Self-adapting selection dynamic production scheduling control system accomplished through computer

A technology of self-adaptive selection and production scheduling, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as difficulties in obtaining training samples, changes in product demand, and delays in raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In conjunction with the content of the technology of the present invention, the following embodiments are further provided:

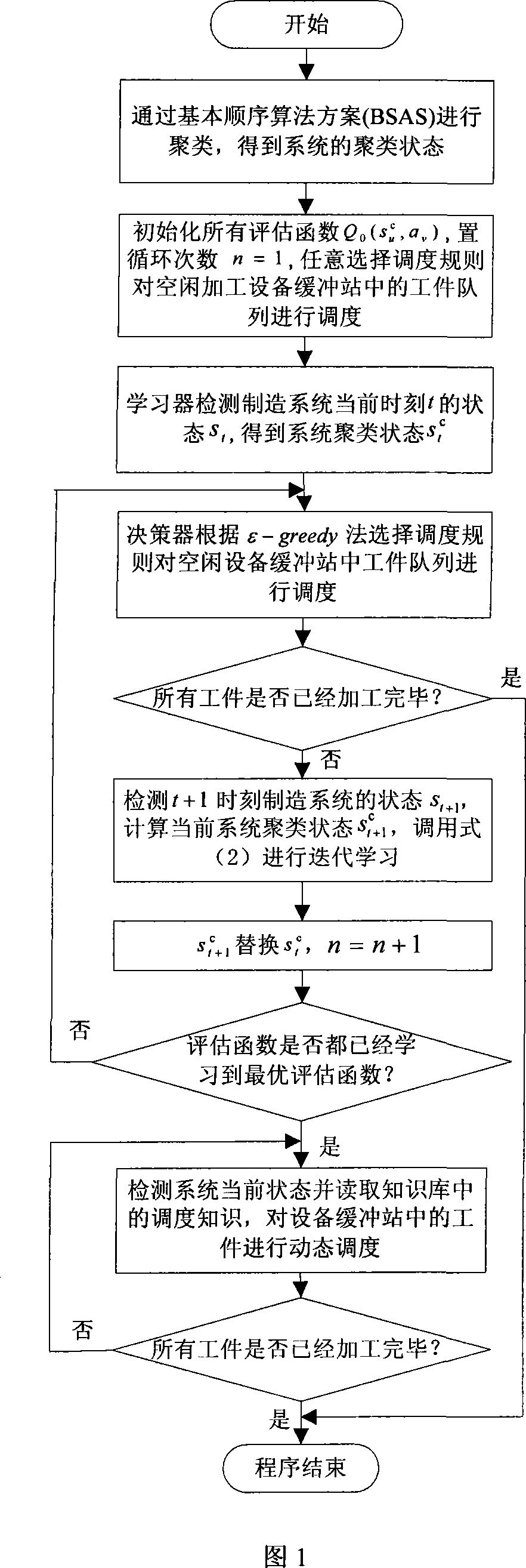

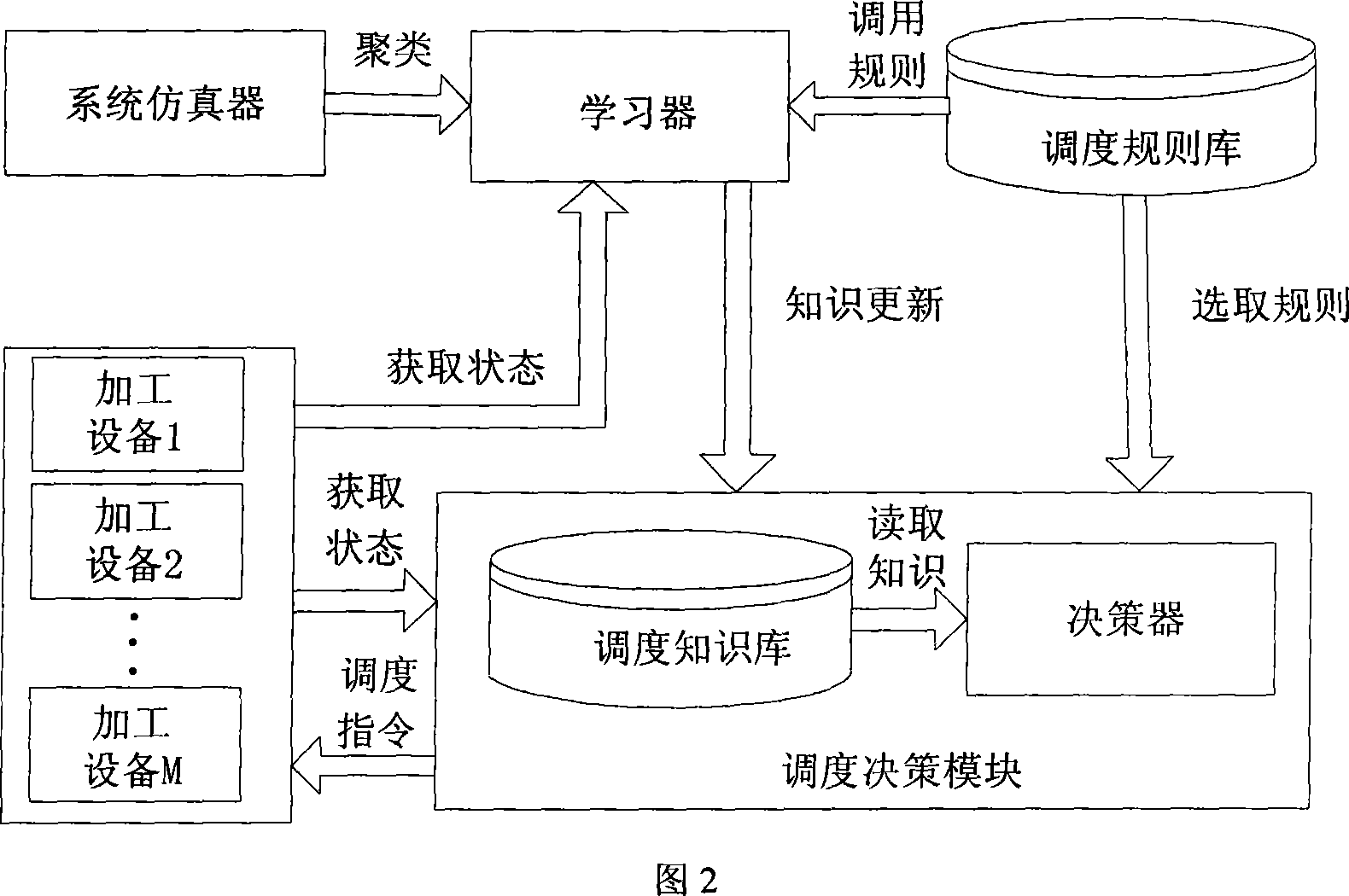

[0054] A kind of self-adaptive selection dynamic production scheduling control system realized by computer provided by the present invention, please refer to Fig. 1, specifically comprises the following several steps:

[0055] Step 1. Cluster the system state to obtain the cluster state of the system:

[0056] 1.1 Initialize the number of clusters x=1, i=1, set the maximum number of clusters as K, and the number of states generated by the system simulator as κ. Running the system simulator, the learner gets the initial state s generated by the simulator 1 , for s 1 Perform feature standardization to get the xth cluster C x = { s 1 } · d ( s t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com