Intelligent carrying robot trolley and management method thereof

A technology of intelligent handling and intelligent car, applied in the field of intelligent robots, can solve problems such as waste of human resources, and achieve the effects of improving safety, tidy workshop and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

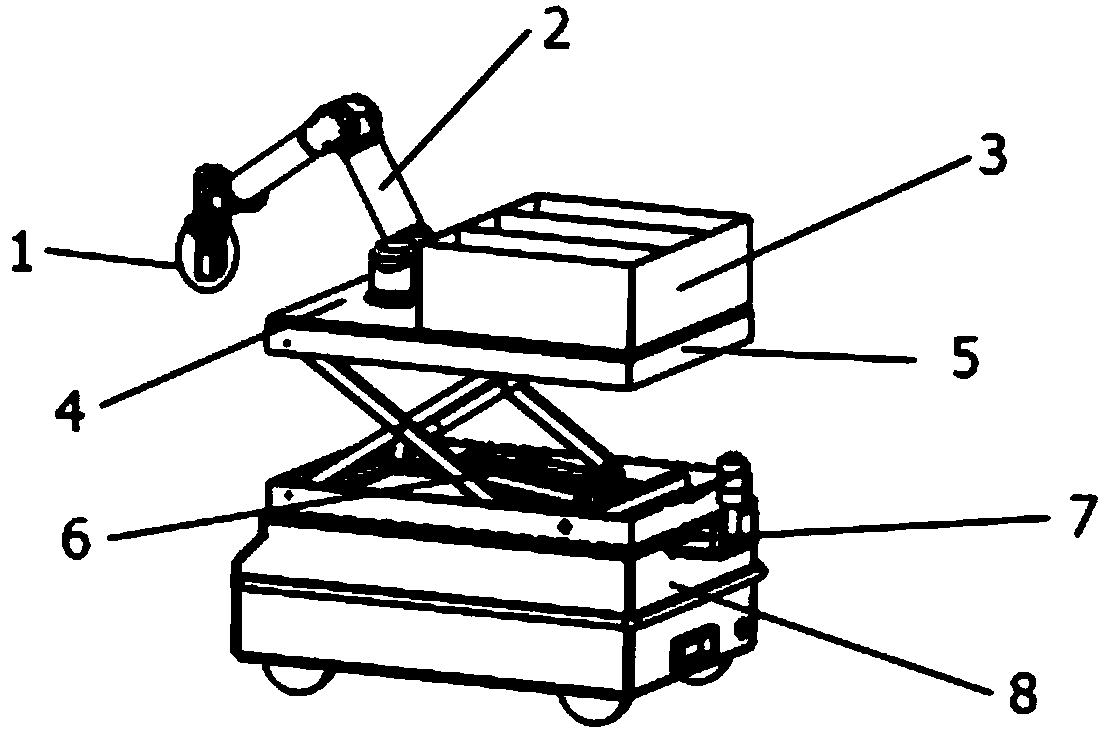

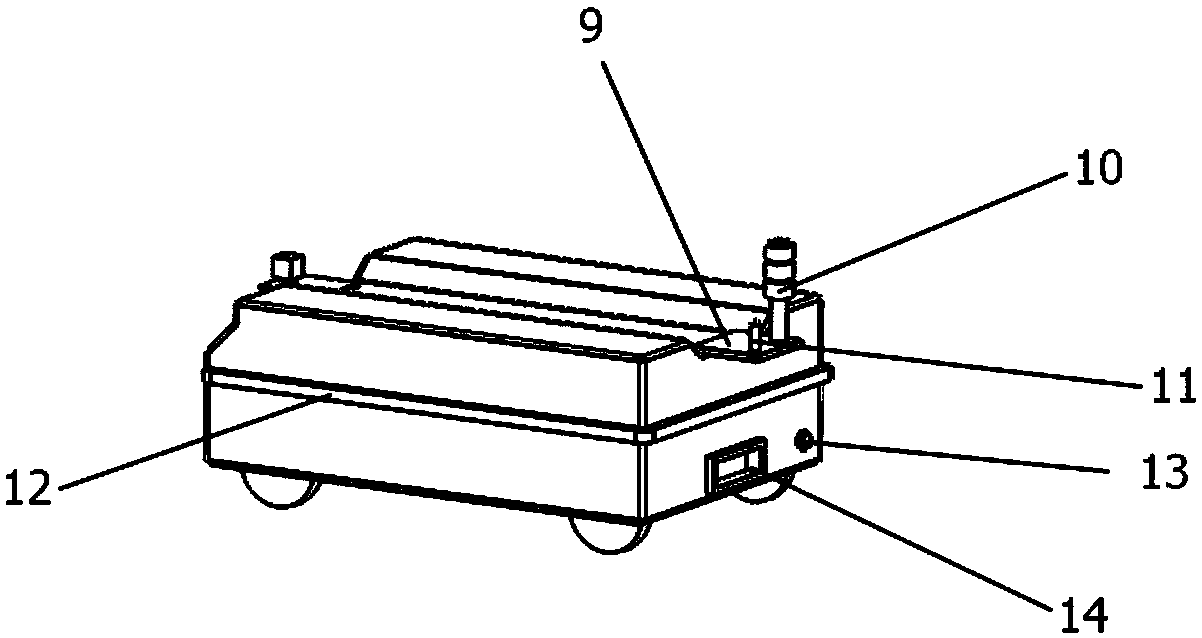

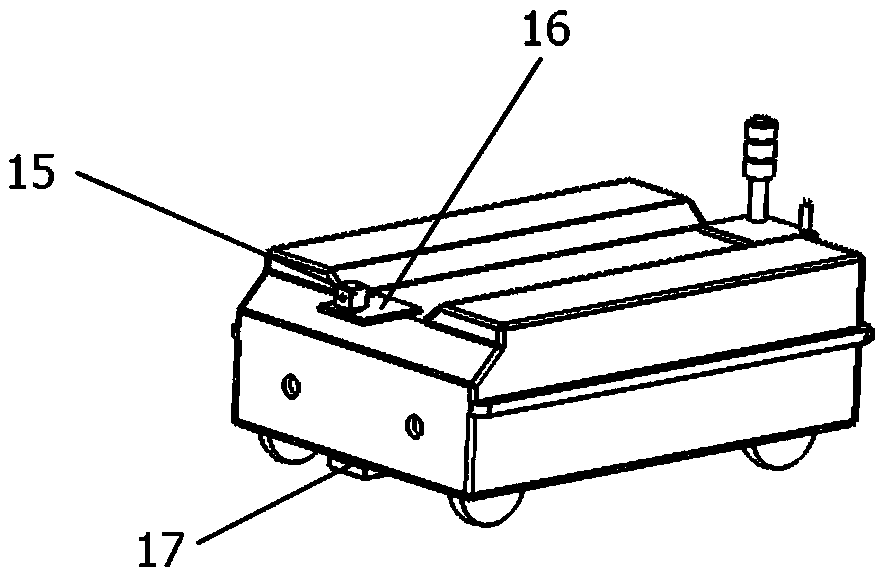

[0043] Embodiment 1, an intelligent handling robot trolley, comprising: a grasping mechanism, a lifting mechanism and a smart trolley, the grasping mechanism is arranged above the lifting mechanism and an upper panel 4 is arranged between them, and the lifting mechanism is installed above the intelligent trolley and between A lower base plate 7 is provided; the grasping mechanism includes a pneumatic gripper 1, a robot 2, a material box 3 and an infrared scanner 18, the material box 3 is placed on the upper panel 4, and the robot 2 is installed on the front end of the material box 3, The pneumatic gripper 1 is connected with the robot 2, and the infrared scanner 18 is installed on the mounting hole of the pneumatic gripper 1 by screw fastening; the smart car includes a smart car system 8, a mounting plate 9, a signal lamp 10, and a signal transmitter 11 , anti-collision strip 12, buzzer 13, charging port 14, laser sensor 15, laser sensor mounting plate 16, path planning module ...

Embodiment 2

[0045] Embodiment 2, a method for managing an intelligent handling robot trolley, comprising the following steps:

[0046] S1, the staff inputs relevant information to the logistics control center terminal, and the logistics control center sends relevant instructions to the central control room according to the information;

[0047] S2, through the communication control of the central control room, the intelligent robot car system feeds back to the computer of the intelligent handling robot car to sort out and calculate the current information and set relevant operation instructions to send;

[0048] S3, the computer sends a signal to the infrared scanner to detect the goods and record relevant data;

[0049] S4, monitoring is carried out through the sensor module of the intelligent handling robot car. The monitoring includes ultrasonic distance measurement, omni-directional obstacle detection, movement detection and laser navigation detection to ensure the stability and safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com