Upright structure of timber architecture and upright structure and foundation connecting method

A connection method and wood structure technology, applied in the field of B64D, can solve the problems of construction, long construction period, high environmental requirements, difficult repair and maintenance, etc. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

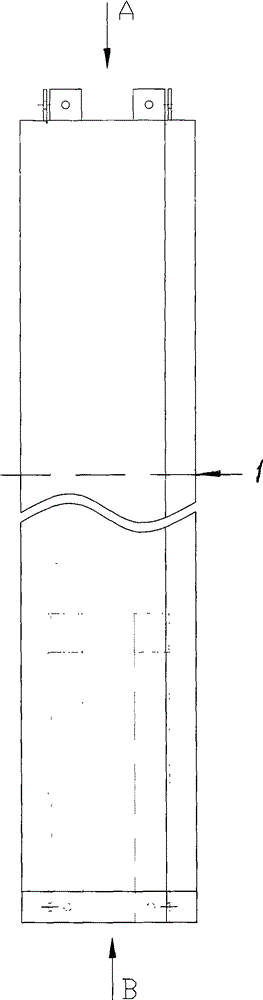

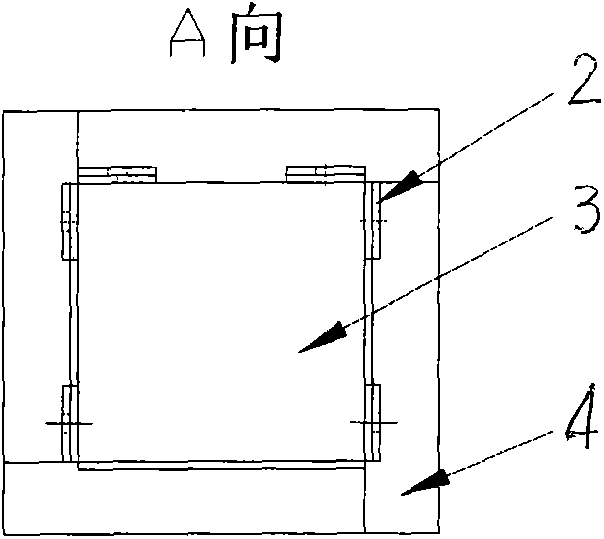

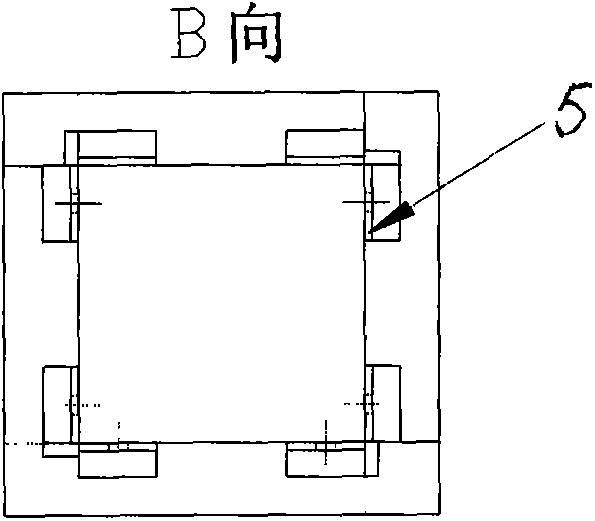

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and its embodiments: the tooth plate is pressed and embedded on the column core by the machine tool, and the tooth plate on the upper part of the column core has a depression, which is convenient for the connection between the column and the column; the tooth plate After the installation is completed, the auxiliary sealing plate is connected with the column core by screws to form a column module; in the construction process, only simple auxiliary positioning is required, and the effective connection of the column can be completed by connecting the tooth plates in the two columns with bolts; finally The column installation can be completed by blocking the bolted connection area with a baffle. The adjustable foundation is also produced in a modular manner in the factory. The required connecting steel parts are pre-embedded in the adjustable concrete through the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com