Stern shaft tail tube device for ship and method for mounting stern shaft tail tube device

A stern tube and stern shaft technology, which is applied in the field of marine stern shaft stern tube devices, can solve the problems of high installation work intensity of stern shaft stern tubes, difficulty in disassembling and assembling large-diameter propellers, and fatigue strength of shafting, etc., and achieves a simple and convenient installation structure. and method, the effect of short cycle and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

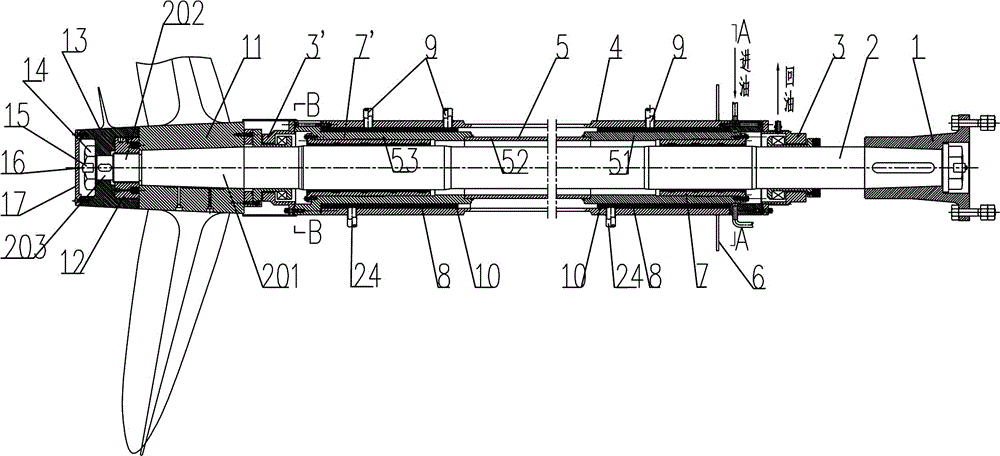

[0040] Head and tail orientation among the present invention are to illustrate attached figure 1 The orientation in the figure 1 The right end is the head end or front end, and the left end is the tail end or back end.

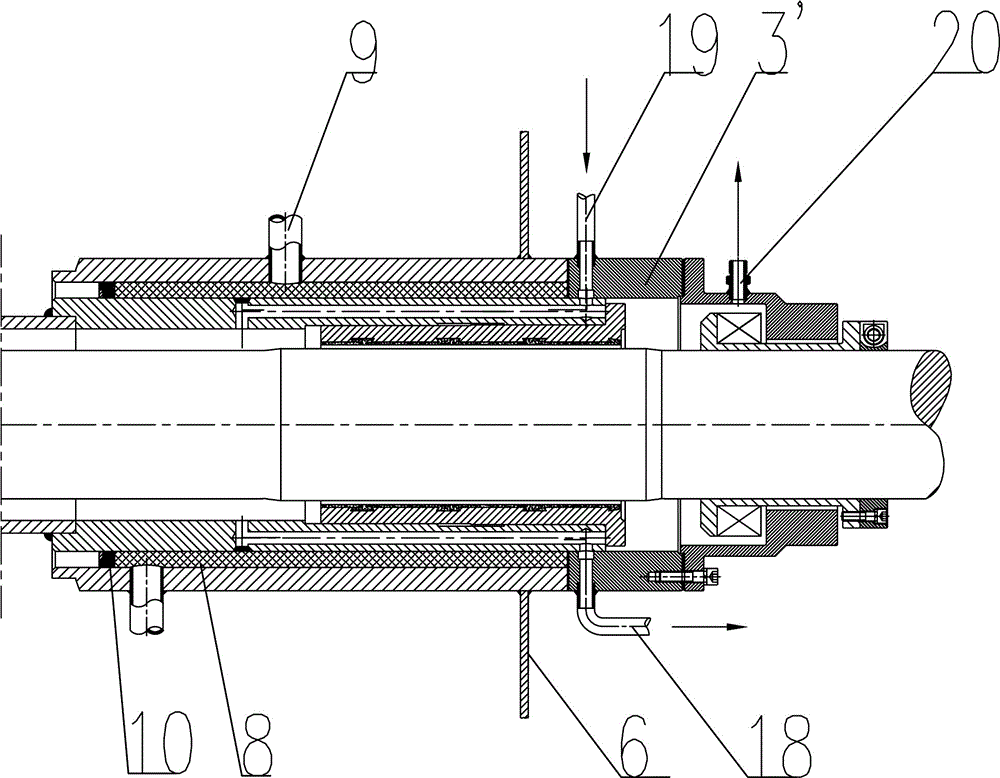

[0041] like Figure 1~6 Among them, a marine stern shaft and stern tube device, the two ends of the stern tube are respectively provided with a head end sealing device 3 and a tail end sealing device 3', wherein the head end sealing device 3 is provided with an oil inlet 19 directly connected to the inner cavity of the stern tube And drain port 18, used to provide lubrication to the bearings. An oil return port 20 is also provided on the head end sealing device 3 . The pipeline distance between the oil inlet 19, the oil discharge port 18 and the oil return port 20 is very short, which is convenient for installation.

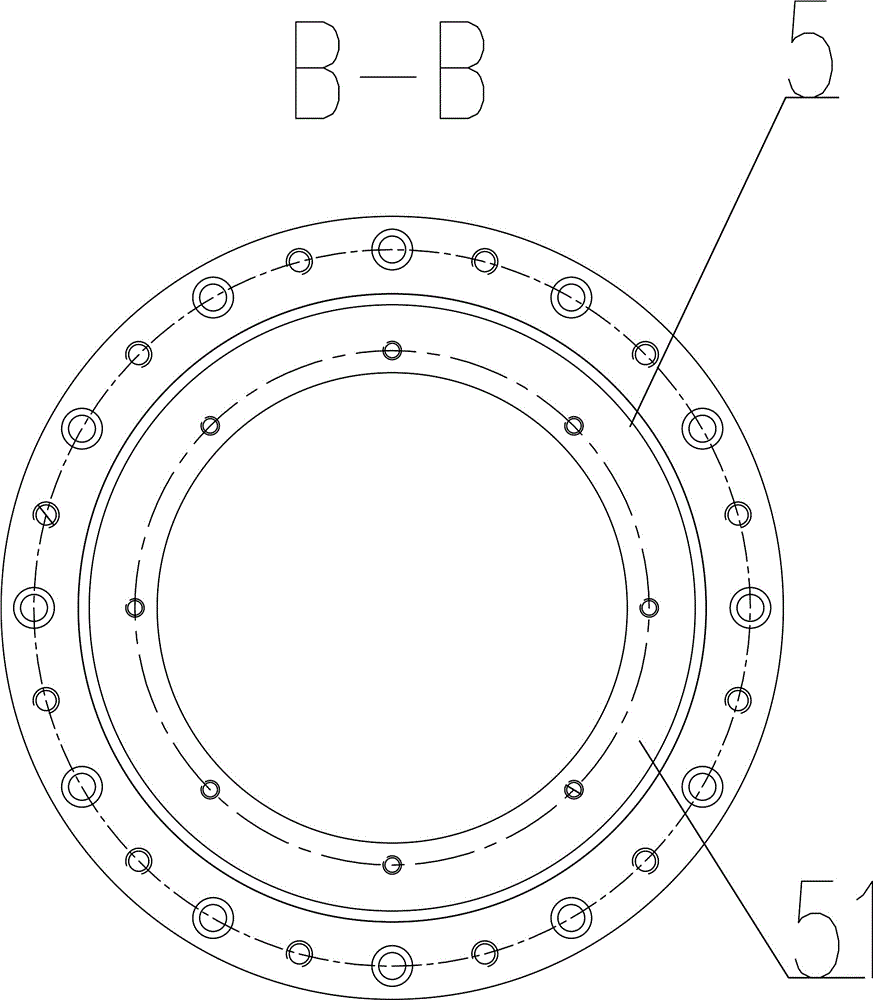

[0042] The structure of the tail pipe is as follows: the outer tail pipe 4 and the inner tail pipe 5 are socketed and connected, the inner t...

Embodiment 2

[0058] The specific manufacturing and installation methods are as follows:

[0059] 1. Workshop manufacturing of inner and outer stern shaft and tail pipes

[0060] 1.1 Outer stern pipe: After rough machining, the qualified front and rear end outer stern pipe steel castings or forged steel parts are assembled and welded together with the middle thick-walled seamless steel pipe. The welding should ensure the concentricity of the two ends of the overall outer stern pipe. The completed integral outer tailpipe is finished in the workshop to meet the design requirements, and it can also be made of integral thick-walled seamless steel pipe.

[0061] 1.2 Inner stern pipe: After rough machining of the qualified head end bearing housing 51 and tail end bearing housing 53, assemble and weld them together with the thick-walled seamless steel pipe connecting pipe 52 in the middle section, and ensure the concentricity of both ends of the overall inner tail pipe during welding. After weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com