Patents

Literature

104results about How to "Improve scheduling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-adapting selection dynamic production scheduling control system accomplished through computer

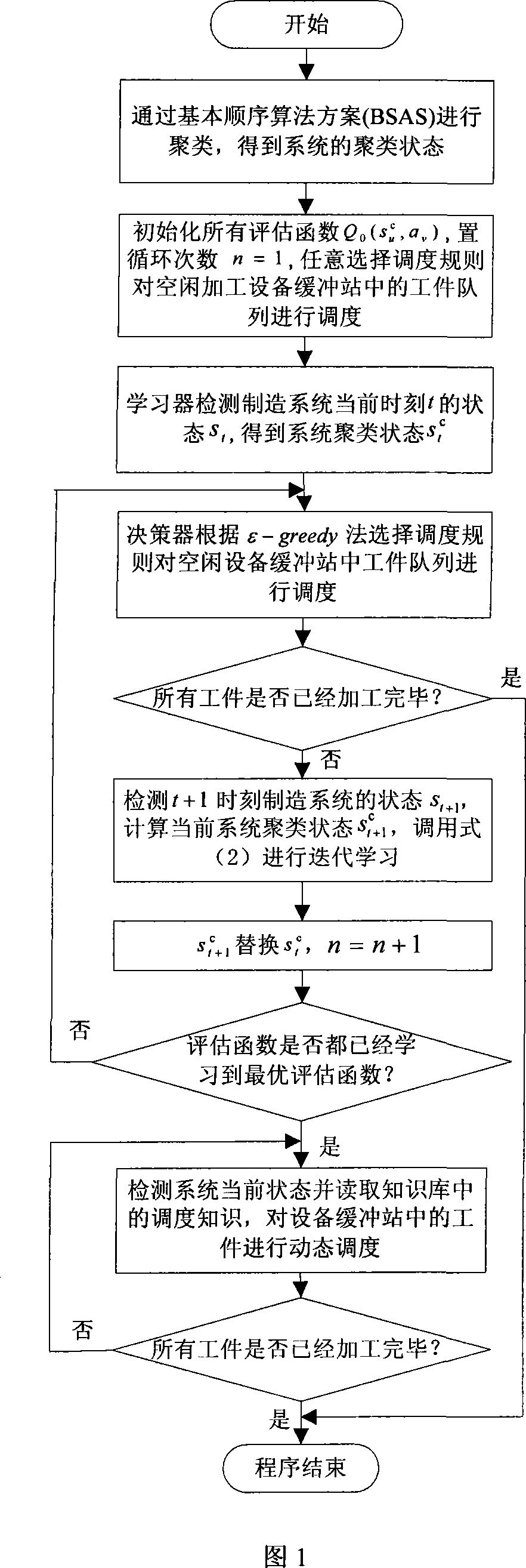

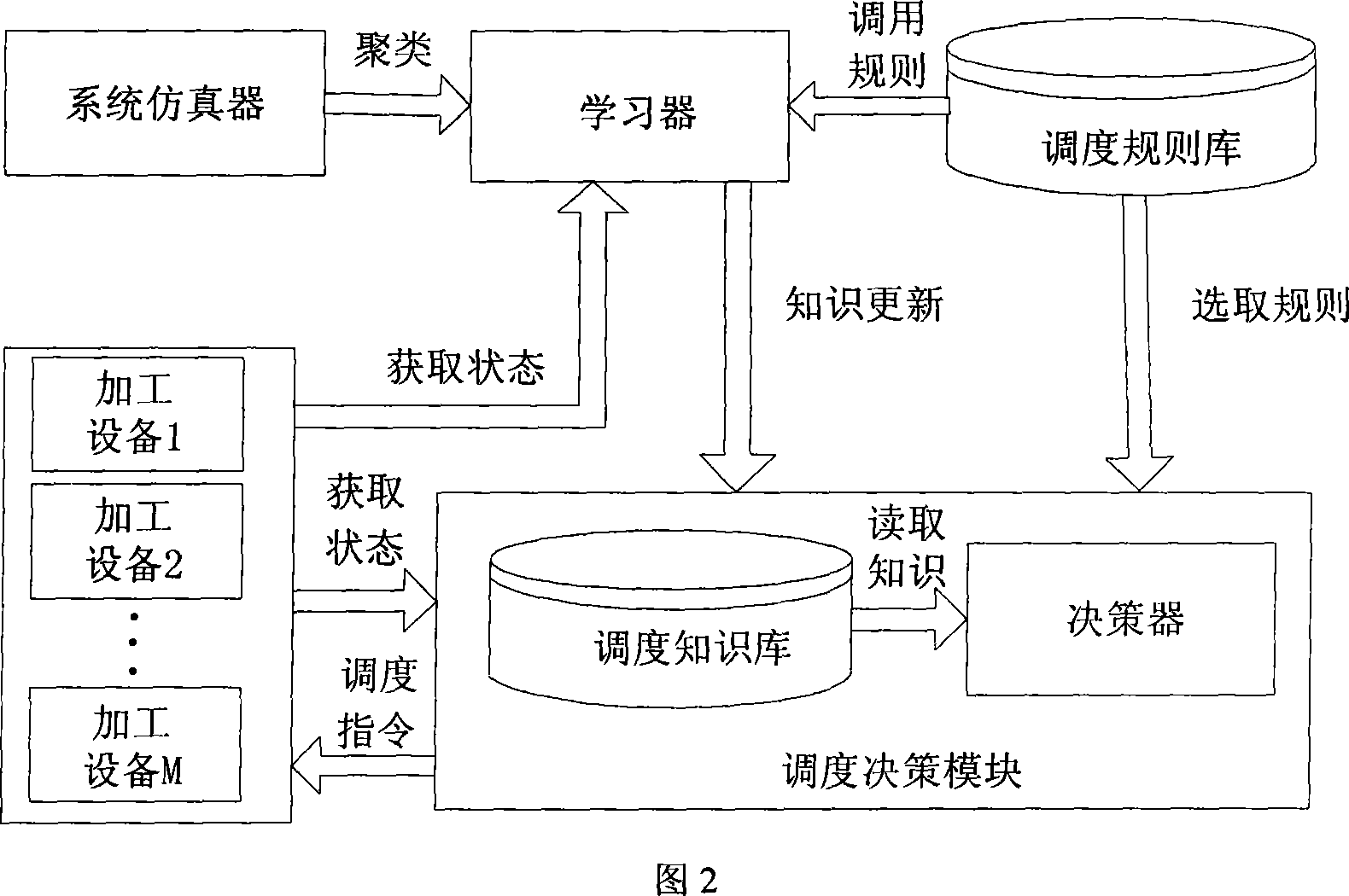

InactiveCN101216710AReduce delaysReduce average time overdueTotal factory controlProgramme total factory controlLearning machineProduction schedule

A self-adaptive selection dynamic production scheduling control system, which is realized via a computer, is characterized in that: the system comprises a system emulator, a learning machine, a decision-making machine, a scheduling rules base, a scheduling knowledge base, a carrier, processing equipments and a buffer station thereof; the buffer station is provided with an optical grating, a sensor and a detection equipment; when a working piece reaches the buffer station and is processed, the learning machine detects the current system status for learning, so as to acquire dynamic scheduling knowledge about the system and update the knowledge in the scheduling knowledge base; when one processing equipment needs to be scheduled, the decision-making machine reads corresponding scheduling knowledge in the scheduling knowledge base according to the detected system status, acquires new scheduling knowledge through continuous interactive learning with the processing system, dynamically selects the scheduling rules based on the status of the processing equipments and the working piece in the system, and chooses the optimized scheduling rules to schedule the processing equipments. The invention can adapt to instable time-varying workshop dynamic production environments, obtain a better working-piece arrangement than prior rule-based scheduling technology, effectively reduce the process waiting time, and improve the fill rate of product delivery time.

Owner:SOUTHEAST UNIV

Workflow scheduling method based on critical path task prospects

ActiveCN107301500AImprove scheduling effectReduce complexityResourcesModel graphPhases of clinical research

The invention relates to a workflow scheduling method based on critical path prospects. The method comprises the steps that a user submits workflow; the workflow is converted into a directed acyclic task model graph (DAG); and scheduling of DAG task nodes is performed, and a workflow scheduling scheme is output. According to the method, a longest path from an entrance task to a current task and a longest path from the current task to an exit task are considered at a task priority determination stage; and influences of critical path tasks and non-critical path tasks on a scheduling result are considered at a resource selection stage. Compared with other methods, completion time of workflow scheduling is short through the method.

Owner:BEIJING UNIV OF TECH

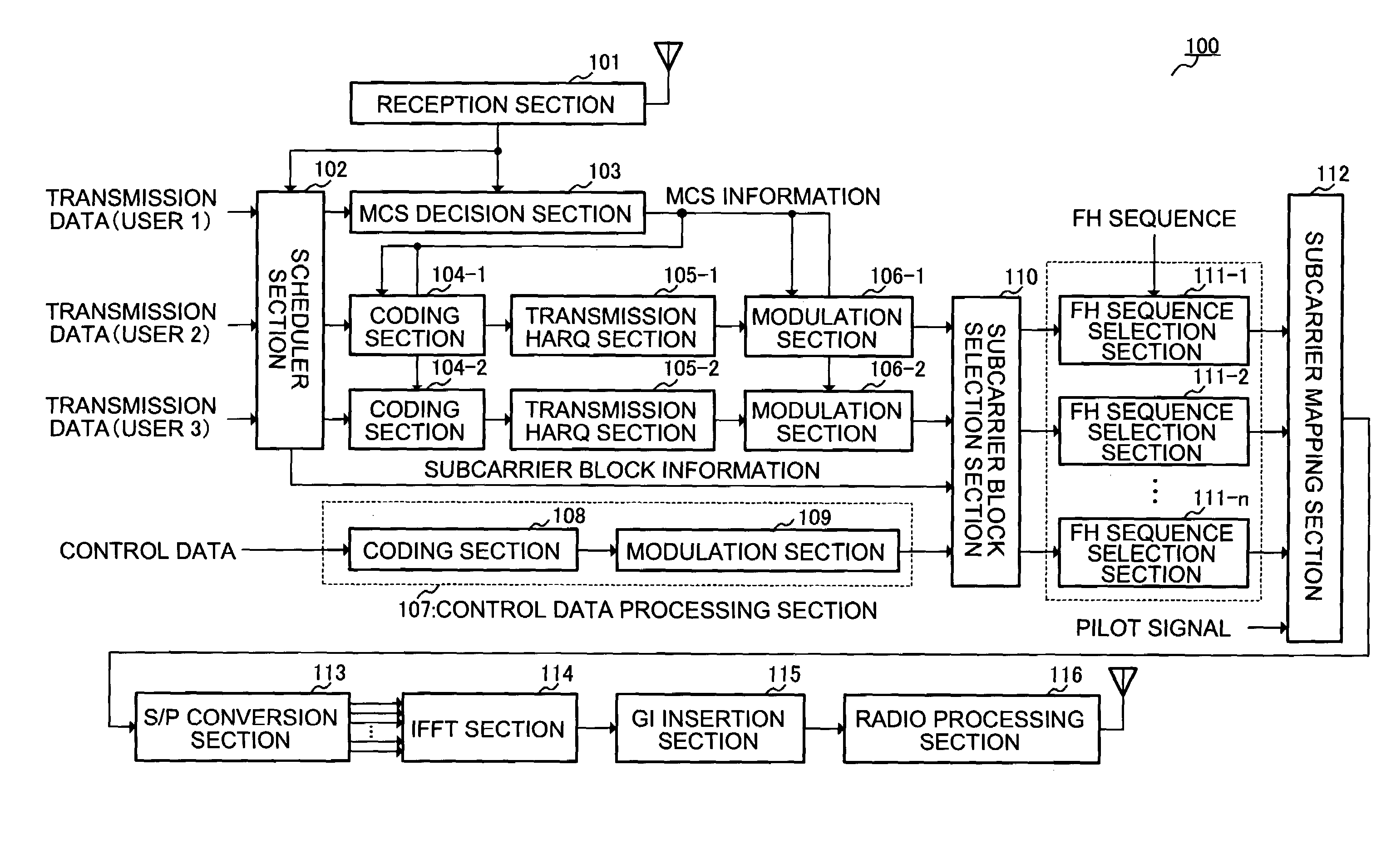

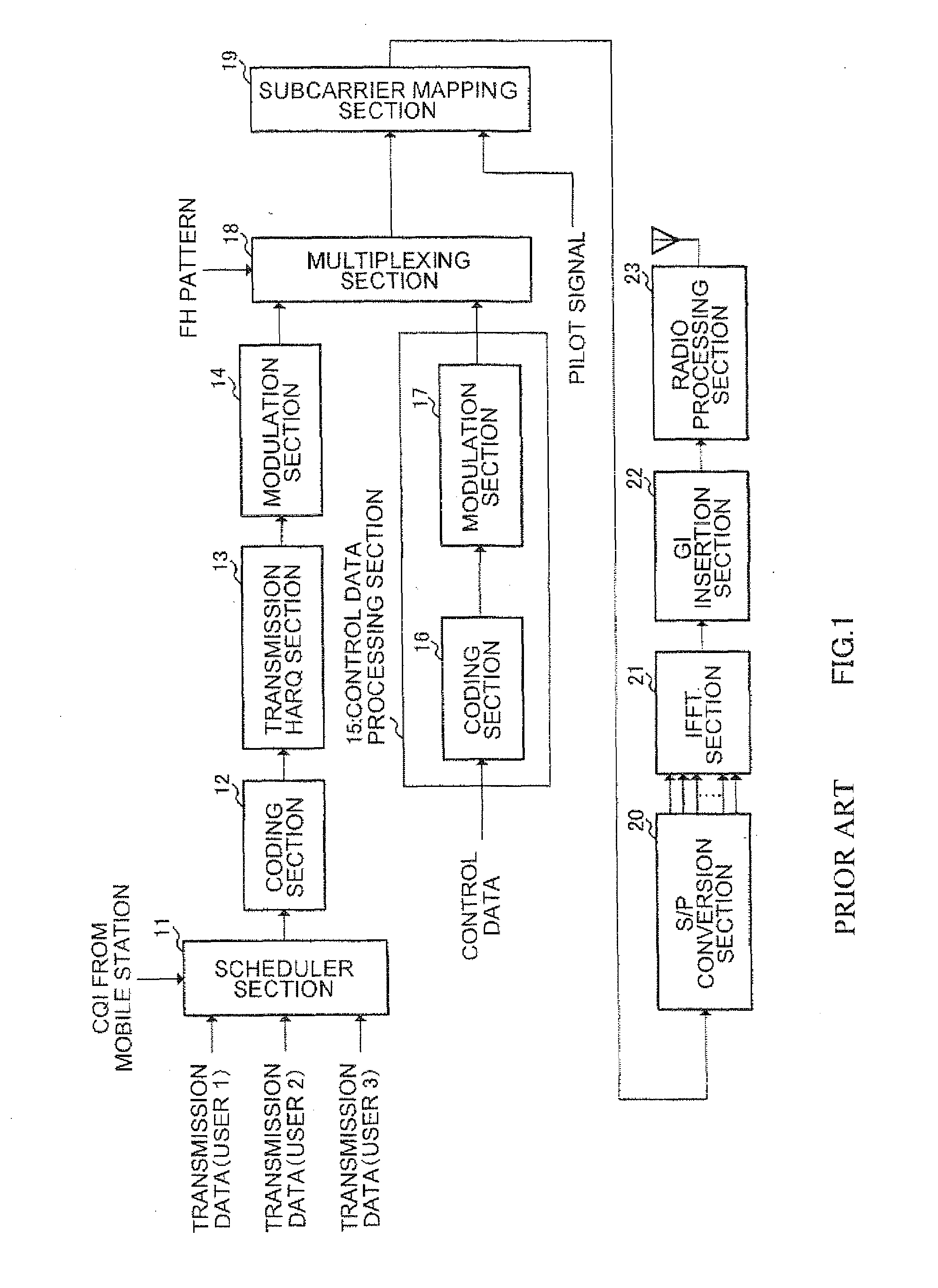

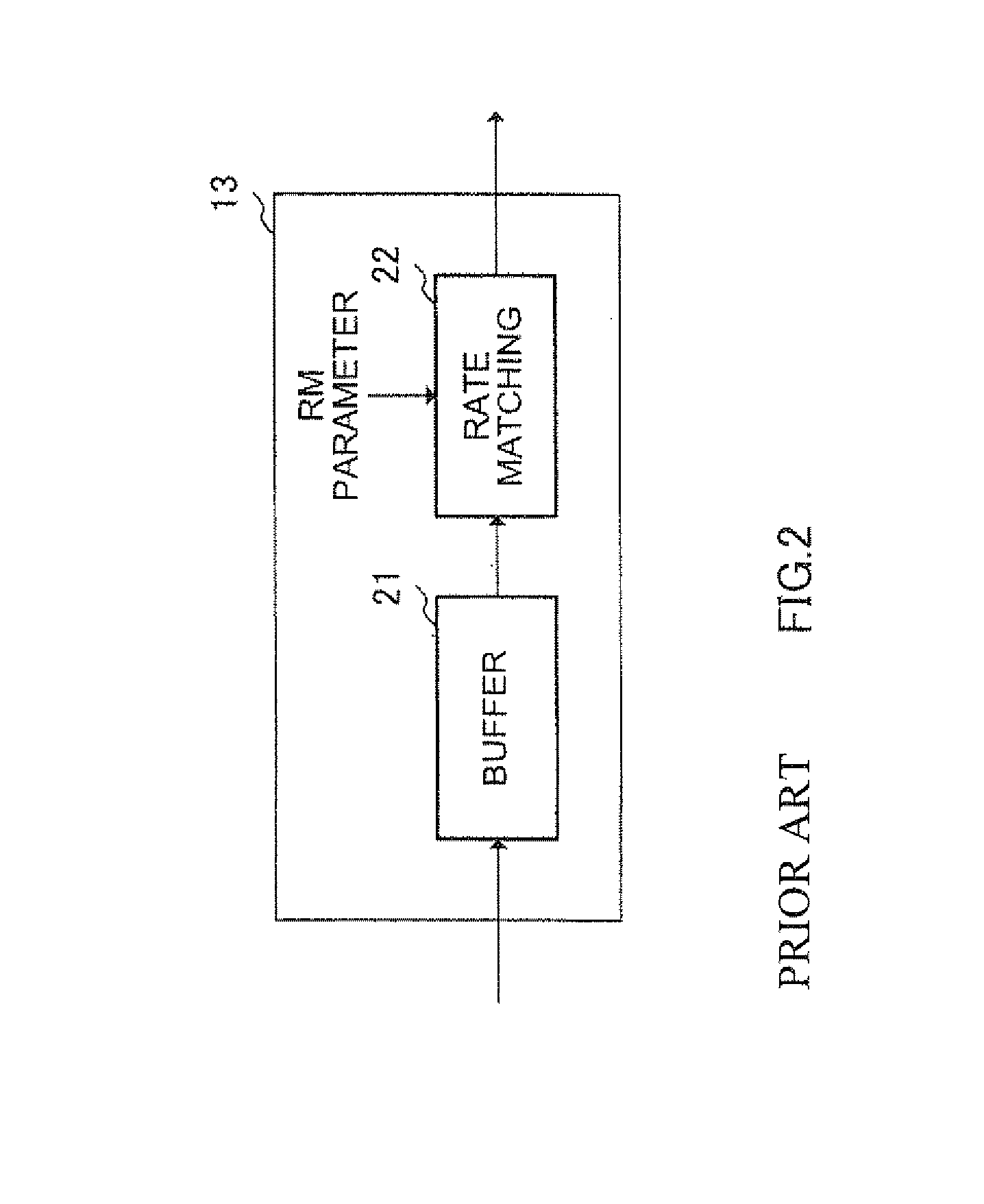

Base station using a multicarrier communication band divided into a plurality of blocks

ActiveUS7660367B2Reduce distractionsHigh speed transmissionCriteria allocationFrequency-division multiplexControl dataTerminal equipment

It is possible to use a frequency of a preferable propagation condition while reducing the other cell interference by hopping. A scheduler section (102) performs scheduling for deciding a user to whom data is transmitted, by using the CQI from each communication terminal device, selects a user signal to be transmitted in the next frame, and decides a sub-carrier block by which the transmission is performed. An MCS judgment section (103) selects a modulation method and a coding method from the CQI of the user signal selected. A sub-carrier block selection section (110) selects a sub-carrier block specified by the scheduler section (102) for each user signal. For each of the sub-carrier blocks, the hopping pattern is selected by FH-sequence selection sections (111-1 to 111-n). A sub-carrier mapping section (112) maps the user signal and the control data to the sub-carrier according to the hopping pattern selected.

Owner:GK BRIDGE 1

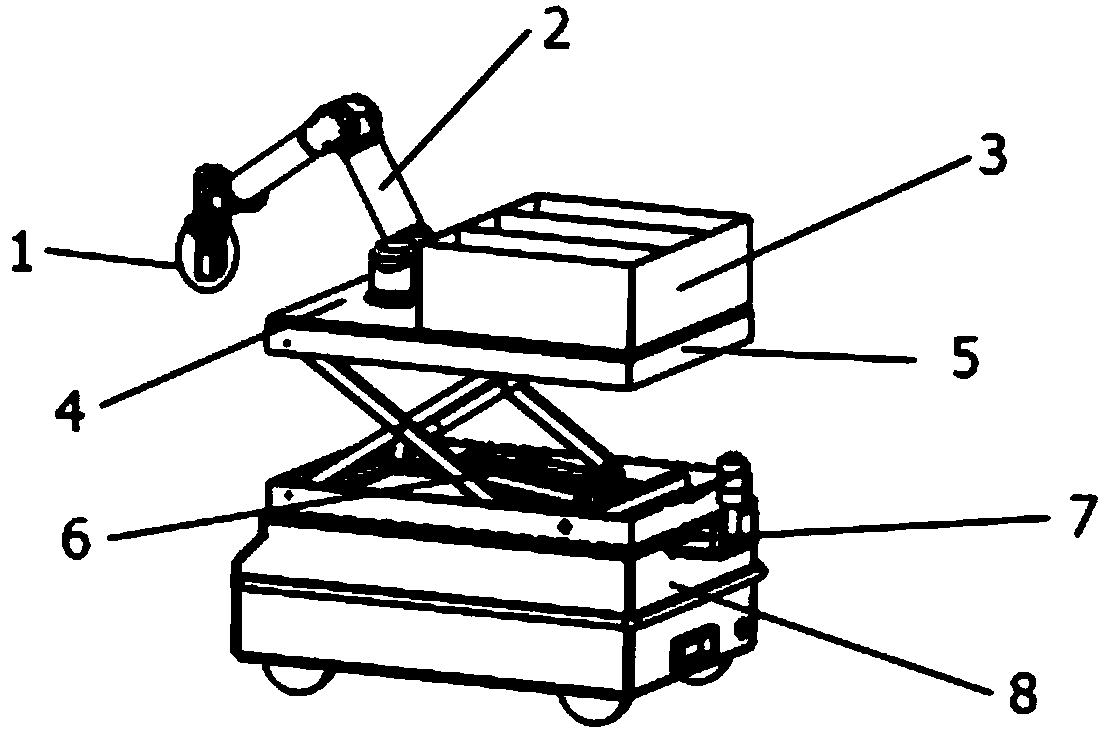

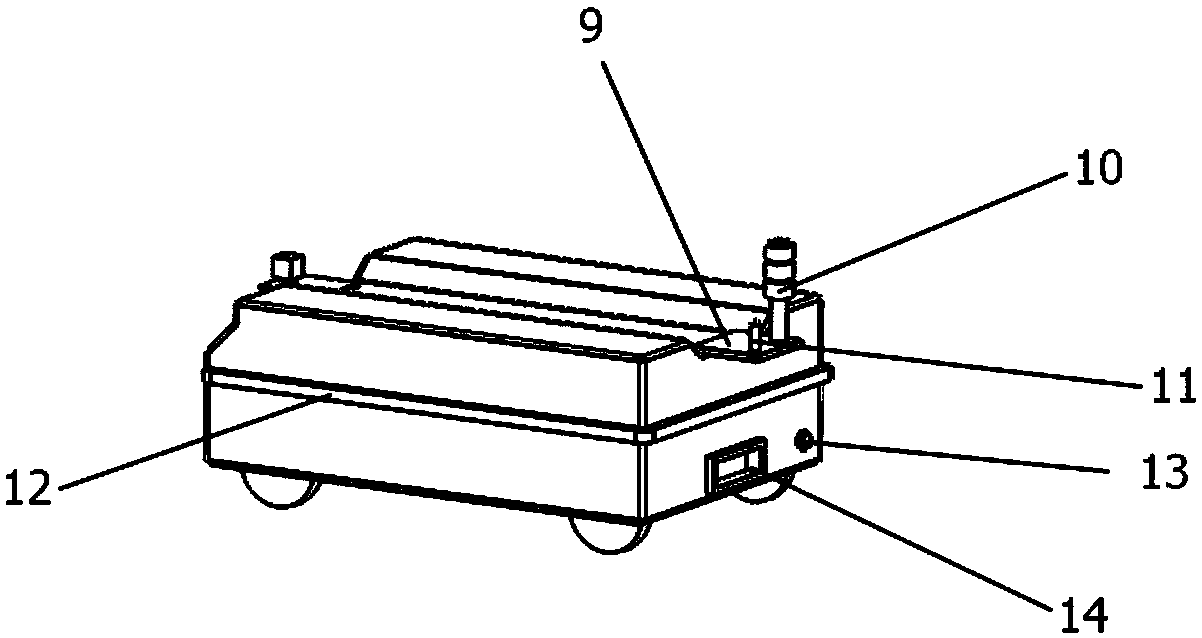

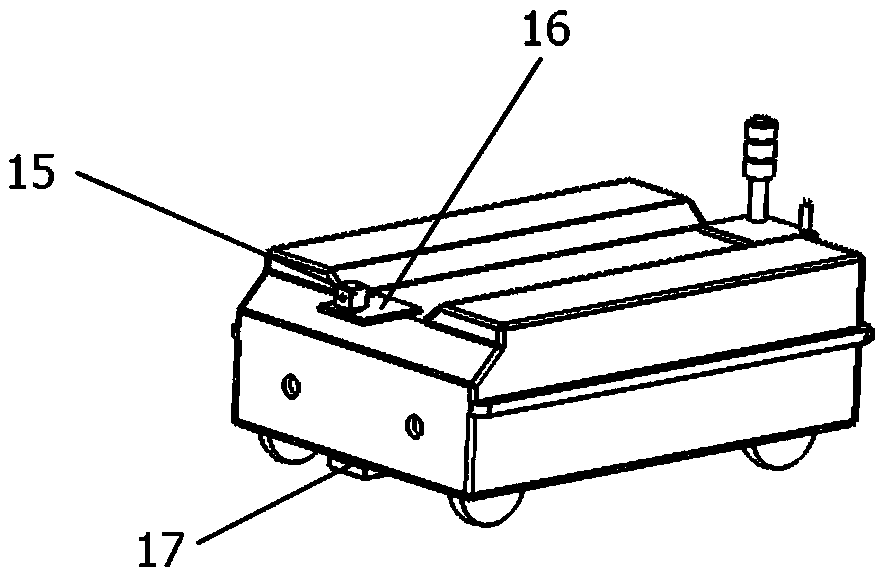

Intelligent carrying robot trolley and management method thereof

InactiveCN108436907AImprove securityLow failure rateProgramme-controlled manipulatorGripping headsLaser sensorAutonomation

The invention provides an intelligent carrying robot trolley and a management method thereof. The intelligent carrying robot trolley comprises a grabbing mechanism, a lifting mechanism and an intelligent trolley, wherein the grabbing mechanism comprises a pneumatic hand grab, a robot, a material box and an infrared scanner; the lifting mechanism comprises a lifting table and a hydraulic cylinder;the intelligent trolley comprises an intelligent trolley system, an installation plate, a signal lamp, a signal transmitter, an anti-collision bar, a buzzer, a charging port, a laser sensor, a laser sensor installation plate and a path planning module; the grabbing mechanism is arranged above the lifting mechanism; an upper panel is arranged between the grabbing mechanism and the lifting mechanism; the lifting mechanism is arranged above the intelligent trolley; and a lower bottom plate is arranged between the lifting mechanism and the intelligent trolley. The intelligent carrying robot trolley and the management method thereof provided by the invention solve the problem that a large number of manpower resources are wasted since processes such as detecting, assembling, disassembling, sorting, carrying and stacking are carried out by using a large number of manpower in the logistics and express delivery industries, and realizes intelligence, automation, and automatic managerial statistics.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Meme evolution multiobjective optimization scheduling method based on objective importance decomposition

InactiveCN105488568AEfficient schedulingImprove scheduling effectData processing applicationsGenetic modelsDecompositionGenetic algorithm

The invention relates to a meme evolution multiobjective optimization scheduling method based on objective importance decomposition, comprising following steps: randomly generating an initial population with volume of N; in every generation of the algorithm, selecting by the current population through binary championship, generating an offspring population by a genetic operator; carrying out fine search to the offspring population by a partial search strategy to obtain improved population; combining the current population, the offspring population and the improved population to generate a population, carrying out mutation operation to the individuals in the population with identical objective size; sorting the individuals in the population through using the rapid nondominated sorting and crowding distance method in the NSGA-II (Nondominated Sorting Genetic Algorithm II), thus selecting N best solutions as the next generation populations. According to the invention, a multiobjective flexible working shop system can be scheduled effectively; the scheduling effect is superior to the existing advanced algorithm; and the method of the invention can be widely applied in the computer application technical field and the production scheduling field.

Owner:TSINGHUA UNIV

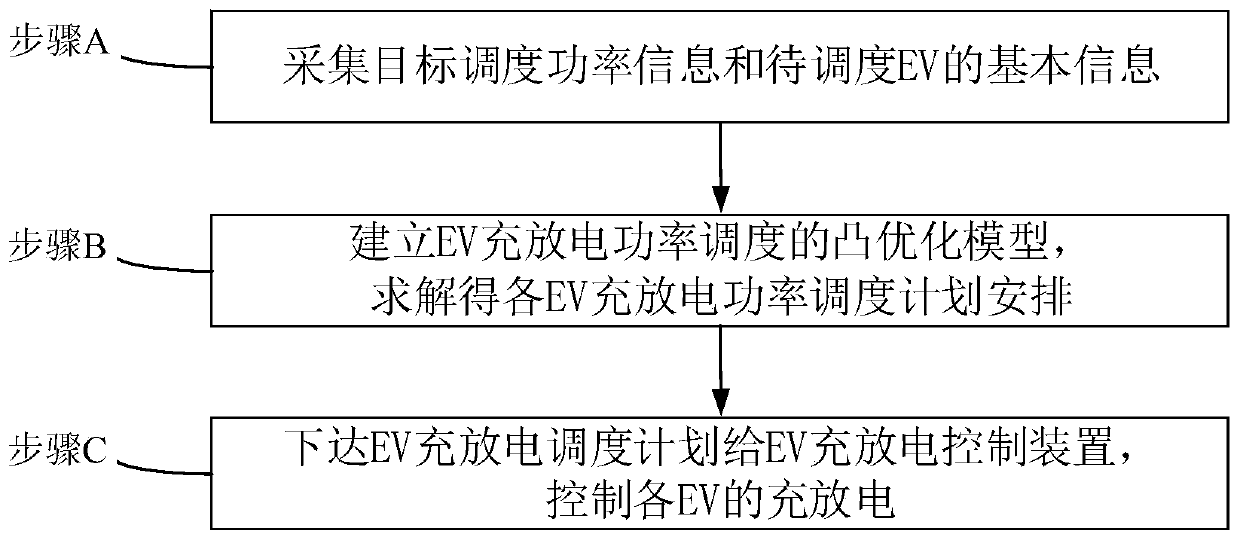

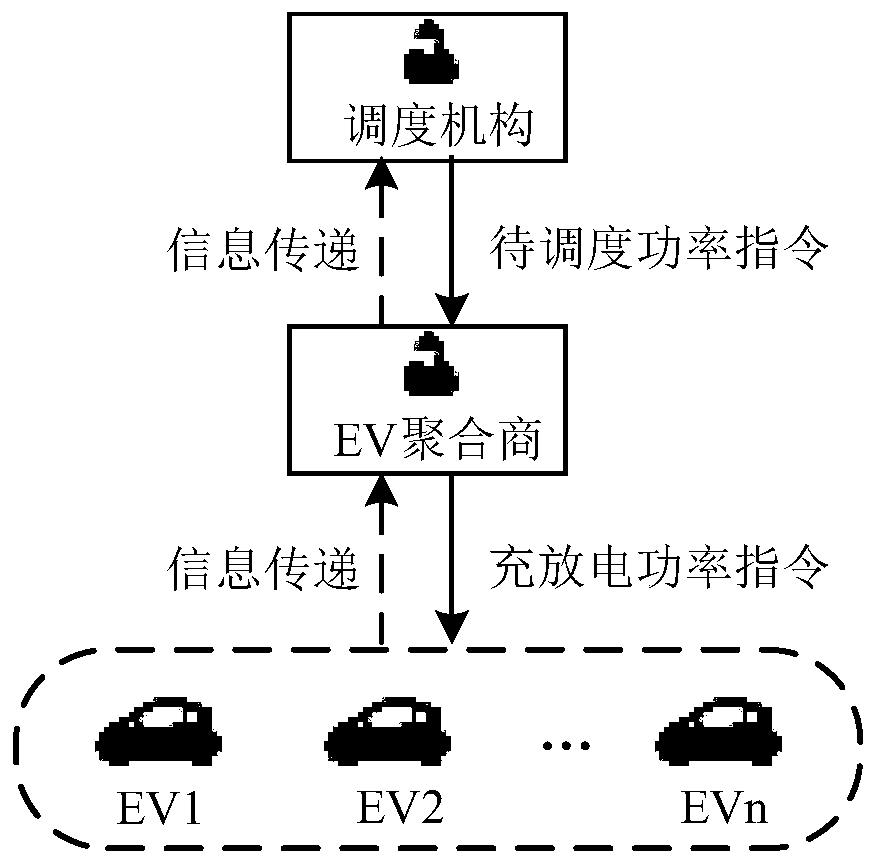

Cluster electric vehicle charge-discharge power optimization management method

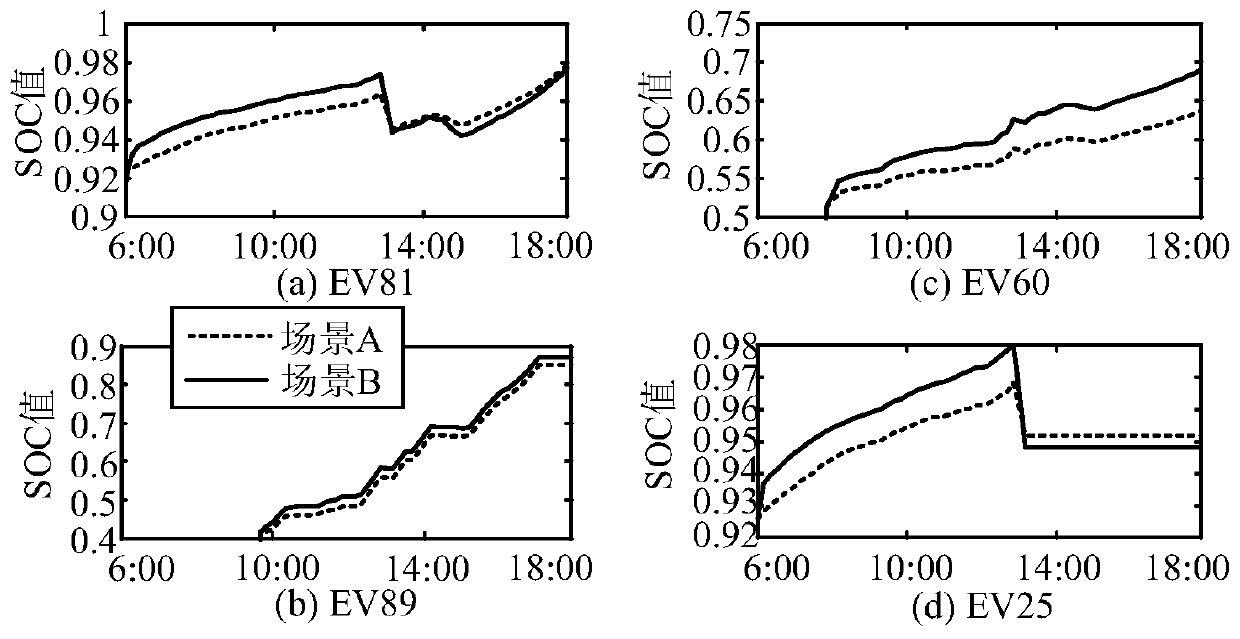

ActiveCN110011342AAvoid problems caused by solvingImprove computing efficiencyAc network load balancingCharge dischargeElectric vehicle

The invention discloses a cluster electric vehicle charge-discharge power optimization management method, and belongs to the technical field of electric vehicle charging and discharging management. The method comprises the steps of: the step A, collecting target dispatching power information and basic information of electric vehicles (EV) to be dispatched; the step B, establishing a convex optimization model of EV charge-discharge power dispatching according to the target dispatching power information and the basic information of the EVs to be dispatched; and the step C, issuing an EV charge-discharge power dispatching plan to EV charge-discharge control devices to control the charge-discharge of each EV. A dispatching mechanism collects the information of each EV through an EV collectionsupplier, then publishes a power command to be dispatched to the EV collection supplier and allows the EV collection supplier to send a charge-discharge power command to each EV charge-discharge control device to perform charge and discharge for the EVs. The cluster electric vehicle charge-discharge power optimization management method avoids the problem caused by non-convex constraint on solvingthe EV charge-discharge model. The method does not need any application condition, has wide application range and is easy to be popularized to the electric automobile or the peak regulation and frequency regulation field participating in energy storage.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

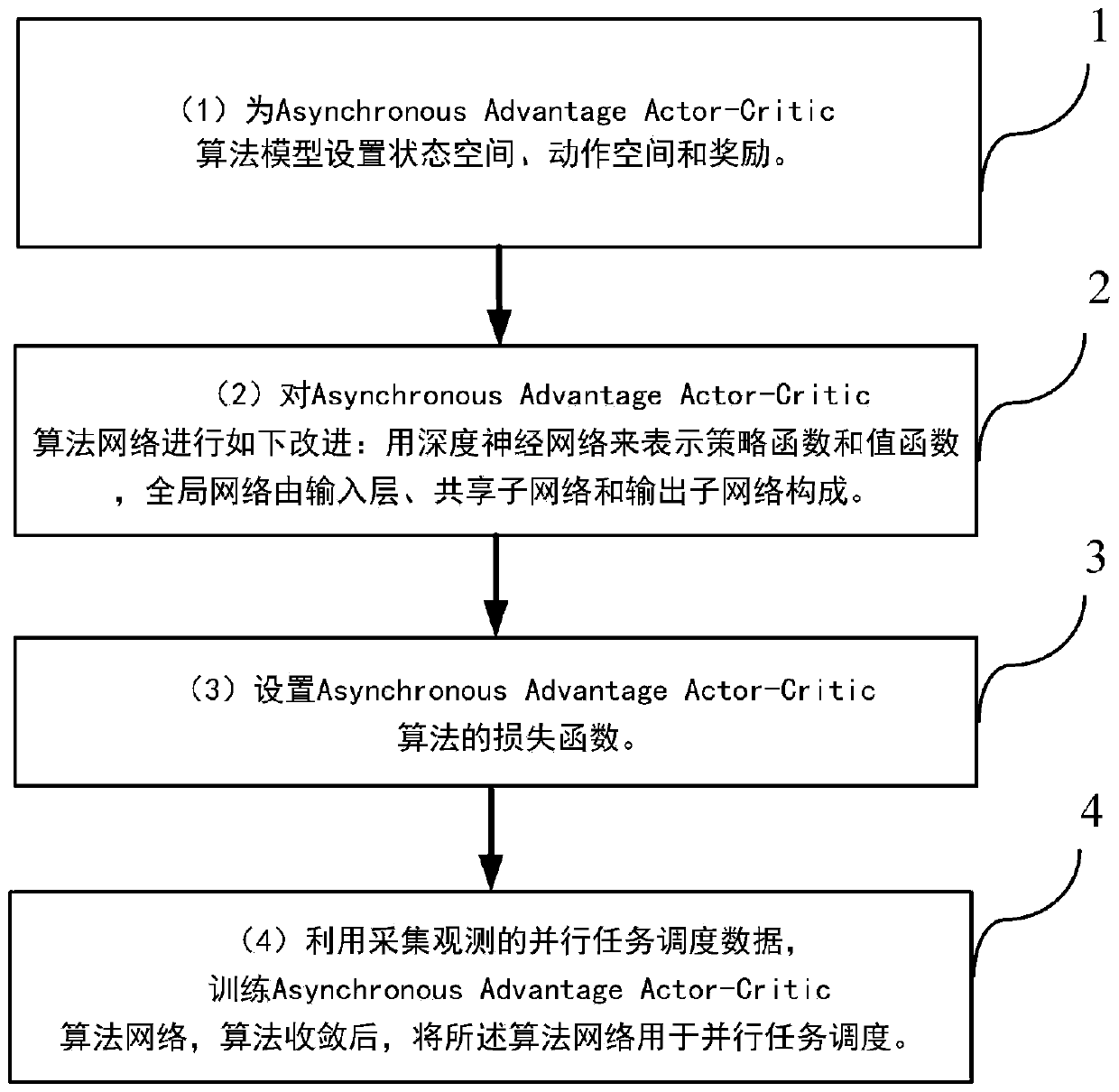

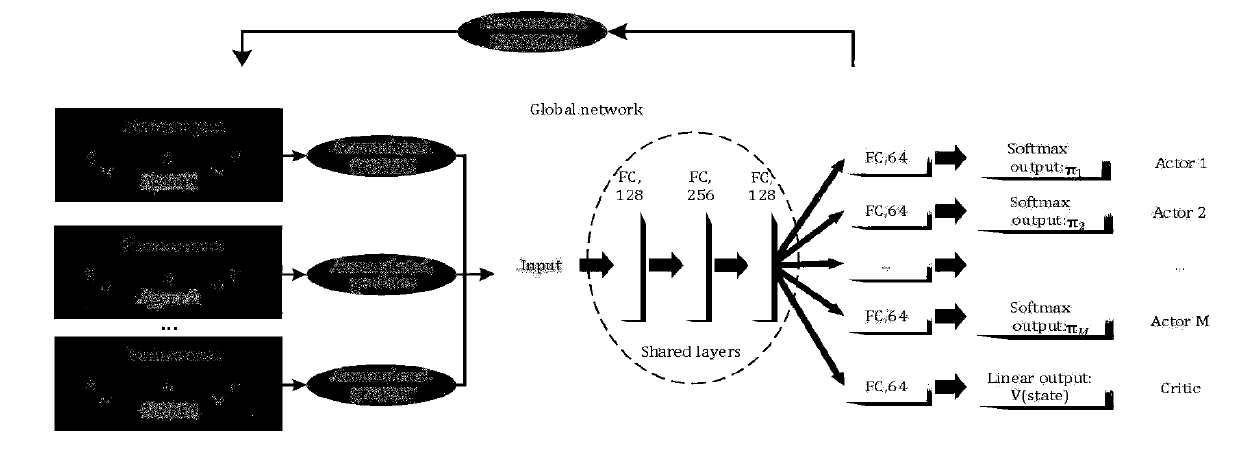

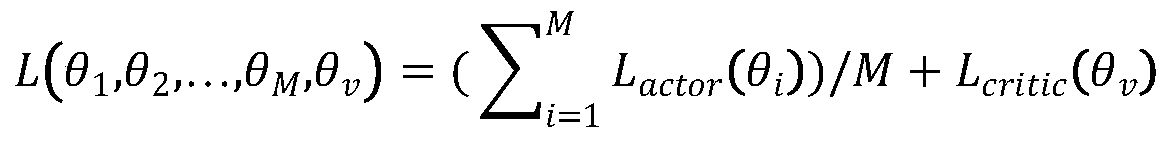

Multi-task reinforcement learning method for realizing parallel task scheduling

InactiveCN110580196AImprove generalizationImprove scheduling effectProgram initiation/switchingRoad vehicles traffic controlGlobal networkDeep neural networks

A multi-task reinforcement learning method for realizing parallel task scheduling is realized based on an asynchronous advantage actor-critic algorithm, and comprises the following operation steps: (1) setting an algorithm model to better solve the parallel multi-task scheduling problem, including setting a state space, setting an action space and setting an award definition; (2) improving the algorithm network as follows: using a deep neural network to represent a strategy function and a value function, wherein the global network is composed of an input layer, a shared sub-network and an output sub-network; (3) setting a new loss function of the algorithm; and (4) training the algorithm network by utilizing the collected and observed parallel task scheduling data, and applying the algorithm network to parallel task scheduling after algorithm convergence.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Integrated search method for large-scale flexible job shop scheduling

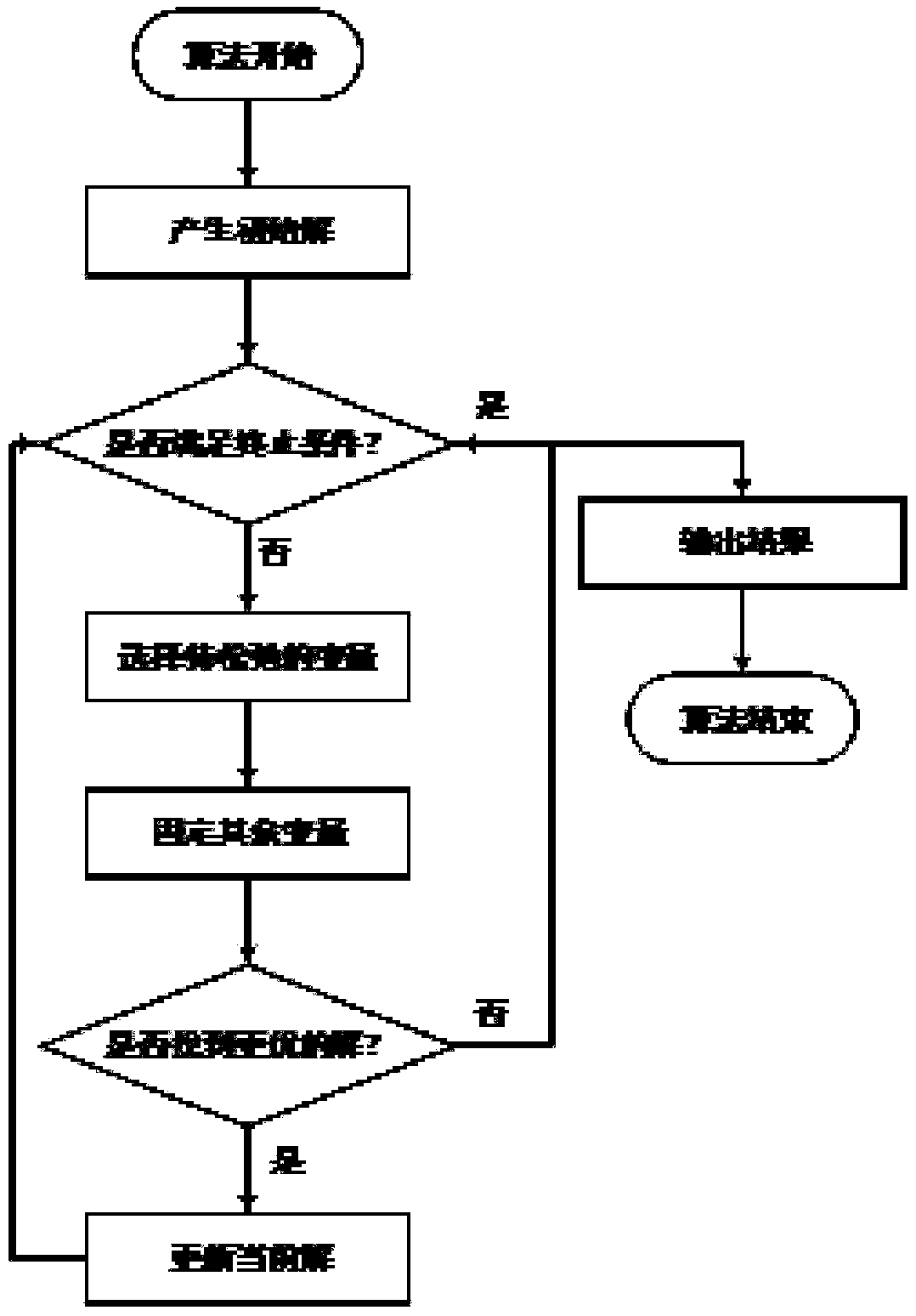

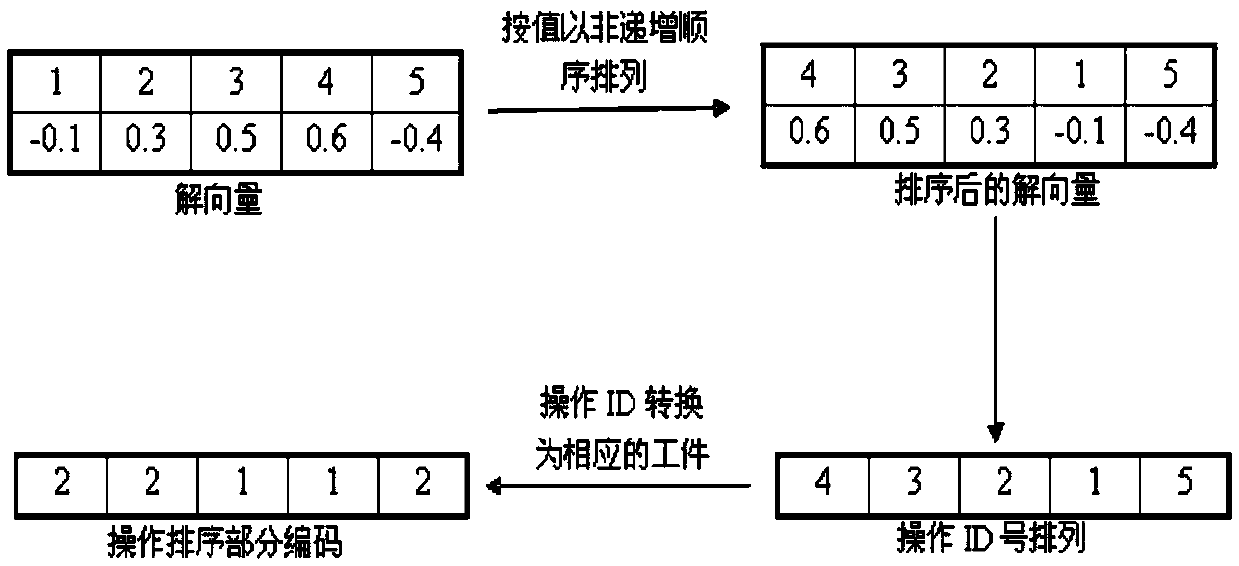

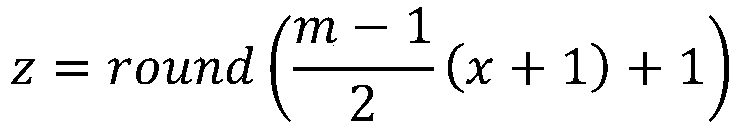

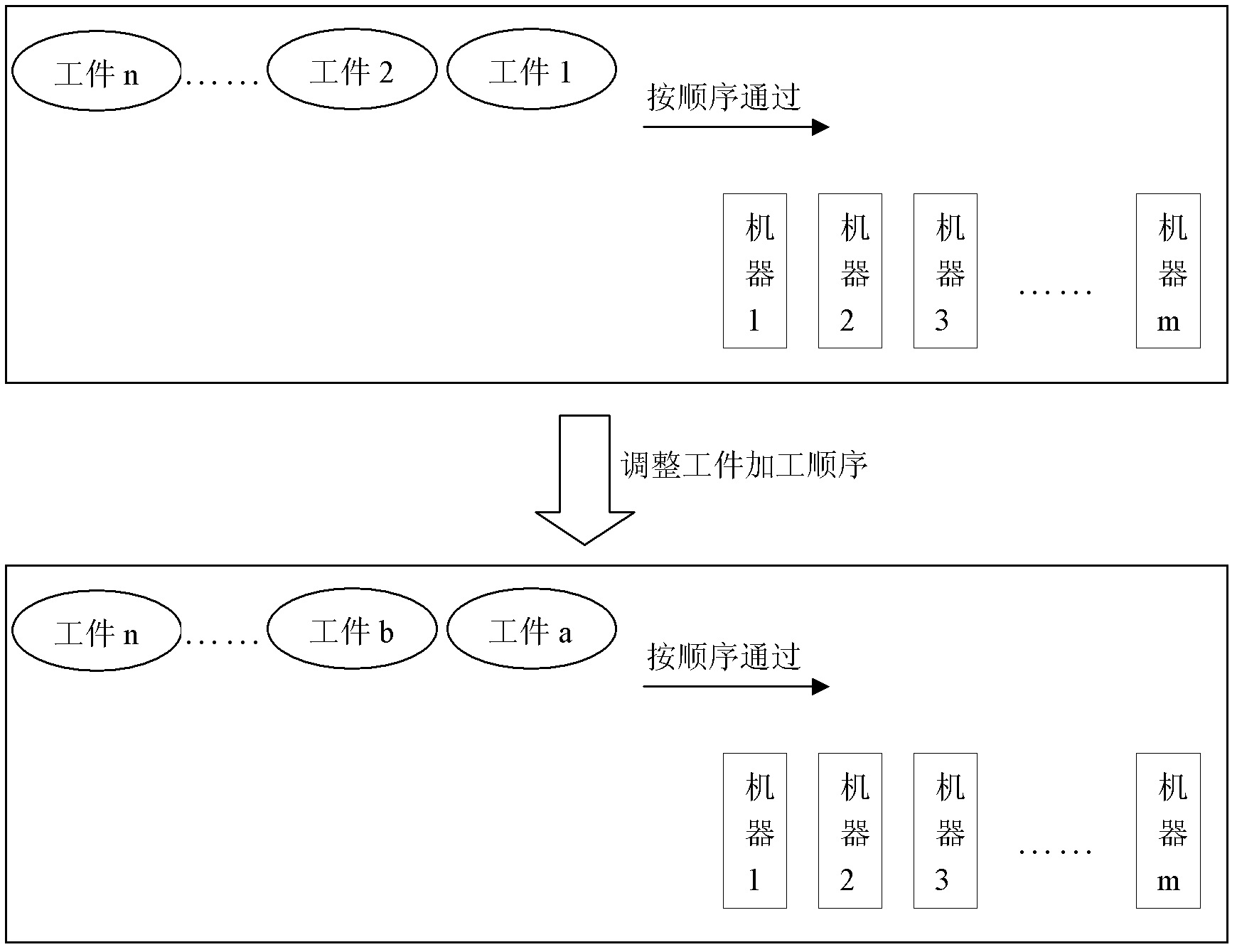

InactiveCN105512954ASolve scheduling problemsGood scheduling effectData processing applicationsManufacturing computing systemsCompletion timeHarmony search

The invention relates to an integrated search method for large-scale flexible job shop scheduling. The integrated search method comprises the following steps that: 1) a solution vector of FJSS (flexible job shop scheduling) to be solved is defined; 2) a solution vector in hybrid harmony search is converted into the codes of a feasible solution of the FJSS; 3) a hybrid harmony search algorithm is adopted to perform harmony search; 4) the solution vector of the harmony search is converted into the scheduling solution of an FJSP problems, and corresponding neighborhoods are designed based on the scheduling solution, and local search is performed through using the designed neighborhoods, and an improved scheduling solution which is obtained through the local search is converted into a solution vector, and the solution vector is utilized to replace the solution vector before the local search, and the search process of the harmony search is continued, so that an optimal solution can be obtained; and 5) the optimal solution which is found based on the hybrid harmony search algorithm is adopted as the initial solution of a large-scale search algorithm, and the large-scale search algorithm is adopted to continue search until a termination condition is satisfied, and scheduling of which the solution is completion time can be obtained.

Owner:TSINGHUA UNIV

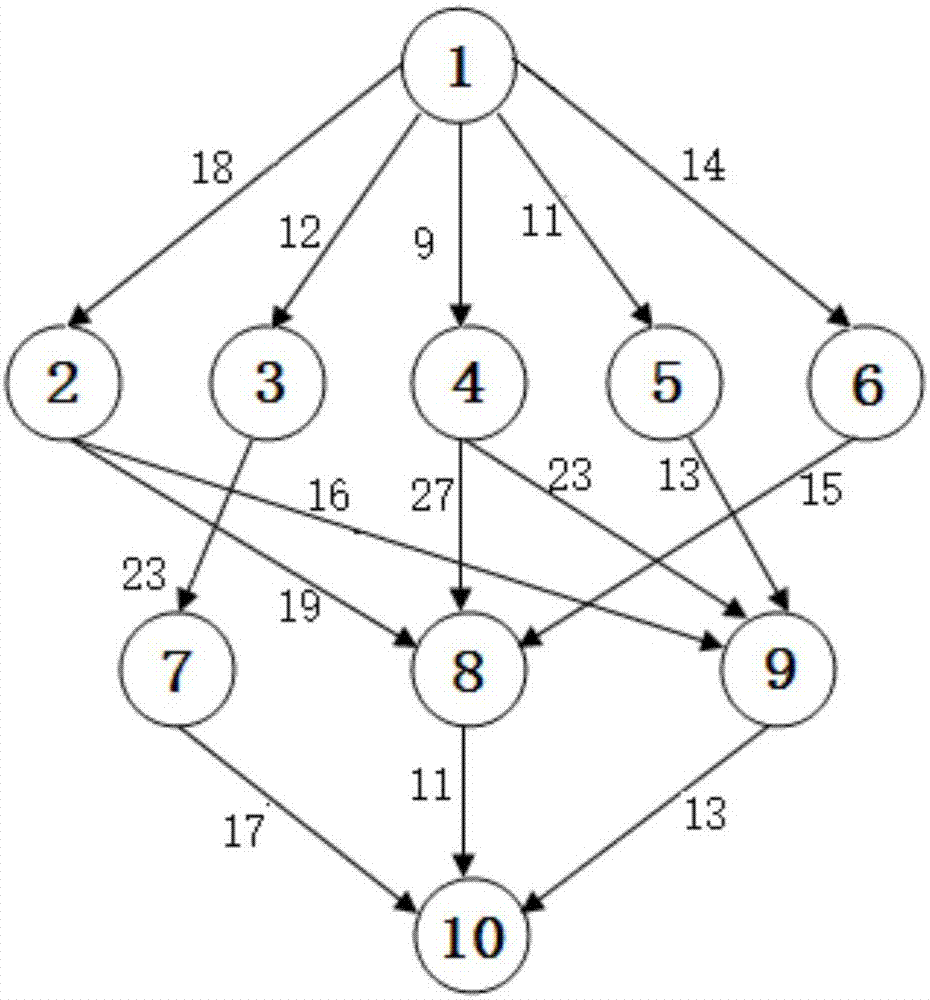

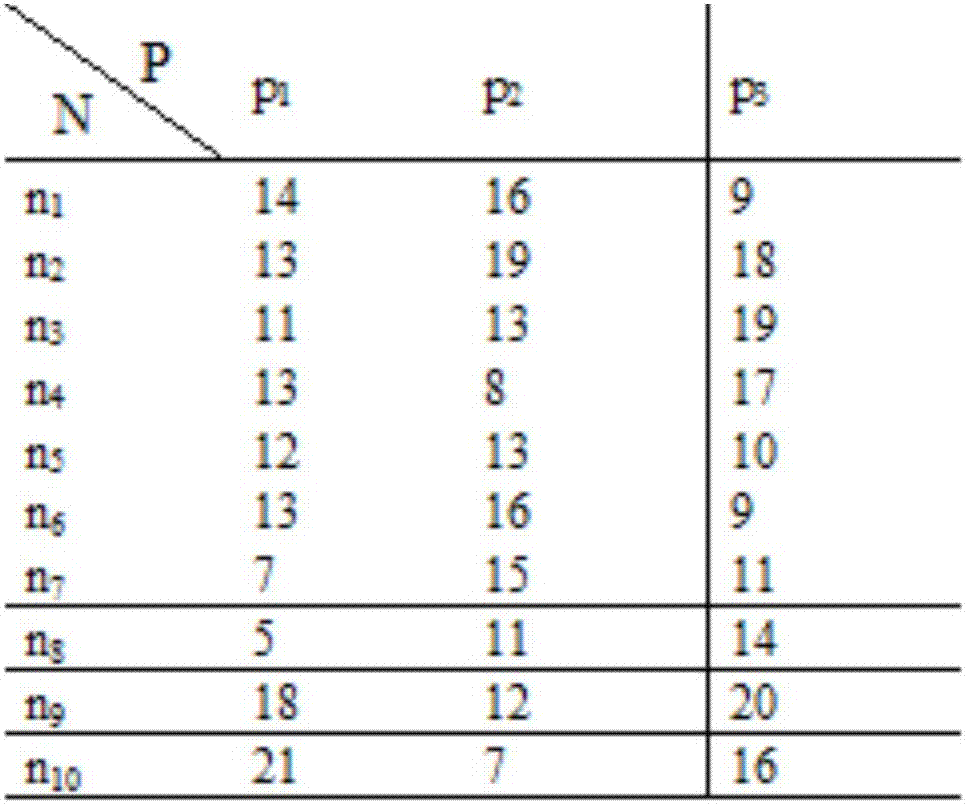

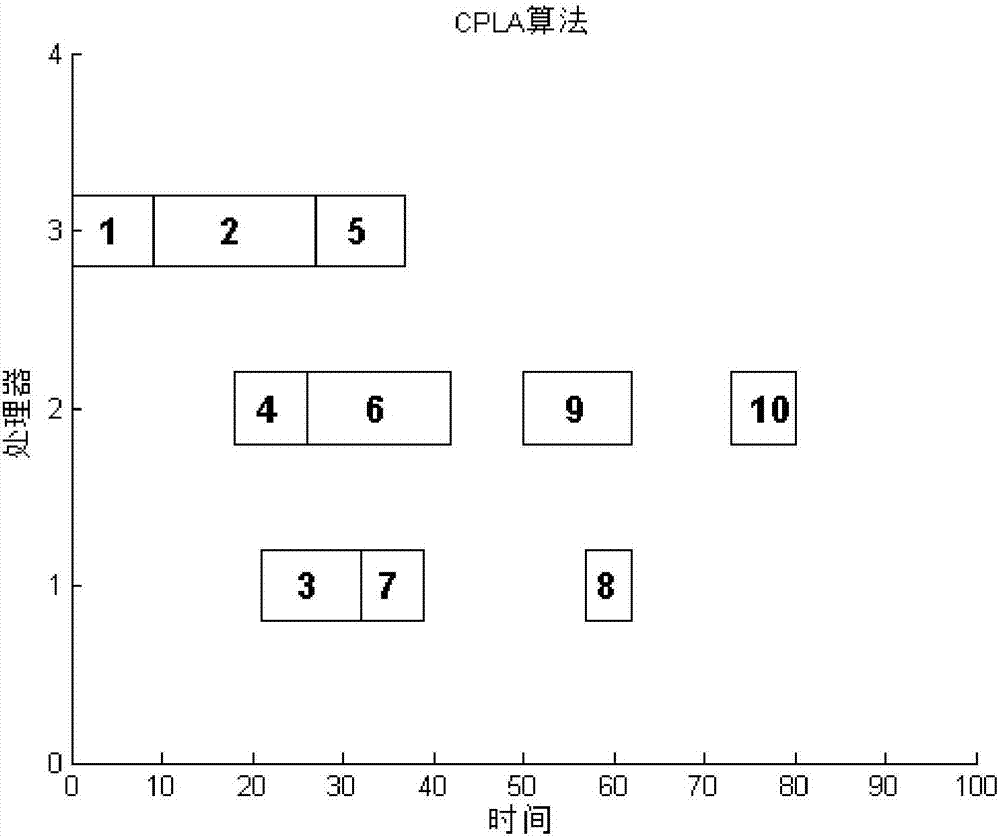

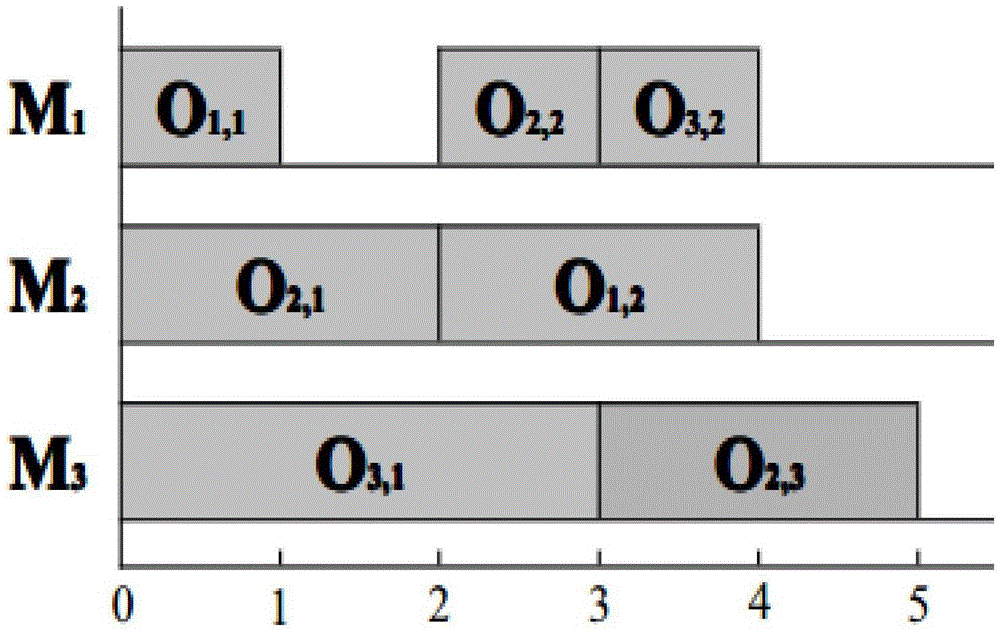

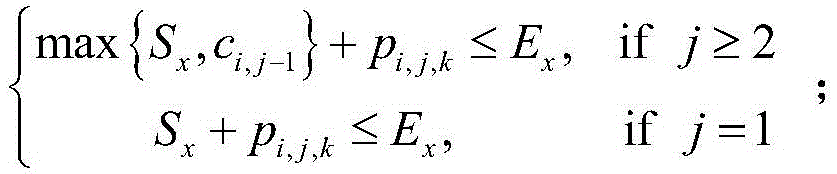

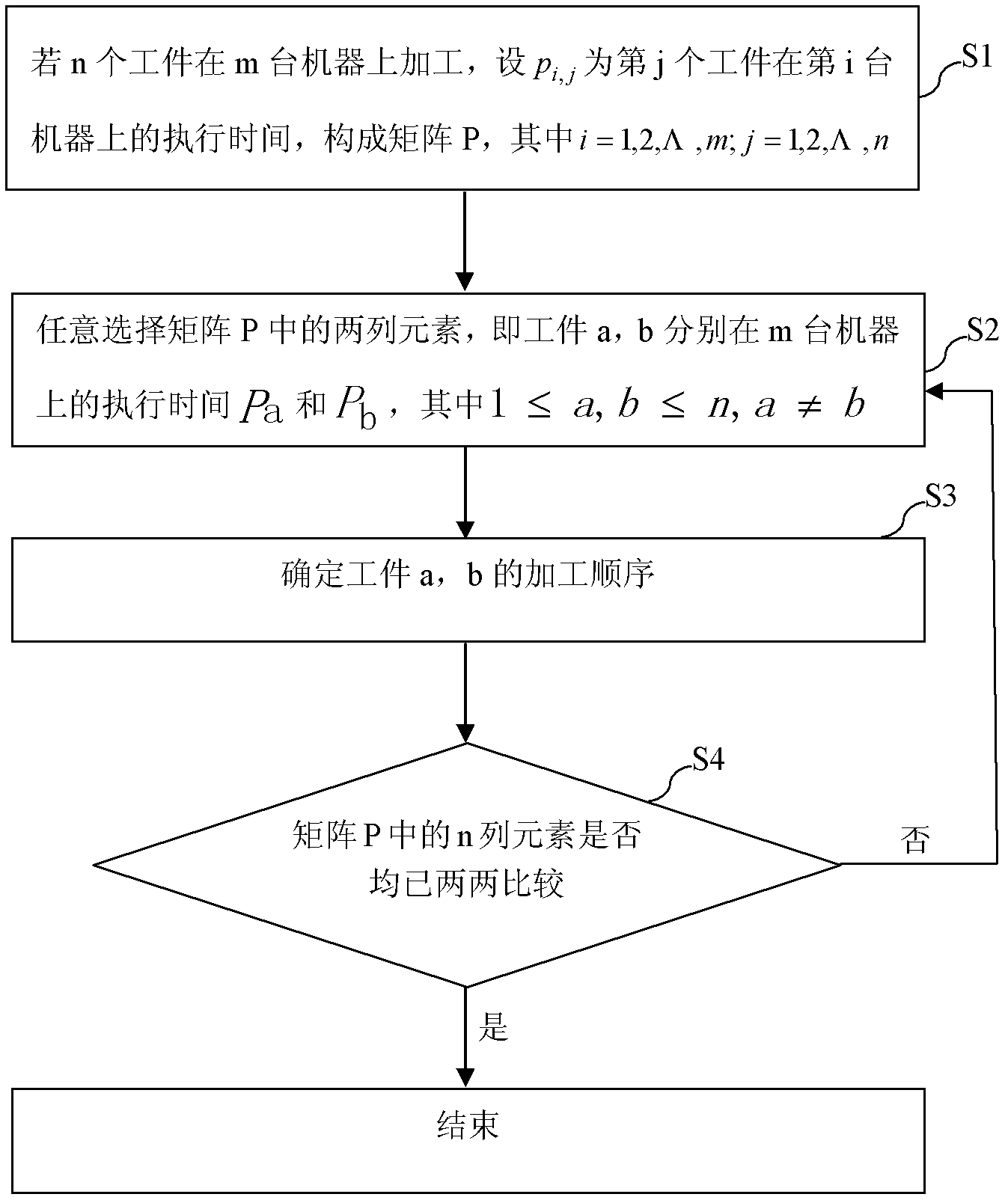

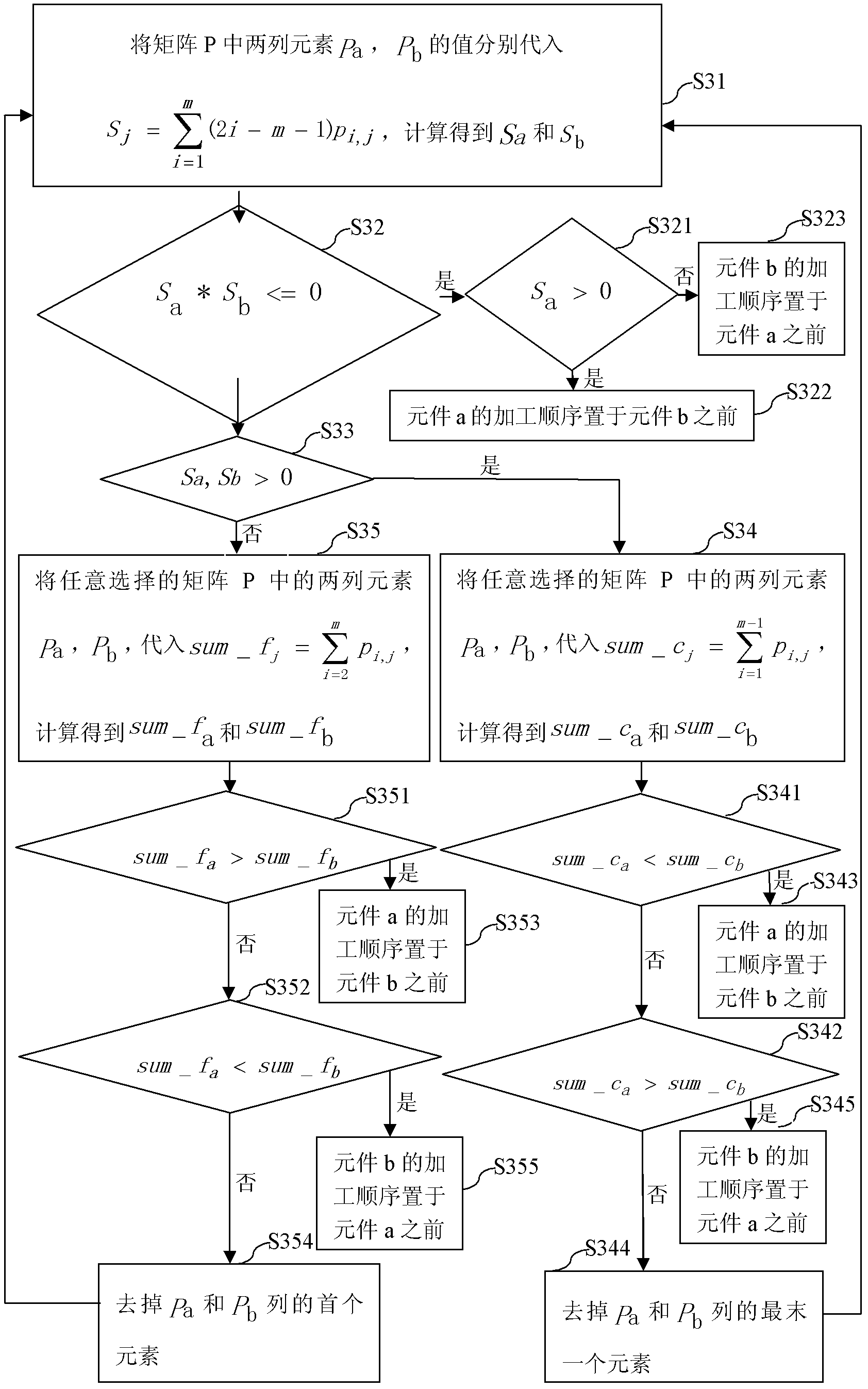

Production line scheduling method based on constructive heuristic algorithm

InactiveCN102566560AReduce waiting timeReduce computational complexityTotal factory controlProgramme total factory controlProduction lineCompletion time

The invention provides a production line scheduling method based on a constructive heuristic algorithm. The method comprises the following steps: S1, setting p(i, j) as the execution time of a jth workpiece on an ith machine if n workpieces are processed on m machines, and constructing a matrix P, wherein i is a natural number from 1 to m, and j is a natural number from 1 to n; S2, randomly selecting two columns of elements in the matrix P, namely the execution time Pa and Pb of workpieces (a, b) on the m machines, wherein a is less than or equal to 1, b is less than or equal to n, and a is not equal to b; S3, determining the processing sequence of the workpieces (a, b); and S4, determining whether n columns of elements in the matrix P are compared pairwise, stopping determination if the n columns of elements are compared, adjusting the workpieces according to the determined processing sequence, and sequentially processing the workpieces on the m machines, otherwise, returning to the step S2. The production line scheduling method provided by the invention can be used for scheduling the production line of a flow shop to achieve the shortest total completion time, and reducing the waiting time of each workpiece before processing by adjusting the workpiece processing sequence. Compared with the prior art, the method provided by the invention has the advantages of low computation complexity, short computation time and better scheduling performance.

Owner:CHENGDU UNIV OF INFORMATION TECH

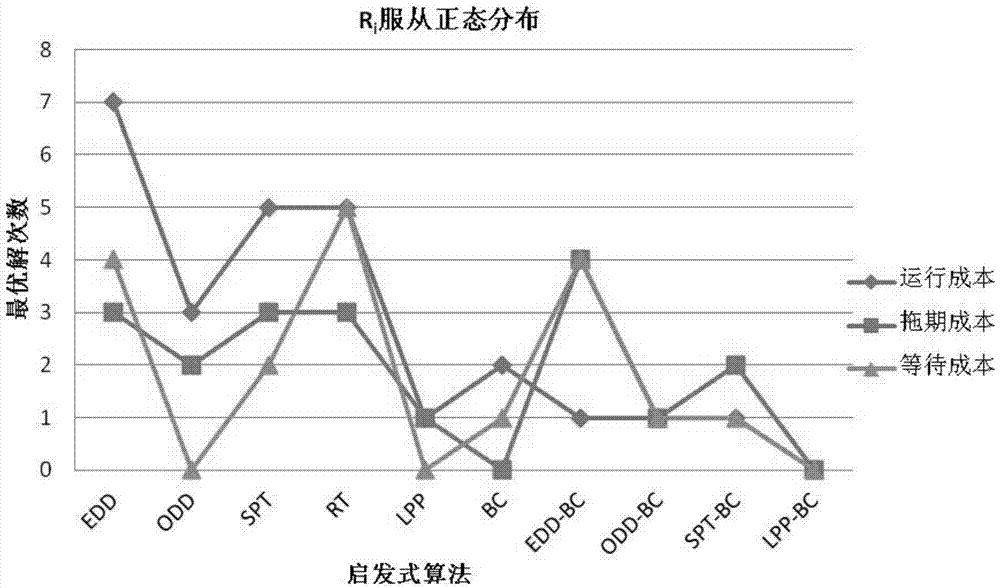

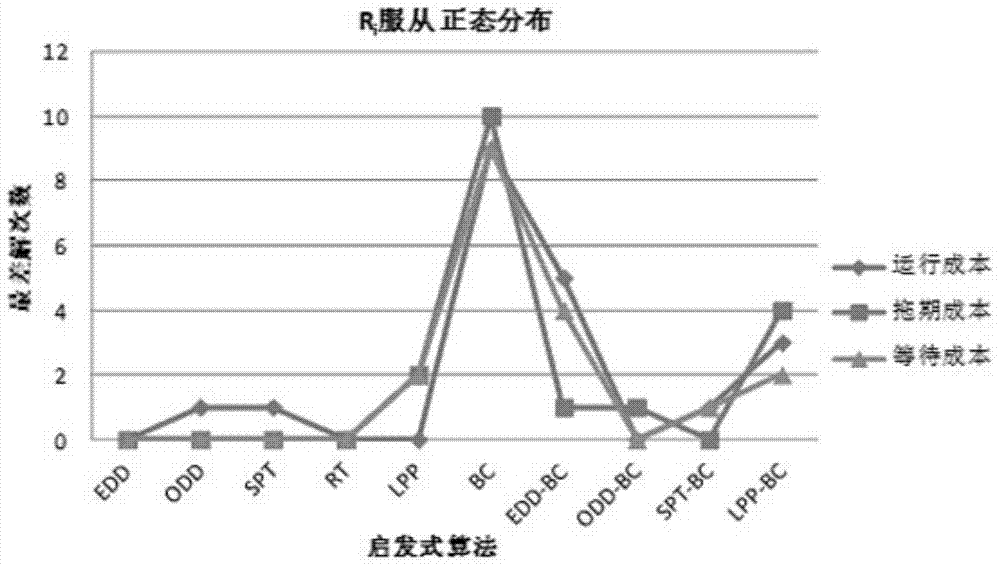

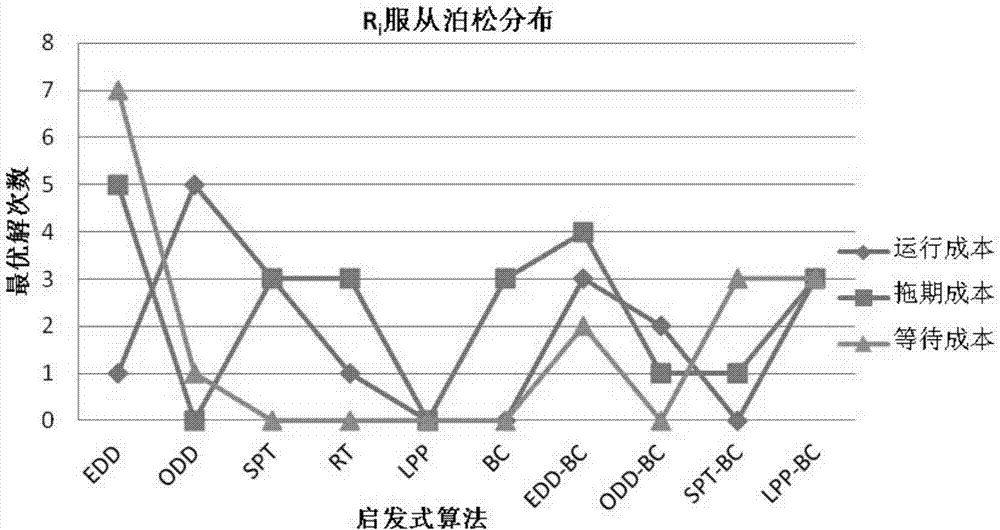

Vulcanizing workshop energy consumption optimized dispatching method based on heuristic rule

InactiveCN104281128AThe effect of energy optimization is obviousImprove energy savingTotal factory controlProgramme total factory controlExperimental methodsEnergy consumption

The invention discloses a vulcanizing workshop energy consumption optimized dispatching method based on the heuristic rule. The method includes the steps that firstly, a vulcanizing workshop energy consumption optimized dispatching model is established; secondly, three types of heuristic rule algorithms are proposed for a tardiness cost optimization target in the dispatching model; thirdly, a minimum operation energy consumption heuristic algorithm is proposed for an energy consumption cost optimization target; fourthly, a control machine 'off-on' state algorithm is proposed for machine waiting and halts which affect energy consumption cost; fifthly, based on the lean principle that the number of state conversion times is reduced for energy conservation, a BC algorithm based on workpiece batch machining is proposed; sixthly, based on the principle that the performance of a combinational rule is superior to that of a simple dispatching rule theory, four heuristic algorithms based on the combinational rule are proposed; seventhly, a segmentation experimental method is adopted for designing a simulation experiment case and a simulation experiment is conducted; eighthly, an experiment result is analyzed. According to the method, the dispatching performance is good, the optimizing effect on vulcanizing workshop energy consumption is obvious, and the good energy conservation effect is achieved.

Owner:GUANGDONG UNIV OF TECH

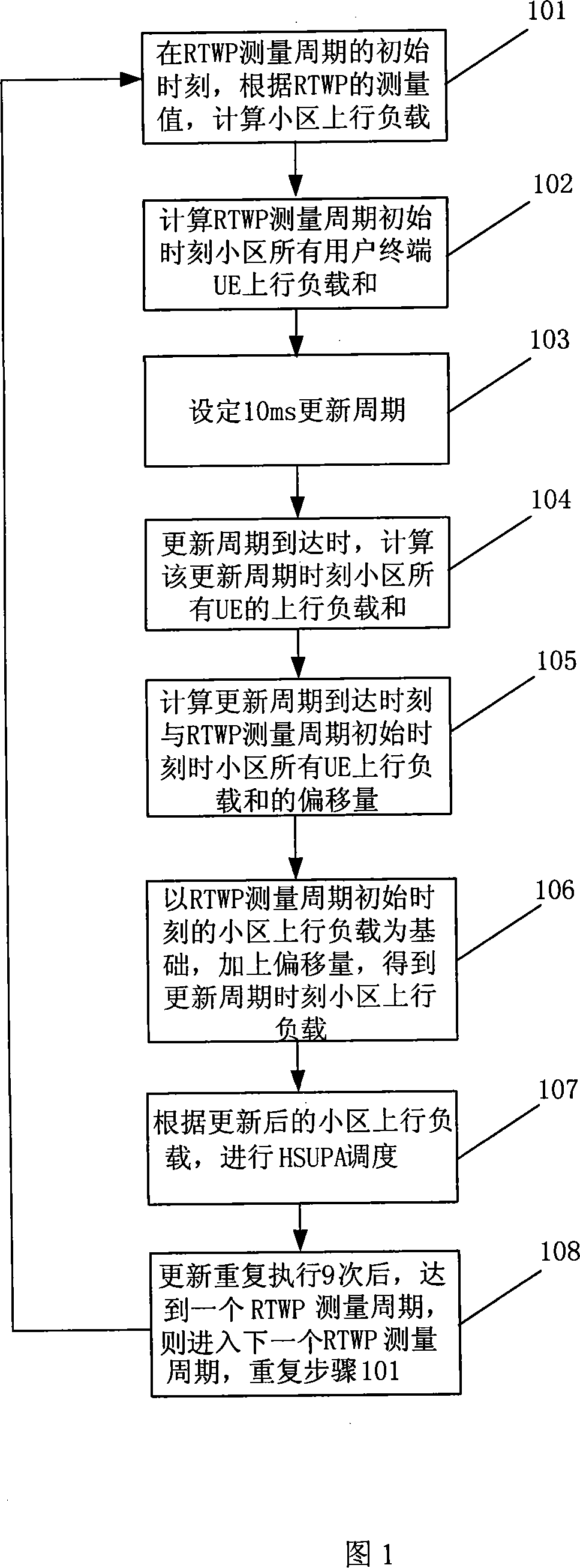

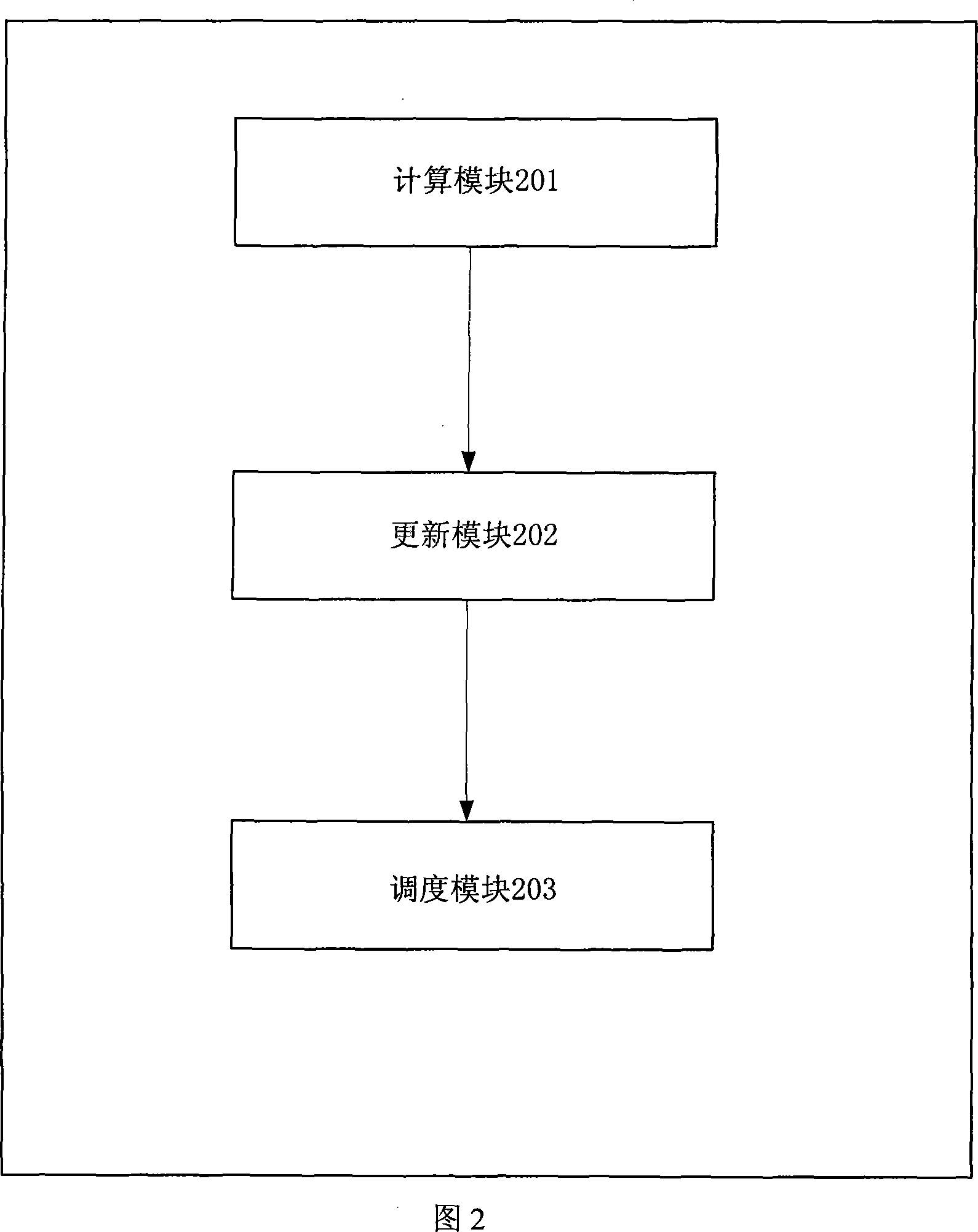

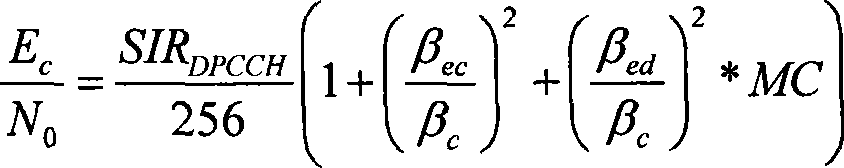

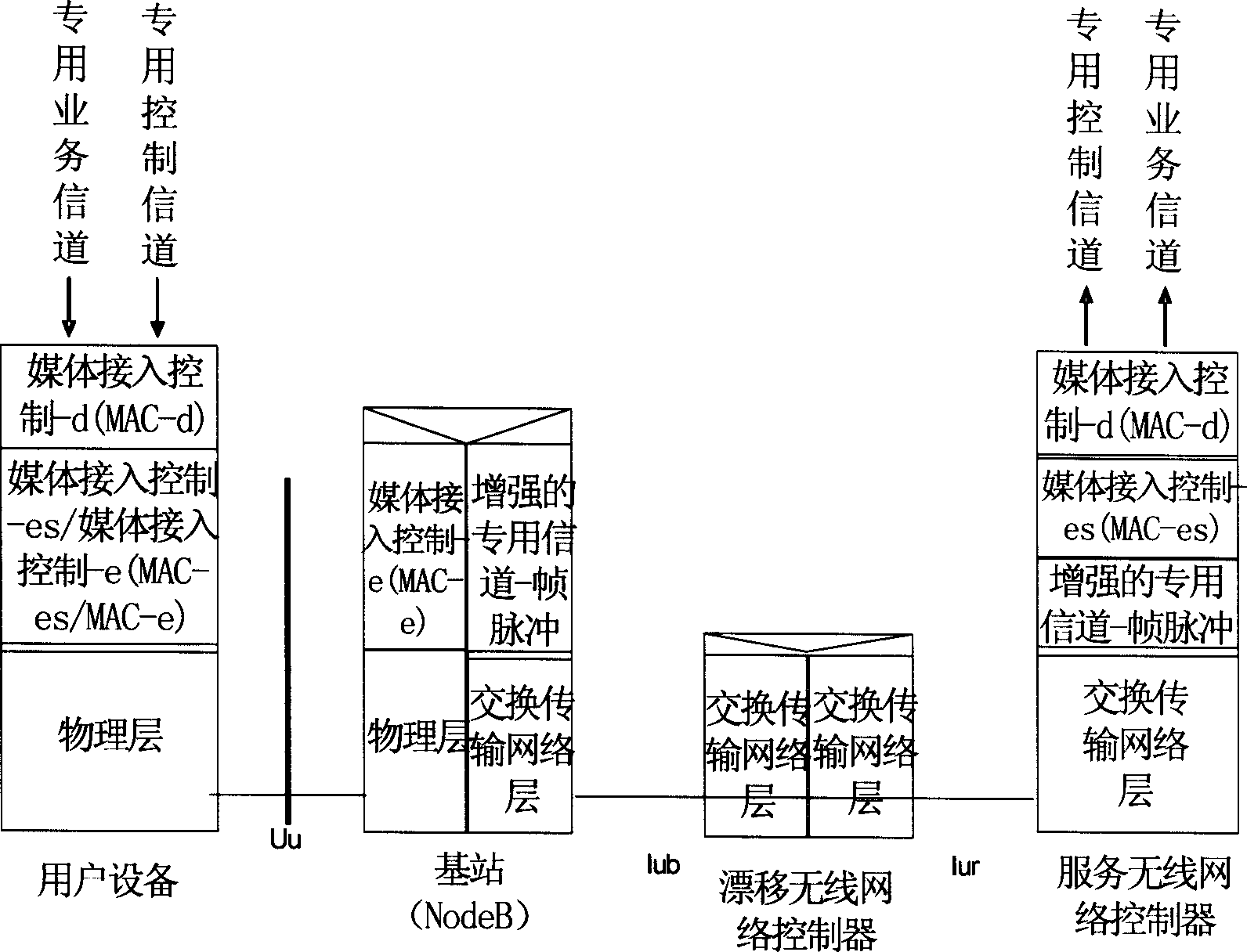

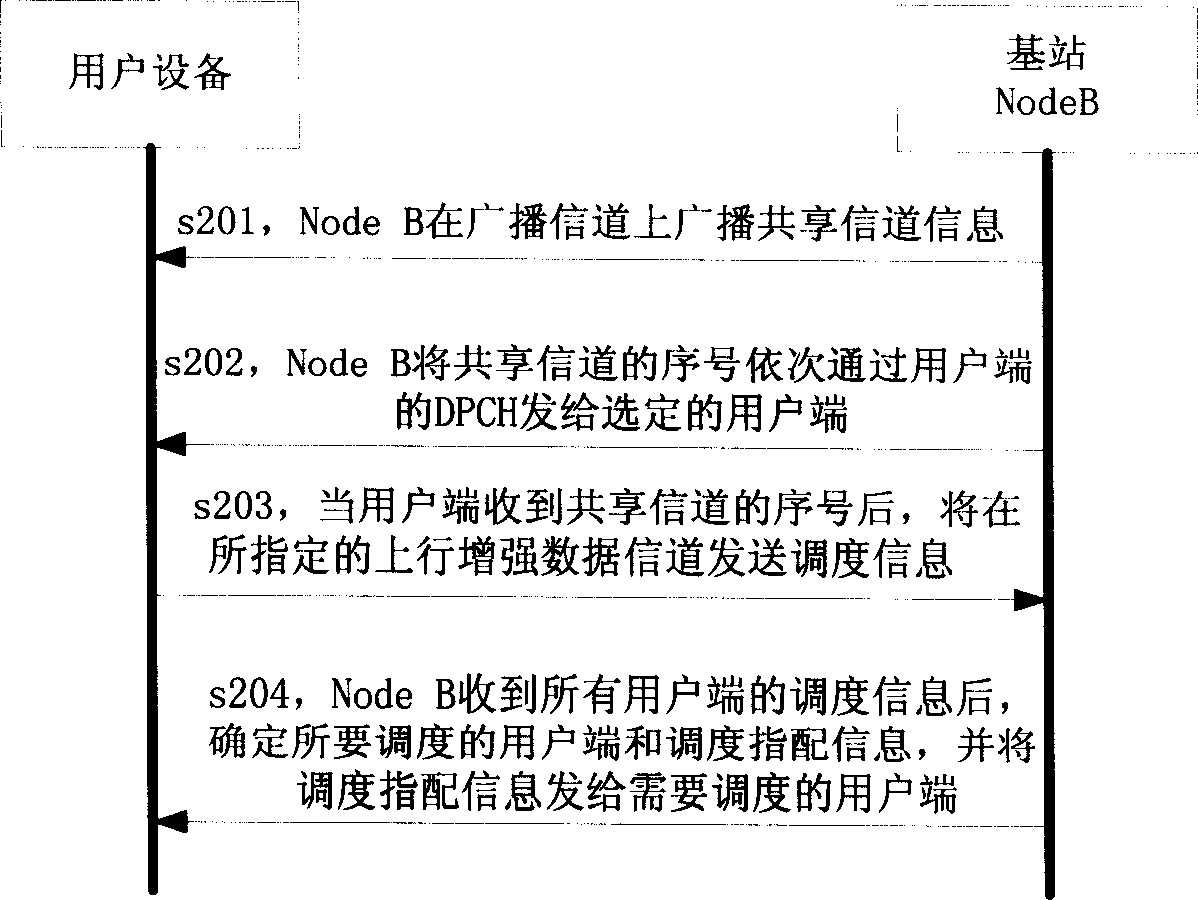

Scheduling method and device for the high-speed uplink packet access technology

InactiveCN101035085AImprove real-time performanceImprove scheduling effectRadio/inductive link selection arrangementsRadio transmission for post communicationWide bandDistributed computing

The invention relates to the wireless communication field, disclosing a scheduling method and device of supporting high-speed uplink packet access (HSUPA) technique, improving scheduling performance of Node B. In the invention, at the initial time of a RTWP (Received Total Wide band Power) measuring cycle, and according to the RTWP measured value, calculating cell uplink load; in the RTWP measuring cycle, regularly updating the cell uplink load; according to the updated cell unlink load, making HSUPA scheduling. And the invention also provides a scheduling device for HSUPA, comprising calculating module, updating module and scheduling module. And the invention can shorten the cycle of updating cell unlink load, and improve cell uplink load estimating realtimeness so as to improve HSUPA scheduling performance.

Owner:SHANGHAI HUAWEI TECH CO LTD

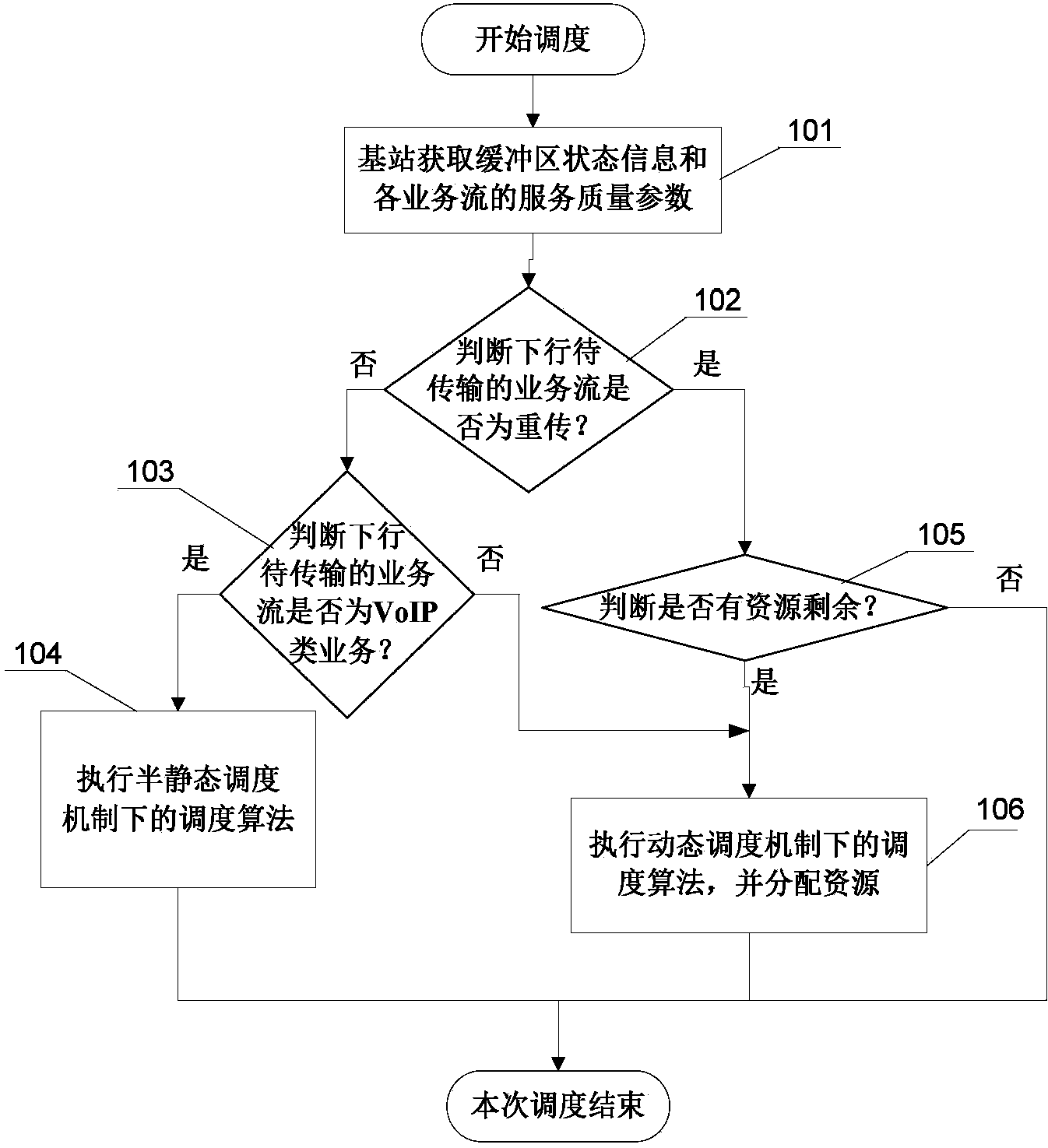

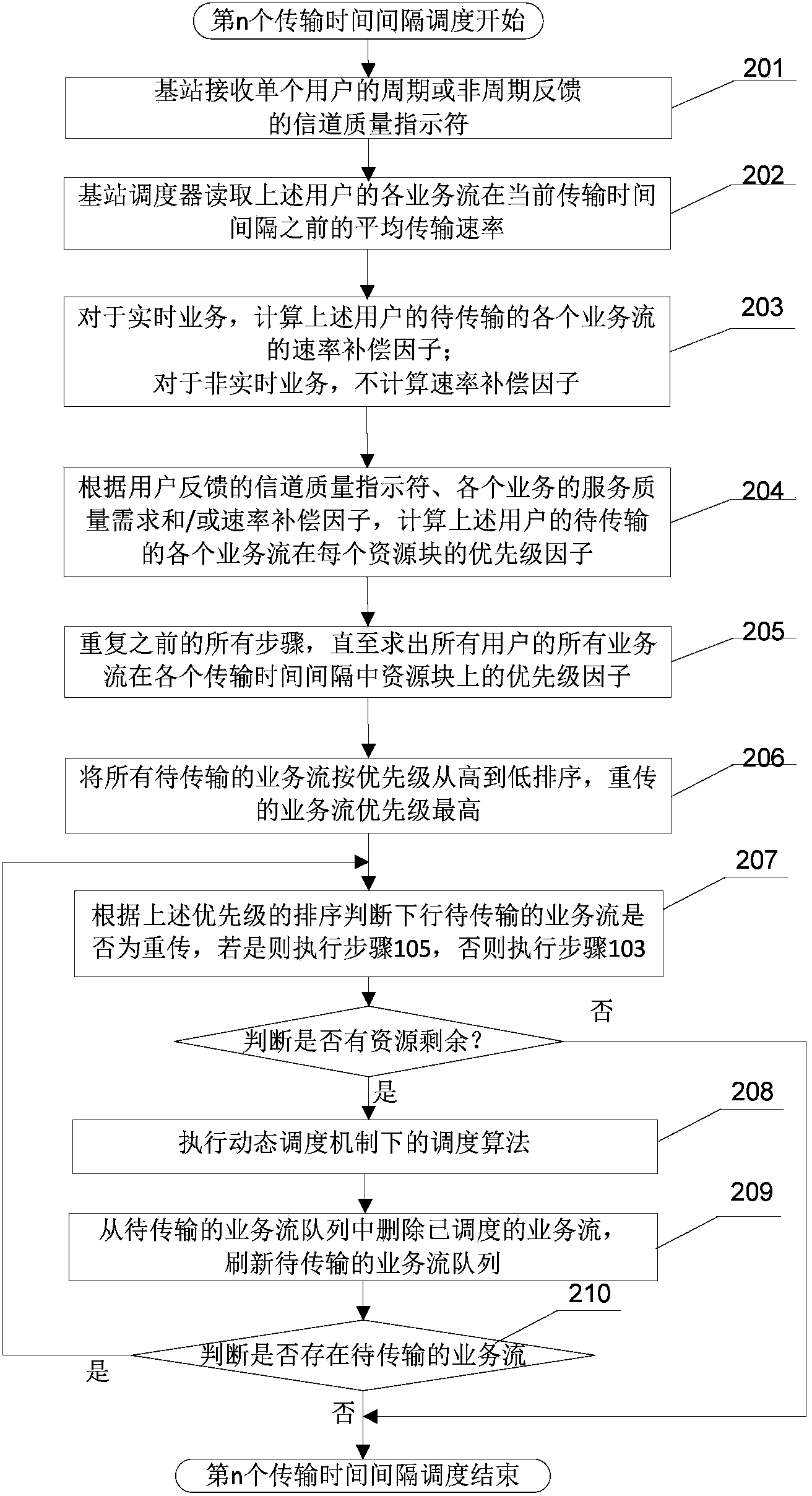

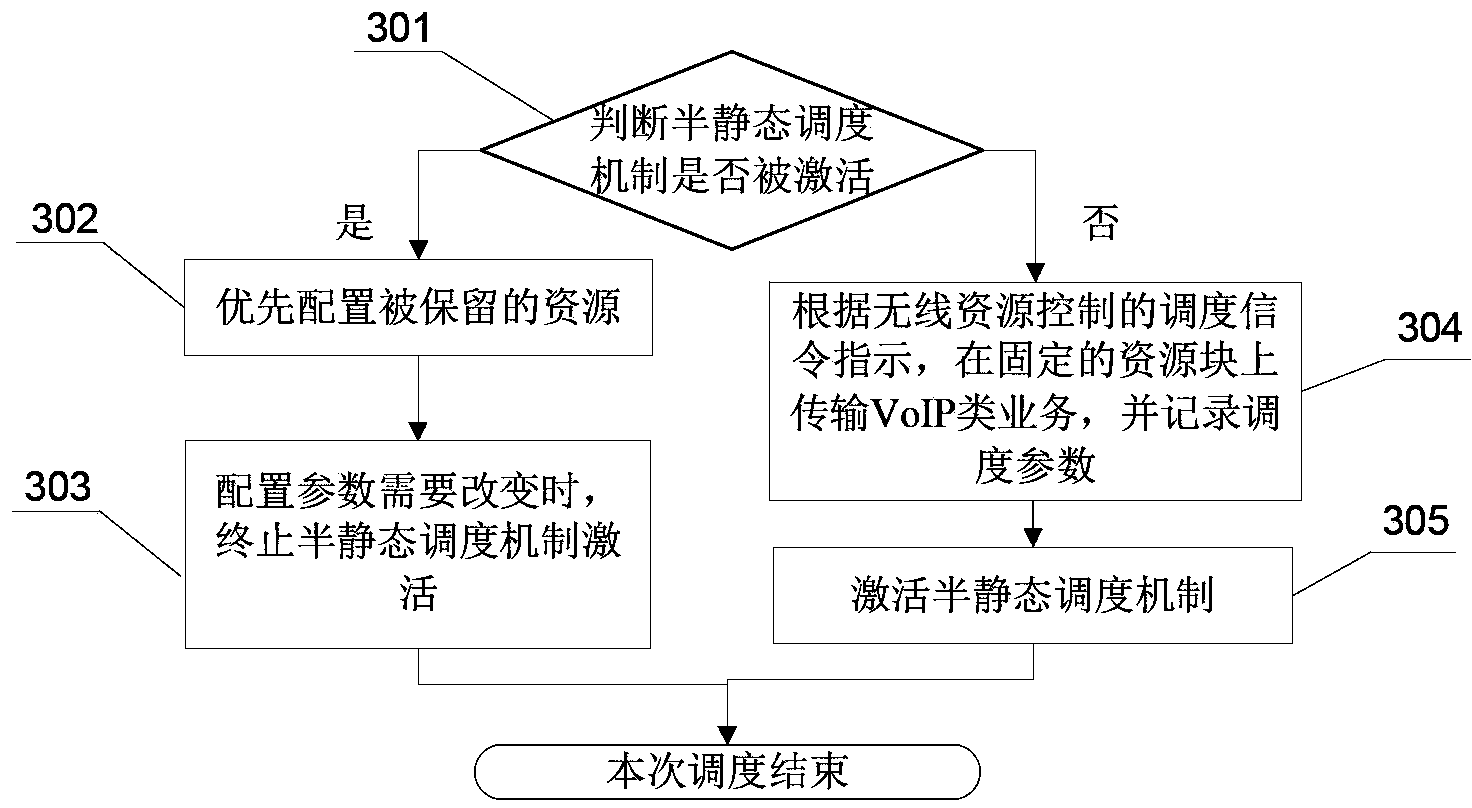

Dynamic and semi-static combined dispatching method in LTE system

ActiveCN103442446ASave signaling resourcesGood scheduling effectWireless communicationQos quality of serviceService flow

The invention discloses a dynamic and semi-static combined dispatching method in an LTE system. The method comprises the steps that a base station obtains status information and parameters, so that whether service flows are retransmitted or not is determined, if not, whether the service flows are VoIP services is further determined, and a dynamic dispatching mechanism or a semi-static dispatching mechanism is carried out on the different service flows. Due to the fact that the semi-static dispatching mechanism and the dynamic dispatching mechanism are combined, the problem of service quality of real-time services and the throughput of non-real-time services are both considered, signaling resources are saved, and limited resources are fully utilized for achieving a better dispatching effect. Furthermore, on the basis of the dynamic dispatching mechanism, according to the improvement on an existing algorithm, calculation can be simplified on the premise that the real-time services and a bit rate are guaranteed, and secondary allocation on remaining resources is achieved. The dynamic and semi-static combined dispatching method in the LTE system can be widely applied in the field of wireless communication.

Owner:ALLWIN TELECOMM +1

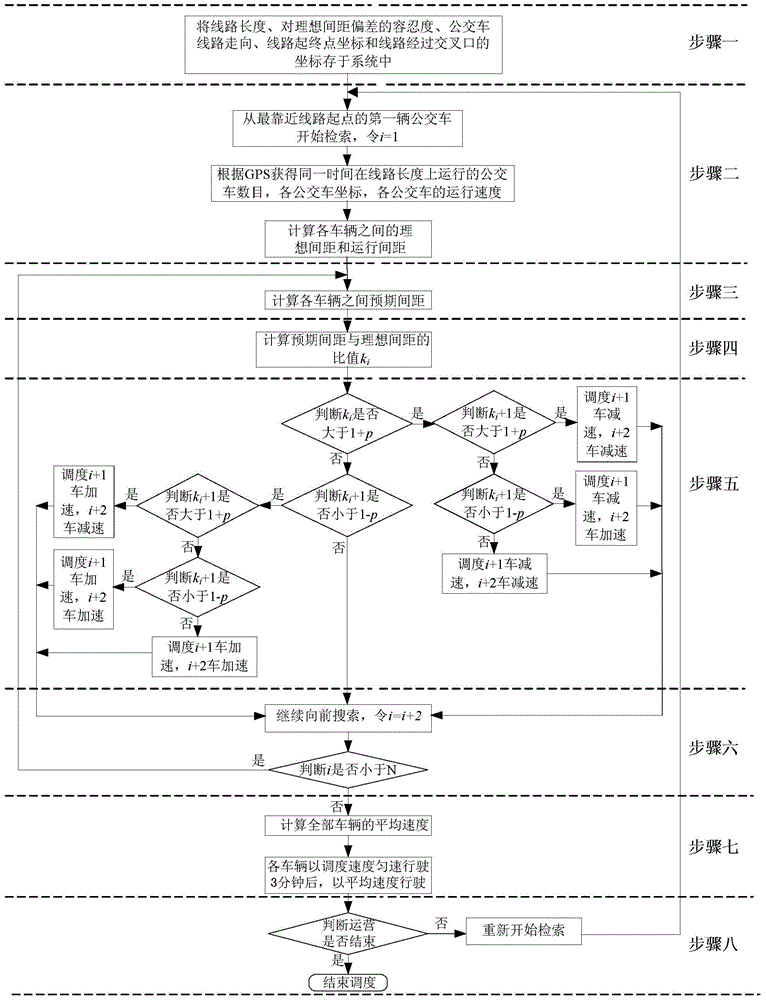

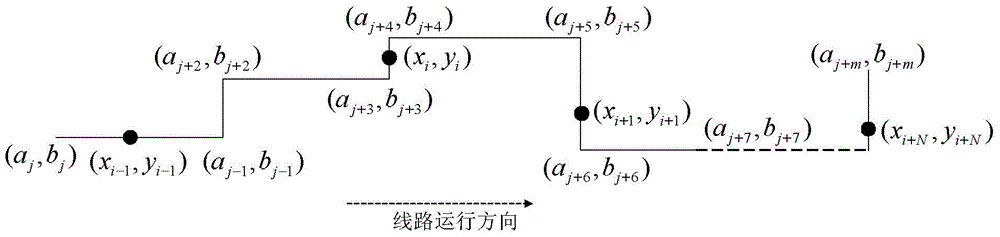

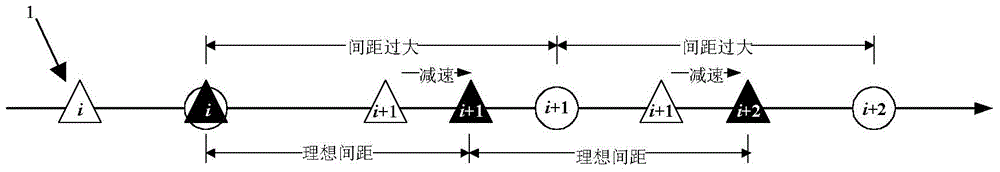

Scheduling method preventing centralized arrival of buses on basis of GPS technology

ActiveCN104464276AGuaranteed service levelScheduling is reliableRoad vehicles traffic controlPunctualityReal-time computing

The invention provides a scheduling method preventing centralized arrival of buses on the basis of a GPS technology, and relates to the field of urban road traffic control. The method aims to solve the problems that in the prior art, arrival punctuality of the buses is poor and arrival time of the buses is not balanced. According to the method, retrieval is performed on the first bus nearest to a route starting point, i is equal to 1, the number, coordinates and running speeds of buses running on a route at the same time are obtained according to a GPS, a ratio interval is judged by calculating running distance, ideal distance and predicted distance between two buses and the ratio of the predicted distance of the two buses to the ideal distance between the two buses, i is equal to i plus 2, i is smaller than N, all the buses are scheduled repeatedly, the average speed of all the buses is calculated, whether operation of the buses is finished or not is judged, data of the running buses are obtained again if operation is not finished, and scheduling is achieved. The method can be used for vehicle scheduling.

Owner:HARBIN INST OF TECH

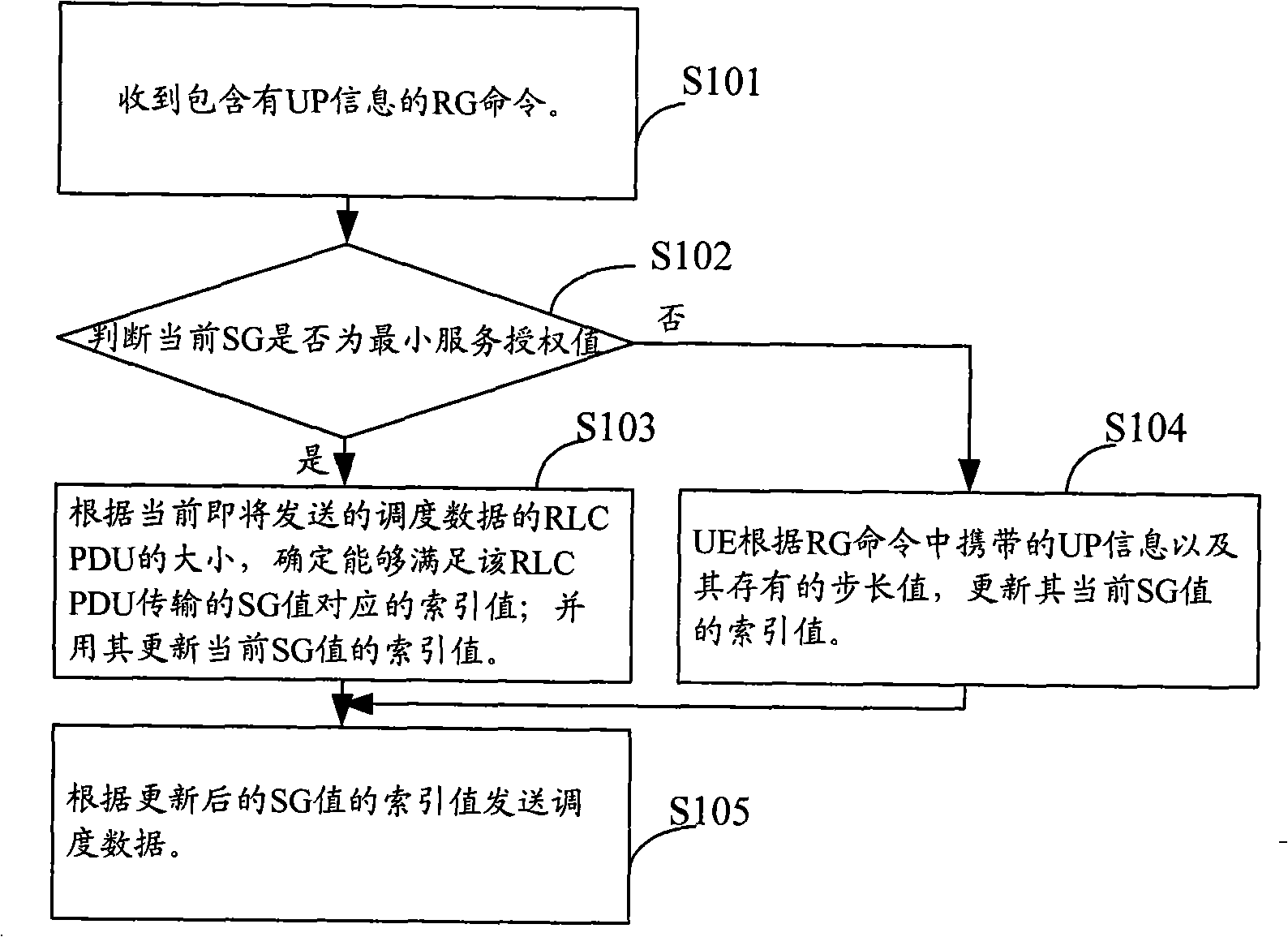

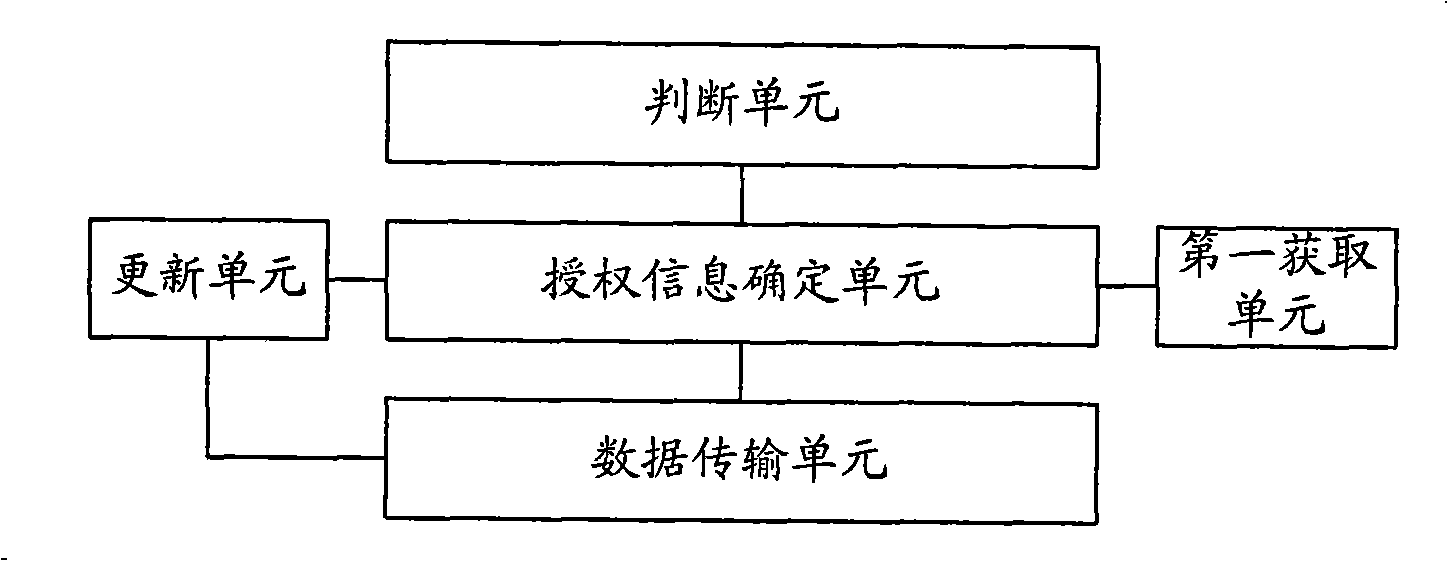

Terminal unit and method for scheduling data according to authorization

InactiveCN101321116AReduce consumptionImprove scheduling efficiencyError prevention/detection by using return channelRadio transmission for post communicationTerminal equipmentAuthorization

Owner:HUAWEI TECH CO LTD

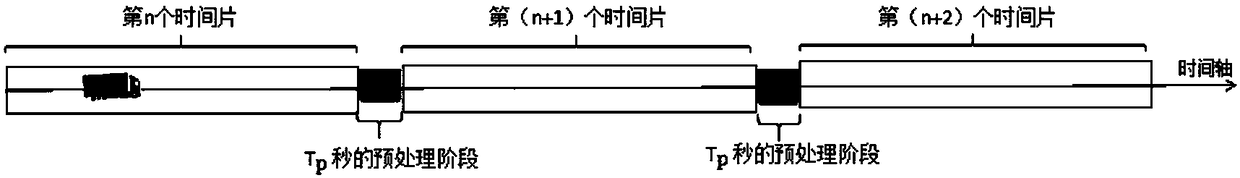

Cloud resource online scheduling method and device for distributed machine learning task

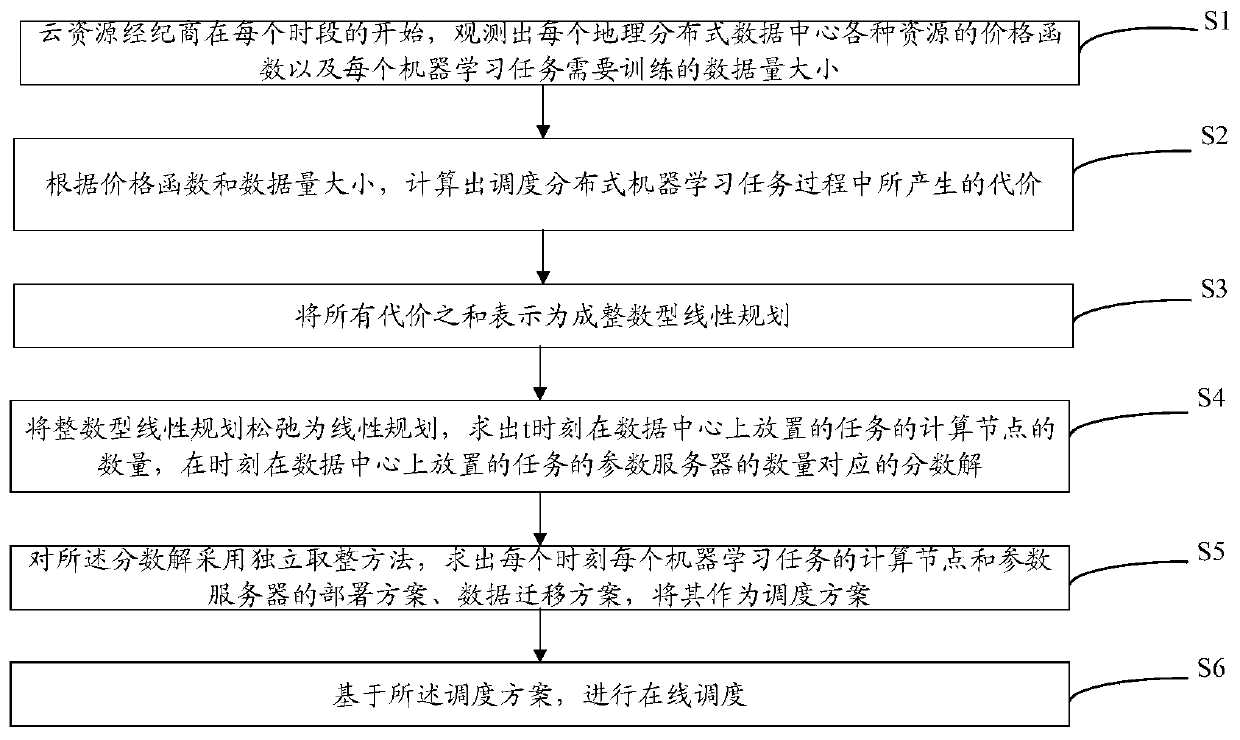

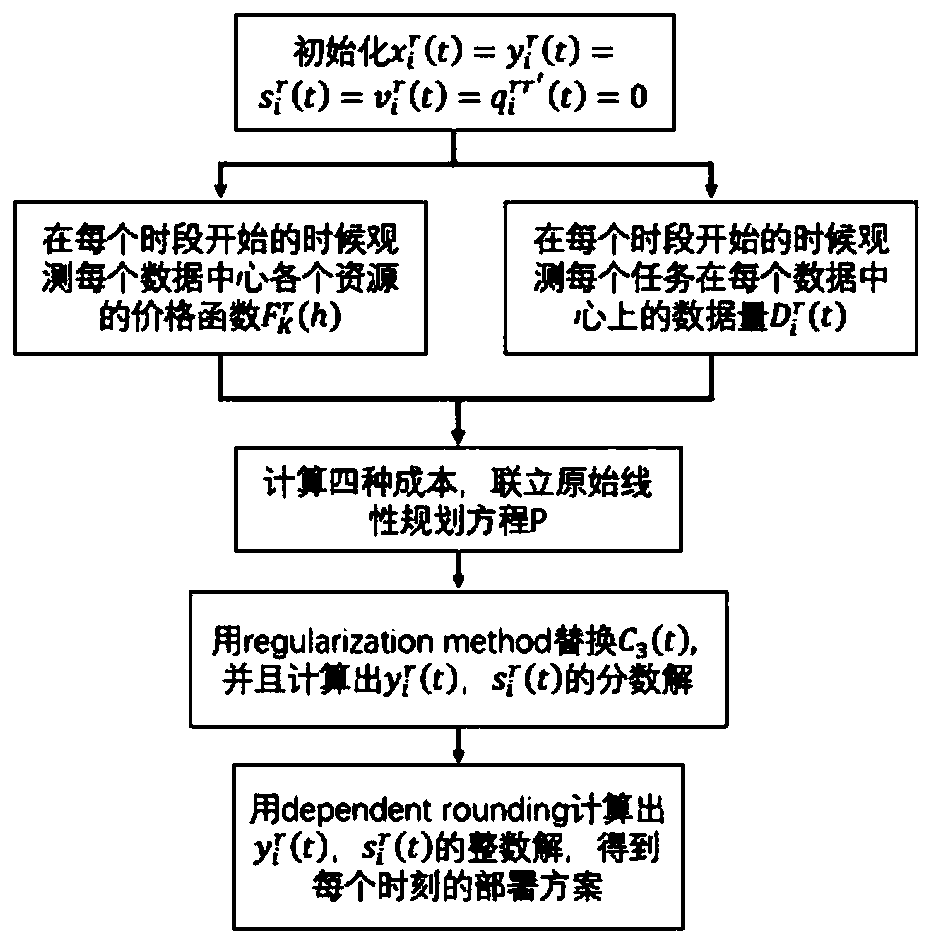

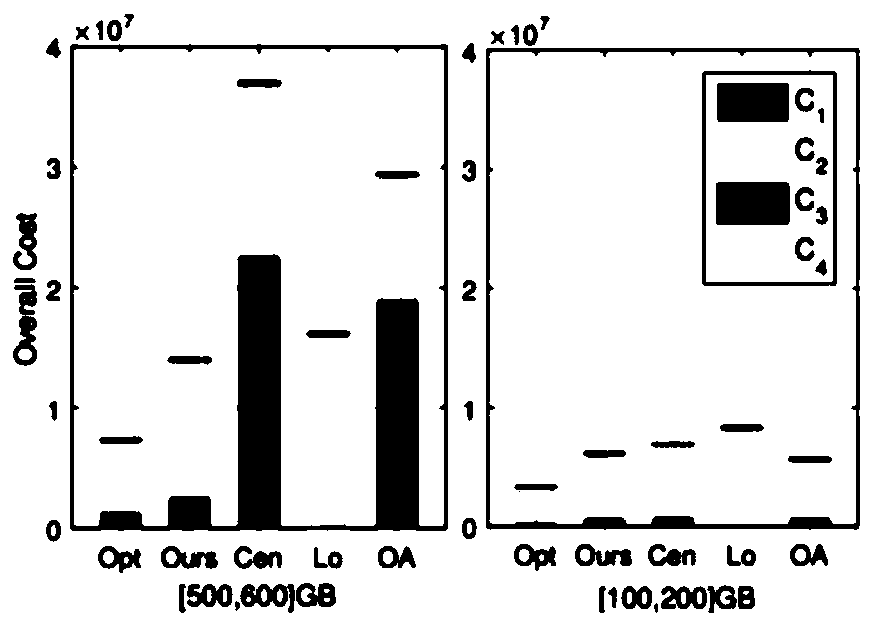

ActiveCN110086650ACutting costsImprove scheduling effectData switching networksNeural learning methodsTask completionRounding

The invention discloses a cloud resource online scheduling method for distributed machine learning tasks. The method comprises the following steps: firstly, starting from each time period, enabling acloud resource broker to observe a price function of each resource of each data center, and the data volume of each task needing to be trained; calculating the sum of all costs generated in the distributed machine learning task scheduling process; representing the sum with integral linear programming; decoupling the relationship between every two adjacent time periods of the relaxed linear programming through a regularization method; converting an online planning problem of the whole T moment which is difficult to process into independent linear planning at each moment. In this way, real-timedecision making can be carried out without depending on future information; and finally, the designed independent rounding method is adopted to solve the deployment scheme and the data migration scheme of the computing node and the parameter server of each machine learning task at each moment, so that the total cost sum is minimum on the basis of ensuring the task completion effect, and the scheduling effect is optimized.

Owner:长三角信息智能创新研究院

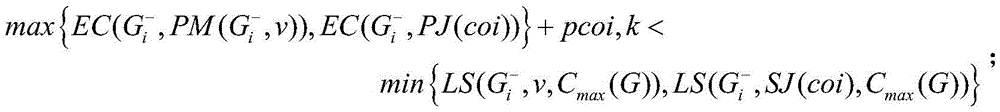

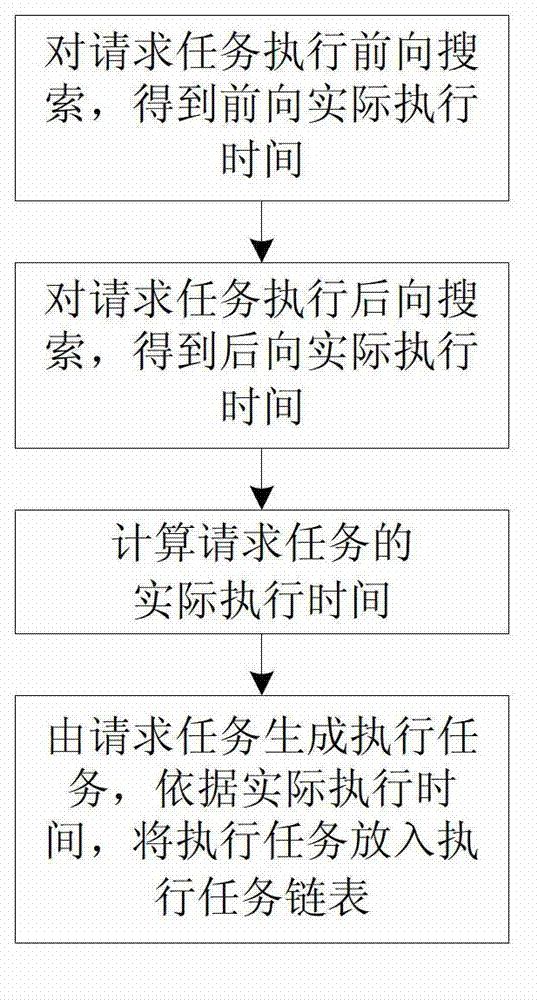

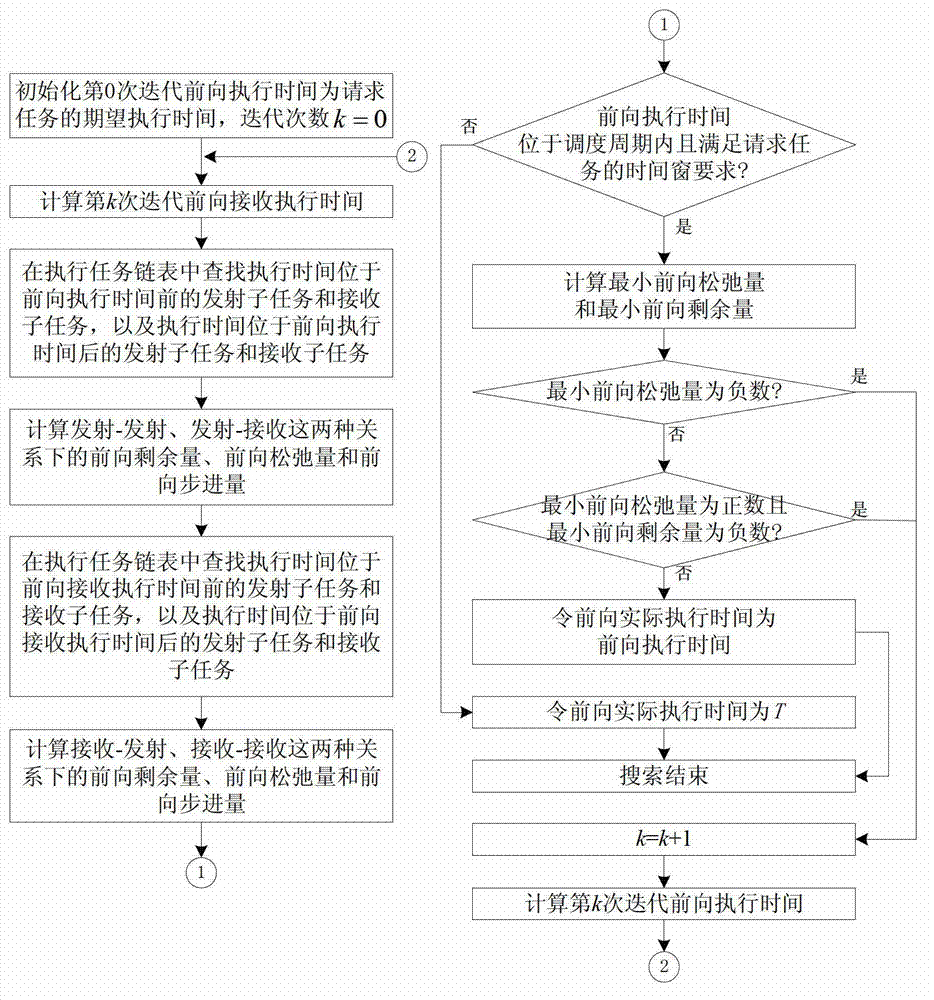

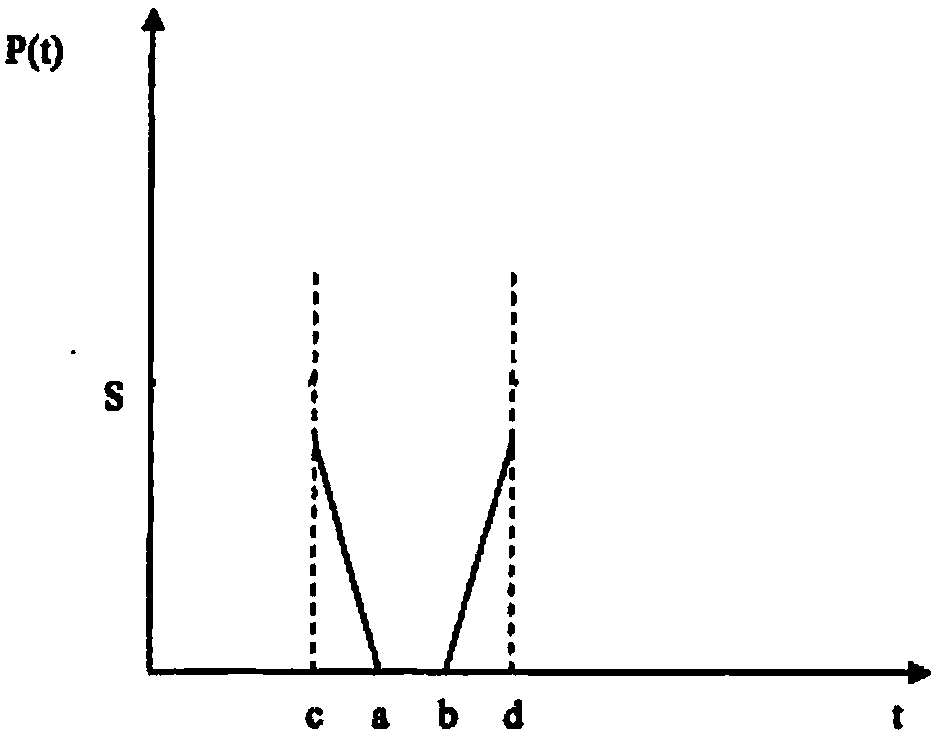

Pulse staggered scheduling method in phased array radar resource management

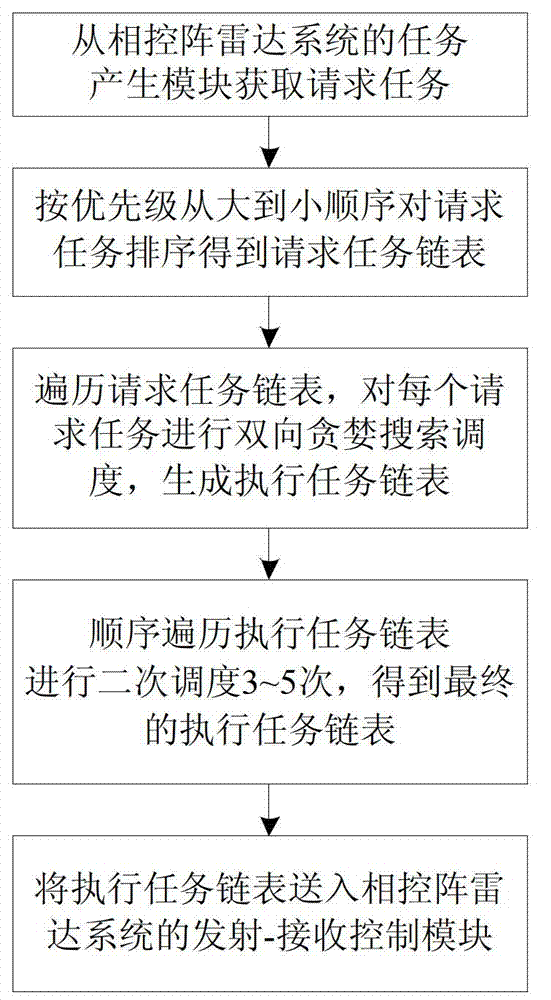

InactiveCN103838623APromote engineering applicationGood task scheduling performanceResource allocationComputer architectureRadar systems

The invention discloses a pulse staggered scheduling method in phased array radar resource management to mainly solve the problem that an existing pulse staggered scheduling method is difficultly applied to real-time engineering realization. The pulse staggered scheduling method comprises the first step of ranking request tasks obtained through a task generating module of a phased array radar system according to the comprehensive priority from large to small to obtain a request task chain R, the second step of sequentially traversing the request task chain R in order to carry out bi-directional greedy search scheduling to obtain an executing task chain E, the third step of sequentially traversing the executing task chain E in order to carry out three to five times of secondary scheduling scanning to obtain a final executing task chain E', and the fourth step of sending the final executing task chain E' into a task executing module of the phased array radar system. The pulse staggered scheduling method is high in real-time performance, can be conveniently applied to the engineering realization and can be used for time, energy and resource management of a phased array radar, and the good pulse staggered scheduling performance can be obtained.

Owner:XIDIAN UNIV

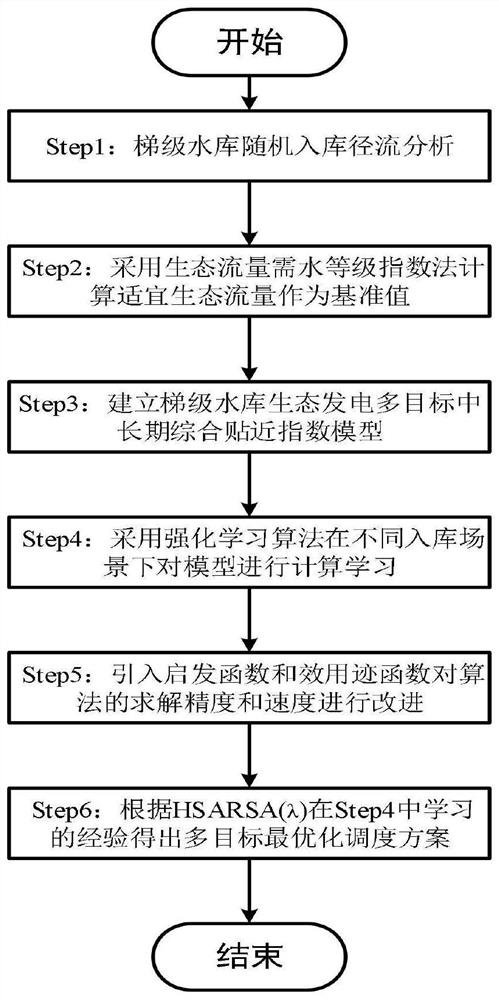

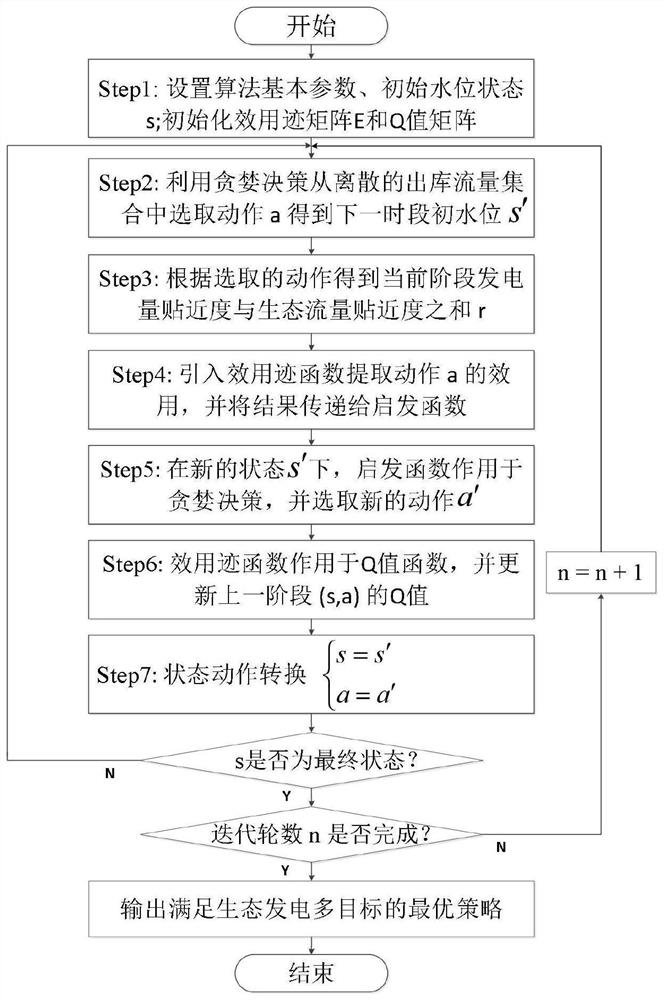

Construction method of cascade reservoir ecological power generation multi-objective medium-and-long-term random scheduling model and optimal scheduling method

ActiveCN112036632AImprove sustainabilityEnsure a virtuous circleForecastingResourcesStream flowOptimal scheduling

The invention provides a construction method of a cascade reservoir ecological power generation multi-objective medium-and-long-term random scheduling model and an optimal scheduling method. The method comprises the following steps of: 1, analyzing random reservoir inflow runoff of a cascade reservoir, and employing an ecological water demand level index method to calculate a suitable ecological flow as an ecological flow reference value; 2, establishing a cascade reservoir ecological power generation multi-objective medium-and-long-term optimization scheduling model which comprises a cascadereservoir power generation amount closeness objective function, an ecological flow closeness objective function and constraint conditions; 3, adopting a reinforcement learning SARSA algorithm to solveand learn the model in different random storage runoff scenes, and introducing a heuristic function and a utility trace function to improve the precision and solving speed of the algorithm; and 4, according to a scheduling rule learned by the algorithm, obtaining a cascade reservoir medium-and-long-term scheduling scheme meeting the maximum ecological power generation comprehensive closeness. According to the methods of the invention, the comprehensive utilization benefit of water resources is improved, and the scheduling effect is improved.

Owner:CHINA THREE GORGES UNIV

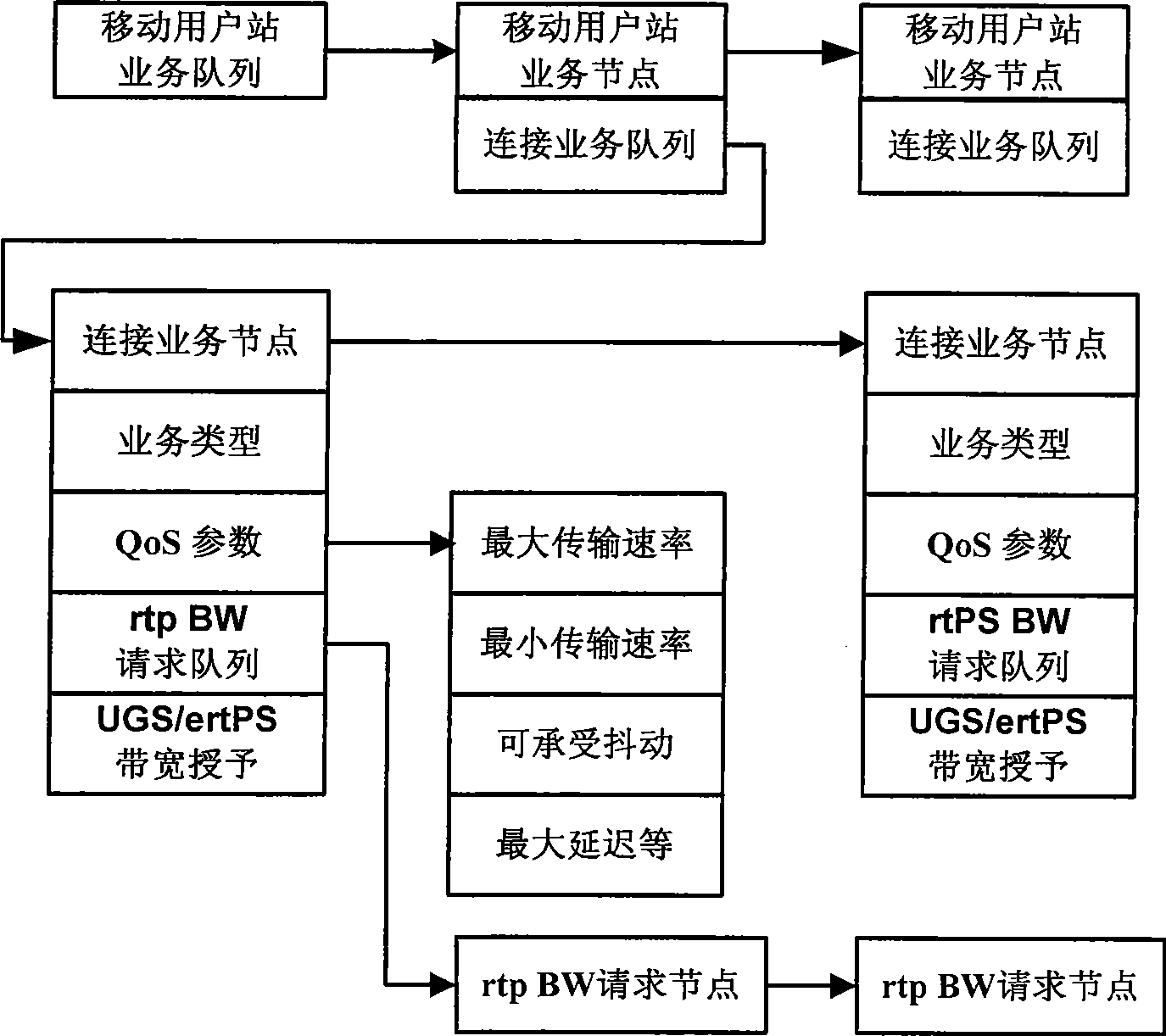

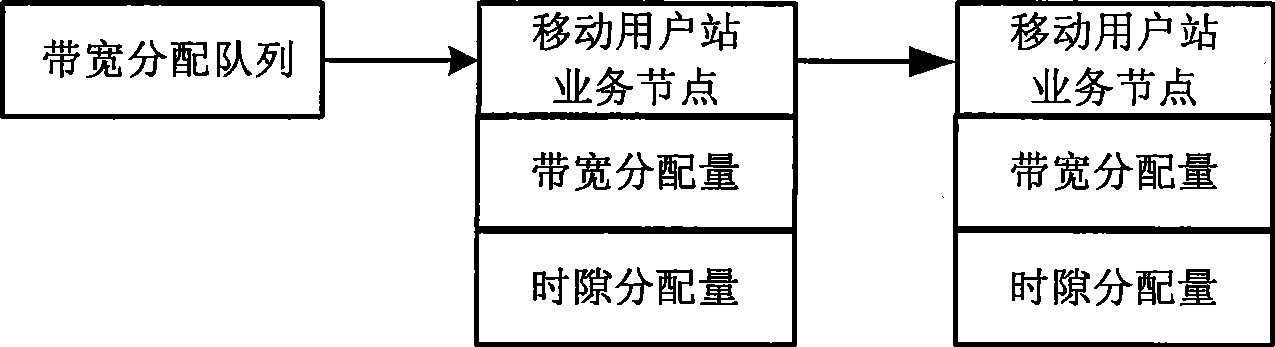

Uplink bandwidth allocation method for broadband wireless metropolitan area network

ActiveCN101478789AReduce network conflictsImprove data throughputNetwork traffic/resource managementNetwork topologiesBandwidth allocationTelecommunications

The invention provides an upstream bandwidth distribution method of a wideband wireless metropolitan area network base station, which is used for realizing the upstream bandwidth distribution between the base station and the mobile user station, and the base station comprises global multi-class mobile user station business queues which are used for managing various businesses of the mobile user station; the method comprises the following steps: calculating the size of bandwidth resources which can be dispatched in the dispatching distribution process of the upstream bandwidth; the bandwidth distribution is sequentially carried out on initial competition ranging, a contention channel and a rapid feedback channel; calculating the residual bandwidth resources, and if the residual bandwidth exists, the bandwidth resources are distributed in the order of first processing UGS / ertPS business, then rtPS business and last nrtPS / BE business for the business in the global multi-class mobile user station business queues according to the height of priority scheme, until the bandwidth resources are completely distributed or the distribution of the bandwidth resources of all the businesses is finished.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

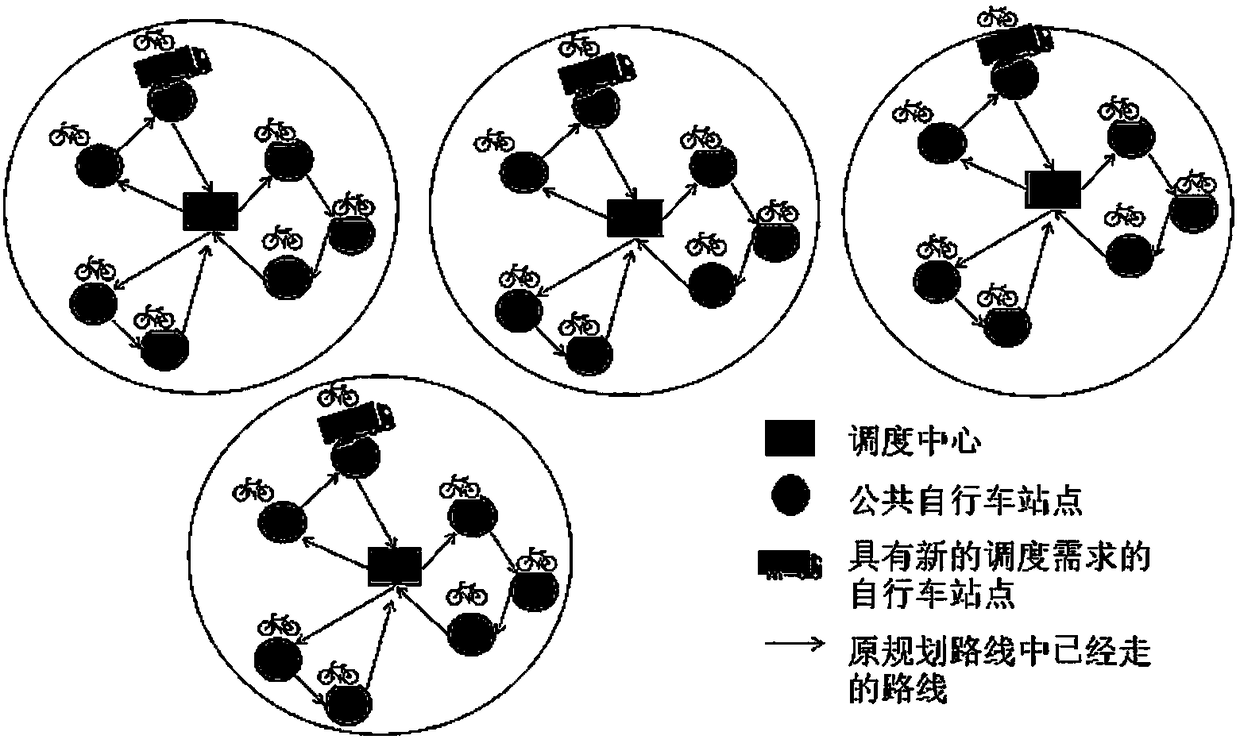

Hybrid heuristic algorithm-based public bicycle dynamic scheduling method

ActiveCN108416513AImprove the disadvantage of premature convergenceImprove global search performanceResourcesStatic dispatchDistributed computing

The invention discloses a hybrid heuristic algorithm-based public bicycle dynamic scheduling method. The method comprises the following steps of 1, performing region management on stations; 2, obtaining related information of the stations, and dividing a whole working region into multiple small sub-regions, wherein the information comprises coordinates of the stations and calculated demand information, and a scheduling center exists in each sub-region and manages all stations belonging to the same sub-region as the scheduling center; 3, judging whether a scheduling scheme needs to be recalculated or not according to a dynamic scheduling policy by an event manager, and if yes, establishing a static scheduling instance by the event manager, wherein the static scheduling instance comprises departure positions, departure time and basic demand information of transport vehicles; and 4, solving a problem by using an improved variable neighborhood ant colony algorithm. According to the method,a better scheduling scheme can be calculated out; the solving efficiency is higher; and the satisfaction of citizens on use of public bicycles can be improved to the maximum extent through a more cost-saving scheduling scheme.

Owner:HANGZHOU DIANZI UNIV

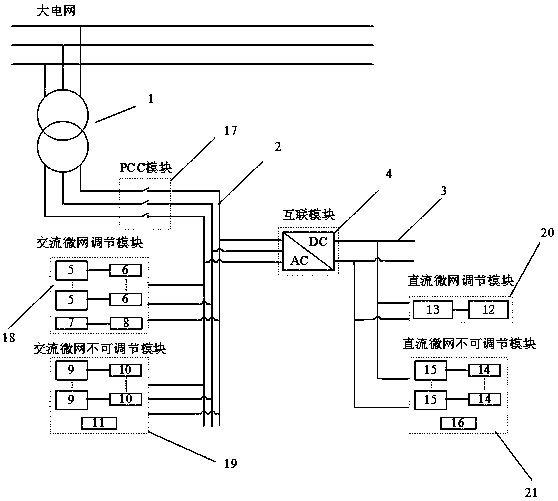

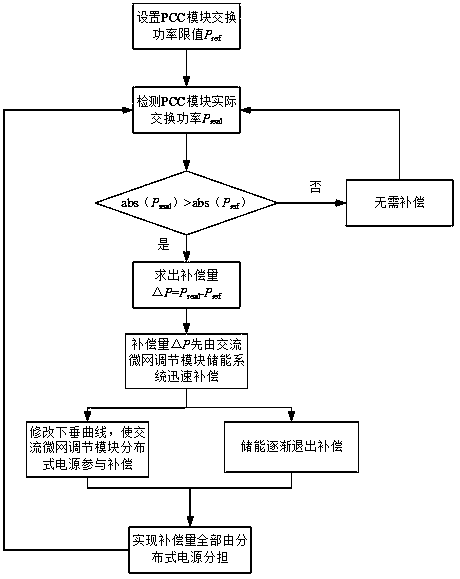

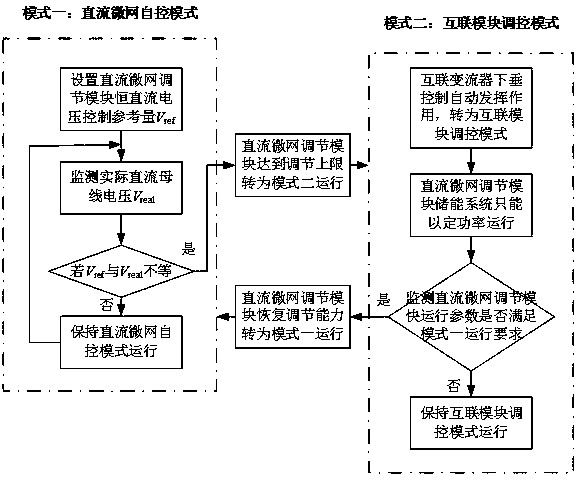

Functional modular microgrid networking and flexible control method

ActiveCN110311379AAchieve interconnectivityQuick responseAc networks with different sources same frequencyModularityAutomatic control

The invention provides an AC / DC hybrid microgrid modular structure and a multi-mode operation mode, and belongs to the field of microgrid modular design and operation control. An AC / DC hybrid microgrid is divided into six modules, and the type and the control mode of distributed power supplies or energy storage in each module are determined. The six modules are a PCC module, an AC microgrid regulation module, an AC microgrid non-regulation module, a DC microgrid regulation module, a DC microgrid non-regulation module and an interconnection module. Double guarantee is provided for the relatively "weak" DC microgrid in the grid-connected microgrid through the conversion operation among the DC microgrid automatic control mode in the grid-connected state, the interconnection module control mode and the island mode in the off-grid state. The controllable distributed power supplies, energy storage and interconnected converters in different modules are combined to be controlled and the microgrid is accessed to a large power grid with a variable power load or power supply. The dependency of MGCC on the communication system is reduced by using a two-layer control method including a module lay and a microgrid layer.

Owner:ECONOMIC TECH RES INST OF STATE GRID HENAN ELECTRIC POWER +2

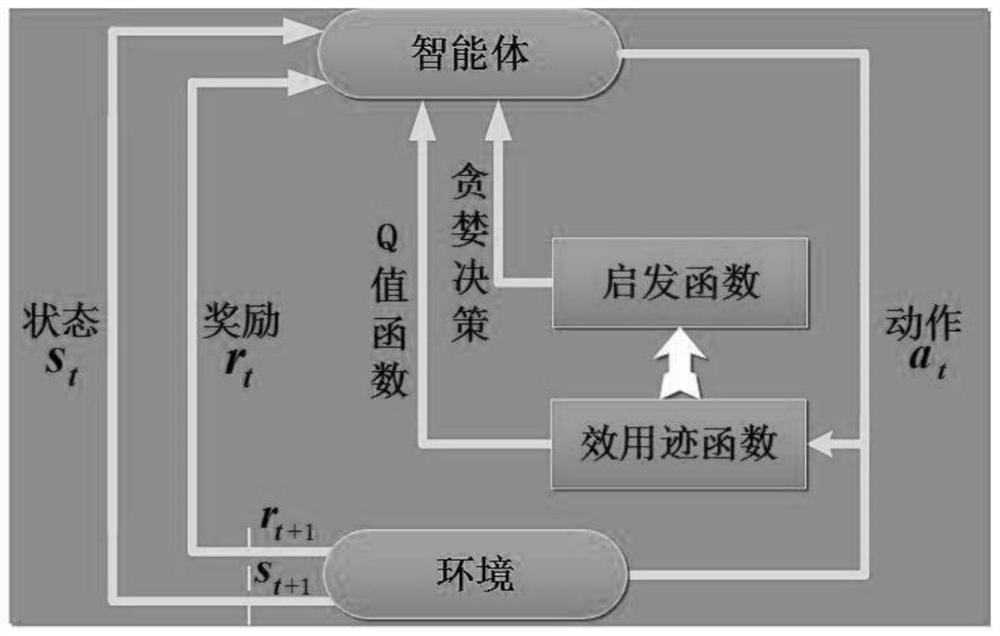

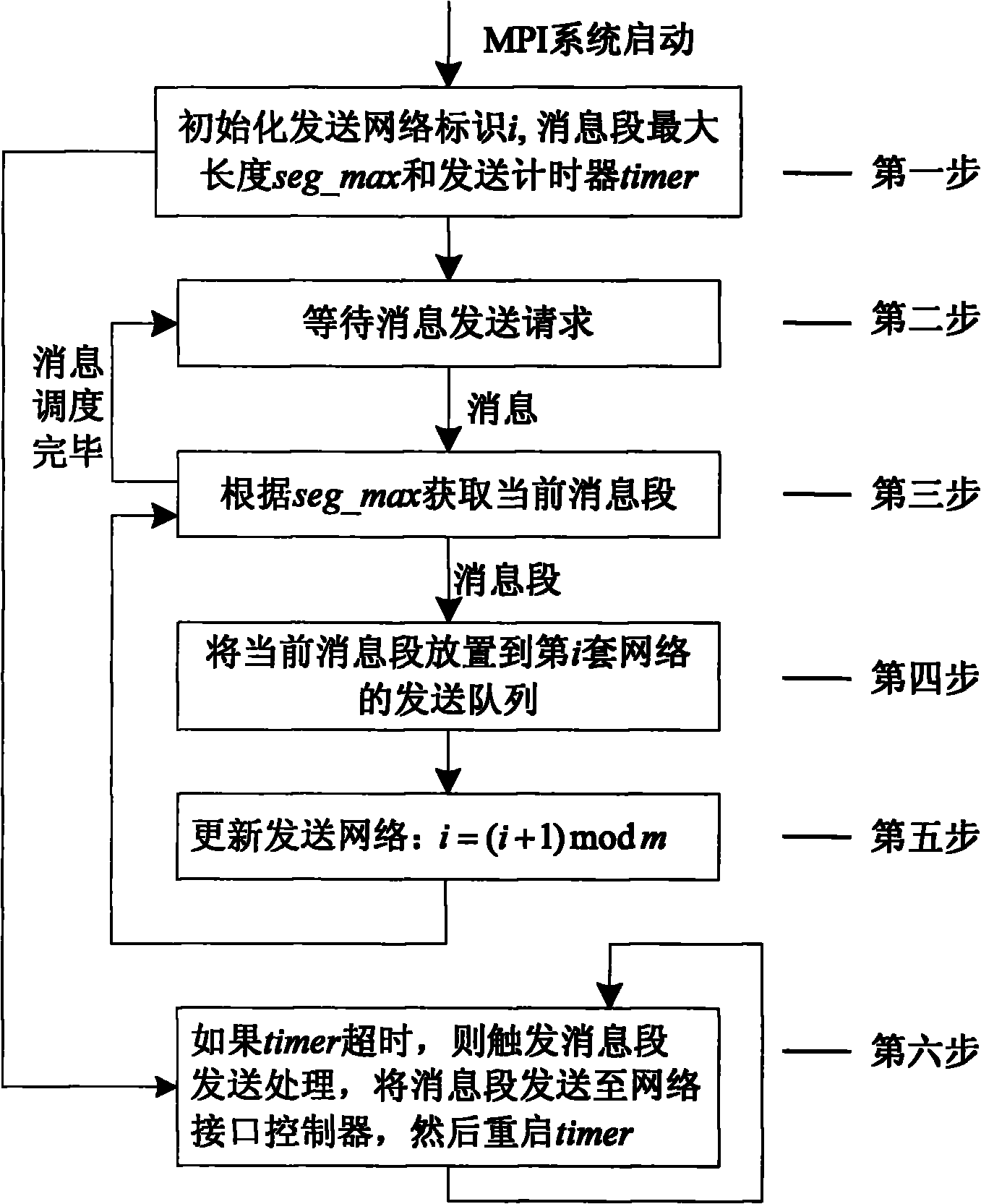

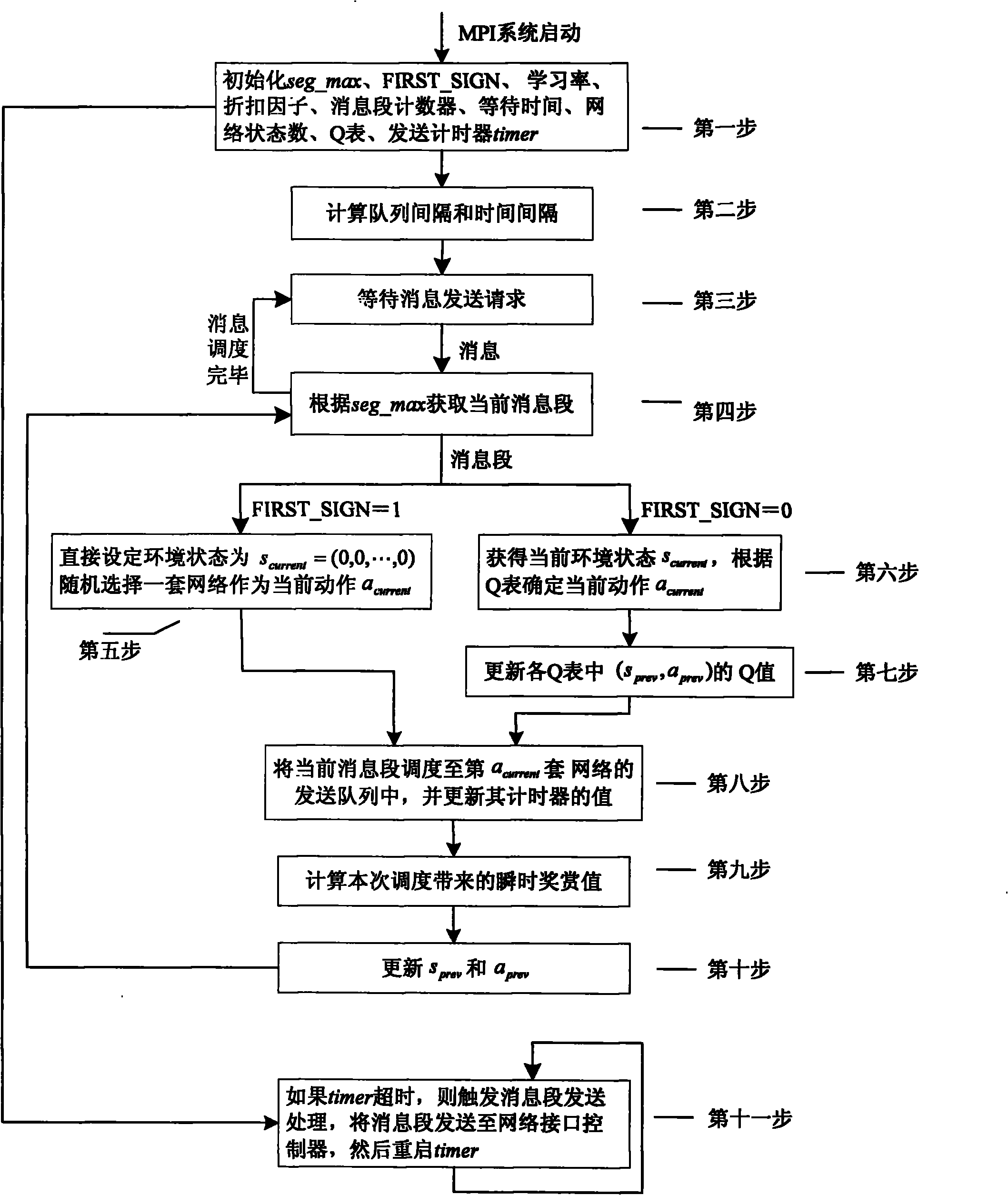

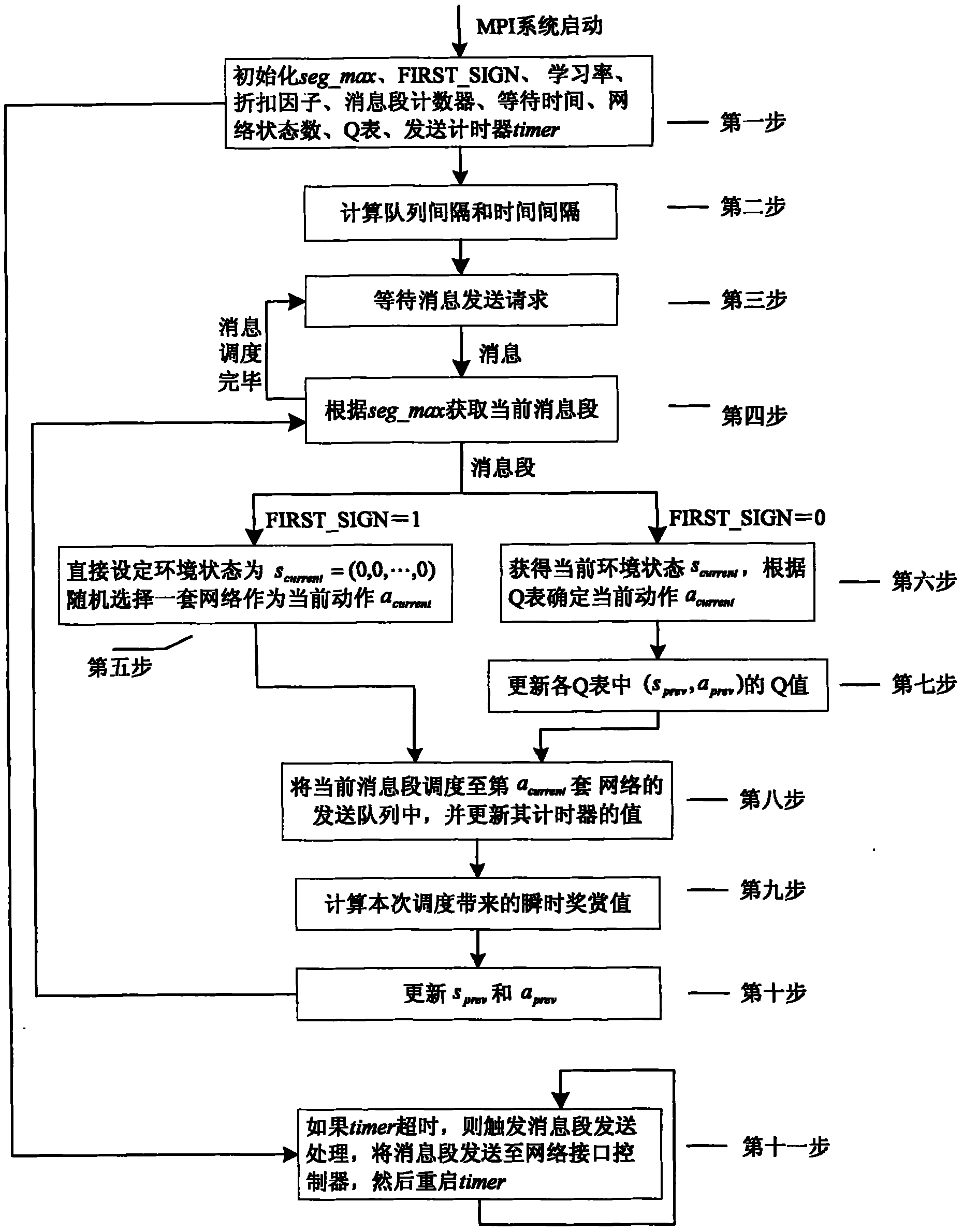

MPI (Moldflow Plastics Insight) information scheduling method based on reinforcement learning under multi-network environment

InactiveCN101833479AGet the latest status in real timeGood application effectInterprogram communicationCombined methodReward value

The invention discloses an MPI (Moldflow Plastics Insight) information scheduling method based on reinforcement learning under a multi-network environment, aiming at overcoming the defect of low practical application performance of a high-performance parallel computer, caused by the traditional circulating scheduling method. The method comprises the steps of: initiating parameters in a process of starting an MPI system, creating Cm<2> Q tables according to a multiple Q table combined method for a computing environment matched with m networks; continuously receiving an MPI information sending request sent by application in a process of starting the MPI system, determining a current information segment, then obtaining a current environment state, scheduling the current information segment to an optimal network according to the state information of historical empirical values stored in the Q tables; and finally, computing an instant reward value obtained by the scheduling and updating Q values in the Q tables. By adopting the invention, the problems that communication loads are distributed unequally, can not adapt to the network state dynamic change and have poor adaptability on the computing environment can be solved, and the practical application performance of the high-performance parallel computer is improved.

Owner:NAT UNIV OF DEFENSE TECH

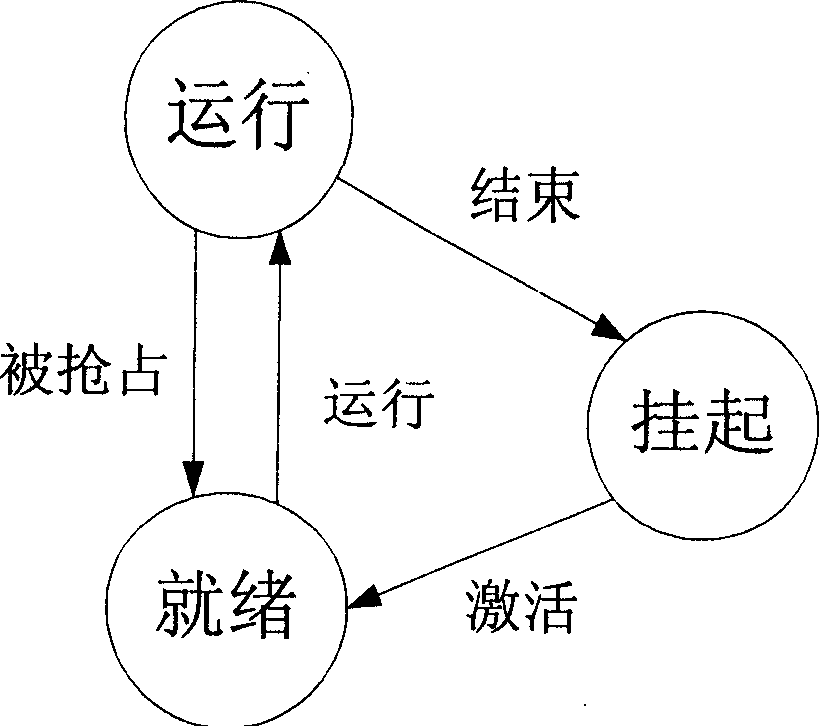

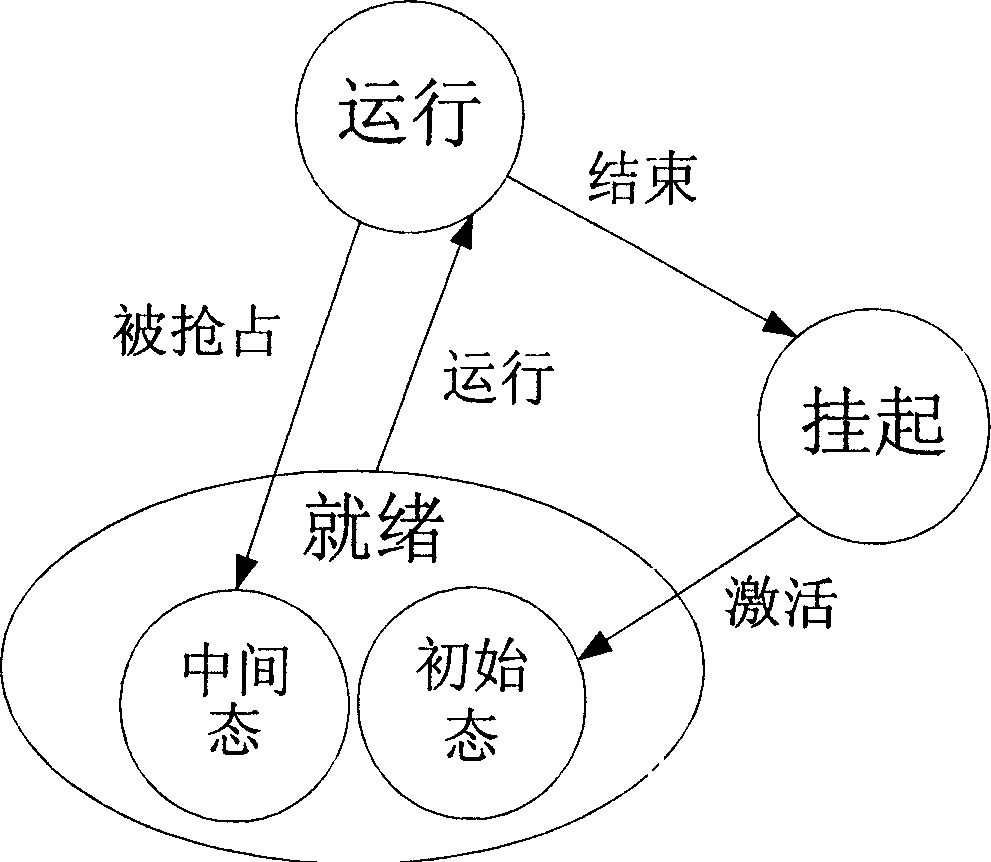

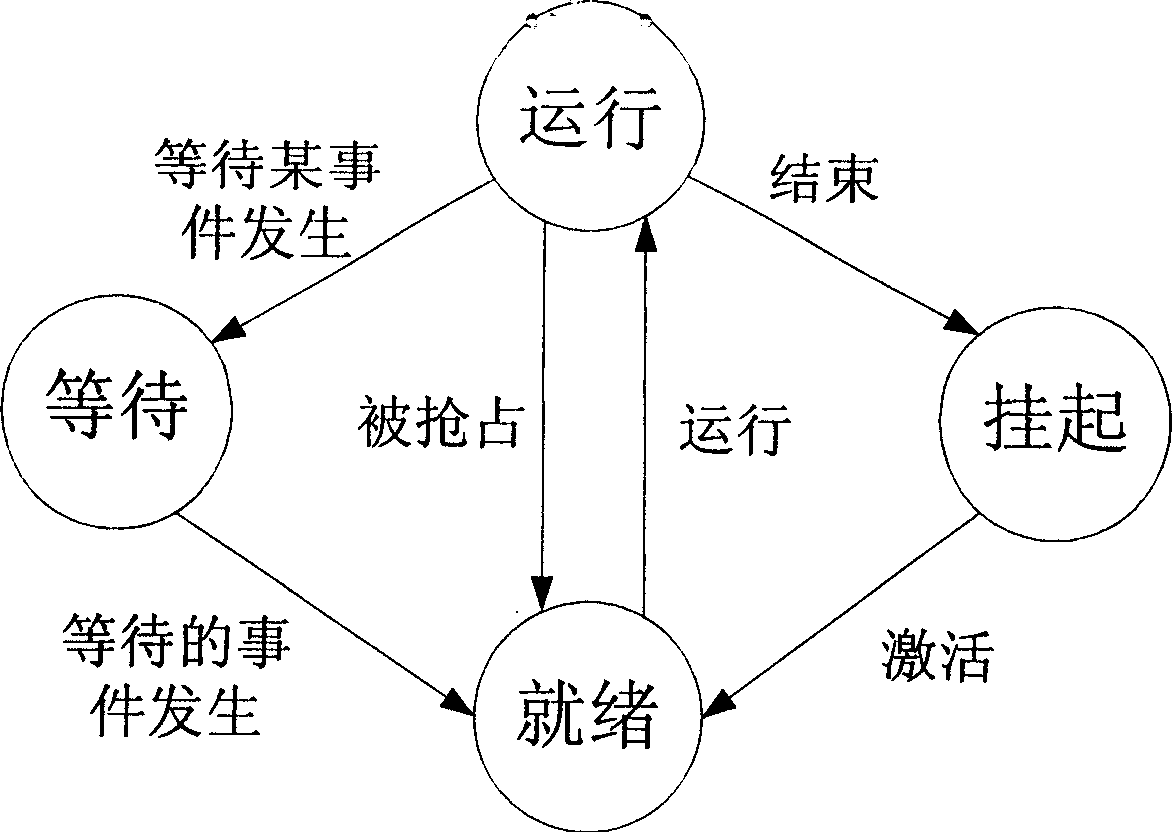

Task scheduling method for embedded real-time operation system supporting OSEK standard

InactiveCN1737764AImprove scheduling effectLess involvedMultiprogramming arrangementsBitwise operationSwitching time

This invention relates to one task dispatching optimization method to support OSEK standard imbedded operation system, which comprises the following steps: a, analyzing each switch situations according to task situation; b, dividing the dispatching process into four steps: finding optimization task in the prepare task; storing the current operation task environment; demoting the CPU needle; restoring optimization task running environment; c, optimizing the dispatching strategy according to four steps covering situation into four types of strategy; d, selecting different dispatching strategy according to real dispatching situation.

Owner:ZHEJIANG UNIV

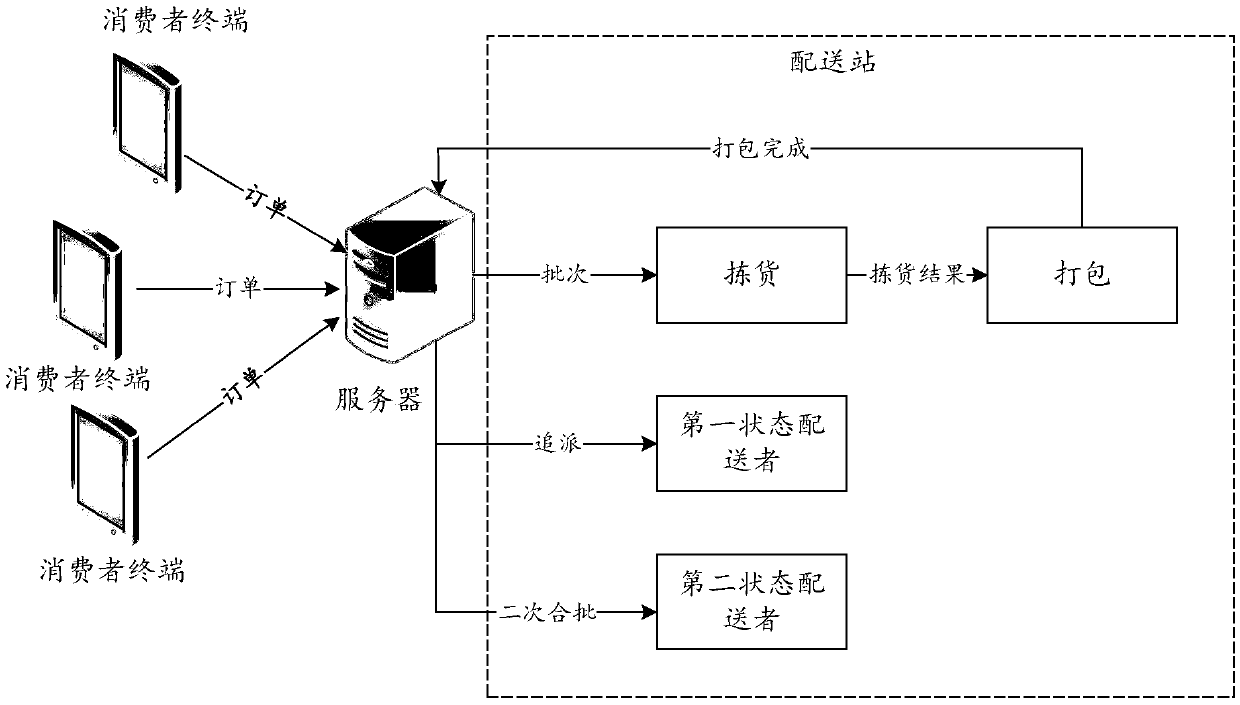

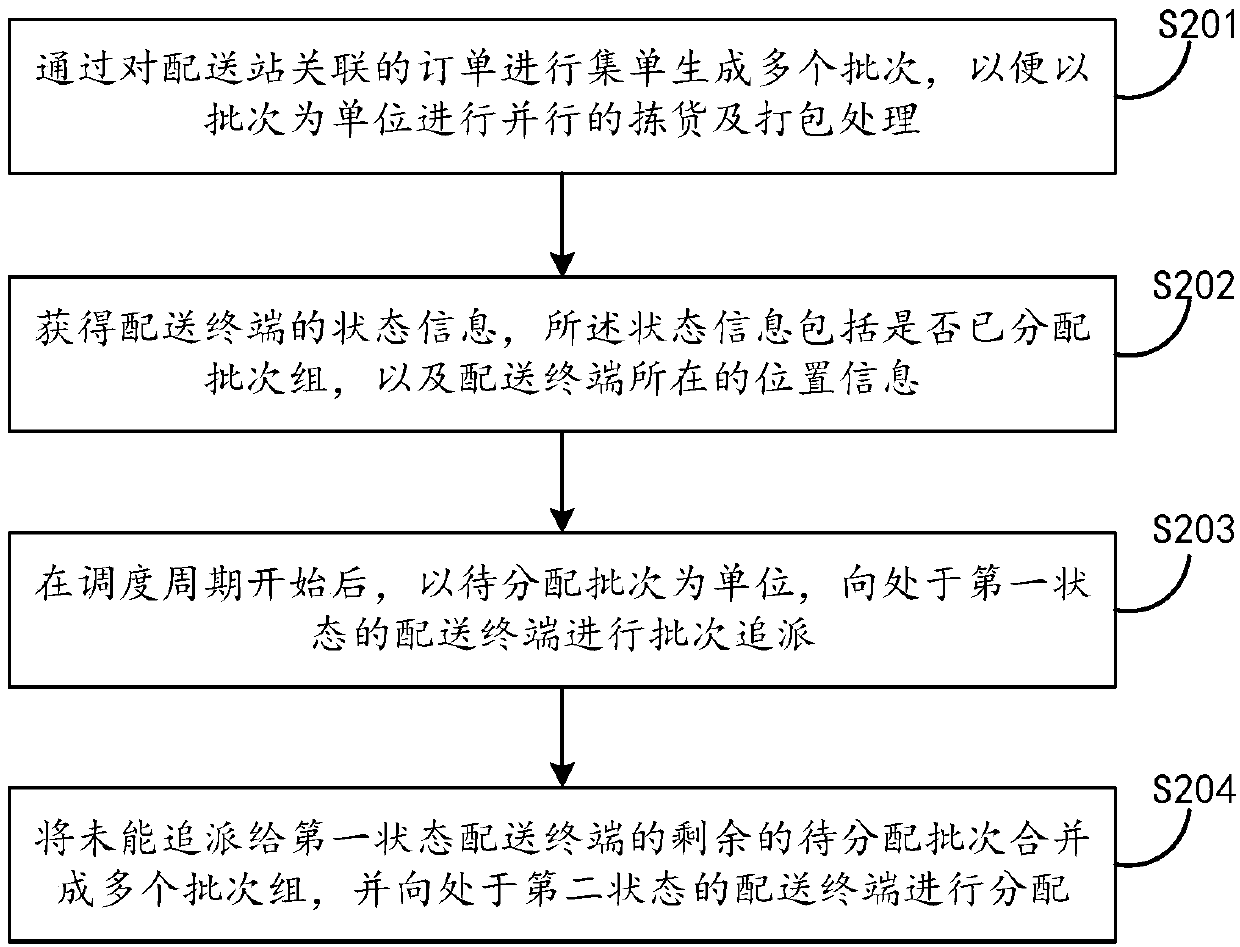

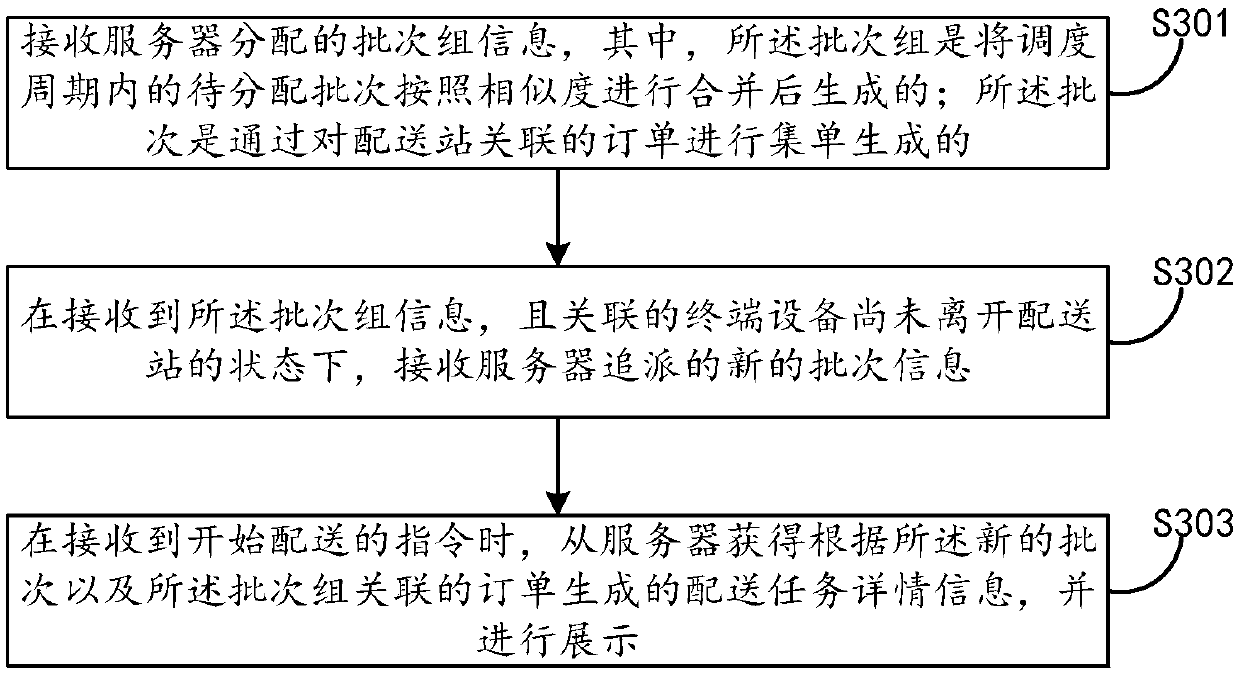

Order batch scheduling method and device and computer system

PendingCN110796402AReduce wasteGuaranteed delivery timelinessLogisticsComputer networkIndustrial engineering

The embodiment of the invention discloses an order batch scheduling method and device and a computer system, and the method comprises the steps: taking a to-be-distributed batch as a unit after a scheduling period starts, and carrying out the batch appointment to a distribution terminal in a first state, wherein the to-be-allocated batch is a batch which has been packaged and is in a to-be-allocated distribution terminal state, the distribution terminals in the first state are the distribution terminals which have been allocated with batch groups and have not left yet after returning to the distribution station; and combining the remaining batches to be allocated, which are not allocated to the delivery terminals in the first state, into a plurality of batch groups, and allocating the batches to be allocated to the delivery terminals in a second state, the delivery terminals in the second state being idle delivery terminals in the delivery station or delivery terminals which are aboutto return to the delivery station and are not allocated with the batch groups. According to the embodiment of the invention, the method can reduce the waste of delivery resources while guaranteeing the delivery time efficiency.

Owner:ALIBABA GRP HLDG LTD

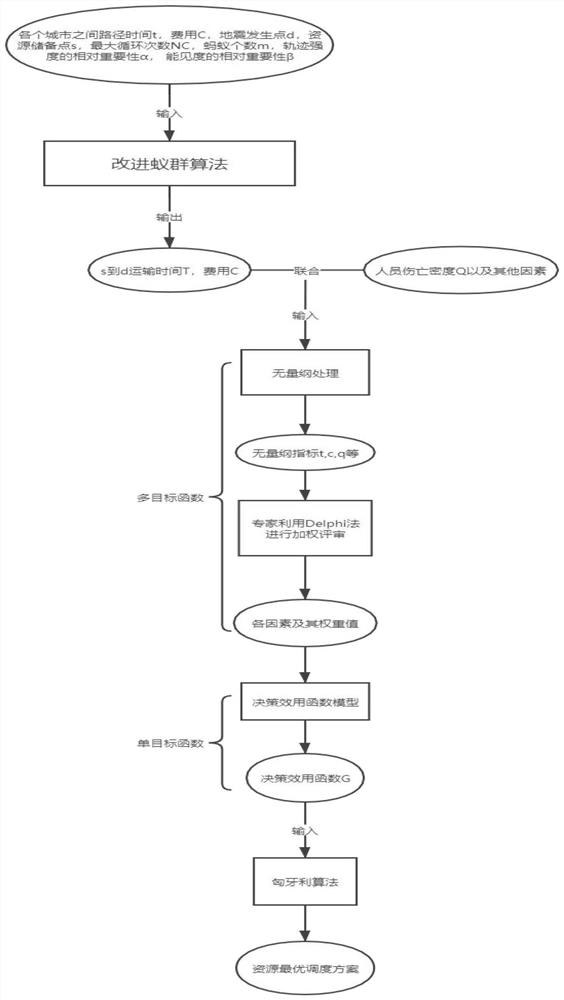

Emergency resource scheduling method based on ant colony algorithm and multi-objective function model

ActiveCN112288152AOptimal Resource Scheduling SchemeSolve technical problems with poor scheduling resultsForecastingArtificial lifeMathematical modelSwarm algorithms

The invention relates to an emergency resource scheduling method based on an ant colony algorithm and a multi-objective function model, belongs to the research category of data analysis, relates to the technical field of ant colony algorithms, Hungary algorithms, optimal paths, resource scheduling and the like. The method mainly aims at selection of emergency resource scheduling schemes during earthquakes, constructs an optimal path selection model between two points and a multi-objective function mathematical model, performs data analysis training by adopting an ant colony optimization algorithm and a Hungary algorithm, and obtains an optimal emergency resource scheduling scheme by utilizing the trained model. The method has the advantages that the path cost can be considered as low as possible under the condition that the time efficiency is the first essentials, the characteristics of timeliness, casualty, economy and the like of emergency material transportation can be refined, theimportance degrees of the characteristics are distinguished through weights, and the most reasonable overall scheduling scheme can be obtained.

Owner:WUHAN UNIV

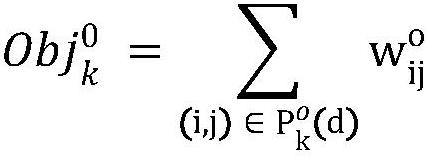

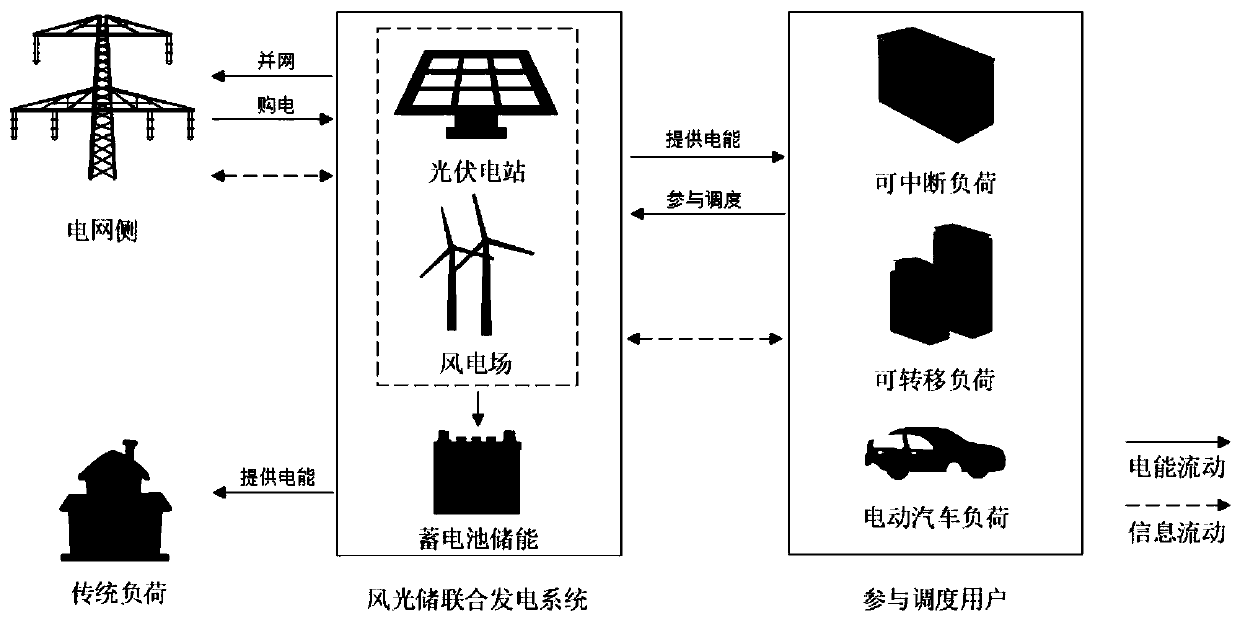

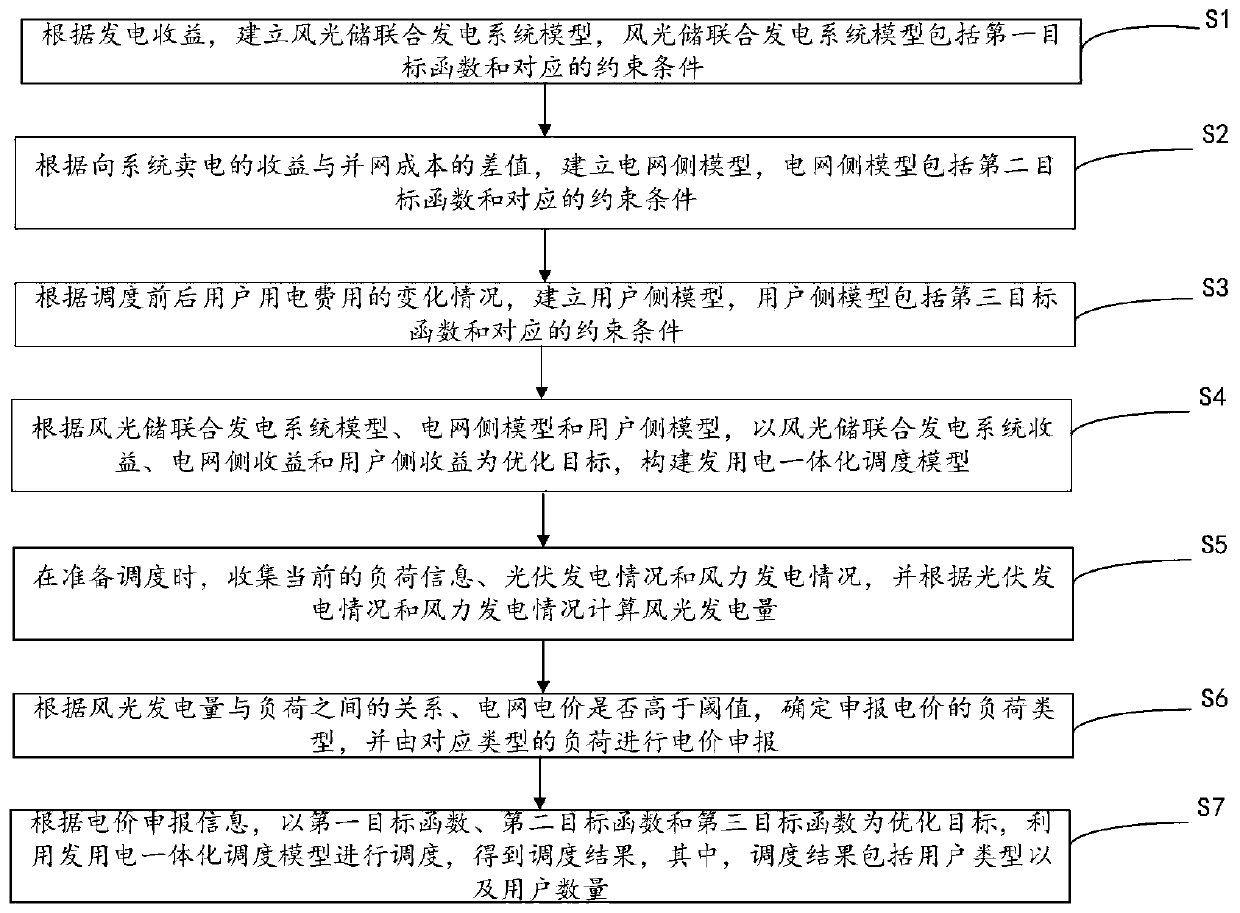

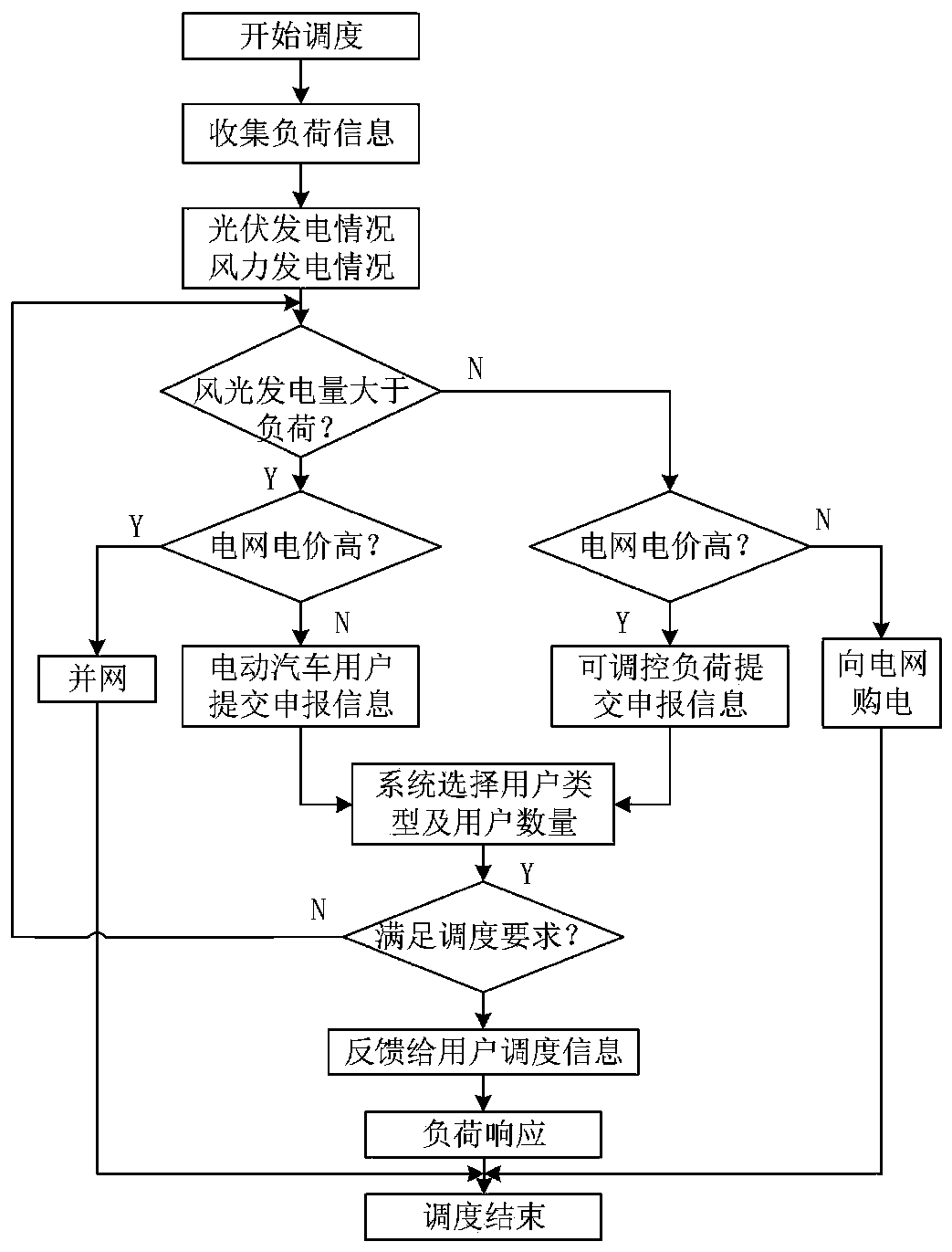

Power generation and utilization integrated scheduling method based on wind-solar-energy-storage combined power generation system

ActiveCN111030096AIncrease the level of interactionImprove scheduling effectClimate change adaptationSingle network parallel feeding arrangementsCurrent loadPower grid

The invention discloses a power generation and utilization integrated scheduling method based on a wind-solar-energy storage combined power generation system. The method comprises the steps: respectively building a wind-solar-energy storage combined power generation system model, a power grid side model and a user side model, and then building a power generation and utilization integrated scheduling model; when preparing to perform scheduling, collecting current load information, photovoltaic power generation conditions and wind power generation conditions, and calculating the wind-solar powergeneration capacity according to the photovoltaic power generation conditions and the wind power generation conditions; determining the load type of the declared electricity price according to the relationship between the wind-solar generating capacity and the load and whether the electricity price of the power grid is higher than a threshold, and declaring the electricity price by the load of the corresponding type; and taking the first objective function, the second objective function and the third objective function as optimization objectives according to the electricity price declarationinformation, and performing scheduling by utilizing the electricity generation and utilization integrated scheduling model to obtain a scheduling result. According to the method, the scheduling effectcan be improved, and the method has important practical significance for improving the renewable energy consumption capacity and optimizing power generation and utilization resources.

Owner:WUHAN UNIV OF TECH

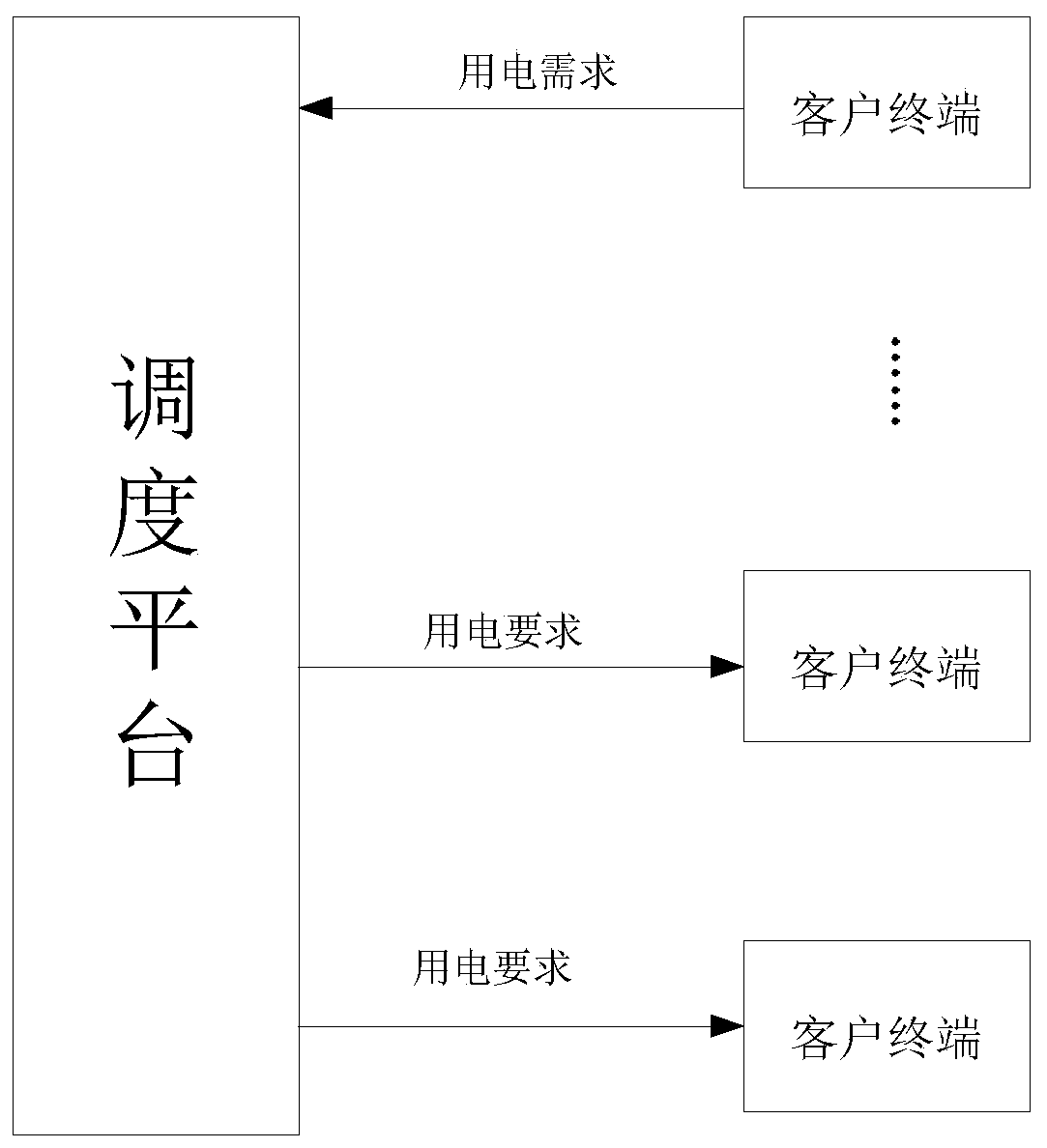

Power utilization dispatching system and method

PendingCN111222745AGood scheduling effectMeet basic needsEnergy industryResourcesReal-time computingPower load

The invention discloses a power utilization dispatching system and method, solves the problem of poor effect of performing power demand side management by utilizing off-peak power utilization in the prior art, and belongs to the field of power load dispatching. The power utilization dispatching system comprises a dispatching platform and a plurality of client terminals, the dispatching platform isused for receiving a power consumption demand of one client in a set time period, determining the power consumption demand for other clients in the time period according to the power consumption demand of the client in combination with schedulable power consumption, and sending the power consumption demand to the corresponding client terminal; and the client terminal is used for counting the electricity consumption time and the electricity consumption of the client, sending the electricity consumption time and the electricity consumption to the dispatching platform, inputting the electricityconsumption demand in a set time period, sending the electricity consumption demand to the dispatching platform, receiving the electricity consumption requirement of the dispatching platform and displaying the electricity consumption requirement.

Owner:黑龙江电力调度实业有限公司 +2

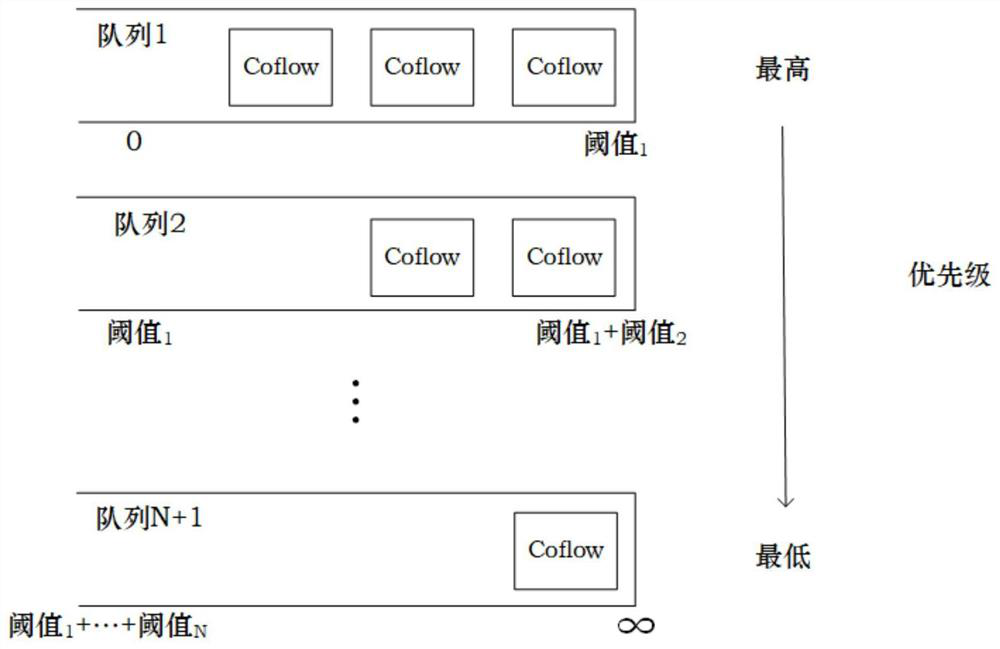

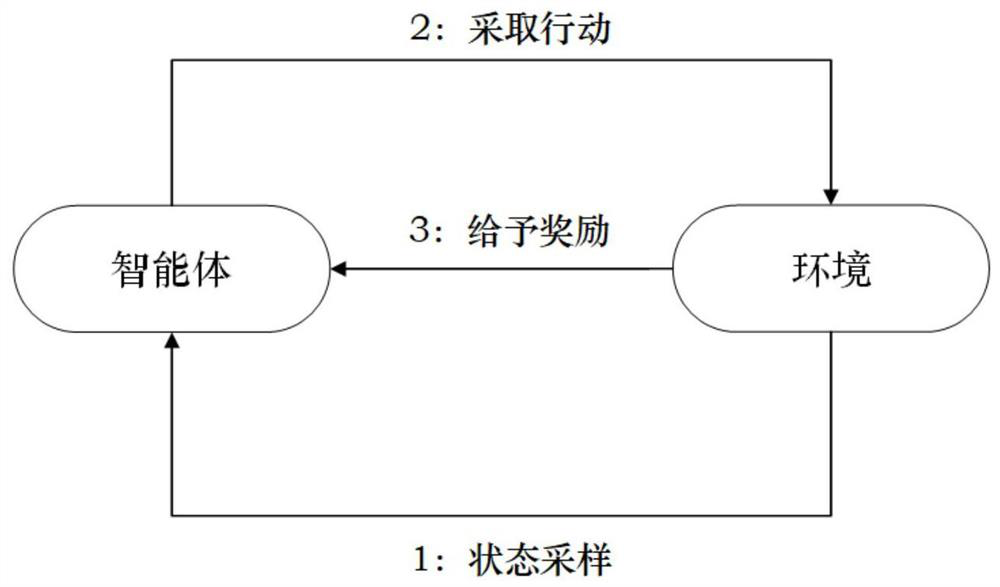

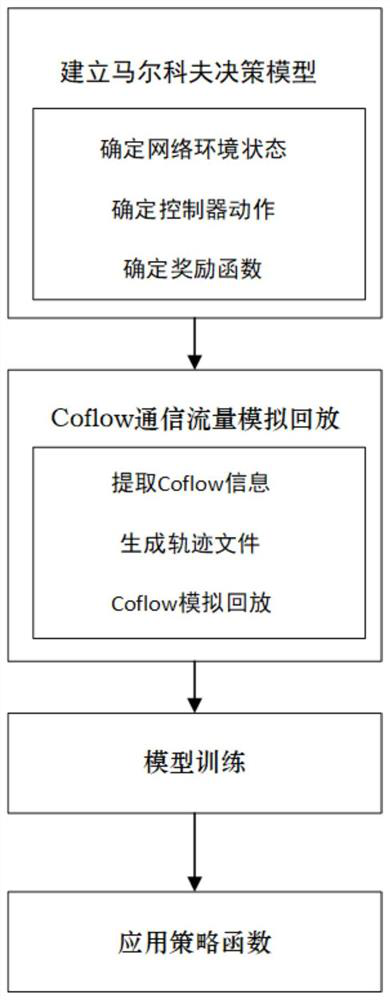

Coflow scheduling method based on deep reinforcement learning

ActiveCN111740925AFine-grained level assignmentImprove scheduling effectNeural architecturesData switching networksCompletion timeDecision model

The invention discloses a Coflow scheduling method based on deep reinforcement learning. Based on deep reinforcement learning and in combination with a multi-level priority queue and a basic flow scheduling algorithm, a Markov decision model is established, a Coflow scheduling strategy is expressed in a formalized mode, and then adjustment of the Coflow scheduling strategy is completed. Accordingto the method, a state matrix is formed by using the data size, the total flow number, the active flow number and the duration of Coflow in the current network environment to represent the network state, define and adjust the action of a flow transmission multistage priority queue, an evaluation equation is established to realize the minimum optimization of the Coflow average completion time. According to the method, deep reinforcement learning and multi-level priority queues are combined, the Coflow scheduling strategy is adjusted through a large number of trial and error and learning in theCoflow sending scheduling environment, more environmental parameters are brought into account compared with a traditional heuristic algorithm, and the transmission efficiency of Coflow is effectivelyimproved.

Owner:BEIHANG UNIV

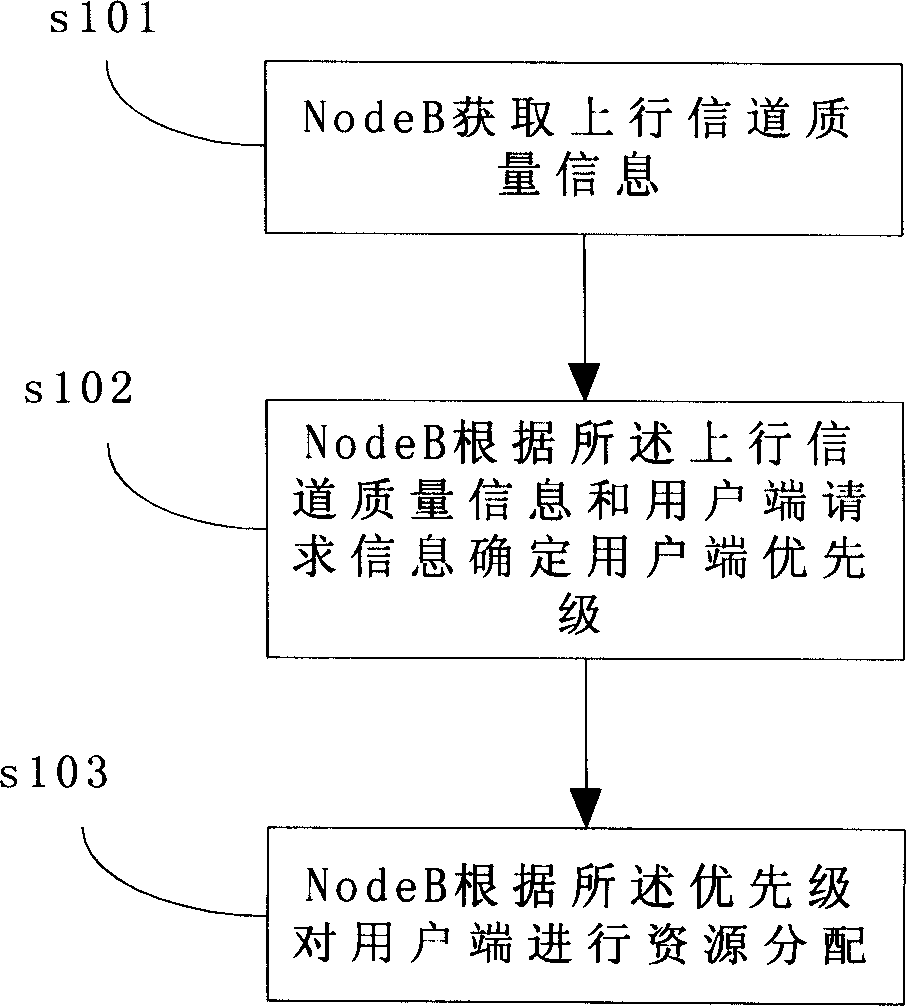

Scheduling method of up-ward reinforcing chain path and method for obtaining upward channel quality information

InactiveCN1852074AImprove uplink throughputImprove throughputError preventionComputer scienceResource allocation

This invention discloses a dispatch method in an up strengthened link including: Node B gets the quality information of an up channel to determine the priority of the user end based on the information and required information then distributes resources to the user end. This invention also discloses a method for obtaining the up channel quality of the user end connected by this local area.

Owner:HUAWEI TECH CO LTD

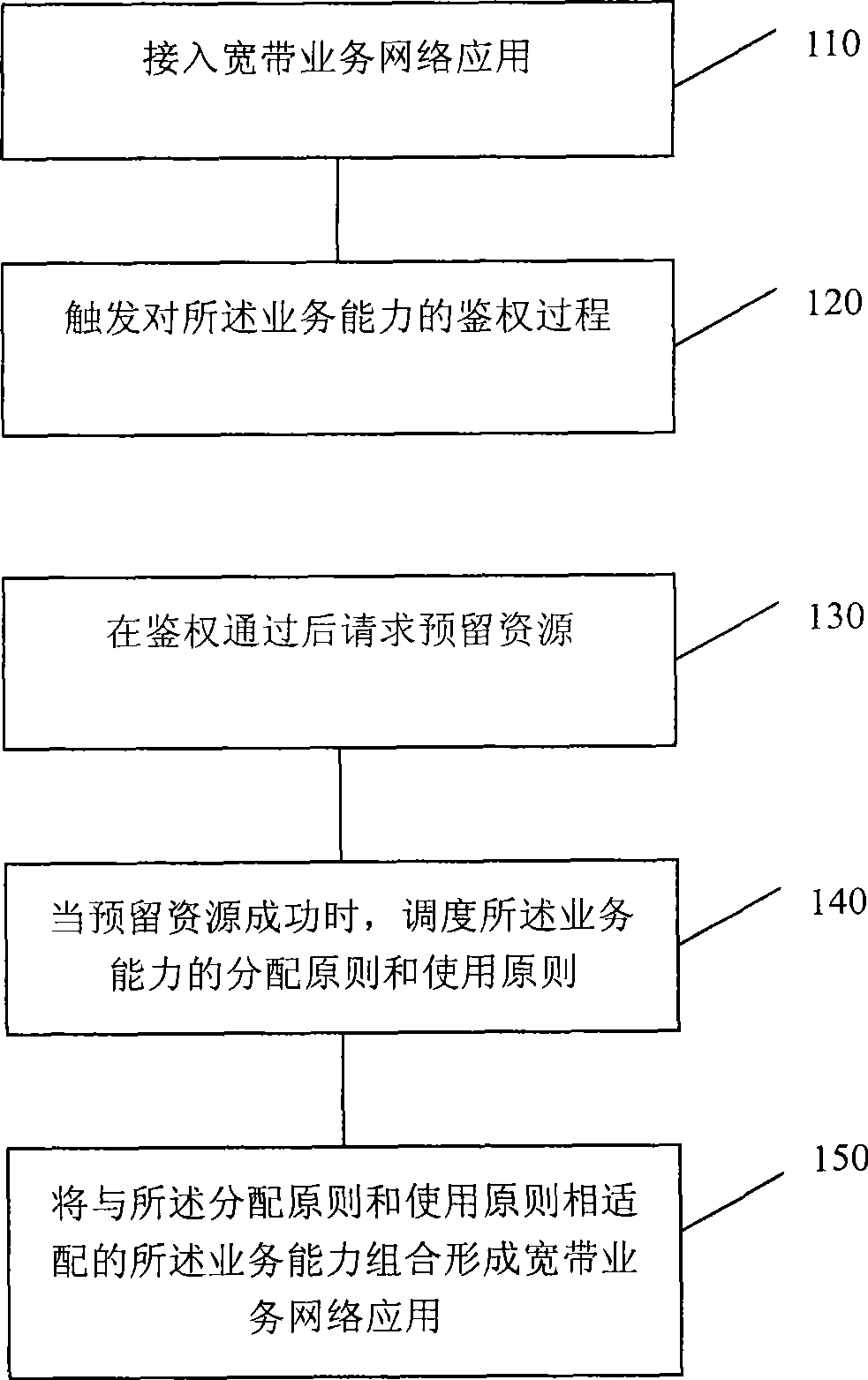

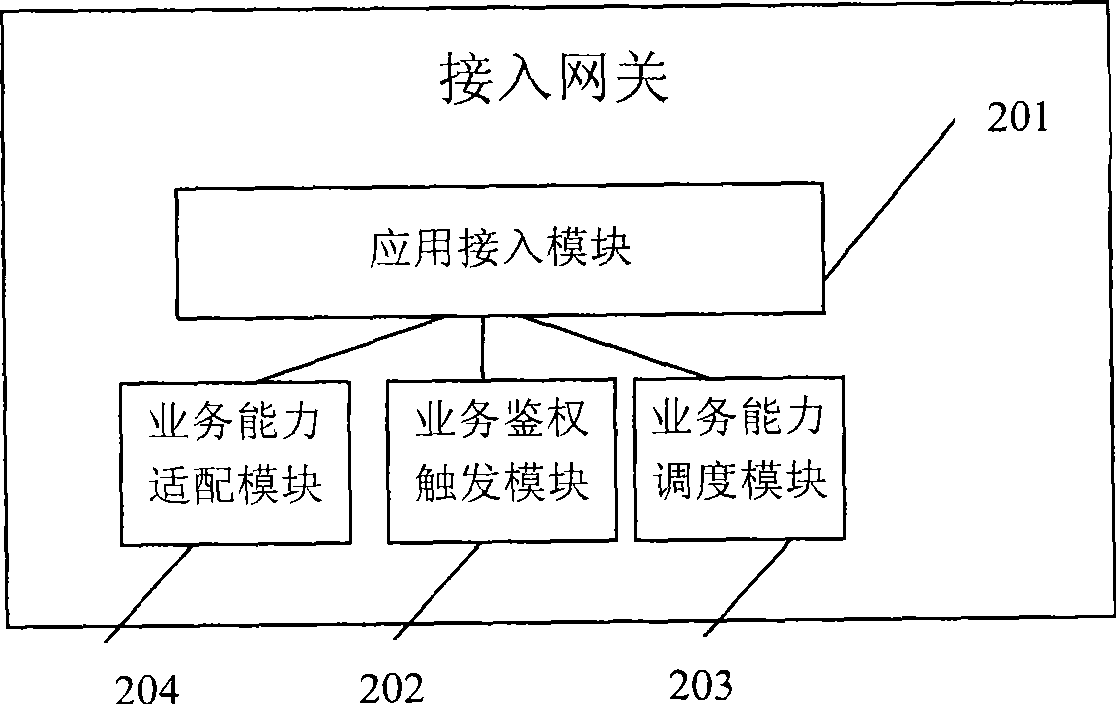

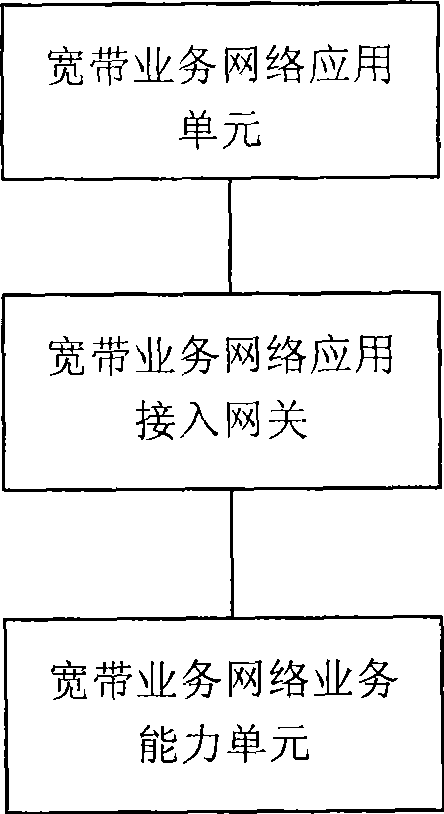

Wideband service network application access method, access system and access gateway

ActiveCN101383764AReduce the number of constructionReduce access pointsData switching by path configurationAccess methodBroadband

The invention provides an accessing method, an access system, and an access gateway for the application of a broadband service network. The invention comprises: accessing all the applications of broadband service networks, (the application of each broadband service network comprises at least one service capacity); triggering the process of authentication of the service capacity; asking for reserved resource after the authentication is approved; scheduling the allocation principle and the application principle of the service capacity when the reserved resource succeeds; combining the service capacities adaptive to the allocation principle and the application principle so as to provide the applications of the broadband service networks. The invention collectively manages and schedules the service capacities under the environment of broadband service network, and can satisfy the diversity of the service capacities and the applications in the broadband service network.

Owner:CHINA TELECOM CORP LTD

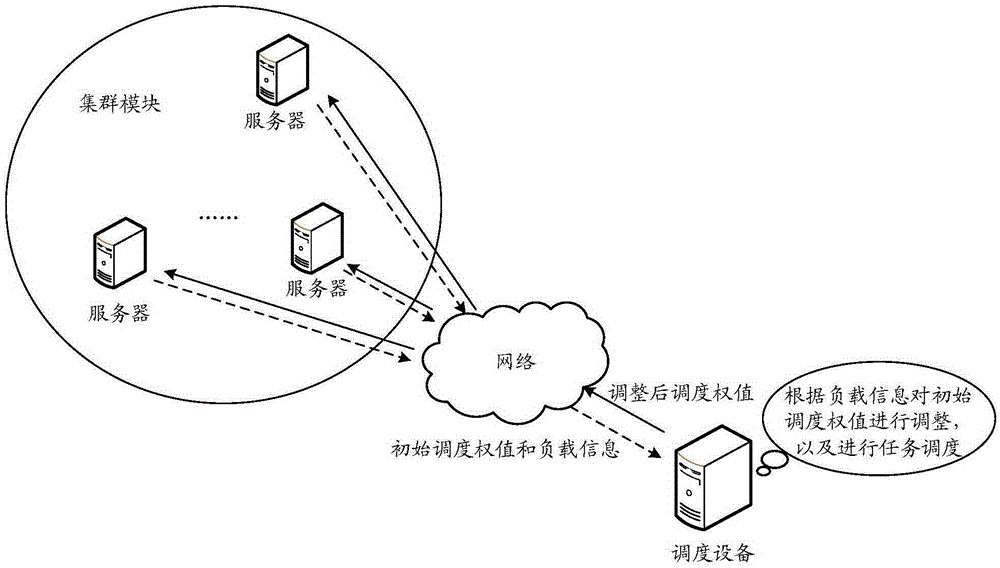

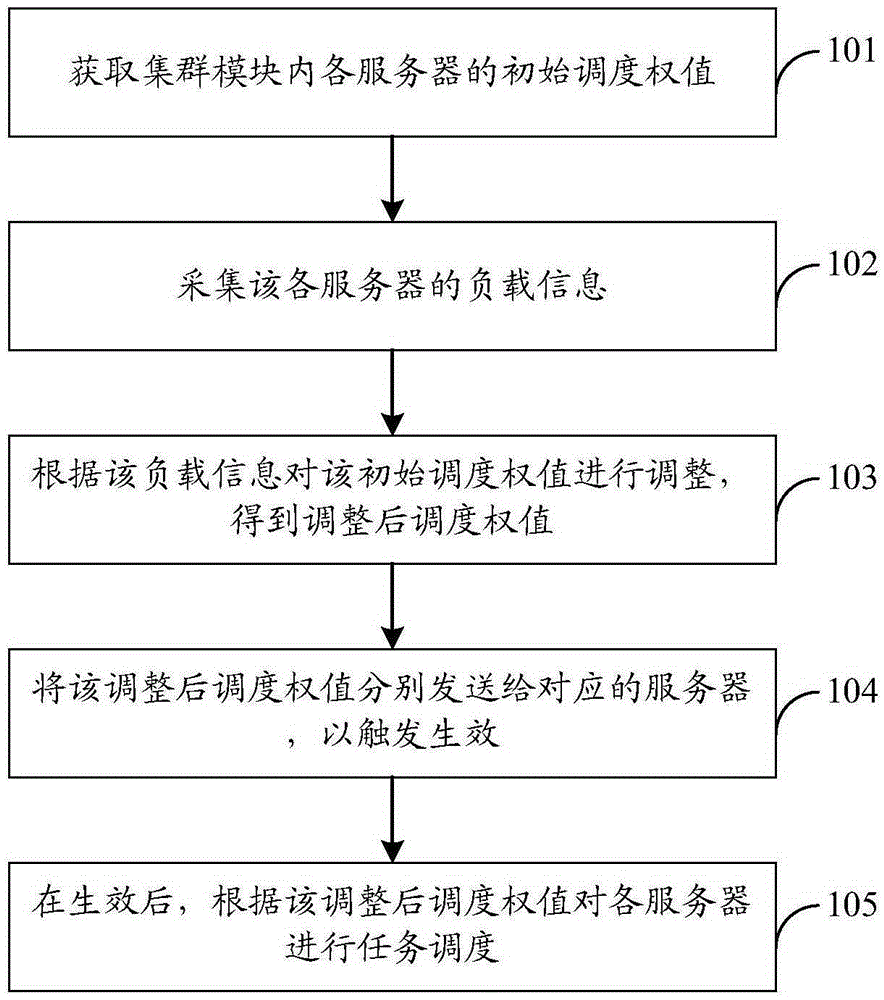

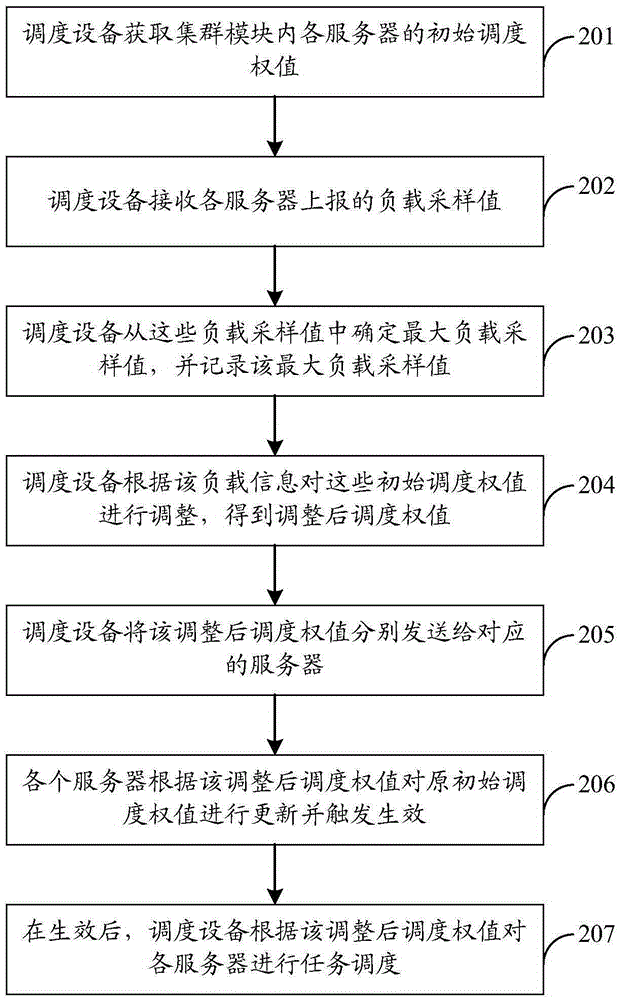

A server scheduling method, apparatus and system

InactiveCN106612310AEnsure safetyFlexible Task SchedulingTransmissionComputer moduleDistributed computing

The embodiment of the invention discloses a server scheduling method, apparatus and system. According to the embodiment of the invention, initial scheduling weights of servers in a cluster module are acquired and load information of each server is collected; then the initial scheduling weights are adjusted according to the load information to obtain the adjusted scheduling weights and the adjusted scheduling weights are sent respectively to the corresponding servers to trigger an effect; and after the effect is taken, task scheduling is carried out on the servers according to the adjusted scheduling weights. According to the scheme, the task scheduling can be more flexibly, accurately and reasonably carried out; the scheduling effect can be improved; and the processing efficiency and the business security can be raised.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com