Magnesium oxychloride foam fireproof concrete lightweight wall composite material and preparation method thereof

A light-weight wall and composite material technology, applied in the field of building materials, can solve the problems of heat insulation, poor sound absorption effect, high product bulk density, high production cost, etc., and achieve the effect of low cost, short time consumption and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

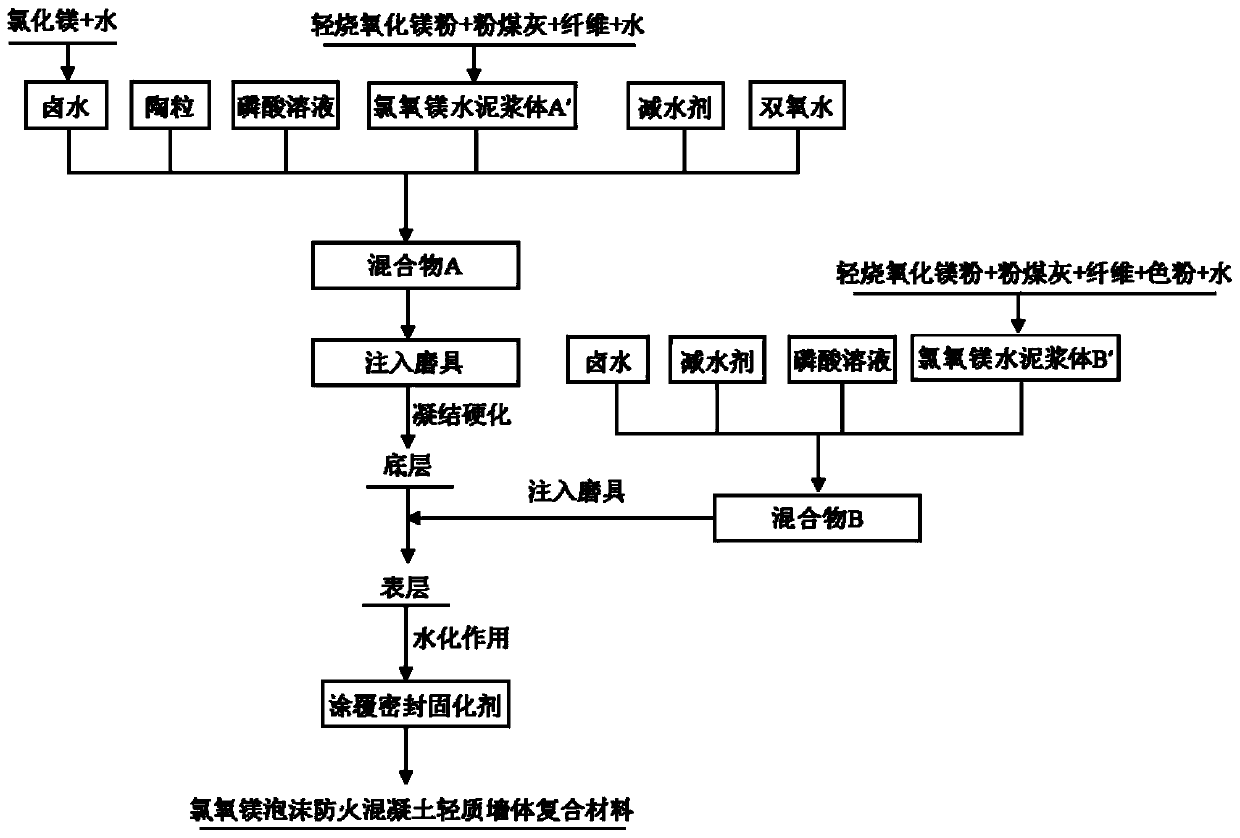

[0042] The preparation method of a kind of magnesium oxychloride foam fireproof concrete lightweight wall composite material of the present embodiment comprises the following steps:

[0043] (1) Magnesium chloride is mixed with water, stirred evenly, and preparation concentration is the bittern of 24 degrees Baume, after standing, get supernatant liquid;

[0044] (2) Moisten the ceramsite with a particle size of 1-3mm, 3-5mm, 5-8mm, and 8-10mm with water (4% of the mass of the ceramsite), and take it out for later use;

[0045] (3) the preparation mass concentration is the phosphoric acid solution of 84~86wt%;

[0046] (4) Take the magnesia, filler and inorganic fiberglass fiber of described weight part, add appropriate amount of water, make magnesium oxychloride cement slurry A';

[0047] (5) Add phosphoric acid solution and liquid polycarboxylate water reducer to brine according to the set ratio, then add wet ceramsite and hydrogen peroxide, mix well and add to magnesium ox...

Embodiment 2

[0057] The preparation method of a kind of magnesium oxychloride foam fireproof concrete lightweight wall composite material of the present embodiment comprises the following steps:

[0058] (1) Magnesium chloride is mixed with water, stirred evenly, and preparation concentration is the bittern of 26 degrees Baume, after standing, get supernatant liquid;

[0059] (2) Moisten the ceramsite with a particle size of 5-8mm, 8-10mm, 10-13mm, and 13-15mm with water (4% of the mass of the ceramsite), and take it out for later use;

[0060] (3) the preparation mass concentration is the phosphoric acid solution of 84~86wt%;

[0061] (4) Take the magnesia, filler and inorganic fiberglass fiber of described weight part, add appropriate amount of water, make magnesium oxychloride cement slurry A';

[0062] (5) Add phosphoric acid solution and liquid polycarboxylate water reducer to brine according to the set ratio, then add wet ceramsite and hydrogen peroxide, mix well and add to magnesiu...

Embodiment 3

[0072] The preparation method of a kind of magnesium oxychloride foam fireproof concrete lightweight wall composite material of the present embodiment comprises the following steps:

[0073] (1) Magnesium chloride is mixed with water, stirred evenly, and preparation concentration is the bittern of 25 degrees Baume, after standing, get supernatant liquid;

[0074] (2) Water the ceramsite with a particle size of 1-3mm, 3-5mm, 5-8mm, 8-10mm, 10-13mm, 13-15mm, 15-18mm, 18-20mm (4% of the ceramsite mass) Moisten, take out and set aside;

[0075] (3) the preparation mass concentration is the phosphoric acid solution of 84~86wt%;

[0076] (4) Take the magnesia, filler and inorganic fiberglass fiber of described weight part, add appropriate amount of water, make magnesium oxychloride cement slurry A';

[0077] (5) Add phosphoric acid solution and liquid polycarboxylate water reducer to brine according to the set ratio, then add wet ceramsite and hydrogen peroxide, mix well and add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com