Patents

Literature

121results about How to "Quick and easy installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED Illumination systems

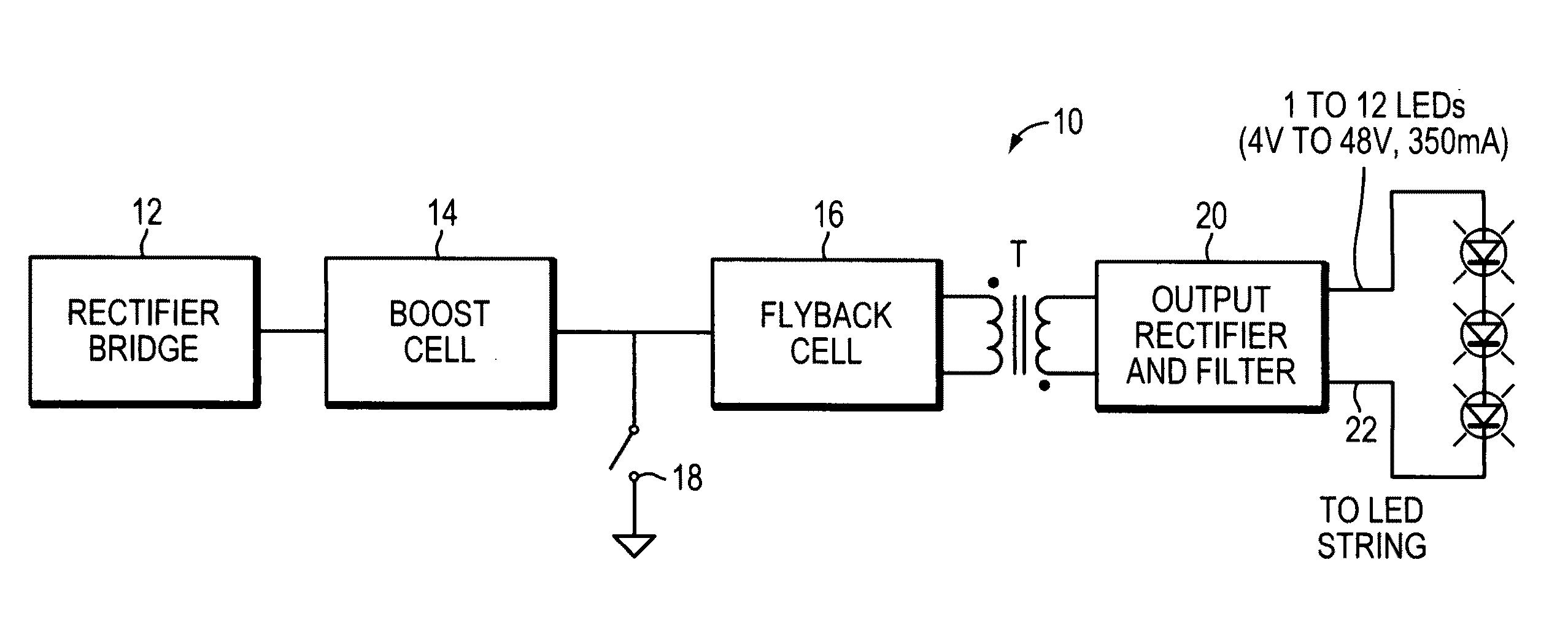

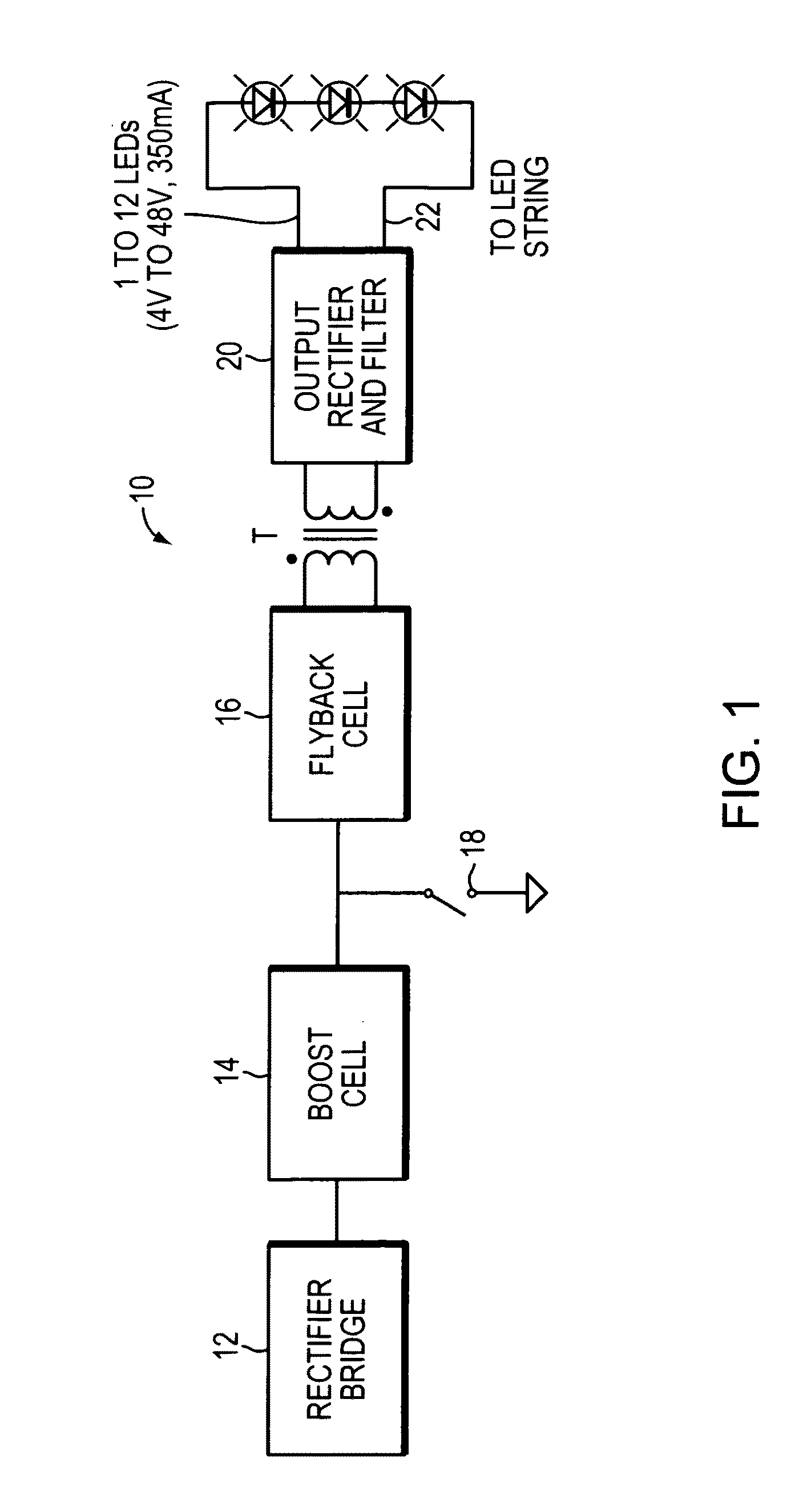

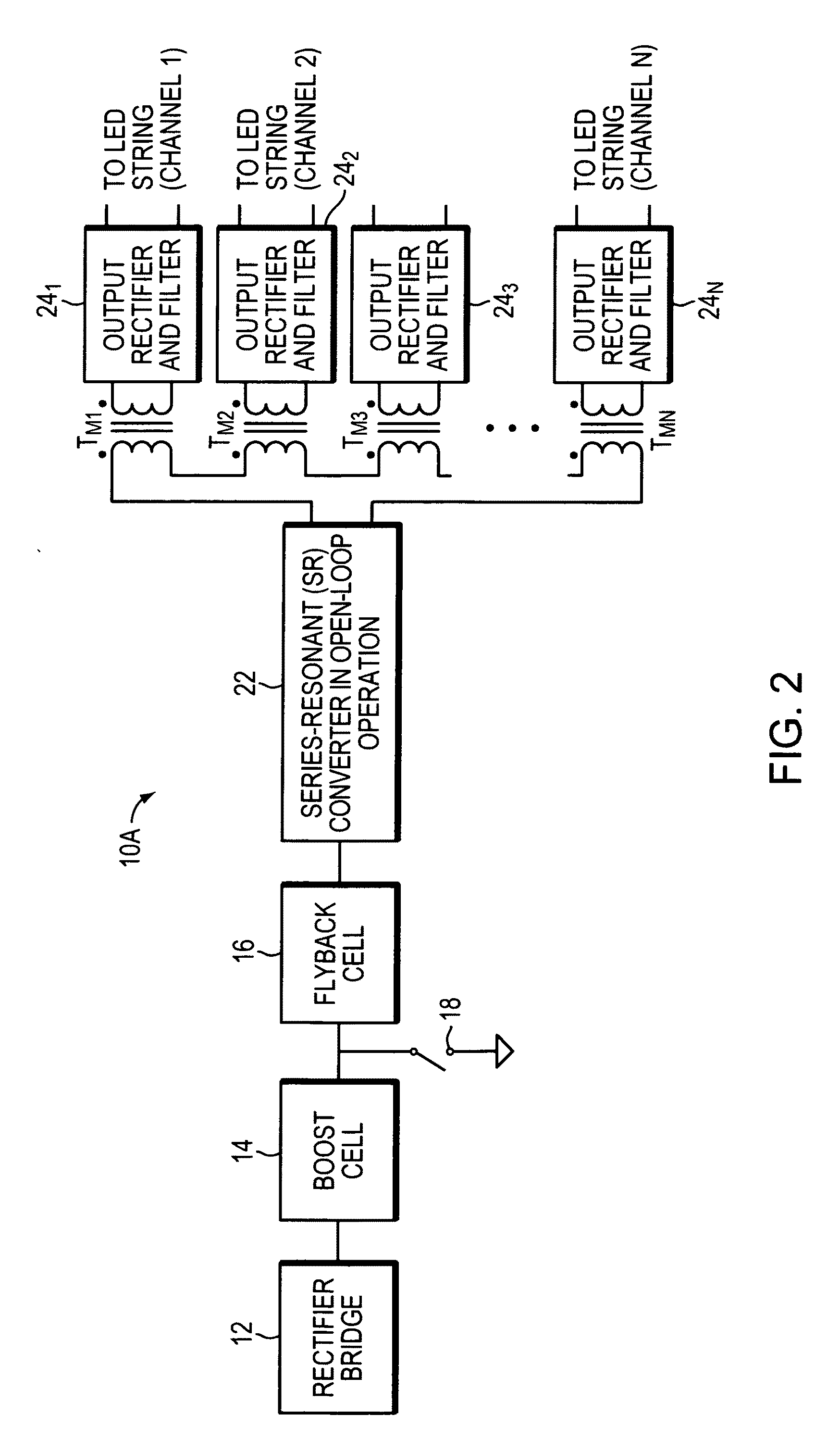

InactiveUS20110309760A1Improve reliabilityLow costEfficient power electronics conversionElectroluminescent light sourcesBuck converterFlyback diode

An illumination system includes a power supply having a boost converter operating in the discontinuous conduction mode, a flyback converter operating in the critical conduction mode, and a switch coupled to the flyback converter. Several light emitting diodes receive power from the power supply. The boost converter may include a boost inductor (LB) and a boost diode (DB), constructed to perform the boost power factor correction (PFC) function. The flyback converter may includes a flyback inductor (LFB) and a flyback diode (DFB) and the power supply may be constructed to turn on the switch around the point where the current flowing in the flyback inductor reaches zero value.

Owner:EMD TECH

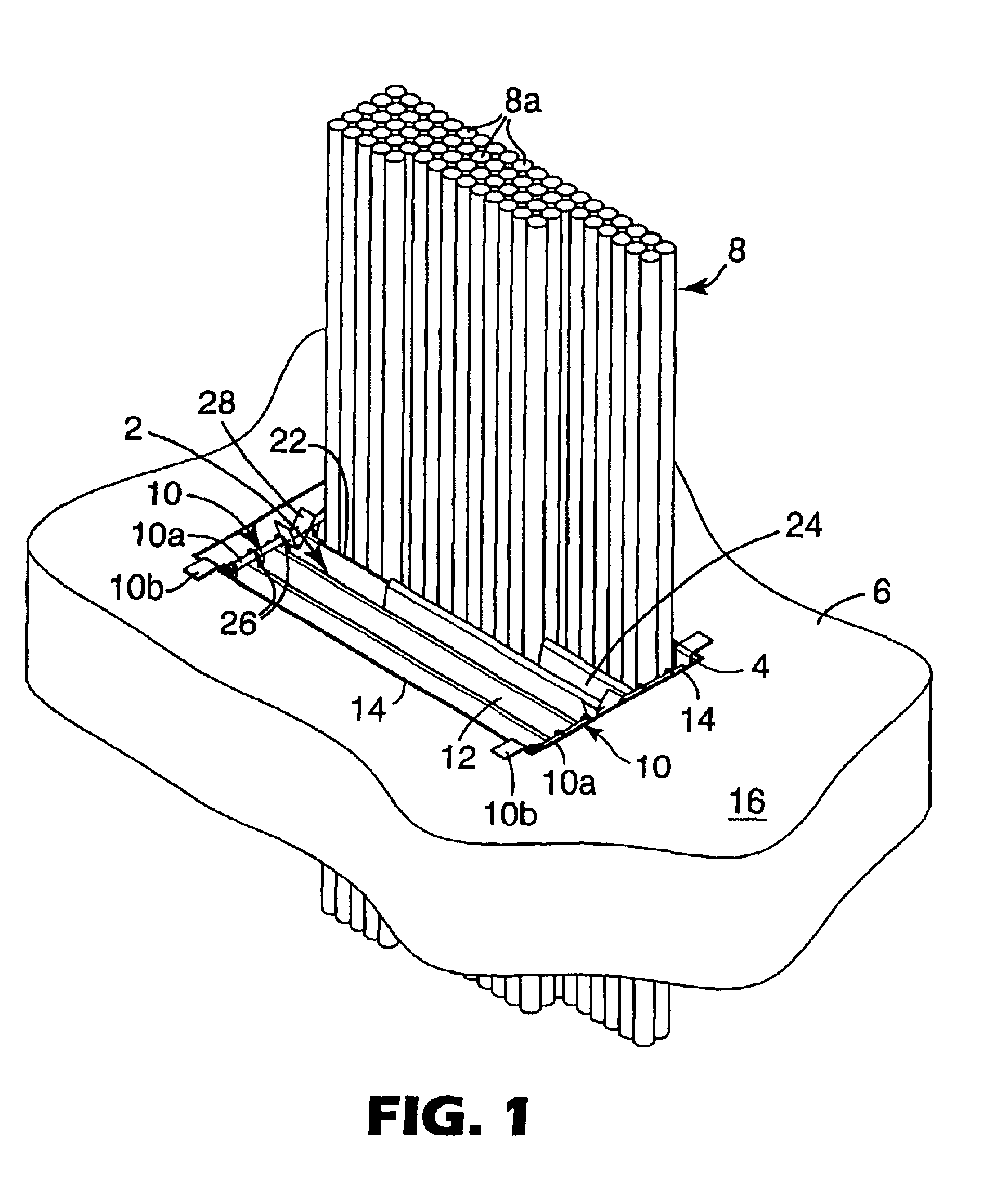

Method and apparatus for firestopping a through-penetration

InactiveUS6928777B2Quickly and easily addedQuickly and easily and removedElectrical apparatusFire proofingBiomedical engineering

An apparatus for creating a firestopping barrier in a through-penetration includes a support mechanism arranged within the through-penetration, firestop material movably connected with the support mechanism, and firestop material arranged between the firestop material movably connected with the support mechanism and the inner surface of the through penetration.

Owner:3M INNOVATIVE PROPERTIES CO

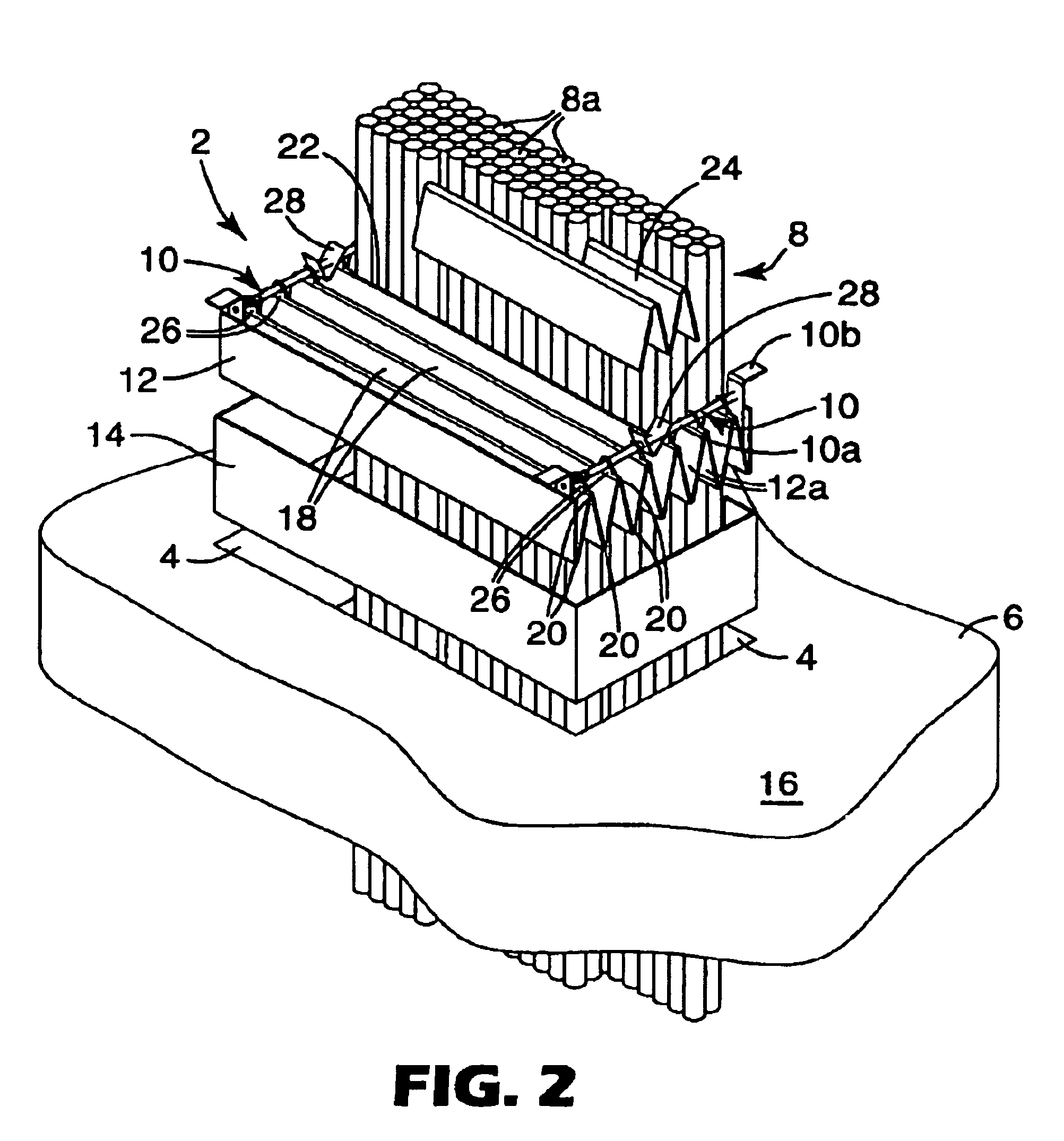

Method and apparatus for firestopping a through-penetration

InactiveUS20060053710A1Quick installationEasily and quickly and servicedElectrical apparatusFire rescueEngineeringMechanical engineering

A method and apparatus for creating firestopping barrier in a partition, such as a wall, floor, or ceiling, that is mounted adjacent the opening includes a housing containing a central opening. The cross-sectional area of the housing is greater than the cross-sectional area of the through-penetration opening, and the housing is arranged external to the through-penetration opening with at least a portion thereof extending along a surface of the partition thereby to allow the housing to be installed adjacent the through-penetration opening. Firestop material is arranged within the housing.

Owner:3M INNOVATIVE PROPERTIES CO

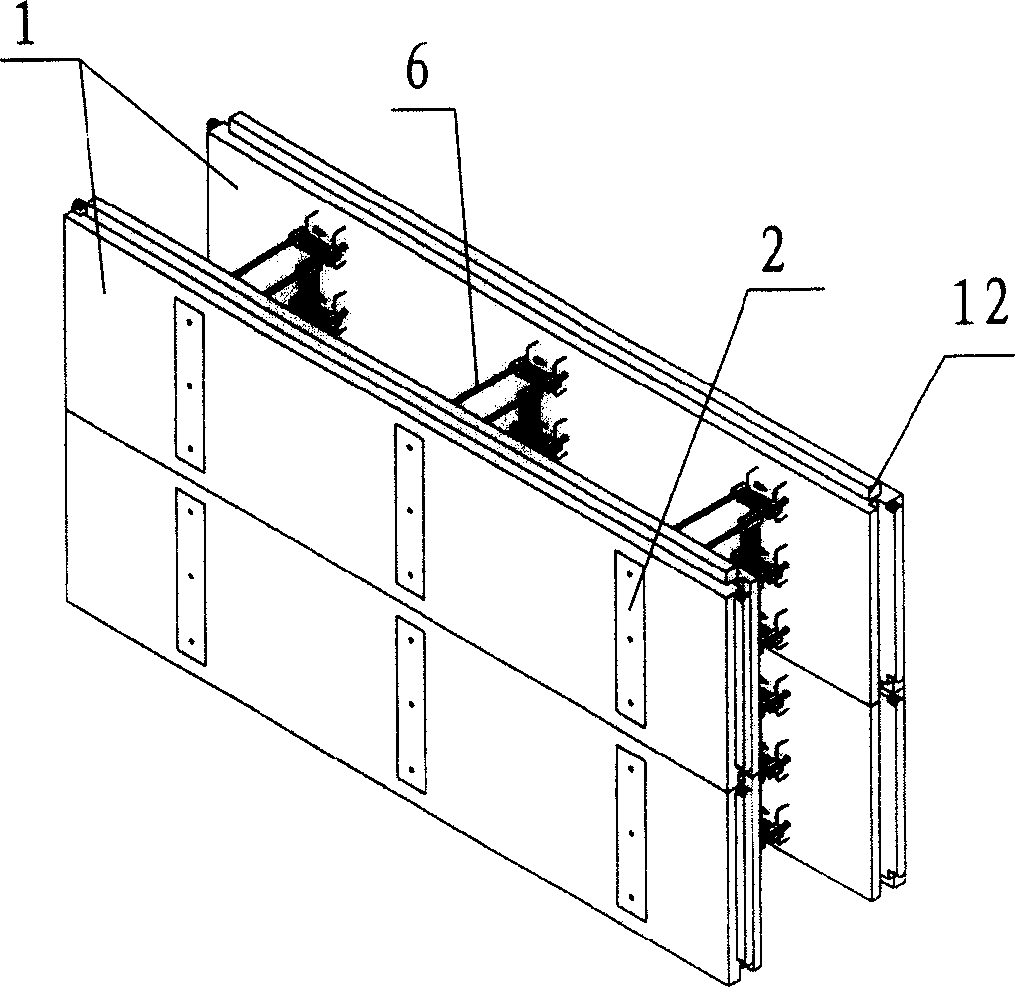

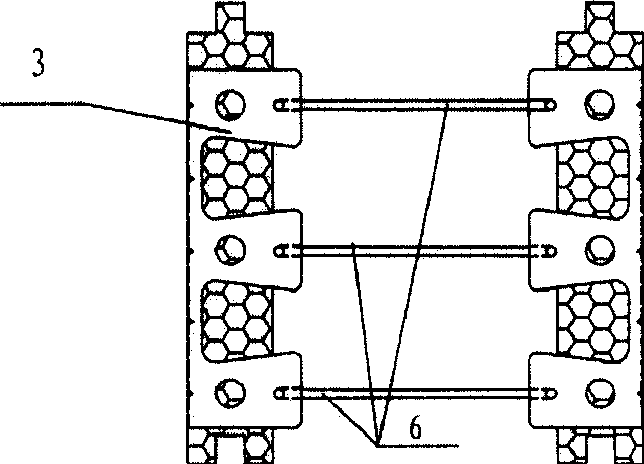

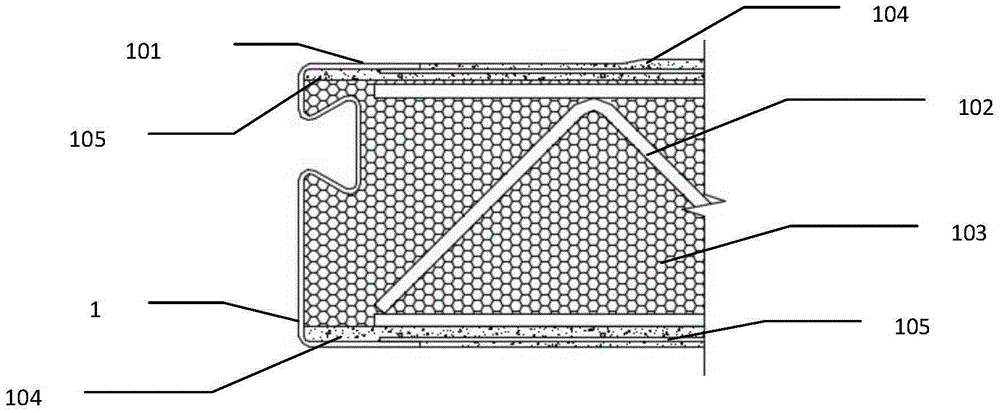

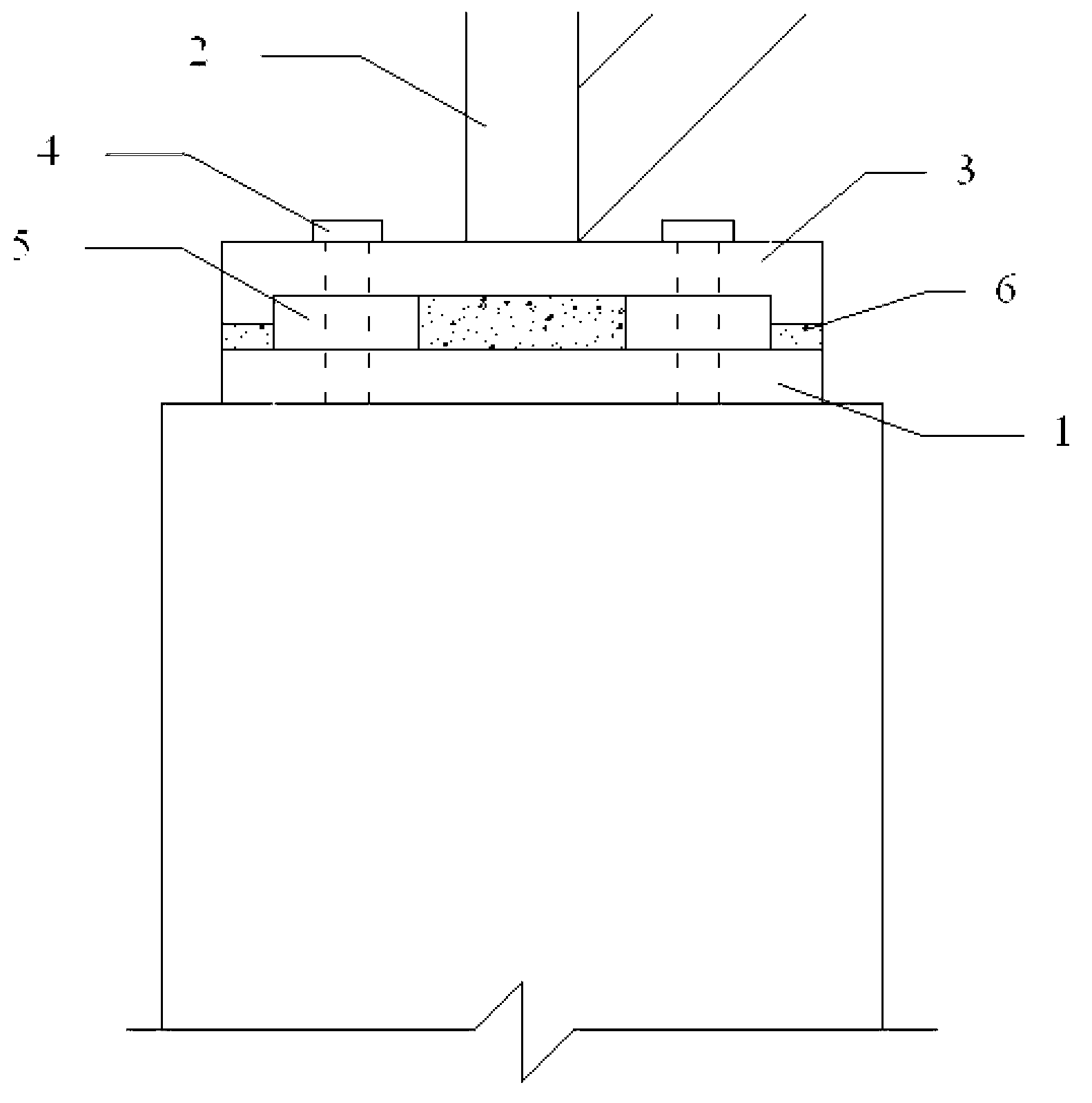

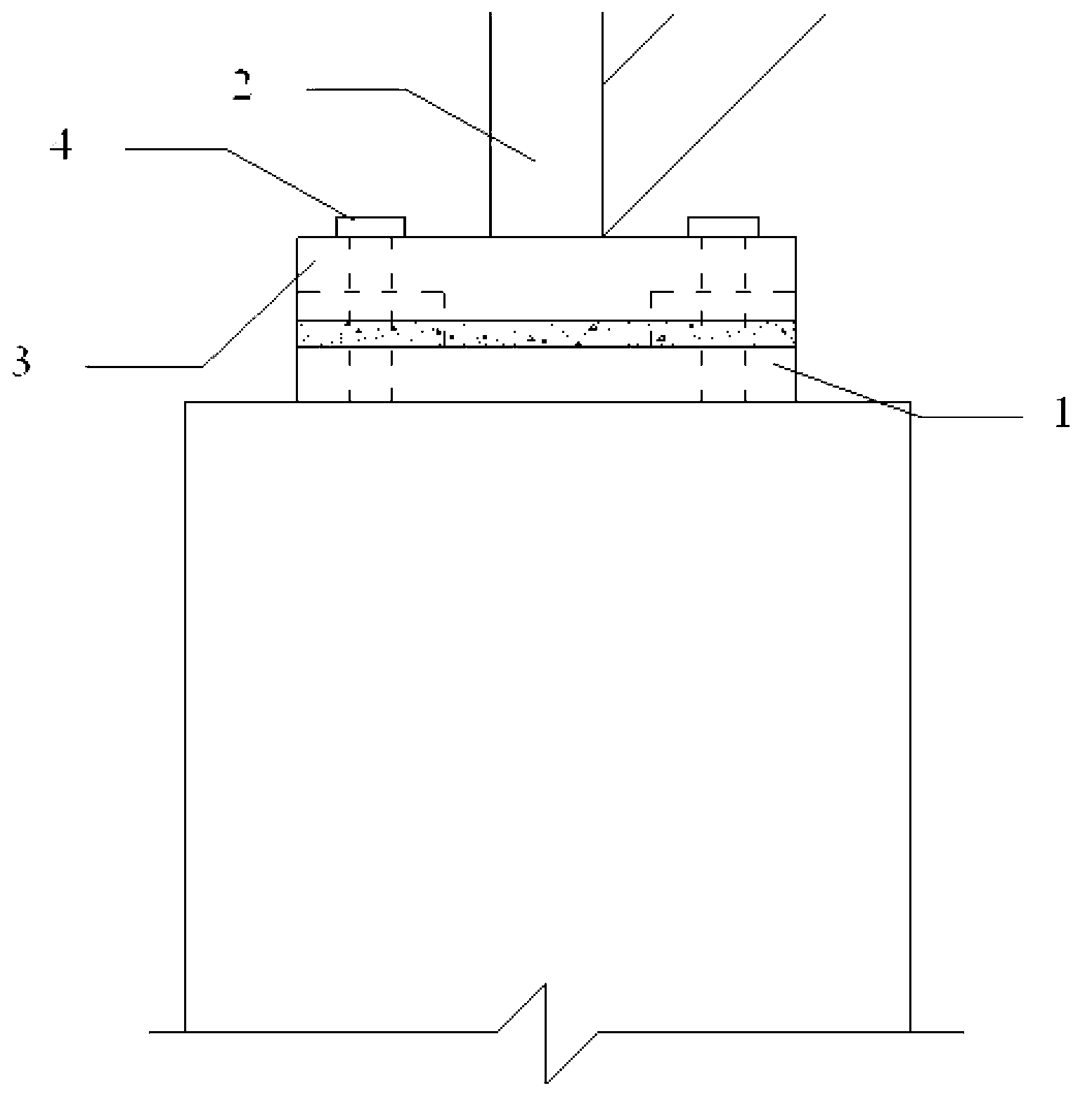

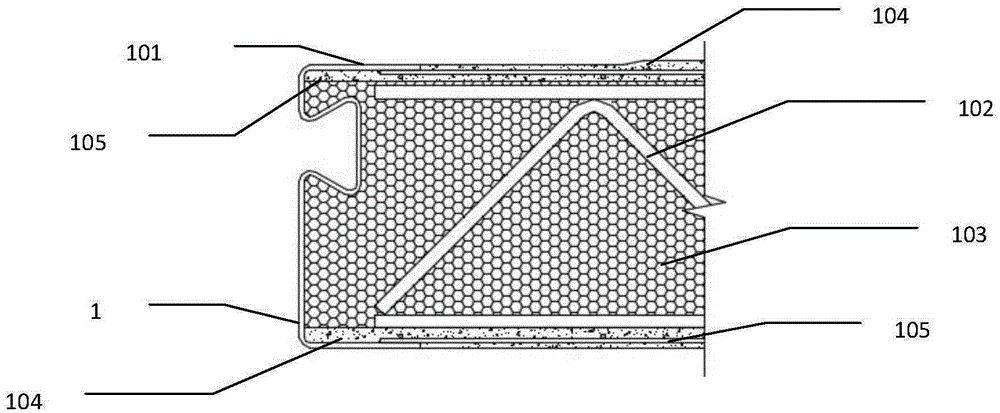

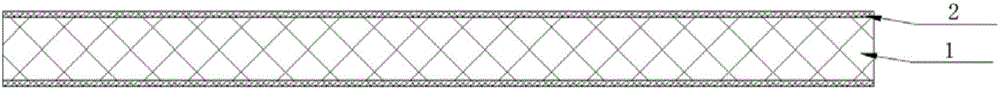

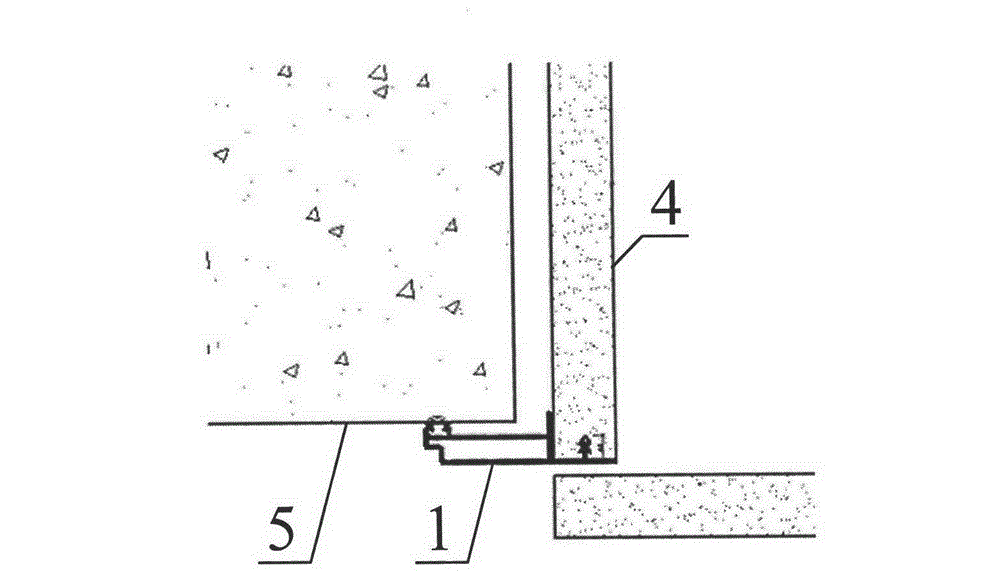

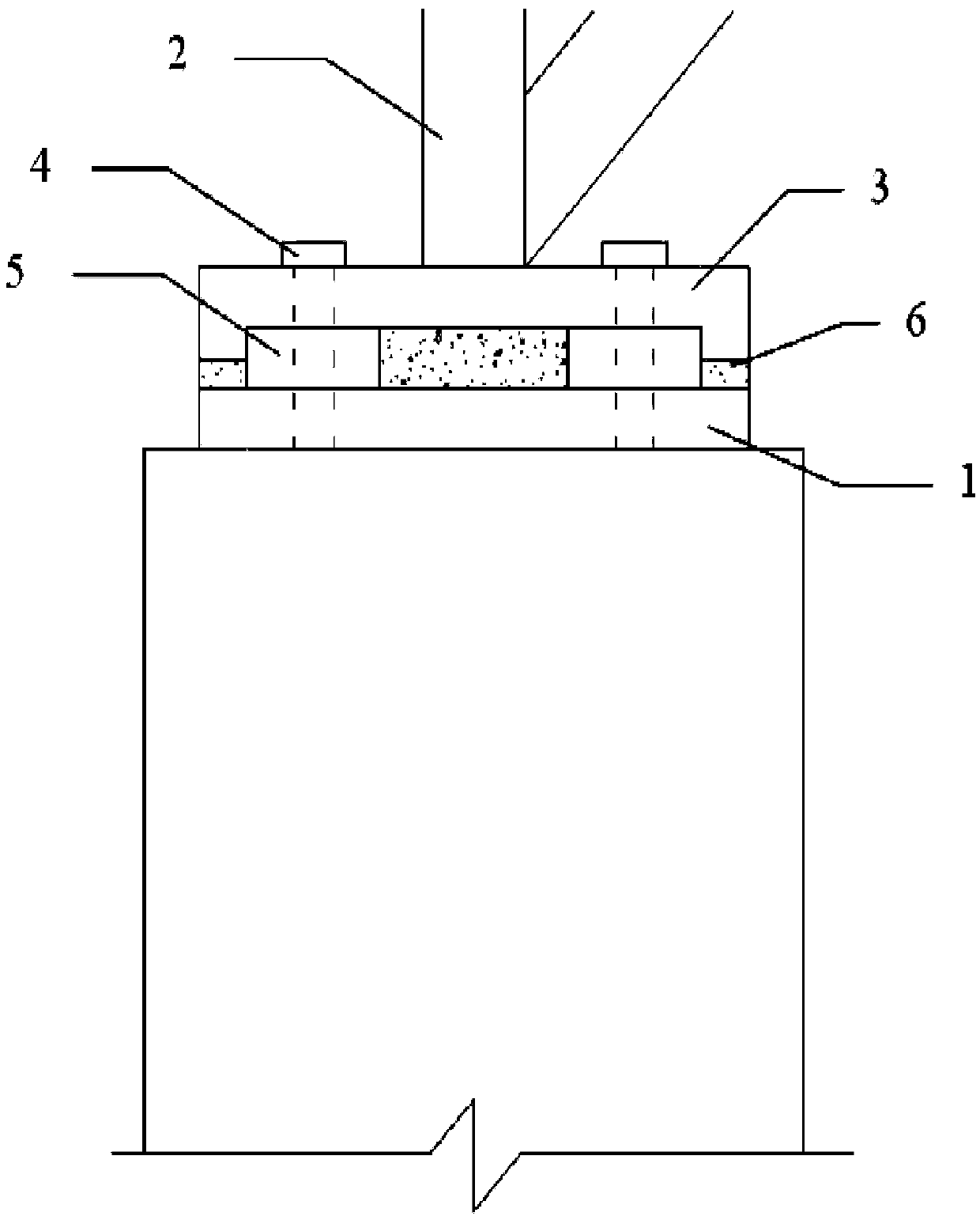

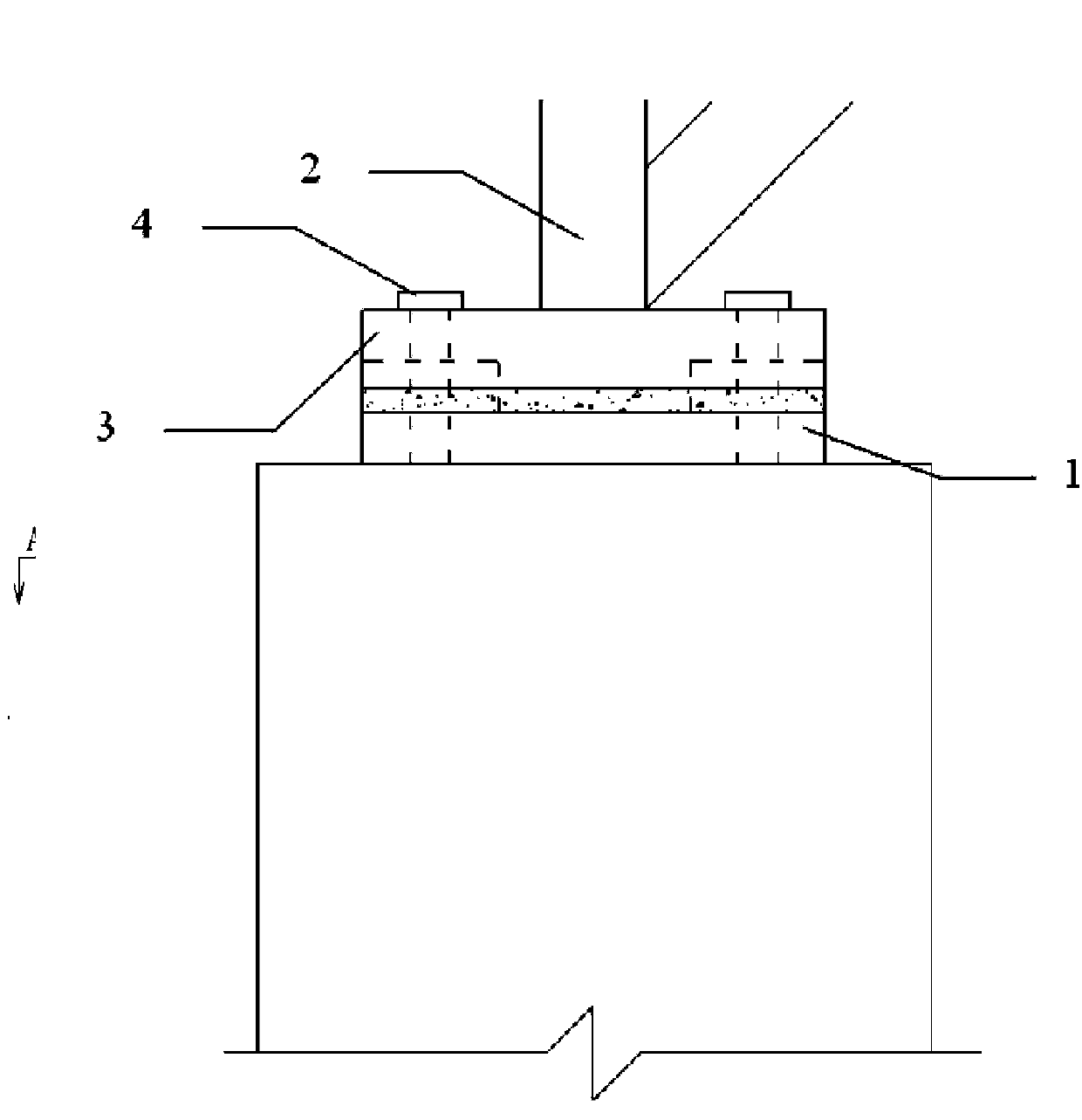

Composite thermal insulation concrete wall and its assembled template

InactiveCN1766248AOmit construction stepsLow costWallsForms/shuttering/falseworksRear quarterThermal insulation

The invention discloses a composite thermal insulation heat-proof concrete wall and assemblage type mould, which is characterized by the following: the wall two-side mould is composed of polystyrene thermal insulation material; double-row tooth fold steel is set in the each side mould; the transverse section of double-row tooth fold steel displays U-shape; the base plate of double-row tooth fold steel and one side surface of mould are in the same plane; two side plates of double-row tooth fold steel extends the other side surface of mould; the attachment connects the through-hole at even distance allocation on two side plates of double-row tooth fold steel; the attachment pierces the hole of double-row tooth fold steel side plate corresponding to two-side mould to connect the wall two sides; the net-hung rivet hole is drilled in the middle part of double-row tooth fold steel along certain vertical distance; the transverse and vertical plugging part connects the same position attachment of double-row tooth fold steel corresponding to the wall two side mould, which locks joint along the transverse and vertical direction. The mould becomes the wall inner and outer side thermal insulation layer after casting the concrete.

Owner:朱秦江

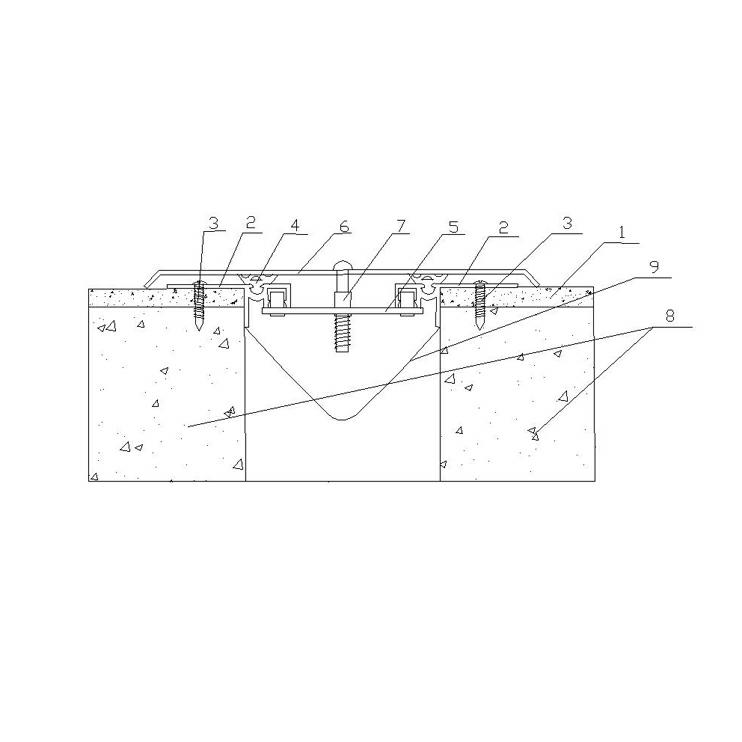

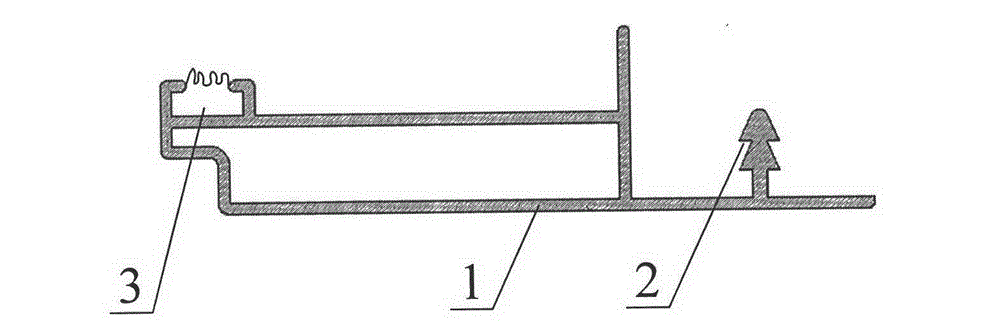

Expansion joint-adjustable dual-waterproof installation construction process

ActiveCN102140848AHigh practical valueNeat appearanceBuilding material handlingArchitectural engineeringExpansion joint

The invention discloses an expansion joint-adjustable dual-waterproof installation construction process, comprising the following process steps of: plastering wall surfaces positioned on the expansion joint; carrying out construction measurement on both sides of the expansion joint; adhering waterstops; installing and fixing an aluminum alloy base; sizing the edges of the aluminum alloy base; embedding rubber strips; assembling and fixing a slide rod and a cover plate; processing the expansion joint, and cleaning an exterior. The invention has the advantages of firm installation, dual waterproofing, large expansion amount and elegant appearance without the raised margins of the cover plate.

Owner:CHINA ZHONGSHE CONSTR ENG GROUP

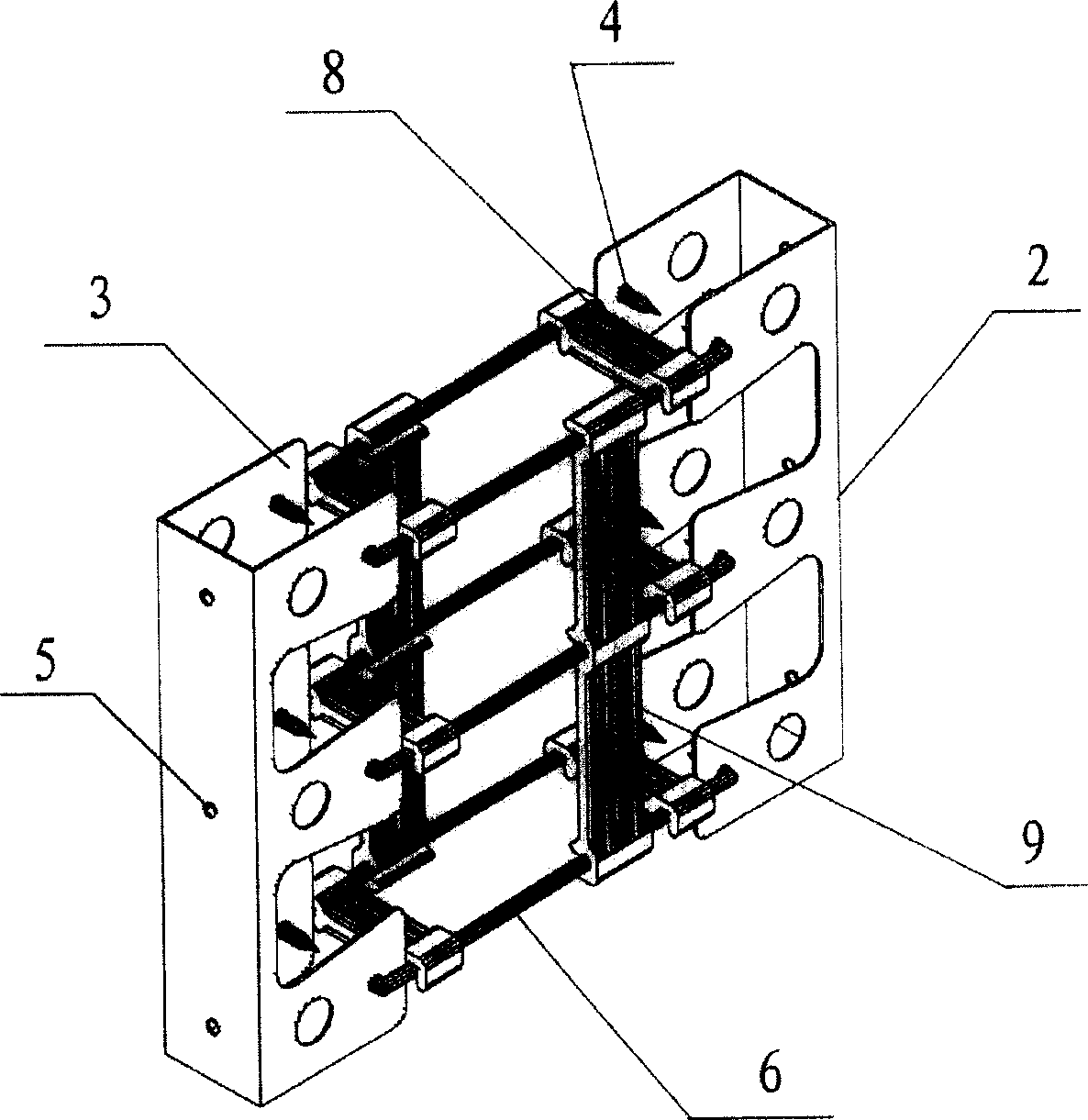

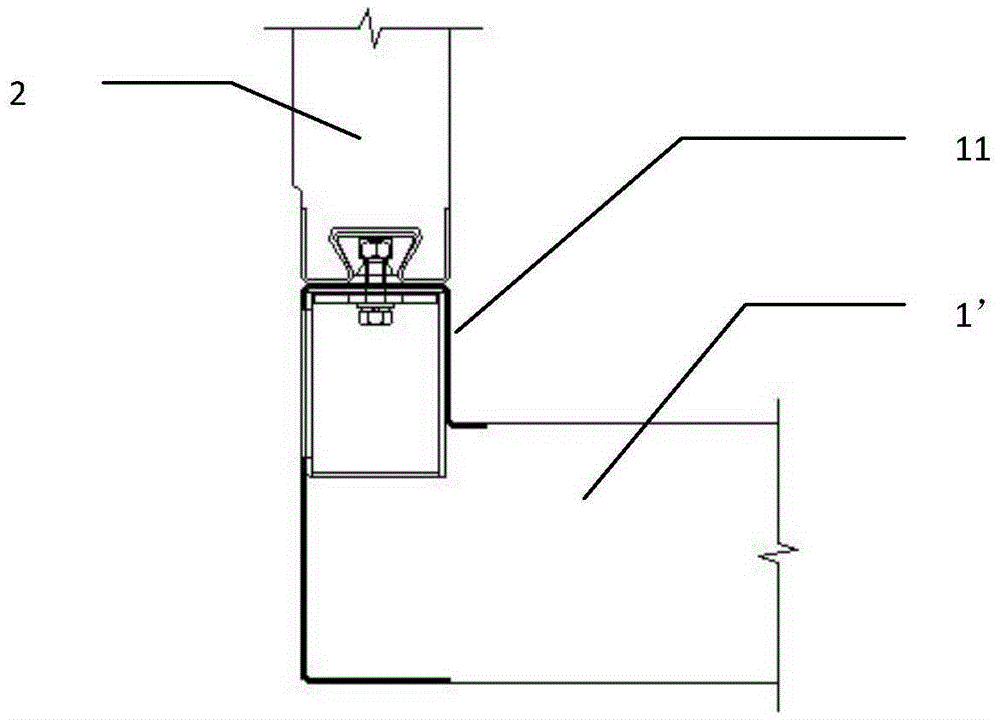

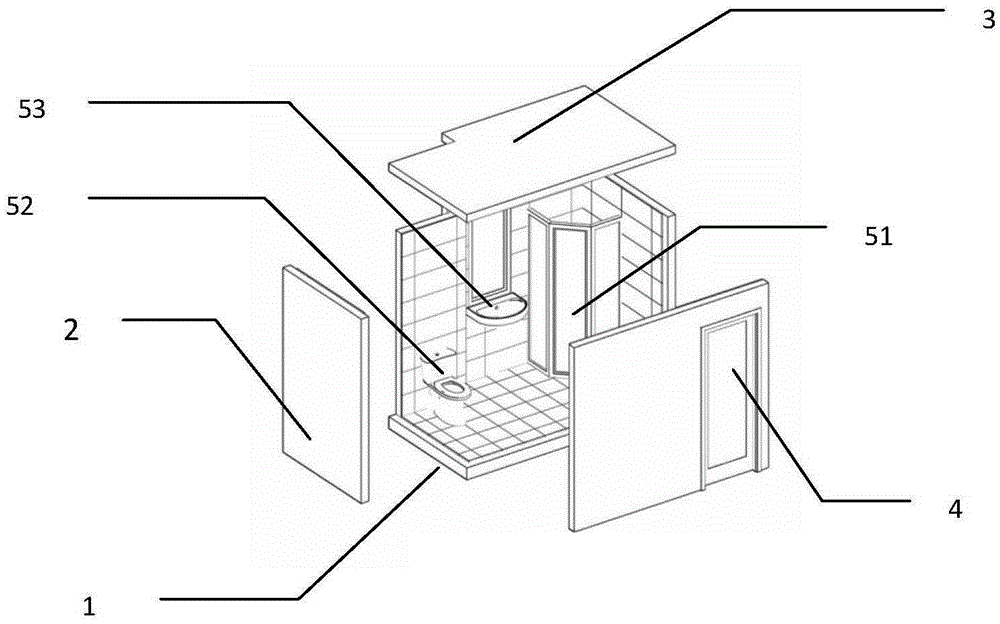

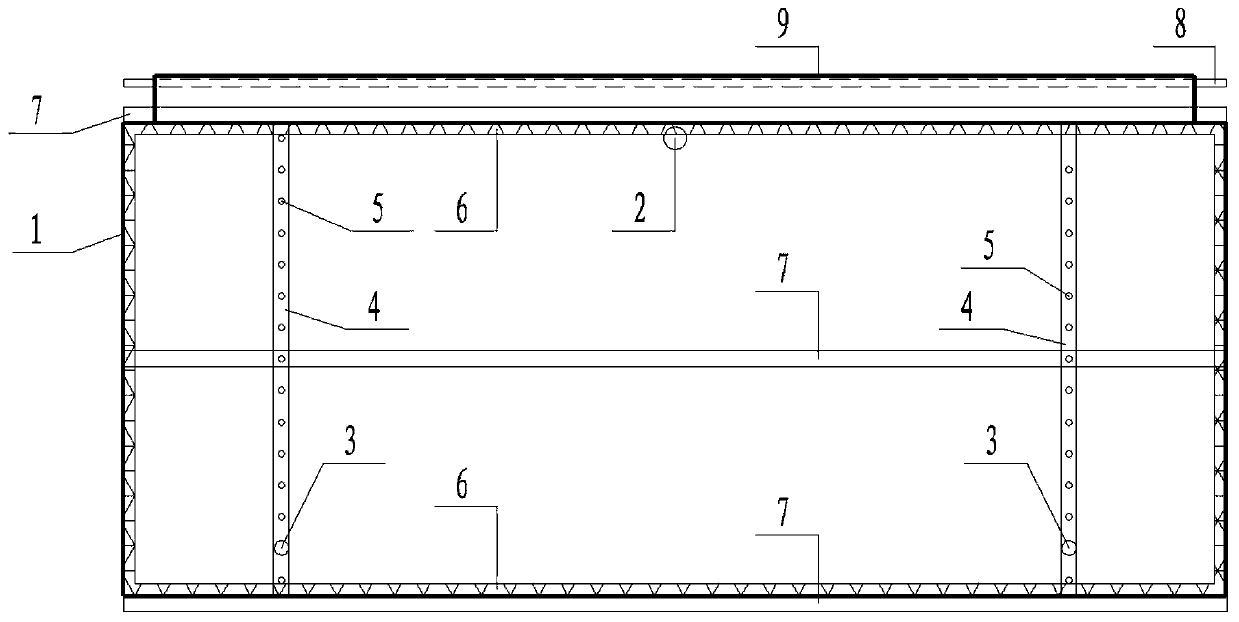

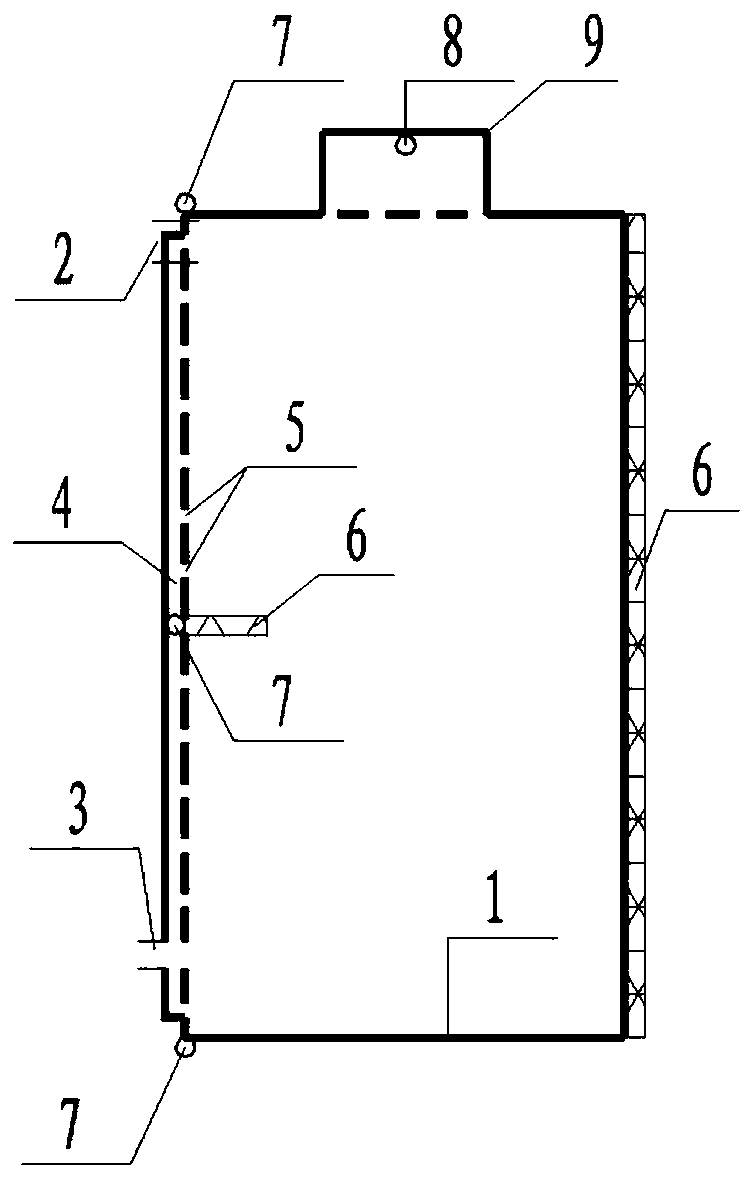

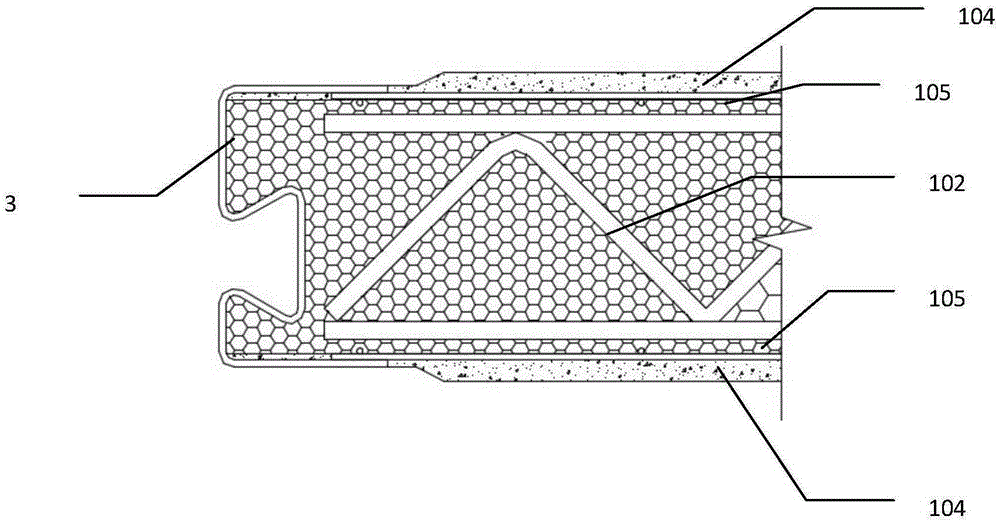

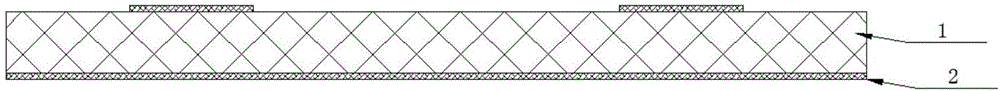

Assembly-type integrated bathroom and construction method thereof

ActiveCN105421826ARefractory hasSound insulation hasSpecial buildingBuilding constructionsThermal insulationBathroom Equipment

The invention relates to an assembly-type integrated bathroom and a construction method thereof. The assembly-type integrated bathroom comprises foaming cement composite bottom plates, foaming cement composite wall plates, foaming cement composite top plates and bathroom equipment; dovetail groove type steel frame edge ribs are arranged in the plates, and each dovetail groove type steel frame edge rib is composed of an upper wing flange, a lower wing flange and a dovetail groove edge rib groove; an embedded part wedge block is arranged in each dovetail groove edge rib groove; all the plates are fixedly connected through bolts, connecting parts and the wedge blocks arranged in the dovetail groove edge rib grooves of the plates. The assembly-type integrated bathroom has the advantages that the foaming cement composite plates obtained through industrialized production are adopted, the fire resistance duration is larger than or equal to 4 hours, the sound insulation is larger than or equal to 42 decibels, raw materials forming the plates adopt inorganic materials and are non-combustible, and the comprehensive properties of energy conservation and environment protection, bearing and thermal insulation, heat insulation, fire resistance, durability, shock resistance, small mass, high strength and the like are achieved; installing operation is easy and convenient, rapidness and firmness are achieved, and environmental pollution and noise emission caused by traditional bathroom construction are reduced. The assembly-type integrated bathroom is an energy-saving and environment-protecting green building product.

Owner:CUBIC DIGITAL TECH CO LTD +2

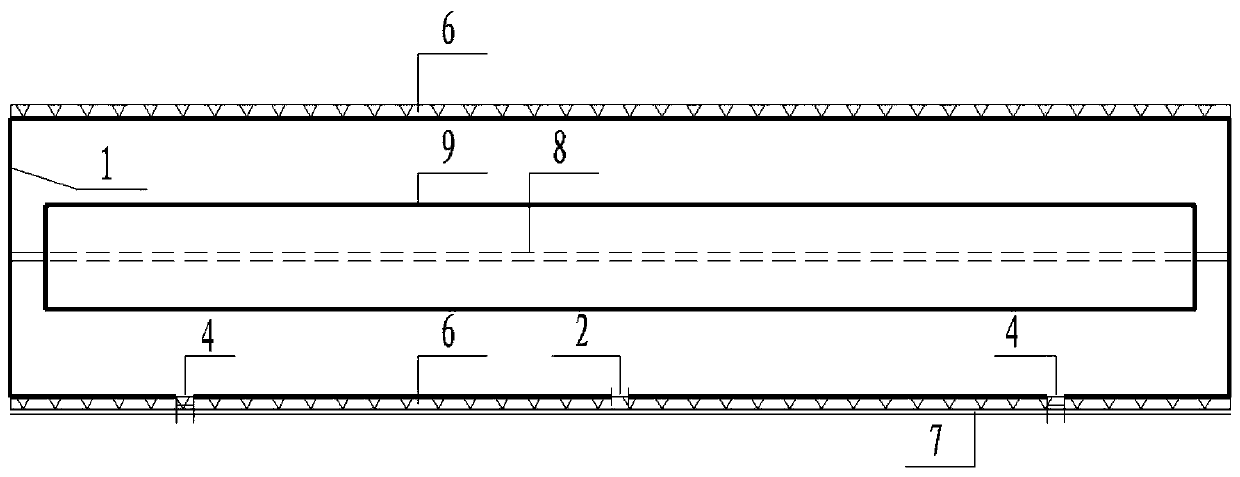

Goaf rapid grouting filling bag synchronous with coal cutting and coal mining method of goaf rapid grouting filling bag

ActiveCN109707442ARapid grouting constructionEnable continuous installationUnderground miningSurface miningWater pipeSmall hole

The invention relates to the technical field of coal mine mining methods, in particular to a goaf rapid grouting filling bag synchronous with coal cutting and a coal mining method of the goaf rapid grouting filling bag. The problems that in the prior art, the filing process is not synchronous and matched with the coal cutting process, the filling speed is low, the filling support effect is poor, asystem is complex, and the investment is high are solved. According to the technical scheme, the goaf rapid grouting filling bag synchronous with coal cutting comprises a bag body, a jacking type ofthe top of the bag body through a folding structure, a secondary grouting pipe is arranged on the upper part of the interior of the folding structure in a penetrating mode, connecting pieces are arranged at the periphery of the outer wall of the bag body, a plurality of water guide pipes are longitudinally arranged on the front side surface of the bag body, a plurality of internal drainage small holes are formed in the surfaces on which the bag body is in contact with the water guide pipes, drainage holes are formed in the bottoms of the outer walls of the water guide pipes, a grouting hole isformed in the middle position of the top of the front side surface of the bag body, rod penetrating pipes are arranged on upper and lower edges and middle of the front side surface of the bag body atintervals, and the problem of the prior art is solved through a certain coal mining method.

Owner:CCTEG BEIJING HUAYU ENG

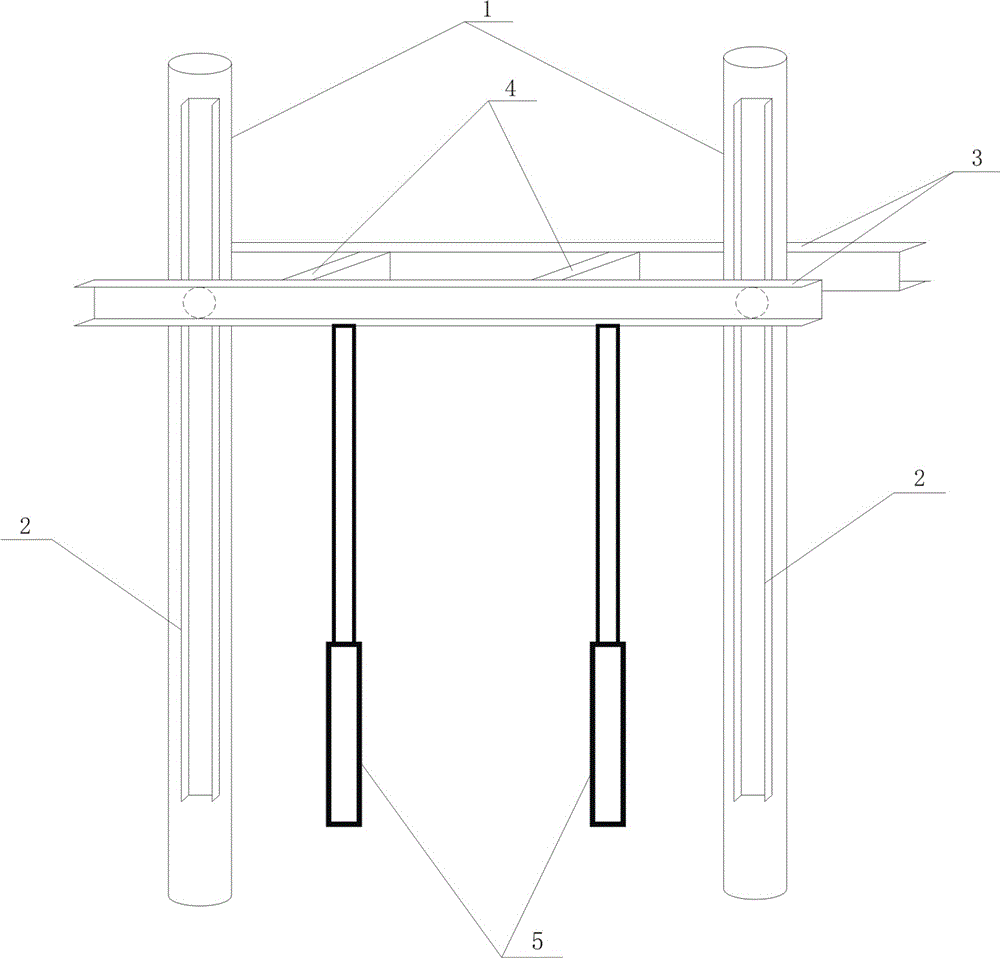

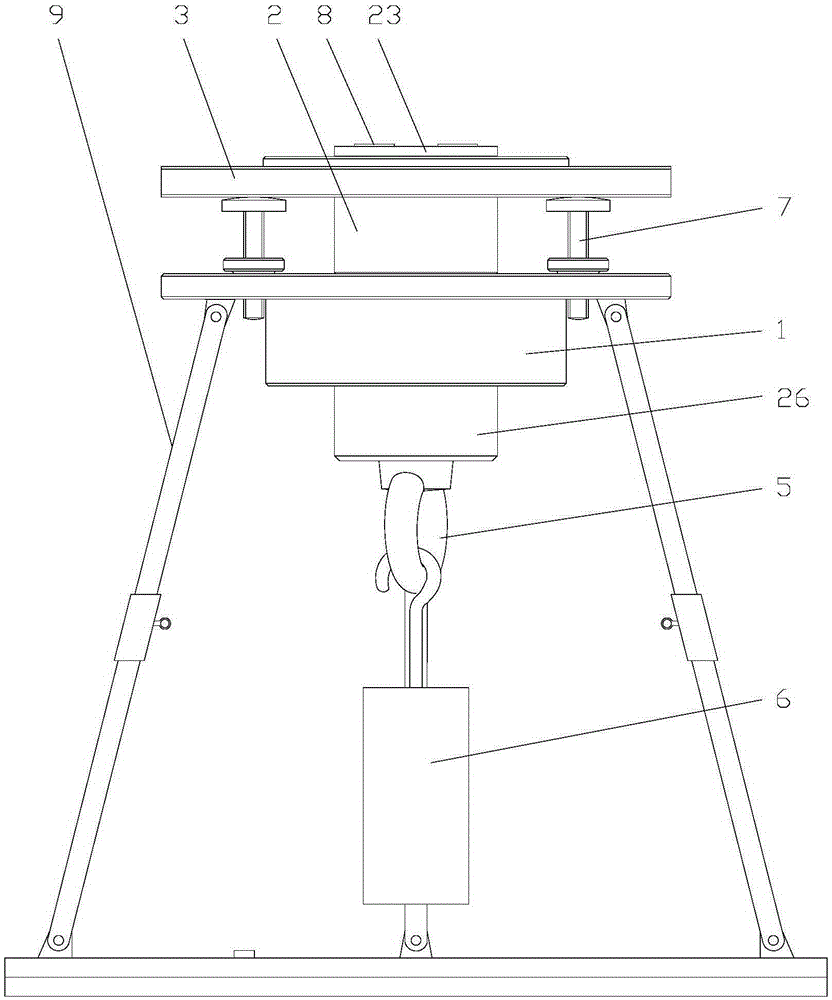

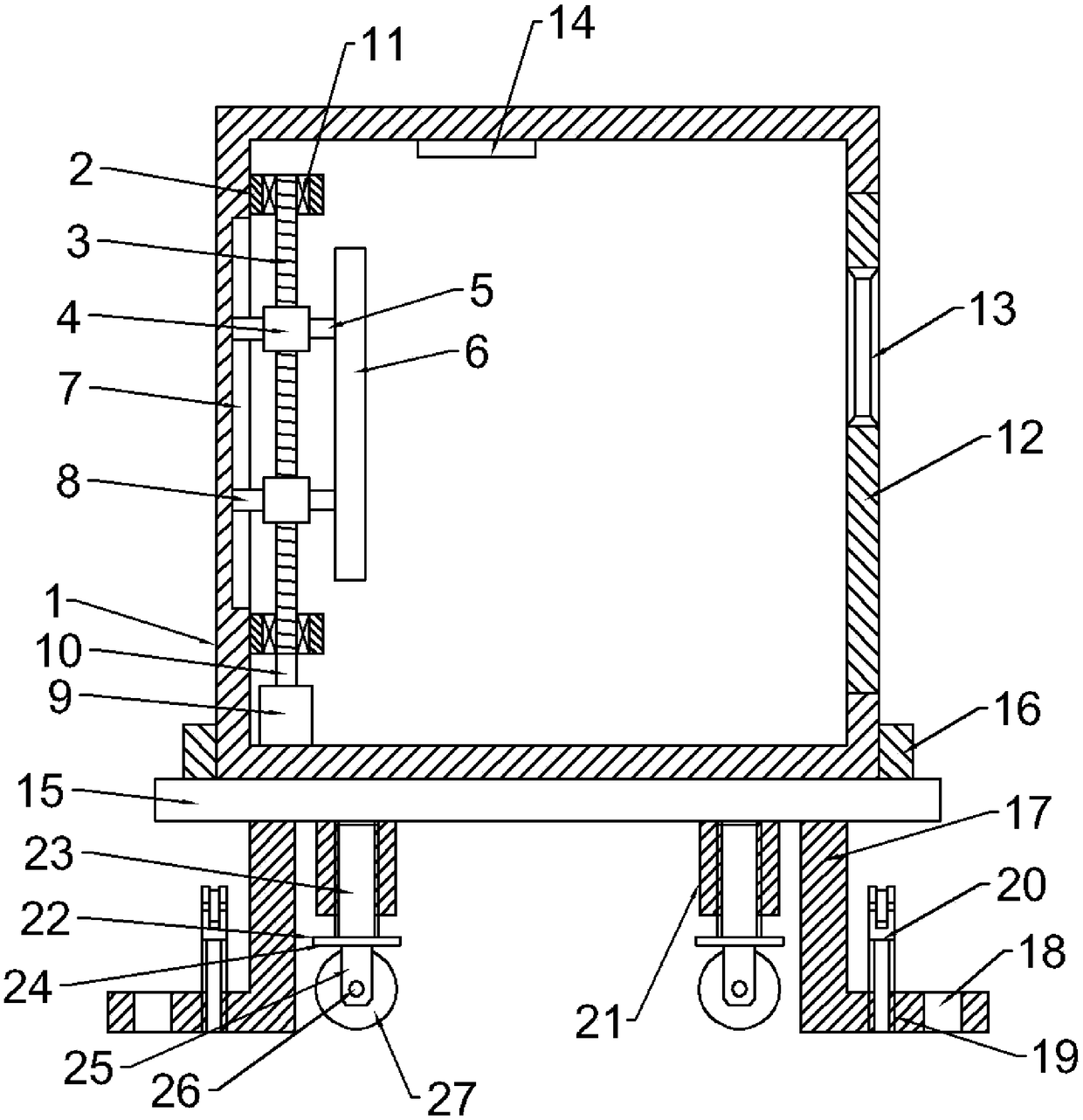

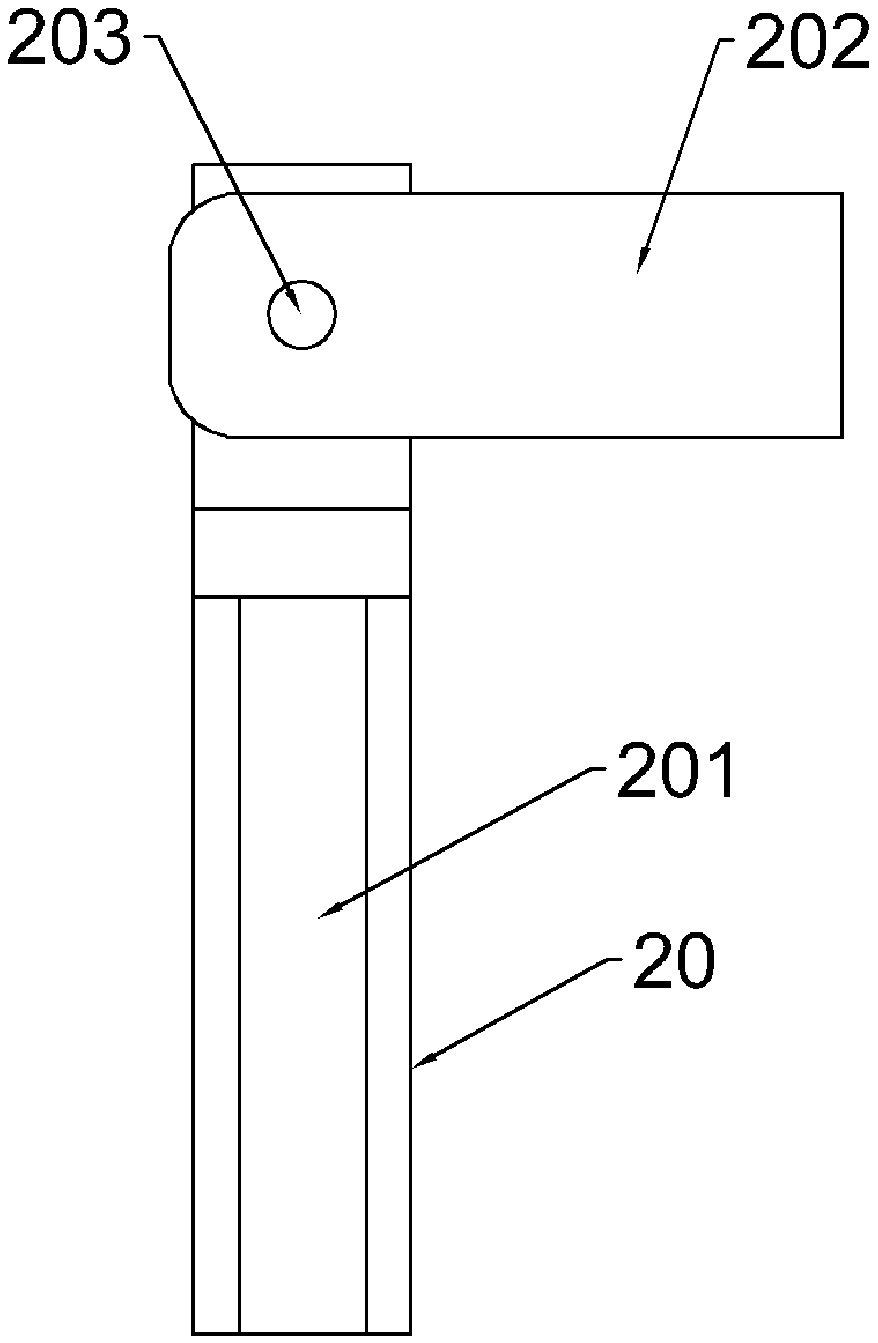

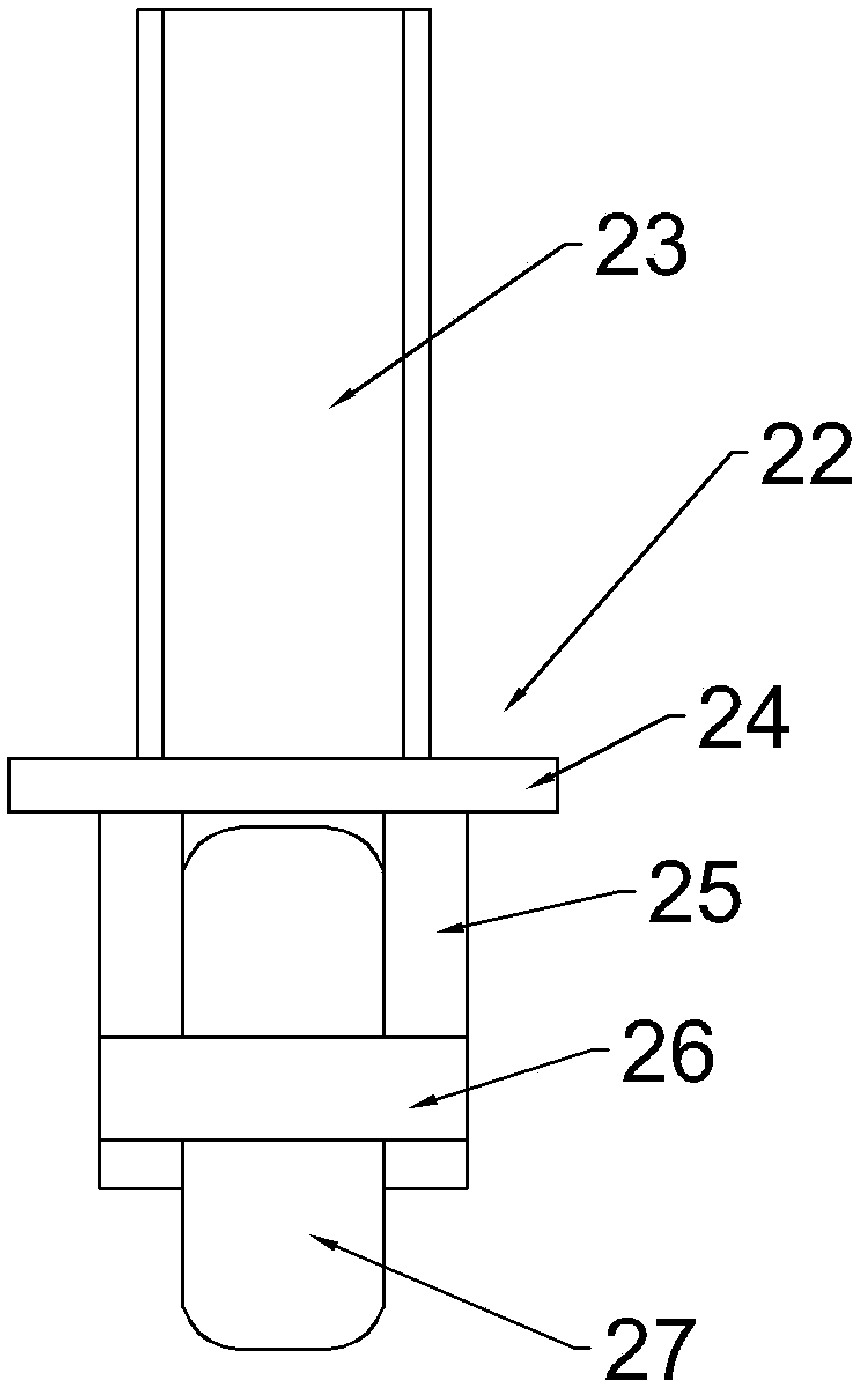

Installation device for pole-mounted transformer

InactiveCN105261447AEasy to operateQuick and easy installationTransformers/reacts mounting/support/suspensionSubstation mounted on poleHydraulic cylinderTransformer

The invention discloses an installation device for a pole-mounted transformer. The installation device comprises fixed steel channels, sliding steel channels and a hydraulic cylinder, wherein two wire poles which are arranged in parallel are respectively provided with the two fixed steel channels; the two fixed steel channels on each wire pole are symmetrically arranged front to back; one sliding steel channel is respectively connected between the two fixed steel channels at the same sides of the two wire poles; two idler wheels are arranged on the rear side surfaces of the sliding steel channels, and are correspondingly assembled in notches in the two fixed steel channels respectively; the two sliding steel channels are fixedly connected with each other through a connecting rib plate; and the hydraulic cylinder is arranged on the lower end surface of the connecting rib plate. Rising and falling of the two sliding steel channels are realized through actions of the hydraulic cylinder; in addition, the two sliding steel channels roll in the fixed steel channels through the idler wheels arranged on the sliding steel channels, so that the sliding steel channels stably rise or fall; when the transformer is installed, the transformer is firstly put on the two sliding steel channels, and then rising of the transformer can be achieved through the hydraulic cylinder, so that the installation operation is convenient, fast, time-saving and labor-saving.

Owner:ELECTRIC POWER OF HENAN LUOYANG POWER SUPPLY +1

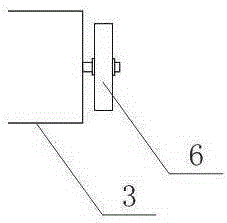

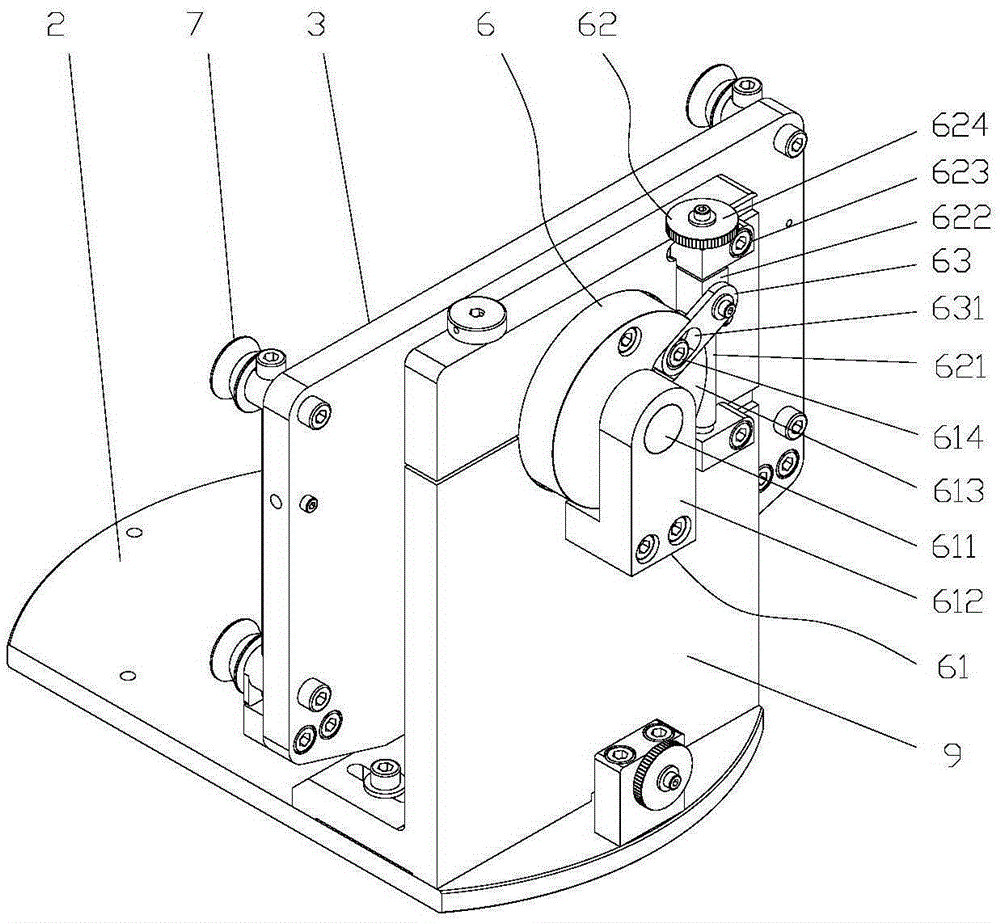

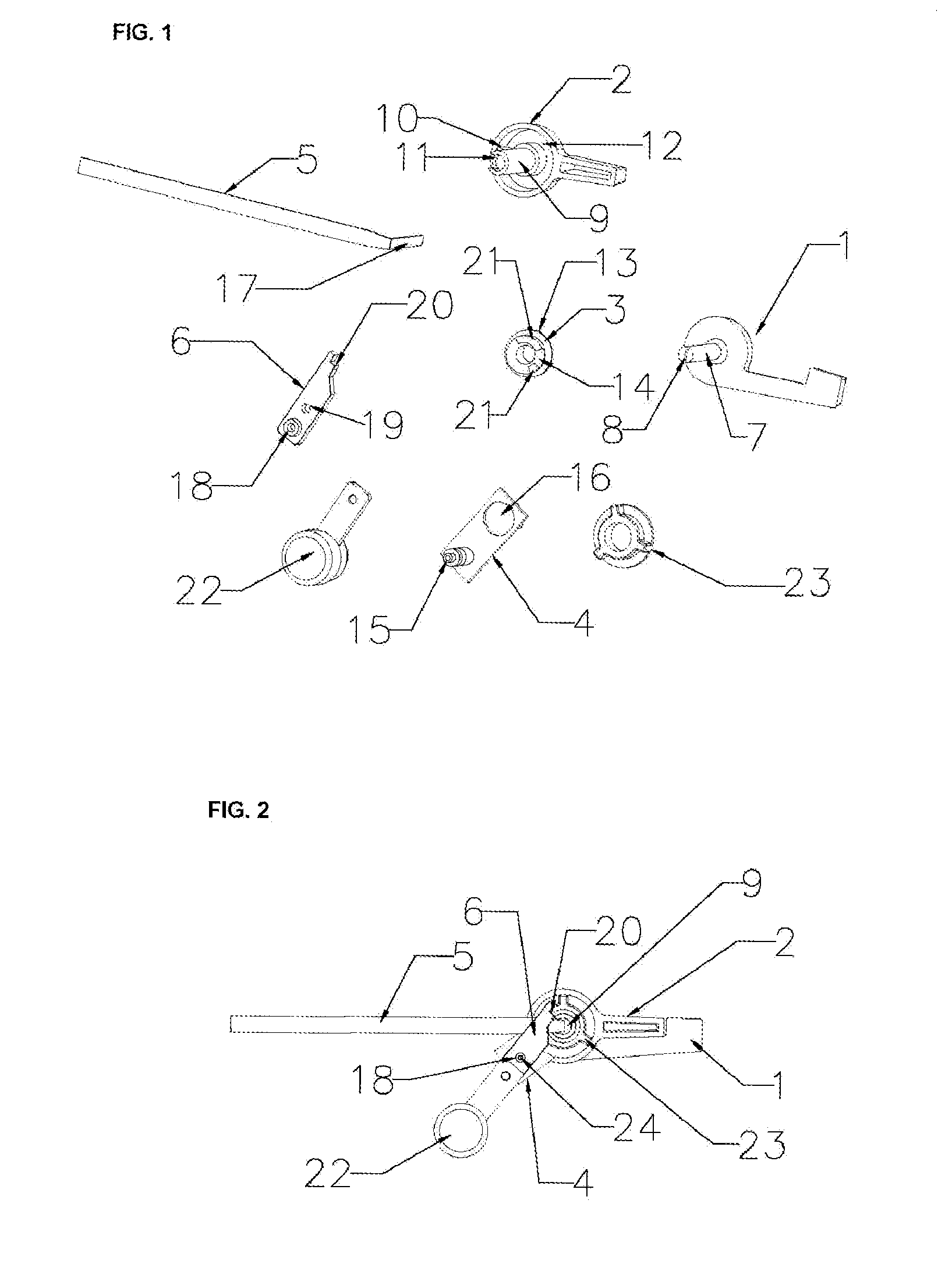

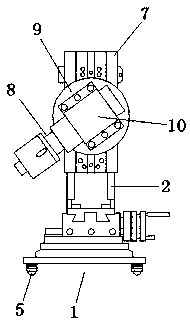

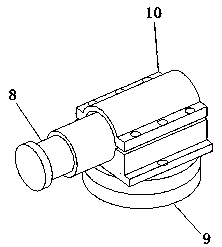

Precise shooting calibration device of small arms

The invention relate to the technical field of calibration devices, in particular to a precise shooting calibration device of small arms. The device comprises a bracket, a horizontal disc, a rail vertical plate, a base and a gun support plate for clamping the small arms, wherein the horizontal disc is horizontally arranged on the bracket through a horizontal adjusting mechanism; the base is vertically arranged on the horizontal disc; the other side surface of the rail vertical plate is rotationally connected with the base through a pitching adjusting mechanism; a rail gap adjustable rail device is arranged on one side surface of the rail vertical plate; and the gun support plate is slidingly arranged on the rail device. The device reduces radial runout of the arms, reduces the damage of recoil to the device, eliminates the influence of the recoil process on the shooting precision, realizes precise solution of average impact point only through aiming, performs precise calibration to eliminate the dependence of the arms calibration on excellent shooters, improves the calibration precision, reduces the labor intensity of calibration work, and promotes the calibration efficiency.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD +1

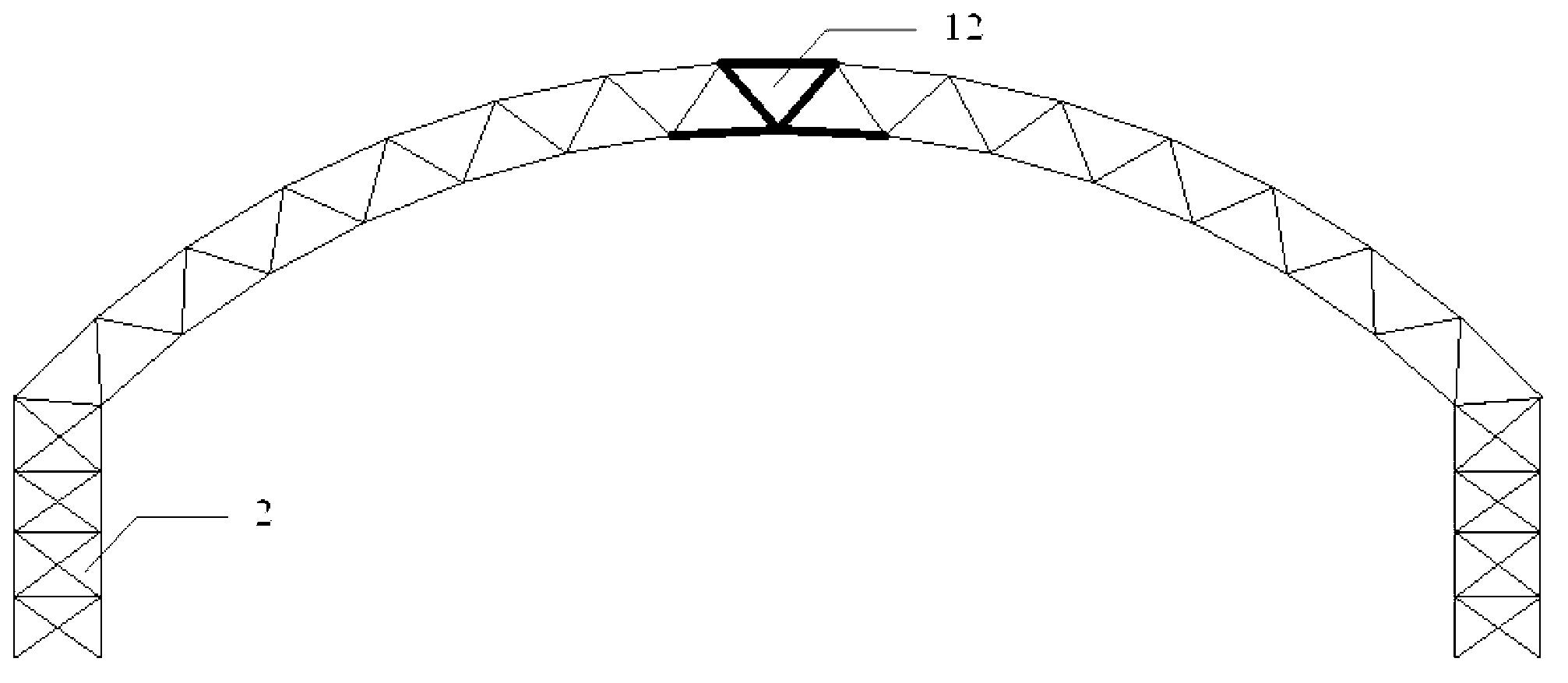

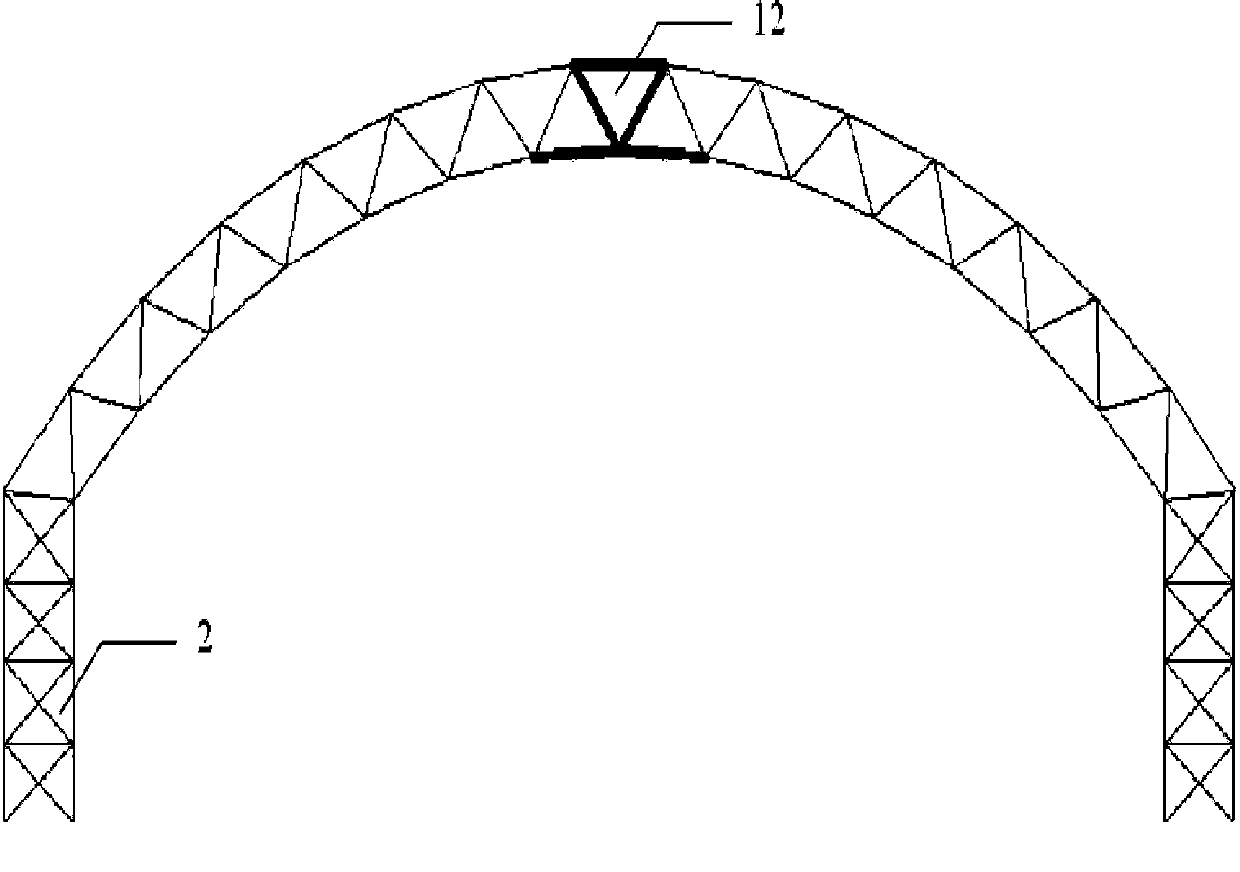

Installing method of extendable latticed shell structure

InactiveCN103075016AAdapt to on-site operationEasy to installBuilding material handlingEngineeringBuilding construction

Owner:BEIJING UNIV OF TECH

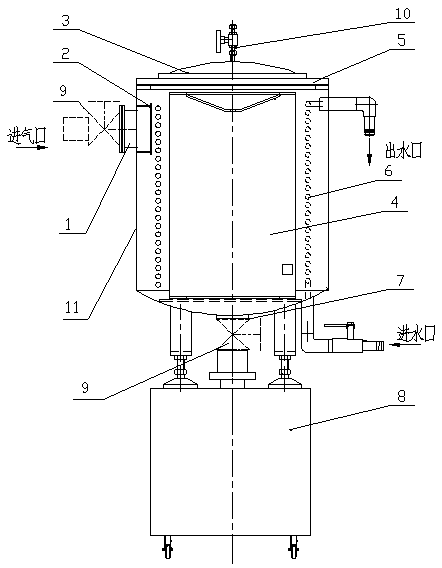

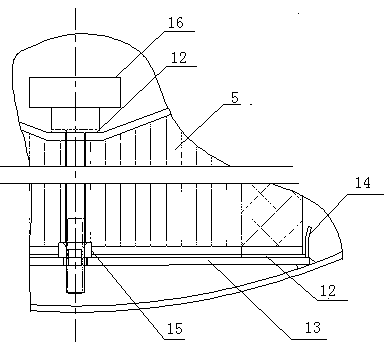

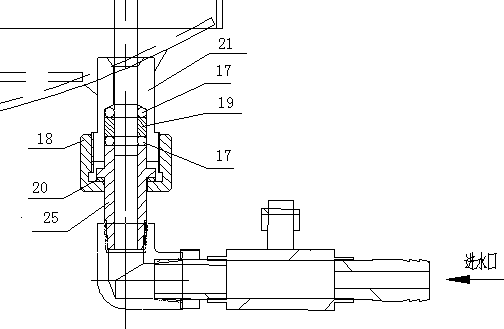

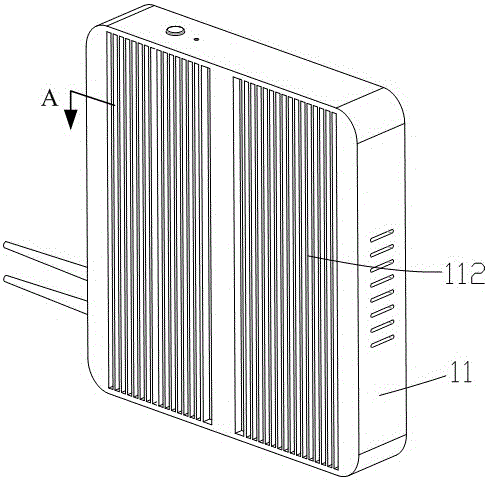

Vacuum filter

InactiveCN105498380AOptimize the installation structureQuick and easy installationHuman health protectionDispersed particle filtrationFiltrationUpstream downstream

The invention discloses a vacuum filter, and belongs to the field of filtration, which is used for solving the problems of cooling and dedusting of high-temperature and dust-contained gas in a vacuum working system. The vacuum filter comprises a cavity body, a diffuser and a filter element, wherein the cavity body is provided with a gas inlet connected with a specific gas pipeline and a gas outlet connected with a vacuum pump; the top end of the cavity body is provided with a top cover connected with the cavity body in a sealed mode; the cavity body is internally provided with the diffuser at the gas inlet; the filter element is installed at the center in the cavity body; the side wall of the filter element is provided with filter holes; the bottom surface of the filter element is provided with an opening leading to the gas outlet of the cavity body, thereby preventing the vacuum pump and an upstream-downstream system from being damaged by high-temperature, corrosive and dangerous dust particles, and solving the problem of too complex and frequent maintaining frequency of the vacuum pump of the vacuum filtration system. From the aspect of environment protection, gas in pipelines can be further cooled down and purified, and air pollution can be reduced.

Owner:青岛赛瑞达电子科技有限公司

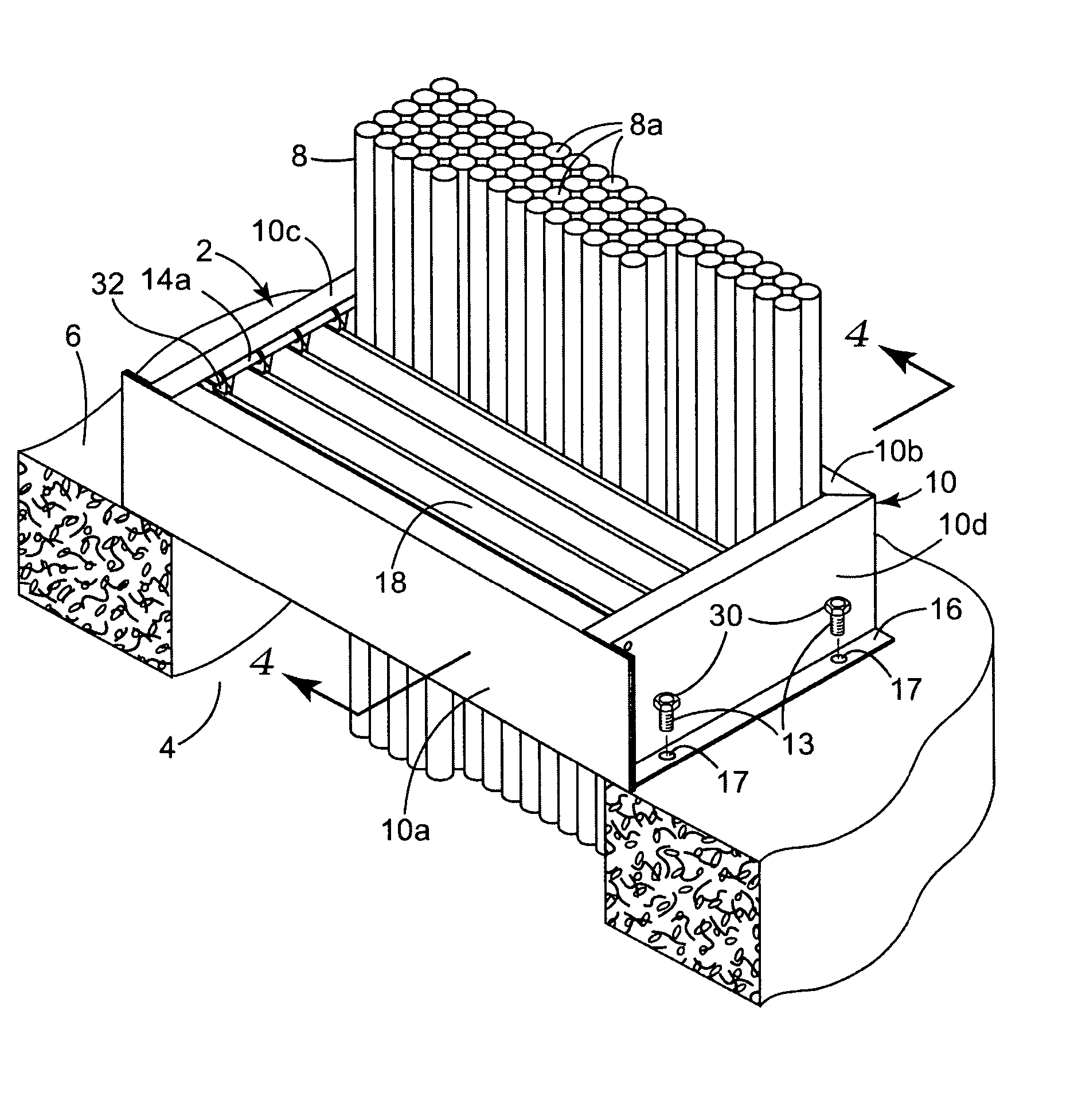

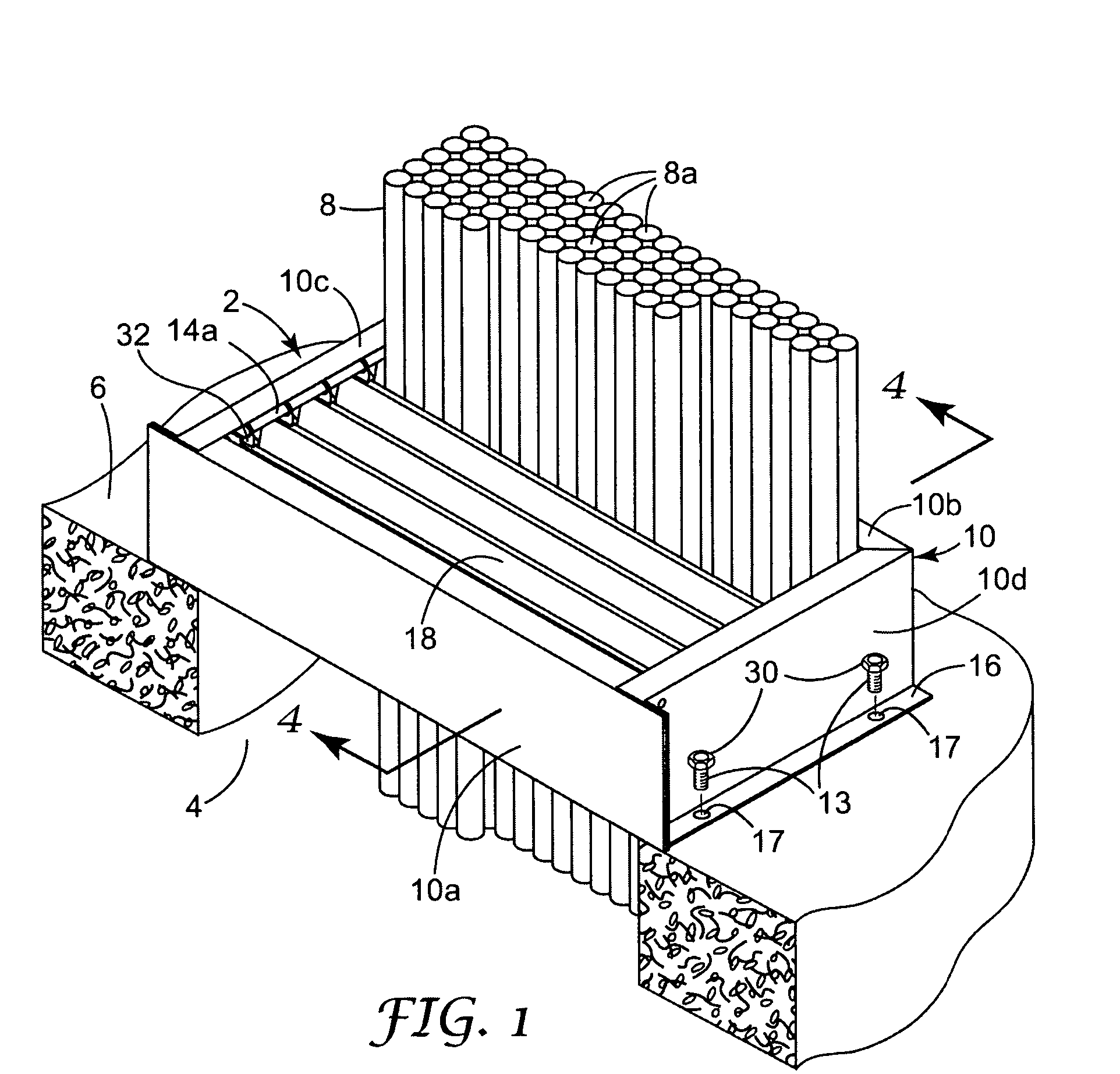

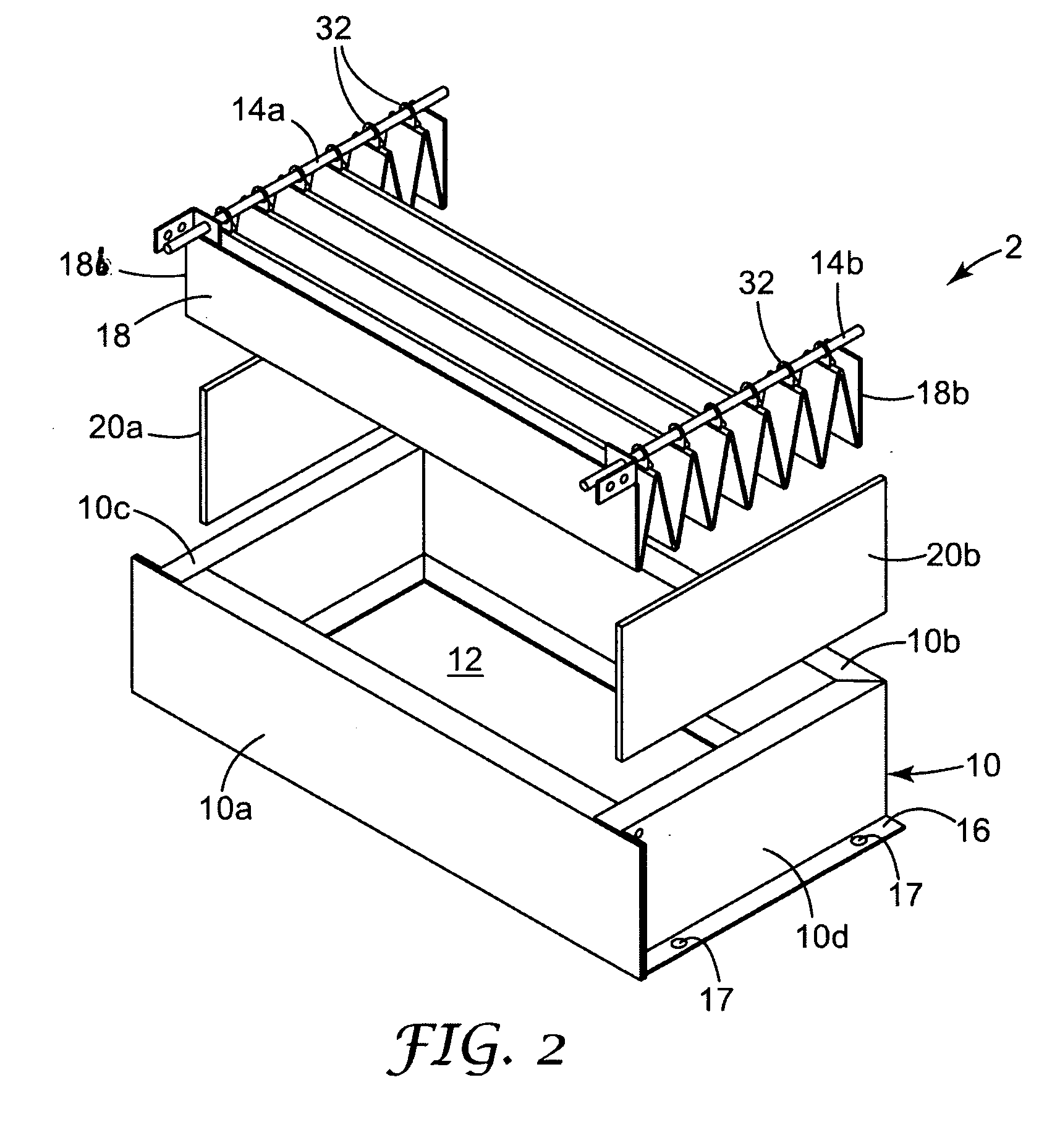

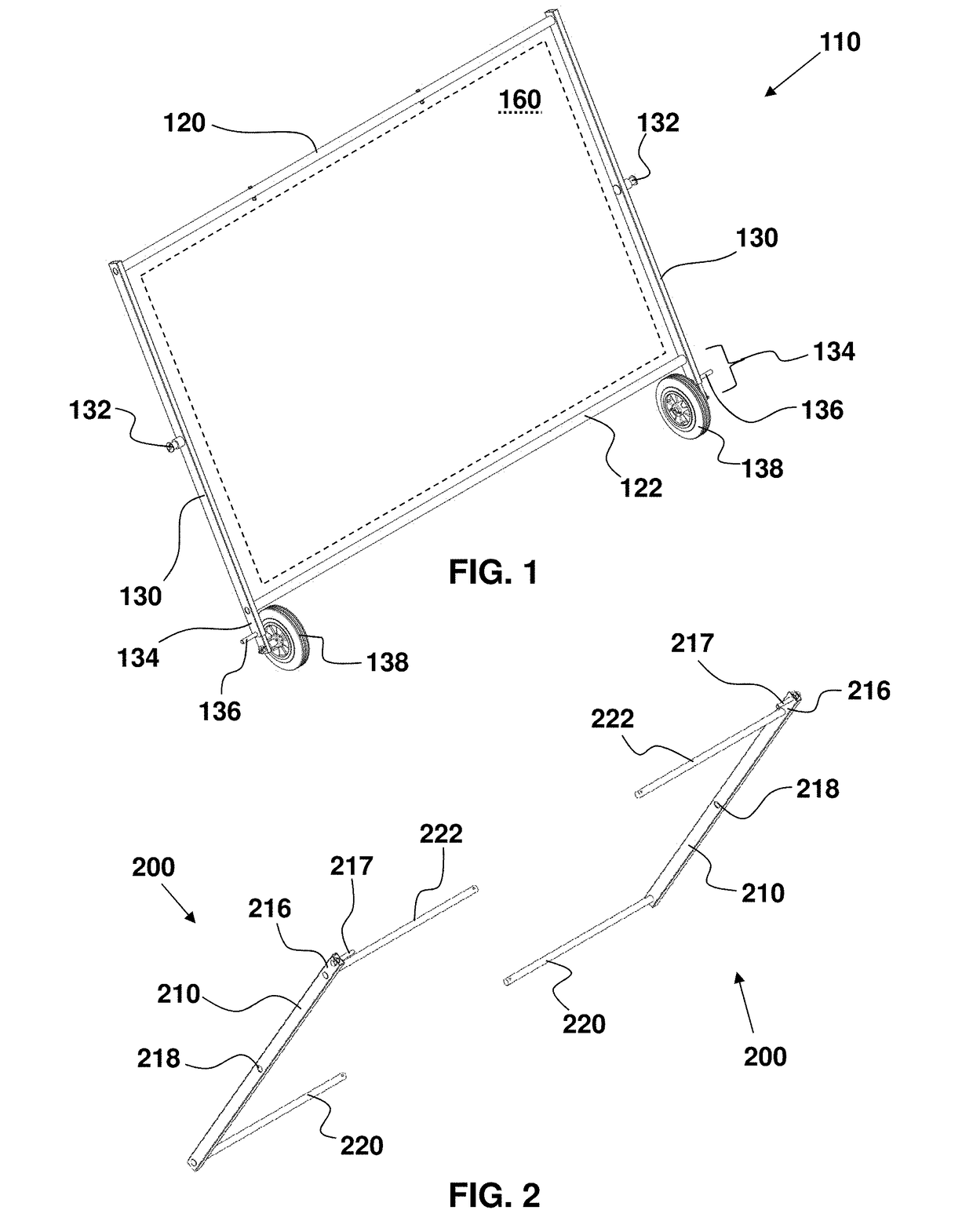

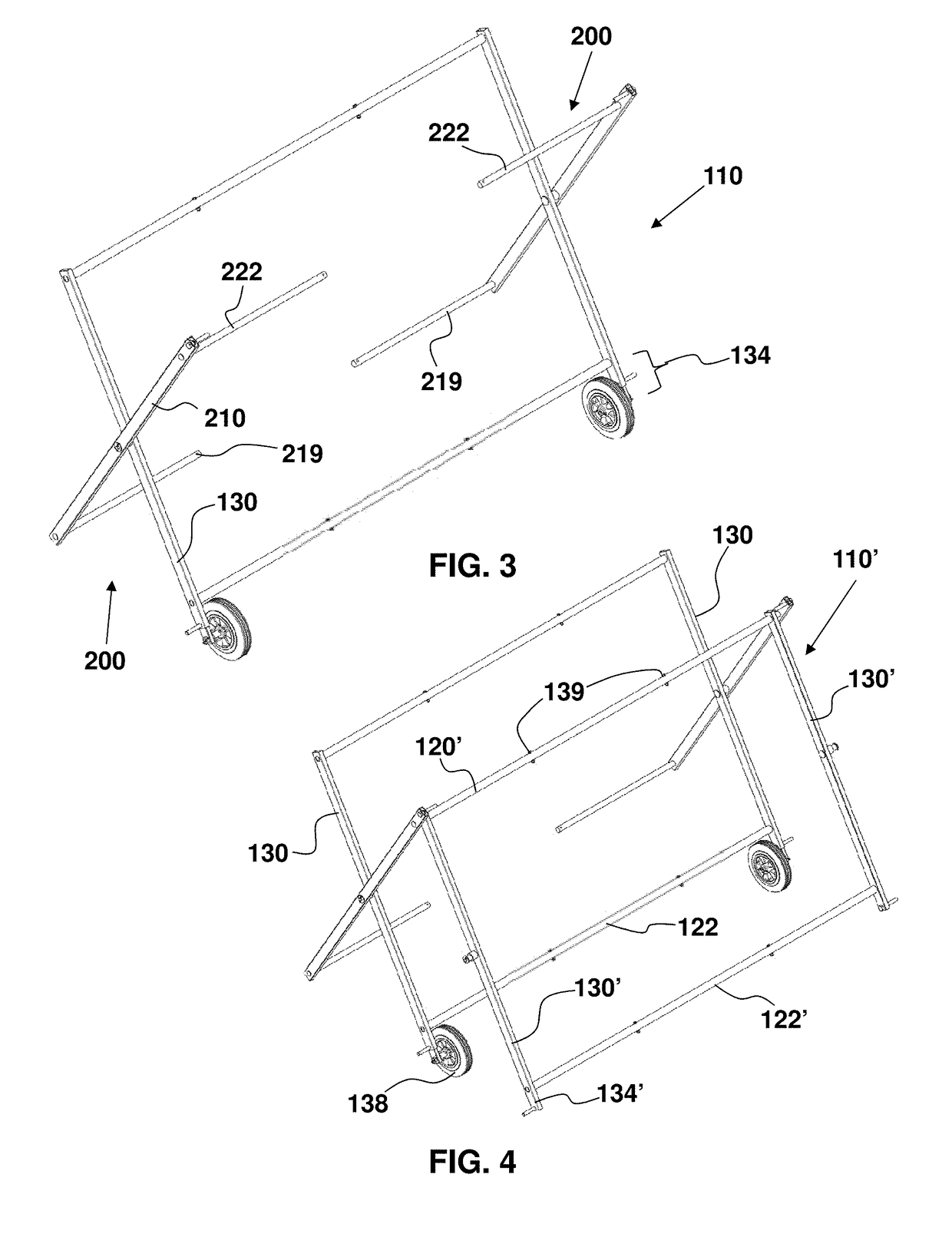

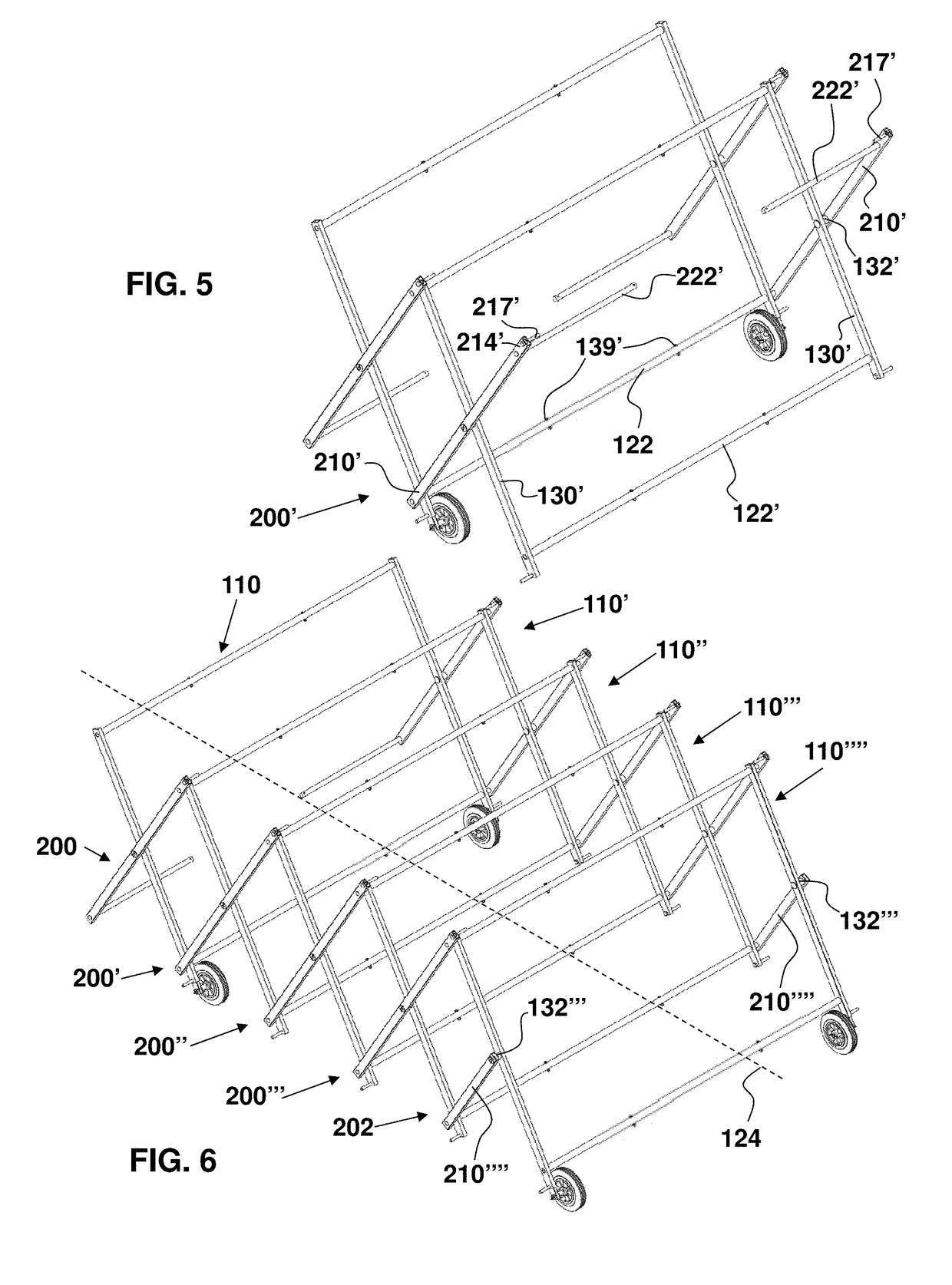

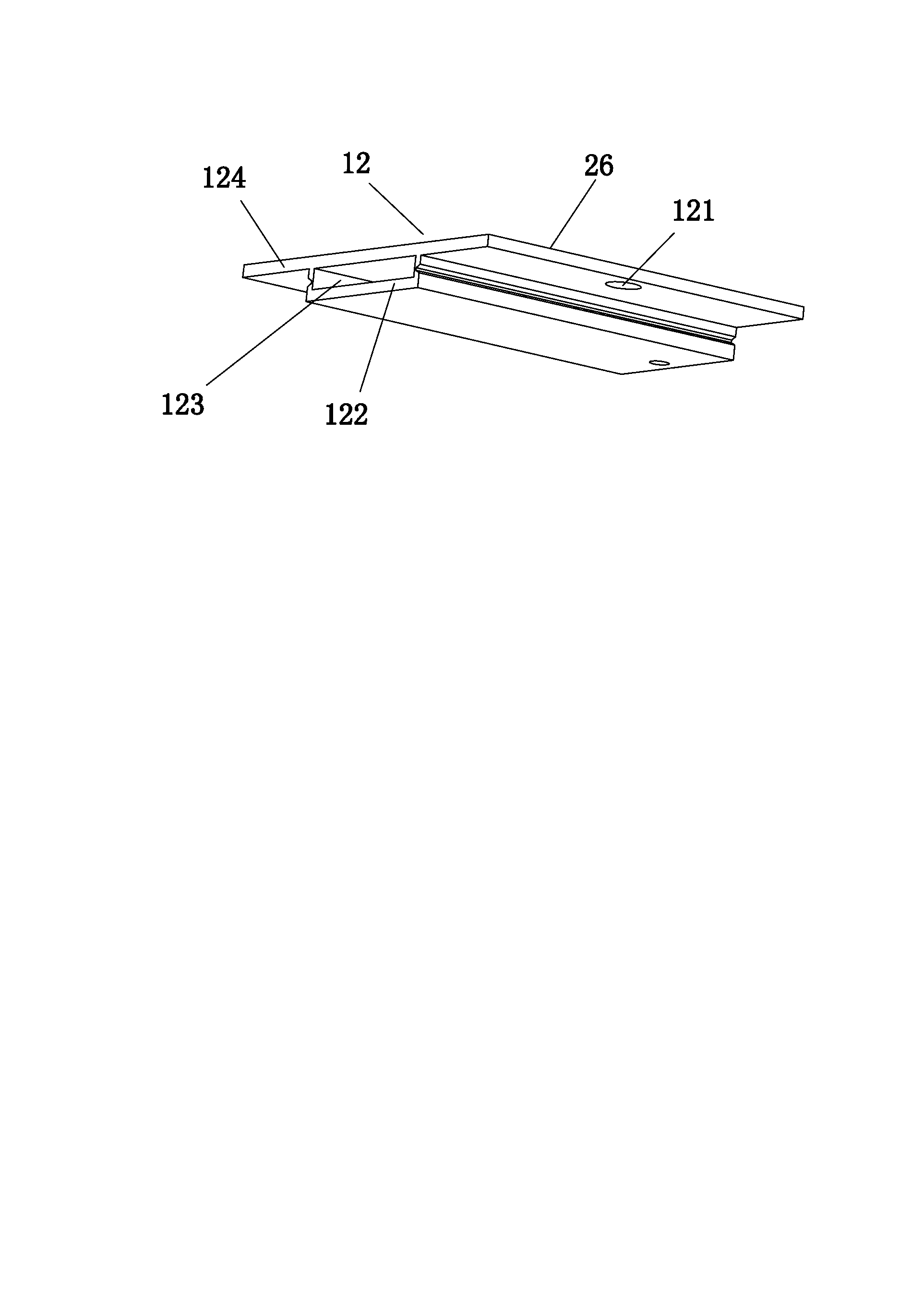

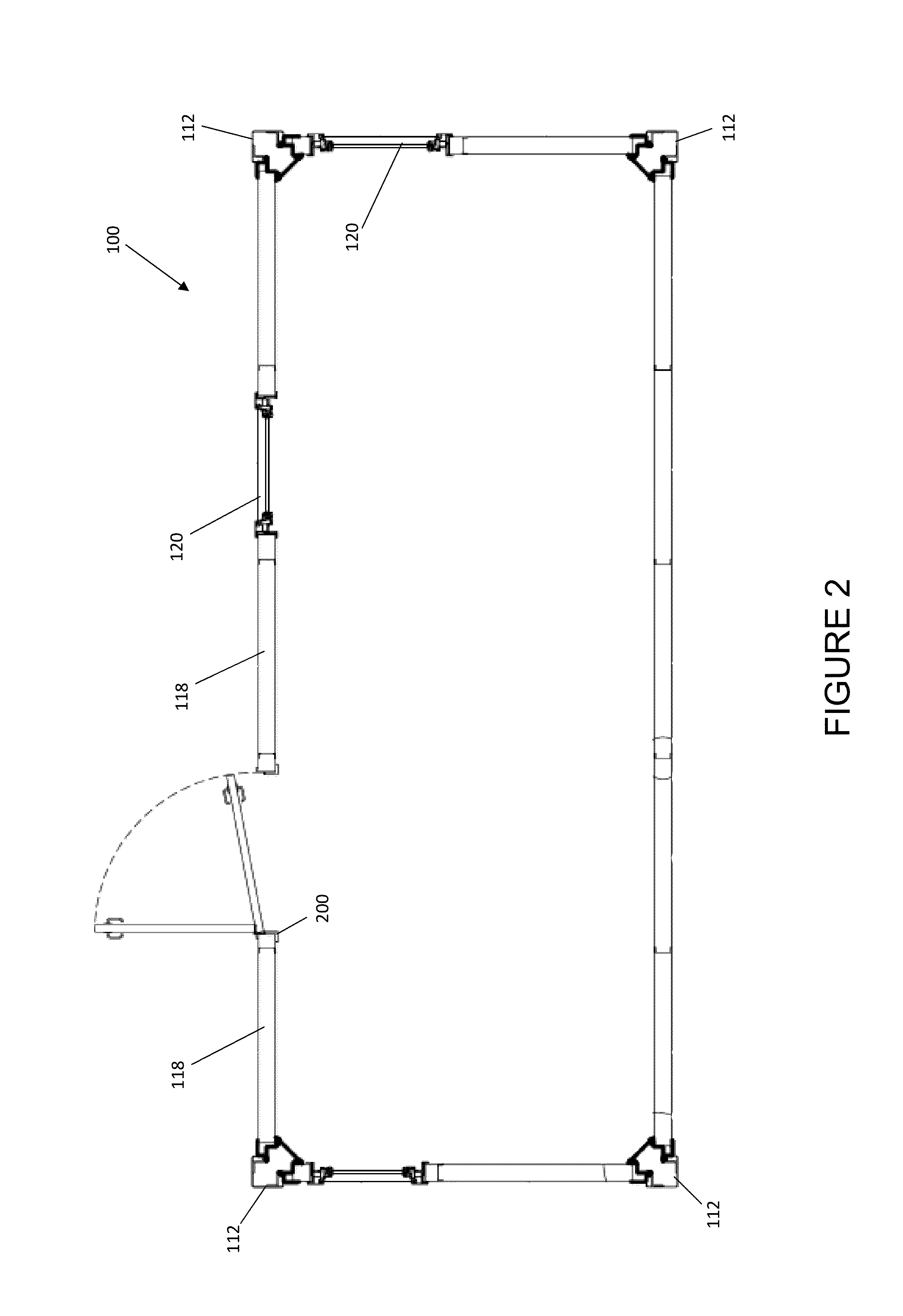

Modular, Retractable, Solar Array and Methods for Manufacturing Same

InactiveUS20190006984A1Quick and easy installationReliable and safe in operationPhotovoltaic supportsPhotovoltaic energy generationEngineeringSurface plate

A portable, retractable, solar racking system comprises a modular set of solar panel frames, each solar panel frame comprising a solar panel, a plurality of arms, and a plurality of struts, the arms and the struts forming a structure to which the solar panel is secured, a pivoting connector assembly mechanically connecting one of the solar panel frames to another one of the solar panel frames to form a solar panel array having a longitudinal extent, the pivoting connector assembly of the solar panel frames configured to collapse the solar panel array along the longitudinal extent into a storage position and to expand the solar panel array along the longitudinal extent into an extended position in which each solar panel is tilted from vertical to an angle away therefrom, and the solar panel array comprising sets of wheels permitting the solar panel array to roll upon ground.

Owner:ALBERTELLA ROBERTO

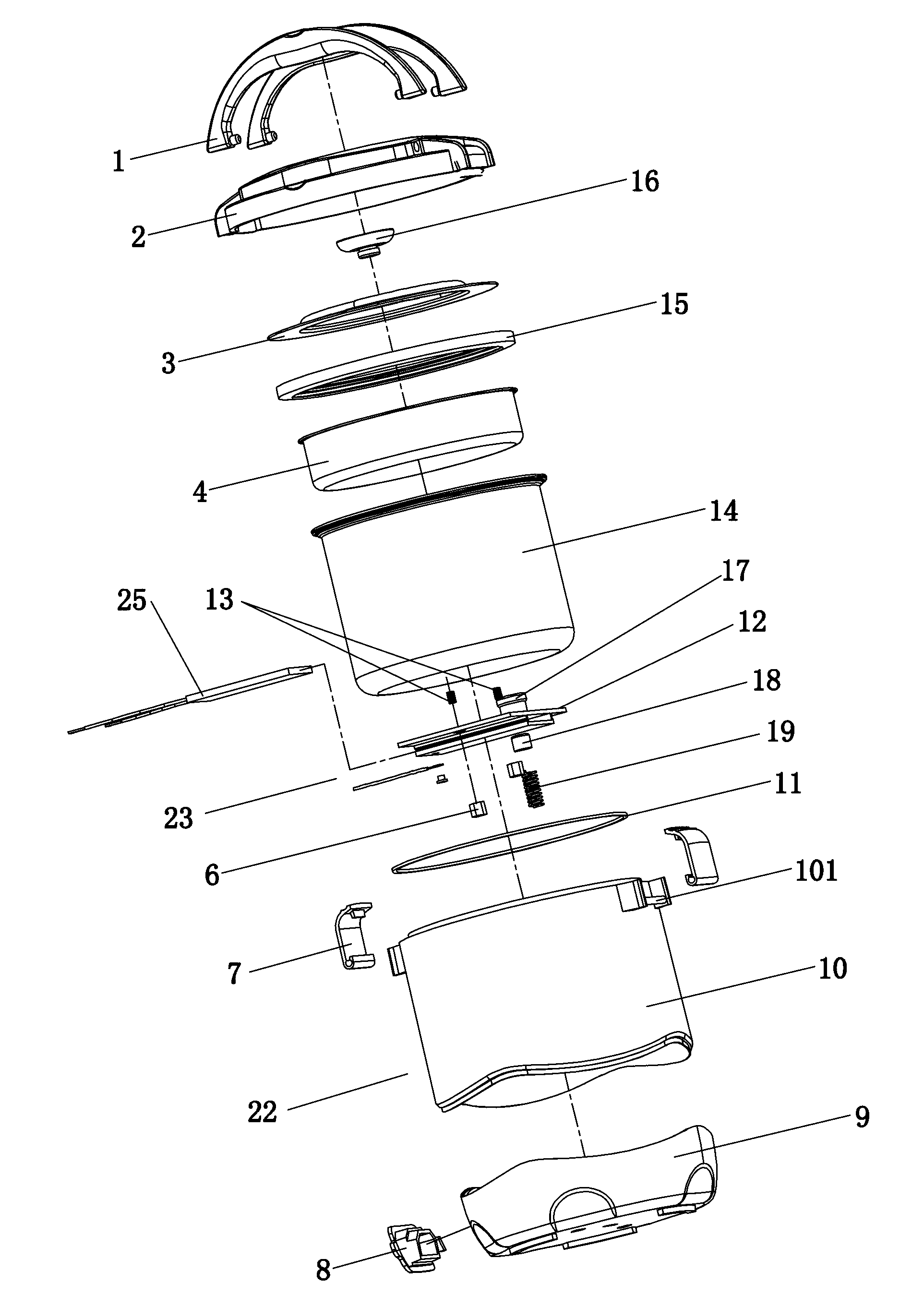

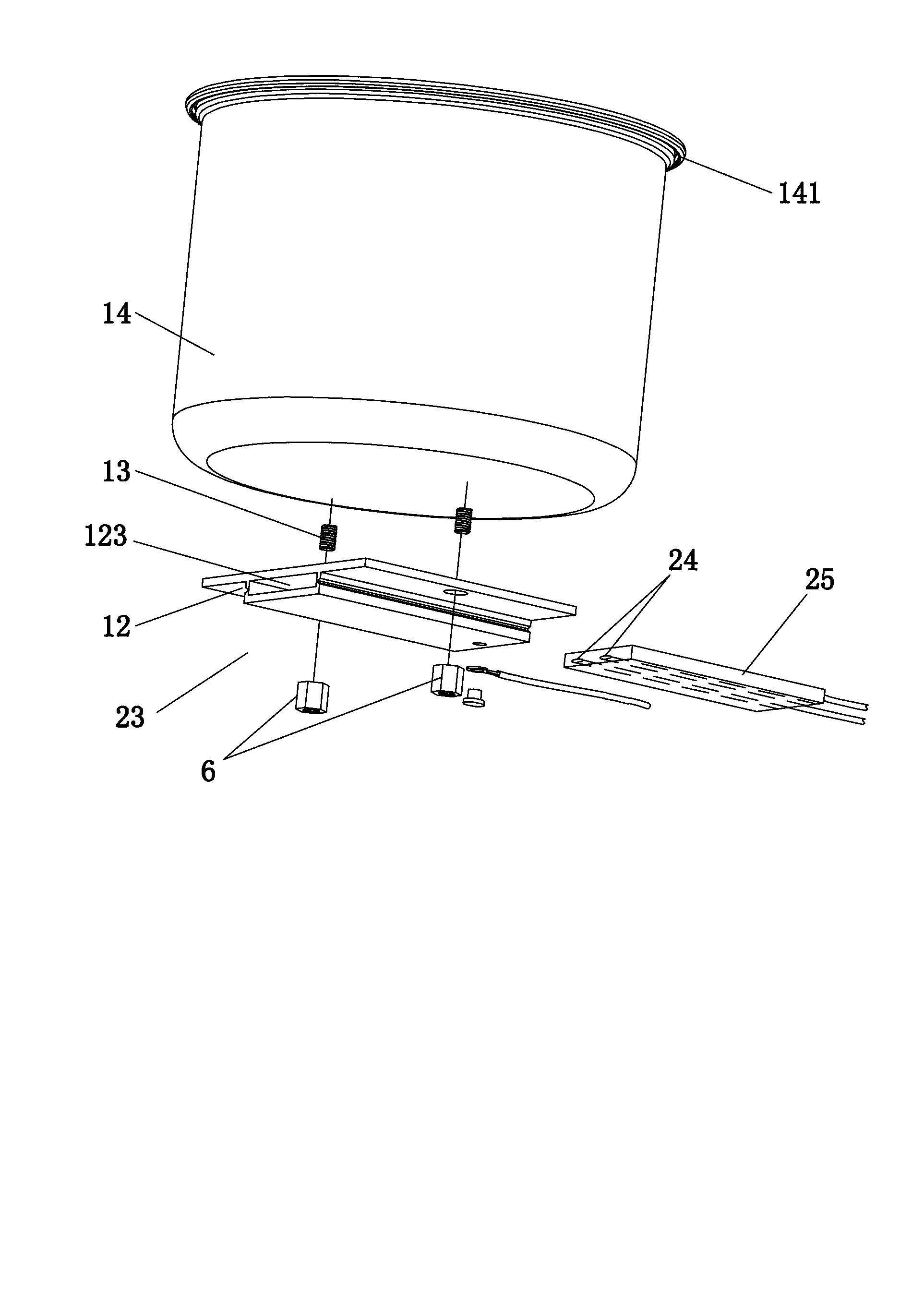

Heating body installing structure of energy-saving mini-sized electric cooker

InactiveCN102697377AOvercome the shortcomings of easy loosening or even falling offReduce wasteWarming devicesElectricityAdhesive

The invention relates to a heating body installing structure of an energy-saving mini-sized electric cooker, comprising an outer pot, an inner container, a cover body and an electric heating body, wherein the inner container is arranged in the outer pot; the electric heating body comprises a heat conducting plate, an electric heating body and an insulation heat conduction layer; a pressing cavity is arranged on the heat conducting plate; the electric heating body is packed by the insulation heat conduction layer; the electric heating body and the insulation heat conduction layer are pressed in the pressing cavity of the heat conducting plate together; a heat conducting face is arranged on the heat conducting plate; the bottom part of the inner container is extended with at least two studs; the part of the heat conducting plate corresponding to every stud is provided with a through hole; the stud is screwed with a nut by penetrating a through hole; and the heat conducting plate is pressed at the bottom part of the inner container by the nut, thus the heat conducting face of the heat conducting plate is clung with the bottom part of the inner container together. As the electric heating body is tightly installed at the bottom part of the inner container by a screwing piece, and with the adoption of the heating body installing structure, the shortcoming that the electric heating body is likely to loose or drop off for using a heat-conducting adhesive, so that the heat can be directly transmitted to the inner container by the heating body, the waste of heat is reduced and the energy-saving effect is realized.

Owner:何志雄

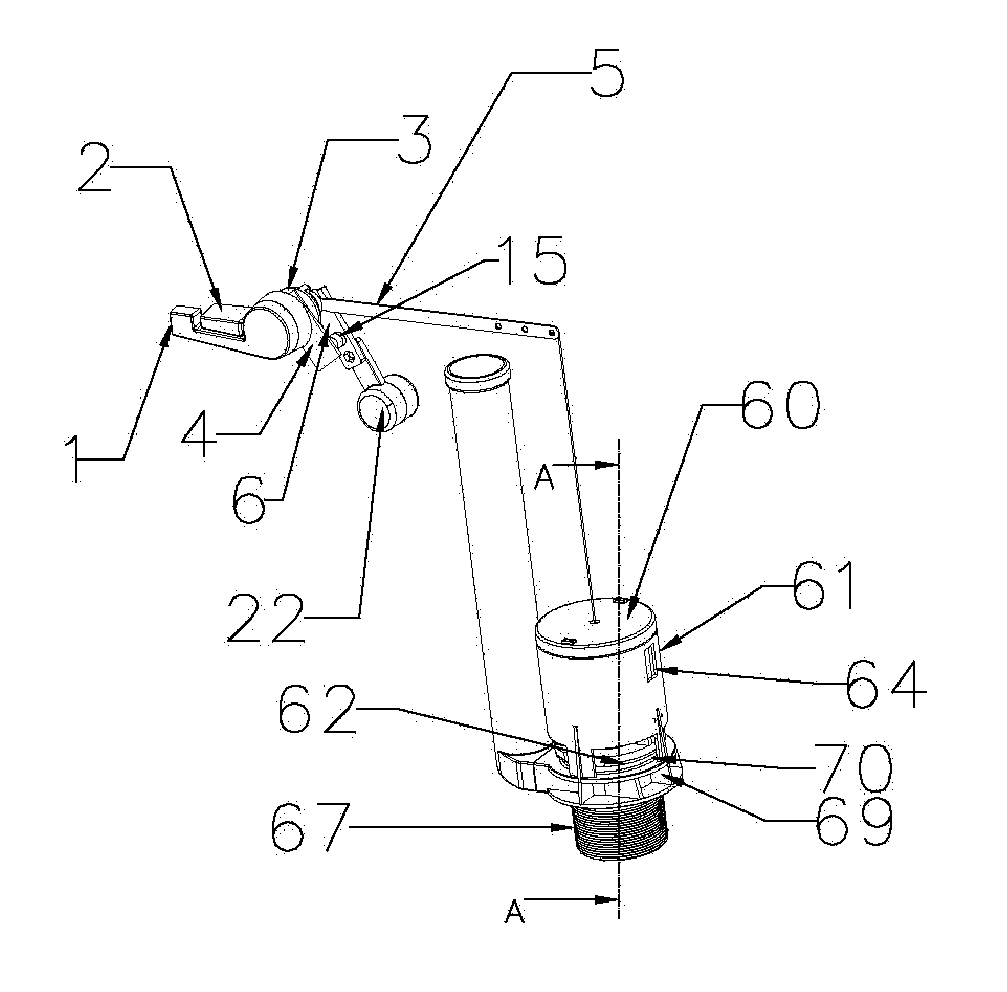

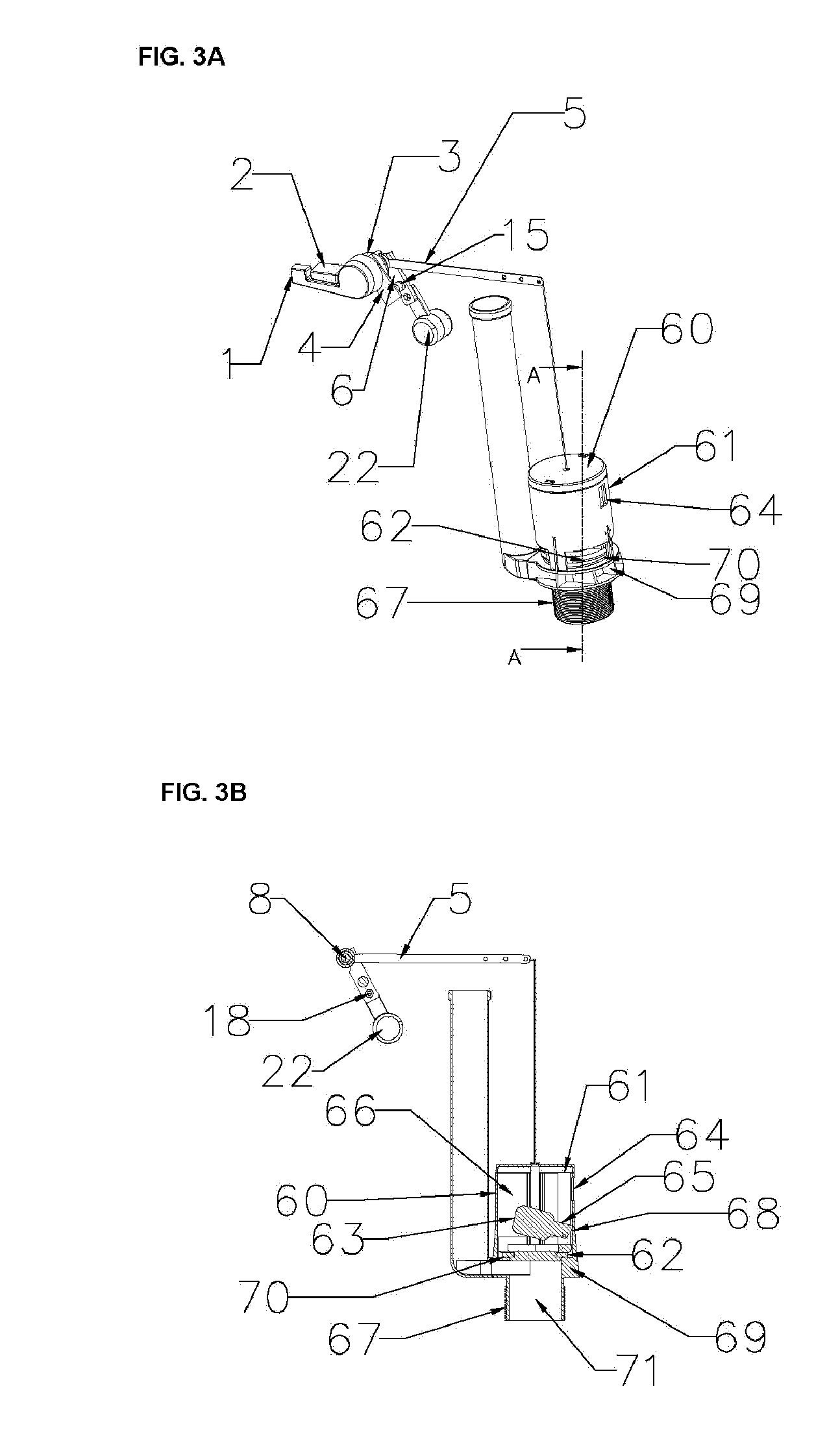

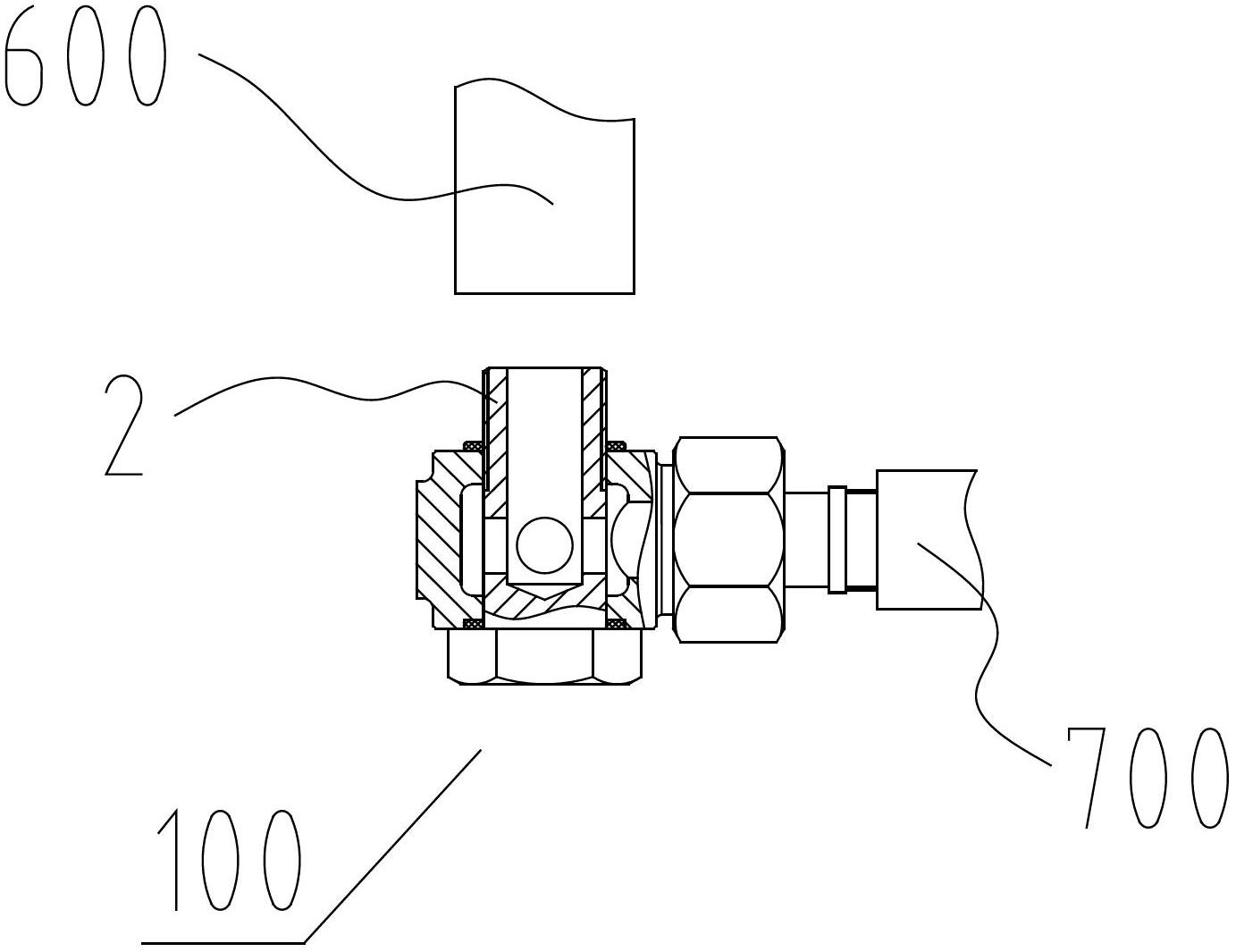

Dual flush device for toilet water tank

InactiveUS20110094022A1Quick and easy installationConvenient operationFlushing devicesInterior spaceEngineering

The present invention is related to a dual flush device for toilet water tank. A manually-operated press handle, in which a first switch-bar and a second switch-bar are intercalated on, is installed on a side-wall of the water tank. The switch-bar has a hollow bed, the tube of the hollow bed has a pivotal hole of the holder. The front edge of a bent-arm conjugates with an axial hole of the second switch-bar, the other end of the bent-arm has a chain which is fixed in a central hole of a moving element of a water-drainer. The round axis of the holder conjugates with a conduct hole of a gliding plate; and the screw nut is fixed by a stud to hold a float-ball under water. The water-drainer has a draining part. Inside the draining part there is a moving element. The moving element has a central hole, and a flush valve at the bottom, and a float-ball held in inner space. Below the draining part, there is provided an outer screw-thread, on the outer screw-thread there is mounted a base. In view of the above disclosure, it is the primary intention of the invention to successfully control the quantity of released water by dual flush. This device is not only a simple structure but also easily using at the user's will.

Owner:LI CHUNG HSIEN

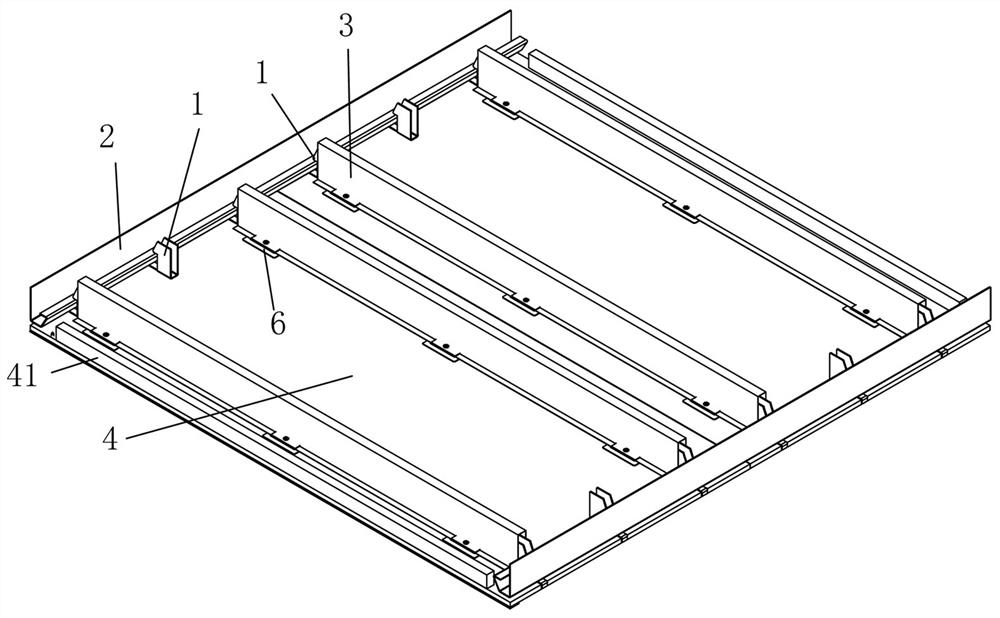

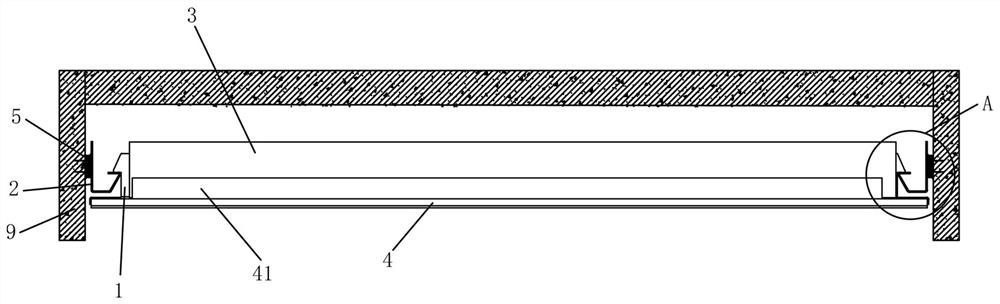

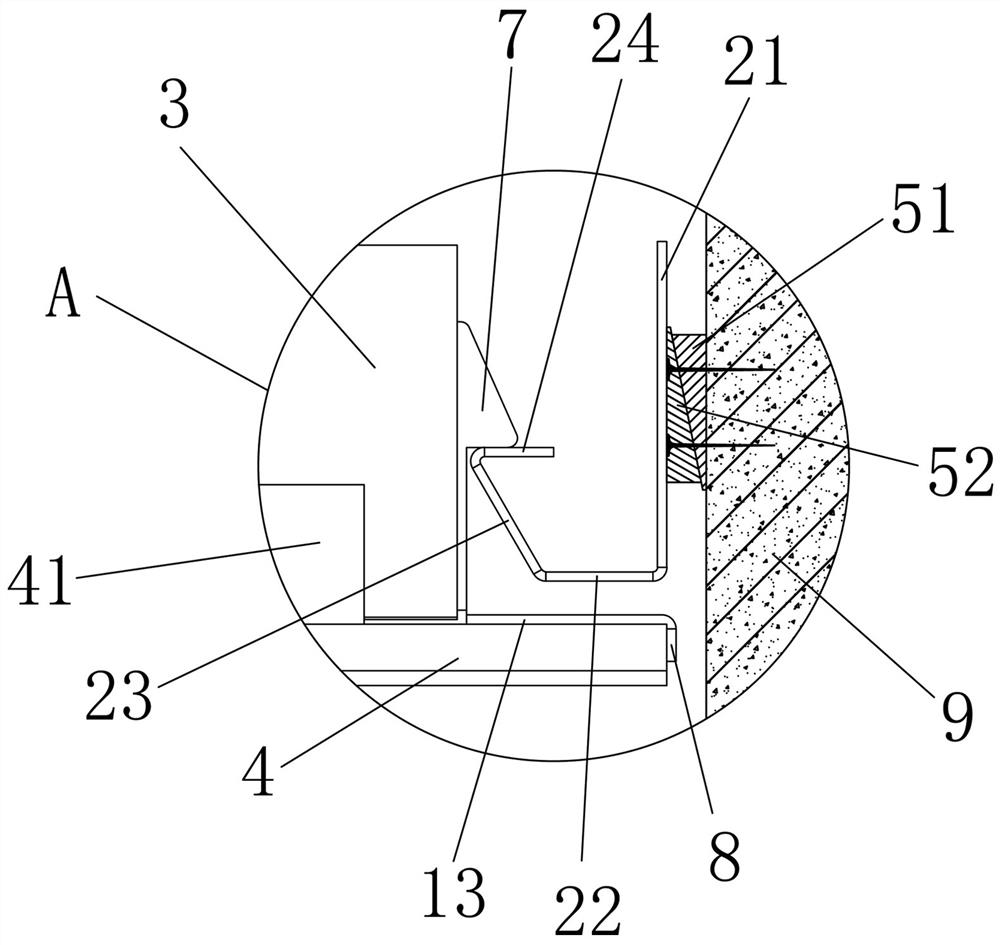

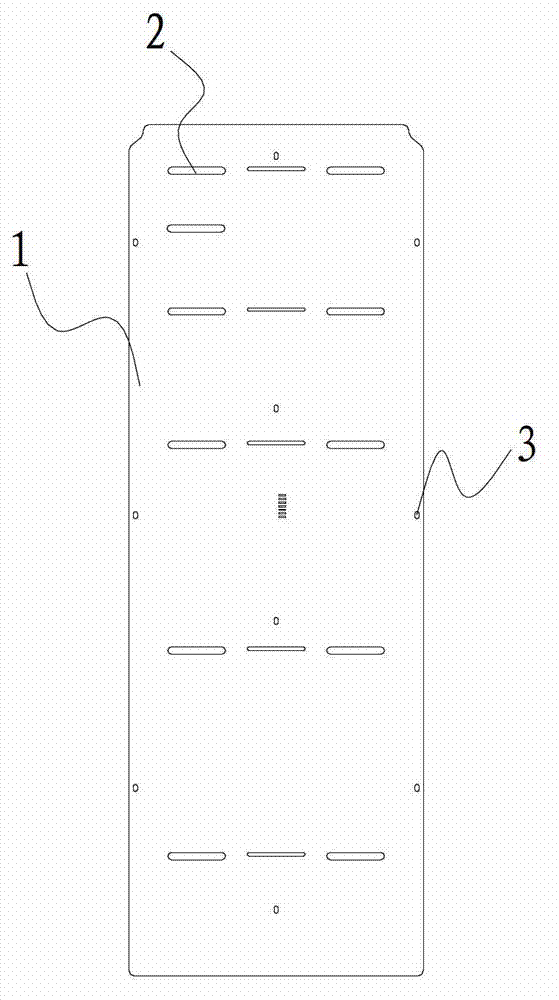

Suspended ceiling edge closing component and mounting method

PendingCN113356437AGuaranteed installation stabilitySimple installation structureCeilingsKeelEngineering

The invention discloses a suspended ceiling edge closing component and a mounting method. The suspended ceiling edge closing component comprises a hanging piece, a fixing piece and a leveling piece; the hanging piece comprises a bottom plate, a first hanging plate, a second hanging plate and a limiting plate; the bottom plate abuts against a suspended ceiling plate in an attached mode; the limiting plate abuts against the end part of the suspended ceiling plate; hanging parts are arranged on the sides, facing the limiting plate, of the first hanging plate and the second hanging plate; the first hanging plate and the second hanging plate are both inserted into a keel and are fixedly connected; the hanging parts are located outside the end part of the keel; the fixing piece comprises a fixing plate and a damping structure; the fixing plate is attached to the wall face and is fixedly connected with the wall face through the leveling piece; the damping structure is fixedly connected to the lower end of the fixing plate; and the damping structure is provided with third elastic plates corresponding to the hanging parts, so that the hanging piece can be hung on the fixing piece after being fixed to the keel, and a connection bearing structure is formed. The suspended ceiling edge closing component has a good damping effect and is fast to mount; a limiting structure is arranged, so that a tight combination relationship is formed; and the edge closing component can be quickly leveled.

Owner:ZHEJIANG YASHA DECORATION

Refrigerator, cover plate of air delivery duct of refrigerator, and manufacturing method for cover plate of air delivery duct

ActiveCN102818416ASimple structureEasy to installLighting and heating apparatusMetal working apparatusAerospace engineering

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

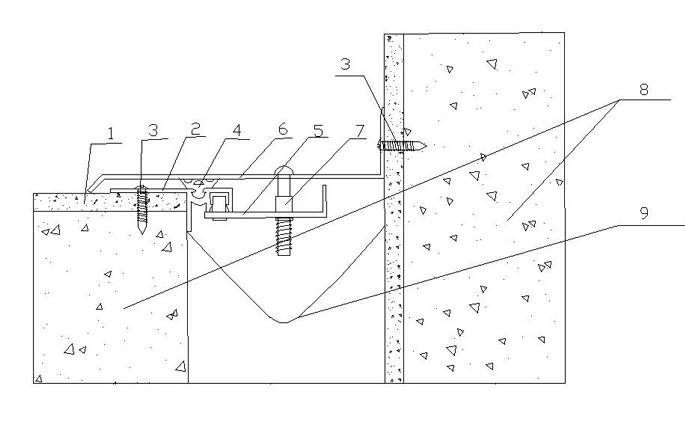

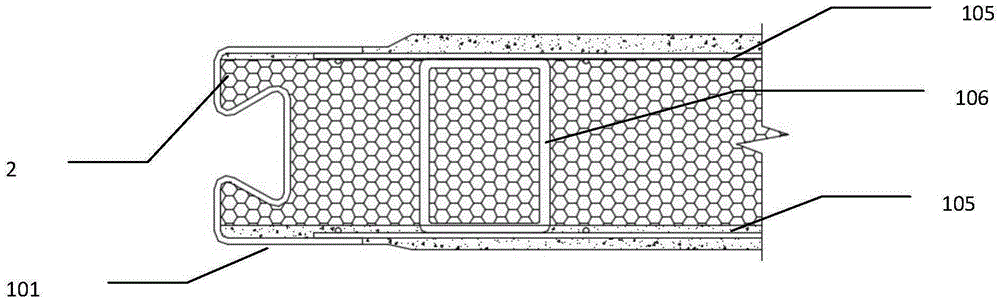

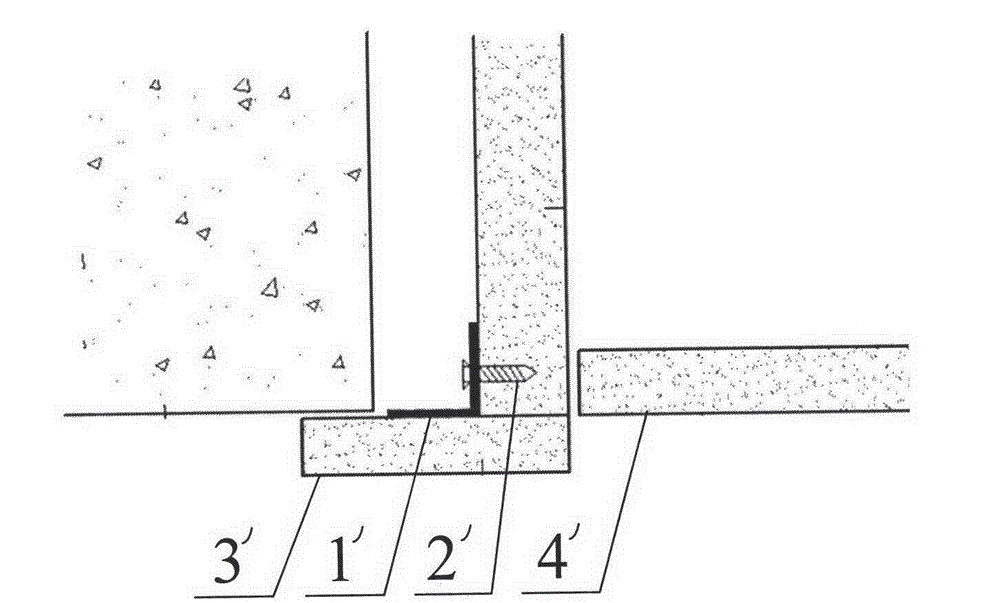

Foaming cement composite plates with dovetail groove type steel edge rib structures and connecting method thereof

The invention relates to foaming cement composite plates with dovetail groove type steel edge rib structures and a connecting method thereof. The foaming cement composite plates with the dovetail groove type steel edge rib structures comprise any kind of foaming cement composite bottom plates, foaming cement composite wall plates and foaming cement composite top plates which are provided with dovetail groove type steel frame edge ribs; each dovetail groove type steel frame edge rib is composed of an upper wing flange, a lower wing flange and a dovetail groove edge rib groove, and an embedded part wedge block is arranged in each dovetail groove edge rib groove; the plates are fixedly connected through bolt parts, right-angle-shaped connecting parts and the wedge blocks arranged in the dovetail groove edge rib grooves of the plates; the wedge blocks are slidable, so that the wedge blocks conveniently find the positions to be quickly installed. According to the foaming cement composite plates with the dovetail groove type steel edge rib structures and the connecting method thereof, installing operation is easy and convenient, rapidness and firmness are achieved, wet operation in a construction site is reduced, and environmental pollution and noise emission caused by construction are reduced. The foaming cement composite plates with the dovetail groove type steel edge rib structures are energy-saving and environment-protecting green building products.

Owner:CUBIC DIGITAL TECH CO LTD +2

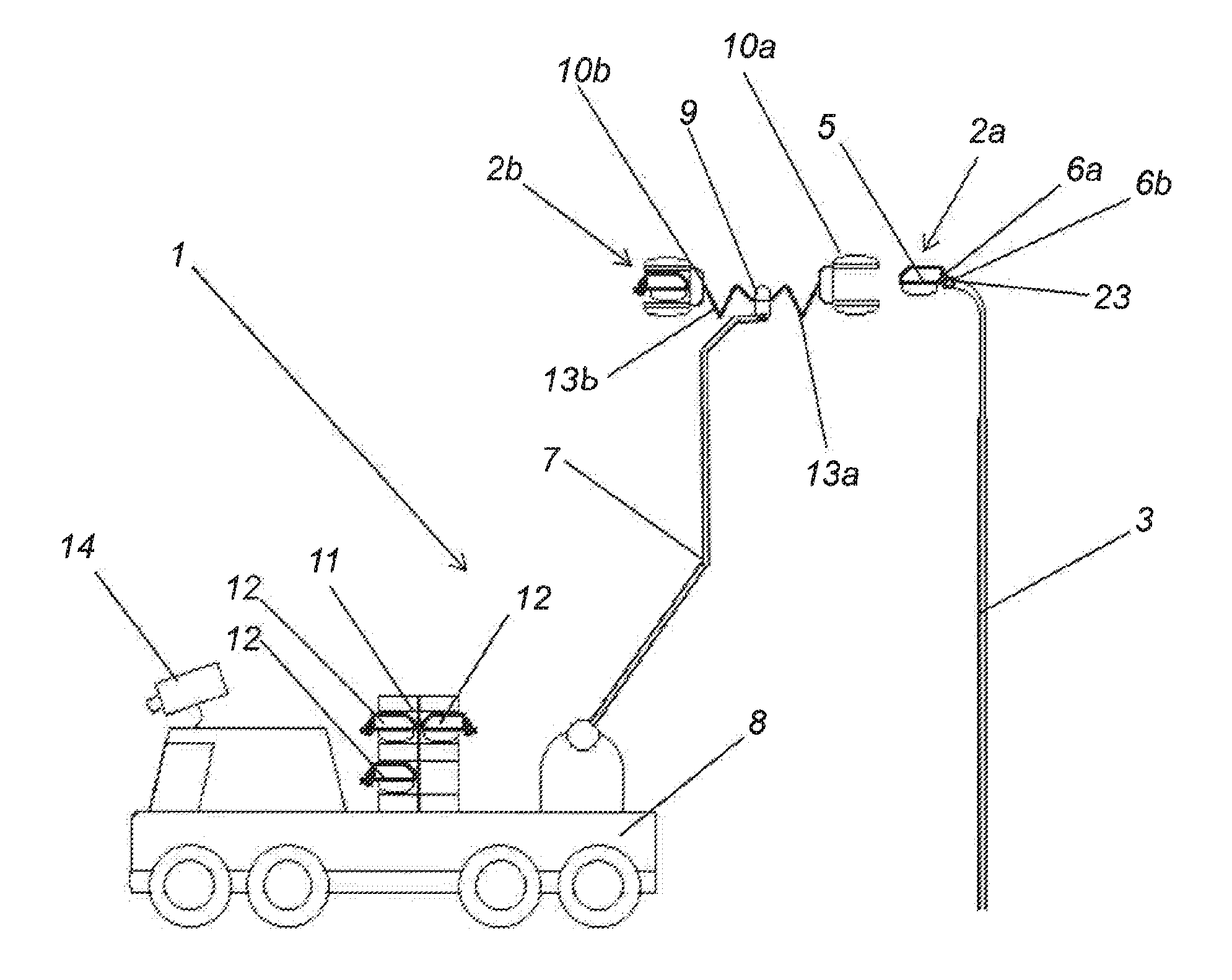

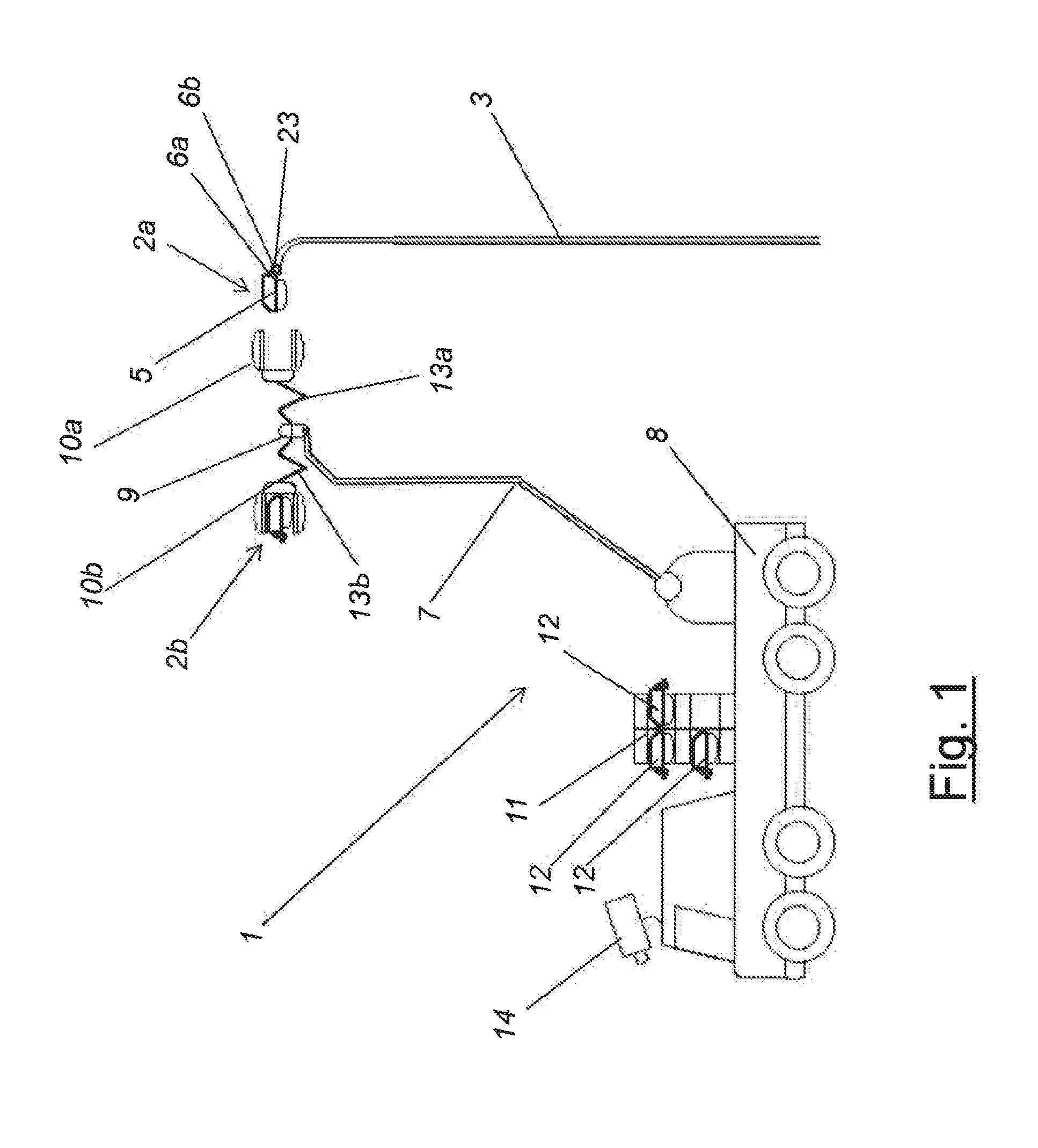

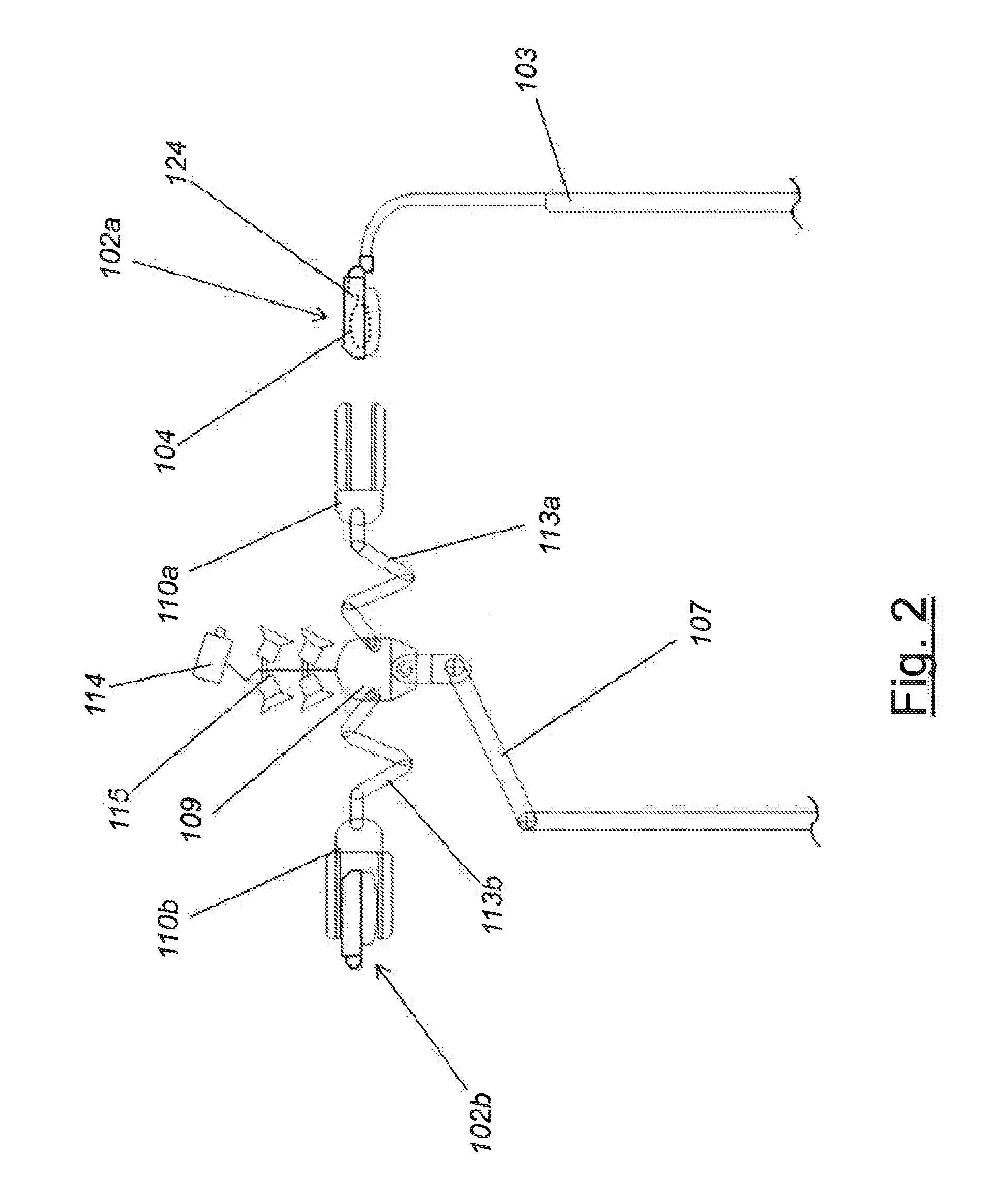

System for replacing street light luminaires

InactiveUS20150040363A1Quick and easy installationMinimal timeMechanical apparatusLighting support devicesCouplingEffect light

A device for the replacement of modular street light luminaires attached to a lighting column, where the modular street light luminaire comprises a light source, optionally a light transmitting cover, and a first coupling device, and where one end of the lighting column has a second coupling device for the attachment of the street light luminaire using the first coupling device, characterised in that the device for the replacement of the modular street light luminaire comprises a transport unit to which at least one arm is mounted, wherein at least one controllable robot is mounted to the arm, wherein at least one grip device is attached to the arm that is adapted to remove and replace street light luminaires.

Owner:STRIHL SCANDINAVIA

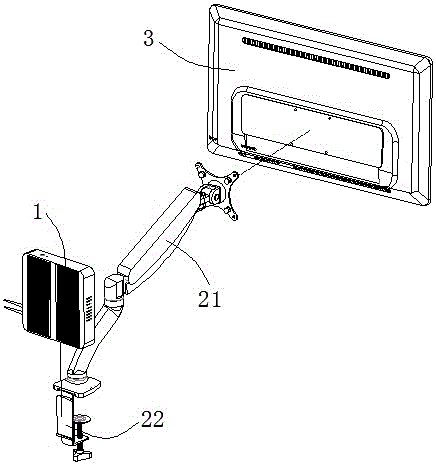

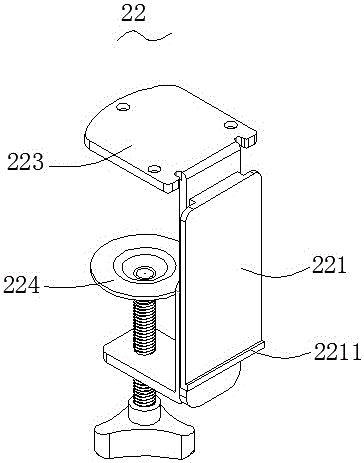

Mechanical arm type computer all-in-one machine

PendingCN105955404AThe fixing method of the whole machine is convenient and quickMiniaturization of the overall structureStands/trestlesHousing of computer displaysDisplay deviceMiniaturization

The invention relates to a mechanical arm type computer all-in-one machine. The mechanical arm type computer all-in-one machine comprises a host, a connection part and a display; the display is movably fixed on the host through the connection part; the host comprises an enclosure and a mainboard arranged in the enclosure; the connection part comprises a universal rocker arm and a connecting piece; one end of the universal rocker arm is connected to the display and used for supporting the display; the other end of the universal rocker arm is fixed on the connecting piece; the connecting piece comprises an insertion connection part and a tightening part, which are fixedly connected relatively; the insertion connection part is used for being detachably connected with the enclosure of the host; and the tightening part is used for fixing an integrated computer on an external support object. According to the mechanical arm type computer all-in-one machine disclosed by the invention, the display is connected with the host through the universal rocker arm; the use angle and the range of the display are not limited; the installation and disassembly manners between the display and the host and the whole fixing manner are convenient and rapid; the mechanical arm type computer all-in-one machine is suitable for various occasions; and the whole structure is miniaturized.

Owner:王磊

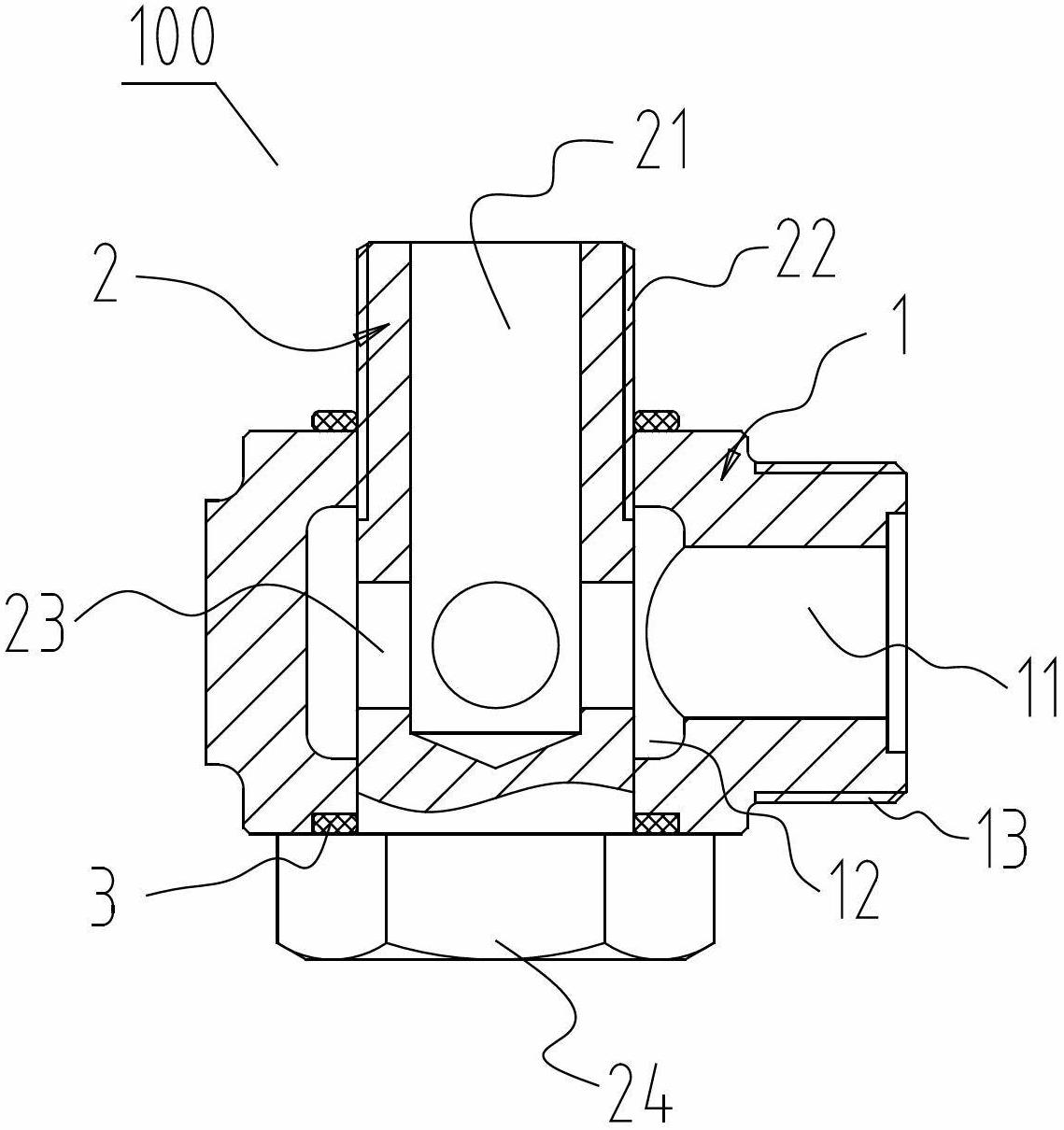

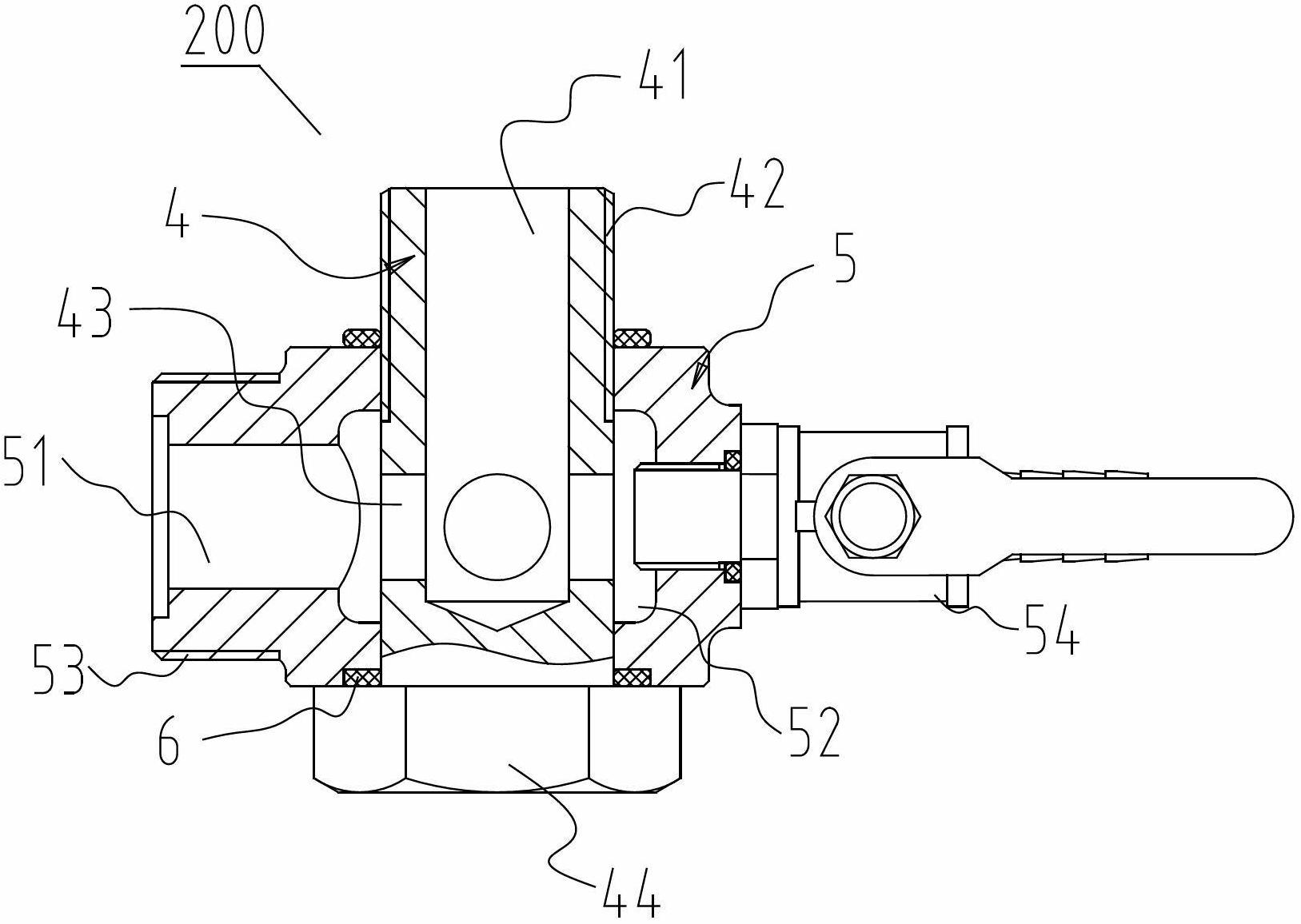

Pipeline corner connector and application method thereof

InactiveCN102661460ASmall footprintEasy to operateAdjustable jointsBranching pipesEngineeringMachining

The invention discloses a pipeline corner connector and an application method of the pipeline corner connector. The pipeline corner connector comprises a connector body which is provided with a hollow channel along the axial direction, a connecting piece which is arranged on the connector body in a penetrating manner and can relatively rotate; a middle axis of the connecting piece and a middle axis of the connector body are arranged to form an angle; and a communication hole which is communicated with the hollow channel is formed in the connecting piece along the axial direction. The pipeline corner connector is mounted by the following steps of: a. fixing a main pipe position communicated with a branch pipe in advance; b. fixedly connecting the connector body with the branch pipe; c. determining a relative position of the branch pipe according to the position of a main pipe; and d. rotating the connecting piece on the connector body and connecting the connecting piece with the main pipe under the condition that the connector body and the branch pipe are immobile. The pipeline corner connector can be mounted on a needed effective position to be positioned and has the advantage of simple structure, convenience for installation and rapidness; an interference position does not need to be preserved on a mounting space and an occupied space is small; and meanwhile, the pipeline corner connector has the advantages of simplicity in early-stage machining, low production cost and suitableness for popularization.

Owner:重庆界石仪表有限公司

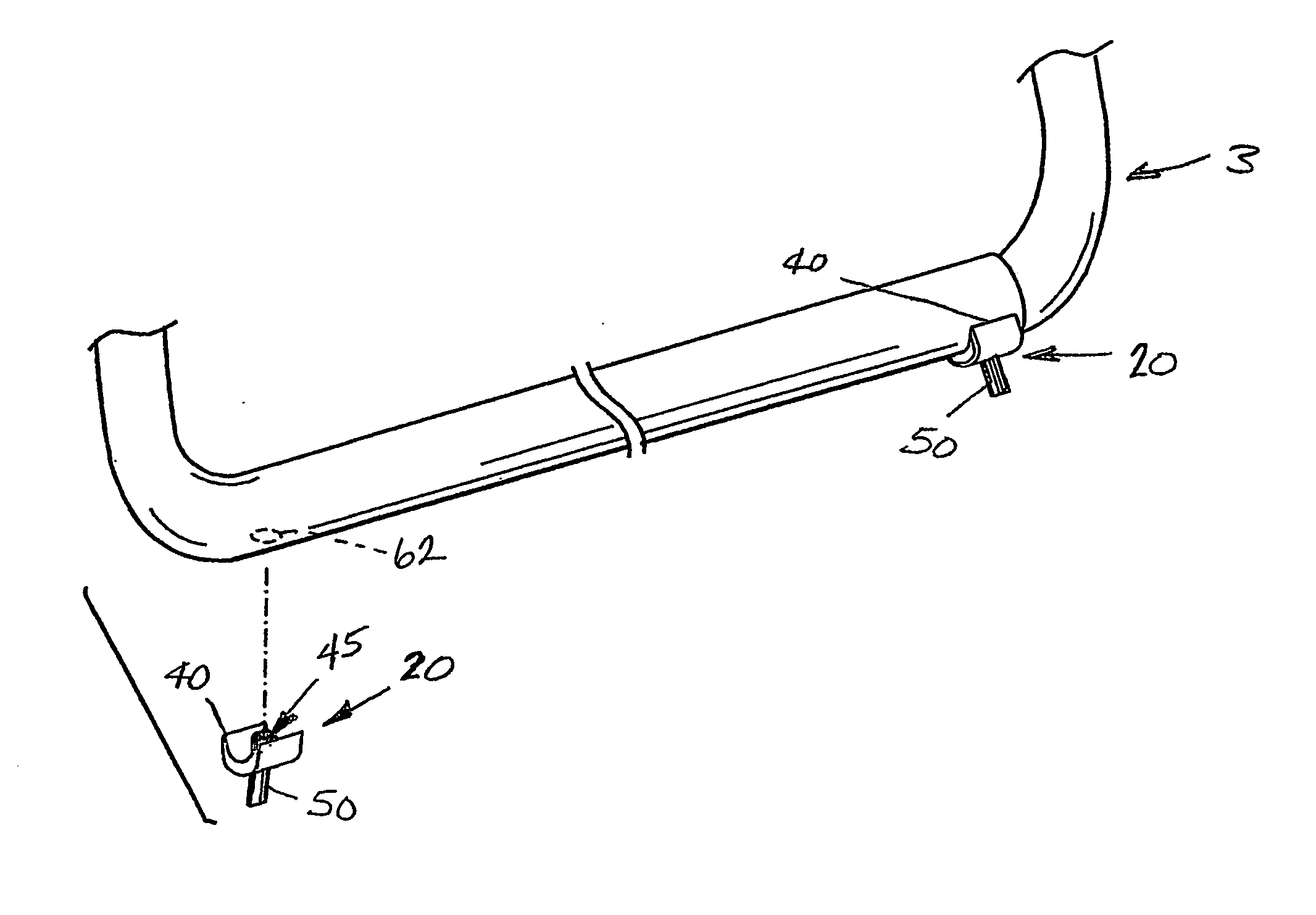

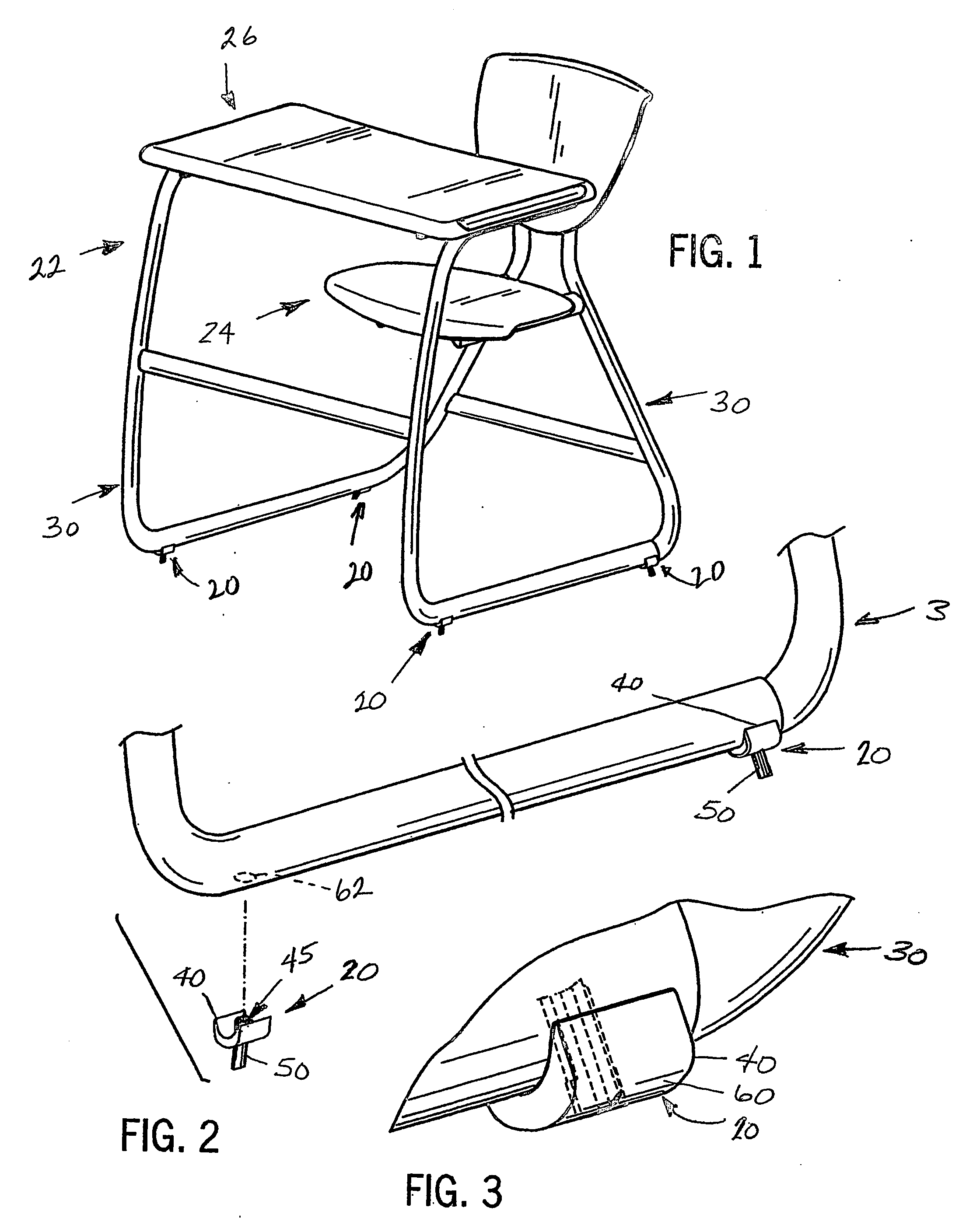

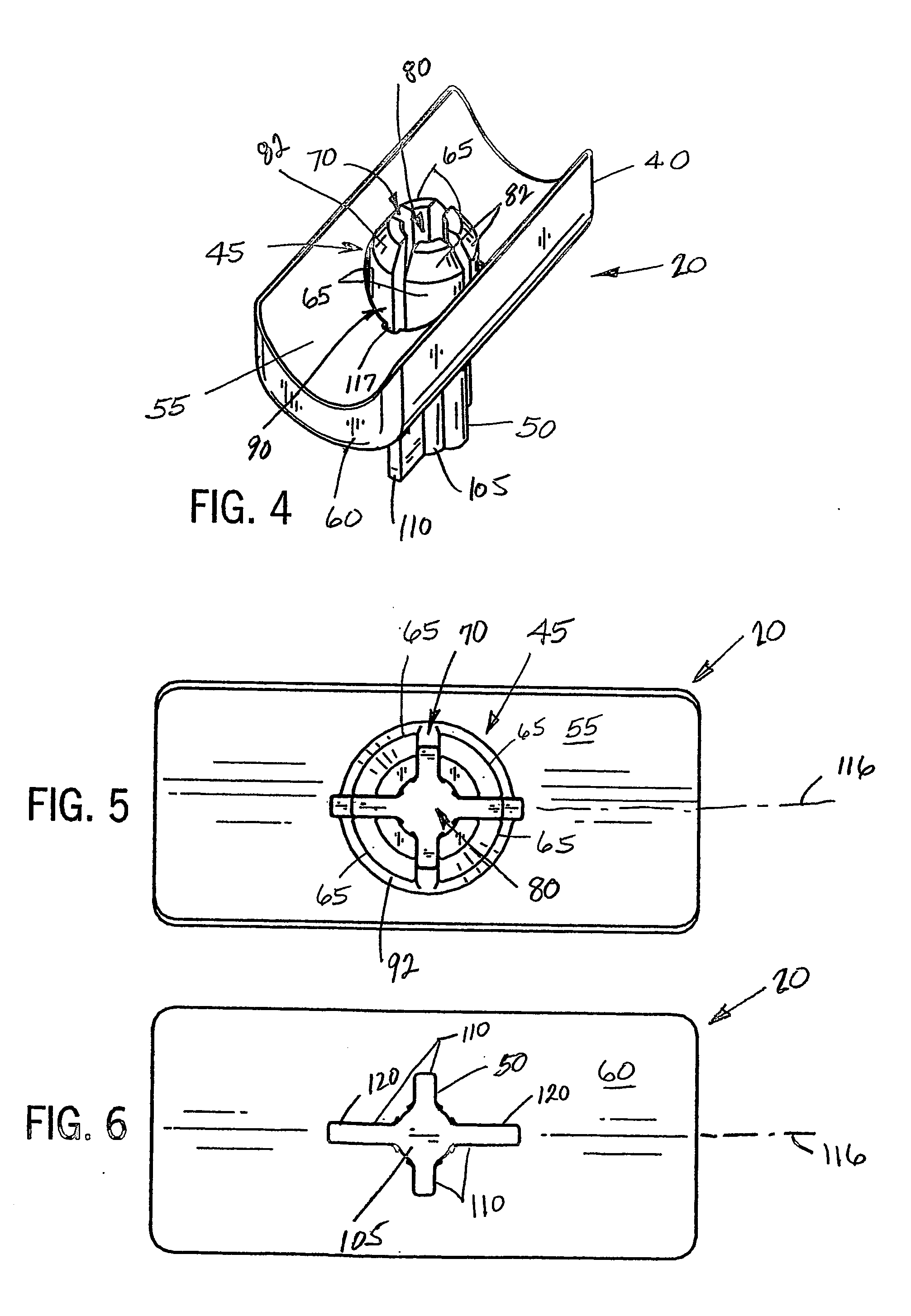

Pound-in glide for an article of furniture

InactiveUS20060054755A1Easily installedQuick and easy installationRivetsScrewsMechanical engineeringEngineering

Owner:KRUEGER INT

Flat bump type non-metal cutting package process and package structure thereof

ActiveCN106158742AReduce stressAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesEtchingEngineering

The invention discloses a flat bump type non-metal cutting package process and a package structure thereof, and belongs to the field of semiconductor manufacturing. The flat bump type non-metal cutting package process comprises the following steps: (1) taking a metal substrate; (2) sticking dry film layers on the front surface and the back surface of the metal substrate respectively; (3) removing part of the dry film layer; (4) plating the front surface of a base bump, connection rib and pin region formed on the metal substrate with a front surface metal layer, and plating connection ribs with silver; (5) removing the dry film layers to expose etching regions; (6) performing half etching to form sunken half-etched regions on the metal substrate, and forming base bumps and pins; (7) embedding chips; (8) performing wiring; (9) performing package and post-curing; (10) sticking the dry film layers again; (11) removing the dry film layers from the metal substrate; (12) performing full etching on the region, which is not covered by dry film, on the back surface of the metal substrate to enable the base bumps and the pins to be protruded out of the surface of a plastic package body; (13) removing the dry film layers; (14) forming pin metal layers; (15) performing cutting. The flat bump type non-metal cutting package process achieves the advantages of high reliability and low tool wear.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

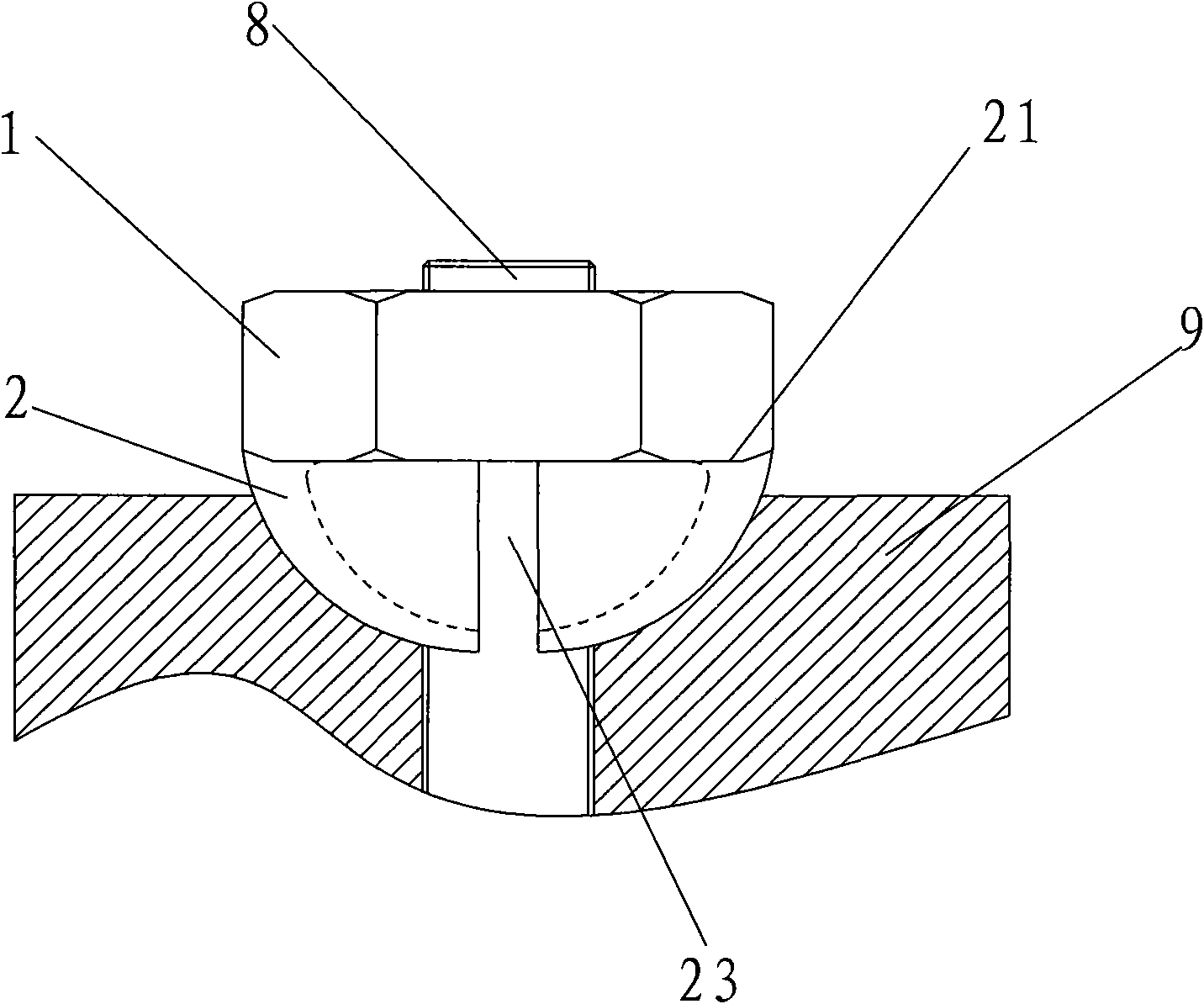

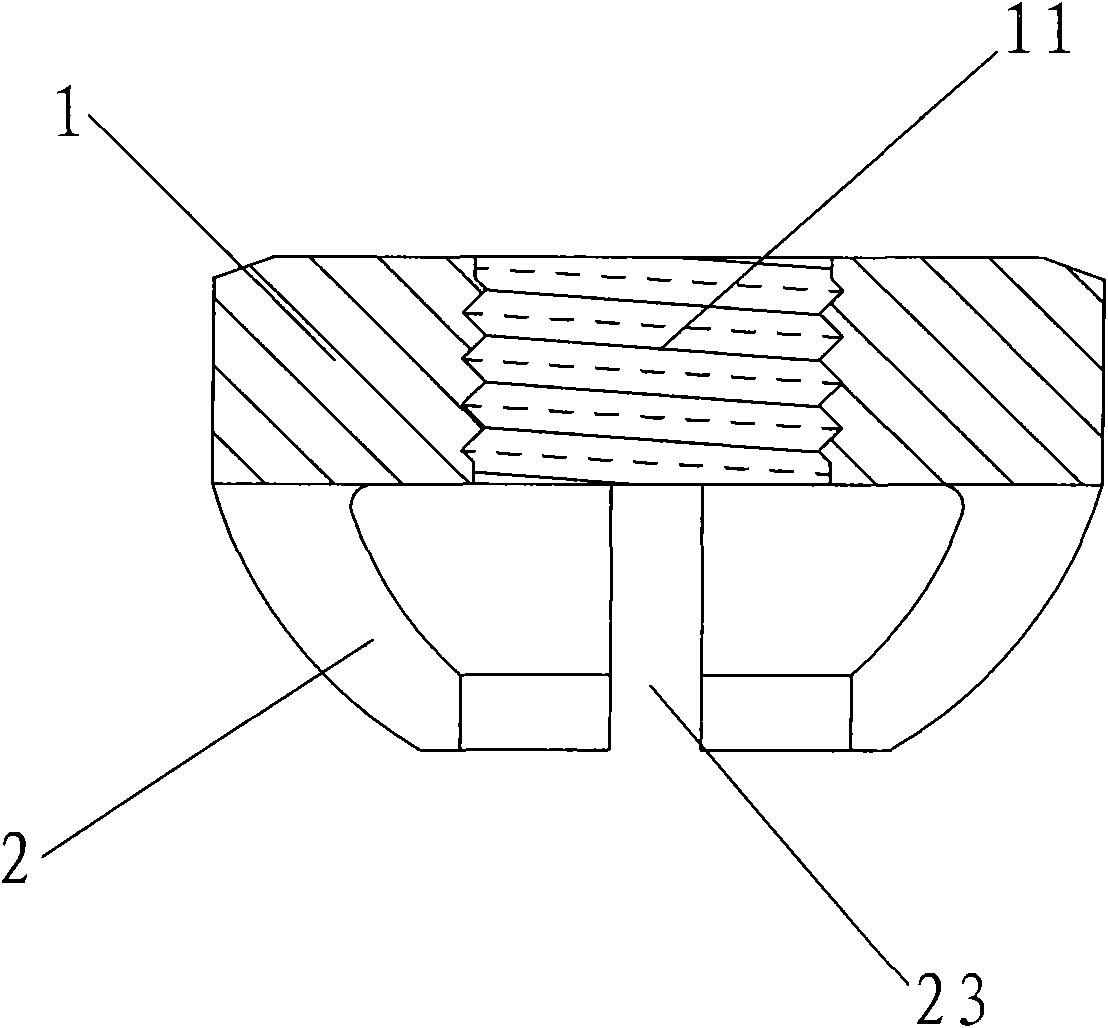

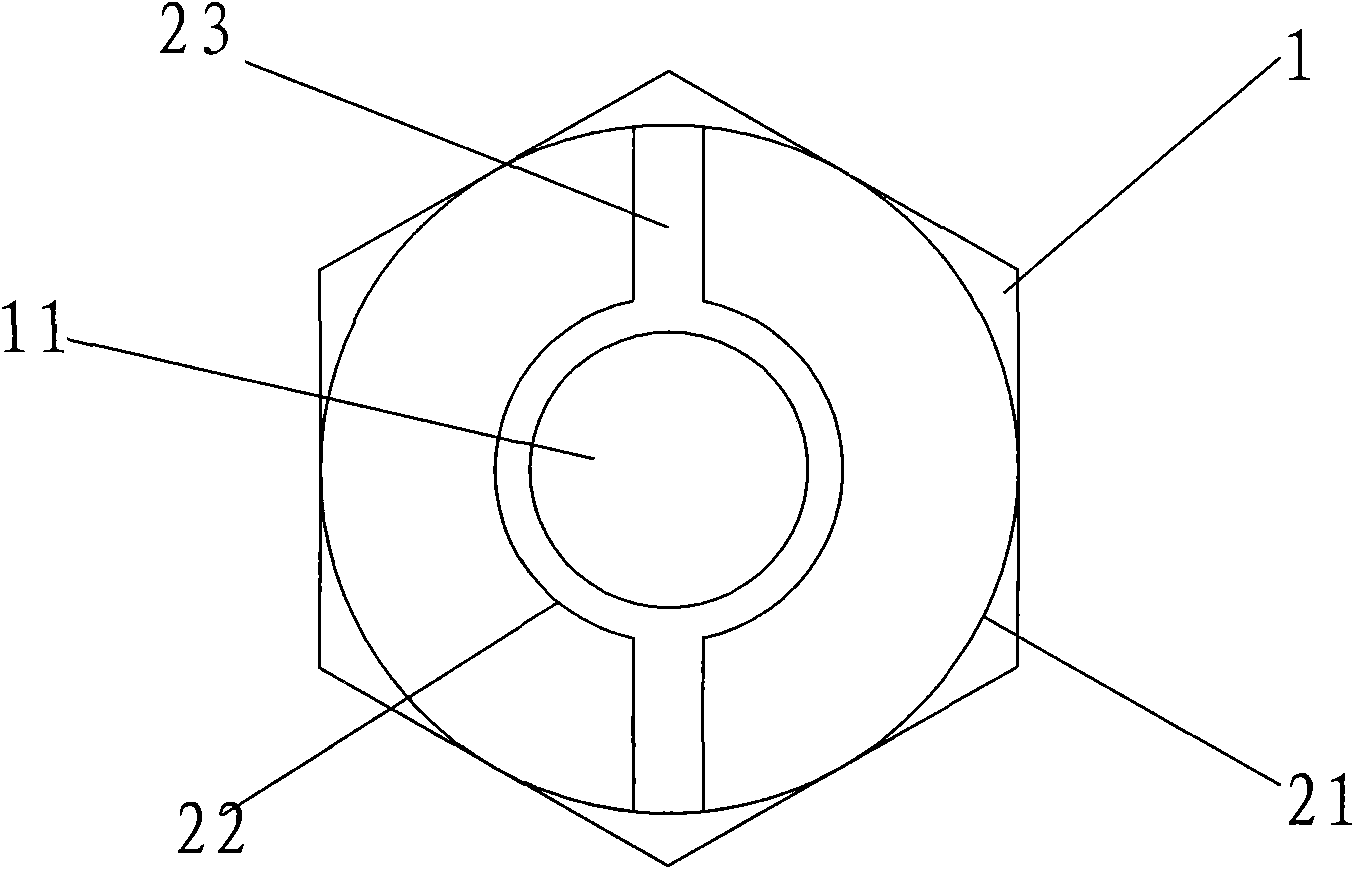

Self-locking nut

The invention relates to a self-locking nut which comprises a nut body and an elastic part, wherein the cross section of the elastic part is a hollow circular shape, the bottom side of the elastic part is fixed on the nut body, and the outer diameter of the bottom side is larger than that of the top; the top is provided with an opening, the size of which is equivalent to the large diameter of a screw hole of the nut body; and one or more rabbet(s) is / are arranged from the opening to the bottom side. The self-locking nut has fewer parts, easy installation and firm locking, so as to shorten the operation time, improve the working efficiency and enhance the fastness of a locking piece.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Closing part

Owner:GUANGXI NANNING LIANYANG BUILDING MATERIAL ITEMS FURNITURE

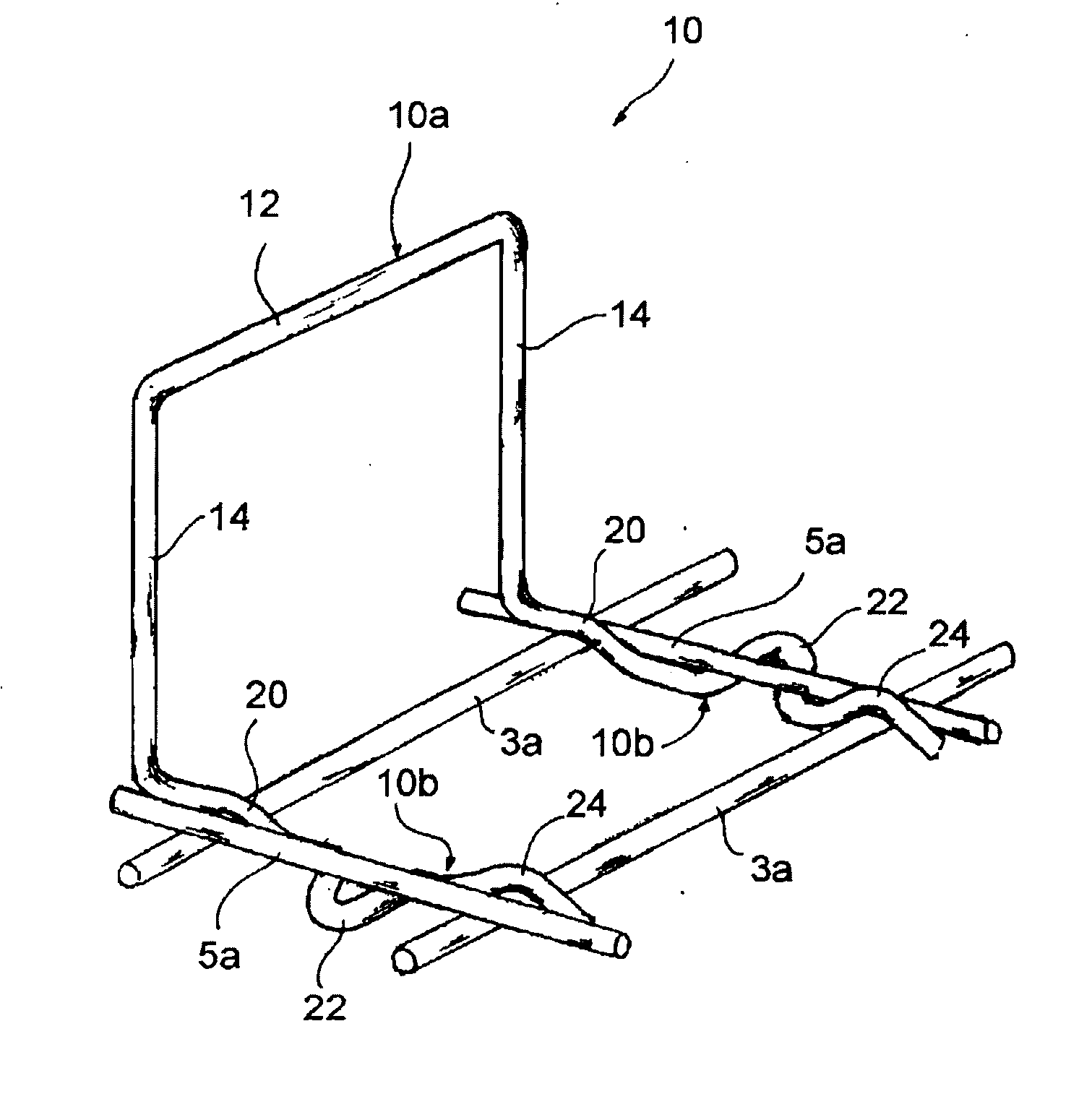

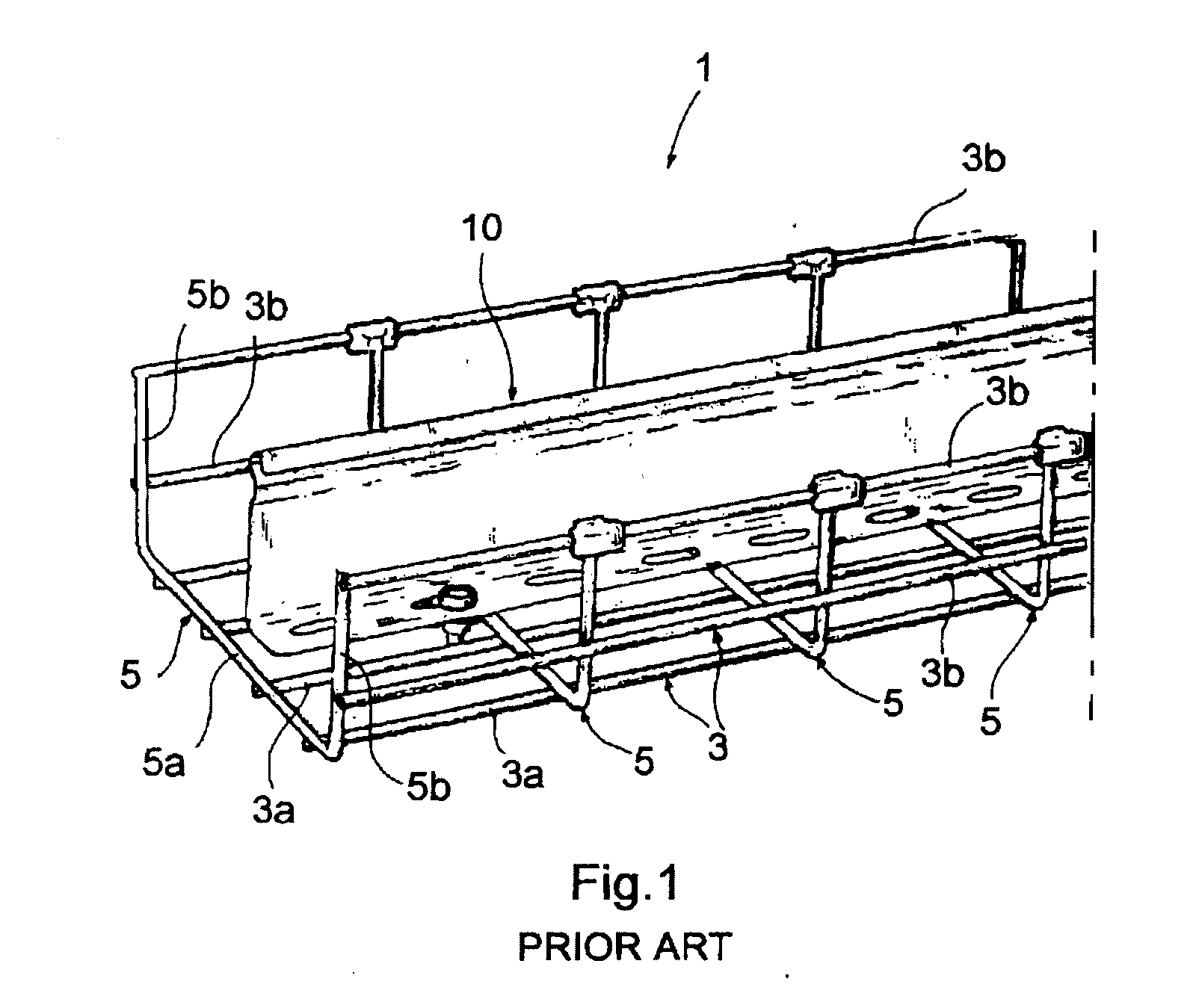

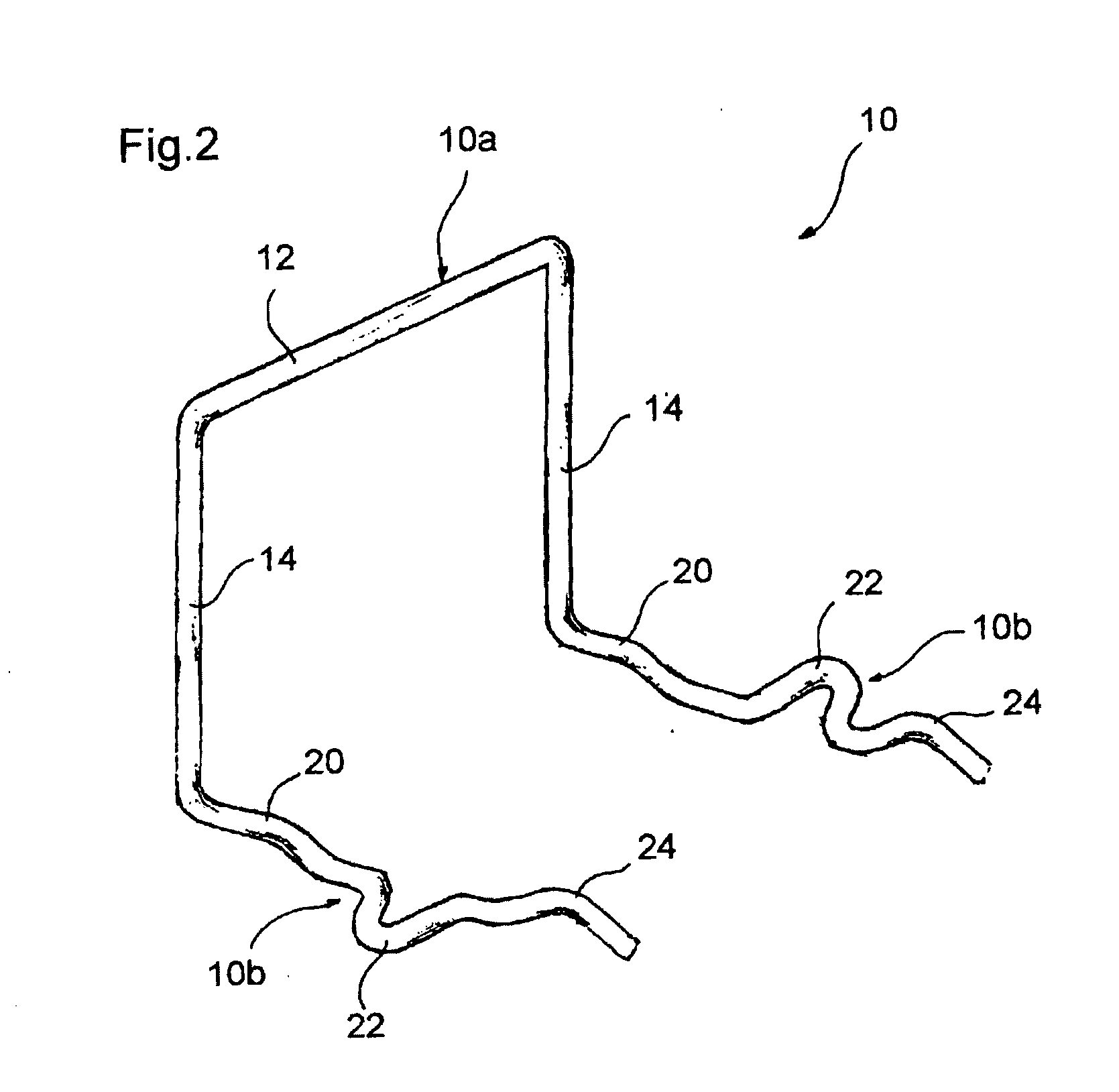

A separator element for a mesh cable duct and a mesh cable duct comprising such element

InactiveUS20070029451A1Easy to produceReduce in quantityPipe supportsElectrical apparatusWire rodEngineering

Owner:LEGRAND ZIBIDO SAN GIACOMO

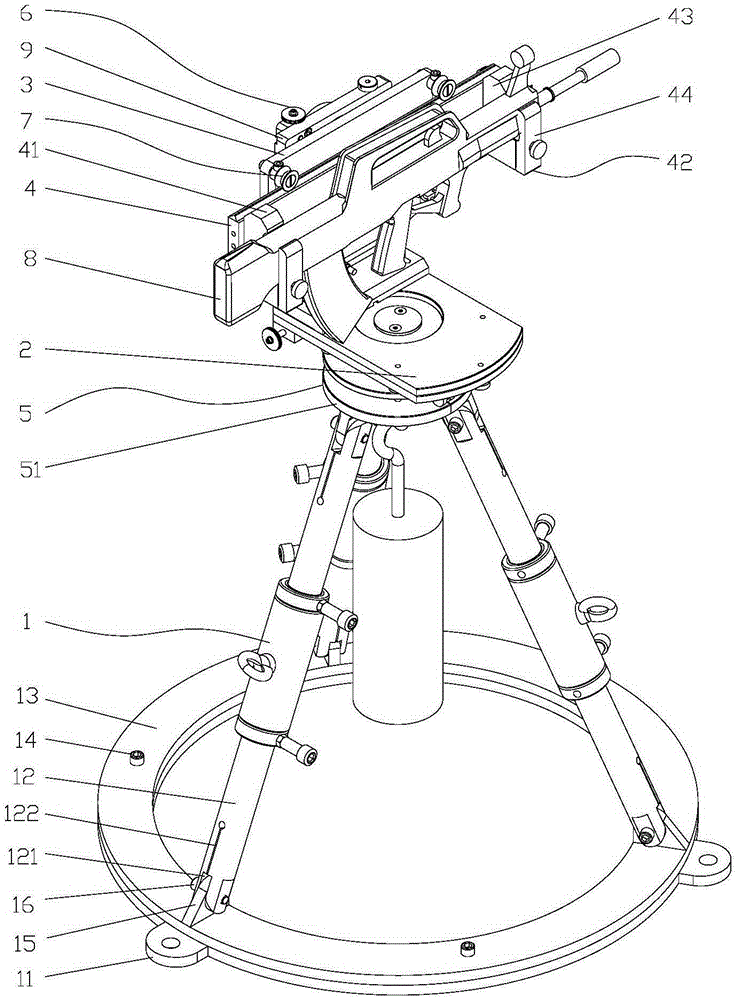

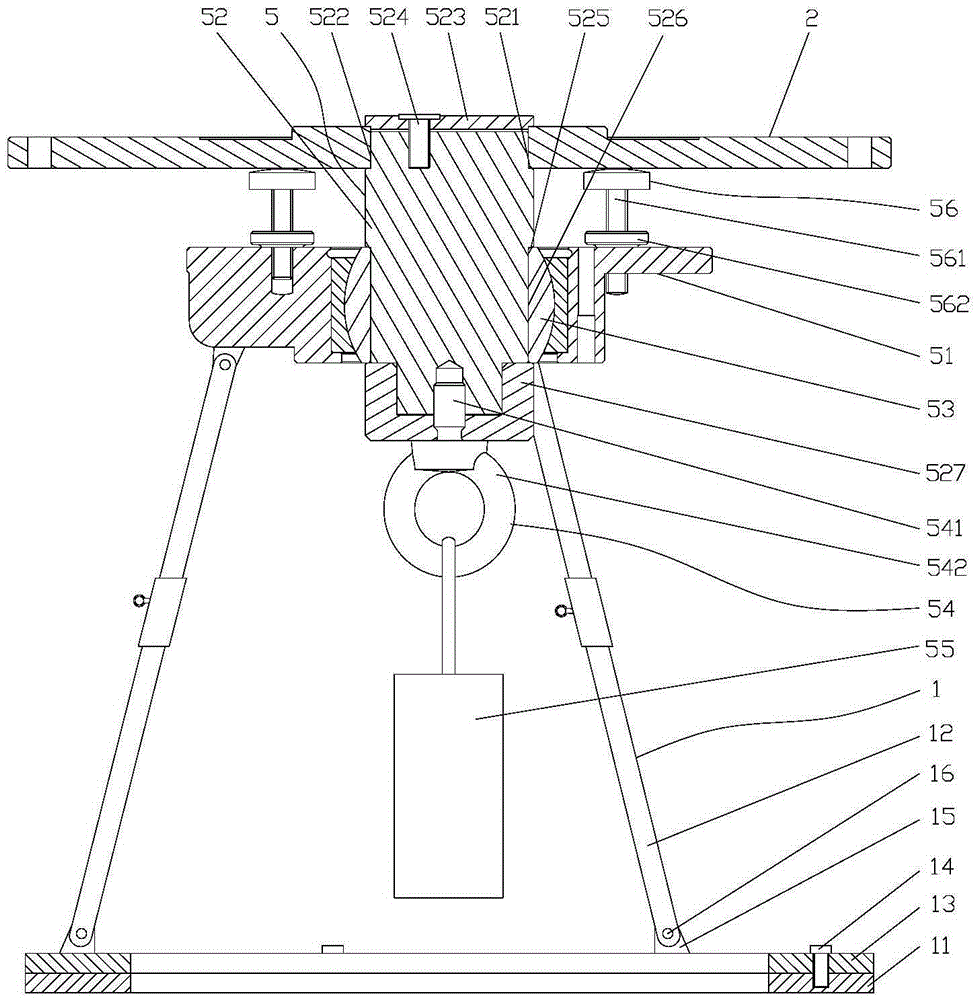

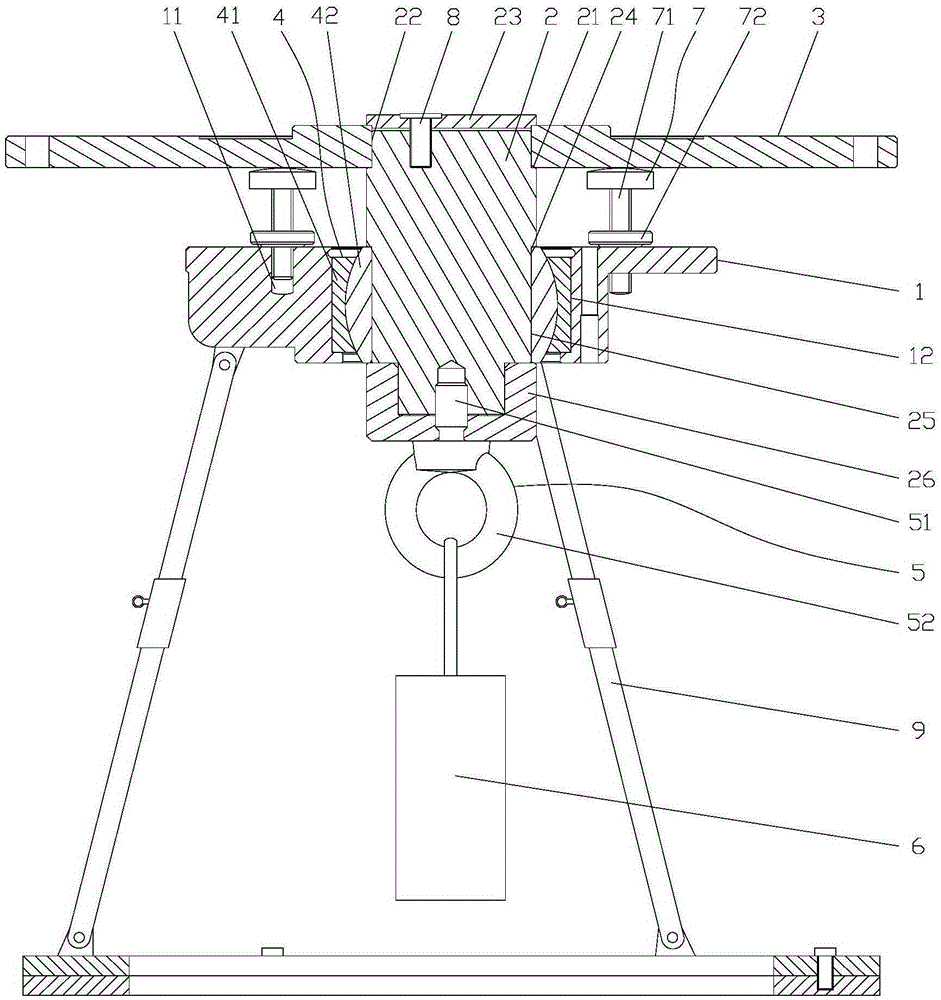

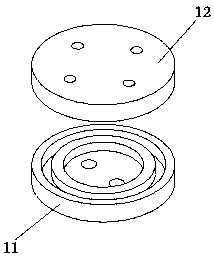

Automatic leveling device based on joint bearing and application thereof

InactiveCN105240664AAffects Horizontal AccuracyAffect stabilityStands/trestlesTargetsEngineeringBearing surface

The invention relates to the technical field of leveling devices, in particular to an automatic leveling device based on a joint bearing and application thereof. The automatic leveling device comprises a bracket, a mounting base, a vertical shaft and a horizontal disc, wherein the mounting base is arranged on the bracket; the joint bearing is arranged in the mounting base; the lower part of the vertical shaft is fixedly inserted in the joint bearing; a connecting piece is arranged in the center place of the lower end surface of the vertical shaft; the other end of the connecting piece is connected with a counterweight block; the upper end of the vertical shaft is vertically and fixedly connected with the horizontal disc; multiple positioning pieces are arranged on the mounting base, are supported on the bottom surface of the horizontal disc in a height adjusting manner, and consist of bolts and nuts; the bolts are inserted in or in threaded connection into positioning holes formed in the mounting base; and the nuts are in threaded connection to the bolts, and are butted against the upper surface of the mounting base. The automatic leveling device is reasonable in design, simple in structure and convenient for use; and no matter which bearing surface is provided with the mounting base and if the mounting base is horizontally mounted, the horizontal disc can be always automatically located in a horizontal state.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

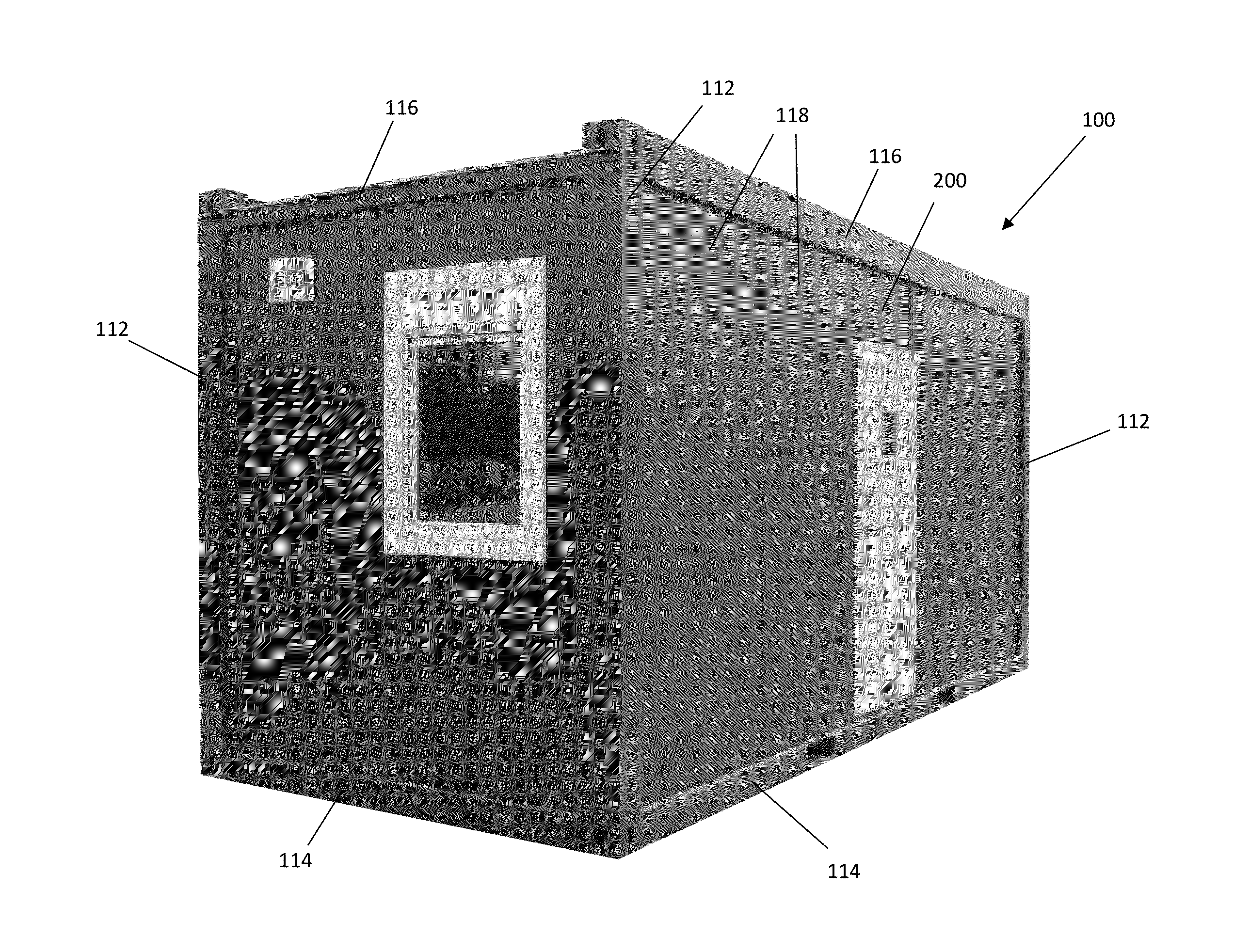

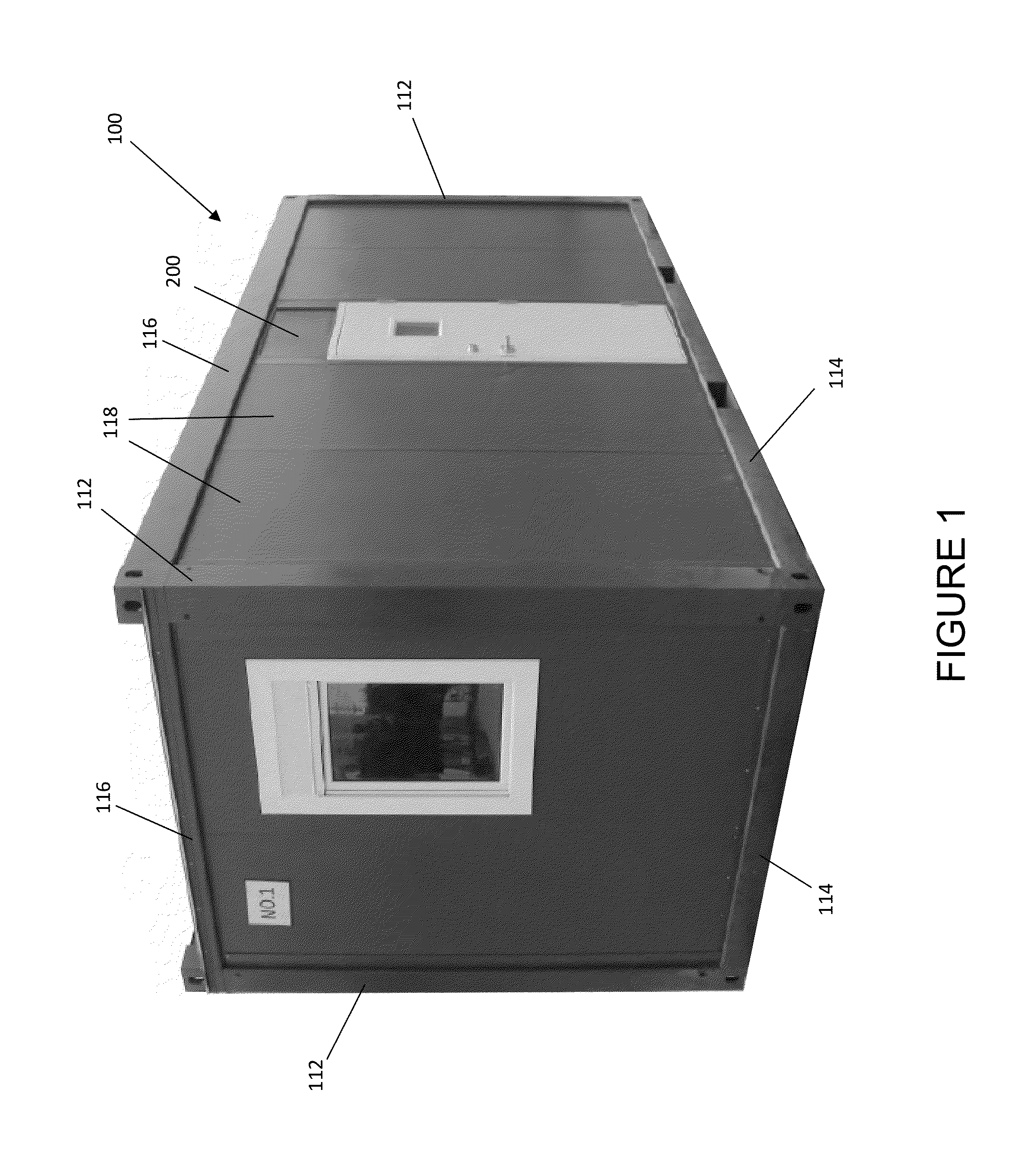

Interlocking wall panels for modular building units

ActiveUS20160017606A1Quick and easy installationEasy to installWallsFloorsModular constructionModularity

Disclosed is a modular building construction having interlocking wall panels that mate with one another and with the frame of the building unit without screws, bolts or other fasteners, but while ensuring a water-tight fit. This configuration significantly simplifies installation of the wall panels into the skeletal frame of the modular building unit, allowing a first wall panel to be joined to an adjacent wall panel in a quick and easy installation step while maintaining the ability to later adjust and / or replace the wall panel.

Owner:WILLIAMS SCOTSMAN INC

A distribution box convenient to adjust the mounting height of internal electric appliances

PendingCN109038292AHeight adjustableChange heightSubstation/switching arrangement detailsMaterial resourcesEngineering

The invention discloses a distribution box convenient to adjust the mounting height of internal electric appliances, and the distribution box includes a box body, a support block, a lead screw, a screw sleeve, a mounting block, a sliding block and a sliding groove, the lower end of the box body is mounted on the support plate, the lower end of the support plate is fixedly connected with a fixed screw sleeve and an L-shaped fixed block, the fixed screw sleeve is screwed with a roller assembly, the roller assembly is provided with a lifting screw, an L-shaped fixed block is provided with a mounting hole and a threaded hole, and a distribution box lifting bolt assembly is mounted in the threaded hole. As the screw rod rotates, the screw sleeve can be driven to move, the threaded sleeve can move up and down along the sliding groove through the sliding block, then the screw sleeve drives the mounting plate to realize the height adjustment inside the box body through the mounting block, thereby changing the height of the electric equipment on the mounting plate, facilitating the mounting and wire arrangement, solving the trouble of the wire arrangement and the mounting, making movement of the distribution box easy, saving manpower and material resources, making operation convenient and quick, and greatly improving the work efficiency.

Owner:江苏信实电气有限公司

Mounting method for extending single-layer latticed shell structure

InactiveCN105507427AAdapt to on-site operationEasy to installBuilding material handlingFunctional changeEngineering

Owner:上海岑闵新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com