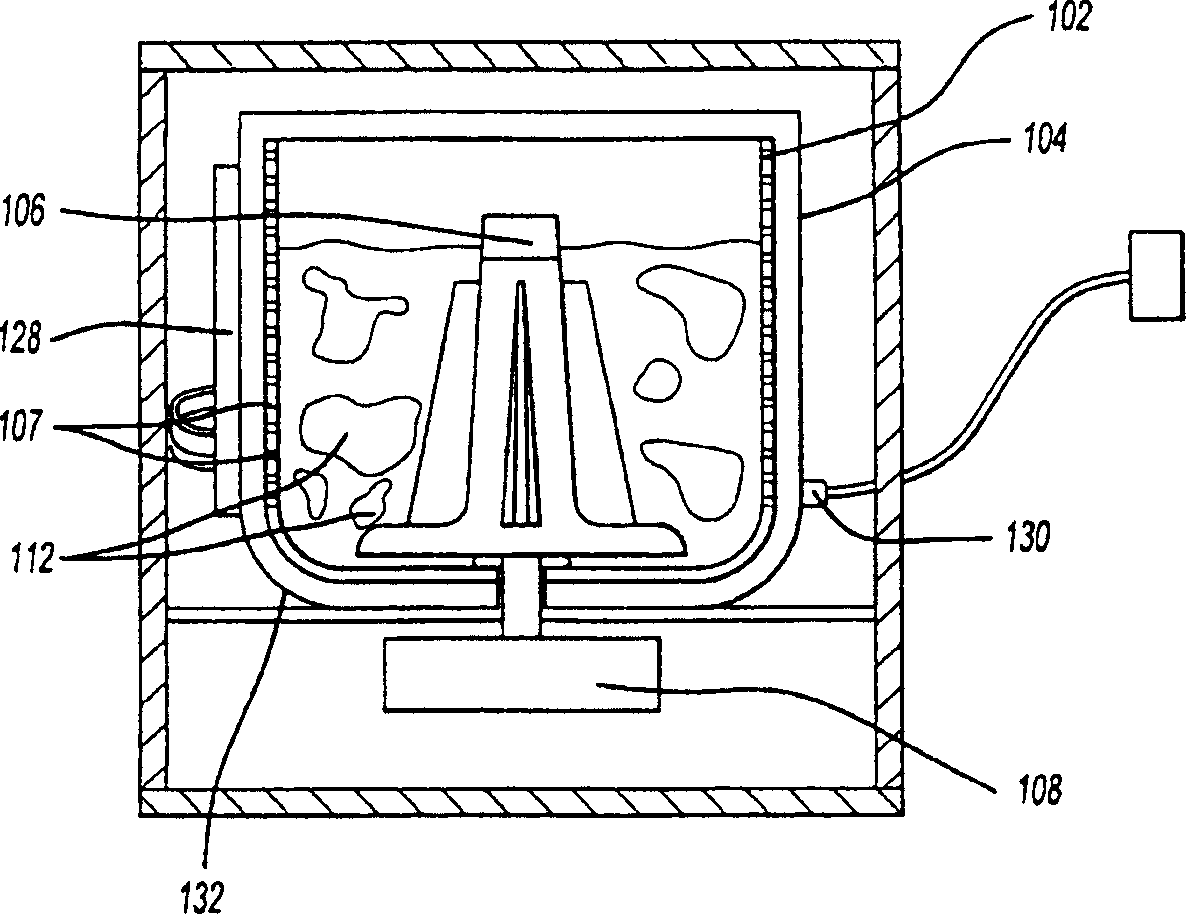

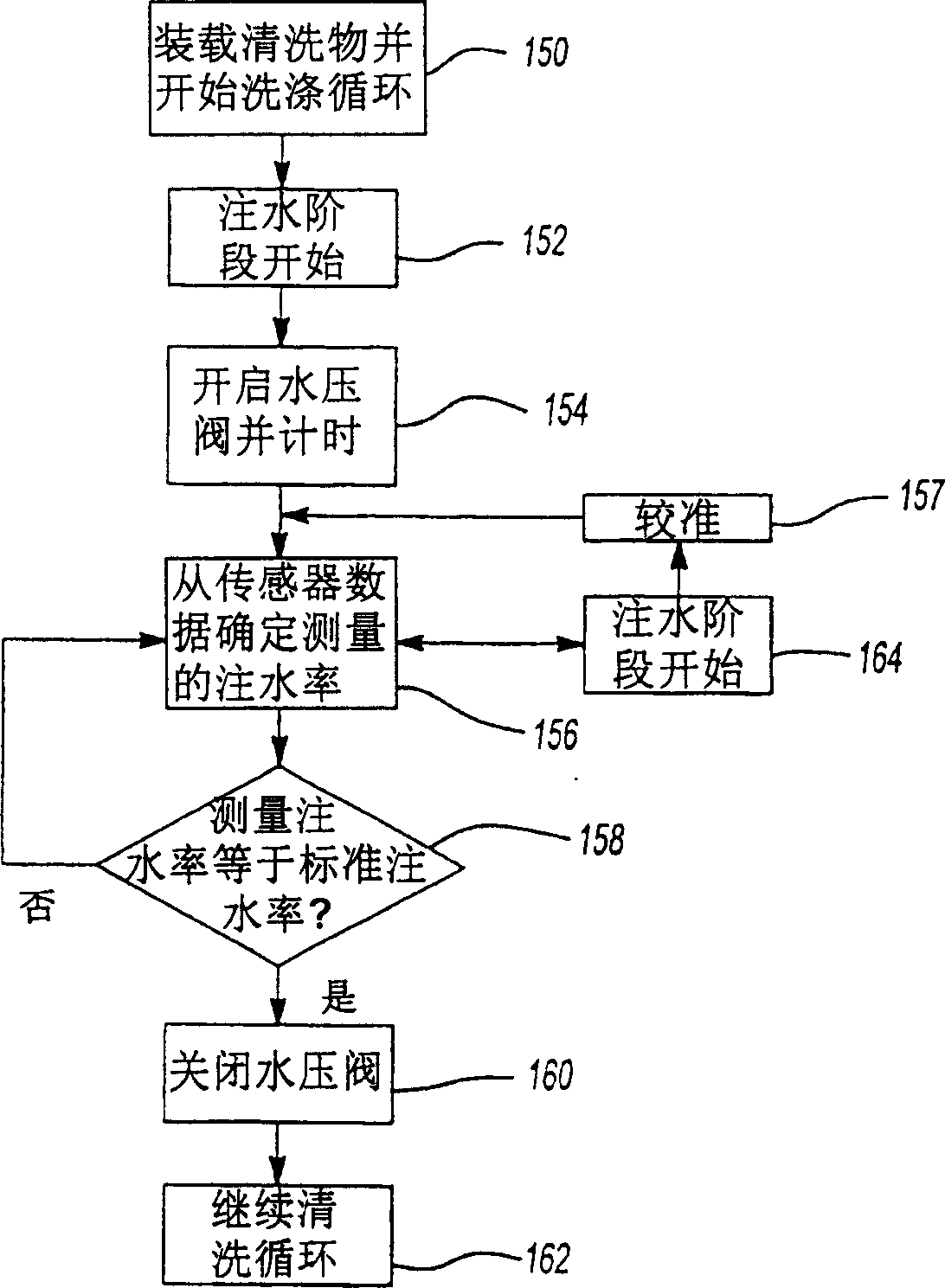

Washing machine with water control and associated method

InactiveUS20050166334A1Other washing machinesControl devices for washing apparatusFill rateEngineering

An automatic washing machine with water level control and associated method. In one embodiment, the washing machine comprises a tub for receiving a load of clothes, a water level sensor taking water level measurements during a water fill stage, and a controller. The controller controls a water valve that introduces water into the washing machine. The controller comprises a timer, a memory and a microprocessor. The microprocessor accesses a signature fill rate of the washing machine when unloaded, receives water level measurements from the sensor during the fill stage, and determines a measured fill rate. The microprocessor compares the measured fill rate to the signature fill rate and shut off the water valve when the measured fill rate is substantially equal to the signature fill rate.

Owner:EMERSON ELECTRIC CO

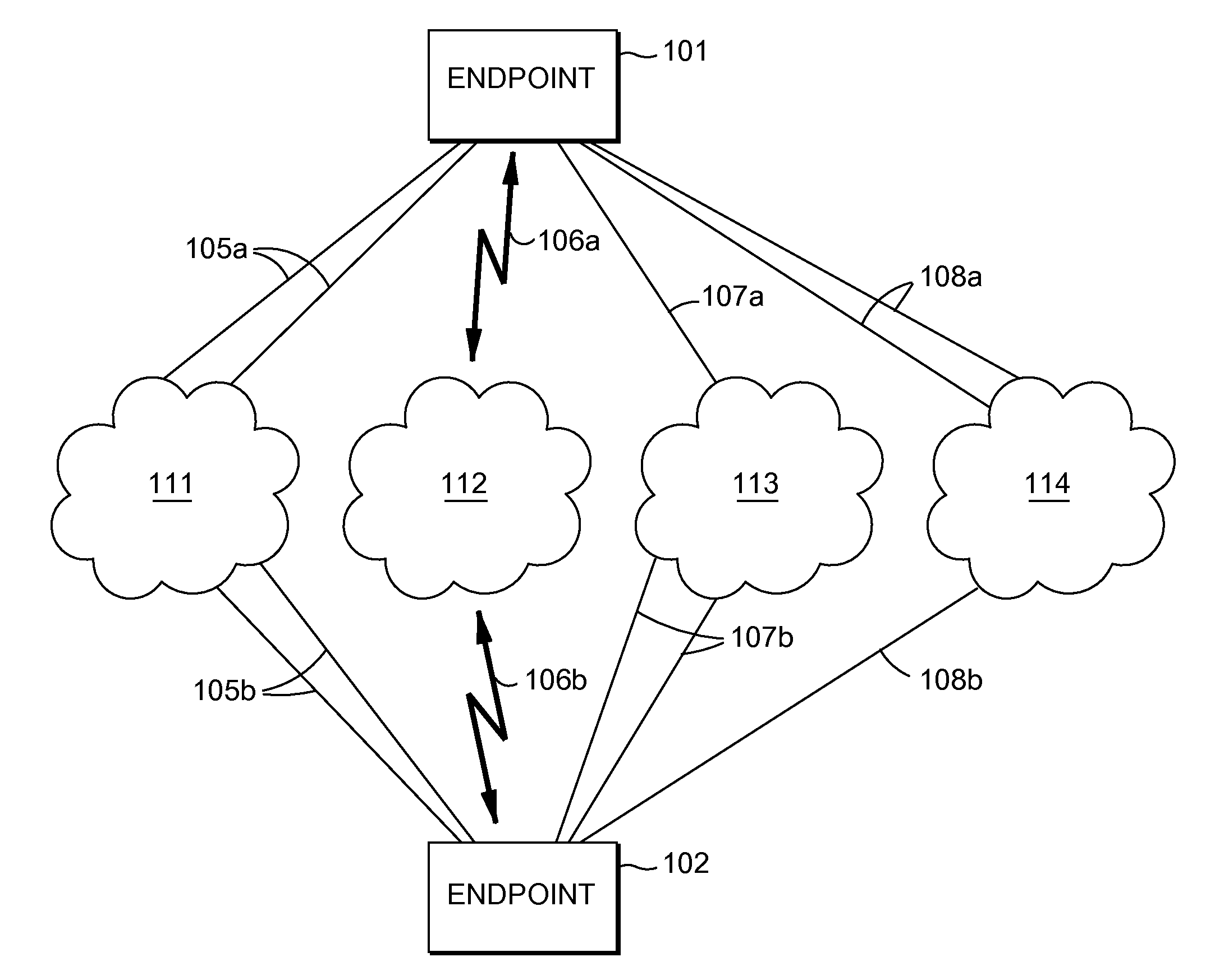

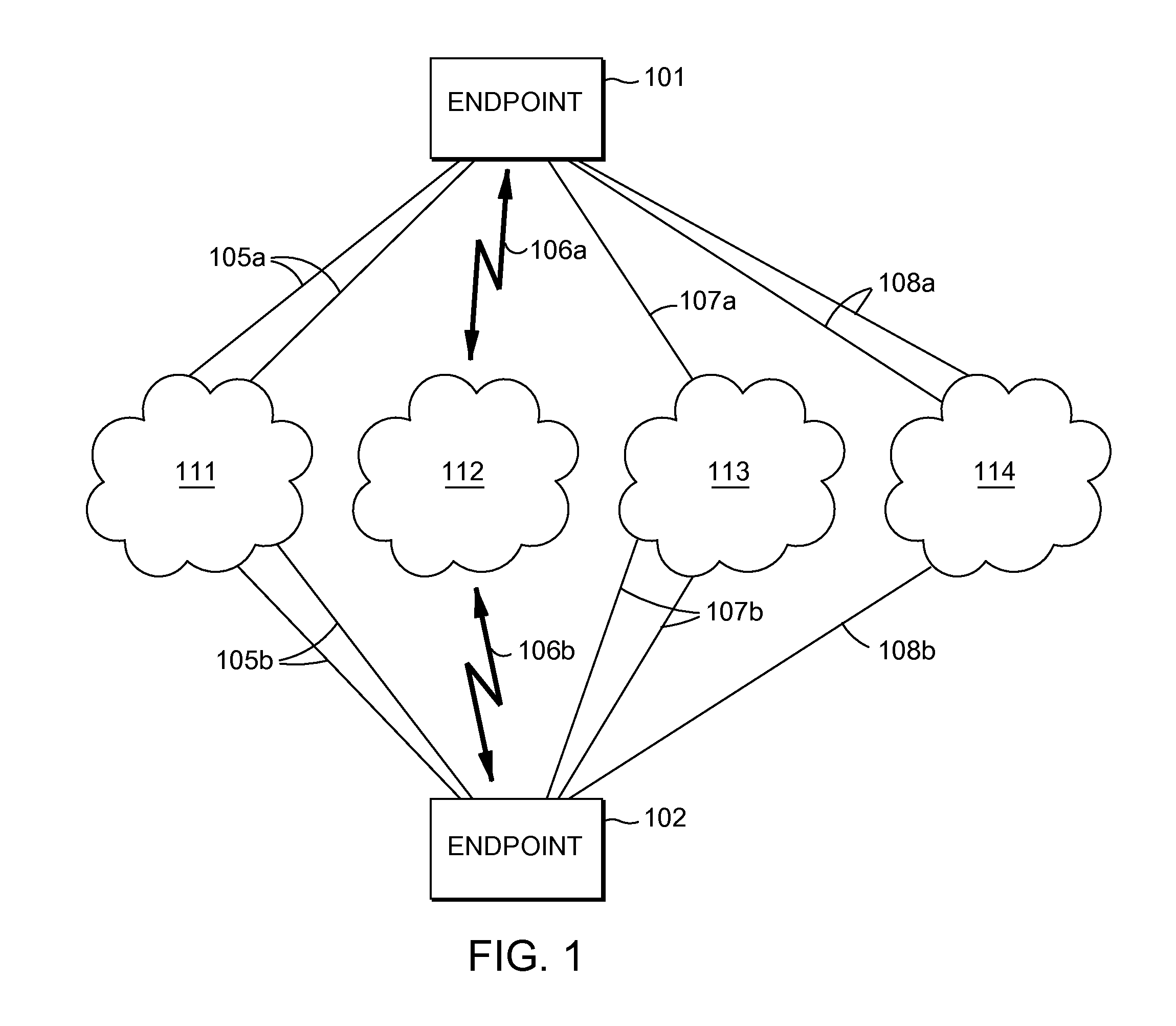

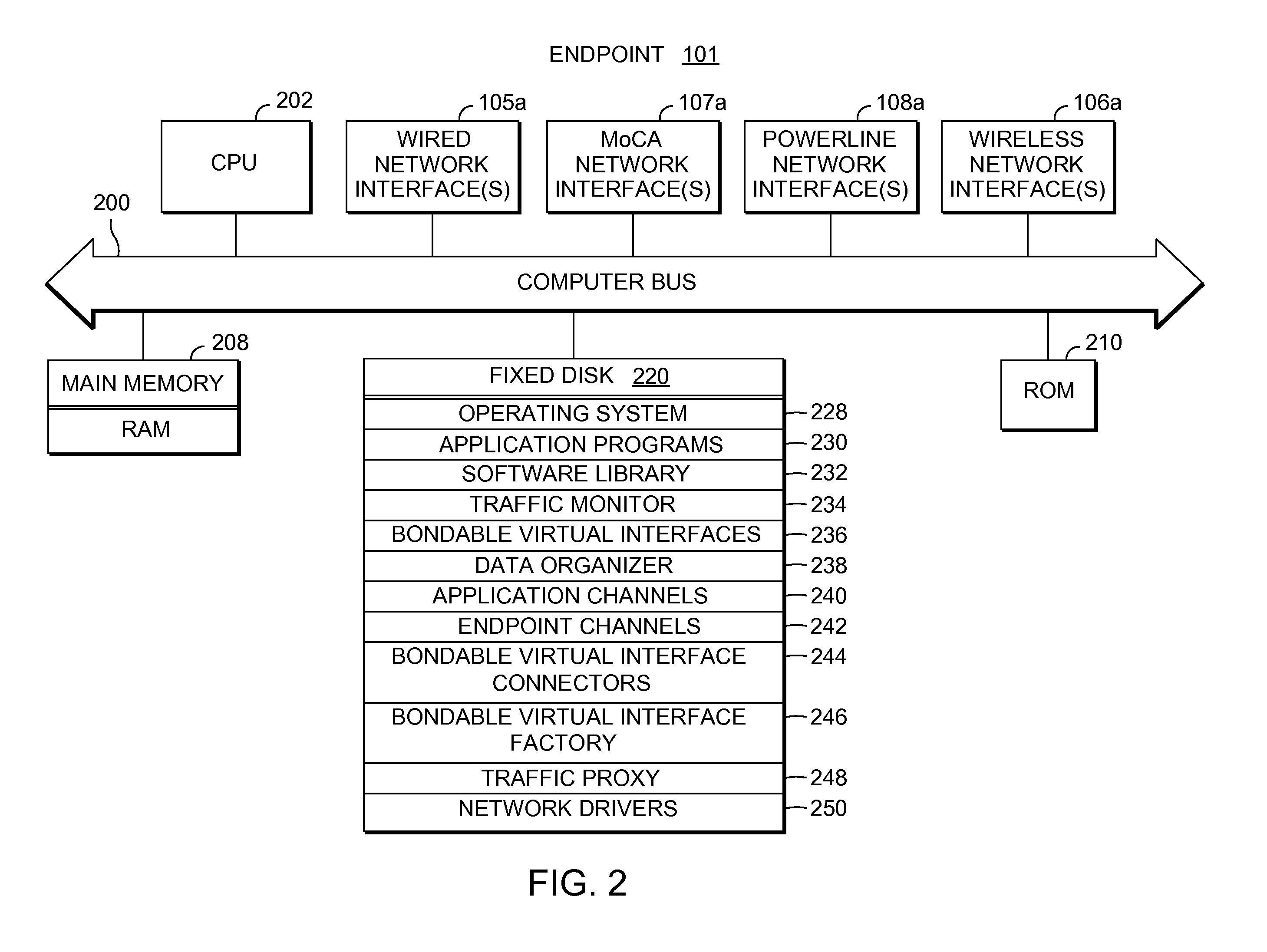

Network streaming over multiple physical interfaces

ActiveUS20110264818A1Data efficientEfficient and high quality streaming dataEnergy efficient ICTMultiple digital computer combinationsFill rateData stream

The present disclosure is directed to controlling a sending of a single data stream from a sending endpoint to a receiving endpoint. Both of the endpoints each have multiple physical interfaces connecting each endpoint to one or more networks. A buffer size is selected for a buffer at the receiving endpoint, and an estimation is made by the receiving endpoint of a fill rate of the buffer. The estimated fill rate is then compared with a target fill rate. Feedback is then sent by the receiving endpoint over one or more of the physical interfaces instructing the sending endpoint to reduce or increase a rate at which data is being sent, if the estimated fill rate is more than the target fill rate or the estimated fill rate is less than the target fill rate, respectively. The splitting and sending of data is then adjusted according to the feedback.

Owner:CANON KK

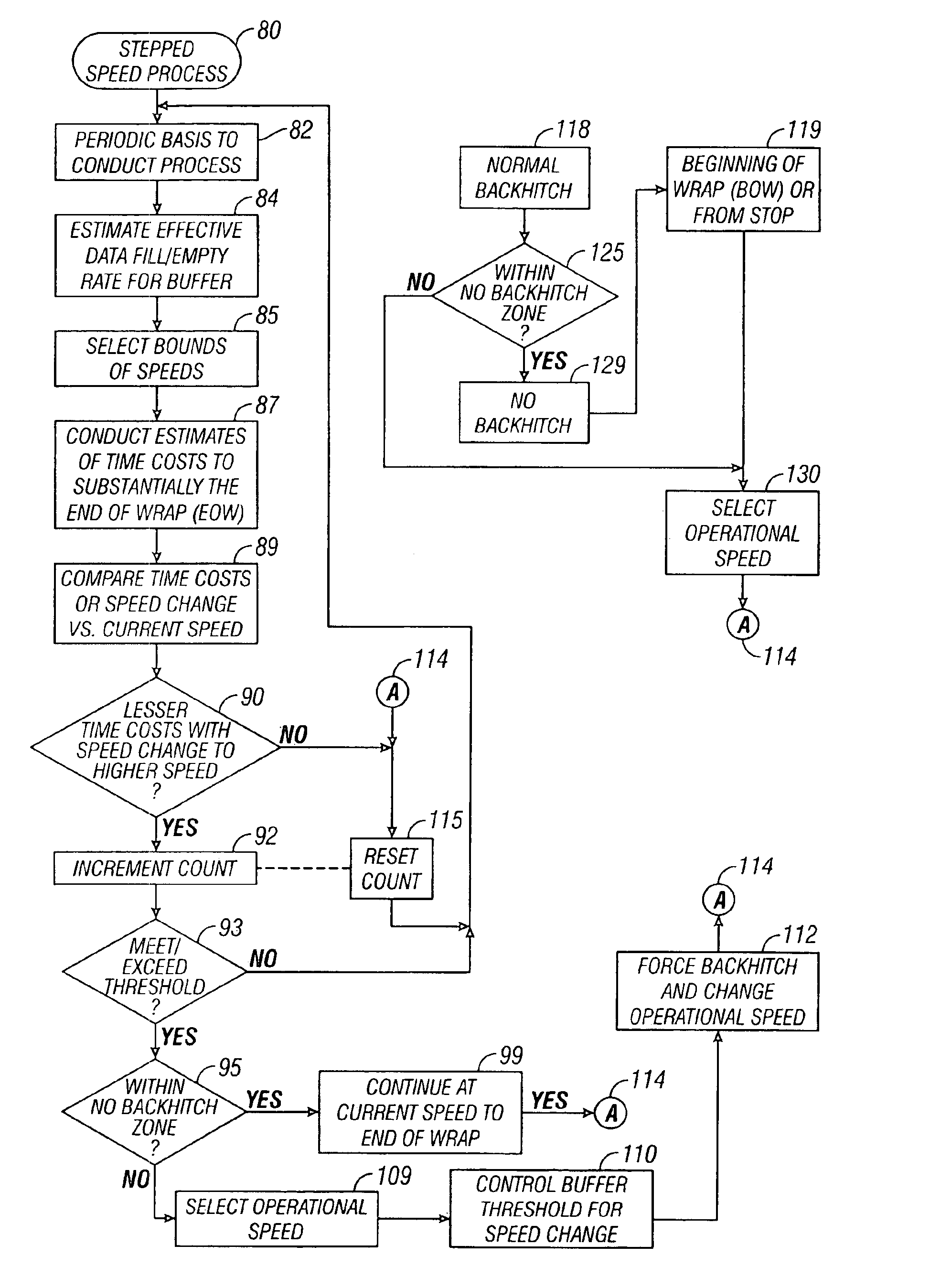

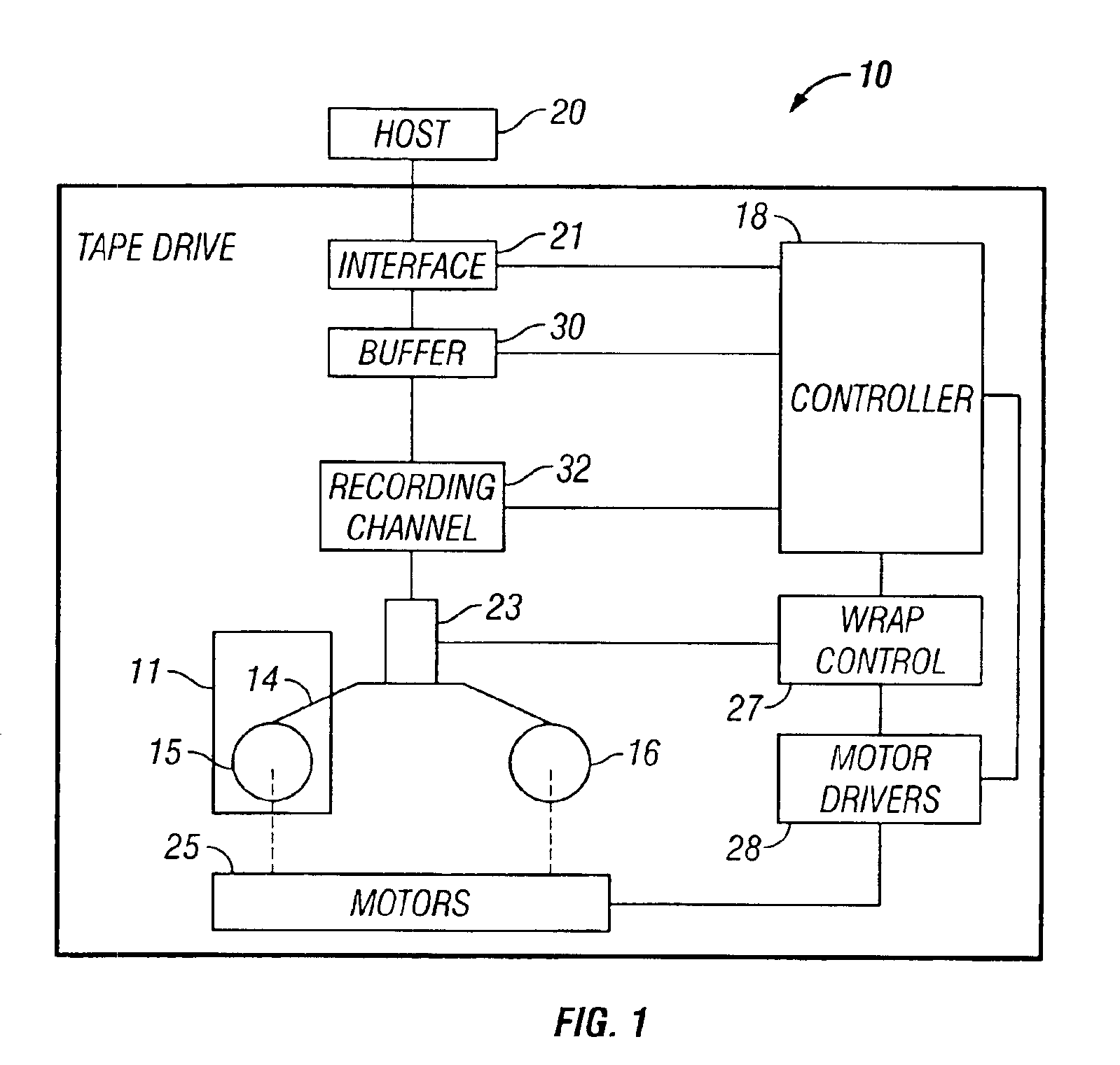

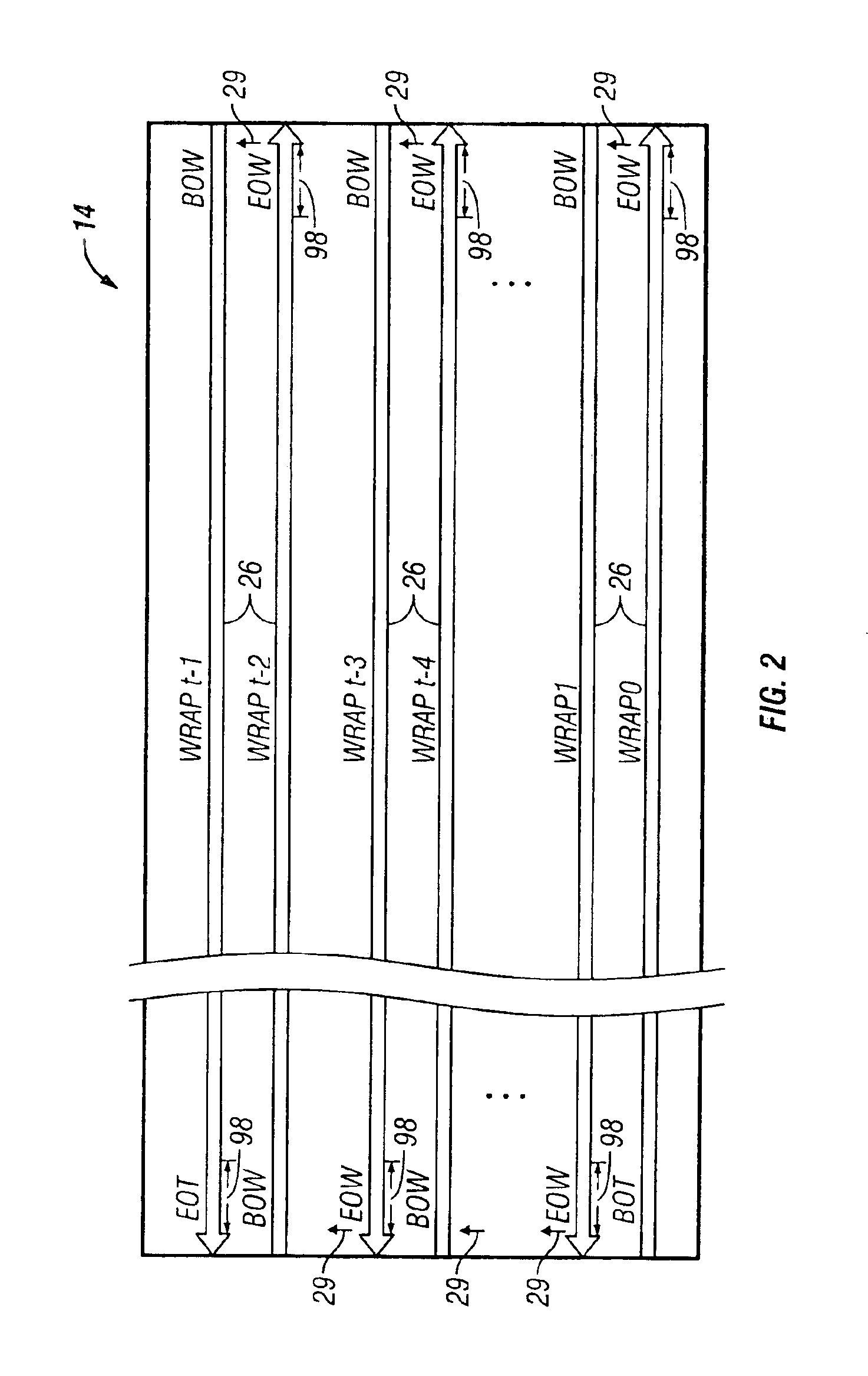

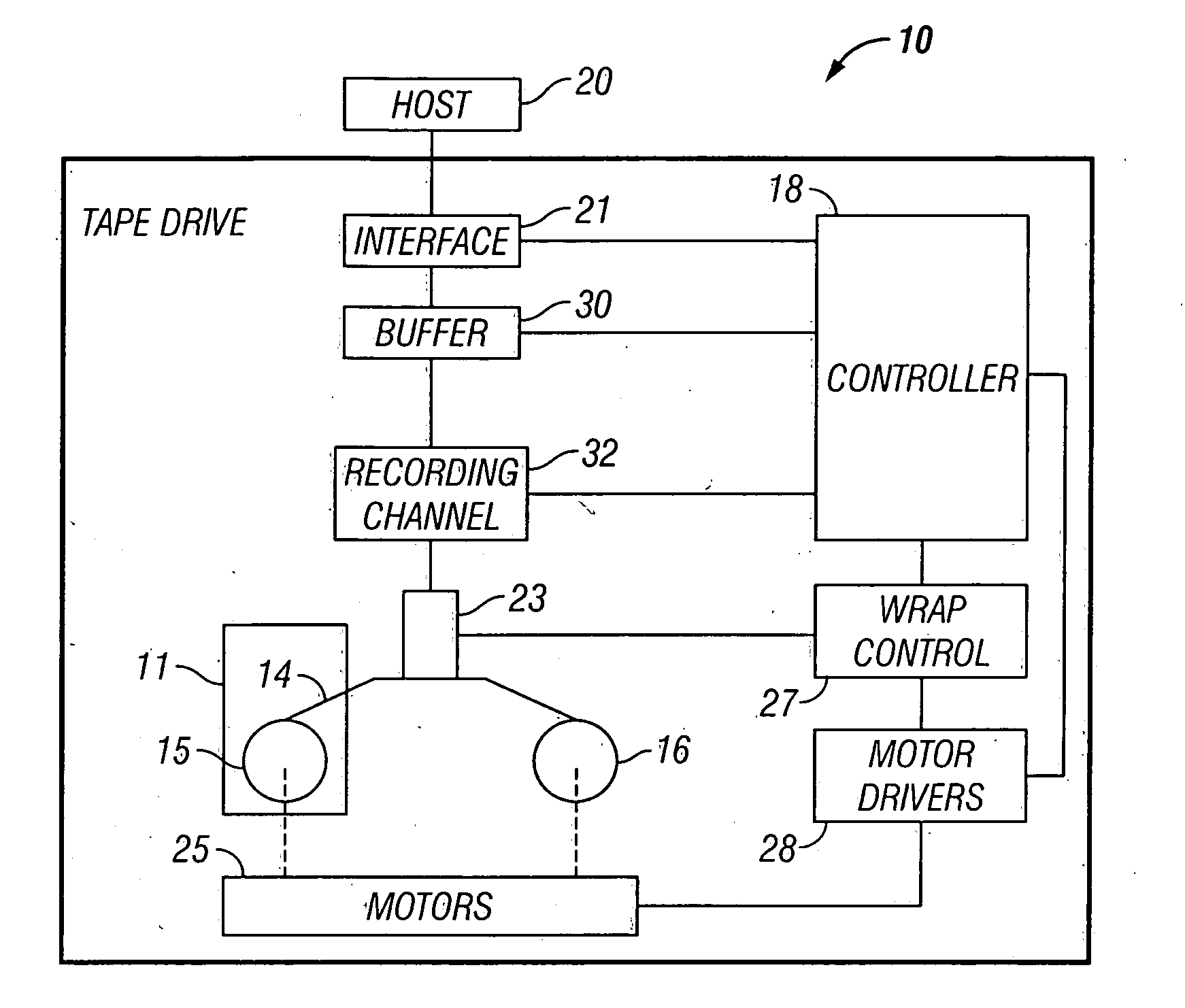

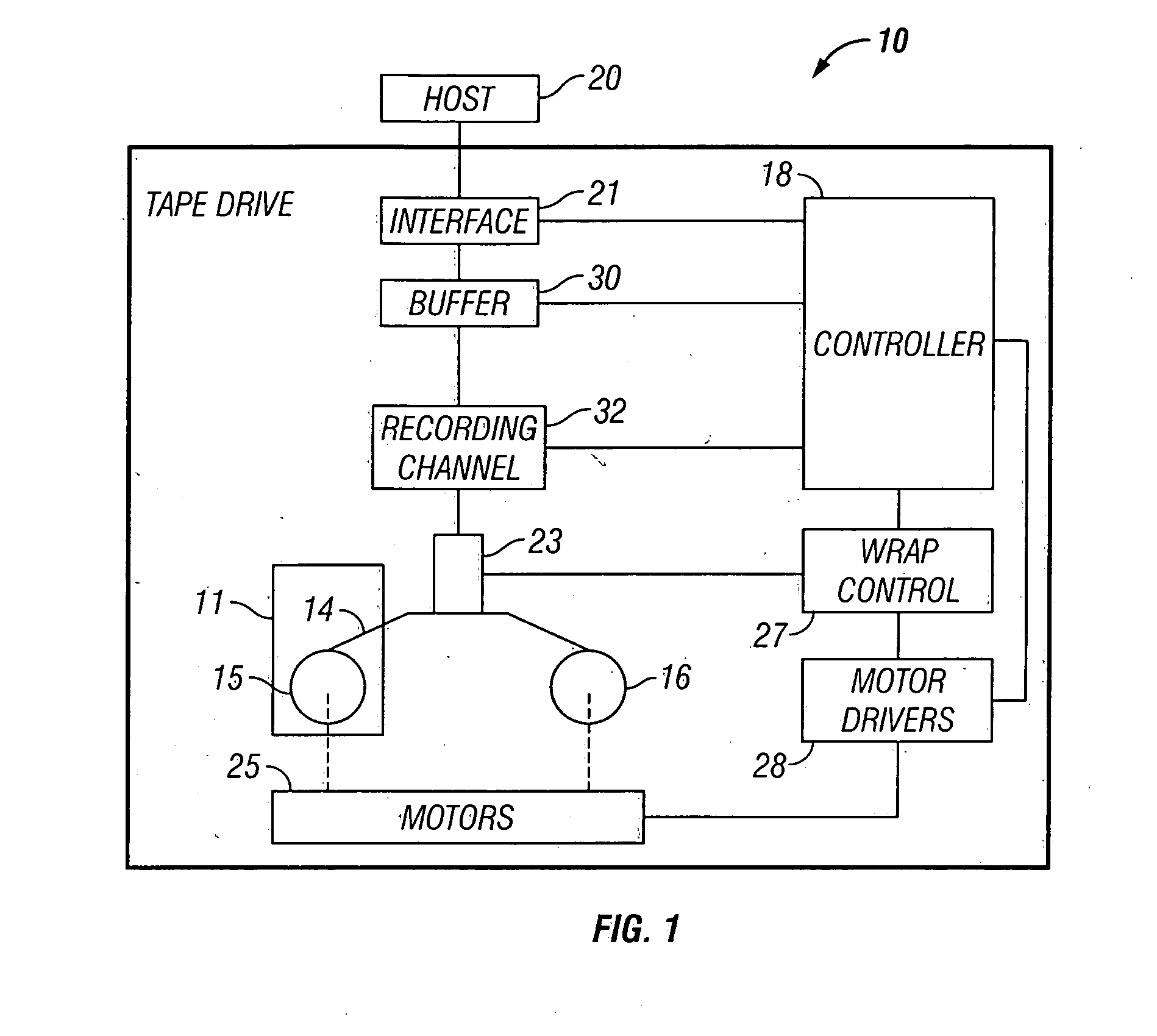

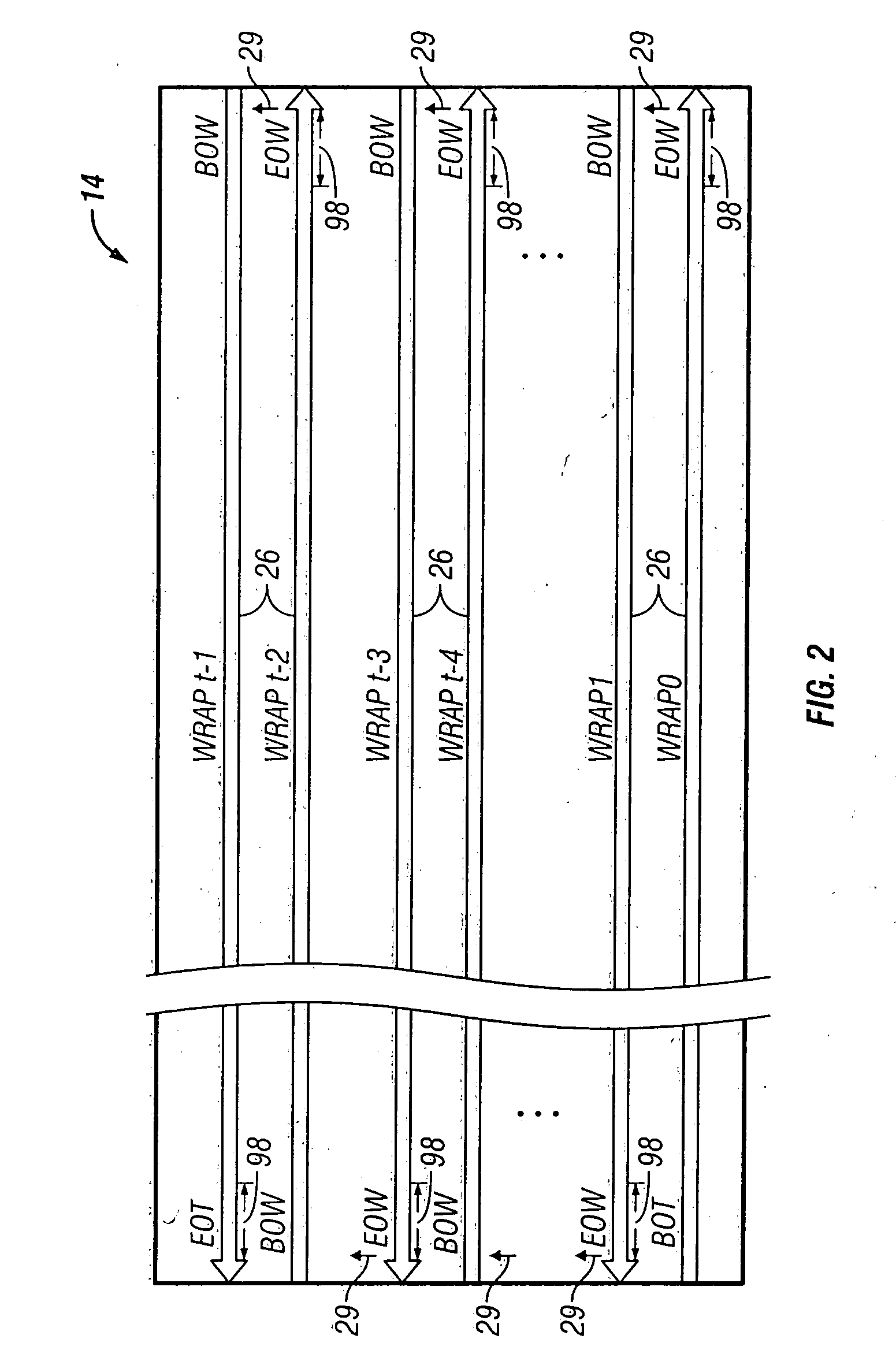

Forced backhitch for speed matching in a multi-speed tape drive

InactiveUS6958878B2Low costRecord information storageCarrier speed control/regulation/indicationFill rateMagnetic tape

In a magnetic tape drive having a plurality of stepped operational speeds, data storage logic estimates, from the effective data fill rate for a data buffer and the drive data write rate, the time cost to continue to operate the magnetic tape drive at the current stepped operational speed from a target to the next end of wrap; estimates, the time cost to force a backhitch of the magnetic tape data storage media and change the stepped operational speed to a higher stepped operational speed and operate the magnetic tape drive at the higher stepped operational speed to the next end of wrap; and determines the lesser time cost.

Owner:INT BUSINESS MASCH CORP

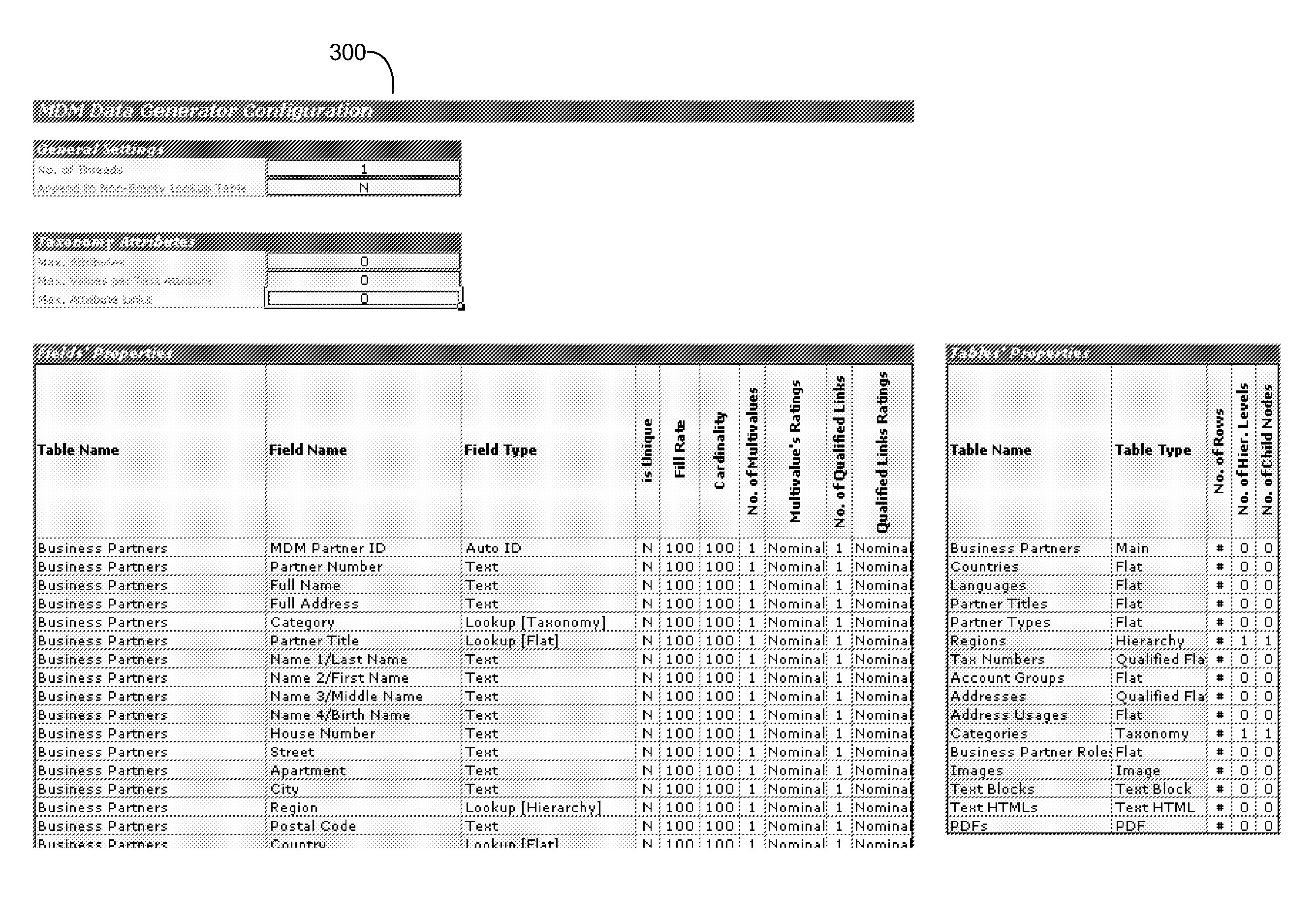

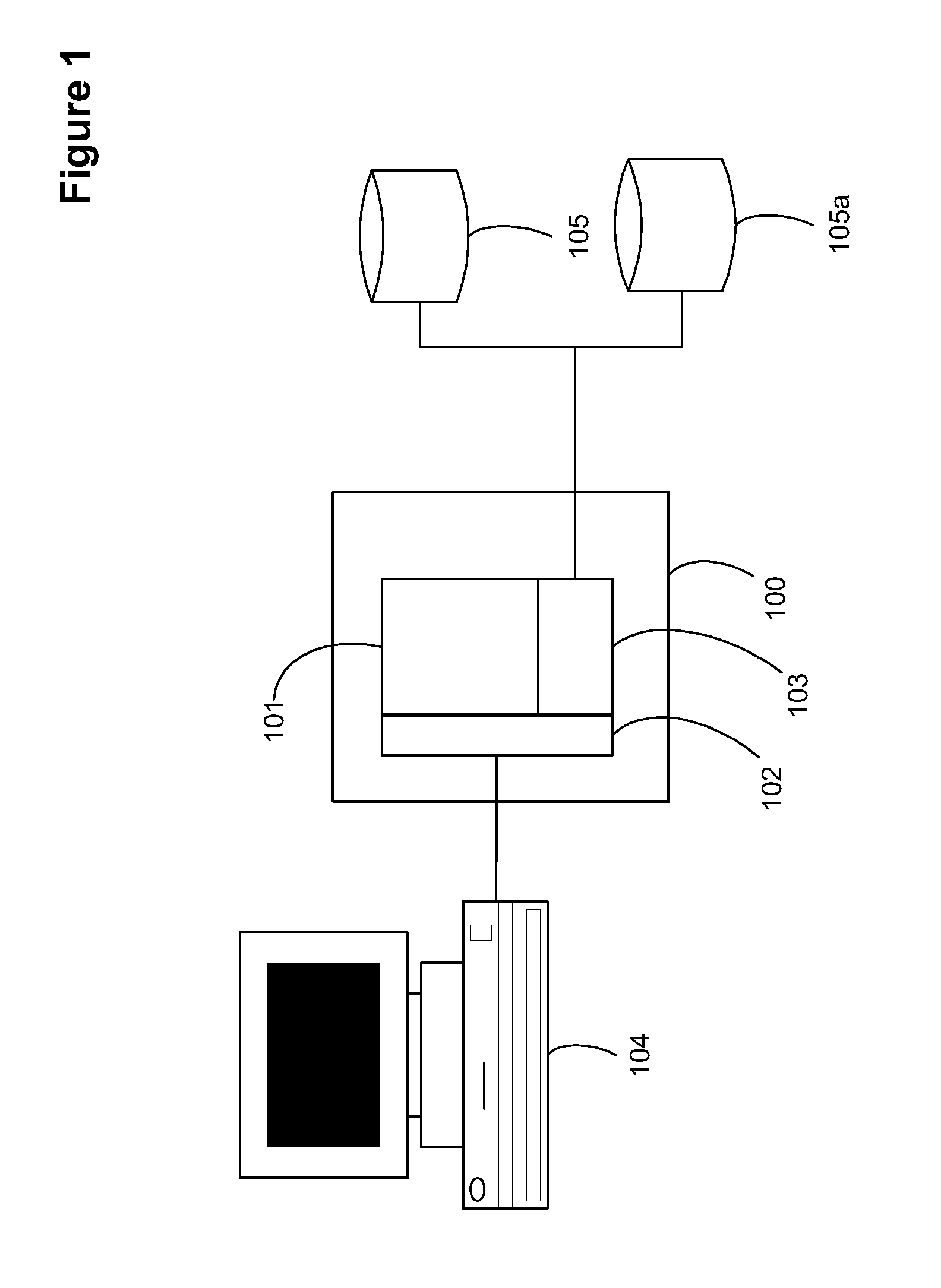

Data generator apparatus testing data dependent applications, verifying schemas and sizing systems

ActiveUS20080256111A1Save a lot of spaceSpeed up the build processError detection/correctionDigital data processing detailsFill rateDatabase schema

A data generator for database schema verification, system sizing and functional test of data dependent applications. Allows for generation of data from random values or from working databases which may be profiled to generate patterns for occurrences of values and sizes of values. The data may be filled with a fill rate that dictates the percentage of fields assigned nulls. Cardinality allows for a fixed number of values to occur across the records for a field. May utilize reference data associated with an existing database to fill fields. Qualifiers and multi-value fields may be filled to mimic real data. Maximum, nominal and average number of occurrences of sizes of data and qualifiers and multi-value data may be specified. May also utilize dictionaries to fill. Hierarchical levels and number of child nodes may also be specified and used in filling taxonomy tables and hierarchy tables for example.

Owner:SAP AG

Submerged-arc welding metal core weldingwire for austenite stainless steel

InactiveCN1820890AImprove deposition efficiencyWell formed weldArc welding apparatusWelding/cutting media/materialsManganeseAlloy

The present invention belongs to the field of material processing technology, relates to the welding technology of austenite stainless steel, and is especially one kind of metal core welding wire for submerged-arc welding of austenite stainless steel. The present invention features that the metal core welding wire has a coating layer of carbon steel belt and ultra low carbon steel belt; and a powder core comprising Cr 34-55 wt%, Ni 20-33 wt%, Mn 3-7 wt%, Mo 4-8 wt%, Fe 4-21 wt%, Bi2O3 0.5-1.5 wt% and Al-Mg alloy 2-10 wt%, and with filling rate of 40-58 %. The present invention has simple production process and excellent welding detachability, and is especially suitable for use in high speed automatic welding.

Owner:BEIJING UNIV OF TECH

Method of conditioning a particle filter

ActiveUS20150285173A1Improve filtration efficiencyThermal propertyAnalogue computers for vehiclesElectrical controlFill rateInternal combustion engine

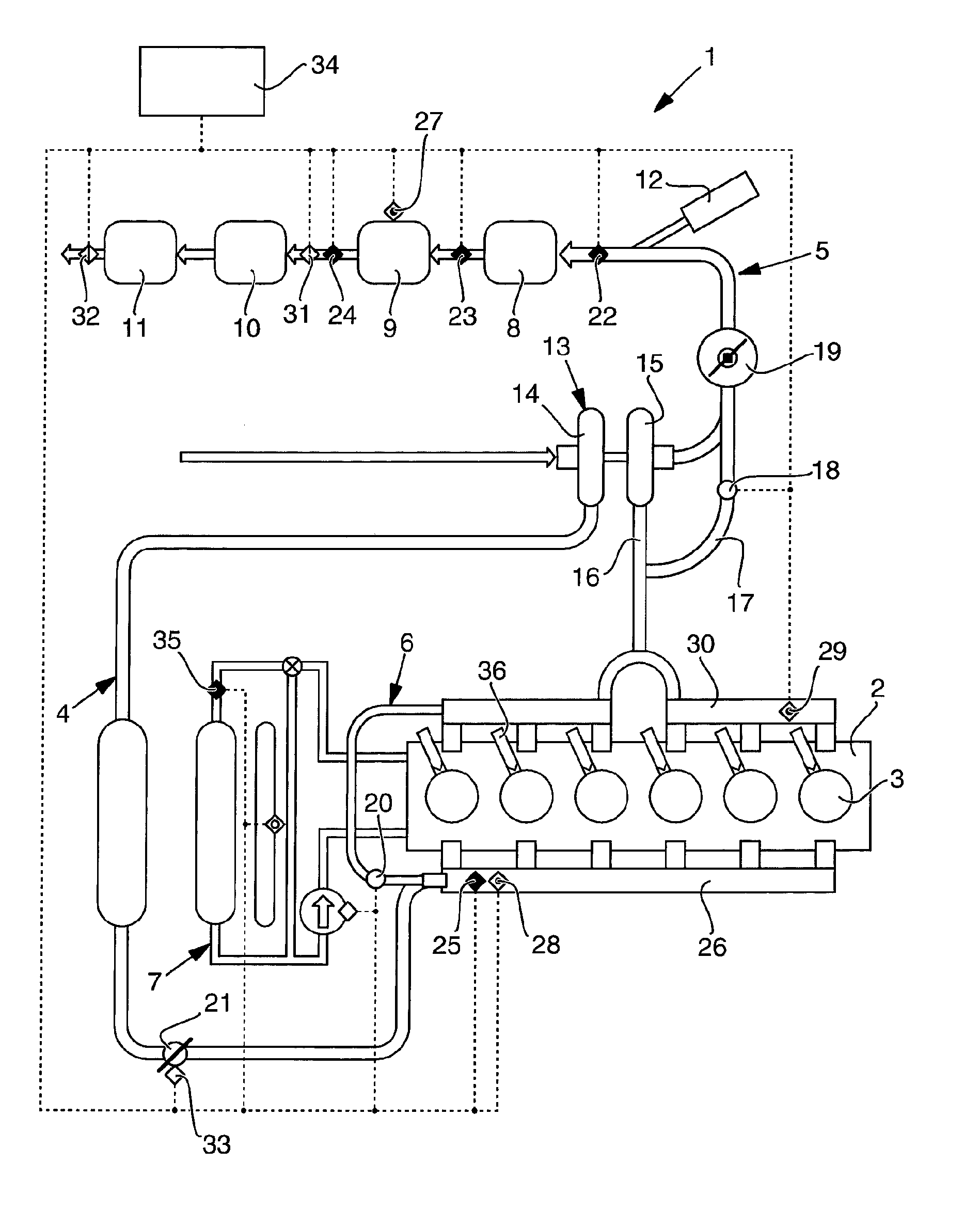

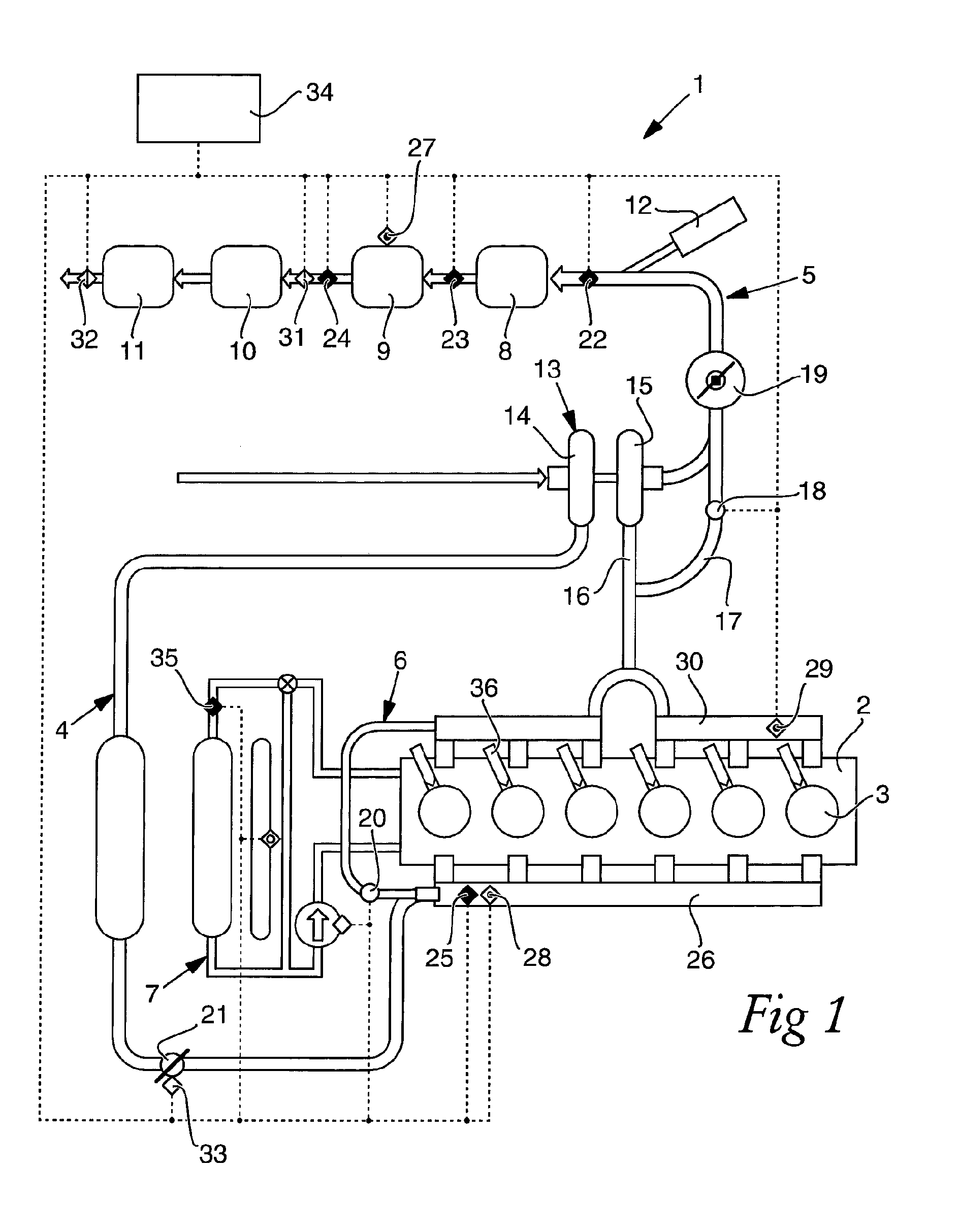

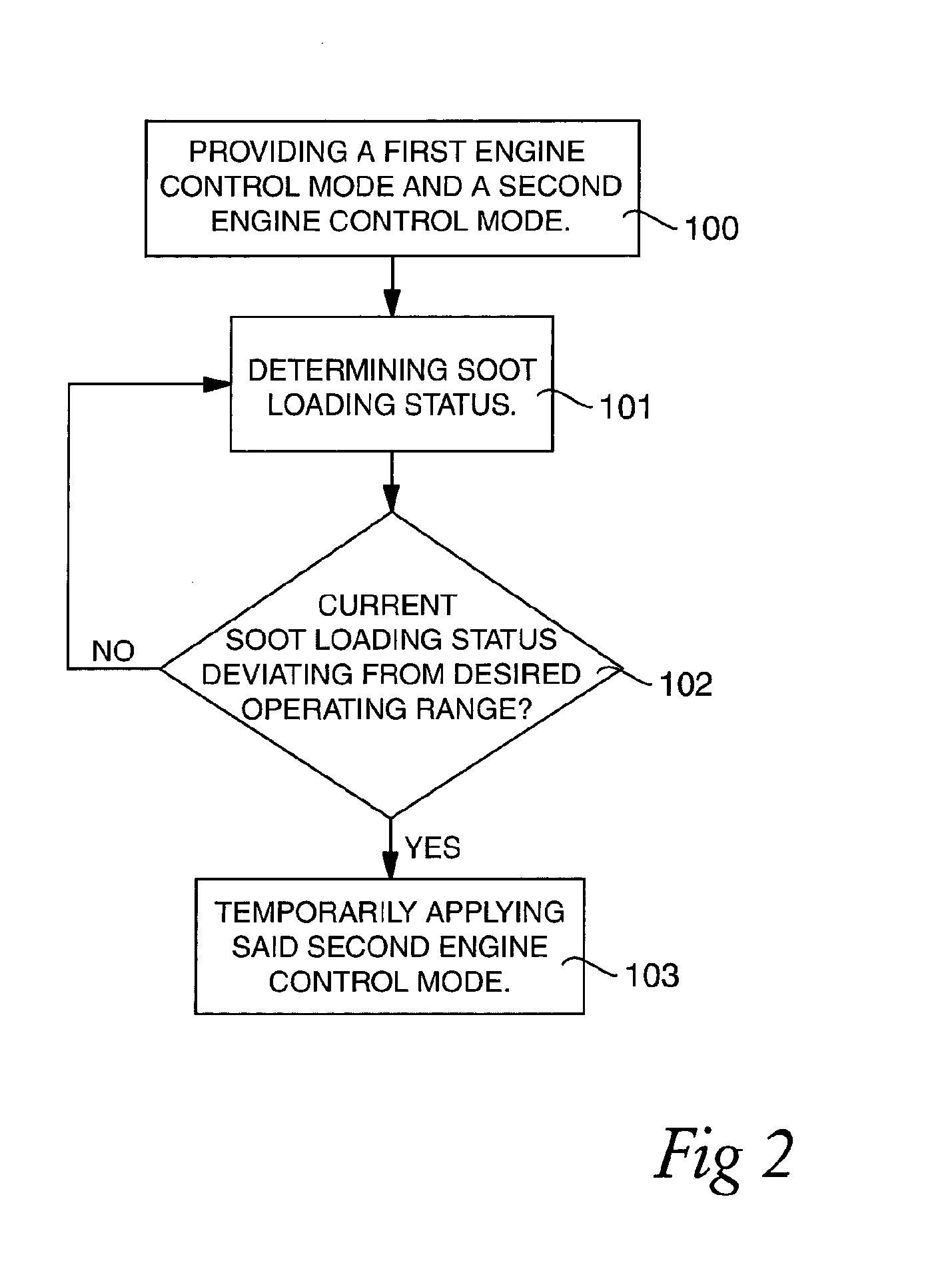

A method of conditioning a particle filter provided for receiving exhaust gases from internal combustion engine is provided and includes providing a first engine control mode and a second engine control mode, wherein in the second engine control mode at least one combustion control parameter that affects the characteristics of particles emitted together with and carried by the exhaust gases from the engine is different in relation to the first control mode such that the filling rate of the particle filter with particles is increased compared to the filling rate that would have been achieved with the first engine control mode, determining a soot loading status of the particle filter, and temporarily applying the second engine control mode to the engine based on the soot loading status.

Owner:VOLVO LASTVAGNAR AB

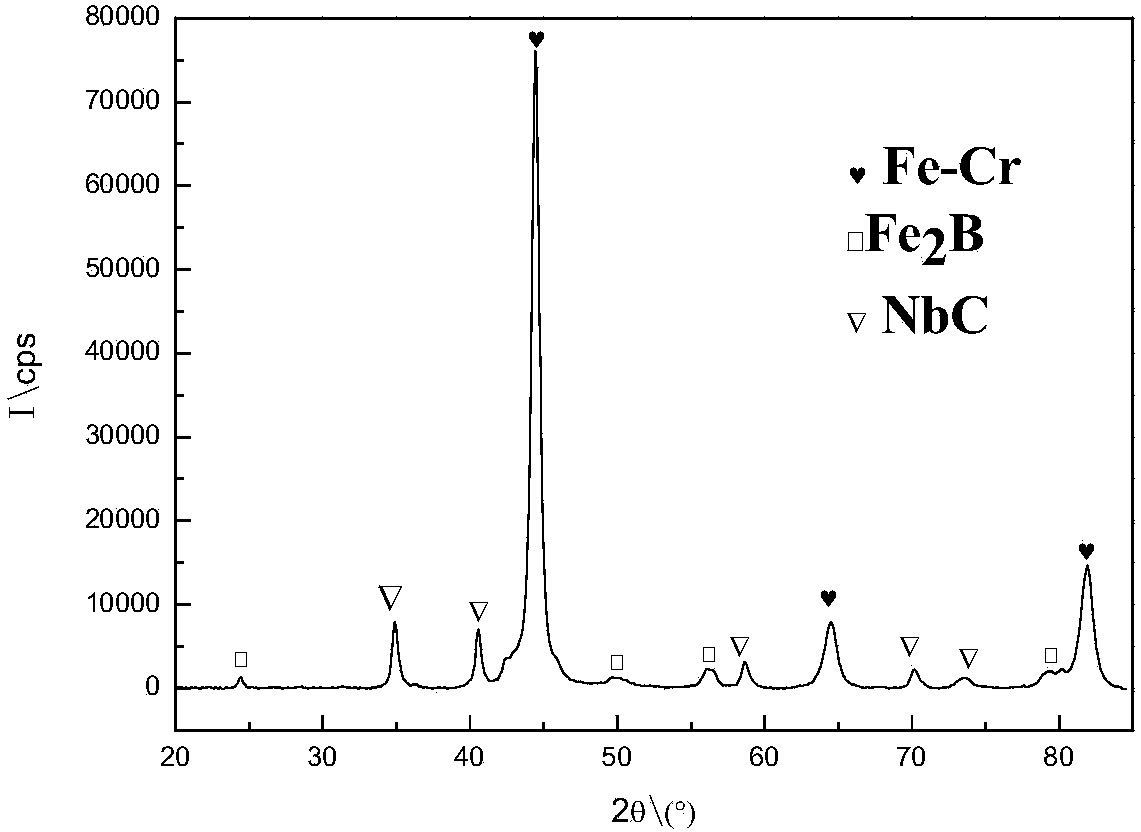

Fe-Nb-Mo-Cr-Mn-B iron-based surfacing flux-cored wire for wear-resistant strip of drill rod joint

InactiveCN103894756AImprove wear resistanceImprove crack resistanceArc welding apparatusWelding/cutting media/materialsBorideCrack resistance

The invention relates to an Fe-Nb-Mo-Cr-Mn-B iron-based surfacing flux-cored wire for a wear-resistant strip of a drill rod joint, and belongs to the technical field of welding materials. A carbon steel strip is adopted to coat flux core powder, filling rate of the flux-cored wire is 20-26%, and alloying elements of the flux-cored wire powder include, by mass, 0.6-1.2% C, 0.8-1.2% of B, 2-9% of Cr, 10-19% of Nb, 4-10% of Mo, 4-10% of Mn, 3-8% of Si, 1-4% of Ti and the balance Fe. Grain structures generated by a coating, carbide and boride after wire surfacing are closely arrayed into a hard metallographic phase to be dispersed in martensite, the size of an NbC hard phase is quite small and is about 1-2 micrometers. No crack exists after welding, average Rockwell hardness is more than 60HRC, and the flux-cored wire has reasonable wear resistance and crack resistance matching performance; surfacing manufacturability is good, weld joints are beautiful in formation, the wear-resistant strip is smooth, the flux-cored wire is few in splash, free of peeling, high in cohesiveness, reusable for surfacing and excellent in compatibility.

Owner:BEIJING UNIV OF TECH

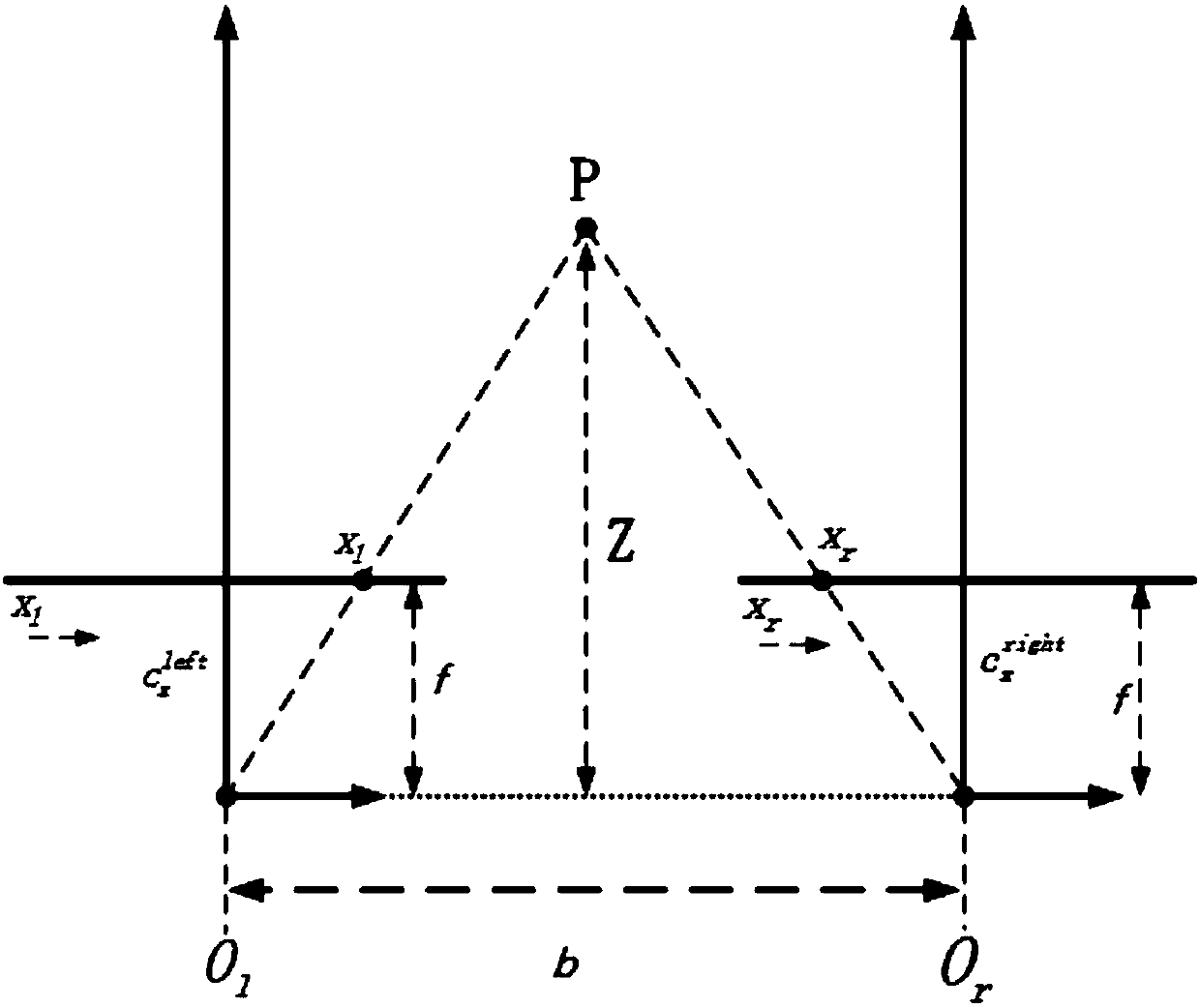

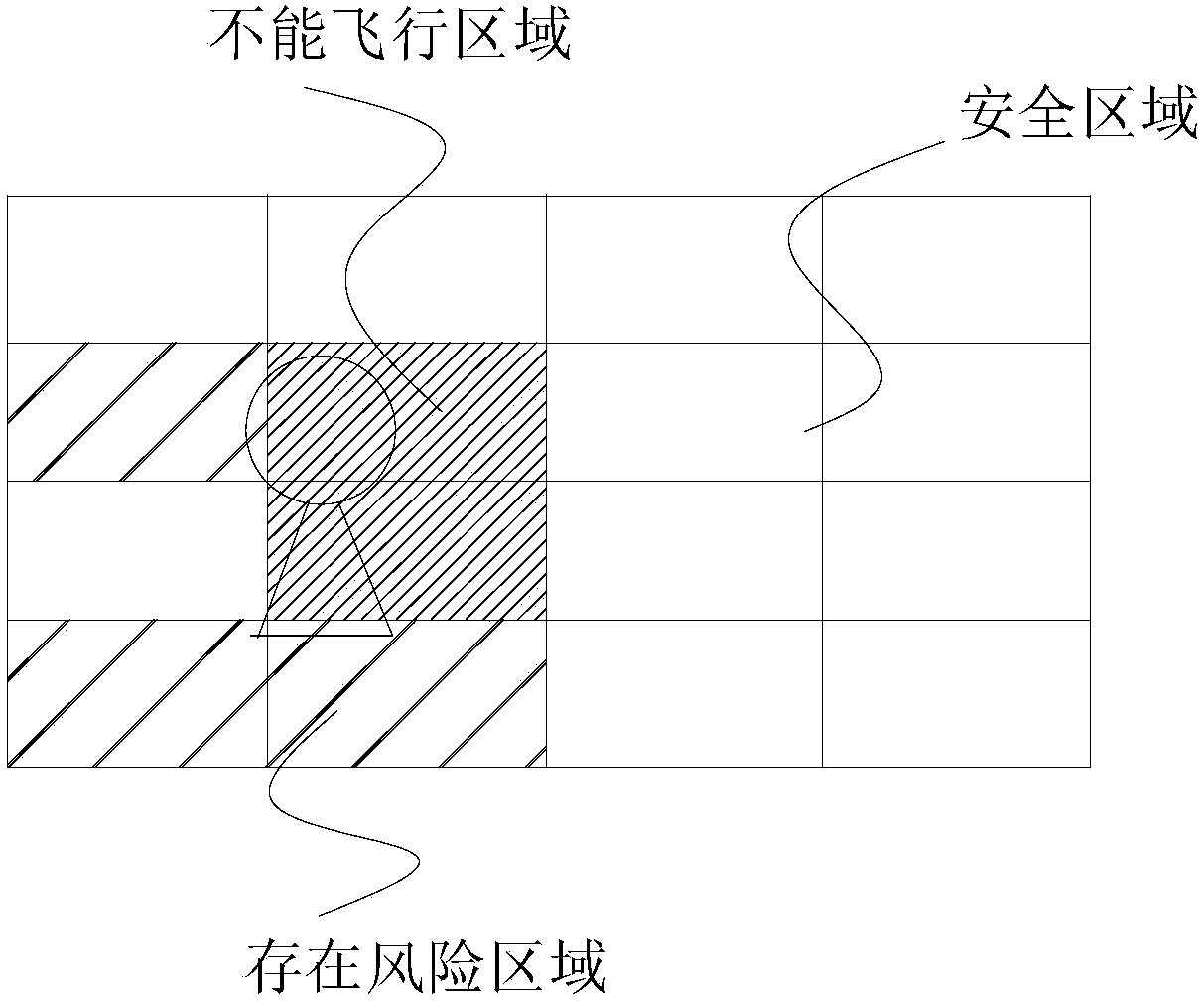

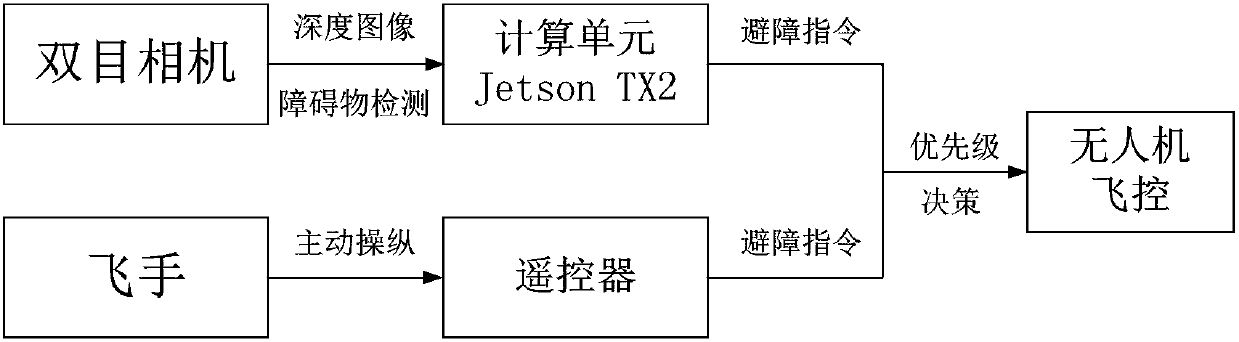

Unmanned plane real time obstacle avoidance method based on binocular visual sense technology

ActiveCN108052111ANatural Stable FusionFast and stable autonomous obstacle avoidancePhotogrammetry/videogrammetryPosition/course control in three dimensionsFill rateParallax

The invention discloses an unmanned plane real time obstacle avoidance method based on the binocular visual sense technology; the method comprises the following steps: 1, using a binocular camera to gather parallax images, carrying out three dimensional reconstruction, and calculating the depth; 2, increasing the threshold, and only identifying obstacles in a scope smaller than the obstacle avoidance radius Zmax; 3, traversing the images, and calculating the obstacle condition of each pixel point; 4, calculating the obstacle filling rate in each grid unit; if the filing rate is >50%, an obstacle is considered to exist; if the filling rate is between 10-50%, an obstacle is unknown and risks exist; if the filling rate is smaller than 10%, the condition is considered safe; 5, analyzing the safety area size and distribution conditions, thus outputting front-back, left-right and up-down motion speeds, and a rotary angle rate of the controlled unmanned plane; 6, allowing a user to control aremote controller while carrying out binocular visual sense obstacle avoidance, thus forming extra front-back, left-right and up-down motion speeds v of the unmanned plane, forming the rotary angle rate [omega], naturally stably fusing with the flight control system, and fast and stably carrying out autonomous obstacle avoidance.

Owner:南京奇蛙智能科技有限公司

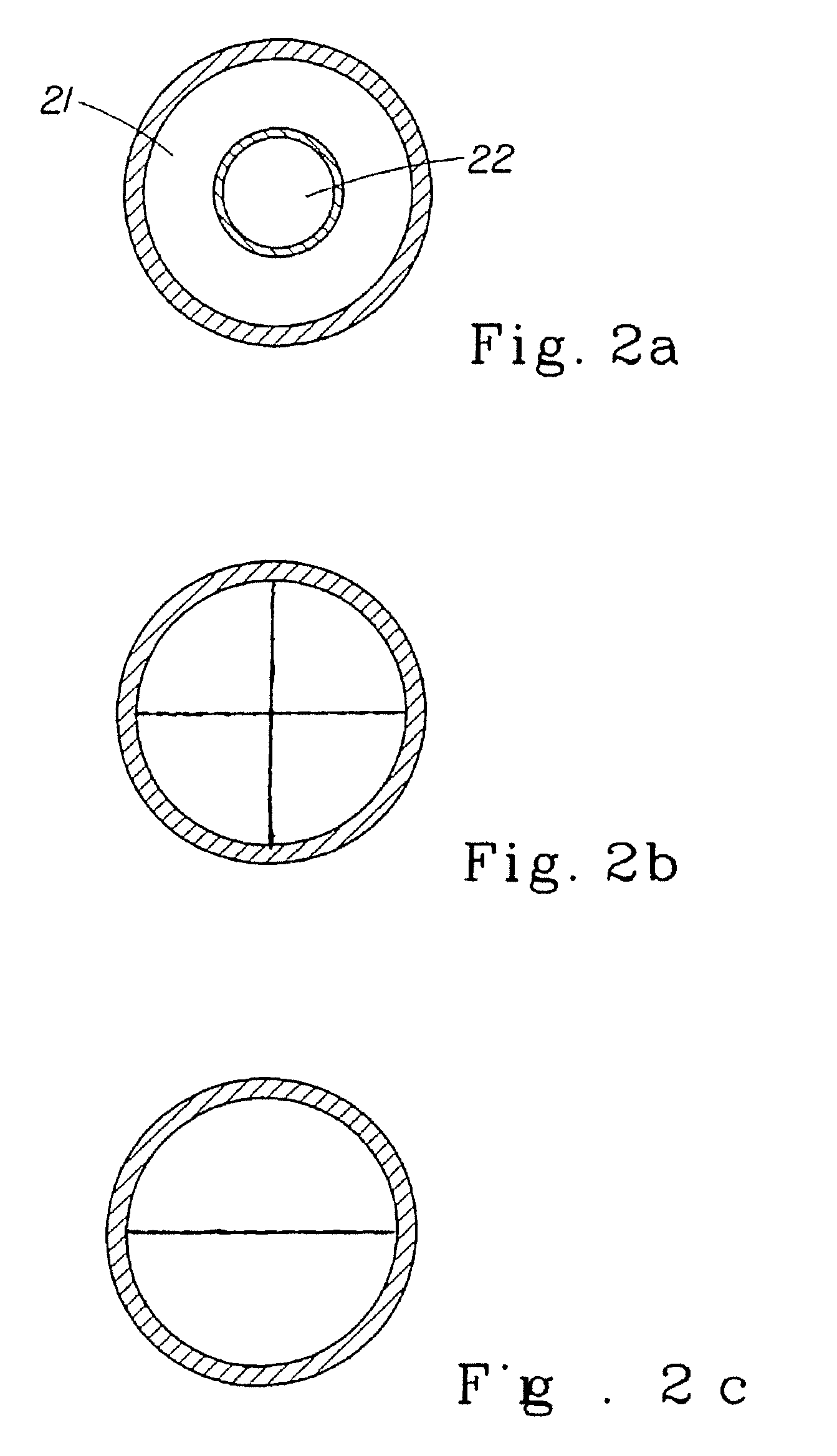

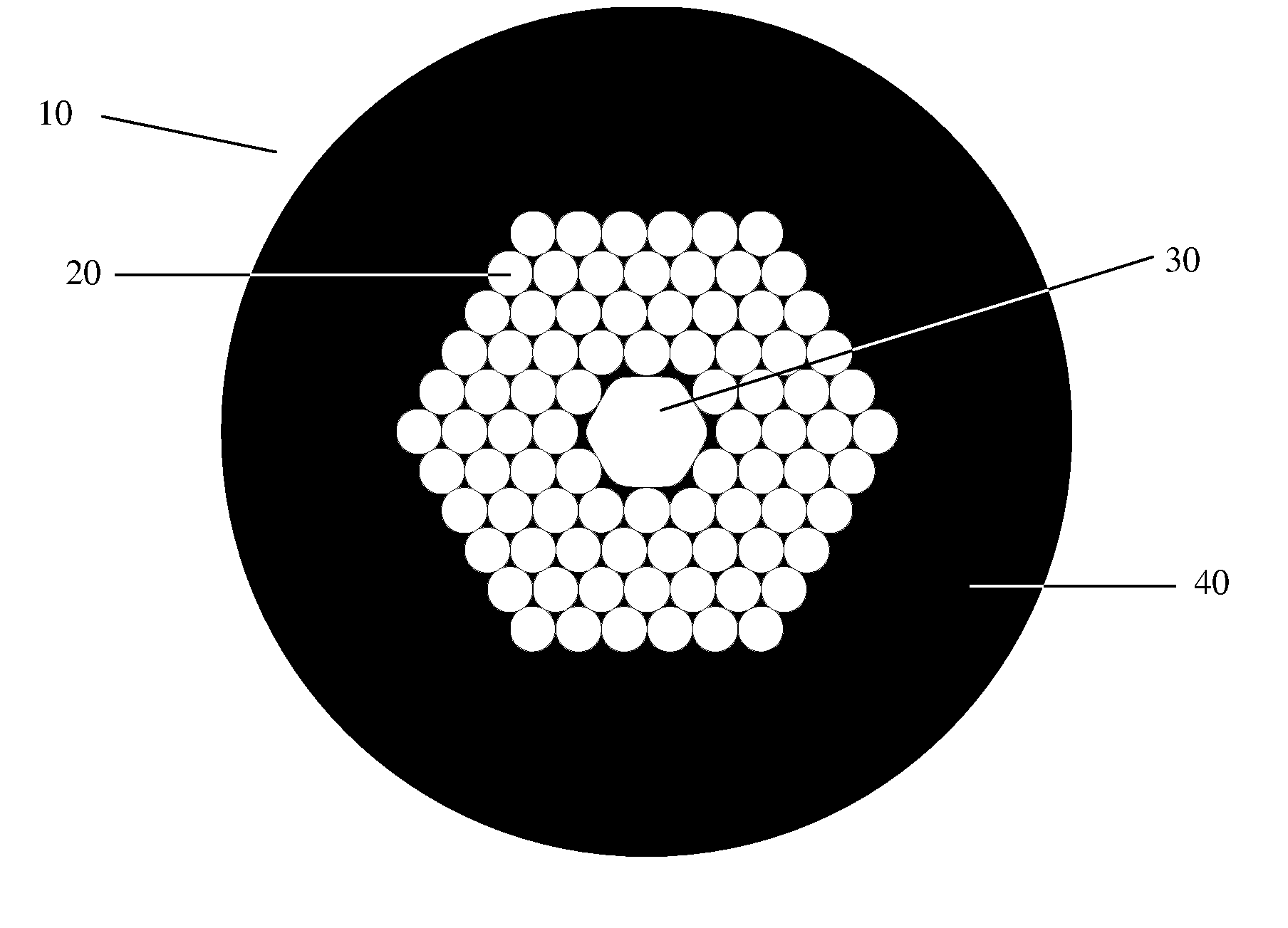

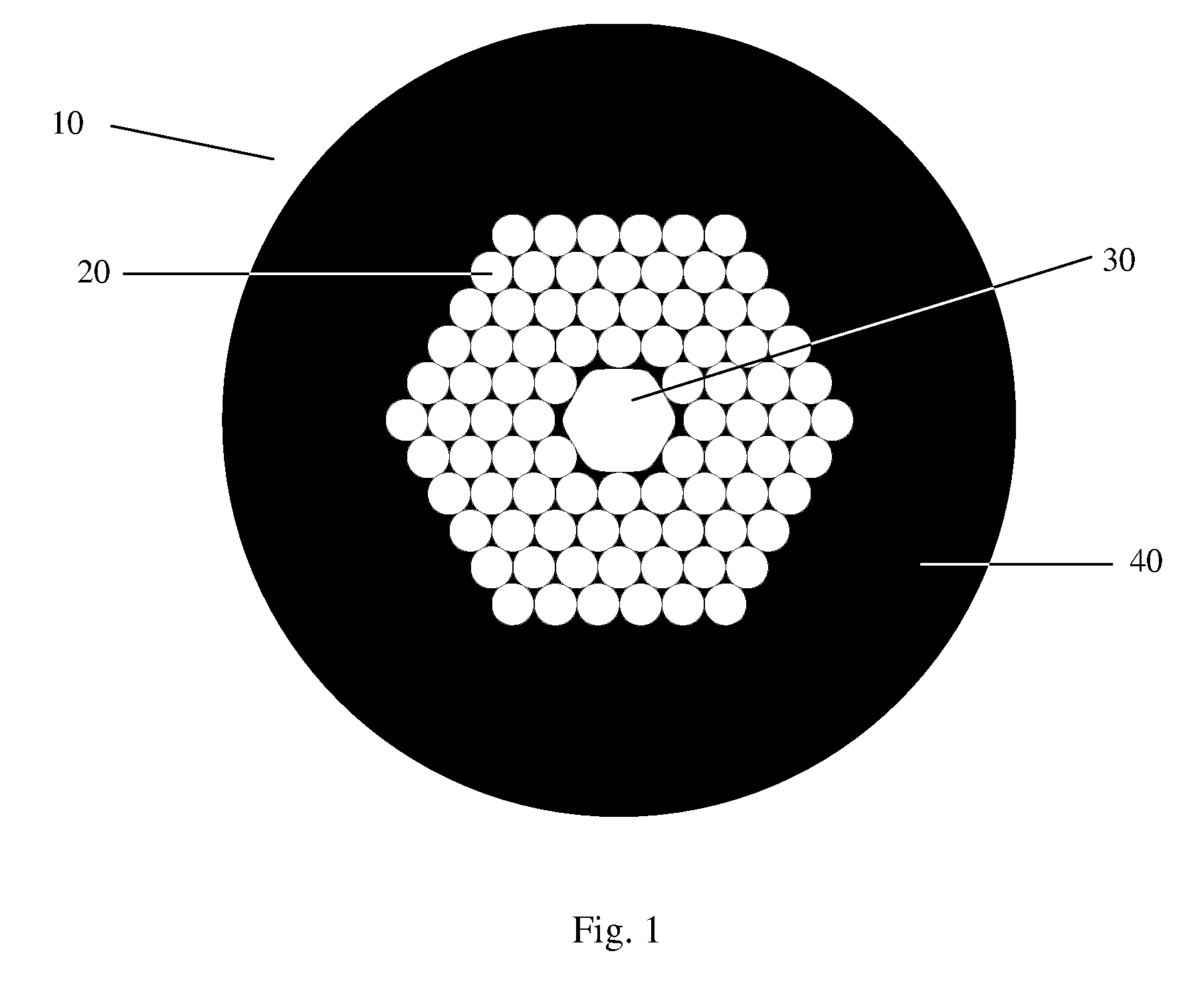

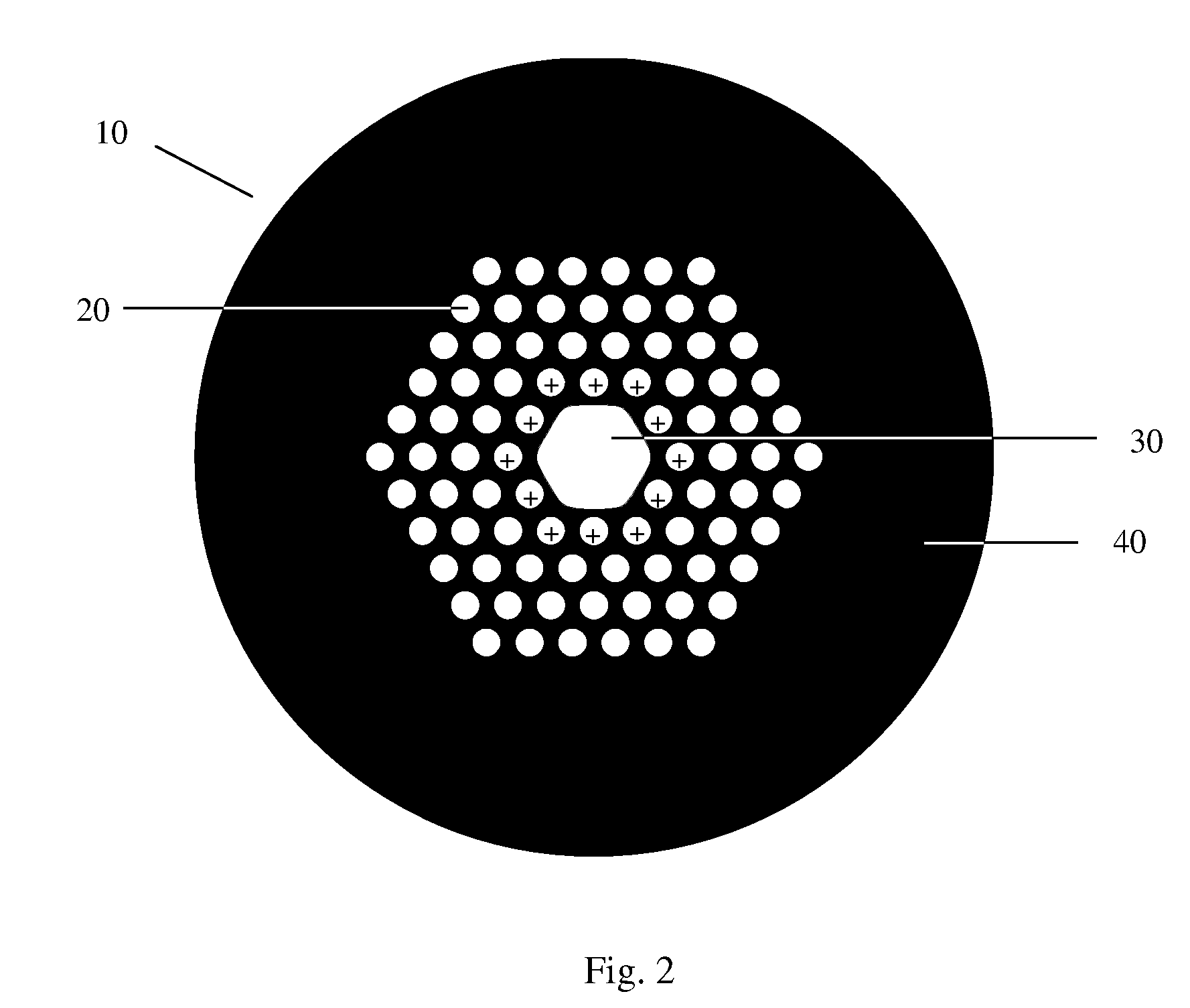

High Air Fraction Photonic Band Gap Fibers

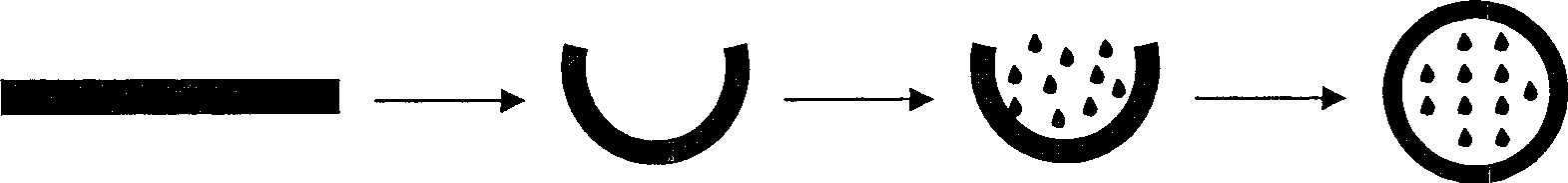

A photonic band gap fiber and method of making thereof is provided. The fiber is made of a non-silica-based glass and has a longitudinal central opening, a microstructured region having a plurality of longitudinal surrounding openings, and a jacket. The air fill fraction of the microstructured region is at least about 40%. The fiber may be made by drawing a preform into a fiber, while applying gas pressure to the microstructured region. The air fill fraction of the microstructured region is changed during the drawing.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

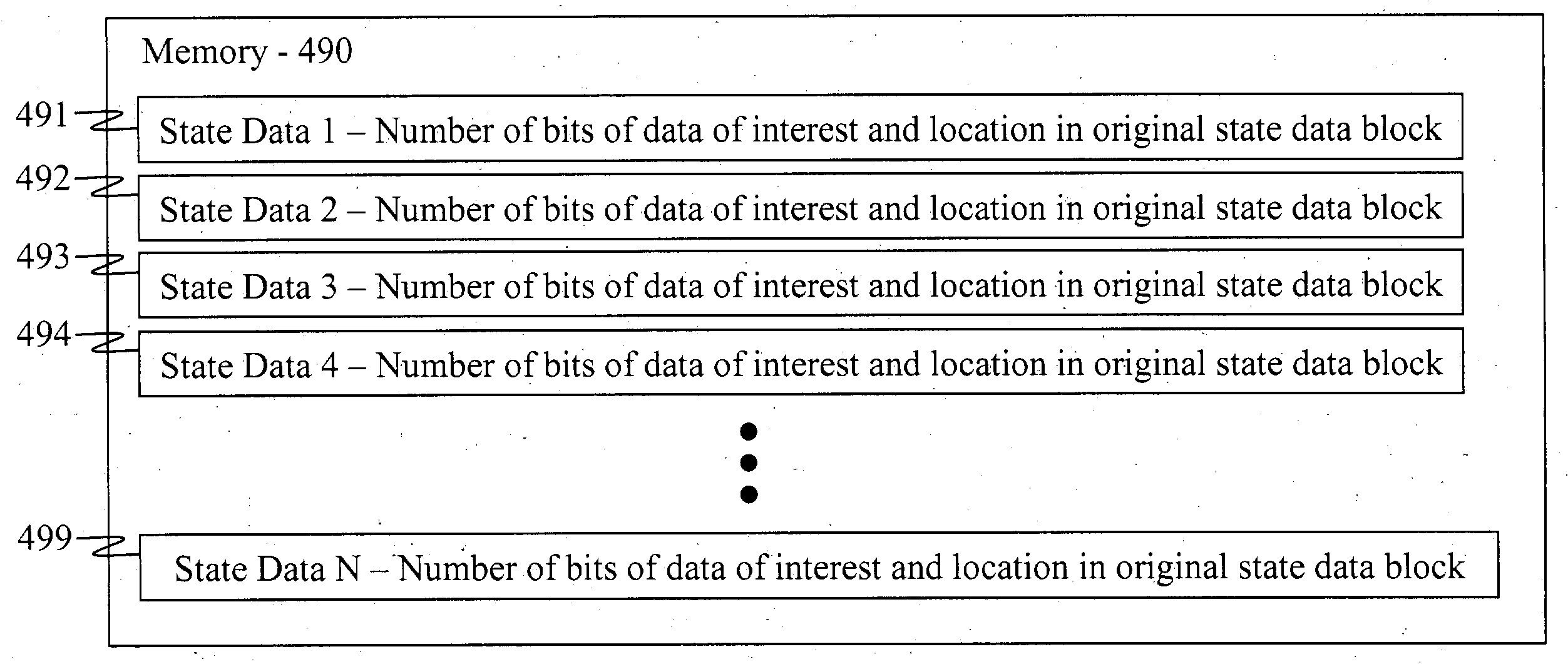

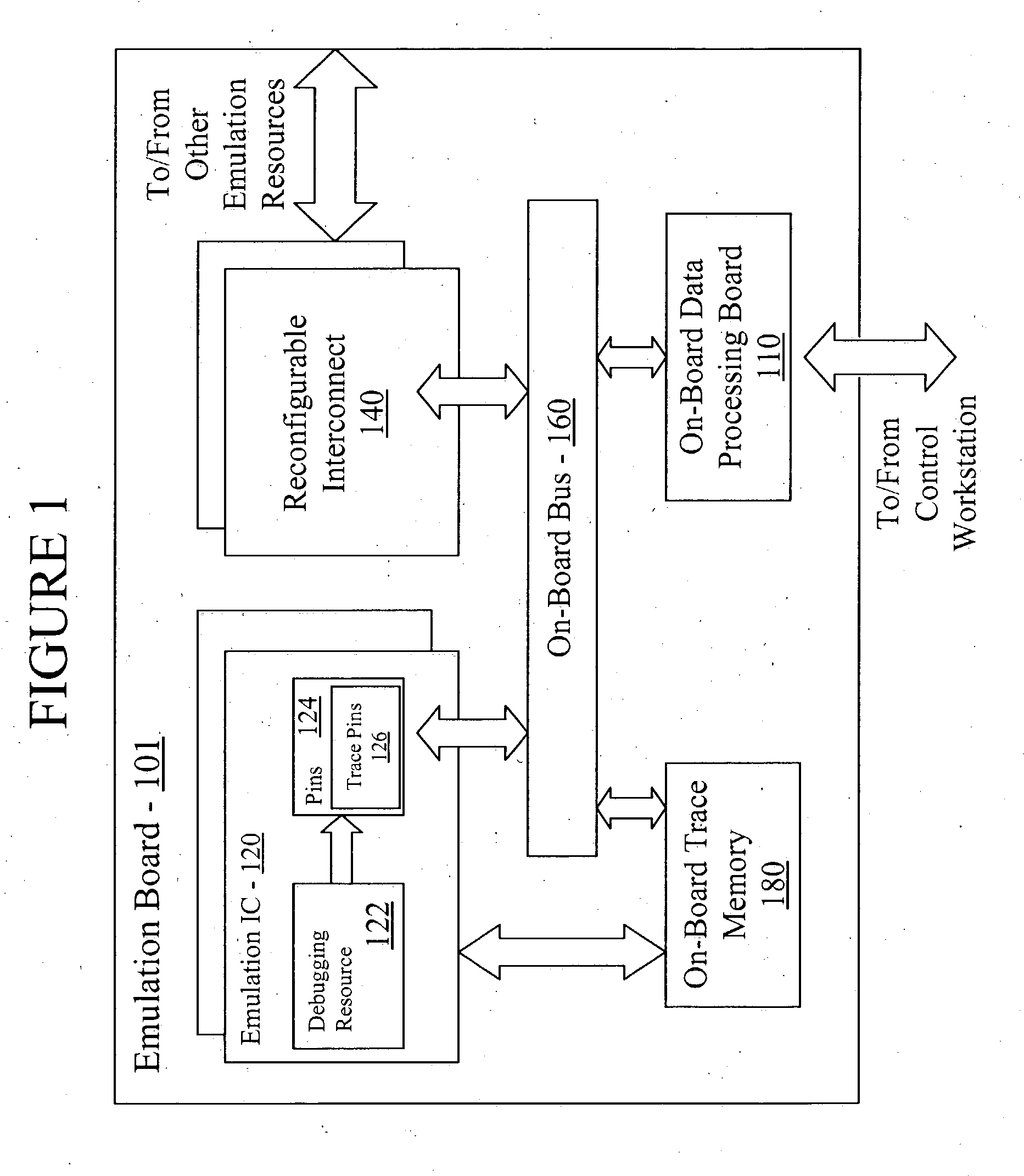

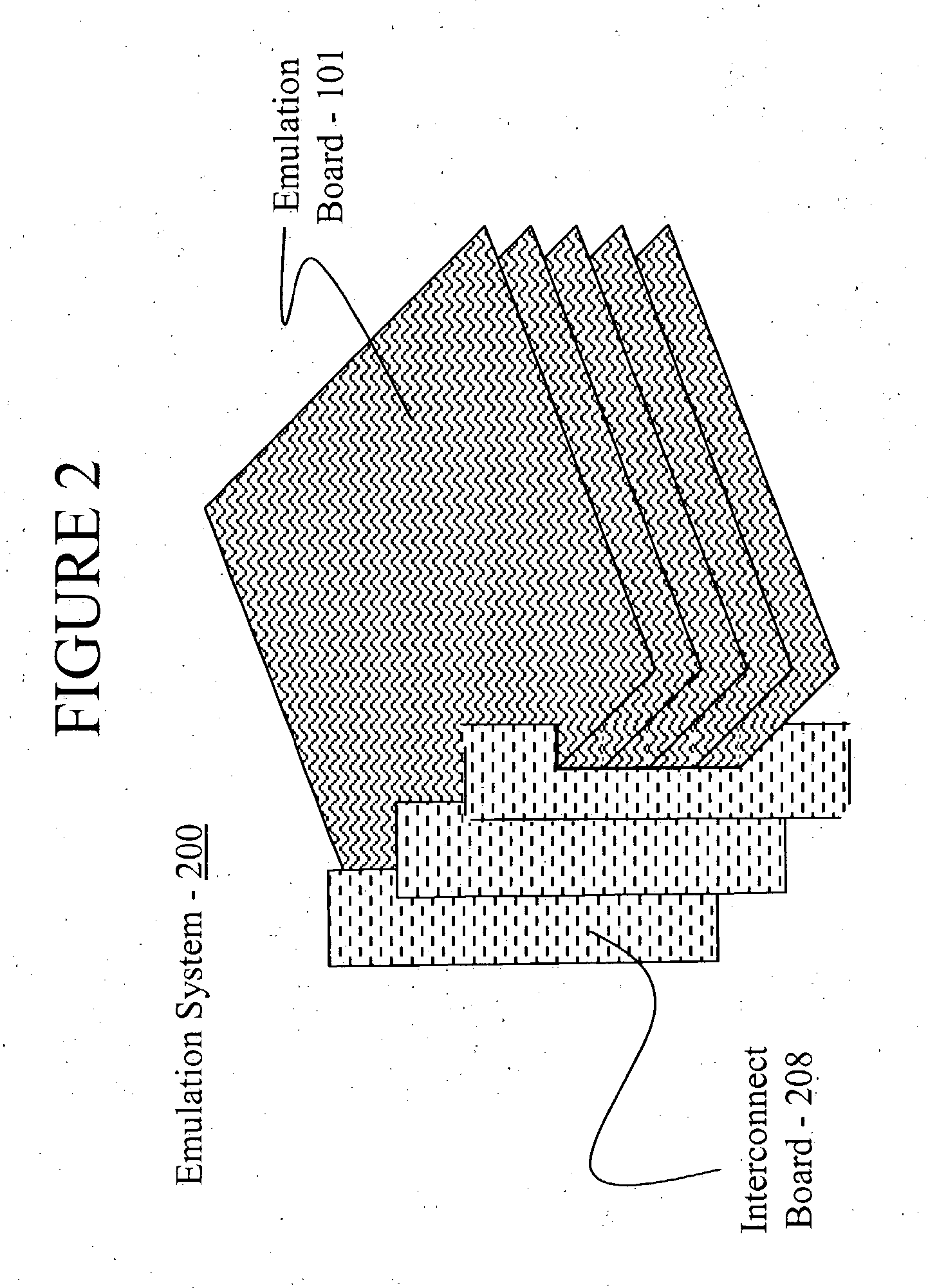

Data compaction and pin assignment

InactiveUS20040267489A1Electrical testingMeasurement arrangements for variableFill rateData compression

A method and system for compacting data and assignment to pins. A first sample of state data is received from a reconfigurable emulation resource. A set of the first sample of state data is stored into a first / current buffer. A second sample of state data is received. A determination is made as to whether the residual storage space of the first / current buffer is full and whether a set of the second sample needs to be portioned into two portions. The set of the second sample is stored in the first / current buffer to the extent it can be accommodated by the residual storage space of the first / current buffer. Any remaining portion of the set of the second sample is stored in a second / back-up buffer. Trace chains are assigned to trace pins based upon a schedule relating to the buffer fill rates.

Owner:MENTOR GRAPHICS HLDG

Organic paddy rice high-yield cultivation method

InactiveCN105993752AInhibit growthImprove germination rateBiocidePlant growth regulatorsFill ratePollination

The invention relates to the field of agricultural cultivation, and relates to a paddy rice cultivation method. The method comprises the following steps: (1) paddy rice seeds are selected, and are subjected to seed soaking for 12-16h with a seed soaking liquid under a temperature of 35-37 DEG C; (2) a seedling-stage fertilizer is sprayed, and a seedling-stage substrate is applied; (2) when the seedlings reach a stage of 5-6 leaves, the seedlings are transplanted into a field spread with a cultivation base fertilizer; (4) when the paddy rice seedlings start tillering, a tillering fertilizer is applied; (5) when the paddy rice seedlings starts flowering, a flowering-stage fertilizer is applied; (6) when the paddy rice seedlings starts filling, a filling fertilizer is applied, and a foliar fertilizer is added; and (7) harvesting is carried out. The method provided by the invention is highly targeting. Targeting fertilization is carried out during various growth periods. With the treatment with the seed soaking liquid, a germination period can be shortened, paddy rice growth can be accelerated, paddy rice stress resistance can be improved, a period from germination to flowering can be shortened, and a flowering period and a fruiting period can be prolonged. During the tillering stage, tillering amount is increased with the tillering fertilizer. With the flowering-stage fertilizer applied during the flowering stage, pollination success rate can be improved. During the filling stage, with the filling fertilizer and the foliar fertilizer, filling rate is greatly improved, yield is improved, and paddy rice grain fullness is improved.

Owner:广德县新农民水稻种植专业合作社

Forced backhitch for speed matching in a multi-speed tape drive

InactiveUS20050088771A1Low costRecord information storageCarrier speed control/regulation/indicationFill rateMagnetic tape

In a magnetic tape drive having a plurality of stepped operational speeds, data storage logic estimates, from the effective data fill rate for a data buffer and the drive data write rate, the time cost to continue to operate the magnetic tape drive at the current stepped operational speed from a target to the next end of wrap; estimates, the time cost to force a backhitch of the magnetic tape data storage media and change the stepped operational speed to a higher stepped operational speed and operate the magnetic tape drive at the higher stepped operational speed to the next end of wrap; and determines the lesser time cost.

Owner:IBM CORP

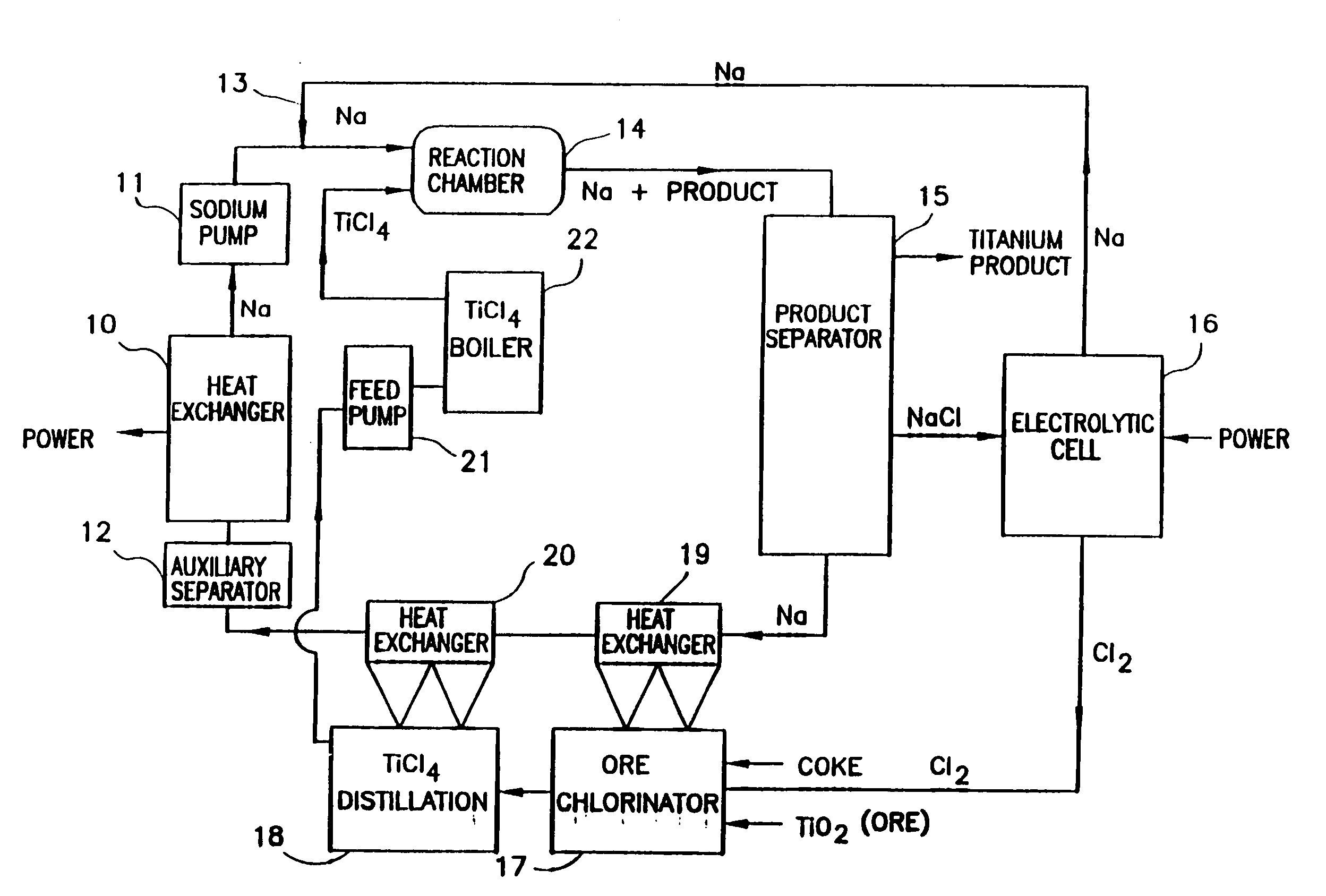

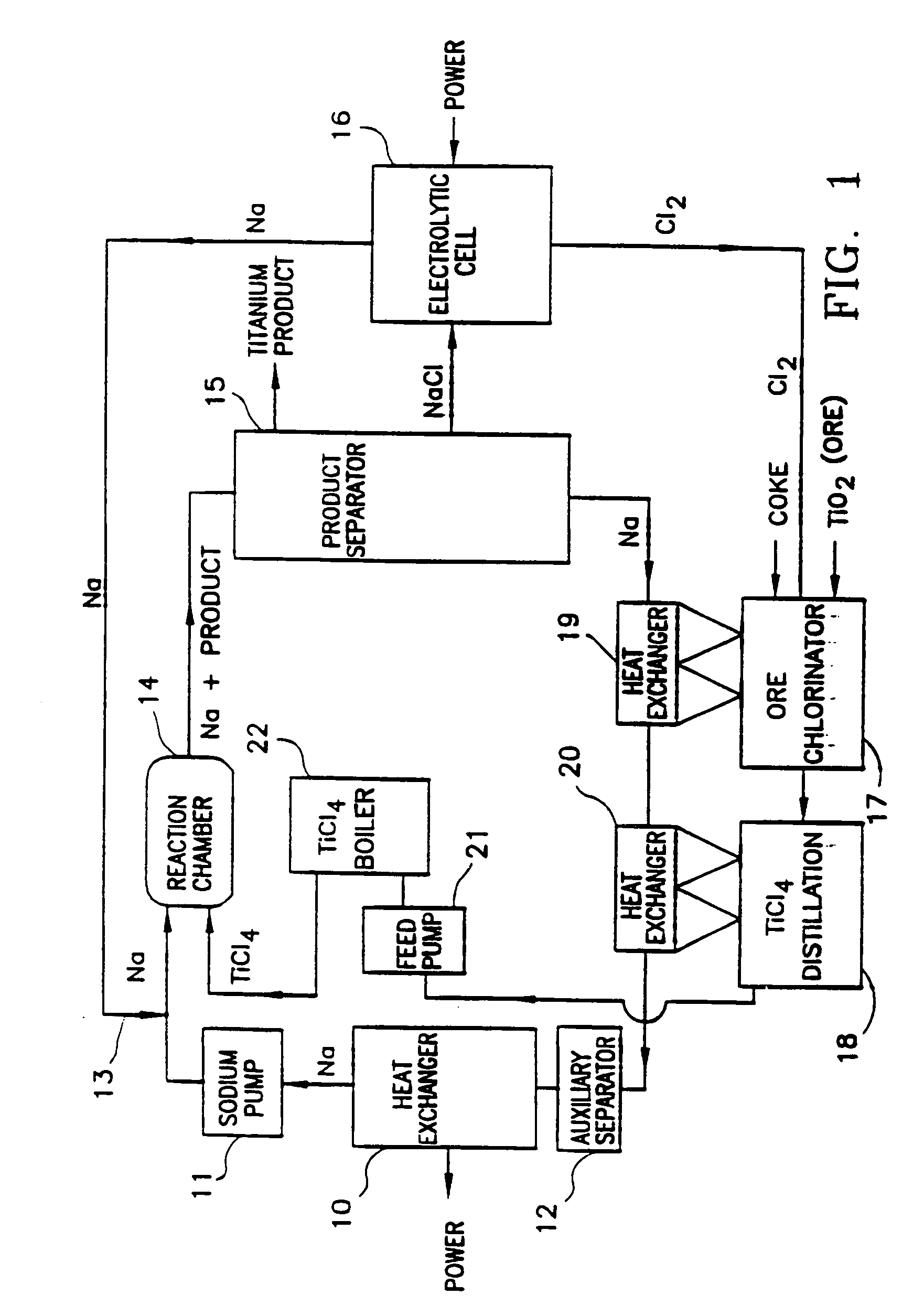

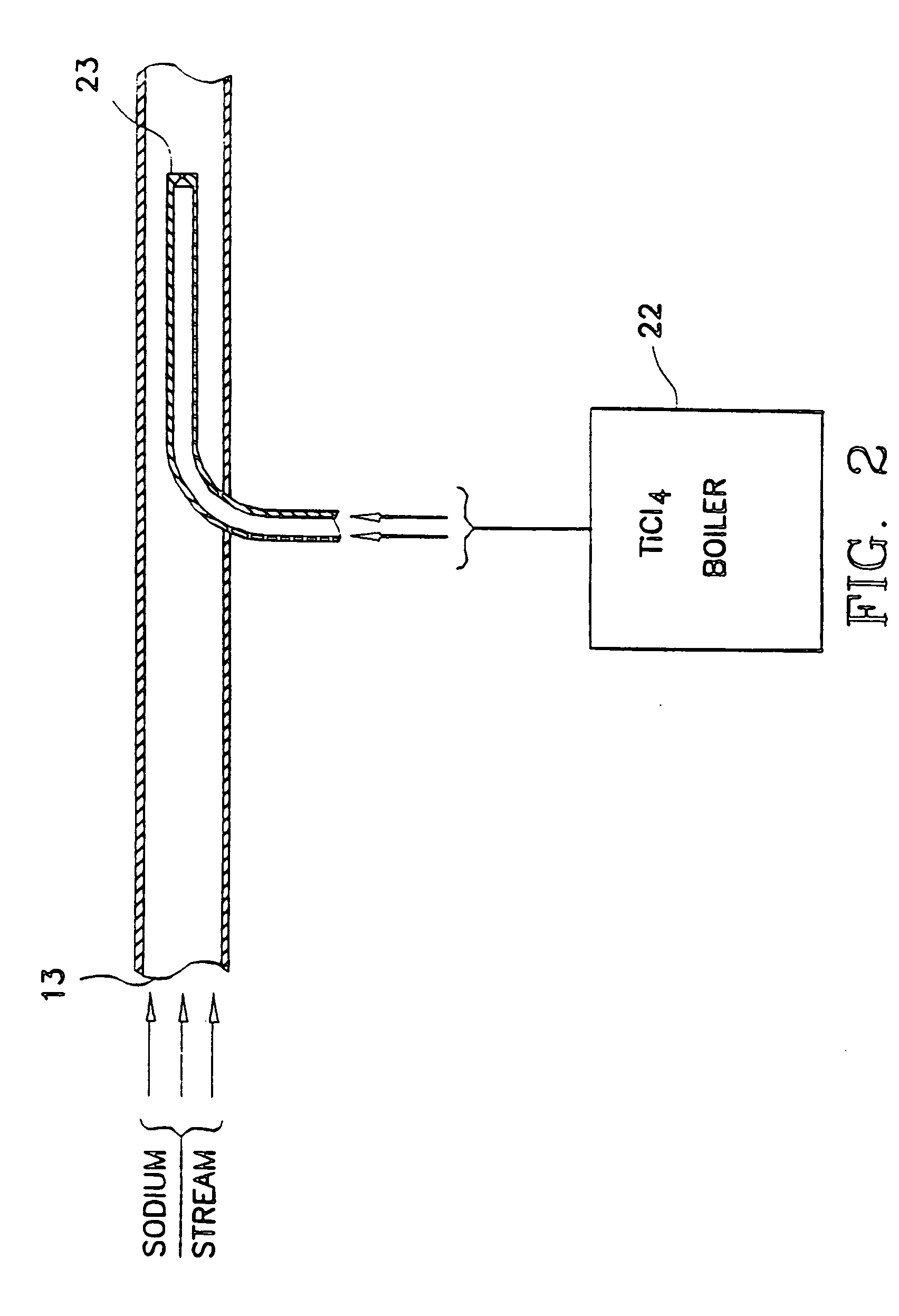

Titanium and titanium alloys

InactiveUS20080187455A1Big cost advantagePrevent sinteringProcess efficiency improvementFill rateTitanium alloy

A titanium powder or alloy powder produced by introducing a TiCl4 vapor into a continuum or flowing stream of sodium metal at a velocity not less than sonic velocity of the vapor wherein the sodium is present in an amount greater than stoichiometric sufficient to maintain substantially all the reaction products below the sintering temperature thereof and wherein said Ti powder has a packing fraction in the range of from about 4% to about 11%. The powders without fines have a particle diameter in the range of from about 3.3 to about 1.3 microns based on a calculated size of a sphere from a BET surface area in the range of from about 0.4 to about 1.0 m2 / g.

Owner:CRISTAL US INC

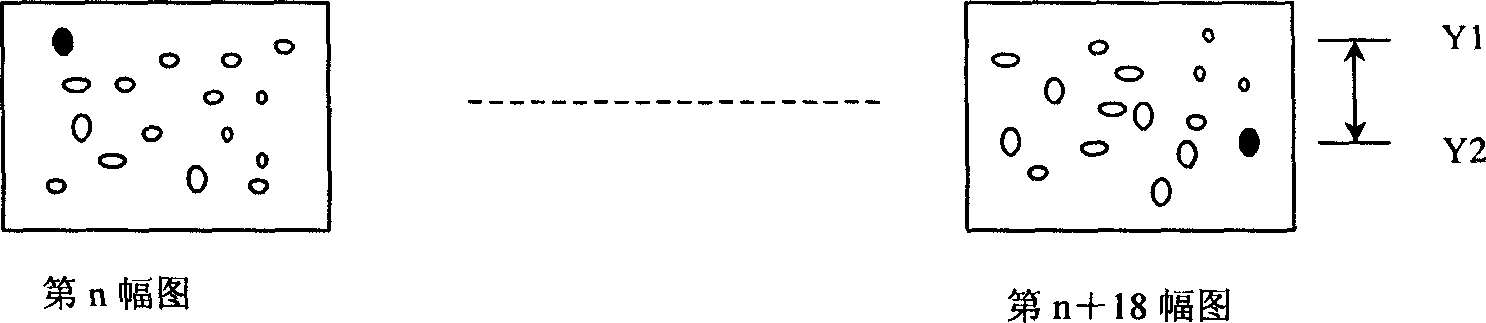

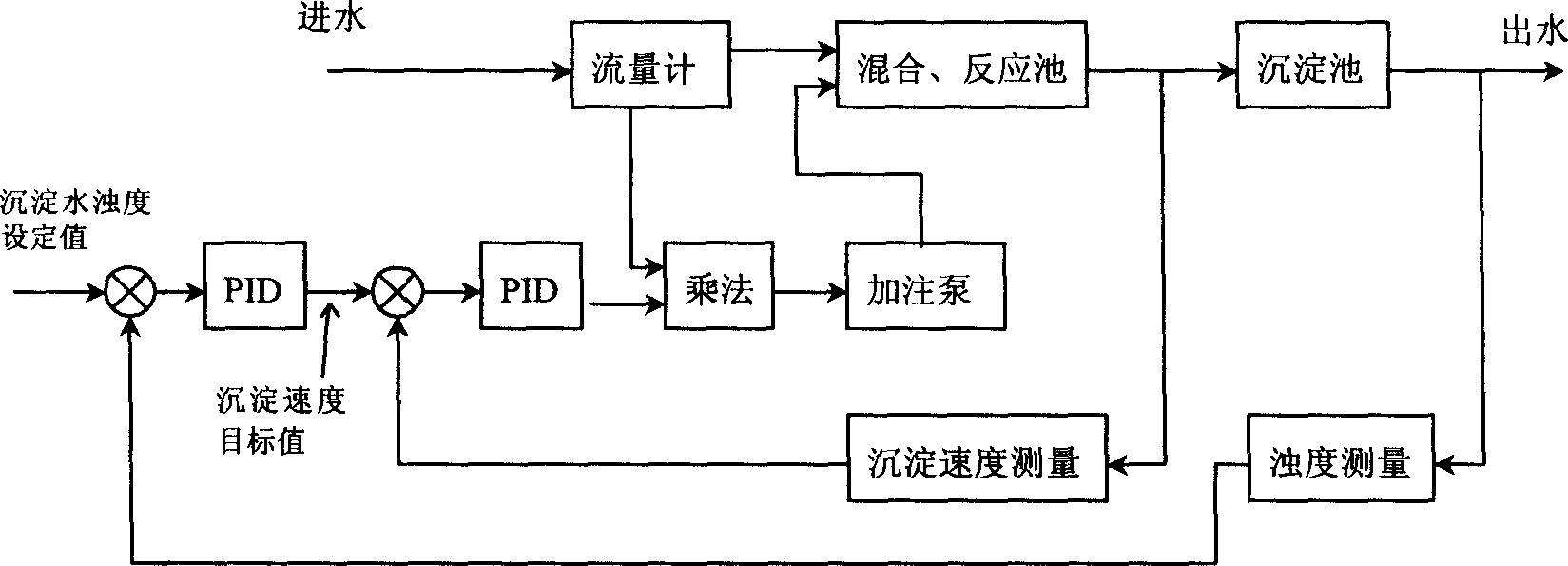

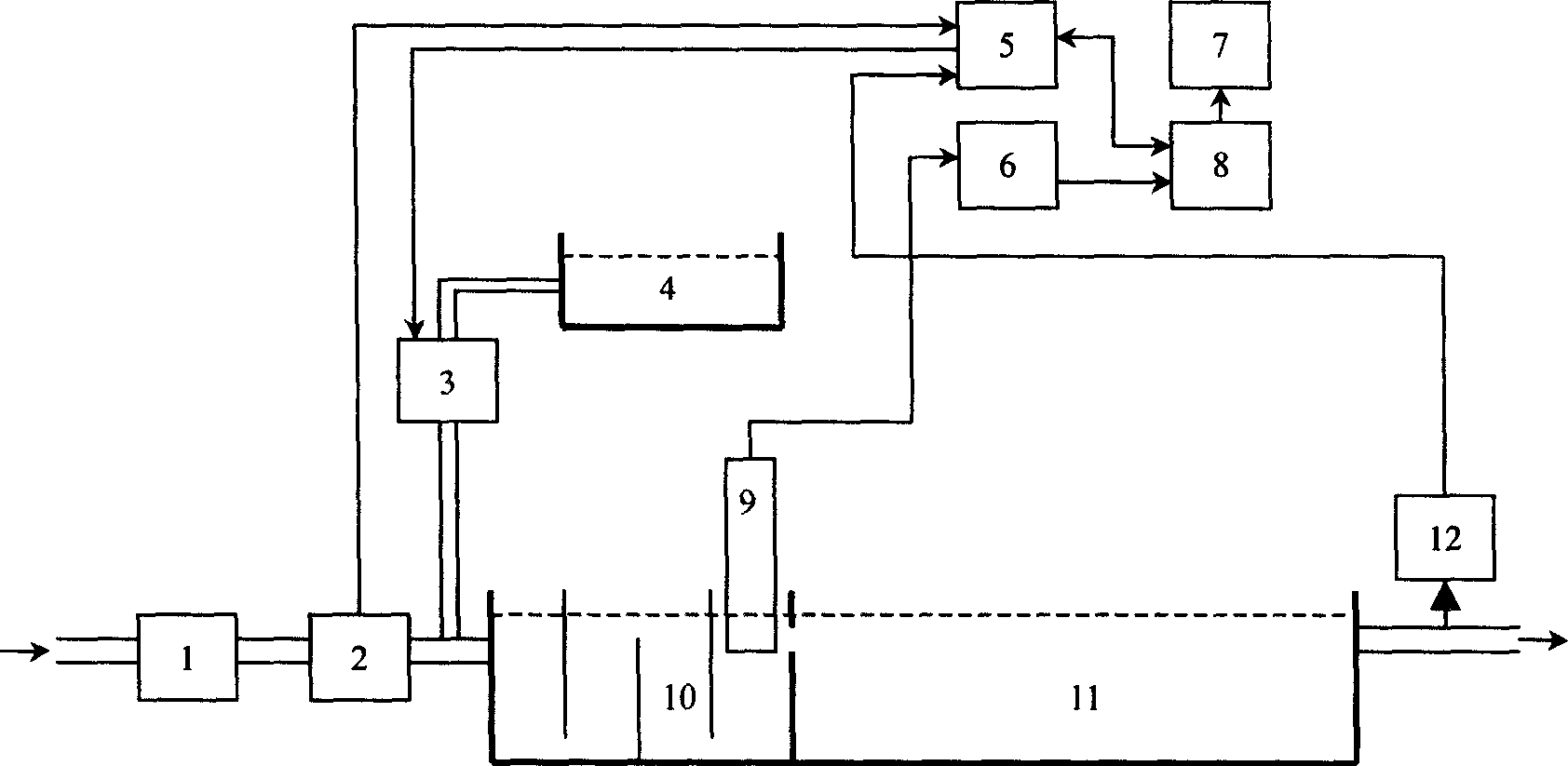

Method and system for controlling coagulant filling rate by on-line measuring flocculate sedimentation speed

InactiveCN1715201AProgram Design ImprovementsDetect directlyControlling ratio of multiple fluid flowsChemical variable controlFill rateComputer science

The present invention relates to method and system for controlling coagulant filling rate by on-line measuring flocculate settling speed. The method includes the steps of: 1. acquiring flocculate moving image in the speed of 2 frames each second and calculating the position of flocculate; 2. calculating the flocculate settling speed based on the flocculate position change; and 3. comparing the detected flocculate settling speed with target value to determine the coagulant filling rate. The system of the present invention has flocculate image acquiring sensor with improved sensing head for fitting the measurement of flocculate settling speed. The present invention measures single parameter for the control of filling rate and the detection method is direct and effective.

Owner:SHANGHAI UNIV

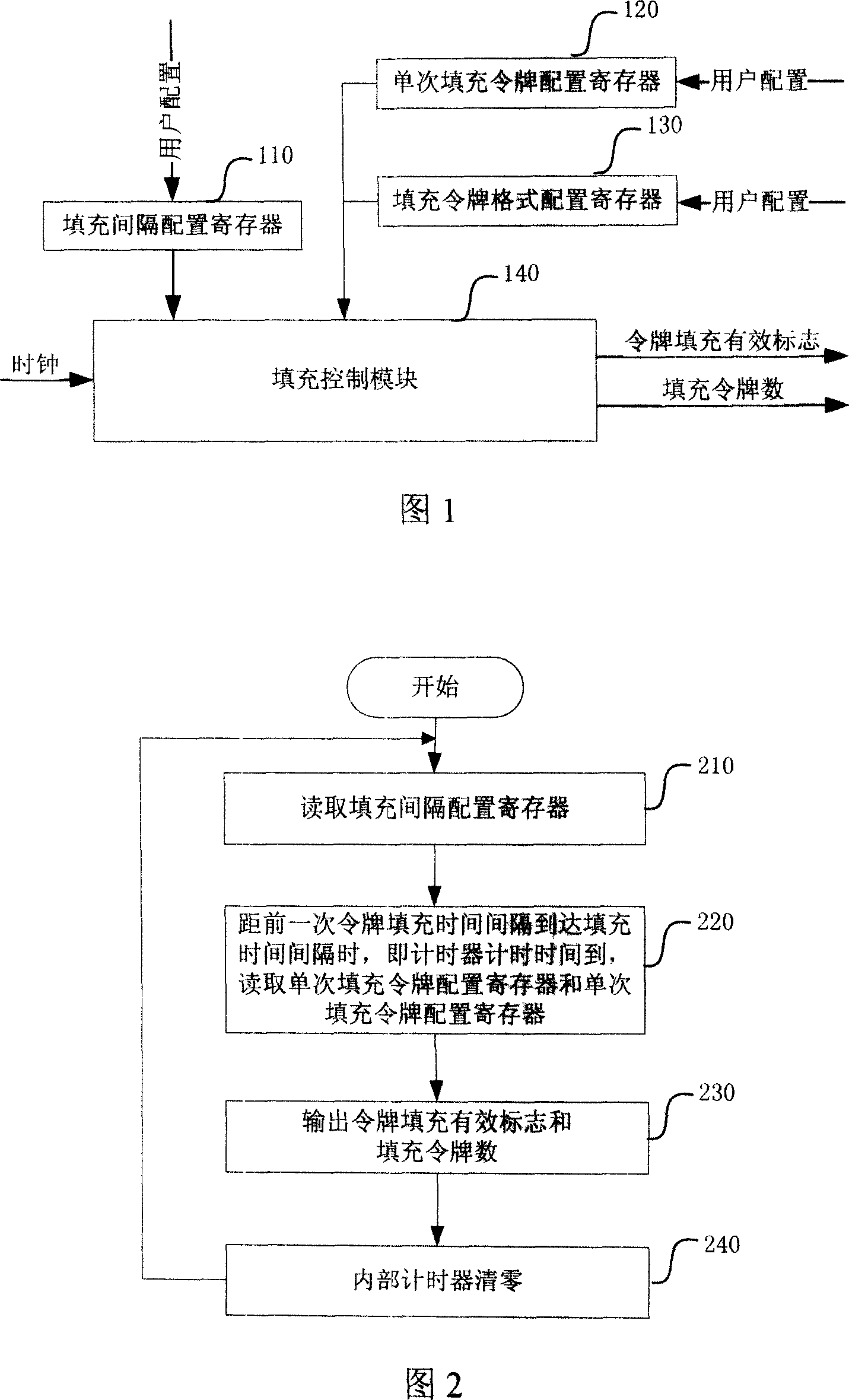

Token bucket fill rate configuration method and device

InactiveCN101026561ASimple structureEasy to implementData switching networksFill rateProcessor register

Owner:ZTE CORP

Washing machine with water control and associated method

An automatic washing machine with water level control and associated method. In one embodiment, the washing machine comprises a tub for receiving a load of clothes, a water level sensor taking water level measurements during a water fill stage, and a controller. The controller controls a water valve that introduces water into the washing machine. The controller comprises a timer, a memory and a microprocessor. The microprocessor accesses a signature fill rate of the washing machine when unloaded, receives water level measurements from the sensor during the fill stage, and determines a measured fill rate. The microprocessor compares the measured fill rate to the signature fill rate and shut off the water valve when the measured fill rate is substantially equal to the signature fill rate.

Owner:EMERSON ELECTRIC CO

Regenrated brick and its production process

InactiveCN1383939ASolve processing problemsLighten the loadSolid waste disposalCeramic shaping apparatusFill ratePorosity

The regenerated brick is produced with waste brick and tile as aggregate, portland cement mortar as adhesive and additive in the weight ratio of 1000 to 100-1000 to 0-100. The production process includes flushing waste brick and tile, crushing and sieving to obtain regenerated material; mixing the regenerated material, portland cement mortar and adhesive; forming in a pressurizing and vibrating forming machine and curing either naturally for 7 days or with steam for 1 day. The regenerated brick has strength of 50 N / sq mm, aggregate filling rate of 10-100%, inner porosity of 40-85% and unit volume weight of 1.2-2.3 g / cu.cm. It has heat insulating, sound isolating and fire resisting property higher than those of available red brick and concrete block and light wall load.

Owner:王辉

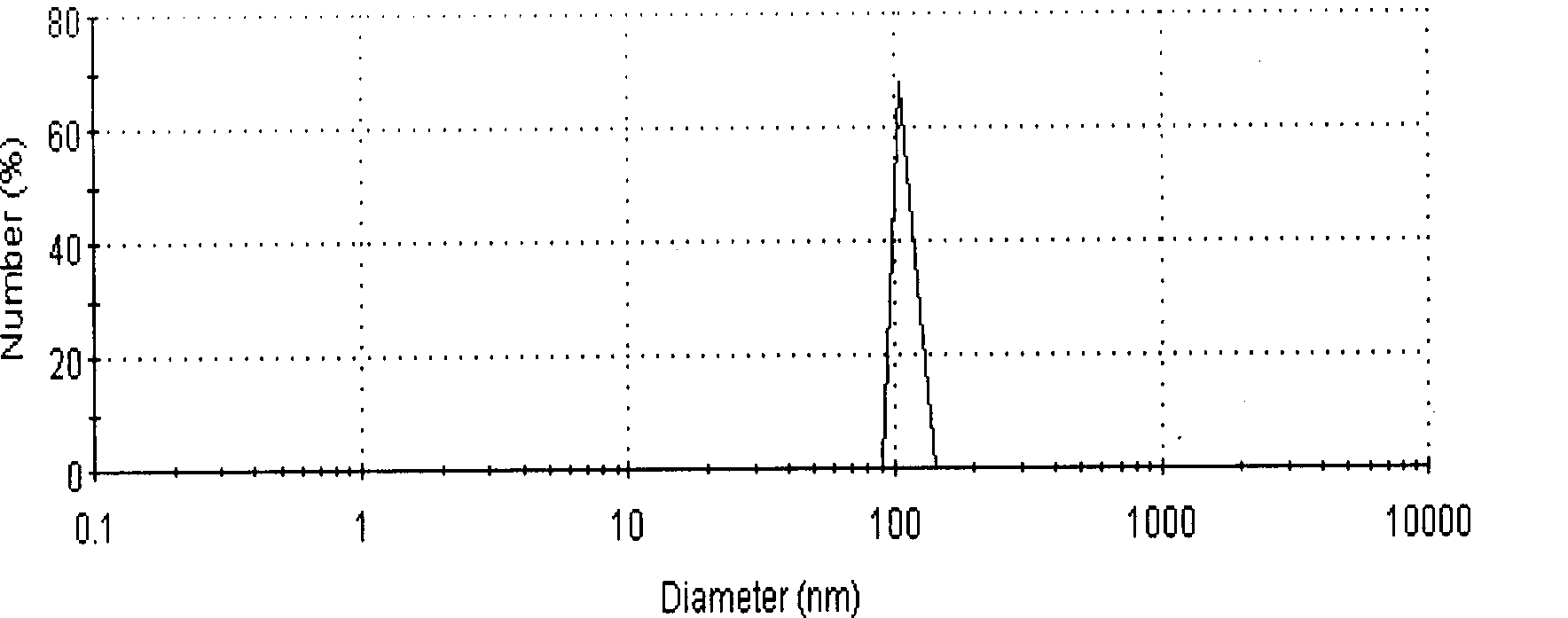

Nano bean pulp processing method

InactiveCN101543276APreserve nutritionAllergenicity reductionFood preparationHigh pressureNanoscopic scale

Nano bean pulp processing method belongs to food processing field, is characterized as: selecting bean pulp of protein content 45+ / -5%, oil content less than 2%, sterilizing 8-12min under 110-130 DEG C and high pressure, quickly cooling, then drying to make water content of 3-16%, microdisintegrating by high speed mechanical impact technology, sifting to make the grain size above 100 mesh and less than 700 mesh, more than 95% of grain size being less than 200 mesh, secondary grinding with rod milling or ball milling, controlling rotation speed at 400-1000 rpm, the grinding medium size being 0.3-2 cm, grinding medium fill rate being 10%-65%, grinding 2-100 hours. The invention has merits of simple process, easy controlled process, narrow final product grain size distribution range; the bean pulp is processed to nano size and kept whole nutrients; the invention implements production and utilization for high value-added bean, largely reduces sensitization of bean pulp, implements low consumption and zero pollution and can be widely used in food processing field such as bean, its product and protein replenisers.

Owner:NANCHANG UNIV

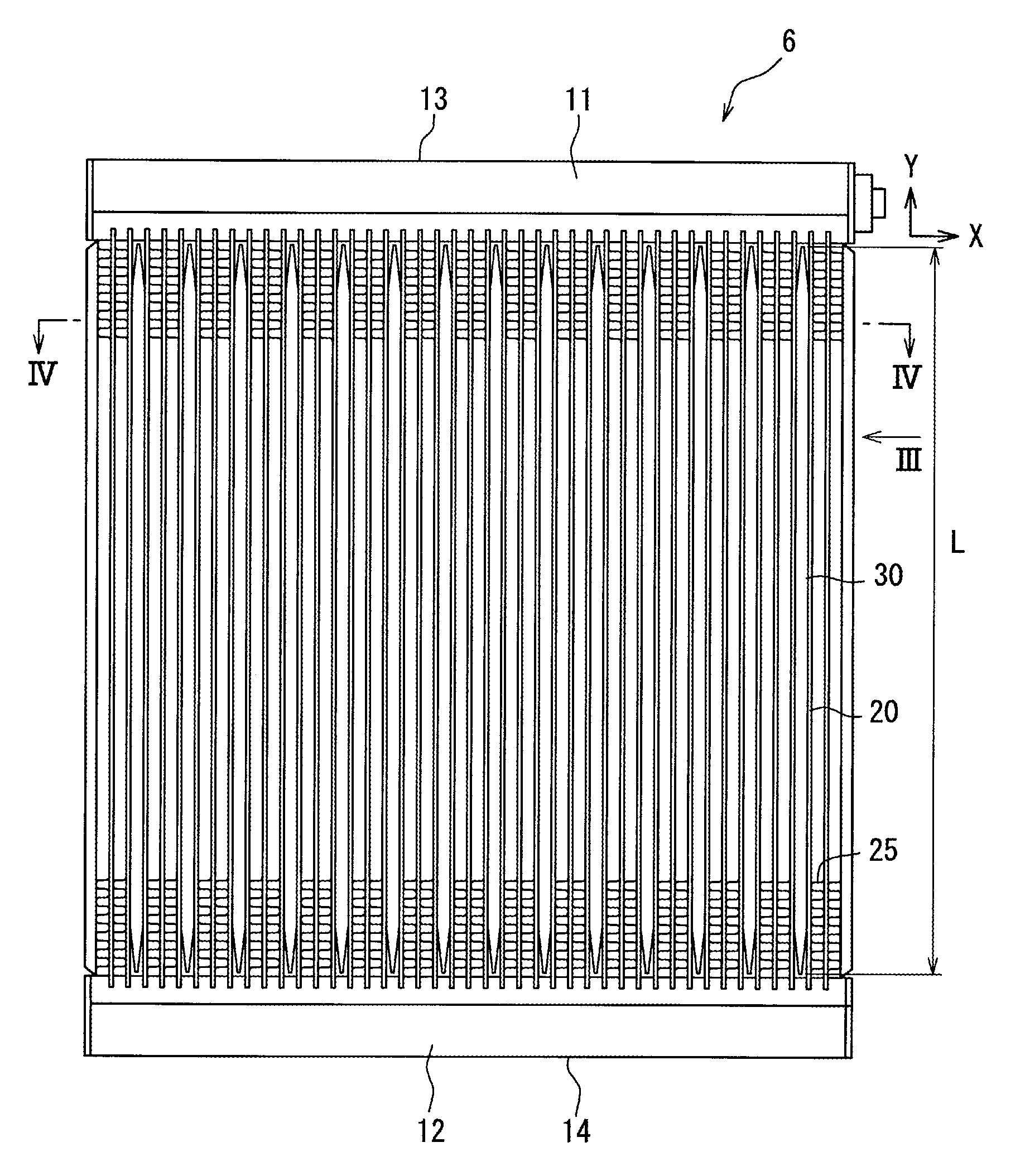

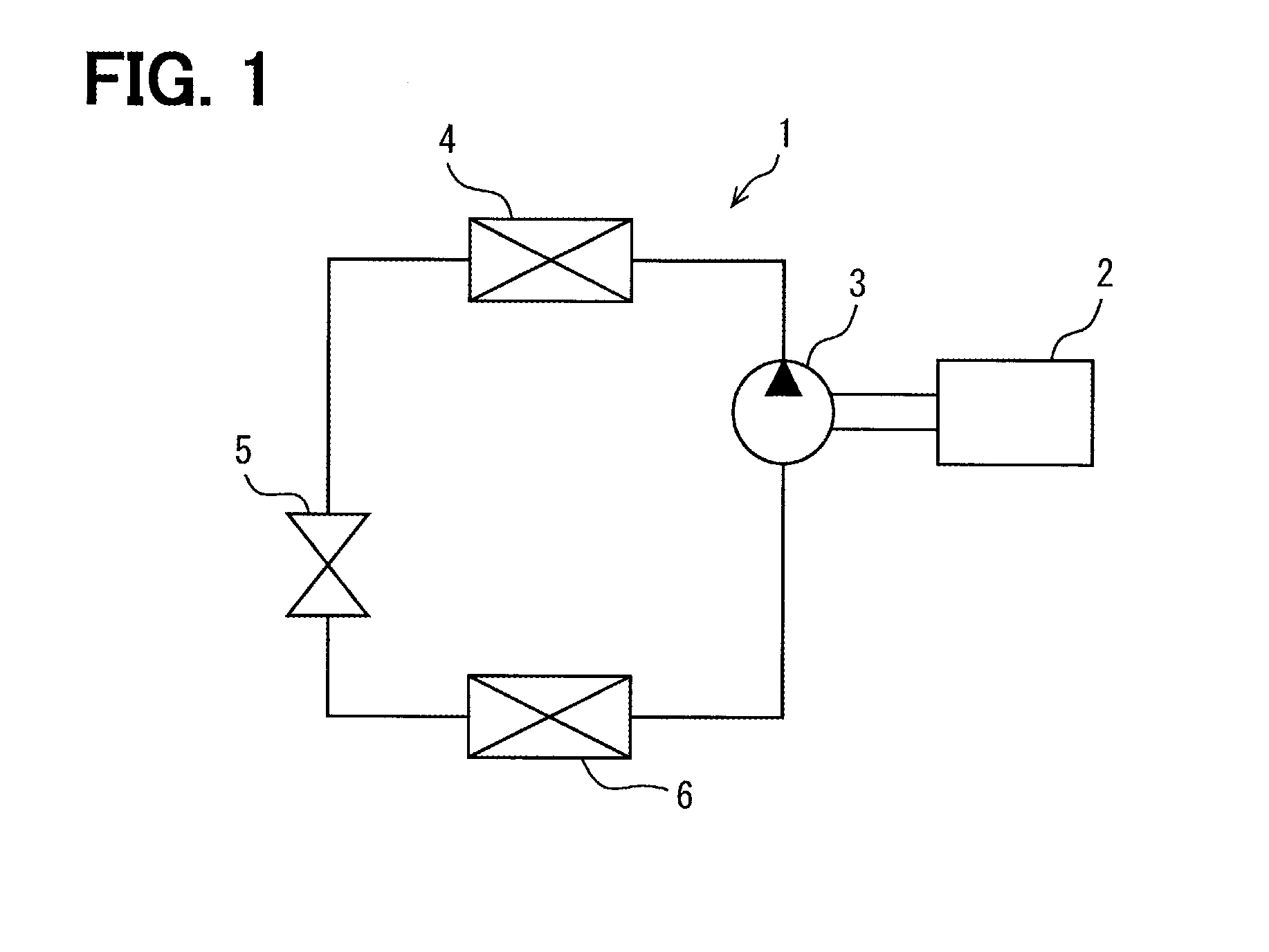

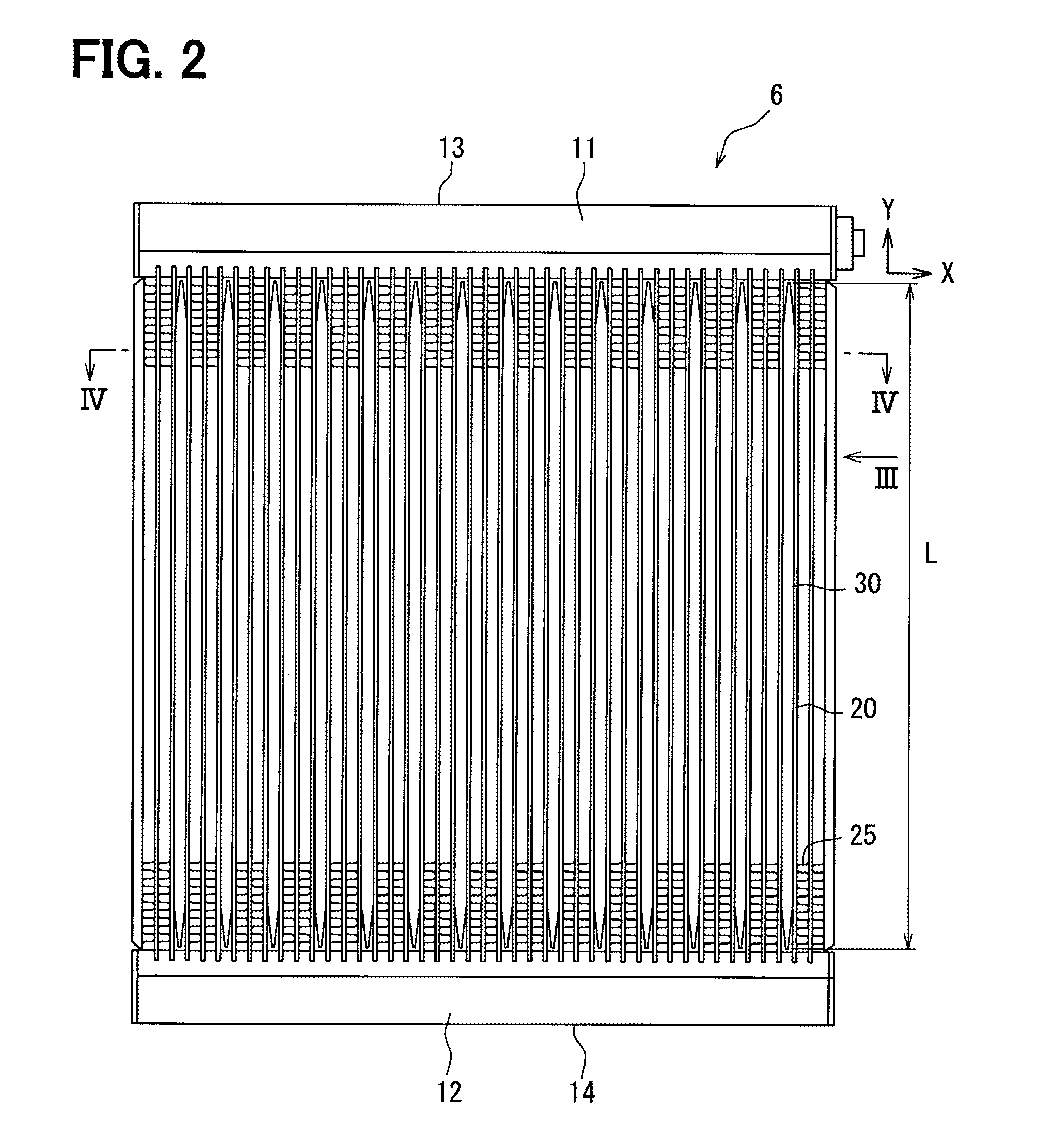

Cold storage heat exchanger

ActiveUS20150198383A1Reduce heat transferAvoid deformationHeat storage plantsVehicle heating/cooling devicesFill rateEngineering

A cold storage heat exchanger has refrigerant pipes fins, and cold-storage-medium containers. The cold-storage-medium container is arranged next to the refrigerant pipe. A cold storage medium is accommodated in the cold-storage-medium container in order to leave an air cell, and to provide a filling ratio of less than 90%. The cold-storage-medium container has a plurality of depressions at an inside of the cold-storage-medium container. The depression is a dimple. The plurality of depressions are joined each other at top parts and provide high rigidity. The cold-storage-medium container is positioned on the refrigerant pipe by an engaging projection. An open end of an open depression is covered by the refrigerant pipe. The cold storage medium can flow into the open depression. Therefore, the cold storage medium may directly contact the refrigerant pipe, and is directly cooled with the refrigerant.

Owner:DENSO CORP

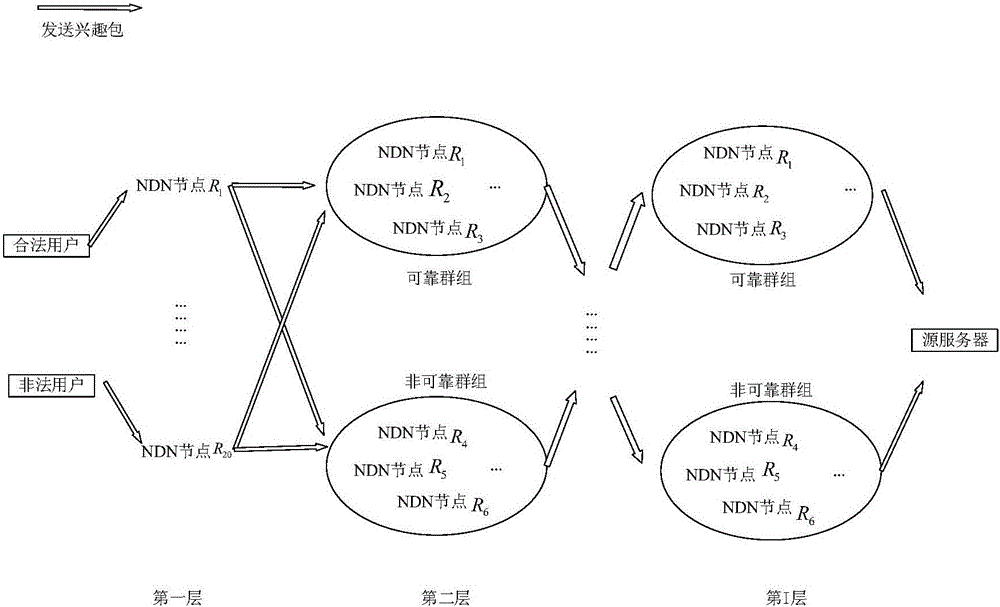

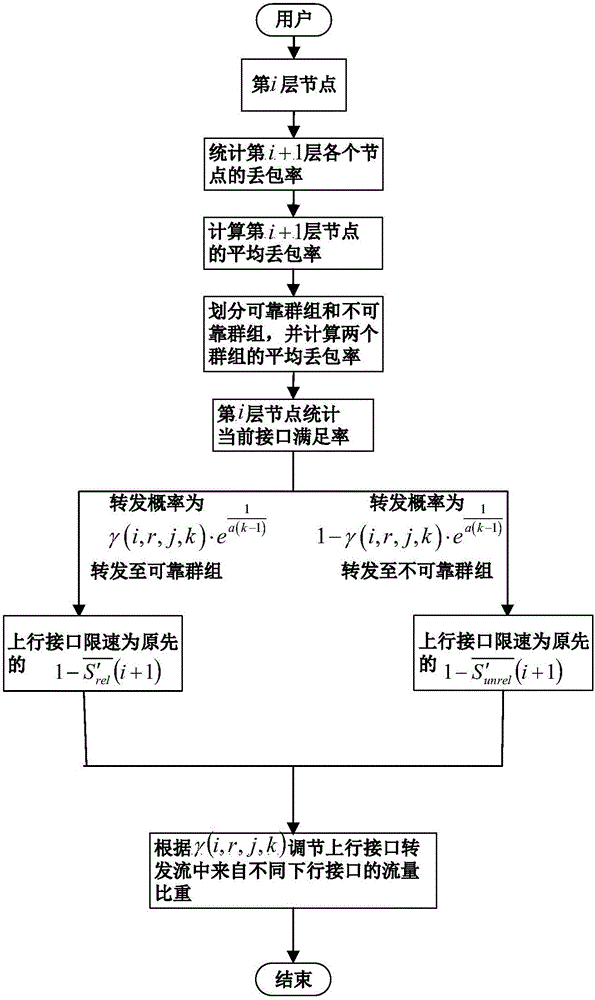

Defending method for malicious request packet of interest attacks in NDN (Named Data Networking)

ActiveCN106131844AGuaranteed reliabilityReduce the probability of packet lossNetwork traffic/resource managementTransmissionTraffic capacityFill rate

The invention discloses a defending method for malicious request packet of interest attacks in an NDN (Named Data Networking). An average packet of interest loss rate of a next hop forwarding node is queried periodically. Selectable forwarding nodes are divided into a reliable group and an unreliable group. A corresponding forwarding probability is set according to a downlink interface packet of interest fill rate of currently received request packets of interest and a requested content class. According to the probability, a certain node in the reliable group and the unreliable group is selected as the forwarding node. The user malicious requests are forwarded to the unreliable group in large probability, thereby converging malicious request streams. On this base, with respect to forwarding traffic of an uplink interface, a speed is limited according to the average packet of interest loss rate of a forwarding target group. The ratio in the forwarding streams after limitation of the speed is determined according to a source interface fill rate of the request packets of interest. The user malicious requests are effectively eliminated. The method can be applied to the NDN with the user malicious requests. The reliability of the network can be effectively ensured.

Owner:JIANGSU UNIV

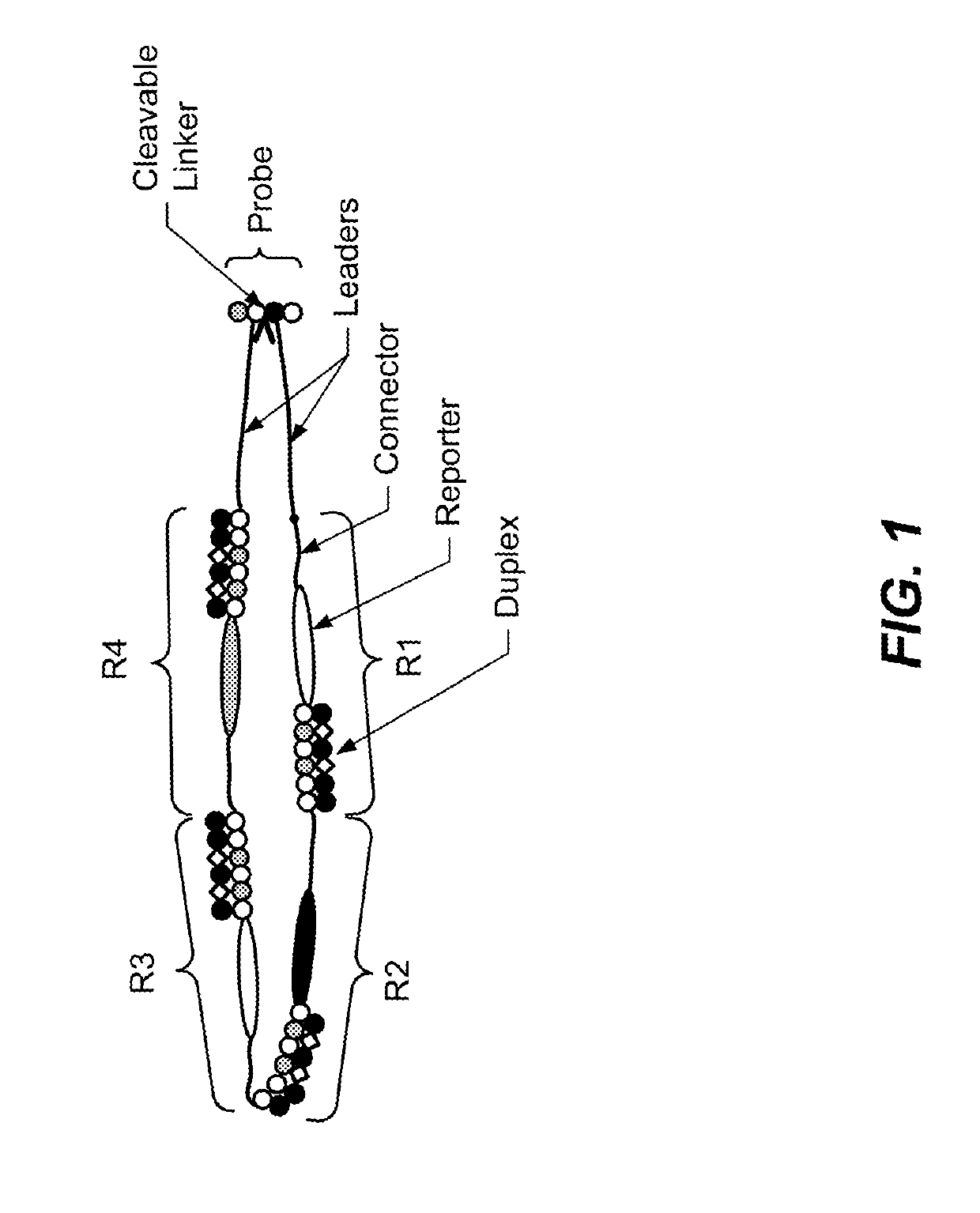

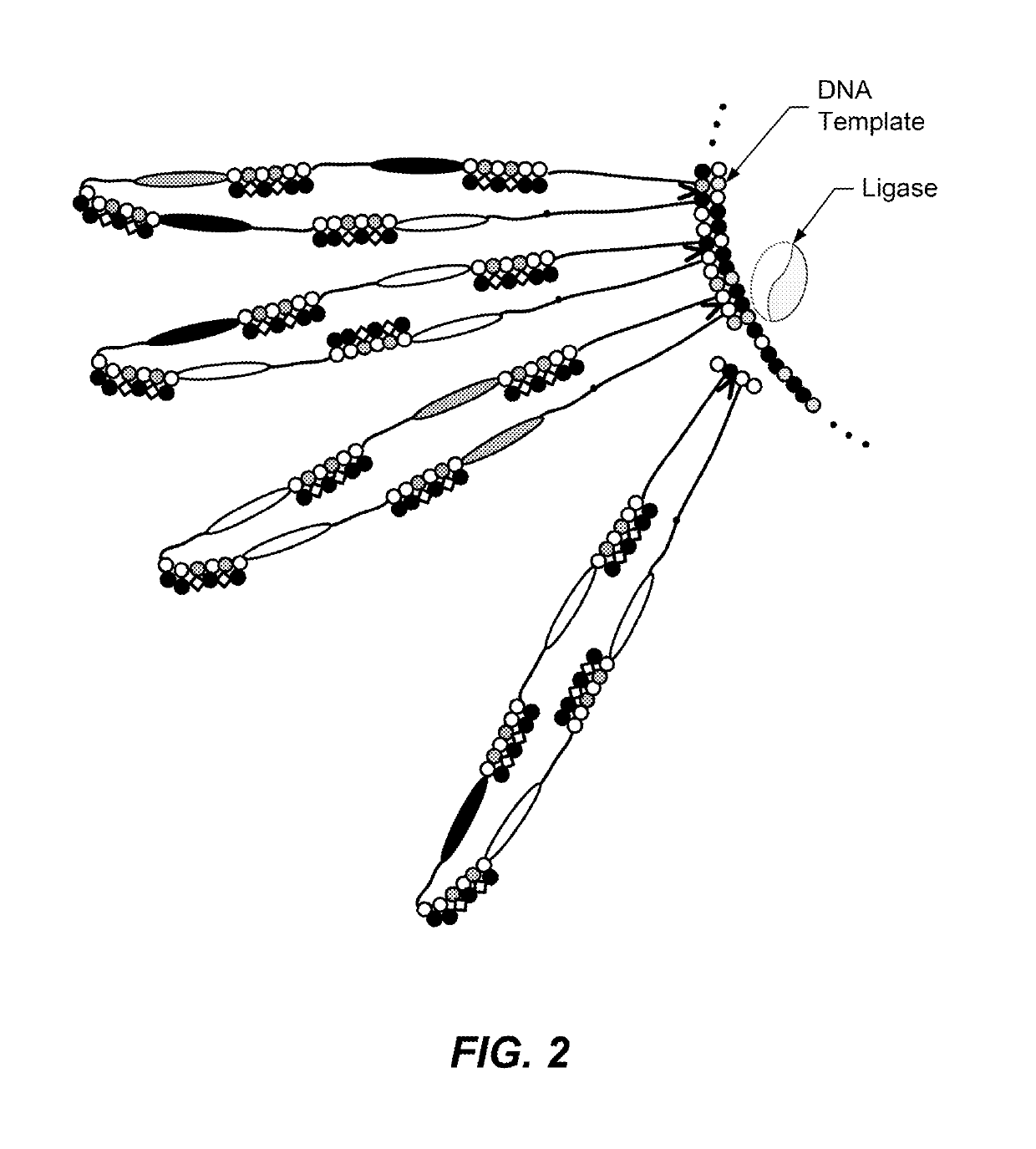

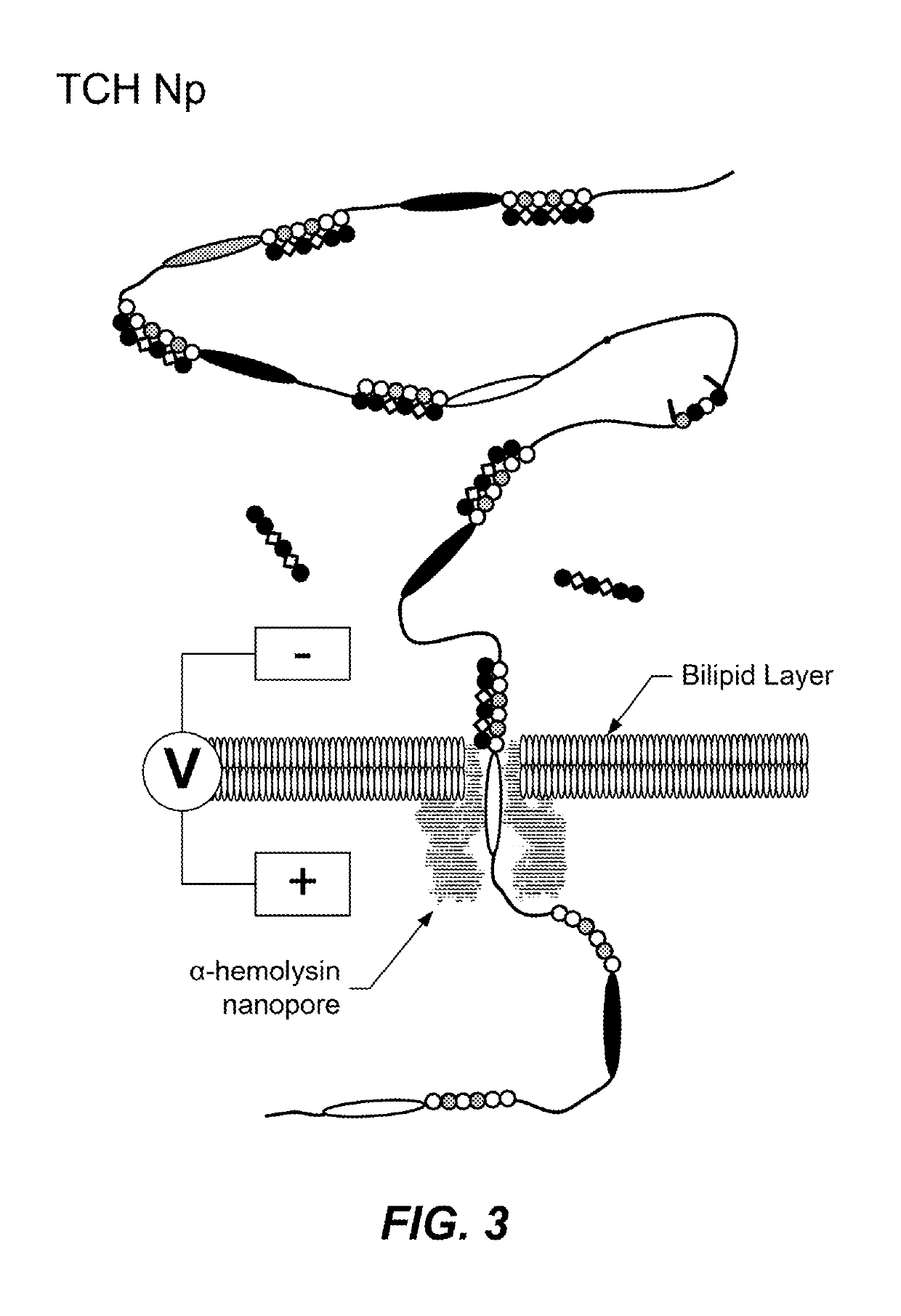

Translocation control for sensing by a nanopore

ActiveUS10457979B2Prevent rapid dissociationImprove stabilityMicrobiological testing/measurementMaterial analysis by electric/magnetic meansFill rateProtein translocation

Translocation control for sensing by a nanopore, as well as methods and products related to the same, are provided. Such methods optimize duplex stability to provide high fill rate (of the hybridization sites) but do not prevent rapid dissociation required for high read rates, as well as controlling the translocation of a target molecule for sensing by a nanopore by use of a selective pulsed voltage. Products related to the same include a reporter construct comprising two or more phosphoramidites.

Owner:ROCHE SEQUENCING SOLUTIONS INC

Welding resistant agent composition for flexible substrate, flexible substrate and preparation method for the flexible substrate

ActiveCN101077956AImprove heat resistanceReduce crystallinityPhotosensitive materials for photomechanical apparatusCircuit susbtrate materialsEpoxyFill rate

The invention provides a solder resist combination of flexible basal plate with excellent flexibility (softness) and thermal resistance, also provides a solder resist combination of flexible basal plate. Even though crosslinking is performed through adequate curing reaction without residung not-curing part, the solder resist combination is reinforced, soft, and with excellent thermal resistance, furthermore, even though the fill rate of fill is increased to improve therma conductivity, it is not easy to rupture and the softness can be kept. The said solder resist combination of flexible basal plate contains (A)hydrogenated biphenyl epoxy resin, (B) rubber shape compound with functional group reacting with epoxy group, or (C) alumina grain.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com