Patents

Literature

44results about How to "Sound insulation has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

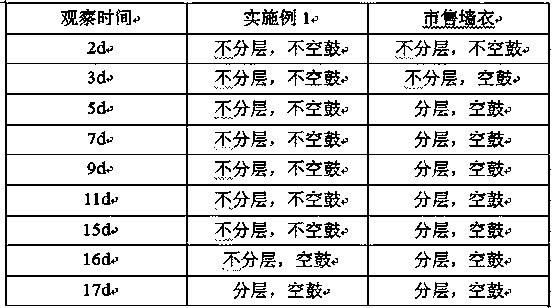

Light sound insulation damping mortar and building construction method

InactiveCN104961397ASound insulation hasWith insulationFlooring insulationsSurface layerConstruction aggregate

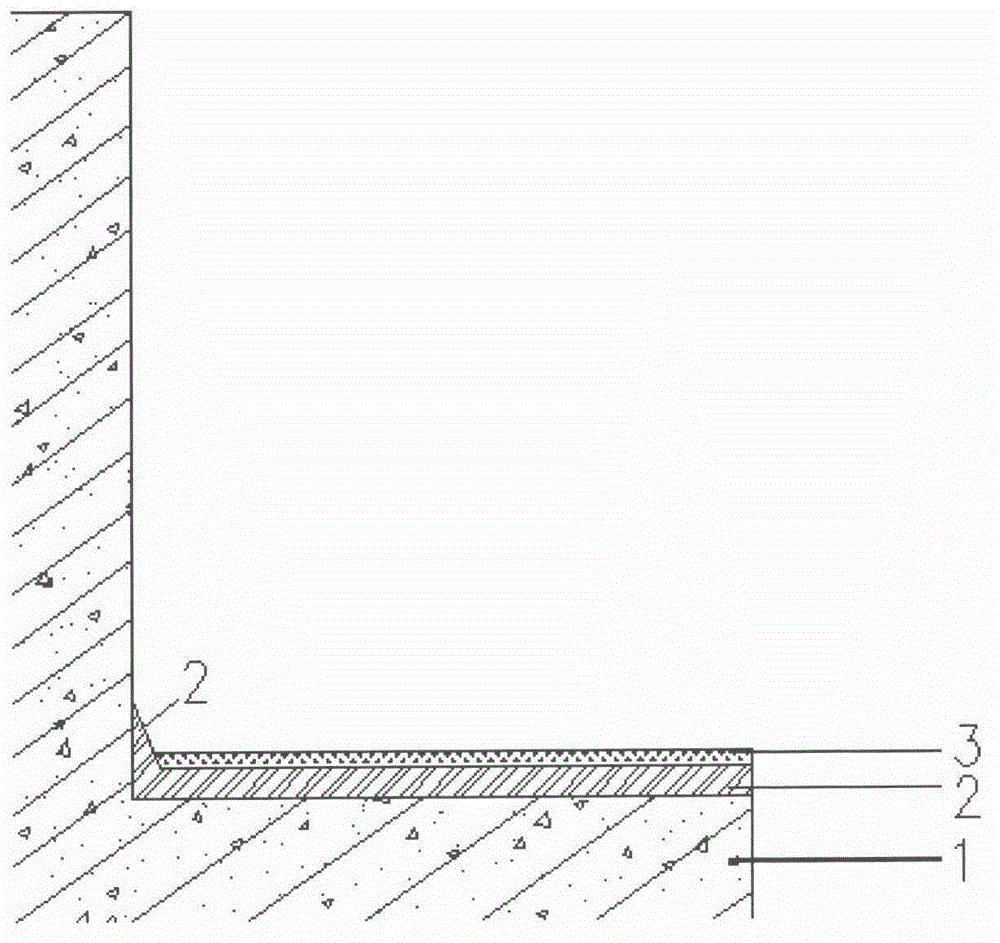

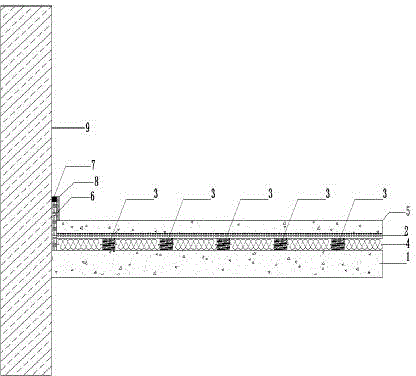

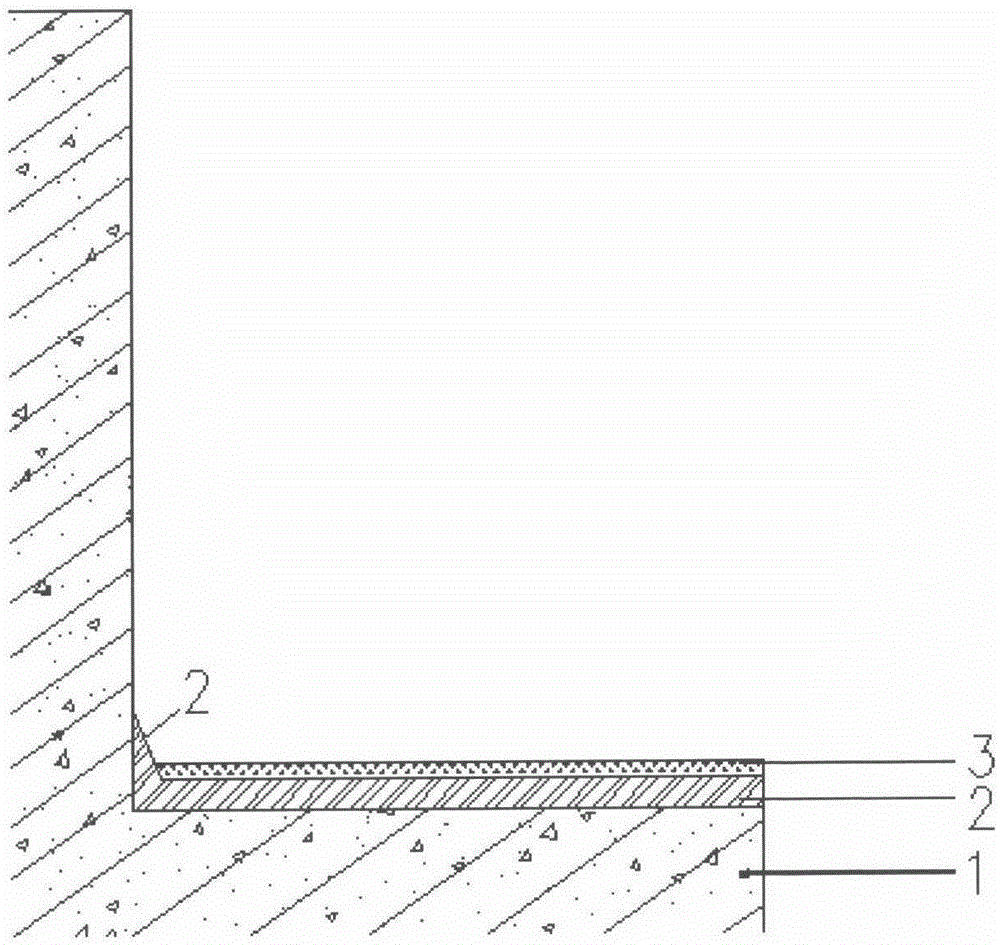

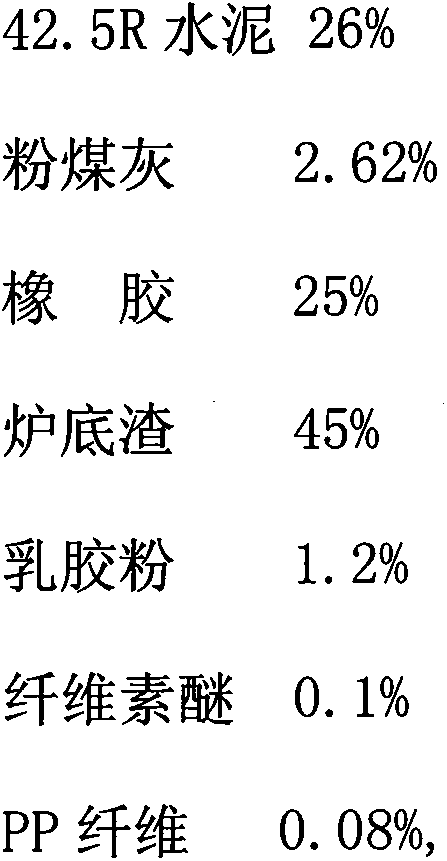

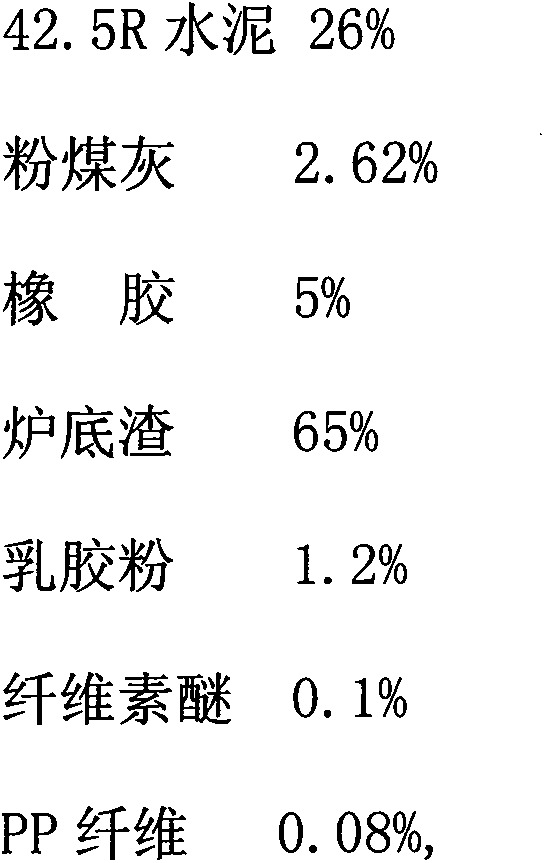

The invention discloses light sound insulation damping mortar. The light sound insulation damping motor is formed by mixing 10-50% of inorganic cementing material, 5-50% of rubber, 10-80% of light sand, 1-50% of aggregate and 0.01-20% of additive. A light sound insulation floor is composed of the light sound insulation damping mortar (2) smeared to the top of a concrete floor (1), a protection surface layer (3) smeared on the upper portion of the light sound insulation damping mortar (2) and the light sound insulation damping mortar (2) which is smeared to the upper wall at a wall corner and exceeds the protection surface layer (3).

Owner:杜飞月

Composite thermal insulation concrete wall and its assembled template

InactiveCN1766248AOmit construction stepsLow costWallsForms/shuttering/falseworksRear quarterThermal insulation

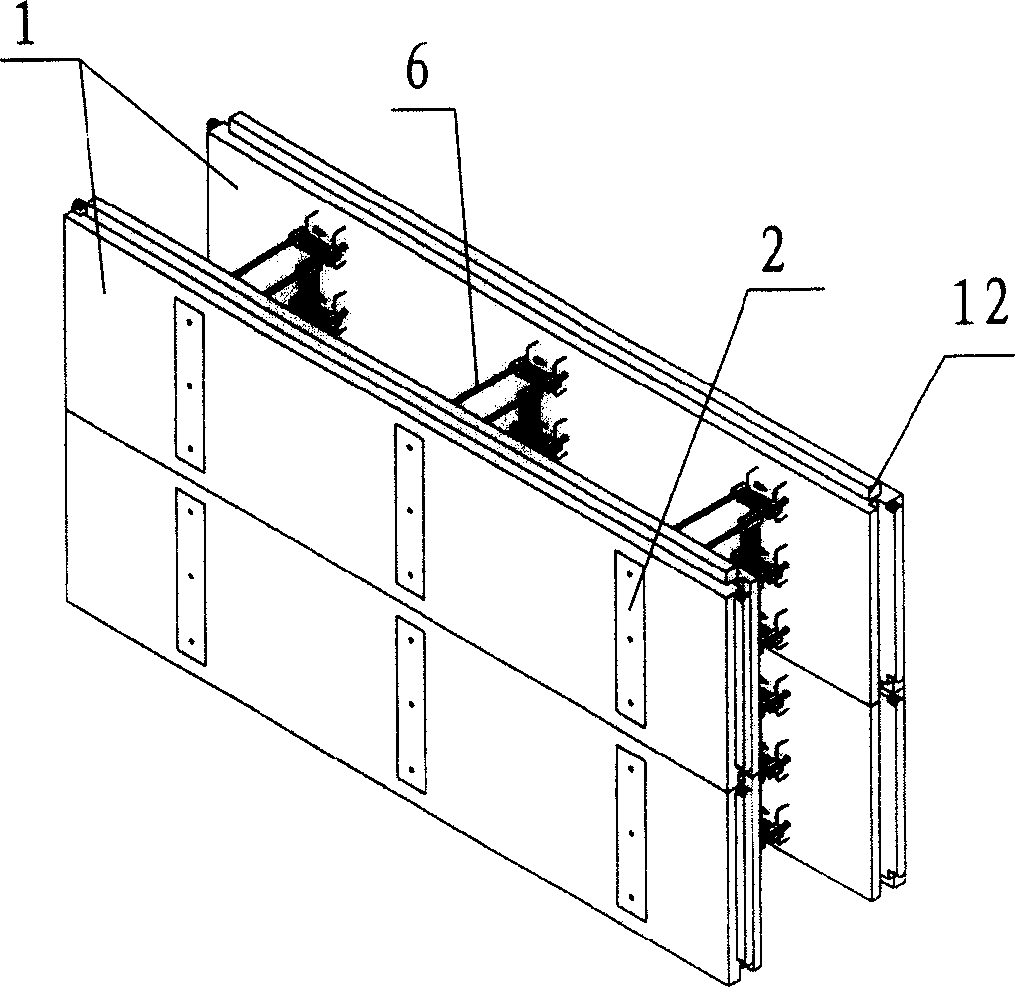

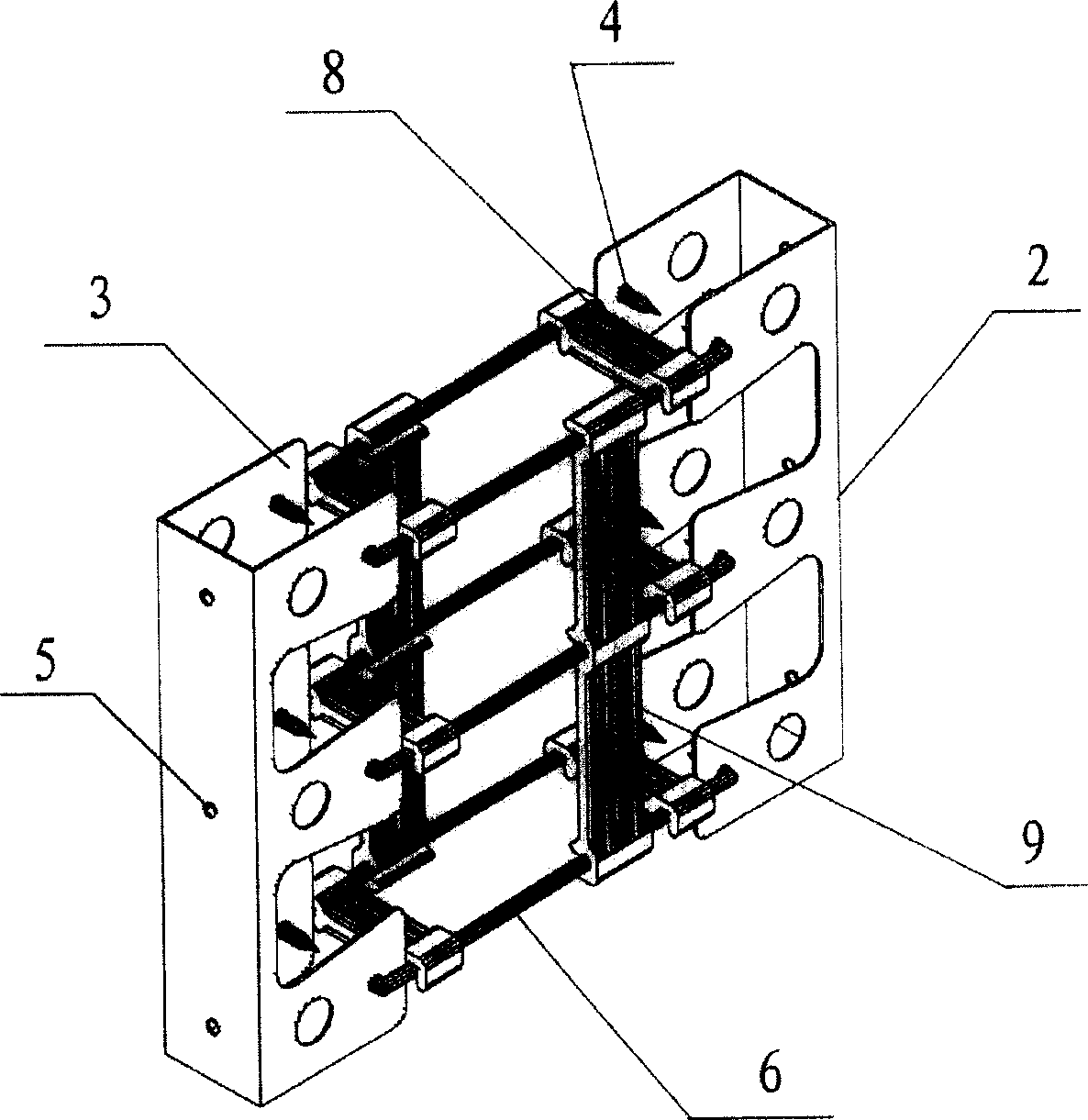

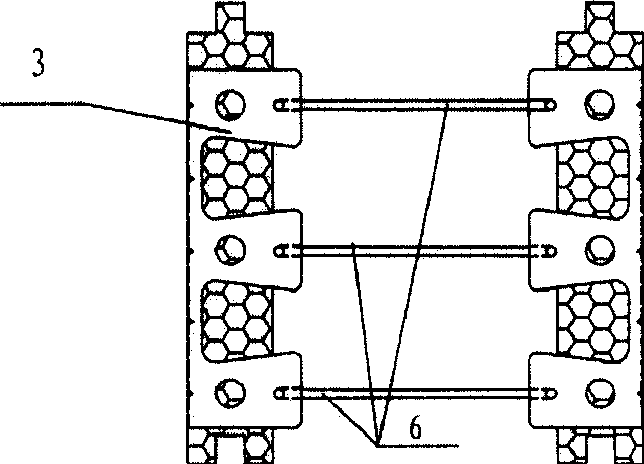

The invention discloses a composite thermal insulation heat-proof concrete wall and assemblage type mould, which is characterized by the following: the wall two-side mould is composed of polystyrene thermal insulation material; double-row tooth fold steel is set in the each side mould; the transverse section of double-row tooth fold steel displays U-shape; the base plate of double-row tooth fold steel and one side surface of mould are in the same plane; two side plates of double-row tooth fold steel extends the other side surface of mould; the attachment connects the through-hole at even distance allocation on two side plates of double-row tooth fold steel; the attachment pierces the hole of double-row tooth fold steel side plate corresponding to two-side mould to connect the wall two sides; the net-hung rivet hole is drilled in the middle part of double-row tooth fold steel along certain vertical distance; the transverse and vertical plugging part connects the same position attachment of double-row tooth fold steel corresponding to the wall two side mould, which locks joint along the transverse and vertical direction. The mould becomes the wall inner and outer side thermal insulation layer after casting the concrete.

Owner:朱秦江

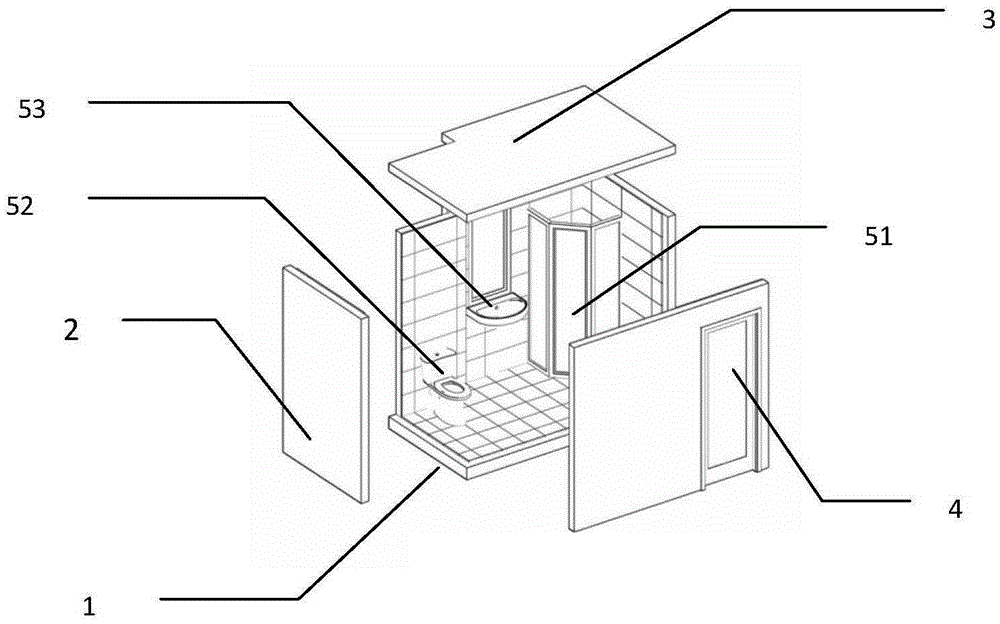

Assembly-type integrated bathroom and construction method thereof

ActiveCN105421826ARefractory hasSound insulation hasSpecial buildingBuilding constructionsThermal insulationBathroom Equipment

The invention relates to an assembly-type integrated bathroom and a construction method thereof. The assembly-type integrated bathroom comprises foaming cement composite bottom plates, foaming cement composite wall plates, foaming cement composite top plates and bathroom equipment; dovetail groove type steel frame edge ribs are arranged in the plates, and each dovetail groove type steel frame edge rib is composed of an upper wing flange, a lower wing flange and a dovetail groove edge rib groove; an embedded part wedge block is arranged in each dovetail groove edge rib groove; all the plates are fixedly connected through bolts, connecting parts and the wedge blocks arranged in the dovetail groove edge rib grooves of the plates. The assembly-type integrated bathroom has the advantages that the foaming cement composite plates obtained through industrialized production are adopted, the fire resistance duration is larger than or equal to 4 hours, the sound insulation is larger than or equal to 42 decibels, raw materials forming the plates adopt inorganic materials and are non-combustible, and the comprehensive properties of energy conservation and environment protection, bearing and thermal insulation, heat insulation, fire resistance, durability, shock resistance, small mass, high strength and the like are achieved; installing operation is easy and convenient, rapidness and firmness are achieved, and environmental pollution and noise emission caused by traditional bathroom construction are reduced. The assembly-type integrated bathroom is an energy-saving and environment-protecting green building product.

Owner:CUBIC DIGITAL TECH CO LTD +2

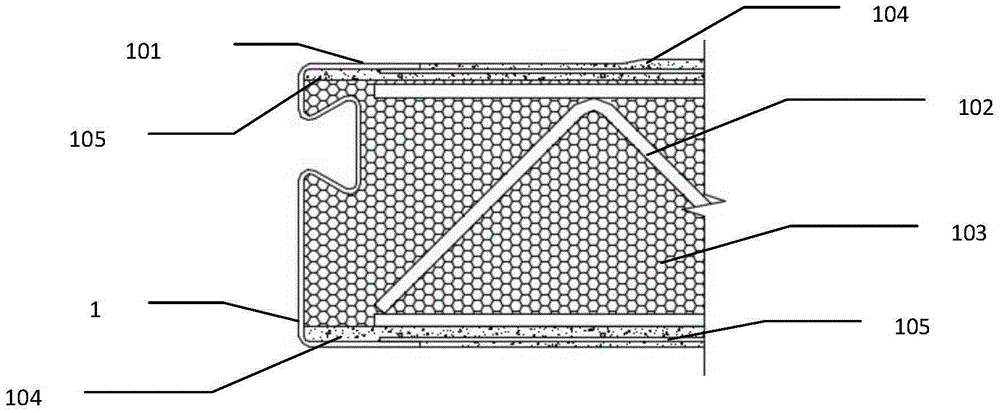

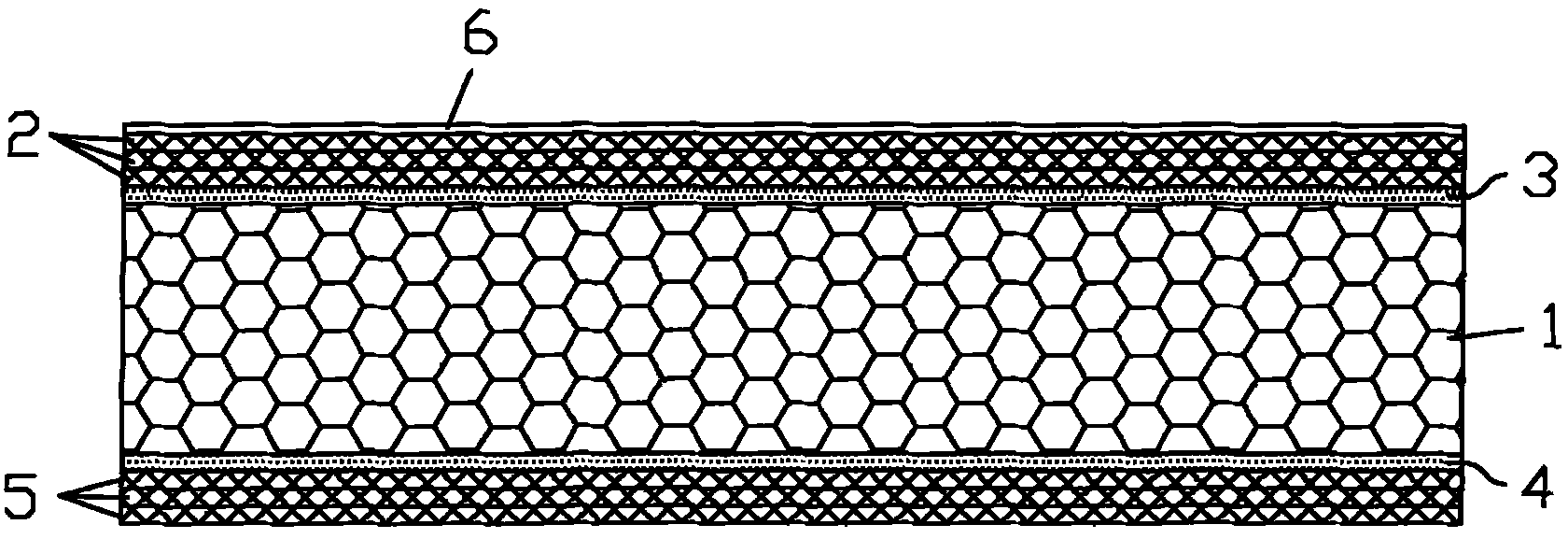

Composite fireproof honeycomb panel

InactiveCN102182273ALow densitySound insulation hasCovering/liningsBuilding componentsGlass fiberCombustion

The invention discloses a composite fireproof honeycomb panel which comprises a honeycomb core, and an upper flame-retardant layer is fixed on the upper surface of the honeycomb core. The upper flame-retardant layer is bonded with and fixed on the honeycomb core by an adhesive layer. The upper flame-retardant layer is composed of one or more layers of glass fiber fabrics or asbestos. According to the invention, a flame-retardant layer composed of one or more layers of glass fiber fabrics or asbestos is disposed on the honeycomb core; since the honeycomb core itself is not inflammable and is soaked by phenolic resin and the like, the formed fireproof honeycomb panel has good flame retardancy, is not inflammable, is not easy to cause fire, and has low heat release rate and low smog density during combustion.

Owner:章明耀

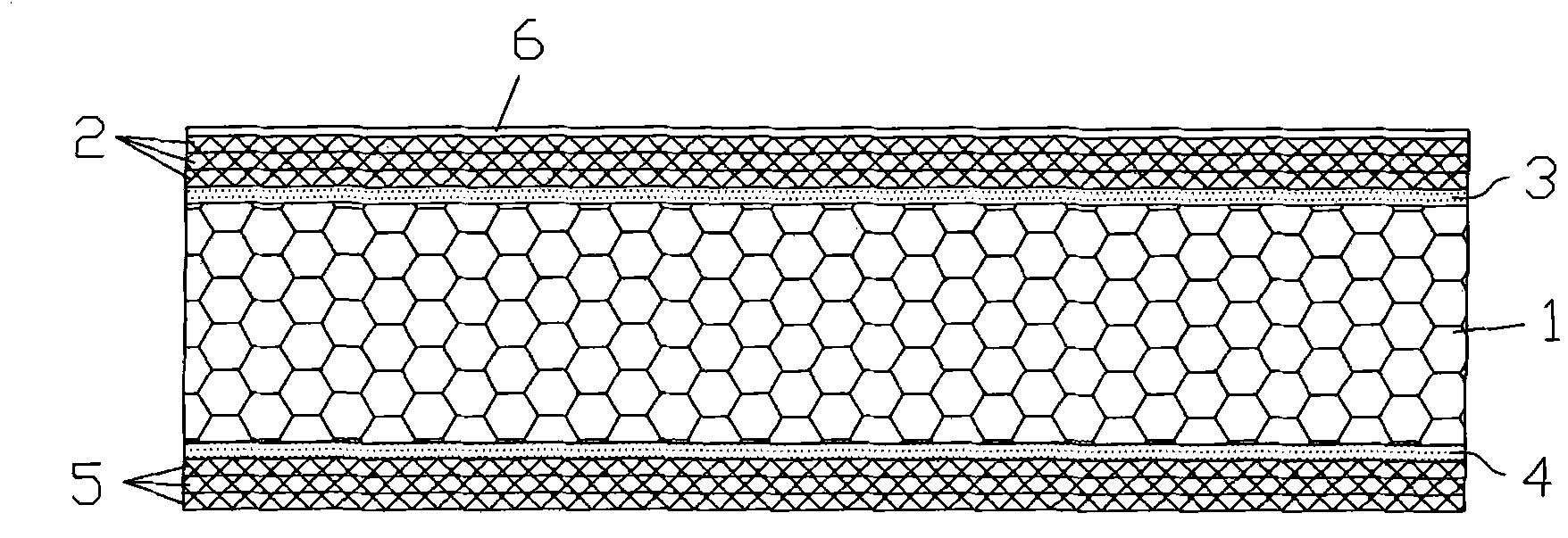

Production method of transparent sound-proof film

InactiveCN103773258AExcellent sound insulation performance indexSound insulation hasFilm/foil adhesivesGraft polymer adhesivesAcrylic resinPolystyrene

The invention belongs to the technical field of glass film production, and particularly relates to a production method of a transparent sound-proof film. The production method comprises the following steps: (1) copolymerizing polystyrene and butyl acrylate so as to synthesize styrene-acrylic resin, wherein the glass transition temperature of the formed styrene-acrylic resin is 15-30 DEG C, and the damping coefficient of the formed styrene-acrylic resin is greater than 0.3; (2) adopting a hot-melting coating machine for coating so as to form a thin film with the thickness of 0.05-1.0mm; and (3) compounding common glass films at the two sides of the styrene-acrylic resin thin film in a thermal compounding manner. The production method of the glass film with excellent sound-proof performance index, provided by the invention, has the advantages that the styrene-acrylic resin thin film with a large damping coefficient is compounded between two layers of common glass films, so that the glass film formed in the end has soundproof property, the selectivity of laminated glass production is improved, and the whole production process is concise, clear and easy to operate.

Owner:TIANJIN SUNRAY PLASTIC PROD

Sound-insulating pad used inside automobile and preparation process of sound-insulating pad

InactiveCN105538841AReduce the soundIsolate the soundVehicle componentsRubber layered productsPolyesterGlass fiber

The invention relates to a sound-insulating pad used inside an automobile and a preparation process of the sound-insulating pad and belongs to the technical field of automobile interior articles. The sound-insulating pad used inside the automobile is formed by bonding a sound-absorbing layer and a sound-insulating layer with bonding glue, wherein the sound-absorbing layer is made of, by weight, 30-60 parts of bamboo charcoal fibers, 50-80 parts of fibrilia, 20-40 parts of polyester fibers and 10-30 parts of glass fibers. The sound-insulating pad used inside the automobile is formed by bonding two layers of materials, the sound-absorbing layer has the sound absorbing effect and is free of toxin and smell, resistant to water and damp and good in air permeability, the sound-insulating layer not only has the sound insulating effect but also has the effects of thermal insulation, dust isolating, sealing and shock absorption, the two layers are bonded together, sound generated by resonance of metal inside the automobile can be lowered, the audio environment inside the automobile can be effectively isolated from the outside, more quietness can be achieved inside the automobile, and the effect of sound equipment inside the automobile can be further improved.

Owner:WUHU XINYUAN SPONGE

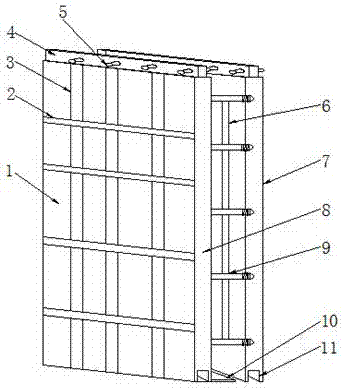

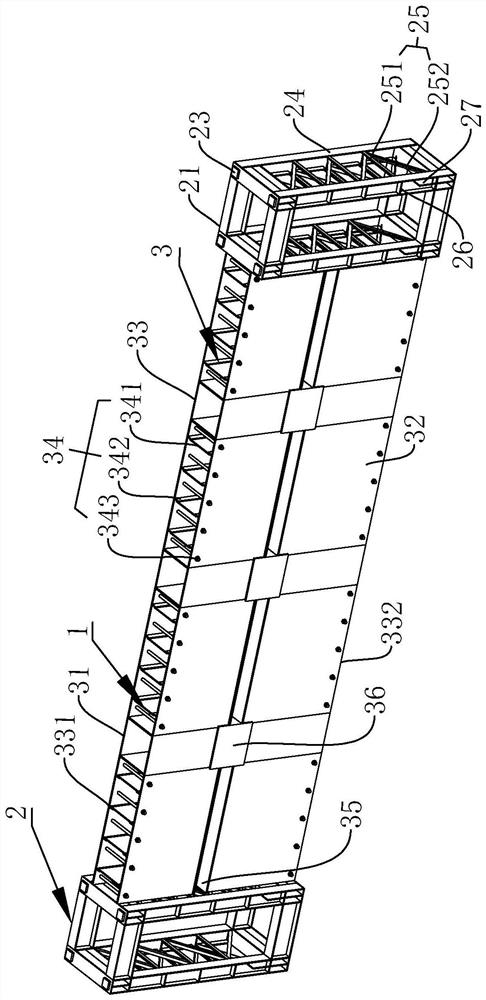

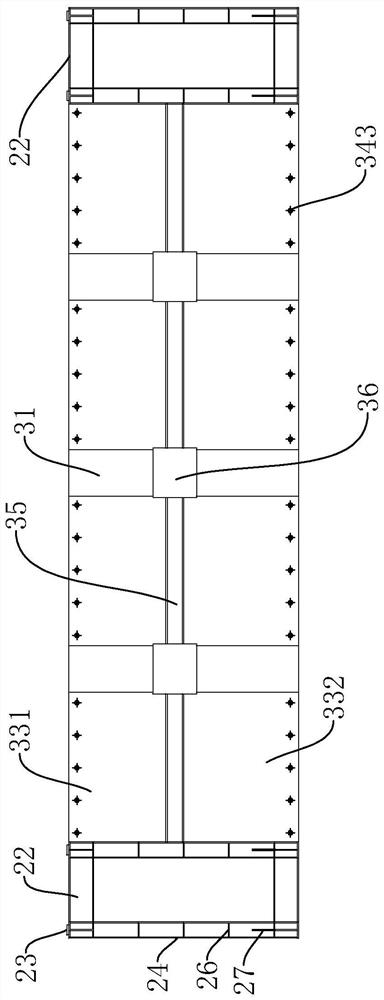

Assembled building wall

ActiveCN107313535AConvenient ArrangementAdjustable thicknessWallsStructural engineeringBuilding construction

The invention discloses an assembled building wall which comprises an assembled wall body, a transverse cover groove, a vertical cover groove, a splicing protrusion, extensible columns, springs and a connecting plate. An exterior wall is arranged on one side of the assembled wall body, an interior wall is arranged on the other side of the assembled wall body, a bottom plate is arranged at the bottom of the inner wall, the splicing protrusion is arranged at the upper end of the interior wall, and a damp-proof layer is arranged on the inner side of the interior wall. The assembled building wall is scientific and reasonable in structure and safe and convenient to use, and interval adjusting bolts are arranged, so that convenience can be brought to working personnel to adjust a distance between the exterior wall and the interior wall, and thickness of the assembled wall body can be adjusted; the splicing protrusion and limiting grooves are arranged, so that convenience is brought to docking of two assembled wall bodies, so that working intensity of the working personnel is reduced effectively; limiting columns are arranged, so that temporary fixing effect is realized during assembling, and working efficiency of the working personnel is improved. The assembled building wall is convenient to mount, low in construction cost and high in building overall performance.

Owner:QINGDAO ZHONGJIAN COMBINATION CONSTR ENG CO LTD

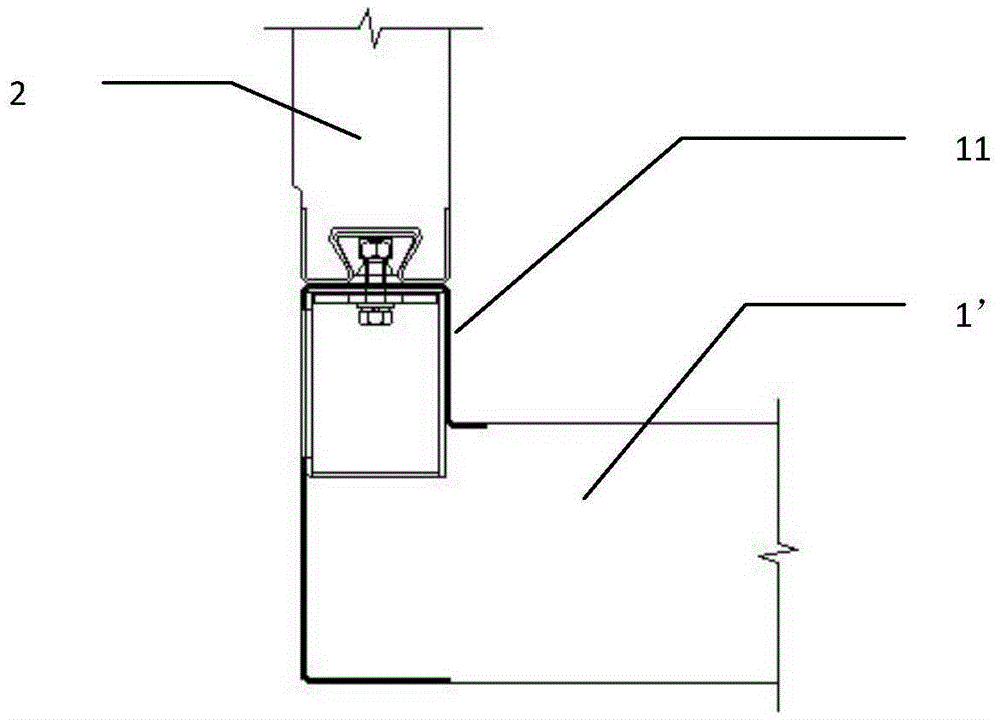

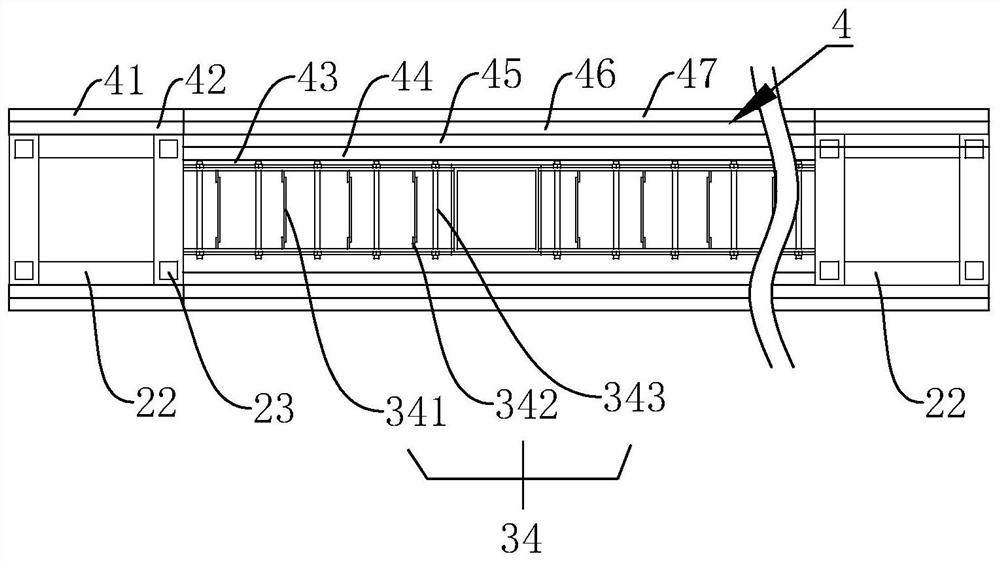

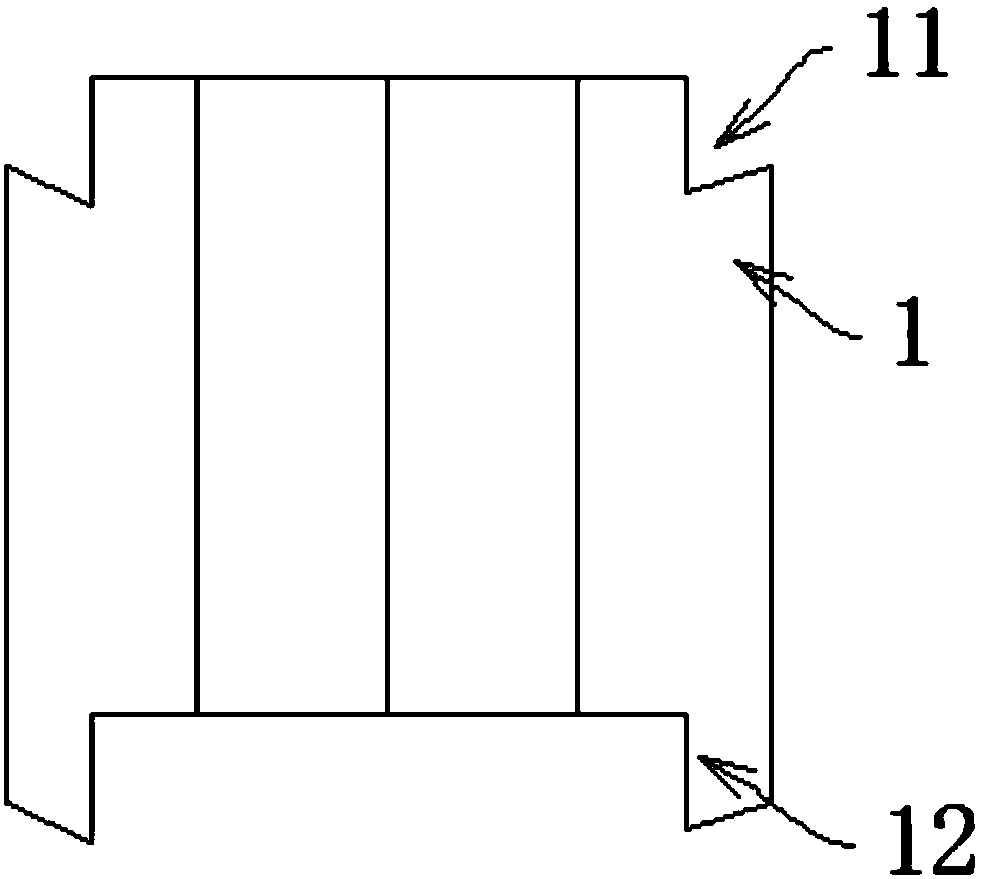

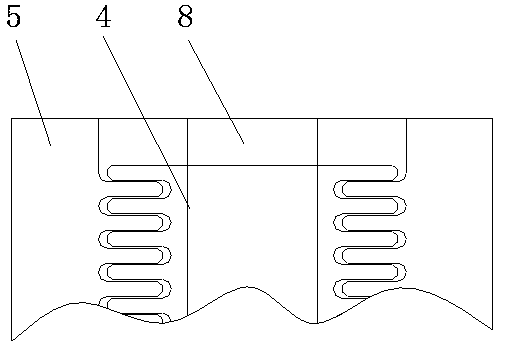

Floating floor structure for sound insulation and vibration reduction of buildings

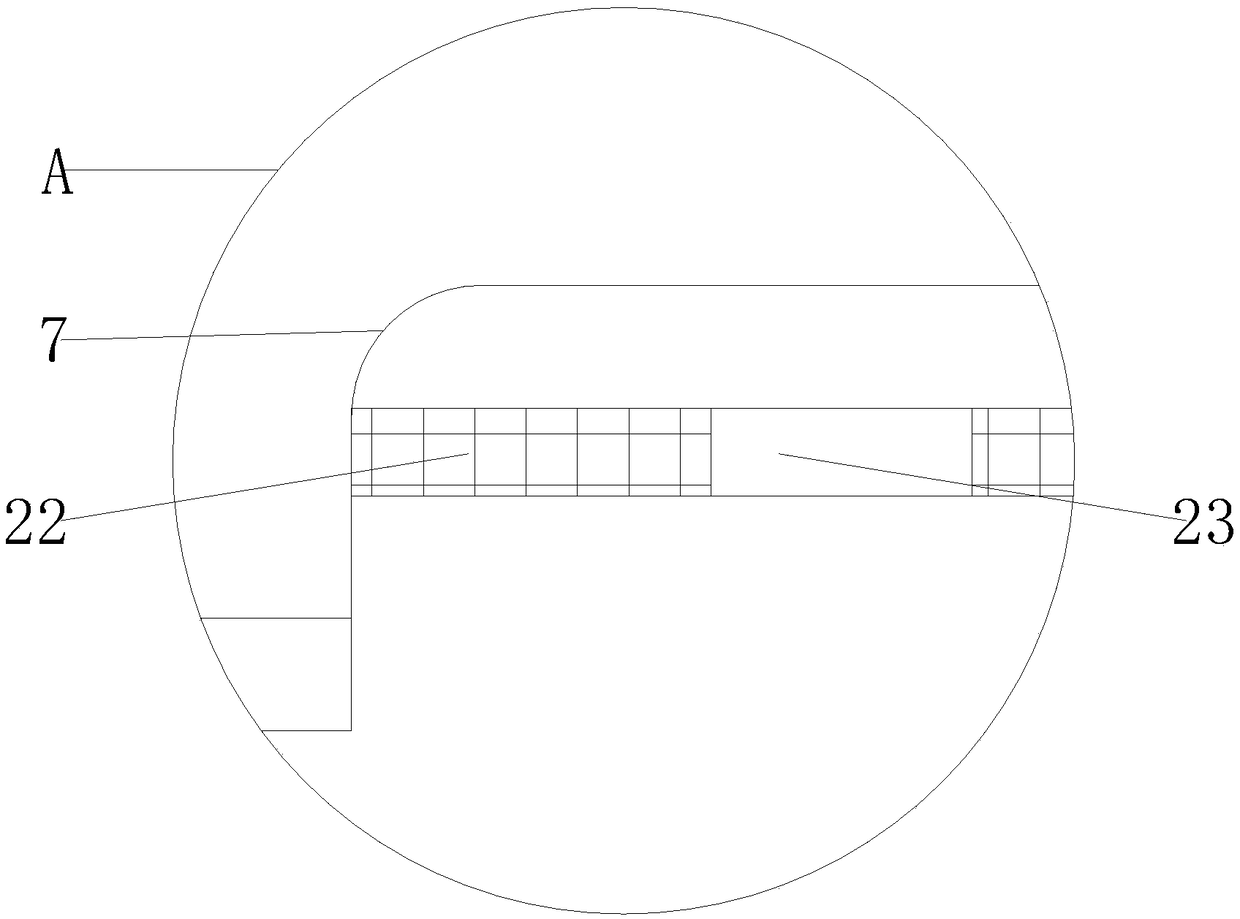

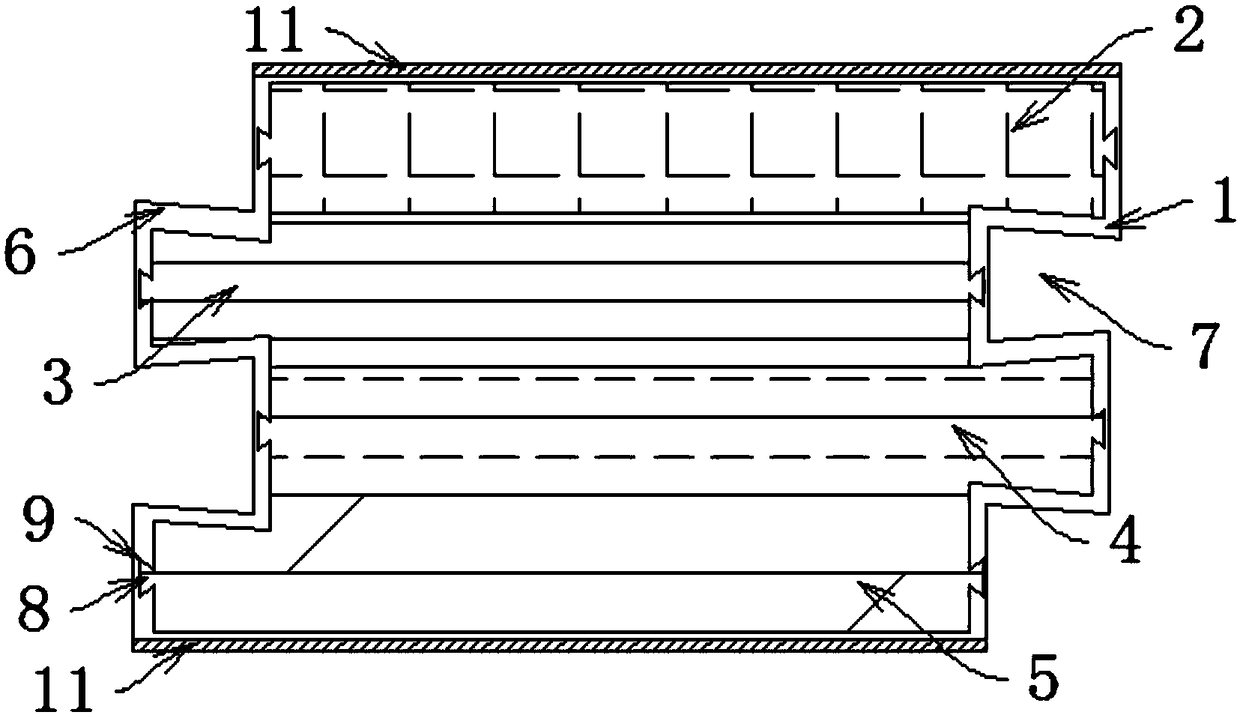

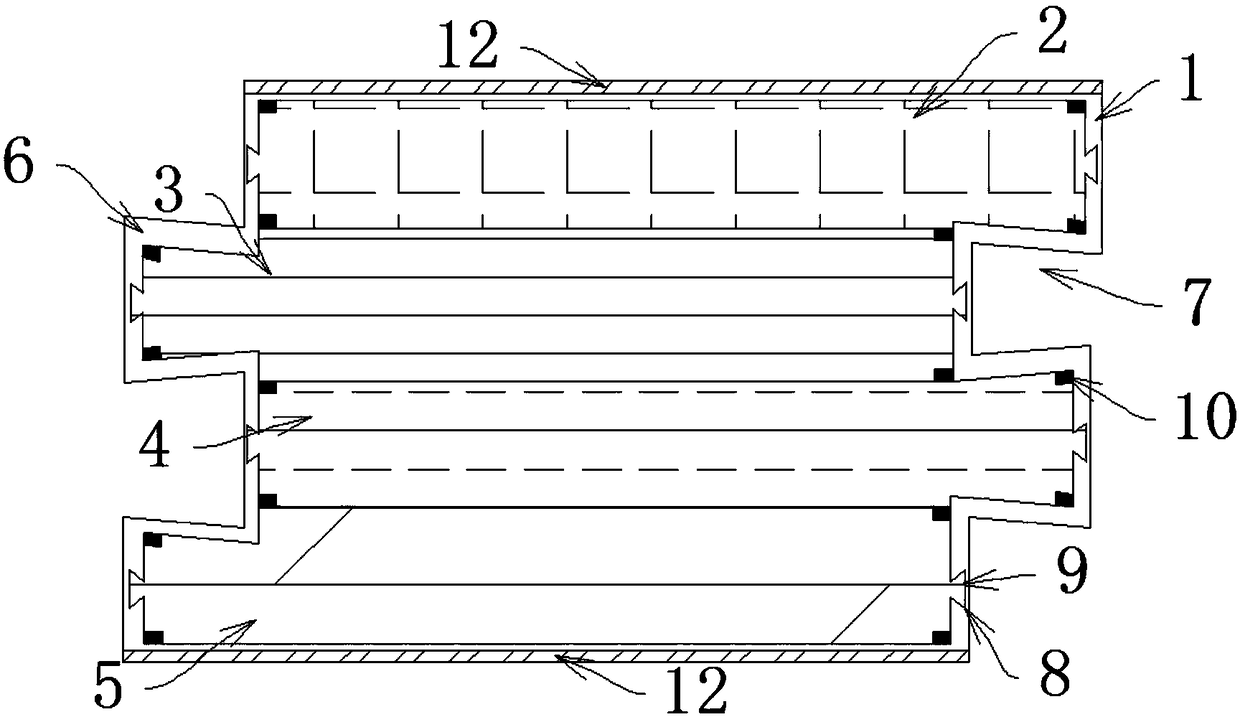

InactiveCN104912244AImprove airborne sound insulation performanceImproved cavity sound insulationFloorsEngineeringSealant

The invention discloses a floating floor structure for sound insulation and vibration reduction of buildings, and is suitable for design and construction of the sound insulation and vibration reduction of cast-in-place floors of housings, hotels, guest houses and the like with high requirements. The floating floor structure comprises a structural wall body and a floor, wherein flexible vibration reduction units are arranged at equal intervals on the upper surface of the floor, and flexible backing boards which are tightly close to the structural wall body are arranged at the periphery of the floor; a supporting layer is arranged on the flexible vibration reduction units; stuffing units are arranged in the space between the supporting layer and the floor; a floating unit layer is paved on the supporting layer; the flexible backing boards are higher than the floating unit layer, and skirting boards which are tightly close to the flexible backing boards are arranged at the periphery of the floating unit layer; sealant is stuffed to the upper ends of the flexible backing boards. According to the floating floor structure disclosed by the invention, high-quality requirements for sound environment of the sound insulation and the vibration reduction of building floors are met, noise caused by indoor activities is separated through the floors, the trouble of structural sound transmission is avoided, and the floating floor structure meets the comprehensive function requirements for sound insulation, vibration reduction, heat preservation and energy conservation.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

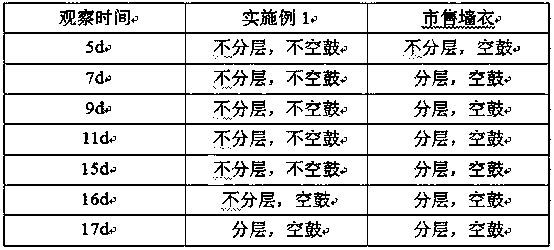

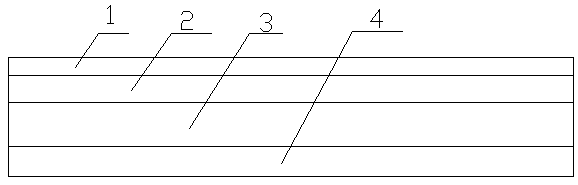

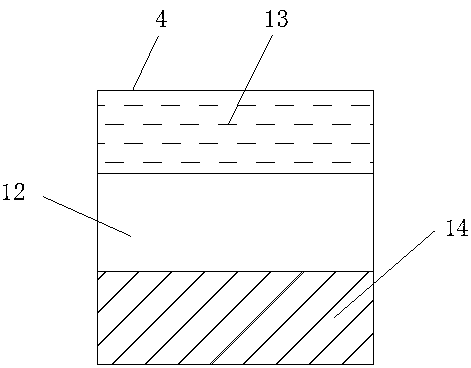

Construction method for lightweight sound-insulating damping mortar and building

InactiveCN105152582ASound insulation hasWith insulationFloorsSound proofingSurface layerMaterials science

The invention provides a lightweight sound-insulating damping mortar for a building. The mortar is prepared from the following components by mass: 10 to 50% of an inorganic cementing material, 5 to 50% of rubber, 10 to 80% of lightweight sand and 0.01 to 20% of an additive. The invention also provides a lightweight sound-insulating floor. The lightweight sound-insulating floor is composed of the lightweight sound-insulating damping mortar (2) which is painted on the top of a concrete floor (1), a protection surface layer (3) which is painted on the lightweight sound-insulating damping mortar (2), and the lightweight sound-insulating damping mortar (2) which is painted on corners, climbs up to walls and exceeds the protection surface layer (3).

Owner:杜飞月

High-density, high-flame-retardation sound-insulation protection rubber and preparation method therefor

InactiveCN105419127ATaking into account flame retardancyTaking into account weather resistanceVulcanizationPolymer science

The invention provides a preparation method for high-density, high-flame-retardation sound-insulation protection rubber and belongs to the rubber field. Firstly, ethylene propylene diene monomers are subjected to plastication and struck into roll films; then chlorinated polyethylene rubber is subjected to thin-passing plastication and struck into roll films; the plastified ethylene propylene diene monomers and the plastified chlorinated polyethylene rubber are placed in a banbury mixer and subjected to rubber combining; then zinc oxide, stearic acid, an activator, an antioxidant, an ultraviolet ray absorber, a fire retardant, an iron-containing compound, a softener and an inorganic filling material are added, mixing is carried out, a ram is lifted, the material is cleaned, mixing and discharging are carried out; sulphur and a vulcanization accelerator are added, thin-passing is carried out, the roll spacing is widened, and batch-off and storing are carried out; a sample is taken, and vulcanization performance test is carried out; the material after storing is subjected to plastication and batch-off, and molding is carried out by a calendar; drum-type vulcanization operation is carried out. The protection rubber is advantageous in that the protection rubber has characteristics of high density, high flame retardation, weather resistance, corrosion resistance and scraping prevention, especially the protection rubber meets the building fire protection B level standard and the processing performance of the material is good.

Owner:TIANJIN RUBBER IND RES INST

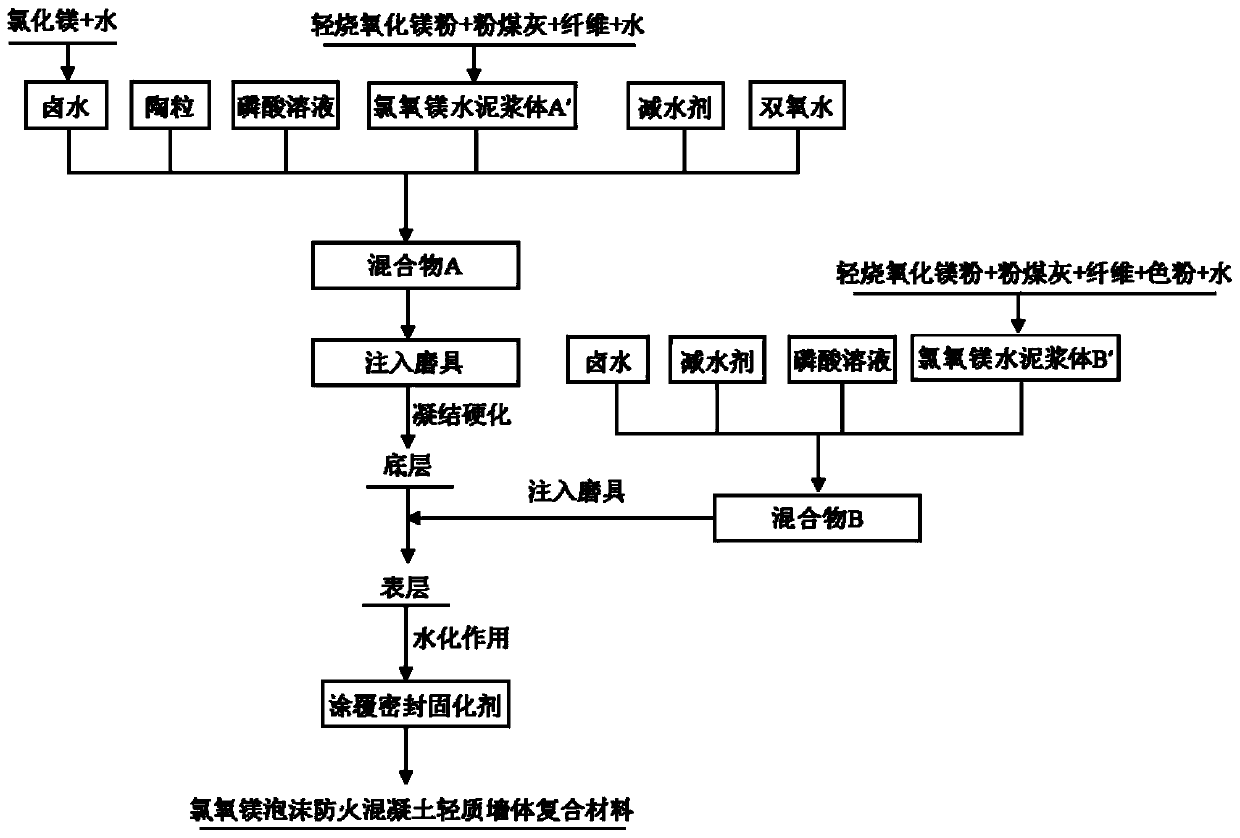

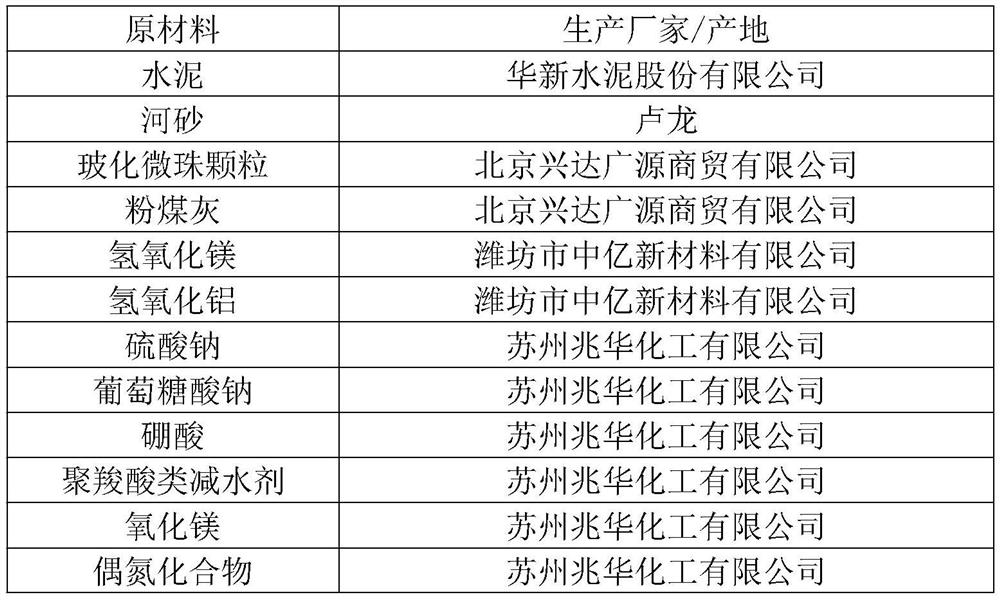

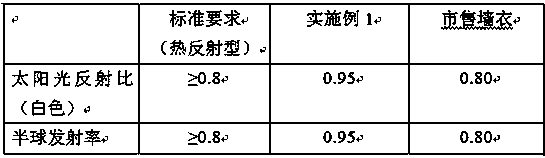

Magnesium oxychloride foam fireproof concrete lightweight wall composite material and preparation method thereof

ActiveCN110407555ALight in massHigh strengthRoof covering using slabs/sheetsCeramic shaping apparatusMagnesiumOxide

The invention discloses a magnesium oxychloride foam fireproof concrete lightweight wall composite material and a preparation method thereof, and belongs to the field of building materials. The composite material comprises a bottom layer and a surface layer; the bottom layer is prepared from, by weight, 10-20 parts of magnesium chloride, 4-6 parts of magnesium oxide, 2-8 parts of water, 0.1-0.2 part of phosphoric acid, 4-8 parts of ceramsite, 3-8 parts of a filler, 0.1-0.2 part of inorganic glass reinforced plastic fibers, 0.1-0.2 part of a liquid polycarboxylate-type water reducing agent and0.1-0.2 part of hydrogen peroxide; the surface layer is prepared from, by weight, 10-20 parts of magnesium chloride, 4-6 parts of magnesium oxide, 2-8 parts of water, 0.1-0.2 part of phosphoric acid,3-8 parts of a filler, 0.1-0.2 part of inorganic glass reinforced plastic fibers, 0.1-0.2 part of a liquid polycarboxylate-type water reducing agent and 0-0.2 part of a toner. The magnesium oxychloride cement foam ceramsite fireproof sound-insulation concrete lightweight wall composite material has the advantages of light weight, high strength, fireproof performance, heat preservation, sound insulation and the like and is an environment-friendly sound absorbing and insulating material; the preparation method of the sound absorbing ceramic material is low in cost, short in consumed time and easy to implement.

Owner:STATE GRID HUNAN ELECTRIC POWER +3

Sound insulation fire-proof partition board

The present invention relates to building material, and provides one kind of sound isolating fireproof partition board. The sound isolating fireproof partition board is produced with plant fiber and cement as main material as well as proper amount of mildew inhibitor, water reducing agent, waterproofing agent, intensifier, etc, and through mixing, forming and surface treatment. It has the features of sound isolation, fire prevention, decoration, light weight, no toxic and harmful matter release, high corrosion resistance, high strength, low cost, etc.

Owner:NANYANG NORMAL UNIV

Heat-resistant and flame-retardant soundproof oil paint and preparation method thereof

InactiveCN104293186AImprove fire performanceImprove fire resistanceBituminous coatingsFiberCarbon fibers

The invention discloses a heat-resistant and flame-retardant soundproof oil paint. The heat-resistant and flame-retardant soundproof oil paint is characterized by being prepared from the following raw materials in parts by weight: 13-16 parts of vinyl ester resin, 3-5 parts of diamino diphenyl sulfone, 1-2 parts of aluminum isopropoxide, 1-3 parts of calcium stearate, 1-2 parts of glass beads, 1-3 parts of hollow microspheres, 2-3 parts of a nano wood fiber, 2-3 parts of a nano bamboo fiber, 2-4 parts of a carbon nanofiber, 42-47 parts of modified asphalt, 5-8 parts of modified waste resin sand, 0.5-1.0 part of pyrocatechin, 1-2 parts of tetrabutyl titanate, 2-3 parts of cassia oil, 1-2 parts of titanium dioxide, 2-3 parts of glass powder, 6-8 parts of methyl acrylate, 6-8 parts of n-butyl acetate, 8-11 parts of methylbenzene and 4-6 parts of hexamethyl phosphinous triamine. The glass beads added to the heat-resistant and flame-retardant soundproof oil paint disclosed by the invention have the characteristics of heat insulation property, sound insulation property, insulativity and low water absorption rate; the hollow microspheres have the characteristics of good sound insulation property, fire resistance and electrical insulating property and high strength; and the added titanium dioxide has strong heat resistance, weather fastness and chemical stability. A plurality of fibers are also added, so that the heat-resistant and flame-retardant soundproof oil paint is safe, environmentally friendly, and free of radiation, and has heat-conducting, antibacterial and bacteriostatic action; and modified waste resin sand is also added to the heat-resistant and flame-retardant soundproof oil paint, so that the problem of environmental pollution is solved, and the fire retardancy and the fire resistance of the oil paint are improved.

Owner:TIANCHANG YINHU PAINT

Preparation method of lightweight sound-insulation wall-decoration artificial stone slab

The invention discloses a preparation method of a lightweight sound-insulation wall-decoration artificial stone slab. The mass ratio of methacrylic acid prepolymer resin to 325-mesh glass beads to 400-mesh glass powder to short-cut glass fiber with the length of 0.3 millimeter to color paste: a wetting dispersant to an antifoaming agent to a promoter to a curing agent is 25-60: 10-30: 15-35: 0.5-3: 0.05-2: 0.05-0.5: 0.001-0.01: 0.25-1: 0.25-1. The preparation method comprises the following steps: pouring the methacrylic acid prepolymer resin into an agitator and stirring; adding the color paste, the wetting dispersant, the antifoaming agent and the curing agent during the stirring process so as to prepare mixed resin; mixing the 325-mesh glass beads, the 400-mesh glass powder and the short-cut glass fiber with the length of 0.3 millimeter, and pouring the mixture into the mixed resin; adding the promoter during uniform stirring process; stirring continuously to prepare a mixed slurry after stirring; and introducing the mixed slurry into a plate-making mould for vacuum solidification, demoulding, and conducting dry brushing and water grinding so as to prepare the lightweight sound-insulation wall-decoration artificial stone slab. The method provided by the invention has advantages of simple process, low equipment requirement and low cost, and is easy for large-scale popularization. In addition, the prepared artificial stone slab has excellent comprehensive properties.

Owner:江苏顺乾新型材料有限公司

Sound-insulation fireproof building material

ActiveCN111807866AIncreased hydration rateImprove setting timeSolid waste managementCeramicwareAggregate (composite)Fire prevention

The invention relates to the technical field of building materials, and in particular, relates to a sound-insulation fireproof building material comprising the following raw materials in parts by weight: 45-60 parts of composite cement, 30-35 parts of graded aggregate, 15-20 parts of a sound insulation component, 3-5 parts of a fireproof component, 1-2 parts of a water reducing agent, 0.5-1.8 parts of a thickening time control component, 2-4 parts of an expansion component, 0.1-0.2 part of a foaming agent, 0.2-0.4 part of a defoaming agent and 0.02-0.04 part of a water retaining agent, whereinthe thickening time control component consists of sodium sulfate, sodium gluconate and boric acid in a mass ratio of (2-4):(0.5-1):(0.6-0.8). The composite cement, the graded aggregate, the sound insulation component, the fireproof component, the water reducing agent, the thickening time control component, the expansion component, the foaming agent, the defoaming agent and the water retaining agent are reasonably proportioned, and all the raw materials are matched with one another, so that the sound-insulation fireproof building material has the advantages of fire prevention, sound insulation, high mechanical strength and short setting time, and has important significance for development of the concrete industry.

Owner:广东潮威建设工程有限公司

Texture coating and preparation method thereof

The invention discloses a texture coating and a preparation method thereof and aims to solve the problems that the existing texture coatings are produced by using artificial color sand and are bad in weather resistance. The texture coating disclosed by the invention is made from aggregate, emulsion and other auxiliaries. The preparation method comprises the following steps: uniformly mixing cement, lime, gypsum, fine sand, waterborne color paste and biomass adhesive, and granulating to obtain the aggregate; and adding softened water, a thickener and a dispersing agent, uniformly stirring and dispersing in a dispersion machine, sequentially adding the emulsion, a film forming auxiliary, the aggregate, propylene glycol, a defoamer and preservative, uniformly stirring and dispersing to obtain the texture coating. The texture coating is friendly to environment and free of formaldehyde and has the characteristics of fire prevention, damp prevention, sound insulation, high strength, good weather resistance and the like.

Owner:GANSU GLDARK NEW MATERIAL

Multifunctional wallpaper and preparing method and application thereof

The invention discloses multifunctional wallpaper and a preparing method and application thereof. The multifunctional wallpaper comprises a bottom coating and a surface layer. The bottom coating comprises, by weight, 90-110 parts of acrylic emulsion of which the solid content is 35% and 1-20 parts of graphene. The surface layer comprises, by weight, 20-50 parts of white cement, 1-10 parts of gypsum, 5-20 parts of mica powder, 3-20 parts of hollow microbeads, 5-30 parts of glass microbeads, 30-50 parts of quartz powder, 0.1-2 parts of cellulose, 0.1-2.0 parts of water reducing agent, 0.1-1.5 parts of wetting agent, 0.1-2.5 parts of calcium formate, 0.3-3.0 parts of anti-cracking fiber, 2-20 parts of emulsion powder, 0.5-10 parts of far infrared ceramic powder and 0.5-15 parts of hydrophobicSiO2 aerogel. The multifunctional wallpaper can be applied to concrete floors, metal roof surfaces, building outer walls and inner walls, and has the effects of thermal insulation, water resistance,heat preservation and rust resistance.

Owner:戴方均 +1

Sound insulation panel

InactiveCN103726580ASound insulation hasSoundproof and beautifulSynthetic resin layered productsSound proofingFire protectionEngineering

The invention discloses a sound insulation panel which comprises a panel body. The sound insulation panel is characterized in that the panel body is of a four-layer composite structure and sequentially comprises a flocking cloth layer, a mineral wool board layer, an aerogel layer and a PCV plate layer. The sound insulation panel is of the four-layer composite structure so as to have the advantages of attractiveness, sound insulation, warm keeping and fire protection, and effectively solves the problem that an existing work shed is poor in sound insulation capacity and heat insulation capacity.

Owner:CHENGDU FANXINJIA TECH

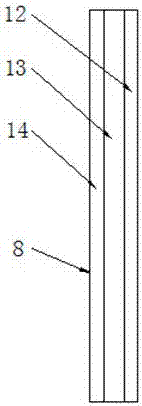

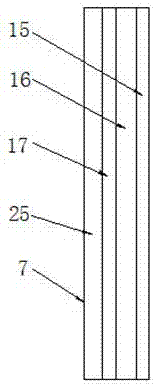

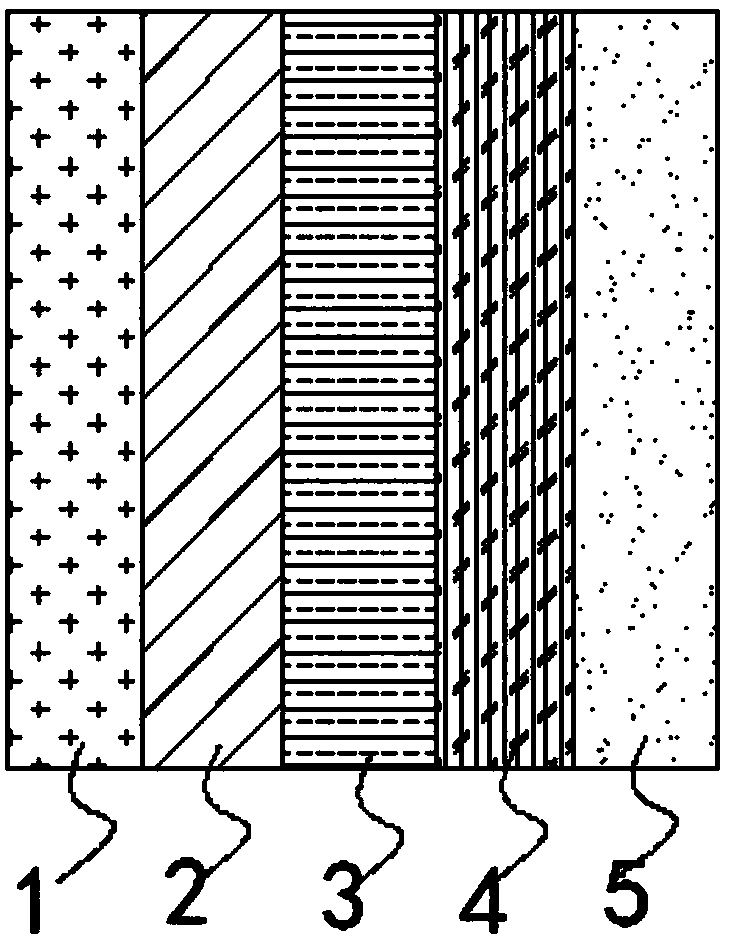

Outer wall coating structure

InactiveCN108071202ACrack resistance hasAnti-crack waterproofFireproof paintsCovering/liningsThermal insulationAnti bacteria

The invention discloses an outer wall structure. The outer wall structure comprises an anti-bacteria coating layer (1), an anti-cracking waterproof coating layer (2), a thermal-insulation coating layer (3), a fireproof sound-proof coating layer (4) and a primer paint layer (5); and the anti-cracking waterproof coating layer is arranged at the inner side of the anti-bacteria coating layer, the thermal-insulation coating layer is arranged at the inner side of the anti-cracking waterproof coating layer, the fireproof sound-proof coating layer is arranged at the inner side of the thermal-insulation coating layer, and the primer paint layer is arranged at the inner side of the fireproof sound-proof coating layer. The outer wall structure is reasonable in structural design, and has the effects of being waterproof, anti-cracking, thermal-insulation, fireproof, and sound-proof.

Owner:JIANGSU HENGHUI FOOD CO LTD

Fabricated light steel structure residential building system

InactiveCN112064784AGood dispersionIncreased load-bearing capacityFloorsHeat proofingFloor slabArchitectural engineering

The invention relates to a fabricated light steel structure residential building system, and relates to the technical field of energy-saving buildings. The system comprises a vertical wall, load-bearing columns, a wall body supporting structure, a wall surface functional structure, horizontal load-bearing frames and load-bearing positioning blocks, a rectangular frame is composed of four load-bearing cross beams which are sequentially connected end to end, vertical load-bearing stand columns are connected between the four corners of two horizontal load-bearing frames, and a plurality of reinforcing ribs are connected between every two adjacent vertical load-bearing stand columns; the bottom of a transverse floor is connected with load-bearing positioning holes corresponding to the load-bearing positioning blocks; and the wall body supporting structure comprises a vertical rectangular steel pipe and a wall body support, a wall body supporting assembly comprises two supporting plates arranged on the transverse floor in a spaced manner, and the two supporting plates are connected into a whole through a wall locking assembly. The system is high in load bearing capacity, energy-saving and environment-friendly, and can be suitable for small high-rise residential buildings.

Owner:深圳千里马装饰集团有限公司

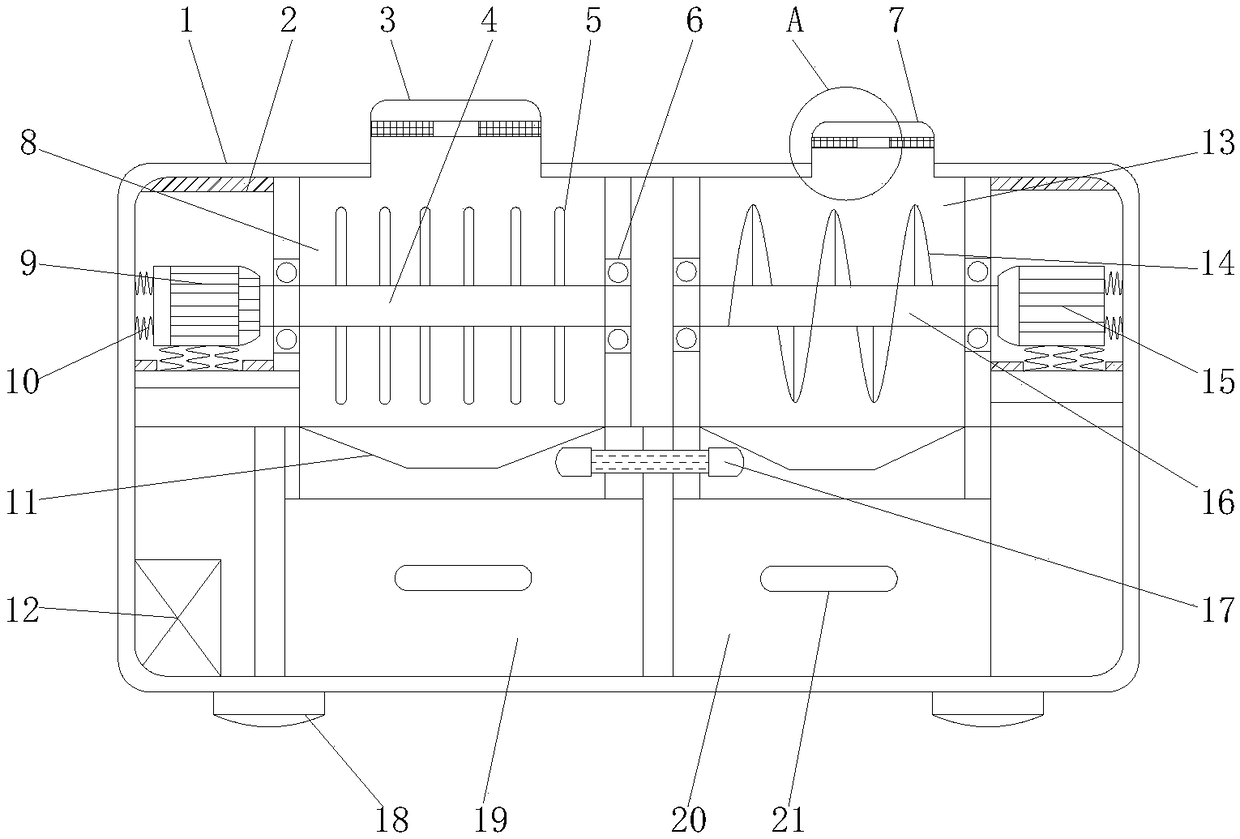

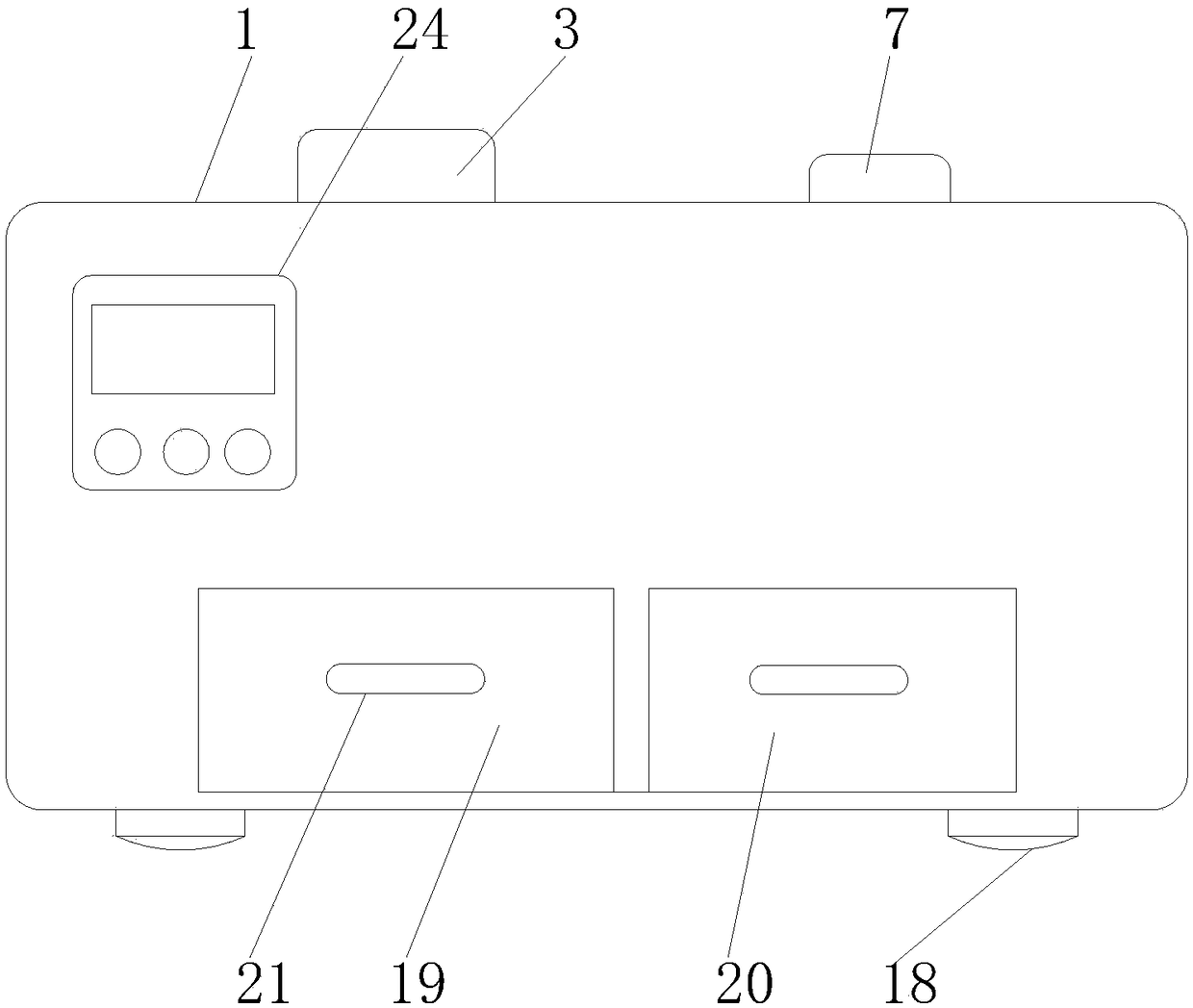

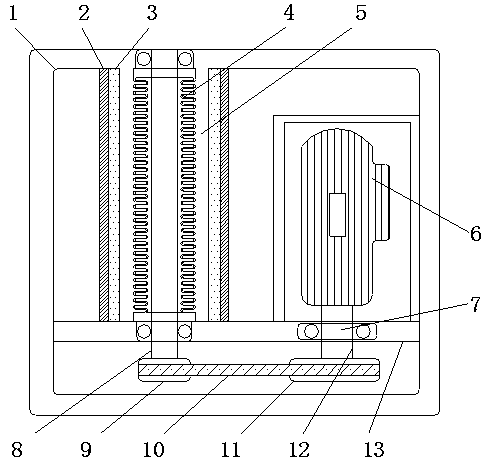

Unmaking device for one-off medical apparatus

InactiveCN109045416ATo achieve the effect of destroying shapeSolve the problem of single function and poor practicabilityInfusion needlesSpiral bladeEngineering

The invention discloses an unmaking device for one-off medical apparatus. The unmaking device comprises a shell body, wherein the inner portion of the shell body is provided with a first unmaking chamber and a second unmaking chamber which are arranged in sequence from left to right, the left end of a first rotating shaft in the first unmaking chamber is rotationally connected with an output end of a first servo motor, the left and right ends of the first rotating shaft are rotationally connected with the inner wall of the shell body through bearings respectively, the first rotating shaft is fixedly provided with a circular blade, the lower left end of the first servo motor is fixedly connected with the inner wall of the shell body through a spring, a damping soundproof felt adheres to theinner wall of the shell body, the right end of a second rotating shaft in the second unmaking chamber is rotationally connected with a second servo motor, and the second rotating shaft is fixedly provided with a spiral blade. The unmaking device for the one-off medical apparatus has the advantages that the damping soundproof felt, the circular blade, the first servo motor, the spring, the spiralblade and the second servo motor are arranged, thereby solving the problem that unmaking work performed by a medical worker is not facilitated due to the fact that an unmaking iron needle function isnot provided and the noise is larger.

Owner:芜湖碧水谣医疗设备科技有限公司

Moisture-resisting self-disinfection environment-friendly sound insulation floor and manufacturing method thereof

InactiveCN111305508AGood hygroscopicityEfficient killingPressure wood treatmentWeft knittingAcetic acidMoisture absorption

The invention discloses a moisture-resisting self-disinfection environment-friendly sound insulation floor and a manufacturing method thereof. A sound insulation material is composed of a packaging material, function filler and a surface wear-resisting layer. The packaging material is an organic matter matrix prepared by adopting 45-56 parts of an ethylene-vinyl acetate polymer by weight as the raw material. The function filler is a bamboo fiber composite prepared by adopting 200-220 parts of sinocalamus affinis and 50-60 parts of glacial acetic acid by weight as raw materials. The surface wear-resisting layer is a wear-resisting composite prepared by adopting 4-5 parts of aluminum oxide powder and 1-1.2 parts of an ethylene-vinyl acetate polymer by weight as raw materials. The moisture-resisting self-disinfection environment-friendly sound insulation floor can achieve moisture absorption, self disinfection, long-time volatilization of disinfection components, softness and sound insulation.

Owner:WEISHAN HONGRUI POWER TECH CO LTD

Environment-friendly heat-insulation building block

InactiveCN108412110AIncrease the lengthImprove insulation performanceConstruction materialBuilding materialAcoustic board

The invention discloses an environment-friendly heat-insulation building block, and belongs to the field of building materials. The environment-friendly heat-insulation building block comprises a building block body. The left end surface and the right end surface of the building block body which is a brick are of sawtooth structures, protruded portions and sunken portions of the left end surface and the right end surface of the brick correspond to one another, a plurality of rectangular sawtooth cavities are formed inside the brick in a staggered arrangement manner, function plates which include a heat-insulation plate, a sound-insulation plate, a fireproof plate and a waterproof plate are sequentially mounted inside the various rectangular cavities and are movably connected with cavity walls inside the bricks by connecting structures, and positioning devices are arranged on the front end surface and the rear end surface of the brick. The environment-friendly heat-insulation building block has the advantages that good heat-insulation effects can be realized by the environment-friendly heat-insulation building block, and the environment-friendly heat-insulation building block has sound-insulation, waterproof and fireproof functions; the construction difficulty can be relieved by the environment-friendly heat-insulation building block in the structural design for workers, and theconstruction efficiency can be effectively improved.

Owner:HENAN YUQIAN TECH TRANSFER CENT CO LTD

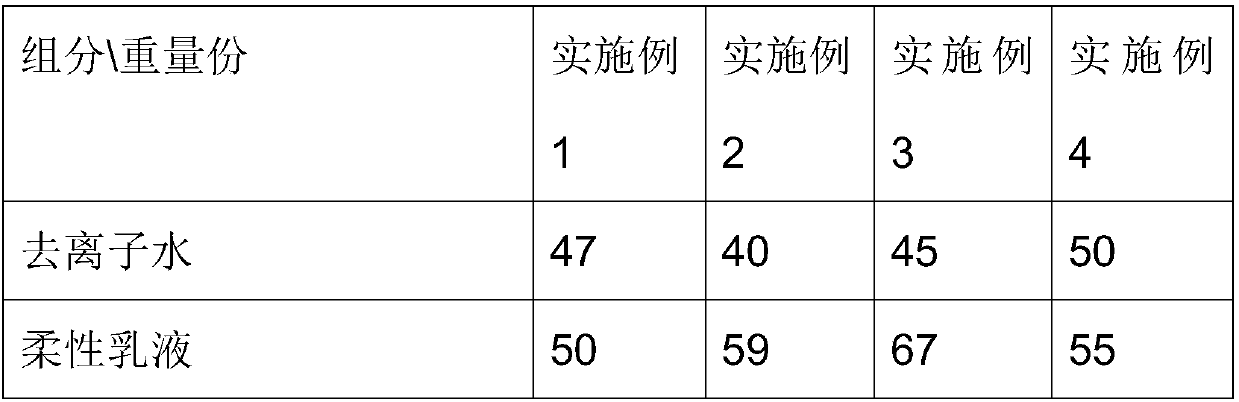

Elastic buffer noise-reduction real stone paint

The invention discloses an elastic buffer noise-reduction real stone paint, which is prepared from the components in parts by weight: 40 to 50 parts of deionized water, 50 to 67 parts of flexible emulsion, 5 to 12 parts of cellulose ether, 6 to 10 parts of polyethylene glycol, 4 to 6 parts of sodium silicate, 3 to 6 parts of dispersing agent, 18 to 25 parts of coalescing agent, 10 to 15 parts of hollow glass beads, 20 to 25 parts of slag cotton fiber, and 200 to 350 parts of natural colored stones. The elastic buffer noise-reduction real stone paint provided by the invention mixes multiple mineral components which are in mutual complementation and correlative dependence so as to form a unified system; a color of the obtained real stone paint is mixed by the natural colored stones, the process is simple, and the elastic buffer noise-reduction real stone paint has the performances of sound absorption and noise reduction, has flexibility, and is a choice of a top-grade building surface spraying material.

Owner:苏州振振好新型建材科技有限公司

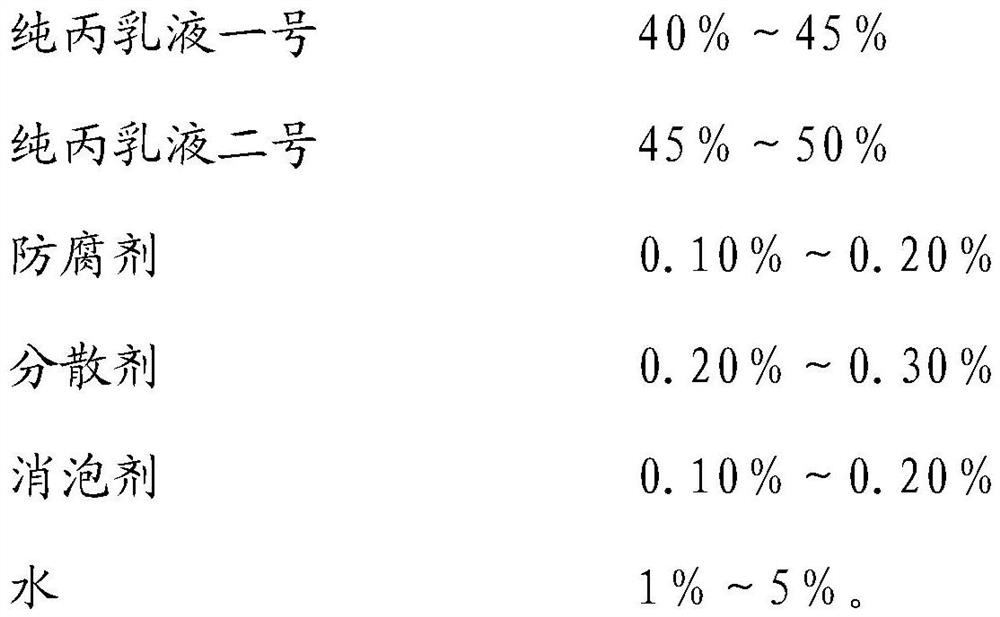

Water-based sound-insulation heat-preservation elastic waterproof coating and preparation method thereof

The invention discloses a water-based sound-insulation heat-preservation elastic waterproof coating which comprises a liquid material and a powder material in a weight ratio of 1: (1.2-1.5). The liquid material component comprises 40%-45% of a pure acrylic emulsion I, 45%-50% of a pure acrylic emulsion II, 0.10%-0.20% of a preservative, 0.20%-0.30% of a dispersing agent, 0.10%-0.20% of a defoaming agent and 1%-5% of a defoaming agent. The powder material comprises 30%-40% of cement, 25%-30% of quartz powder, 15%-20% of wollastonite, 5%-15% of a thermal insulation material, 5%-10% of a modified sound insulation material, 0.02%-0.05% of cellulose ether and 0.4%-1% of a water reducing agent. By adopting the technical scheme of the invention, the modified waterproof thermal insulation material is added, the product is enabled to have waterproof and thermal insulation dual functions, and the modified sound insulation material is also added so that the sound insulation effect of the modified polymer cement-based waterproof slurry is improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

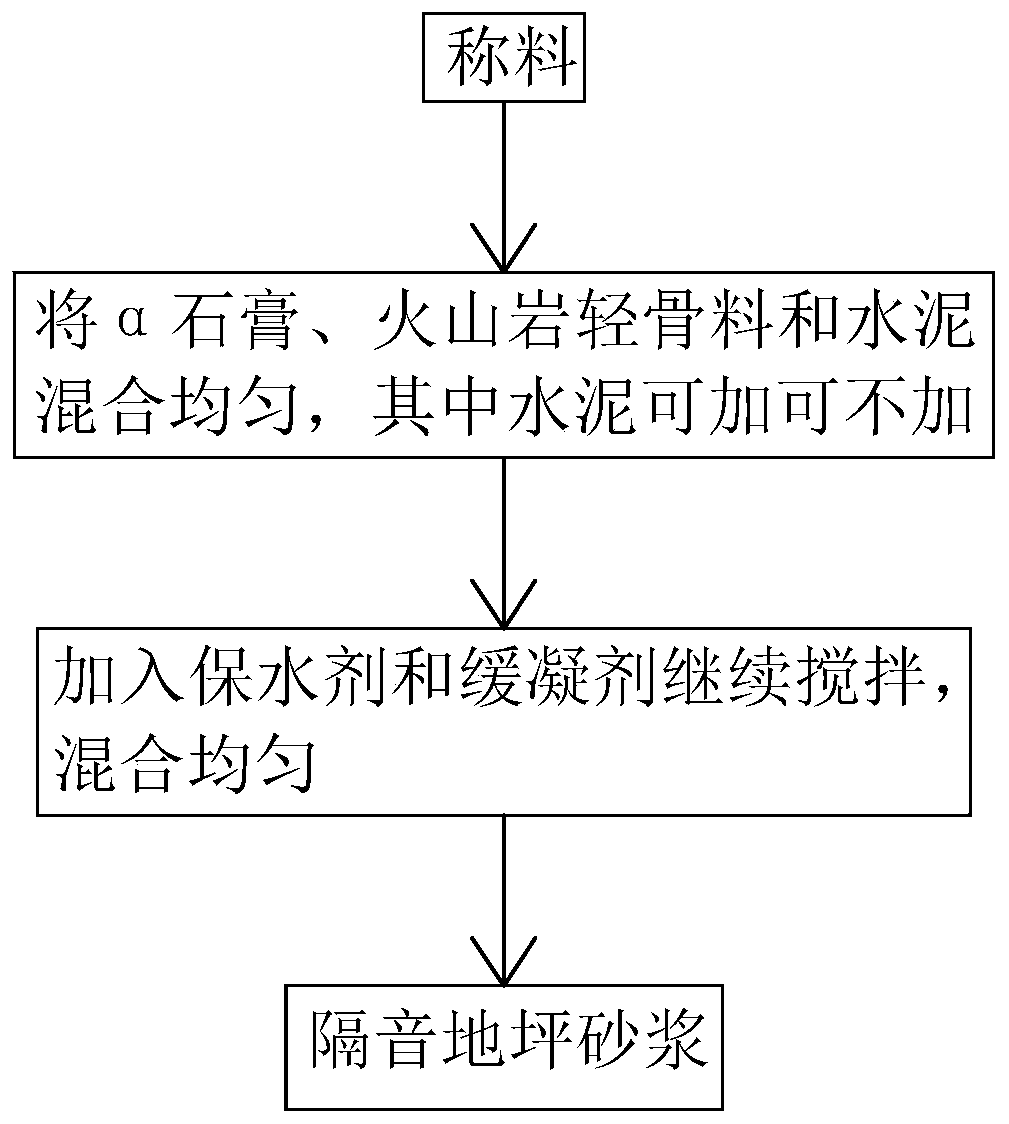

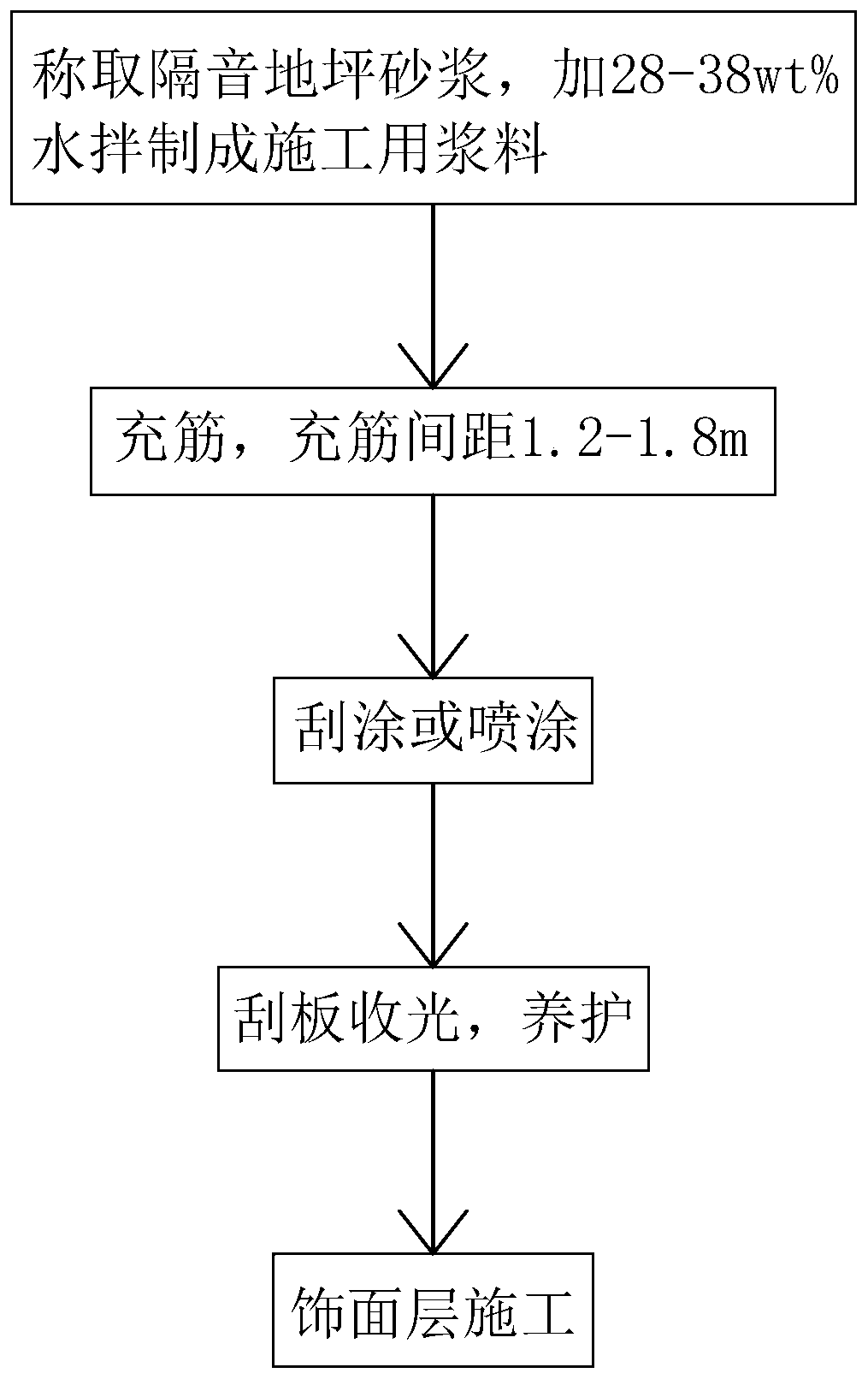

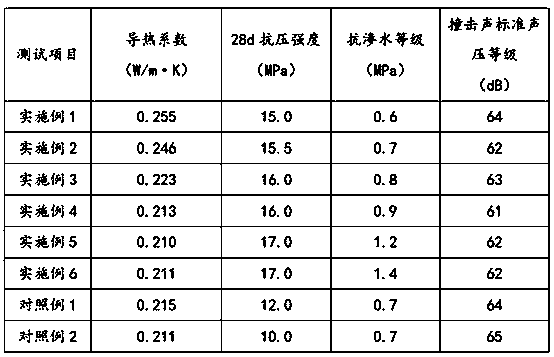

Sound insulation terrace mortar, preparation method thereof and sound insulation terrace construction method

InactiveCN110204295AHigh compressive strengthImprove water resistanceFlooringSteel barConstruction aggregate

The invention discloses sound insulation terrace mortar and relates to the technical field of building decoration materials. The sound insulation terrace mortar is technically characterized by comprising, by weight, 80-90 parts of alpha gypsum, 10-20 parts of volcanic rock lightweight aggregate, 0.5-3 parts of a water retaining agent, 0.5-3 parts of a retarder and 0-10 parts of cement; the densityof the volcanic rock lightweight aggregate is 200-500 kg / m<3>, and the strength of the volcanic rock lightweight aggregate is 1-5 MPa; the 28d compressive strength of the cement is higher than or equal to 52.5 MPa. The sound insulation terrace mortar has the advantages of being lightweight, great in sound insulation performance, high in compressive strength and capable of facilitating construction. The invention also correspondingly discloses a preparation method and application of the sound insulation terrace mortar. In addition, the invention also correspondingly discloses a sound insulation terrace construction method. The sound insulation terrace construction method comprises the steps of mortar modulation, filling of reinforced steel bars, scraping or spraying, caring and the like, and the construction process is simple and efficient; a constructed terrace has the advantages of good sound insulation effect, great heat preservation effect and excellent pressure resistance and water seepage resistance.

Owner:苏州绿乘轻质绿色材料有限公司

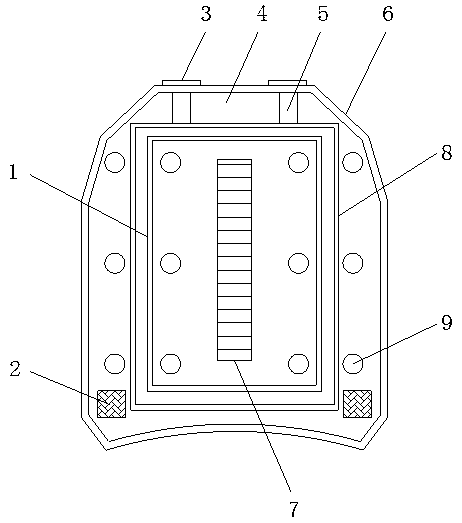

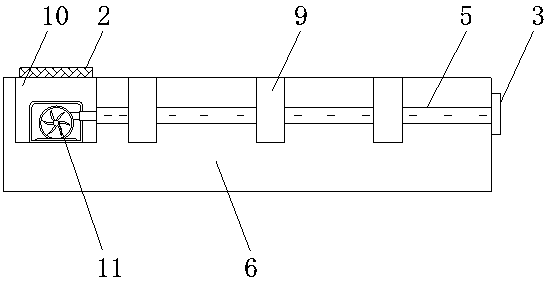

Carbon fiber engine cover for automobile

PendingCN108454708AImprove axial strengthHigh modulusSuperstructure subunitsPropulsion coolingCarbon fibersAgricultural engineering

The invention discloses a carbon fiber engine cover for an automobile. The carbon fiber engine cover comprises an engine cover body. The upper and lower portions inside the engine cover body are provided with a thermal insulating layer and a waterproof layer respectively, a carbon fiber layer is arranged in the center inside the engine cover body, the engine cover body comprises an outer installing plate, a sound insulating plate and an inner installing plate, the outer installing plate and the inner installing plate are arranged at the front and rear ends of the engine cover body respectively, the sound insulating plate is arranged between the outer installing plate and the inner installing plate, lightening holes are formed in the two sides of the front surfaces of the outer installing plate and the inner installing plate at equal intervals, electronic refrigeration pieces are electrically connected to the middle of the surface of the inner installing plate, and the bottoms of the two sides of the surface of the outer installing plate are fixedly connected with fans through formed installing grooves. By arranging the carbon fiber layer, the sound insulating plate, the waterprooflayer, the fans, a wind direction flow guiding groove, the electronic refrigeration pieces and the lightening holes, the carbon fiber engine cover has the advantages of prolonging the service life andachieving sound insulation, waterproofness, exhaust, heat dissipation and low weight.

Owner:HENAN DONGHAI COMPOUND MATERIALS

Wall body sound insulation building materials

Wall body sound insulation building materials are prepared from the following raw materials in parts by weight: 14 to 22 parts of wollastonite, 4 to 8 parts of floating beads, 8 to 14 parts of gelatinized starch, 4 to 7 parts of redispersible rubber powder, 5 to 7 parts of stabilizers, 2 to 4 parts of maleic anhydride, 5 to 10 parts of kieselguhr, 8 to 12 parts of opened expanded perlite, 6 to 15 parts of inorganic thickeners, 15 to 22 parts of plant granules, 12 to 16 parts of organic-silicon flame retardants, 4 to 7 parts of additives, 15 to 26 parts of waste straws, and 10 to 22 parts of ore waste stone dust. The wall body sound insulation building materials provided by the invention have the beneficial effects of heat insulation and sound insulation, and have the advantages of convenient construction, low cost and energy conservation.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

Sound-proof heat insulation light wall

InactiveCN100515982CSound insulation hasSound insulation withSolid waste managementFiberReducing agent

The present invention relates to building material, and provides one kind of sound isolating and heat insulating light wall. The sound isolating and heat insulating light wall is produced with plant fiber and cement as main material as well as proper amount of mildew inhibitor, water reducing agent, waterproofing agent, intensifier, etc, and through mixing, pressing, and forming. It has the features of sound isolation, heat insulation, light weight, no toxic and harmful matter release, high corrosion resistance, high strength, low cost, etc.

Owner:NANYANG NORMAL UNIV

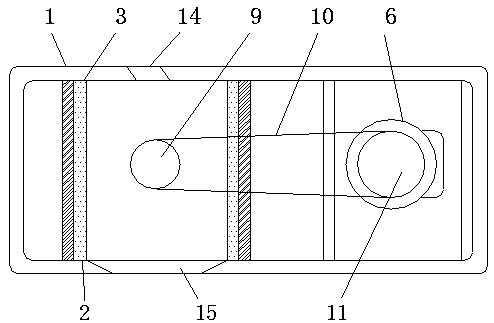

Cutting device for shredder

InactiveCN108772154ASolve the problem of increased power consumption, not energy saving and environmental protectionAchieve the desired effectSound producing devicesGrain treatmentsElectric machinePulley

The invention discloses a cutting device for a shredder. The cutting device comprises a case; a motor is mounted inside the case; the output end of the motor is rotatably connected with a second rotating shaft; a fixed plate is fixed below the motor; the second rotating shaft is fixedly connected with a second belt pulley through the bearing of the fixed plate; the second belt pulley is rotatablyconnected with a first belt pulley through a belt; the upper end of the first belt pulley is fixedly provided with a first rotating shaft; the first rotating shaft passes through the fixed plate and is rotatably connected with a bearing on the case; the outer wall of the first rotating shaft is fixedly provided with cutting blades; the cutting blades and cutting knives fixed on the inner wall of the case are alternately arranged; and the left and right ends of the cutting blades are bonded with damping soundproofing felt. The cutting device of the invention solves the problem that the use of adouble-axis cutting knife increases power consumption, is not energy-saving and environment-friendly, generates noise and affects the work efficiency of people during operation through arrangement ofthe damping soundproof felt, the cutting blades, the cutting knives and the second rotating shaft.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com