Vacuum filter

A filter and vacuum technology, applied in the field of filters, can solve the problems of damage to vacuum pump pipelines, environmental pollution, etc., and achieve the effects of fast gas circulation, high filtration efficiency, and convenient installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

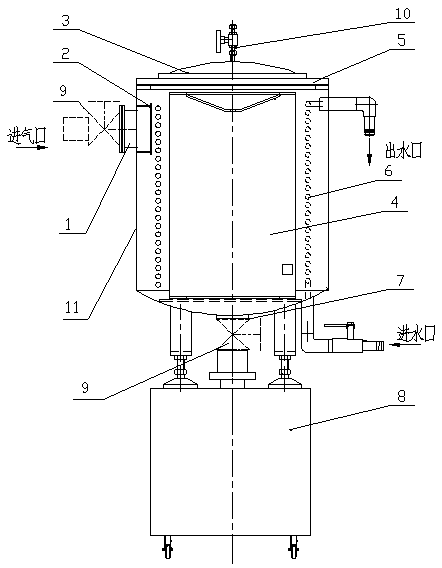

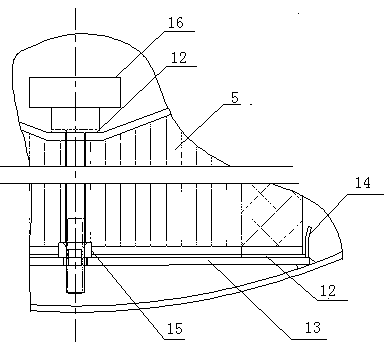

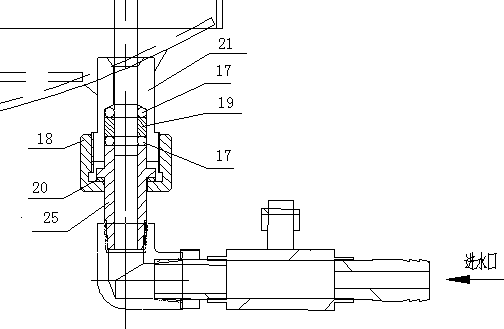

[0025] Combine below Figure 1 to Figure 5 The vacuum filter of the present invention is further described in detail.

[0026] Such as figure 1 As shown, the vacuum filter of the present invention includes a cavity 11 , a top plate 4 , a quick opening cover 5 , a flow equalizer plate 2 , a cooling pipe 6 , a filter element 5 , and a vacuum pump 8 .

[0027] The cavity 11 is a cylindrical shell, the bottom surface is an outwardly convex arc, the side is provided with an air inlet 1, and the bottom surface is provided with an air outlet 7, the air inlet 1 is connected with a specific gas pipeline through a control valve 9, and the air outlet 7 is connected to the vacuum pump 8 through the control valve 9, so that under the action of the vacuum pump 8, the specific process gas enters the cavity 11 from the inlet 1.

[0028] The center in the cavity 11 is provided with a filter element 5, the filter element 5 is a cylindrical shell, and the side wall is provided with filter hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com