Crawling robot top cover screw locking device matched with rotary type vehicle

A screw-locking and rotating technology, which is applied in the field of screw-locking devices on the top cover of crawling robots, can solve the problems of lower production costs, low production efficiency, and cumbersome positioning, and achieve the goals of reducing energy consumption, convenient positioning, and reducing the number of up and down lifts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

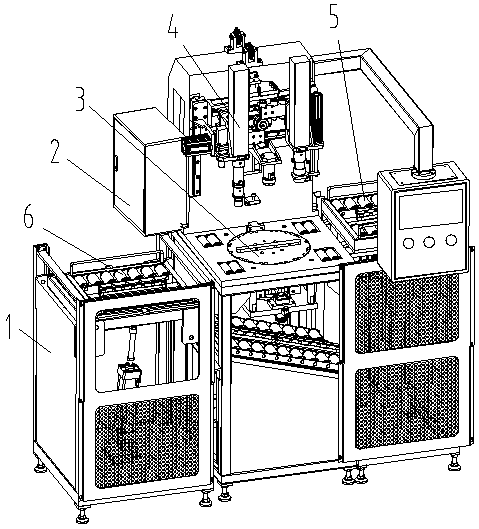

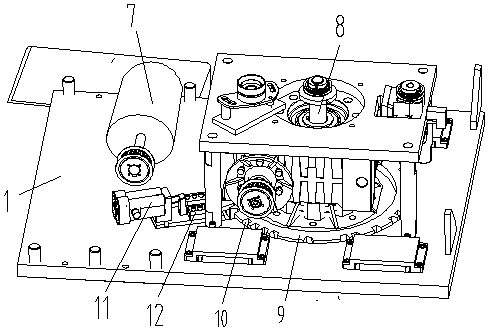

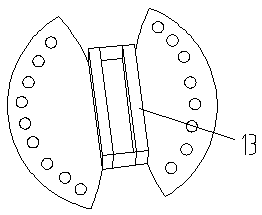

[0037] Such as Figure 1-Figure 7As shown, the specific structure of the present invention is: a crawling robot top cover locking screw device matched with a rotary carrier, which includes a frame 1 and a power distribution control box 2, and the frame 1 is provided with a loading Device 3, the loading device 3 is equipped with a locking screw device 4, the loading device 3 includes a turntable motor 7 and a turntable shaft 8 that are arranged on the frame 1 and cooperate with each other, and the turntable shaft 8 is A turntable 9 is provided, the upper part of the turntable 9 is provided with a protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com