Patents

Literature

66results about How to "Precise loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

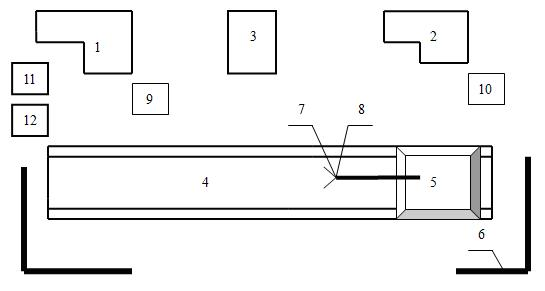

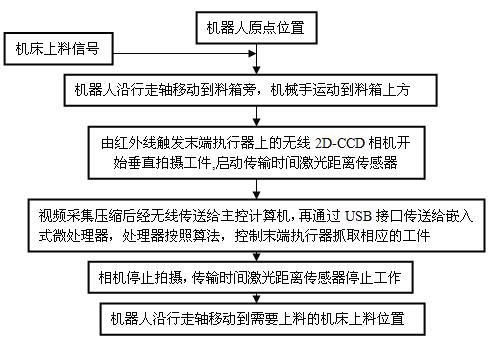

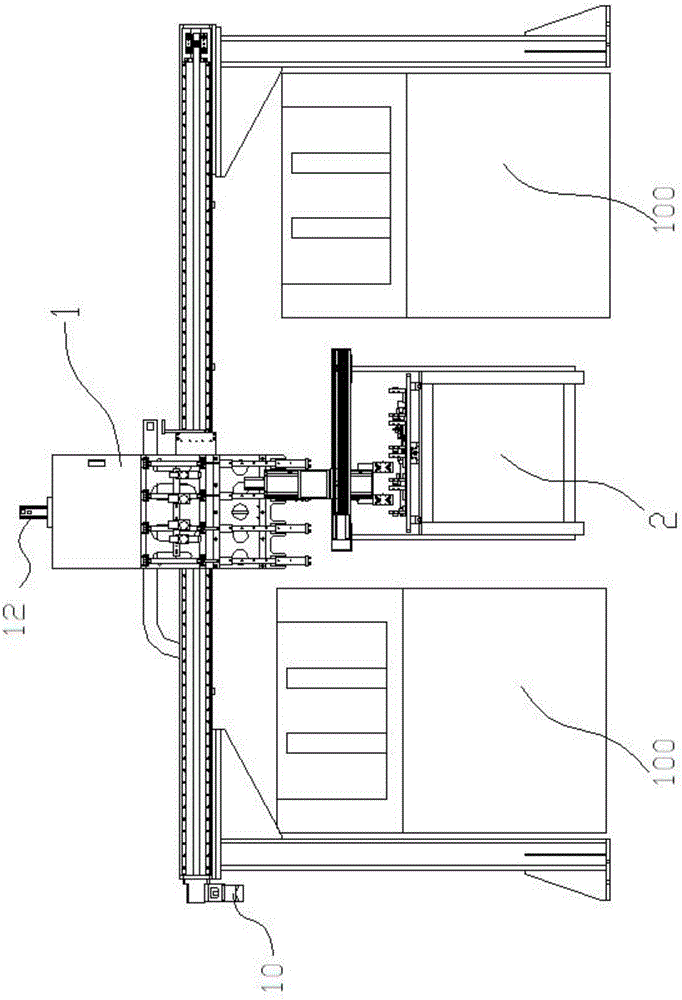

Method for controlling feeding and discharging of mobile robot serving two numerically controlled machines

ActiveCN102073303AAccurate identificationPrecise loading and unloadingNumerical controlNumerical controlIndustrial robotics

The invention relates to a method for controlling the feeding and discharging of a mobile robot serving two numerically controlled machines, belonging to the technical filed of the system for controlling the feeding and discharging of the industrial robot. The position video information and shape video information of a wireless 2D-CCD acquisition workpiece which is arranged on the end effector ofthe robot are adopted, and after the acquired video information is subjected to video acquisition and compression and then transmitted wirelessly, the processed video signal is received by a wirelessUSB (universal serial bus) receiver and transmitted to a master control computer through a USB interface, and the end effector is controlled to grab workpieces by an embedded microprocessor accordingto the recognition algorithm. The workpieces can be identified correctly and grabbed by adopting the recognition algorithm, and the correct feeding and discharging can be realized, thus the working efficiency can be improved, and the manual labor can be saved.

Owner:JIANGSU TEWEI MACHINE TOOL MFG

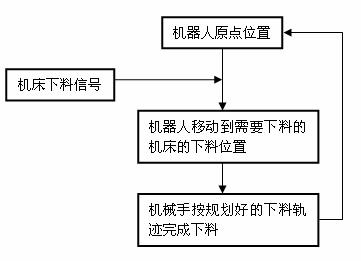

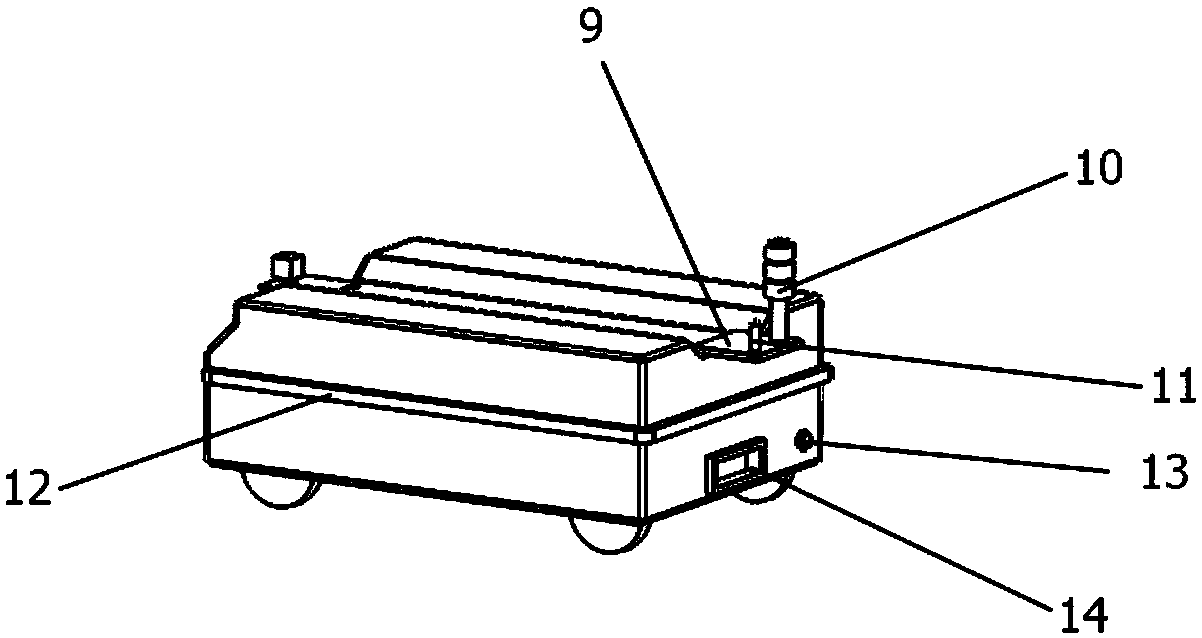

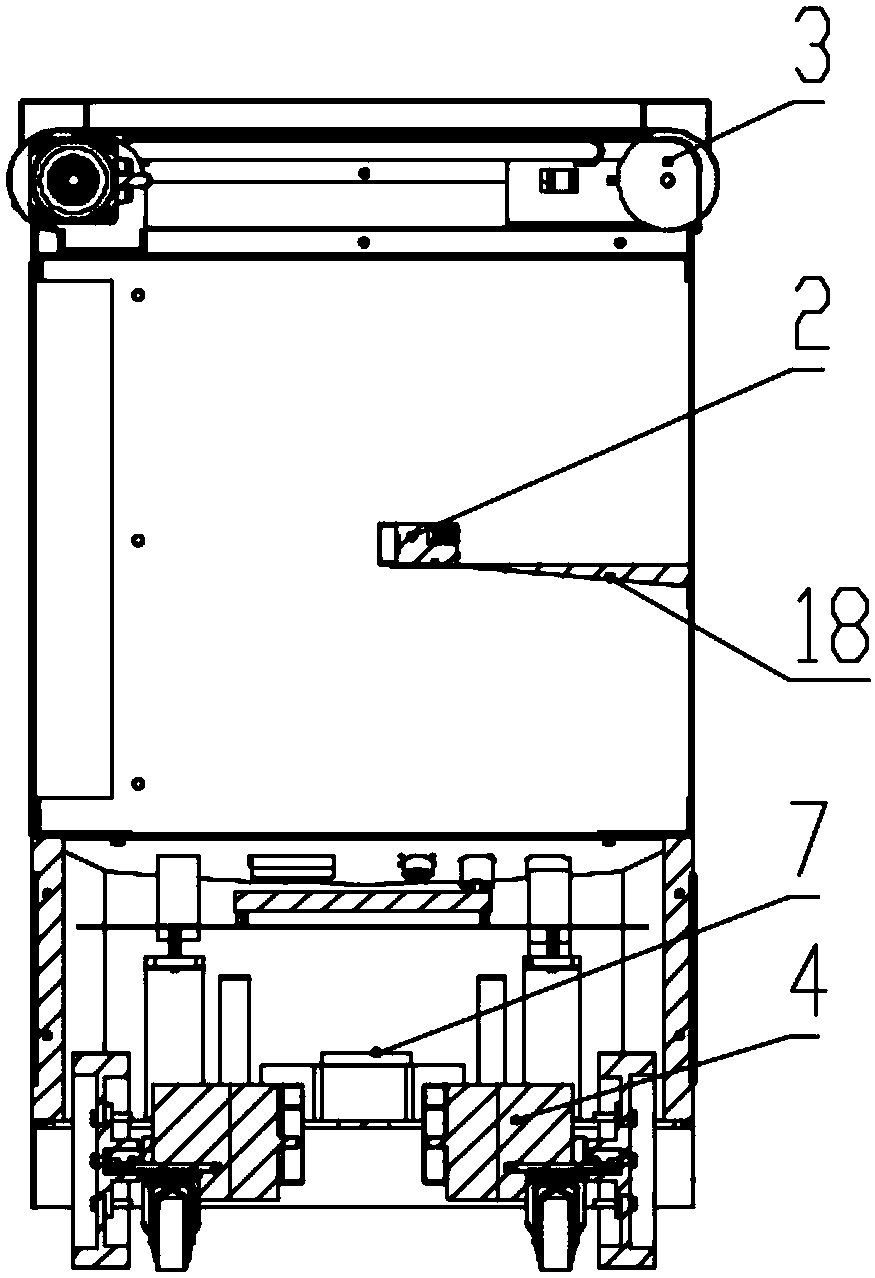

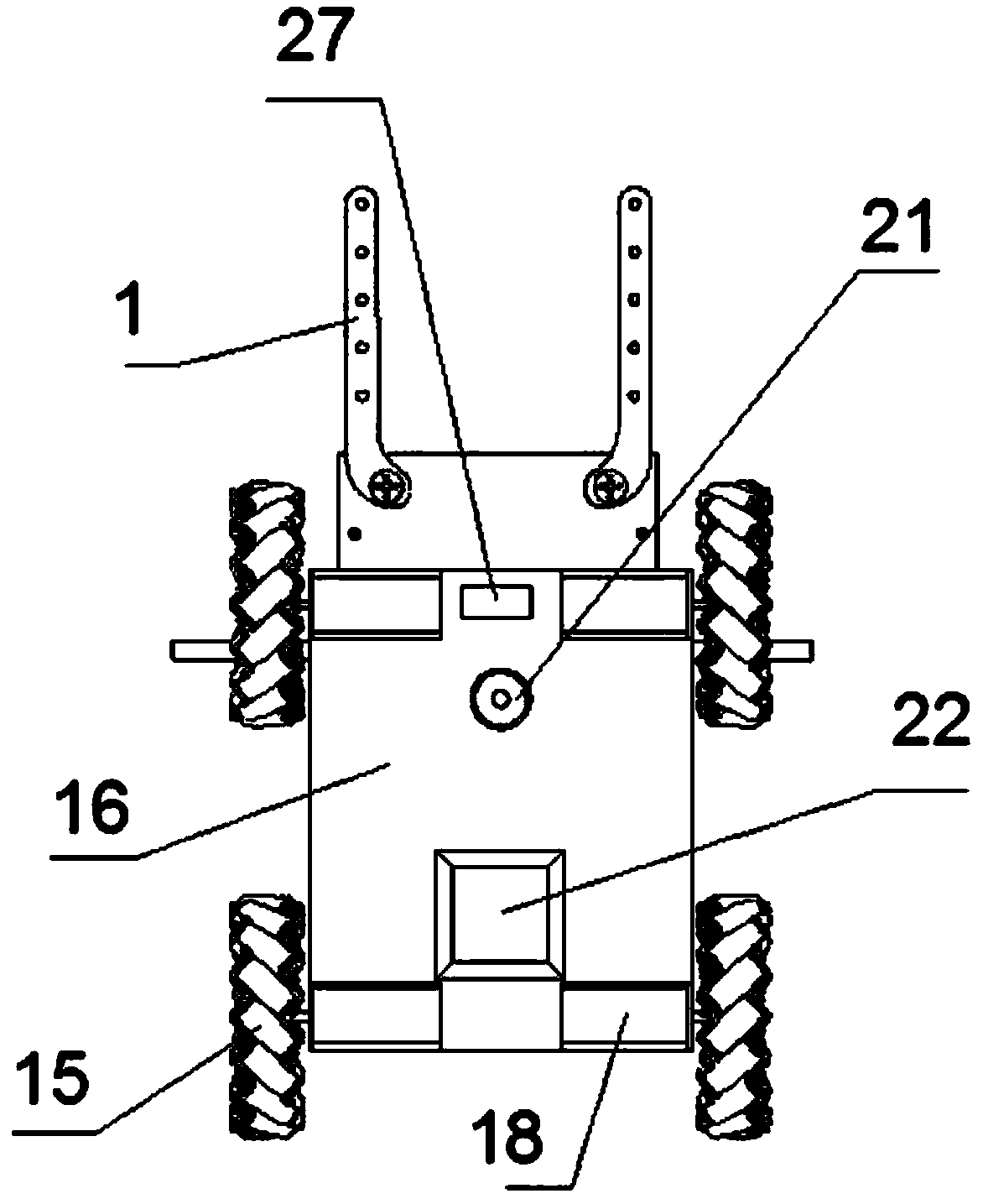

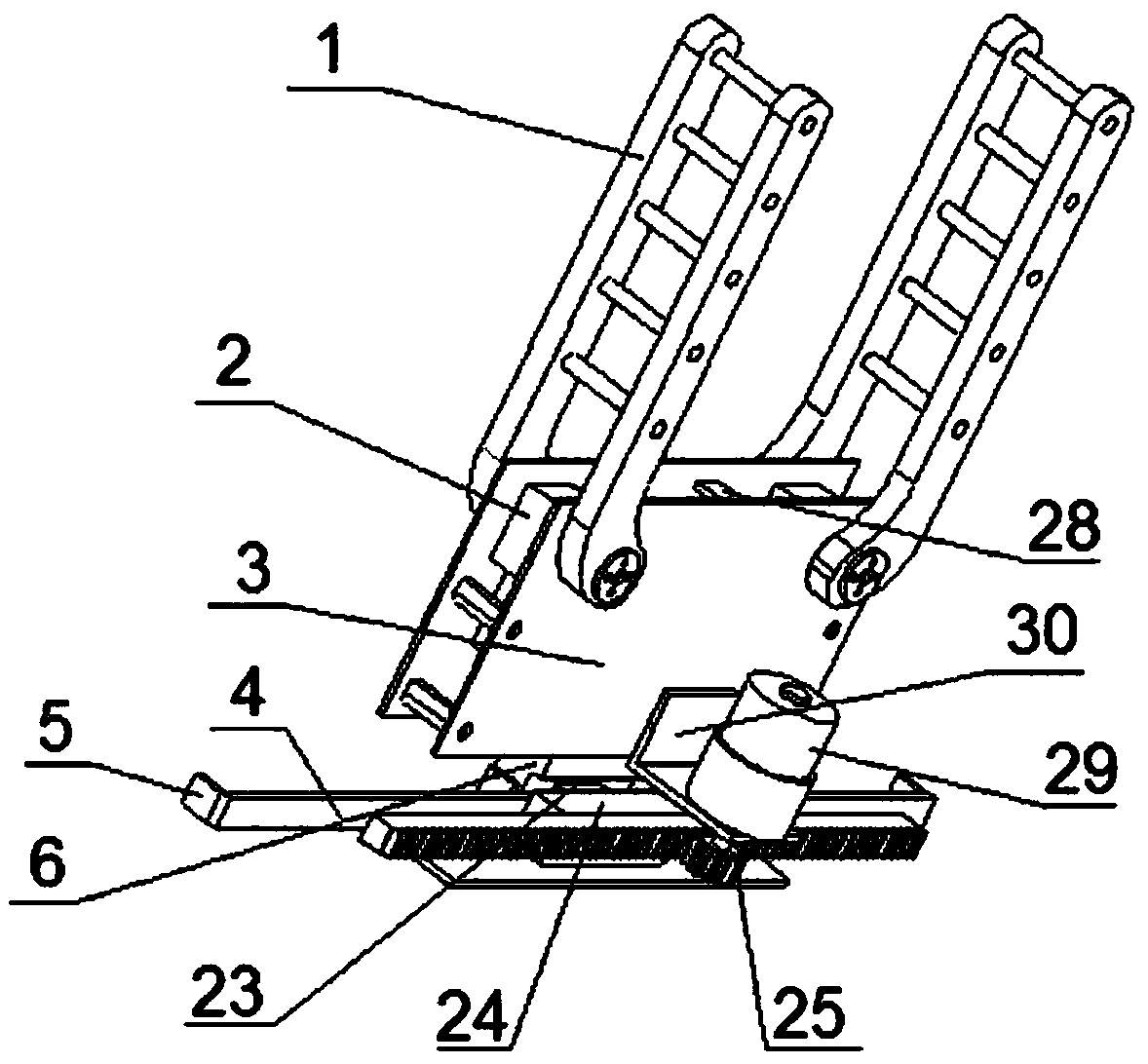

Intelligent carrying robot trolley and management method thereof

InactiveCN108436907AImprove securityLow failure rateProgramme-controlled manipulatorGripping headsLaser sensorAutonomation

The invention provides an intelligent carrying robot trolley and a management method thereof. The intelligent carrying robot trolley comprises a grabbing mechanism, a lifting mechanism and an intelligent trolley, wherein the grabbing mechanism comprises a pneumatic hand grab, a robot, a material box and an infrared scanner; the lifting mechanism comprises a lifting table and a hydraulic cylinder;the intelligent trolley comprises an intelligent trolley system, an installation plate, a signal lamp, a signal transmitter, an anti-collision bar, a buzzer, a charging port, a laser sensor, a laser sensor installation plate and a path planning module; the grabbing mechanism is arranged above the lifting mechanism; an upper panel is arranged between the grabbing mechanism and the lifting mechanism; the lifting mechanism is arranged above the intelligent trolley; and a lower bottom plate is arranged between the lifting mechanism and the intelligent trolley. The intelligent carrying robot trolley and the management method thereof provided by the invention solve the problem that a large number of manpower resources are wasted since processes such as detecting, assembling, disassembling, sorting, carrying and stacking are carried out by using a large number of manpower in the logistics and express delivery industries, and realizes intelligence, automation, and automatic managerial statistics.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

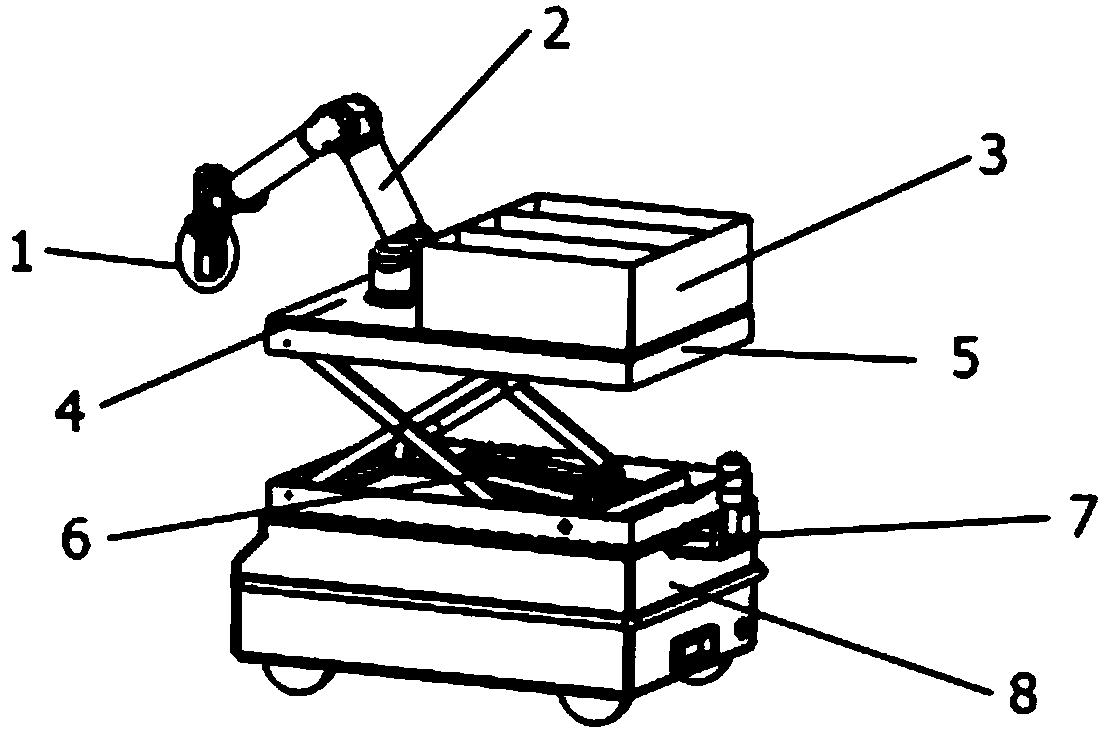

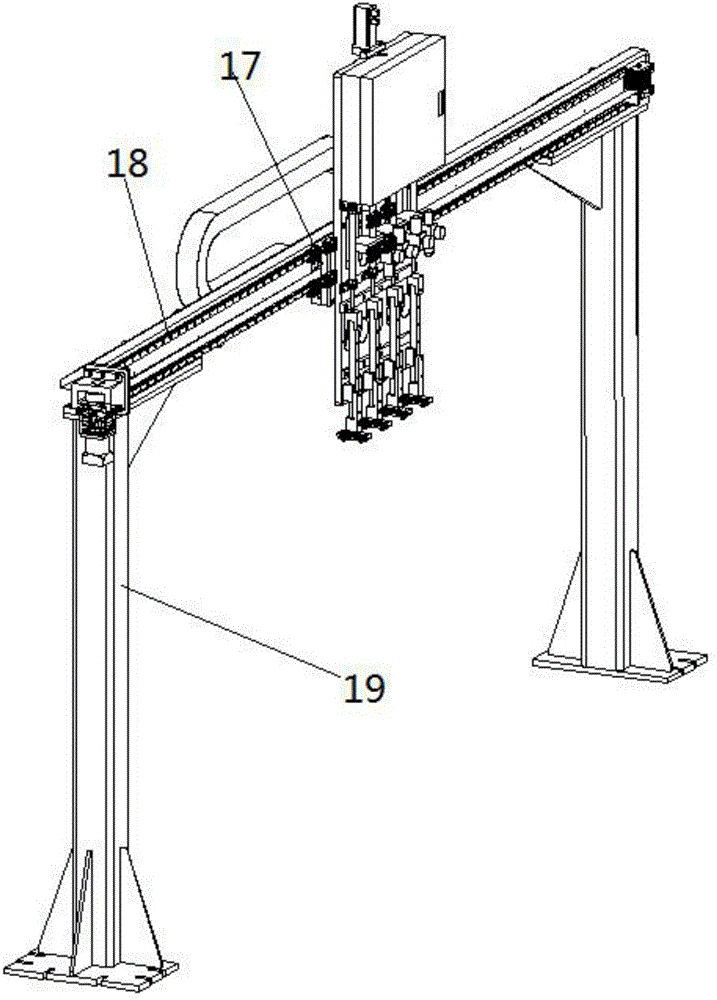

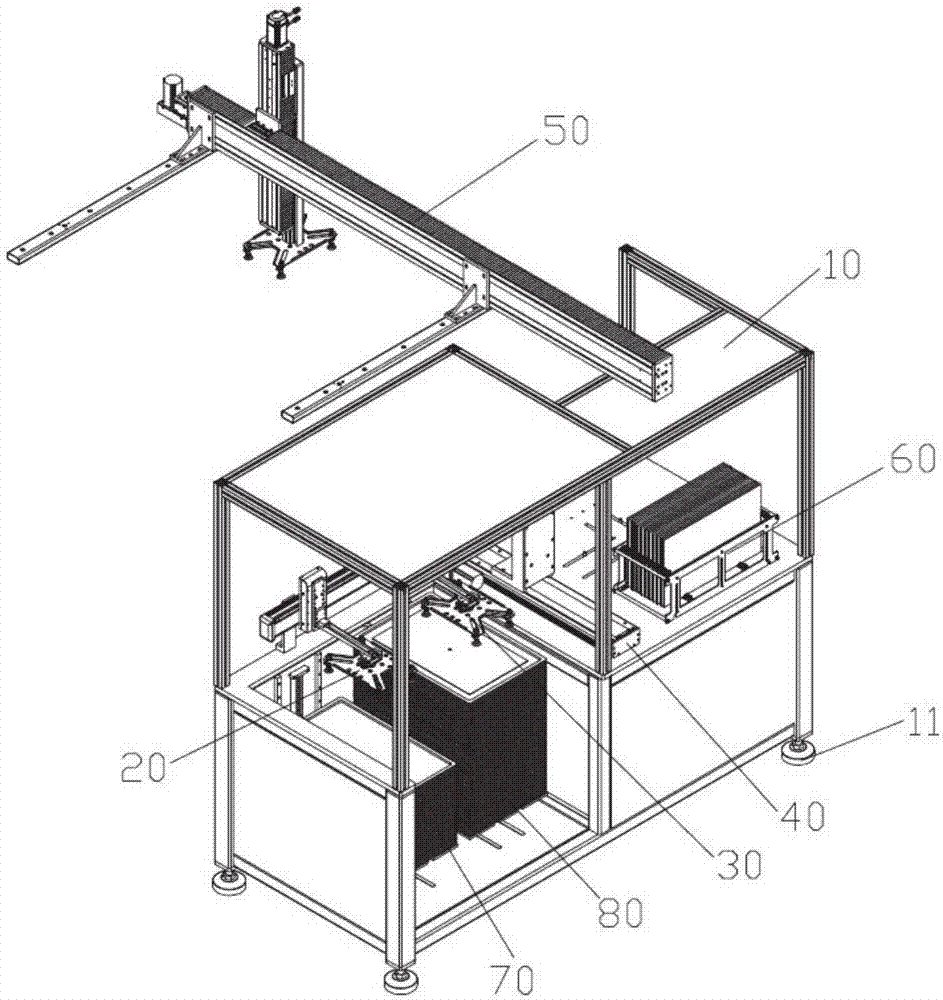

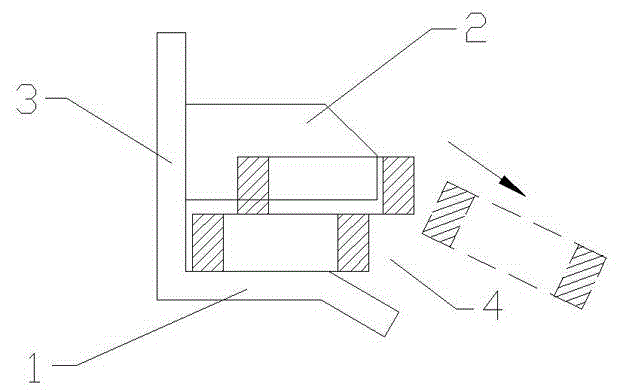

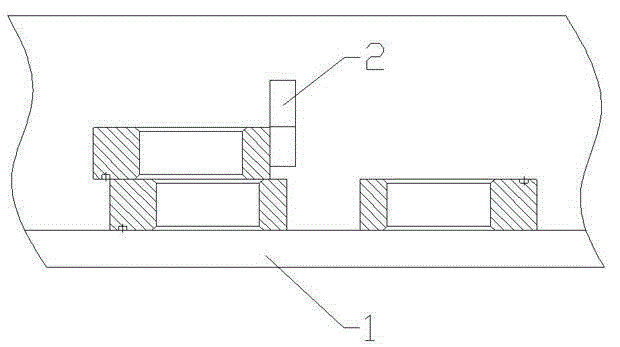

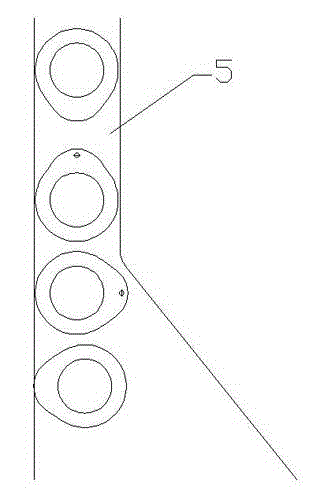

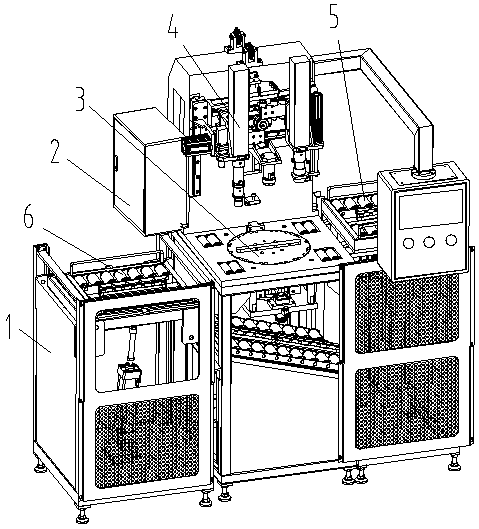

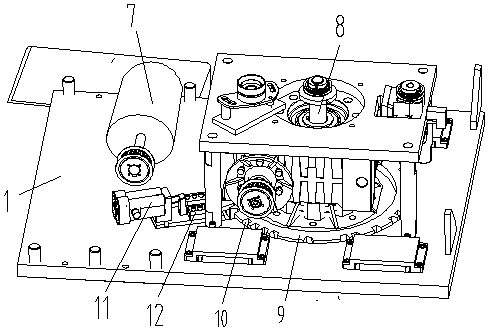

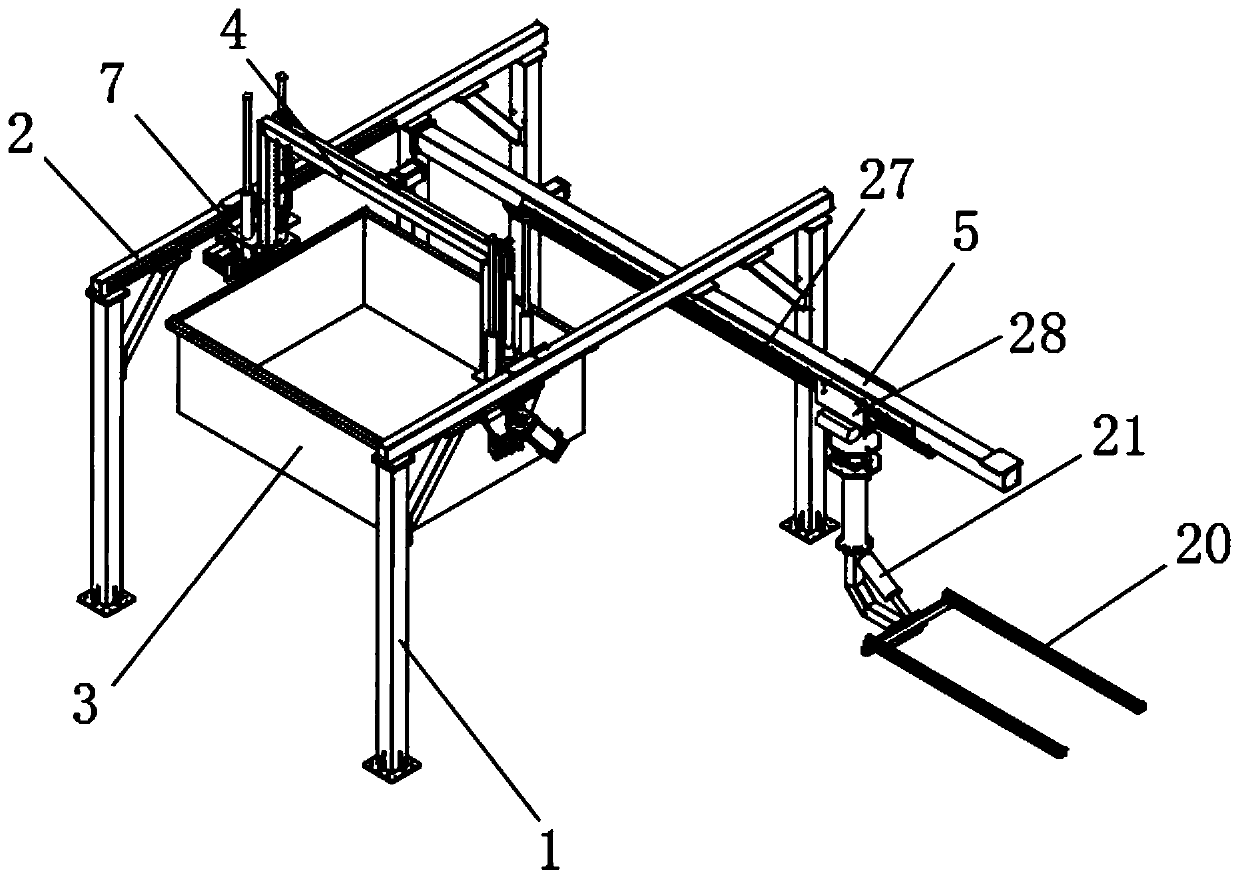

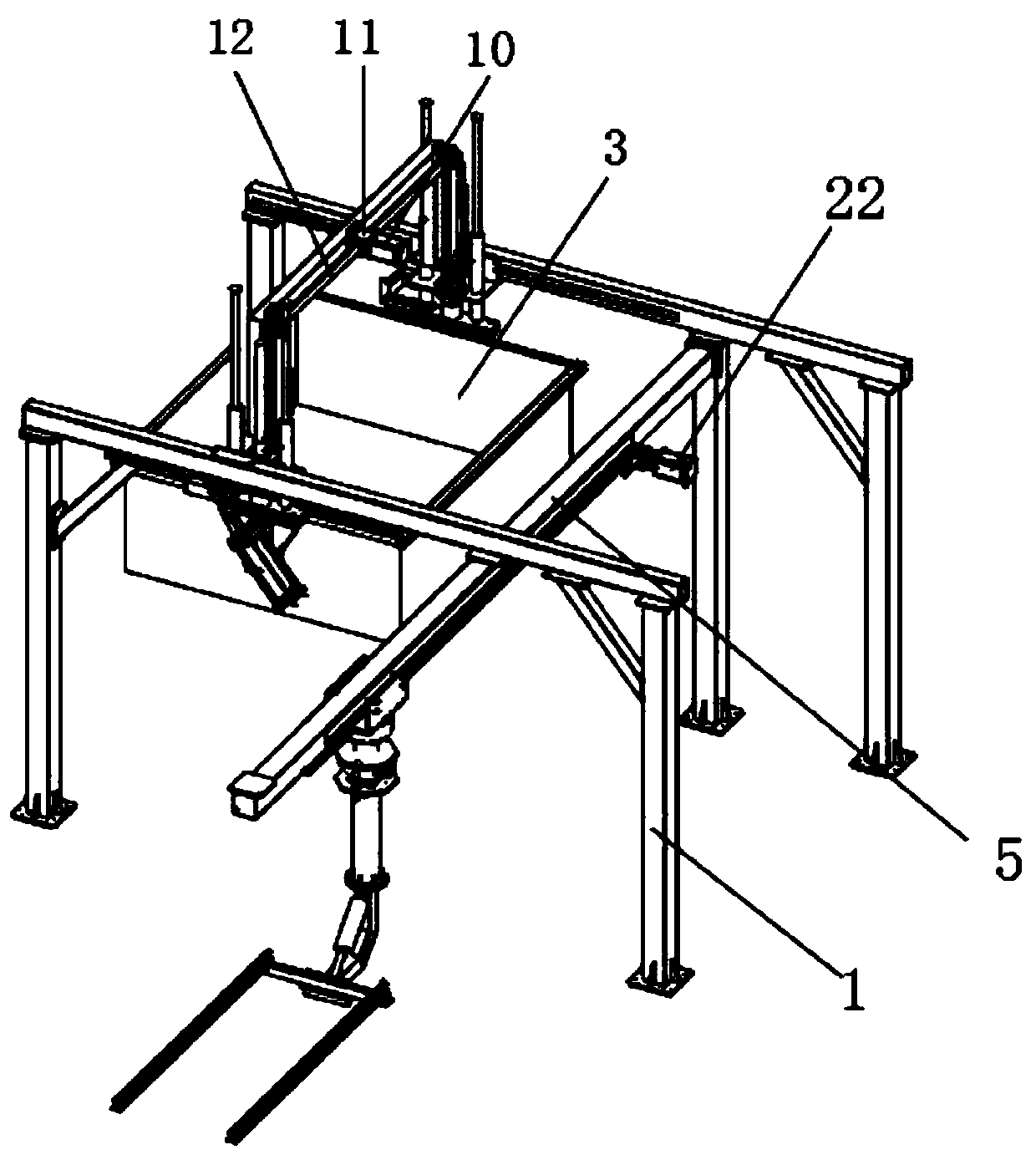

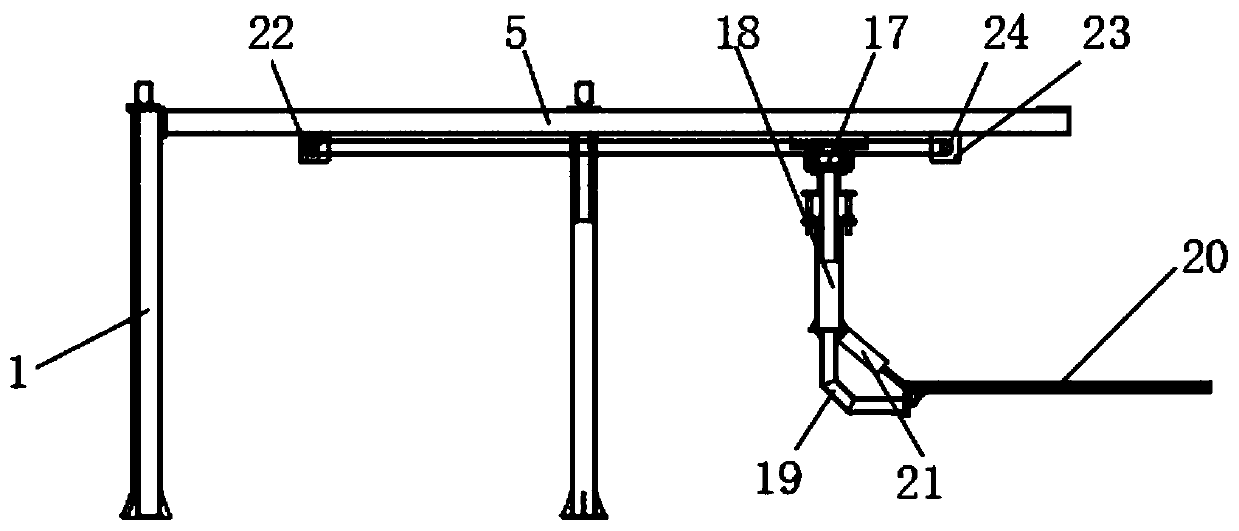

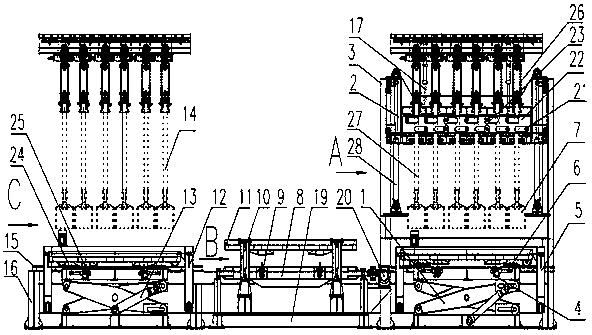

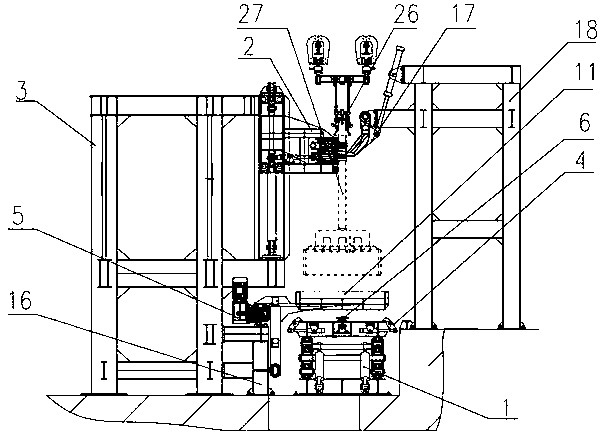

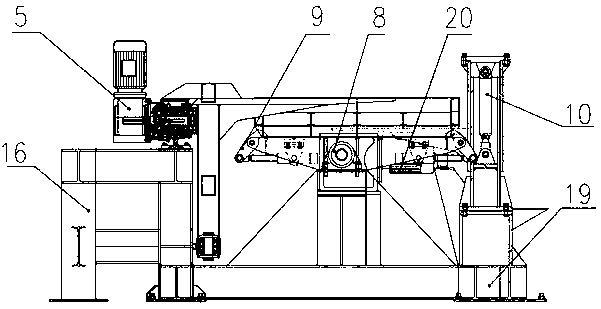

Full-automatic feeding and discharging equipment for engraving and milling machine

ActiveCN106081619APrecise loading and unloadingPrecise positioningCharge manipulationConveyor partsEngravingSlide plate

The invention discloses a full-automatic feeding and discharging device for a engraving and milling machine. The full-automatic feeding and discharging device equipment comprises a manipulator device and a storage bin device. The manipulator device comprises a fixed portal fixing frame which comprises a left stand column, a right stand column and a cross beam mounted at the top ends of the left stand column and the right stand column. A transverse guide rail, which is arranged in the transverse direction, is fixedly mounted on the cross beam. A transverse sliding seat, which can slide in the transverse direction, is arranged on the transverse guide rail. A transverse driving mechanism, which drives the transverse sliding seat, is mounted at one end of the transverse guide rail. A longitudinal sliding seat, which can slide in the longitudinal direction, is arranged on the transverse sliding seat. The storage bin device comprises a machine table. A Y-axis sliding plate, which can slide in the Y-axis direction, is arranged on the machine table, and is driven by a Y-axis motor mounted on the machine table. Multiple groups of discharging and clamping units, which are parallely arranged at an equal interval, are mounted on the Y-axis sliding plate. The full-automatic feeding and discharging device is suitable for the engraving and milling machine is particularly suitable for machining mobile phone glass, and can realize full-automatic and accurate feeding and discharging, manpower is not required, the labor cost is reduced greatly, and besides, compared with a general manipulator, the full-automatic feeding and discharging device is more stable in structure, and more accurate in positioning.

Owner:东莞市小智人机器人有限公司

Automatic material loading equipment

PendingCN106976342APrecise loading and unloadingNo manualOther artistic work equipmentsManipulatorMachineManipulator

The invention discloses automatic material loading equipment. The automatic material loading equipment comprises a machine frame, a recycling manipulator, a positioning manipulator, a finished product manipulator and a material loading manipulator which is connected with a precise engraving machine; a positioning area is formed on the machine frame; after a workpiece on a material box is transferred to the positioning area by the positioning manipulator, the material box is taken away by the recycling manipulator; the workpiece is moved to the precise engraving machine for machining by the material loading manipulator; the workpiece which is machined on the material loading manipulator is taken out by the finished product manipulator. After the technical scheme is adopted, precise loading and unloading are realized without manpower, the labour cost is greatly reduced, and the automatic material loading equipment is suitable for batch production because the recycling manipulator, the positioning manipulator, the finished product manipulator and the material loading manipulator are arranged on the equipment.

Owner:深圳市宇瀚智慧装备科技有限公司

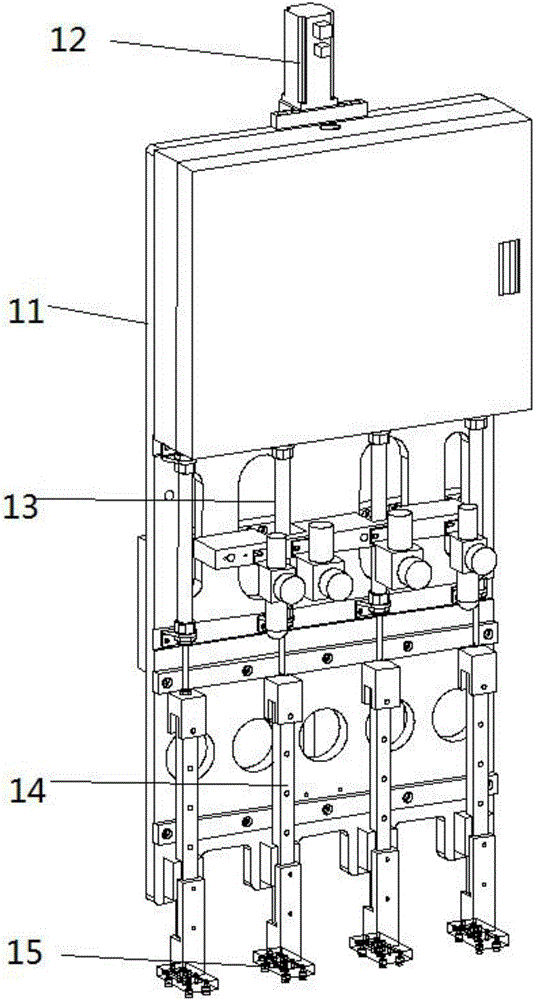

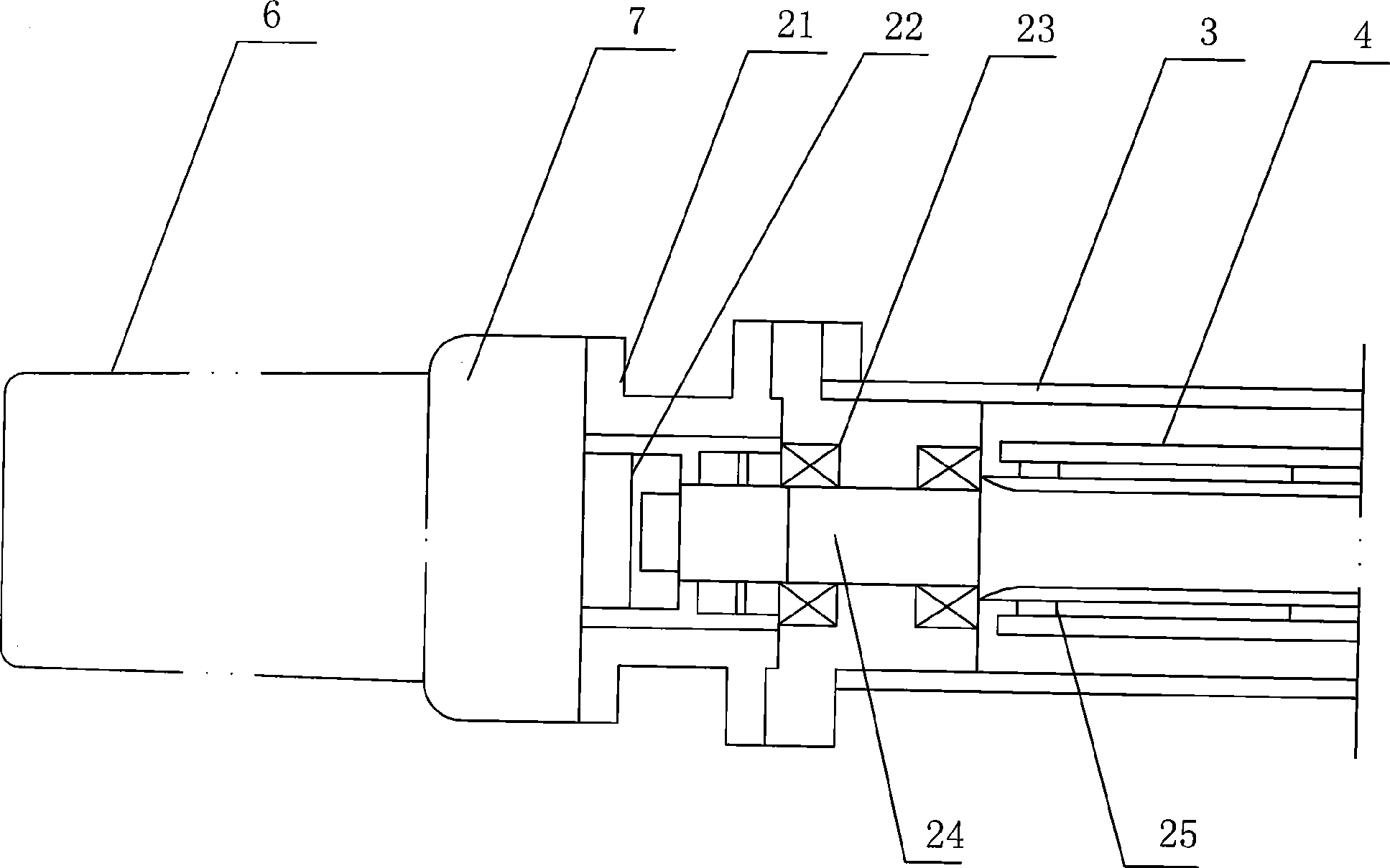

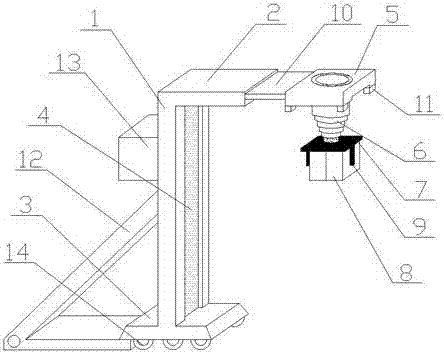

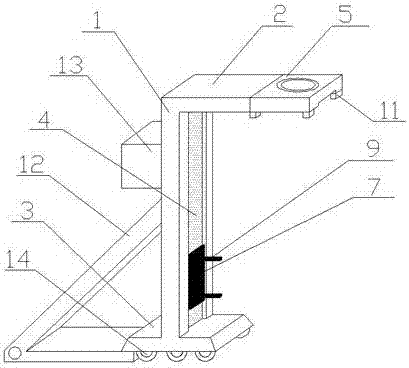

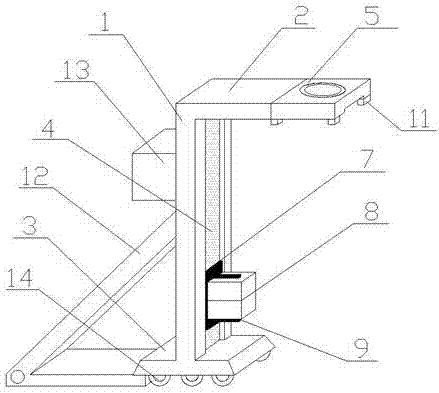

Electric lifting device

The invention discloses an electric hoisting device, which comprises a substrate, a main arm, a cross arm, a hoisting mechanism, a telescopic arm and a rotating main shaft, wherein an electric rotating mechanism is arranged between the substrate and the main arm; the electric rotating mechanism comprises a driving motor I, a speed reducer I, a driving gear, a rotating disk and a gear ring which is fixedly connected with the outer wall of a center hole I of the substrate, the output shaft end of the driving motor I is connected with the speed reducer I, the speed reducer I is fixedly connected with the rotating disk, the lower end of an output shaft of the speed reducer I is fixedly connected with the driving gear, and the driving gear is meshed with the gear ring; and the rotating main shaft is fixedly connected with a center hole II of the rotating disk, and the lower end of the main arm is fixedly connected with the upper end face of the rotating disk. The electric hoisting device can make the main arm automatically rotate and can control the position in real time. The electric hoisting device also comprises an electric telescopic mechanism which can operate the flexibility of the telescopic arm to carry out charging and discharging operation on goods with high difficulty and accurate position according to the distance for charging and discharging the goods.

Owner:NINGBO ELEVATOR WINCH MFG

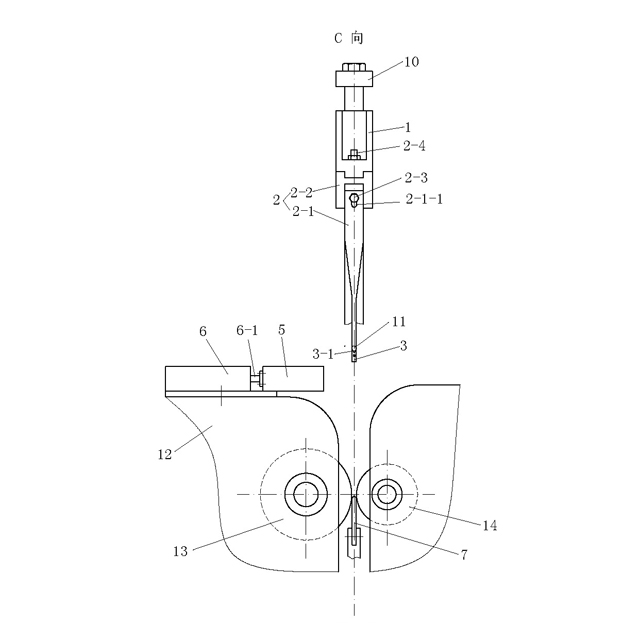

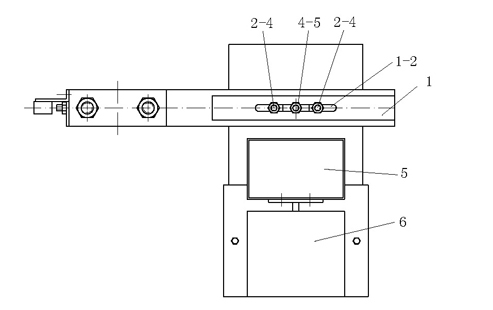

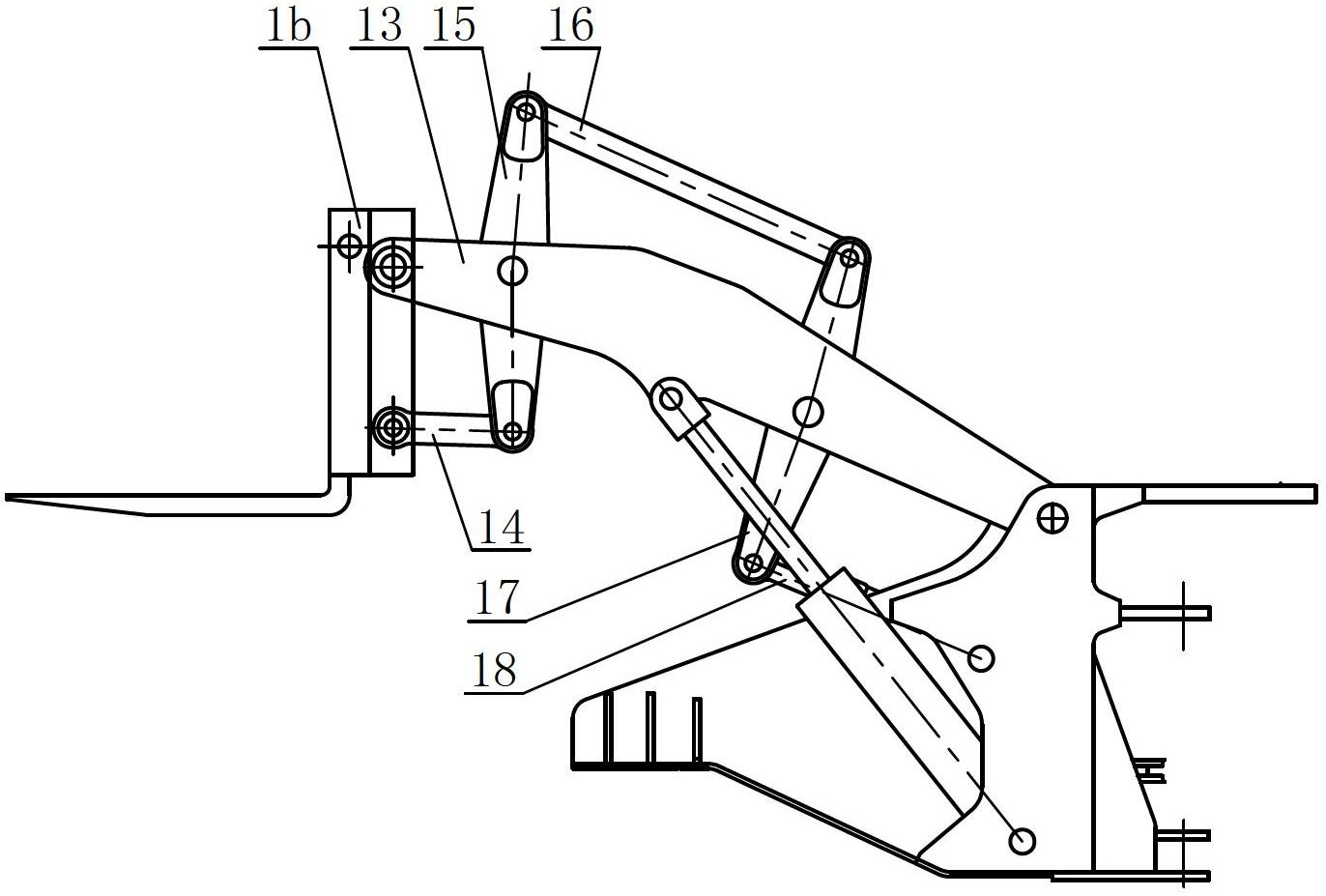

Mechanical arm device of centerless grinding machine

ActiveCN102069430AAvoid runoutRealize profilingProgramme-controlled manipulatorRevolution surface grinding machinesHydraulic cylinderRobotic arm

The invention discloses a mechanical arm device of a centerless grinding machine, which comprises a supporting plate, a bracket fixed on a main machine rack, a hydraulic cylinder fixed on the lower part of the bracket, a pair of guide pillars fixed on the upper part of the bracket and a lifting seat for driving the pair of guide pillars to slide by a piston rod of the hydraulic cylinder. A pair of mechanical arms for arranging work pieces on the supporting plate is arranged on the lifting seat. The thicknesses of the lower parts of the two mechanical arms are smaller than that of the work piece. An elastic pressure plate component is arranged between the two mechanical arms on the lifting seat. The device has a simple structure; and the pair of mechanical arms supports the two ends of each work piece to realize loading and unloading, and is driven by the hydraulic cylinder, so that the loading and unloading are more stable and accurate and entire-shaft profiling can be realized. The device solves the problem that the conventional centerless grinding machine cannot machine a combined slender shaft consisting of a plurality of concentric cylinders with different diameters, and compared with the conventional device utilizing ordinary external grinding, improves the machining accuracy and reduces the rejection rate.

Owner:常州市武滚轴承有限公司

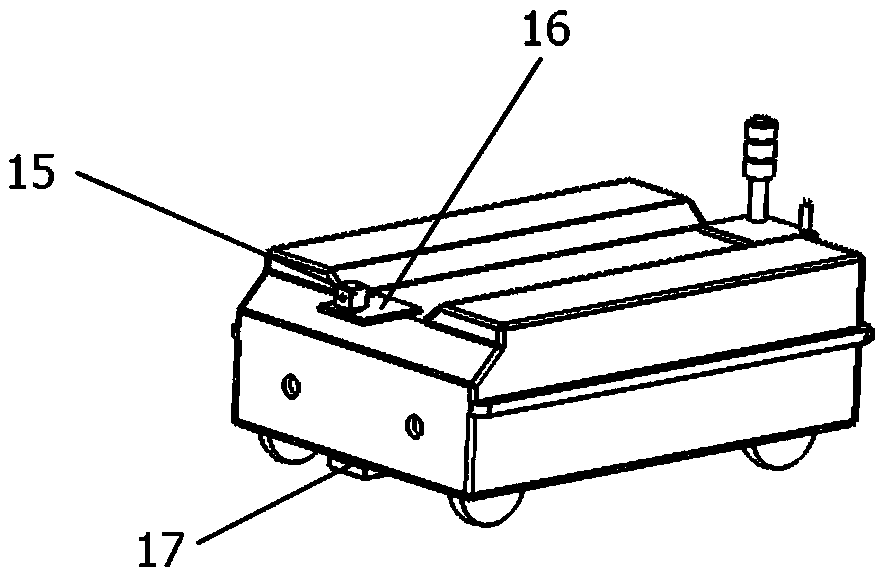

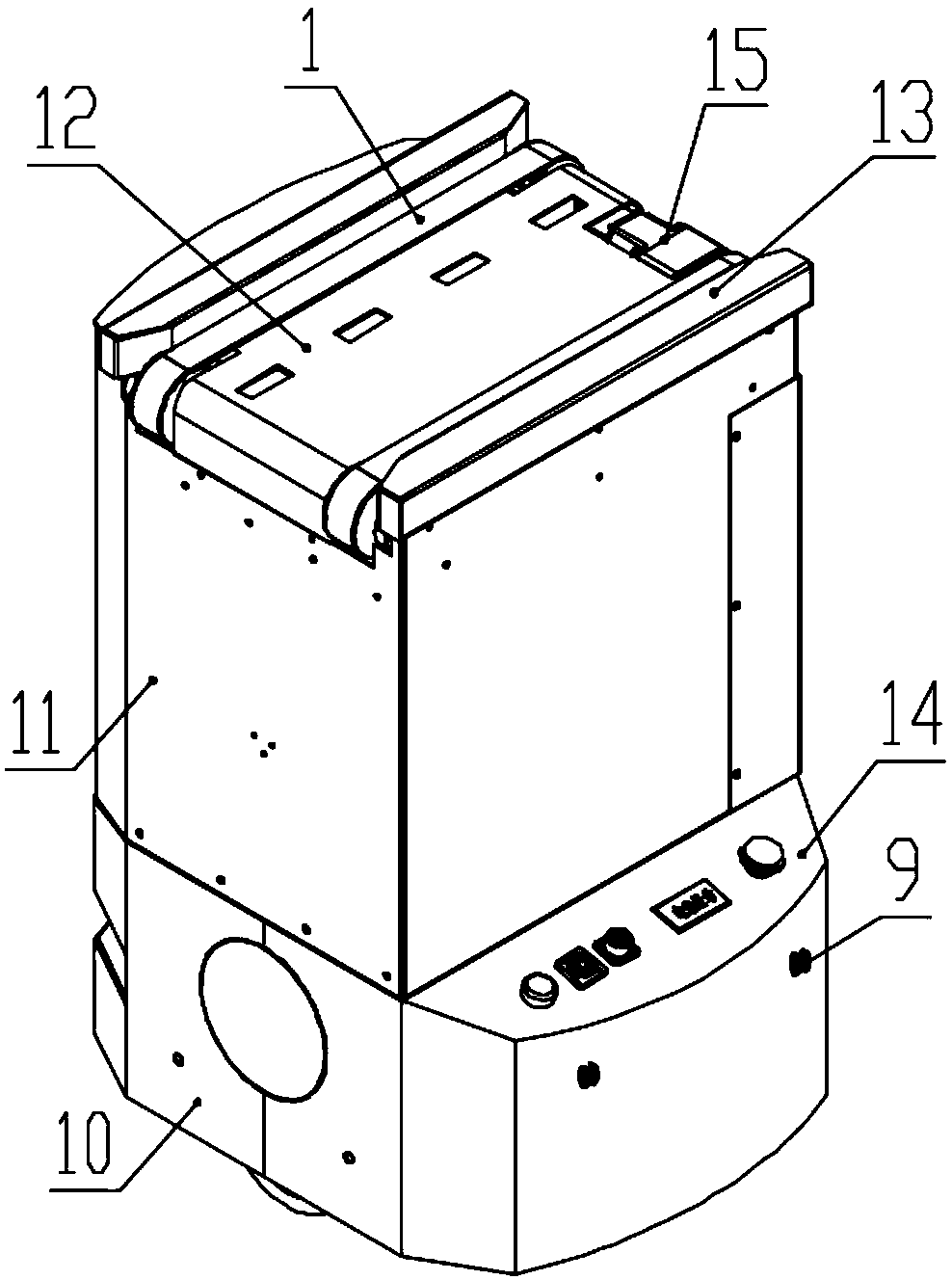

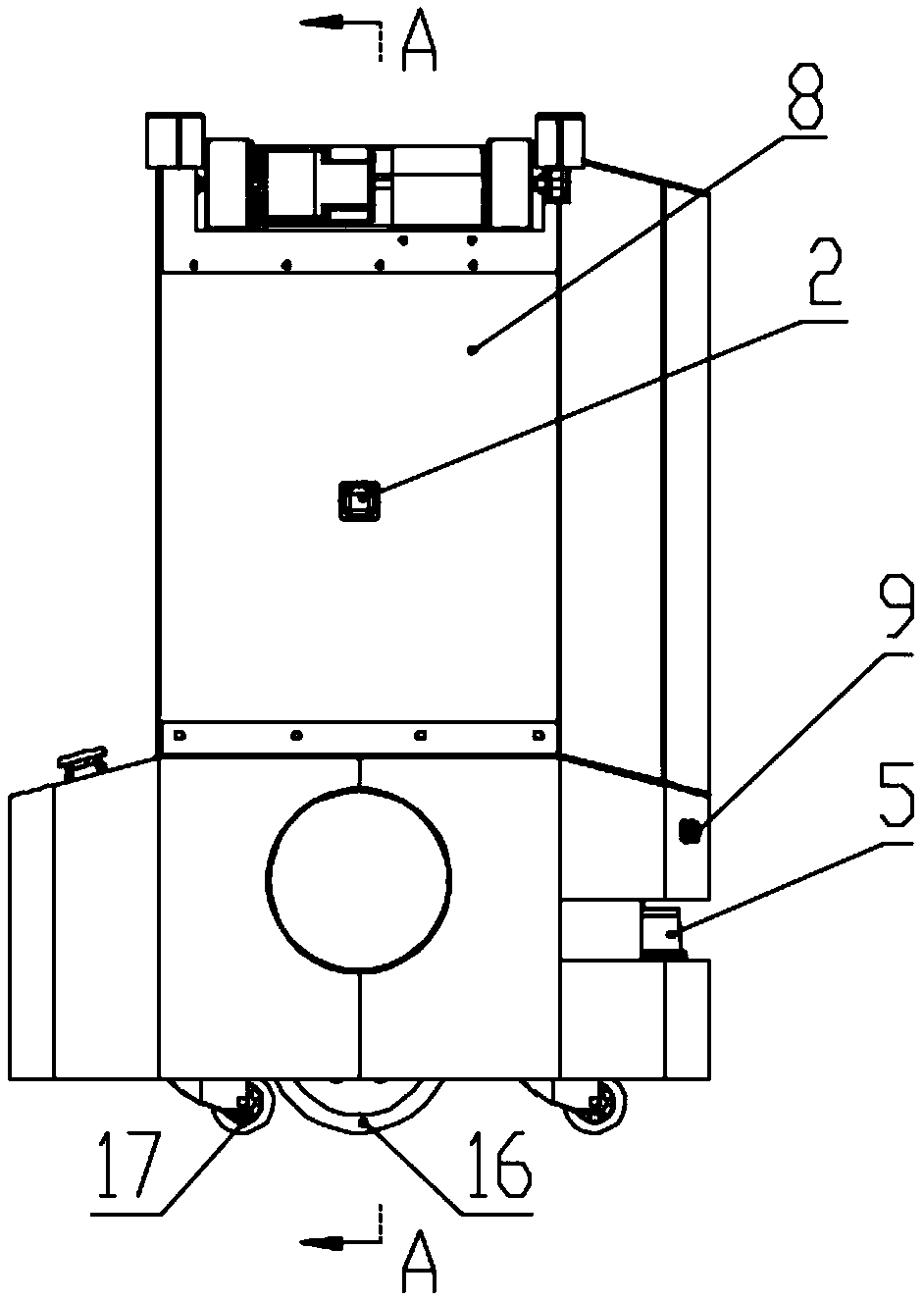

Transportation robot based on laser/vision integrated navigation

PendingCN109278894AAdjust paths in real timePrecise positioningVehicle componentsPosition/course control in two dimensionsVehicle frameRadar

The invention relates to a transportation robot based on laser / vision integrated navigation. The transportation robot comprises a wheeled machine frame and an upper case frame mounted on the wheeled machine frame, wherein a laser radar is mounted on the front side of the wheeled machine frame; ultrasonic radars are mounted on the front side and the rear side of the wheeled machine frame; a controlpanel is arranged on the wheeled machine frame and positioned behind the upper case frame; the left side of the upper case frame is set as a transparent window; a high-definition camera is arranged on the back side of the transparent window; a conveying mechanism arranged along the left-right direction is arranged on the top side of the upper case frame; a control module and a traveling system are also arranged inside the wheeled machine frame; and the control module is separately connected to the traveling system, the laser radar, the ultrasonic radars, the control panel, the high-definitioncamera and the conveying mechanism. The transportation robot based on the laser / vision integrated navigation according to the invention improves the navigation precision to 10 mm, and is highly precision in stopping and accurate in loading and unloading.

Owner:KUNSHAN GUIBU ROBOT TECH CO LTD

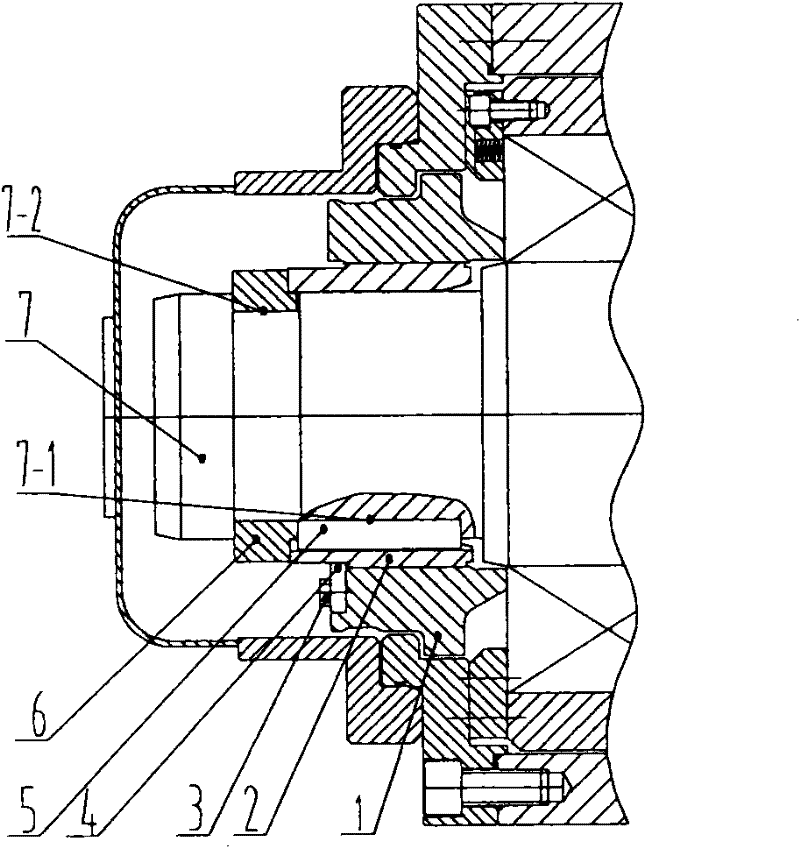

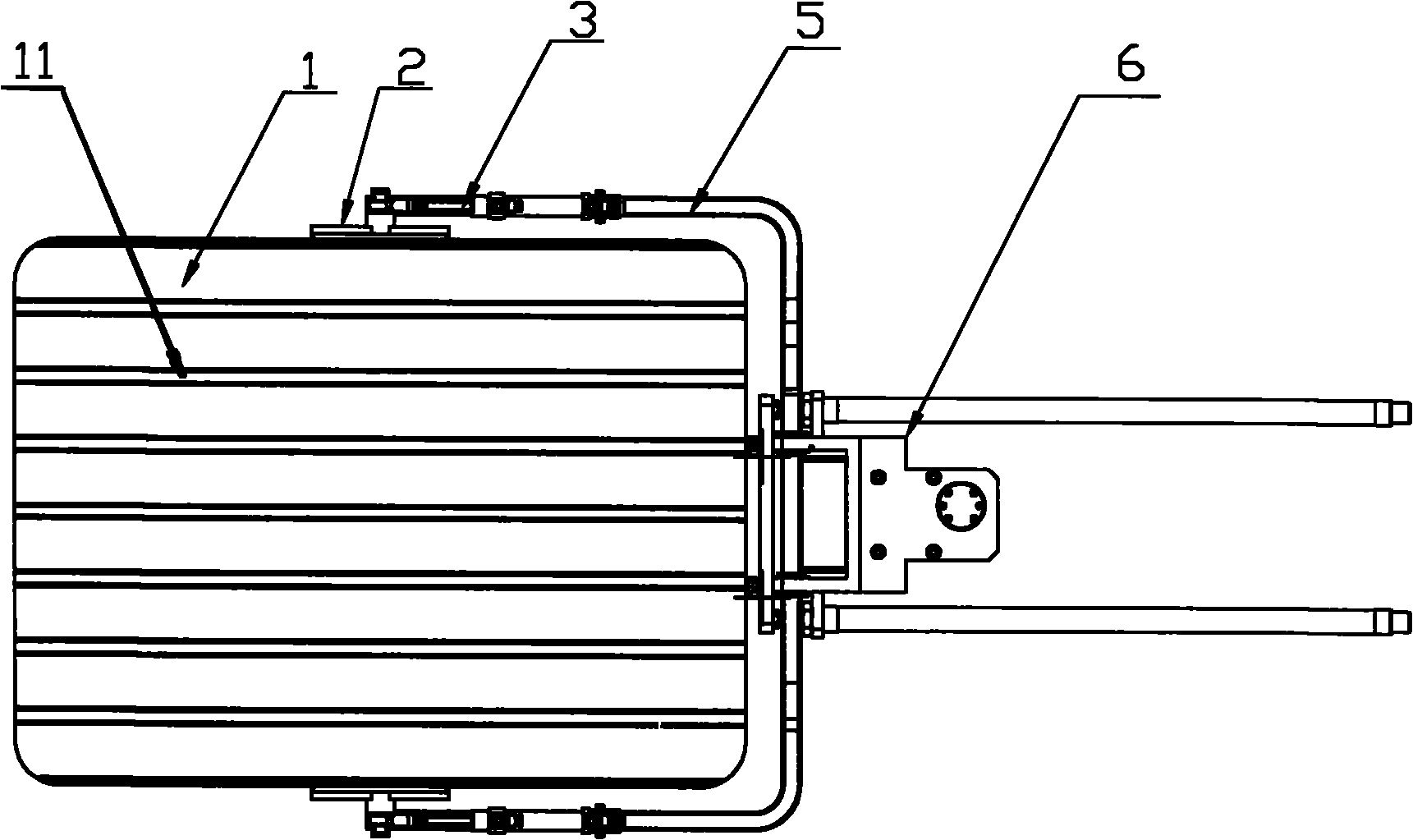

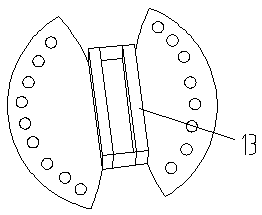

Hydraulic rapid locking device for oil film bearing

InactiveCN102230499APrecise loading and unloadingOperational securityBearing unit rigid supportHydraulic cylinderHydraulic brake

The invention relates to a hydraulic rapid locking device for an oil film bearing. The locking device comprises a short pattern hydraulic cylinder, a locking plate, a square key, a snap ring assembly etc., wherein the short pattern hydraulic cylinder comprises a cylinder sleeve, a piston, a cylinder cover, a nut, a sealing and a quick-change joint, etc. The locking device is characterized by changing a machinery locking into a hydraulic locking, wherein an original roller structure is maintained, and the machinery locking is changed into the hydraulic locking by utilizing present space; and a locking nut and a volution are omitted to change into a short pattern hydraulic cylinder structure. While loading and unloading of the oil film bearing, the quick-change joint on a hydraulic tool is connected to the short pattern hydraulic cylinder to start the hydraulic tool; pressure oil enters into a locking oil pocket or a dismounting oil pocket; and a locking pressure and a dismounting pressure are controlled quantificationally to complete bearing locking or dismounting. The locking device has effects of convenient loading and unloading, accurate quantification, rapidness and safety.

Owner:TAIYUAN HEAVY IND

Balance weight type rear steering forklift

InactiveCN102700633AEasy to viewPrecise loading and unloadingLifting devicesTractor-trailer combinationsVehicle frameEngineering

The invention discloses a balance weight type rear steering forklift. The balance weight type rear steering forklift comprises a front frame, a rear frame, a working device, a cab, an engine, a torque converter and a gearbox, and is characterized in that the front frame and the rear frame are hinged through a pin shaft, the hinged point is close to rear wheels, and two steering cylinders capable of pushing the rear frame to horizontally rotate relative to the front frame are symmetrically mounted between the front frame and the rear frame; and the working device, the cab, the engine, the torque converter, the gearbox and an upper balance weight are mounted on the front frame, and a lower balance weight is mounted on the rear frame. The balance weight type rear steering forklift is well stressed and is stable to steer after goods are loaded; the view range of a driver is wide, the goods can be accurately and quickly loaded and unloaded, and the working efficiency is high; and multiple functions are achieved.

Owner:FUJIAN FUDA MACHINERY

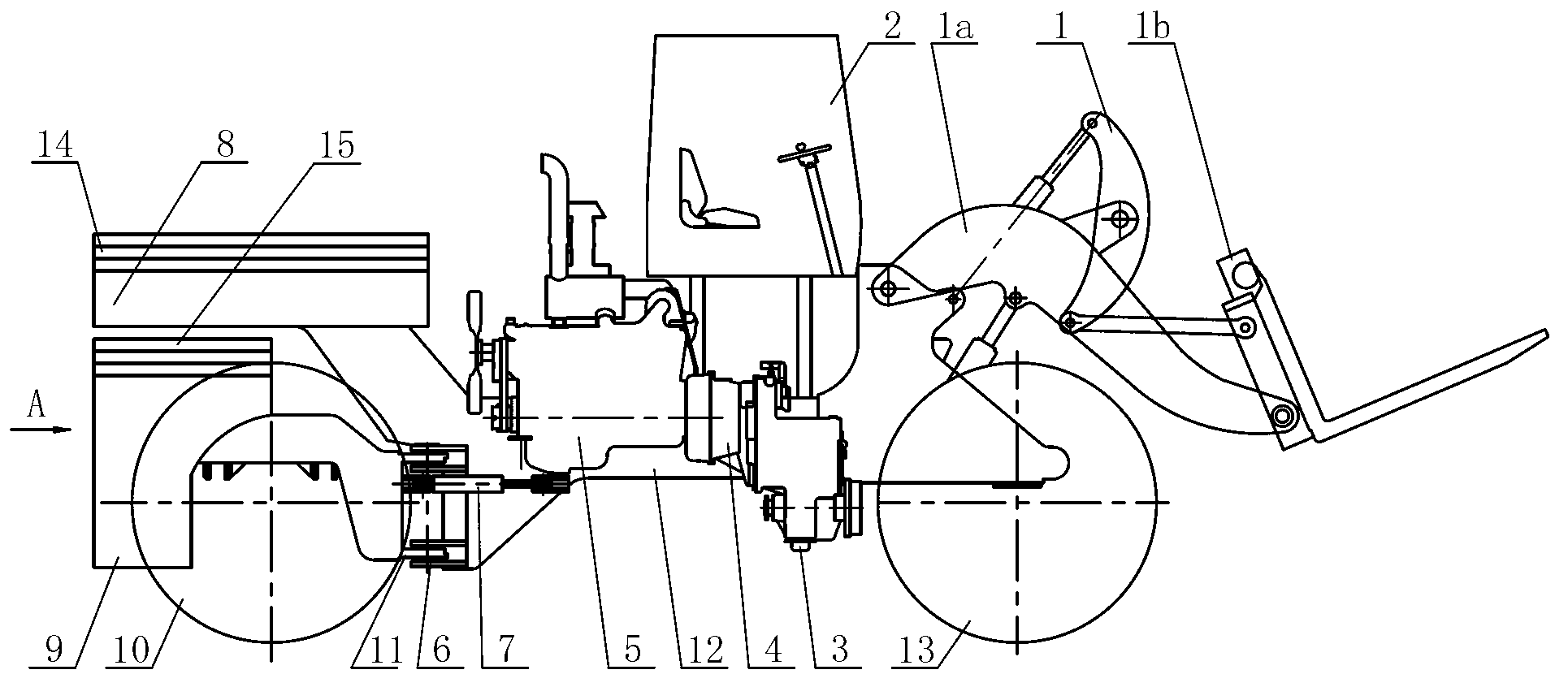

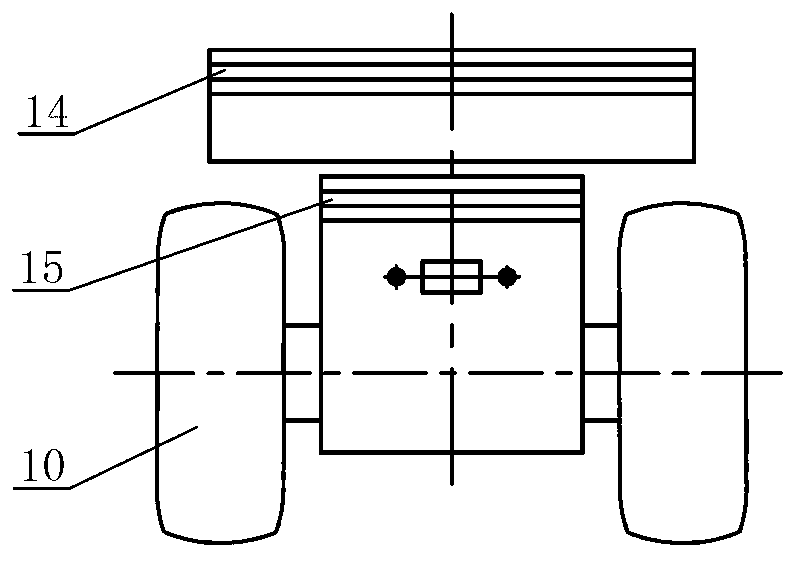

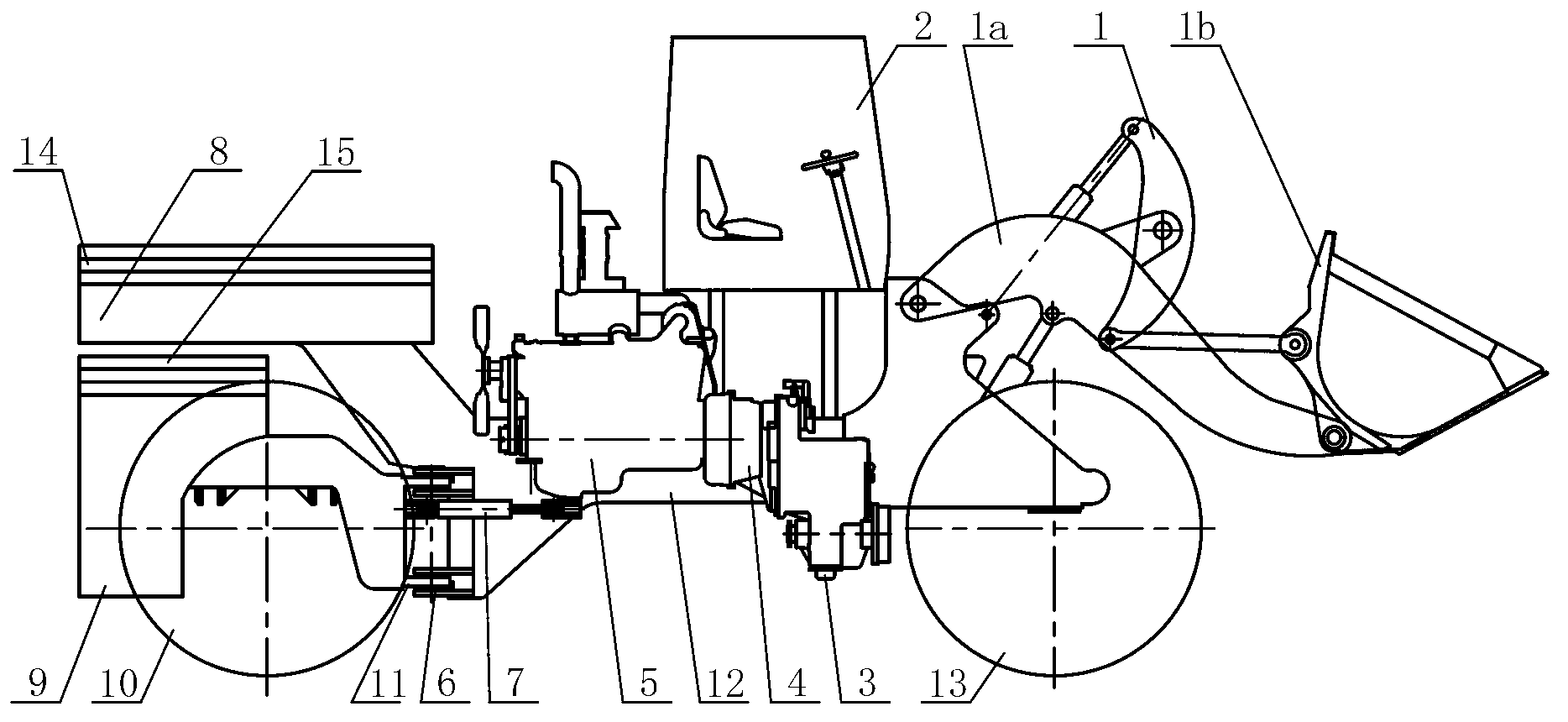

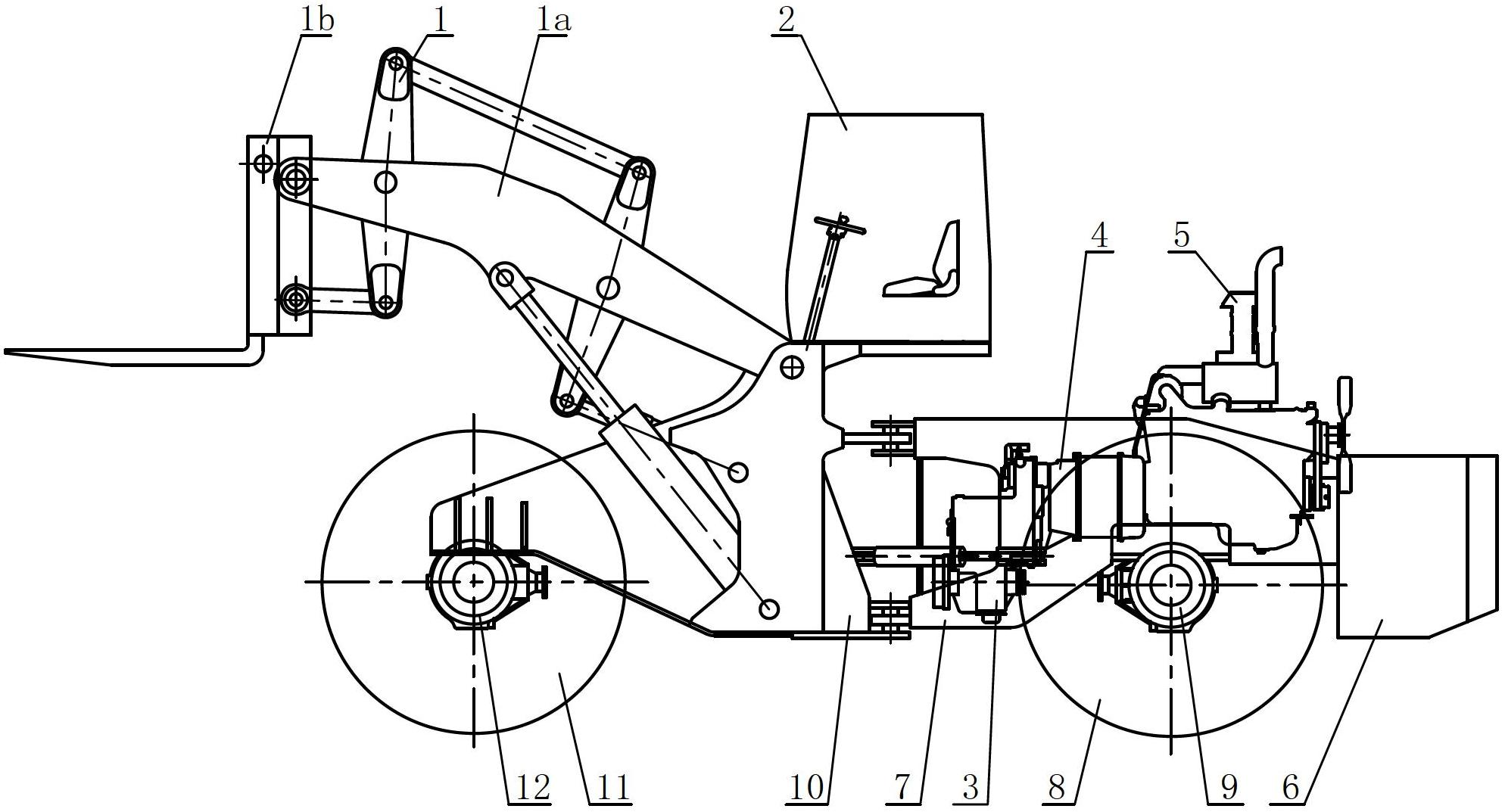

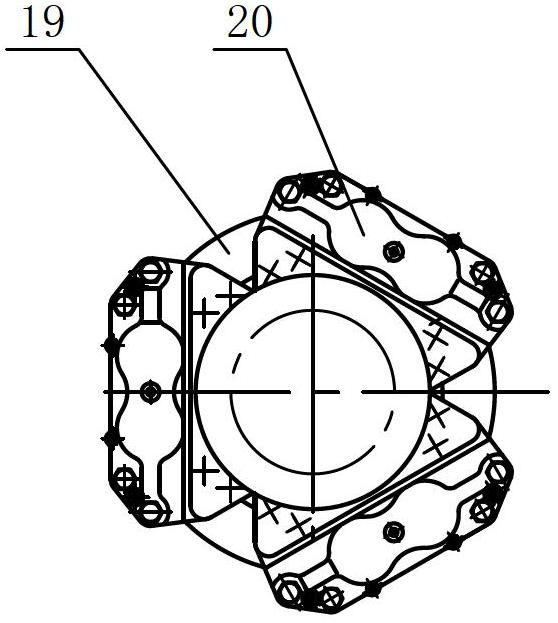

Forklift truck

ActiveCN102689856AGood viewAccurate loading and unloading of goodsLifting devicesTractor-trailer combinationsVehicle frameEngineering

The invention relates to a forklift truck, comprising a front frame, a rear frame, a working device, a steering room, an engine, a torque converter, a transmission gear, a front drive bridge and a rear drive bridge. The forklift truck is characterized in that the working device and the steering room are mounted on the front frame; the engine, the torque converter, the transmission gear and a balancing weight are mounted on the rear frame; a lift mechanism of the working device is an eight-bar mechanism; brake devices are symmetrically mounted at both ends of the drive bridge; and each of the brake devices consists of a brake disc and three brake calipers which are evenly distributed along the circumference of the brake disc. The forklift truck has the advantages of wide vision for drivers, stability in cargo loading and unloading, high quality and working efficiency, reliability in braking and multiple functions.

Owner:FUJIAN FUDA MACHINERY

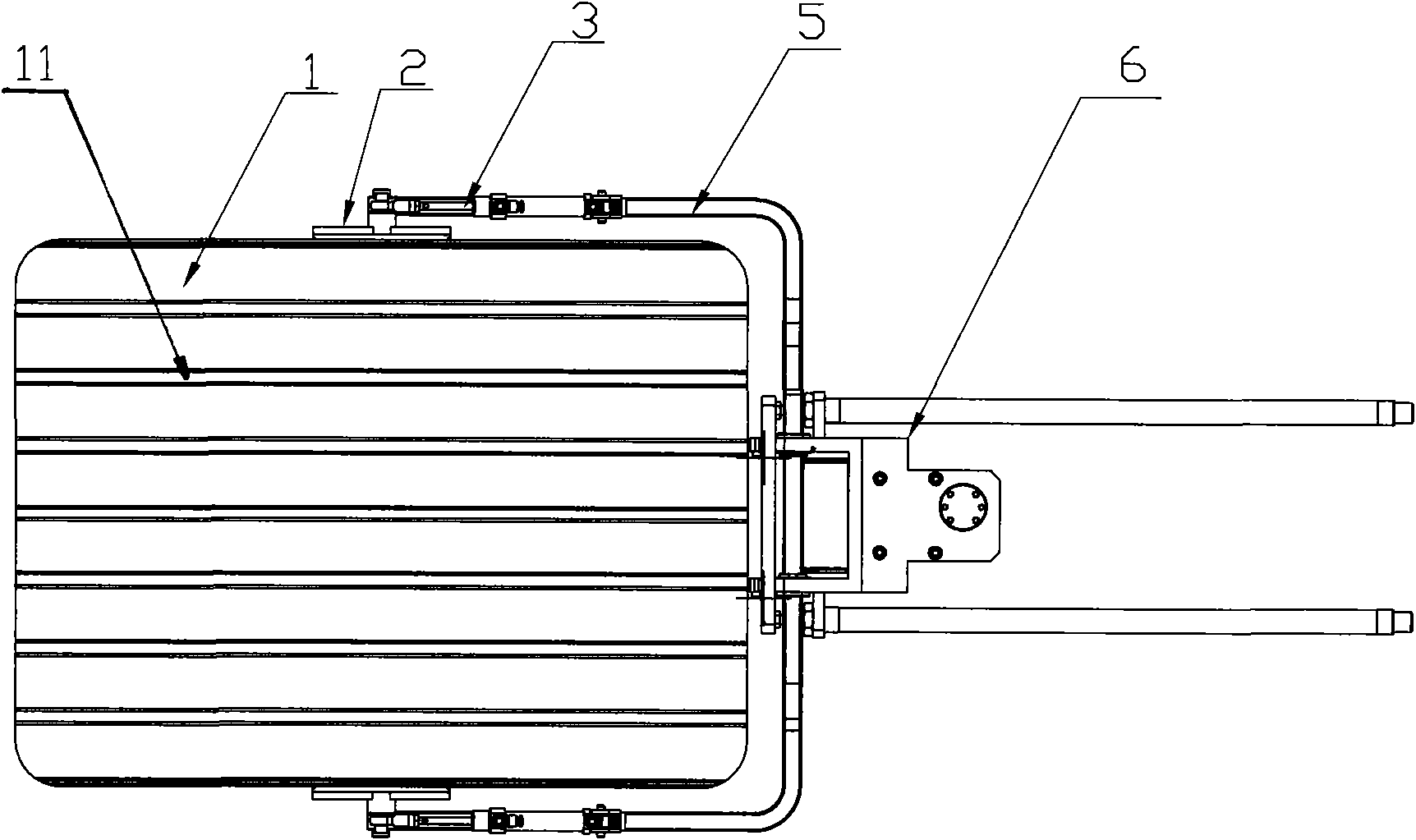

Device for assembling and disassembling tray

ActiveCN101987715AQuick loading and unloadingPrecise loading and unloadingLifting devicesStacking articlesFour-bar linkageEngineering

The invention discloses a device for assembling and disassembling a tray, which comprises a plug board, plug board shelves, a telescopic supporting rod, a permanent seat, a U-shaped supporting arm and a fixed arm. In the invention, by taking the using direction as a reference, the left side and the right side of the plug board are respectively and fixedly provided with a plug board shelf, and thelower ends of the outer side walls of the two plug board shelves are hinged with the inner side walls of the opening ends of the U-shaped supporting arm; the end wall of the U-shaped supporting arm away from the opening end is fixed and positioned at one end of the fixed arm, and the upper sides of the two side walls of the U-shaped supporting arms are respectively and fixedly provided with a permanent seat of which the upper end can be hinged with the fixed end of the telescopic supporting rod; the movable end of the telescopic supporting rod is hinged with the upper ends of the plug board shelves; and one end of the plug board close to the fixed arm can be accommodated in the inner space of the U-shaped supporting arm. In the invention, the plug board is easy to control to turn over through a four-bar linkage mechanism, thus trays can be quickly and accurately assembled and disassembled, thereby the assembly and disassembly efficiency of the trays is improved.

Owner:苏州澳昆智能机器人技术有限公司

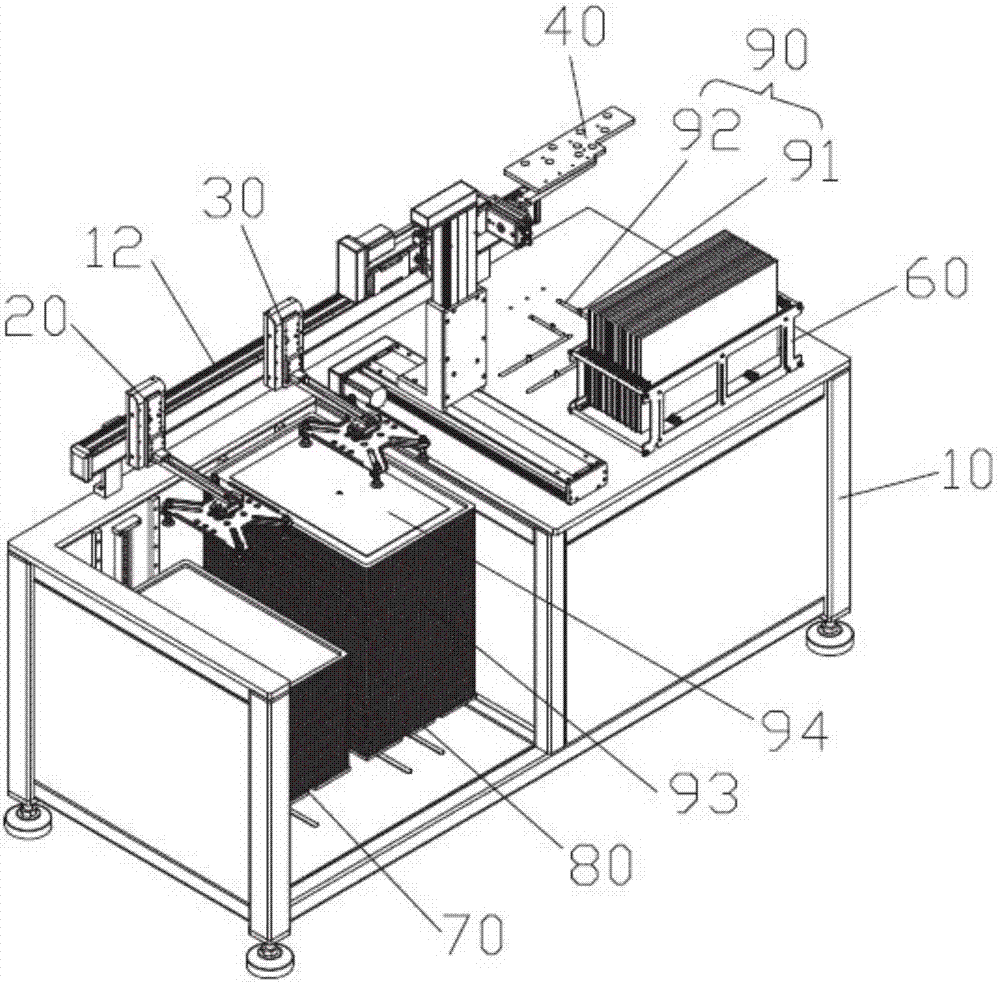

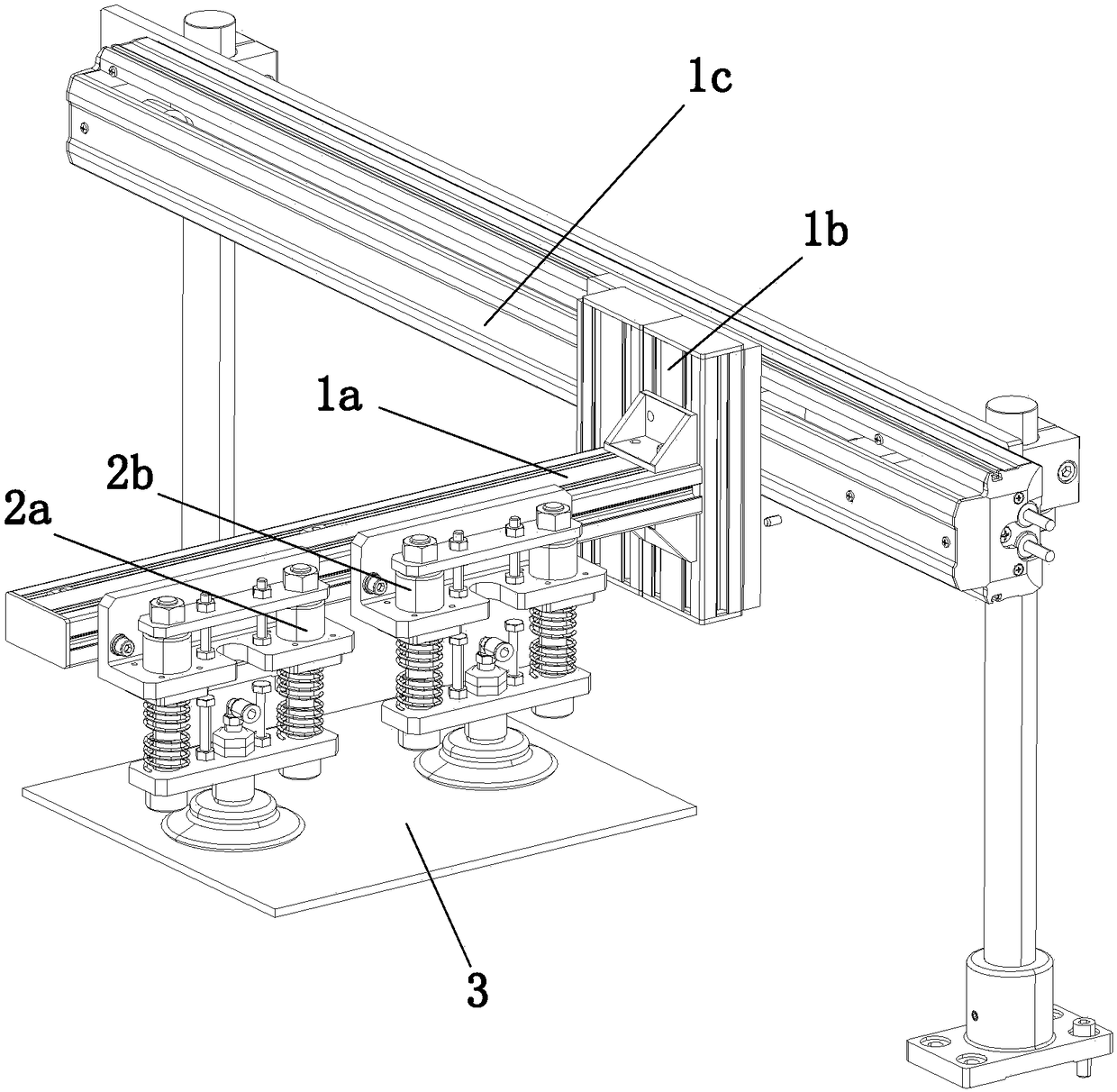

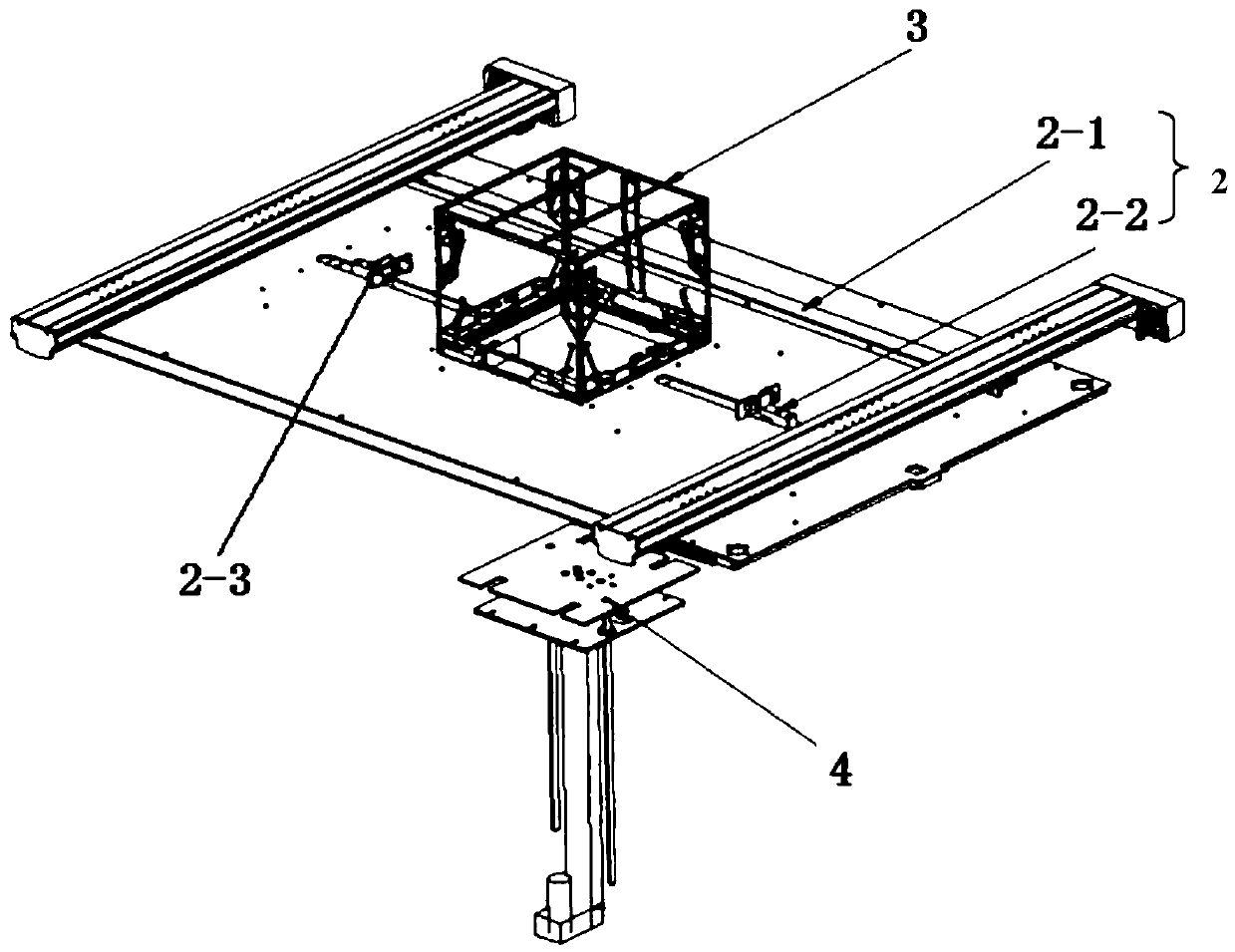

Thin sheet conveying device

InactiveCN108328323APrecise loading and unloadingReduce manufacturing costConveyorsConveyor partsMechanical engineeringThin sheet

The invention relates to the field of conveying equipment and particularly relates to a thin sheet conveying device. The thin sheet conveying device comprises a sucking device, a conveying device anda control device; the sucking device is matched with the conveying device in a transmission manner; the sucking device and the conveying device are both electrically connected with the control device;the sucking device comprises a first sucking mechanism and a second sucking mechanism which are arranged in a spaced manner; the conveying device comprises a first driving component, a second drivingcomponent and a third driving component, wherein the first driving component is used for driving the sucking device to move in the X-axis direction; the second driving component is used for driving the sucking device and the first driving component to move in the Z-axis direction; the third driving component is used for driving the sucking device, the first driving component and the second driving component to move in the Y-axis direction; the control device comprises a controller and a sensor component; and the sensor component is electrically connected with the controller. The thin sheet conveying device provided by the invention can realize precise feeding and discharging of thin sheets, saves a limiting mechanism and lowers the production cost.

Owner:YUNHEMAN WALKER TOYS CO LTD

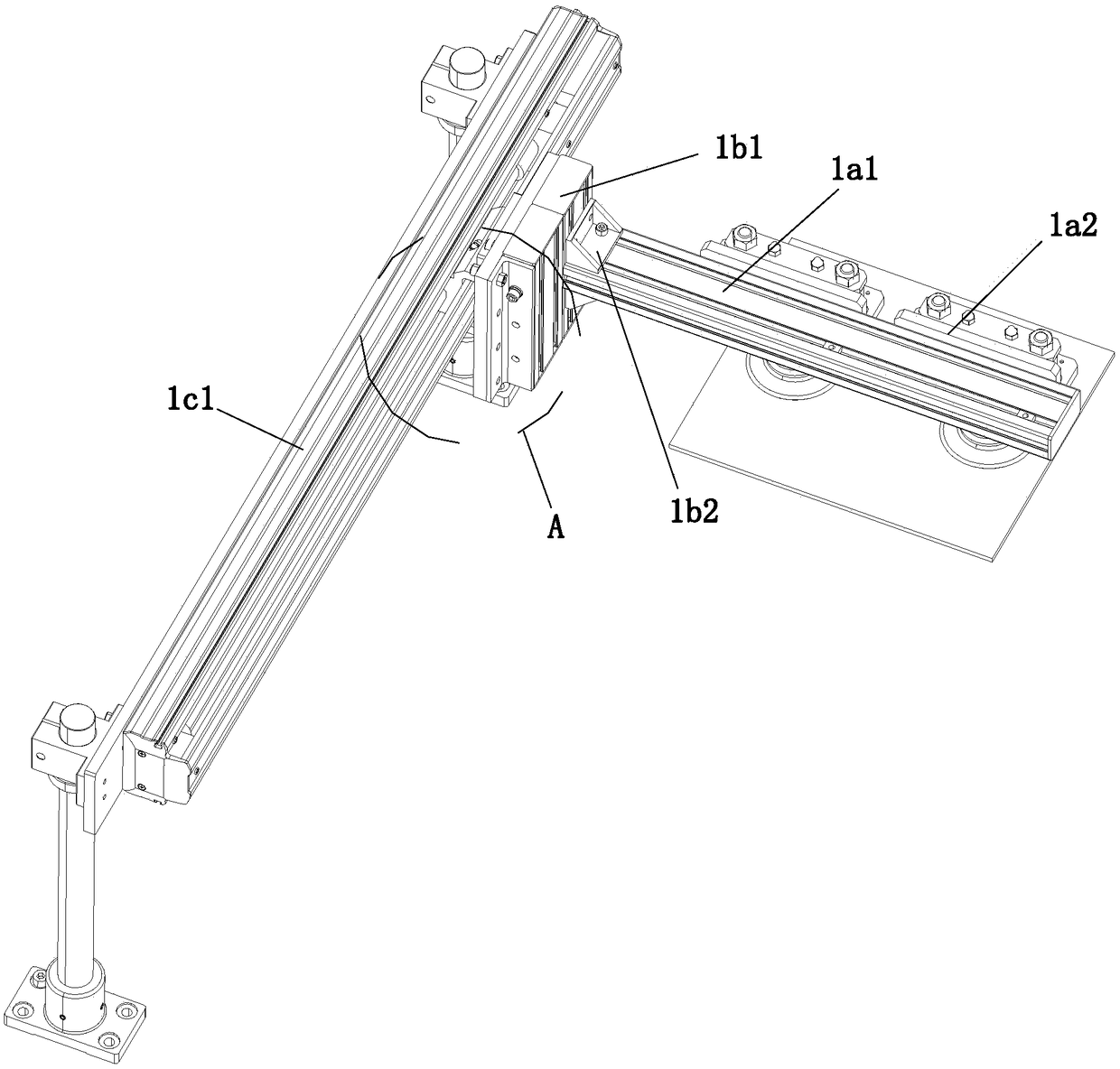

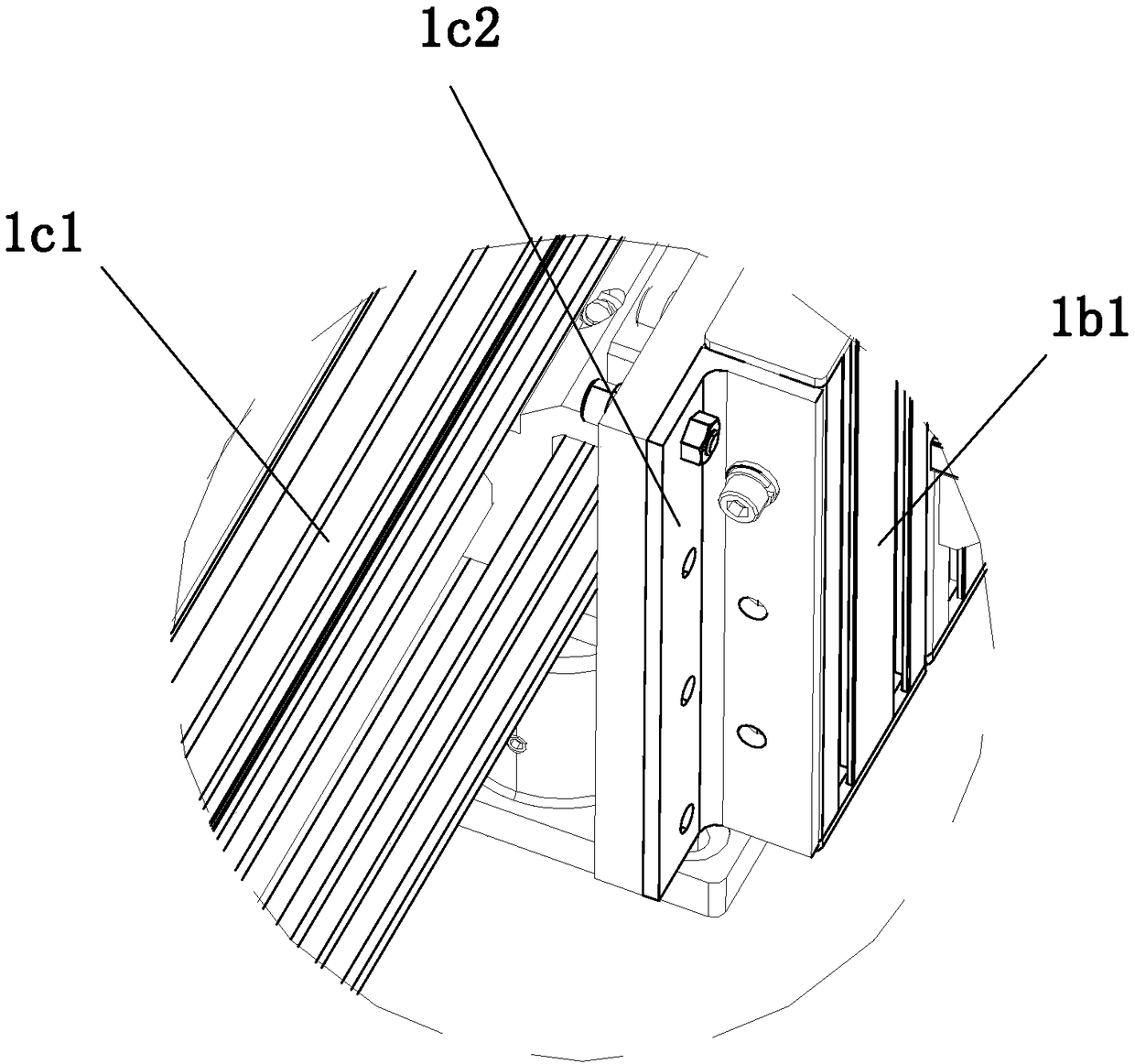

Adsorption loading and unloading device

ActiveCN111634681APrecise loading and unloadingPrecise positioningConveyor partsControl theoryVertical motion

The invention discloses an adsorption loading and unloading device which comprises a three degree-of-freedom feeding mechanism and an adsorption platform, wherein the three degree-of-freedom feeding mechanism comprises a coarse adjustment mechanism and a fine adjustment mechanism; the coarse adjustment mechanism comprises a rotary motion module, a horizontal motion module and a vertical motion module, and the horizontal motion module is arranged on the rotary motion module; the upper end of the vertical motion module is rotationally connected with the horizontal motion module, and the lower end of the vertical motion module is rotationally connected with the fine adjustment mechanism; the rotary motion module, the horizontal motion module and the vertical motion module can respectively drive the fine adjustment mechanism to doe rotary motion, horizontal motion and vertical motion; the adsorption platform is connected with the fine adjustment mechanism; and the lower end of the adsorption platform is used for adsorb an object to be taken. The invention can provide the adsorption loading and unloading device with high-strength adsorption, accurate and rapid positioning, a flexible and adaptive curved adsorption surface and high security, so as to solve the problems of the prior art.

Owner:JILIN UNIV

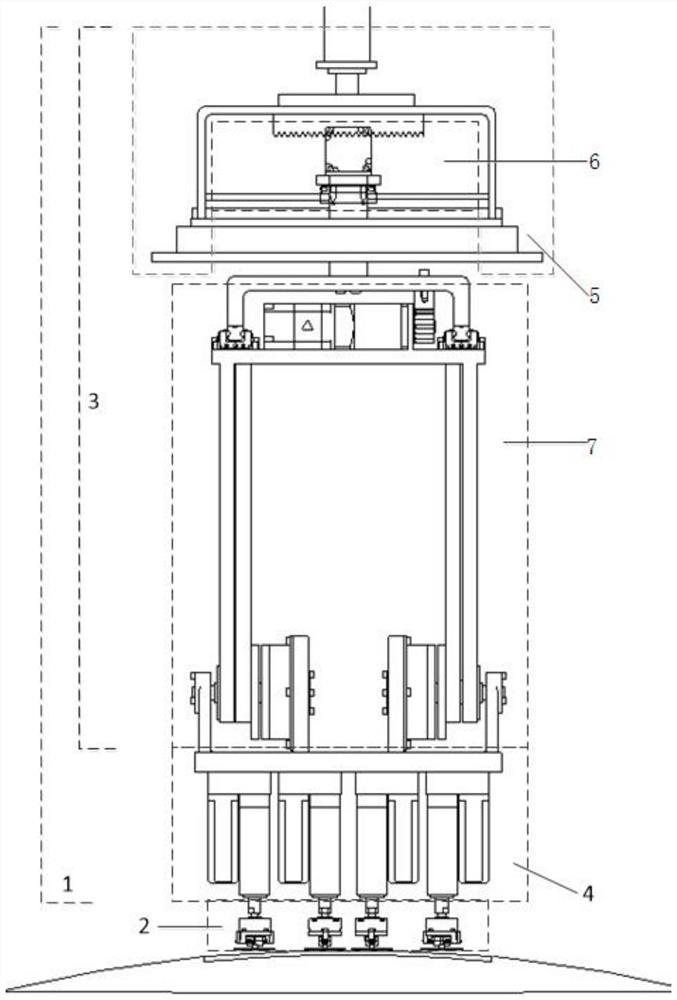

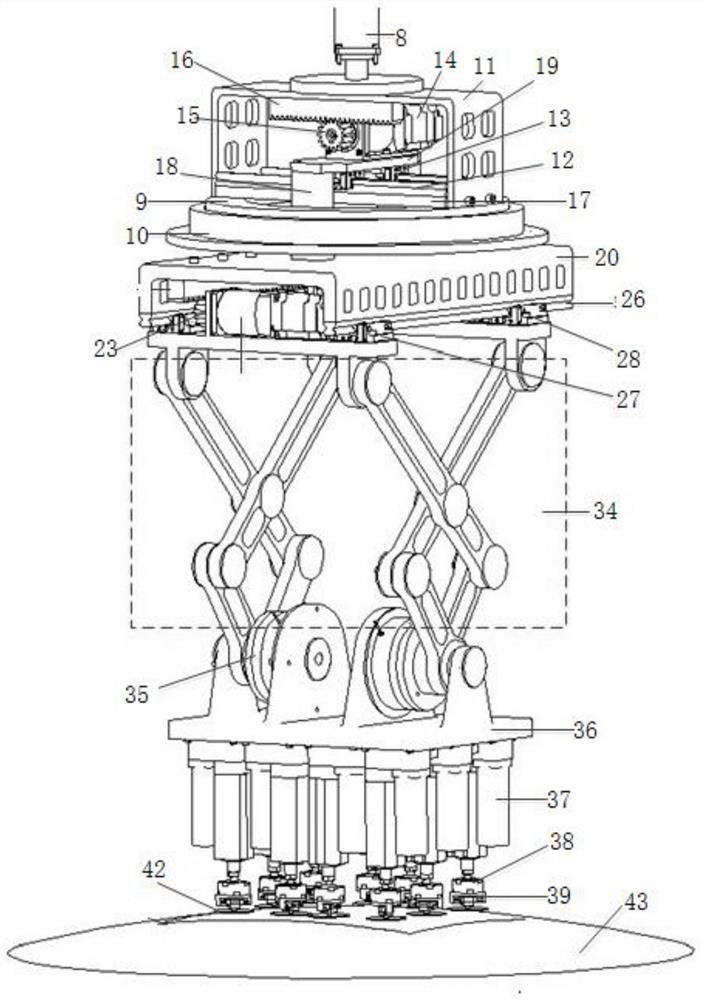

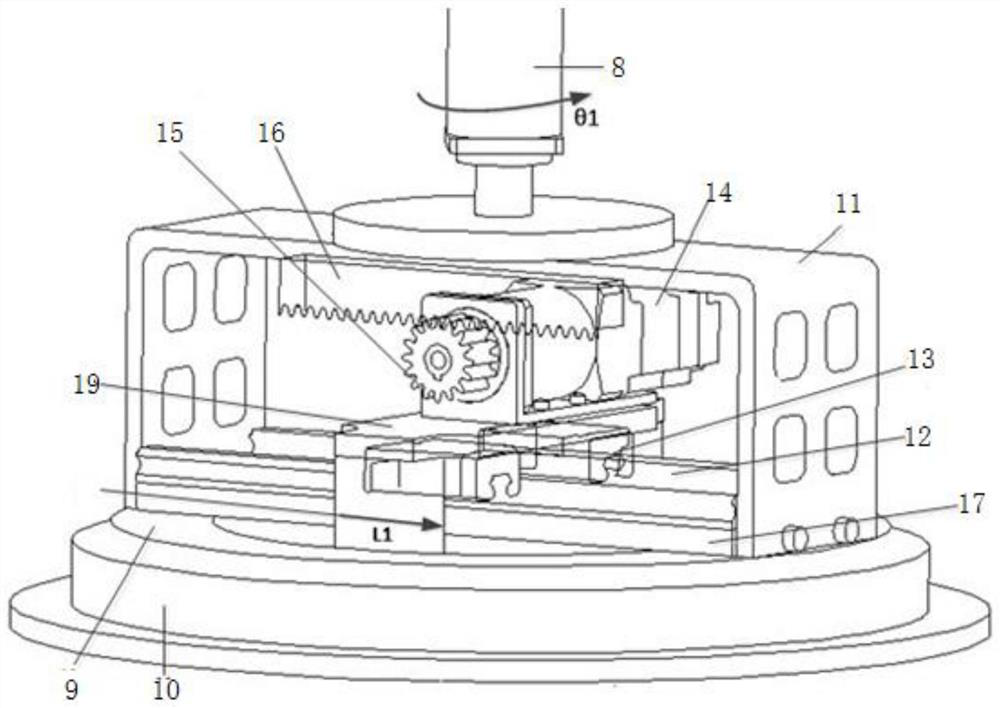

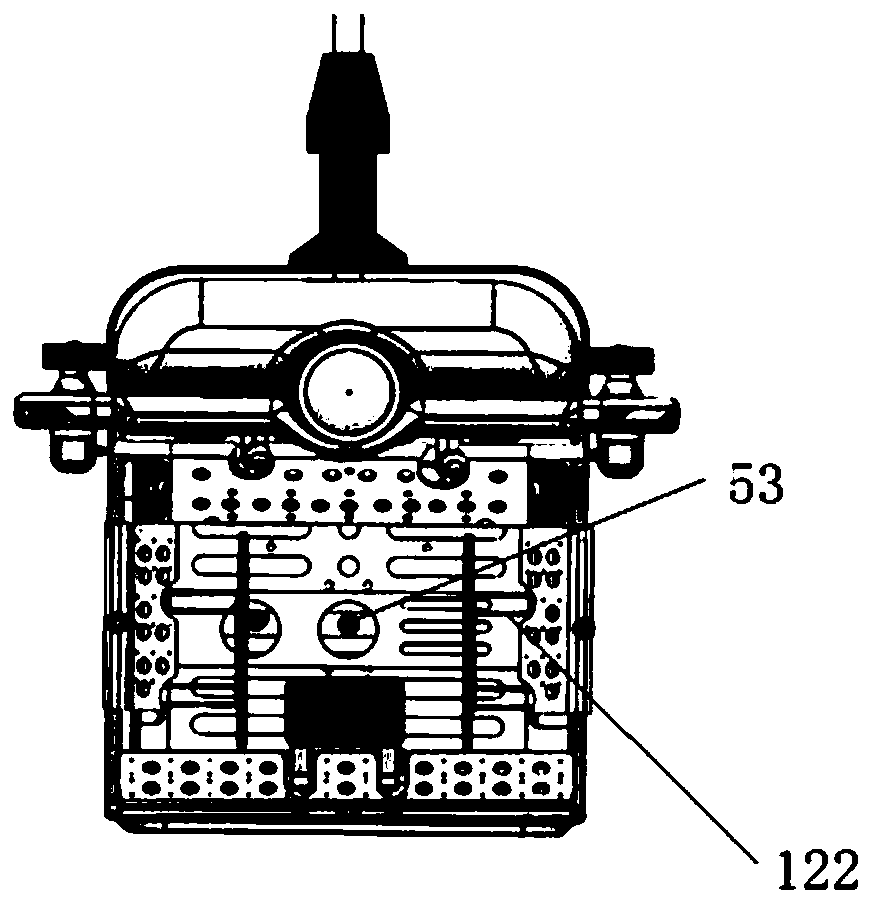

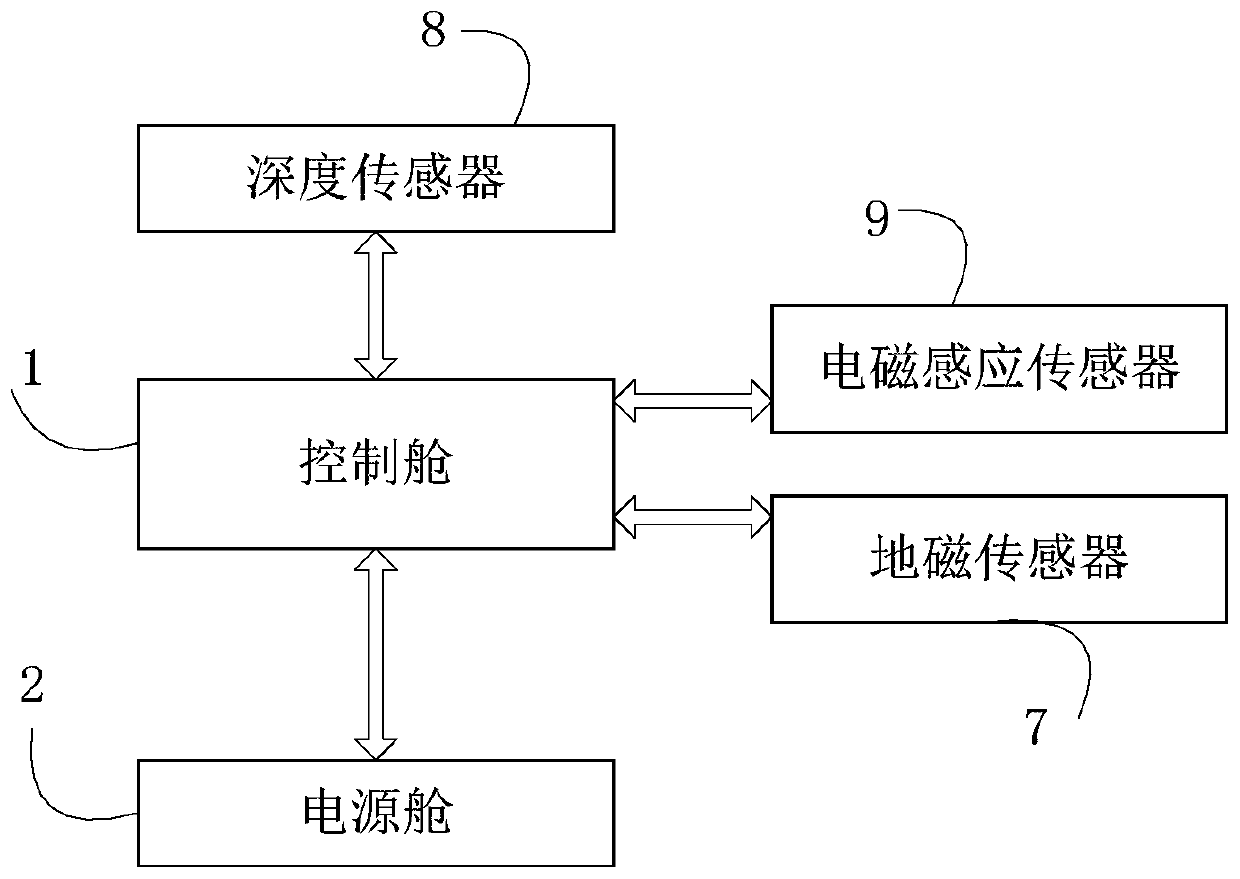

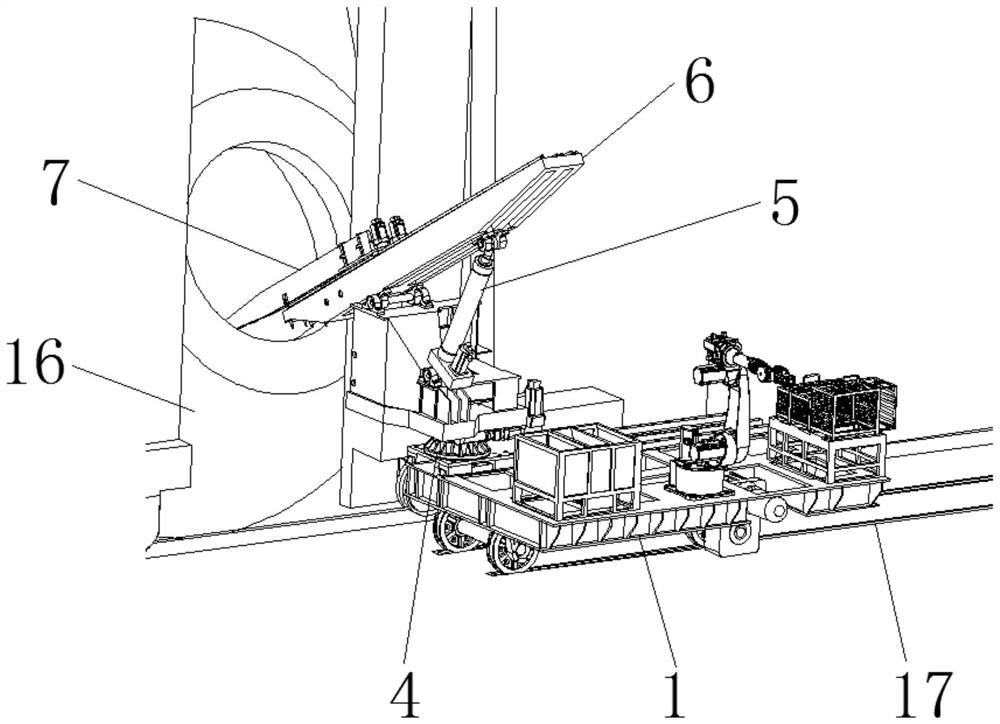

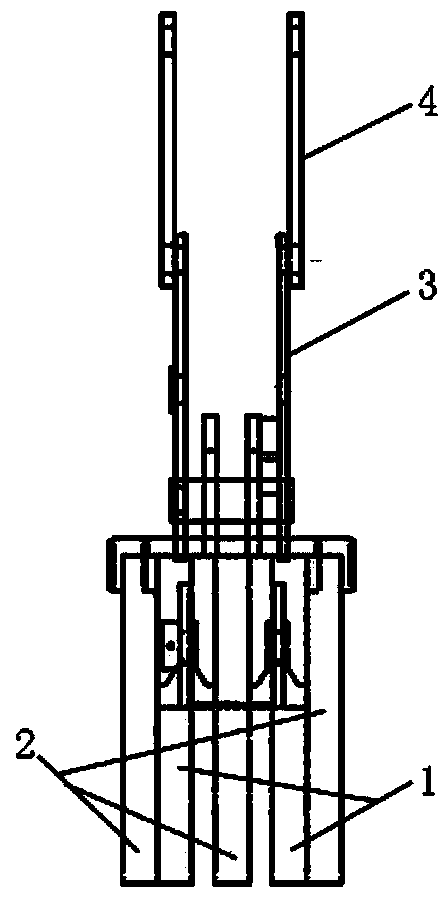

Underwater laying/recovering system for small AUV cluster

PendingCN111516805AEnsure safetyPrecise loading and unloadingLifeboat handlingMarine engineeringFishery

The invention discloses an underwater laying / recovering system for a small AUV cluster. The system comprises a recovery structure, a telescopic structure and an automatic cable arranging mechanism; the recovery structure is used for storing AUVs underwater; the telescopic structure is used for fixing the recovery structure and lifting and conveying the recovery structure to the inlet of a mother ship; the automatic cable arranging mechanism is arranged on the mother ship, connected with the telescopic structure and used for receiving the AUVs conveyed by the recovery structure; the recovery structure comprises an ROV power structure located on the upper portion of the recovery structure and used for controlling an AUV recovery process; the bottom end of the ROV power structure is fixedly connected with a recovery cabin structure used for loading the AUVs. According to the system, the AUVs are laid / recovered in a soft-hard combined mode; a telescopic guide rail hard link design is adopted above the sea surface, so that the AUVs are completely prevented from colliding with the mother ship in the recovery process; a flexible connection mode that an umbilical cable is connected with the recovery mechanism is adopted below the sea surface, so that convenience is provided for the free movement of the recovery mechanism.

Owner:DALIAN MARITIME UNIVERSITY +1

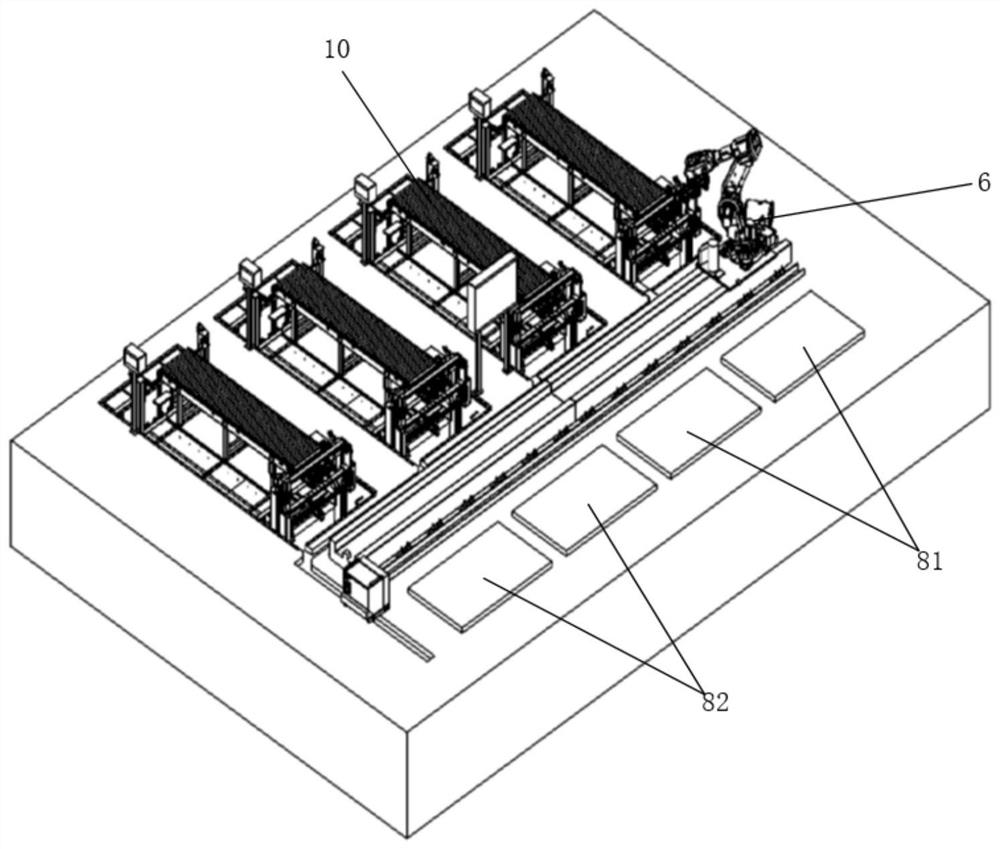

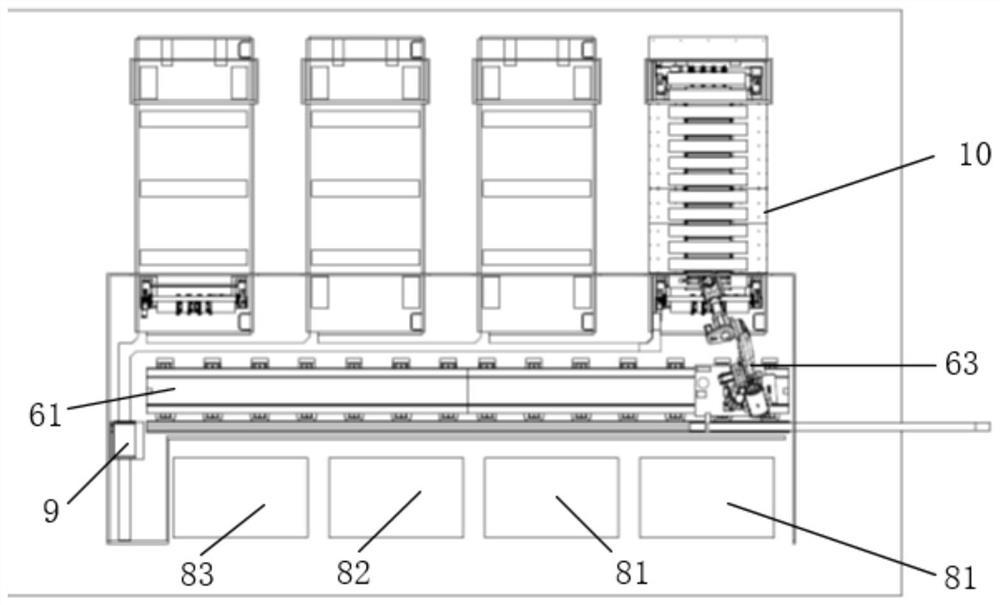

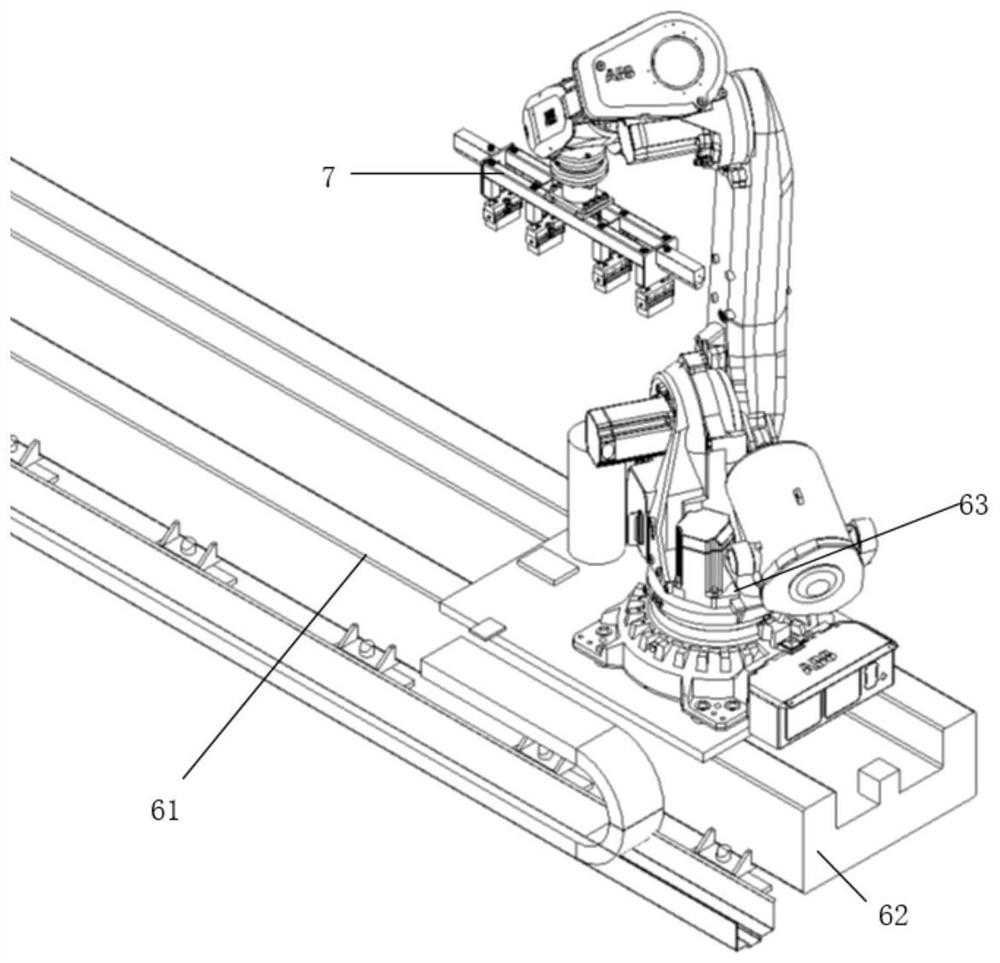

Railway turnout base plate welding production line and control method

ActiveCN112548386AShorten the pathReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineControl system

The invention relates to a railway turnout base plate welding production line and a control method. The railway turnout base plate welding production line comprises a carrying robot with a gripper device, welding stations and a base plate stacking area, and the base plate stacking area comprises a raw material area and a finished product area; the multiple welding stations are arranged side by side along a walking path, each welding station comprises a material conveying workbench, a material returning table, a lifting conveying device and a lifting overturning conveying device, and the conveying directions of the material conveying workbenches and the material returning tables are opposite; and the carrying robot, the gripper device, the material conveying workbenches, the material returning tables, the lifting conveying devices and the lifting overturning conveying devices are in communication connection through a control system. By means of the arrangement, base plates are carried through the carrying robot, so that the labor intensity of workers is reduced, time is saved, and efficiency is improved; and through the design of the material returning tables, the base plates can beconveyed back to the initial feeding position, so that feeding and discharging operations of the base plates are located in the same area, the walking path of the carrying robot is better reduced, and the working efficiency is further improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Plastic molding die charging crane

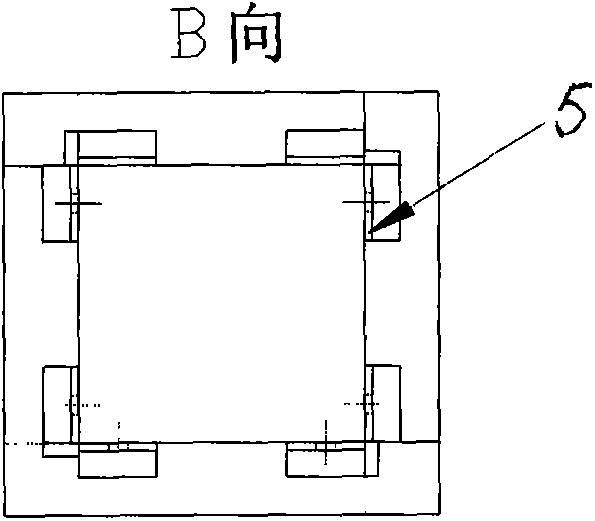

The invention relates to a plastic molding die charging crane. The charging crane comprises a vertical rack, a transverse rack, a base, a disk, a loading device and a control device. The vertical rack and the transverse rack is perpendicularly connected with each other, and a magnetic conveying groove which is coherently connected is formed in the vertical rack. The base is arranged under the vertical rack, the loading device is connected with the transverse rack, a magnetic telescopic head is arranged in the middle, the disk can be inlaid in the magnetic conveying groove and move along the magnetic conveying groove, when the disk moves to the position of the magnetic telescopic head, the disk is tightly attracted to the bottom end of the telescopic head through the magnetic force. A plastic molding die is loaded on the disk, the width of the loading device is squre-shaped, and is the same as the outer frame of an injection molding machine die, and meanwhile, infrared angle centering machines are arranged at four top angles correspondingly, and the control device can control the working process of the whole mechanism. The plastic molding die loading machine has the characteristics of being safe, clear in labor division, high in work efficiency and good in cleanability.

Owner:YANCHENG FENGSHUN HOME FURNISHING TECH CO LTD

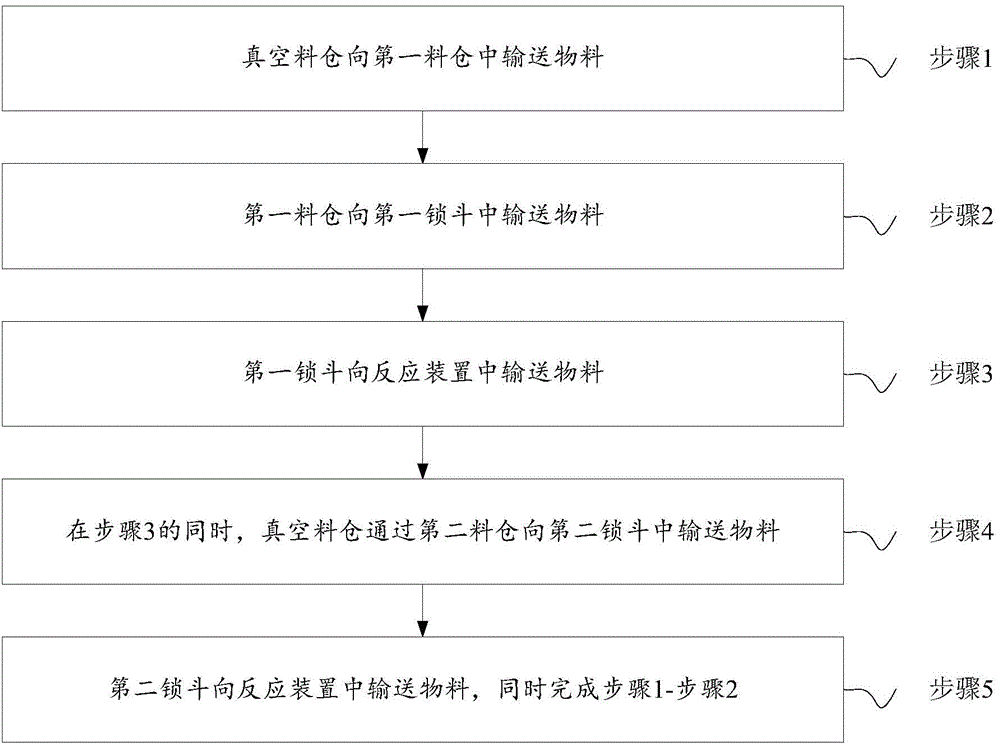

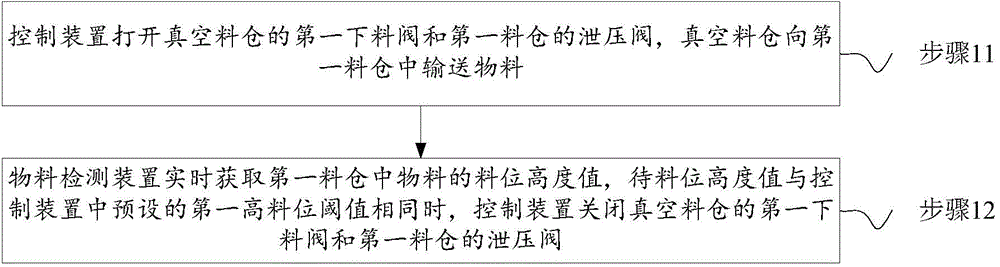

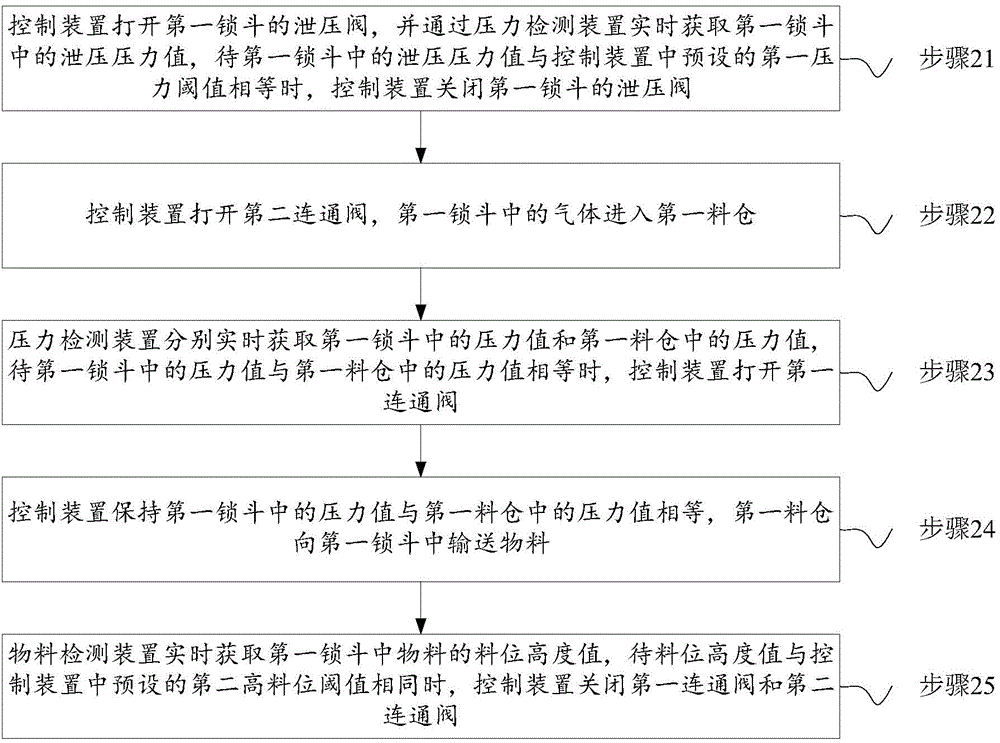

Dense-phase conveying control method and system

ActiveCN104692127APrecise movement controlPrecise loading and unloadingBulk conveyorsTransfer procedureEngineering

The invention discloses a dense-phase conveying control method and system, relates to the technical field of pneumatic conveying, and solves the problems that switching continuity among conveying systems and material conveying stability are affected easily due to manual control for a parallel conveying mode, the safety is poorer and the efficiency is lower. According to the dense-phase conveying control method, a material detection device and a pressure detection device acquire the material level height values and pressure values of bins and lock hoppers of the conveying systems in real time respectively, and feed the material level height values and the pressure values back to a control device; the control device compares the material level height values and the pressure values with preset high and low material level threshold values and pressure threshold values respectively, and controls opening and closing of valves according to comparison results; and the control device controls a vacuum bin to convey materials automatically to a reaction device alternately through the conveying systems according to the material level height values and the pressure values of the conveying systems. The dense-phase conveying control method and system are mainly applied to a material conveying process.

Owner:ENN SCI & TECH DEV

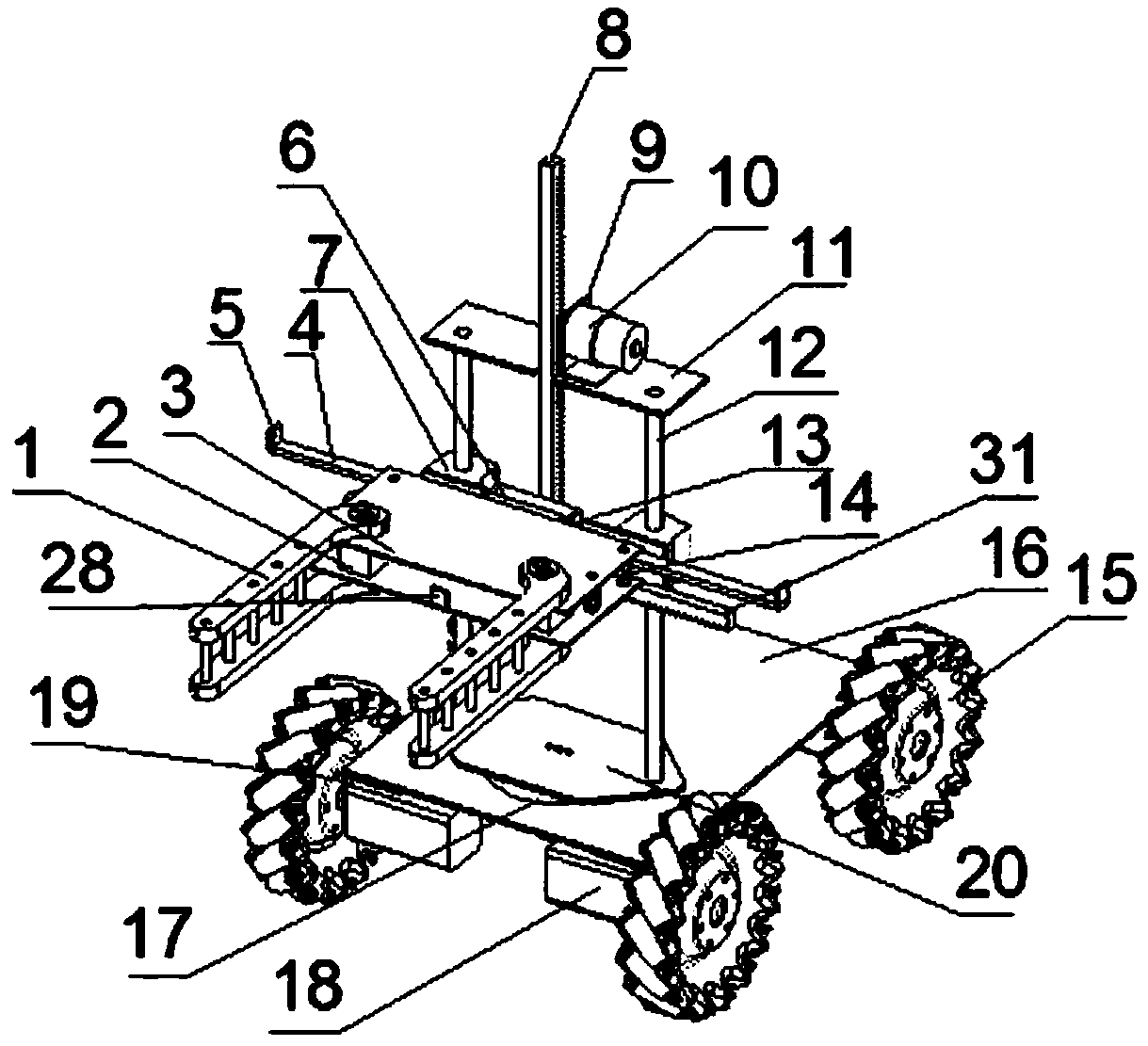

Quick and efficient intelligent warehouse robot

The invention provides a quick and efficient intelligent warehouse robot. The quick and efficient intelligent warehouse robot is mainly composed of a driving device, a rotating device, a lifting device, a manipulator, a UWB positioning module, a camera and an upper computer system; the driving device independently drives four Mecanum wheels through four motors; the driving device, the rotating device, the lifting device and the manipulator are sequentially connected; and the driving device, the rotating device, the lifting device, the manipulator, the UWB positioning module and the camera areall connected to the upper computer system. The driving device adopts the Mecanum wheels as driving wheels, and thus the robot can quickly moves to the next working point after loading and unloading work of one point is completed. The quick and efficient intelligent warehouse robot can quickly and precisely reach the specified point through the UWB positioning module, the manipulator can move leftand right along a sliding rail, thus the robot can complete multiple times of loading and unloading work by stopping at one point, in this way, the overall moving time of the robot is saved, and thepositioning error caused in the overall moving process of the robot can further be reduced.

Owner:SOUTHWEST PETROLEUM UNIV

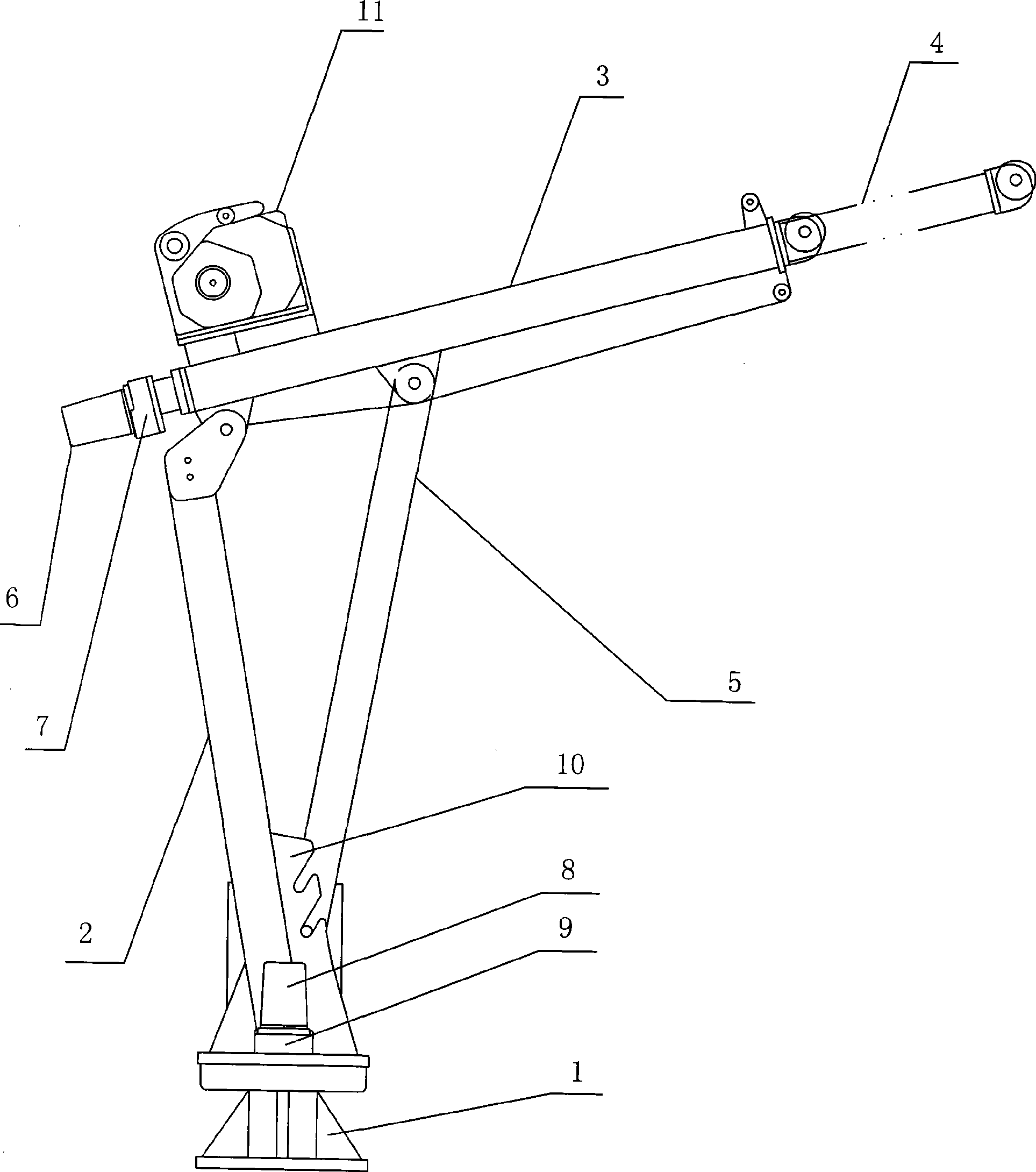

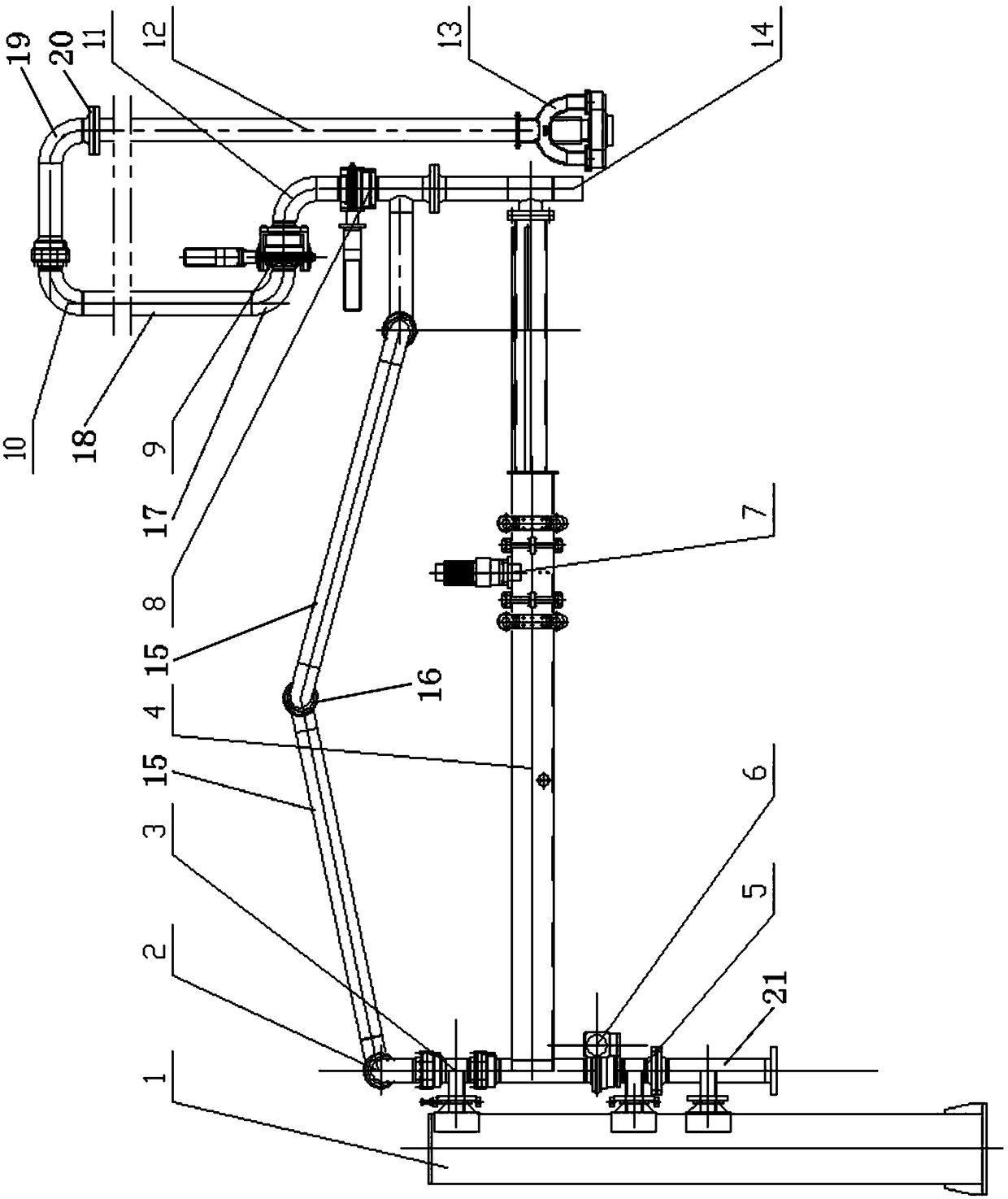

Cantilever type automatic aligning oil-unloading crane tube

PendingCN108793048ARealize automatic alignmentRealize sealed loading and unloading operationsLiquid transferring devicesEngineeringCantilever

The invention relate to train tank car liquid loading and unloading equipment, in particular to a cantilever type automatic aligning oil-unloading crane tube. The upper-end pipe orifice of a first connecting pipe is in stationary sealing communication with the lower-end pipe orifice of a second connecting pipe, any two adjacent third connecting pipes in an articulated pipe set are in dynamic sealing communication, the upper-end pipe orifice of the first section of third connecting pipe in the articulated pipe set communicates with a fourth connecting pipe, the lower-end pipe orifice of a horizontal rotating pipe is in dynamic sealing communication with the upper-end pipe orifice of a fourth connecting pipe, the lower-end pipe orifice of a lower arc segment-shaped connecting pipe is in dynamic sealing communication with the upper-end pipe orifice of the horizontal rotating pipe, the upper-end pipe orifice of an upper arc segment-shaped connecting pipe is in dynamic sealing communicationwith the upper-end pipe orifice of a second vertical rotating pipe, the lower-end pipe orifice of the second vertical rotating pipe is in stationary sealing communication with the upper-end pipe orifice of a vertical hanging pipe, the lower-end pipe orifice of the hanging pipe fixedly hangs an immersed pump and is in stationary sealing communication with a liquid outlet of the immersed pump. One-key automatic loading and unloading can be realized, and the closed loading operation can be completed.

Owner:新疆中拓新能源技术股份有限公司

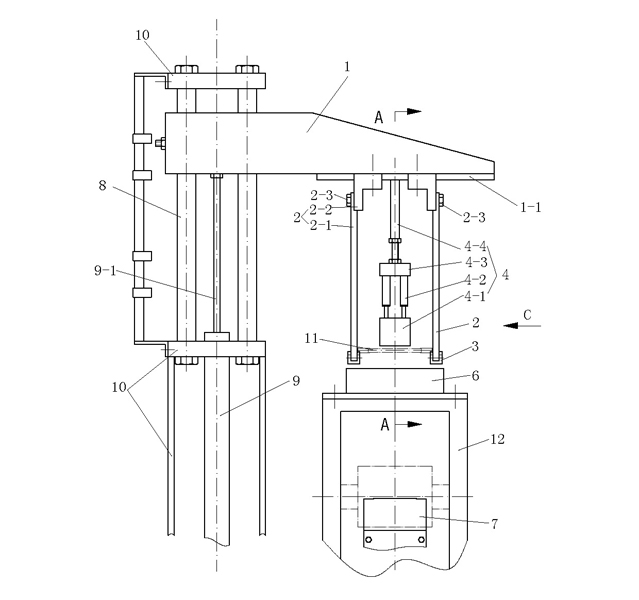

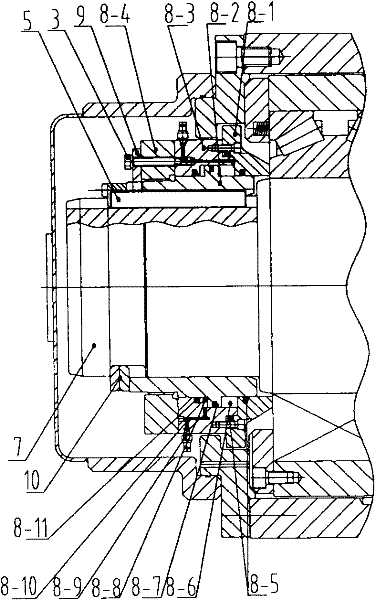

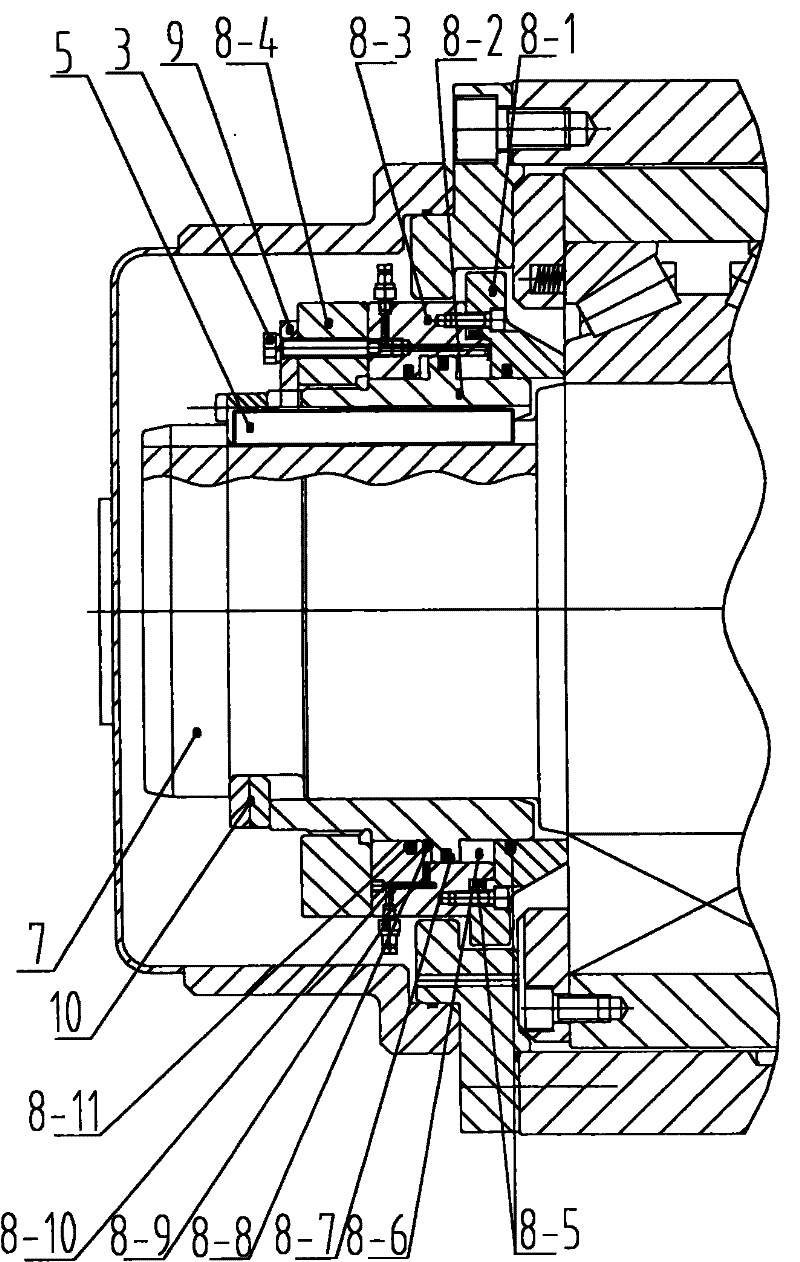

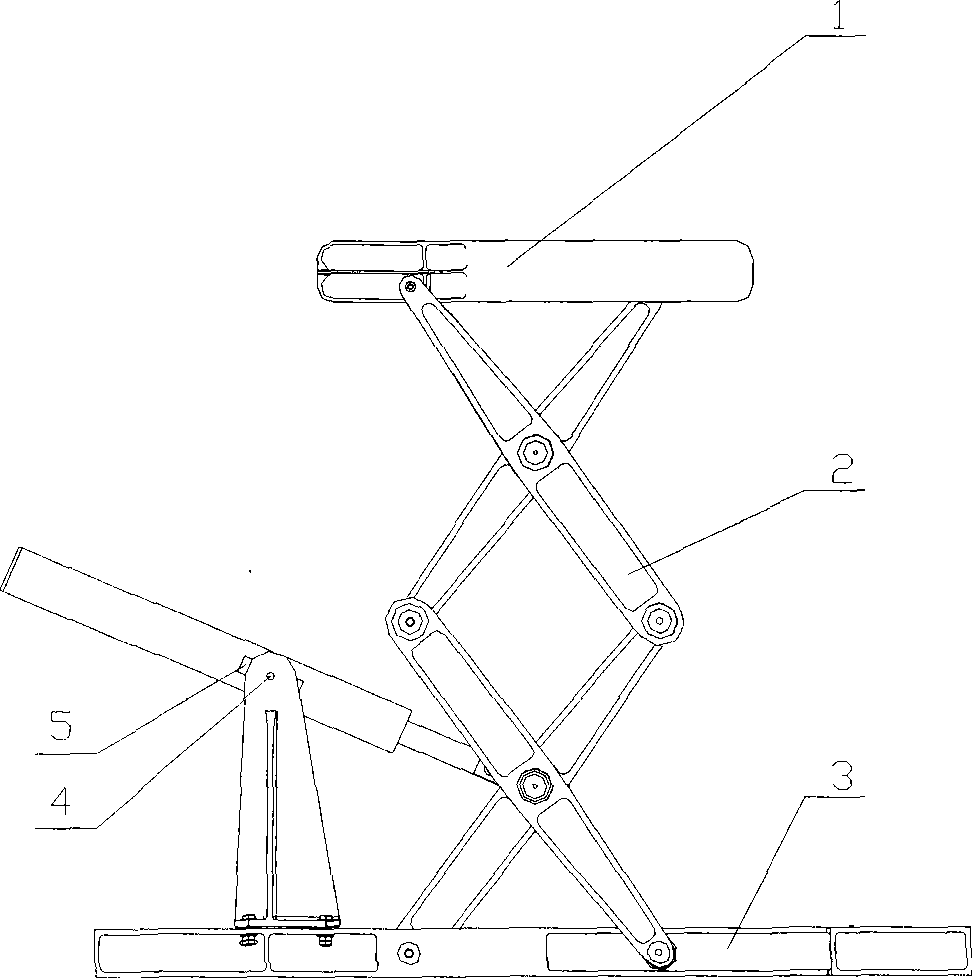

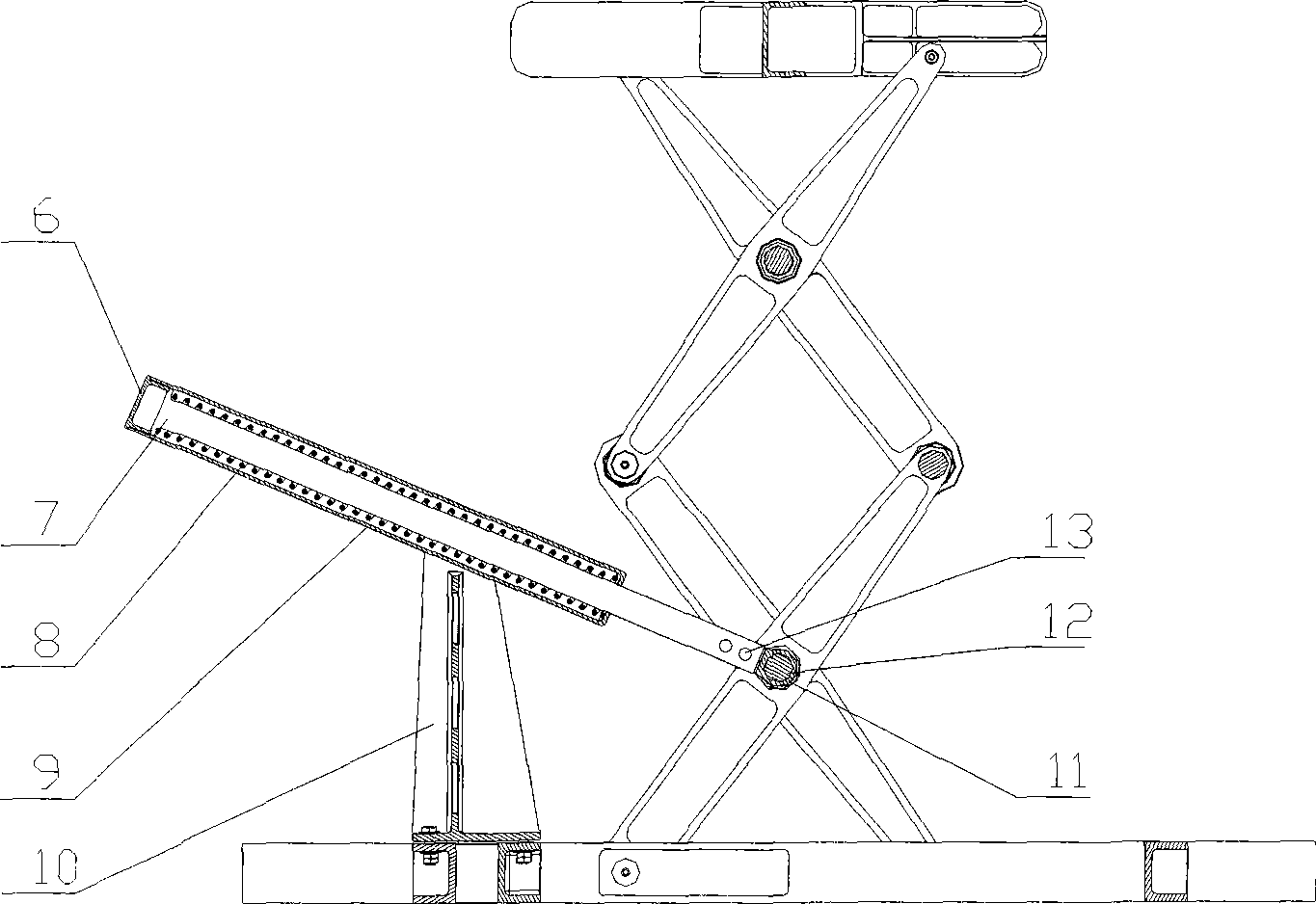

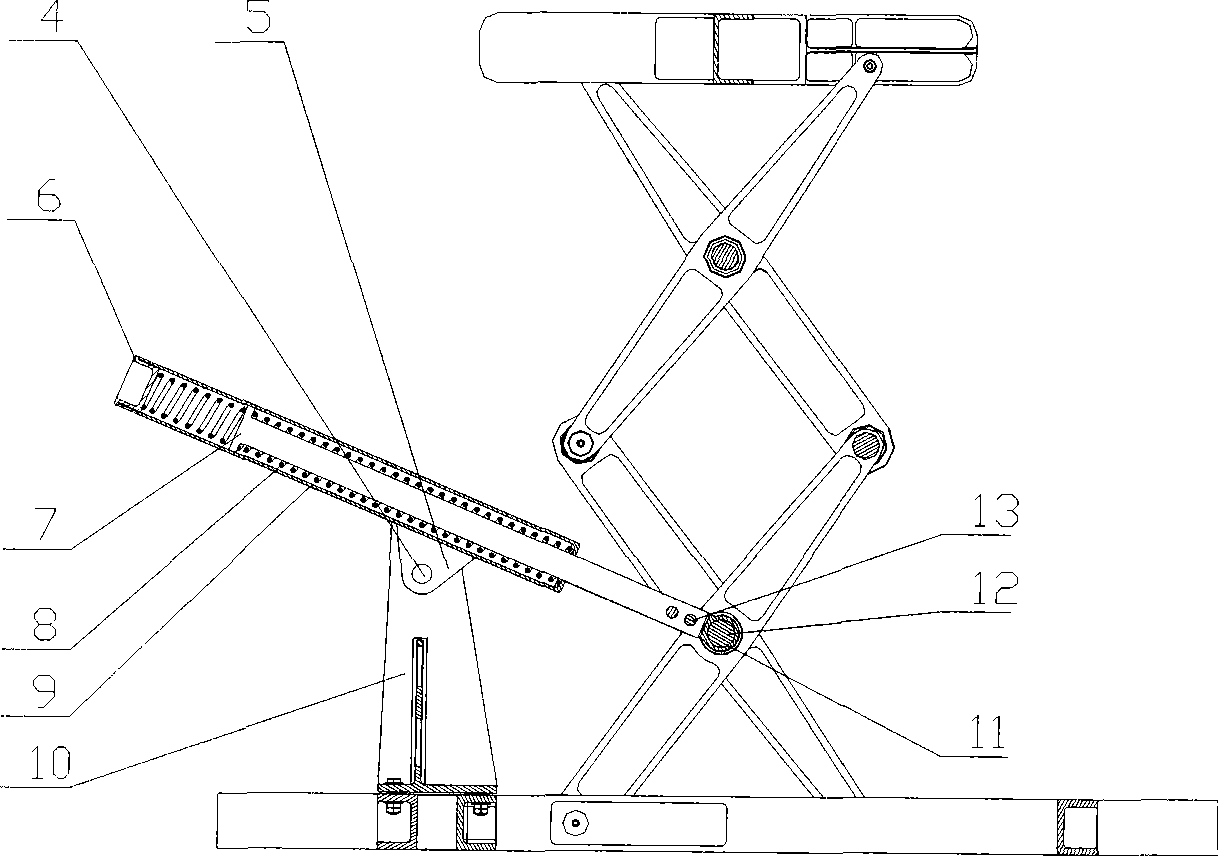

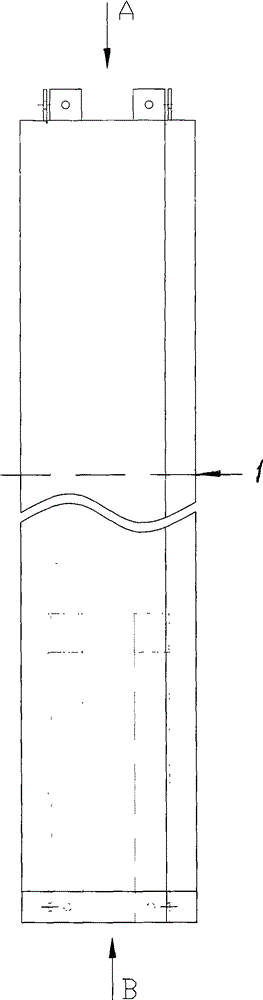

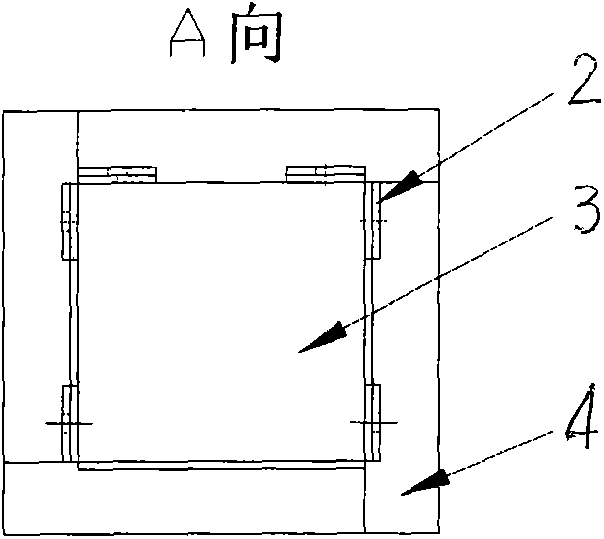

Rapid unpowered bearing lifting mechanism

InactiveCN101439830AQuick loading and unloadingPrecise loading and unloadingLifting framesPotential energyEngineering

The invention relates to a quick unpowered load-bearing lifting mechanism. The lifting mechanism comprises a bearing platform, a shear lifting arm and a chassis, wherein one end of an actuating rod of an actuating drum is connected with a connection rotary shaft of a cross point at the lower part of the shear lifting arm through an actuating drum force-feed connecting piece; the actuating drum force-feed connecting piece is connected with the actuating rod through a connecting pin; and the inside of the actuating drum is provided with a compression spring which is sleeved on the actuating rod so as to ensure that the front and back strokes of the actuating rod have elastic restore inside an actuating drum body. The quick unpowered load-bearing lifting mechanism realizes balance between the gravity of a lifting heavy object and the elasticity of the spring by means of elastic energy change in the spring caused by the potential energy change in the heavy object during lifting; because the heavy object is in a balanced state, the heavy object can be stopped within any variation range of lifting height; therefore, when the heavy object needs to be lifted, just a tiny outside force (including manpower) can lift or drop the heavy object within a certain lifting range.

Owner:AVIC CHENGDU AIRCRAFT DESIGN & RES INST

Upright structure of timber architecture and upright structure and foundation connecting method

InactiveCN104652607AQuick installation and removalQuick installationStrutsPillarsFloor levelStress effects

The invention discloses an upright structure of a timber architecture and an upright structure and foundation connecting method. The upright structure of the timber architecture and the upright structure and foundation connecting method solve the disadvantage of the background technology that there is no mature architecture upright connecting mode in China. The upright structure of the timber architecture and the upright structure and foundation connecting method are characterized in that a hollow A is formed in a toothed plate 2, and a connecting hole is formed in the end; a baffle plate 6 is connected with the joint between two upright cores 3; each of three vertical surfaces of each upright core is connected with two toothed plates 2; four auxiliary seal plates 4 are respectively connected with the upright cores 3; a connecting steel disc 8 is cast in a concrete pier 13, and connecting holes 9 and 10 expose out of the concrete pier 13; a foundation bolt 19 is embedded in a prefabricated ground pile 16; a connecting plate 11 is arranged on the prefabricated ground pile 16, and a fastening base plate 17 and a fastening screw cap 18 are connected and fixed with the foundation bolt 19. The upright structure of the timber architecture has advantages of beautiful appearance, modular design, simple structure and good stress effect. The segmented mode of the upright enables the stress continuity to be improved, the upright module connecting surface is far away from the floor surface, and the stress concentration is avoided. All the uprights are the same in size, the production and assembly are easy to perform, and the interchangeability is strong.

Owner:贵州贵飞飞机设计研究院有限公司

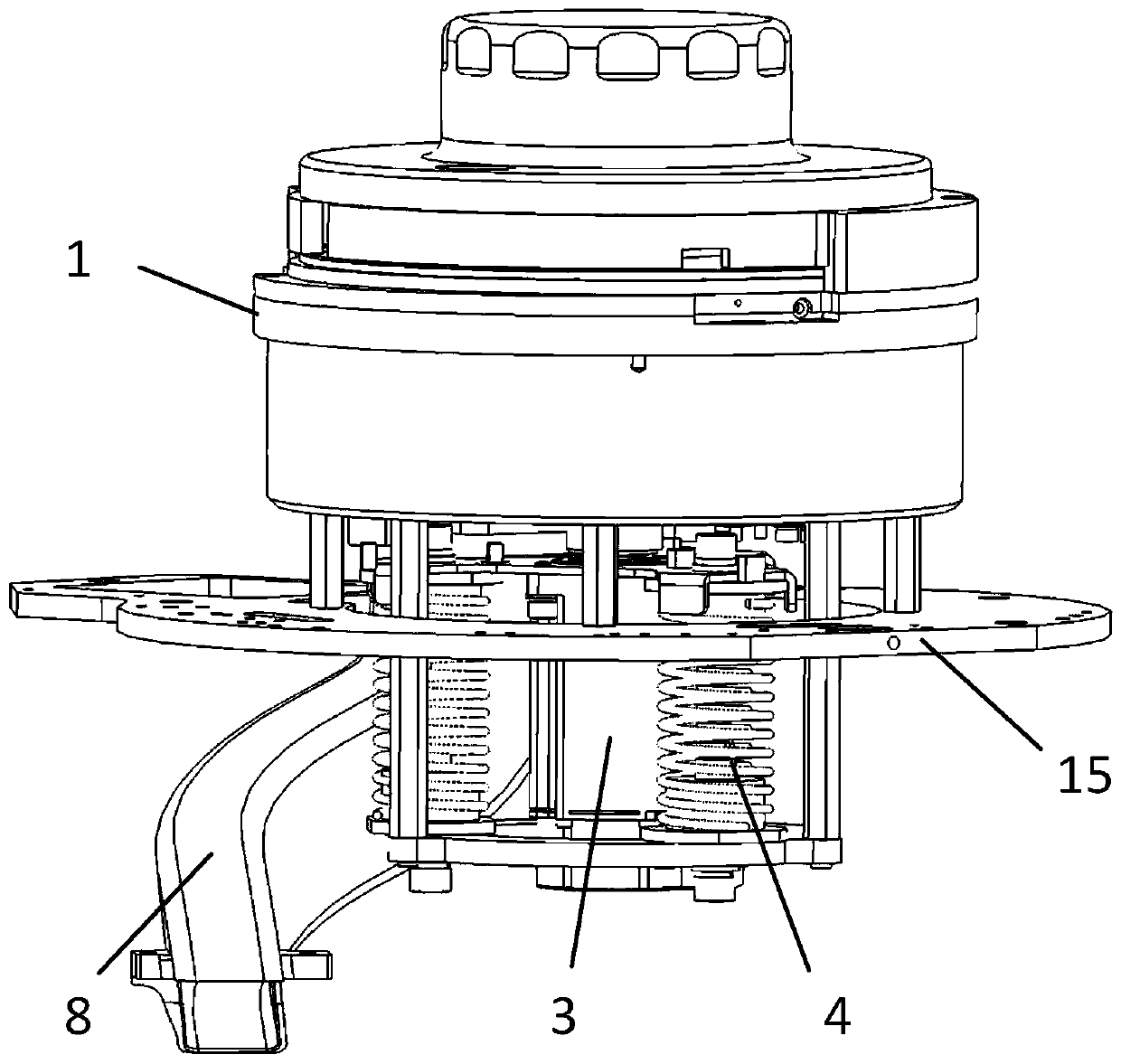

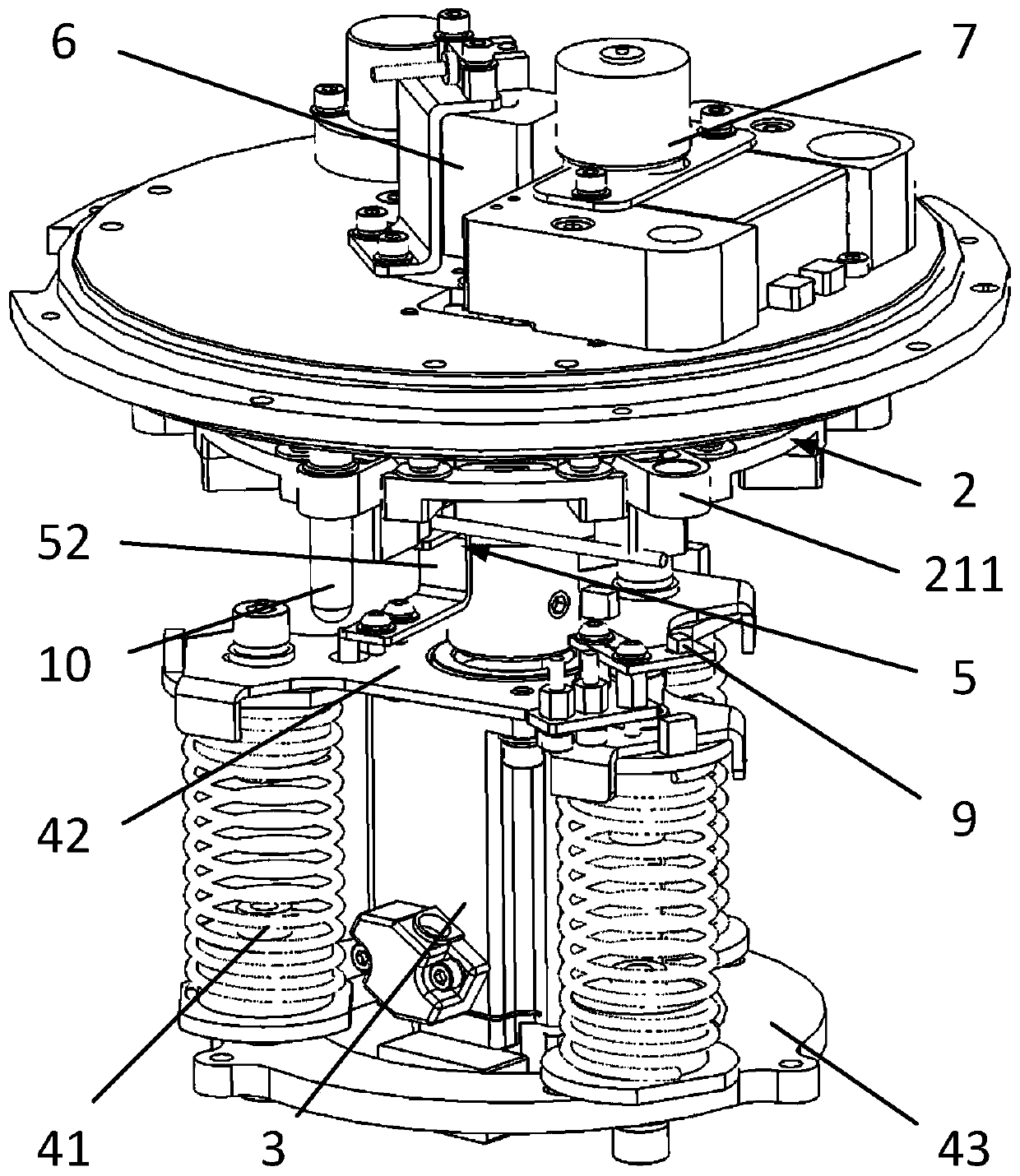

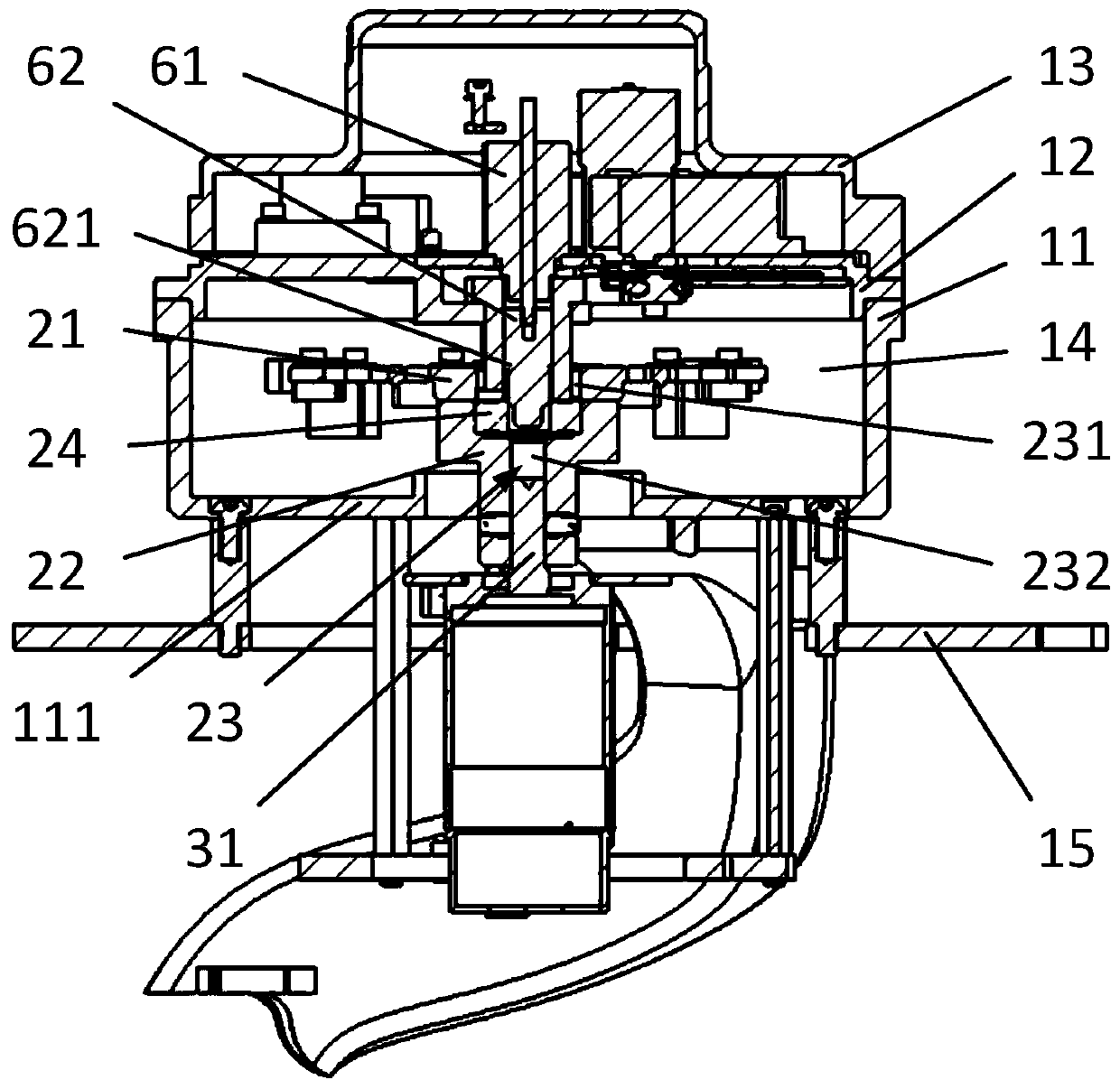

Centrifugal mechanism and in vitro detection analyzer

PendingCN111195565APrecise positioningPrecise loading and unloadingCentrifugesMaterial analysisDISC assemblyCentrifuge

The invention relates to a centrifugal mechanism and an in vitro detection analyzer. The centrifugal mechanism comprises a centrifugal disc assembly, a circumferential positioning mechanism and a horizontal positioning mechanism, a positioning hole is formed in the centrifugal assembly in the vertical direction, the circumferential positioning mechanism comprises a circumferential detection sensor, the circumferential detection sensor is used for detecting the circumferential position of the centrifugal disc assembly, thus the centrifugal disc assembly is circumferentially positioned, the horizontal positioning mechanism comprise a positioning driving mechanism and a positioning piece which are connected in a transmission mode, the positioning driving mechanism can drive the positioning piece to move in the vertical direction, so that the positioning piece is inserted into the positioning hole, and thus the centrifugal disc assembly is horizontally positioned in a radial-centered mode.According to the centrifugal mechanism, a centrifugal cup can be accurately positioned.

Owner:SHANGHAI UPPER BIO TECH PHARMA

Automatic feeding system for cam blank

The invention relates to an automatic feeding system for a cam blank, which comprises a modeling material channel, wherein the modeling material channel is equipped with an adjusting device, and mainly comprises two modeling rails that are parallel to each other in a transmission direction; shapes of the two opposite side faces on the two modeling rails are matched with outlines of curved surfaces on the two sides of a flange part of the cam blank; a space for accommodating the flange part of the cam blank is reserved between the two modeling rails; and the adjusting device is used for adjusting a pointing direction of the axial front-rear end of the cam blank conveyed on the modeling material channel. According to the automatic feeding system, the automatic and accurate feeding and blanking of the cam blank are realized, so that the pointing direction of the axial front-rear end of the cam blank output from a discharge end of the automatic feeding system, and a pointing direction of a tip point of a flange can correspond to technological requirements of the cam blank in a subsequent procedure during a processing course; an effect of an error due to manual adjustment on the shape of the cam blank entering the subsequent procedure is avoided; and the shape uniformity of cam products can be ensured.

Owner:BEIJING BEINEI ENGINE PARTS

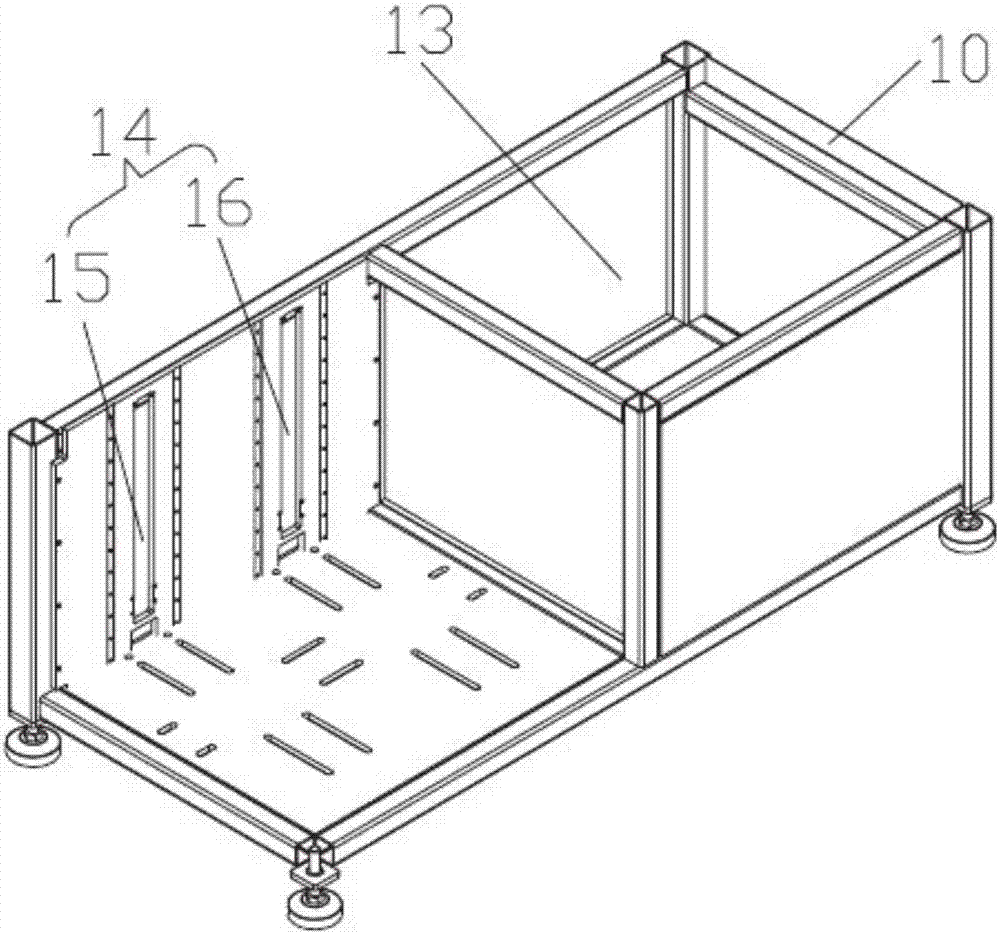

Crawling robot top cover screw locking device matched with rotary type vehicle

ActiveCN109693104AImprove efficiencyPrecise positioningMetal working apparatusDistribution controlEngineering

The invention relates to a crawling robot top cover screw locking device matched with a rotary type vehicle. The crawling robot top cover screw locking device comprises a machine frame and a power distribution control box, wherein a material loading device is arranged on the machine frame, and a screw locking device is matched with the material loading device; the material loading device comprisesa rotating disk motor and a rotating disk rotating shaft, wherein the rotating disk motor and the rotating disk rotating shaft are mutually matched, and a rotating disk is arranged on the rotating disk rotating shaft; a raised block matched with a matching groove of a top cover is arranged on the upper part of the rotating disk, and rotating disk clamping teeth are uniformly arranged on the lowerpart of the rotating disk; and a rotating disk position clamping air cylinder is arranged on the machine frame, and a rotating disk position clamping block matched with the rotating disk clamping teeth is connected to the rotating disk position clamping air cylinder. According to the crawling robot top cover screw locking device matched with the rotary type vehicle, the rotating disk is adopted and used for material loading of the top cover, and the raised block matched with the matching groove of the top cover is arranged on the rotating disk, it is ensured that the top cover cannot rotate relative to the rotating disk when the top cover rotates, the screw locking device does not need to be moved, the positioning is convenient, the screw locking efficiency is high, and the low-cost production can be realized.

Owner:江苏大盛铁塔制造有限公司

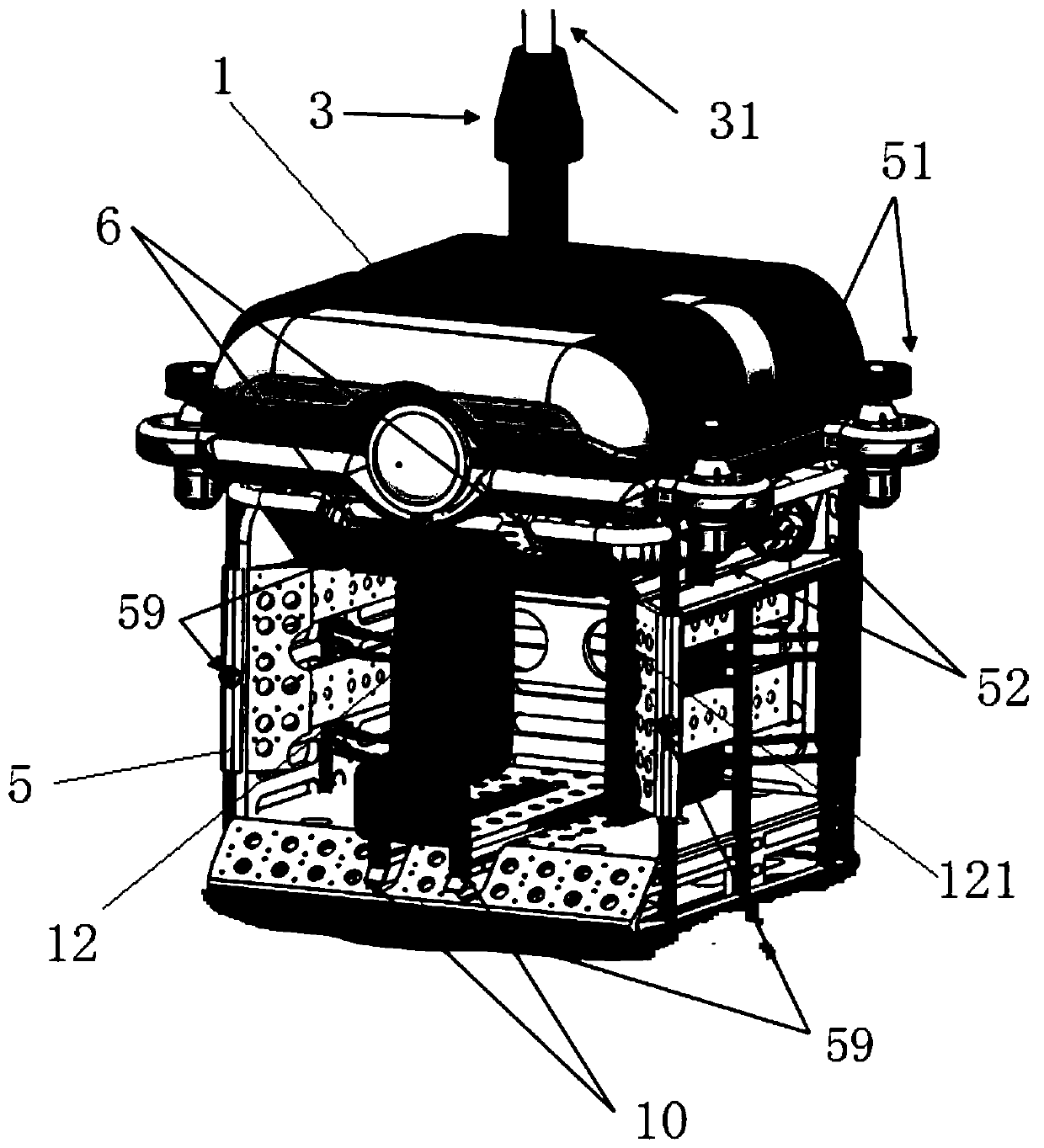

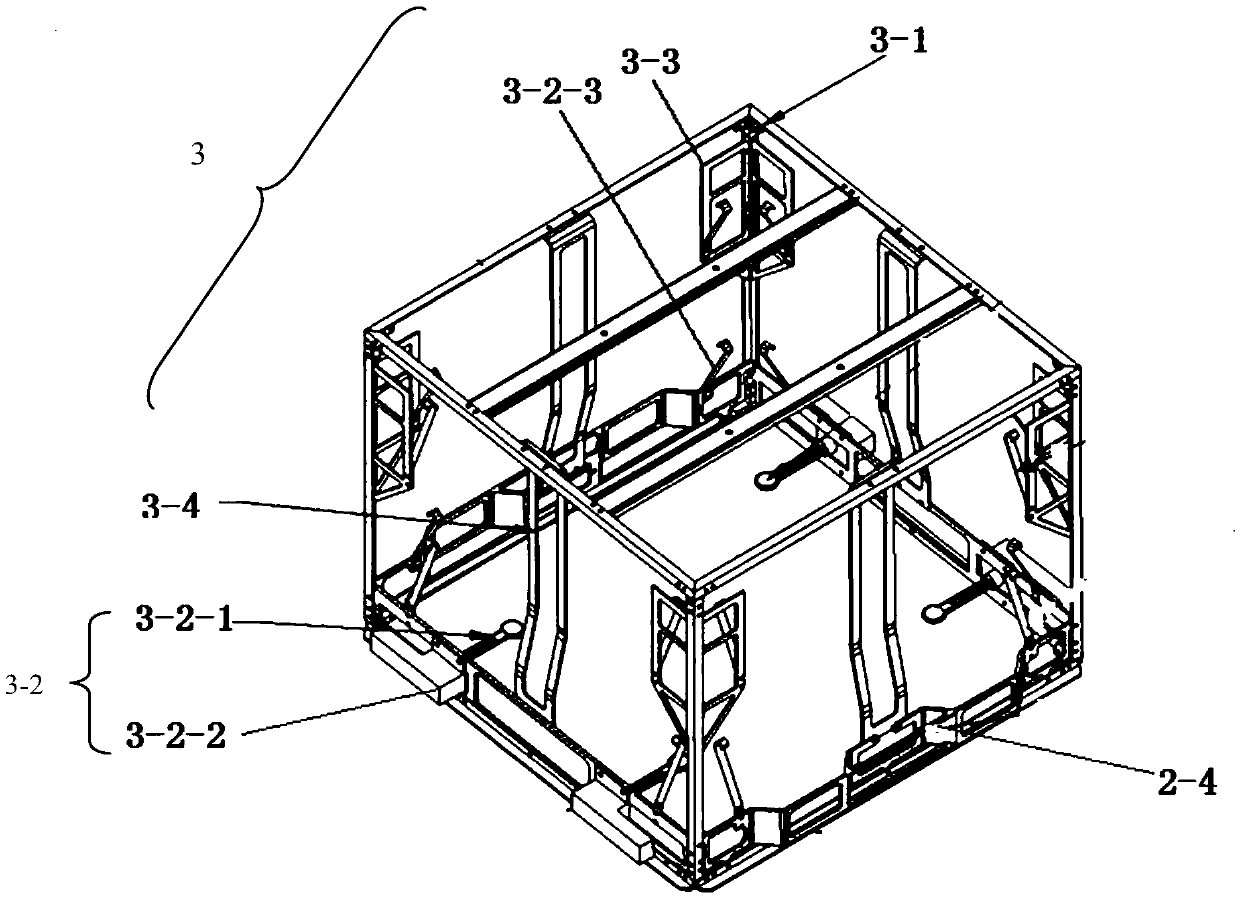

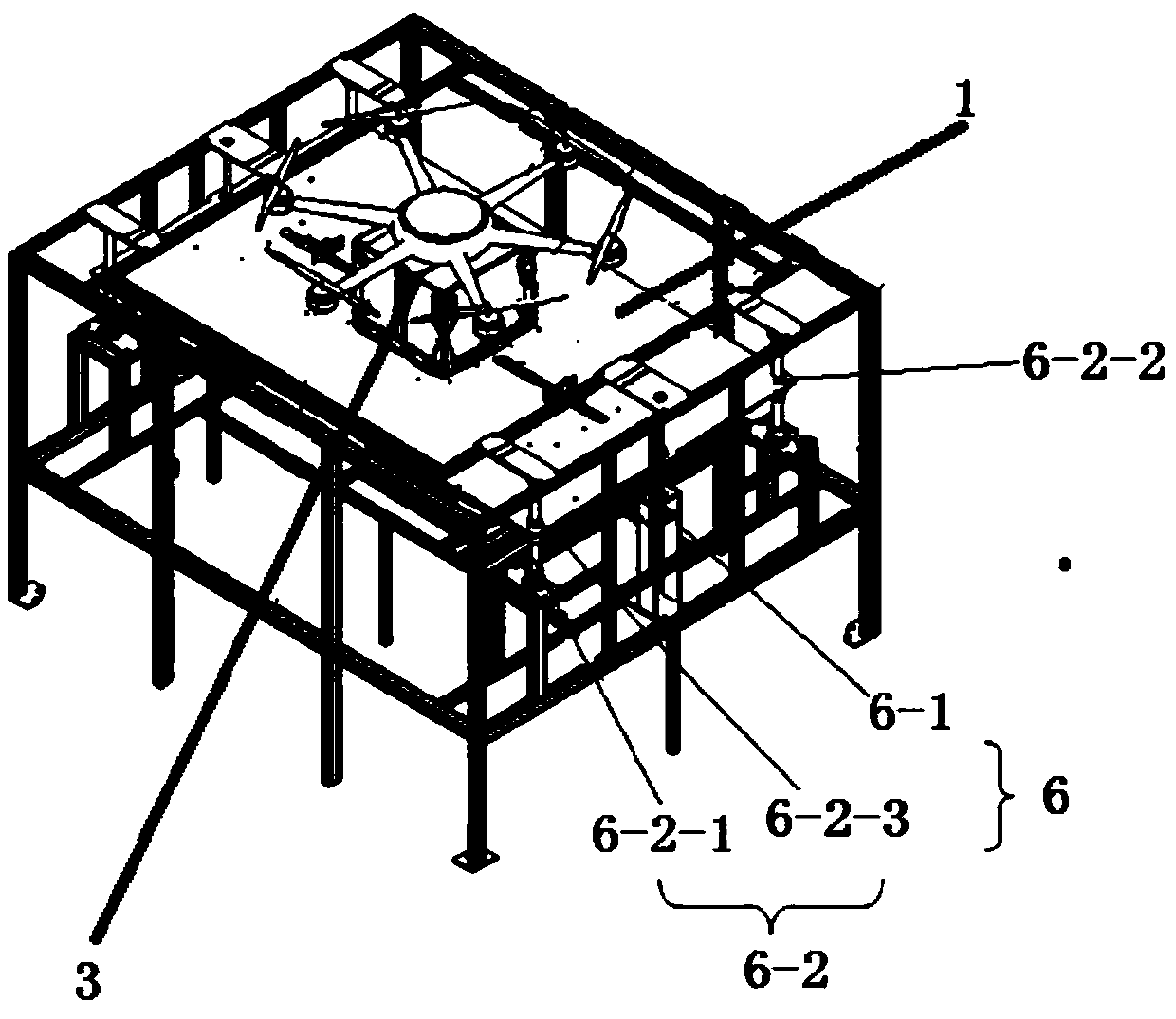

Cargo box loading and unloading device of logistics unmanned aerial vehicle warehouse and control method

PendingCN110871907APrecise loading and unloadingAvoid leaningFreight handling installationsParking areaLogistics management

The invention discloses a cargo box loading and unloading device of a logistics unmanned aerial vehicle warehouse. The cargo box loading and unloading device comprises a parking platform with the center being a parking area, a position adjusting mechanism and a lifting platform, wherein the parking platform is driven to move up and down, and the position adjusting mechanism and the lifting platform are used for adjusting the plane position of the warehouse on the parking platform; the warehouse is of a box type structure with a lower opening, the warehouse comprises a box body and a lifting mechanism used for loading and unloading cargo boxes, and a loading and unloading hole allowing the cargo boxes to penetrate through is formed in the middle of the parking area; the lifting platform isdriven to move up and down so as to penetrate through the loading and unloading hole from the lower part to enter the warehouse to be used for conveying the cargo boxes to the warehouse or unloading the cargo boxes from the warehouse; and the box body is provided with an avoiding groove used for enabling the lifting mechanism to correspond to the lifting platform. According to the cargo box loading and unloading device, the cargo boxes can be automatically loaded and unloaded, and the situation that the placed cargo boxes incline or fall off in the conveying process can be avoided.

Owner:一飞智控(天津)科技有限公司

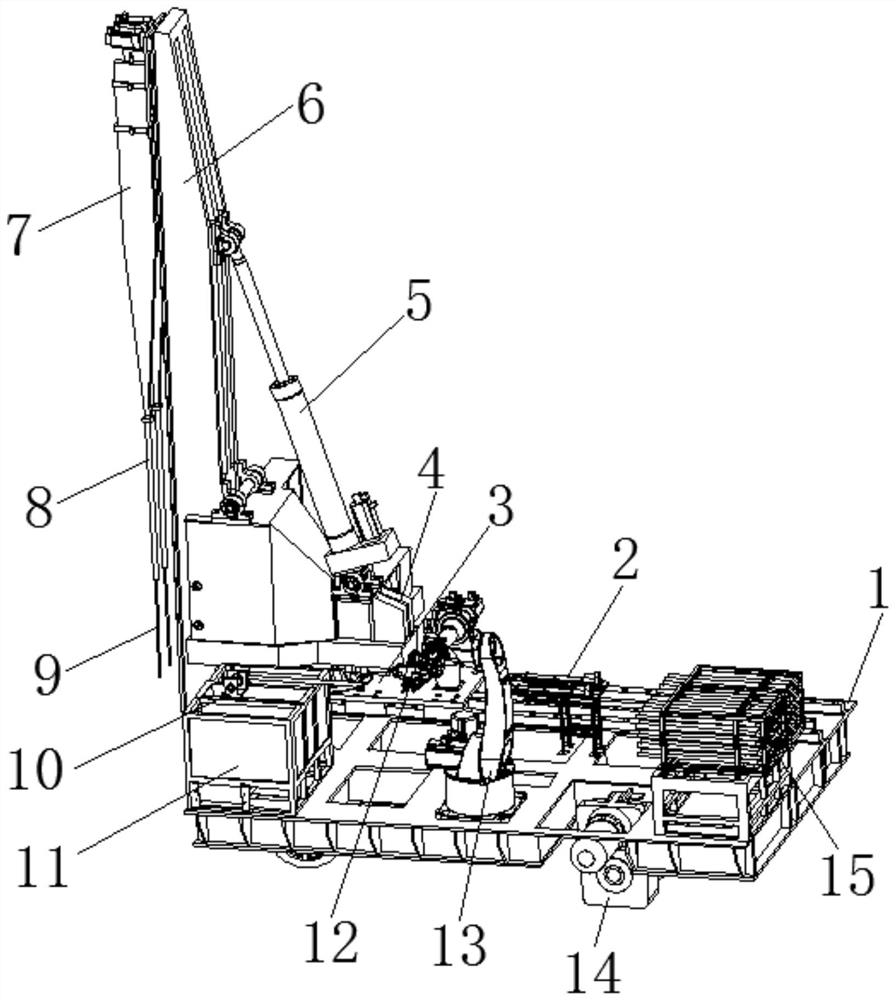

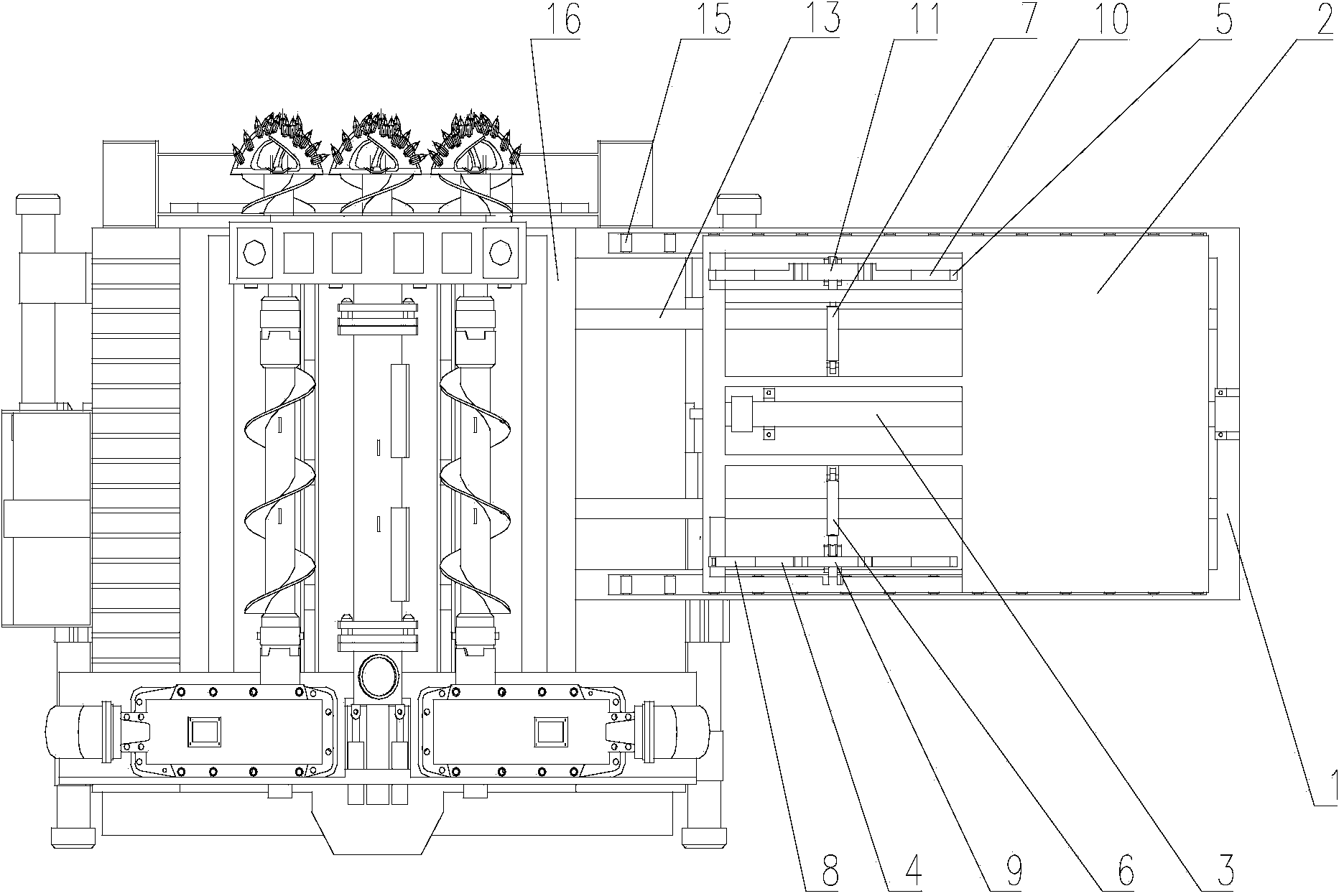

Steelmaking automatic temperature measuring and sampling equipment and temperature measuring and sampling method thereof

ActiveCN111855025ASolve the deformationSolution success rateThermometer applicationsSteelmakingControl theory

The invention discloses steelmaking automatic temperature measuring and sampling equipment and a temperature measuring and sampling method thereof in the technical field of steelmaking. According to the equipment, a walking vehicle linearly moves and is fixed on a heavy rail; a robot gripper is mounted at the arm end of a robot; a pneumatic hammer device is mounted at the top of a collecting bin;a transverse moving vehicle linearly moves and is fixed at the top of the walking vehicle; a rotating device is mounted at the top of the transverse moving vehicle; the rotating axis of the rotating device is perpendicular to the top of the walking vehicle; one end of an overturning plate and one end of a second telescopic device are hinged to the rotating device; the other end of the second telescopic device is hinged with the overturning plate; a temperature measurement and sampling gun connecting plate moves linearly on the overturning plate and is fixed; and a temperature measurement and sampling gun is arranged on the temperature measurement and sampling gun connecting plate. According to the invention, the problems that a temperature measuring and sampling gun deforms and is prone todamage, the installation success rate of a temperature measuring and sampling sleeve is low, the deformation amount of the temperature measuring and sampling gun cannot be accurately judged visuallyand the like are solved, automatic temperature measuring and sampling are achieved, and the success rate of temperature measuring and sampling is high.

Owner:HAIXI (FUJIAN) INST CHINA ACAD OF MASCH SCI&TECH GRP

Unloading device used for copper product machining

ActiveCN111099377AEasy to unloadImprove work efficiencyLoading/unloadingProduction lineElectric machinery

The invention discloses an unloading device used for copper product machining. The unloading device comprises two pairs of supporting rods. A top transverse rod is installed on the two supporting rodsin each pair. A collection tank is arranged between the two top transverse rods. The two sides of the collection tank are connected with connection bases in a rotating manner. A fourth cylinder is installed on the upper surface of each connection base. A connection flat plate is installed at the top end of each fourth cylinder. A transverse beam is installed at the bottoms of the two top transverse rods. A movable plate is connected to the transverse beam in a sliding manner. A second motor is installed at the bottom of the movable plate. The output end portion of the second motor is connected with a second cylinder. The bottom end of the second cylinder is connected with a connection arm. An object containing frame is hinged to one end of the connection arm. The unloading device can automatically conduct material carrying on copper products, time and labor are saved, the unloading device can meet copper product machining production lines with different height differences, the objectcontaining frame and the collection tank are convenient to move and regulate, unloading is conducted in a turnover manner, unloading is rapid and convenient, and the work efficiency is high.

Owner:安徽慧枫再生资源科技有限公司

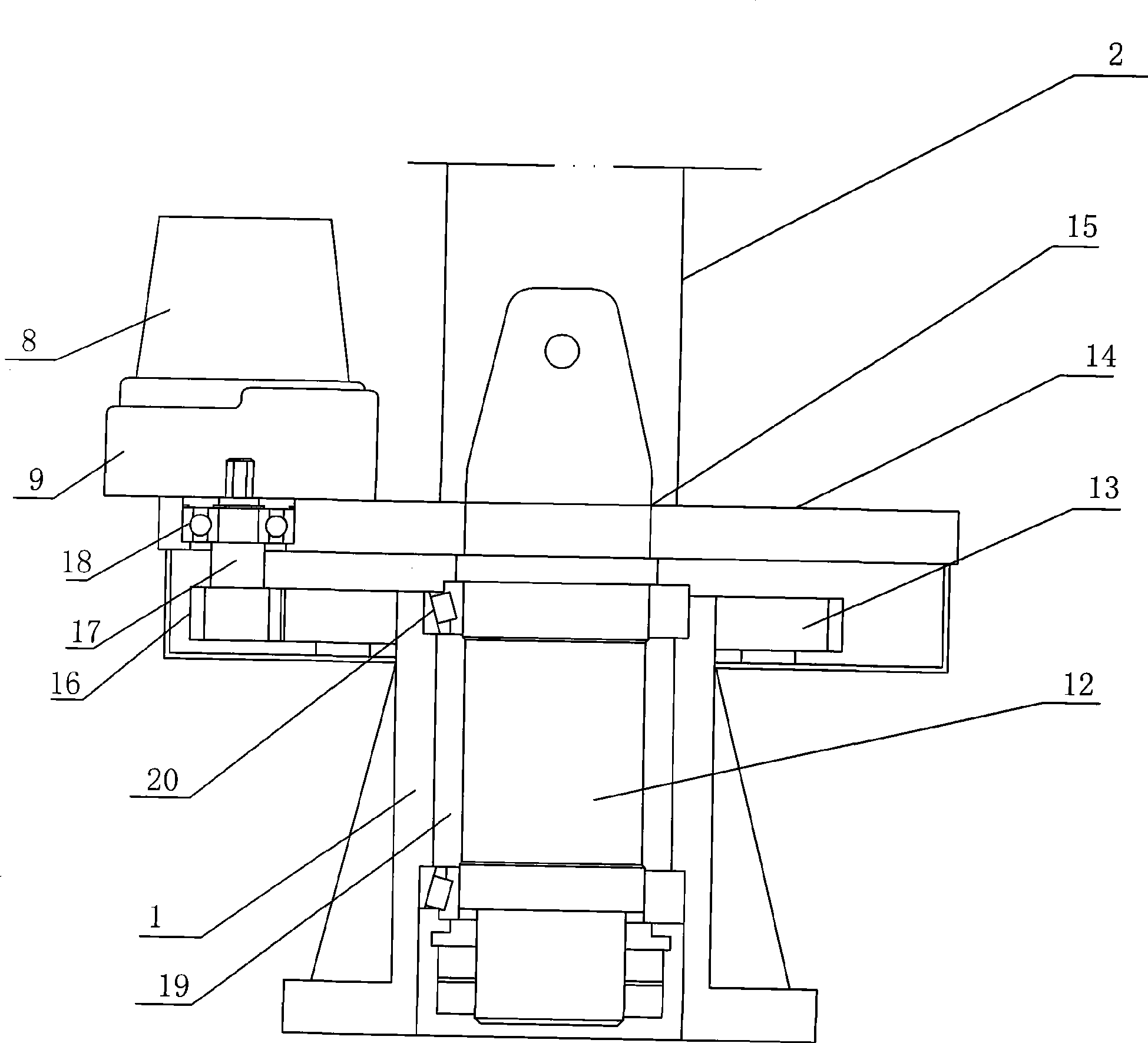

Anode loading and unloading station

The invention relates to anode carbon block assembling equipment in the electrolytic aluminum industry, in particular to an anode loading and unloading station. According to the anode loading and unloading station, an anode scrap can be fast and accurately contained in a catenary suspension bell jar, and an assembled new anode can be demounted from the catenary suspension bell jar. The anode loading and unloading station is composed of an anode scrap loading station, a tip-over station, an anode unloading station, a first transfer car and a second transfer car which are connected together in series through a rail support. Steel rails are mounted on the rail support. The first transfer car and the second transfer car are mounted on the steel rails, the first transfer car can operate back and forth between the anode scrap loading station and the anode scrap unloading station along the steel rails, and the second transfer car can operate back and forth between the anode unloading stationand the anode loading station along the steel rails. The anode loading and unloading station is simple, accurate and fast in loading and unloading, manual assistance is not needed, the labor cost is effectively reduced, and meanwhile the labor intensity of workers is greatly reduced.

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

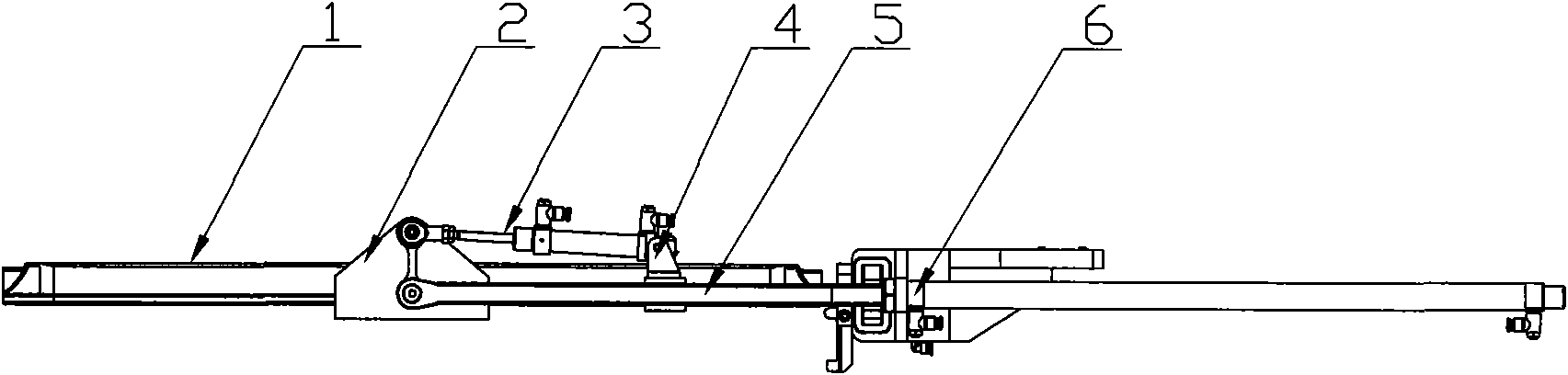

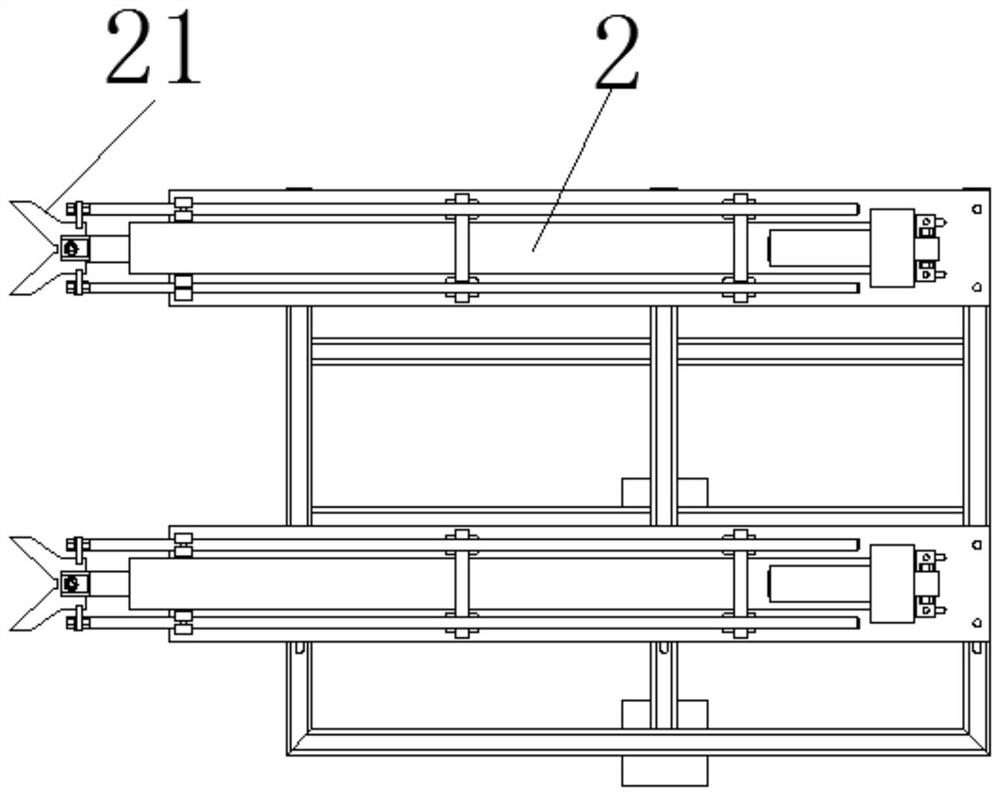

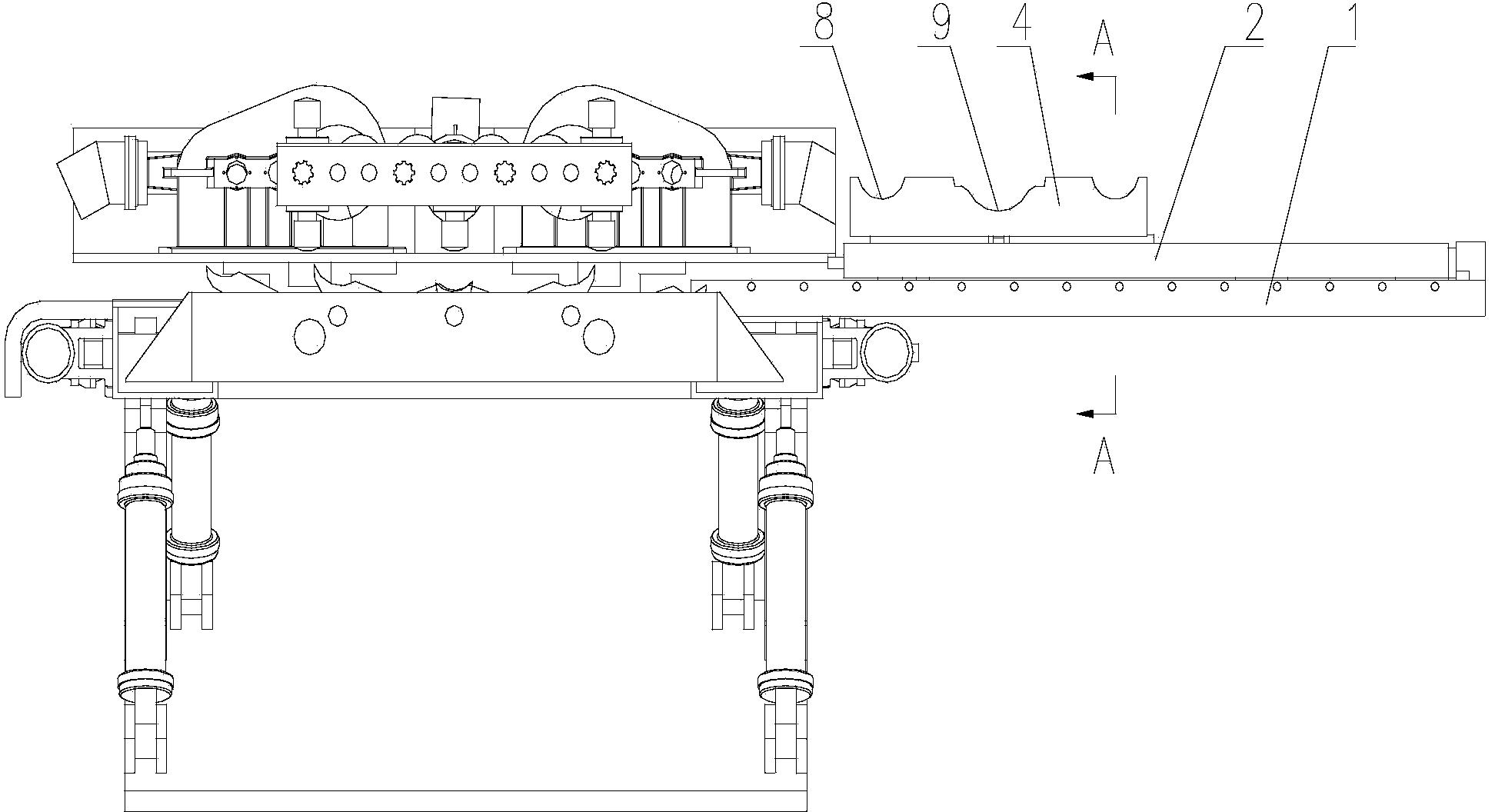

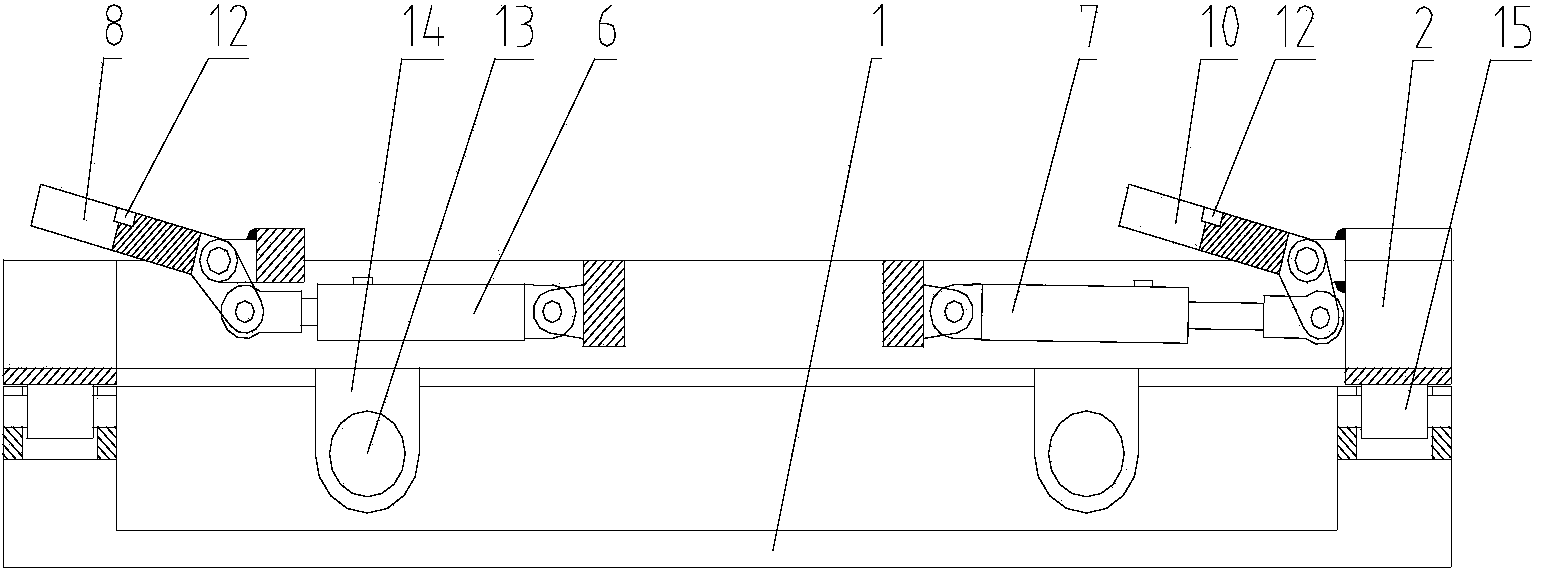

Automatic loading and unloading platform for drill rod group

ActiveCN103541671ASmooth loading and unloadingRealize loading and unloadingDrilling rodsDrilling casingsSingle degree of freedomReverse execution

The invention discloses an automatic loading and unloading platform for a drill rod group. The automatic loading and unloading platform comprises a bottom plate, a sliding table, a side sliding driving device and a drill rod group positioning component, the sliding table is slidably connected to the bottom plate by single degree of freedom and is driven by the side sliding driving device to slide in a reciprocating manner, the drill rod group positioning component is mounted on the sliding table, drill rods and air ducts are combined to form the drill rod group which can be conveyed to the space between a spindle of a spiral drill type coal mining machine and a connected drill rod group through the sliding table after the drill rod group is placed and positioned on the automatic loading and unloading platform for the drill rod group, a main engine is controlled to advance, so that the drill rod group can be connected, the sliding table can return to an original position after connection, a next drill rod group is mounted, the drill rod group can be detached by the aid of reverse execution, manual loading and unloading can be replaced, the labor intensity of workers is reduced, the drill rod group can be accurately positioned, the drill rods are successfully loaded and unloaded, time consumption is reduced, and the mining efficiency of coal beds is improved.

Owner:CHONGQING UNIV

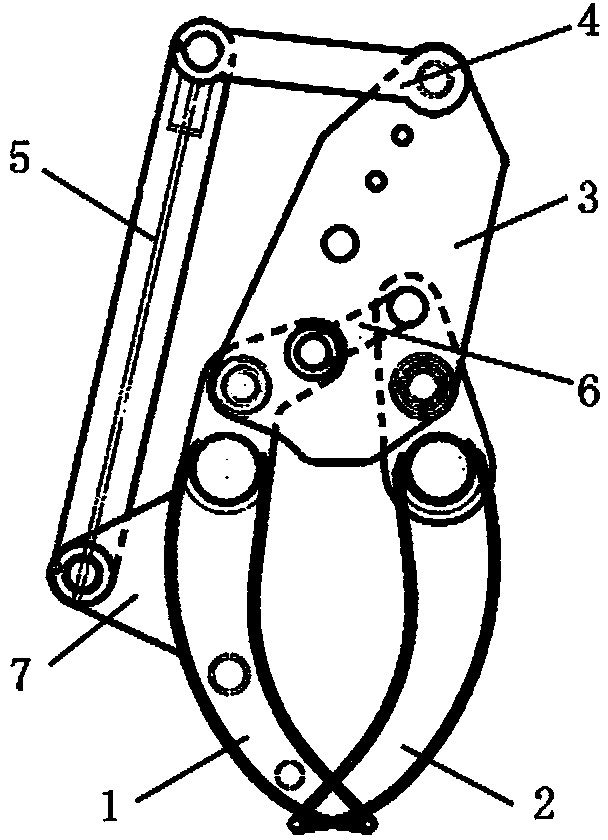

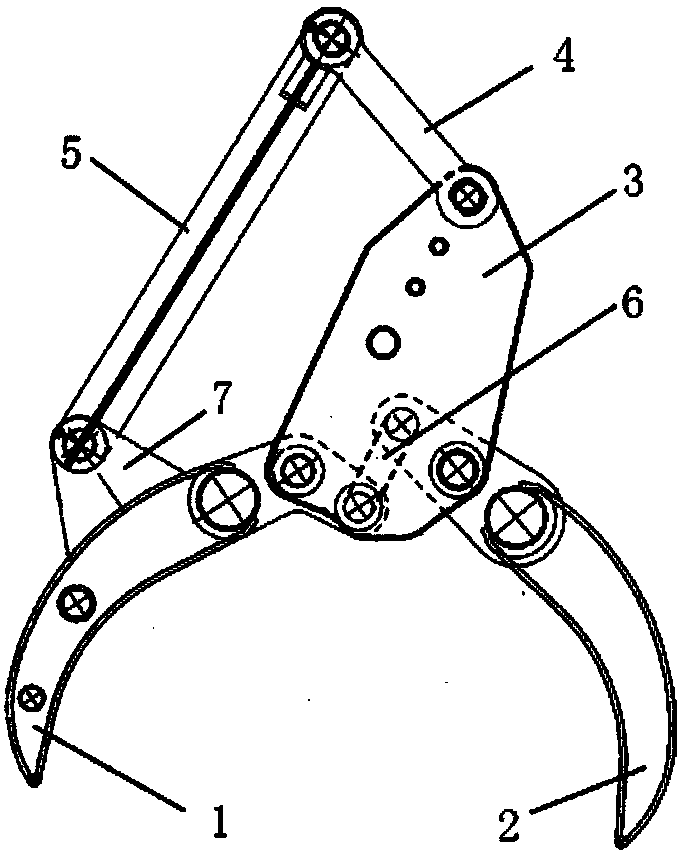

Multipurpose mechanical gripper

Owner:黄全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com